Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

70results about How to "Improve the vibration damping effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

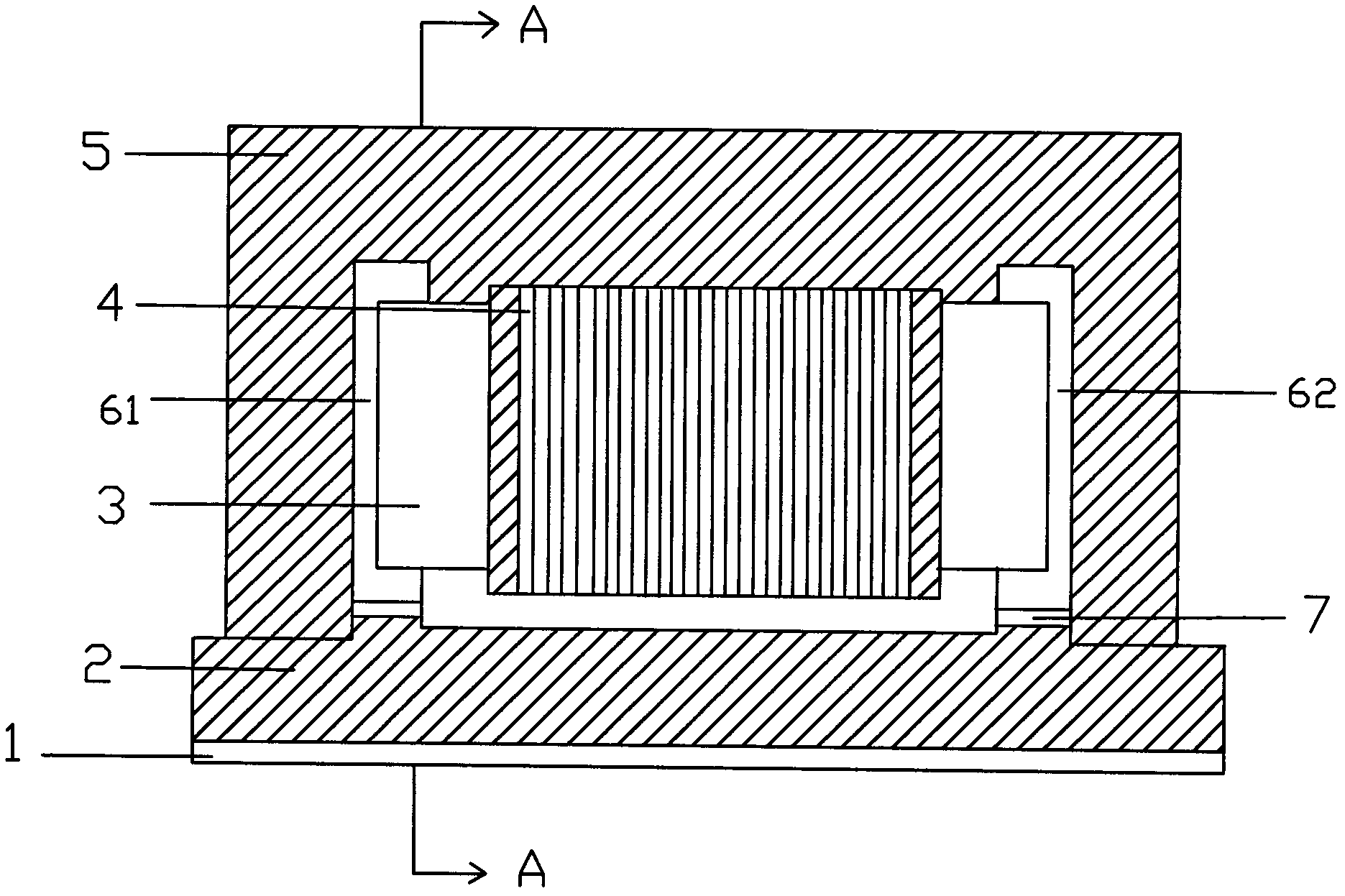

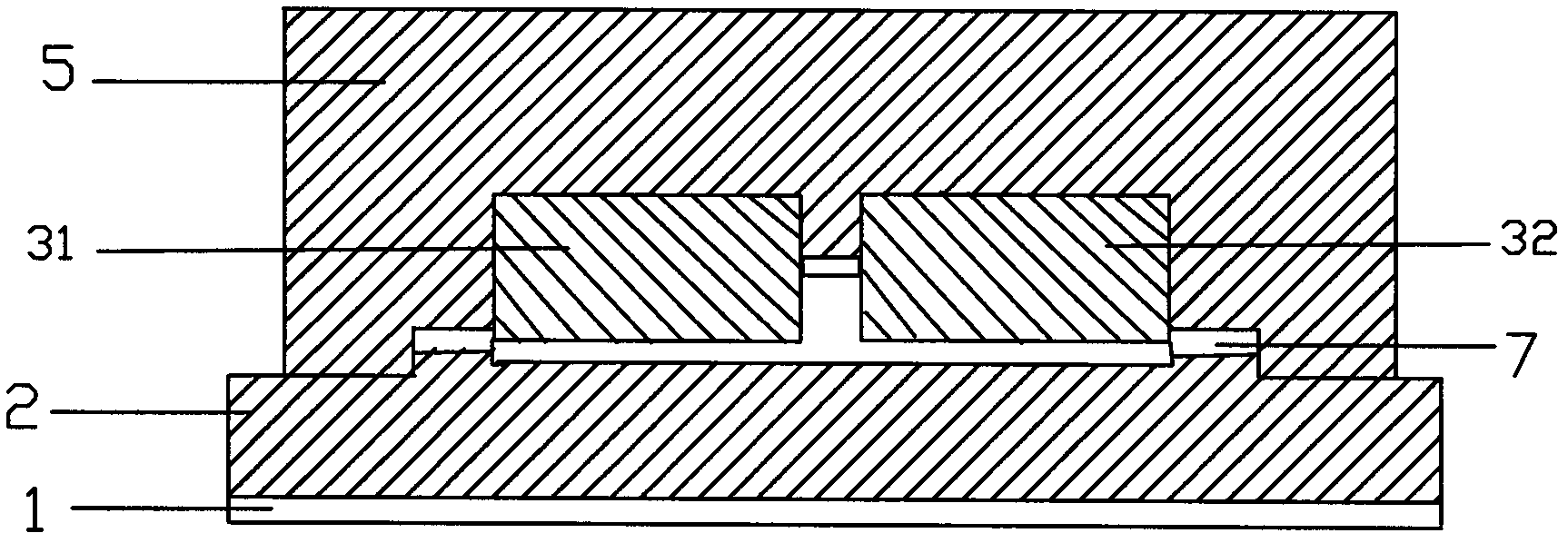

Reactor

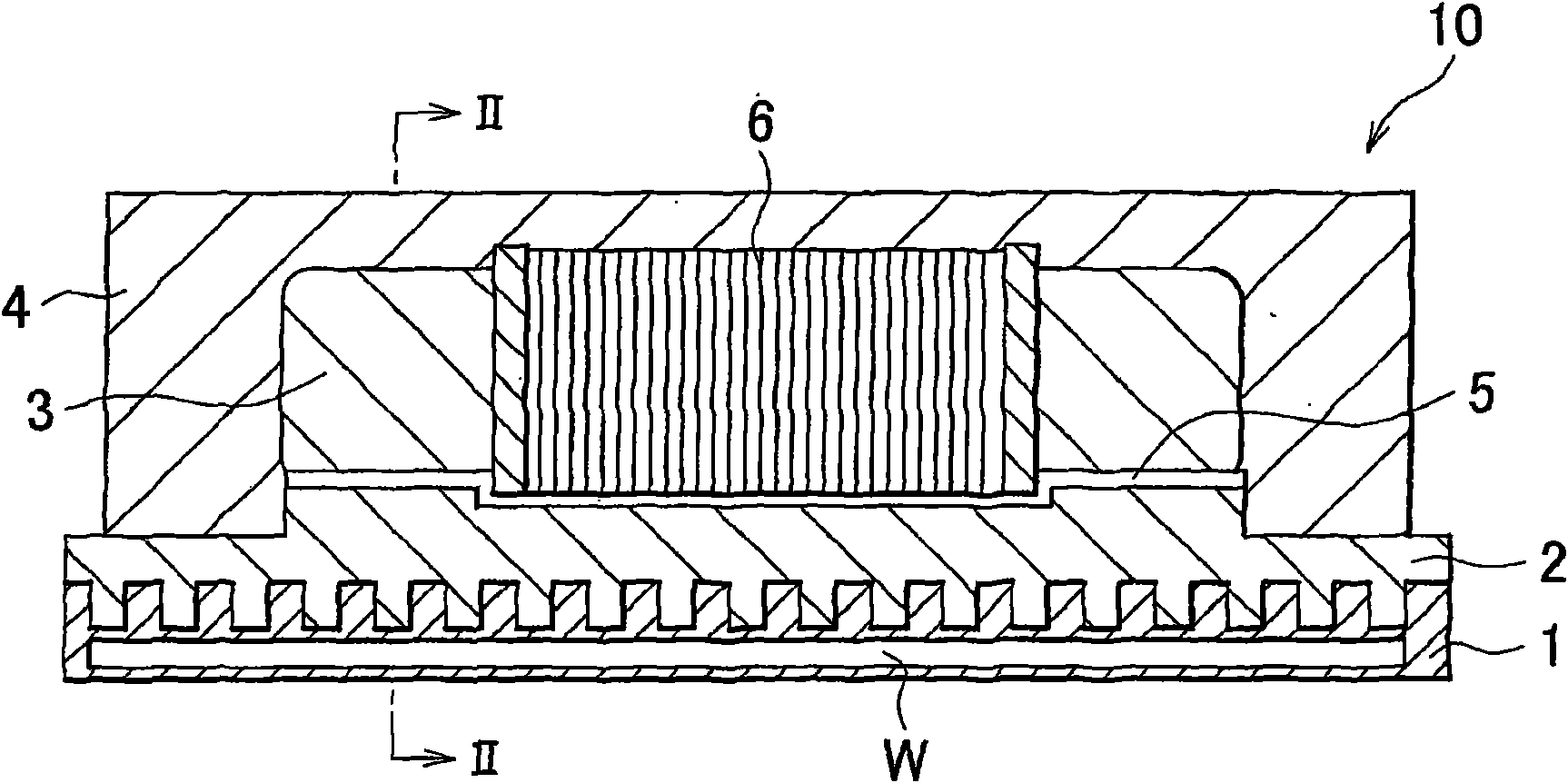

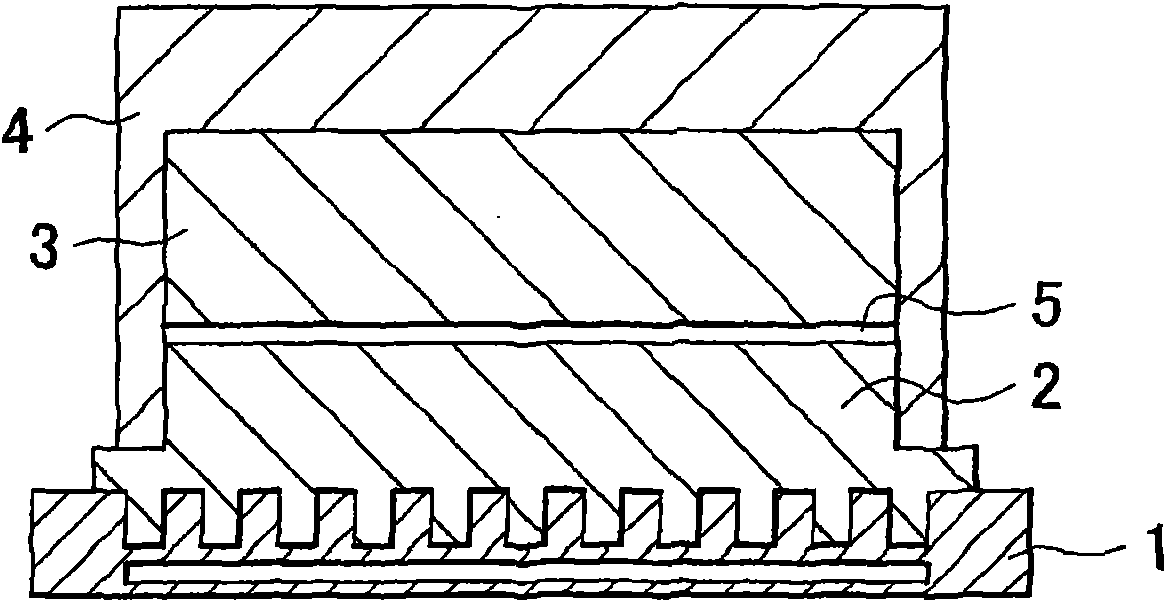

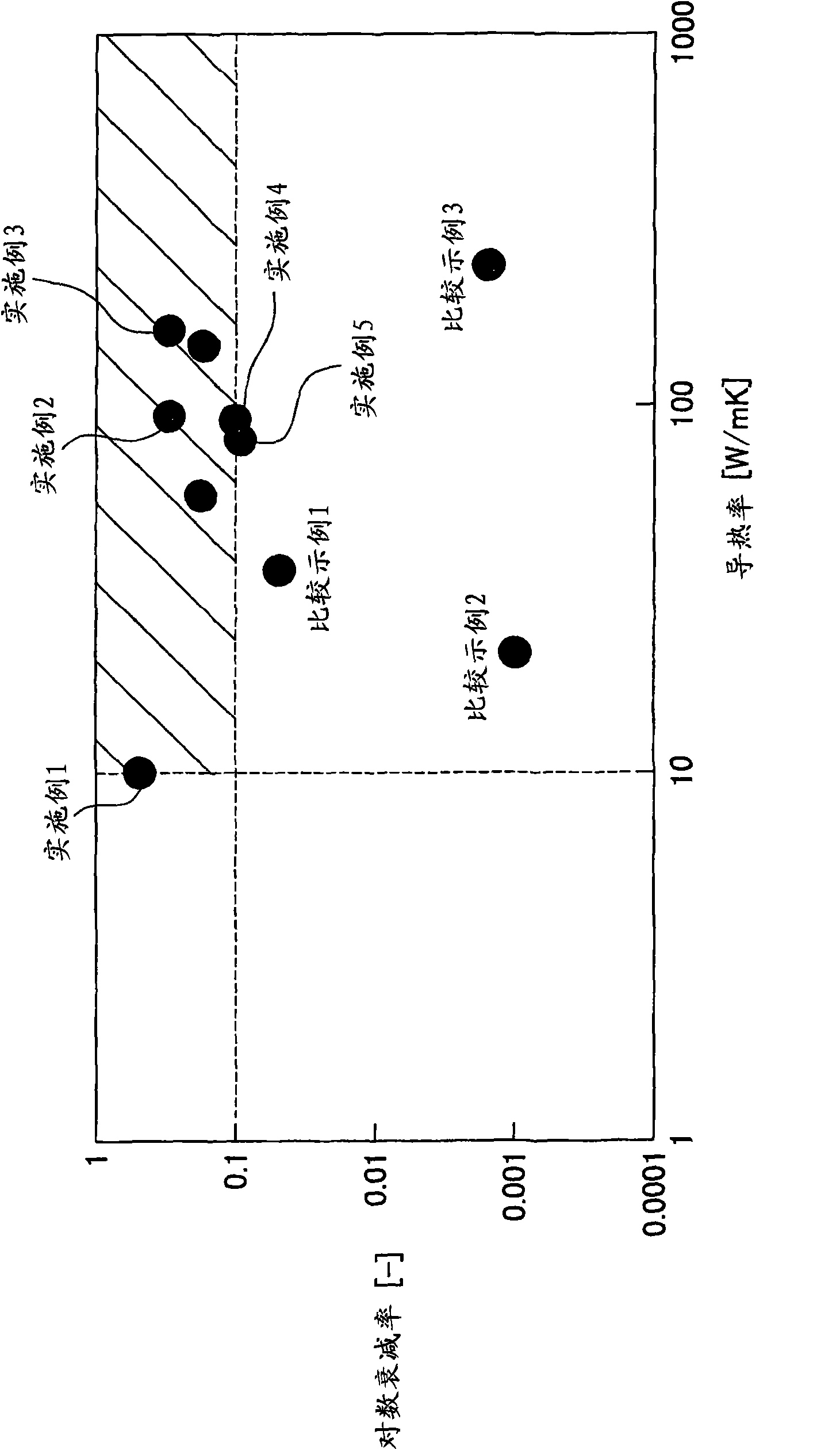

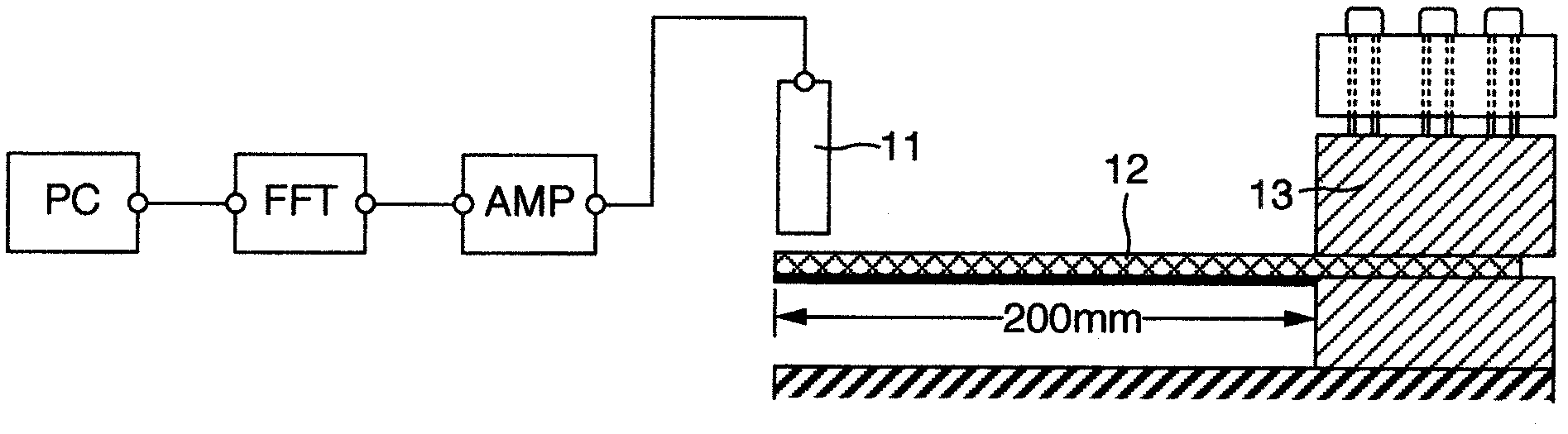

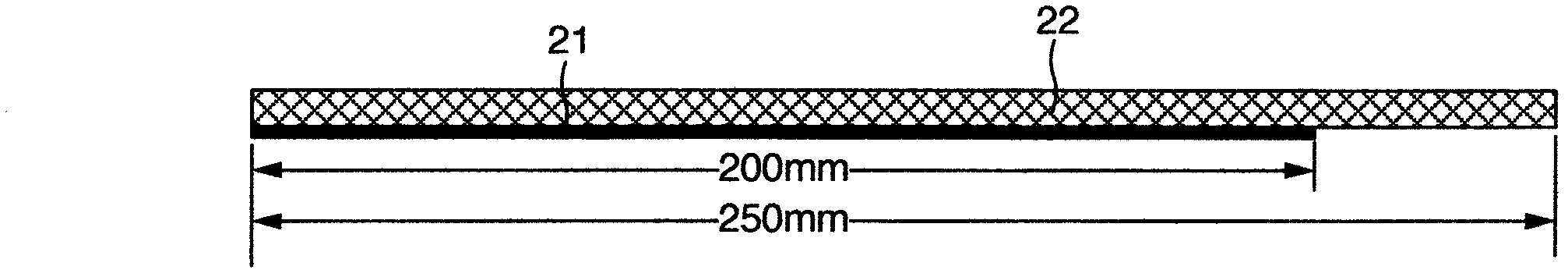

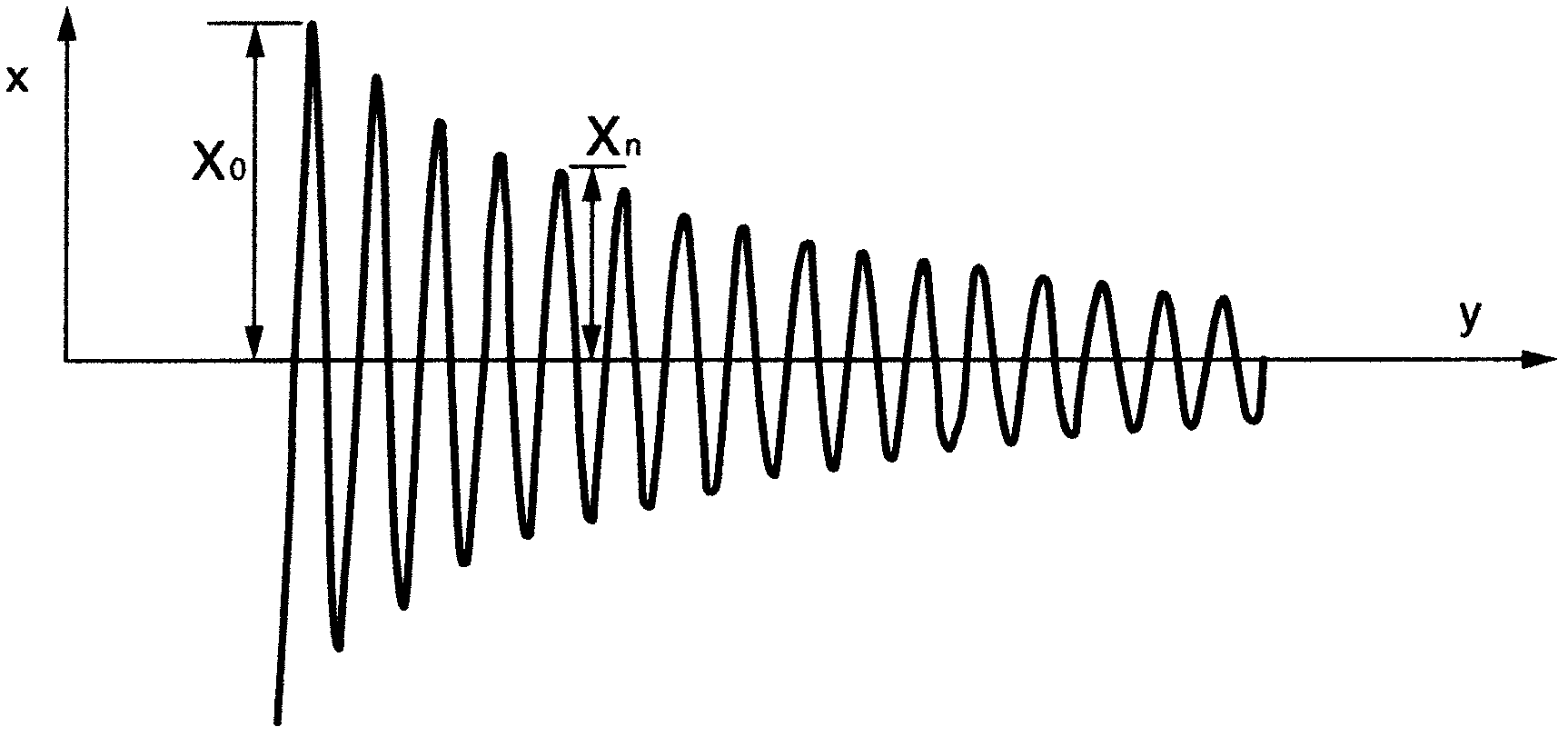

InactiveCN101689420AImprove cooling effectImprove the vibration damping effectTransformers/inductances coolingFixed inductancesAlloyMetal

A reactor includes a cooling block; a heat radiation base affixed to the cooling block; a reactor core that includes a coil, and that is affixed to the heat radiation base; and a resin molded body formed on the heat radiation base to cover the reactor core. The heat radiation base is formed of a metal or an alloy that has a predetermined logarithmic decrement and predetermined heat conductivity. The predetermined logarithmic decrement is equal to or higher than 0.1, and the predetermined heat conductivity is equal to or higher than 10 W / mK.

Owner:TOYOTA JIDOSHA KK

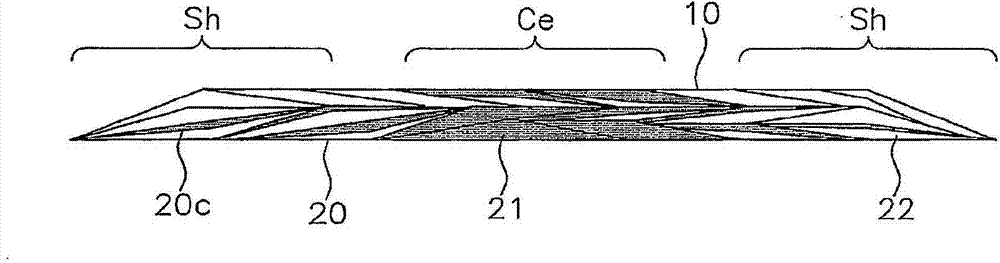

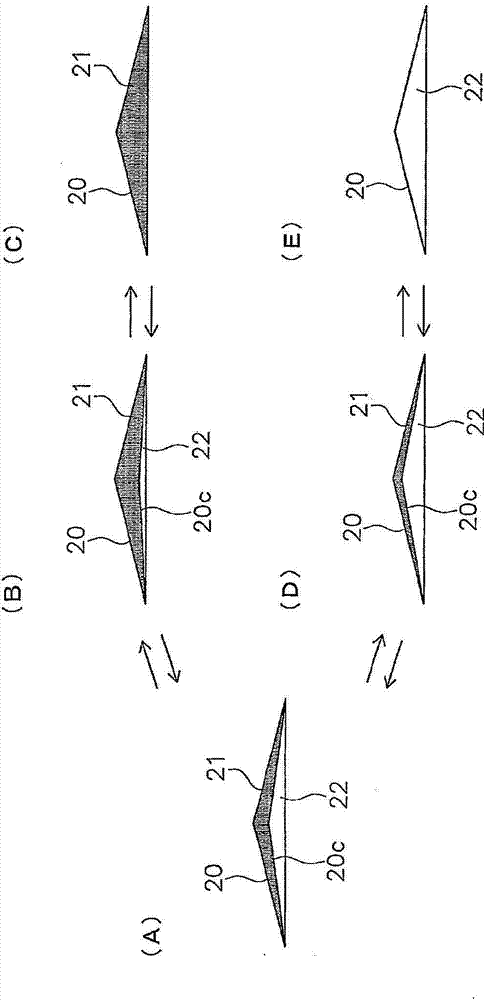

Pneumatic tire manufacturing method and pneumatic tire

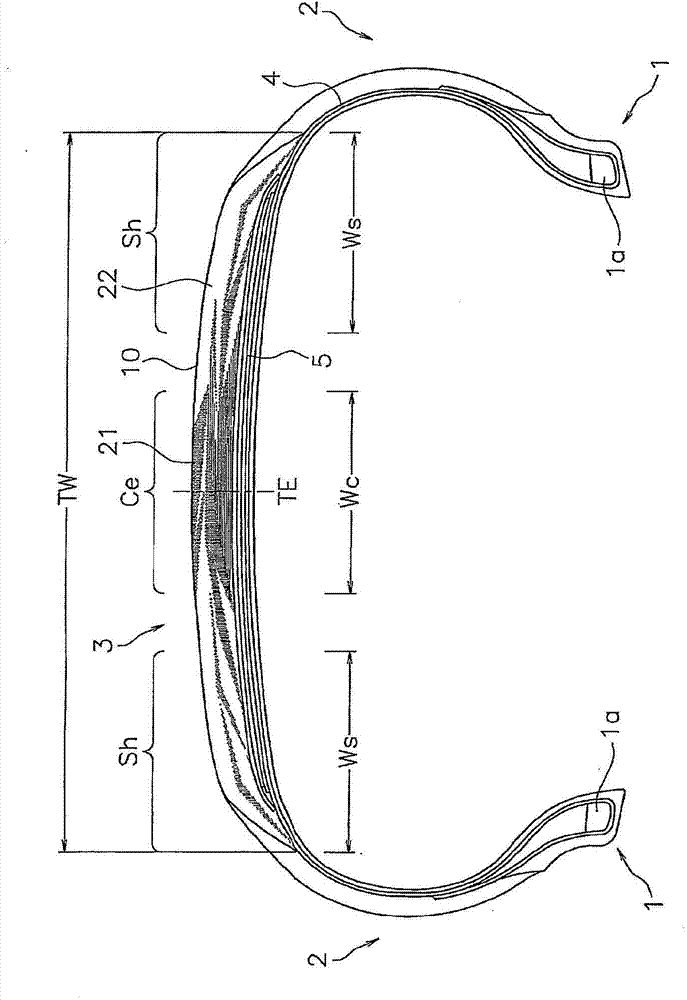

ActiveCN104512202AImprove rigidityImprove the vibration damping effectTyresTyre tread bands/patternsEngineeringTire manufacturing

A method of manufacturing a pneumatic tire has a winding step of forming a rubber ribbon winding body constructing a tread rubber by spirally winding a rubber ribbon obtained by co-extruding a first rubber and a second rubber which are different in hardness. The first rubber is mainly arranged in a first area by making a cross sectional area ratio of the first rubber greater than that of the second rubber. The second rubber is mainly arranged in a second area by making the cross sectional area ratio of the first rubber smaller than that of the second rubber. A portion in which the cross sectional area ratio of the first rubber becomes smaller by smaller is provided from the first area toward the second area. The rubber ribbon retaining a compound interface is superposed and wound to at least a part of the second area.

