Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

45results about How to "Improve bending and torsional performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hollow chamber structural component and method for producing same

InactiveUS7879435B2High mechanical load capacityImprove carrying capacityVehicle seatsEnvelopes/bags making machineryAdhesiveMechanical engineering

Owner:REHAU AG & CO

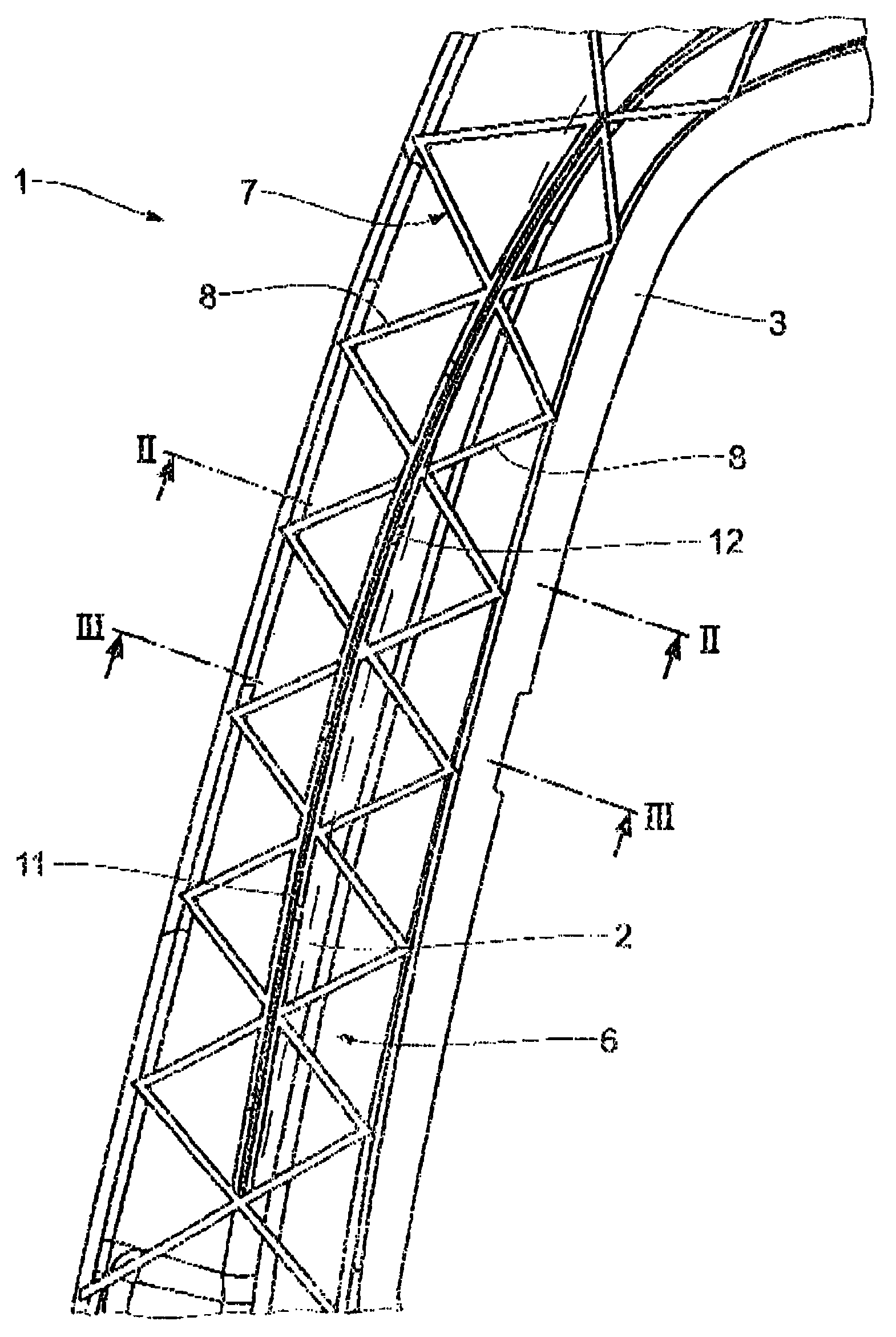

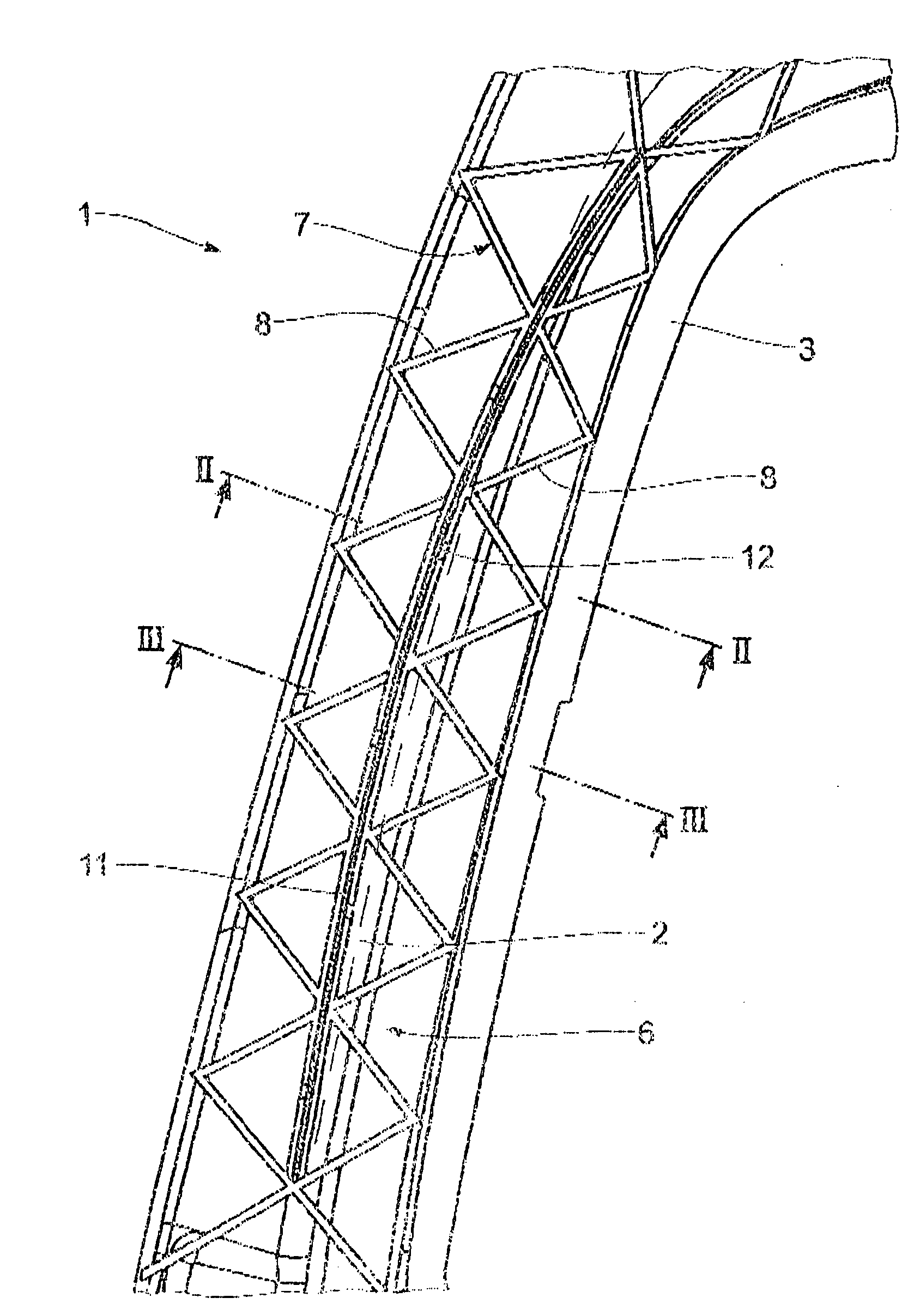

Hollow chamber structural component and method for producing same

InactiveUS20080014388A1Increased intrinsic stabilityHigh mechanical load capacityEnvelopes/bags making machineryVehicle seatsAdhesiveEngineering

A hollow chamber structural component includes a shell component which extends along a main extension direction. A cover component is attached to the shell component, wherein a hollow chamber is disposed between the shell component and the cover component and extends in the main extension direction. A reinforcing structure is arranged in the hollow chamber and comprises: a synthetic support structure, which follows at least in some sections the main extension direction and rests with at least some sections against an inside of the shell component; and at least one reinforcing element that follows at least in some sections the main extension direction and is joined to the synthetic support structure with the aid of a layer of adhesive.

Owner:REHAU AG CO

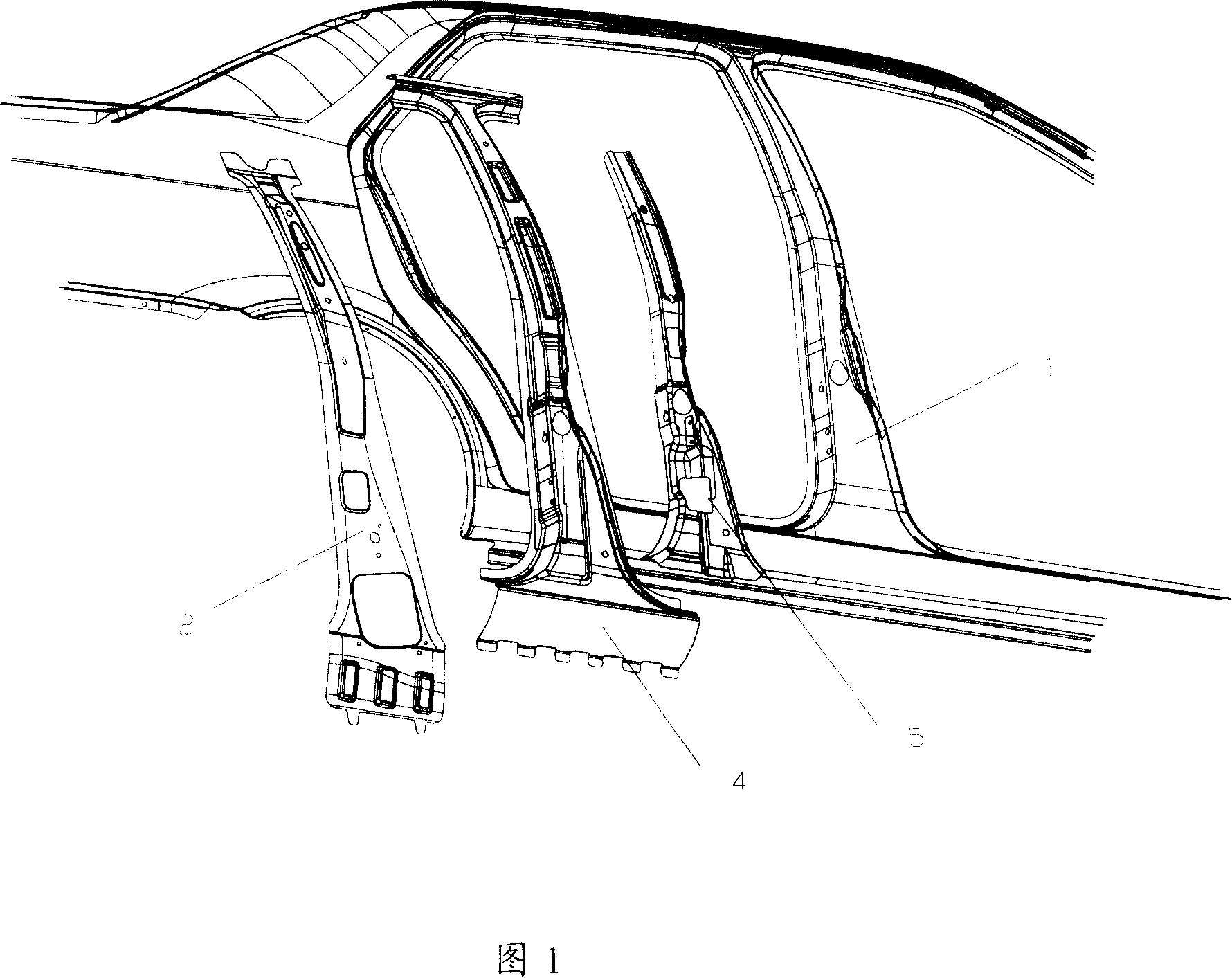

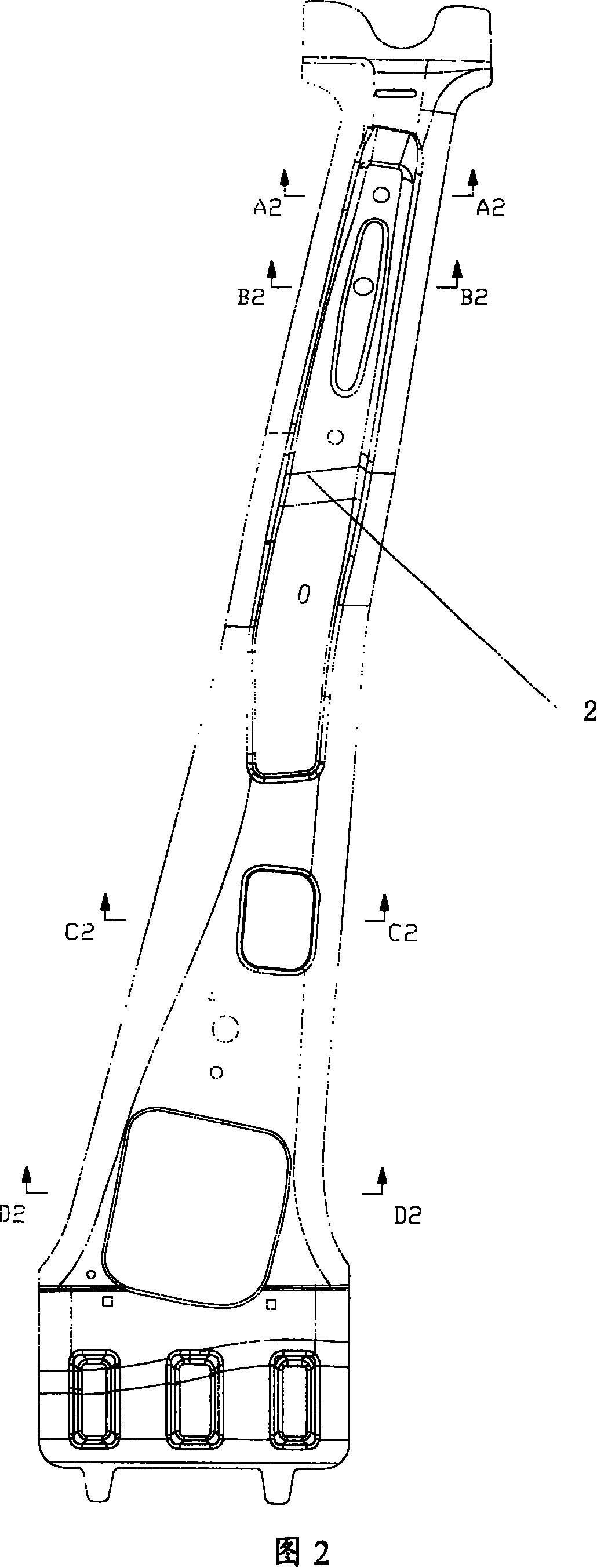

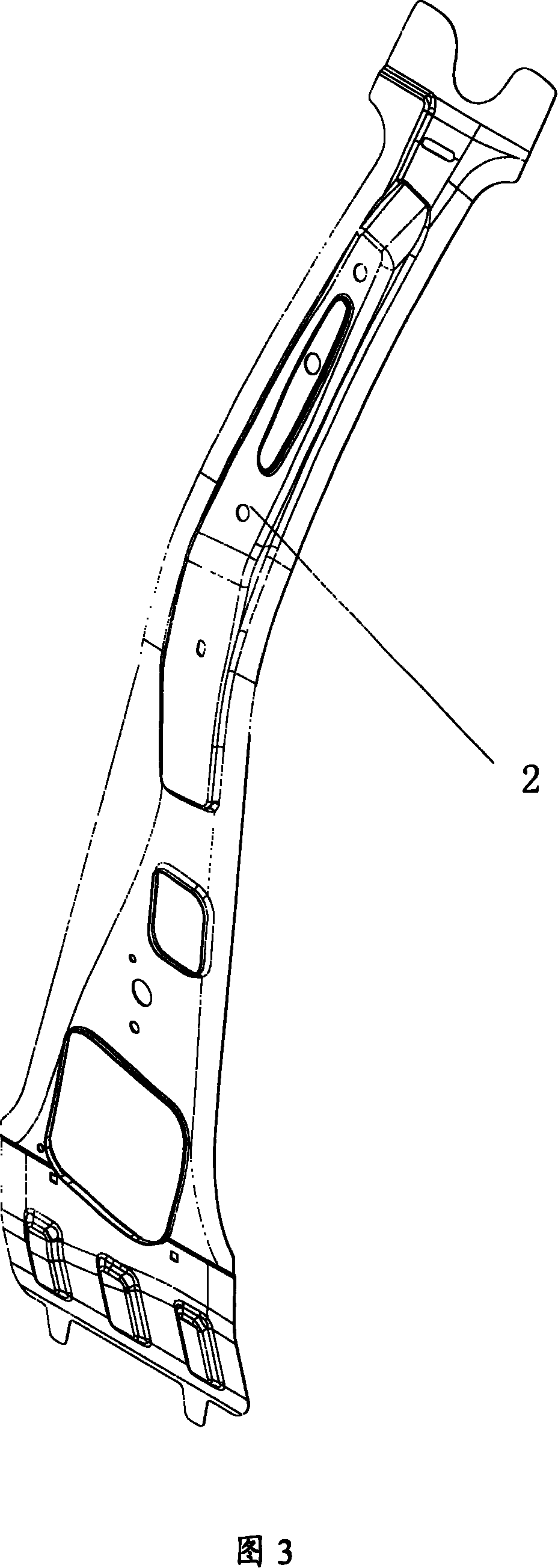

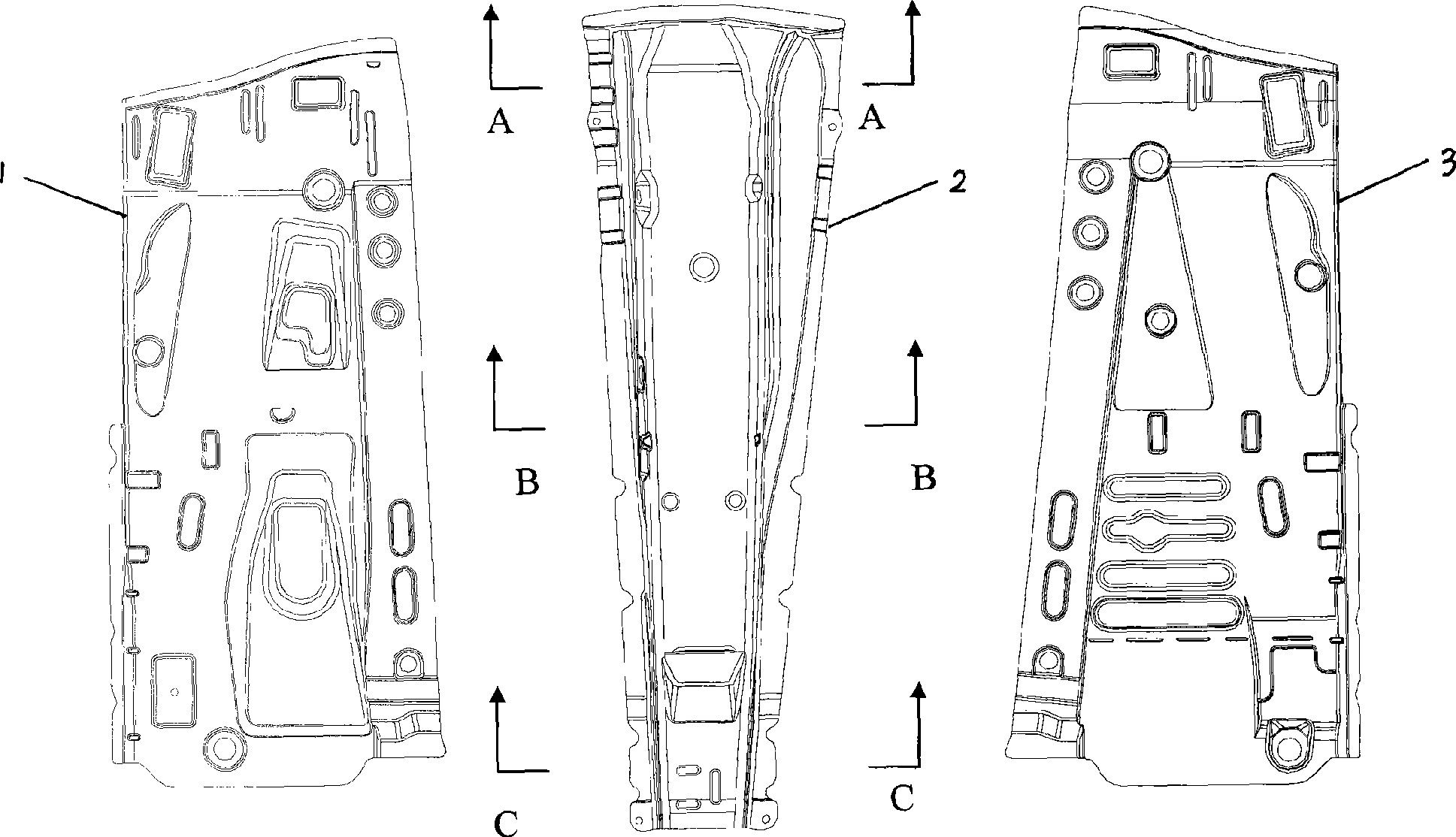

Car middle column

InactiveCN101121420AEnhanced rigidity and resistance to bending and torsionSolve side collision safetySuperstructure subunitsCentral cylinderEngineering

The present invention discloses a central cylinder for a saloon car, including a side wall outside plate and a central cylinder internal plate arranged on the side wall outside plate. The present invention is characterized in that the present invention also includes at least one reinforcing plate of the central cylinder arranged between the central cylinder internal plate and the side wall outside plate. The technical problem solved by the present invention is to provide a central cylinder of the saloon car to solve the safety problem for the side collision, of which the rigidity and the ability of bending and twisting resistance are reinforced.

