Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

43results about How to "Improve classification processing efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

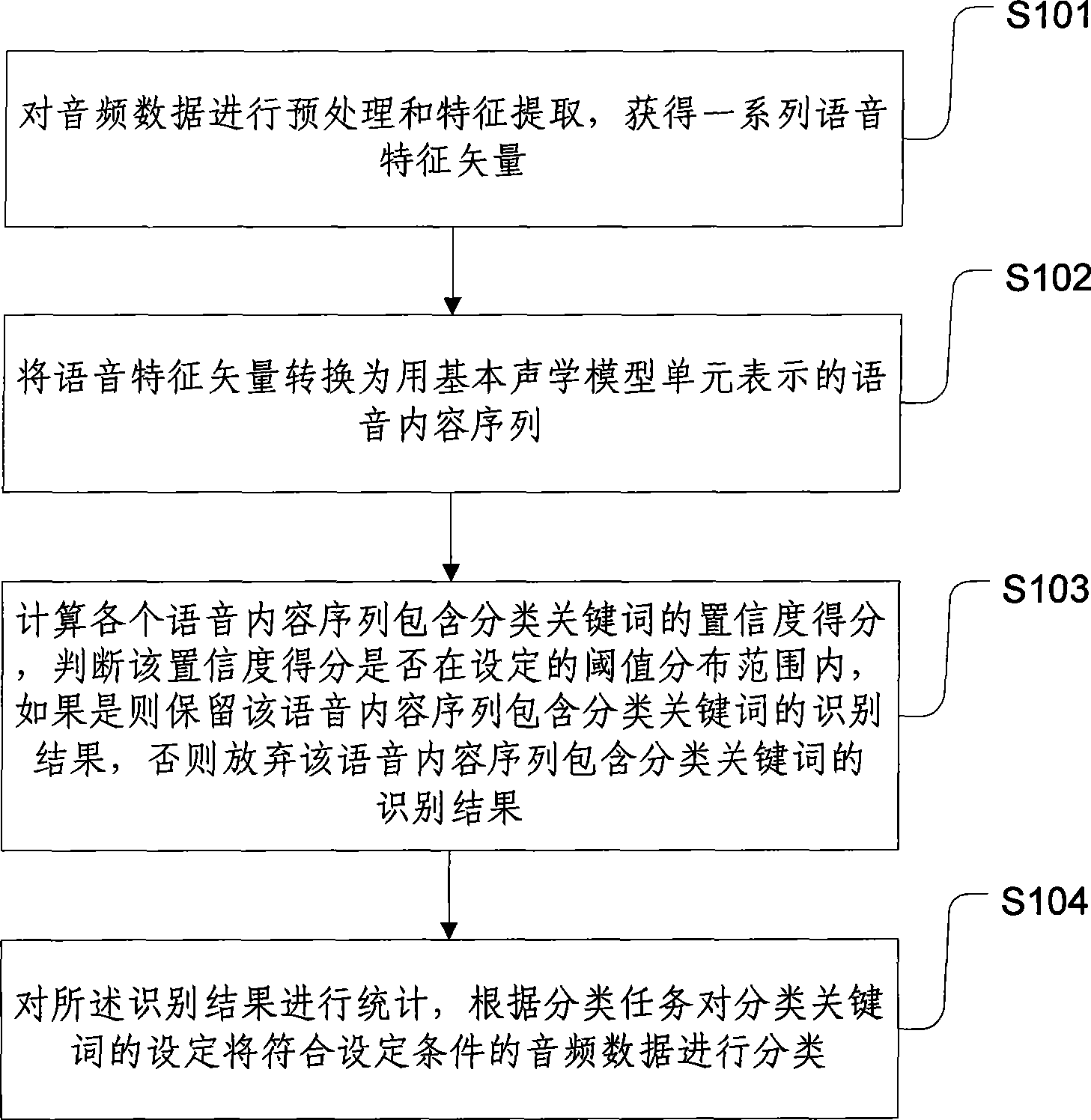

Audio frequency rapid classification method based on content

InactiveCN101447185AImplement classificationQuickly change the category of the classificationSpeech recognitionFeature vectorFeature extraction

The invention discloses an audio frequency rapid classification method based on content, comprising the following steps: pretreatment and character extraction are carried out on audio frequency data, and a series of speech feature vectors are obtained; the speech feature vectors are converted into speech content sequences which are represented by a basic acoustic model unit AU and the speech content sequences comprising classification key words are recognized according to a created word list; the confidence score of every speech content sequence comprising the classification key words is calculated; whether the confidence score is within a set threshold distribution range is judged, and if yes, recognizing results of the speech content sequences comprising the classification key words are reserved; the recognizing results are counted, and the audio frequency data which accord with set conditions are classified according to the set of a classification task on the classification key words. The method fully utilizes content information and can realize complex classifications conveniently and process a plurality of audio data files in a parallel way. The efficiency of the file classification processing is high.

Owner:SHENZHEN RAISOUND TECH +1

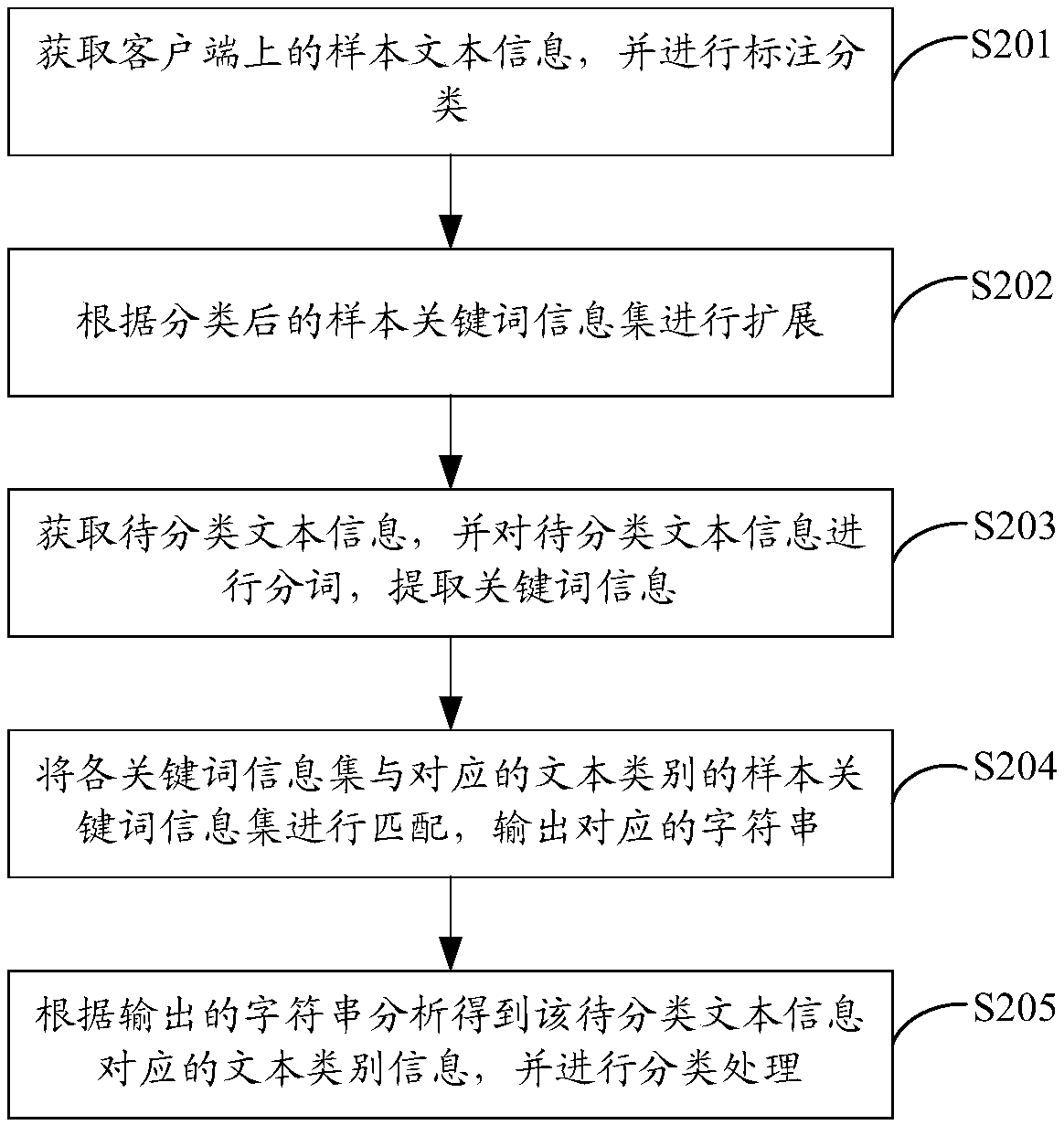

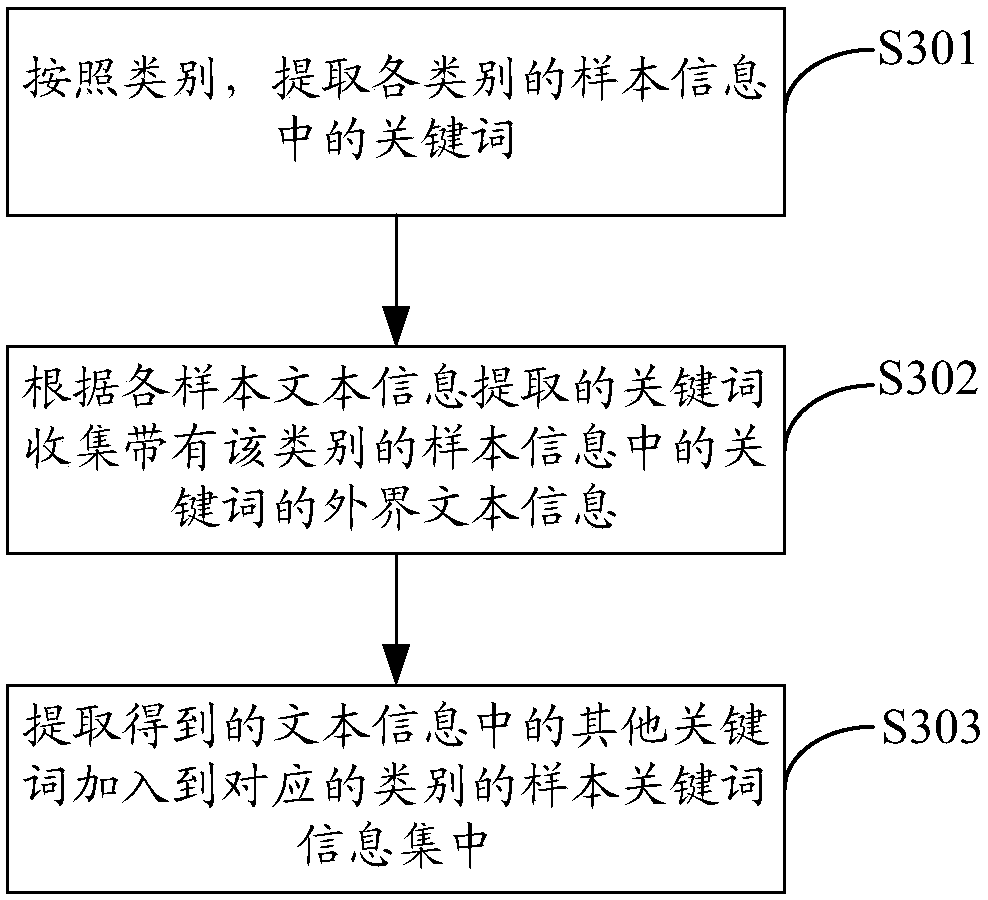

Text information classification method and device

PendingCN107766371AImprove efficiencyShorten the analysis cycleSpecial data processing applicationsText database clustering/classificationData miningData science

The embodiment of the invention provides a text information classification method and device. According to the method, a sample keyword information set of a text category is set in advance, and a corresponding relation between the sample keyword information set and text category information is established, so that a matching foundation is provided for subsequent classification of to-be-classifiedtext information; and during classification processing of the to-be-classified text information, keyword information is extracted from the to-be-classified text information according to preset rules,and the text category information corresponding to the to-be-classified text information is obtained through matching according to the corresponding relation between the sample keyword information setand the text category. Through the information classification mode, it is only needed to perform system automatic matching, classification processing efficiency is greatly improved, the analysis cycle is shortened, a manual allocation error is lowered, and matching accuracy is improved.

Owner:ZTE CORP

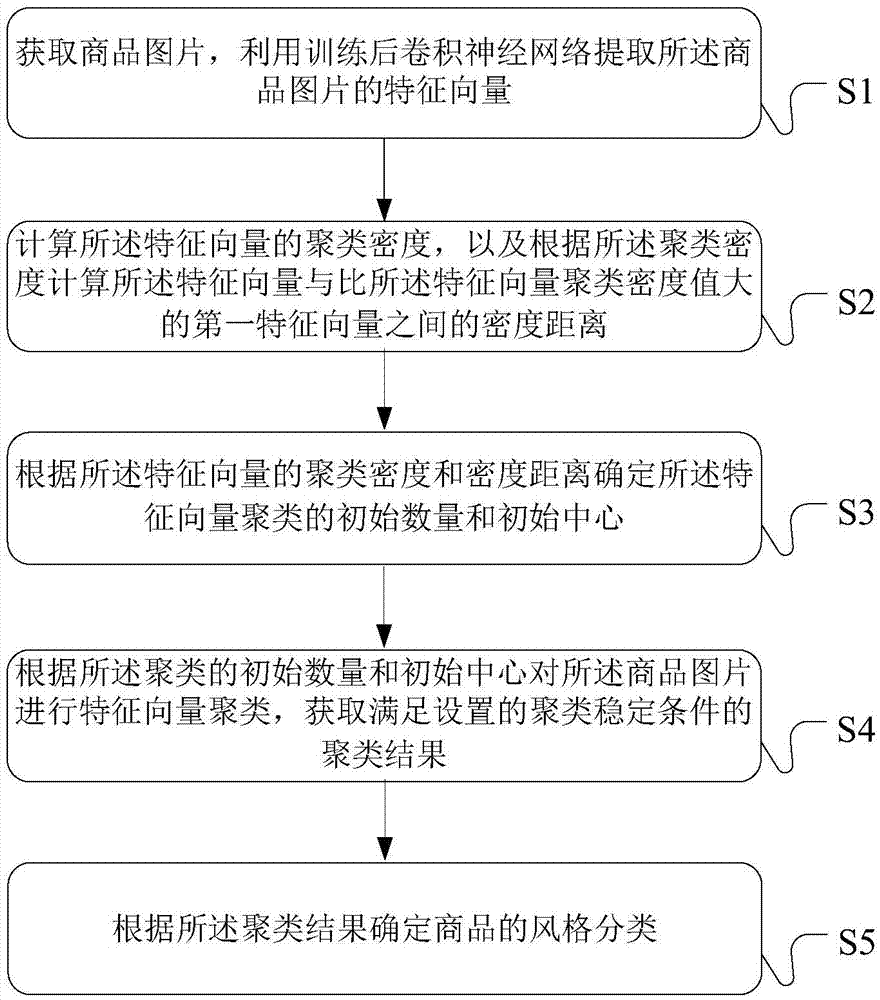

Commodity style classification determination method and apparatus thereof

InactiveCN106874923AImprove transaction conversion rateImprove accuracyCharacter and pattern recognitionFeature vectorUltimate tensile strength

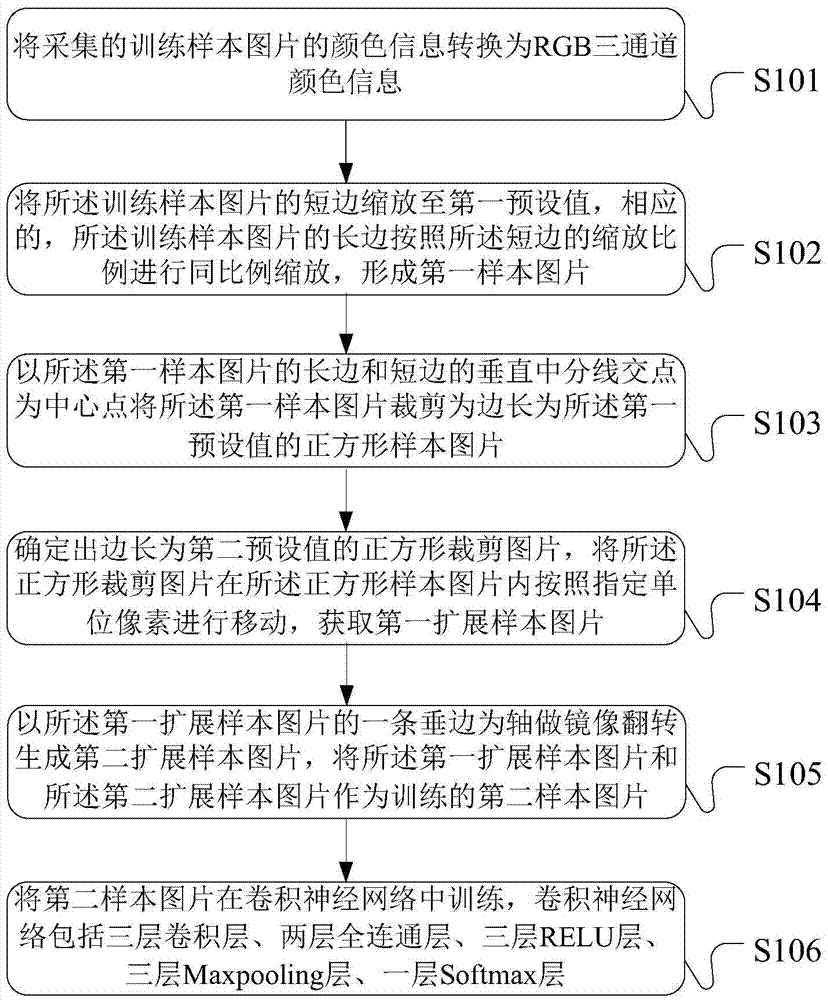

The invention provides a commodity style classification determination method and an apparatus thereof. The method comprises the following steps of acquiring a commodity picture, and using a trained convolutional neural network to extract a characteristic vector of the commodity picture; calculating cluster density of the characteristic vector, and according to the cluster density, calculating a density distance between the characteristic vector and a first characteristic vector whose cluster density value is greater than a cluster density value of the characteristic vector; according to the cluster density of the characteristic vector and the density distance, determining an initial quantity and an initial center of a characteristic vector cluster; according to the initial quantity and the initial center of the cluster, carrying out characteristic vector clustering on the commodity picture, and acquiring a cluster result of a cluster stabilization condition satisfying setting; and according to the cluster result, determining commodity style classification. In the technical scheme provided in embodiments of the invention, an automatic, rapid, accurate and reliable classification basis is provided for a commodity style, accuracy and efficiency of commodity style classification are increased, and working strength of a worker is reduced.

Owner:ALIBABA GRP HLDG LTD

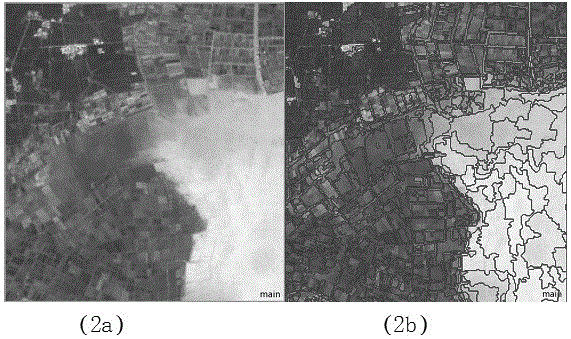

Lake water area information extraction method based on Landsat OLI multispectral image

ActiveCN105957079AImprove processing efficiencyReduce workloadImage enhancementImage analysisImage segmentationAtmospheric correction

The invention discloses a lake water area information extraction method based on Landsat OLI multispectral image, and the method comprises the following steps: 1) preprocessing including calibration, geometric correction, atmospheric correction, clipping and embedding is performed on Landsat OLI multispectral data; 2) the preprocessed multispectral data is divided by adopting a multiscale image segmentation method; 3) two user-defined normalized difference water body indexes and MNDWI (Modified Normalized Difference Water Index) are constructed; 4) threshold values are separately set for three normalized difference water body indexes, and water area information is extracted; 5) series water area objects are exported, and water area vector data is generated; 6) the Landsat OLI multispectral image is cut by using the water area vector data, and the water area information data is obtained. According to the invention, the first and second waveband information of the Landsat OLI is comprehensively utilized, the water area information extraction speed and precision are improved, and essential data is provided for following scientific research.

