Feed mixing and crushing device for agriculture

A technology of mixing, crushing and feeding, which is applied in the field of agricultural machinery, can solve the problems of large use limitations and unsuitable mixing of green materials, and achieve the effects of improving quality, improving the effect of squeezing water, and avoiding the loss of nutrients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

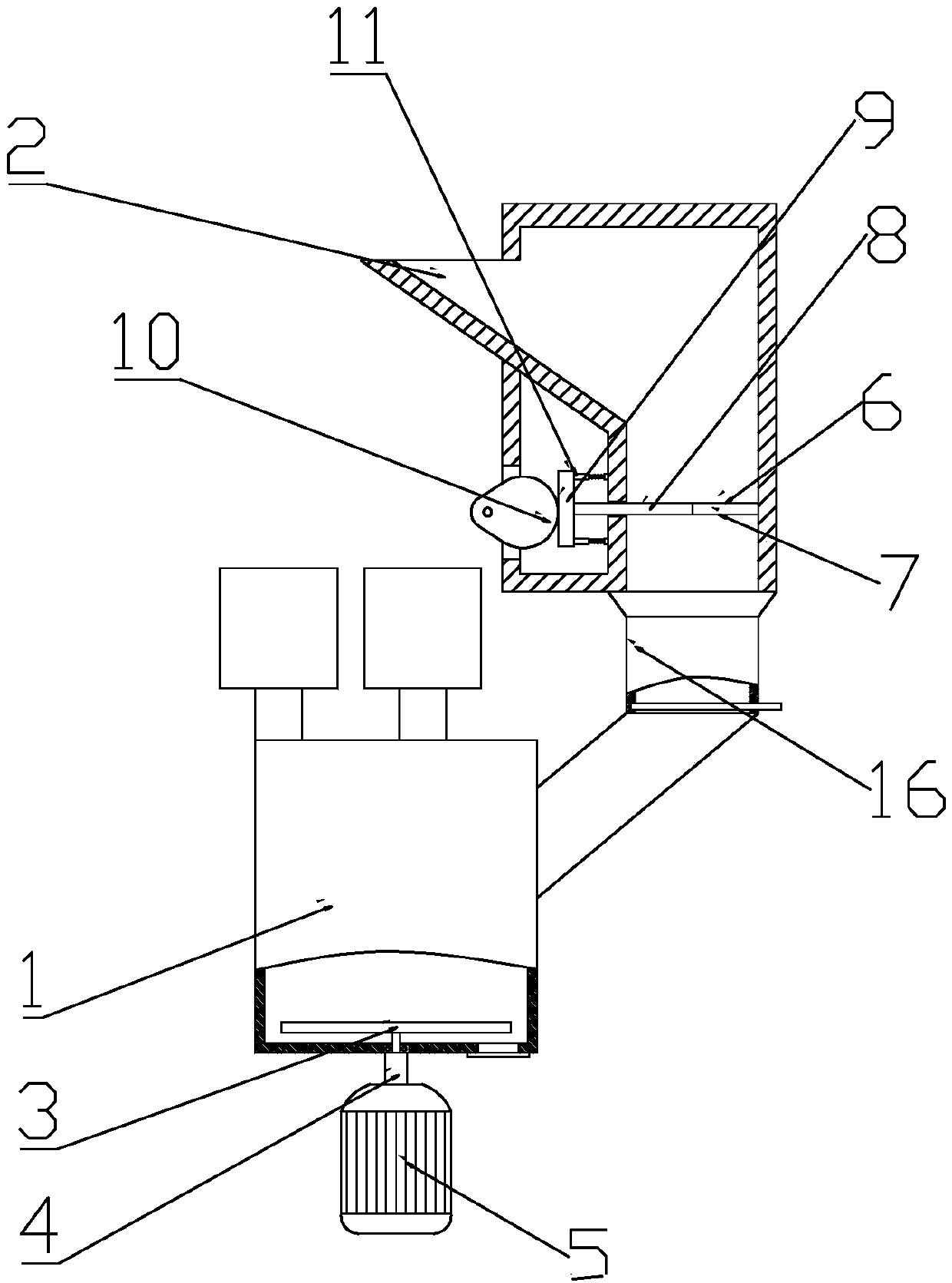

[0018] see figure 1 , figure 2 with image 3 , an agricultural feed mixing and crushing device, comprising a mixing box 1, a feeding bin 2, a stirring blade 3, a stirring shaft 4, a motor 5, and a quantitative bin 21, the feeding bin 2 is arranged above the mixing box 1 , the inside of the stirring box 1 is provided with the stirring blade 3, the stirring blade 3 is welded and fixed on the top of the stirring shaft 4, the stirring shaft 4 extends downwards and is installed on the motor 5, the feeding The interior of the warehouse 2 is provided with a cutting mechanism 6, which is used to cut the green material into uniform small sections. The cutting mechanism 6 includes a fixed blade 7, a moving blade 8, a push plate 9, a cam 10 and a reset buffer mechanism 11. The fixed blade 7 is welded and fixed on the inner wall on the right side of the feed bin 2, the movable blade 8 is arranged on the left side of the fixed blade 7, and the movable blade 8 is slid left and right and ...

