High-precision and high-strength cold-drawing forming die for special-shaped D-shaped pipe

A molding die and high-strength technology, applied in the direction of wire drawing dies, etc., can solve the problems of unsatisfactory performance, dimensional accuracy and productivity, and achieve the effects of simplifying complex machining, improving surface roughness and dimensional accuracy, and improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

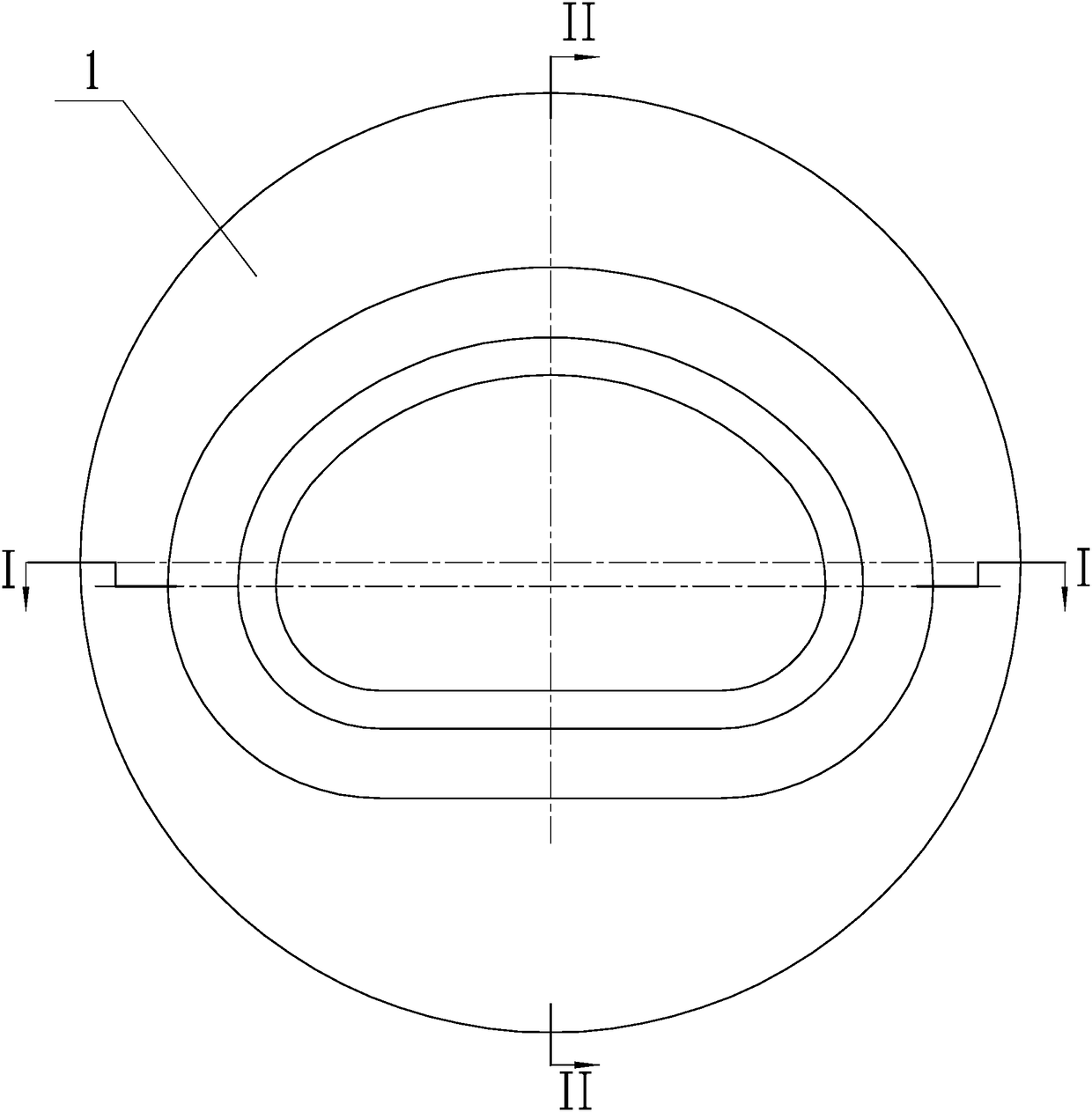

[0029] Such as Figure 1-7 As shown, a high-precision, high-strength cold-drawing mold for special-shaped D-shaped pipes includes an outer mold 1 and an inner membrane 2;