Owner:HUAIYIN TEACHERS COLLEGE

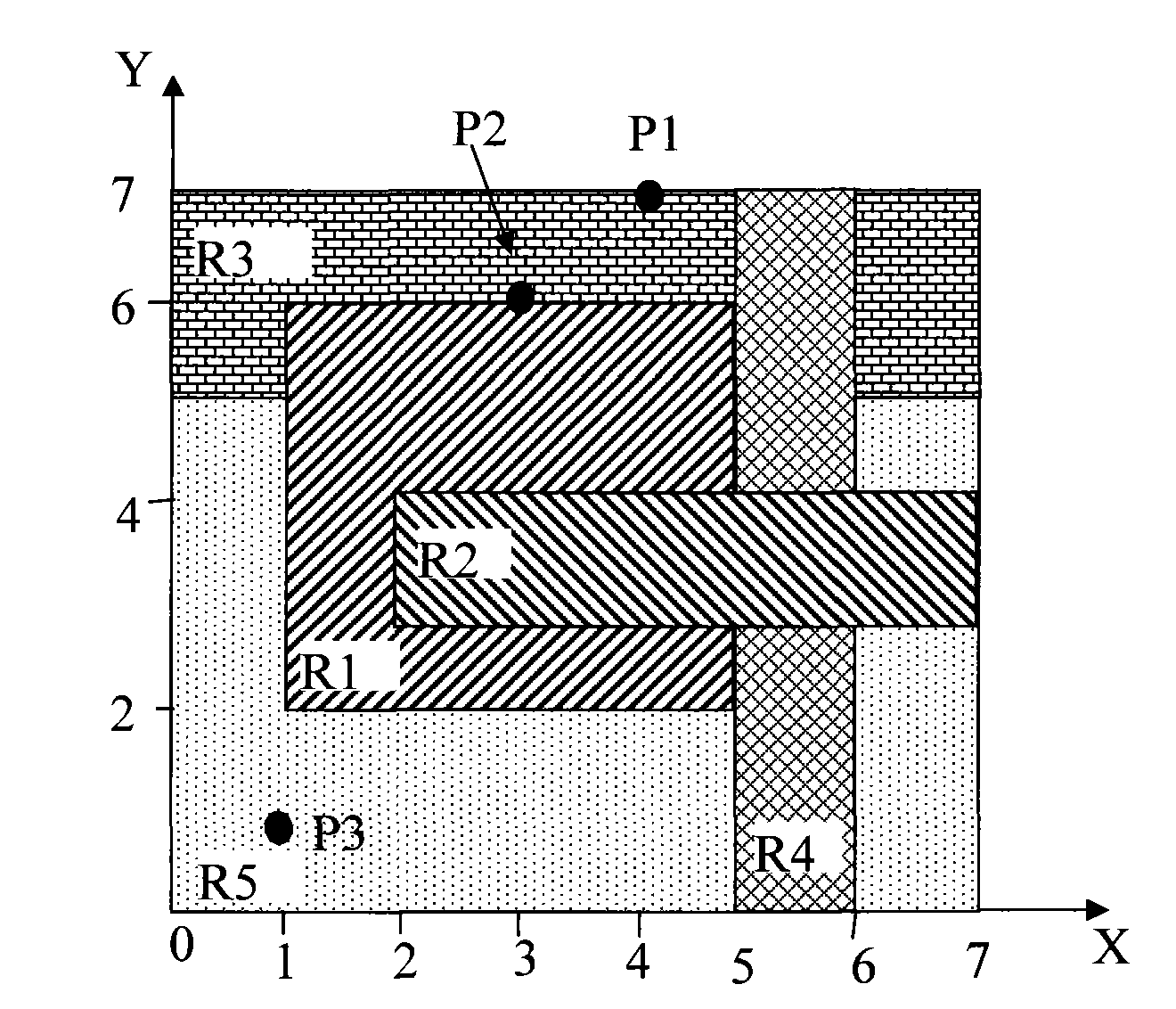

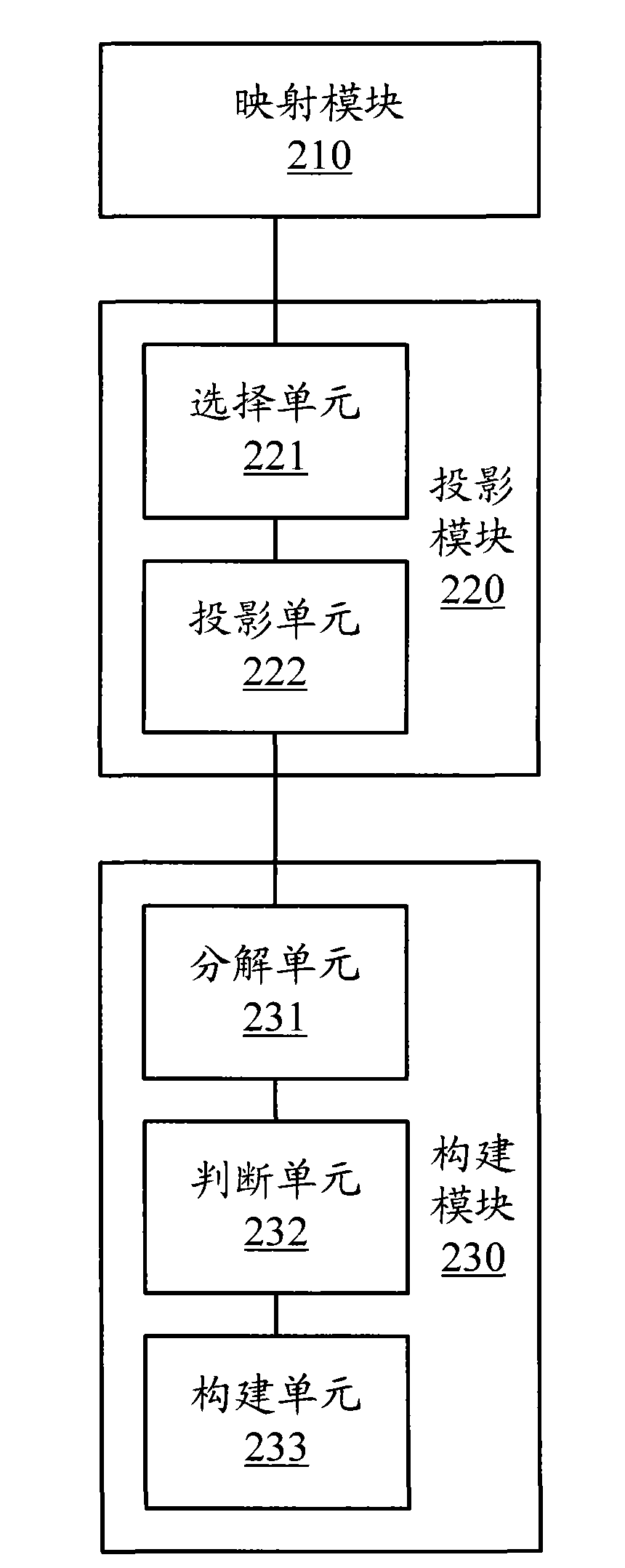

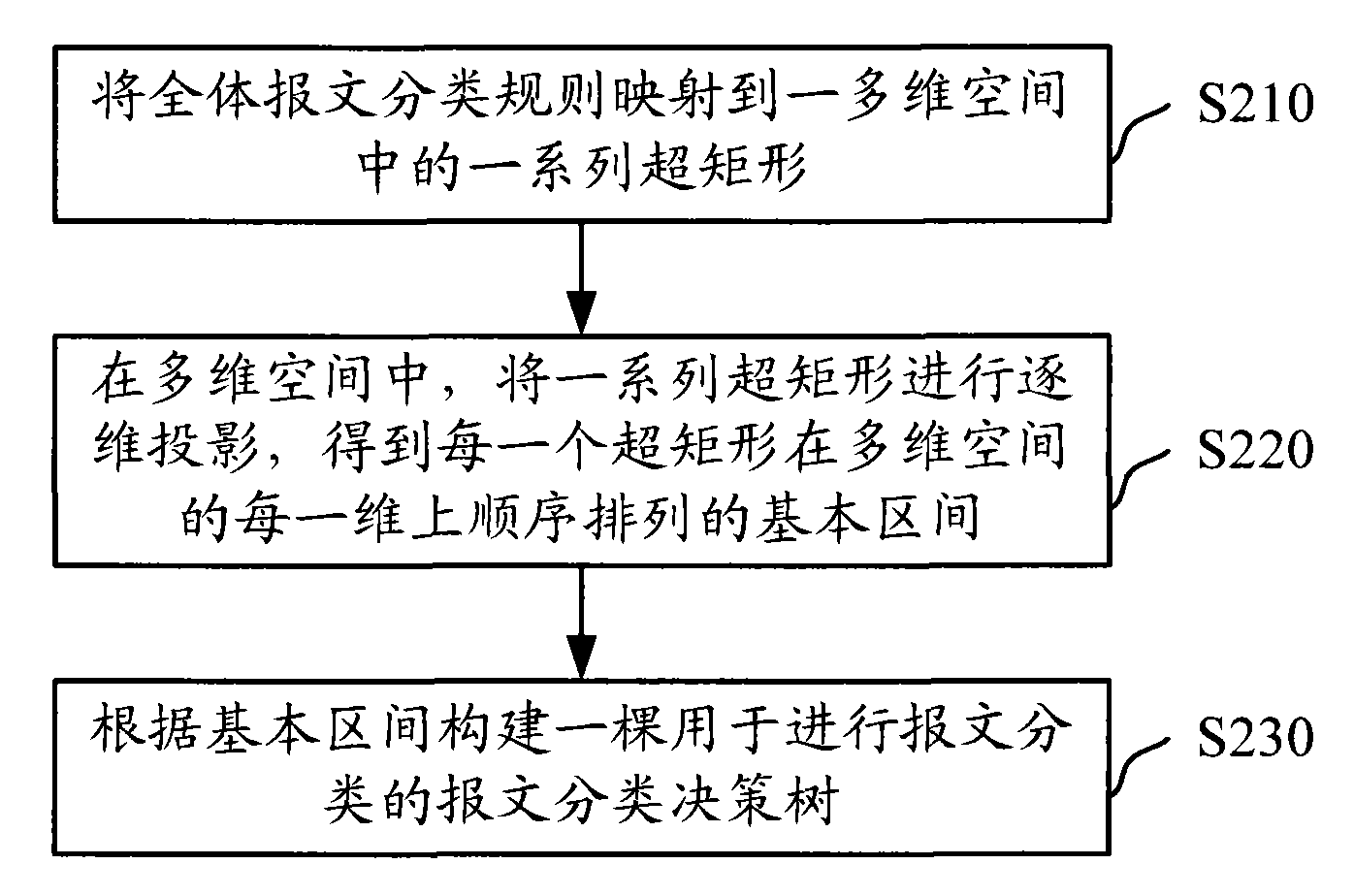

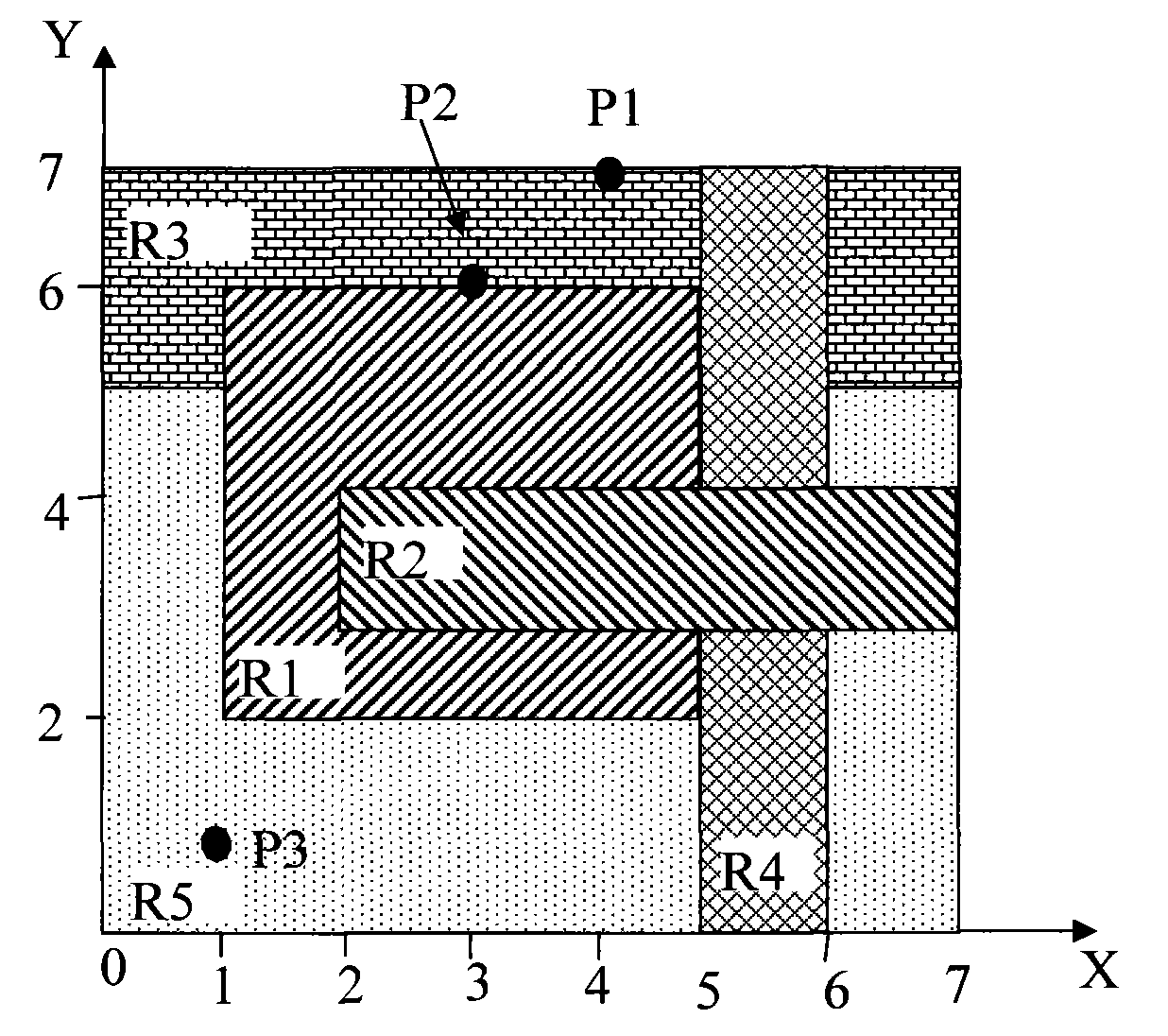

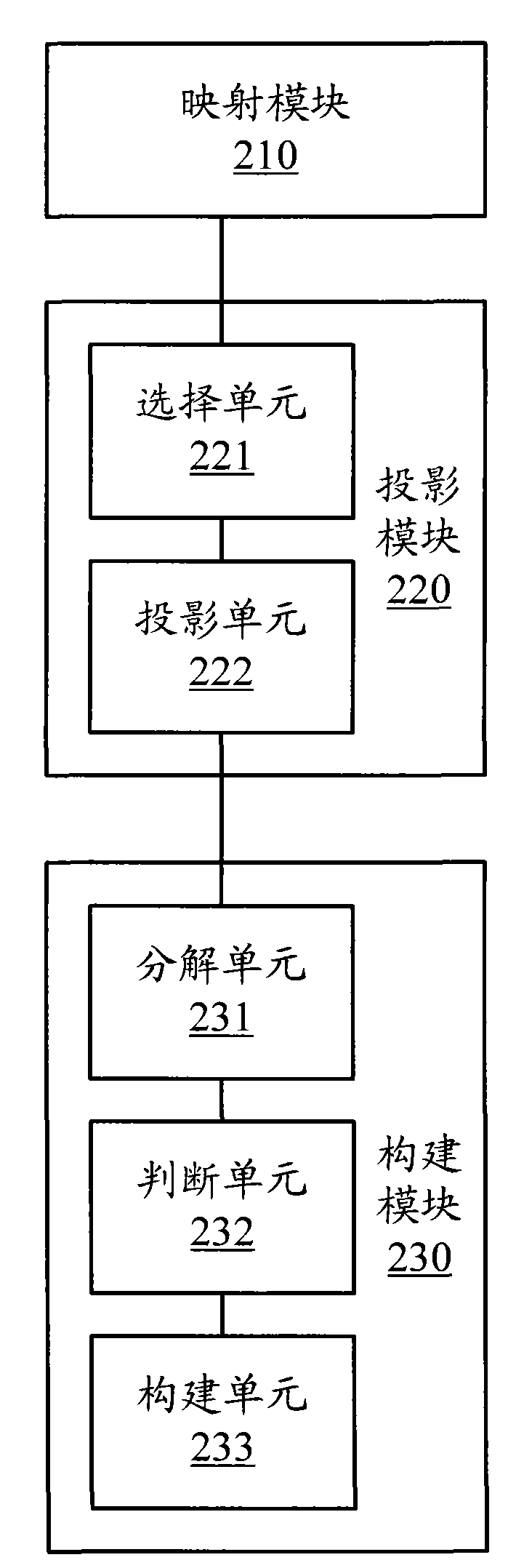

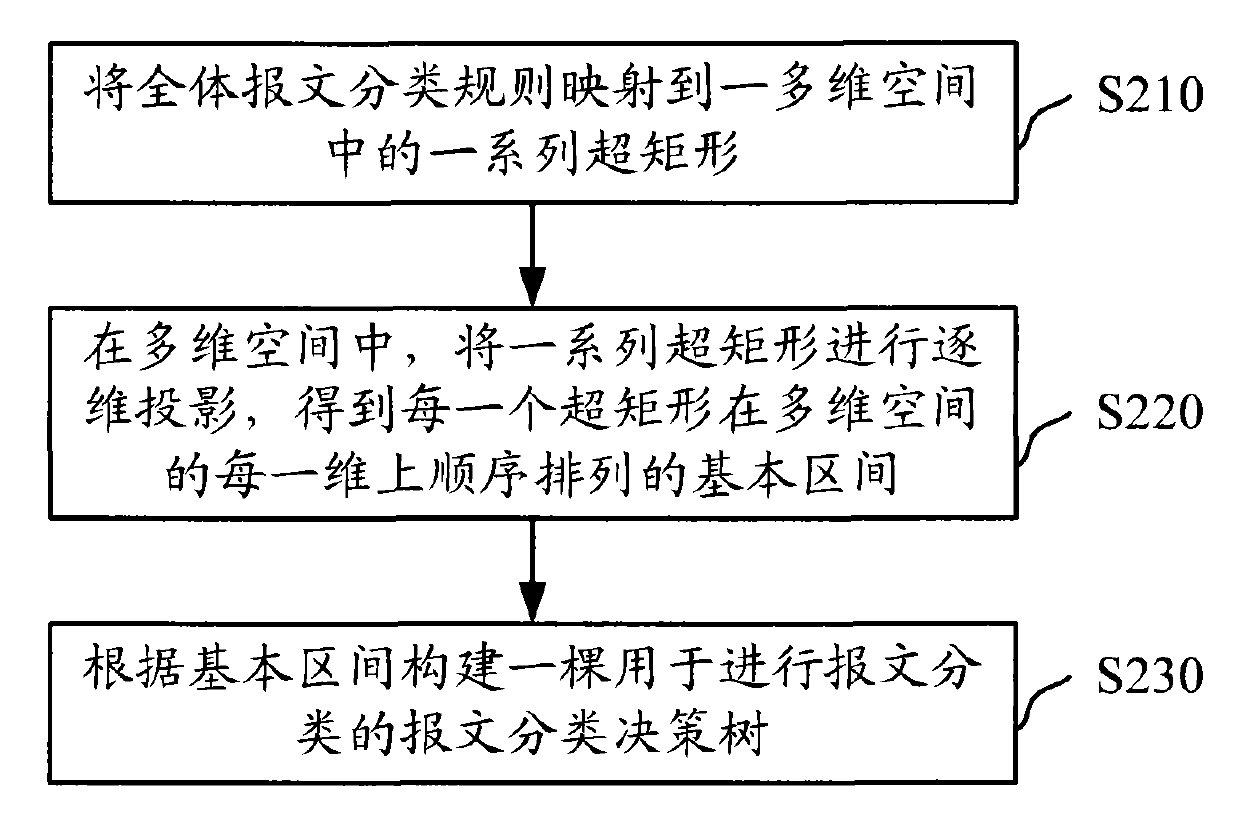

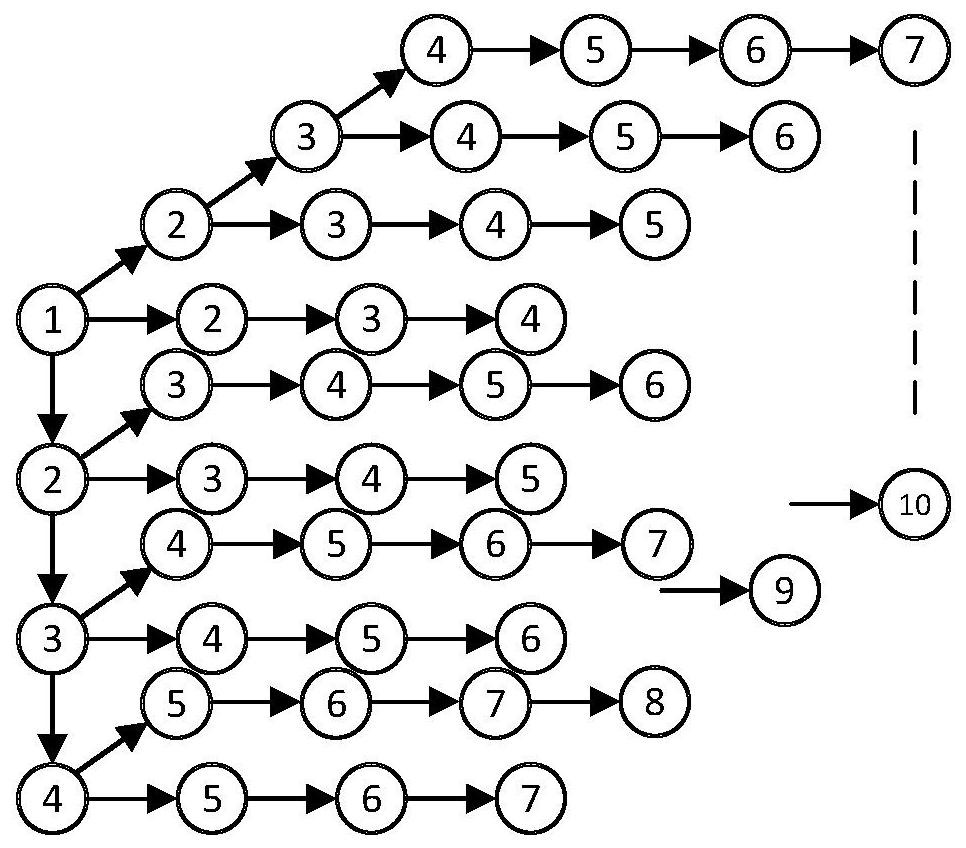

Message classification decision establishing system and method and message classification system and method

InactiveCN102255788AImprove classification processing efficiencyGuaranteed classification efficiencyData switching networksClassification ruleDecision taking

The invention discloses a message classification decision establishing system and method and a message classification system and method, which are used for establishing an efficiently-matched message classification system and realizing efficient message classification. The message classification decision establishing method comprises the following steps of: mapping all message classification rules onto a series of hyper-rectangles in a multi-dimensional space; dimensionally projecting the series of hyper-rectangles gradually in the multi-dimensional space to obtain the basic interval of each hyper-rectangle sequentially arranged on each dimension of the multi-dimensional space; and establishing a message classification decision tree for message classification according to the basic intervals. Compared with the prior art, the invention has the advantages that: the message classification decision tree established in the embodiment of the invention has a very small number of layers, and the message classification processing efficiency is high.

Owner:BEIJING VENUS INFORMATION TECH +1

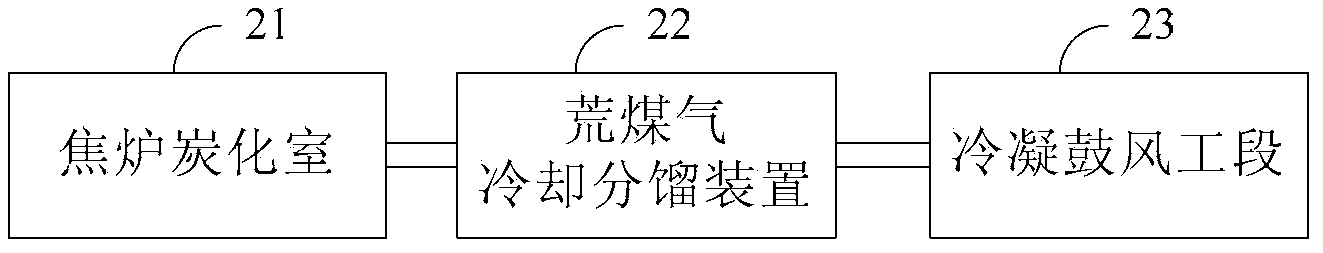

Raw gas cooling and fractionation method and coking apparatus

ActiveCN103509608AImprove recycling efficiencyReduce energy consumptionGas purification by non-gaseous materials condensationDistillation gas withdrawalBoiling pointFractionation

The invention provides a raw gas cooling and fractionation method and a coking apparatus. The raw gas cooling and fractionation method is used for recycling raw gas discharged from a coking chamber of a coke oven; according to the method, the raw gas discharged from the coking chamber of the coke oven is cooled step by step, and different fractions in the raw gas are extracted step by step according to the boiling points of the fractions in the sequence from high boiling point to low boiling point. With the raw gas cooling and fractionation method, energy consumption and pollution are reduced, production cost is lowered down, and recovery efficiency of the raw gas is improved.