Owner:TOYO TIRE & RUBBER CO LTD

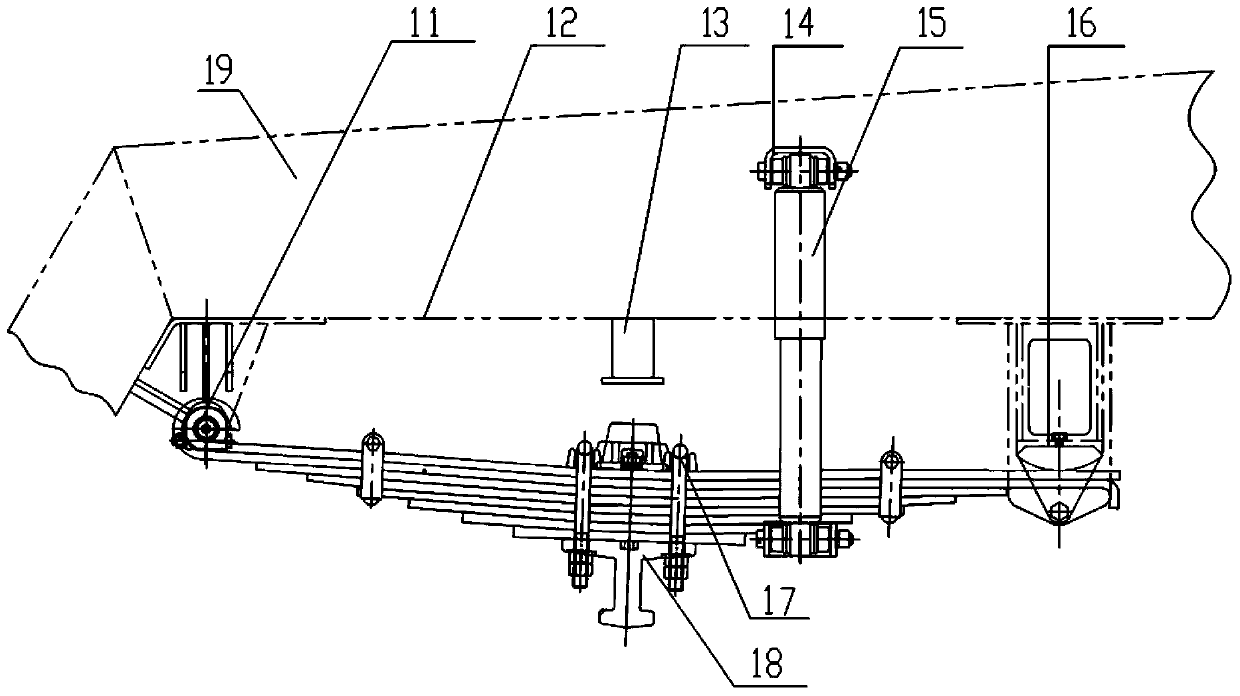

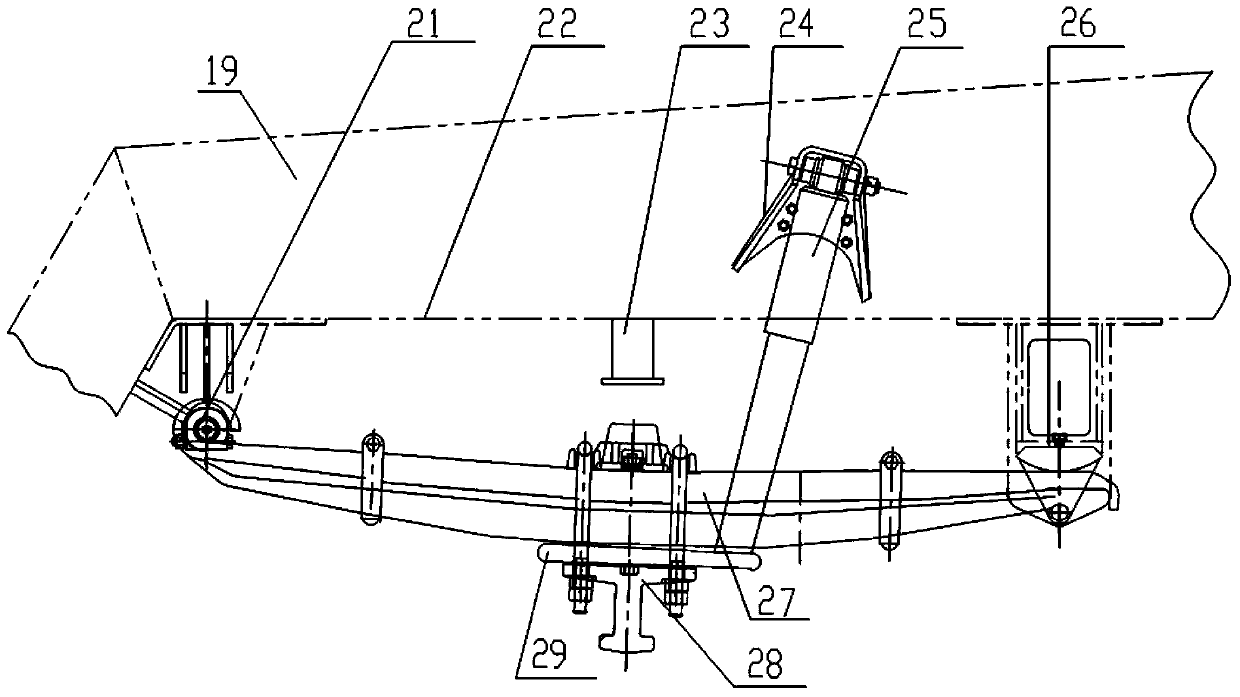

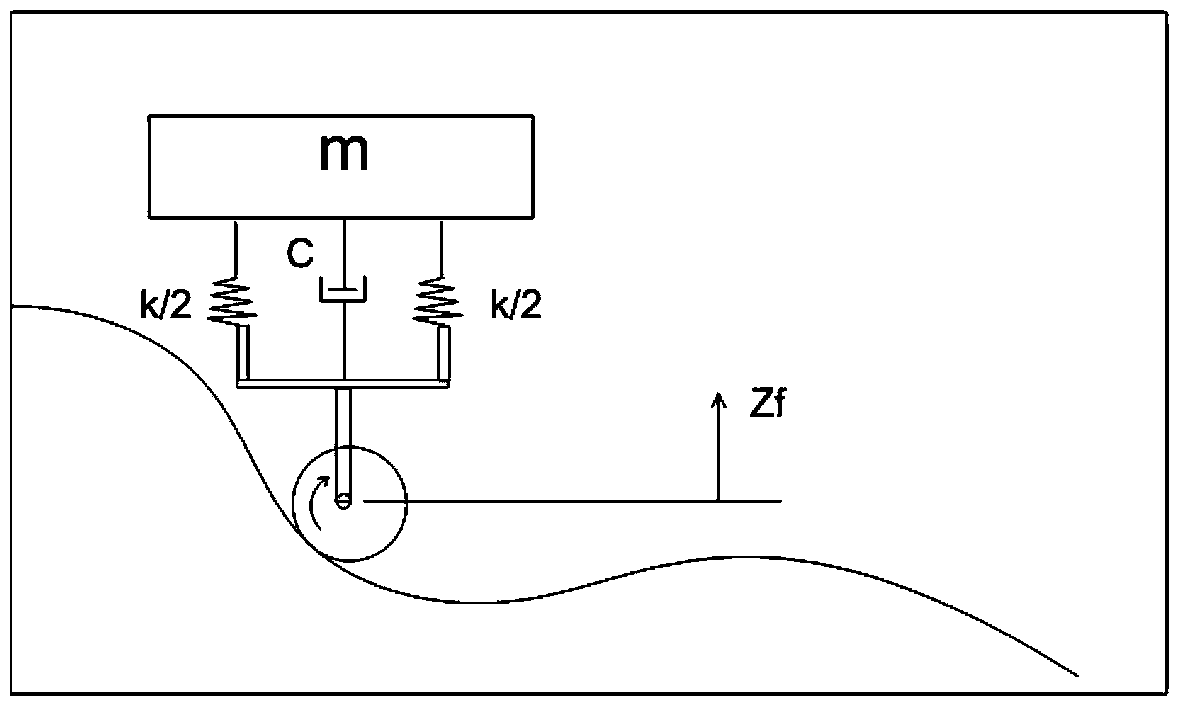

Suspension damping structure for engineering vehicles

InactiveCN103386869ANot easy to damageReduce wearResilient suspensionsVehicle frameControl engineering

The invention discloses a suspension damping structure for engineering vehicles, relates to the technical field of engineering machinery and solves the technical problems of poor damping effect and easy damage in the prior art. The suspension damping structure comprises a front suspension damping structure and / or a rear suspension damping structure; the front suspension damping structure comprises a front steel plate spring assembly and a front damper; the front steel plate spring assembly comprises a front end support, a rear end support, a fixing bolt and at least two front steel plate reeds stacked together; the front end support and the rear end support are respectively and fixedly connected with a frame of the engineering vehicle; the thickness of each front steel plate reed is gradually reduced from the middle of the front steel plate reed to the direction of any end of two ends of the front steel plate reed in the length direction; and a gap is remained between every two adjacent front steel plate reeds in the front steel plate reeds stacked together. The suspension damping structure for the engineering vehicles are used for improving the damping effect and reliability of the engineering vehicles.

Owner:XUZHOU HEAVY MASCH CO LTD

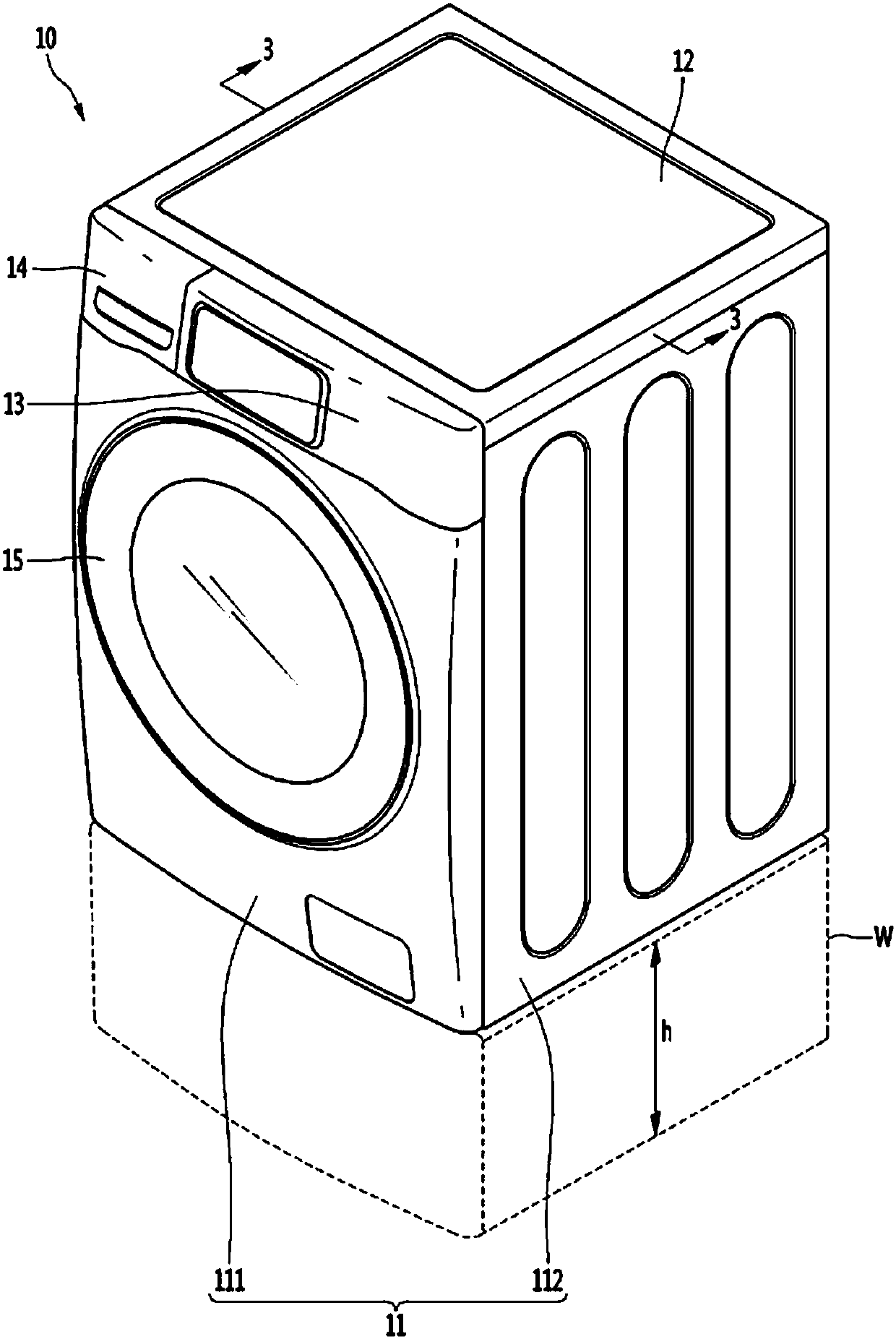

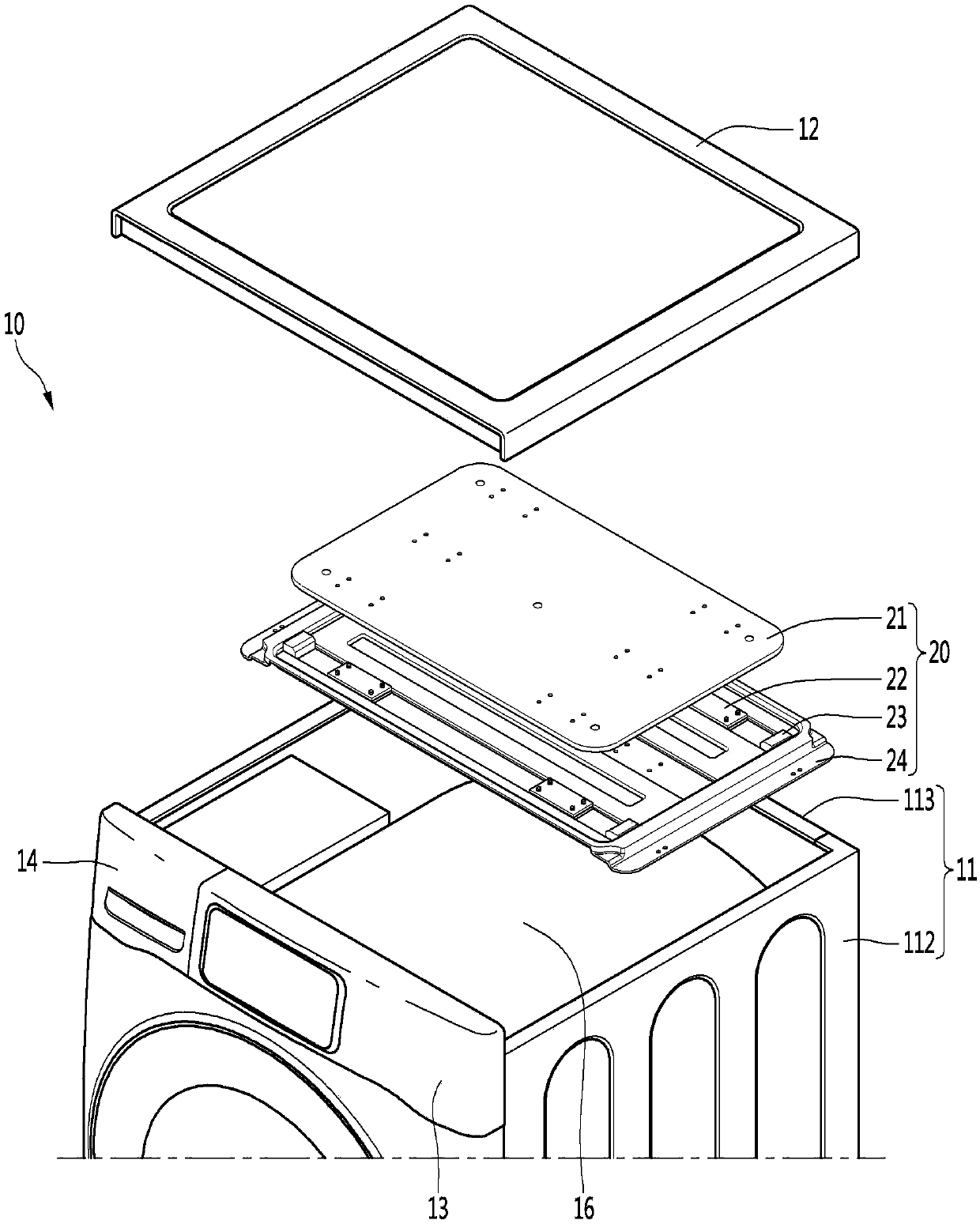

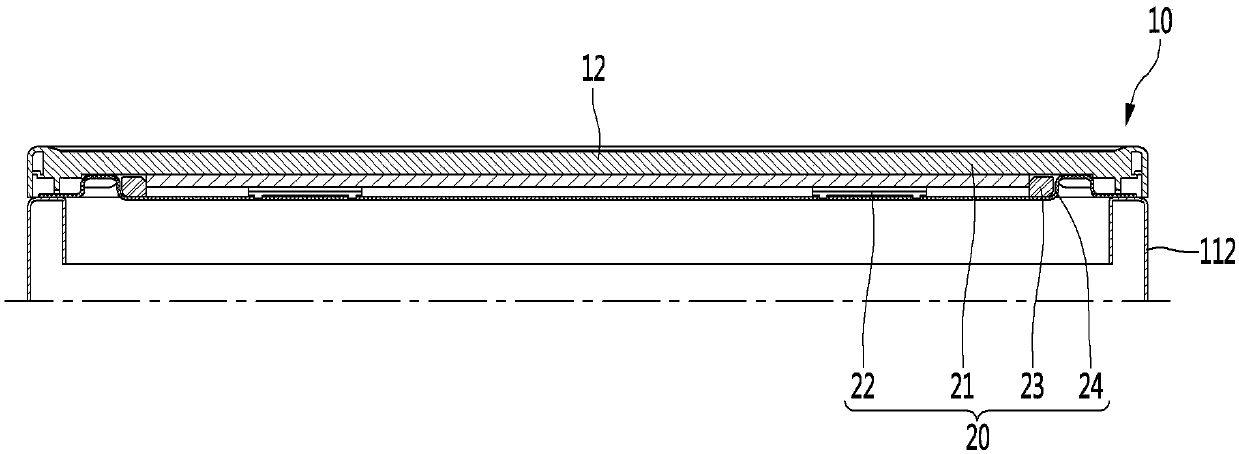

Laundry treating apparatus

ActiveCN107587313AImprove vibration damping abilityImproved vibration reduction effectNon-rotating vibration suppressionOther washing machinesLaundryEngineering

The invention relates to a laundry treating apparatus which includes a cabinet, a drum accommodated in the cabinet, a tub accommodating the drum, and a dynamic absorber provided to absorb oscillationof the cabinet. The dynamic absorber includes a support plate coupled to the cabinet, mass bodies movably provided on the support plate, and sliders arranged between the mass bodies and the support plate, and the sliders can enable the mass bodies to perform reciprocating motion on the support plate while attenuating due to frictional force.

