Ordered screening regeneration equipment for waste battery

A technology for used batteries and regeneration equipment, applied in the direction of solid waste removal, etc., can solve problems such as unfavorable sorting and treatment, and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

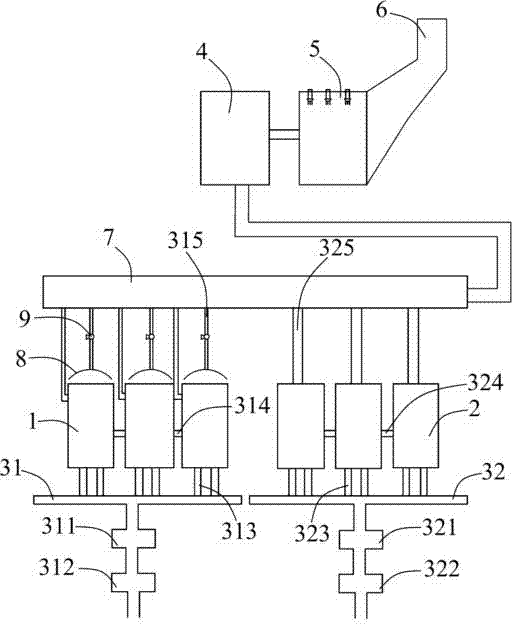

[0022] Such as figure 1 Shown is an orderly screening and regeneration equipment for waste batteries according to the present invention, which includes a low-temperature furnace 1, a refining furnace 2, a gas pipeline, a dust removal room 4, a water curtain dust removal device 5 and a chimney 6, wherein the gas pipeline includes separate The first gas pipeline 31 and the second gas pipeline 32. Two first small gas supply pipes 313 are connected between the gas chamber of each low-temperature furnace 1 and the first gas pipeline 31, and two second small gas supply pipes 313 are connected between the gas chamber of each refining furnace 2 and the second gas pipeline 32. Air supply pipe 323 . The gas chambers of several low-temperature furnaces 1 are connected through the first transverse pipe 314 , and the gas chambers of several refining furnaces 2 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com