Owner:HUATAI YONGCHUANG BEIJING TECH CO LTD

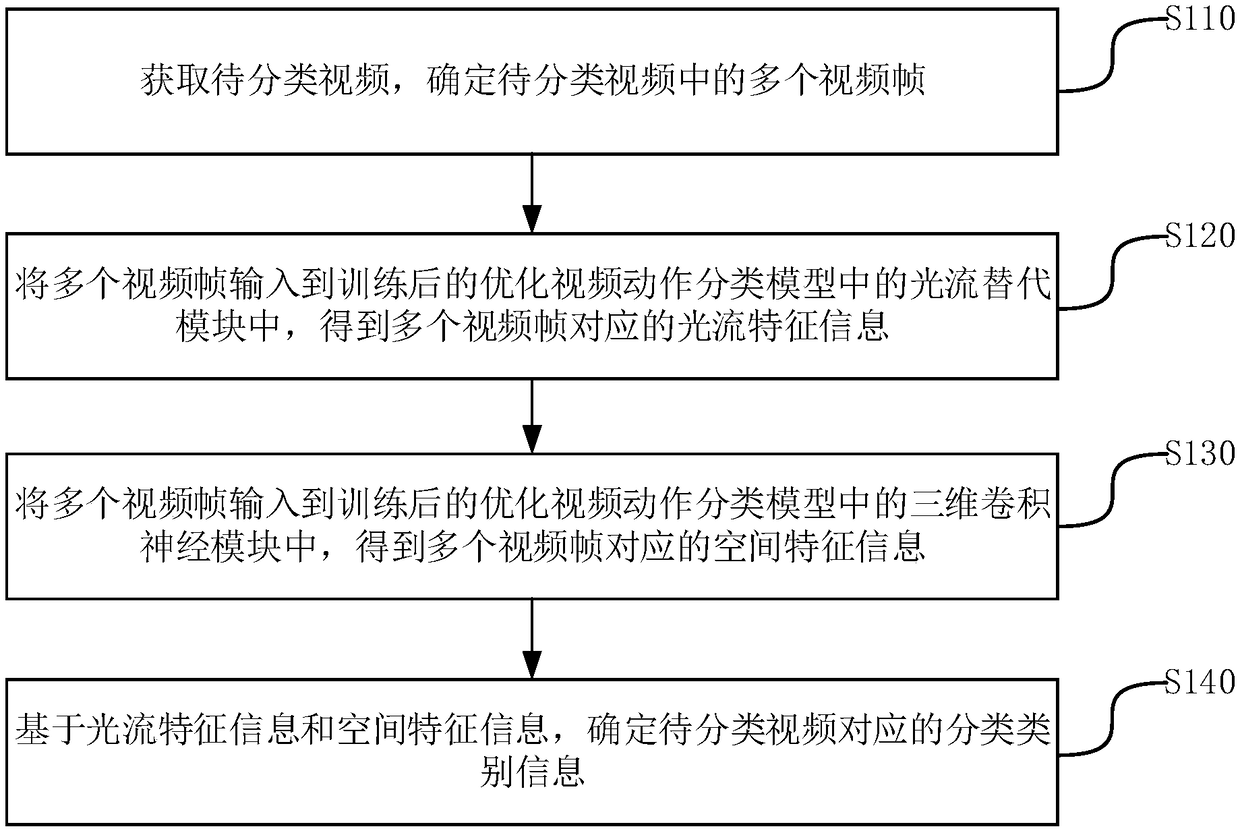

Method, apparatus, computer device and storage medium for classifying video actions

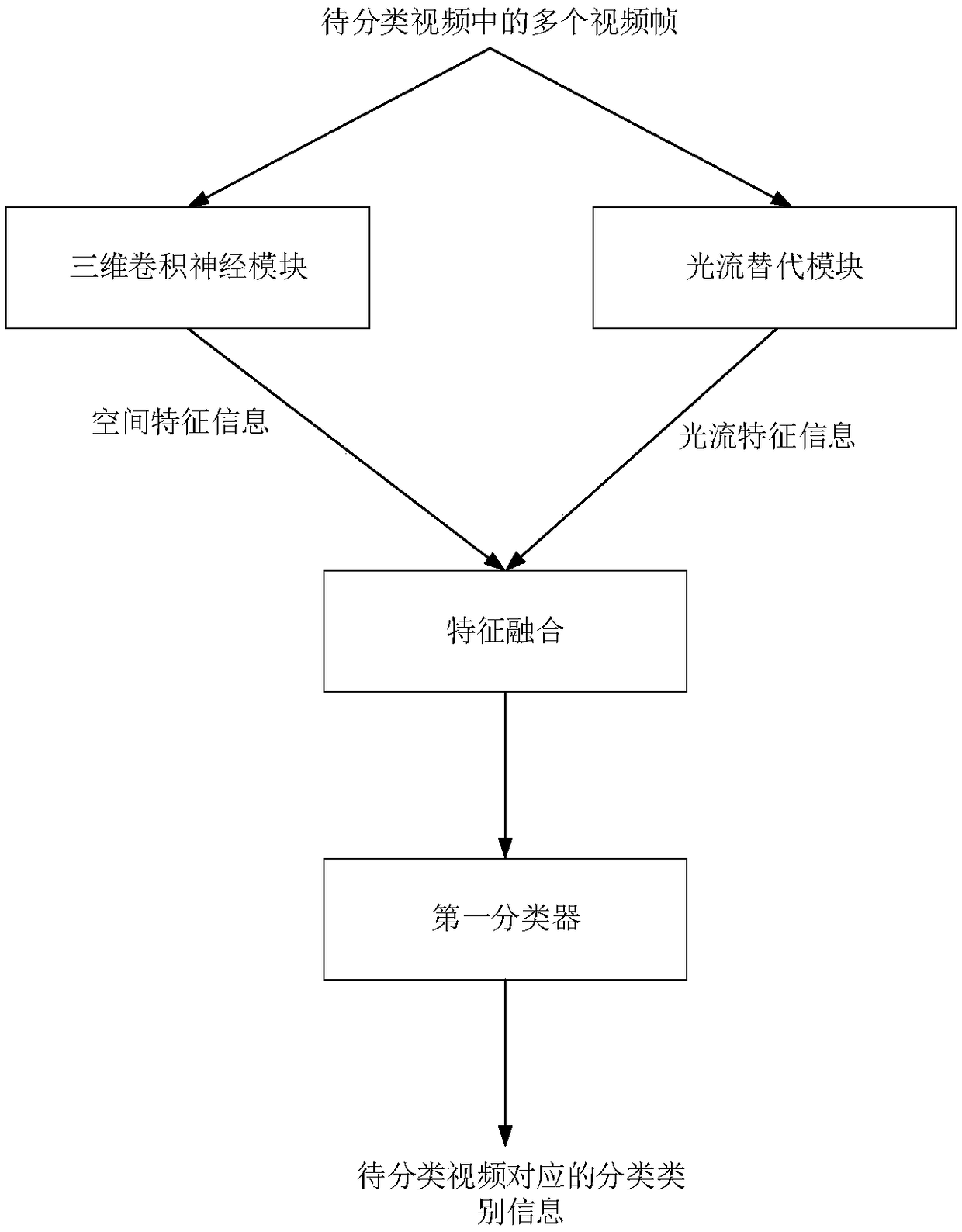

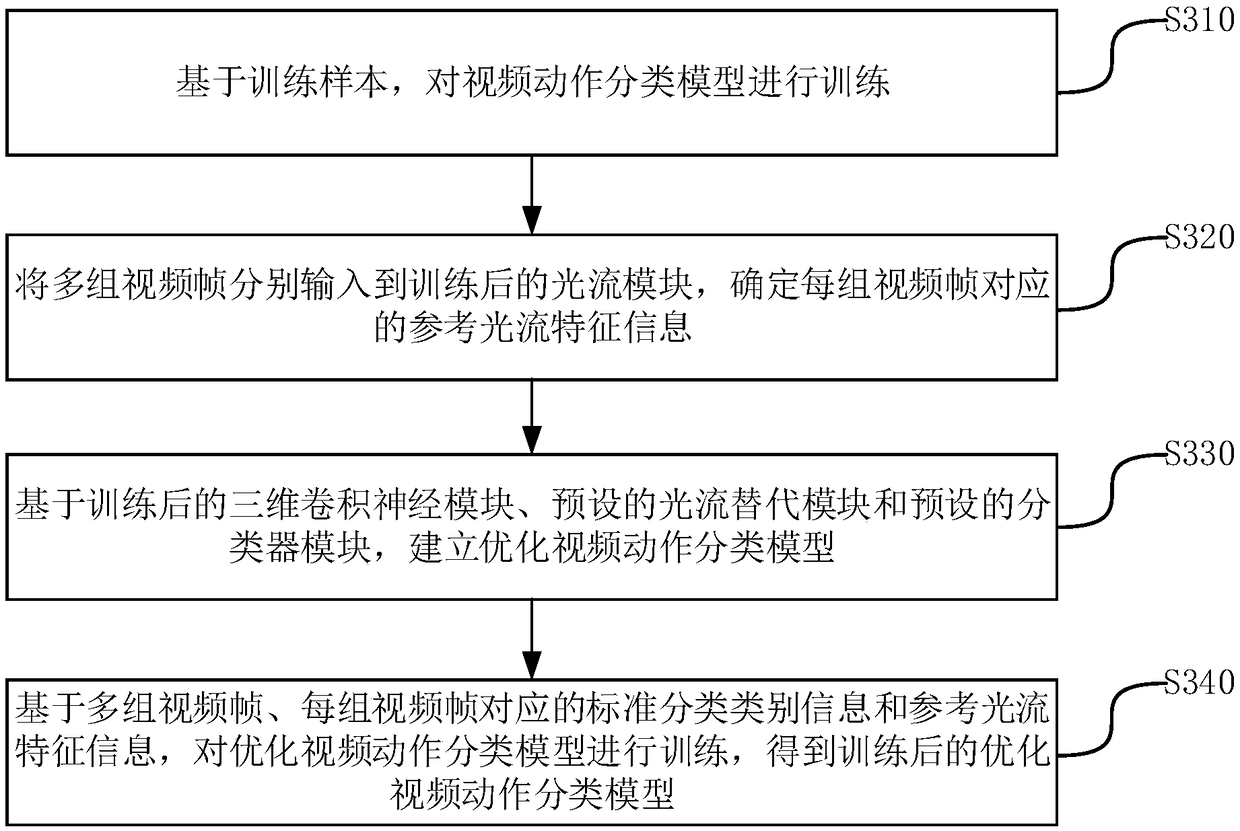

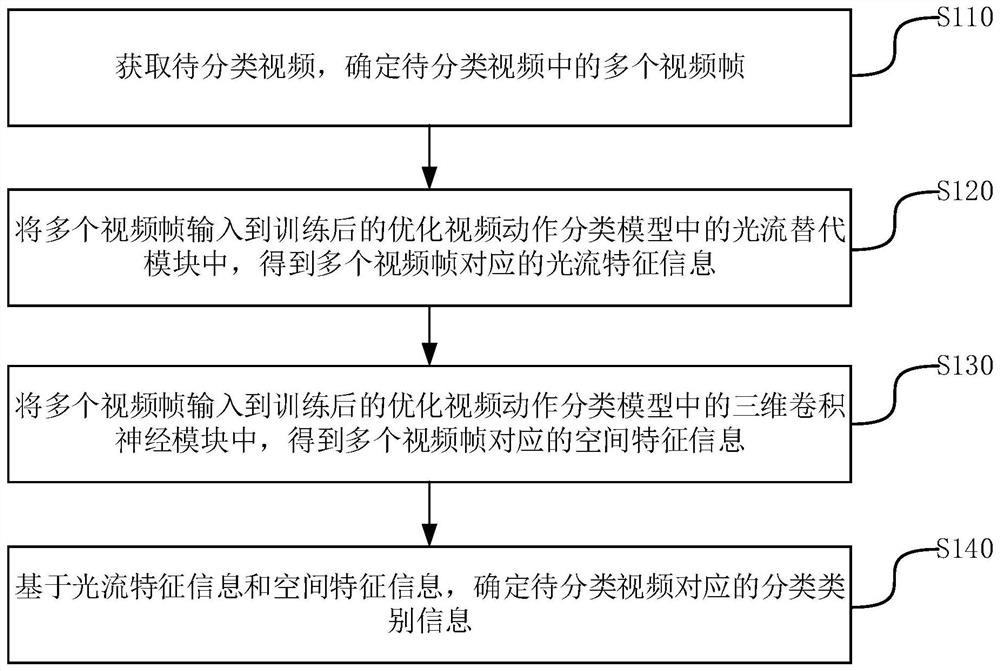

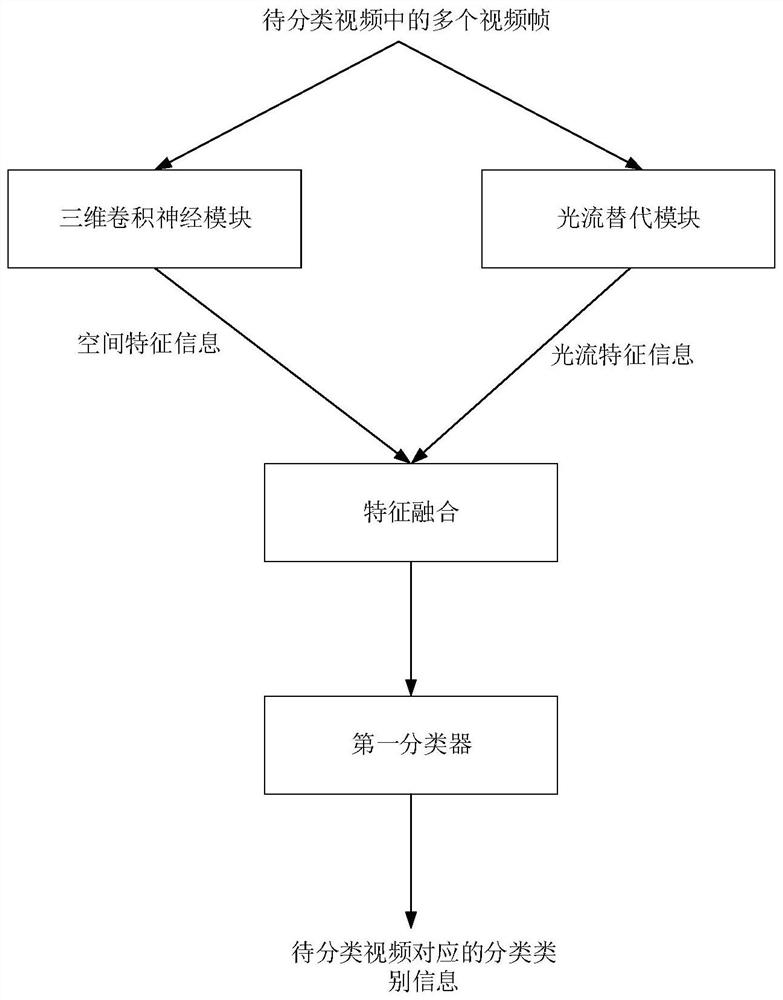

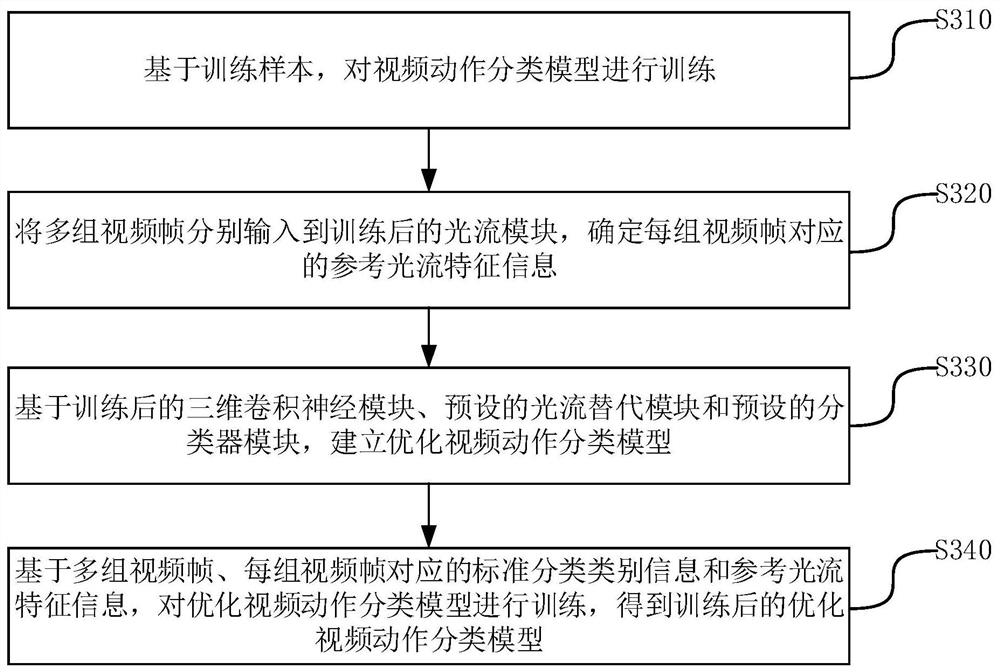

ActiveCN109376696AImprove classification processing efficiencyCharacter and pattern recognitionNeural architecturesPattern recognitionComputer module

The invention relates to a method, an apparatus, a computer device and a storage medium for classifying video actions, belonging to the technical field of machine learning models. The method comprisesthe following steps: obtaining a video to be classified and determining a plurality of video frames in the video to be classified; A plurality of video frames are inputted into an optical flow substitution module in an optimized video motion classification model after training, and optical flow characteristic information corresponding to the plurality of video frames is obtained. A plurality of video frames are input into a three-dimensional convolution neural module in the optimized video motion classification model after training, and the spatial characteristic information corresponding tothe plurality of video frames is obtained. Based on the optical flow characteristic information and the spatial characteristic information, the classification category information corresponding to thevideo to be classified is determined. By adopting the invention, a plurality of video frames of a video to be classified can be directly used as inputs of an optical flow substitution module in the model, and the optical flow substitution module can directly extract optical flow characteristic information corresponding to the plurality of video frames of the video to be classified, thereby further improving the efficiency of classification processing.