Owner:SHANGHAI HUAPU AUTOMOBILE CO LTD

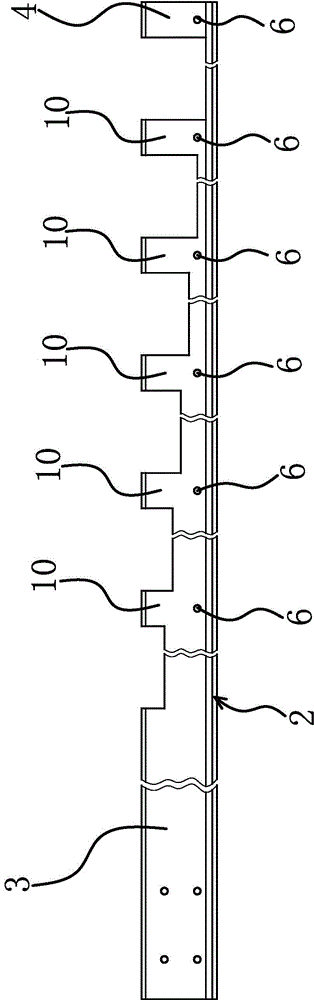

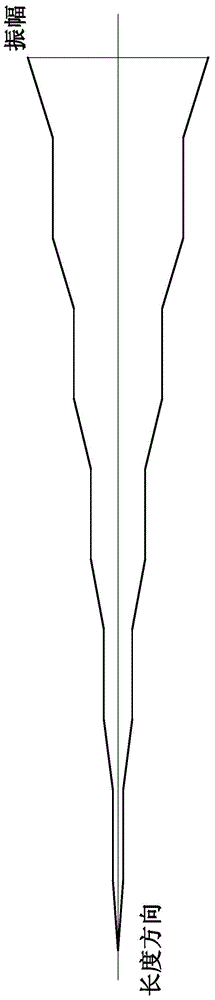

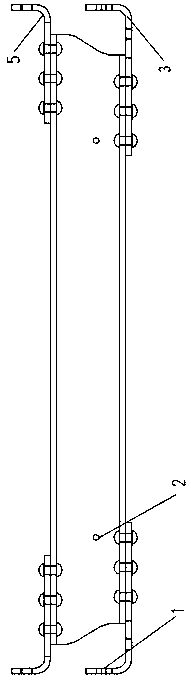

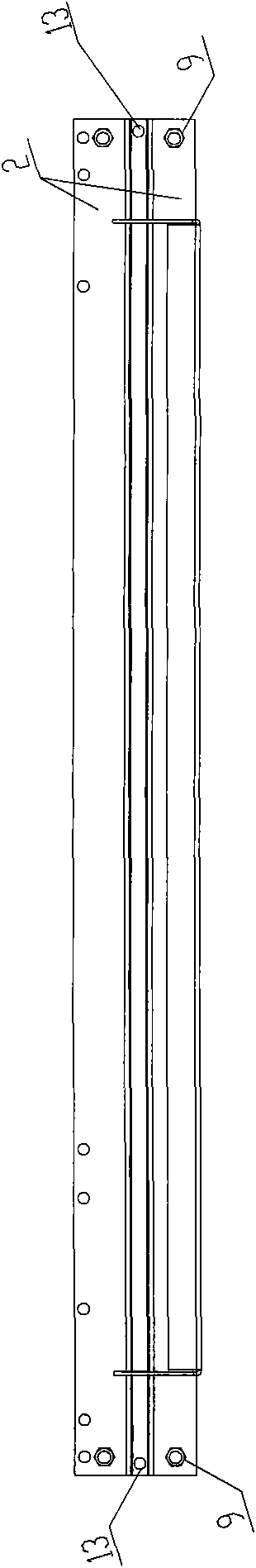

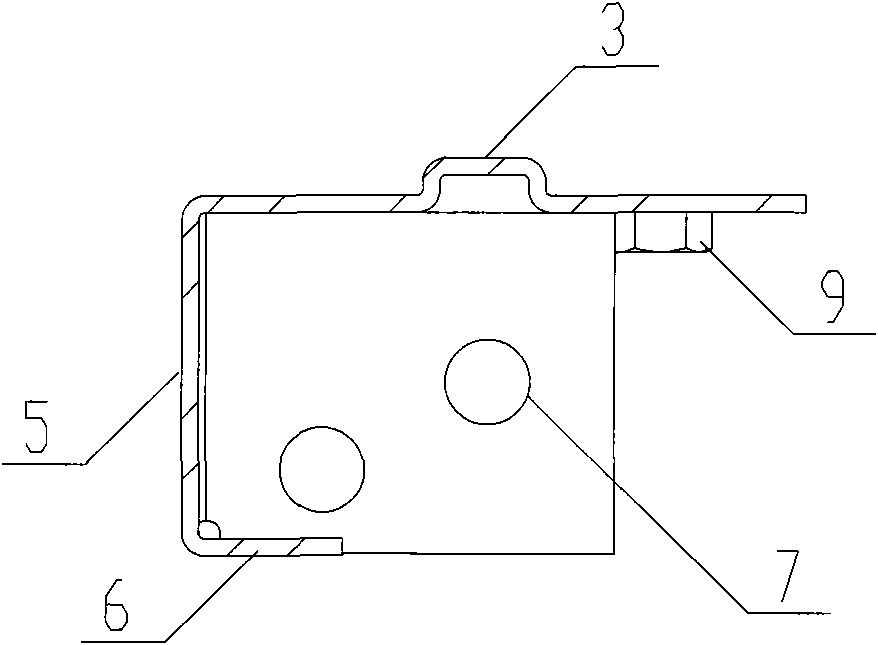

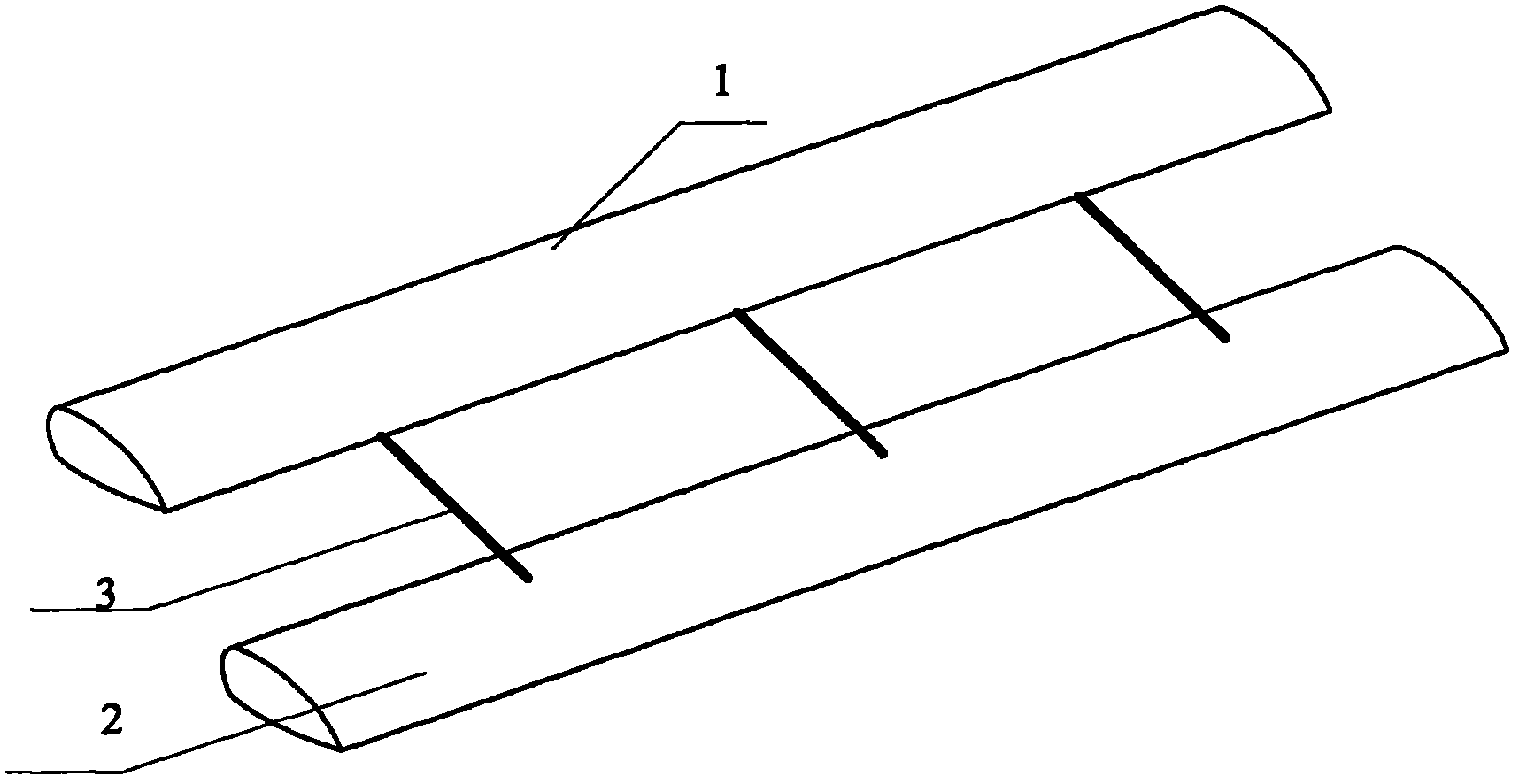

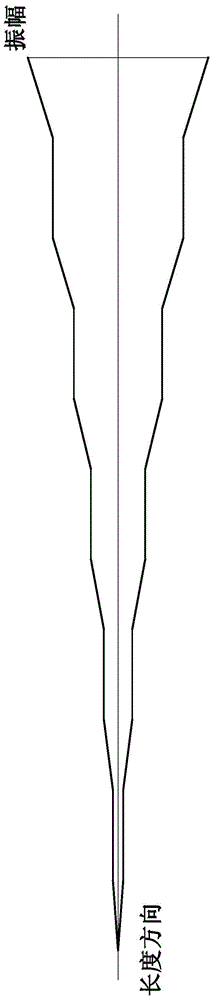

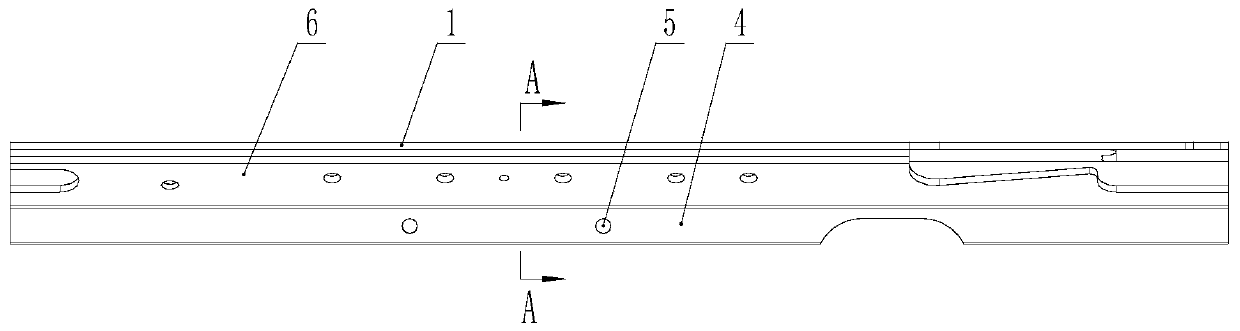

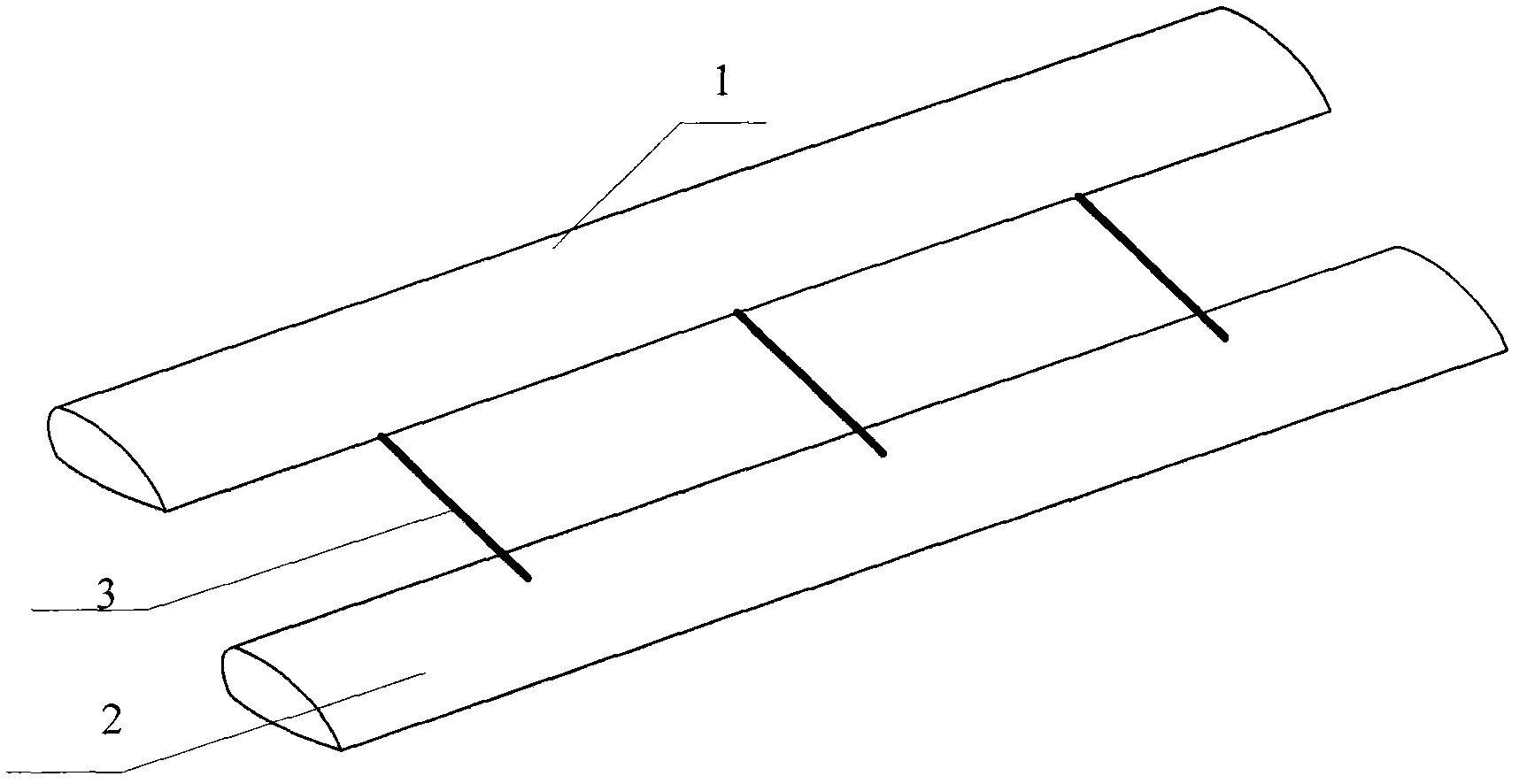

Rigidity-flexibility transition busbar

The invention provides a rigidity-flexibility transition busbar and belongs to the technical field of an electrified railway and urban rail transit overhead contact line. The invention solves the problems of high transition hardness and cost of an existing rigidity-flexibility transition busbar. The rigidity-flexibility transition busbar comprises a busbar body; both ends of the busbar body respectively are a rigid connection end and a flexible connection end; the lower part of the busbar body is provided with a wire clamping jaw; a rigidity-flexibility transition part for enabling the rigidity of the busbar body to be gradually reduced is arranged between the rigid connection end and the flexible connection end; the upper surface of the rigidity-flexibility transition part is a continuous transition inclined plane; the busbar body is provided with a plurality of connection through holes running through the busbar body along the length direction; locking bolts are respectively arranged in the connection through holes; each locking bolt is sleeved with a positioning sleeve; and both end faces of each positioning sleeve are respectively pressed against the inner lateral surface of the busbar body. The rigidity-flexibility transition busbar adopts the continuous transition inclined plane to carry out transition and hard spots in the rigidity-flexibility transition busbar are eliminated.

Owner:浙江旺隆轨道交通设备有限公司

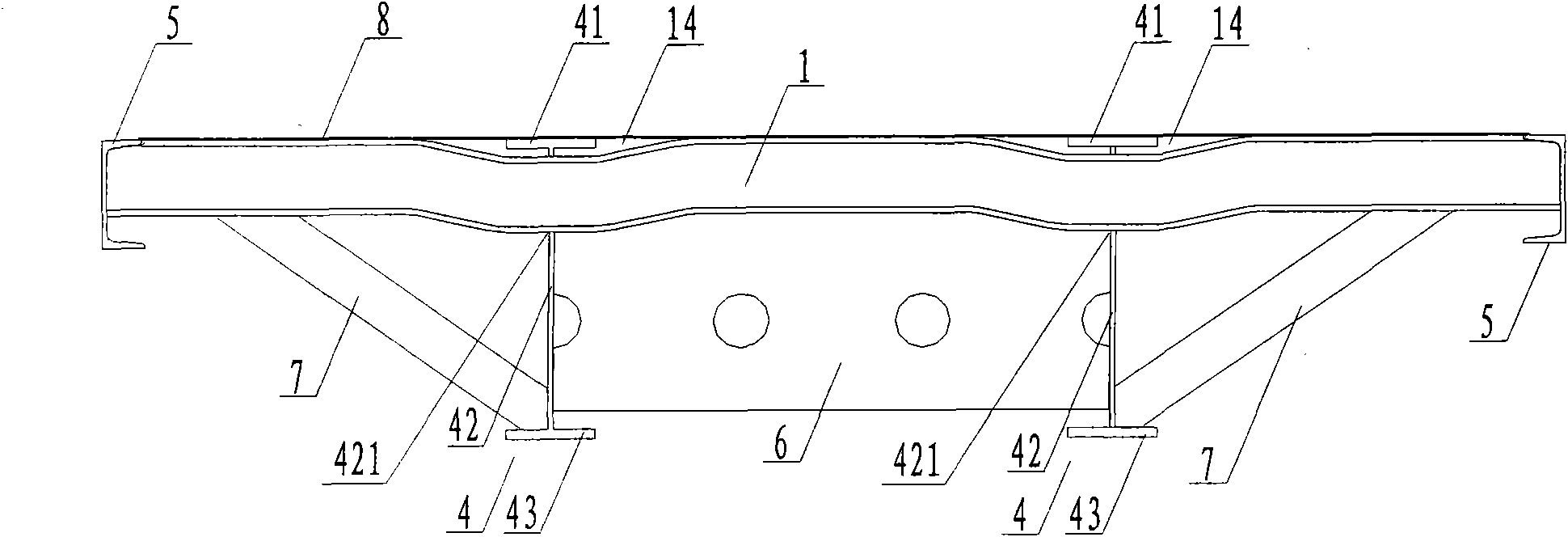

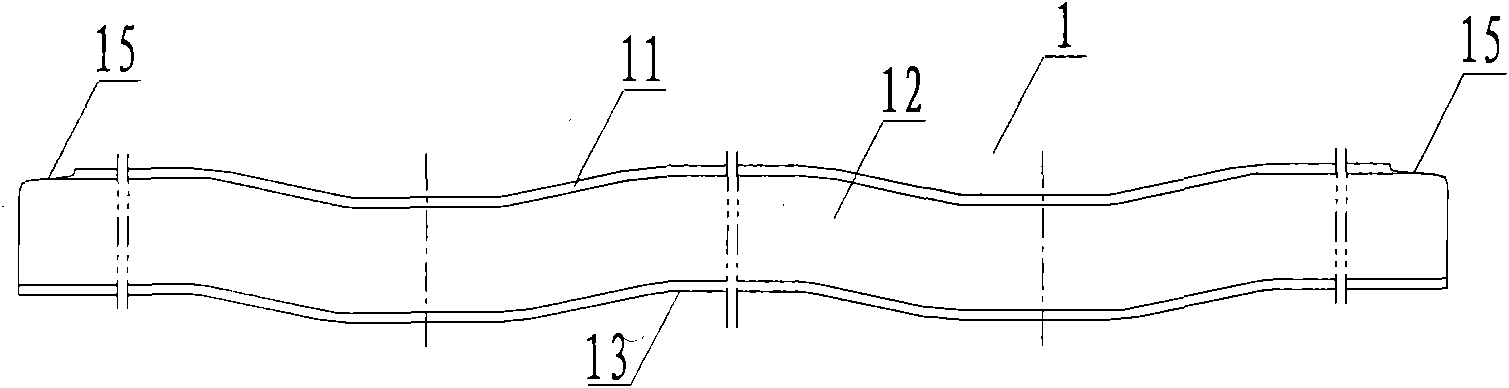

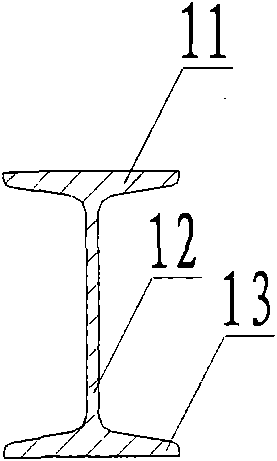

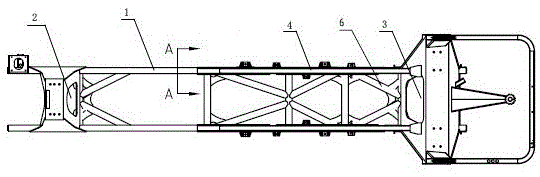

Freight truck frame and freight truck with frame

InactiveCN102050148ANovel structureEven by forceUnderstructuresItem transportation vehiclesConvex structureVehicle frame

The invention discloses a freight truck frame, which comprises longitudinal beams, side beams and a penetrating beam with a concave-convex structure. The penetrating beam penetrates the longitudinal beams and is connected with the side beams; a top end face of the penetrating beam is flush with those of the longitudinal beams and the side beams; a plurality of mounting parts which are recessed towards the bottom and extend transversely are arranged on the penetrating beam opposite to the longitudinal beams in a matching mode; the longitudinal beams are connected to the mounting parts; and the cross section of the penetrating beam is bilaterally symmetrical relative to a transverse centre line of the penetrating beam. The freight truck is provided with the freight truck frame. The freight truck and the freight truck frame reduce the dead weight of the whole truck, increase the stress section and enhance the bending resistance and torsion resistance, and can meet different load requirements.