Owner:LG ELECTRONICS INC

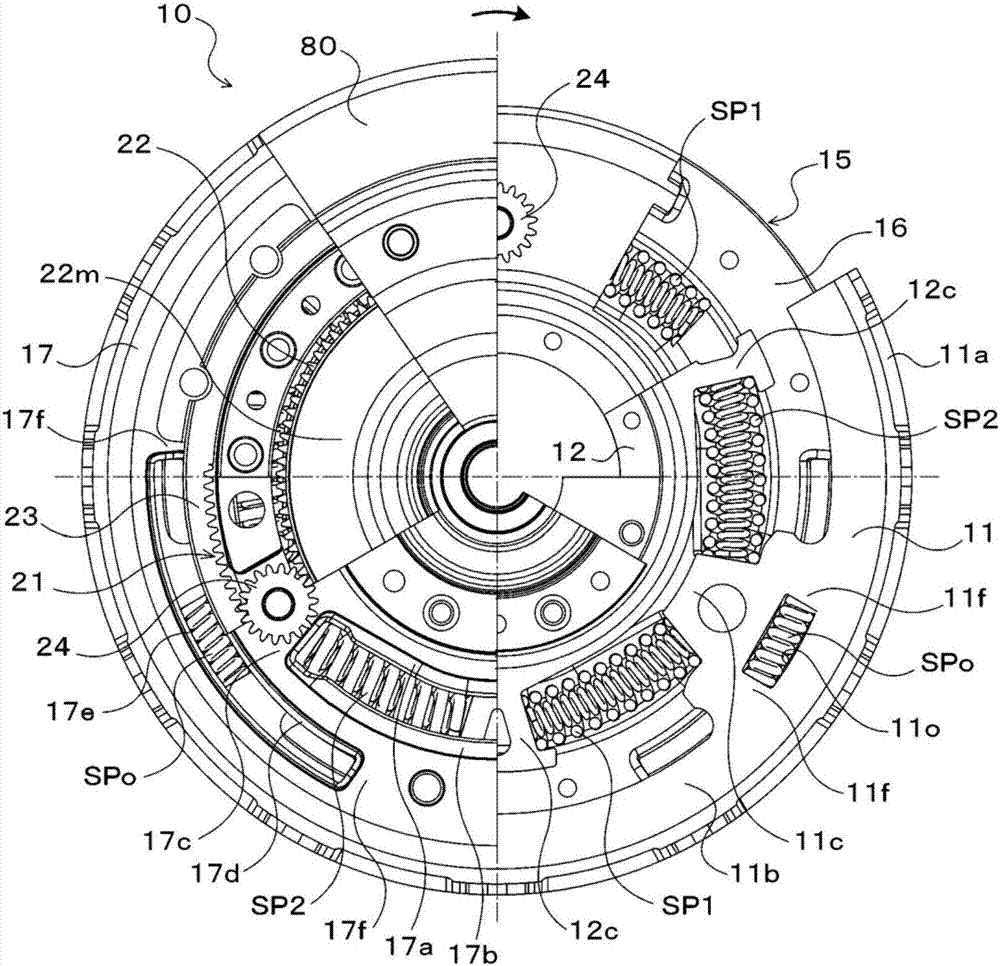

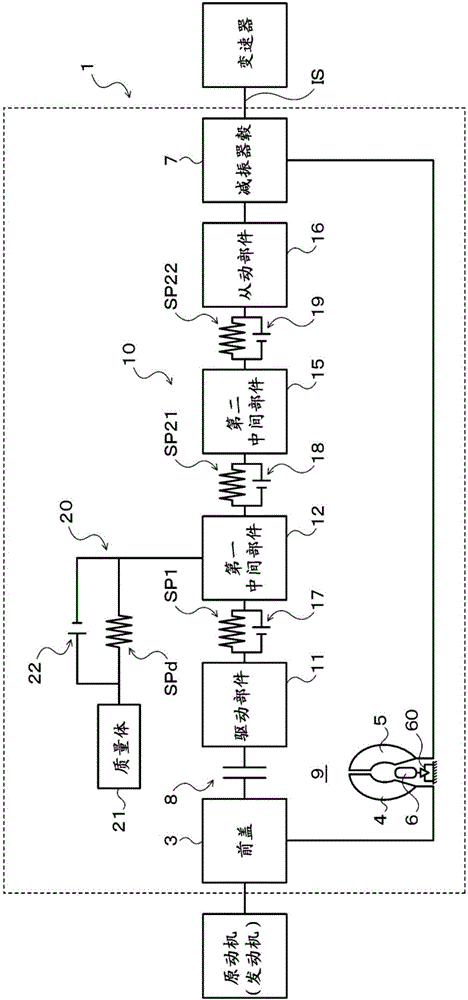

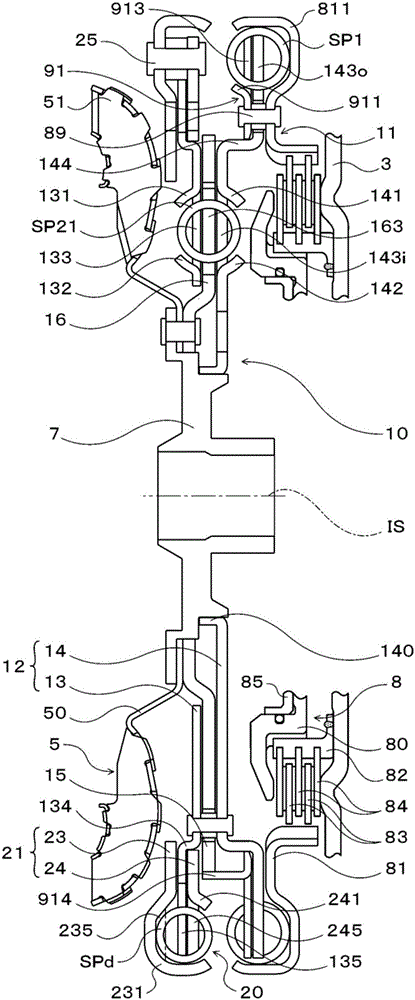

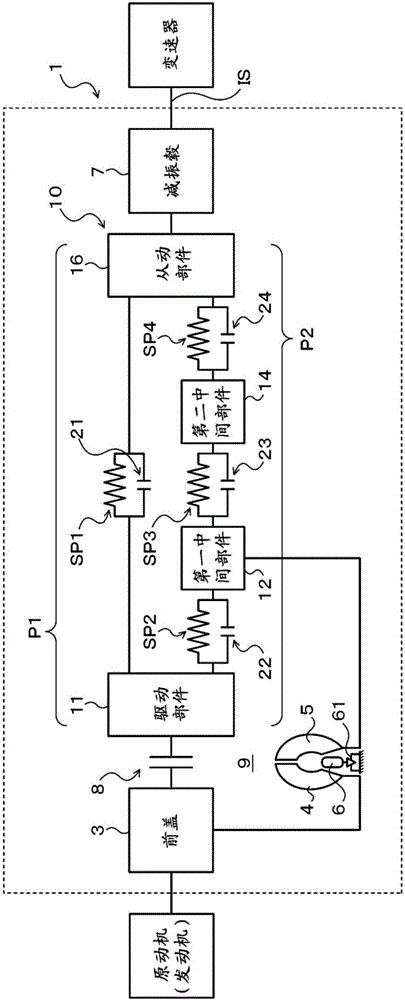

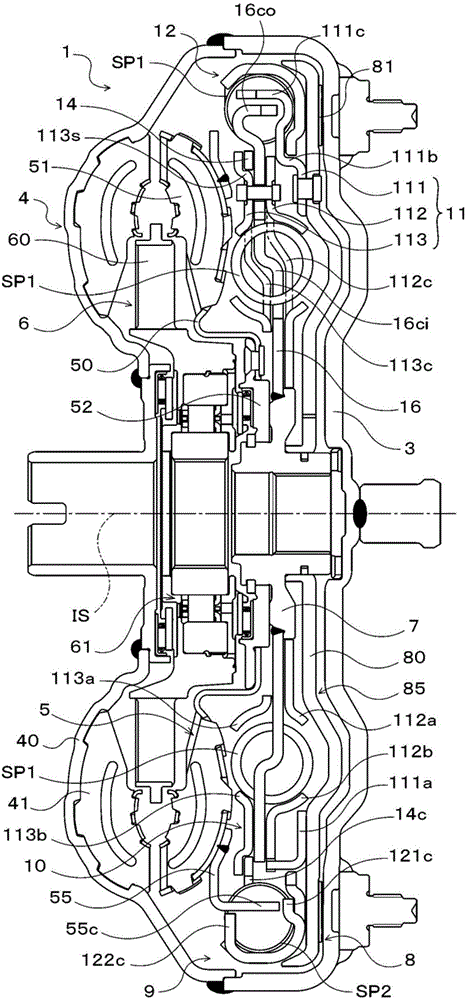

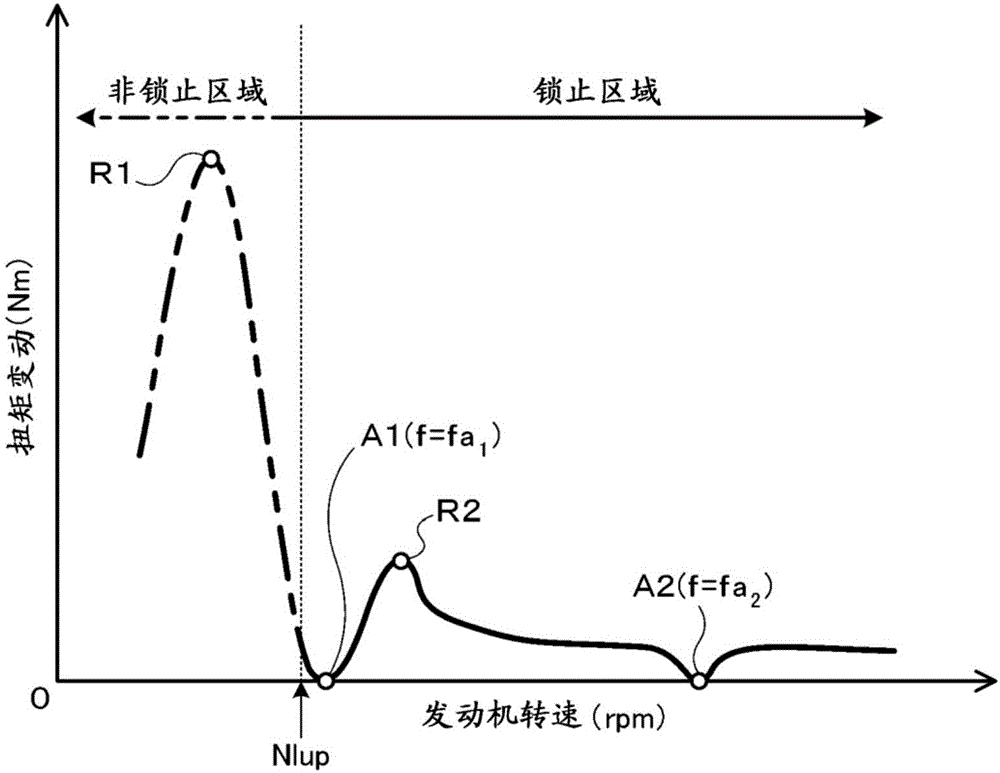

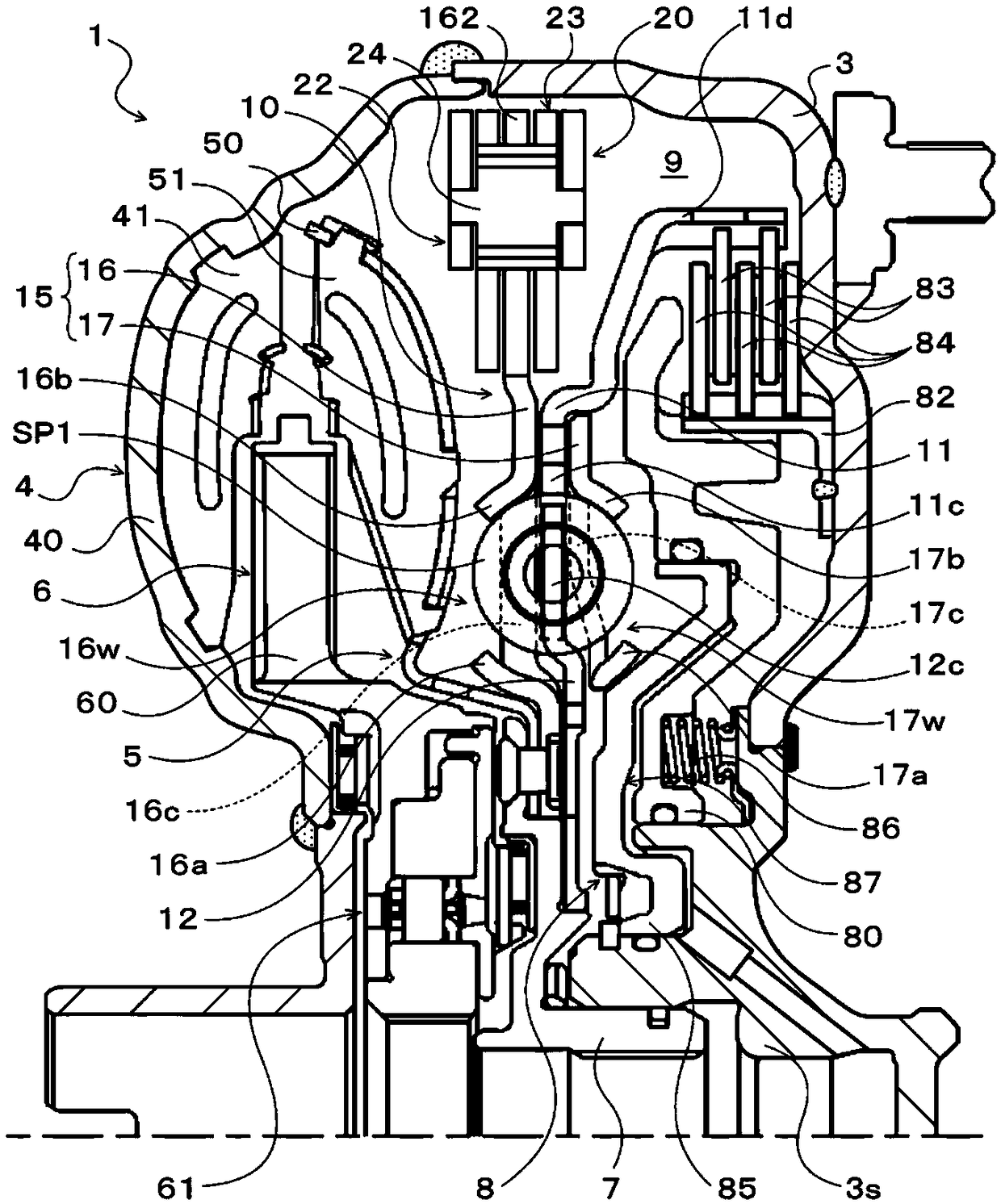

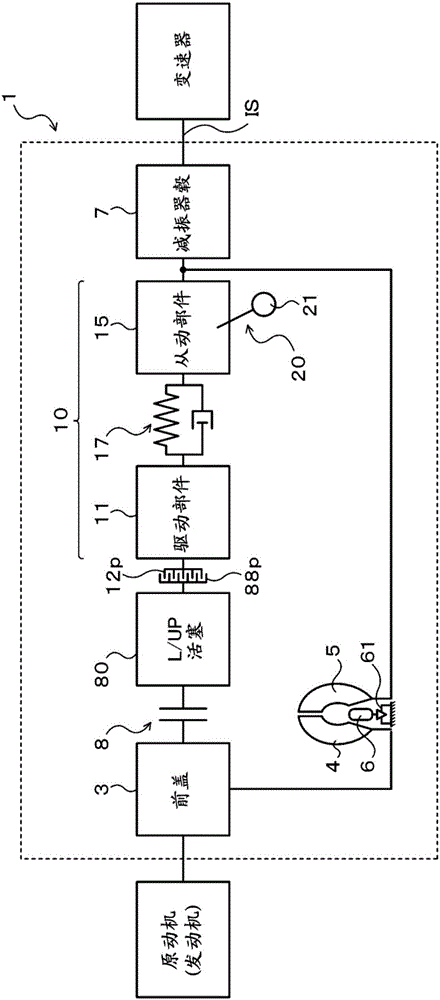

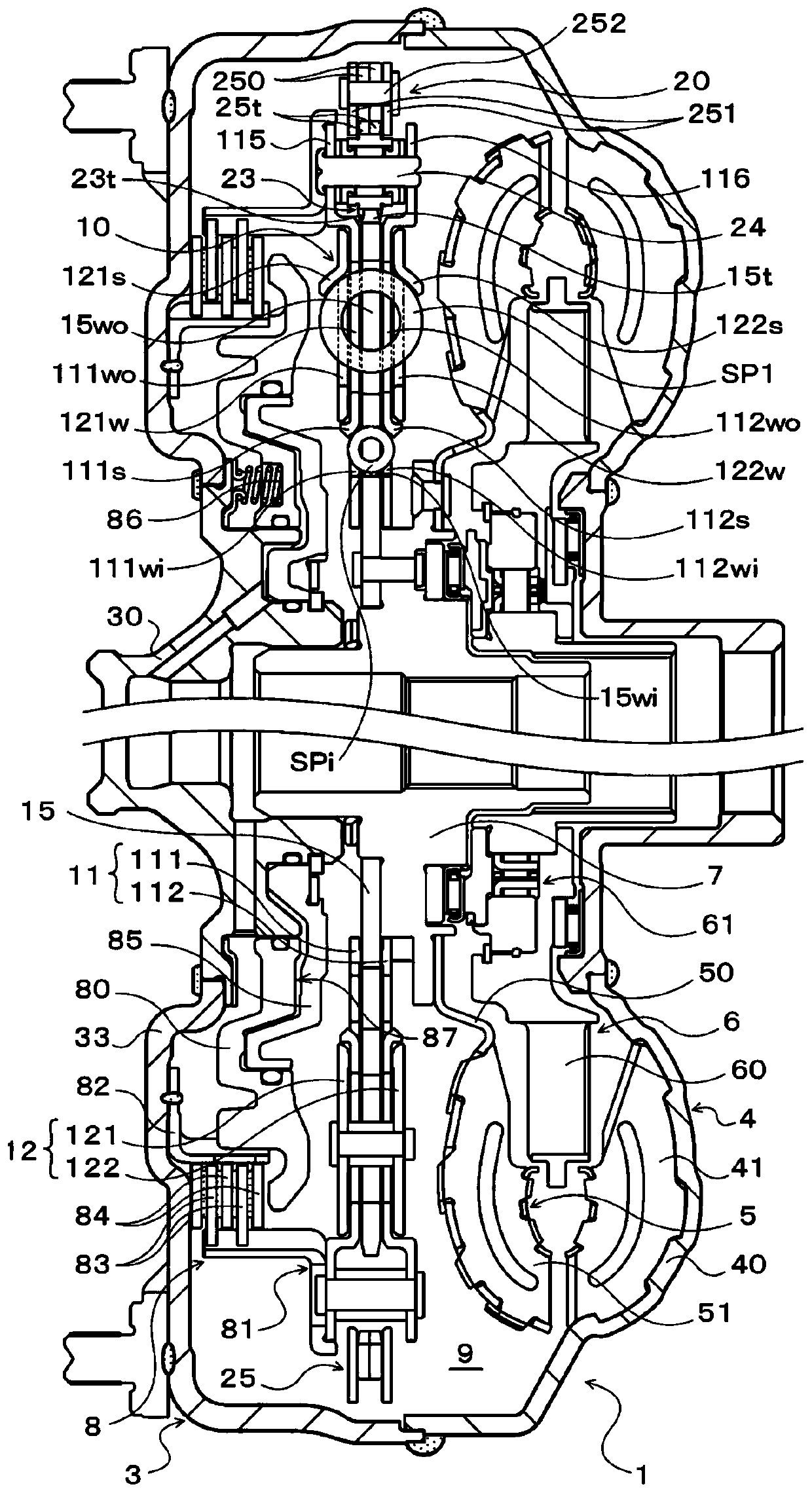

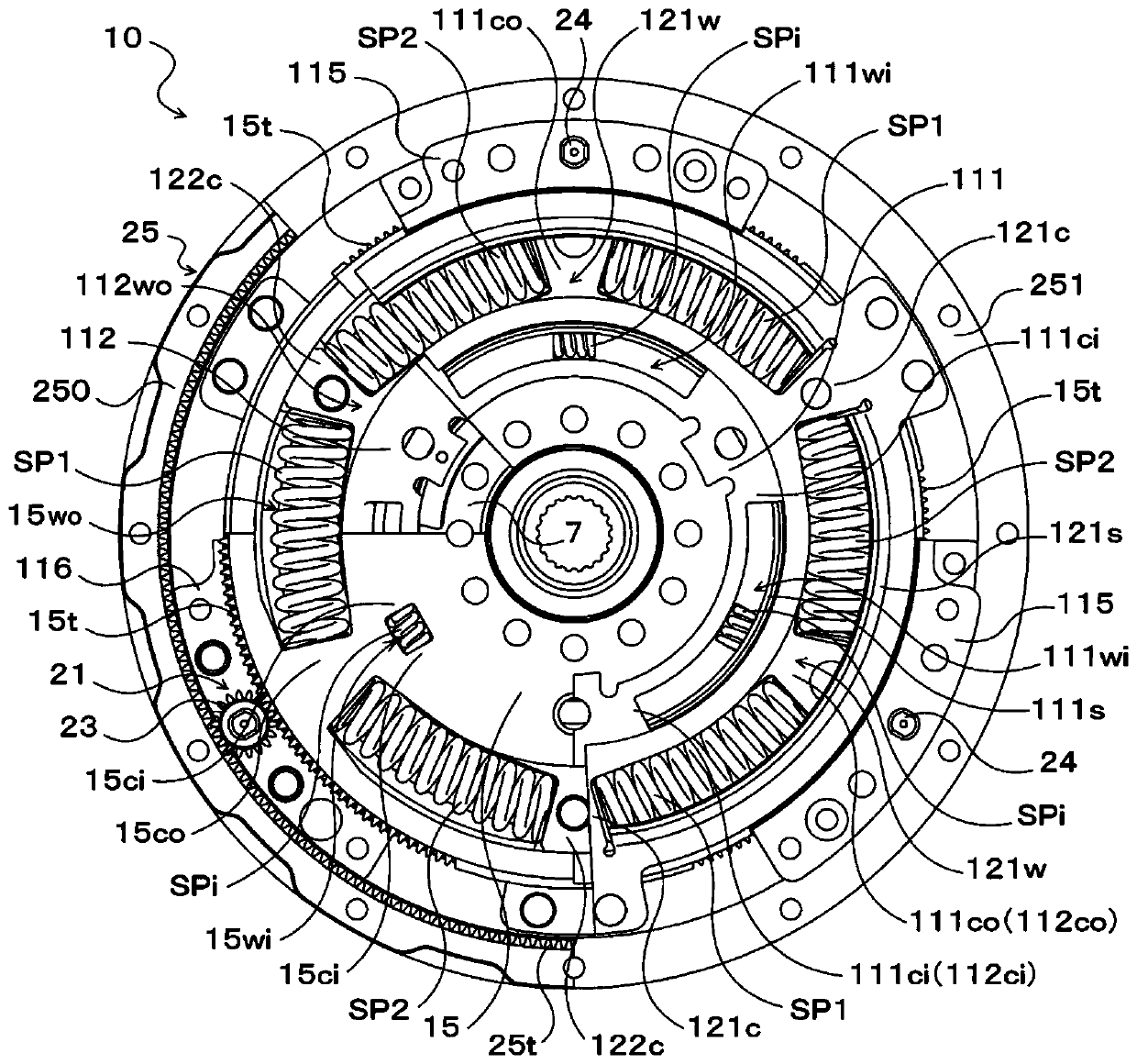

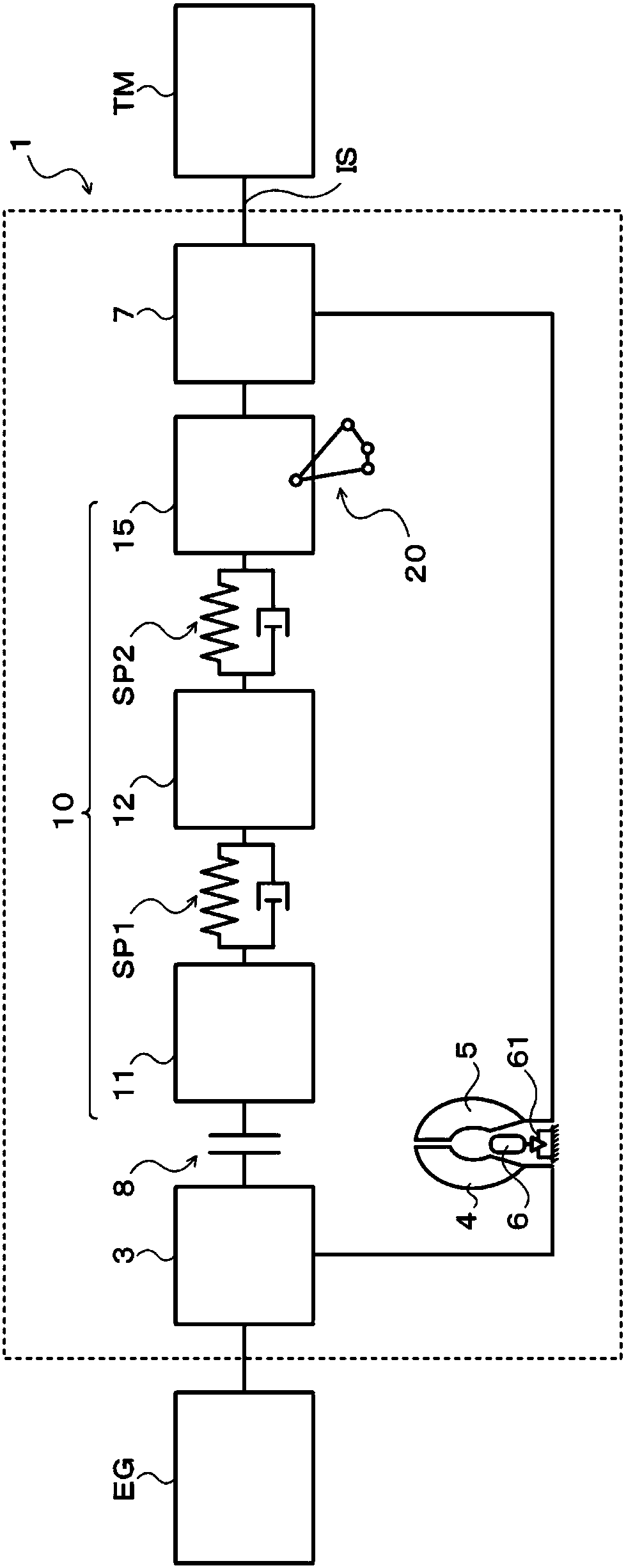

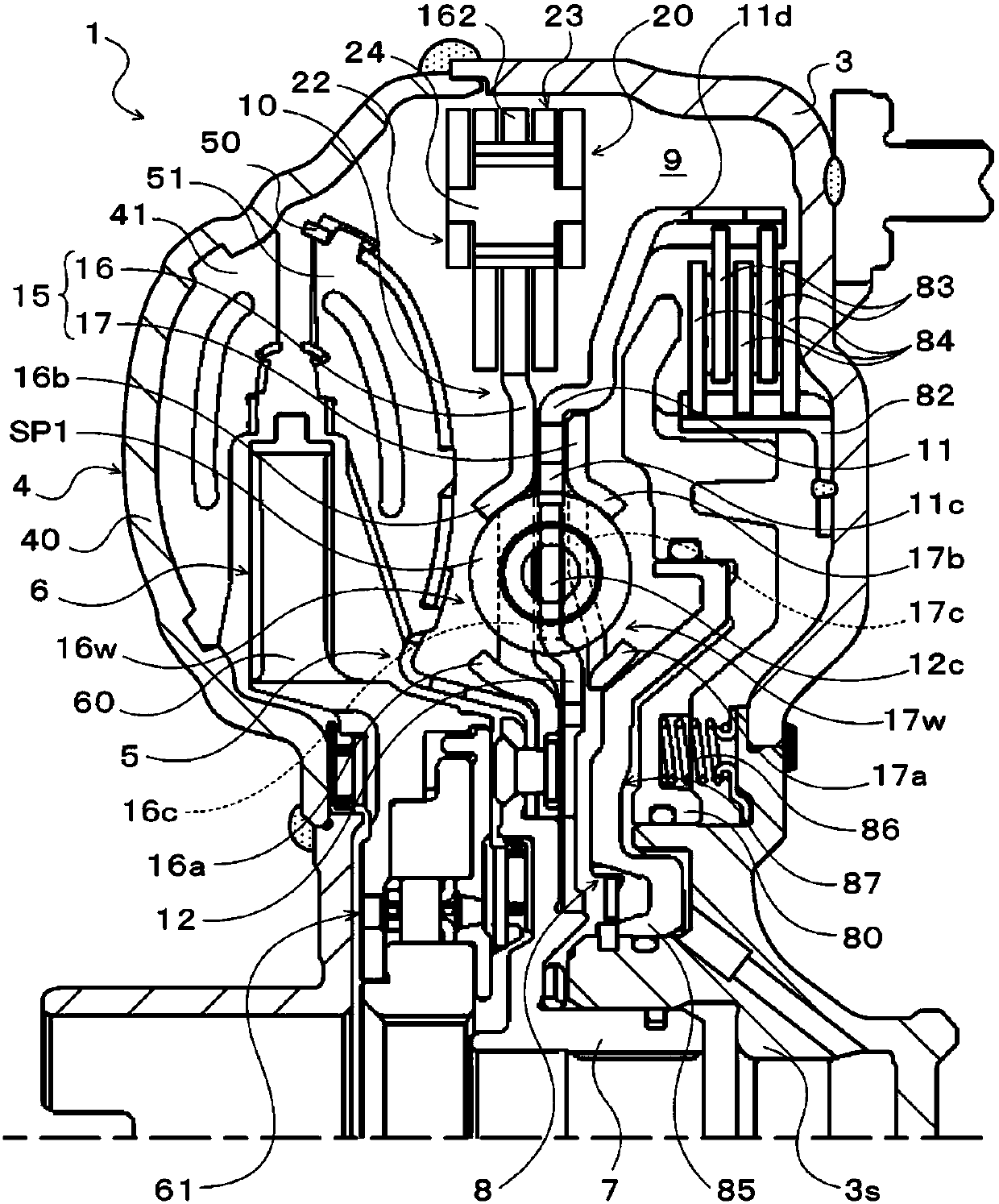

Damper device

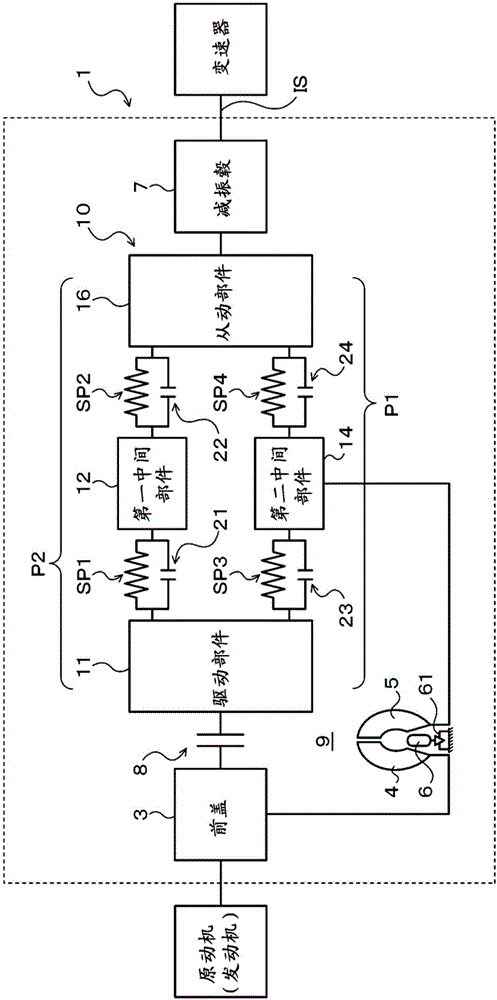

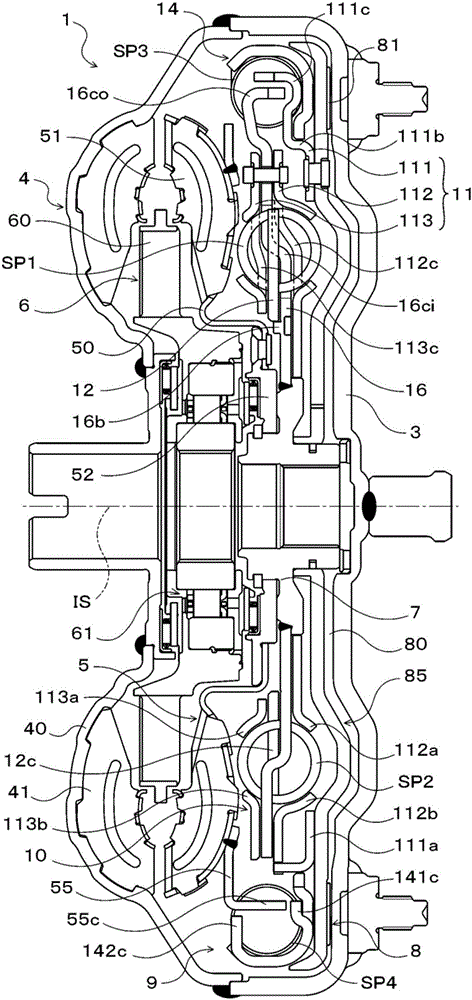

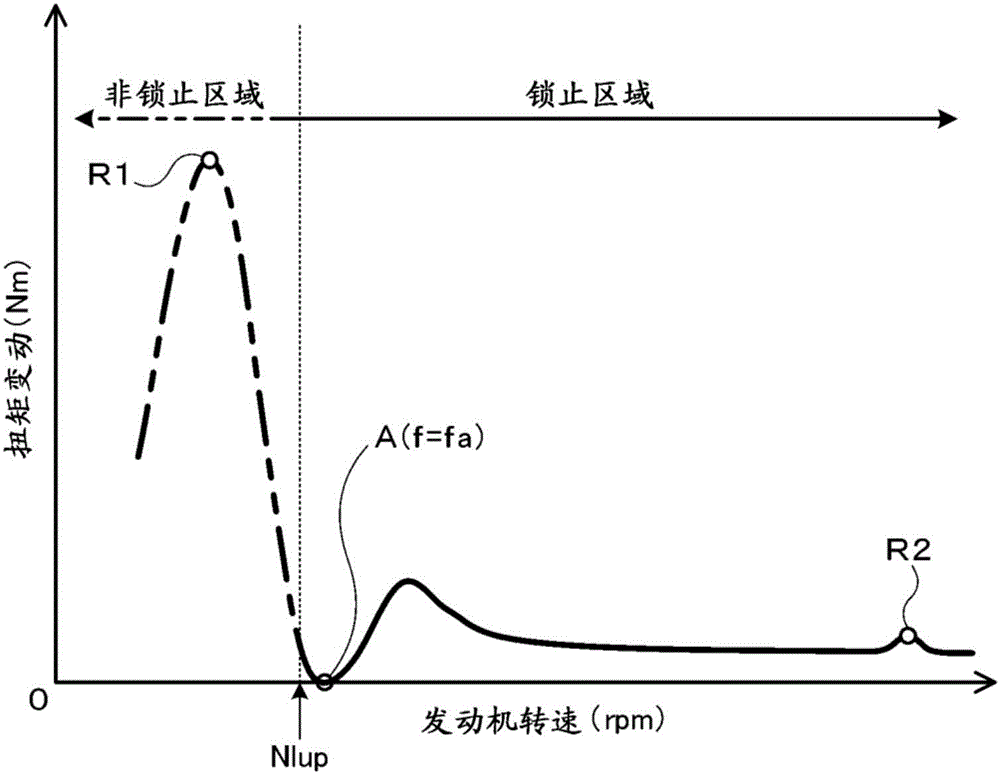

InactiveCN106536970AImprove the vibration damping effectFriction clutchesFluid gearingsTorque transmissionControl theory

Provided is a damper device 10 comprising the following between a drive member 11 and a driven member 16: a first torque transmission path P1 that includes a first spring SP1, a first intermediate member 12, and a second spring SP2; and a second torque transmission path P2 that includes a third spring SP3, a second intermediate member 14, and a fourth spring SP4. The first and second springs SP1 and SP2 are arranged so as to be aligned along the circumferential direction of the damper device 10. The third and fourth springs SP3 and SP4 are arranged so as to be aligned along the circumferential direction of the damper device 10 more to the outside in the radial direction of the damper device than the first and second springs SP1 and SP2.