Owner:BEIJING DAJIA INTERNET INFORMATION TECH CO LTD

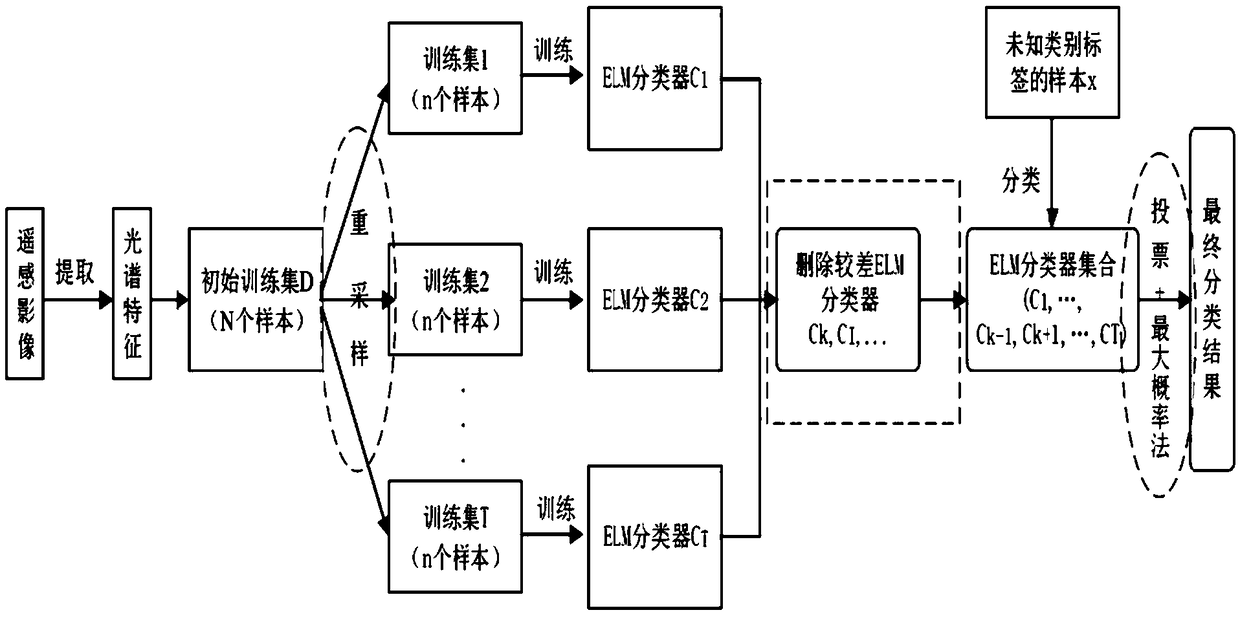

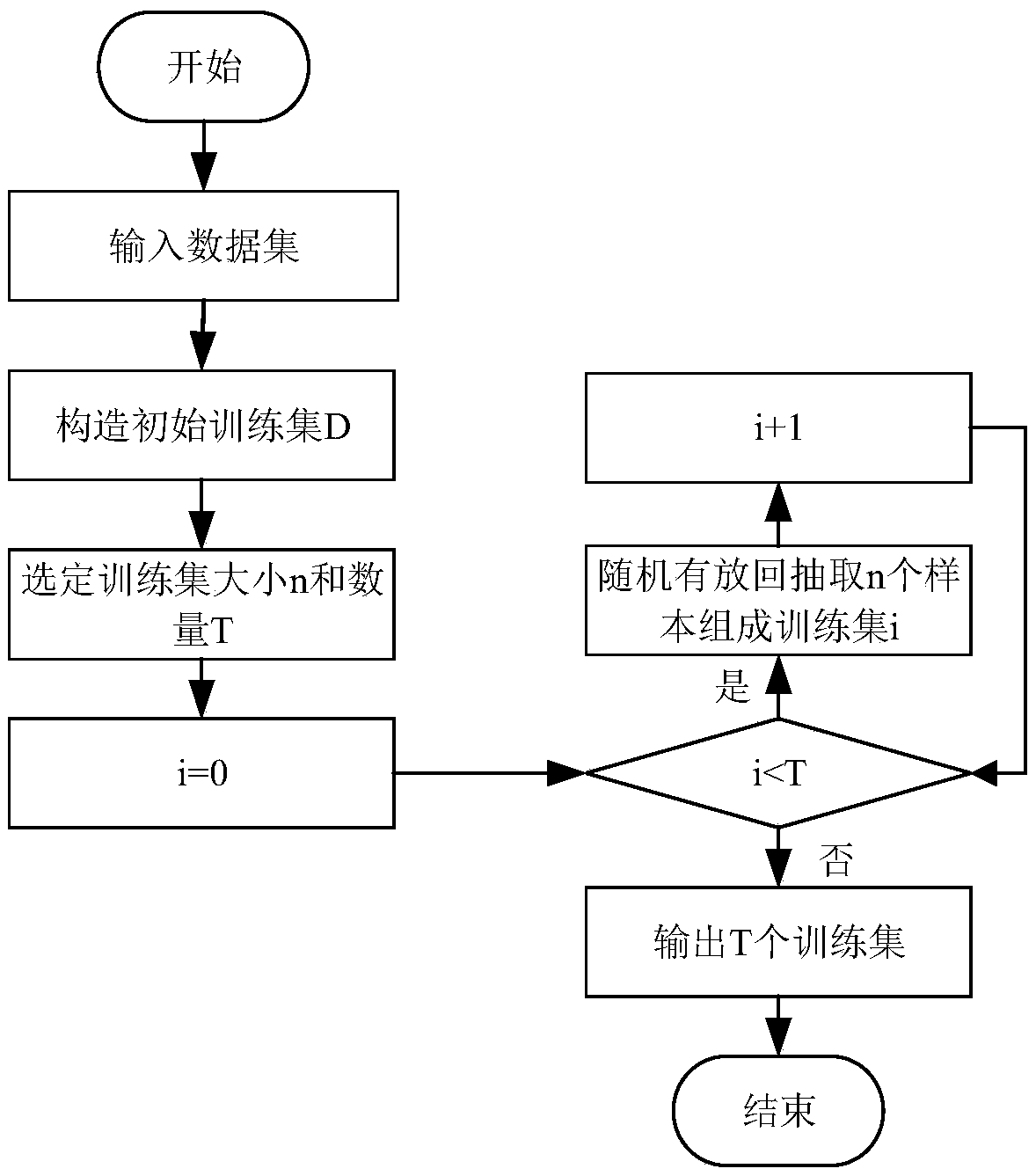

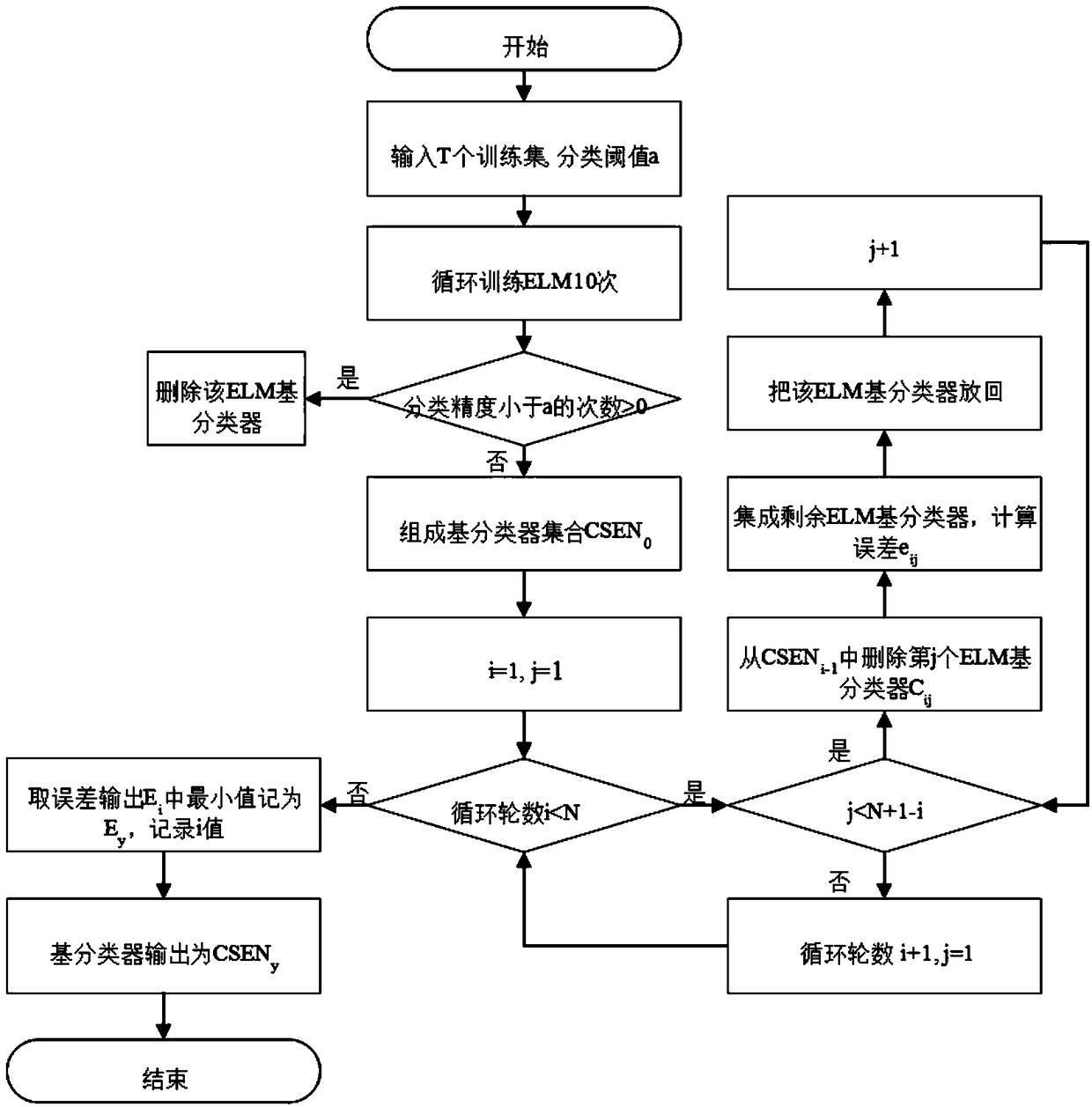

Optimal classification of land use and cover based on ELM for hyperspectral remote sensing images

InactiveCN109344777AImprove generalization performanceImprove classification accuracyScene recognitionTraining data setsClassification result

The invention discloses an ELM-based optimized classification method for land use and cover of hyperspectral remote sensing images, which comprises the following steps: firstly, a plurality of ELM-based classifiers are constructed, and a training data set is constructed for each ELM-based classifier; Then, T ELM-based classifiers are trained based on the training data sets of each ELM-based classifier, and the classification and prediction results of training samples in each training data set are obtained. Then, the ELM-based classifier set is pruned based on the classification prediction results. Finally, the hyperspectral remote sensing images to be classified, The spectral features of each pixel point are extracted, and the feature data of the object to be classified are obtained and inputted into the ELM-based classifiers in the set of classifiers retained after pruning, and the hyperspectral remote sensing images to be classified are classified and judged by ensemble, and the classification results of the hyperspectral remote sensing images to be classified are outputted. The invention realizes an optimized classification method for land use and cover of hyperspectral remote sensing images, which improves classification accuracy and classification processing efficiency.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

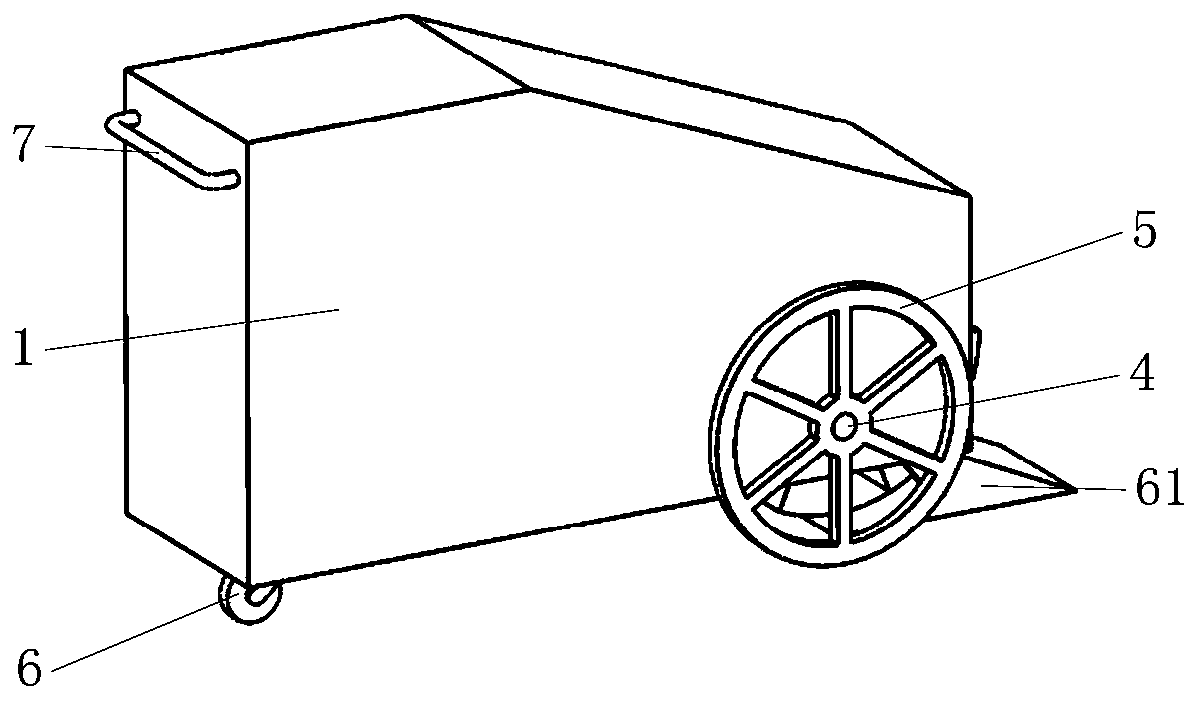

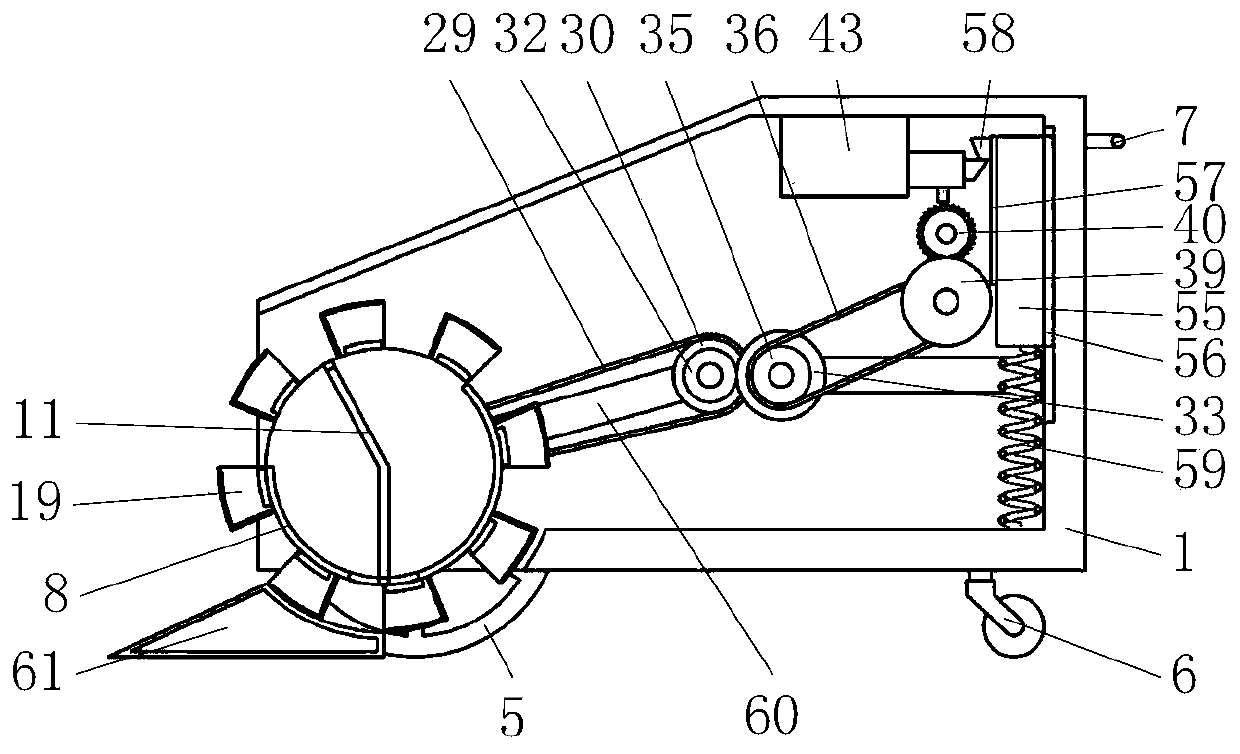

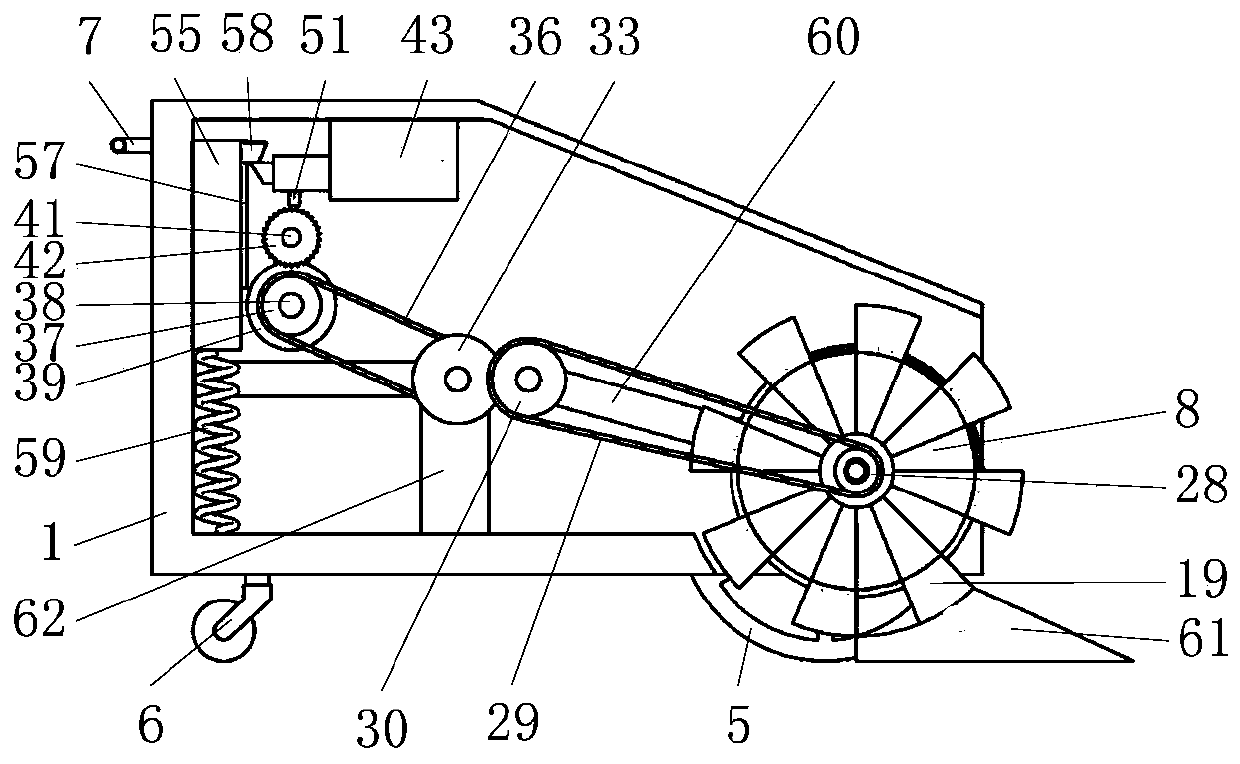

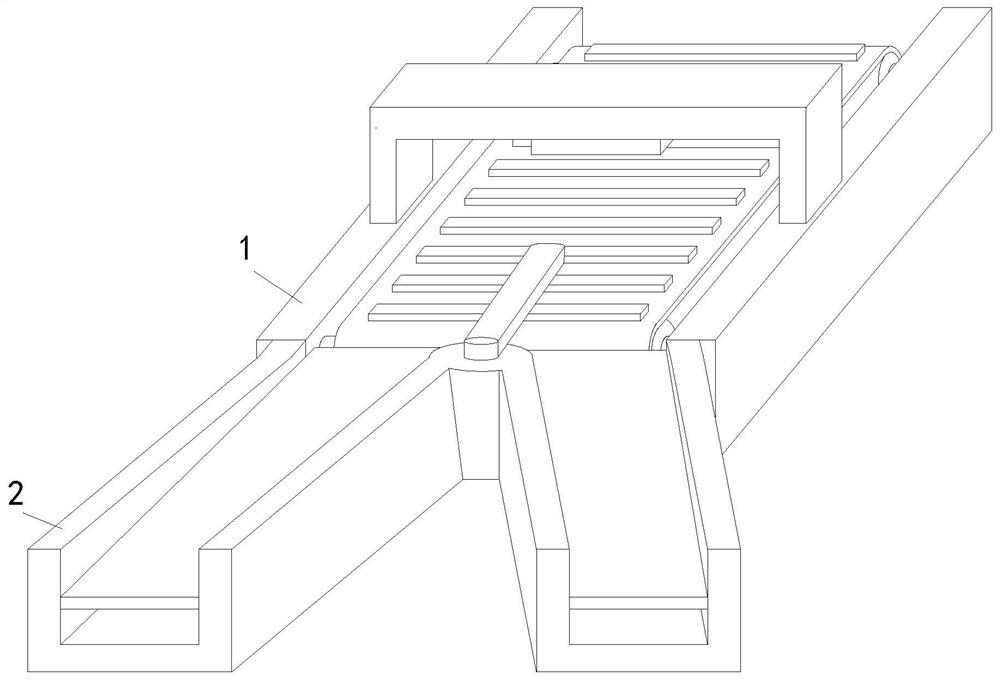

Collecting vehicle for garbage sorting

InactiveCN110029613AExpand the scope of useEfficient collectionRoad cleaningAutomotive engineeringRefuse collection

Owner:CHANGSHU GAOTONG INTELLECT EQUIP CO LTD

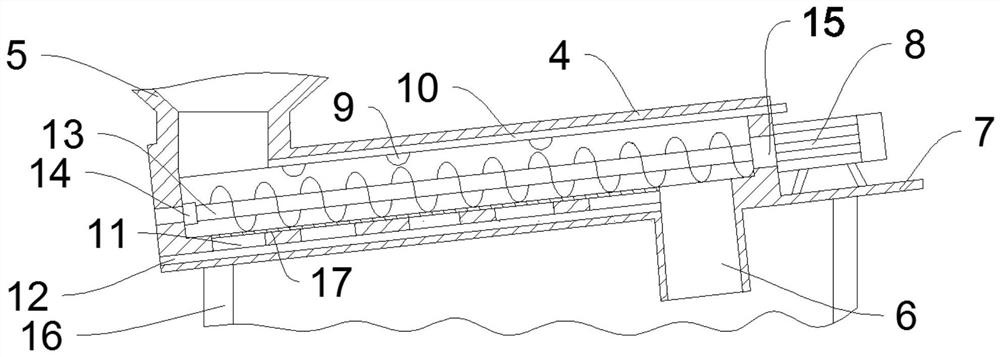

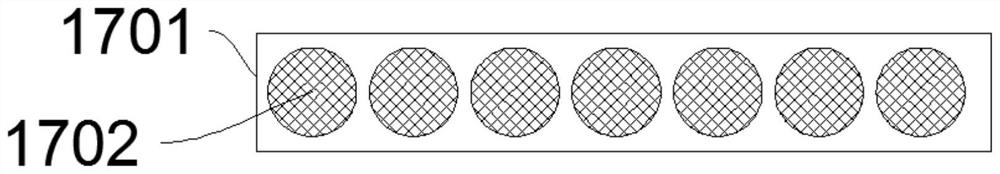

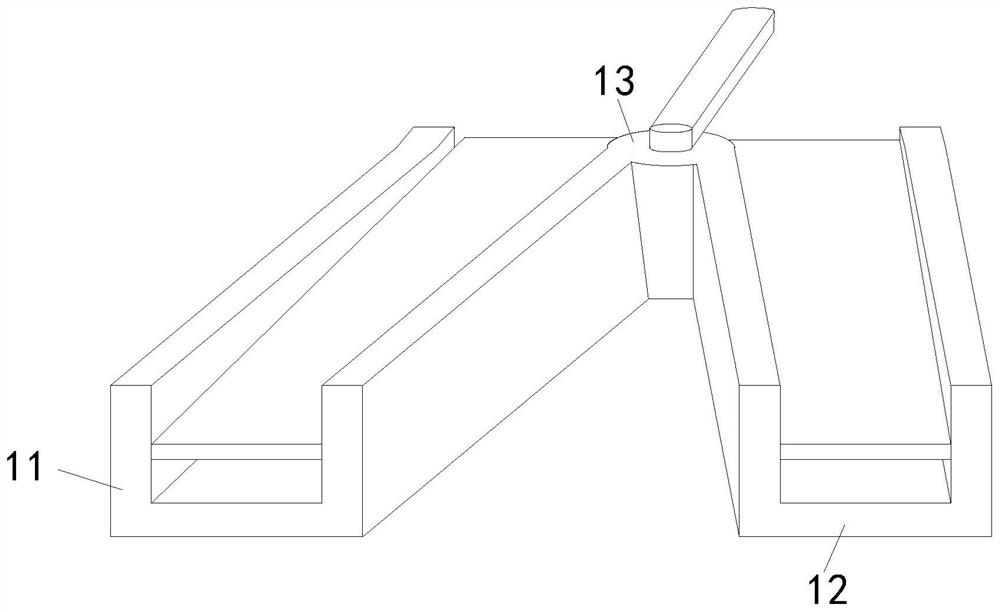

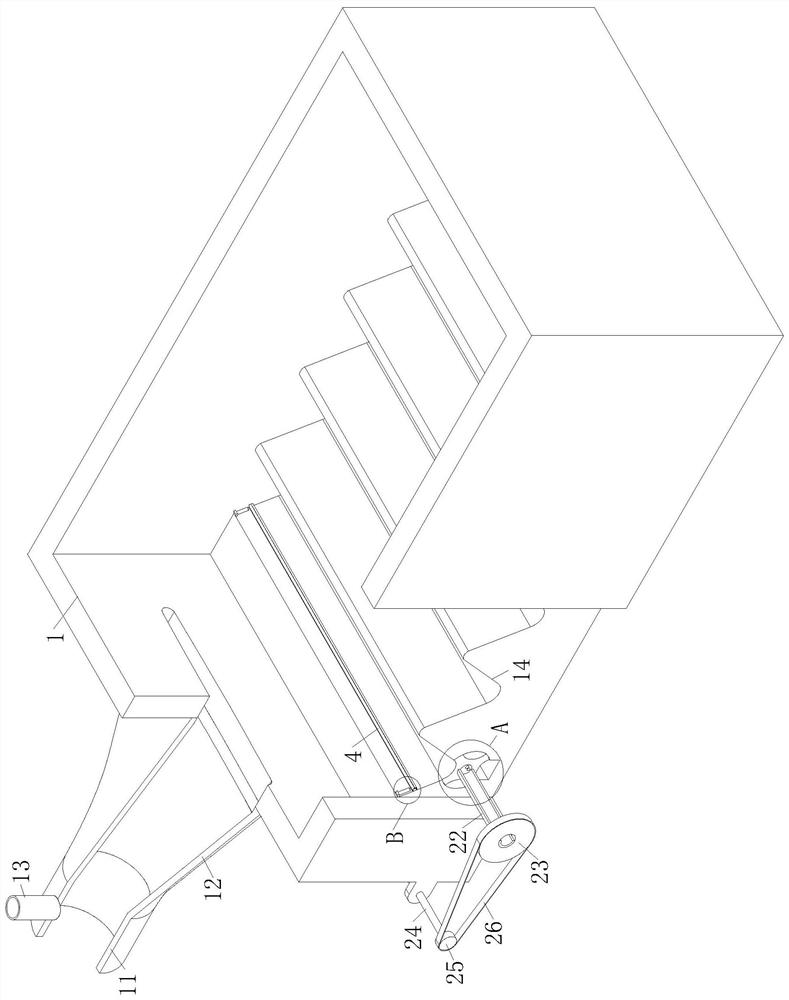

Leaf removing, skin cutting and stalk scraping type straw skin-stalk separation device and method

PendingCN111452162AAchieve peeling effectImprove mechanical propertiesOptical detectionCuttersEngineeringBiomass c

The invention discloses a leaf removing, skin cutting and stalk scraping type straw skin-stalk separation device and method, belongs to the technical field of biomass energy utilization, and solves the problems that an existing separation machine is incomplete in straw skin-stalk separation, poor in separation effect, low in production capacity and high in energy consumption. The device is characterized in that a feeding device, a leaf removing device, a positioning and cutting device, a clamping device and a stalk scraping device are arranged on a rack in sequence; the feeding device is usedfor feeding the straw into the leaf removing device; the leaf removing device is used for removing straw leaves, tearing off the straw leaves, tearing off the leaves, and feeding the straw into the positioning and cutting device; the positioning and cutting device is used for positioning and cutting the straw, longitudinally cutting the straw and feeding the straw into the clamping device; the clamping device is used for clamping the straw and driving the straw to move forwards to the stalk scraping device; and the stalk scraping device is used for separating the straw skin and stalk. The device and the method are used for straw skin-stalk separation treatment.