Owner:CIMC VEHICLES (GROUP) CO LTD +1

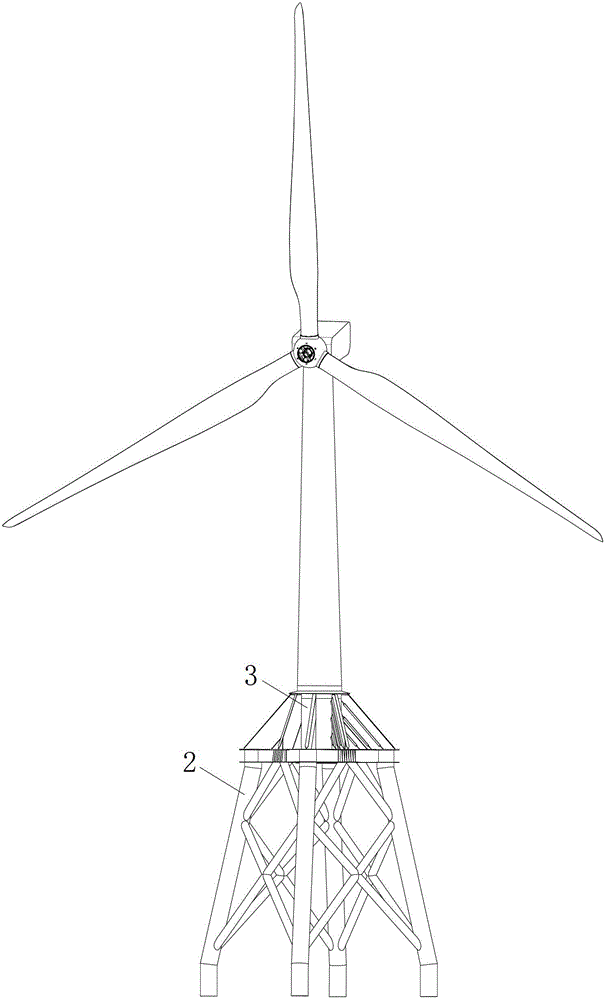

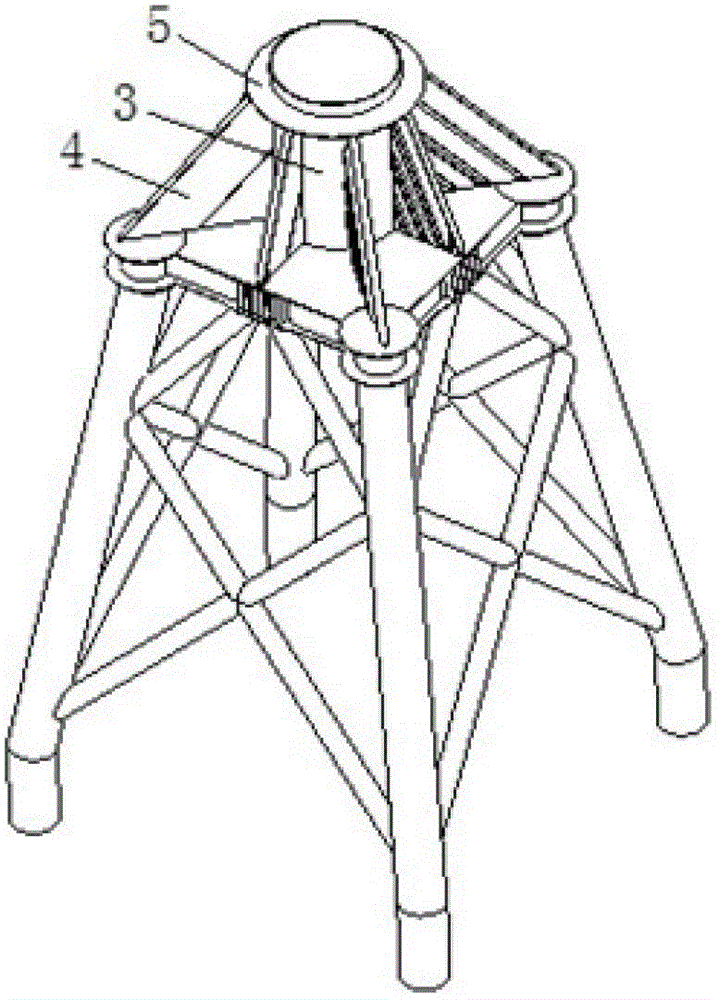

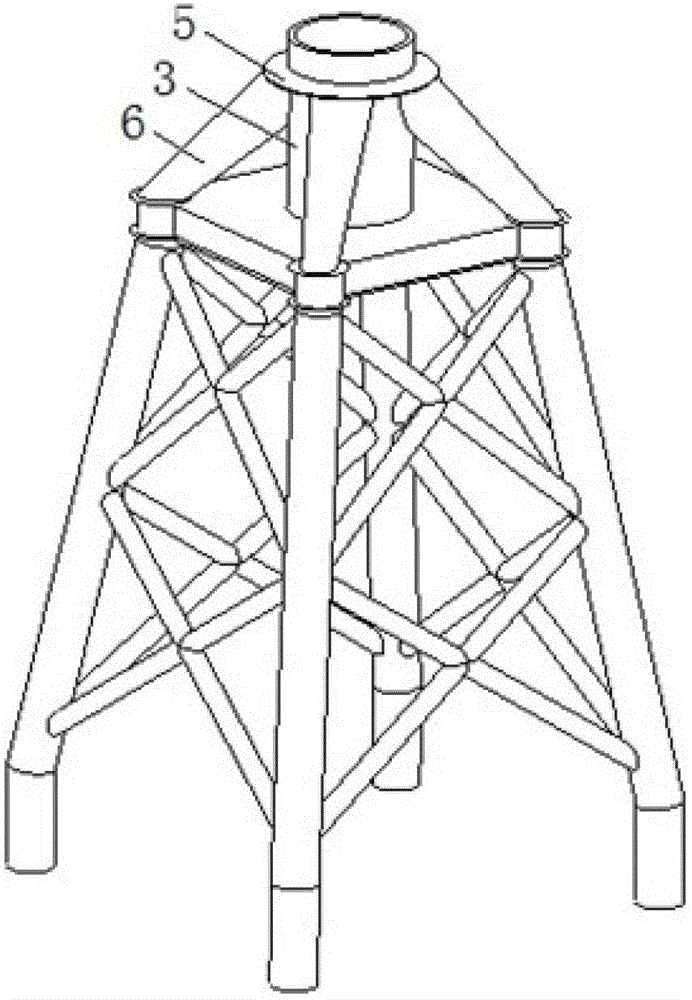

Improved connection structure for WTGS (wind turbine generator system) tower and basic connection transition section

InactiveCN103147932ASimple processAccuracy is easy to guaranteeTowersWind motor componentsWind forceElectrical and Electronics engineering

The invention discloses an improved connection structure for a WTGS tower and a basic connection transition section. The structure comprises a comprises a fan base provided with a basic platform; the transition section connected with the tower is arranged on the basic platform; a reinforcing ring is arranged on the transition section; the inner side of the reinforcing ring is connected with the outer wall of the transition section; and the lower side of the reinforcing ring is connected with the basic platform through a plurality of supports. The invention aims at providing the improved connection structure for the WTGS tower and the basic connection transition section. According to the improved connection structure, the reinforcing ring is added in a connection position of the transition section and the supports and is connected with the supports and the transition section directly, therefore, the connection rigidity between the upper ends of the supports and the transition section is enhanced, the load of a fan can be transmitted uniformly to each support, the stress concentration in the connection position of the upper ends of the supports and the transition section is reduced, and the bending and torsion resistant capacities of the tower and the basic connection transition section are improved.

Owner:GUANGDONG MINGYANG WIND POWER IND GRP CO LTD

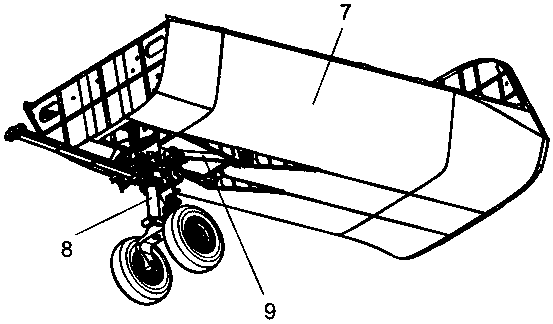

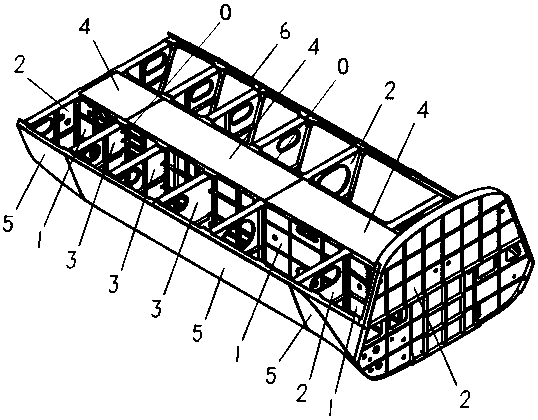

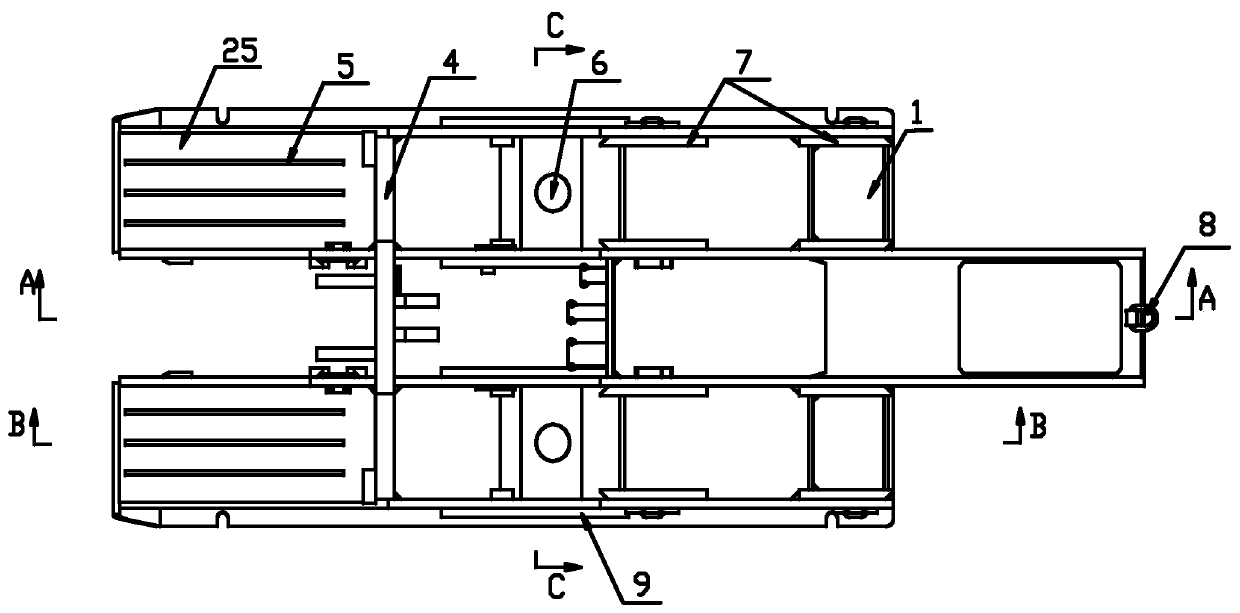

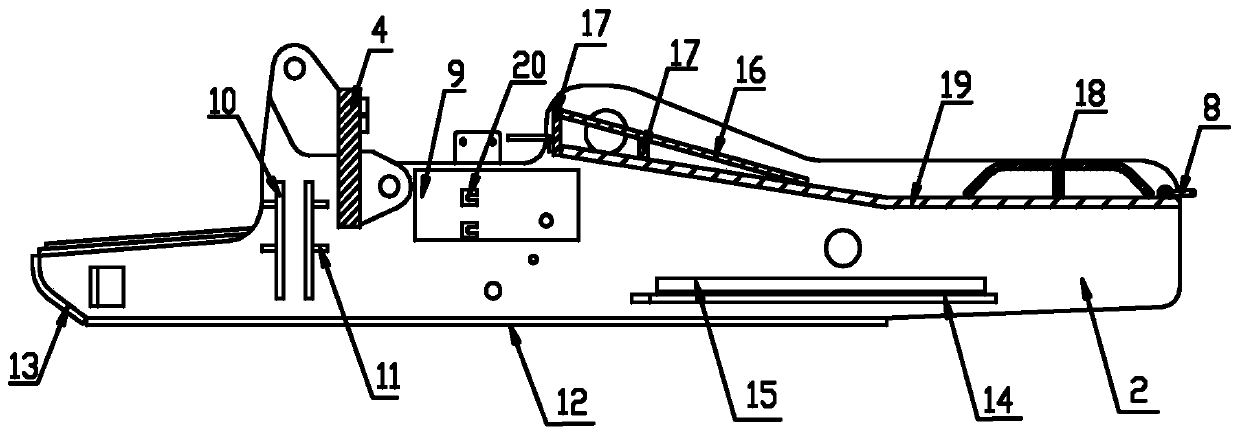

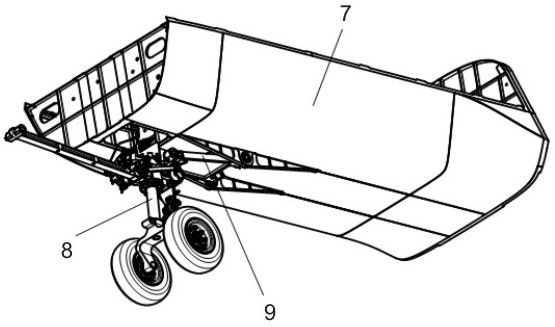

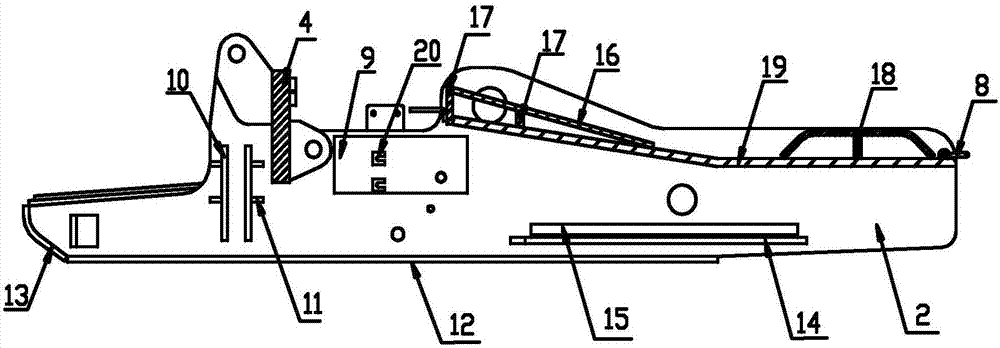

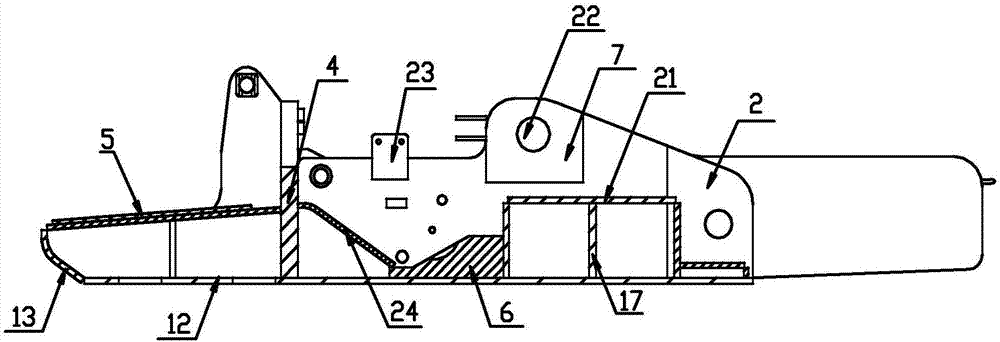

Drone noselanding gear well section based on catapult-assisted take-off

ActiveCN107891965AThe overall structure is light in weightReduce loadFuselage framesFuselage bulkheadsCatapultWall plate

The invention discloses a drone noselanding gear well section based on catapult-assisted take-off. A landing gear well comprises partition frames at the two ends, a girder connected with the partitionframes and a skin; a landing gear fixing compartment is arranged in the middle of the landing gear well, a framework of the landing gear fixing compartment comprises four main girders, the main girders are fixedly connected with the partition frames, and partition plates are arranged at both the two sides of each main girder and the partition frames; the main girders and the partition plates forman integrated wall plate girder, the wall plate girder is hinged to a landing gear main support and a landing gear slant supporting rod, and openings are formed in the skin at the lower portion of the landing gear fixing compartment. The landing gear well is of a box body type structure low in structural weight, the openings are formed among the main girders, the rigidity of other parts of the landing gear well and the rigidity of an overall aircraft cannot be lowered, and additional strength reinforcement setting is also not needed; the wall plate girder penetrating through the whole box body has the advantages of being continuous in stress and short and direct in force transmitting path, and transmitting of instantaneous impact large loading concentrated force and torque inside the structure is benefited.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

