Rigidity-flexibility transition busbar

A busbar, rigid and flexible technology, applied in the field of electrified railway and urban rail transit overhead catenary, can solve the problems of inconvenient processing, high production cost, hard point weakening, etc., achieve good power receiving effect, convenient processing, and prolong service life The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

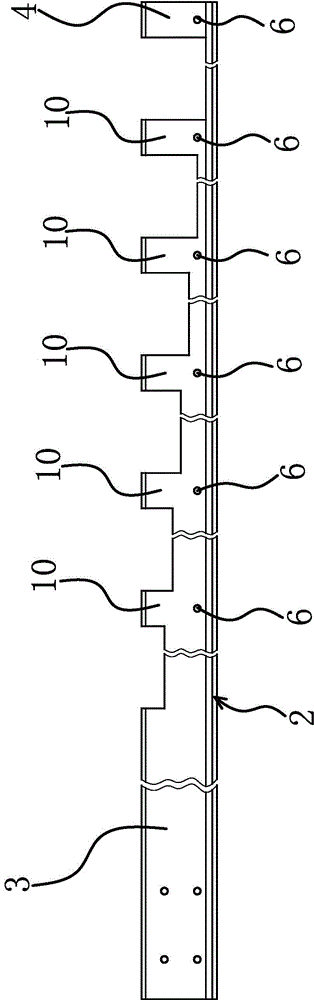

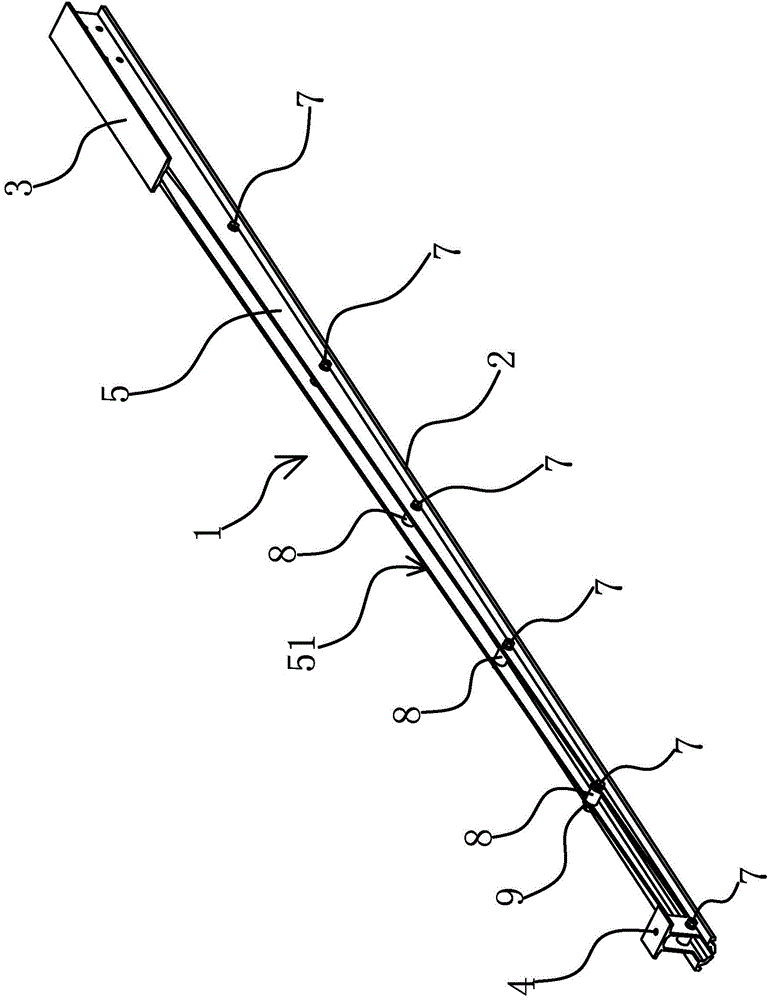

Image

Examples

Embodiment 2

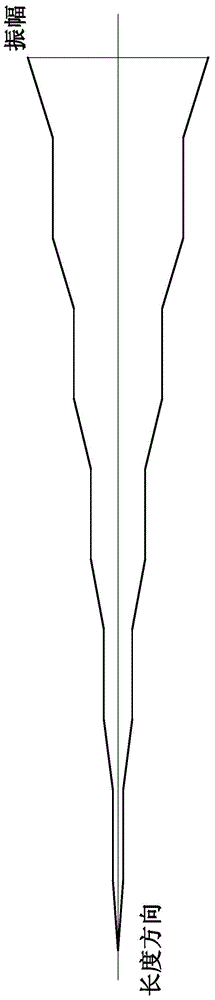

[0043] The technical solution in this embodiment is basically the same as that in the first embodiment, except that in this embodiment, the transition slope 51 is distributed along a continuous curve. The continuous curve distribution form is adopted, and more materials on the rigid-flexible transition part 5 are removed by wire cutting, which reduces the weight of the rigid-flexible transition busbar and makes the rigid-flexible transition busbar lighter for transportation and installation, and the entire transition process Smoother and more natural. In the actual production and manufacturing process, the curve is a multi-radian shear curve, an involute, a parabola or an elliptic curve. According to the length and dimension requirements of the rigid-flexible transition busbar and actual production and installation needs, various curves can be used as reference curves for processing the rigid-flexible transition portion 5 .

Embodiment 3

[0045] The technical solution in this embodiment is basically the same as that in Embodiment 1 or Embodiment 2, except that in this embodiment, the wall thickness of the positioning sleeve 8 is 5 mm.

Embodiment 4

[0047] The technical solution in this embodiment is basically the same as that in Embodiment 1 or Embodiment 2, except that in this embodiment, the wall thickness of the positioning sleeve 8 is 10 mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com