Front end assembly structure of stainless steel staircase step

An assembly structure, stainless steel technology, used in escalators, transportation and packaging, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

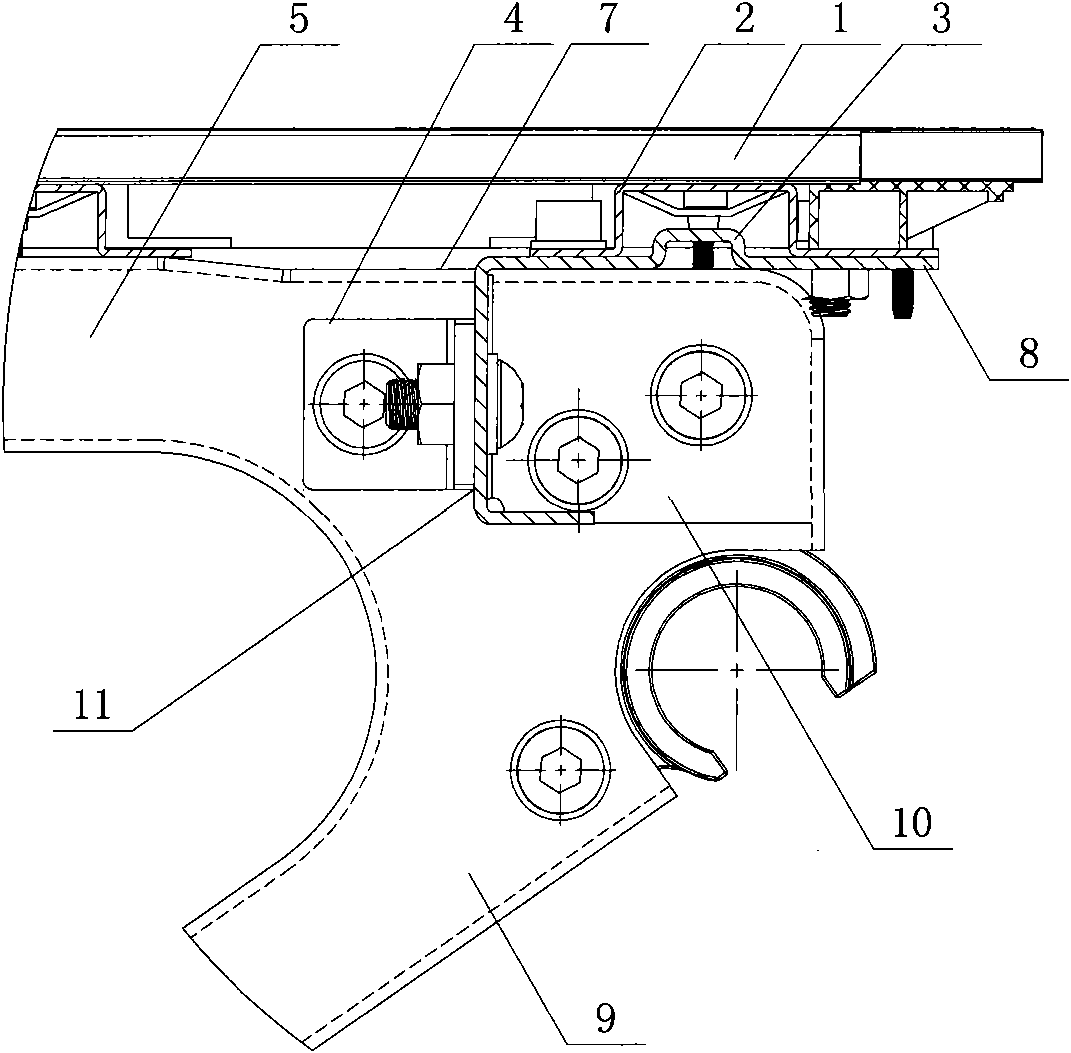

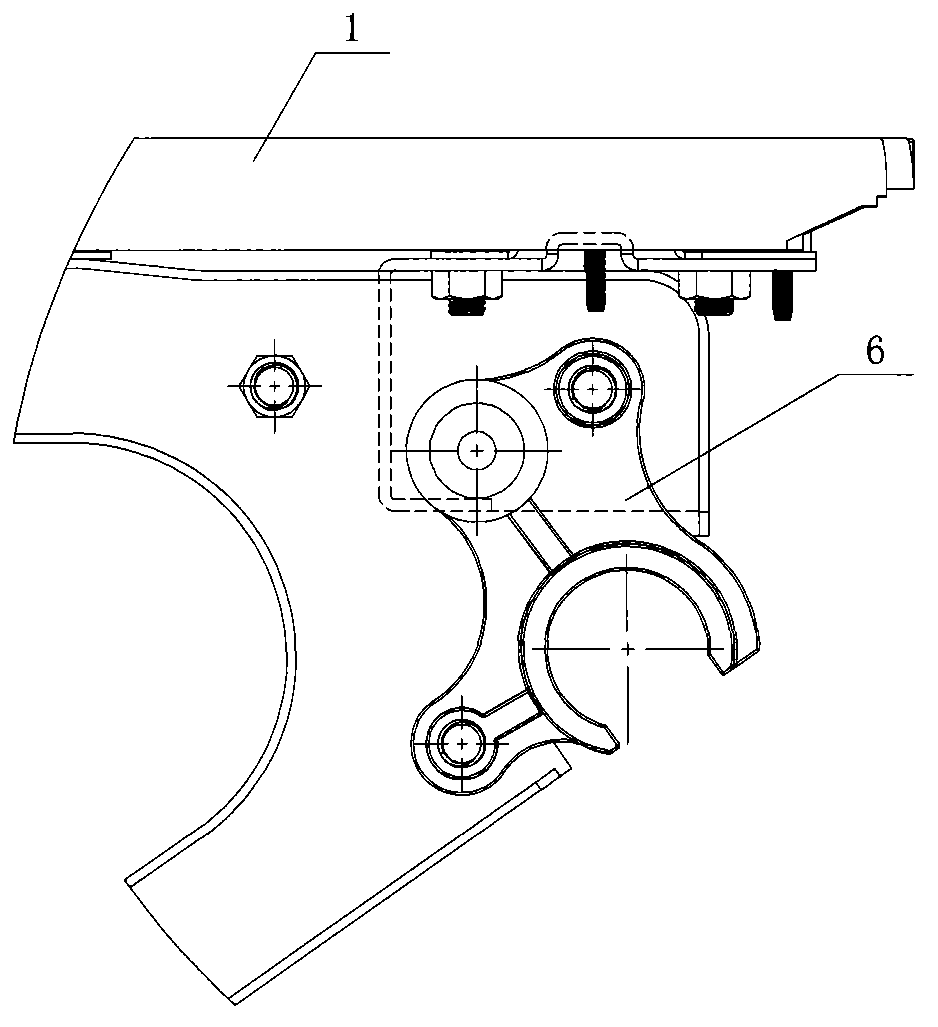

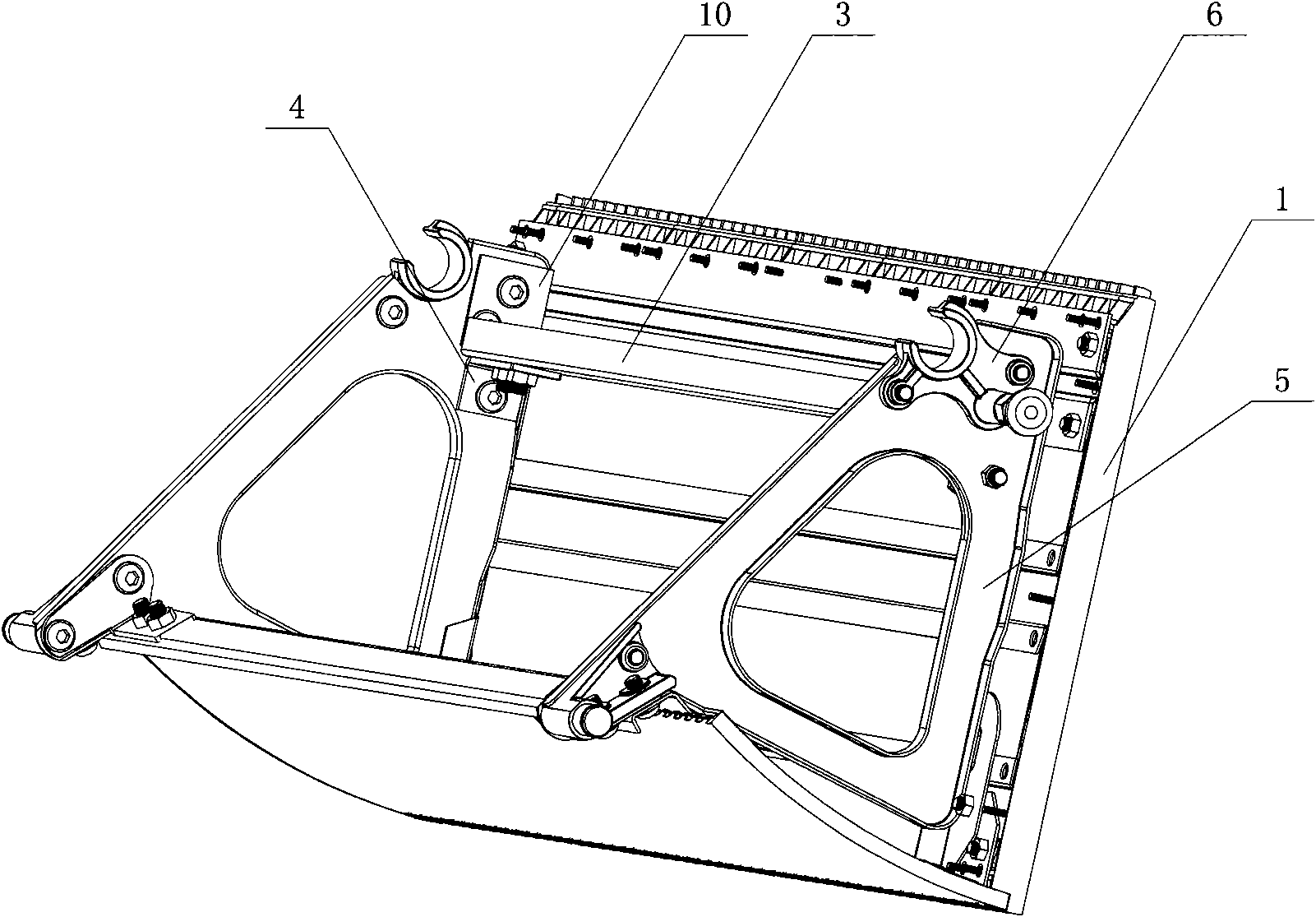

[0010] Below in conjunction with the accompanying drawings of the description, the implementation and essential features of this case will be further described.

[0011] Such as Figure 1~3 As shown, the embodiment of the present invention is a stainless steel escalator step front end assembly structure, and two parallel triangle brackets 5 are positioned and connected as a whole by the front end crossbeam 3 with screws. They realize horizontal and vertical positioning by two kinds of positioning surfaces 7 , 8 , 9 , 10 perpendicular to each other. At the same time, the specific span positioning of the two triangular brackets 5 is realized by using the front beam 3 and the vertical positioning surfaces 10 at both ends. In order to enhance the structural stability after the two are connected, an angle piece 4 is provided, and it is integrated with 3 and 5 with a screw transition. The two main shaft wheel bases are connected by screws to the plate surface on one side of the tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com