Partition organization for front floor of vehicle body

A block structure and front floor technology, which is applied to the upper structure, upper structure sub-assembly, vehicle parts, etc., can solve the problems of reducing the rigidity and strength of the front floor, inconvenient production and transportation, and reduced occupant comfort. The weight of the vehicle body is beneficial to vibration reduction and the effect of improving comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

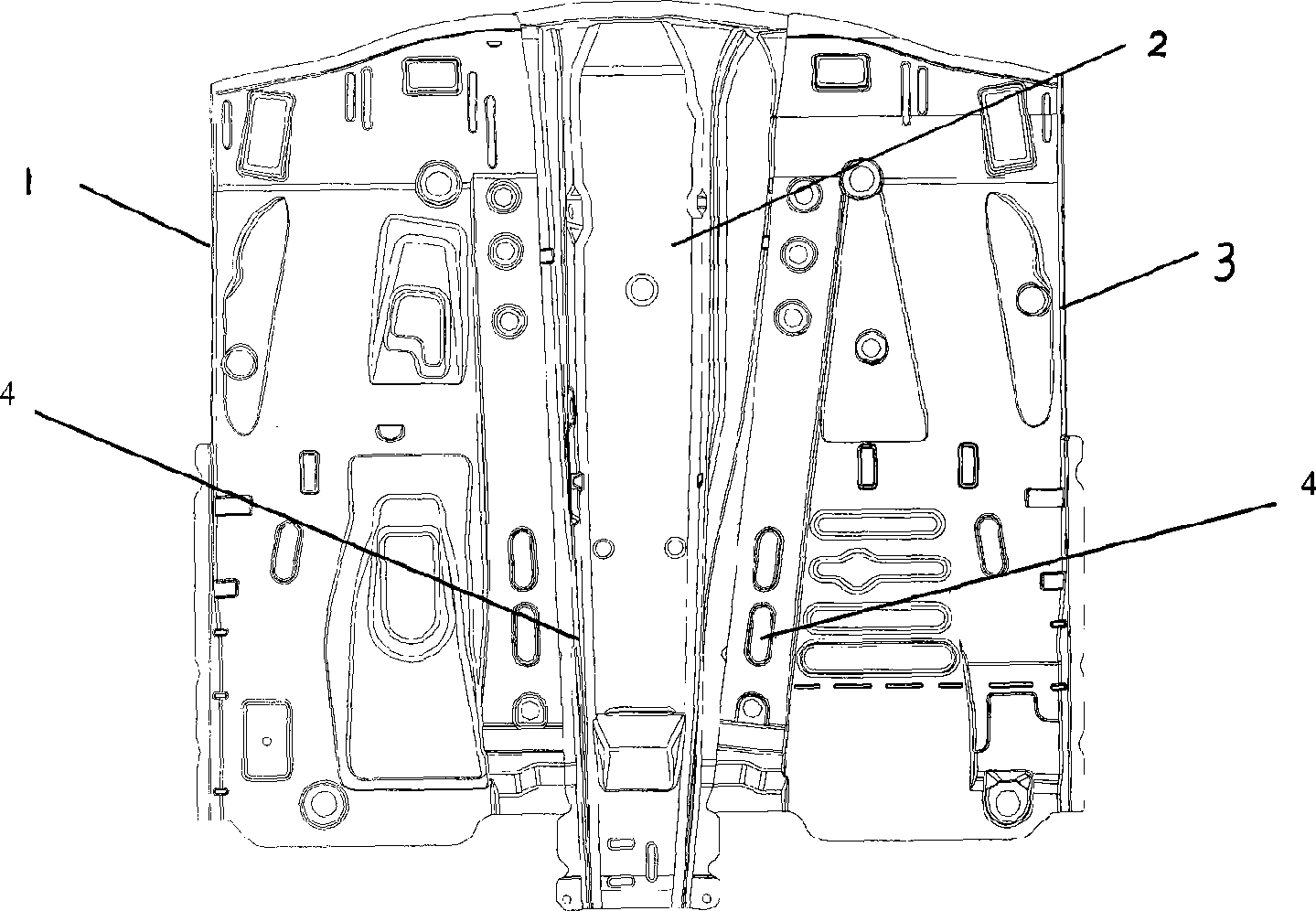

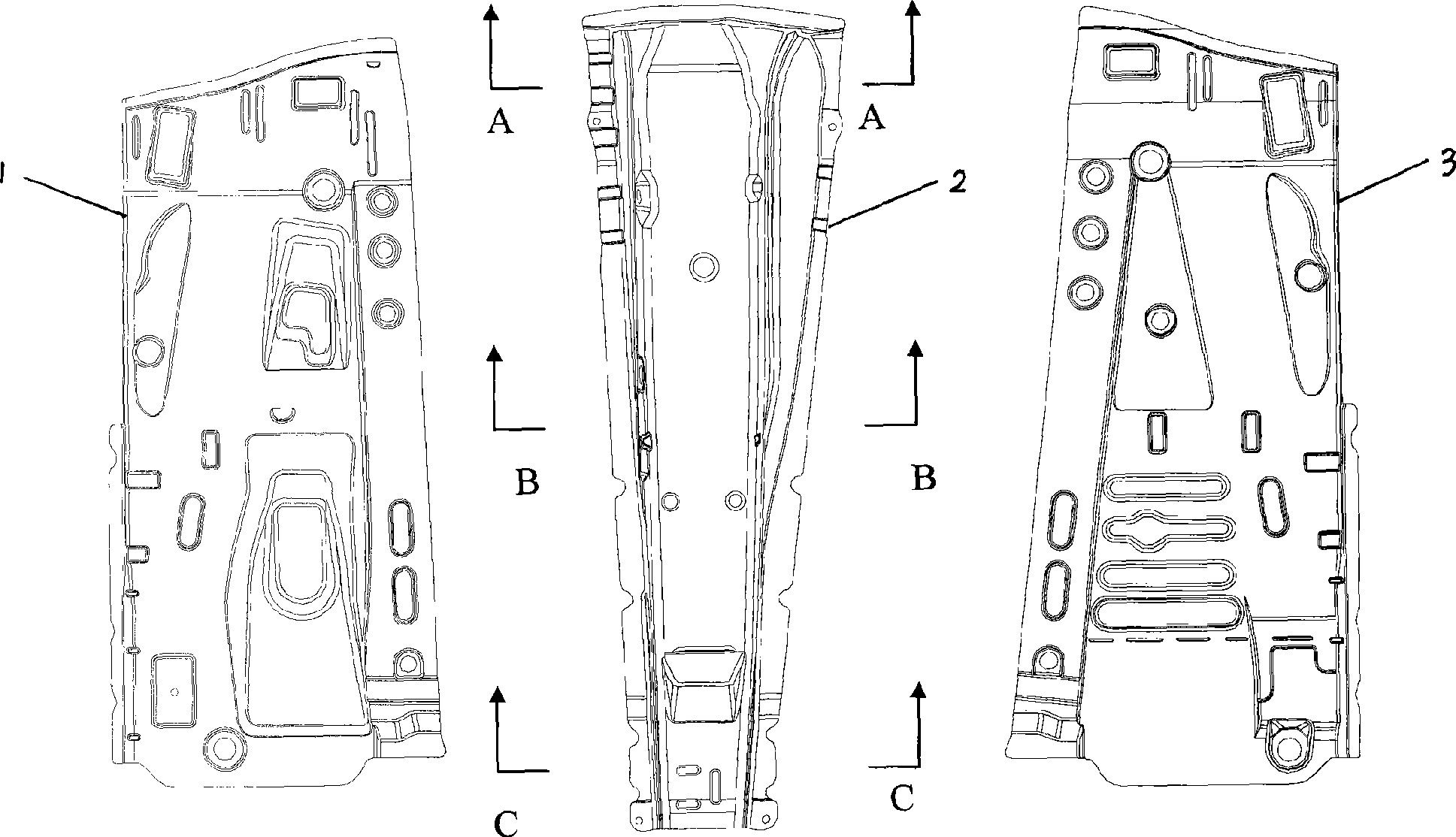

[0016] Such as figure 1 and figure 2 As shown, the front floor is divided into front floor left 1, front floor middle bulge 2 and front floor right 3. The parts of each part form an integral floor plate shell by spot welding, and 4 is the welding edge. The front floor left and front floor right are made of very mature ordinary cold-rolled steel plates for the body, DC01 with a thickness of 0.7mm. The central bulge is made of phosphorus-containing high-strength steel plate B210P1 with a thickness of 1.2mm.

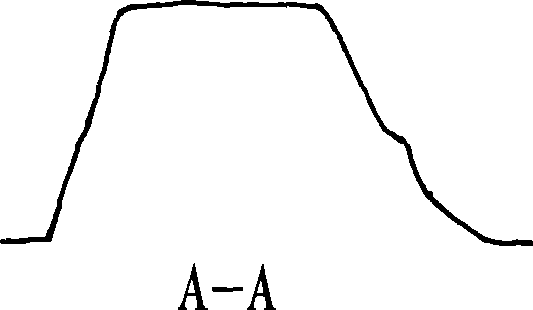

[0017] see Figure 3A , Figure 3B , Figure 3C , wherein the cross-section of the bulge 2 in the front floor is several fonts, and is a variable cross-section structure in which the cross-section gradually decreases from one end to the other end.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com