Semi-closed and semi-open stiffening rib and stiffening plate

A stiffener and semi-opening technology, applied in the field of stiffeners, can solve the problems of poor torsional and bending rigidity of open ribs of stiffeners, increase the cross-sectional area of the lower edge of stiffeners, and difficult welding of closed ribs, etc., to increase flexibility Sex and strain, avoid welding fatigue factor, improve the effect of torsion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

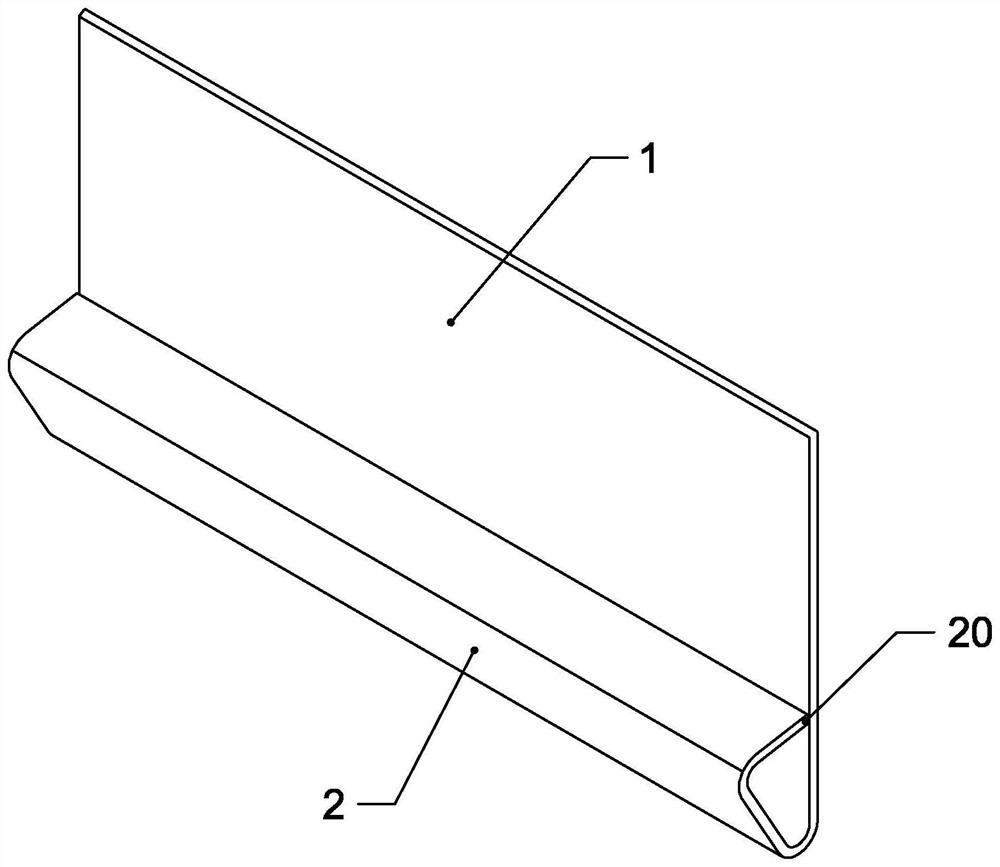

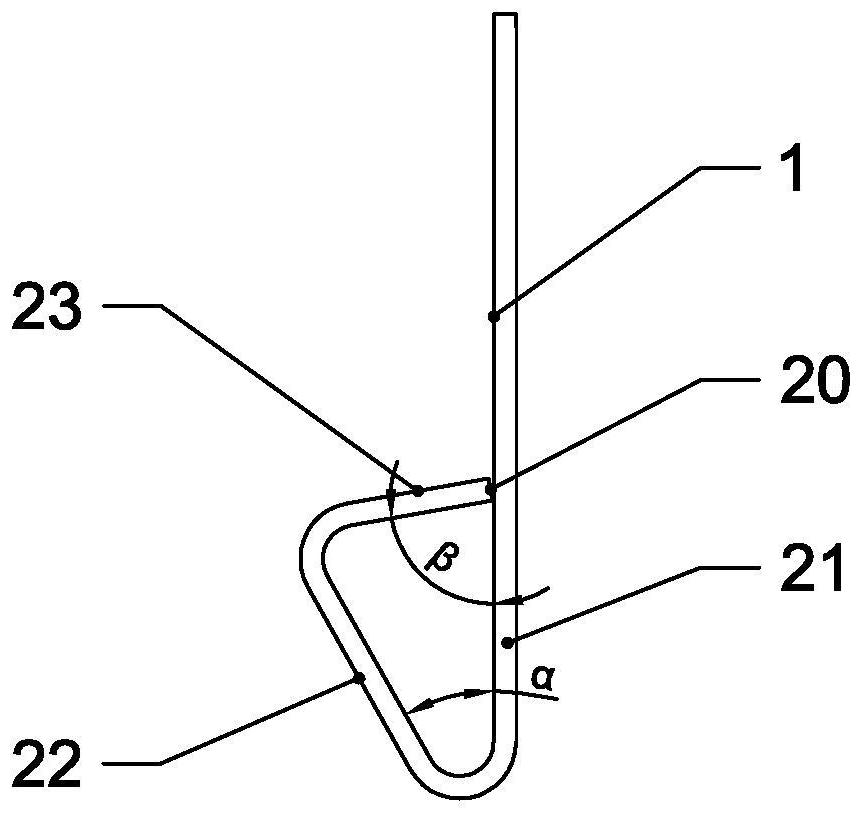

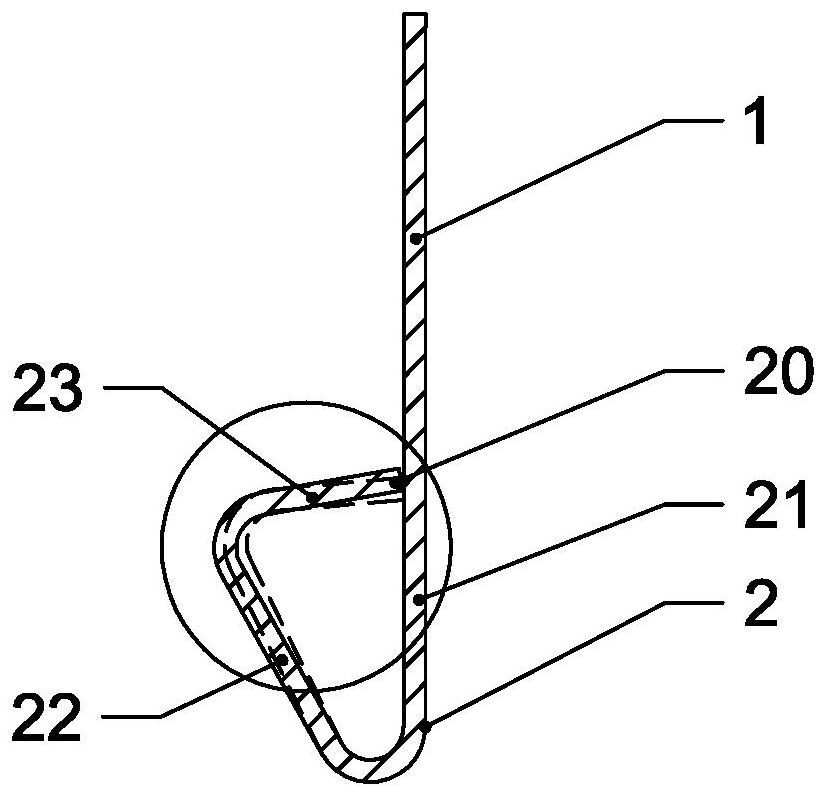

[0036] like figure 1As shown, Embodiment 1 provides a half-closed half-open stiffening rib for a stiffening plate, the stiffening rib is a long strip, and the stiffening rib is formed from a sheet of steel plate, including a web 1 and a flange portion 2, The web 1 and the flange portion 2 are integrally connected; the flange portion 2 is tubular, formed by the steel plate at the lower part of the web 1 to form a tubular member, and the flange portion 2 has a tail end 20 close to the web 1 . like Figure 4 As shown in the partial enlarged view of , there is a small gap between the tail end 20 and the web 1 or a natural fit, and the distance between the tail end 20 and the web 1 is 0-15 mm. The tail end 20 and the web 1 are not welded, but can also be partially welded.

[0037] The upper part of the stiffening rib is a web 1, and the lower part is surrounded by a tube, forming a half-open and half-closed structure. Compared with the traditional open rib, such as the spherical...