Owner:NORTHEAST FORESTRY UNIVERSITY

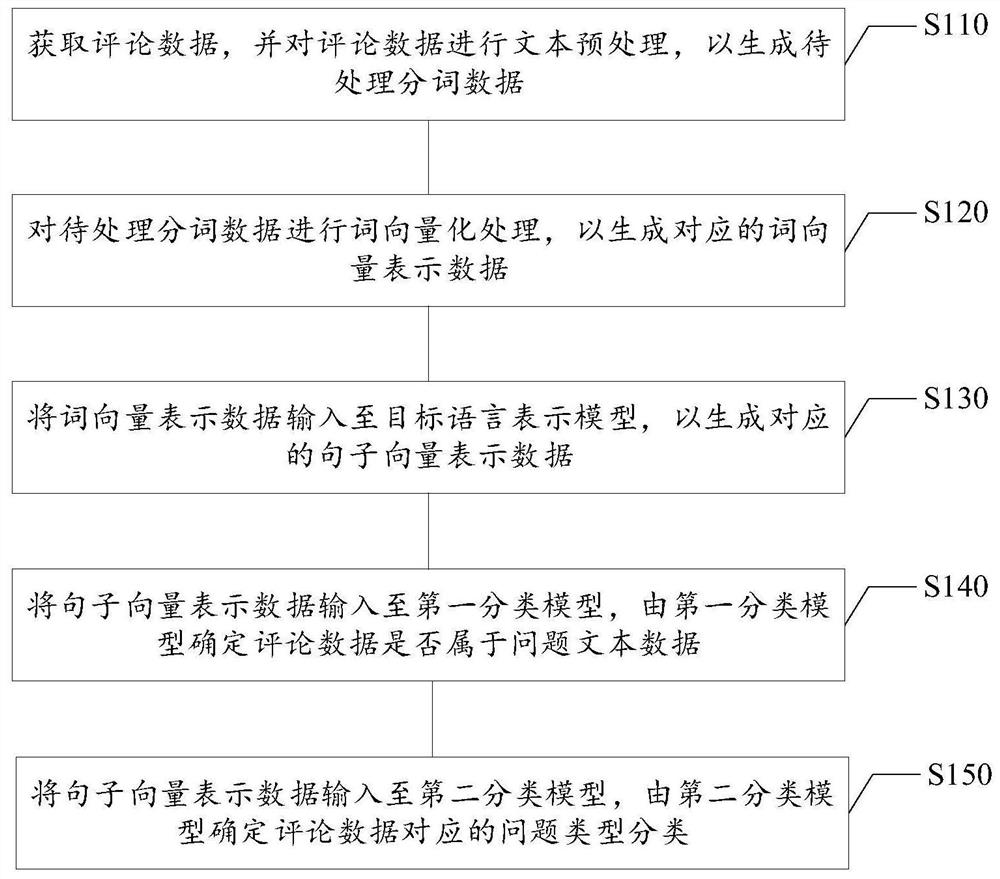

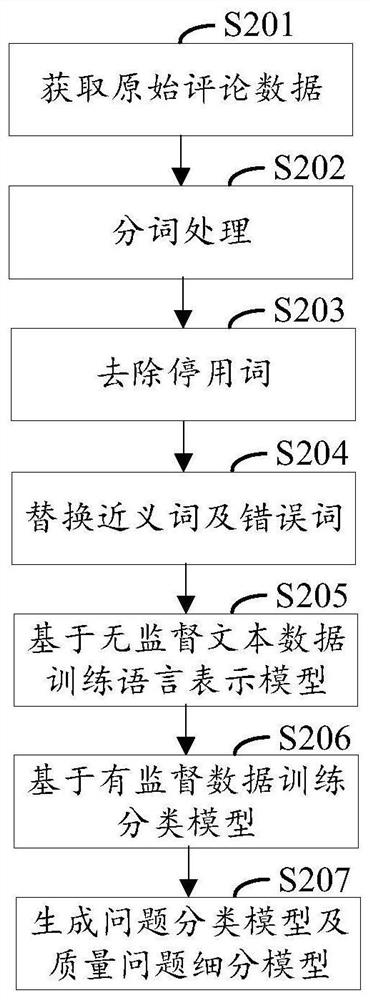

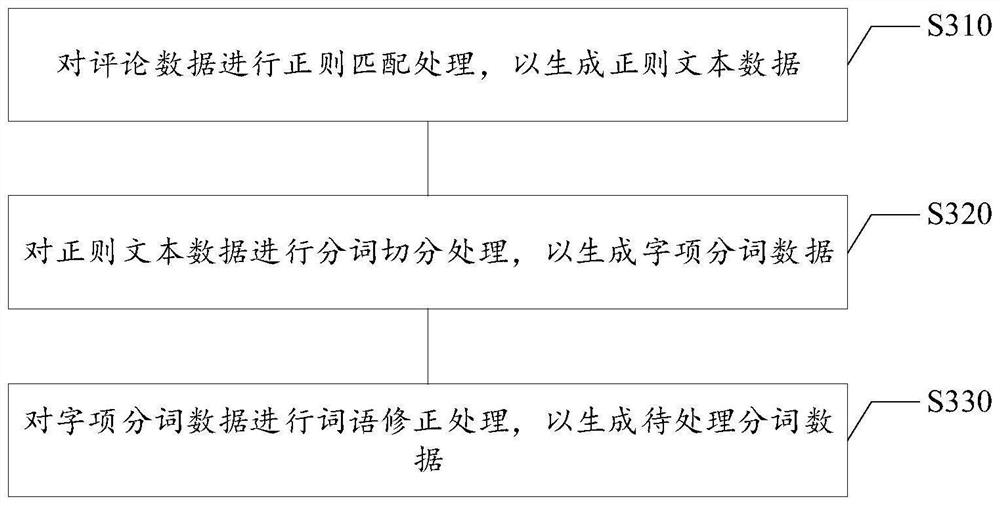

Text classification method and device based on comment data, equipment and medium

PendingCN111753082AImprove classification processing efficiencyImprove accuracySemantic analysisSpecial data processing applicationsMachine learningLanguage representation

The invention relates to a text classification method and device based on comment data, equipment and a medium, relates to the technical field of natural language processing, and can be applied to a scene of classifying text data. The text classification method based on the comment data comprises the steps of obtaining the comment data, and performing text preprocessing on the comment data to generate to-be-processed word segmentation data; performing word vectorization processing on the to-be-processed word segmentation data to generate corresponding word vector representation data; inputtingthe word vector representation data into a target language representation model to generate corresponding sentence vector representation data; and respectively inputting the sentence vector representation data into a first classification model and a second classification model, determining whether the comment data belongs to question text data by the first classification model, and determining question type classification corresponding to the comment data by the second classification model. According to the method and the device, comment texts with quality problems and specific classifications of the quality problems can be screened out through information mining of the comment data.

Owner:BEIJING WODONG TIANJUN INFORMATION TECH CO LTD +1

Message classification decision establishing system and method and message classification system and method

InactiveCN102255788BImprove classification processing efficiencyGuaranteed classification efficiencyData switching networksDecision takingClassification rule

The invention discloses a message classification decision establishing system and method and a message classification system and method, which are used for establishing an efficiently-matched message classification system and realizing efficient message classification. The message classification decision establishing method comprises the following steps of: mapping all message classification rules onto a series of hyper-rectangles in a multi-dimensional space; dimensionally projecting the series of hyper-rectangles gradually in the multi-dimensional space to obtain the basic interval of each hyper-rectangle sequentially arranged on each dimension of the multi-dimensional space; and establishing a message classification decision tree for message classification according to the basic intervals. Compared with the prior art, the invention has the advantages that: the message classification decision tree established in the embodiment of the invention has a very small number of layers, and the message classification processing efficiency is high.

Owner:BEIJING VENUS INFORMATION TECH +1

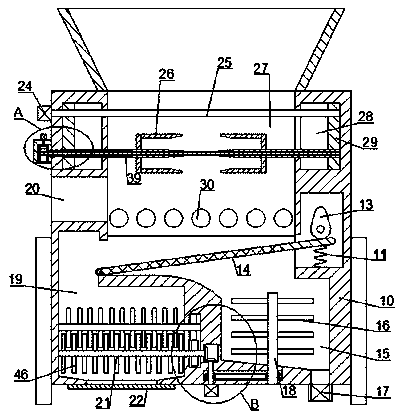

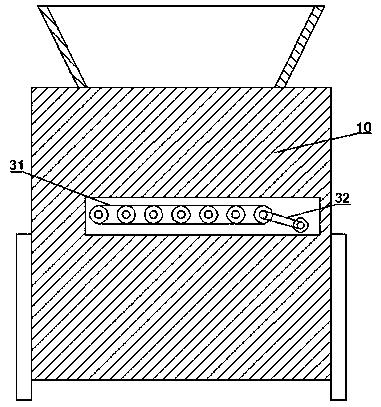

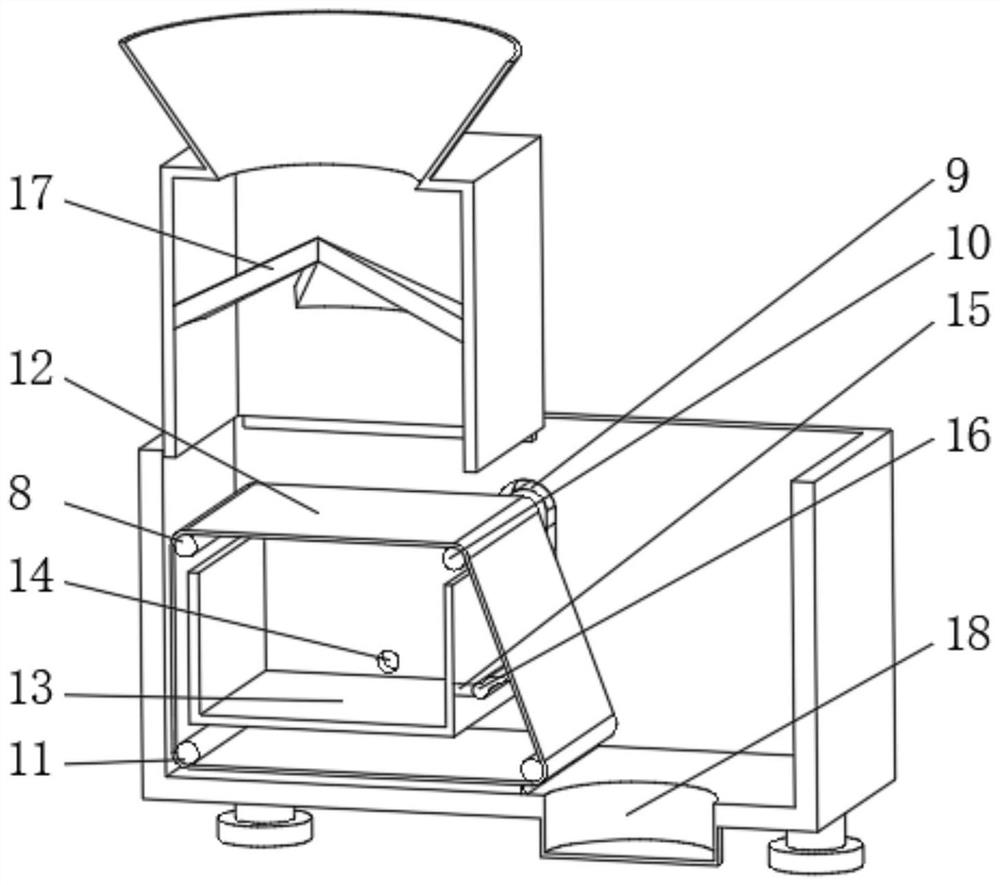

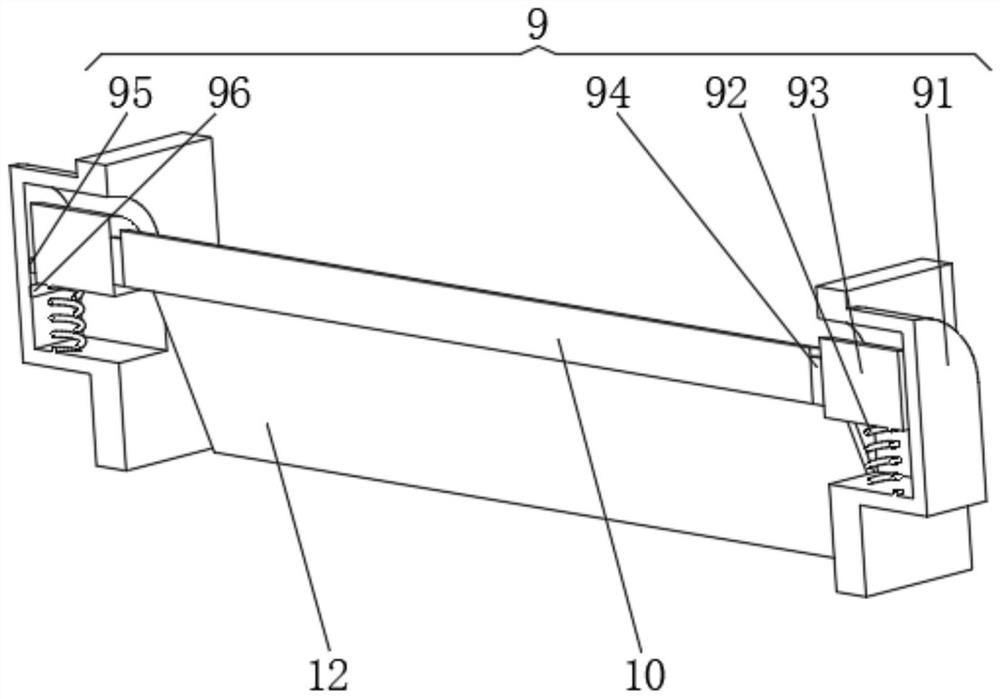

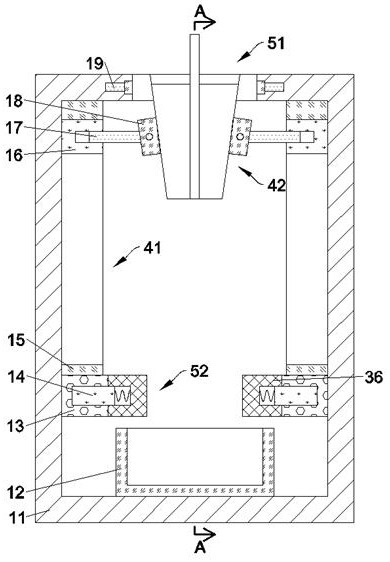

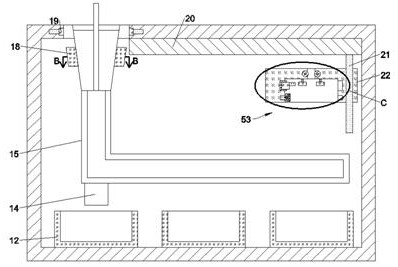

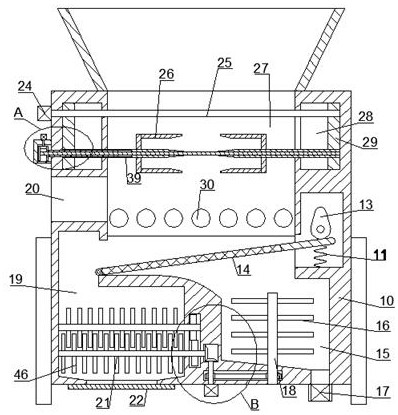

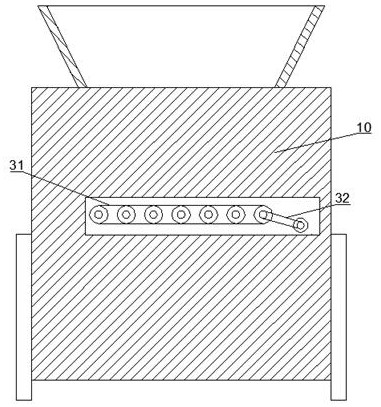

Residential household waste treatment equipment

ActiveCN111203311AImprove classification processing efficiencySimple structureWater contaminantsWater/sewage treatmentWine bottleWastewater

The invention discloses residential household waste treatment equipment. The residential household waste treatment equipment comprises a main machine body, wherein a crushing cavity is arranged in themain machine body; the opening of the crushing cavity is designed upwards; a plurality of rotary rollers are arranged in the crushing cavity in a rolling mode, and relatively great articles such as wine bottles can be separated on the rotary rollers; two bag crushing shafts which are symmetrical left and right are rotatably arranged in the crushing cavity; crushing forks are fixedly arranged on the two bag crushing shafts; the crushing forks can preliminarily crush household waste; and the bottom of the crushing cavity is provided with a filter screen in a vibrating mode. The residential household waste treatment equipment can automatically crush garbage bags; after crushing is accomplished, the rotary rollers rotate, so that waste such as wine bottles in garbage are exhausted outwards from an outlet, other impurities drop into the crushing cavity and are crushed by a crushing knife, and wastewater enters a decomposition cavity to decompose, so that garbage classifying treating efficiency is greatly improved. The residential household waste treatment equipment is simple in structure, is convenient to operate, and is convenient to popularize and use.

Owner:青岛松上环境工程有限公司

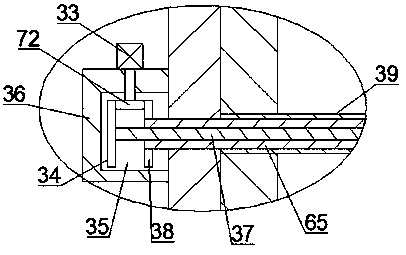

Ore classification soil treatment device

ActiveCN112474313ASolve pollutionImprove classification processing efficiencySievingScreeningSoil treatmentMining engineering

The invention belongs to the field of ore processing, and particularly relates to an ore classification soil treatment device. The ore classification soil treatment device comprises a cleaning assembly, a scattering assembly and a classification assembly; the cleaning assembly comprises water outlet holes, sludge discharge holes, a cleaning assembly shell, a conveying assembly and a filter screen;a first support is arranged below the cleaning assembly shell; the cleaning assembly shell is obliquely arranged; the included angle between the central axis of the cleaning assembly shell and the horizontal plane is 10 degrees to 25 degrees; a water injection pipe is arranged at the upper end of the inner wall of the cleaning assembly shell; the water injection pipe is provided with a pluralityof groups of water outlet holes; the plurality of groups of water outlet holes are distributed at equal intervals in the central axis direction of the cleaning assembly shell; one end of the water injection pipe penetrates out of the cleaning assembly shell; a plurality of groups of sludge discharge holes are formed at the bottom end of the inner wall of the cleaning assembly shell; and the problem of dust pollution in the ore processing process is solved, the classification treatment efficiency is improved, and the problem that ore can cause large impact on equipment is solved.

Owner:TANGSHAN TIANHE TECH DEV

Device for automatically stacking drilled circuit boards according to expansion and contraction

PendingCN114269066AImprove classification processing efficiencyTransport is stable and efficientConveyorsPrinted circuit manufactureElectric machineryEngineering

The invention discloses a device for automatically stacking drilled circuit boards according to expansion and contraction, and relates to the technical field of circuit boards. Comprising a conveying device and a sorting device, an output port of the conveying device is fixedly connected with an input port of the sorting device, the conveying device comprises a conveying frame, a conveying belt is rotatably connected to the inner wall of the conveying frame, a support is fixedly installed at the top of the conveying frame, and a CCD detector is fixedly connected to the bottom of the support; and the CCD detector is positioned above the conveying belt. According to the circuit board sorting device, the conveying device is arranged, a motor is used for driving a driving shaft to be in linkage with a driven shaft to jointly drive a conveying belt for transmission, the conveying belt is promoted to drive a circuit board to slide, and a CCD detector is matched to pick up information of the circuit board, so that the circuit board is preprocessed and classified before being sorted; therefore, the whole classification treatment only needs to place the circuit board on the conveyor belt by a worker, so that the classification treatment efficiency of the circuit board is remarkably improved.

Owner:LONGNAN JUNYA ELECTRONICS TECH CO LTD

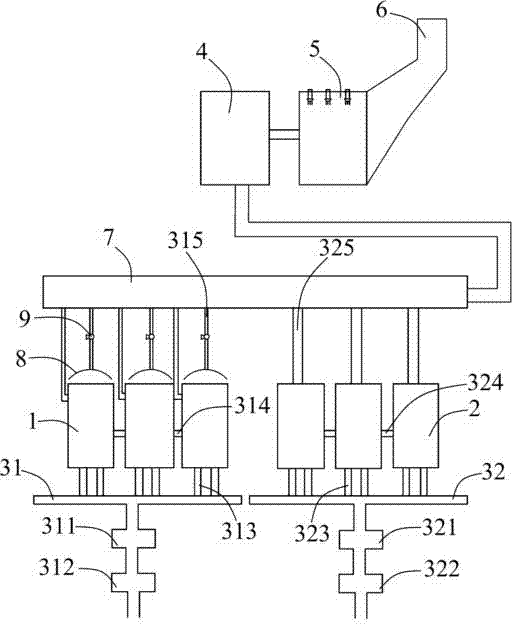

Ordered screening regeneration equipment for waste battery

ActiveCN103785672AImprove efficiencyPrevention of defects that are detrimental to classification processingSolid waste disposalFlueGas pipeline

The invention discloses ordered screening regeneration equipment for a waste battery. The ordered screening regeneration equipment comprises multiple low temperature furnaces, multiple refining furnaces, a gas pipeline, a dust extraction room, a water curtain dust removal device, a flue and a chimney, wherein the gas pipeline comprises a first gas pipeline and a second gas pipeline which are separated from each other; two first small gas supply pipes are connected between a gas chamber of each low temperature furnace and the first gas pipeline; two second small gas supply pipes are connected between a gas chamber of each refining furnace and the second gas pipeline; the gas chambers of the multiple low temperature furnaces are communicated with one another through a first transverse pipeline; the gas chambers of the multiple refining furnaces are communicated with one another through a second transverse pipeline; an exhaust chamber of each low temperature furnace is communicated with the flue through a first vertical pipeline; an exhaust chamber of each refining furnace is communicated with the flue through a second vertical pipeline; the flue is communicated with the dust extraction room; the dust extraction room is communicated with the water curtain dust removal device; an exhaust hole of the water curtain dust removal device is communicated with the chimney.

