Magnetic damping composite material and preparation method thereof

A composite material and magnetic damping technology, applied in the field of functional materials, can solve the problem of low damping factor, and achieve the effect of improving wear resistance and delaying aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

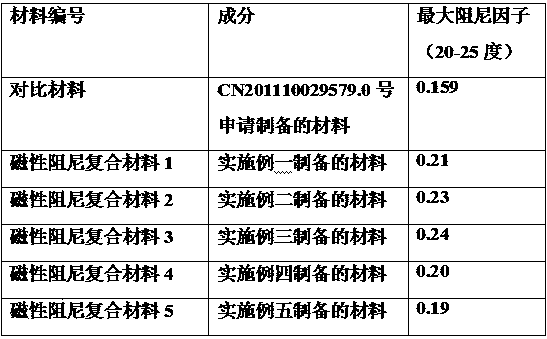

Examples

Embodiment 1

[0028] Magnetic damping composite material of the present invention, its preparation method is as follows:

[0029] 1) Preparation of cerium manganese composite oxide

[0030] Raw materials by weight percentage: Mn 3 o 4 12%, WO 3 0.005%, CeO 2 0.2%, MoO 3 0.05%, ZnO 12%, the rest is Fe 2 o 3 For batching, the purity of each raw material is greater than 99.9%; each raw material is mixed and crushed in a sand mill, and then the powder is dried at 120 ° C, and then sieved after drying, the sieve is 180 mesh, and then in the Pre-calcined at 870°C for 70 minutes, crushed and ground after pre-calcined to obtain cerium-manganese composite oxide powder with a particle size of 130-150 microns;

[0031] 2) Preparation of waste cement

[0032] Take the waste cement of the above ingredients, grind it into waste cement powder with a particle size of 130-150 microns, and set aside;

[0033] 3) Preparation of waste cement cerium manganese composite oxide complex

[0034] Accor...

Embodiment 2

[0038] Magnetic damping composite material of the present invention, its preparation method is as follows:

[0039] 1) Preparation of cerium manganese composite oxide

[0040] Raw materials by weight percentage: Mn 3 o 4 16%, WO 3 0.02%, CeO 2 0.5%, MoO 3 0.080%, ZnO 14%, the rest is Fe 2 o 3 For batching, the purity of each raw material is greater than 99.9%; each raw material is mixed and crushed in a sand mill, and then the powder is dried at 130°C, and then sieved after drying. The sieve is 220 mesh, and then in Pre-fired at 900°C for 80 minutes, crushed and ground to obtain niobium-manganese complex oxide powder with a particle size of 130-150 microns;

[0041] 2) Preparation of waste cement

[0042] Take the waste cement of the above ingredients, grind it into waste cement powder with a particle size of 130-150 microns, and set aside;

[0043] 3) Preparation of waste cement cerium manganese composite oxide complex

[0044] According to the weight ratio of 0.5...

Embodiment 3

[0048] Magnetic damping composite material of the present invention, its preparation method is as follows:

[0049] 1) Preparation of cerium manganese composite oxide

[0050] Raw materials by weight percentage: Mn 3 o 4 14%, WO 3 0.01%, CeO 2 0.4%, MoO 3 0.07%, ZnO 13%, the rest is Fe 2 o 3 For batching, the purity of each raw material is greater than 99.9%; each raw material is mixed and crushed in a sand mill, and then the powder is dried at 125°C, and then sieved after drying with a sieve of 200 mesh, and then in the Pre-calcined at 890°C for 75 minutes, crushed and ground after pre-calcined to obtain cerium-manganese composite oxide powder with a particle size of 130-150 microns;

[0051] 2) Preparation of waste cement

[0052] Take the waste cement of the above ingredients, grind it into waste cement powder with a particle size of 130-150 microns, and set aside;

[0053] 3) Preparation of waste cement cerium manganese composite oxide complex

[0054] Accord...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com