Embodiment 2

[0044] like Figure 5 and Image 6 As shown, the difference between Embodiment 2 and Embodiment 1 is that: in Embodiment 2, the end of the web 1 away from the flange portion 2 has a corrugated portion 11, and the corrugated direction of the corrugated portion 11 extends along the length of the stiffener, and the further toward the web The end wave height is higher.

[0045] Restricted by the height-to-thickness ratio of stiffener plate thickness and rib height, using higher beam height or rib height often requires increasing the plate thickness of the rib, which not only increases the material cost, but more importantly, the dead weight of the bridge deck system is too large and weakens. its applicability in long-span bridges. By rolling the corrugated shape on the stiffener web 1, the virtual thickness of the stiffener web 1 is increased, and the shear resistance and buckling resistance of the stiffener are improved. The weld is changed from the traditional single-directio...

Embodiment 3

[0048] like Figure 7 , 8 As shown, the difference between Embodiment 3 and Embodiment 1 is that the stiffening rib also includes a connecting plate 3 connected to the other end of the web 1, and the connecting plate 3 and the web 1 have an included angle φ, 85°≤φ≤95° . The connection plate 3 has connection holes 31 . The connecting plate 11 is used to connect with the stiffened panel. When connecting, the connecting plate 11 is attached to the panel, which can be fixed by welding, or connected by an assembly method such as bolt connection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com