End support operation cable

A supporting device and cable technology, applied in the direction of shafts and bearings, flexible shafts, linear motion shafts, etc., can solve the problems of increased cost and lower vibration damping performance, and achieve the effect of easy assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0049] Examples and comparative examples are given below to specifically illustrate the use effect of the terminal support device of the present invention.

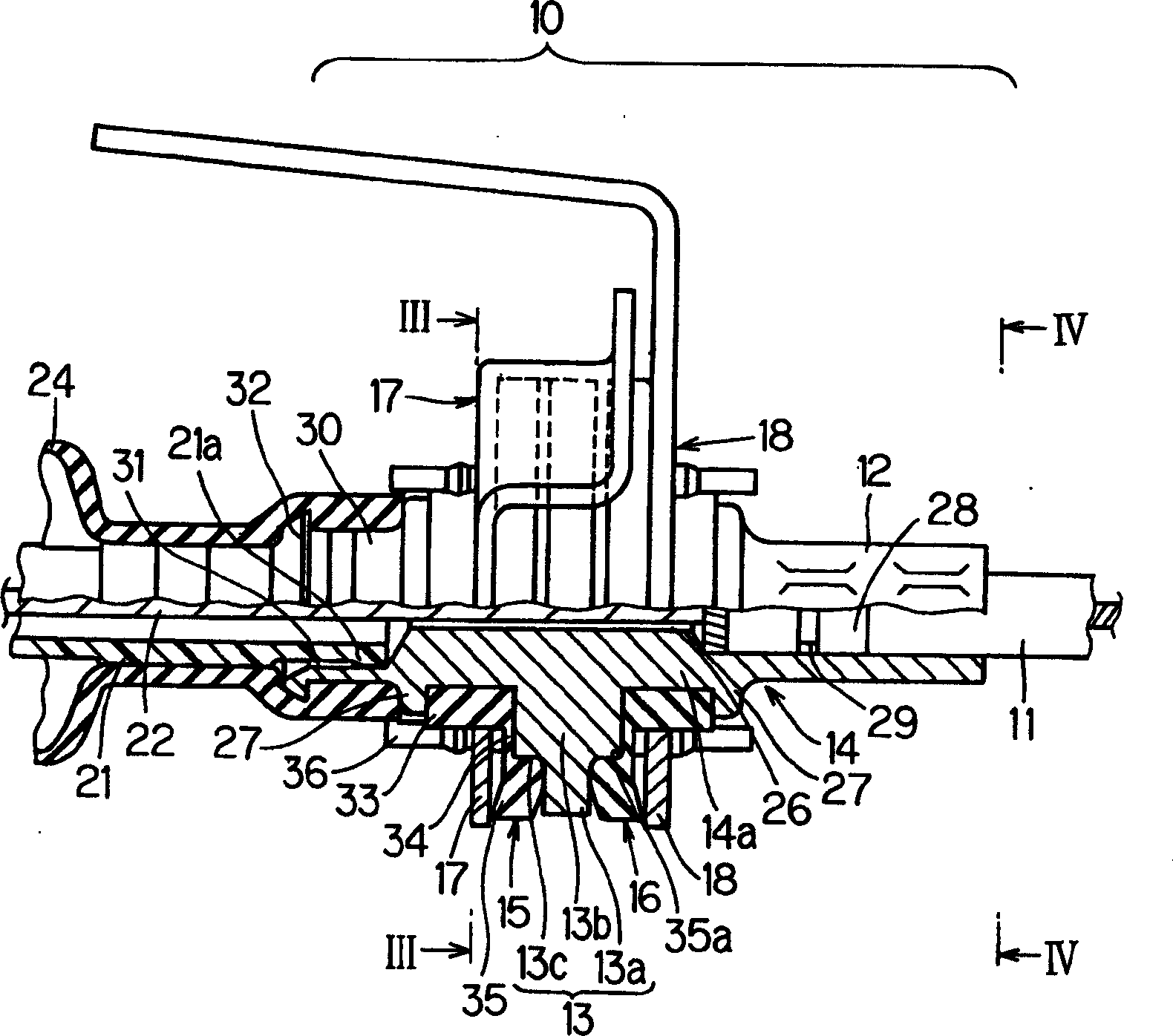

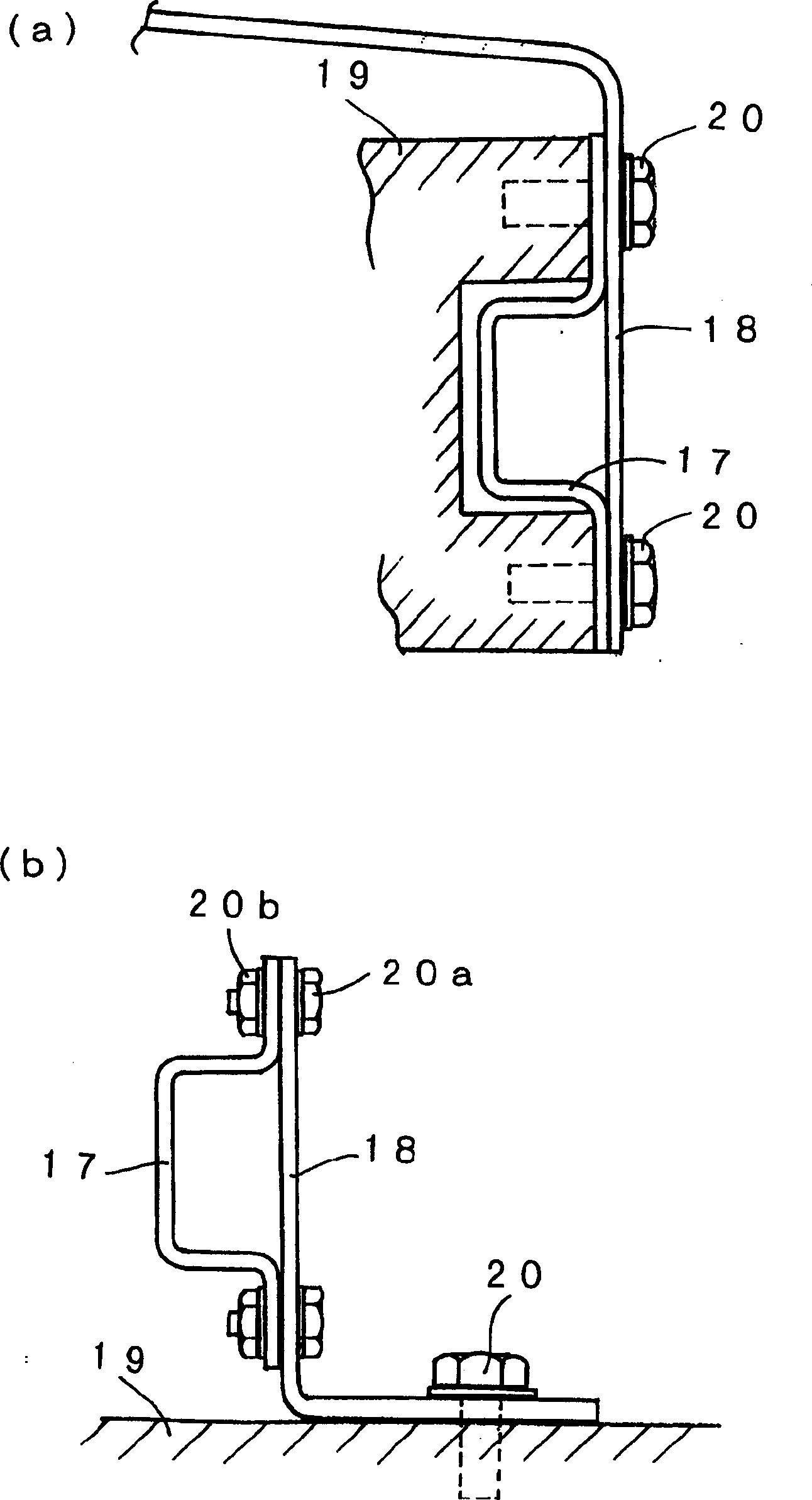

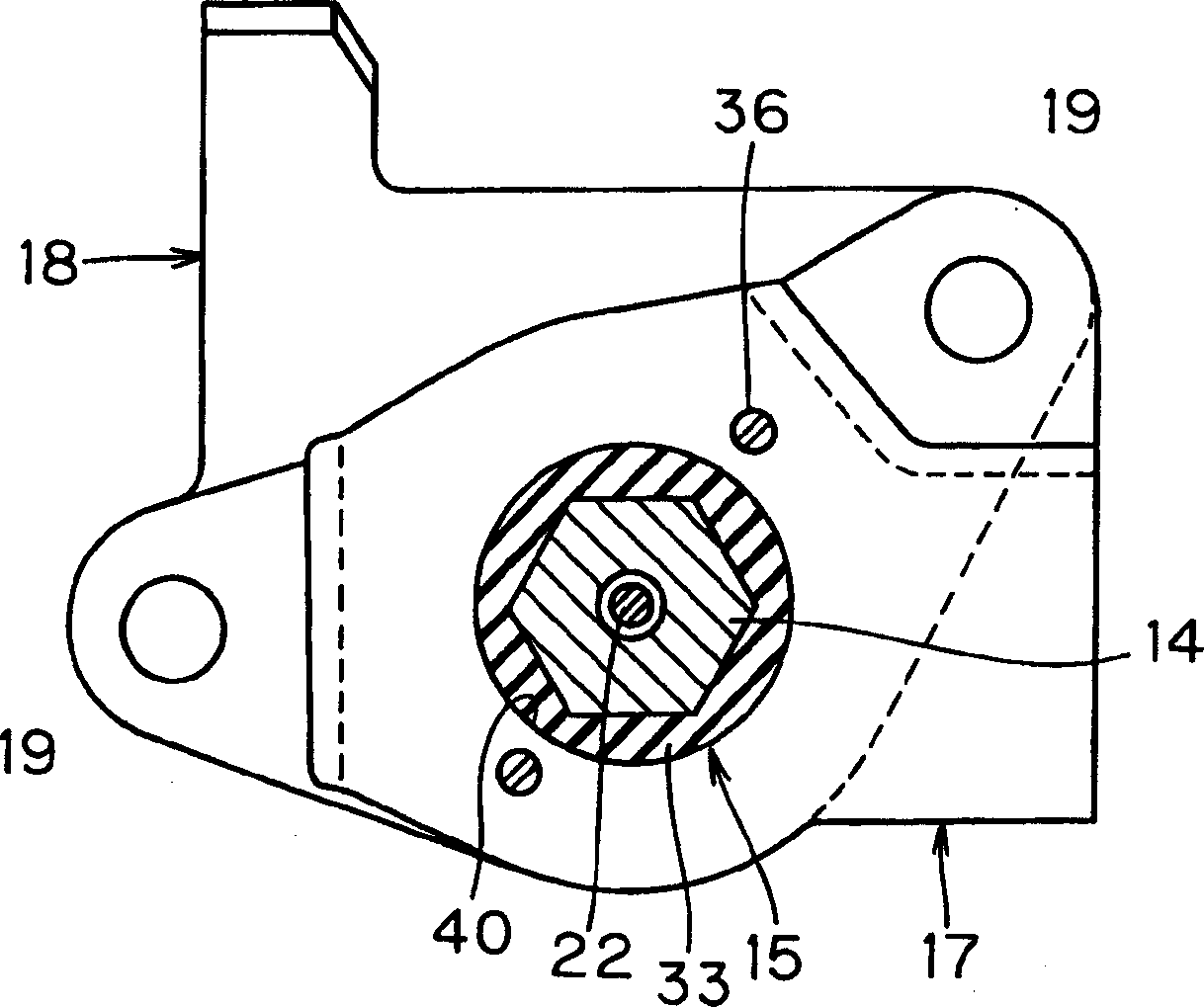

[0050] [Example] will Figure 7 The end support 62 is shown mounted to the AT cable. The outer diameter of the damping blocks 15 and 16 is 38 mm, the inner diameter is 16 mm, the thickness of the disc-shaped part 63 is 3.5 mm, the material is EPDM, and the rubber hardness is Hs50. In addition, the degree of clamping of the retaining plate is such that the disk-shaped portion 61 is reduced from its natural thickness to about 1.3 mm. picture Figure 7 This is attached to the support 64 as shown, and the other end of the AT cable is attached to the rod bracket 65 . In this state, a predetermined magnitude of vibration (vibration acceleration Gf) is applied to the end support device 62 at various vibration frequencies in the T direction, B direction, and H direction, and the magnitude of the T-direction vibration transmitt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com