Owner:XINXIANG HUARUI POWER SUPPLY MATERIAL

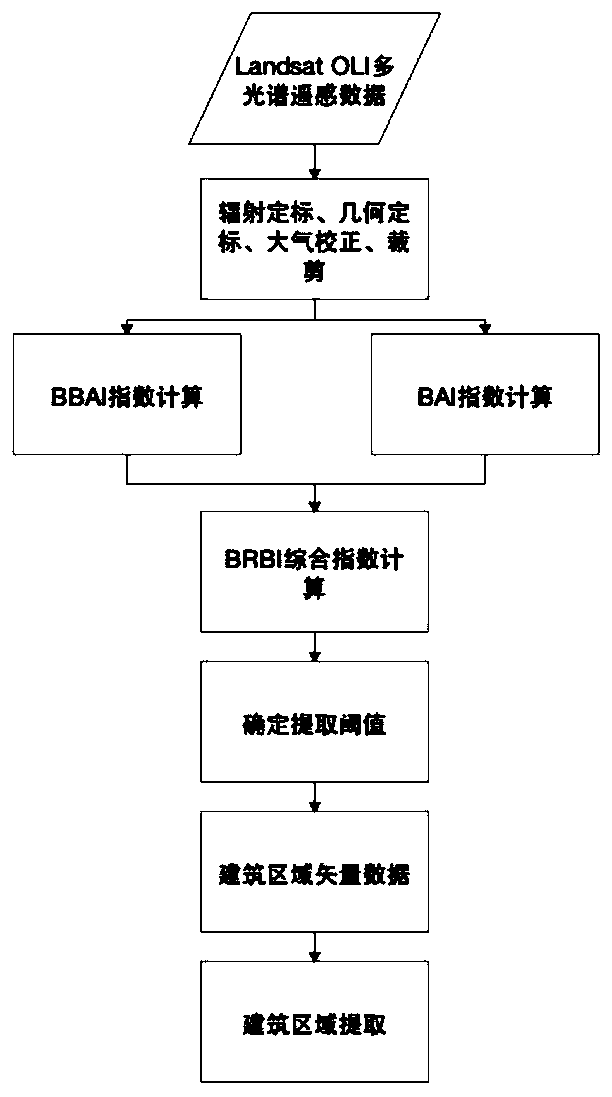

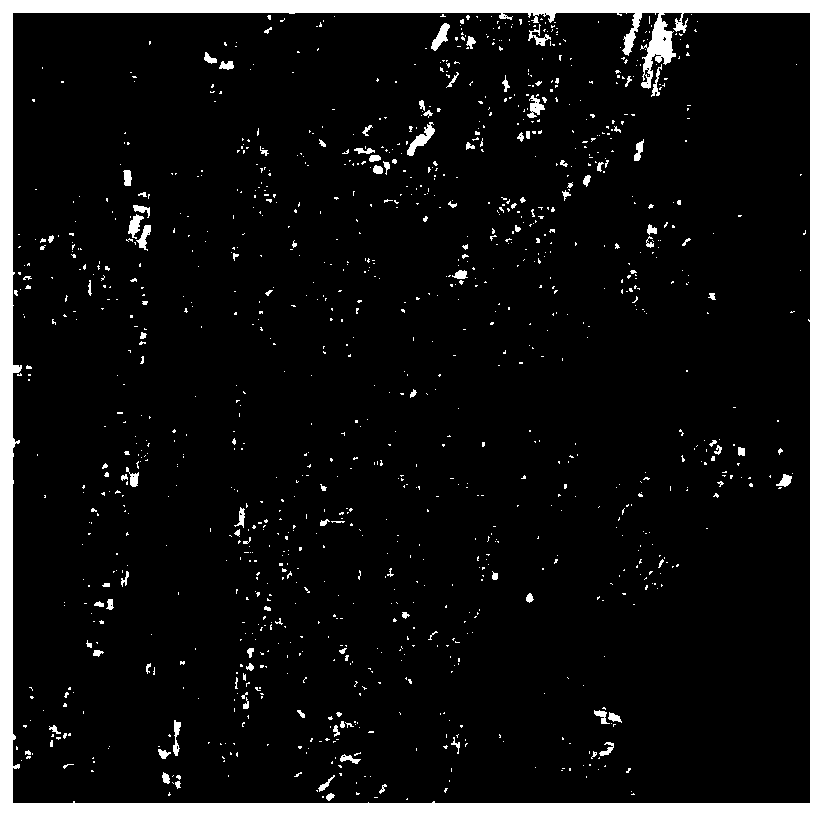

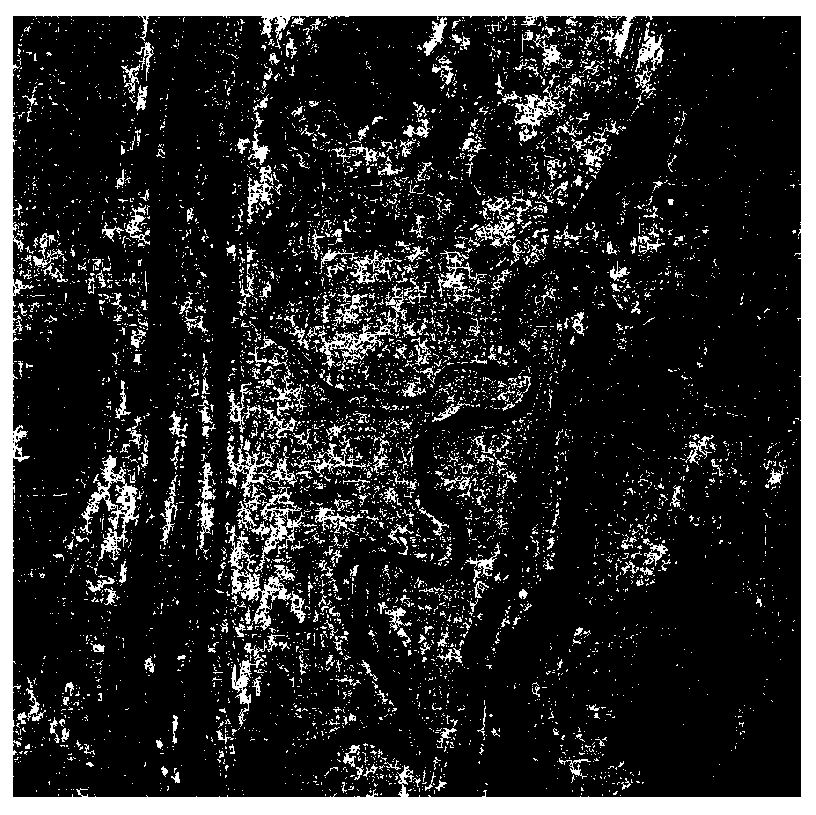

Building index construction and building area rapid extraction method for inhibiting bare land

The invention requests to protect a building index construction and building rapid extraction method based on a Landsat OLI multispectral image, and the method comprises the following steps: 1), carrying out the preprocessing of Landsat OLI multispectral data, including radiation calibration, geometric correction, atmospheric correction, and cutting; 2) constructing a building index model which comprises two secondary indexes; 3) selecting an optimal threshold value for the index model, and extracting building area information; 4) exporting continuous building area information, and generatingbuilding area vector data; And 5) cutting the Landsat OLI multispectral image by using the building area vector data to obtain building area data. According to the building area information extractionmethod, the second waveband information, the third waveband information, the fourth waveband information, the fifth waveband information, the sixth waveband information and the seventh waveband information of the Landsat OLI are comprehensively utilized, images of bare land information are eliminated to the maximum degree, the building area information extraction speed and precision are improved,and related data are provided for subsequent research.

Owner:CHONGQING UNIV OF POSTS & TELECOMM

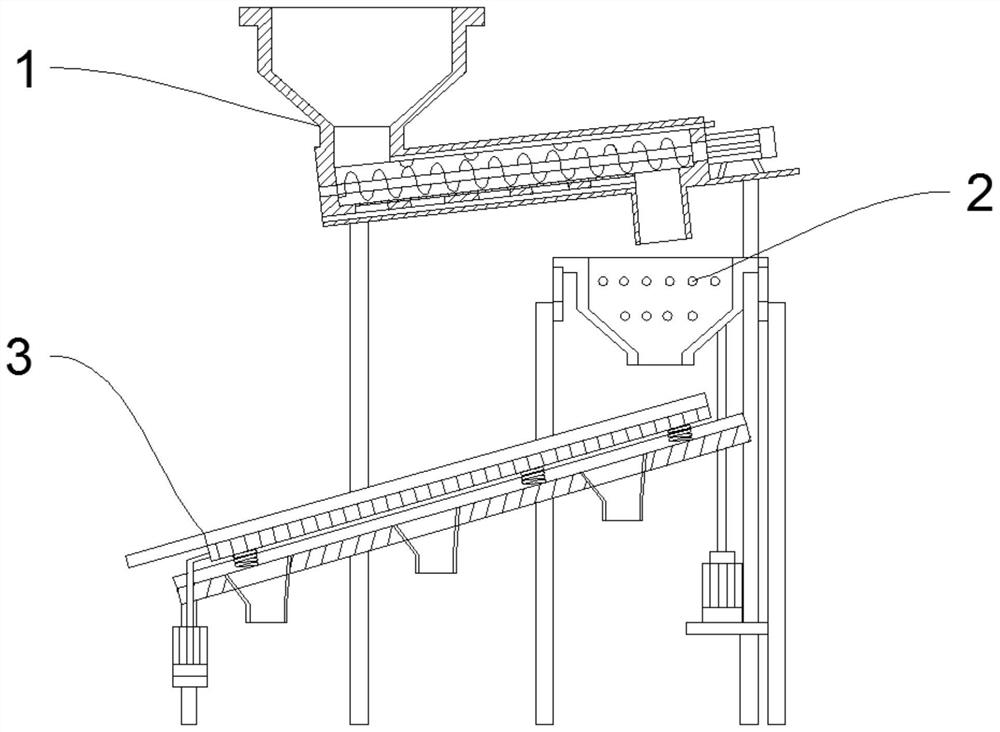

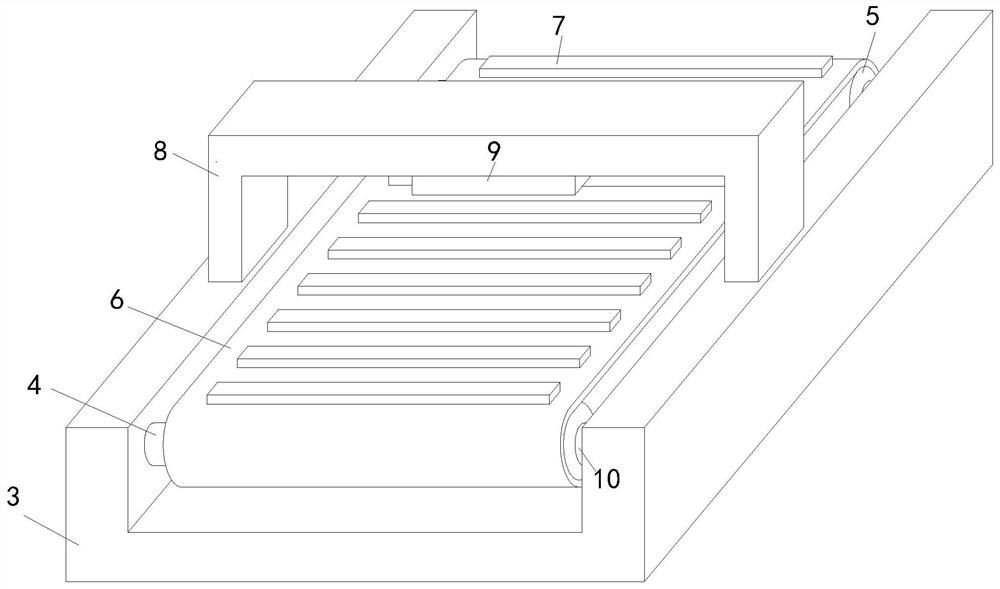

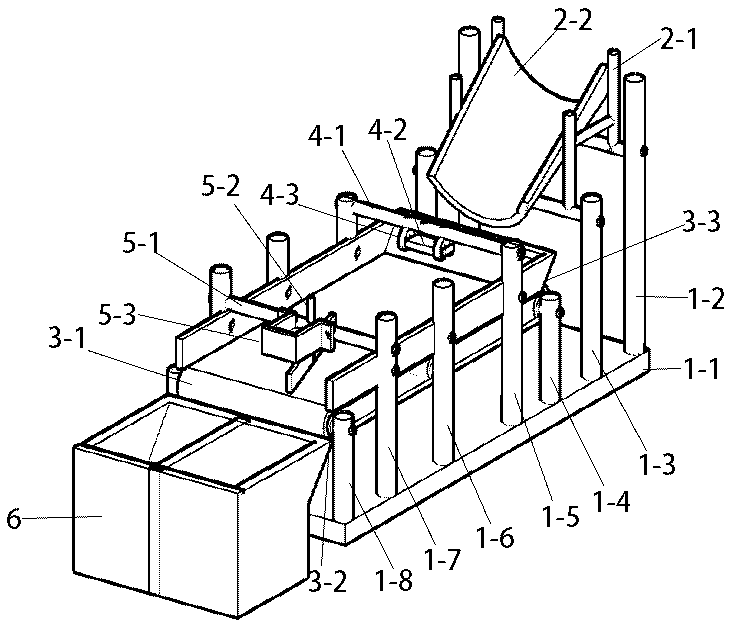

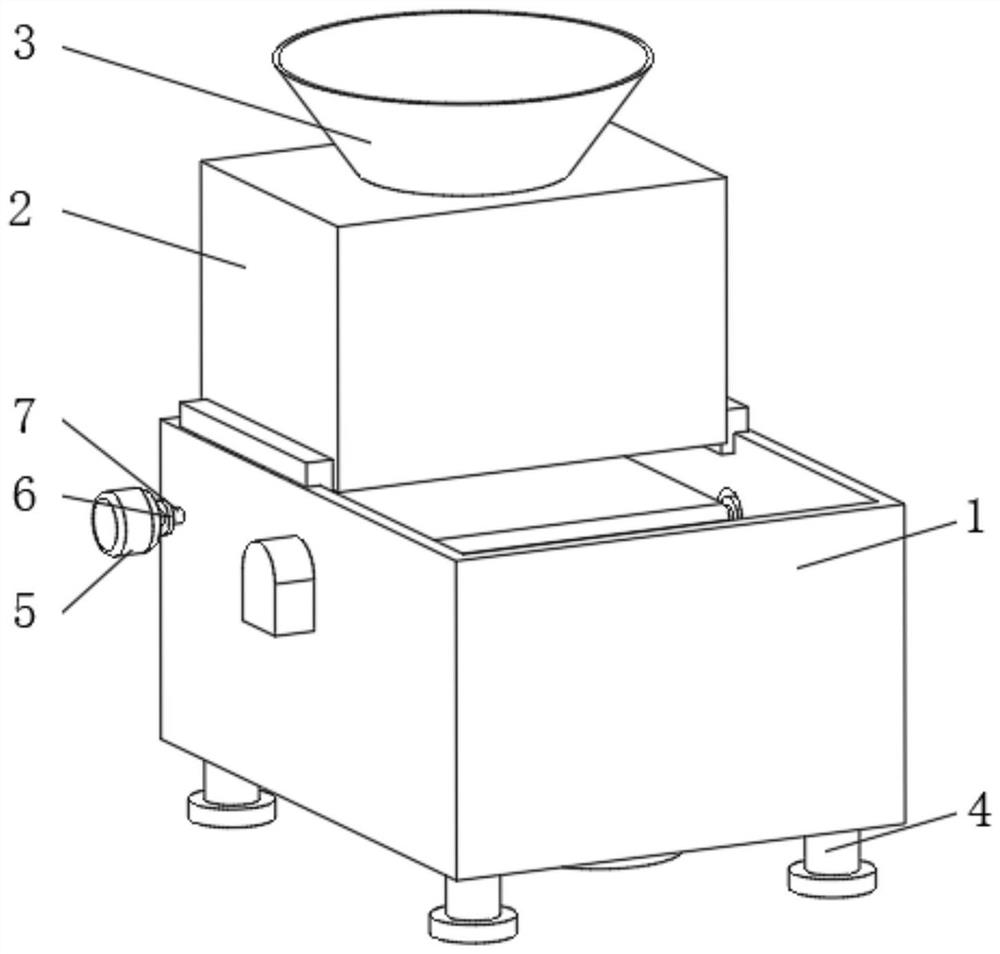

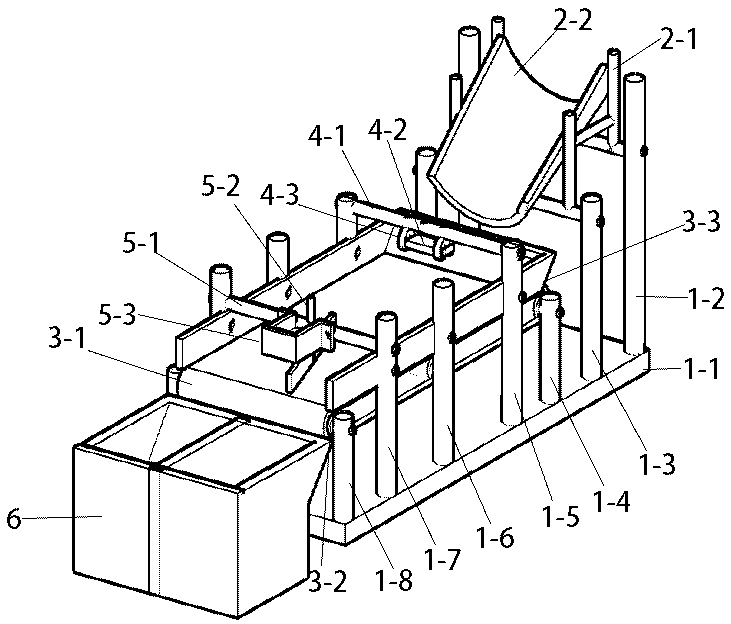

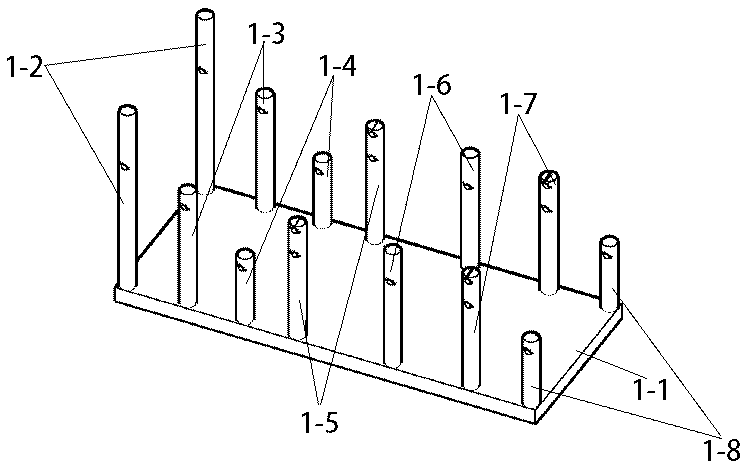

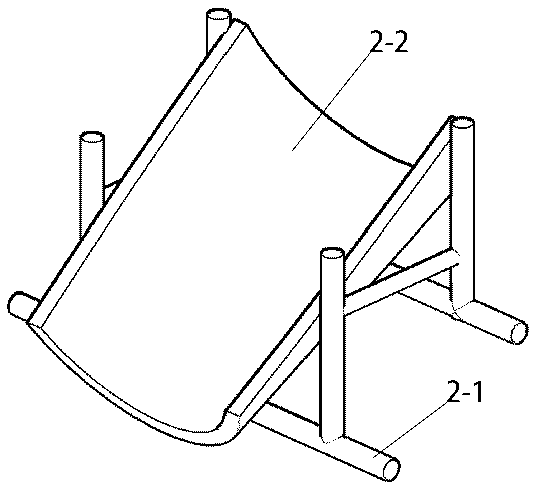

Outer space chili automatic classifying device

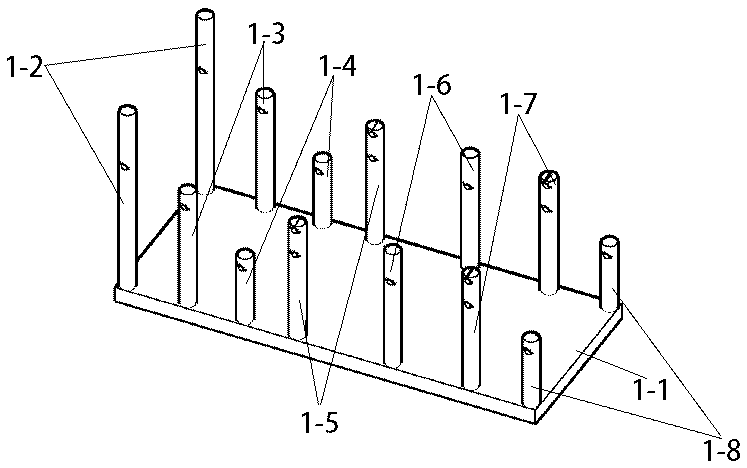

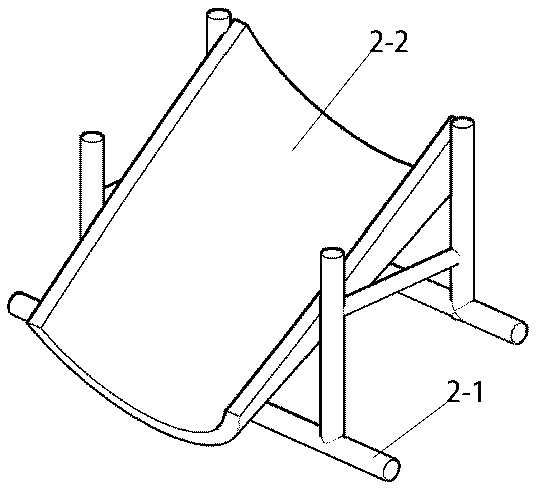

ActiveCN106423914AImprove classification processing efficiencyStable structureSortingEngineeringMechanical engineering

The invention discloses an outer space chili automatic classifying device. The outer space chili automatic classifying device comprises a baseplate bracket 1, a slide device 2, a conveying device 3, a color identifying module 4, a rotary classifying module 5 and a classifying barrel 6. The outer space chili automatic classifying device is characterized in that the slide device 2 is mounted on the baseplate bracket 1; the slide device 2 can be used for sending outer space chili into the conveying device 3; the color identifying module 4 and the rotary classifying module 5 are arranged above the conveying device 3; and after the color of the outer space chili is identified through the color identifying module 4, the rotary classifying module 5 can send the outer space chili into the classifying barrel 6 according to the color of the outer space chili identified by the color identifying module 4. Aiming at the problem of low efficiency in traditional manual classification of the outer space chili, the invention aims to provide the outer space chili automatic classifying device with firm structure and convenience for installation.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA ZHONGSHAN INST

