Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36results about How to "Improve anti-twist performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

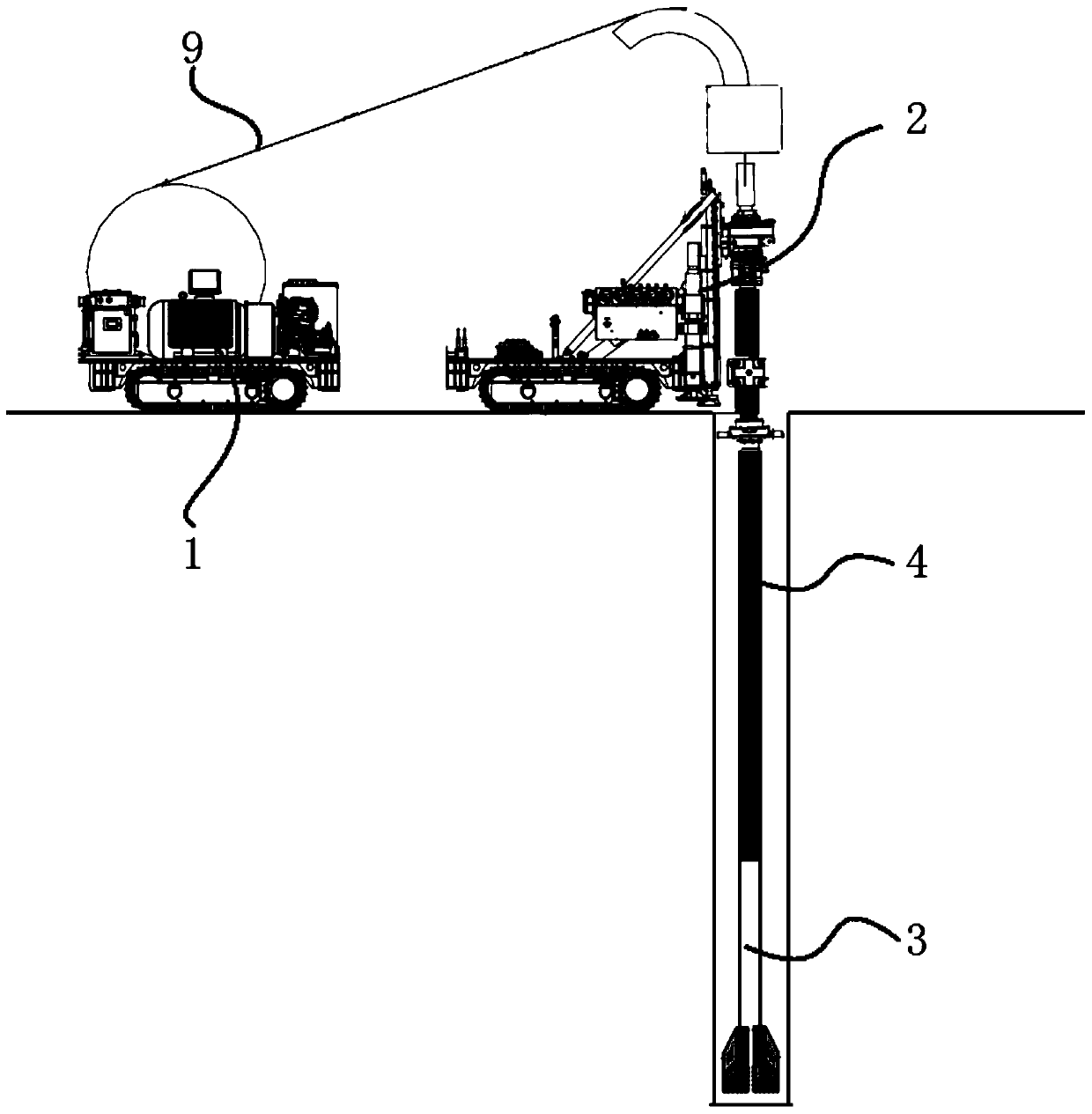