Owner:AISIN AW CO LTD

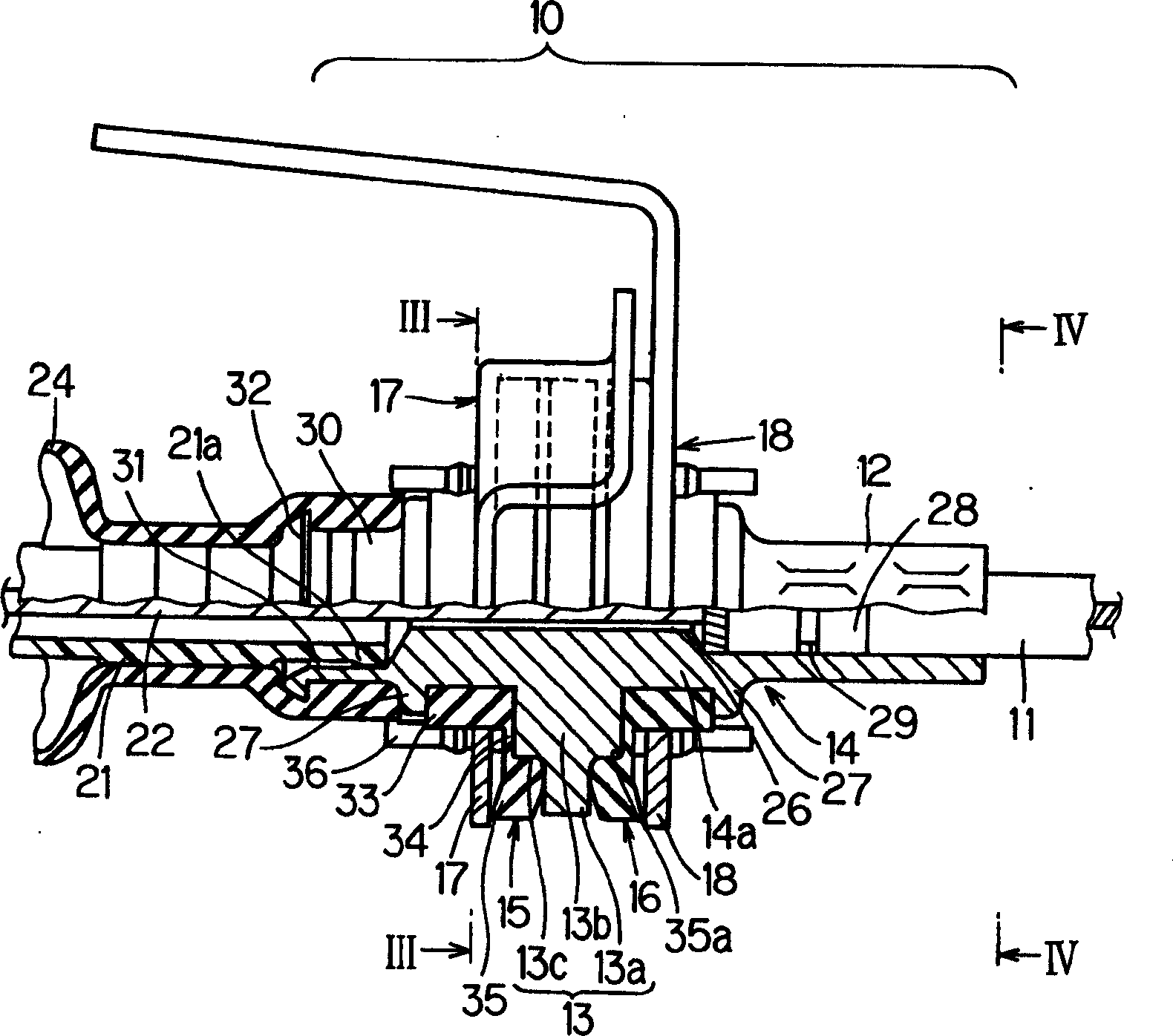

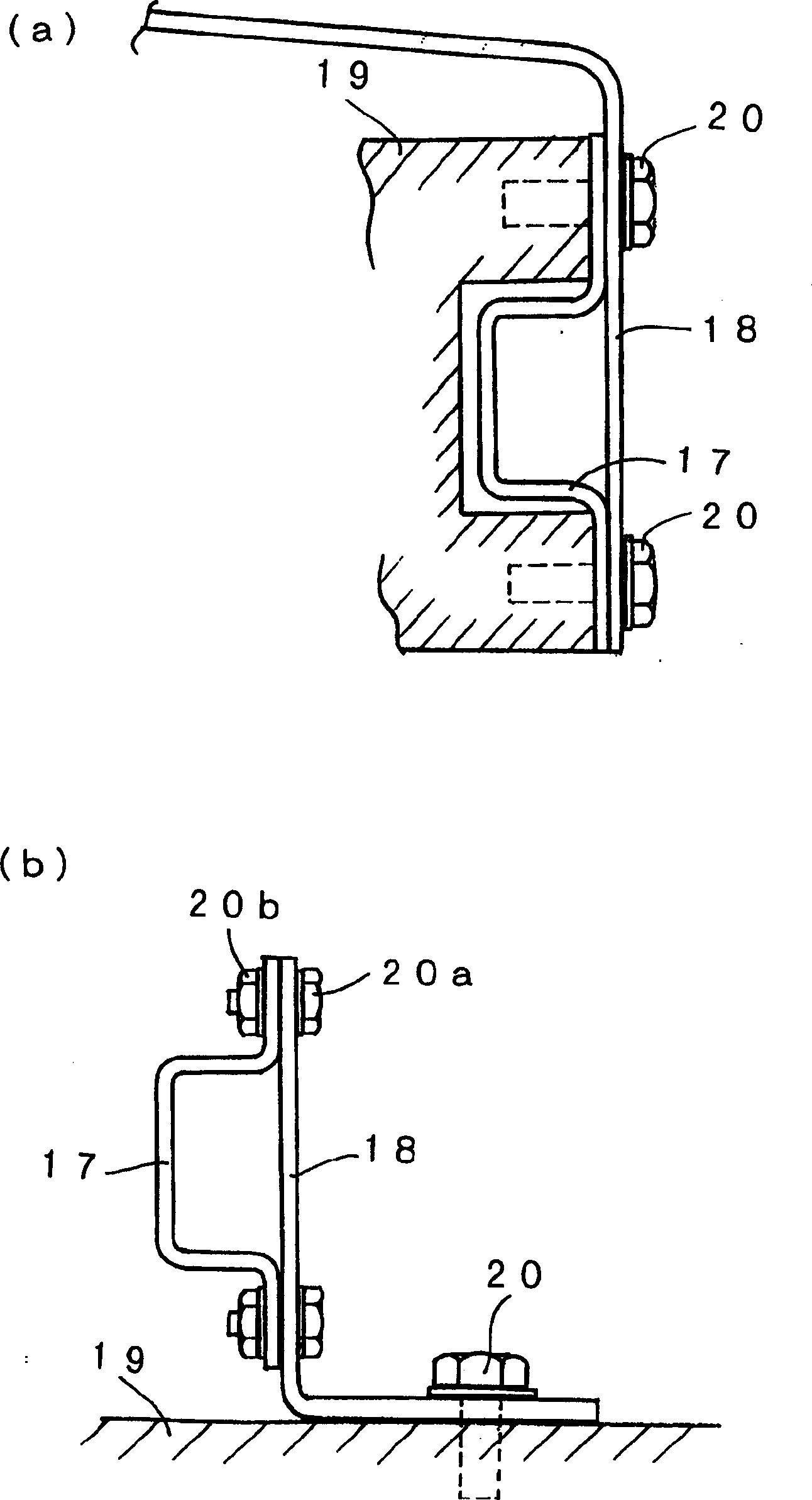

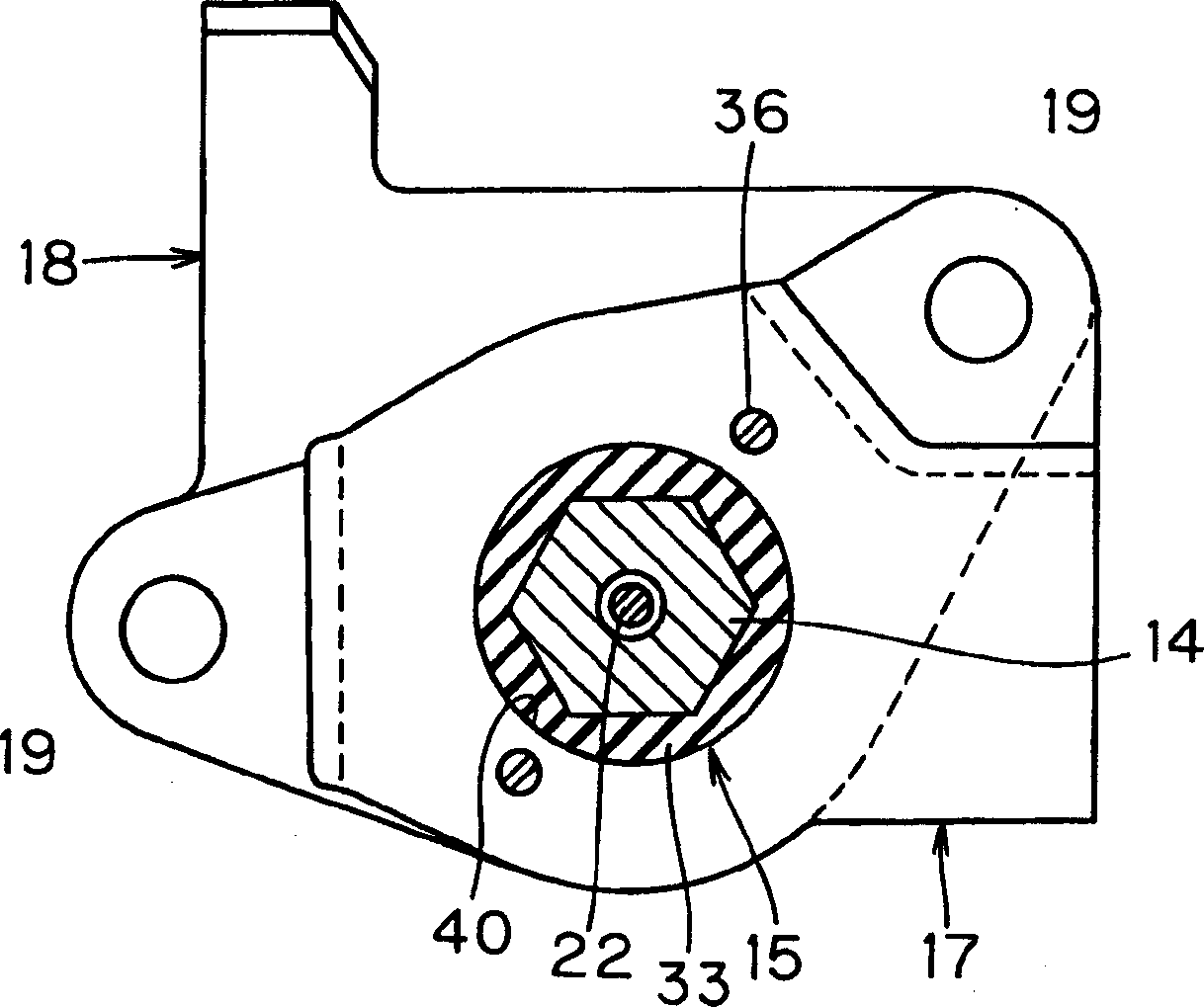

End support operation cable

InactiveCN1485549AImprove the vibration damping effectNot easy to passShaft for linear movementEngineeringMechanical engineering

The terminal support device 10 is equipped with a casing cap 14 which has a conduit pipe fixing part 12 at one end and a flange 13 at the central part 14a, a pair of ring shaped dampers 15, 16 which are arranged so as to abut to both sides of the flange 13 at the outer periphery of the casing cap, and a first holding plate 17 and a second holding plate 18 which press to hold these dampers to the flange 13 side so as not to restraint their periphery.

Owner:NIPPON CABLE SYSTEM INC +1

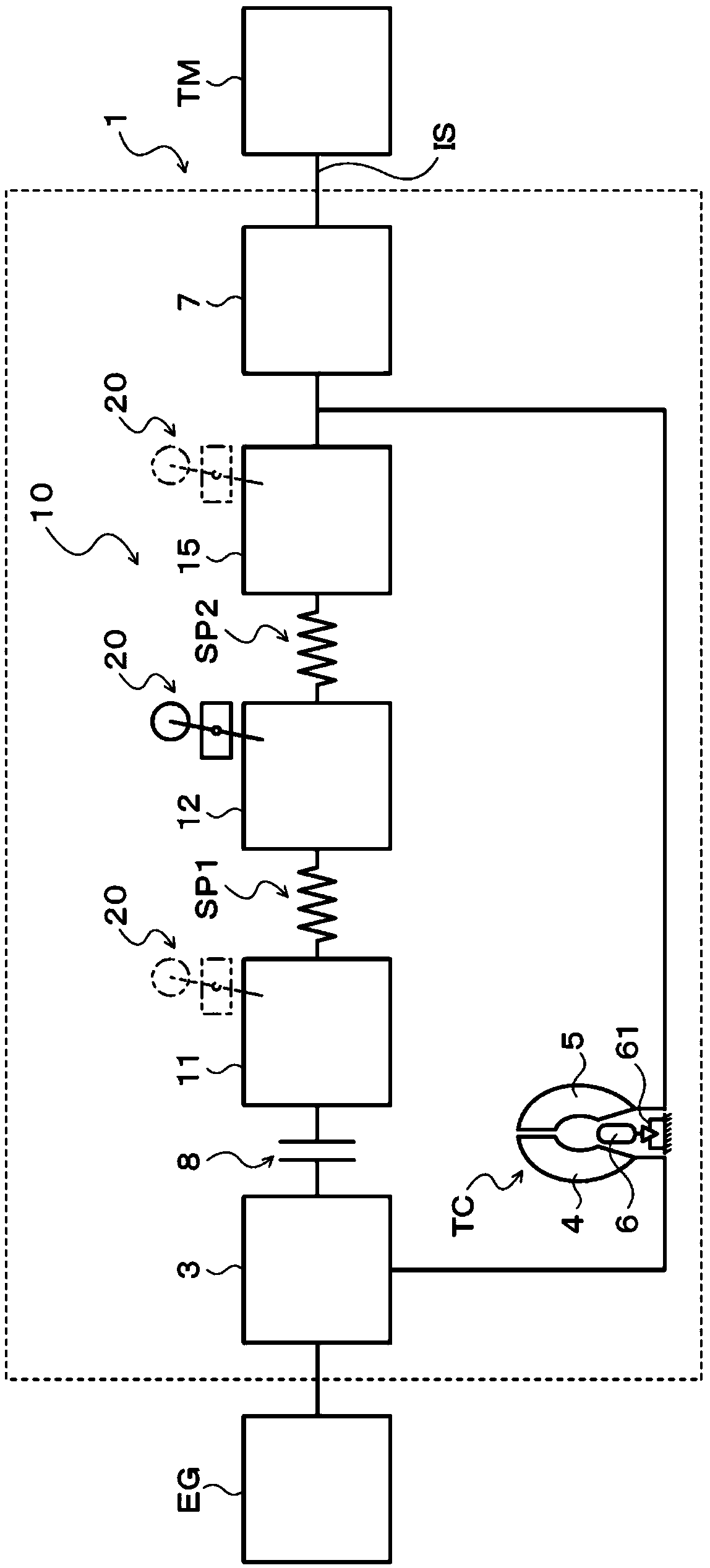

Damper apparatus

ActiveCN107110323AImprove the vibration damping effectFluid gearingsVibration suppression adjustmentsInertial massTorque transmission

A damper apparatus (10Y) includes a first inner spring (SP1') for transmitting torque between a drive member (11Y) and an intermediate member (12Y), a second inner spring (SP2') for transmitting torque between the intermediate member (12Y) and a driven member (15Y), and a rotational inertial mass damper (20Y) having a sun gear (22) as a body of mass that rotates according to the relative rotation between the drive member (11Y) and the driven member (15Y), the rotational inertial mass damper (20Y) being provided in parallel with a torque transmission path (TP) that includes the intermediate member (12Y) and first and second inner springs (SP1, SP2), and the damping ratio Zeta of the intermediate member (12) being a value of less than 1, as determined on the basis of the inertia moment (J2) of the intermediate member (12Y) and the rigidities (k1, k2) of the first and second inner springs (SP1', SP2').

Owner:AISIN AW INDUSTRIES CO LTD +1

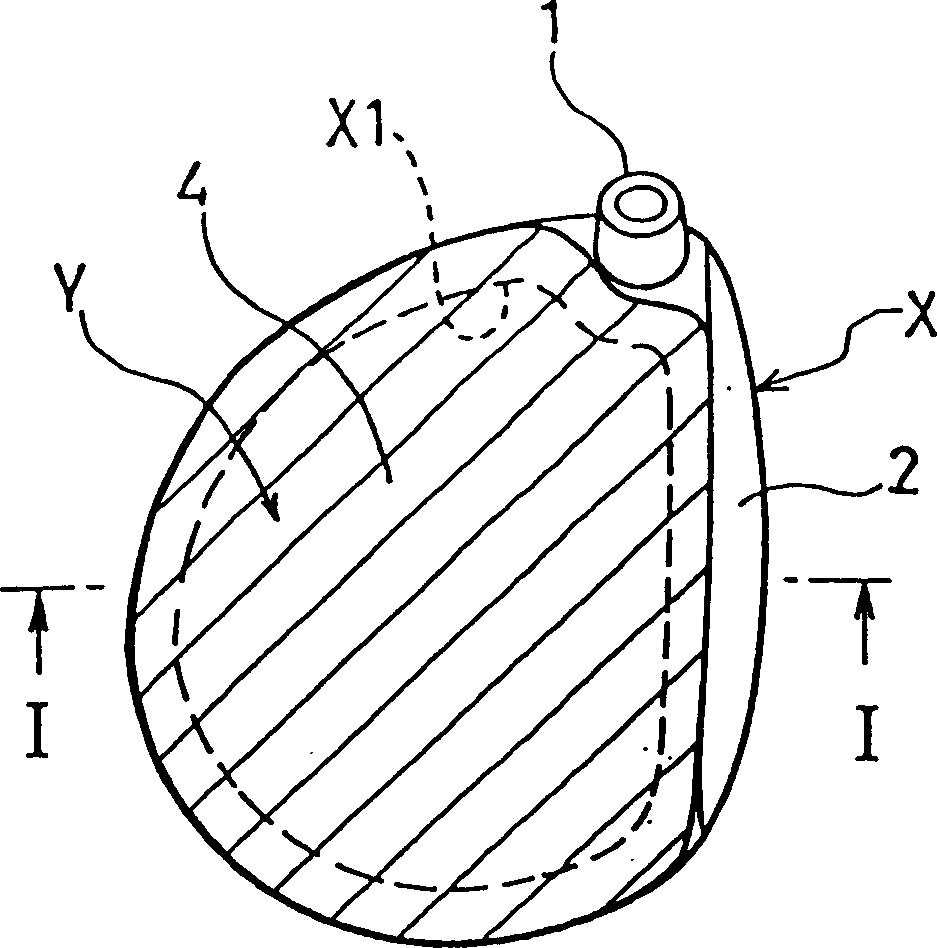

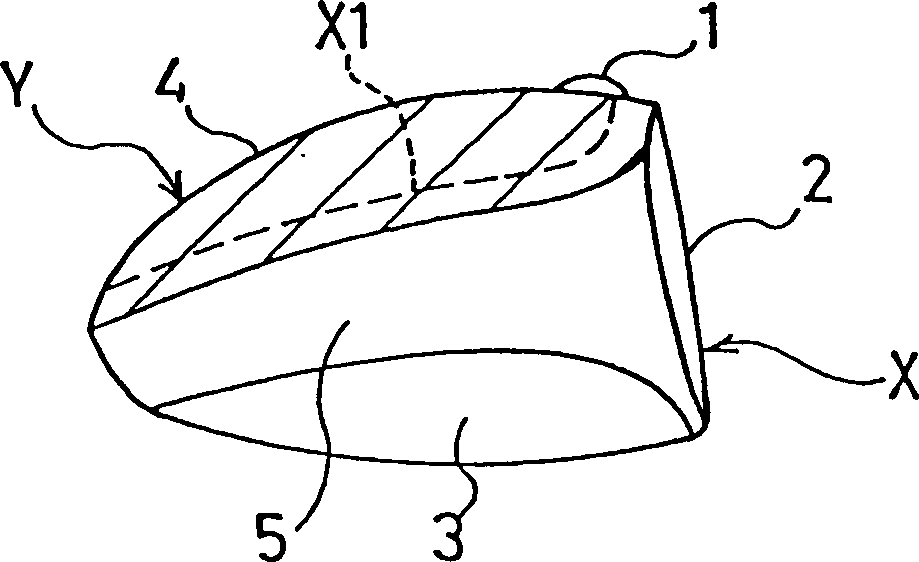

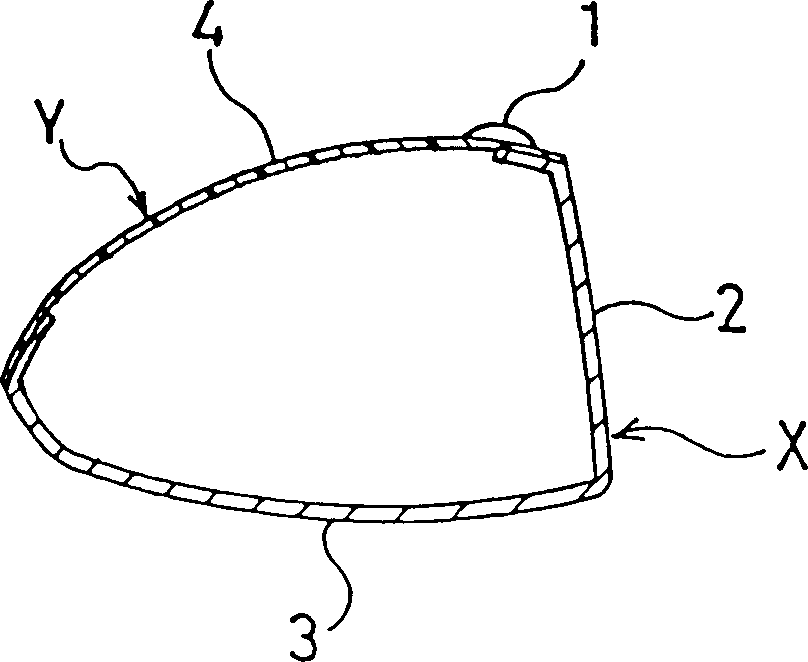

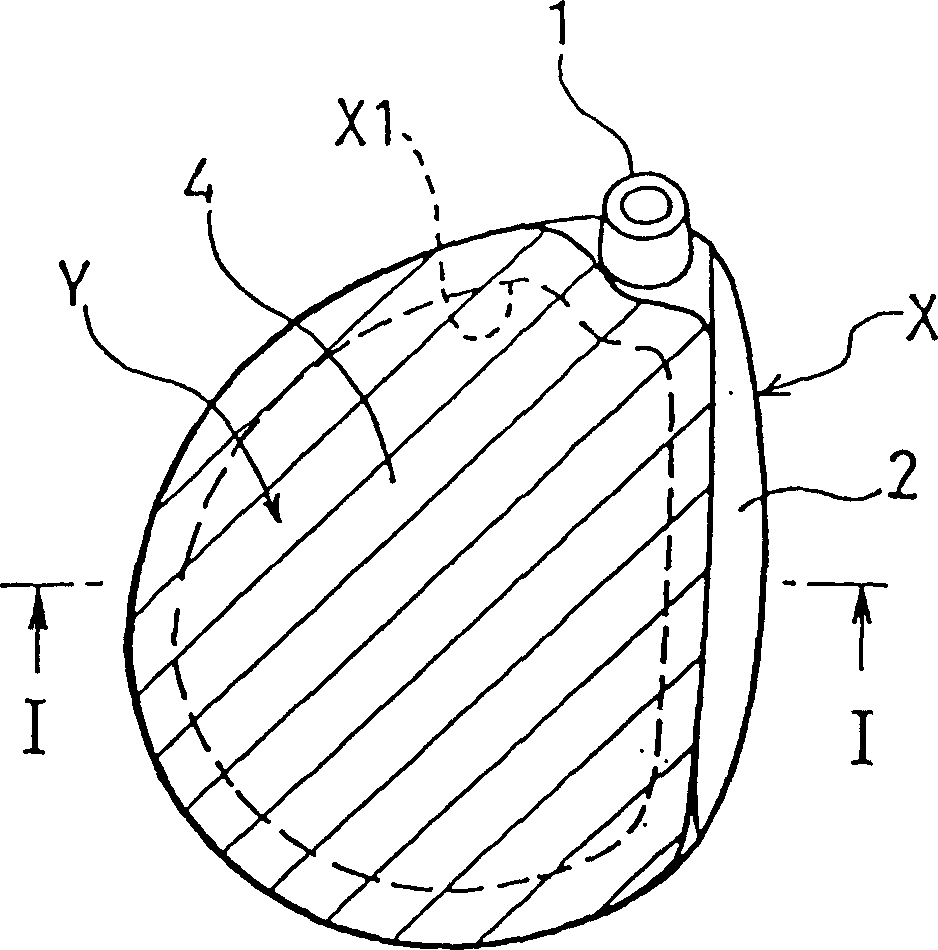

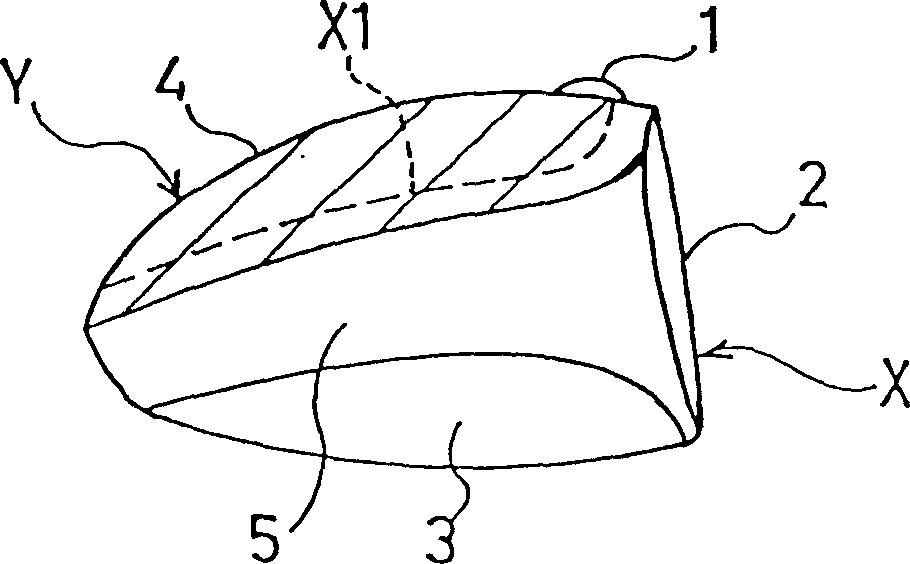

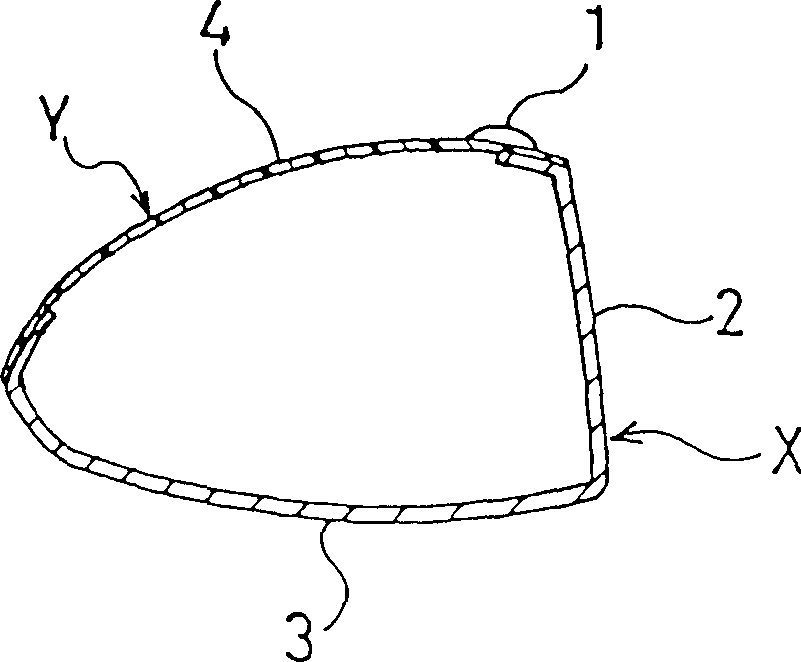

Golf club head

InactiveCN1539534AImprove convenienceSignificant effect and effectGolf clubsRacket sportsVibration attenuationFiber

A golf club head with vibration attenuation and very nice beating sound features that there is a hollow structure in at least one of neck, face, bottom, crown and side part, which is made of the fibre reinforced plastics and metal.

Owner:YOKOHAMA RUBBER CO LTD

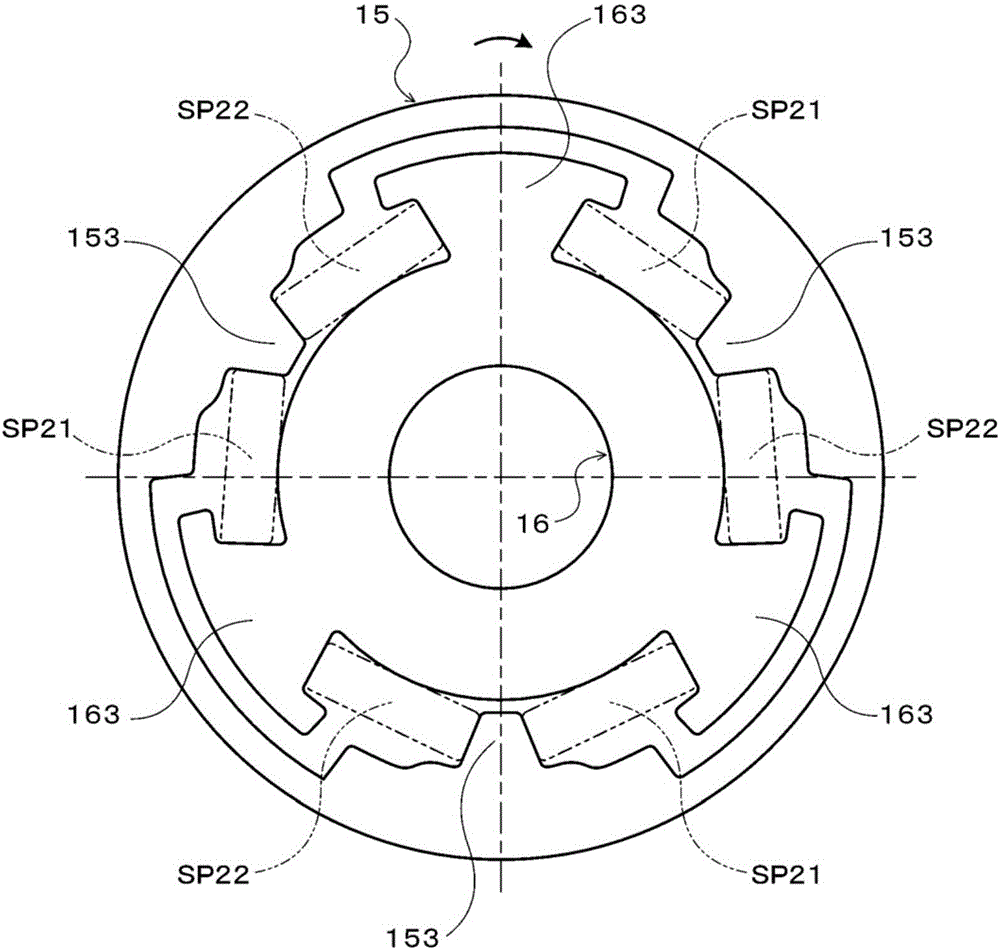

Damper device

ActiveCN106233032AImprove the vibration damping effectReduce rigidityRotating vibration suppressionYielding couplingCoil springControl theory

A damper device (10) includes: a dynamic damper coupled to a first intermediate member; and first and second inner springs (SP21, SP22) which operate in series with each other and which are straight coil springs interposed between a second intermediate member (15) and a driven member (16) so as to restrict an outward displacement of the springs (SP21, SP22) at the respective ends thereof in a radial direction of the damper device (10). A gap is formed between bodies (Bsp) of the first and second inner springs (SP21, SP22) and a spring contact portion (163) of the second intermediate member (15) or the driven member (16).