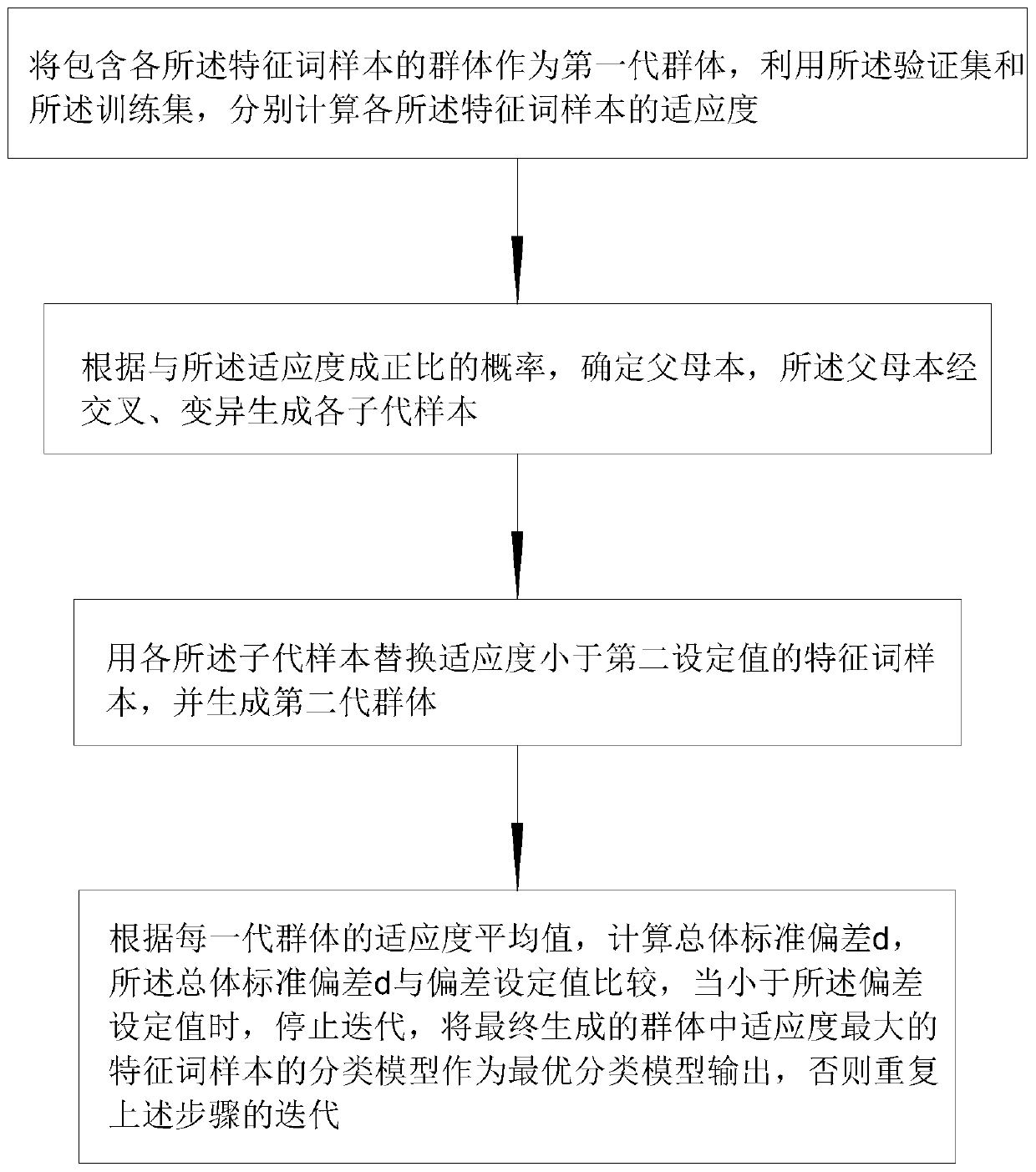

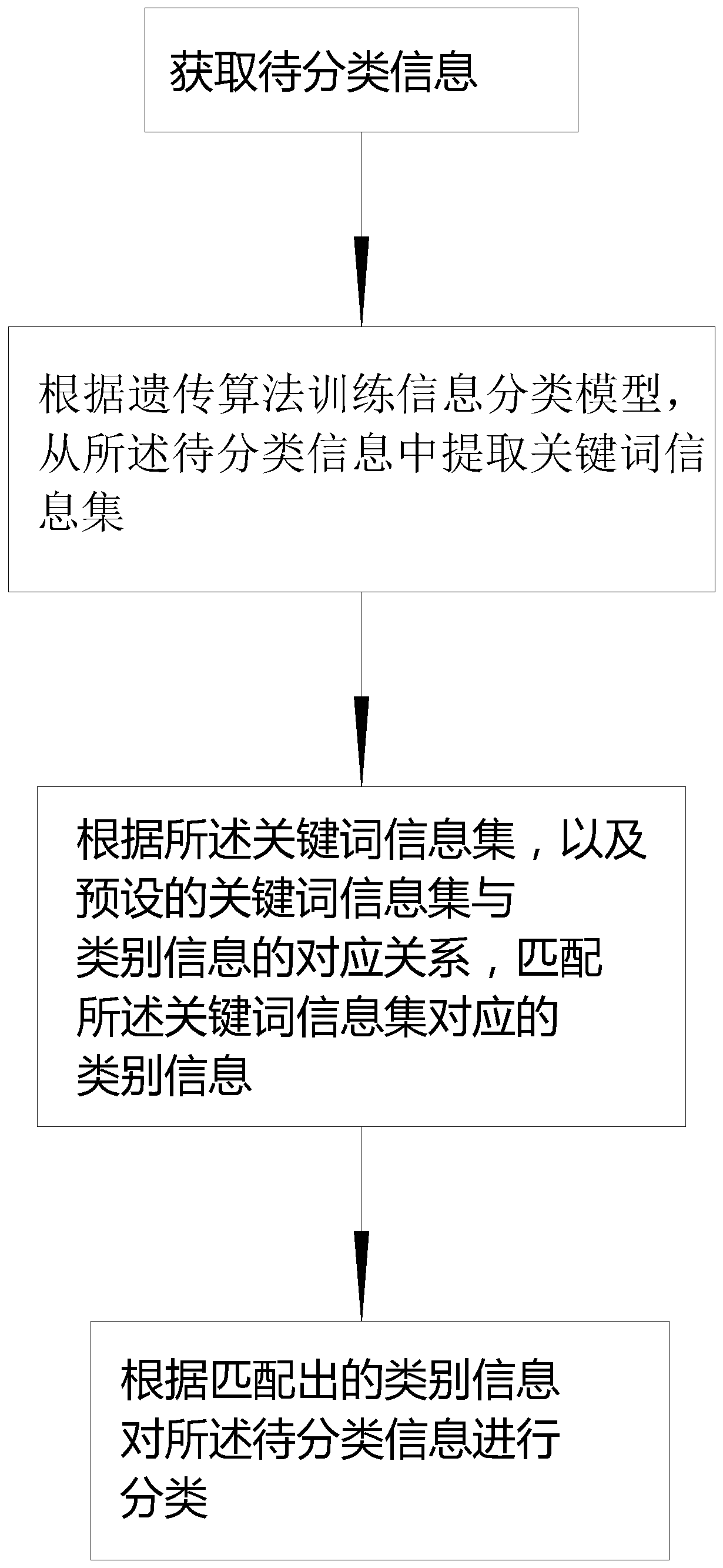

Information classification method based on genetic algorithm

InactiveCN110413774ASolve the problem of too much manual interventionEfficient training effectData processing applicationsSpecial data processing applicationsClassified informationAlgorithm

The invention provides an information classification method based on a genetic algorithm. The information classification method comprises the following steps of obtaining to-be-classified information;training an information classification model according to a genetic algorithm, extracting a keyword information set from the to-be-classified information, and the keyword information set comprises atleast one piece of keyword information; matching category information corresponding to the keyword information set according to the keyword information set and a preset corresponding relationship between the keyword information set and the category information; and classifying the to-be-classified information according to the matched category information. According to the information classification method based on the genetic algorithm, the classification processing efficiency is greatly improved, and the analysis period is shortened.

Owner:厦门美域中央信息科技有限公司

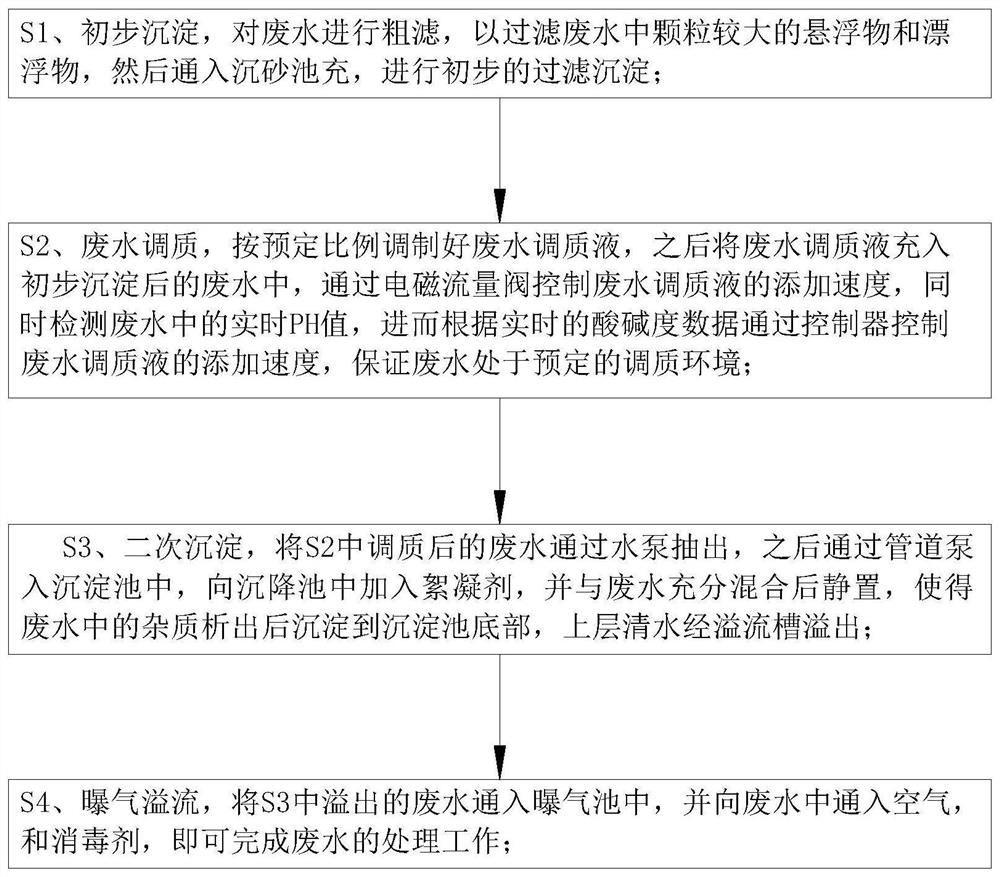

Energy-saving treatment process for textile printing and dyeing wastewater

InactiveCN111875102AImprove dispersion uniformityImprove sedimentation efficiencySpecific water treatment objectivesWater aerationTextile printerProcess engineering

The invention belongs to the technical field of wastewater treatment, and particularly relates to an energy-saving treatment process for textile printing and dyeing wastewater. A settlement tank usedin the process comprises a tank body, wherein a water inlet pipe is arranged on one side of the tank body and is communicated with the tank body through a connecting pipe; one end, close to the tank body, of the connecting pipe is in flat gradual transition, so that the distribution uniformity of wastewater after being introduced into the tank body is improved; the water inlet pipe is communicatedwith a branch pipe, and the branch pipe is communicated with a flocculating agent through a valve; the tank body is provided with a group of continuously arranged wavy grooves, and sediments of different particles are classified through the wavy grooves, so that the treatment efficiency of the sediments is further improved. According to the invention, a flocculating agent is introduced into the wastewater through the branch pipe communicated with the water inlet pipe, so that the flocculating agent is matched with one end, close to the tank body, of the connecting pipe to form flat gradual transition; therefore, the wastewater in the water inlet pipe and the flocculating agent uniformly form a stratospheric layer, the dispersion uniformity of the wastewater in the tank body is improved, and the sedimentation efficiency of the flocculating agent is further improved.

Owner:李子生

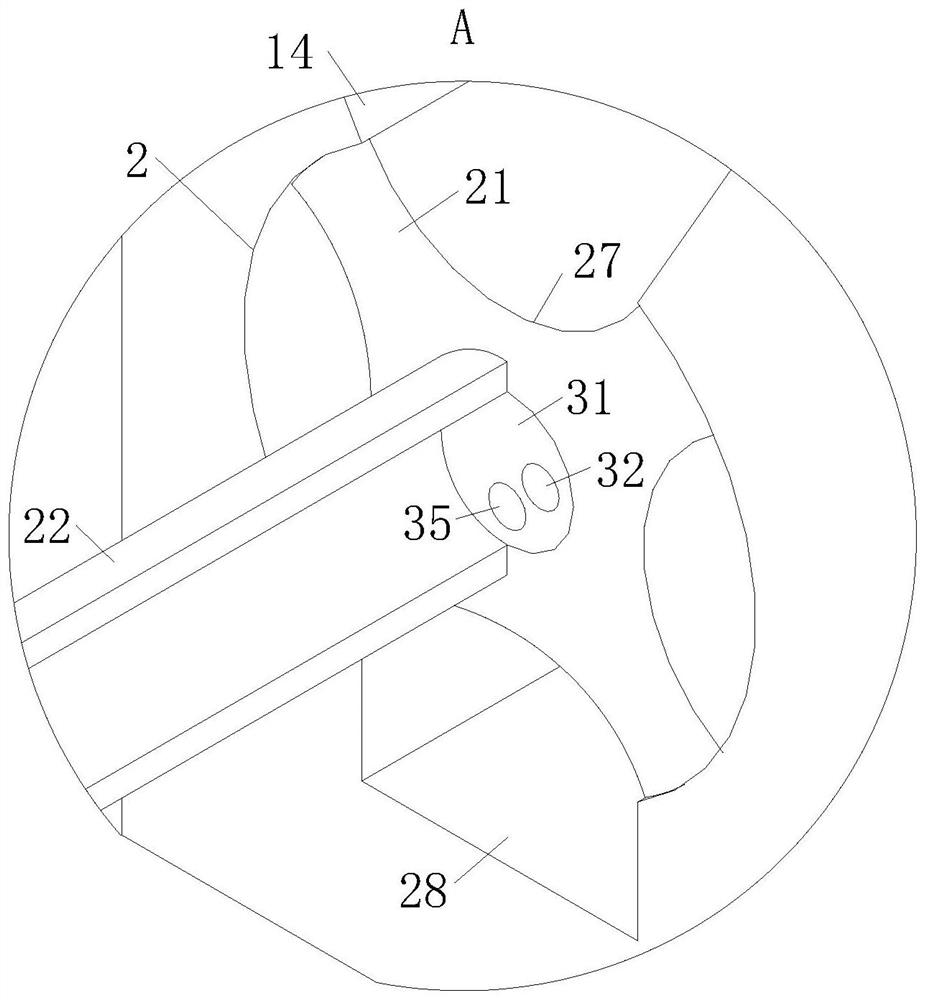

Sludge recycling device

PendingCN114315084ASpeed up filteringHigh recovery rateSludge treatmentStationary filtering element filtersElectric machineDrive shaft

The invention discloses a sludge recycling device which comprises a recycling frame, the top of the recycling frame communicates with a connecting frame, the side, away from the recycling frame, of the connecting frame communicates with a feeding pipe, supporting bases are evenly installed at the bottom of the recycling frame, and a driving motor is installed on the outer side of the recycling frame. The output end of the driving motor is connected with a rotating shaft through a transmission, the end, away from the transmission, of the rotating shaft penetrates through the recycling frame to be connected with a driving shaft, the inner wall of the recycling frame is rotationally connected with a control shaft through a control device, and a water collecting frame is installed at the position, close to the driving shaft, of the inner wall of the recycling frame. And one side of the water collecting frame communicates with a water outlet pipe, and conical baffles are evenly installed on the inner wall of the connecting frame. According to the sludge recycling device, dewatered sludge can be automatically collected, the purpose of automatically replacing the filter screen is achieved, and the sludge filtering speed is effectively increased.

Owner:席芳芳

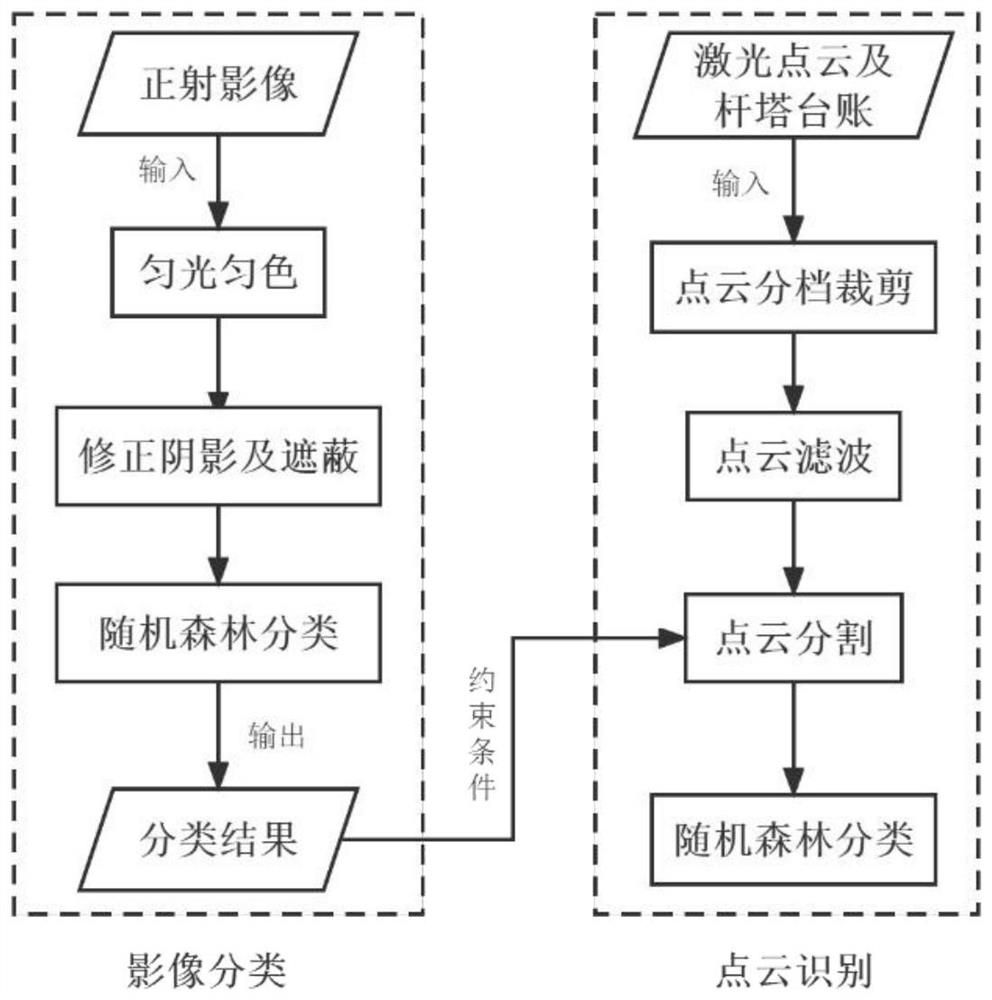

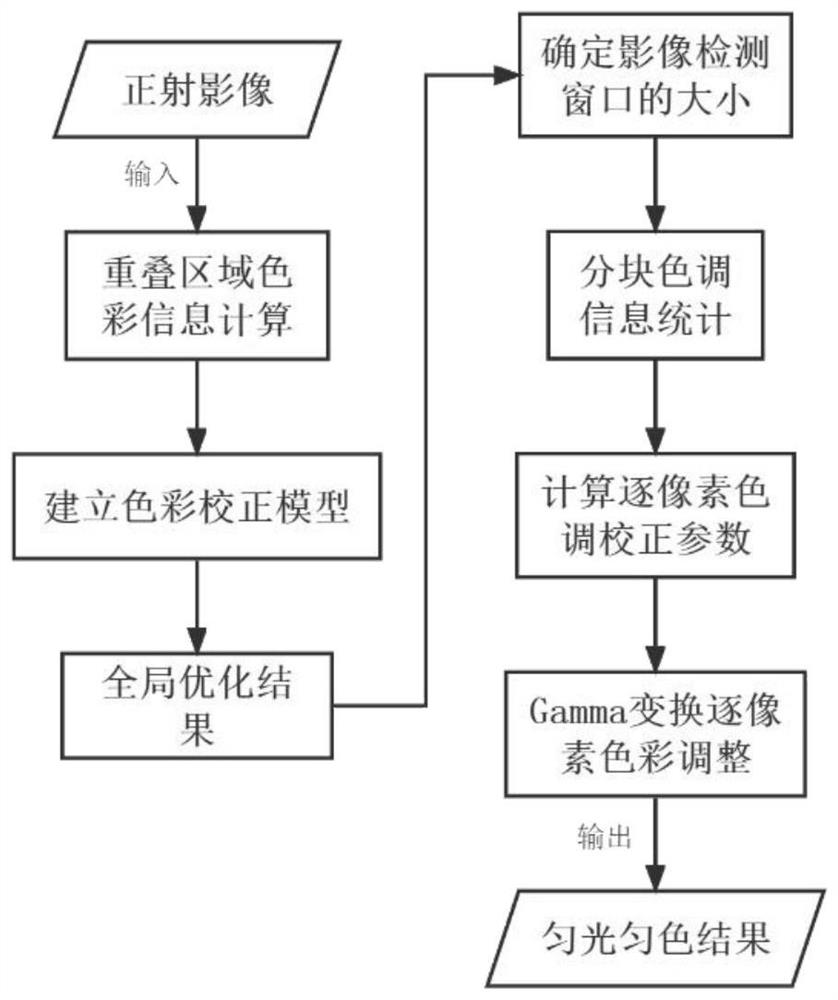

Laser point cloud ground object automatic identification method fusing line channel orthoimage

PendingCN114842262AHigh precisionHigh-resolutionCharacter and pattern recognitionMachine learningAlgorithmEngineering

The invention discloses a line channel orthoimage fused laser point cloud ground object automatic identification method comprising the following steps: collecting line channel orthoimage data, and pre-processing the line channel orthoimage data; adopting a random forest algorithm to identify and classify the corrected orthoimage; the method comprises the following steps: collecting line channel laser point cloud data and tower standing book data, preprocessing the laser point cloud data, extracting ground point cloud and tower and power line point cloud, and taking the remaining laser point cloud data as target point cloud; and carrying out point cloud segmentation on a target point cloud by taking an orthoimage classification result as a constraint condition, and carrying out fine classification on a coarse classification result by adopting a random forest algorithm to obtain a point cloud recognition result. On the basis of various characteristics of the orthoimage, the two-dimensional advantage of the orthoimage and the three-dimensional advantage of the laser point cloud are combined, the point cloud classification precision is improved, point cloud classification parallel processing is added on the basis of orthoimage classification, and the point cloud classification processing efficiency is improved.

