Microwave curing method and device for composite shaft parts

A technology for shaft parts and composite materials, which is applied in the microwave curing of shaft parts made of composite materials, and in the field of solidification of shaft parts made of composite materials, can solve the problems of deformation forming cycle, poor consistency, high energy consumption, etc., and achieve the improvement of interface bonding force , Fast heating speed and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A microwave curing method for shaft parts made of composite materials. First, the uncured Shuangma resin-based composite material is laid on the surface of a smooth mandrel coated with a release agent to form a shaft part to be cured, and then the to-be-cured The shaft parts are set in a vacuum bag, and the two ends of the vacuum bag are sealed with high temperature resistant tape, and then vacuumed to compact the shaft parts to be cured. After vacuuming and standing still for at least 30 minutes without air leakage Microwave curing oven heating and curing. Then put the compacted shaft parts to be cured together with the mandrel into the microwave curing oven, set the heating parameters of the microwave curing oven according to the composite material heating process, raise the temperature to 180°C at 5°C / min, and keep it warm for 150 minutes. Heating and curing composite shaft parts; after the final heat preservation period is over, the shaft parts are directly removed ...

Embodiment 2

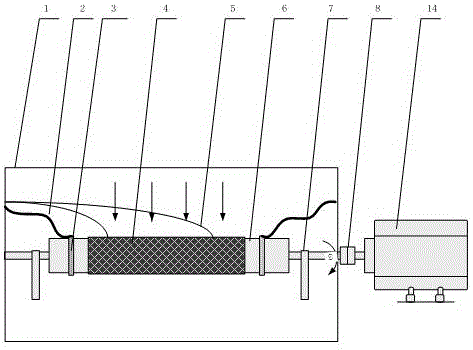

[0032] Such as figure 1 , 2 shown.

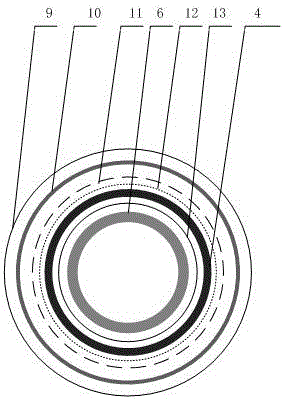

[0033] A microwave curing device for composite material shaft parts, which includes a microwave curing oven 1, a mandrel 6 and a vacuum device, the mandrel is in the shape of a constant diameter or a stepped structure, and the formed shaft parts are correspondingly equal diameter or a structure with multiple shoulders, the two ends of the mandrel 6 are supported on the supporting device 7 in the microwave curing furnace 1, and the position where the composite shaft parts 4 are formed on the mandrel 6 is coated with There is a release agent layer 13, a release cloth 12 is installed on the surface of the composite shaft parts 4, a porous isolation film 11 is provided on the surface of the release cloth 12, and a ventilating film 11 is provided on the surface of the porous isolation film 11. Felt 10, vacuum bag 9 suits on air felt 10, as figure 2 As shown, the two ends of the vacuum bag 9 are fixed on the mandrel 6 by high temperature adhe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com