Light anti-bending and anti-torsion bionic composite material and preparation method thereof

A biomimetic composite material, bending and twisting technology, applied in chemical instruments and methods, synthetic resin layered products, transportation and packaging, etc., can solve the problems of large weight, low bending and torsional strength, poor chemical stability, etc., and achieve small specific gravity , Larger specific strength and larger specific modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

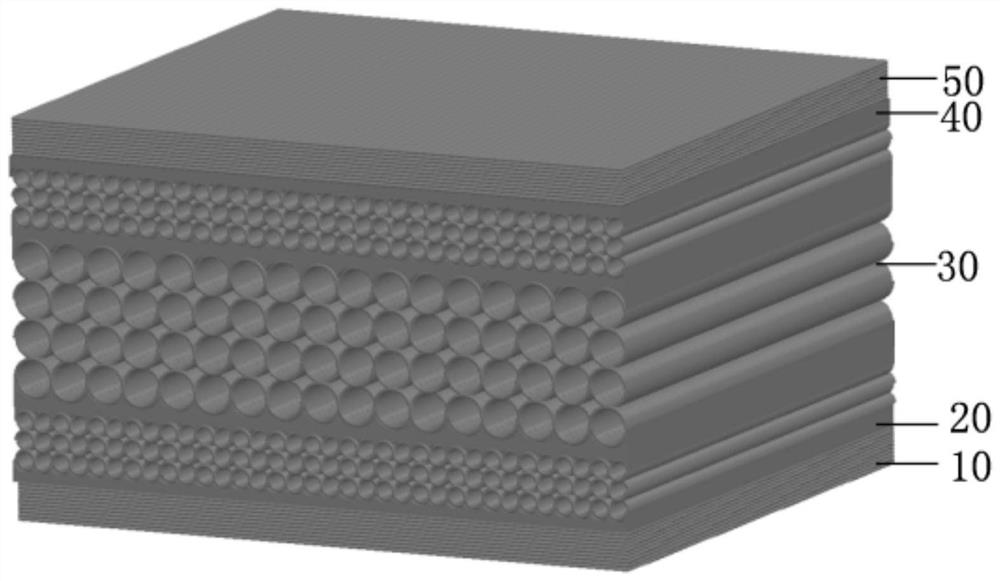

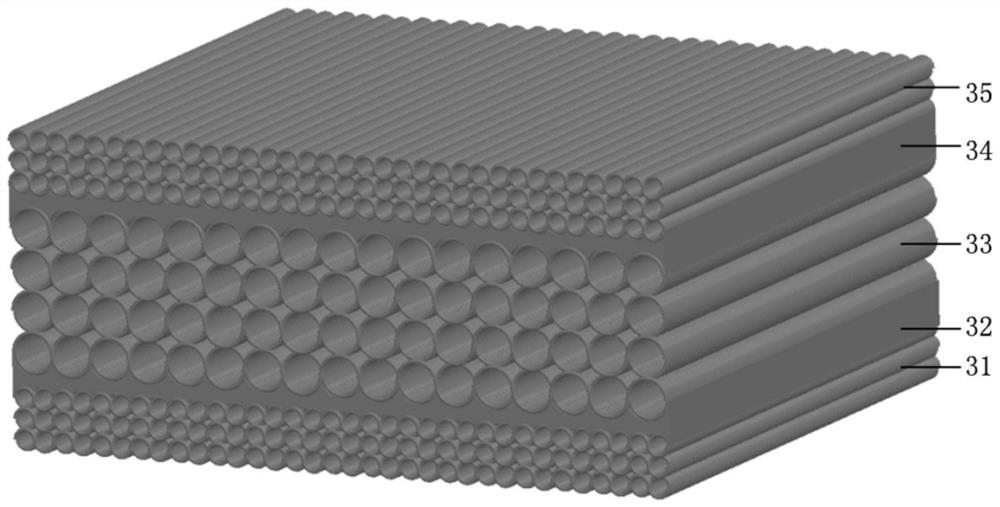

[0034] The present invention provides a light-weight bending-resistant bionic composite material and its preparation method. In order to make the purpose, technical solution and effect of the present invention clearer and clearer, the present invention will be further described in detail below. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

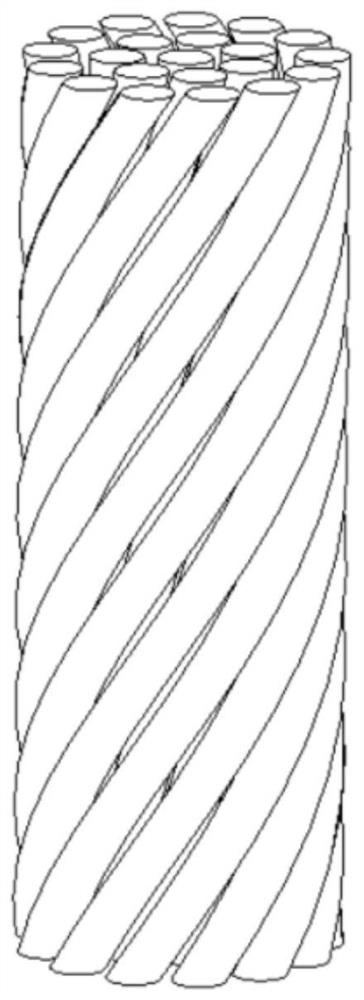

[0035]There are many light-weight, high-strength, high-toughness, high specific stiffness, and bending-torsion-resistant materials in nature for researchers to study and study, get inspiration from them, and carry out combined bionic design for daily design and manufacturing. As a flying animal, bird far exceeds other flying animals such as mammals (bats) and insects in terms of efficiency and time. Studies have shown that the reason why birds have such efficient flight capabilities is due to the structural properties of their feather...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com