High-temperature-resistant epoxy glue film and preparation method thereof

An epoxy adhesive film, high temperature resistant technology, used in epoxy resin adhesives, adhesives, polymer adhesive additives, etc., can solve problems such as unfavorable assembly, affecting production efficiency, energy consumption, shedding, etc. The molding time, the preparation process are simple and easy, and the heating and curing time is short.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

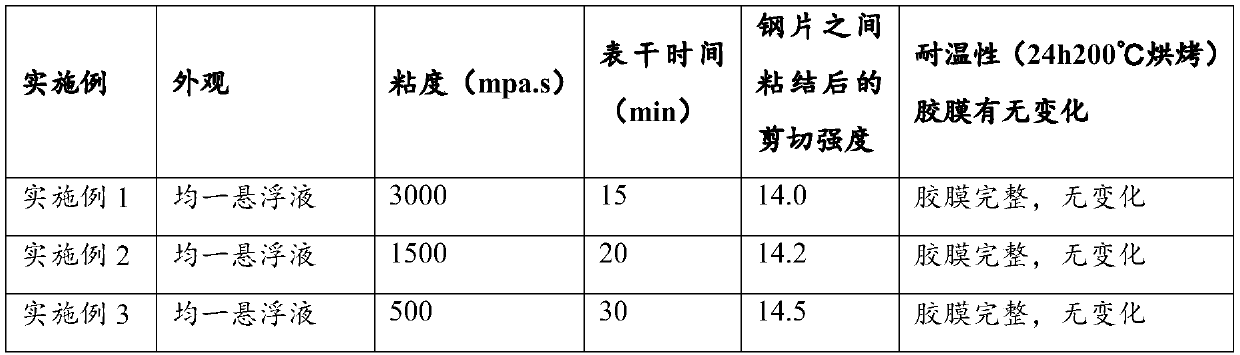

Examples

Embodiment 1

[0030] The present embodiment provides a high temperature resistant epoxy adhesive film, which is composed of the following percentages of raw materials:

[0031] 62 parts of resin,

[0032] 7 parts of toughening agent,

[0033] 20 parts of curing agent,

[0034] 35 parts of solvent.

[0035] In this embodiment, the resins are 43 parts of solid bisphenol A resin and 9 parts of liquid phenolic resin.

[0036] In this embodiment, the solvent is ethyl acetate.

[0037] In this embodiment, the toughening agent is 7 parts of liquid nitrile rubber.

[0038] In this embodiment, the curing agent is modified imidazoles: aromatic amine curing agent in a ratio of 5:15 to mix 20 parts of the curing agent.

[0039] A preparation method of a high temperature resistant epoxy adhesive film, comprising the following steps:

[0040] 1) Weigh the raw materials of each component in proportion;

[0041] 2) under the condition that the rotating speed of the mixer is 500r / min, the resin is di...

Embodiment 2

[0044] The present embodiment provides a high temperature resistant epoxy adhesive film, which is composed of the following percentages of raw materials:

[0045] 100 parts of resin,

[0046] 7 parts of toughening agent,

[0047] 20 parts of curing agent,

[0048] 30 parts of solvent.

[0049] In this embodiment, the resins are 45 parts of solid bisphenol A resin and 55 parts of liquid phenolic resin.

[0050] In this embodiment, the solvent is ethyl acetate.

[0051] In this embodiment, the toughening agent is 7 parts of liquid nitrile rubber.

[0052] In this embodiment, the curing agent is modified imidazoles: aromatic amine curing agent in a ratio of 5:15 to mix 20 parts of the curing agent.

[0053] A preparation method of a high temperature resistant epoxy adhesive film, comprising the following steps:

[0054] 1) Weigh the raw materials of each component in proportion;

[0055] 2) under the condition that the rotating speed of the mixer is 500r / min, the resin is ...

Embodiment 3

[0058] The present embodiment provides a high temperature resistant epoxy adhesive film, which is composed of the following percentages of raw materials:

[0059] 20 parts of resin,

[0060] 7 parts of toughening agent,

[0061] 20 parts of curing agent,

[0062] 35 parts of solvent.

[0063] In this embodiment, the resins are 10 parts of solid bisphenol A resin and 10 parts of liquid phenolic resin.

[0064] In this embodiment, the solvent is ethyl acetate.

[0065] In this embodiment, the toughening agent is 7 parts of liquid nitrile rubber.

[0066] In this embodiment, the curing agent is modified imidazoles: aromatic amine curing agent in a ratio of 5:15 to mix 20 parts of the curing agent.

[0067] A preparation method of a high temperature resistant epoxy adhesive film, comprising the following steps:

[0068] 1) Weigh the raw materials of each component in proportion;

[0069] 2) under the condition that the rotating speed of the mixer is 500r / min, the resin is d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com