Front end cross beam of stainless steel staircase step

A stainless steel and escalator technology, applied in escalators, transportation and packaging, etc., can solve the problems of poor bending and torsion resistance, unclear assembly standards, etc., achieve clear assembly, reduce investment in process equipment, and improve bending and torsion performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

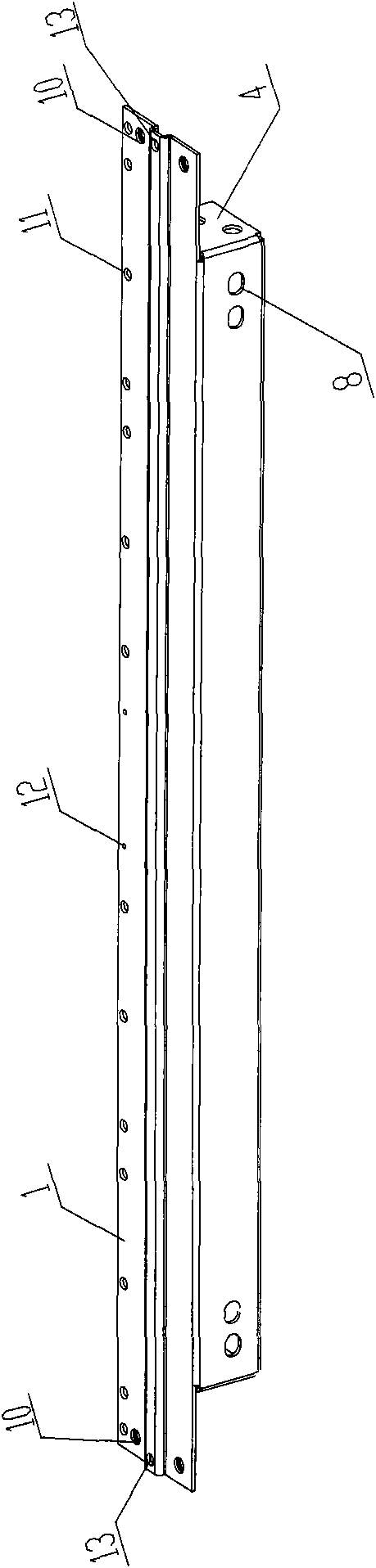

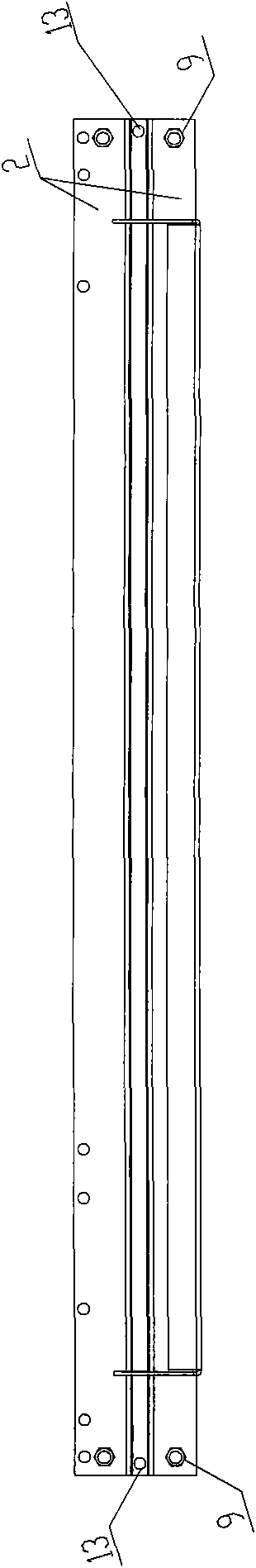

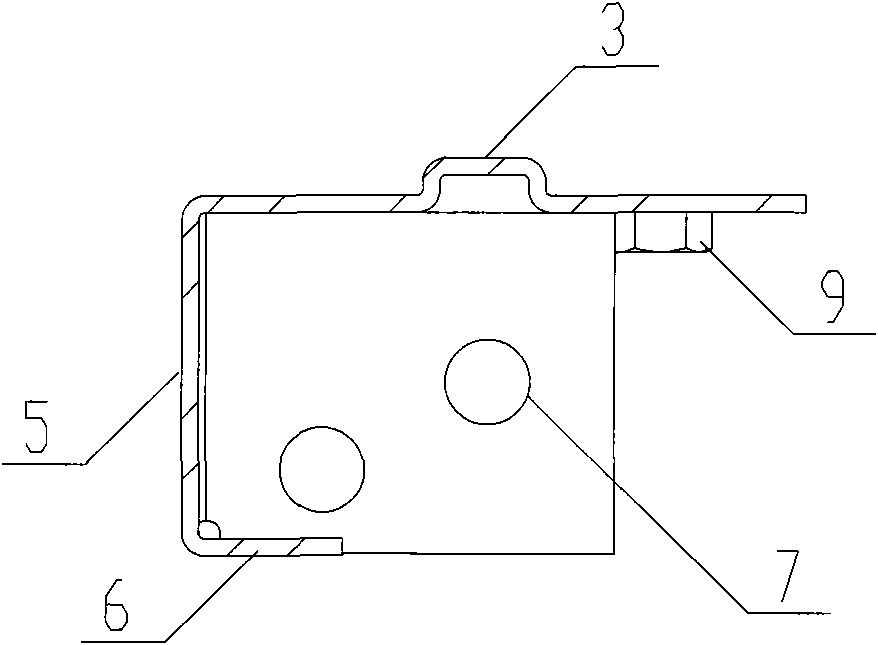

[0012] Below in conjunction with the accompanying drawings, the specific implementation and the essential features of the present invention will be further described. like Figure 1-3 As shown, the embodiment of the present invention is a step front beam, which can be molded and bent by a steel plate with a thickness of 1.8mm. The lower plate surfaces at both ends of the beam body in the horizontal direction are horizontal installation positioning surfaces 2, and the inner concave strip-shaped reinforcing ribs 3 are punched out on the lower plate surface of the beam body 1, and the front frame of the pedal assembly is opened on the plate surface of the beam body 1 The screw connection relief hole 11 and the front frame connection screw hole 12 of the pedal assembly, and weld nut holes 10 are opened at symmetrical positions at both ends of the beam body 1 in the length direction, and the welding nut 9 is inserted into the positioning welding from the lower plate surface for the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com