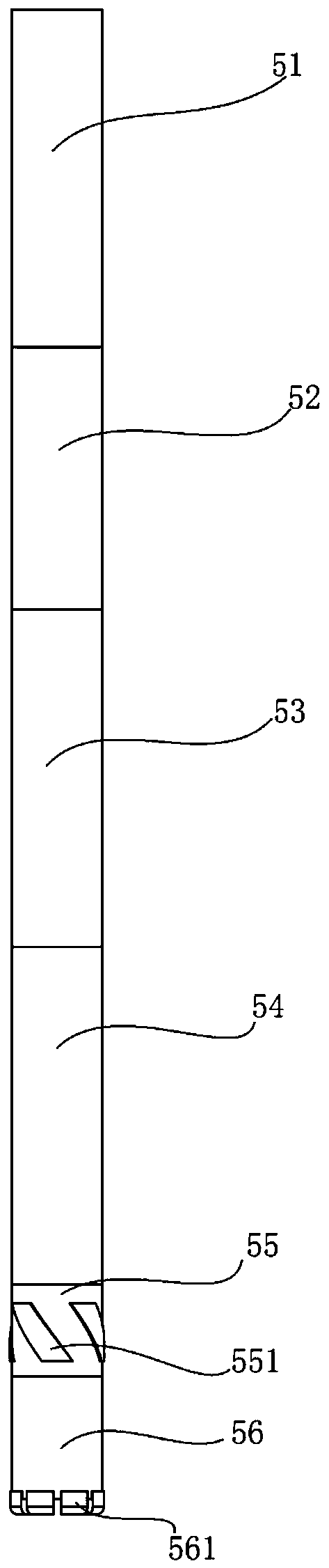

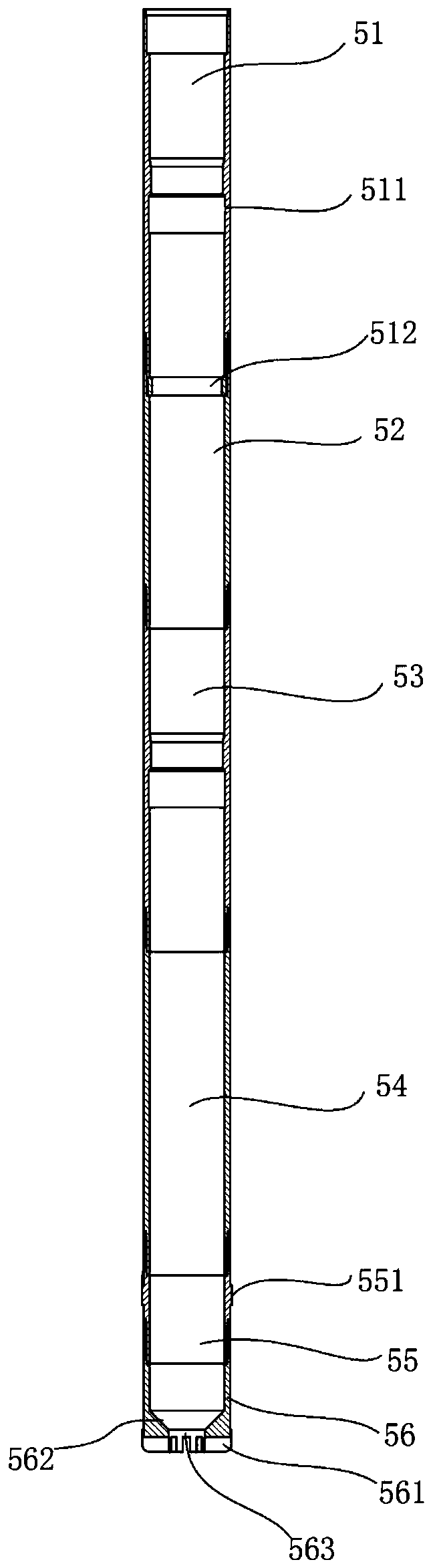

