Front spring front support cross beam assembly

A technology of beam assembly and front bracket, applied in the directions of substructure, transportation and packaging, vehicle components, etc., to achieve the effect of improving bending and torsion resistance, being easy to manufacture, and strengthening beams

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

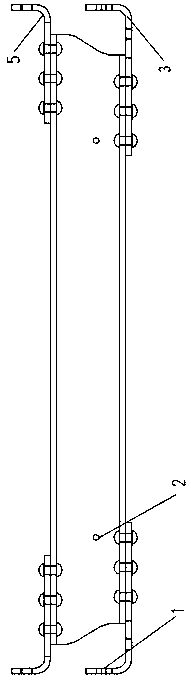

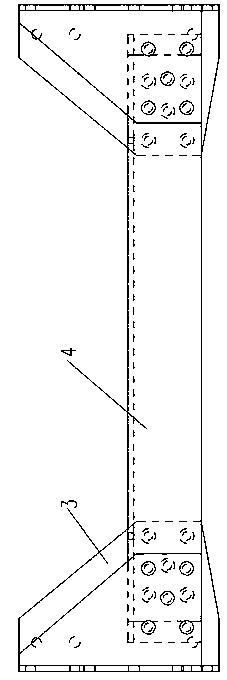

[0017] Such as figure 1 with figure 2 As shown, the front spring front bracket beam assembly includes a beam 4 made of a section of channel steel, two upper wing plates 5 and two lower wing plates 3 . The beam includes an upper leg board and a lower leg board, and the upper leg board is positioned right above the lower leg board. Both the upper wing plate and the lower wing plate are bent upward at 90° and both include a vertical portion and a horizontal flat portion. The two upper wing plates are arranged oppositely and their upright parts are located outside the horizontal flat part. The horizontal flat parts of the two upper wing plates are respectively riveted with the two ends of the upper leg plate by rivets, the two lower wing plates are arranged oppositely and their vertical parts are located outside the horizontal flat parts, and the horizontal flat parts of the two lower wing plates are respectively connected with the two ends of the lower leg plate. The parts a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com