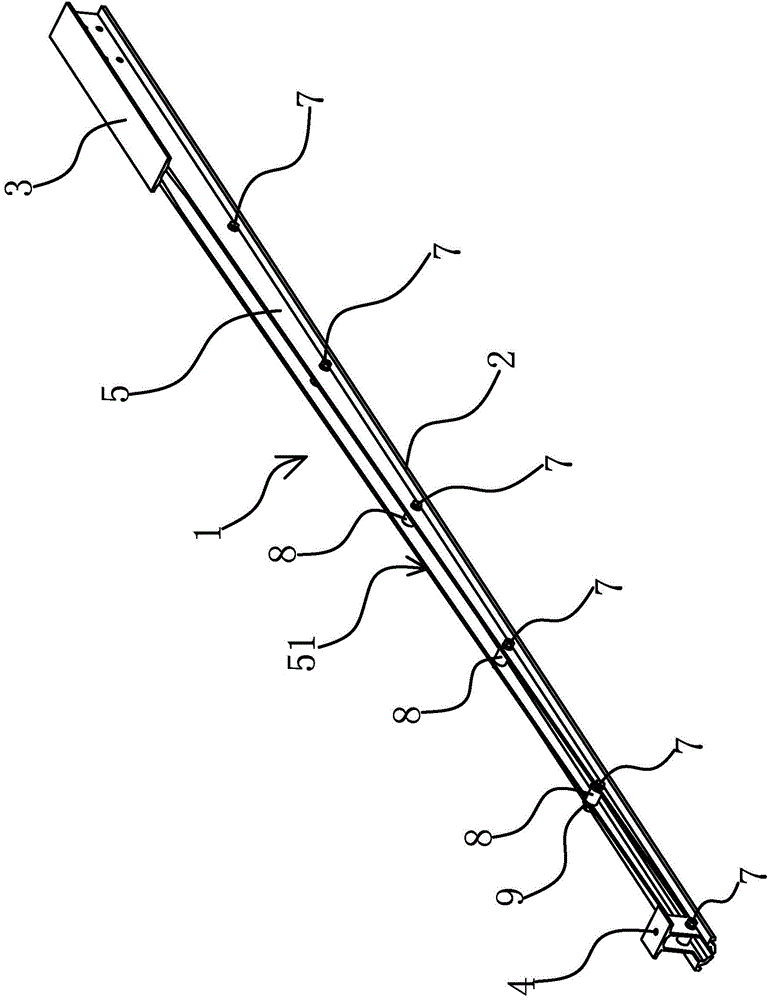

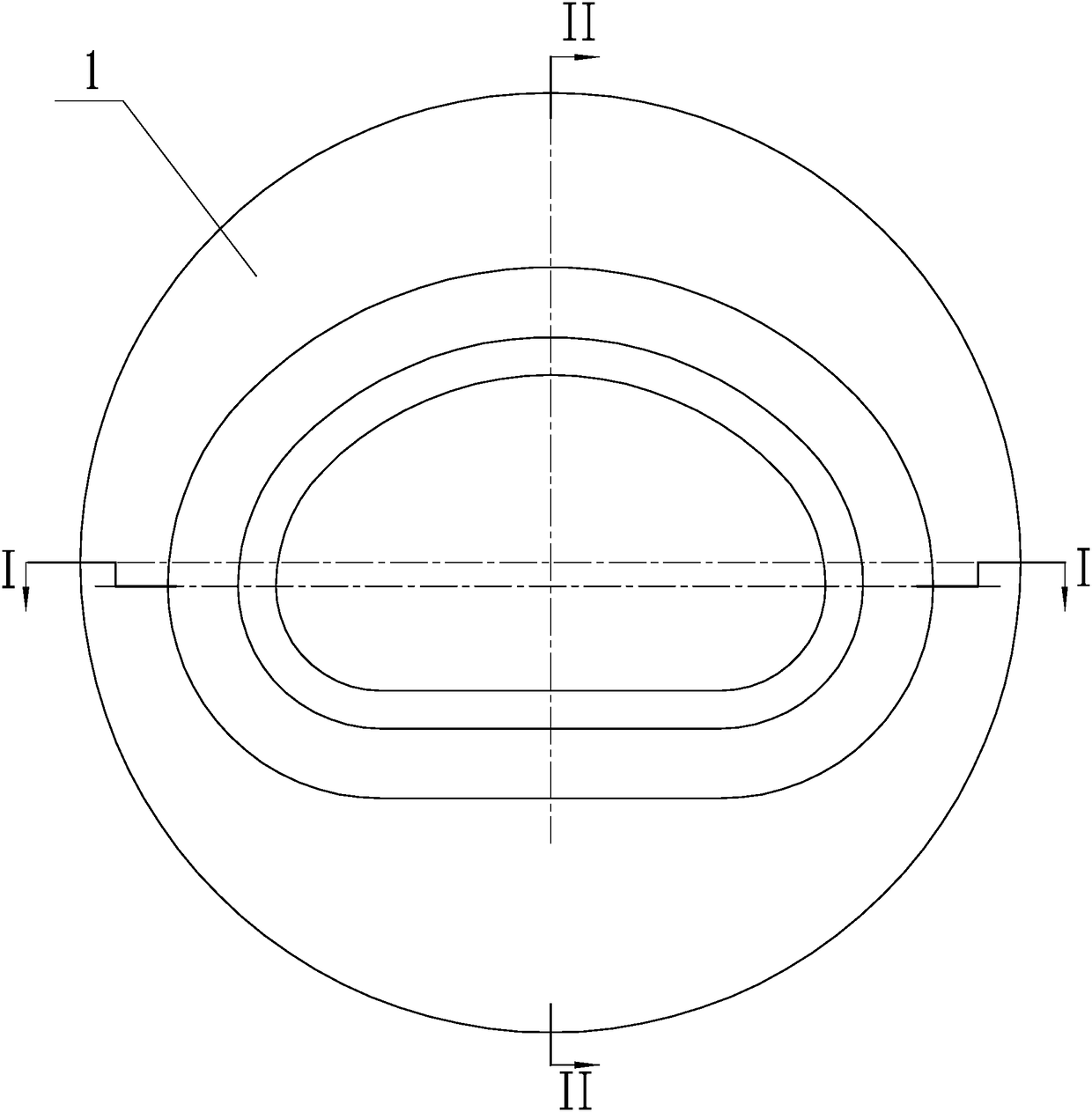

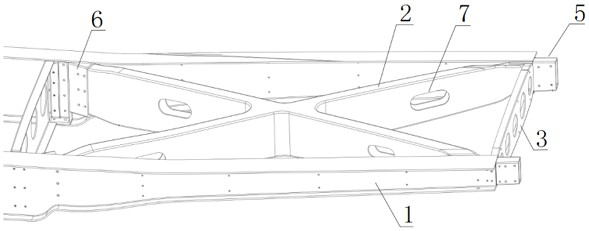

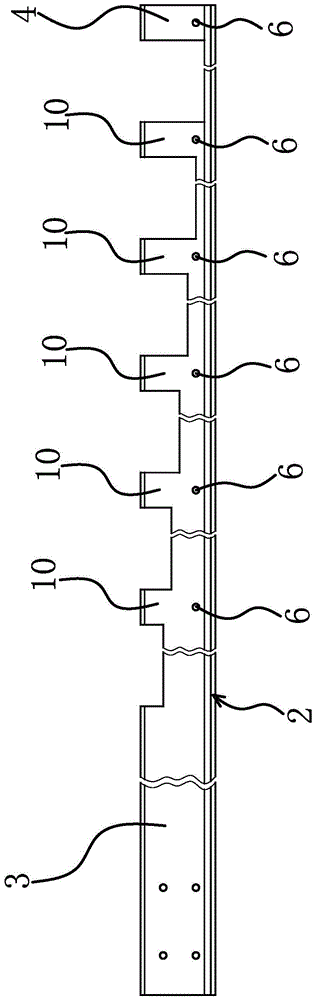

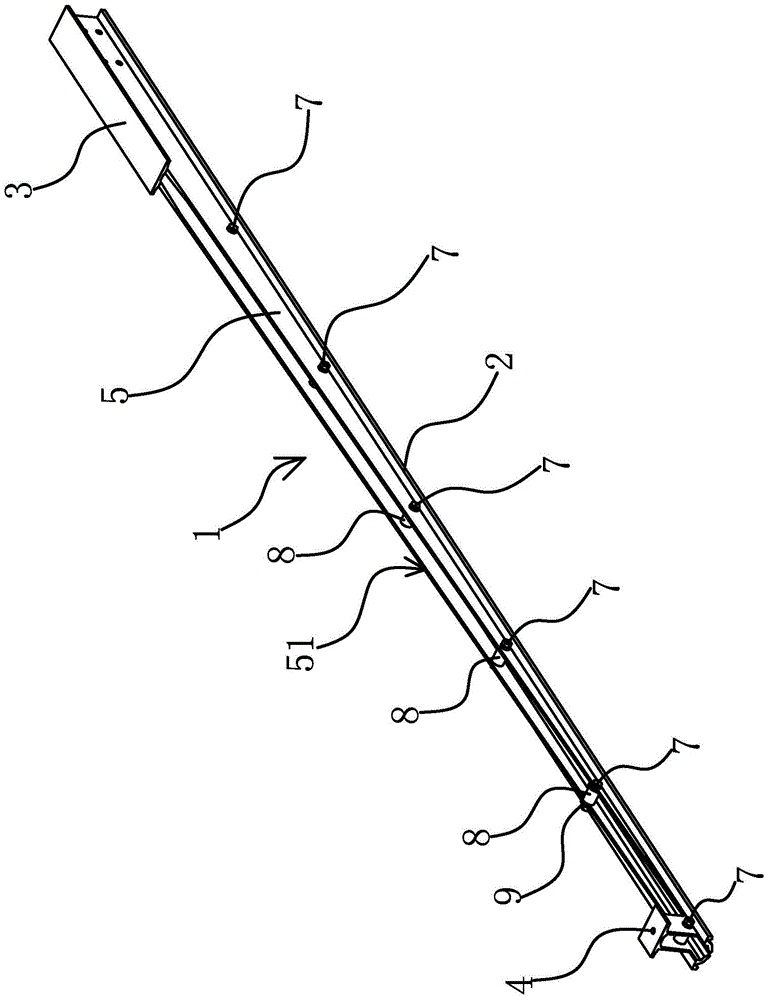

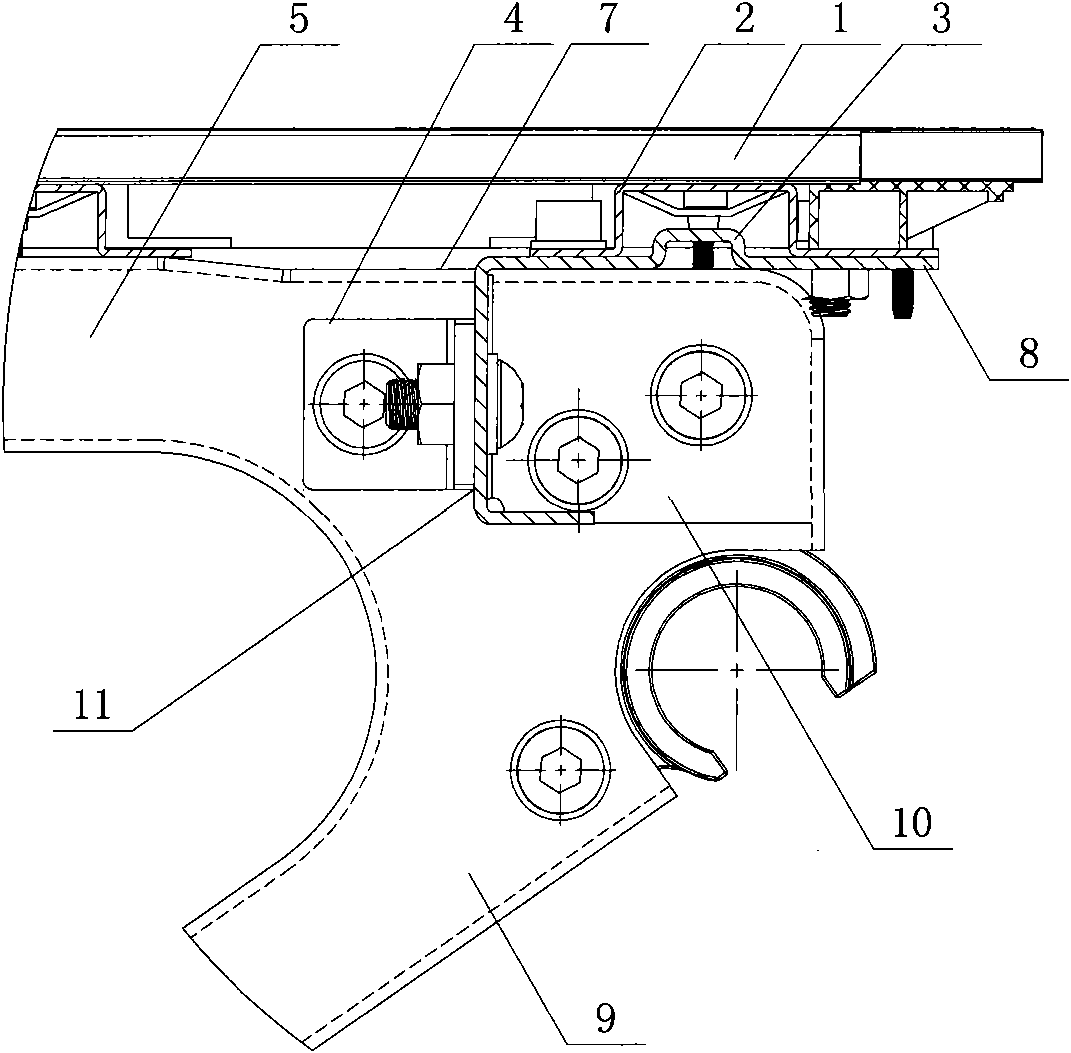

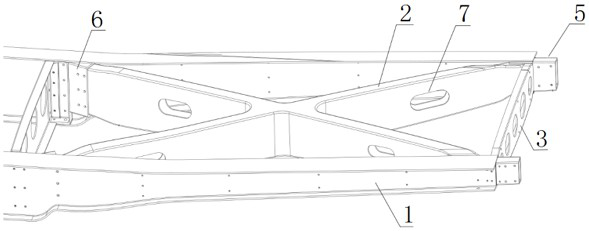

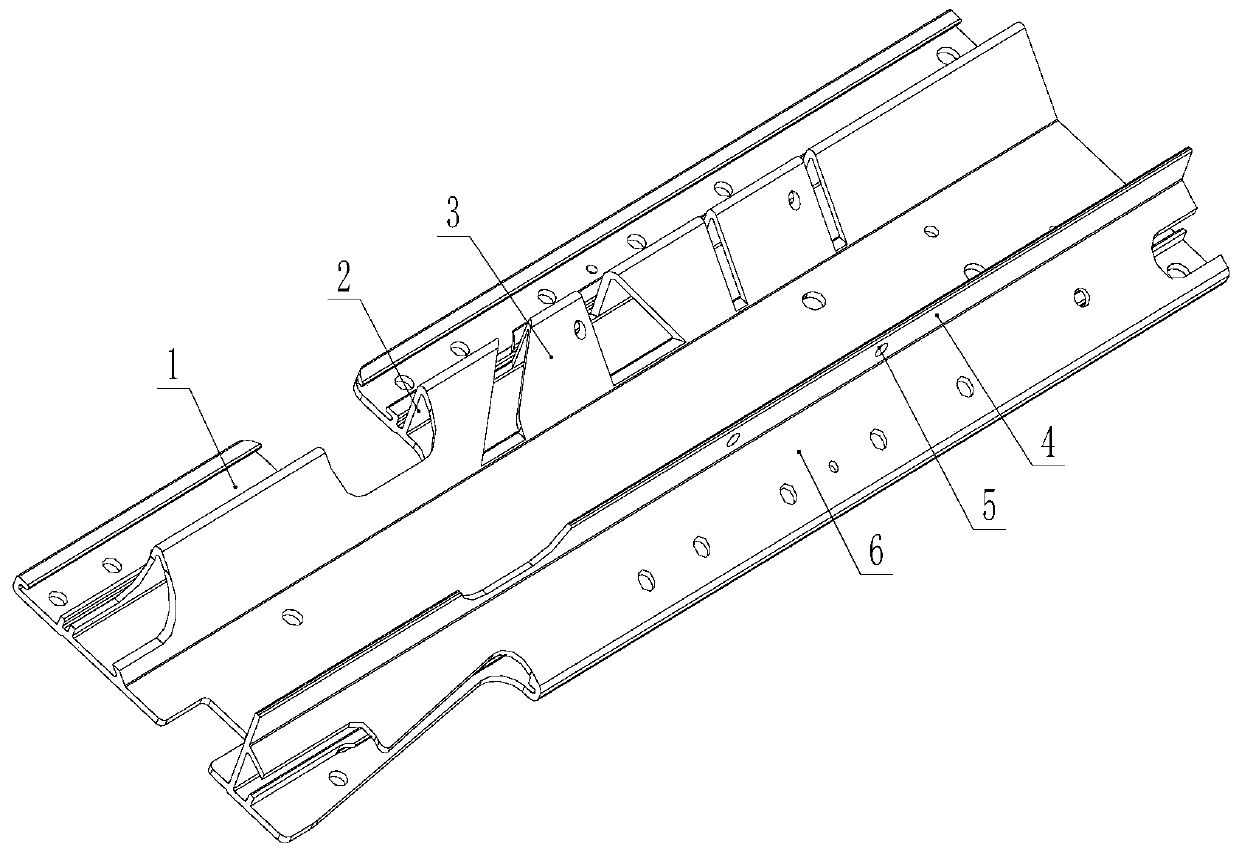

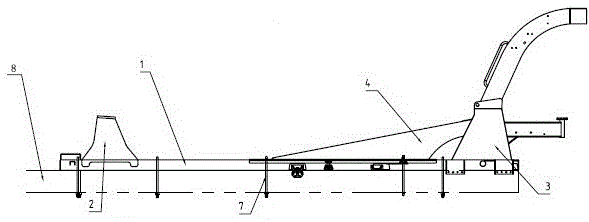

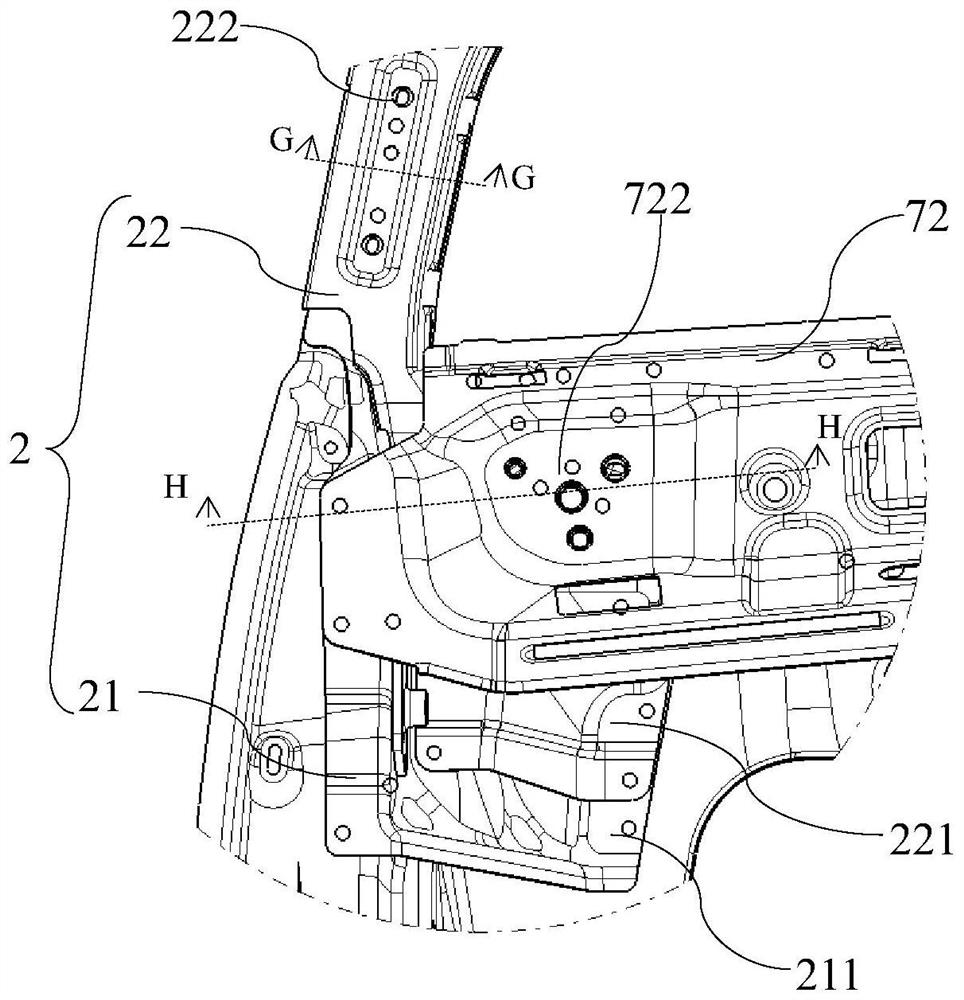

Frame structure and automobile with frame structure

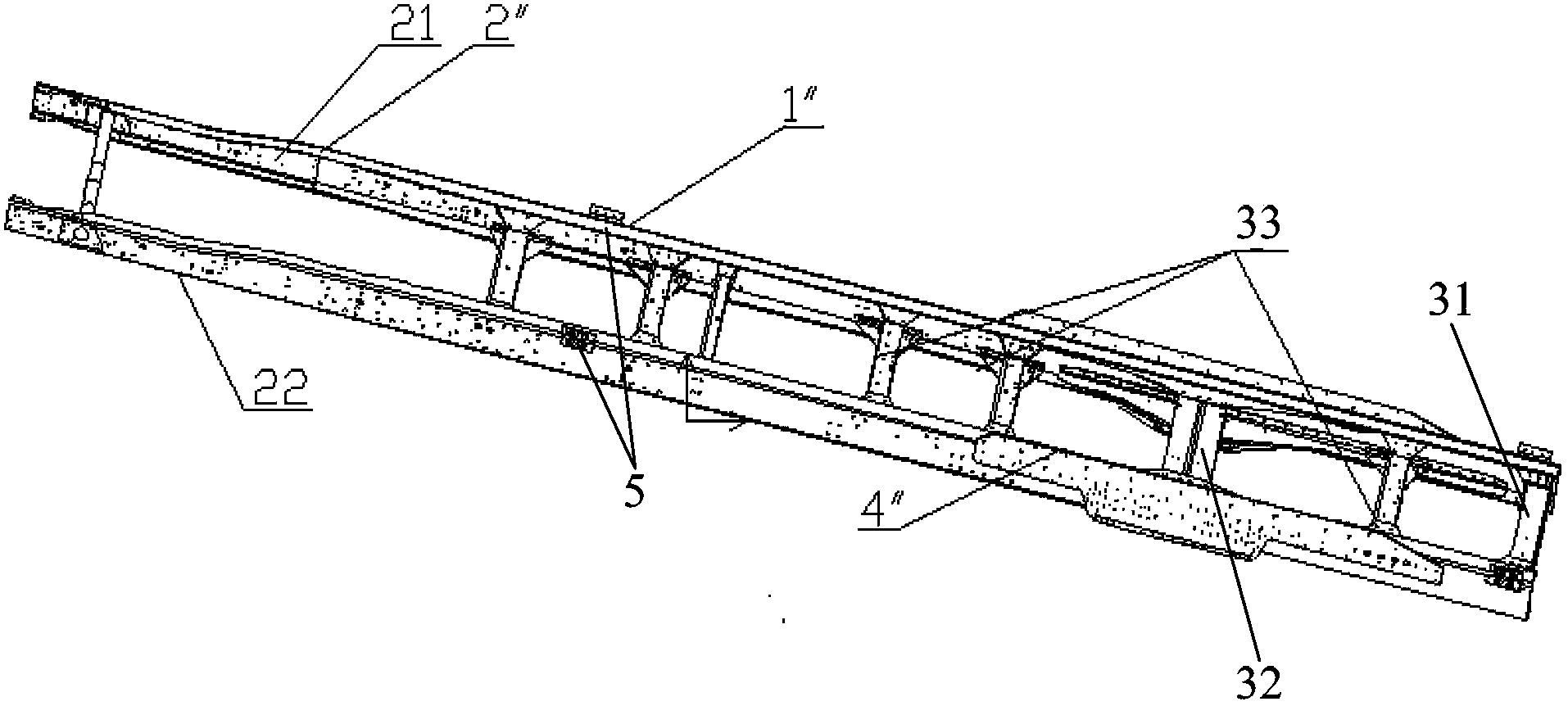

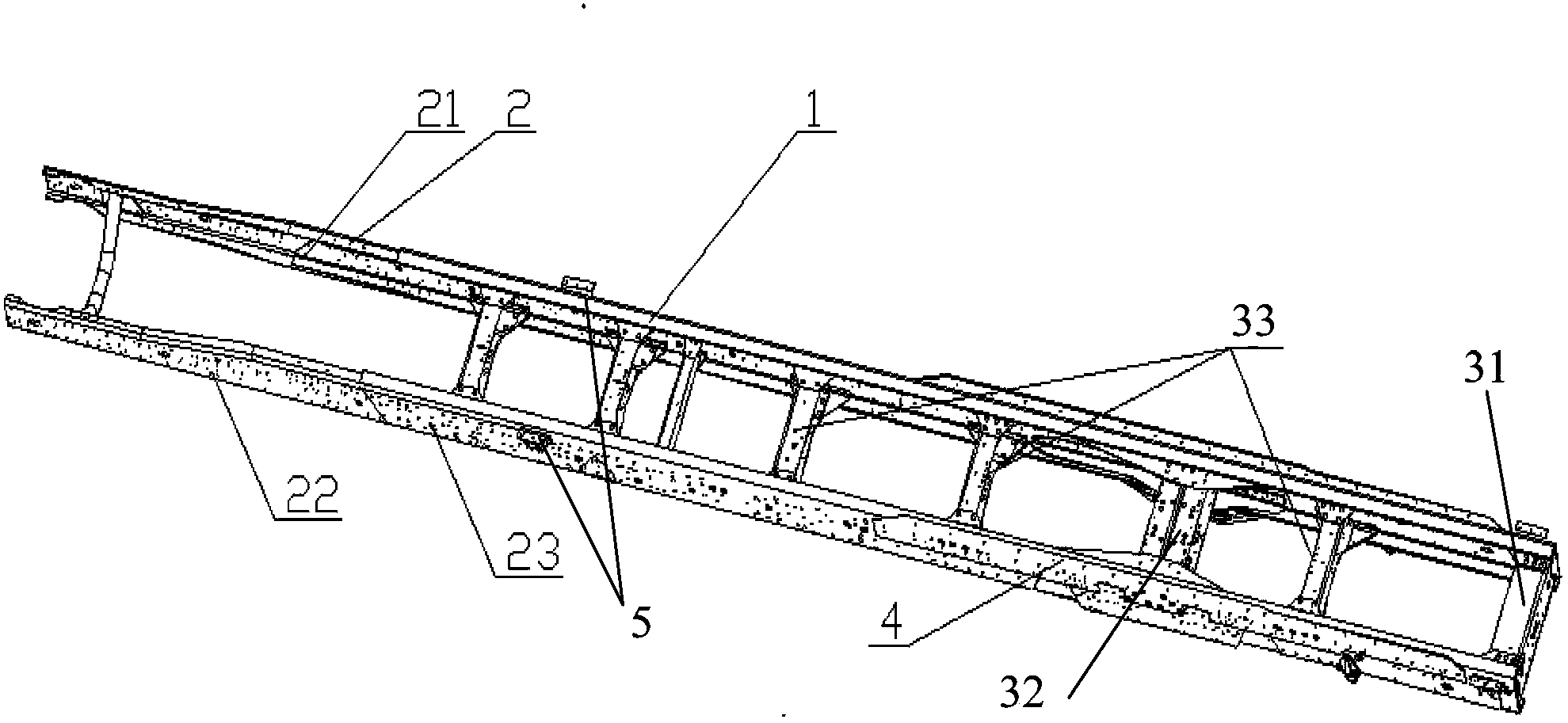

ActiveCN103538628ASimple structureImprove bending and torsional performanceUnderstructuresVehicle frameEngineering

The invention provides a frame structure (1). The frame structure (1) comprises two longitudinal beam assemblies (2), a rear tail beam (31), a balancing suspension cross beam (32) and at least one common cross beam (33), wherein the longitudinal beam assemblies (2), the rear tail beam (31), the balancing suspension cross beam (32) and the at least one common cross beam (33) form a framework structure. Each longitudinal beam assembly (2) comprises a variable cross section longitudinal beam (22), a lining beam (21) and an outer reinforcing beam (23), wherein the lining beam (21) is fixed to the inner side of the variable cross section longitudinal beam (22), the tail portion of the lining beam (21) stretches to the tail end of the frame, and the front portion of the lining beam (21) stretches to the variable cross section; the outer reinforcing beam (23) is fixed to the outer side of the variable cross section longitudinal beam (22), the tail portion of the outer reinforcing beam (23) stretches to the tail end of the frame, and the front portion of the outer reinforcing beam (23) goes beyond one mounting front end locating point (5).