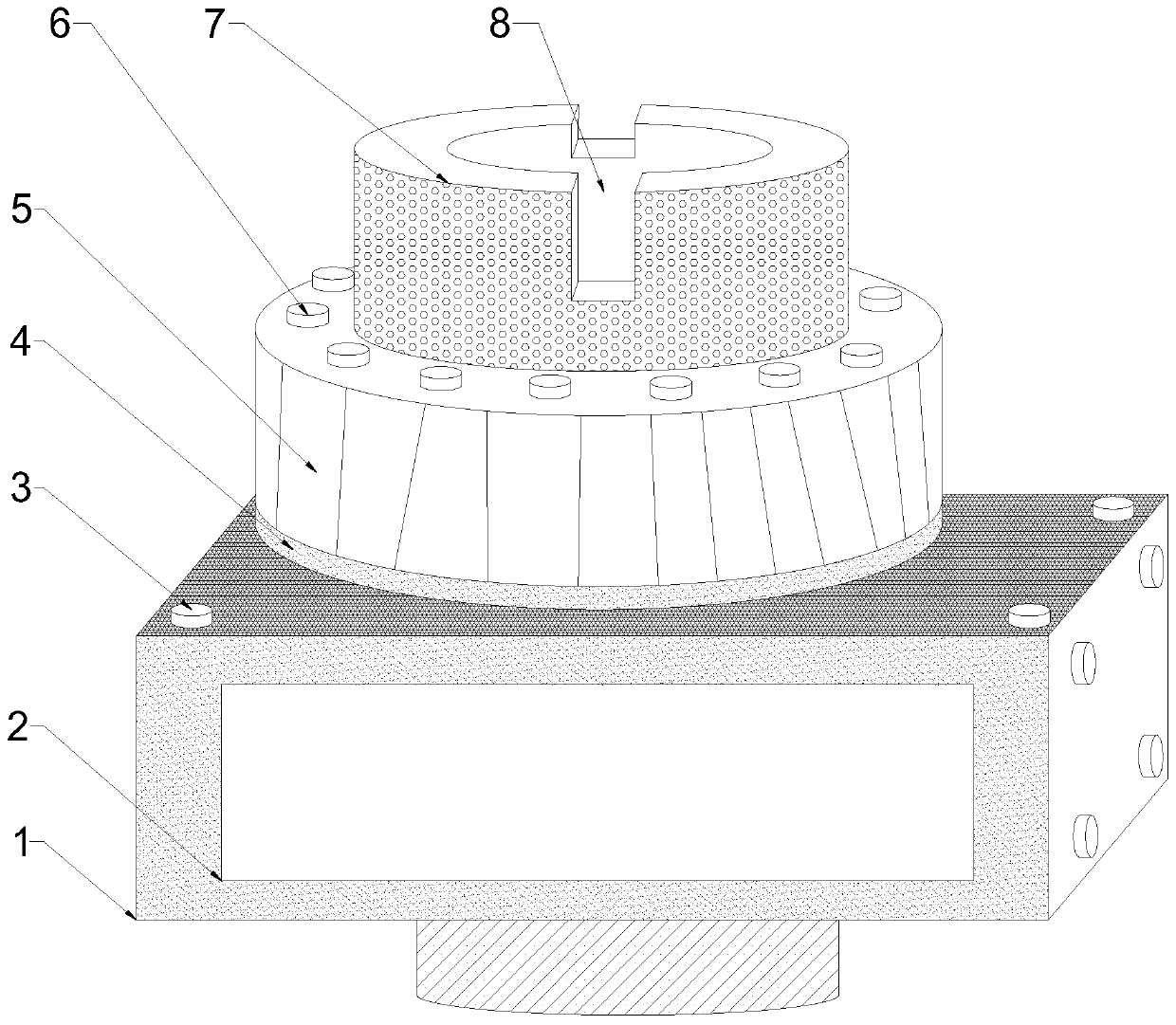

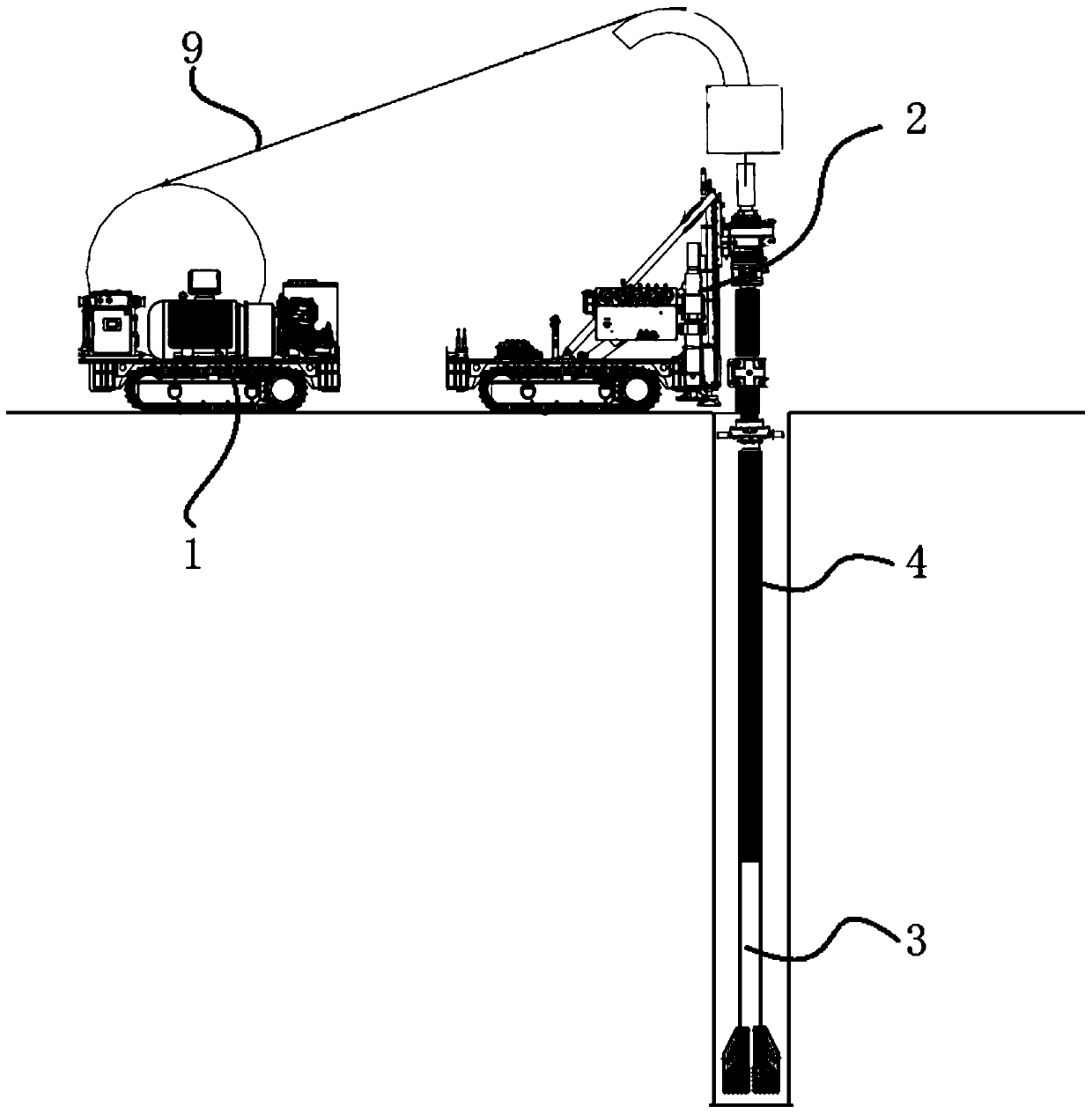

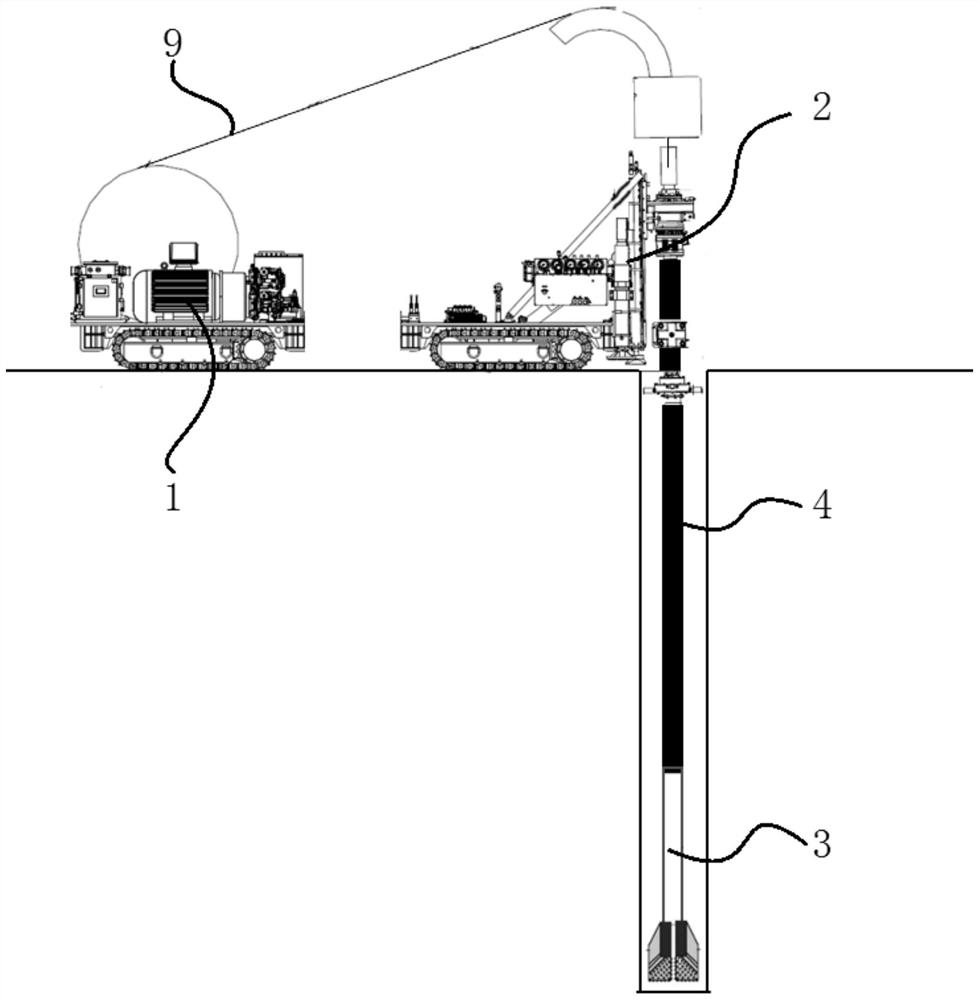