Embodiment 2

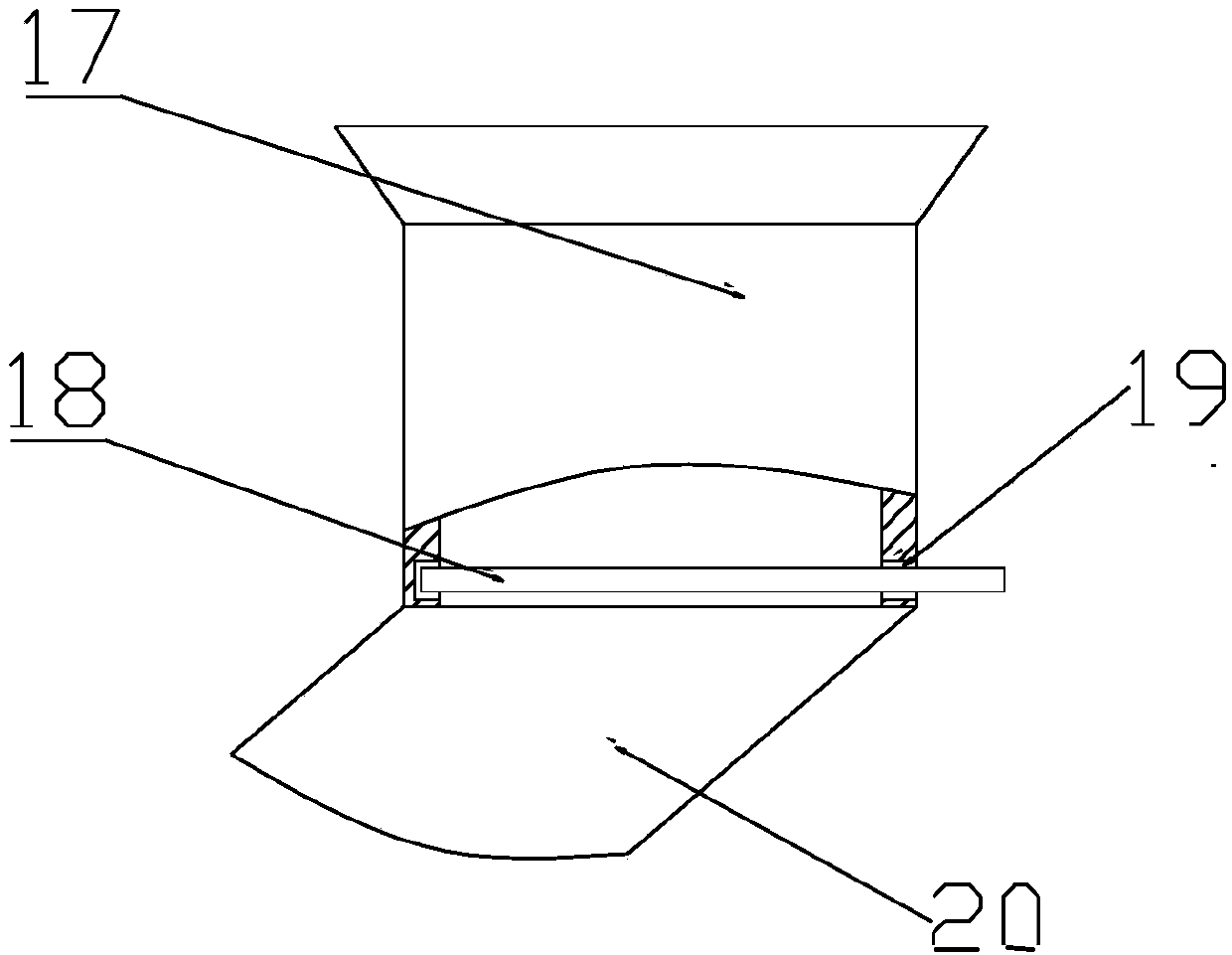

[0020] see Figure 4 with Figure 5 Compared with Embodiment 1, the present embodiment 2 differs only in that a water squeezing mechanism 22 is arranged on the left side of the feed bin 2, which is used for squeezing water before the green material is cut, reduces the moisture in the green material, and improves the green material. Mixed quality; the squeezing mechanism 22 includes a conveyor belt 23, a pressure wheel 24 and a wheel frame 25, the pressure wheel 24 is arranged above the conveyor belt 23, and the pressure wheel 24 is rotatably mounted on the wheel frame 25 ; The outer peripheral surface of the pressure wheel 24 is welded and fixed with teeth 30, and the teeth 30 can improve the water squeezing effect; A connecting rod 28 is installed at the limit position above the spring 27, and the spring 27 plays a buffering reset effect to avoid the blockage of the green material between the pressure roller 24 and the conveyor belt 23.

[0021] The working principle of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com