Owner:EXAMING & EXPERIMENTAL CENT OF ULTRAHIGH VOLTAGE POWER TRANSMISSION COMPANY CHINA SOUTHEN POWER GRID

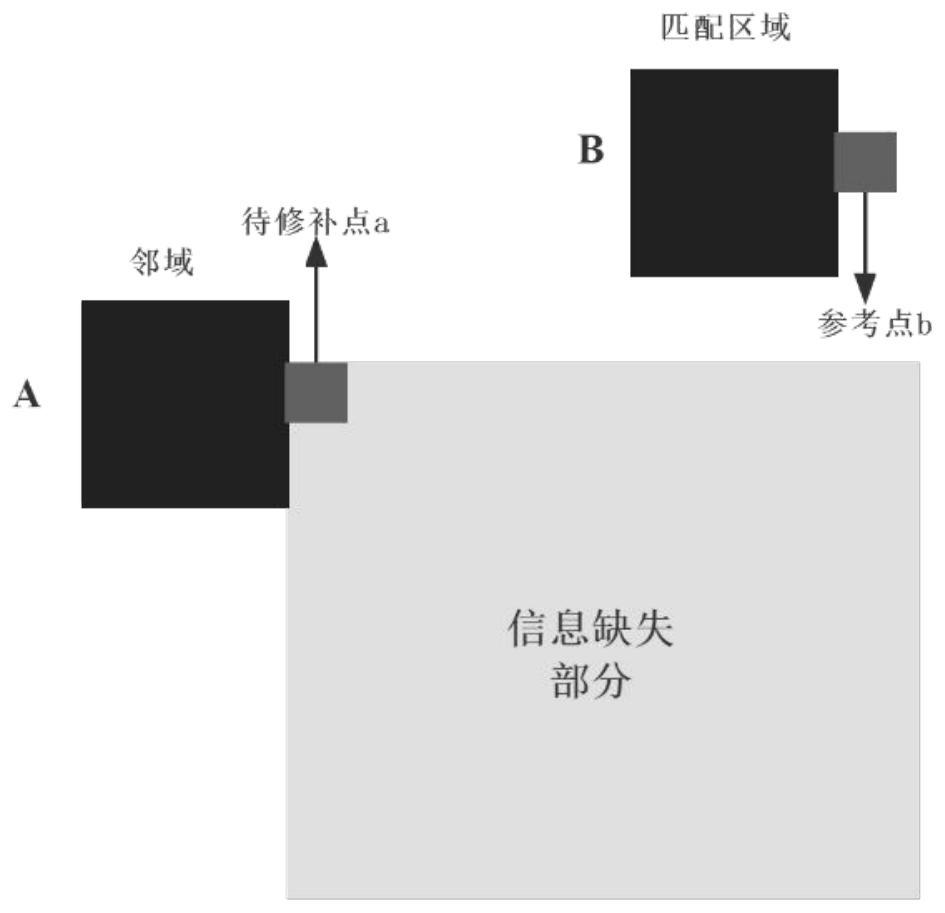

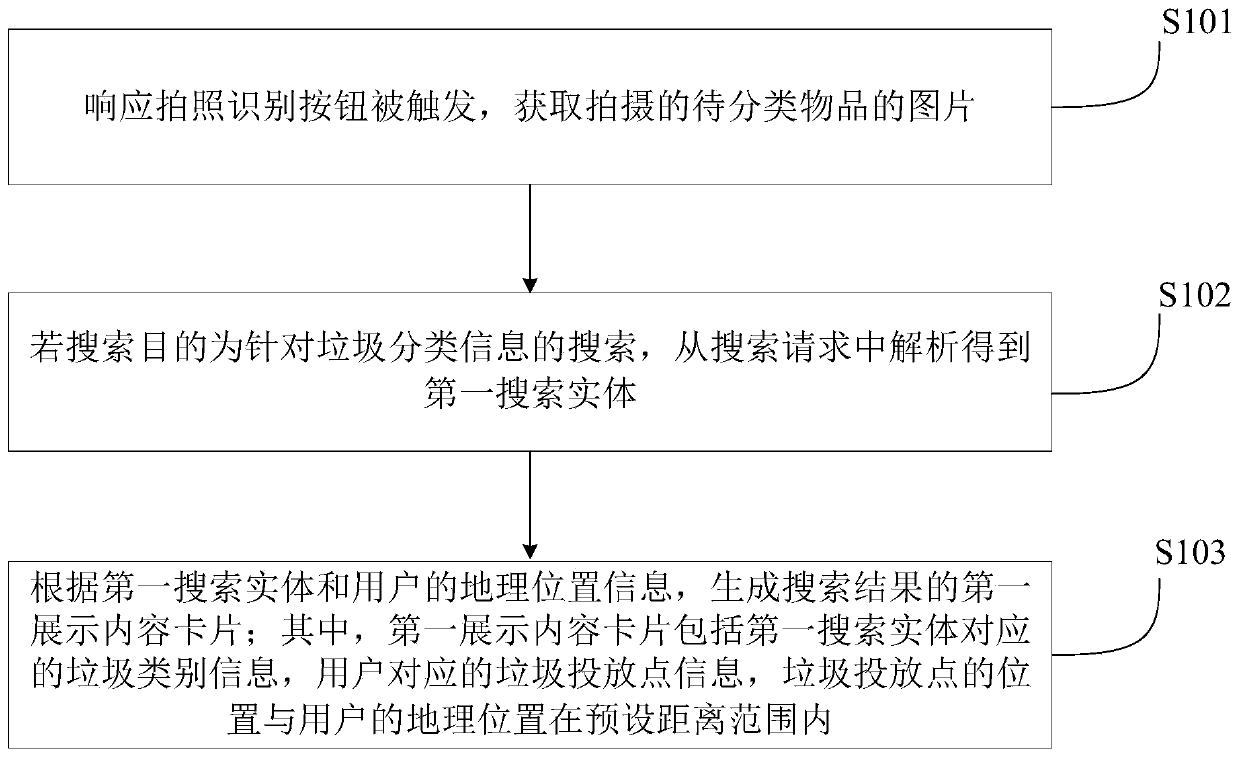

Information search method and device, electronic equipment and storage medium

PendingCN111400583AImplement automatic searchImprove classification processing efficiencyData processing applicationsDigital data information retrievalClassified informationEngineering

The invention provides an information search method and device, electronic equipment and a storage medium, and the method comprises the steps: responding to a search request of a user, and determininga search purpose of the search request; if the search purpose is search for the junk classification information, analyzing the search request to obtain a first search entity; generating a first display content card of the search result according to the first search entity and the geographical location information of the user, wherein the first display content card comprises junk category information corresponding to the first search entity and junk throwing point information corresponding to the user. By the adoption of the scheme, automatic searching of the garbage classification informationand the throwing information is achieved through determination of the user position and analysis of the search entity, manpower occupation is avoided, and the garbage classification processing efficiency is improved.

Owner:BEIJING BYTEDANCE NETWORK TECH CO LTD

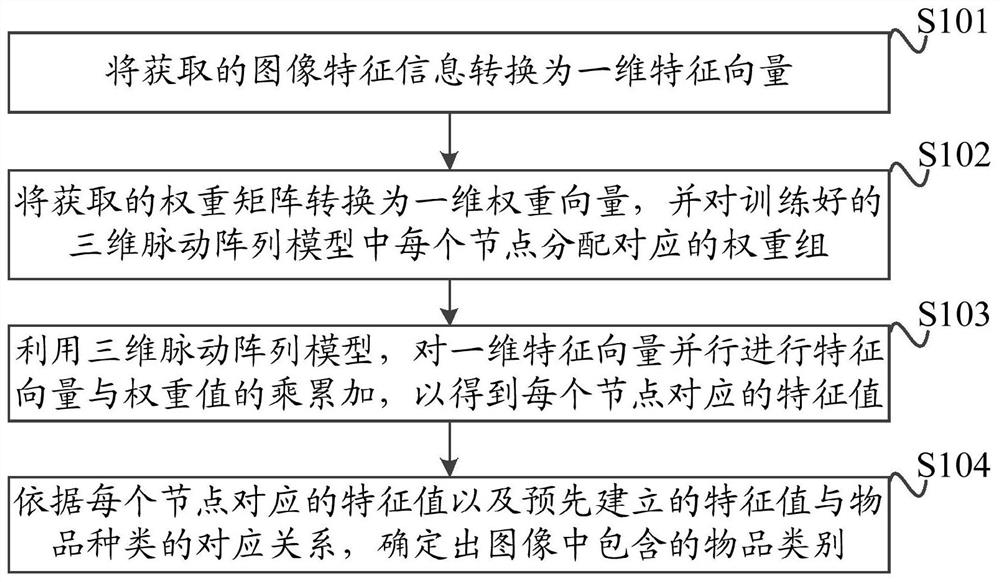

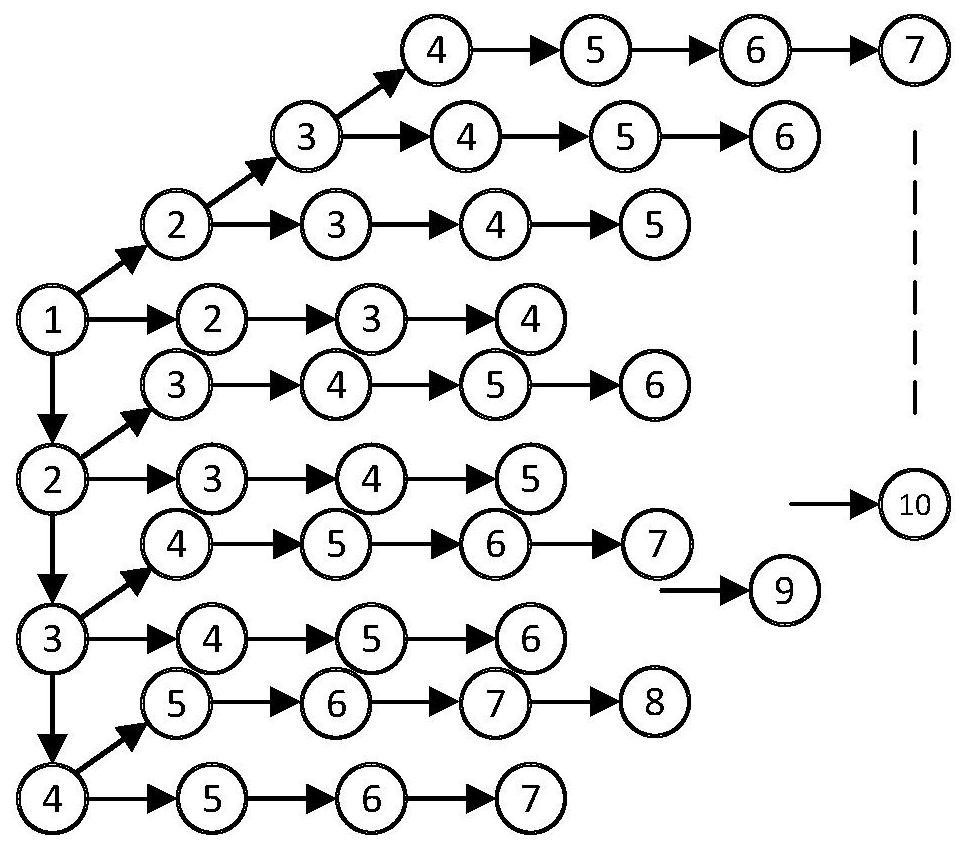

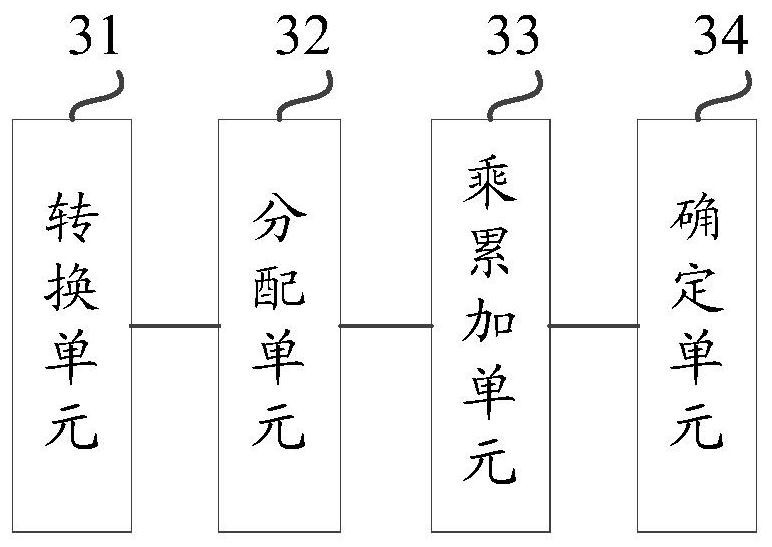

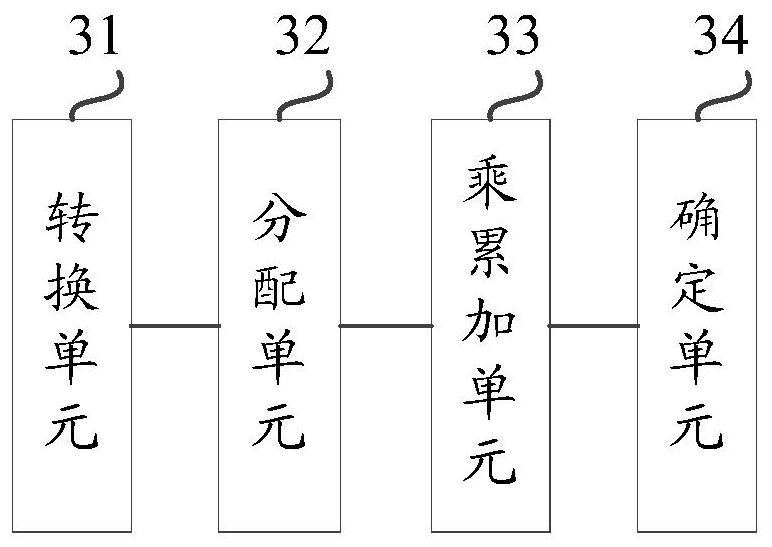

Image recognition method and device based on pulsation array and medium

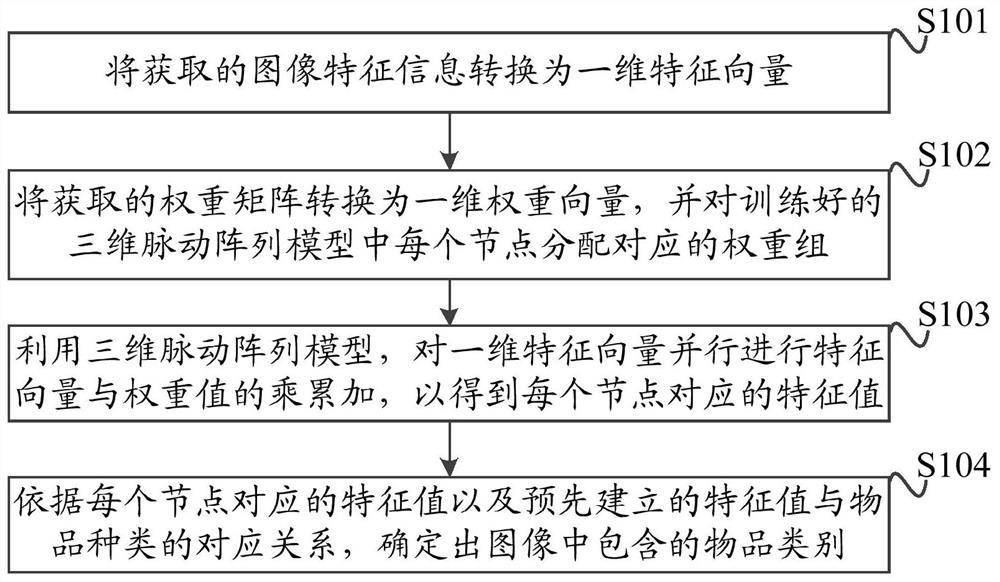

ActiveCN112085128AImprove classification processing efficiencyReduce complexityCharacter and pattern recognitionNeural architecturesFeature vectorAlgorithm

The embodiment of the invention discloses an image recognition method and device based on a pulsation array, and a medium. The method comprises the steps: converting obtained image feature informationinto a one-dimensional feature vector; and converting the obtained weight matrix into a one-dimensional weight vector, and allocating a corresponding weight group to each node in the trained three-dimensional pulsation array model; performing multiplication and accumulation of the feature vectors and the weight values on the one-dimensional feature vectors in parallel by using a three-dimensionalpulsation array model to obtain a feature value corresponding to each node; enabling the feature values of different values to reflect the article category contained in the image, and determining thearticle category contained in the image according to the feature value corresponding to each node and the pre-established corresponding relationship between the feature value and the article category. According to the method, after one-dimensional conversion is carried out on the to-be-calculated image feature information and the weight value, the one-dimensional feature vector is calculated by adopting a framework of carrying out accelerated calculation by adopting the pulsation array model, so that the parallelism degree of vector calculation is fully expanded, and the classification processing efficiency of the image is effectively improved.

Owner:INSPUR SUZHOU INTELLIGENT TECH CO LTD

Milk tea cup classification recycling device special for shopping mall

InactiveCN112960311AAvoid shakingEasy to removeTransportation and packagingSolid waste disposalEngineeringProcess engineering

The invention relates to the field of garbage treatment, in particular to a milk tea cup classification recycling device special for a shopping mall. The milk tea cup classification recycling device special for the shopping mall is intended to perform classification recycling on milk tea cups, different materials are separately recovered, and milk tea or feeding residues left in the milk tea cups are independently treated. The milk tea cup classification recycling device for the shopping mall comprises a garbage classification box body with the top provided with a throwing opening with a diameter of a milk tea cup, wherein a movable clamping device is arranged in the garbage classification box body, the movable clamping device comprises two cup body clamping blocks for clamping milk tea cups with different diameters by rotating and changing the distance, four straightening electric push rods which are distributed at equal angles are arranged in the garbage throwing opening of the garbage classification box body, and the straightening electric push rods straighten a suction pipe through stretching out and drawing back.

Owner:深圳市大西美商贸有限公司

Method, device, computer equipment and storage medium for video action classification

ActiveCN109376696BImprove classification processing efficiencyCharacter and pattern recognitionNeural architecturesComputer graphics (images)Engineering

Owner:BEIJING DAJIA INTERNET INFORMATION TECH CO LTD

A method, device and medium for image recognition based on pulsation array

ActiveCN112085128BImprove classification processing efficiencyReduce complexityCharacter and pattern recognitionNeural architecturesFeature vectorAlgorithm

The embodiment of the present invention discloses an image recognition method, device and medium based on a pulsation array, which converts the acquired image feature information into a one-dimensional feature vector; converts the acquired weight matrix into a one-dimensional weight vector, and uses the trained Each node in the 3D systolic array model is assigned a corresponding weight group. Using the three-dimensional systolic array model, the one-dimensional feature vector is multiplied and accumulated by the weight value in parallel to obtain the corresponding feature value of each node. The feature values with different values can reflect the category of items contained in the image, and the category of items contained in the image can be determined according to the feature value corresponding to each node and the corresponding relationship between the feature value and the item category established in advance. After the image feature information and weight value to be calculated are transformed into one dimension, the structure of accelerated calculation using the pulsating array model is used to calculate the one-dimensional feature vector, which fully expands the parallelism of vector calculation and effectively improves the image classification processing efficiency.

Owner:INSPUR SUZHOU INTELLIGENT TECH CO LTD

A residential garbage disposal equipment

ActiveCN111203311BImprove classification processing efficiencySimple structureWater contaminantsWater/sewage treatmentWine bottleWastewater

The invention discloses residential household waste treatment equipment. The residential household waste treatment equipment comprises a main machine body, wherein a crushing cavity is arranged in themain machine body; the opening of the crushing cavity is designed upwards; a plurality of rotary rollers are arranged in the crushing cavity in a rolling mode, and relatively great articles such as wine bottles can be separated on the rotary rollers; two bag crushing shafts which are symmetrical left and right are rotatably arranged in the crushing cavity; crushing forks are fixedly arranged on the two bag crushing shafts; the crushing forks can preliminarily crush household waste; and the bottom of the crushing cavity is provided with a filter screen in a vibrating mode. The residential household waste treatment equipment can automatically crush garbage bags; after crushing is accomplished, the rotary rollers rotate, so that waste such as wine bottles in garbage are exhausted outwards from an outlet, other impurities drop into the crushing cavity and are crushed by a crushing knife, and wastewater enters a decomposition cavity to decompose, so that garbage classifying treating efficiency is greatly improved. The residential household waste treatment equipment is simple in structure, is convenient to operate, and is convenient to popularize and use.

Owner:青岛松上环境工程有限公司

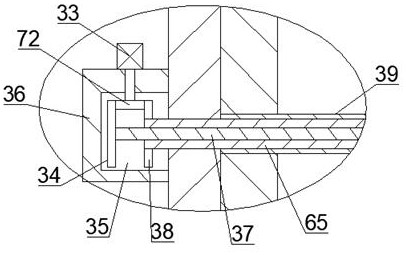

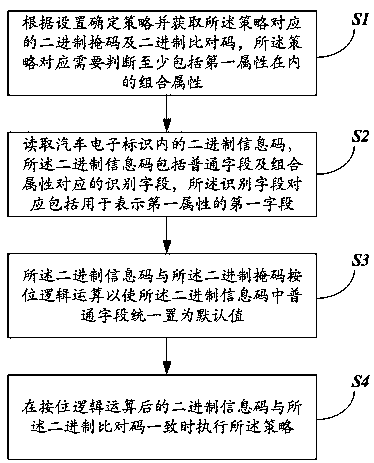

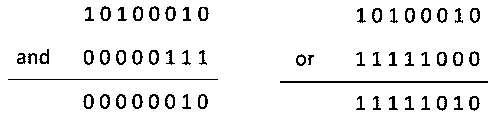

Method and system for classification and processing of automobile electronic identification

ActiveCN107067042BImplement classification processingSimple way of judgingCo-operative working arrangementsCharacter and pattern recognitionElectronic identificationBinary information

The present invention provides a method and system for classifying and processing automotive electronic identifications, wherein the method for classifying and processing automotive electronic identifications includes the following steps: determining a strategy according to settings and obtaining a binary mask and a binary comparison code corresponding to the strategy, and the strategy corresponds to the required Judging the combination attribute including at least the first attribute; reading the binary information code in the electronic identification of the vehicle, the binary information code includes the common field and the identification field corresponding to the combination attribute, and the identification field corresponds to the identification field used to indicate the first The first field of the attribute; the binary information code and the binary mask are logically operated by bits so that the common fields in the binary information code are uniformly set to default values; the binary information code after the bitwise logical operation and the described The strategy is executed when the binary comparison codes are consistent. The invention simplifies the judging mode of classification processing for vehicle management and improves the efficiency of classification processing.

Owner:JIANGSU BELLON TECH

A kind of space pepper automatic sorting device

ActiveCN106423914BImprove classification processing efficiencyStable structureSortingEngineeringMechanical engineering

The invention discloses an outer space chili automatic classifying device. The outer space chili automatic classifying device comprises a baseplate bracket 1, a slide device 2, a conveying device 3, a color identifying module 4, a rotary classifying module 5 and a classifying barrel 6. The outer space chili automatic classifying device is characterized in that the slide device 2 is mounted on the baseplate bracket 1; the slide device 2 can be used for sending outer space chili into the conveying device 3; the color identifying module 4 and the rotary classifying module 5 are arranged above the conveying device 3; and after the color of the outer space chili is identified through the color identifying module 4, the rotary classifying module 5 can send the outer space chili into the classifying barrel 6 according to the color of the outer space chili identified by the color identifying module 4. Aiming at the problem of low efficiency in traditional manual classification of the outer space chili, the invention aims to provide the outer space chili automatic classifying device with firm structure and convenience for installation.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA ZHONGSHAN INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com