Owner:BEIQI FOTON MOTOR CO LTD

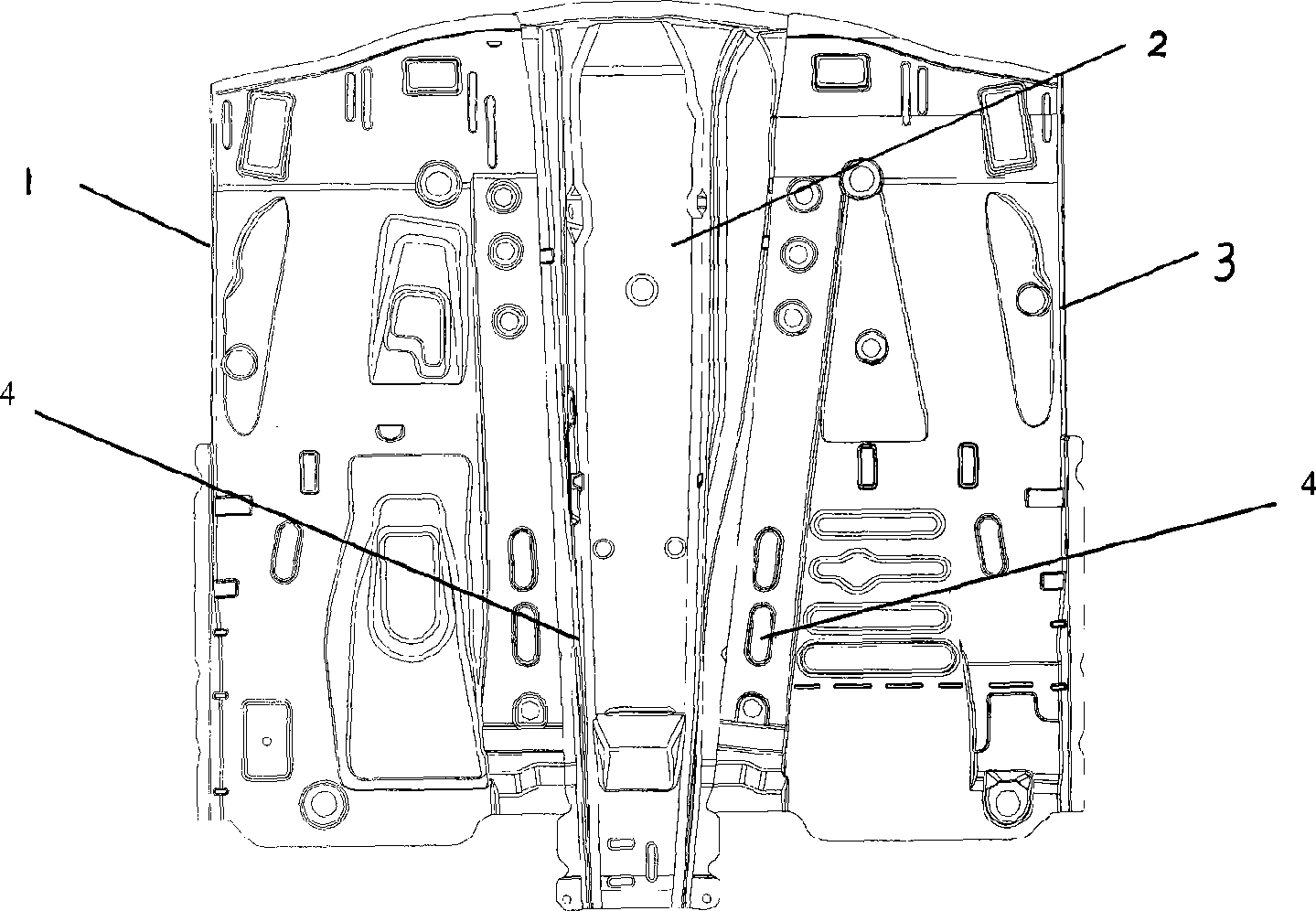

Partition organization for front floor of vehicle body

InactiveCN101428648AHigh strengthImprove rigiditySuperstructure subunitsStructural engineeringSpot welding

The invention relates to a front floor partition structure of a vehicle body. A front floor is divided into the following three parts: a left front floor, a middle bulge of the front floor and a right front floor which are connected into a whole through spot welding to form the front floor. The middle bulge of the front floor has convex-shaped cross section, and has variable-cross section structure with gradually decreased cross section from one end to the other end. After the partition mode is adopted, the different requirement of each block on the material is optimized, and the rigidity of the entire front floor is improved. At the same time, the partition structure is more favorable for the shaping of a single block, is convenient for workers to transport after the area is reduced, and also reduces the requirement on the equipment. In addition, because being independent after partitioning, the middle part of the floor acts as a beam, and the convex-shaped variable-cross section design of the bulge in the front floor improves the bending resistance and torsional resistance. Furthermore, the invention is more favorable for protecting the safety of people.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

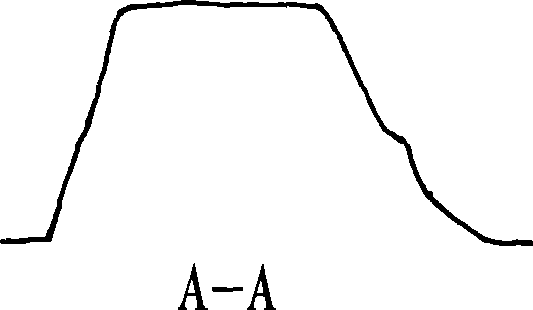

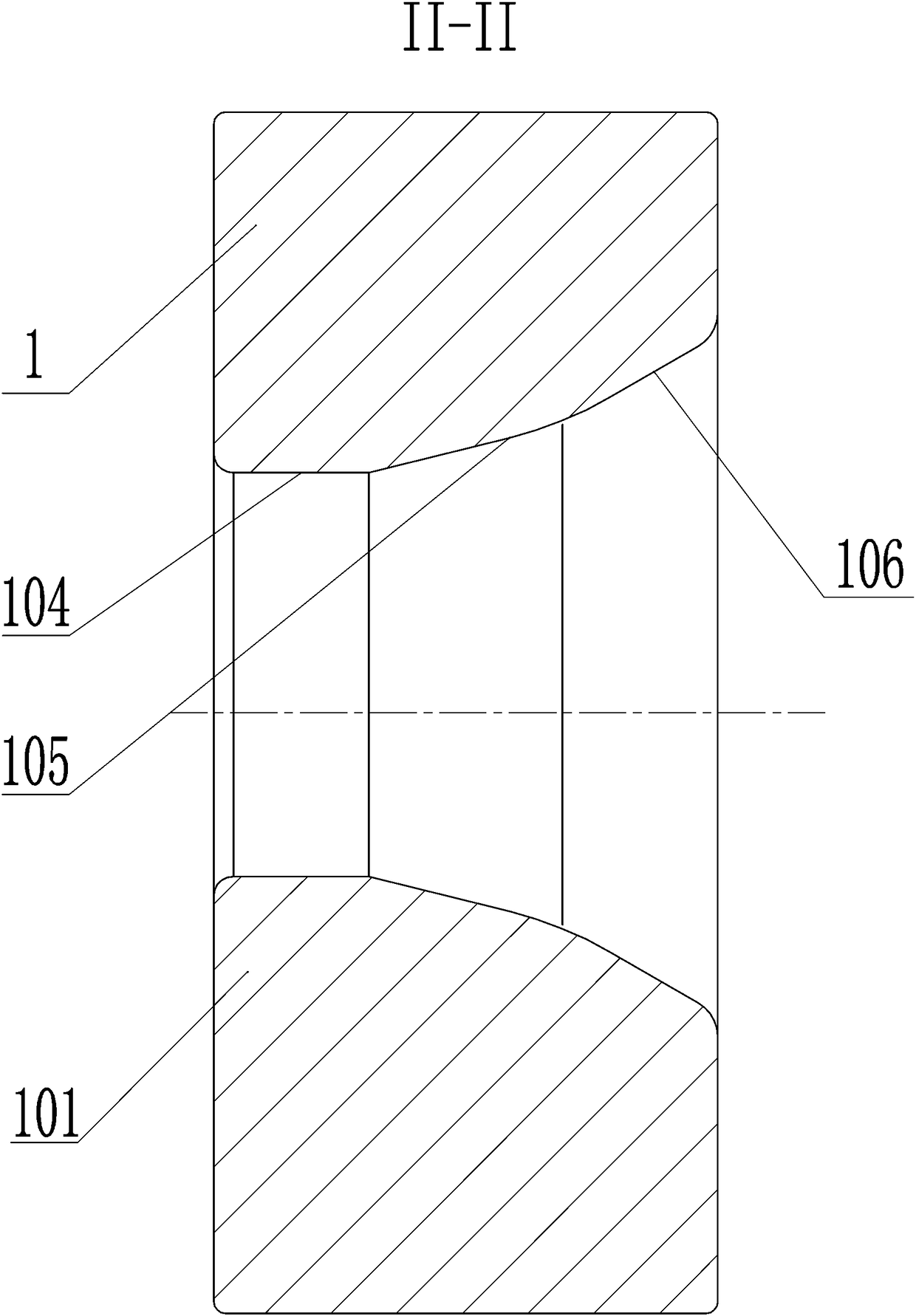

High-precision and high-strength cold-drawing forming die for special-shaped D-shaped pipe

InactiveCN108687148AQuality improvementHigh tensile strengthDrawing diesUltimate tensile strengthMachining

The invention discloses a high-precision and high-strength cold-drawing forming die for a special-shaped D-shaped pipe. The high-precision and high-strength cold-drawing forming die comprises an outerdie body and an inner die body, and the outer die body comprises an outer die main body. The outer die main body is of an axisymmetric structure, the overall shape structure of the outer die main body is a cylinder, and a forming die cavity is machined in the center of the outer die main body. The first circular-arc inlet section is machined on the section inner contour in the forming die cavity,wherein the section inner contour penetrates through the symmetry axis of the forming die cavity and is parallel to the forming die cavity. The first circular-arc inlet section is in transition connection with the first circular-arc transition section, and the other end of the first circular-arc transition section is in transition connection with the first straight section. By adopting the high-precision and high-strength cold-drawing forming die as well as a cold-drawing auxiliary process, the special-shaped D-shaped pipe can be machined and produced, and then steel pipes of various specialshapes or special properties on oil downhole tools and construction machines can be machined. Complex machining can be simplified, the structural weight is greatly reduced, steel is saved, and throughmachining hardening, the strength of finished pipe metal is greatly improved.

Owner:宜昌中南精密钢管有限公司

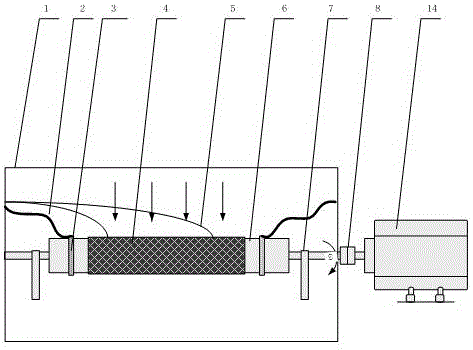

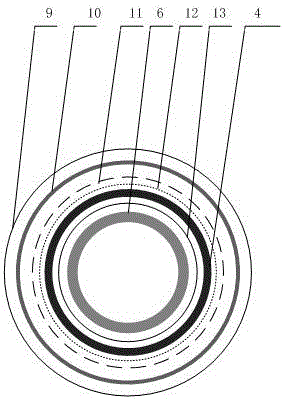

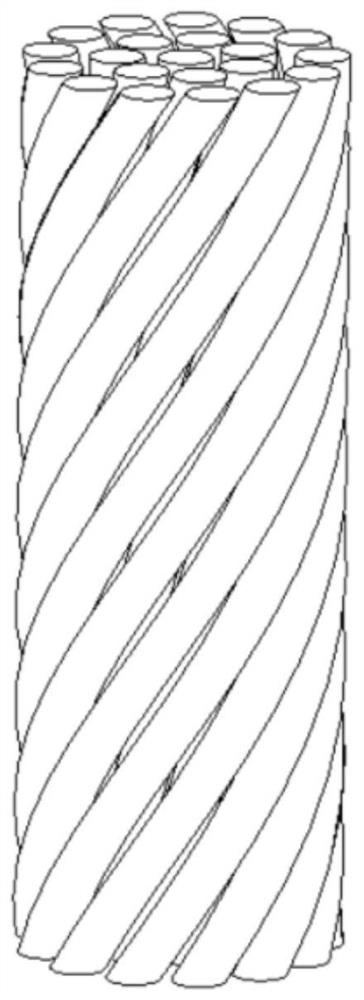

Microwave curing method and device for composite shaft parts

The invention relates to a microwave curing method and a microwave curing device of a composite shaft part. The method is characterized by comprising the following steps: firstly, laying uncured composite materials on the surface of a smooth mandrel coated with a release agent, so as to form a to-be-cured shaft part, then arranging the to-be-cured shaft part in a vacuum bag in a sleeving manner, sealing both ends of the vacuum bag by high temperature resistant adhesive tapes, then vacuumizing the vacuum bag, so as to compact the to-be-cured shaft part, then putting the compacted to-be-cured shaft part and the mandrel into a microwave curing oven, setting heating parameters of the microwave curing oven according to a composite material heating process, and heating and curing the composite shaft part; after the final heat preservation time is finished, directly moving the shaft part out of the curing oven and cooling in the outdoor environment. The microwave curing method has the advantages of short heating and curing time, low energy consumption, good temperature uniformity and easiness in control.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

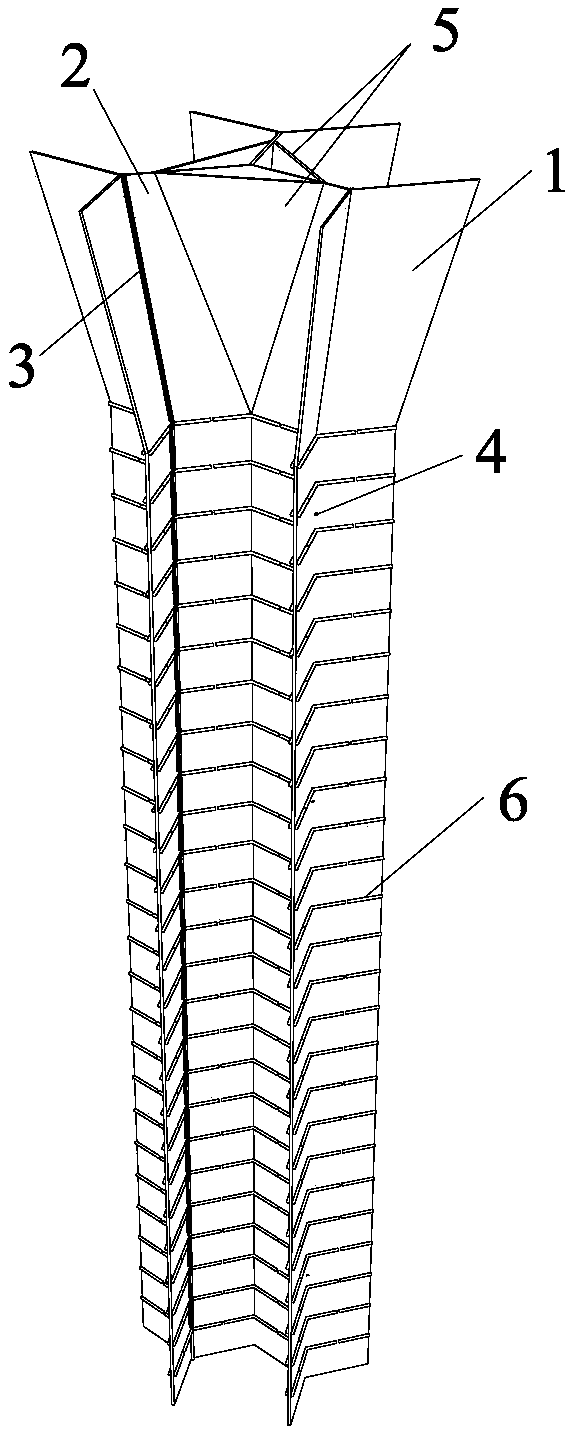

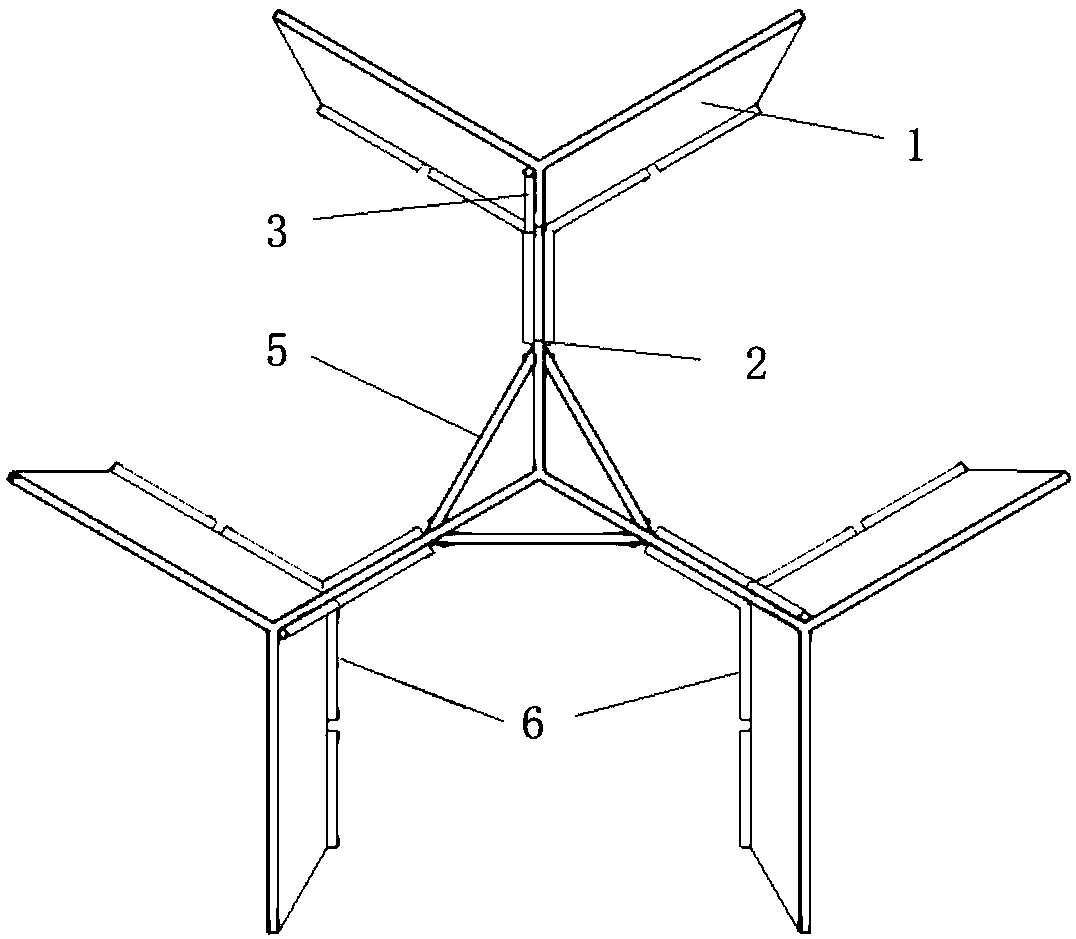

Multi-wing-sheet pile structure applicable to soft soil foundation and construction method

PendingCN108301397AEasy to recycleControl construction qualityBulkheads/pilesStructural engineeringEngineering

The invention discloses a multi-wing-sheet pile structure applicable to a soft soil foundation and a construction method. By means of the multi-wing-sheet pile structure applicable to the soft soil foundation and the construction method, the problem that existing pile forms such as cast-in-place piles or prefabricated tubular piles or sheet piles are not good in sedimentation reduction effect in the soft soil foundation can be solved. The multi-wing-sheet pile structure has the beneficial effect that bending resistance and torsion resistance of the pile structure are improved. According to thescheme, the multi-wing-sheet pile structure applicable to the soft soil foundation comprises three or more inner wing sheets and outer wing sheets, wherein the number of the outer wing sheets is theintegral multiples that of the inner wing sheets; the three inner wing sheets are arranged in the Y form; every two outer wing sheets are connected with the end of the corresponding inner wing sheet,and every two outer wing sheets and the corresponding inner wing sheet are arranged in the Y form; and the multi-wing-sheet pile structure is in rotary arrangement along the lower end points of the Yforms and is in a Y shape or a snowflake shape, and grouting guide pipes are longitudinally arranged at the ends of the inner wing sheets.

Owner:SHANDONG JIANZHU UNIV

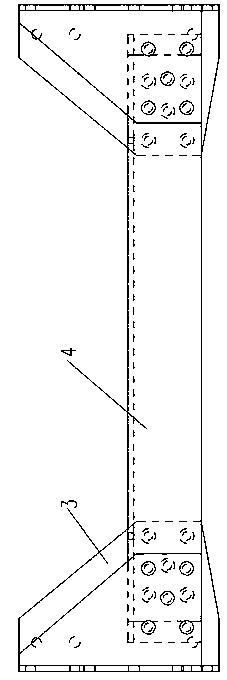

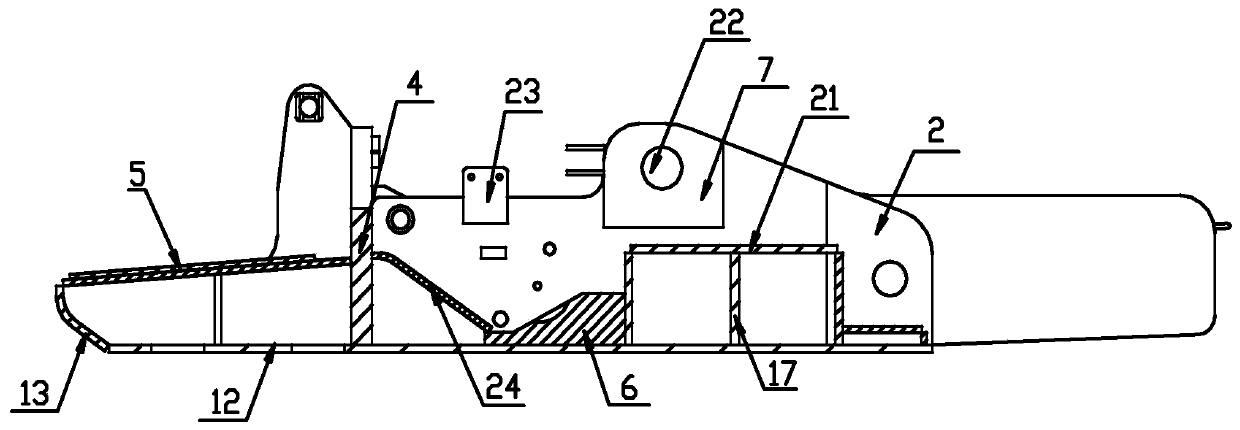

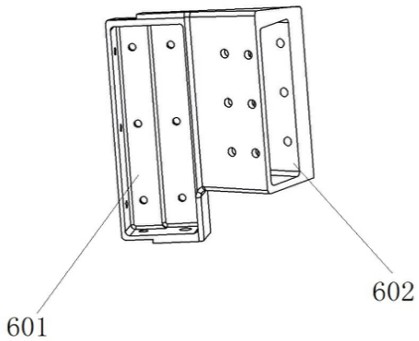

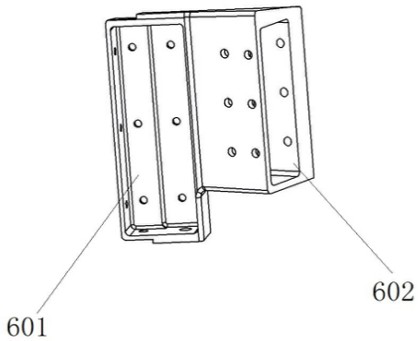

Front spring front support cross beam assembly

InactiveCN103587580AStable supportImprove bending and torsional performanceUnderstructuresVehicle frameRivet

The invention provides a front spring front support cross beam assembly. The front spring front support cross beam assembly comprises a cross beam formed by a section of box iron, two upper wing boards and two lower wing boards. The cross beam comprises an upper leg board and a lower leg board, the upper leg board is arranged over the lower leg board, the upper wing boards and the lower wing boards are all bent boards bent upwards by 90 degrees and respectively comprise a vertical portion and a transverse portion, the two upper wing boards are arranged opposite to each other, the vertical portions of the two upper wing boards are arranged on the outer sides of the transverse portions of the two upper wing boards, the transverse portions of the two upper wing boards are riveted to the two end portions of the upper leg board respectively through rivets, the two lower wing boards are arranged opposite to each other, the vertical portions of the two lower wing boards are arranged on the outer sides of the transverse portions of the two lower wing boards, the transverse portions of the two lower wing boards are riveted to the two end portions of the lower leg board respectively through rivets, the two upper wing boards are arranged over the two lower wing boards respectively and correspondingly, and the two upper wing boards and the two lower wing boards are respectively provided with a bolt hole used for being connected with frame bolts. The front spring front support cross beam assembly can play the role in reinforcing the cross beam of a frame, effectively support a left front spring front support and a right front spring front support, and greatly improve the bending-resisting capability of a whole vehicle chassis.

Owner:SINO TRUK JINAN POWER

Front end cross beam of stainless steel staircase step

InactiveCN101570301AImprove bending abilityEffective control of assembly accuracyEscalatorsShaped beamStructural engineering

The invention relates to a front end cross beam of a stainless steel staircase step, in particular to a front end cross beam of a split assembled step, and belongs to the field of escalator manufacture. The lower part of a lath shaped beam body is provided with a first support reinforcing surface vertical to the beam body and a second support reinforcing surface parallel to the beam body respectively; and the cross sectional shape of the cross beam is a semi-closed shape surrounded by the lath shaped beam body, the first support reinforcing surface and the second support reinforcing surface, and each surface is formed by continuously bending. The invention solves the technical problem and provides the technical task that the front end cross beam overcomes the defects that the front end cross beam structure of the prior stainless steel staircase step has poor bending resistance and torsional property and has no or indefinite assembly standard, and provides the front end cross beam with definite anti-deforming aim, rigidity and strength meeting standard code requirements, and definite assembly and positioning standards.