Owner:AISIN AW CO LTD

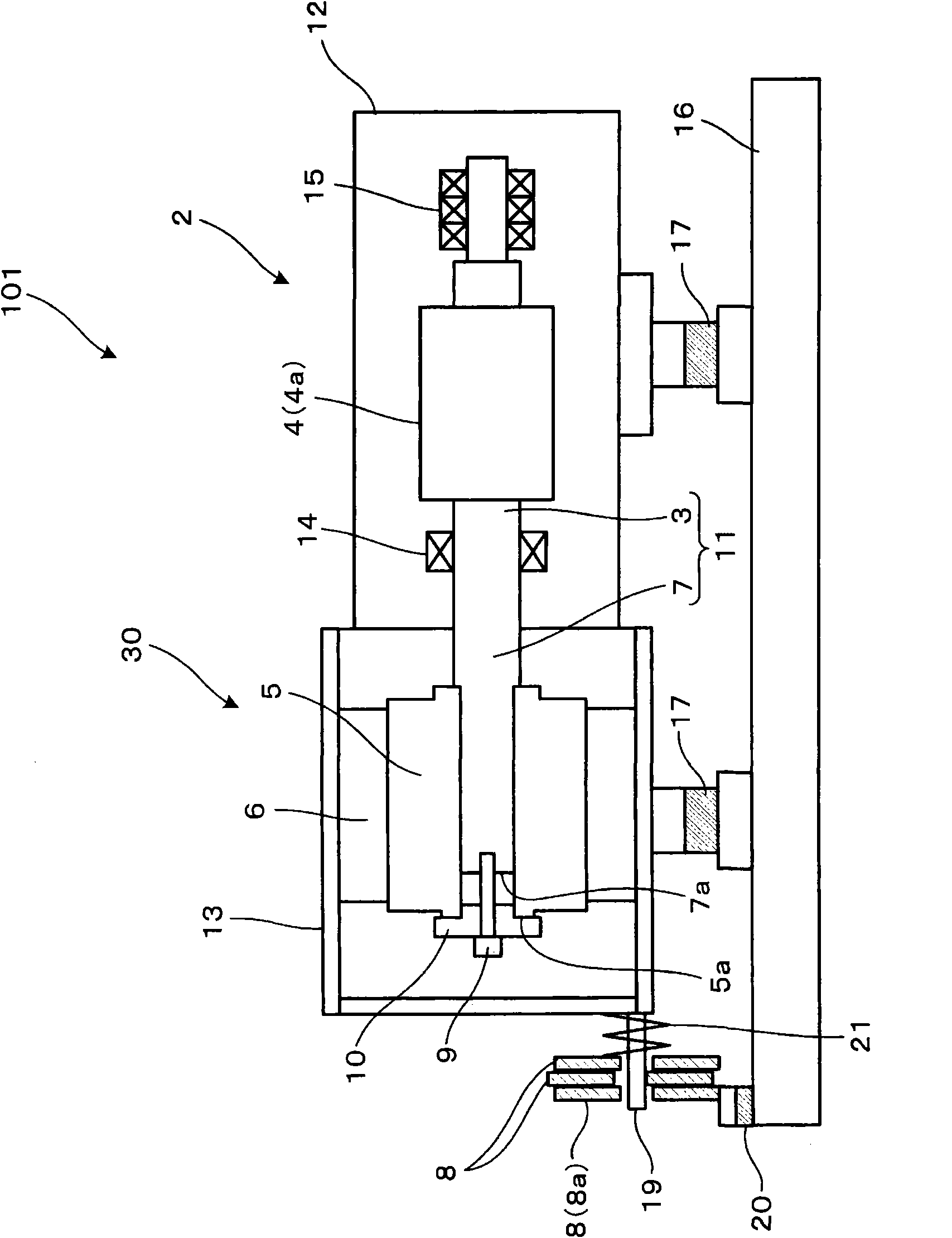

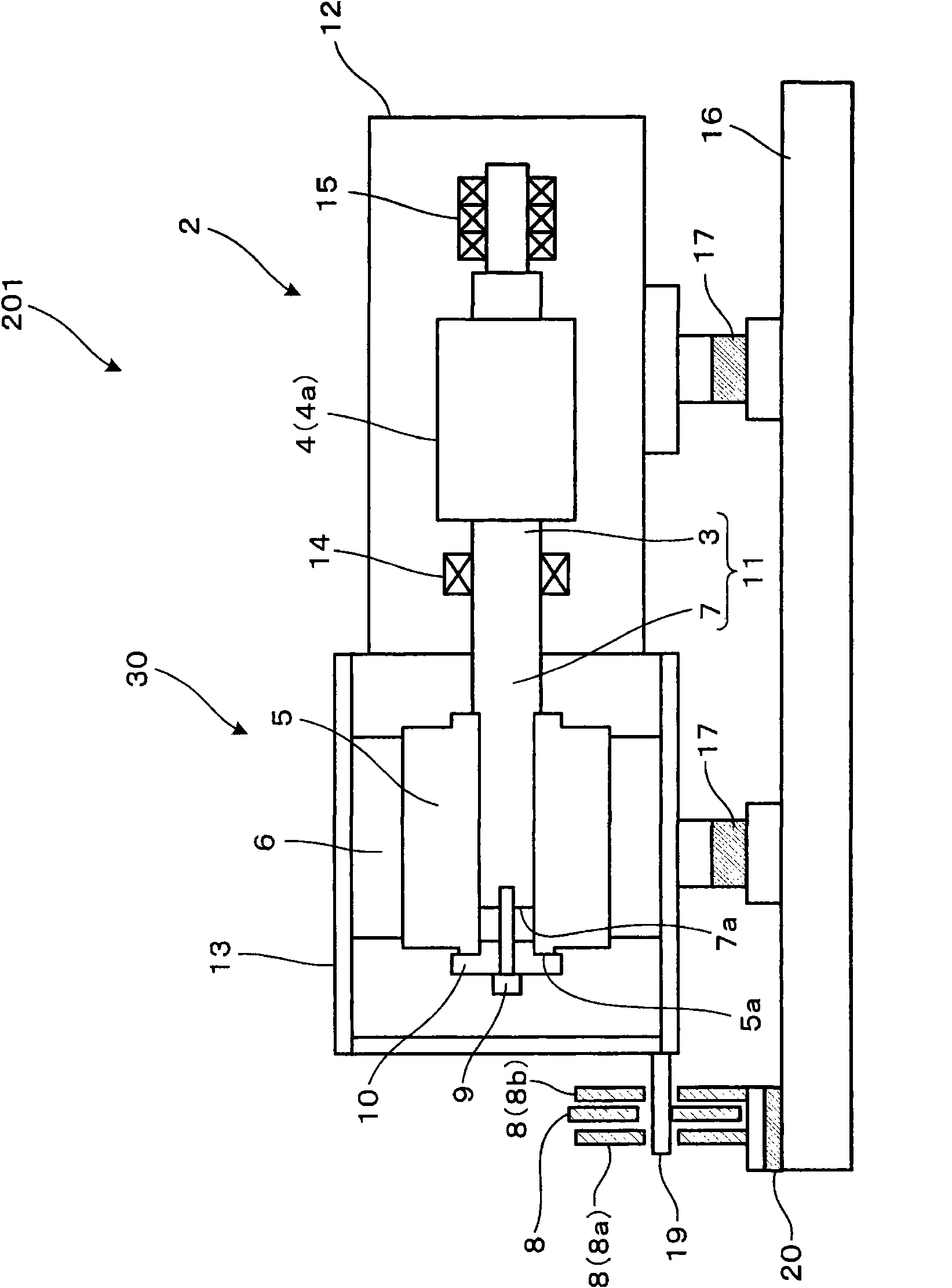

screw compressor

ActiveCN102278308ADissipate vibrational energyReduce vibrationRotary piston pumpsRotary piston liquid enginesVibration attenuationRelative displacement

The invention provides a screw type compressor, which is capable of improving vibration attenuation. A rod-shaped member (19) loosely inserted into a plurality of heavy hammers (8) is equipped on a motor shell (13) in a projecting way. At least one of the multiple heavy hammers (8) is combined with a frame (16). And at least one of the multiple heavy hammers (8) is not combined with the frame (16). When the motor shell (13) is vibrating, the rod-shaped member (19) collides with the heavy hammers so as to disperse the vibration energy. Furthermore, relative displacement which is suitably present between the heavy hammer (8a) combined with the frame (16) and another heavy hammer (8) not combined with the frame in a low-amplitude area leads to sliding friction between the above two heavy hammers. The vibration energy is thus further dispersed.

Owner:코벨코컴프레서가부시키가이샤

Heat radiation reactor

InactiveCN103035369ACompact structureReduce noiseTransformers/inductances coolingTransformers/inductances coils/windings/connectionsVibration attenuationConductor Coil

The invention discloses a heat radiation reactor, comprising a heat radiation base and two coil windings, wherein each coil winding comprises two hollow iron columns, coils wound on the iron columns, and clamping plates arranged at the both ends of the coil windings; the heat radiation base is provided with a cooling block and a resin molding body; and the heat radiation base covers the two coil windings. With the adoption of the manner, the heat radiation reactor provided by the invention has the advantages of simple and compact structure, small noise in a working process, high heat radiation property and high vibration attenuation property.

Owner:汪正新

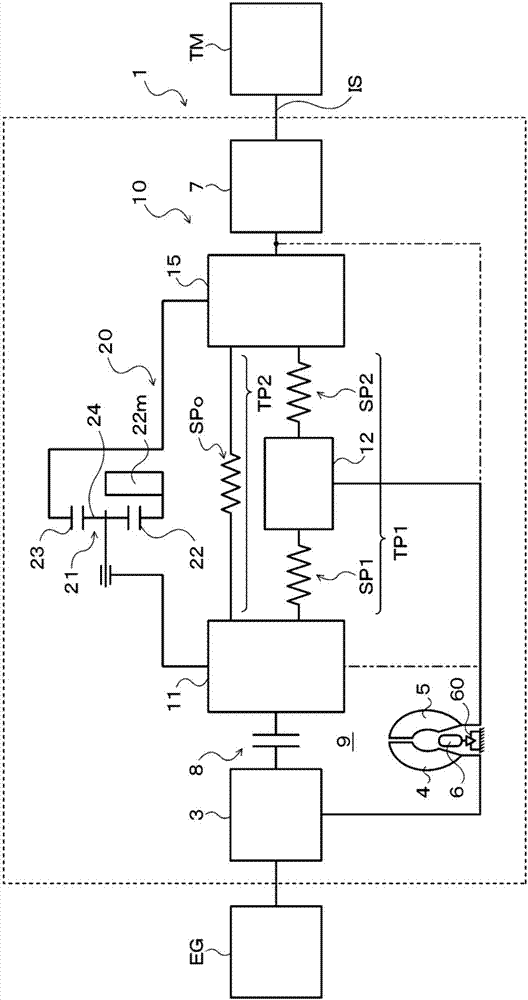

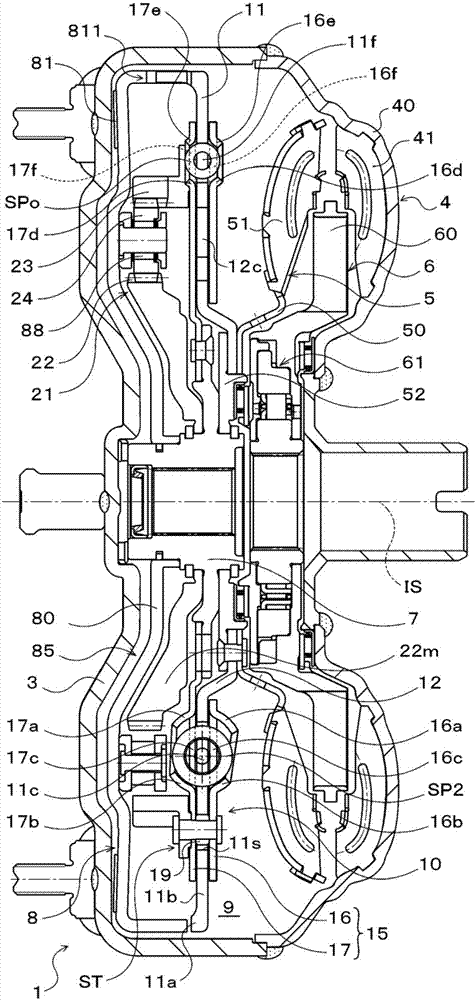

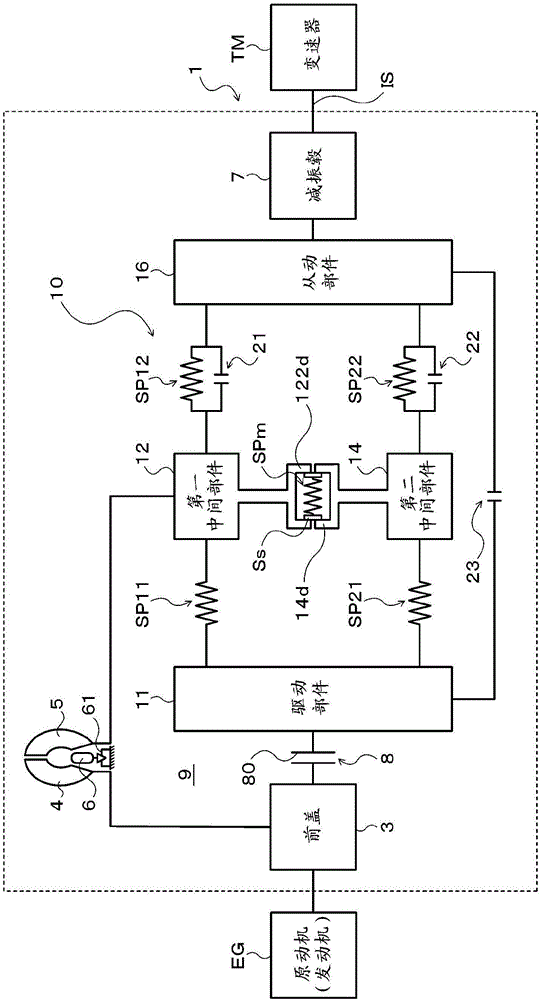

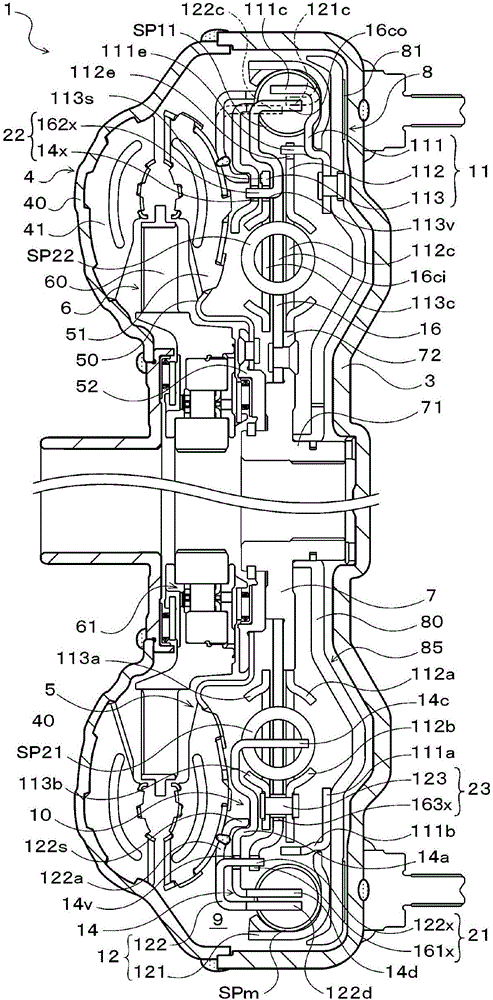

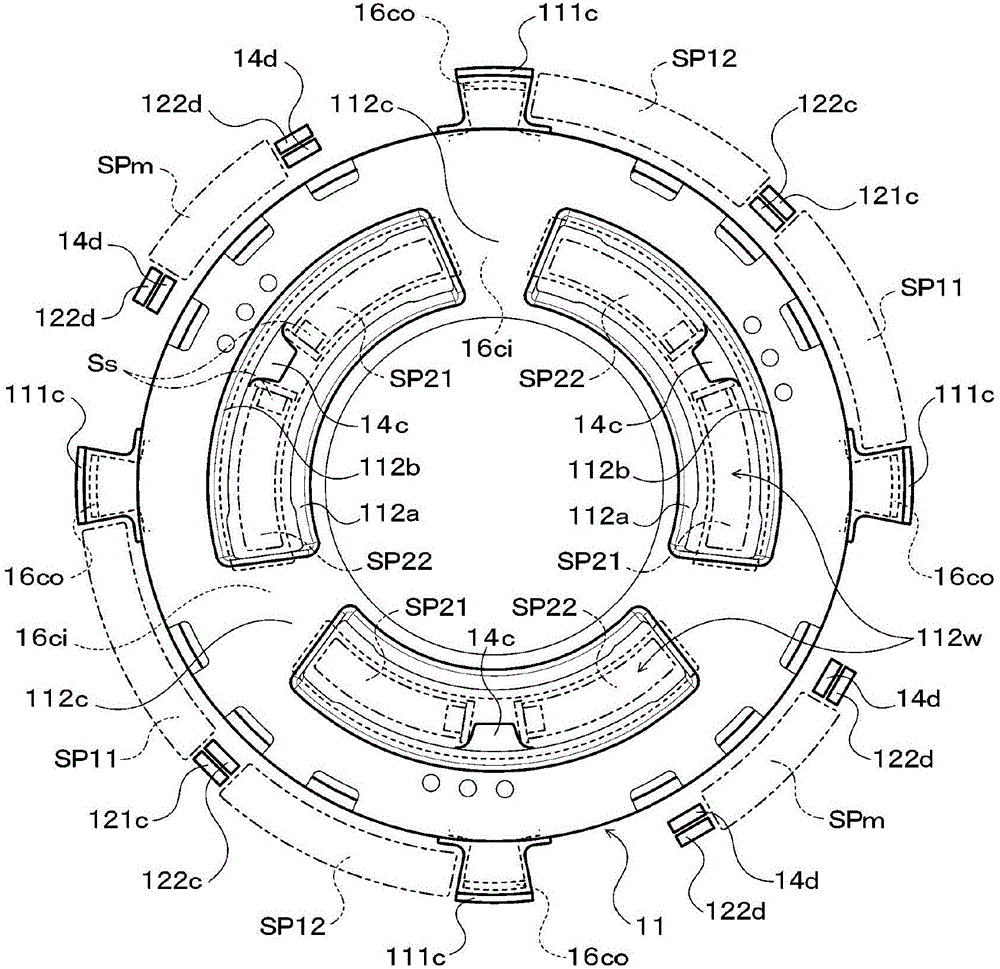

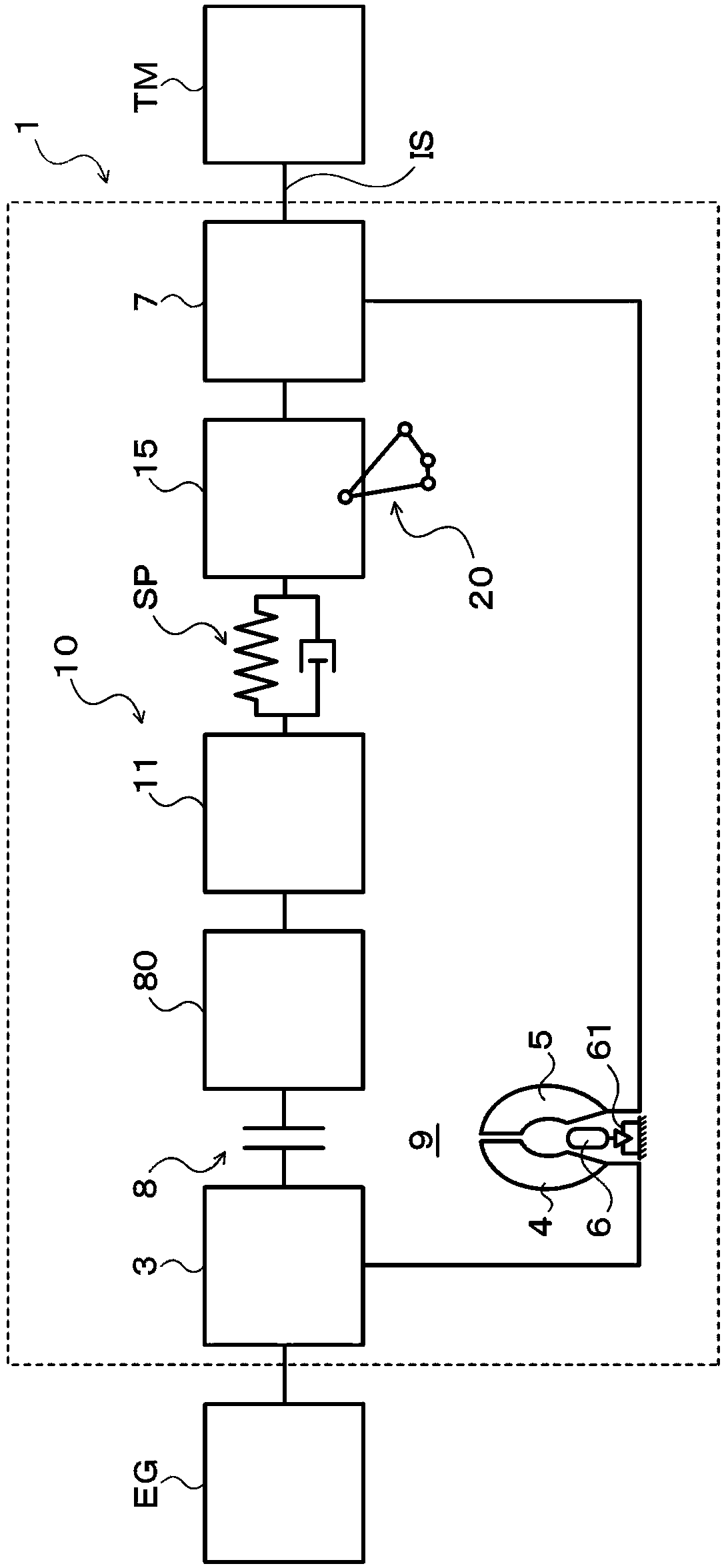

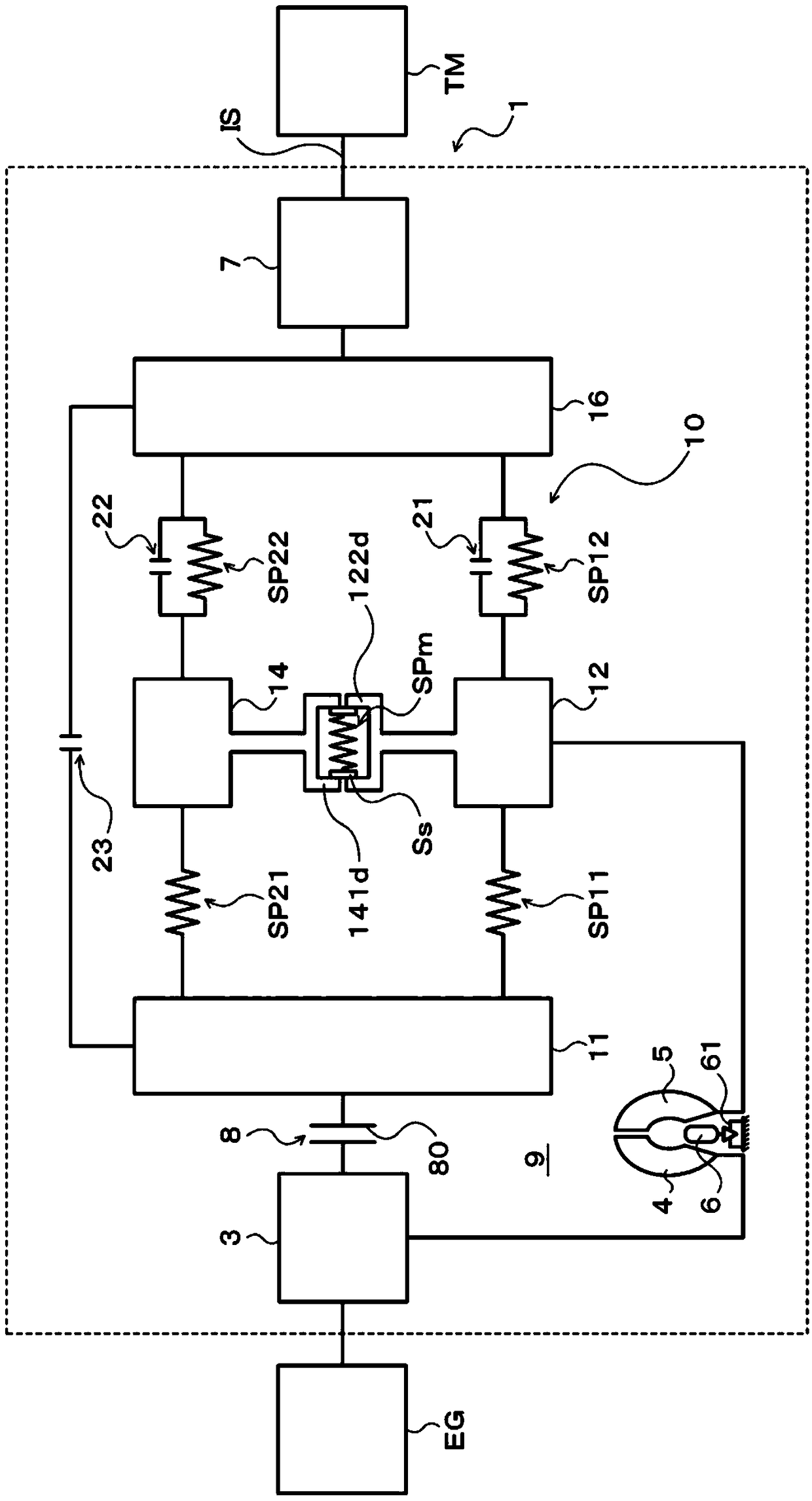

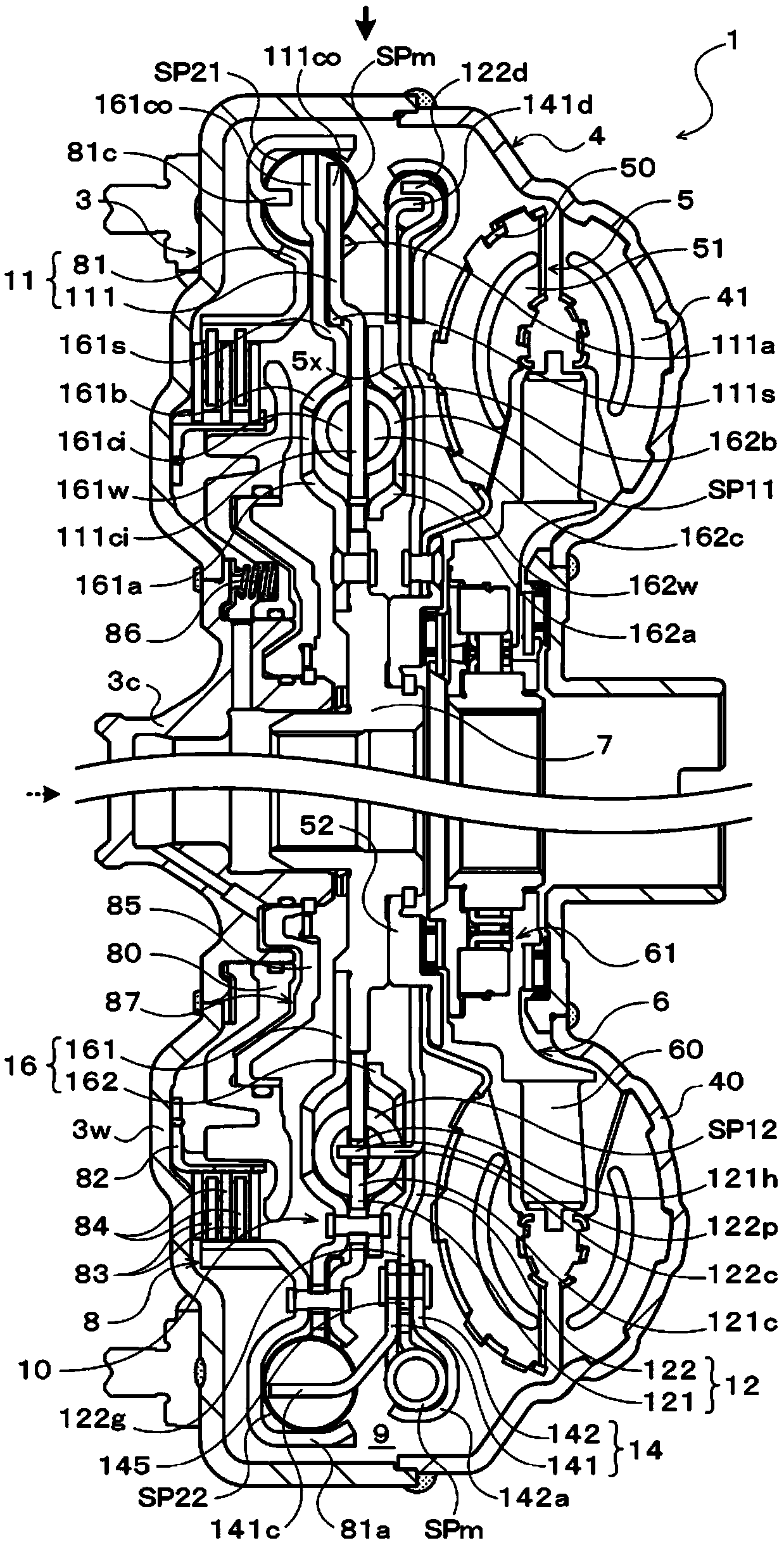

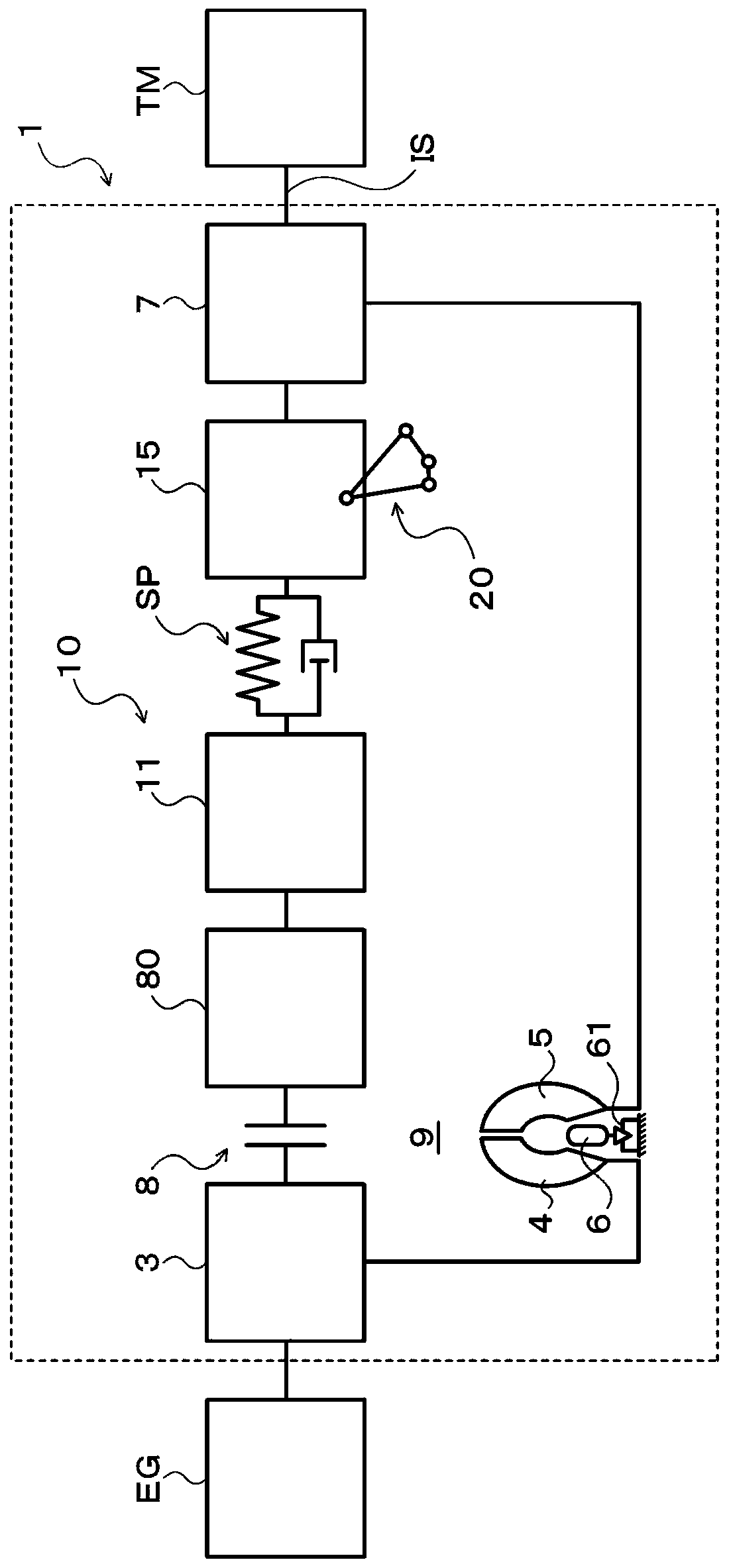

Damper device

ActiveCN106687710ARigid adjustmentGuaranteed rigiditySpringsSprings/dampers functional characteristicsControl theory

