Preparation method of a force-responsive nanoscale photonic crystal material

A photonic crystal and responsive technology, applied in optics, optical components, instruments, etc., can solve the problems of difficulty in preparing nanometer-scale photonic crystals, limited precision level of photonic crystals, poor structure controllability, etc., and shorten the preparation cycle , short preparation cycle, and the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

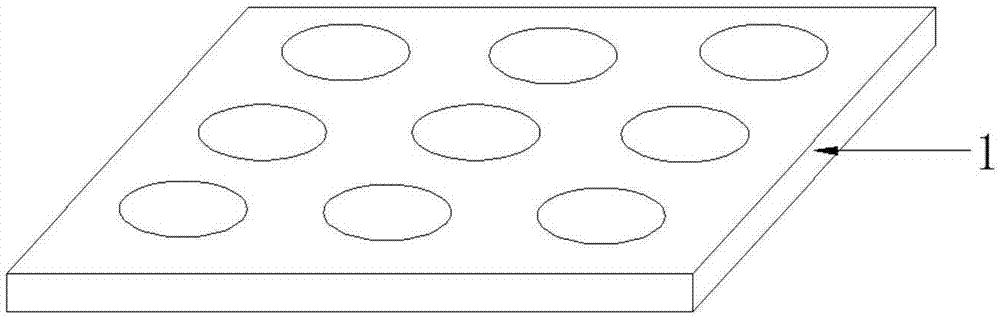

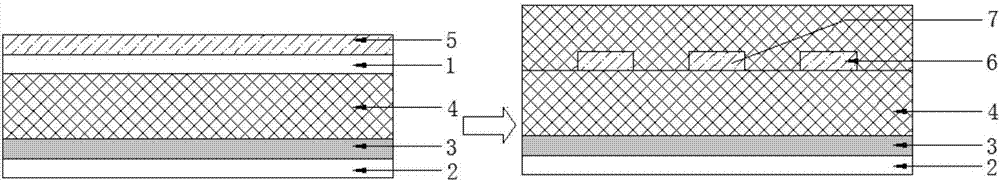

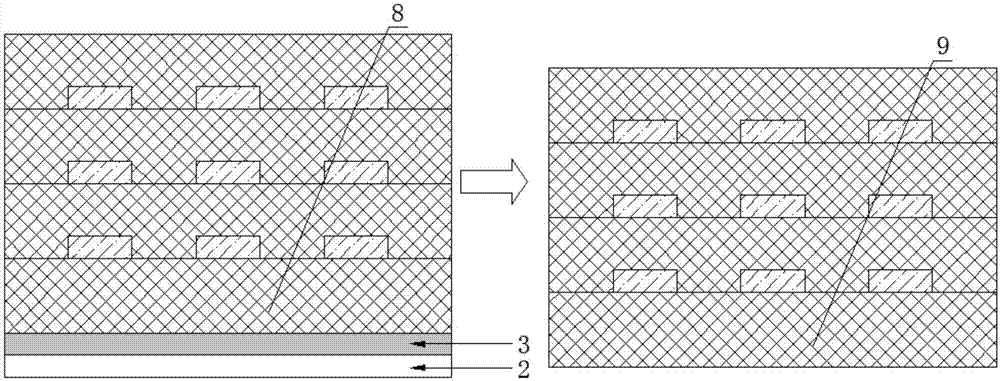

[0045] 1. If figure 1 As shown, the preparation steps of the quartz template with photonic crystal pattern are as follows:

[0046] (1) According to actual needs, pre-design the structural parameters of photonic crystals, mainly including: the surface structure is a hexagonal columnar lattice, the lattice period is 200nm, the diameter of the raised columns is 100nm, and the height of the raised columns is 150nm. The effective area is 20×20mm 2 .

[0047] (2) According to the structural parameters of the photonic crystal above, design the structural parameters of the quartz template, mainly including: the surface structure is a hexagonal array of columnar holes, the lattice period is 200nm, the diameter of the columnar holes is 100nm, and the height of the columnar holes is 150nm , the effective area is 20×20mm 2 .

[0048] (3) Take a quartz substrate (size is 25mm × 25mm), according to the structural parameters of the above-mentioned quartz template, use electron beam lith...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com