Owner:SUZHOU BENYI MECHANICAL & ELECTRICAL EQUIP

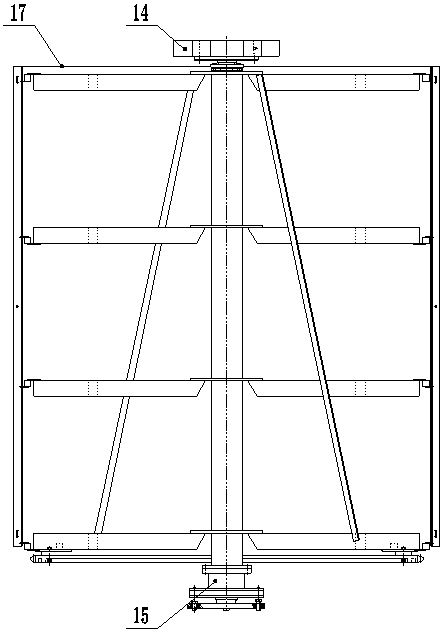

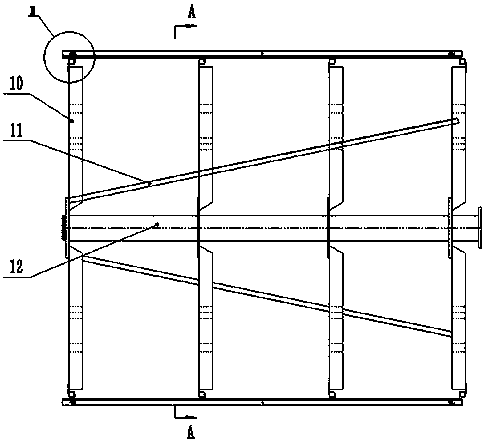

A hydraulic support base

ActiveCN106988771BHigh strengthImprove bending and torsional performanceProps/chocksArchitectural engineeringStructural engineering

Owner:SHANDONG ENERGY HEAVY EQUIPMENT GROUP HENGTU TECH CO LTD

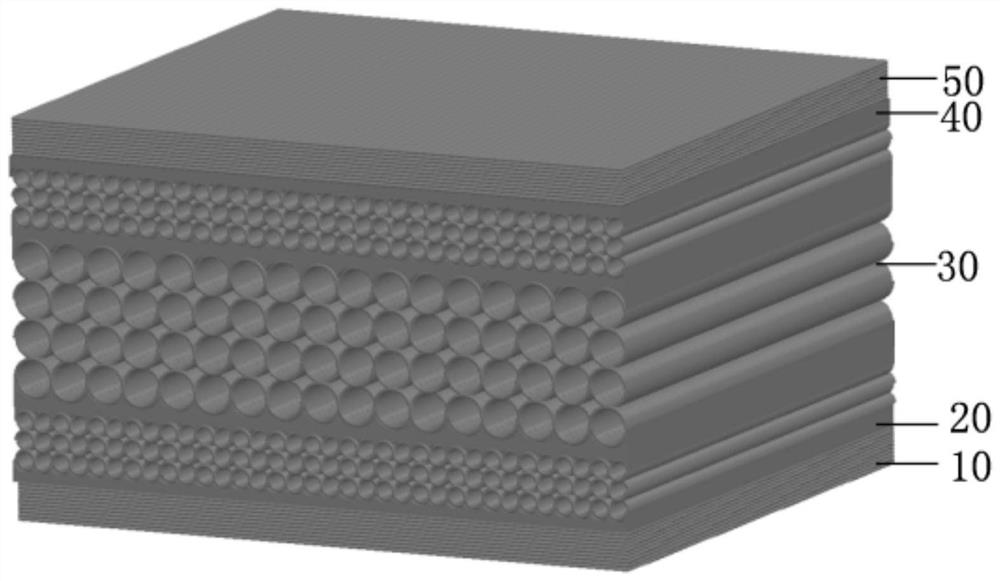

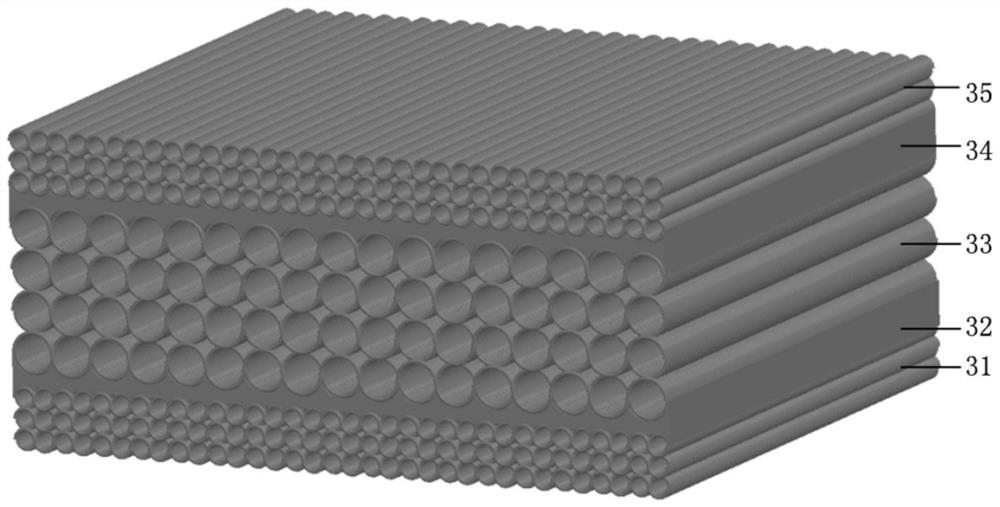

Light anti-bending and anti-torsion bionic composite material and preparation method thereof

ActiveCN112721341AImprove bending and torsional performanceEnhanced interlayer anti-peeling abilitySynthetic resin layered productsLaminationFiberCeramic materials

The invention discloses a light anti-bending and anti-torsion bionic composite material and a preparation method thereof. The composite material comprises a bottom layer, a lower partition plate layer, a hollow structure middle layer, an upper partition plate layer and an outer layer which are sequentially arranged in a stacked mode from bottom to top; the hollow structure middle layer comprises a first-stage dense hole structure, a loose hole upper-layer structure, a first-stage loose hole structure, a loose hole lower-layer structure and a second-stage dense hole structure which are sequentially stacked from bottom to top; and the first-level compact pore structure, the first-level loose pore structure and the second-level compact pore structure are each composed of a woven fiber resin layer, and each woven fiber resin layer is formed by alternately winding weft-wise fibers and warp-wise fibers on a core film. The middle layer of the hollow structure is arranged in the mode that the outside is dense and the inside is sparse, the weight of the material can be reduced, the specific rigidity of the material can be improved, when the material is bent, the upper surface of the middle layer of the hollow structure bears tensile stress, the lower surface of the middle layer of the hollow structure bears tensile pressure, and the bending resistance and toughness of the material are improved.

Owner:JILIN UNIV

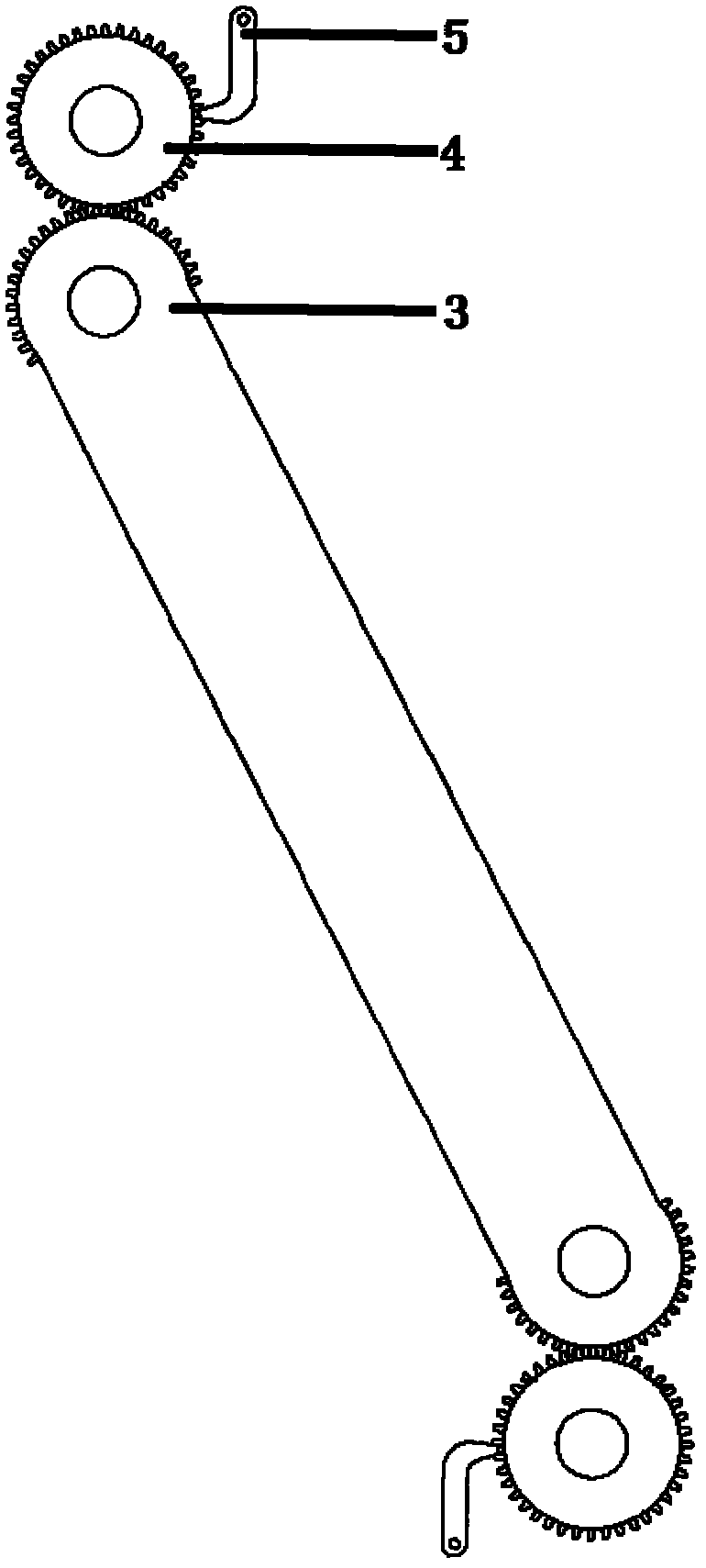

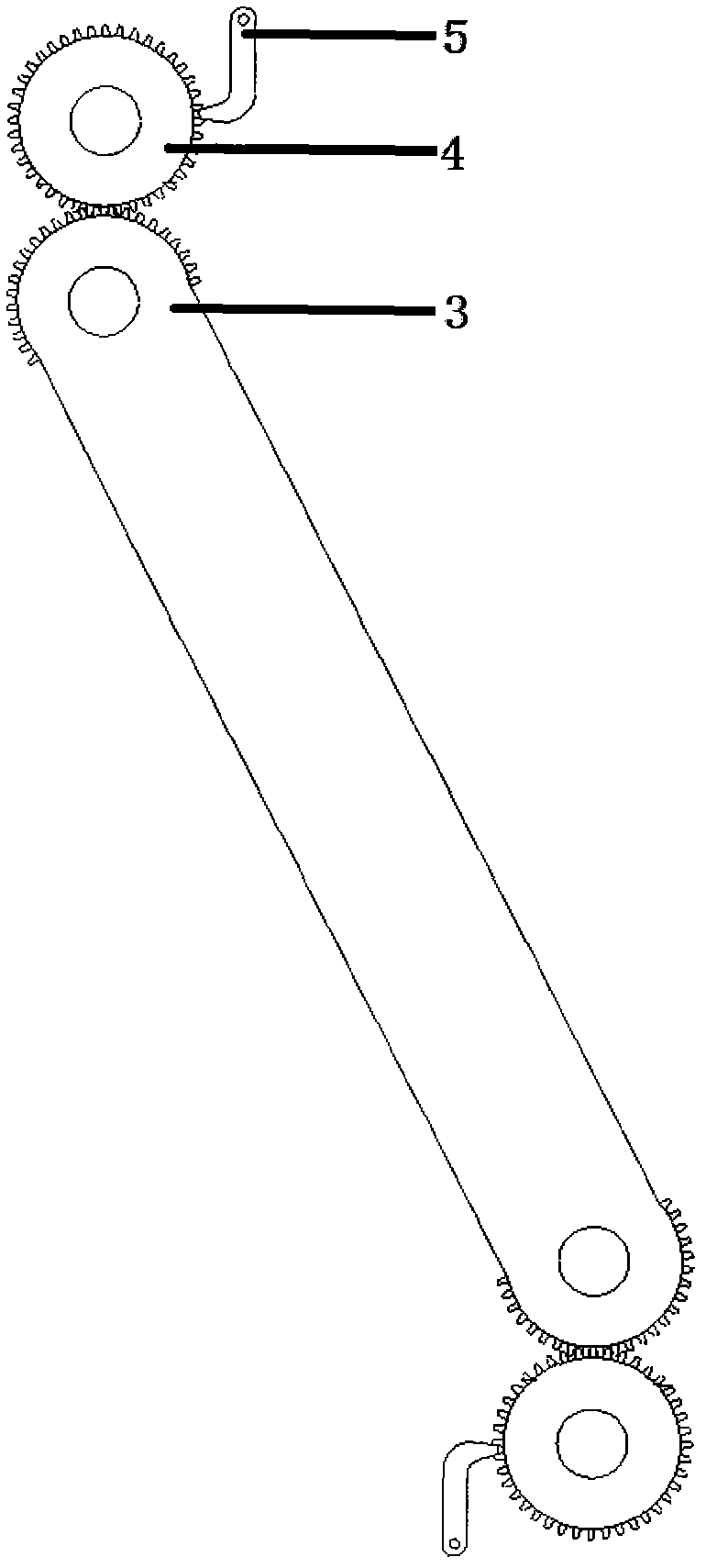

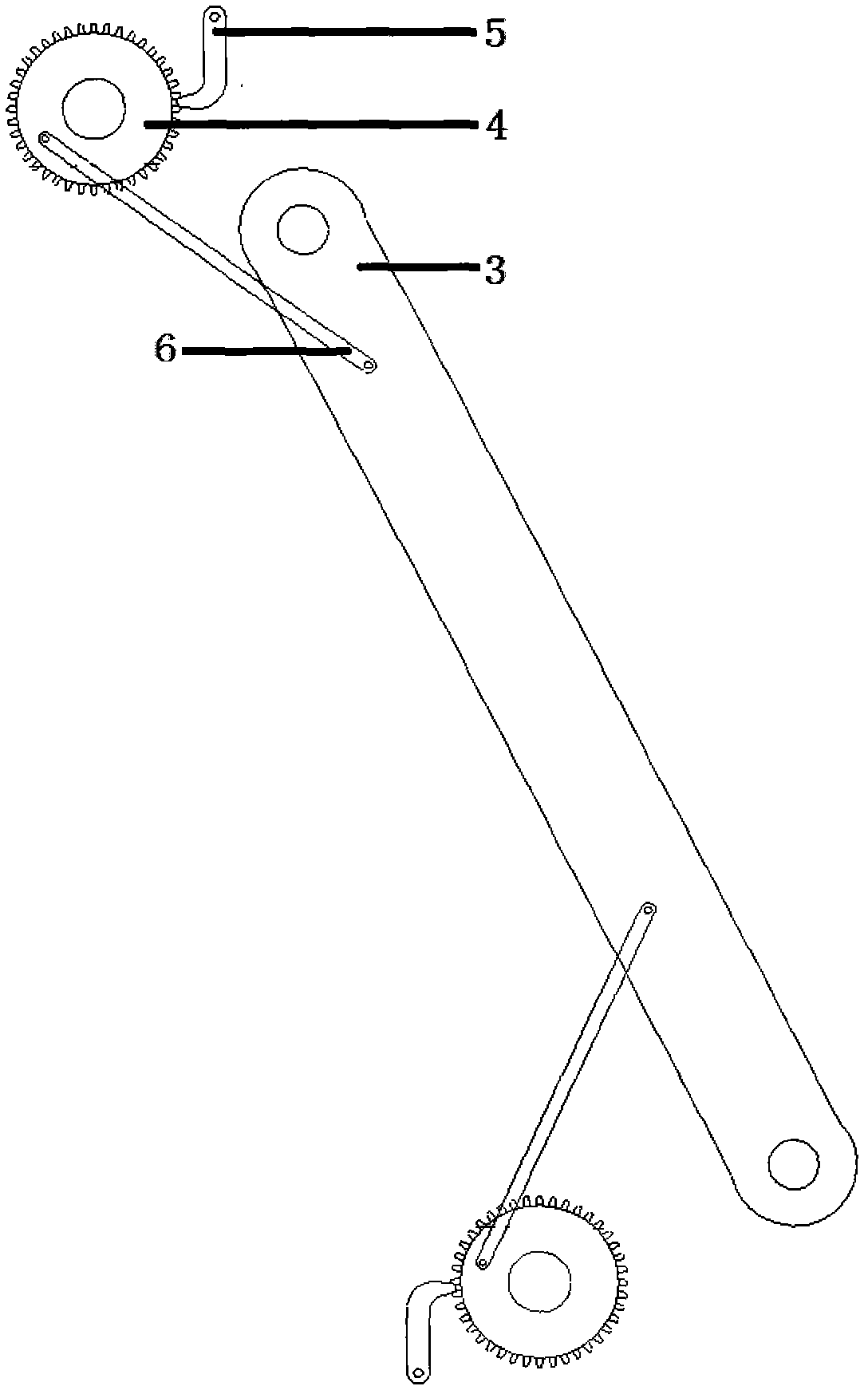

Deformable biplane configuration

The invention provides a deformable biplane configuration. The configuration comprises an upper wing, a lower wing and a plurality of parallel distributed deformation mechanisms, wherein the upper wing and the lower wing are connected through the deformation mechanisms; each deformation mechanism comprises a connecting strut and 1 to 2 motion mechanisms; a drive mechanism and a locking device are arranged on each motion mechanism which is fixed on the upper wing or the lower wing; one end of the connecting strut is mechanically connected with the motion mechanism, while the other end of the connecting strut is mechanically connected with the motion mechanism or fixedly connected with the upper wing or the lower wing; the drive mechanism drives the motion mechanism to drive the connecting strut to ensure that the upper wing and the lower wing rotate in 0 to 180 degrees in the course direction and the height direction; and when the upper wing and the lower wing move to a set position, the locking device locks the motion mechanism, and positions of the upper wing and the lower wing are fixed. Regarding the wing configuration mode of a solar plane, the deformable biplane configuration is adopted, compared with single plane configuration, under a condition that the same wing type, the same wingspan and the same aspect ratio of a single wing are adopted, through the deformable biplane configuration, the takeoff weight can be increased, the effective load can be increased, the induced drag of the wings can be reduced, and the area of a solar cell panel can be increased, so that the solar energy absorption capacity can be improved, and the energy consumption of night flight can be reduced.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