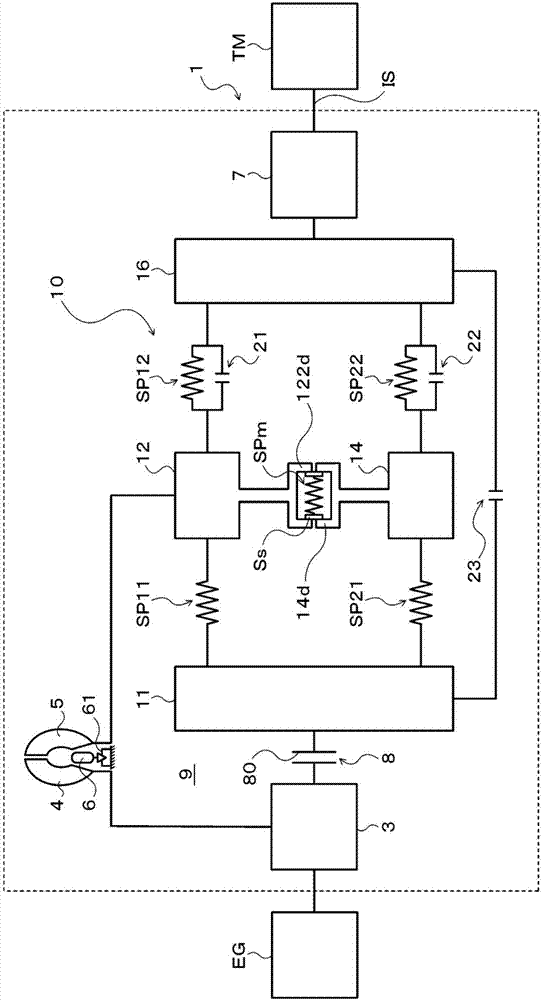

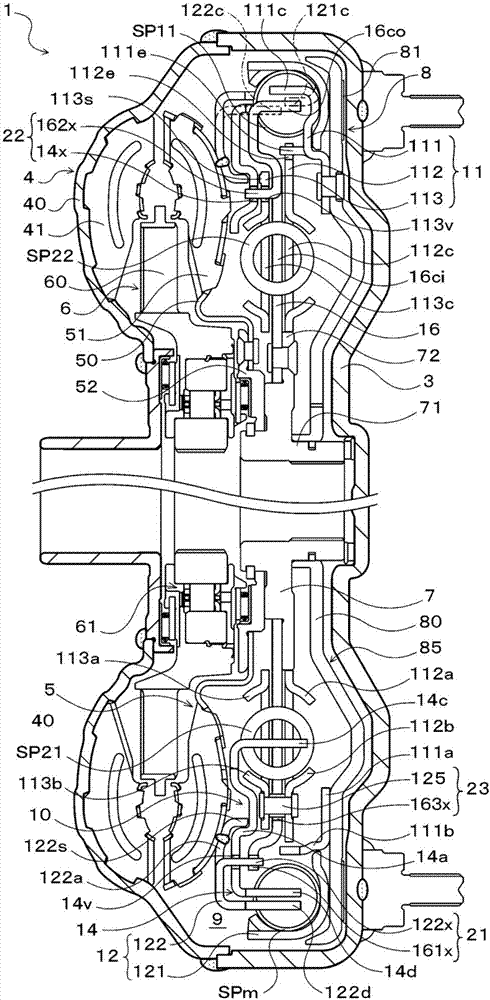

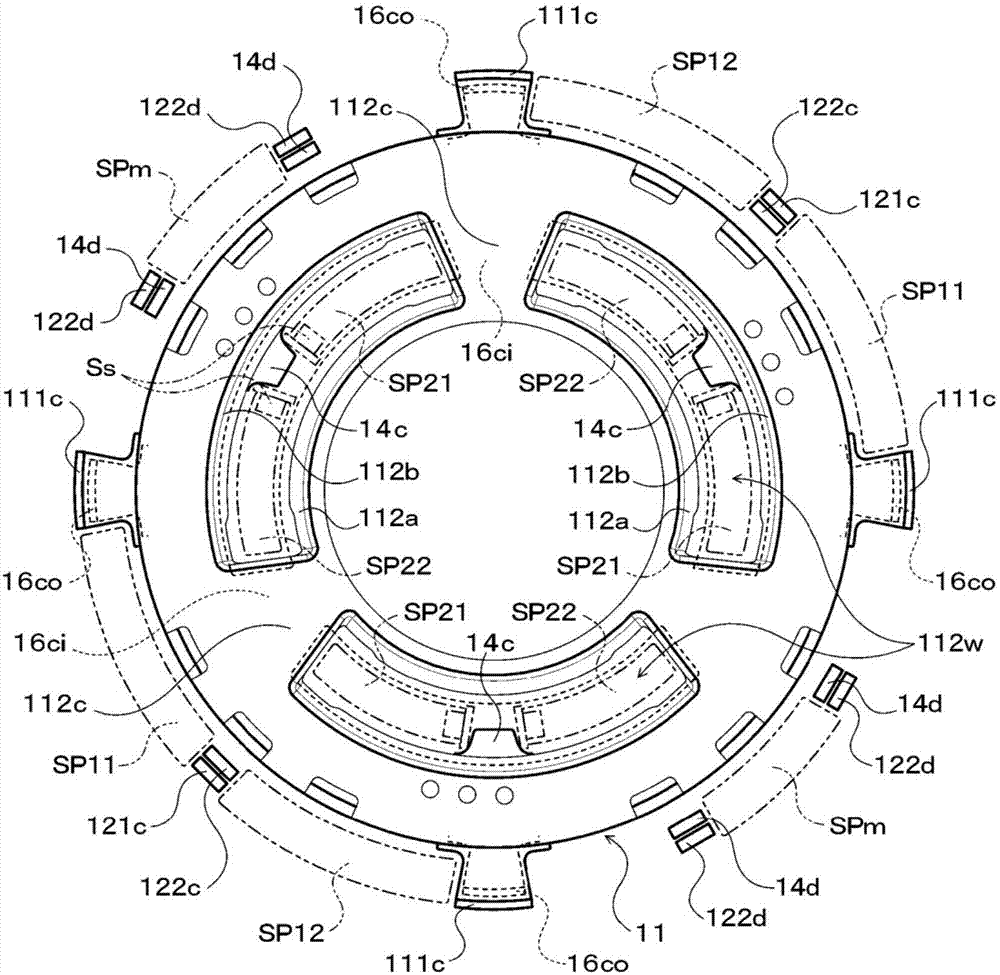

A damper device 10 includes: a drive member 11 to which torque from an engine EG is transmitted; a driven member 16; a first intermediate member 12; a second intermediate member 14; a first outer spring SP11 for transmitting torque between the drive member 11 and the first intermediate member 12; a second outer spring SP12 for transmitting torque between the first intermediate member 12 and the driven member 16; a first inner spring SP21 for transmitting torque between the drive member 11 and the second intermediate member 14; a second inner spring SP22 for transmitting torque between the second intermediate member 14 and the driven member 16; and an intermediate spring SPm for transmitting torque between the first intermediate member 12 and the second intermediate member 14.

Owner:AISIN AW CO LTD

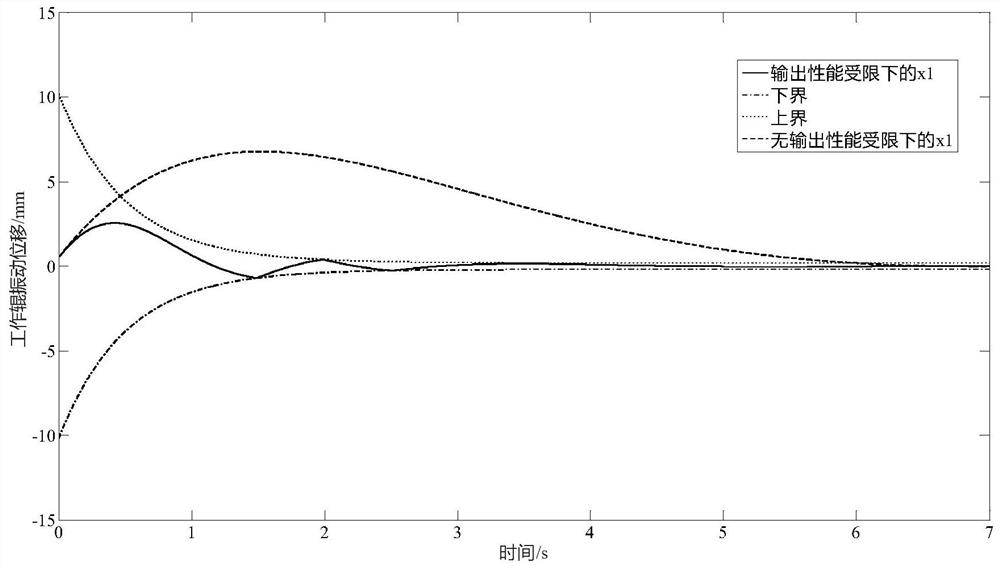

Design method of rolling mill vertical vibration suppression controller based on self-adaptive fuzzy backstepping

ActiveCN111723442AEnsure stabilityImprove the vibration damping effectGeometric CADVibration control deviceVertical vibrationBackstepping

The invention provides a method for designing a rolling mill vertical vibration suppression controller based on self-adaptive fuzzy backstepping, which comprises the following steps of: firstly, establishing a four-degree-of-freedom mechanical-hydraulic coupling nonlinear model of rolling mill vertical vibration according to a dynamic principle of a rolling mill vibration system; setting the vertical vibration displacement of the working roll of the rolling mill to be close to zero as a control target according to the condition that the vertical vibration of the rolling mill causes the workingroll to jump up and down; and finally, in combination with a nonlinear model of rolling mill vertical vibration, selecting a proper Lyapunov function, solving a virtual controller, an actual controller and an adaptive law which enable V (t) to tend to zero when t tends to be infinite, and finally obtaining the predetermined performance controller design method for suppressing rolling mill vertical vibration. According to the method, the rolling mill vertical vibration nonlinear model more conforming to the actual working condition is established, the characteristic that the servo valve has adead zone and the limitation on roller vibration displacement are considered, the rolling mill vertical vibration suppressor is designed, vertical vibration occurring in the high-speed rolling processis rapidly and actively suppressed, and the stability of the high-speed plate and strip rolling process is guaranteed.

Owner:YANSHAN UNIV

Casing for electronic device, method for manufacturing same, and electronic device

InactiveCN102625607AImprove the vibration damping effectAvoid breakingMagnetic/electric field screeningDigital data processing detailsEngineeringPersonal computer

There are provided a casing for an electronic device and an electronic device, which are free from undesirable sticking of dust due to static electricity in a plastic electronic device as well as malfunctions and failures of a built-in device such as a computer; have improved weatherability, impact resistance, and vibration-damping property; and are superior in design properties. A casing for various types of electronic devices, such as compact electronic devices, e.g., a mobile terminal (portable telephone etc.), portable gaming terminal, and portable player; a personal computer (main unit and monitor); OA devices such as electronic devices used in offices; and AV devices, such as a television, recording device, radio, printer, copier, and facsimile machine is molded with plastic and a knit / woven fabric is pasted to the plastic substrate.

Owner:菱田岩

Damper device

InactiveCN106536991AImprove the vibration damping effectYielding couplingFluid actuated clutchesTorque transmissionControl theory

A damper device (10) is configured in such a manner that a first torque transmission path (P1) and a second torque transmission path (P2) which is provided in parallel with the first torque transmission path (P1) are arranged between a drive member (11) and a driven member (16). The first torque transmission path (P1) includes a first spring (SP1) for transmitting torque between the drive member (11) and the driven member (16). The second torque transmission path (P2) includes: first and second intermediate members (12, 14); a second spring (SP2) for transmitting torque between the drive member (11) and the first intermediate member (12); a third spring (SP3) for transmitting torque between the first intermediate member (12) and the second intermediate member (14); and a fourth spring (SP4) for transmitting torque between the second intermediate member (14) and the driven member (16).

Owner:AISIN AW CO LTD

Vibration damping device and design method therefor

ActiveCN108713113AImprove the vibration damping effectRotating vibration suppressionSpringsInertial massCentre of rotation

The invention provides a vibration damping device and a design method therefor. The vibration damping device is disposed in an oil chamber and includes: a support member that rotates integrally with arotating element around the center of rotation of the rotating element to which the torque from an engine is transmitted; a restoring force generation member that is connected to the support member and can pivot along with the rotation of the support member; and an inertial mass body that is connected to the support member via the restoring force generation member and pivots around the center ofrotation in conjunction with the restoring force generation member, along with the rotation of the support member. The order of the vibration damping device is larger than the sum of the excitation order of the engine and an offset value taking into consideration the effect of oil inside the oil chamber, and a reference order, which is a convergence value of the order of the vibration damping device operating in the oil chamber when the amplitude of the vibration of the input torque transmitted to the rotating element becomes smaller, becomes larger than the excitation order.

Owner:AISIN AW CO LTD

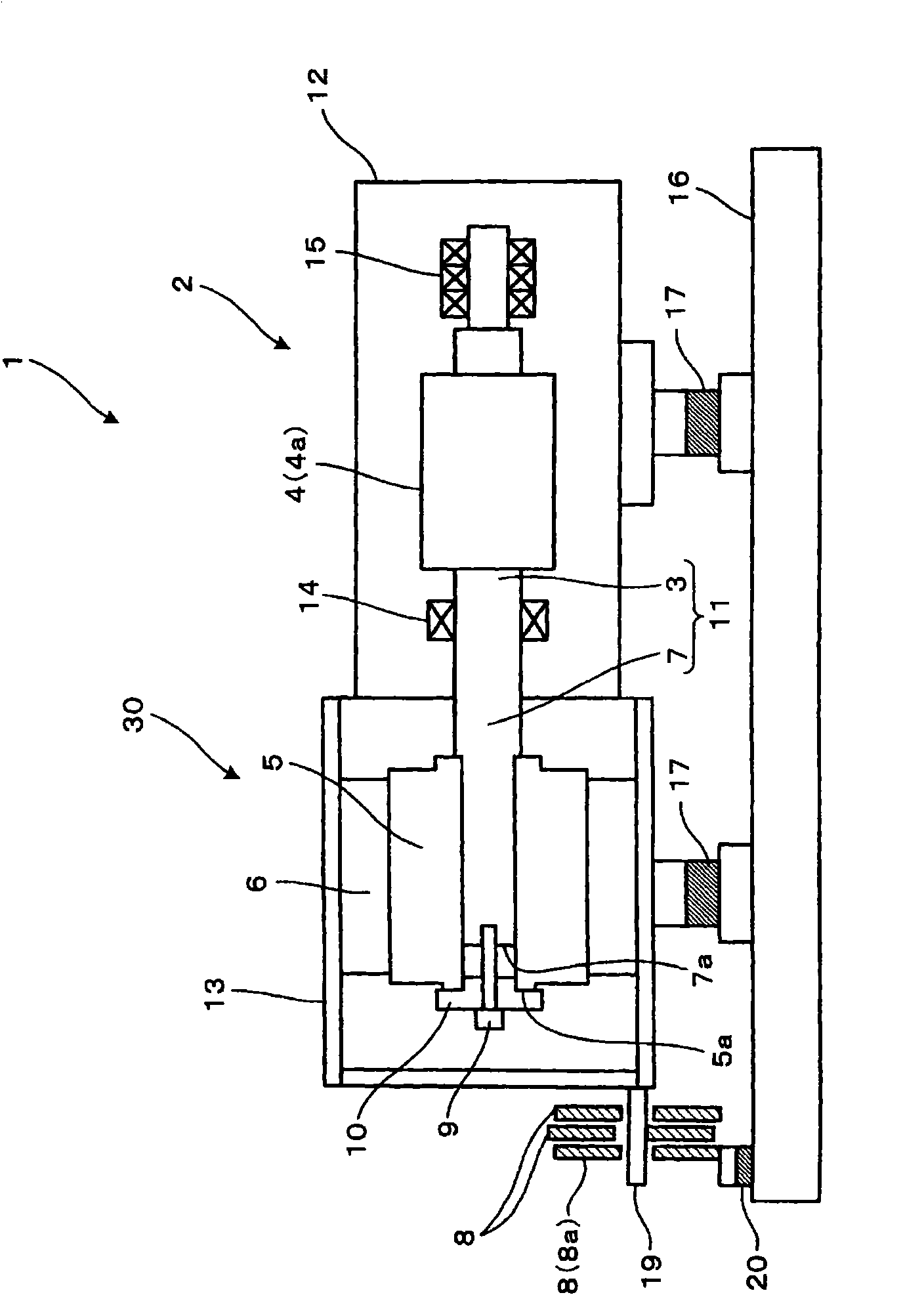

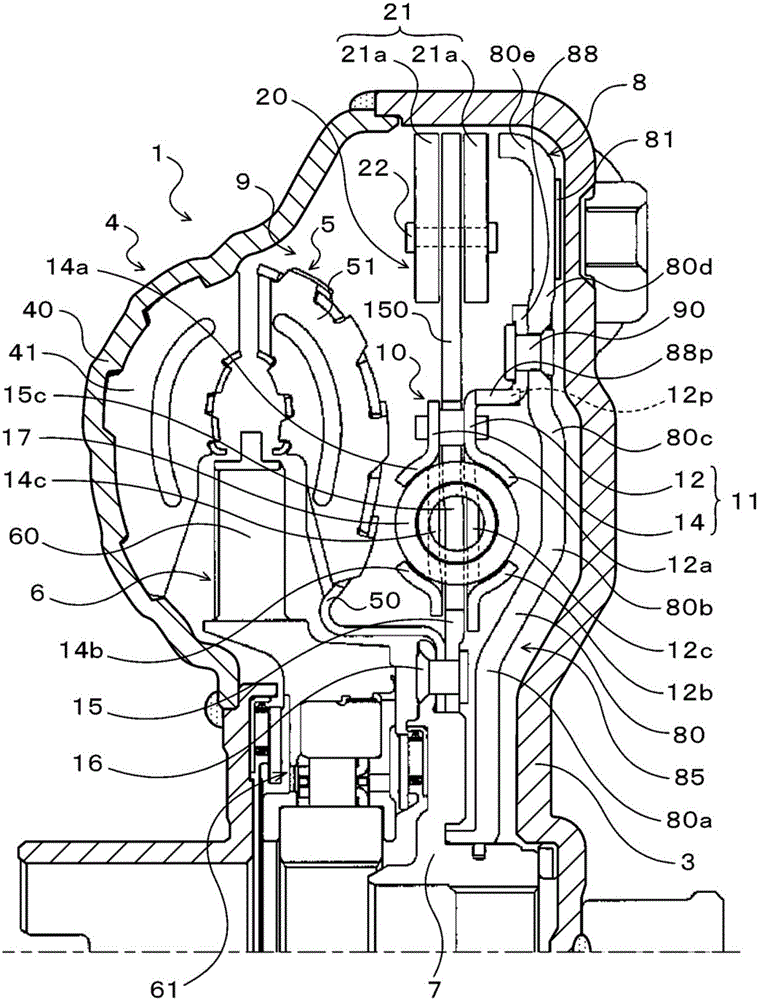

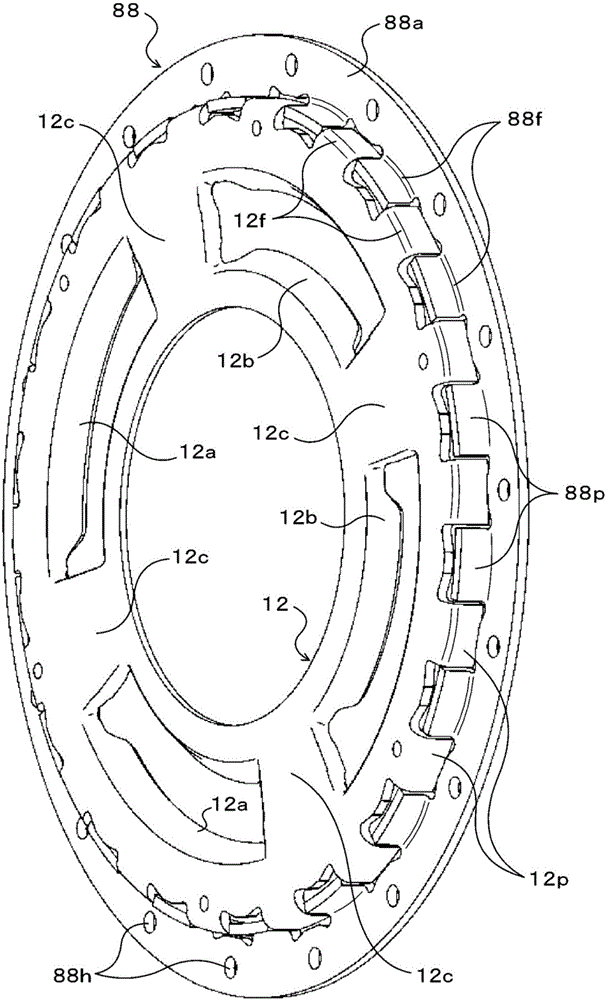

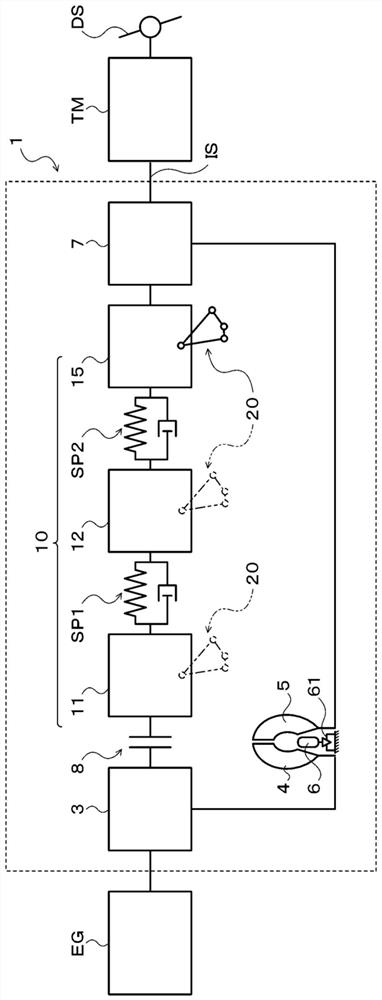

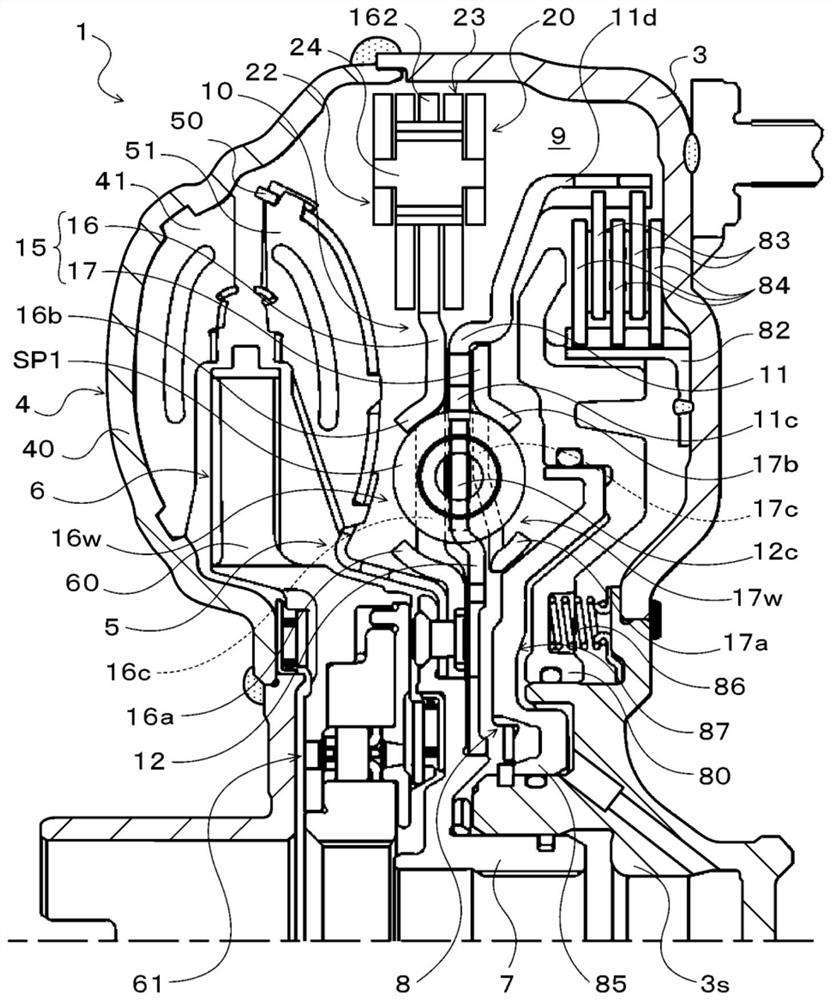

Starting device

ActiveCN105934607AIncrease axial lengthSecure configuration spaceRotating vibration suppressionFluid gearingsSingle plateEngineering

A starting device (1) comprises a damper mechanism (10), a single-plate lock up clutch (8) that can execute lock-up to couple a front cover (3) and an input shaft of a transmission via the damper mechanism (10), and a centrifugal pendulum vibration absorber that comprises a driven member (15) of the damper mechanism (10) as a supporting member and a plurality of pendulum mass bodies (21). A lock up piston (80) of the lock up clutch (8) and a driving member (11) of the damper mechanism (10) are coupled to each other at a position more to the inside in the radial direction than the plurality of pendulum mass bodies (21) so as to rotate unitedly.

Owner:AISIN AW CO LTD

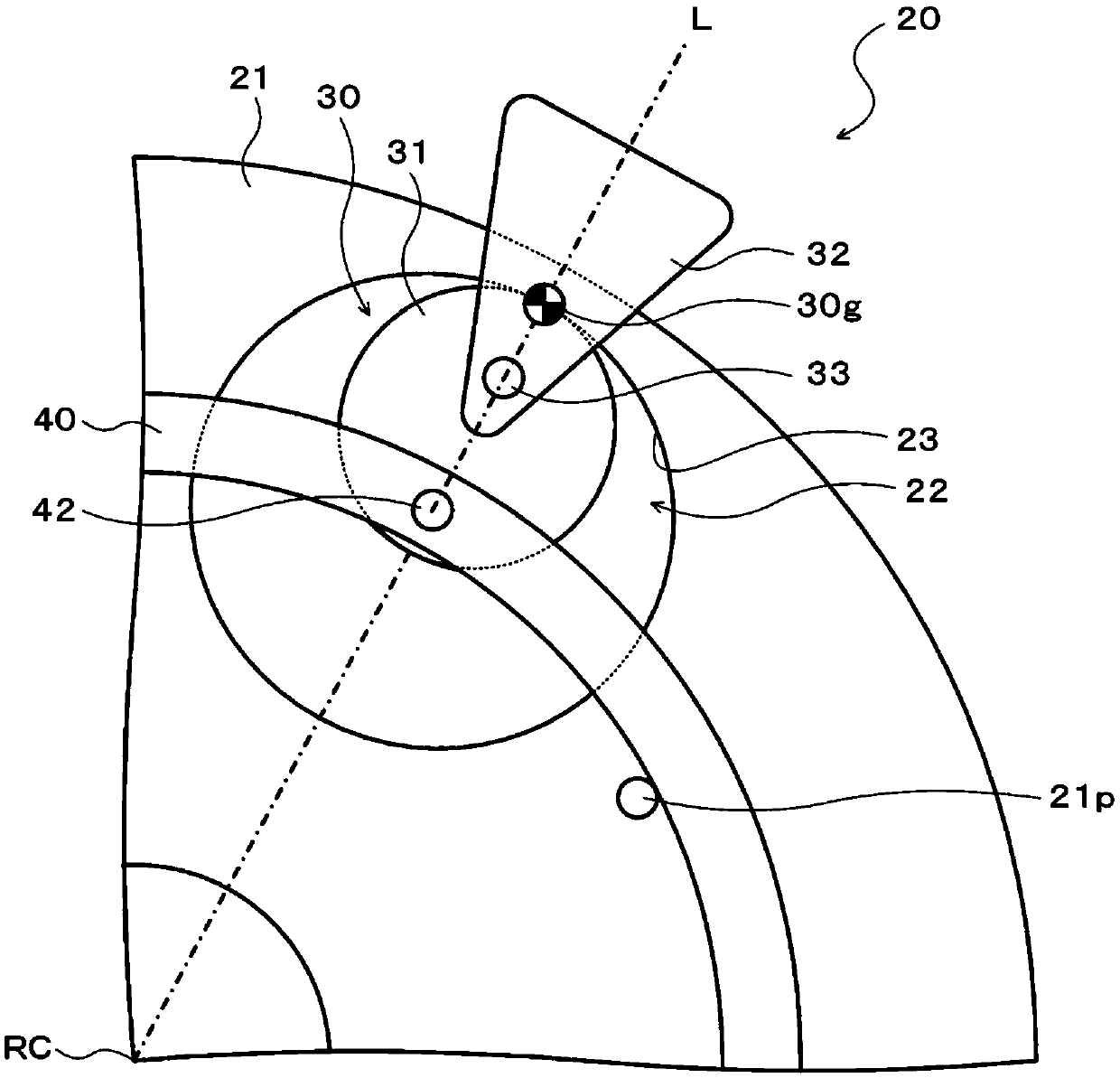

Vibration-damping device

InactiveCN109642638AReduce vibrationImprove the vibration damping effectRotating vibration suppressionFluid gearingsVibration attenuationCentre of rotation

The invention aims to improve vibration-damping performance. This vibration-damping device is provided with a concave-surface-shaped guide surface 23 formed in a support member 21 so as to curve toward the outer periphery of the support member 21, a mass object 30 that rolls over the guide surface 23 while being pushed against the guide surface 23 by centrifugal force accompanying the rotation ofthe support member 21, and an inertia ring 40 that is rotatably linked to the mass object 30 and that swings around the rotational center of the support member 21. When in a state of equilibrium, thecenter of gravity of the mass object 30 is positioned farther radially outward than is the position where the mass object 30 and the inertia ring 40 are linked. When the support member 21 rotates, theinertia ring 40 swings relative to the support member 21 around the rotational center of the support member 21, and the mass object 30 rolls over the guide surface 23.