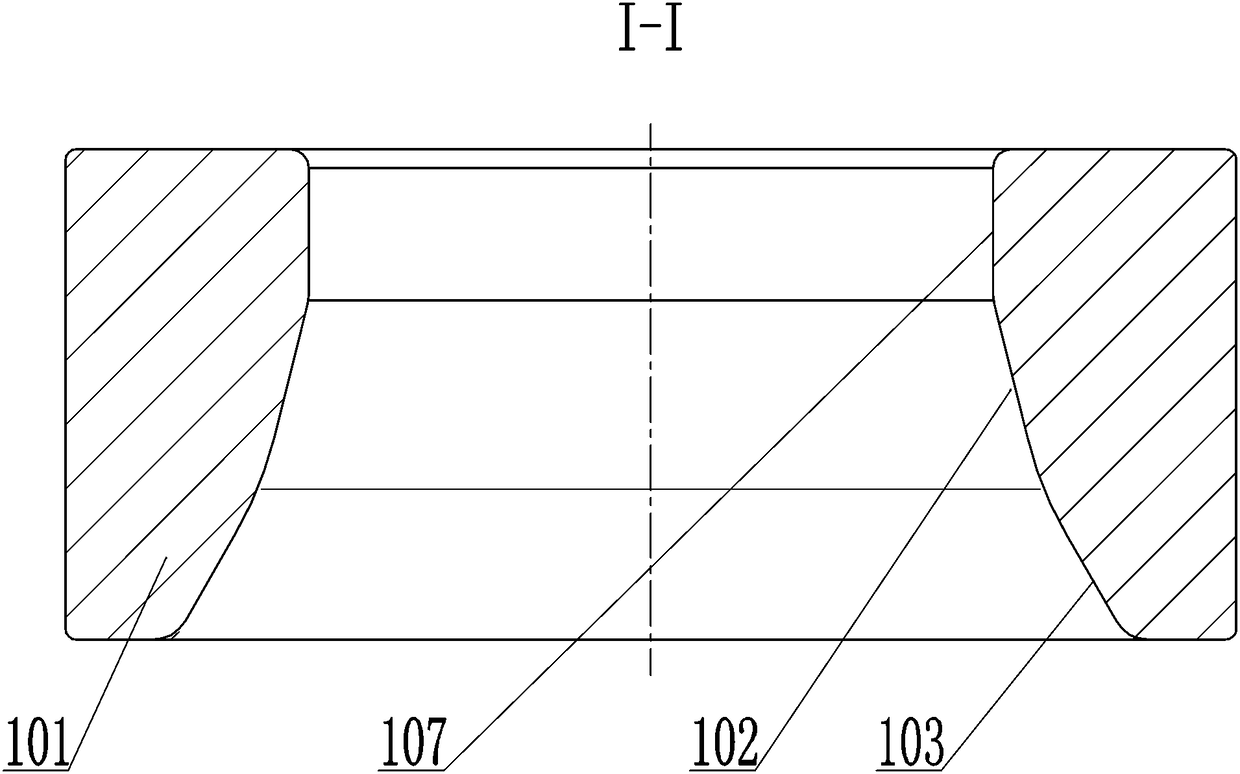

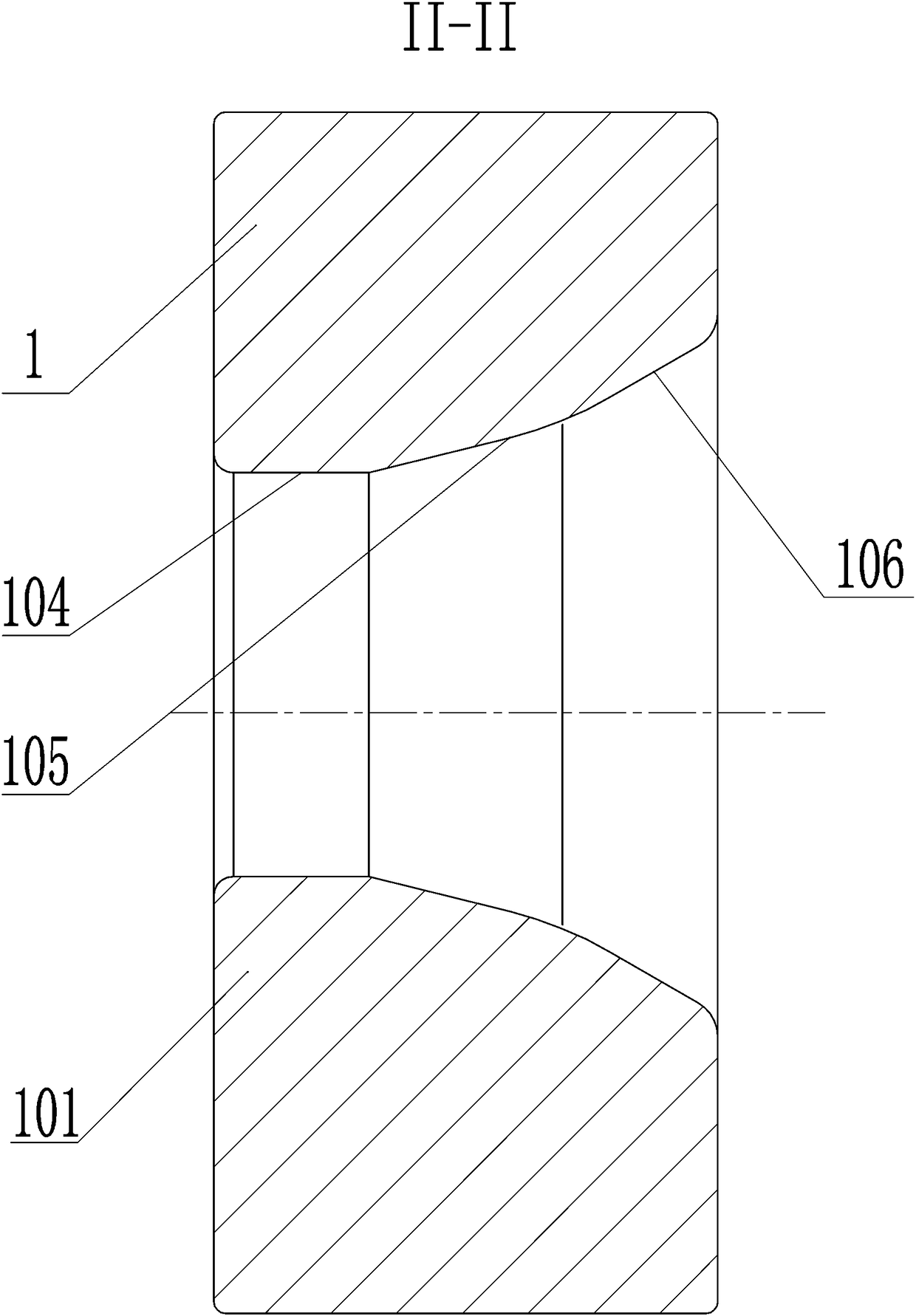

[0030] Further, the outer mold 1 includes an outer mold body 101, the outer mold body 101 adopts an axisymmetric structure, and its overall shape structure is a cylinder, and a molding cavity is processed in its center;

[0031] Further, a first circular arc inlet section 106 is processed on the inner contour of the section passing through the symmetry axis of the molding cavity and parallel to it, and the first circular arc inlet section 106 transitions with the first arc transition section 105 Connected, the other end of the first circular arc transition section 105 is transitionally connected with the first straight section 104;

[0032] Further, a second circular arc inlet section 103 is processed on the inner contour of the section perpendicular to the plane where the axis of symmetry of the molding c...

Embodiment 2

[0038] Such as Figure 7 : The raw material is martensitic stainless steel 13Cr, the outer diameter is 159mm, the wall thickness is 10.5mm, and the length is 6300mm. Cold drawing of the outer mold can obtain a steel pipe with a length of 180mm, a width of 104mm, and a wall thickness of 10mm, which is similar to a D-shaped steel pipe. This steel pipe has high dimensional accuracy and mechanical performance indicators. Moreover, it has a large moment of inertia and section modulus, and has a large ability to resist bending and torsion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com