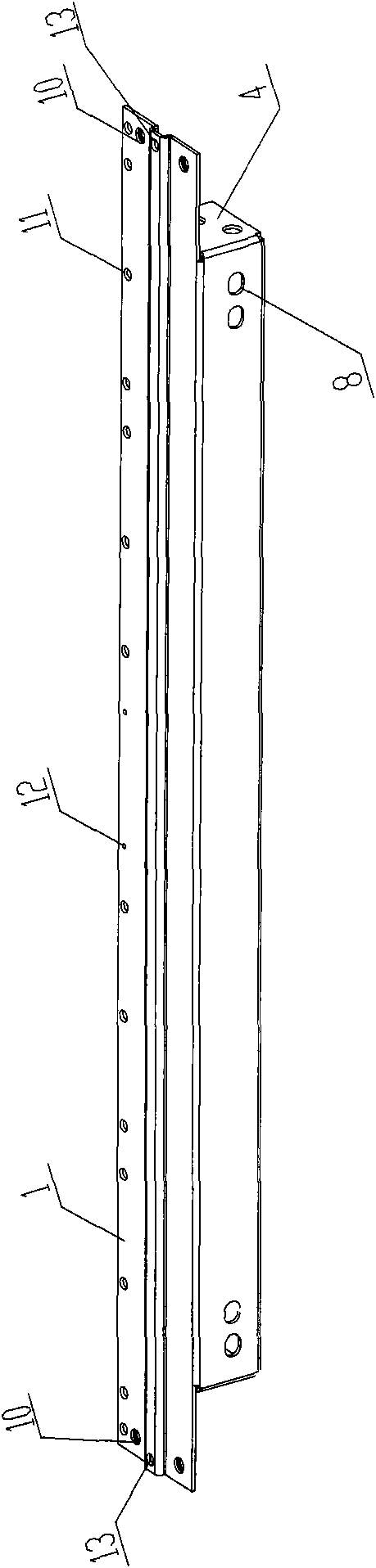

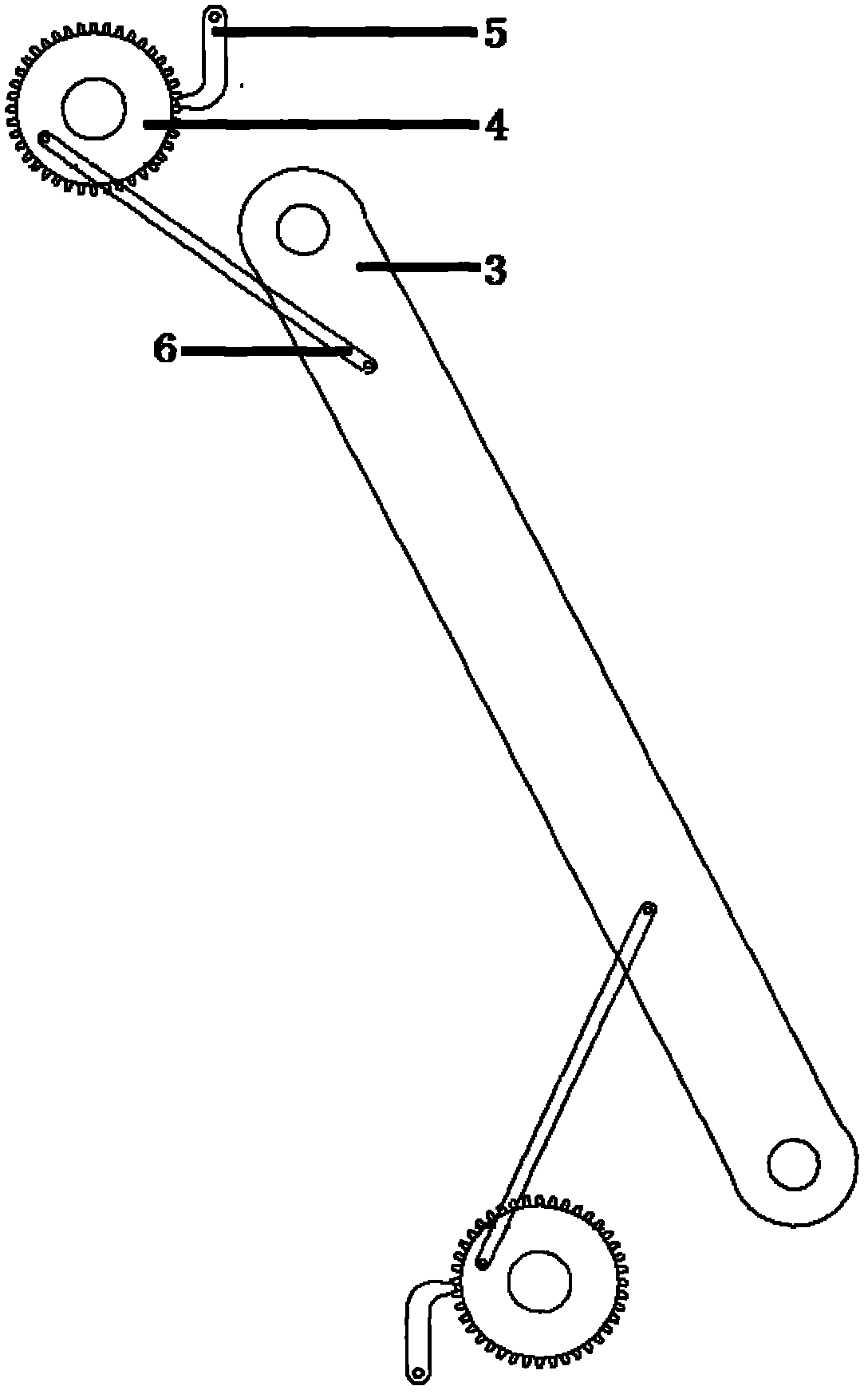

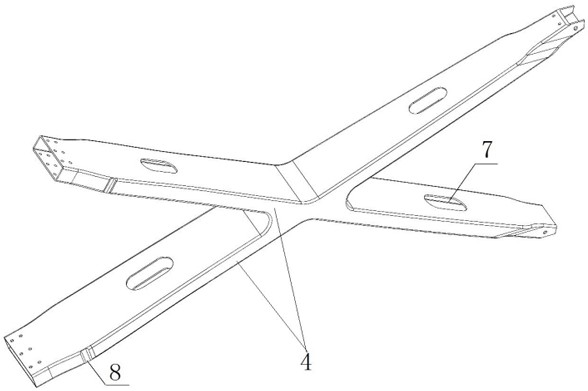

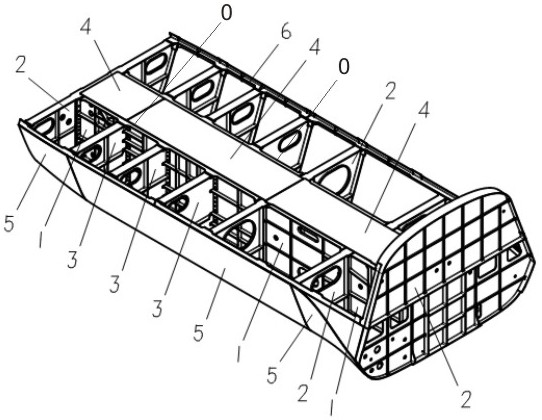

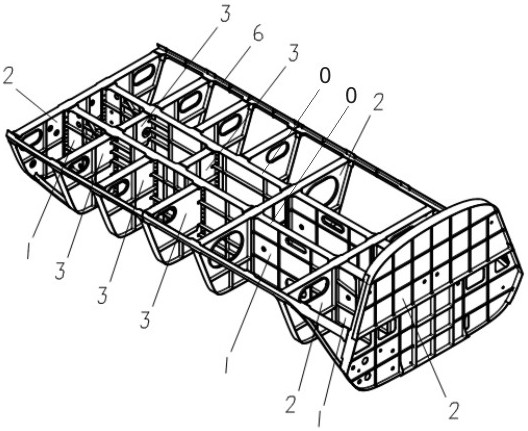

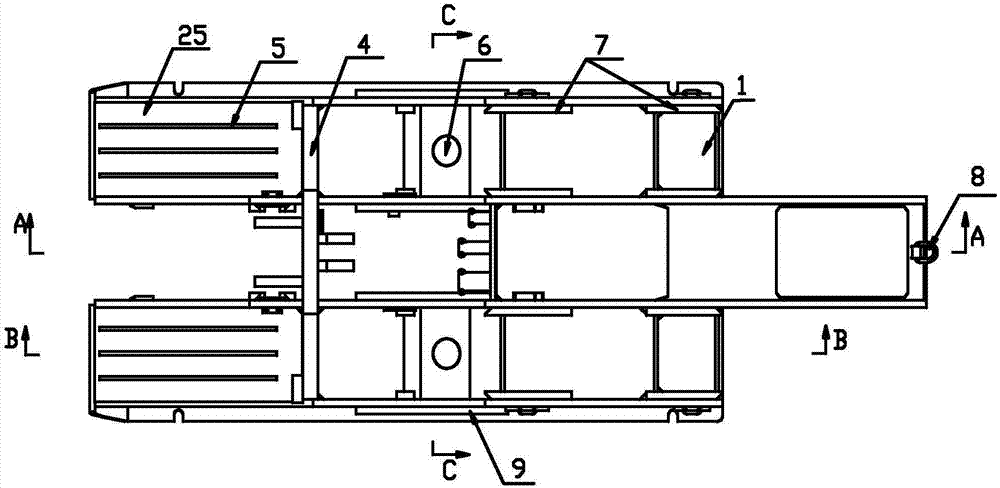

Wing spar of a compound wing aircraft

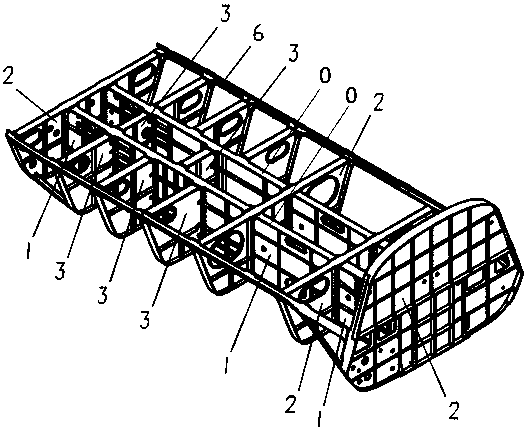

ActiveCN114104261BReduce structural weightImprove bending and torsional performanceSpars/stringersFlight vehicleStructural engineering

The invention discloses a wing spar of a compound-wing aircraft, which comprises two transverse integral beams arranged horizontally opposite to each other, and a cross-type load-bearing beam for carrying bending and torsional moments is arranged between the two transverse integral beams. The interior of the cross-type load-bearing beam is a hollow structure, and the ends of the cross-type load-bearing beam are fixedly connected with two transverse integral beams; both ends of the two transverse integral beams are provided with an end rib for carrying bending and torsional moments. The two transverse integral beams are connected and fixed by two end ribs. The cross-type load-bearing beam has a hollow structure as a whole, which greatly reduces the structural weight of the wing. At the same time, the cross-type load-bearing beam greatly improves the resistance of the load-bearing beam Bending and torsional performance, the cross-type load-bearing beam is equipped with a water channel, which simply and effectively solves the problem of water storage and drainage inside the wing spar, and the addition of end ribs can obtain a lighter weight under the premise of determining a certain bending and torsional strength. the weight of.

Owner:中国空气动力研究与发展中心空天技术研究所

A Rigid-Flexible Transitional Busbar

The invention provides a rigid-flexible transition busbar, which belongs to the technical field of electrified railway and urban rail transit overhead catenary. It solves the problems of transitional hardness and high cost in the existing rigid-flexible transition busbar. The rigid-flexible transitional bus bar includes a bus bar body. The two ends of the bus bar body are respectively a rigid connection end and a flexible connection end. The lower part of the bus bar body has a clamping jaw. The rigid-flexible transition part whose body rigidity gradually decreases, the upper surface of the rigid-flexible transition part is a continuous transition slope; the bus bar body is distributed along the length direction with several connecting through holes passing through the bus bar body, and locks are respectively installed in the connecting through holes. Each locking bolt is covered with a positioning sleeve, and the two end surfaces of the positioning sleeve respectively abut against the inner surface of the main body of the bus bar. The rigid-flexible transitional busbar adopts a continuous transition slope for transition, eliminating hard points in the rigid-flexible transitional busbar.

Owner:浙江旺隆轨道交通设备有限公司

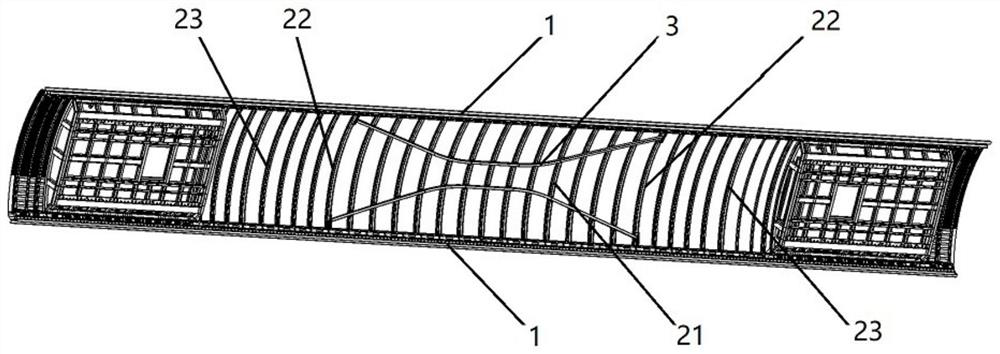

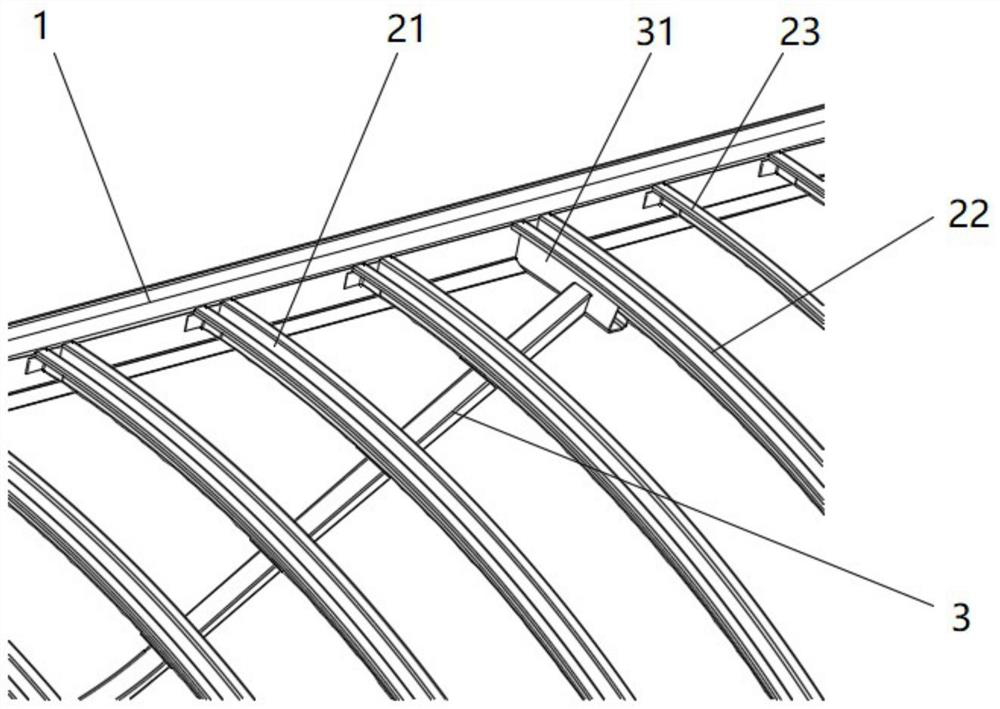

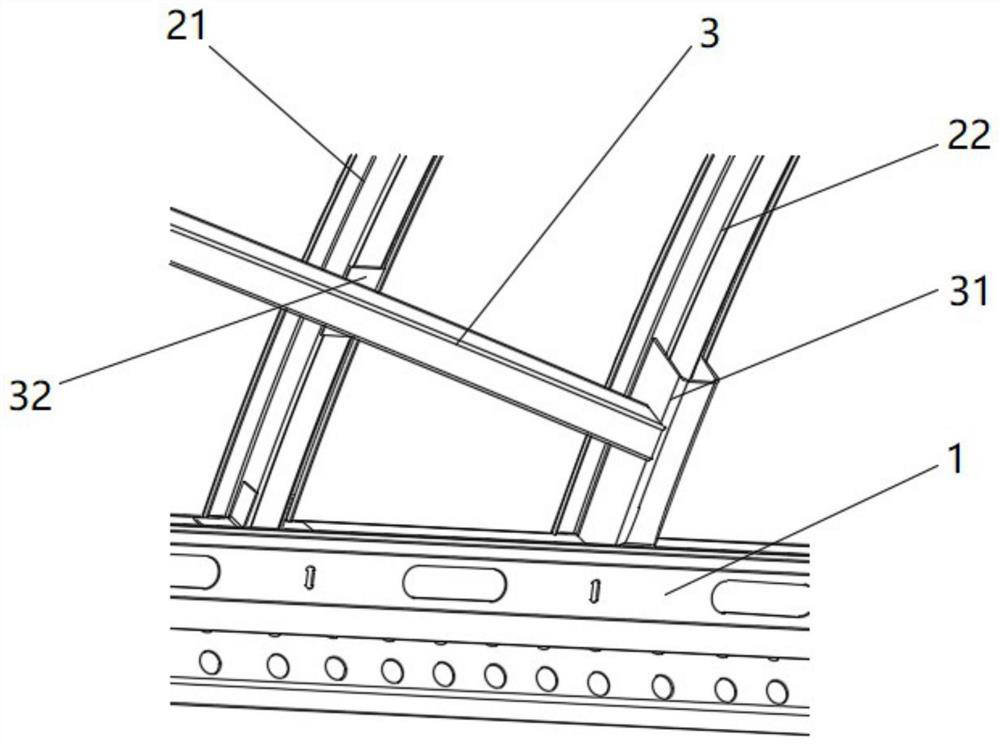

Roof framework structure, vehicle body and rail vehicle

ActiveCN111806481AImprove bending and torsional performanceCapable of resisting vertical bendingRailway roofsClassical mechanicsEngineering

The invention relates to rail vehicles, and particularly relates to a roof framework structure, a vehicle body and a rail vehicle. The roof framework structure comprises a pair of roof edge beams arranged at intervals and a plurality of camber beams connected between the pair of roof edge beams. The structure further comprises a pair of reinforcing beams. The multiple camber beams comprise two door area camber beams located at the two ends of the roof edge beam respectively, and the two ends of each reinforcing beam are connected to the ends, close to the same roof edge beam, of the two door area camber beams respectively. And the pair of reinforcing beams is oppositely bent along a force transmission direction. In the invention, topological optimization is carried out on a vehicle body stress and a force propagation path; therefore, the reinforcing beam is additionally arranged in the roof framework structure according to a topological optimization result; and a longitudinal load capacity and a bending resistance and torsion resistance ability of the roof framework structure are improved, particularly, the roof framework structure has vertical bending resistance so that the roof framework structure meets requirements for the longitudinal load capacity and the bending resistance and torsion resistance ability of a vehicle body.

Owner:CRRC QINGDAO SIFANG CO LTD

Front end assembly structure of stainless steel staircase step

InactiveCN101570299AEffective control of precisionAnti-deformation purpose is clearEscalatorsStructural engineeringAssembly structure

The invention relates to a front end assembly structure of a stainless steel staircase step, in particular to a front end assembly structure of a split assembled step, and belongs to the field of escalator manufacture. By using a horizontal positioning surface as a standard, a front end cross beam for realizing height horizontal positioning is placed above triangular brackets and the horizontal positioning surface which are arranged in parallel; the triangular brackets and the horizontal positioning surface are contacted and connected with and position a first vertical positioning surface and a second vertical positioning surface to realize the vertical positioning and specific size span positioning of two triangular brackets. The invention solves the technical problem and provides the technical task that the structure overcomes the technical defects in the front end assembly structure of the prior stainless steel staircase step, and provides an implementation proposal for the front end assembly structure of the step with good integrity, deformation resistance, definite assembly standard aim, large overload capacity, convenient assembly and easy quality control.

Owner:SUZHOU BENYI MECHANICAL & ELECTRICAL EQUIP

Wing spar of composite wing aircraft

ActiveCN114104261AReduce structural weightImprove bending and torsional performanceSpars/stringersFlight vehicleStructural engineering

The invention discloses a wing spar of a composite wing aircraft, which comprises two transverse integral beams which are horizontally arranged oppositely, a crossed bearing beam for bearing bending torque is arranged between the two transverse integral beams, and the inside of the crossed bearing beam is of a hollow structure; the end parts of the crossed bearing beams are fixedly connected with the two transverse integral beams; the two ends of the two transverse integral beams are each provided with one end rib plate used for bearing bending and torsional moment, the two transverse integral beams are connected and fixed through the two end rib plates, the whole cross type bearing beam is of a hollow structure, the structural weight of the wing is greatly reduced, meanwhile, the bending and torsional resistance of the bearing beam is greatly improved through the cross type bearing beam, and the bearing beam is suitable for being popularized and applied. The water passing grooves are formed in the crossed bearing beams, so that the problem that water stored in the wing spar is discharged is simply and effectively solved, and lighter weight can be obtained on the premise that certain bending and torsional strength is determined by adding the end rib plates.

Owner:中国空气动力研究与发展中心空天技术研究所

Automobile body aluminum profile water tank column and automobile

ActiveCN109159821BFirmly connectedIncrease productivitySuperstructure subunitsPropulsion coolingStructural engineeringMechanical engineering

Owner:ZHEJIANG GEELY HLDG GRP CO LTD +2

A UAV front landing gear compartment based on catapult take-off

ActiveCN107891965BThe overall structure is light in weightDoes not weaken stiffnessFuselage framesFuselage bulkheadsMechanical engineeringAirplane

The invention discloses a drone noselanding gear well section based on catapult-assisted take-off. A landing gear well comprises partition frames at the two ends, a girder connected with the partitionframes and a skin; a landing gear fixing compartment is arranged in the middle of the landing gear well, a framework of the landing gear fixing compartment comprises four main girders, the main girders are fixedly connected with the partition frames, and partition plates are arranged at both the two sides of each main girder and the partition frames; the main girders and the partition plates forman integrated wall plate girder, the wall plate girder is hinged to a landing gear main support and a landing gear slant supporting rod, and openings are formed in the skin at the lower portion of the landing gear fixing compartment. The landing gear well is of a box body type structure low in structural weight, the openings are formed among the main girders, the rigidity of other parts of the landing gear well and the rigidity of an overall aircraft cannot be lowered, and additional strength reinforcement setting is also not needed; the wall plate girder penetrating through the whole box body has the advantages of being continuous in stress and short and direct in force transmitting path, and transmitting of instantaneous impact large loading concentrated force and torque inside the structure is benefited.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

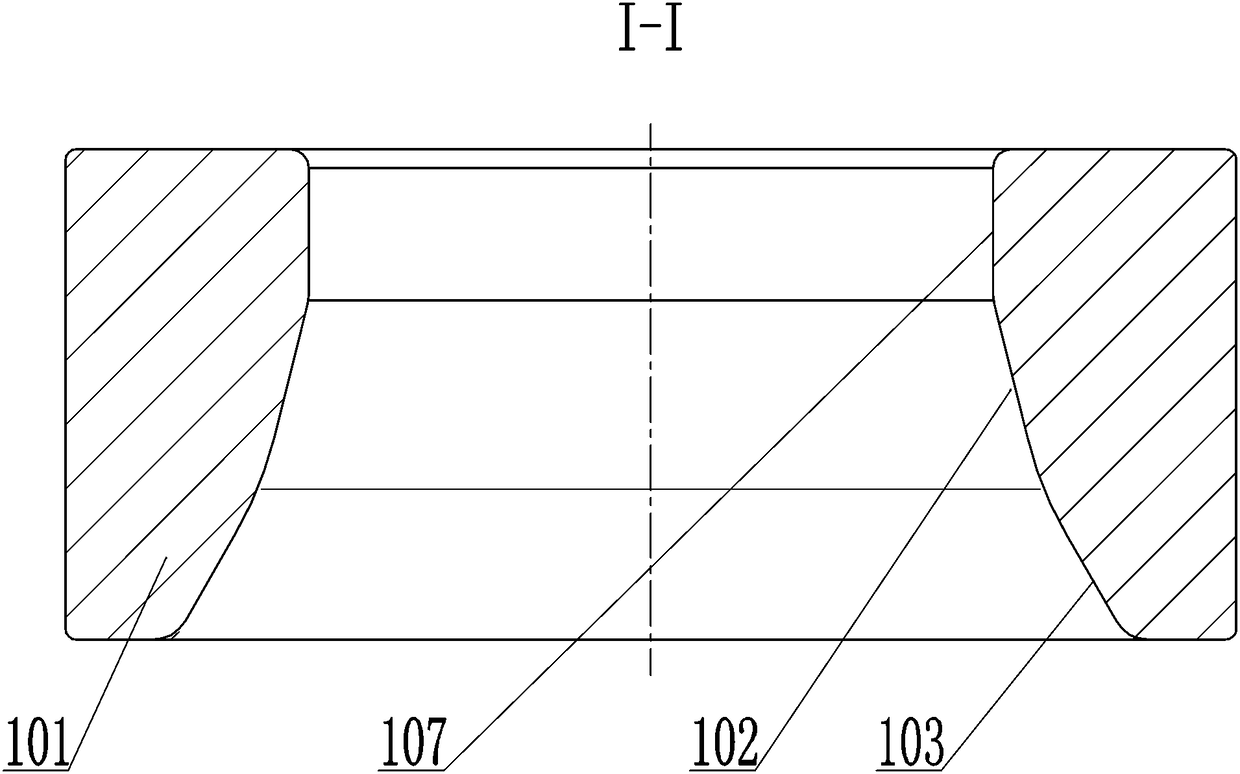

Hydraulic support base

ActiveCN106988771AHigh strengthImprove bending and torsional performanceProps/chocksStructural engineeringUltimate tensile strength

The invention relates to a hydraulic support base. The hydraulic support base comprises a main reinforcement and two groove bodies defined by base plates. The main reinforcement comprises internal main reinforcement bodies and external main reinforcement bodies, an attached plate is arranged on the position, corresponding to a connecting hole of a connecting rod, of the internal side of the main reinforcement, and a reinforcing plate is arranged on the position, corresponding to a pillar nest, of the external side of the main reinforcement. The internal main reinforcement bodies and the external main reinforcement bodies are connected through a first horizontally-arranged cover plate, the adjacent internal main reinforcement bodies are connected through second obliquely-arranged cover plates, and a third obliquely-arranged cover plate connected with a gap bridge is arranged on the pillar nest and connected with the internal main reinforcement bodies and the external main reinforcement bodies. A second reinforcement plate is arranged outside the internal main reinforcement bodies in the length direction of the internal main reinforcement bodies, and a lifting lug is arranged on the second reinforcement plate. According to the hydraulic support base, by arranging the attached plate and the reinforcing plate on the main reinforcement, the strength and the anti-bending and anti-torque capacities of the hydraulic support base are improved, the stressed area of the base is increased, the overall length of the base and the length of a sidewalk are increased, the overall height of the hydraulic support base is decreased, and the hydraulic support base is suitable for exploitation of a thin coal seam.

Owner:SHANDONG ENERGY HEAVY EQUIPMENT GROUP HENGTU TECH CO LTD

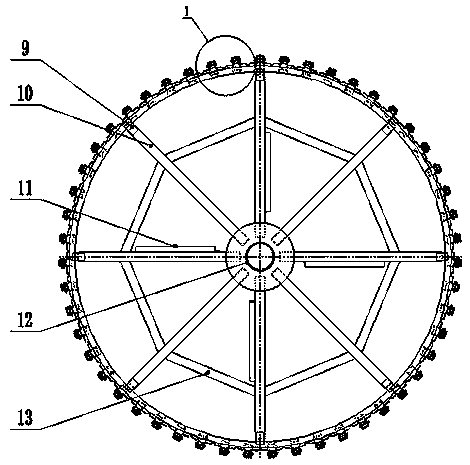

Spiral n-shaped material friction rotating cage

The invention relates to a spiral n-shaped material friction rotating cage. The rotating cage comprises a rotating cage shaft and the friction rotating cage body composed of a rotating cage upper section and a rotating cage lower section; the rotating cage shaft is arranged at the center of the rotating cage upper section and the rotating cage lower section, and the rotating cage shaft is connected with a driving device; the rotating cage shaft is fixedly connected with multiple layers of connecting rods, the connecting rods of the rotating cage shaft is connected with a section bar circular ring through connecting plates, and n-shaped straight-strip frameworks are connected to the section bar circular ring through special-shaped connecting plates; and a lap joint is formed between every two adjacent n-shaped straight-strip frameworks, and equal-length plastic protective strips are arranged on the outer sides of the n-shaped straight-strip frameworks. The rotating cage has the advantages that the overall rigidity of the periphery of the rotating cage is improved, gaps between every two adjacent straight-strip frameworks are reduced, the overall rigidity of the rotating cage is improved, the difficulty of cleaning the rotating cage is reduced, and the sanitary grade of the rotating cage is improved.