Owner:AISIN AW CO LTD

Golf club head

InactiveCN1248752CImprove convenienceSignificant effect and effectGolf clubsRacket sportsVibration attenuationFiber

Owner:THE YOKOHAMA RUBBER CO LTD

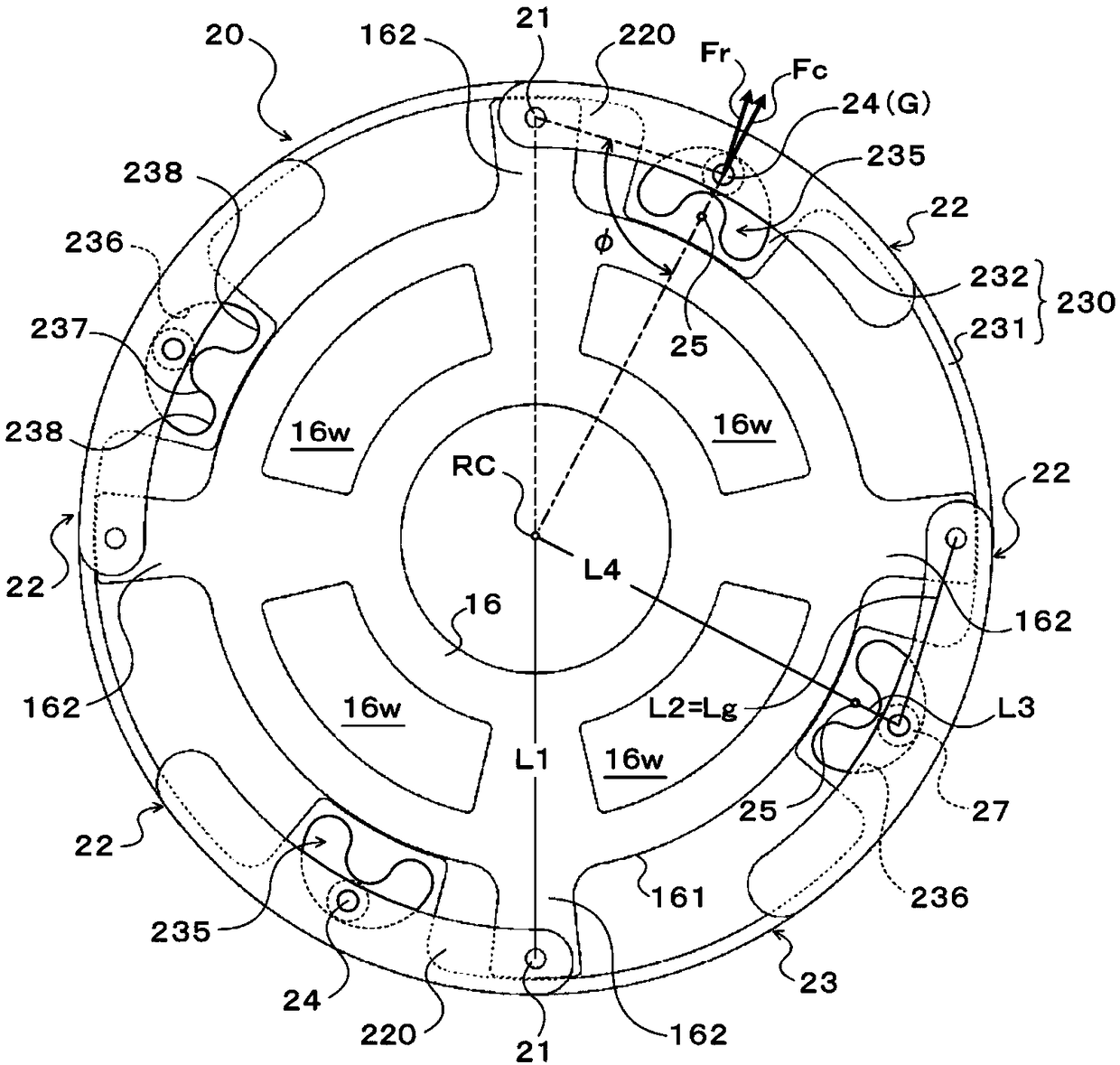

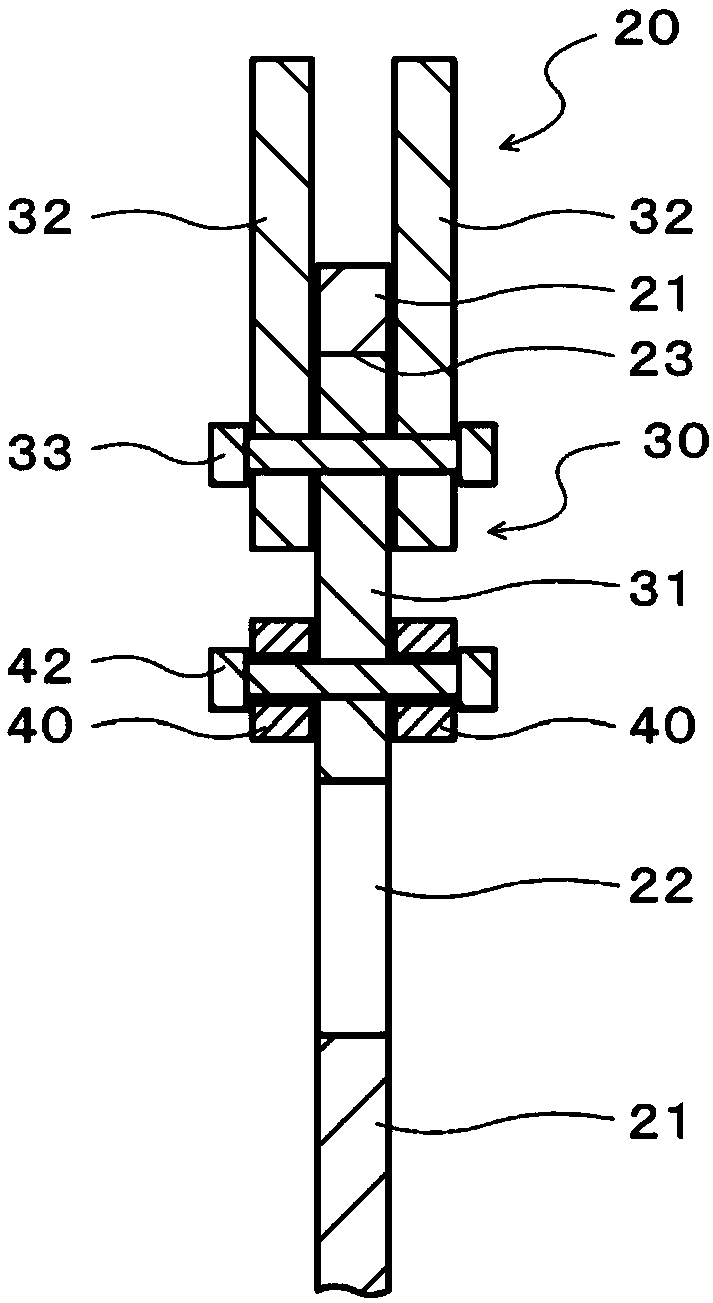

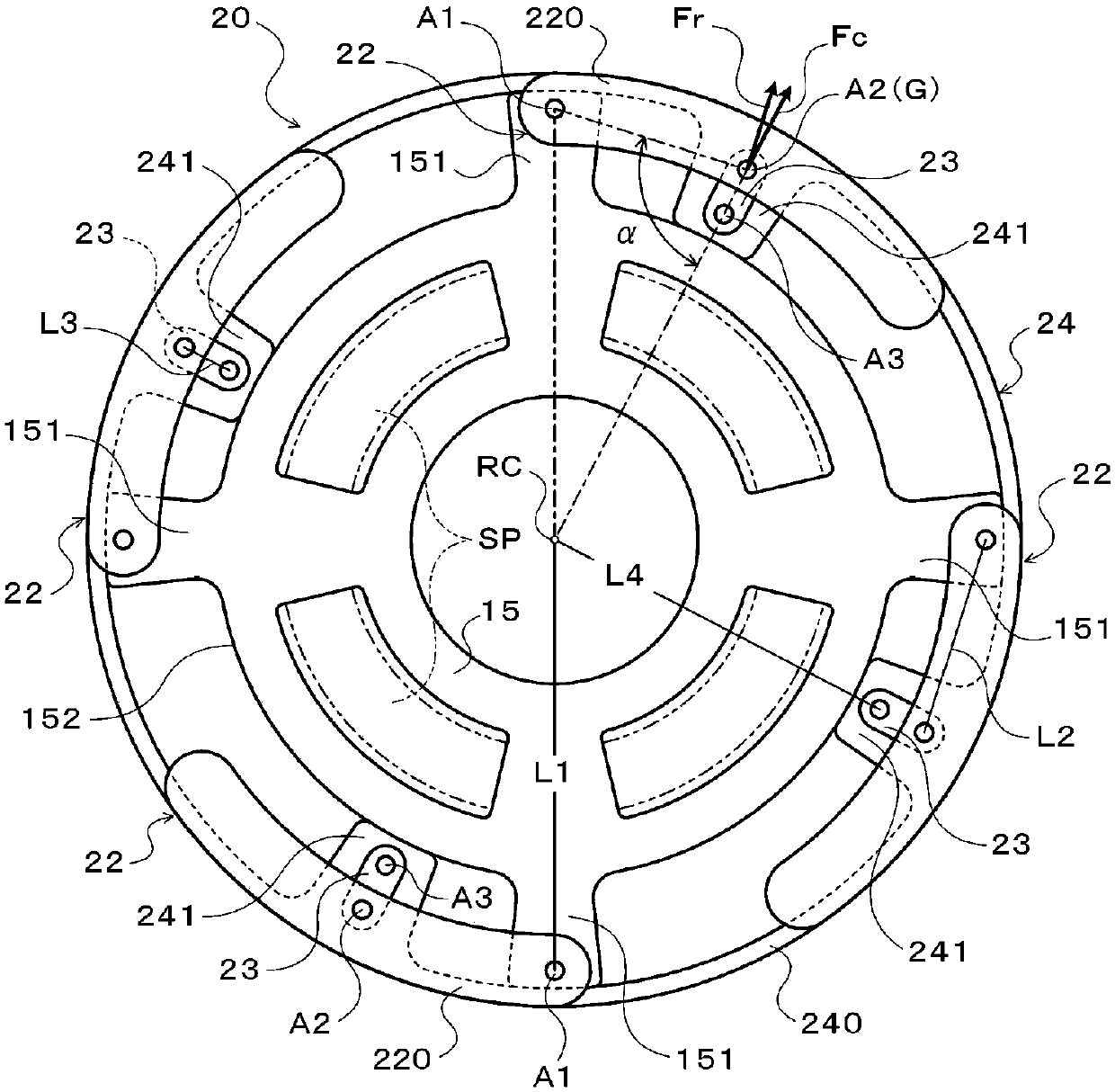

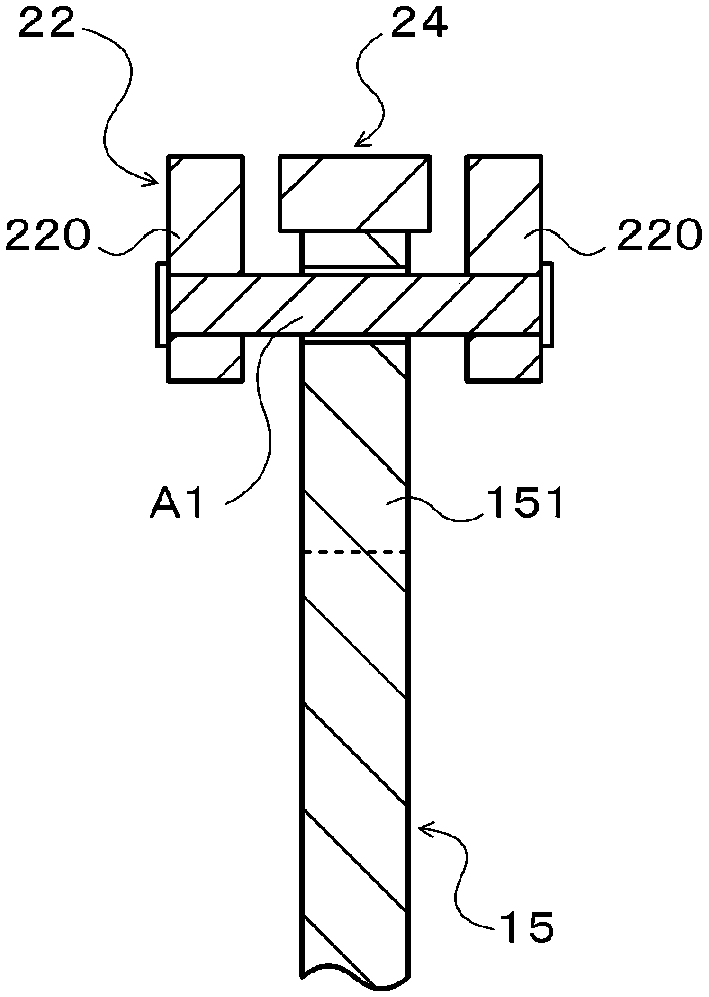

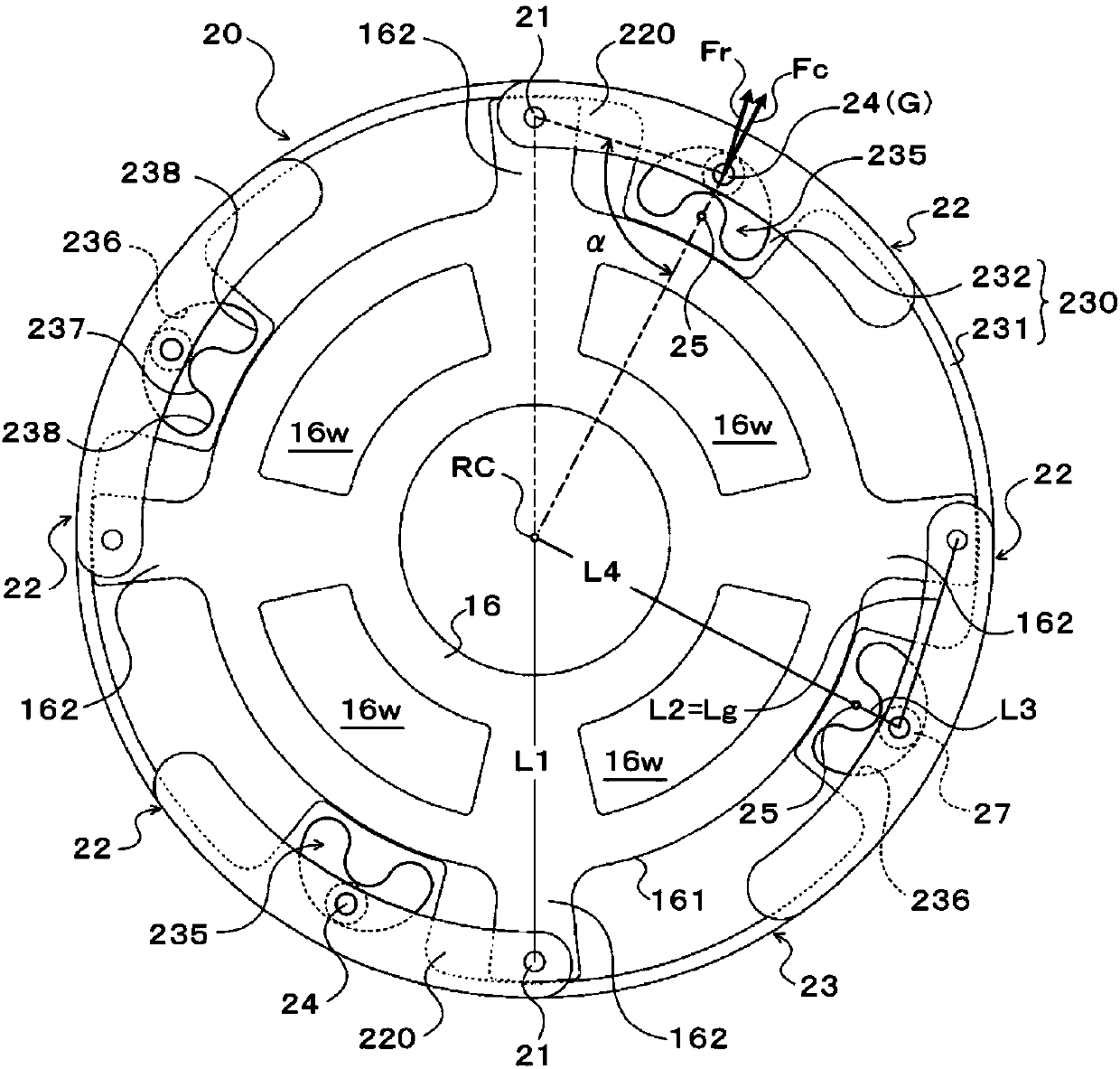

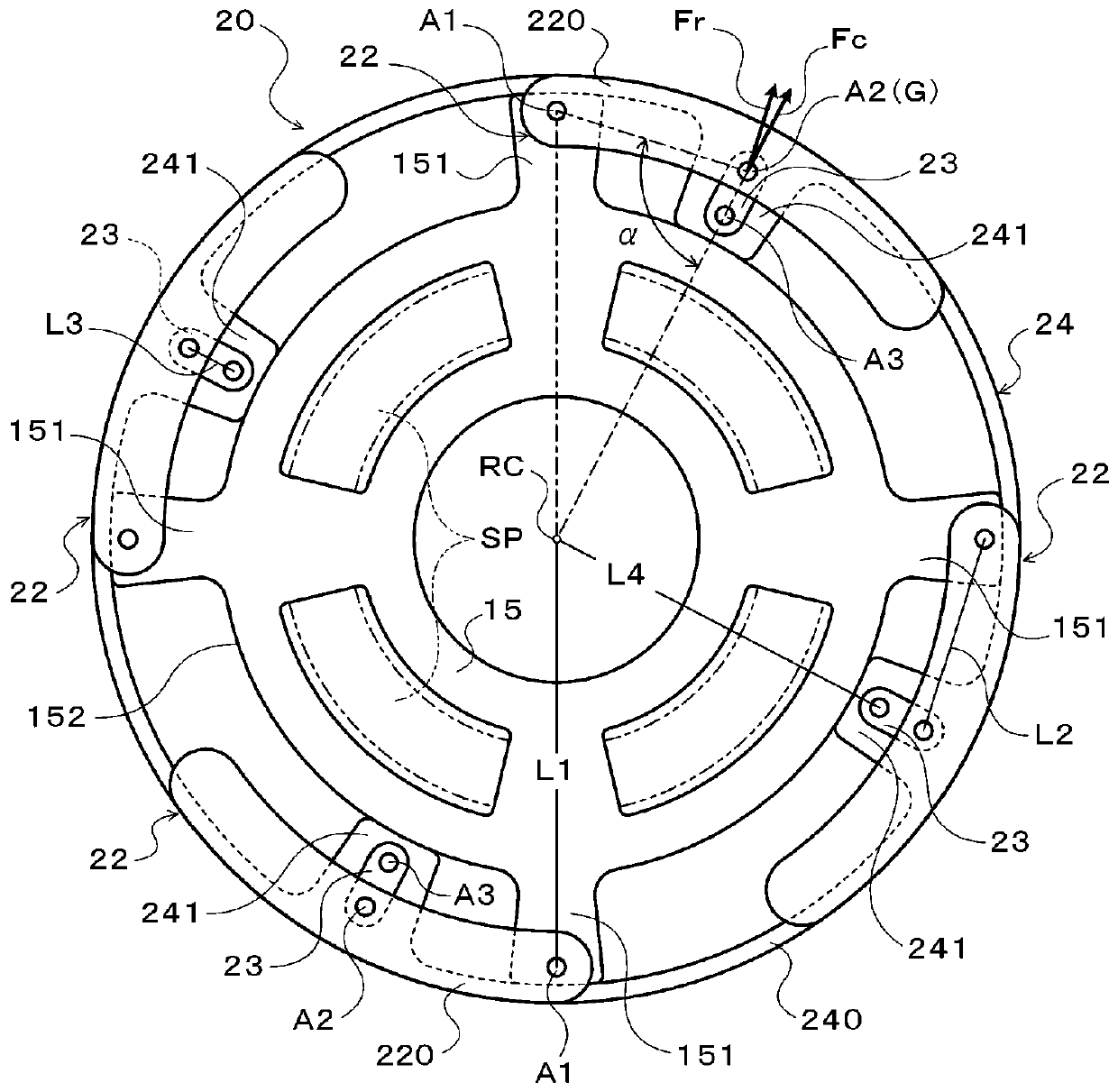

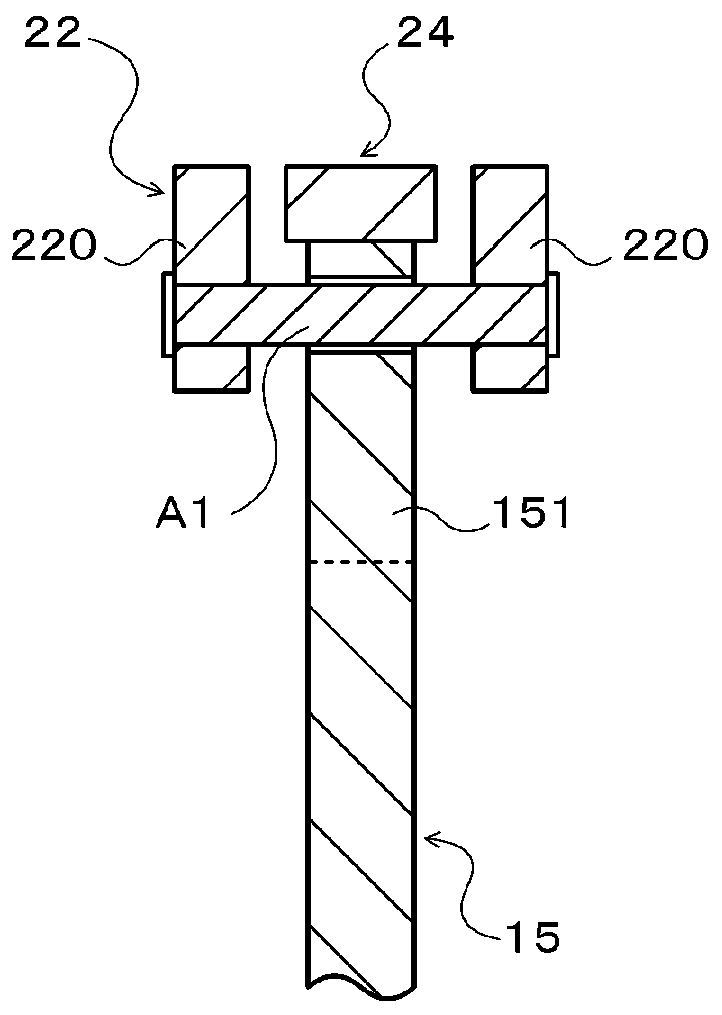

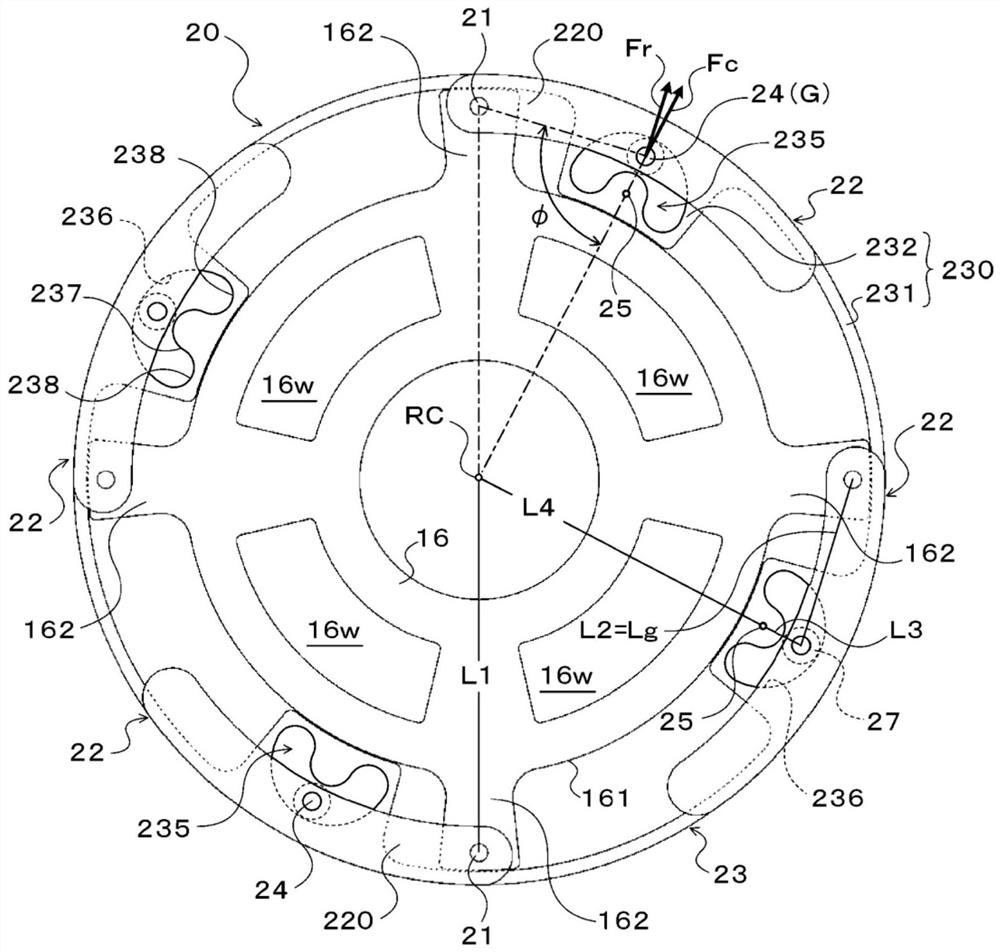

Vibration-damping device

InactiveCN107709826AIncrease equivalent stiffnessWeight increaseRotating vibration suppressionYielding couplingInertial massEngineering

A vibration-damping device 20 includes crank members 22 that are linked to a driven member 15 via first linking shafts A1 and that are capable of swinging about the first linking shafts A1 along withthe rotation of the driven member 15, and an inertial mass body 24 that is linked to the driven member 15 via the crank members 22 and connecting rods 23 and that swings around a rotational center RCin tandem with the crank members 22 along with the rotation of the driven member 15. As part of the centrifugal force acting on the crank members 22 along with the rotation of the driven member 15, certain force components, which act in a direction orthogonal to a direction leading from the center of a first linking shaft A1 to a center of gravity G, constantly act on the crank members 22 as return force for returning the inertial mass body 24 to the center of the range of swinging, and these force components reach a maximum when the inertial mass body 24 is positioned in the center of the range of swinging.

Owner:AISIN AW CO LTD +2

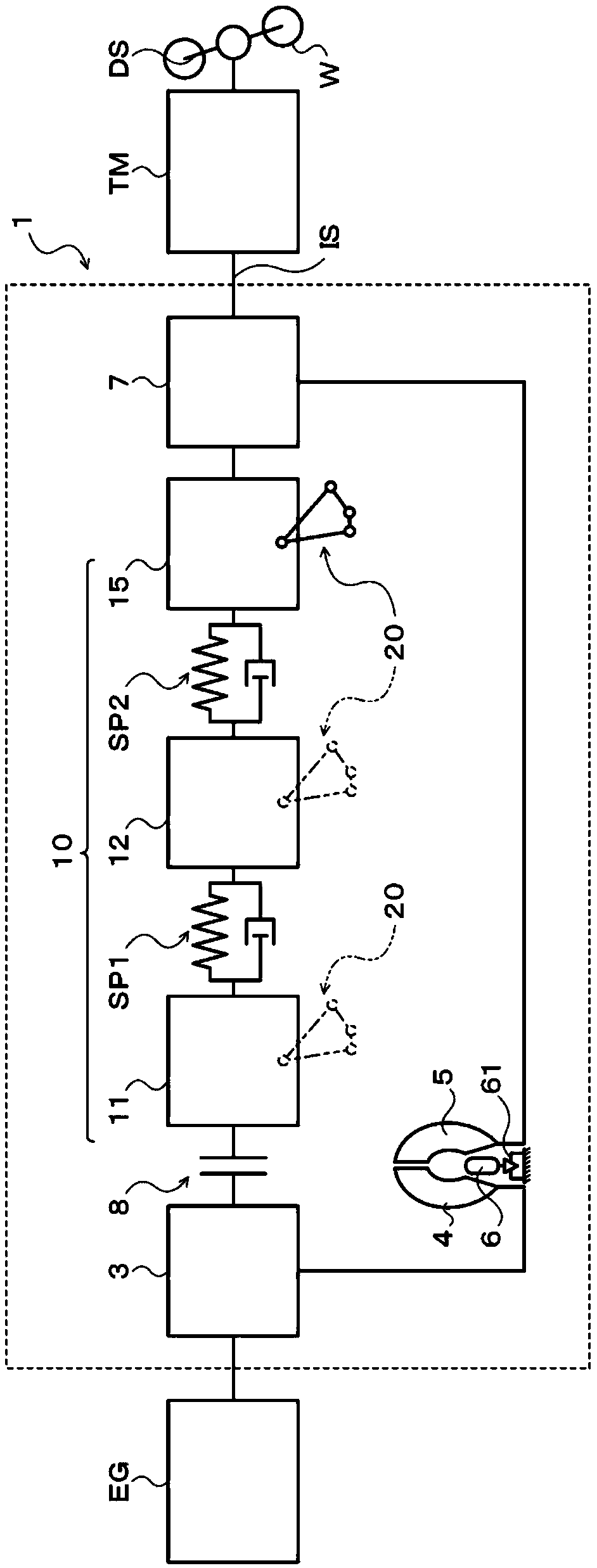

Damper device and starting device

ActiveCN108700170AImprove the vibration damping effectEasy to set up and appropriateFluid gearingsVibration suppression adjustmentsElastomerControl theory

This damper device includes an input element through which torque from an engine is transferred, an output element, a first intermediate element, a second intermediate element, a first elastic body that transfers torque between the input element and the first intermediate element, a second elastic body that transfers torque between the first intermediate element and the output element, a third elastic body that transfers torque between the input element and the second intermediate element, a fourth elastic body that transfers torque between the second intermediate element and the output element, and a fifth elastic body that transfers torque between the first intermediate element and the second intermediate element. The third and fourth elastic bodies are positioned to the outside of the first and second elastic bodies in a radial direction of the damper device. The fifth elastic body is positioned to the outside of the first and second elastic bodies in the radial direction and with agap between the fifth elastic body and the third and fourth elastic bodies in an axial direction of the damper device. The fifth elastic body, when viewed from the axial direction, at least partiallyoverlaps with the third and fourth elastic bodies in the radial direction.

