Design method of rolling mill vertical vibration suppression controller based on self-adaptive fuzzy backstepping

A technology of self-adaptive fuzzy design method, applied in rolling mill control device, vibration control, metal rolling, etc., can solve problems such as dead zone of electro-hydraulic servo valve spool

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0104] In order to elaborate the technical content, achieved purpose and effect of the present invention, the following will be described in detail in conjunction with the accompanying drawings.

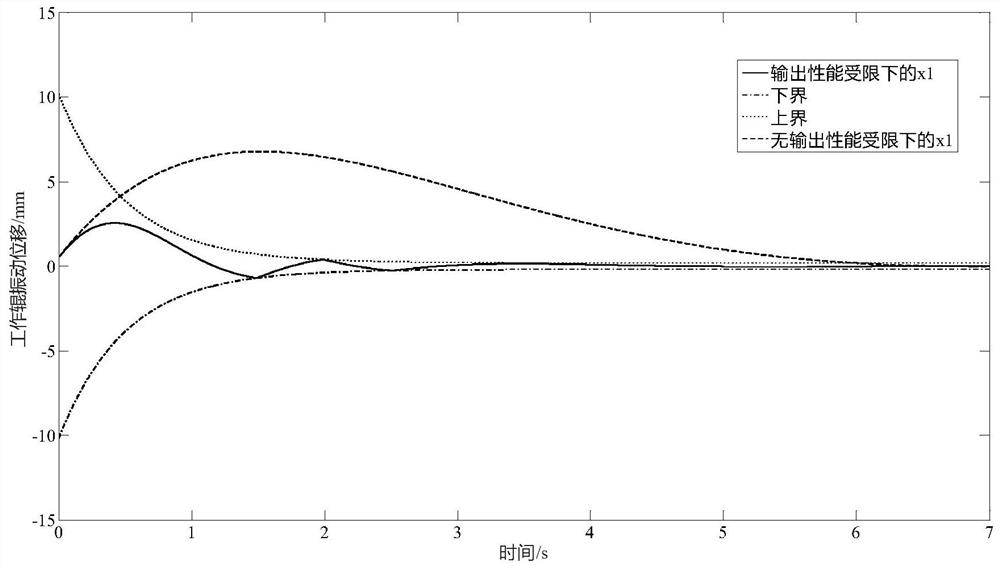

[0105] The design method of rolling mill vertical vibration suppression controller based on adaptive fuzzy backstepping, such as figure 1 As shown, firstly, according to the dynamic principle of rolling mill vibration system, the nonlinear model of rolling mill vertical vibration is established; then, the control target of suppressing rolling mill vibration is determined according to the actual working conditions; finally, combined with the nonlinear model of rolling mill vertical vibration and the suppression of rolling mill The vibration control objective is to design an adaptive backstepping controller. The specific design method steps of the controller are as follows:

[0106] S1, such as figure 2 As shown, the parameters of the mechanical-hydraulic coupling vibration system o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com