Owner:SIFANG TECH GRP CO LTD

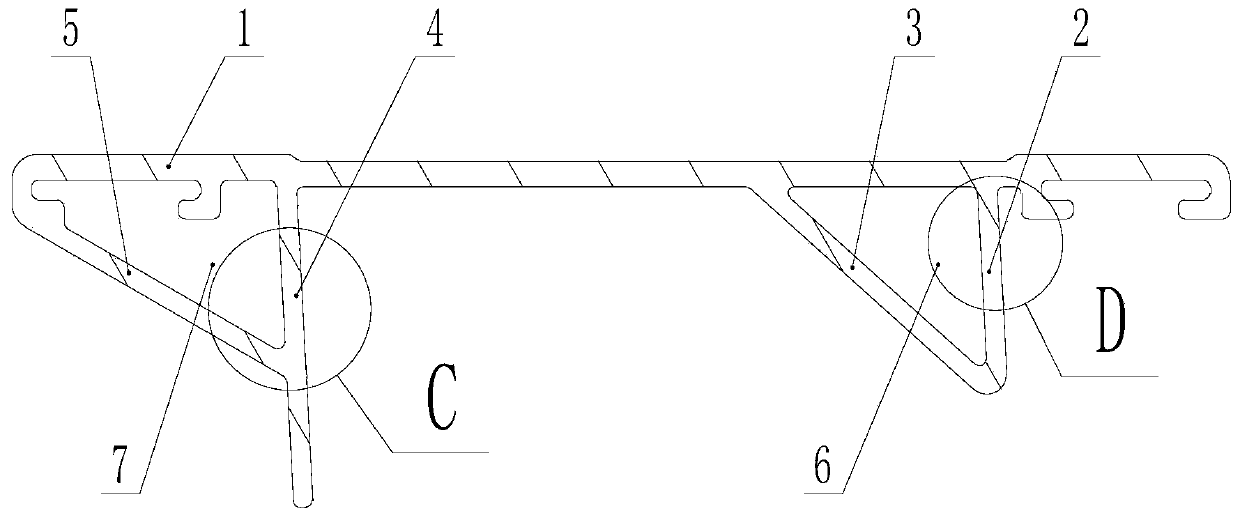

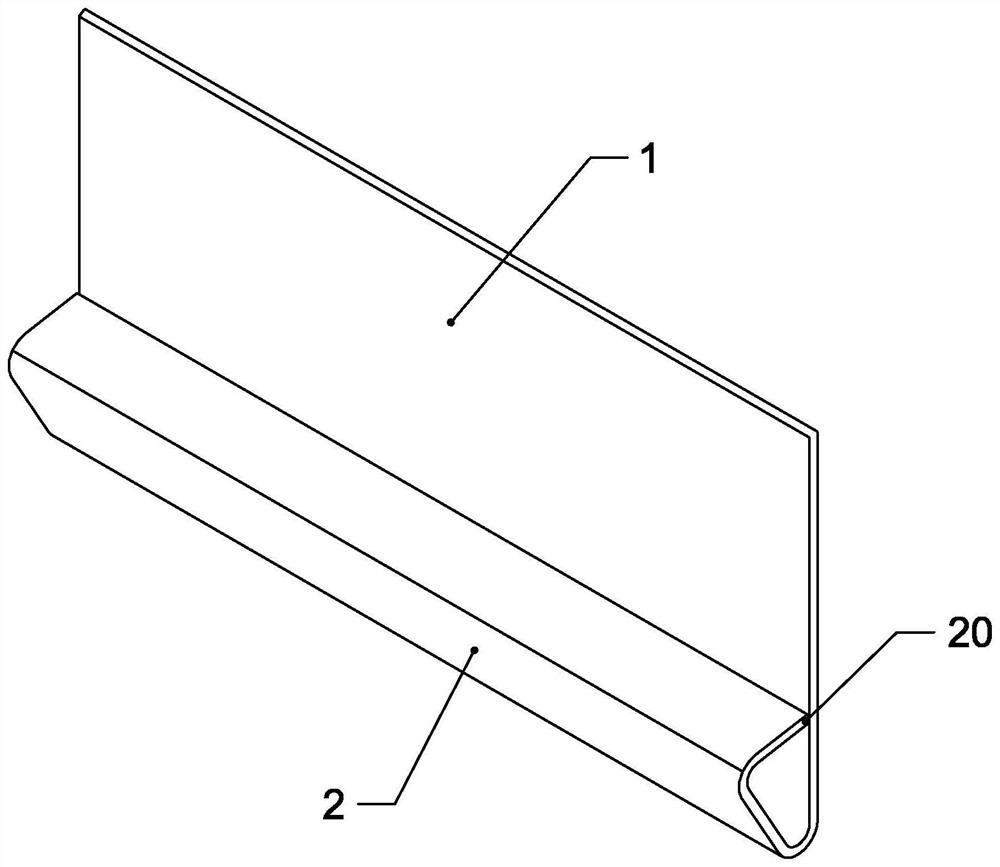

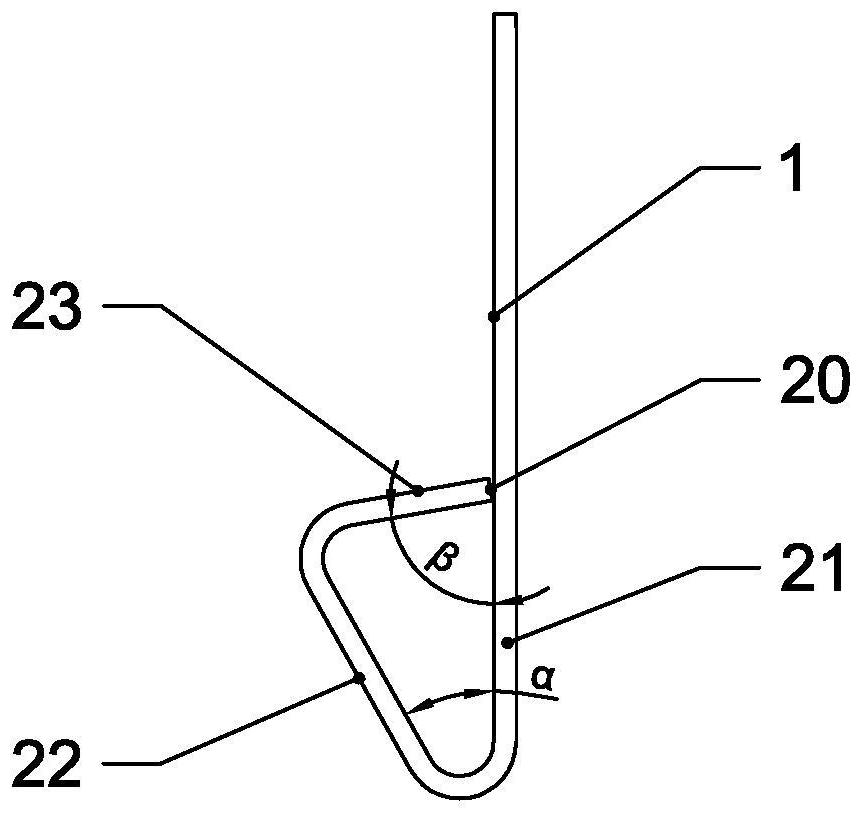

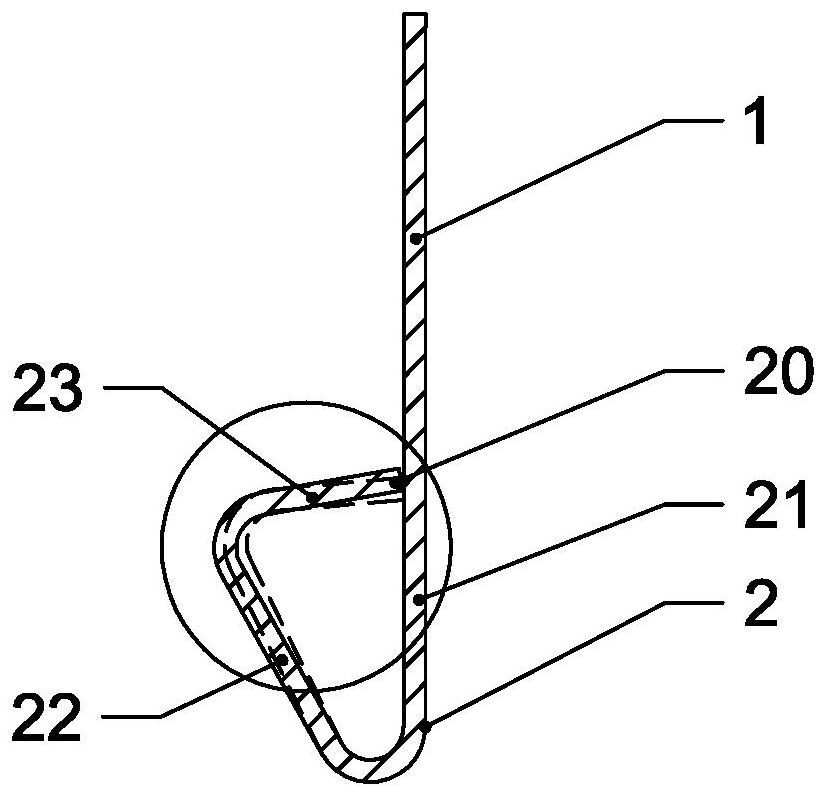

Semi-closed and semi-open stiffening rib and stiffening plate

PendingCN114808693ASolution to increase bending resistanceSolve the problem of torque moment of inertiaBridge structural detailsInfinitesimal deformationEnergy absorption

The invention relates to the field of stiffening plates, discloses a semi-closed and semi-open stiffening rib and a stiffening plate comprising the stiffening rib, and solves the problems that in an existing stiffening plate, an open rib is poor in torsion resistance and flexural rigidity, and a closed rib is large in welding difficulty, prone to fatigue cracking and the like. According to the technical scheme, the reinforcing rib is characterized by comprising a web plate (1) and a flange part (2), the reinforcing rib is formed by forming a steel plate, and the web plate (1) and the flange part (2) are integrally connected; the flange part (2) is tubular and is defined by forming a steel plate at the lower part of the web plate (1), the flange part (2) is provided with a tail end (20) close to the web plate (1), and the distance between the tail end (20) and the web plate (1) is 0-15mm. The upper portion adopts the open section, the connection advantage of the open rib is reserved, the lower steel plate is bent to form the flange portion capable of being naturally closed, the section of the lower edge of the rib is increased, and meanwhile the torsion resistance and the bending resistance of the stiffening rib are greatly improved through small deformation energy absorption of the lower section.

Owner:ZHEJIANG CTB WAVEFORM STEEL WEB

Deformable biplane configuration

The invention provides a deformable biplane configuration. The configuration comprises an upper wing, a lower wing and a plurality of parallel distributed deformation mechanisms, wherein the upper wing and the lower wing are connected through the deformation mechanisms; each deformation mechanism comprises a connecting strut and 1 to 2 motion mechanisms; a drive mechanism and a locking device are arranged on each motion mechanism which is fixed on the upper wing or the lower wing; one end of the connecting strut is mechanically connected with the motion mechanism, while the other end of the connecting strut is mechanically connected with the motion mechanism or fixedly connected with the upper wing or the lower wing; the drive mechanism drives the motion mechanism to drive the connecting strut to ensure that the upper wing and the lower wing rotate in 0 to 180 degrees in the course direction and the height direction; and when the upper wing and the lower wing move to a set position, the locking device locks the motion mechanism, and positions of the upper wing and the lower wing are fixed. Regarding the wing configuration mode of a solar plane, the deformable biplane configuration is adopted, compared with single plane configuration, under a condition that the same wing type, the same wingspan and the same aspect ratio of a single wing are adopted, through the deformable biplane configuration, the takeoff weight can be increased, the effective load can be increased, the induced drag of the wings can be reduced, and the area of a solar cell panel can be increased, so that the solar energy absorption capacity can be improved, and the energy consumption of night flight can be reduced.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

A sub-frame of a large-volume concrete mixer truck

ActiveCN103863398BImprove local bending and torsional performanceImprove stressConcrete transportationUnderstructuresStress conditionsVehicle frame

The invention discloses an improved auxiliary frame of a large-earthwork concrete mixing carrier. The auxiliary frame mainly solves the problems that loads of the mixing carrier increase substantially and a prior auxiliary frame cracks easily. The improved auxiliary frame comprises an auxiliary beam, a front table, a rear table, an inclined tensioned support, a U-shaped bent plate and an inclined support, wherein the front table is arranged at one end above the auxiliary beam, the rear table is arranged at the other end above the auxiliary beam, the U-shaped bent plate is arranged on the auxiliary beam, the inclined tensioned support is arranged between the U-shaped bent plate and the rear table, and the inclined support is arranged between an auxiliary beam cross support at the front end of the bottom of the rear table and the U-shaped bent plate. The strength of the auxiliary frame of the concrete mixing carrier can be well improved, the improved auxiliary frame can be used under all kinds of large-earthwork concrete mixing carrier using conditions, local tension resistance of the auxiliary frame of the concrete mixing carrier is improved, and stress conditions of the auxiliary frame are fully optimized.

Owner:SHANTUI JANEOO MACHINERY

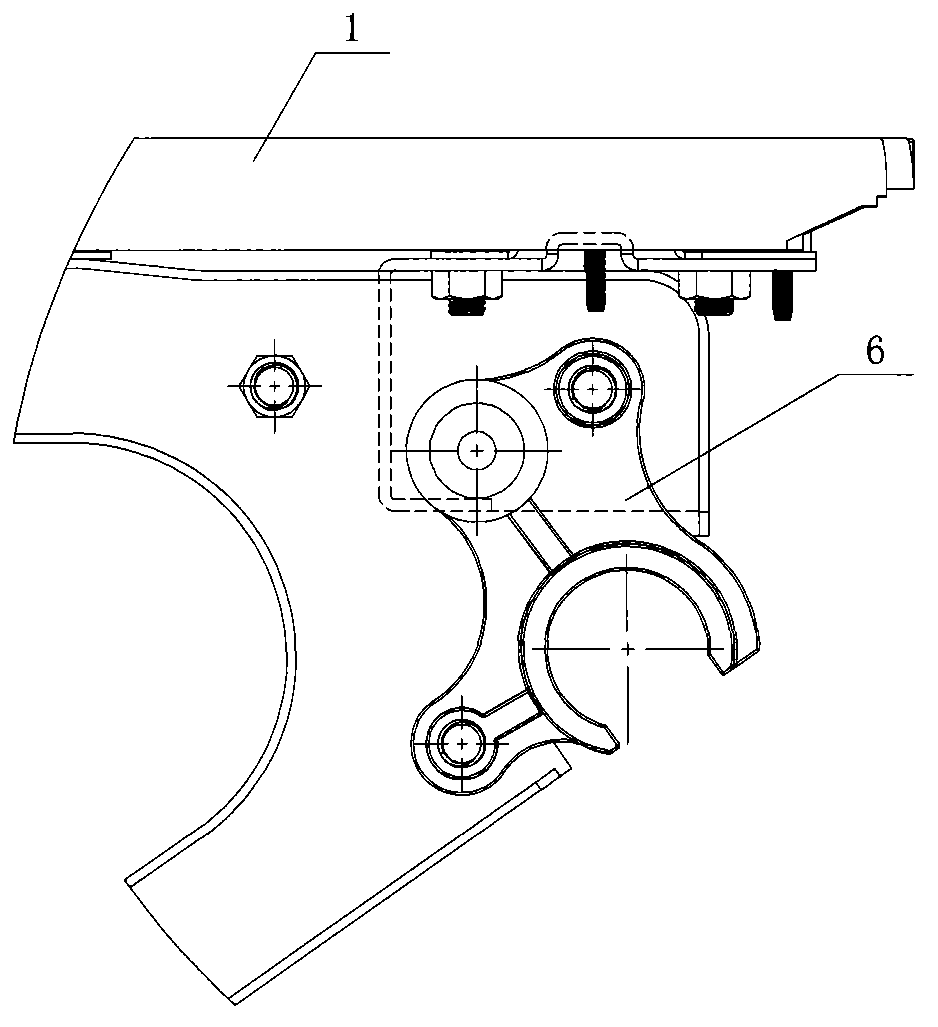

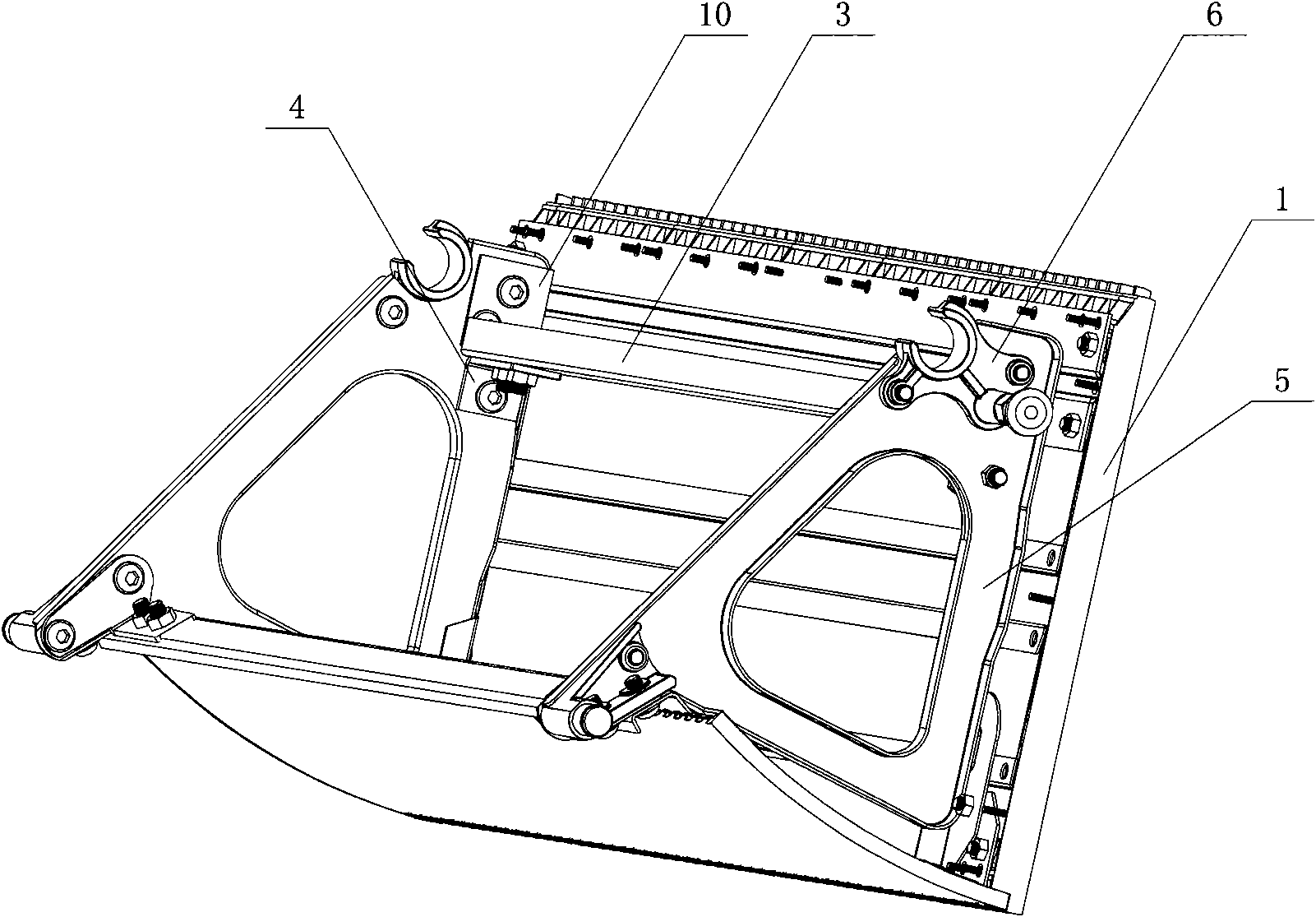

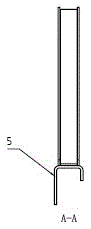

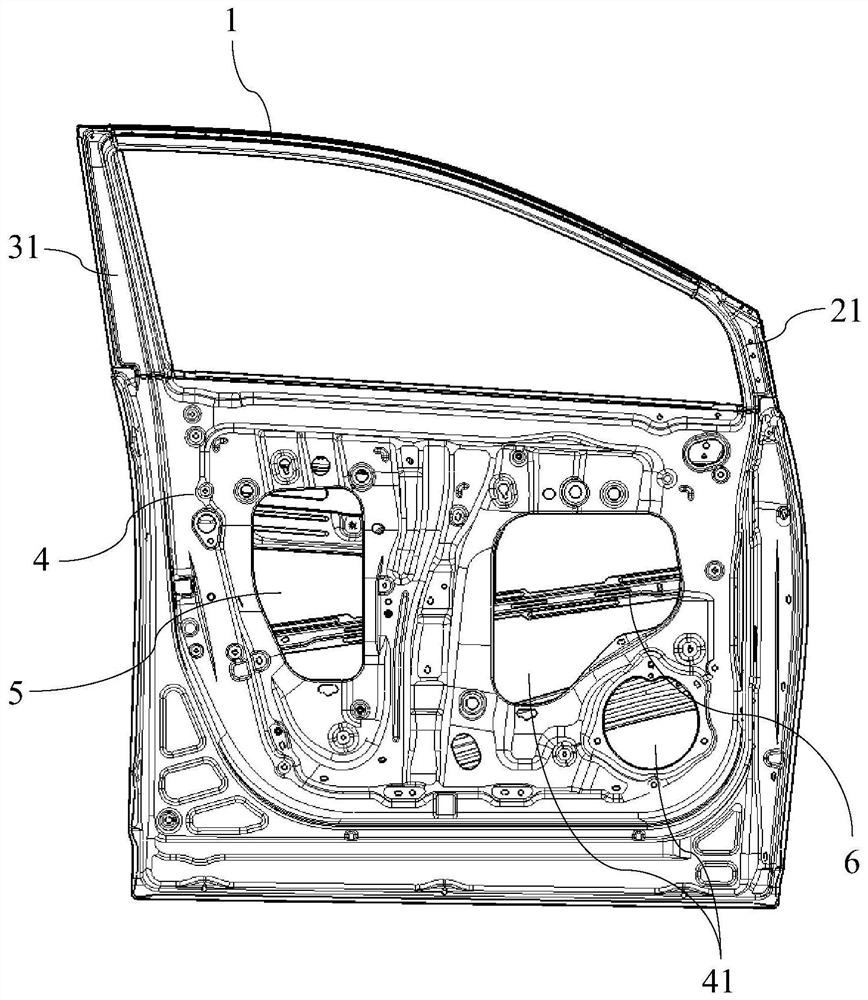

A kind of car door and window frame structure and automobile

In order to overcome the problems of paint cracking and welding seam fatigue caused by insufficient rigidity and strength of existing car door and window structures, the present invention provides a car door and window frame structure, including door inner panels, door outer panels, window frame front components, window A frame rear assembly, a waistline reinforcement assembly and an upper sash, the sash front assembly includes a sash front outer panel and a sash front inner panel overlapping each other, the sash front outer panel and the sash front A first cavity is formed between the inner panels at the front of the window frame, the rear assembly of the window frame includes an outer panel at the rear of the window frame and an inner panel at the rear of the window frame which overlap each other, the outer panel at the rear of the window frame and the outer panel of the window frame A second cavity is formed between the inner panels at the rear of the window frame. At the same time, the invention also discloses an automobile comprising the above-mentioned vehicle door and window frame structure. The car door and window frame structure provided by the invention can ensure sufficient connection rigidity and strength of the window frame, and avoid paint cracking and sheet metal rusting caused by solder joints and seam welding cracks.

Owner:GUANGZHOU AUTOMOBILE GROUP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com