Owner:AISIN AW CO LTD

Damper device

InactiveCN107407368ANatural vibration frequency is smallThe natural vibration frequency is maintainedYielding couplingFluid gearingsEngineeringControl theory

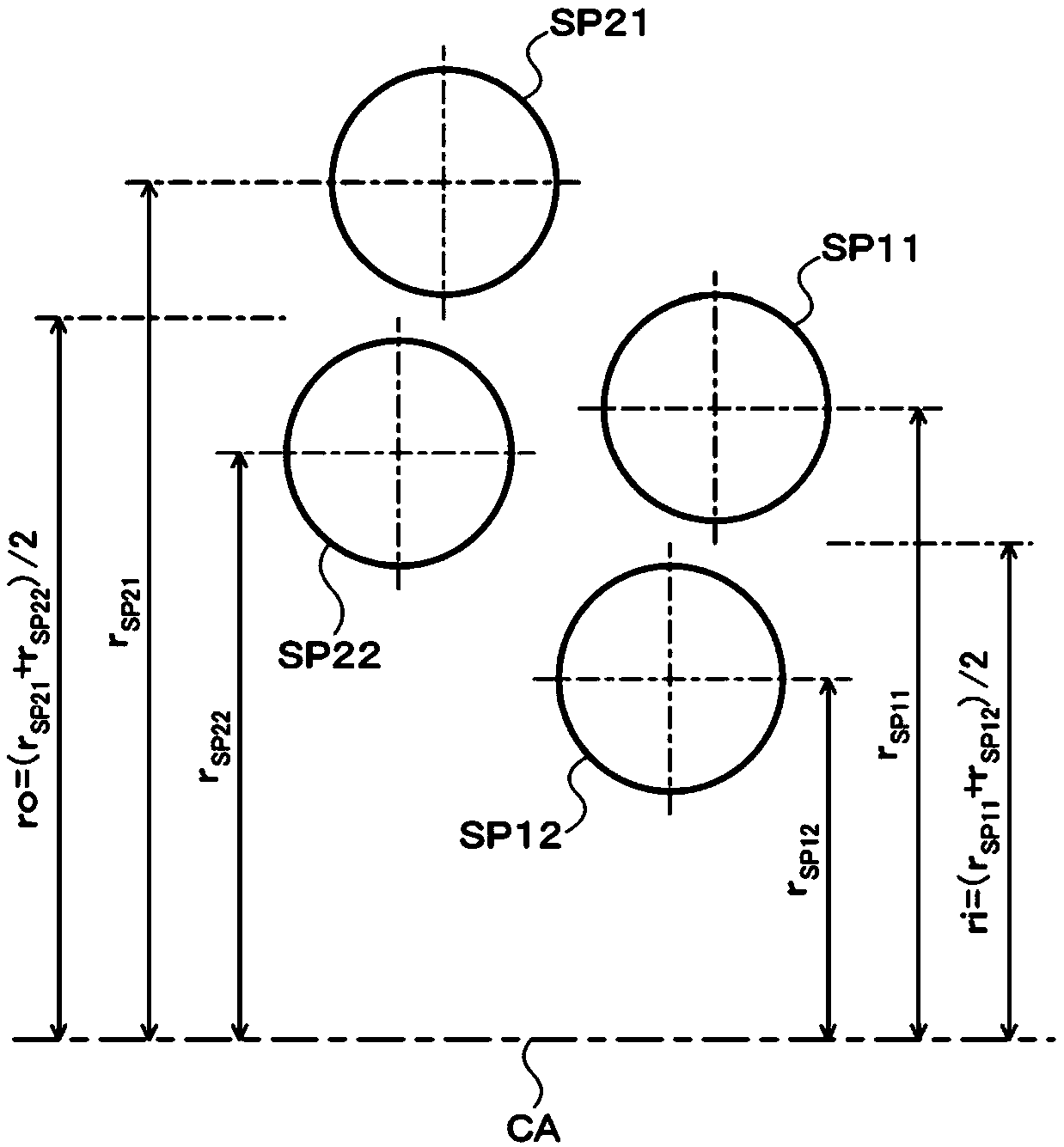

The invention provides a damper device. A damper device (10) comprises: a first outer spring (SP11) for transmitting torque between a drive member (11) and a first intermediate member (12); a second outer spring (SP12) for transmitting torque between the first intermediate member (12) and a driven member (16); a first inner spring (SP21) for transmitting torque between the drive member (11) and a second intermediate member (14); a second inner spring (SP22) for transmitting torque between the second intermediate member (14) and the driven member (16); and an intermediate spring (SPm) for transmitting torque between the first intermediate member (12) and the second intermediate member (14). The first and second outer springs (SP11, SP12) corresponding to the first intermediate member (12), which has a smaller natural frequency than the second intermediate member (14), are disposed on the radially outer side of the first and second inner springs (SP21, SP22) corresponding to the second intermediate member (14).

Owner:AISIN AW CO LTD

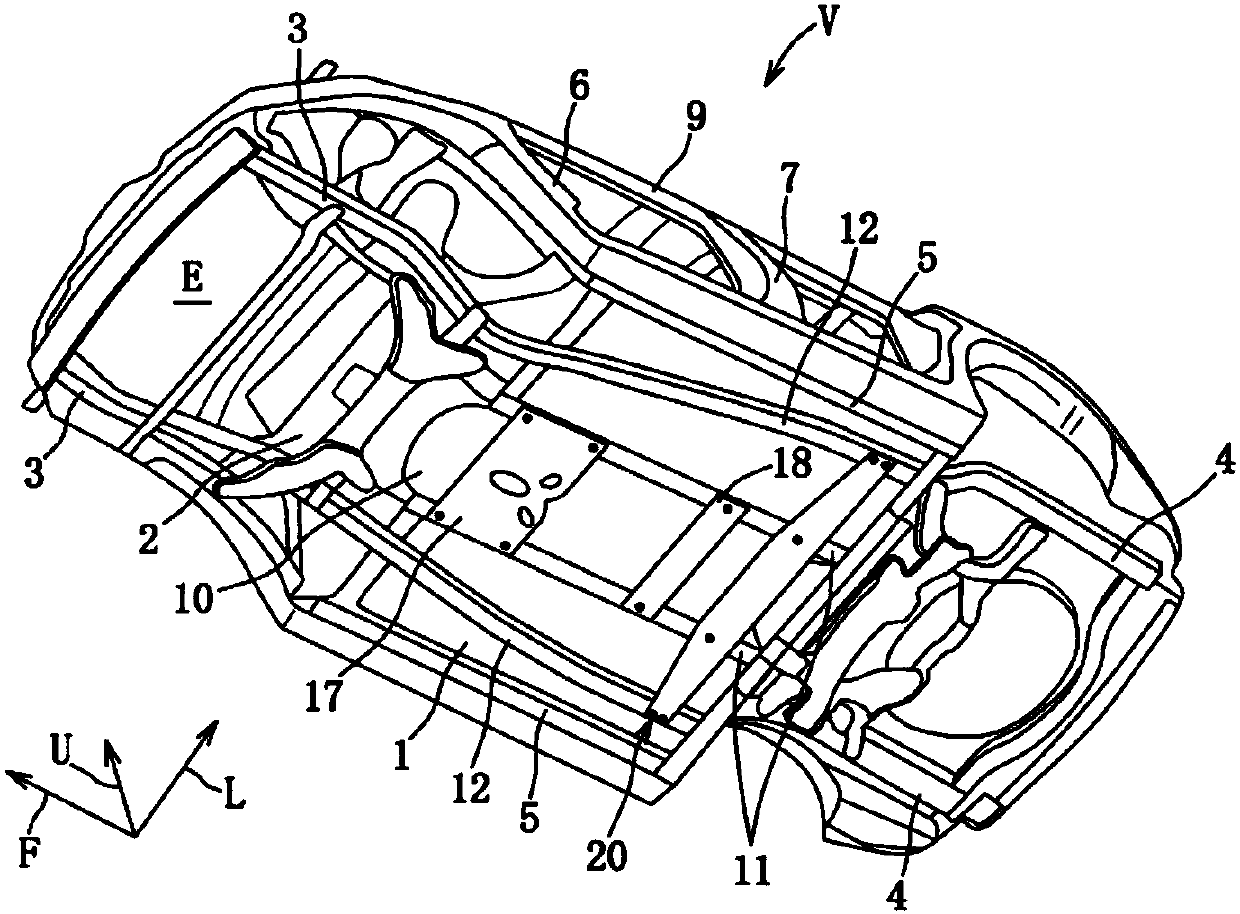

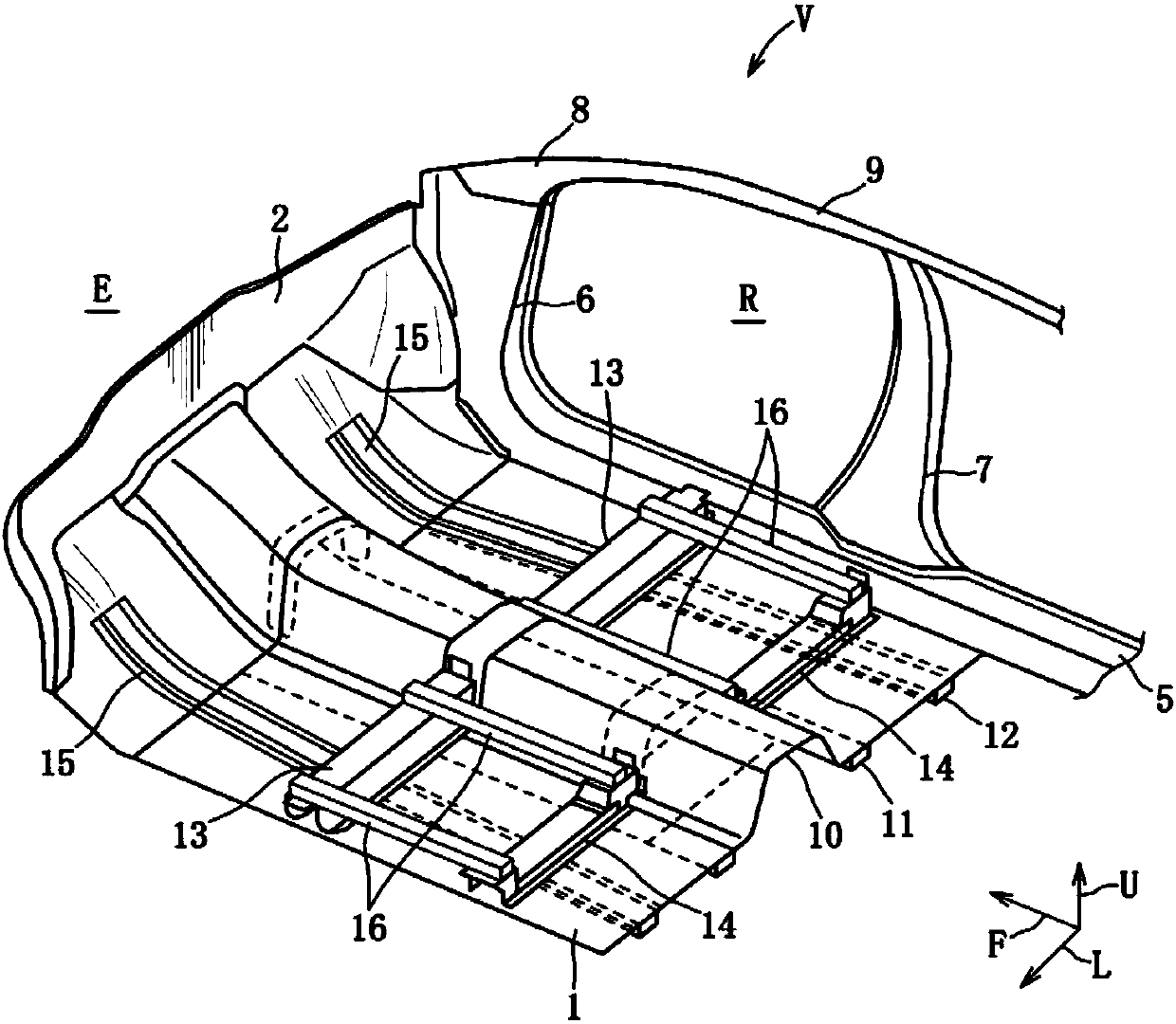

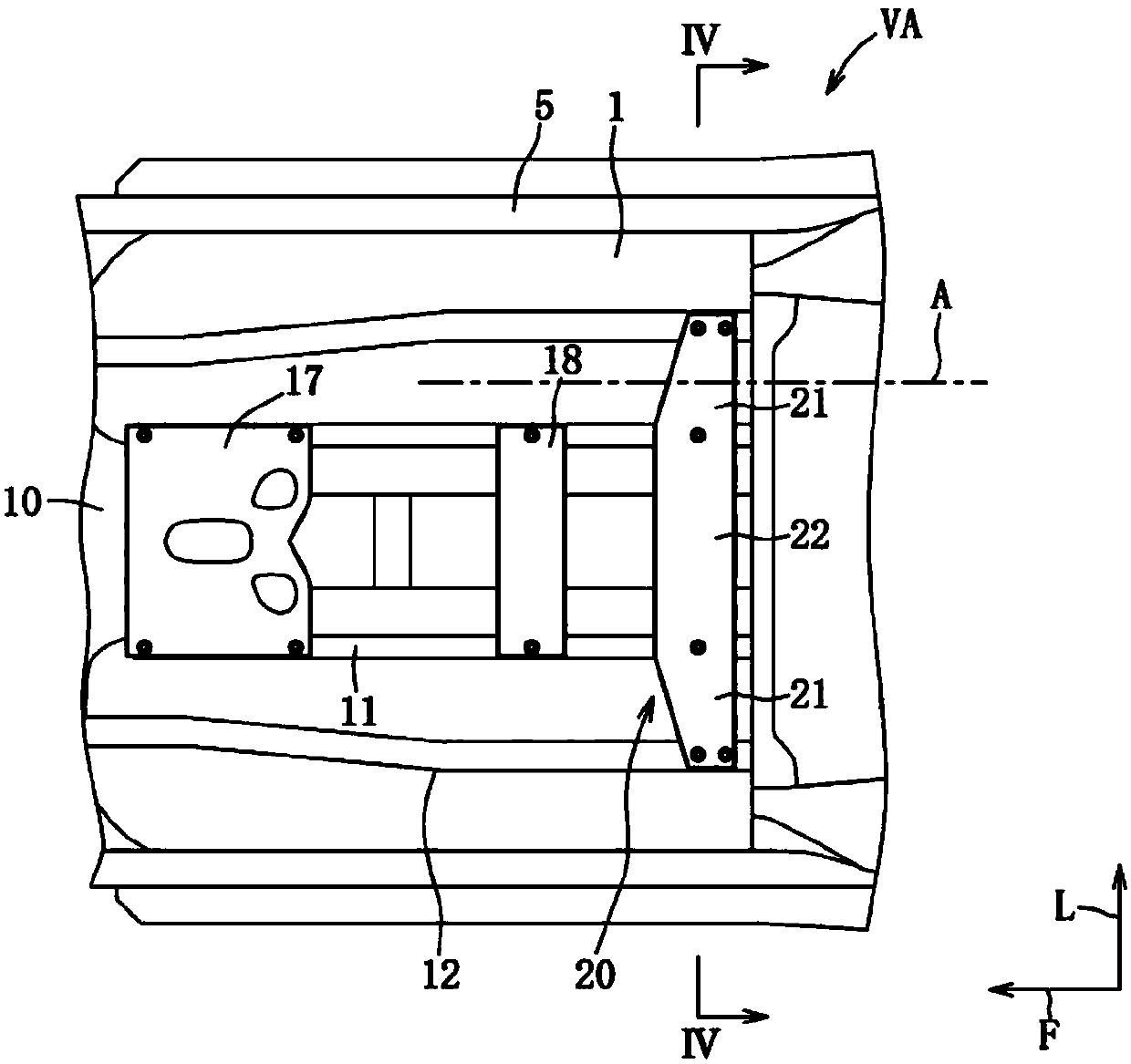

Reinforcing structure of vehicle body

InactiveCN107640226AImprove the vibration damping effectVehicle sub-unit featuresUnderstructuresFiberStrain energy

The invention provides a reinforcing structure of a vehicle body, the strain-energy storing capacity of the band plate made of a synthetic resin added with a reinforcing material is fully utilized, sothat the vibration damping performance of the floor panel is improved. There are provided a floor panel (1), a tunnel portion (10) which is provided to protrude at the floor panel (1), a pair of right-and-left tunnel side frames (11), a pair of right-and-left floor frames (12), and a band plate (21) which is made from carbon fiber reinforced plastic, an inward end portion which being connected tothe tunnel side frame (11) and an outward end portion of which being connected to the floor frame (12), wherein the band plate portion (21) includes a first displacement following portion (21a) whichis configured to be displaced, following displacement of the tunnel side frame (11) and a second displacement following portion (21b) which is configured to be displaced, following displacement of the floor frame (12), and the first displacement following portion (21a) and the second displacement following portion (21b) are configured to be asymmetrical relatively to a longitudinal-directional axis.

Owner:MAZDA MOTOR CORP

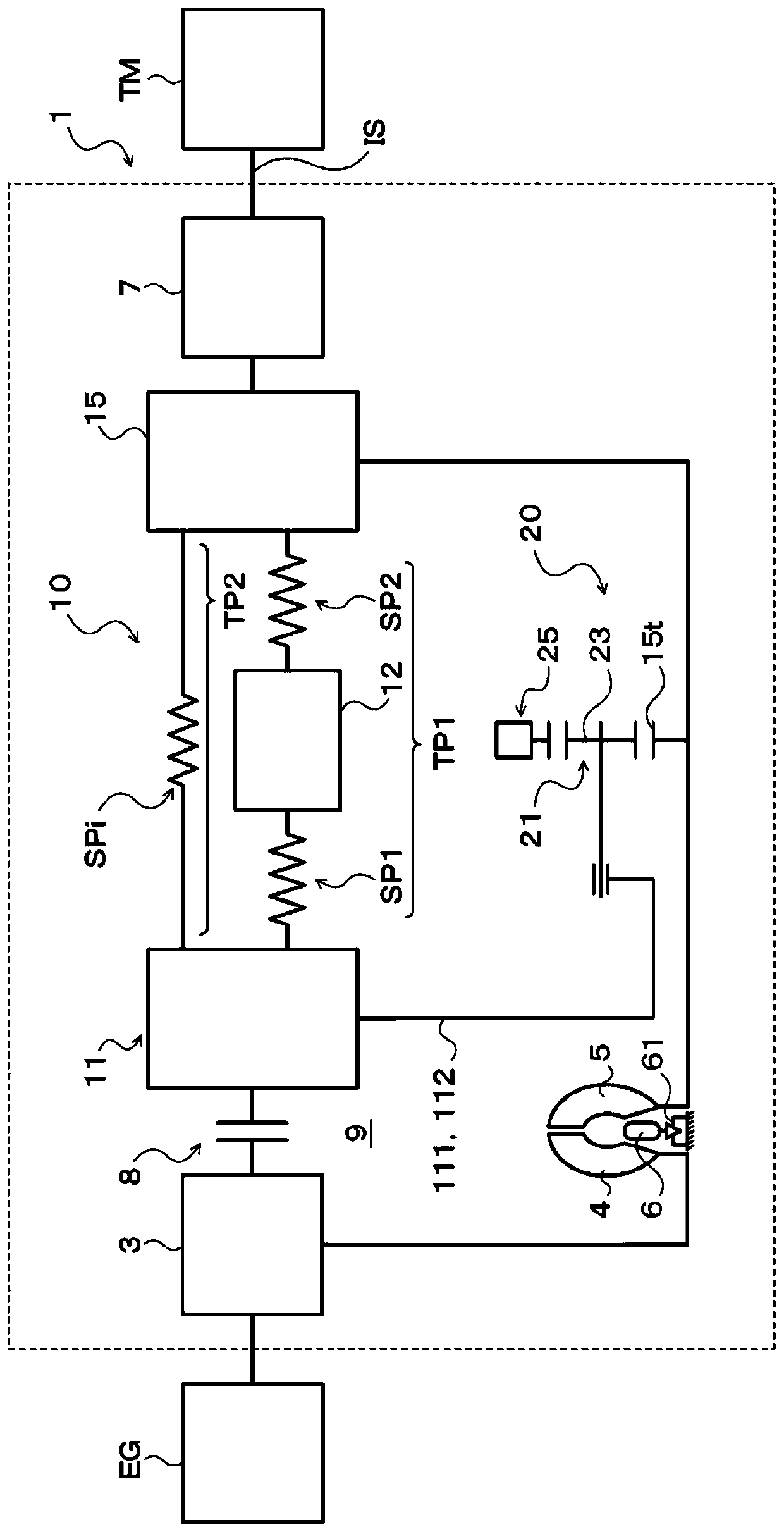

Damper device

InactiveCN109790905AImprove the vibration damping effectSmall backlashRotating vibration suppressionFlywheelsEngineeringPinion

The rotational inertia mass damper (20) of a damper device has a planetary gear (21) including: a driven member (15) having external teeth (15t) and serving as a sun gear; a plurality of pinion gears(23); first and second input plate members (111, 112) for rotatably supporting the plurality of pinion gears (23) and serving as a carrier; and a ring gear (25) meshing with the plurality of pinion gears (23) and functioning as a mass body. The ring gear (25) has two gear bodies (250 (250a, 250b)) arranged in the direction of the axis of the planetary gear (21) and connected to each other. The internal teeth (25t (25ta, 25tb)) of the two gear bodies are offset from each other in the circumferential direction of the two gear bodies.

Owner:AISIN AW INDUSTRIES CO LTD +1

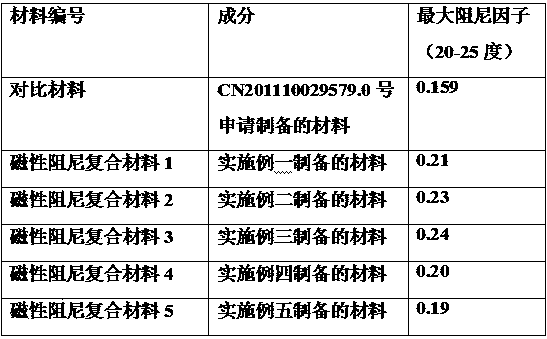

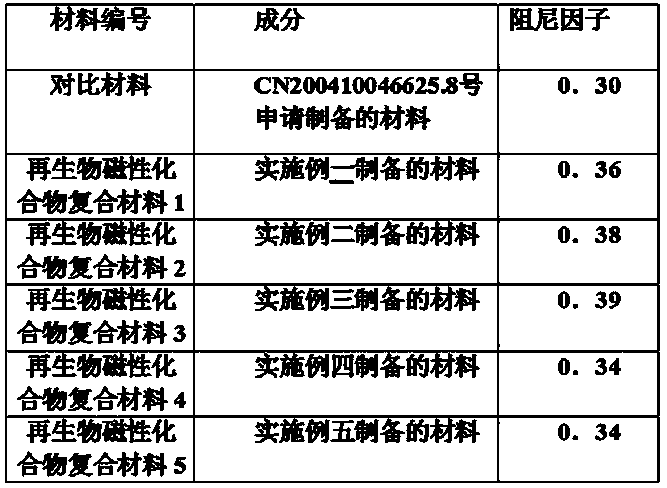

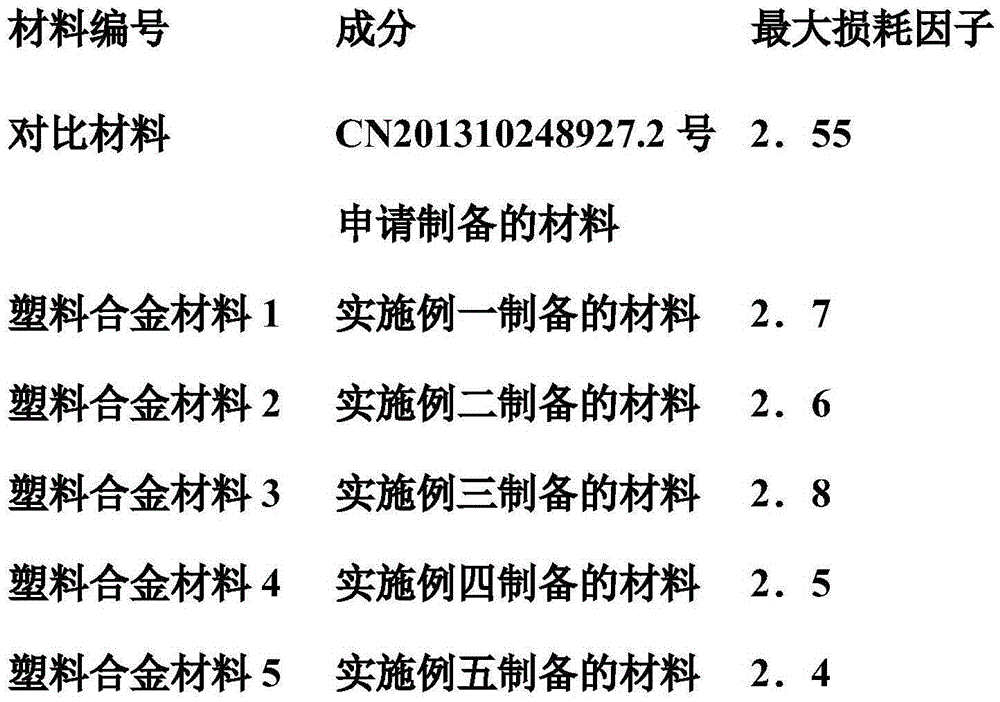

Magnetic damping composite material and preparation method thereof

The invention belongs to the field of functional materials, and in particular relates to a magnetic damping composite material and a preparation method thereof. The material comprises the following components in percentage by weight: 8 to 10 percent of kaolin, 8 to 11 percent of magnesium oxide, 24 to 28 percent of waste cement cerium-manganese composite oxide composite body, and the balance of phenolic resin. The invention aims to provide a magnetic damping composite material, which has the characteristic of high maximum damping factor. The invention also aims to provide the preparation method of the magnetic damping composite material, which has a simple process, and is low in production cost and applicable to industrial production.

Owner:江苏利泷半导体科技有限公司

Combined regenerated substance and magnetic compound material and preparation method thereof

The invention belongs to the field of functional materials and in particular relates to a combined regenerated substance and magnetic compound material and a preparation method thereof. The material comprises the following components by weight percent: 2%-5% of chromium sesquioxide, 11%-15% of bentonite, 20%-25% of a waste glass iron-praseodymium magnetic oxide complex body and the balance of phenolic resin. The material provided by the invention is pollution-free and relatively higher in damping performance and has a vibration attenuation effect. The preparation method provided by the invention is simple in process, low in production cost and suitable for industrial production.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

Vibration damping device

InactiveCN108027012AWeight increaseImprove the vibration damping effectRotating vibration suppressionFluid gearingsInertial massEngineering

This vibration damping device includes: a supporting member which rotates integrally with rotating elements; restoring force generation members which are rotatably connected to the supporting member with first connecting shafts interposed therebetween; an inertia mass body which is rotatable about the center of rotation of the rotating elements; second connecting shafts which are each supported byone of the corresponding restoring force generation member and the inertia mass body, and connects the restoring force generation member and the inertia mass body in a relative rotatable manner; andguide portions which are each formed on the other side of the corresponding restoring force generation member and the inertia mass body, and guides the corresponding second connecting shaft. With therotation of the supporting member, each of the second connecting shafts rocks about the corresponding first connecting shaft while maintaining the center distance to the first connecting shaft constant, and rocks about a virtual shaft while maintaining the center distance to the virtual shaft constant, the virtual shaft being set so that the relative position with respect to the inertia mass bodyis invariant.

Owner:AISIN AW CO LTD

A kind of magnetic compound polymer plastic alloy material and preparation method thereof

The invention belongs to the field of organic materials, and in particular relates to a magnetic compound polymer plastic alloy material and a preparation method thereof. The material comprises the following components in percentage by weight: 10 to 15 percent of silicon dioxide, 8 to 15 percent of vanadium oxide, 22 to 25 percent of blast furnace slag niobium-manganese complex oxide composite body, and the balance of urea-formaldehyde resin. The invention aims to provide the magnetic compound polymer plastic alloy material, which has a high damping function. The invention also aims to provide the preparation method of the magnetic compound polymer plastic alloy material, which has a simple process, and is low in production cost and applicable to industrial production.

Owner:镇江泰福机电有限公司

Vibration damping device

InactiveCN107709826BIncrease equivalent stiffnessWeight increaseRotating vibration suppressionYielding couplingVibration attenuationInertial mass

Owner:AISIN AW CO LTD +2

Vibration damping device

ActiveCN108700157BIncrease the moment of inertiaImprove the vibration damping effectRotating vibration suppressionFluid gearingsVibration attenuationCrank

The present invention provides a vibration damping device. The vibration damping device (20) includes: a crank member (22) capable of swinging with the rotation of the drive member (15) to which torque from the engine (EG) is transmitted; and an inertial mass body (23 ), which is connected to the driving part (15) via the crank part (22), and swings around the center of rotation (RC) in conjunction with the rotation of the driving part (15) and the crank part (22), and the vibration damping device (20) Designed as, the effective order (q eff ) becomes larger as the amplitude of the vibration of the input torque transmitted from the engine (EG) to the drive member (15) becomes larger.

Owner:AISIN AW CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com