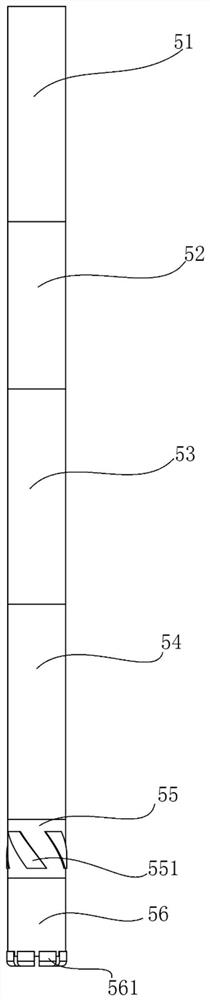

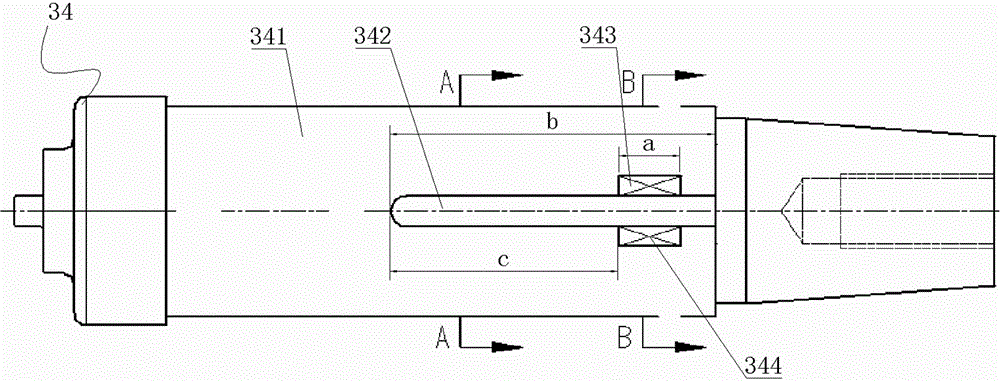

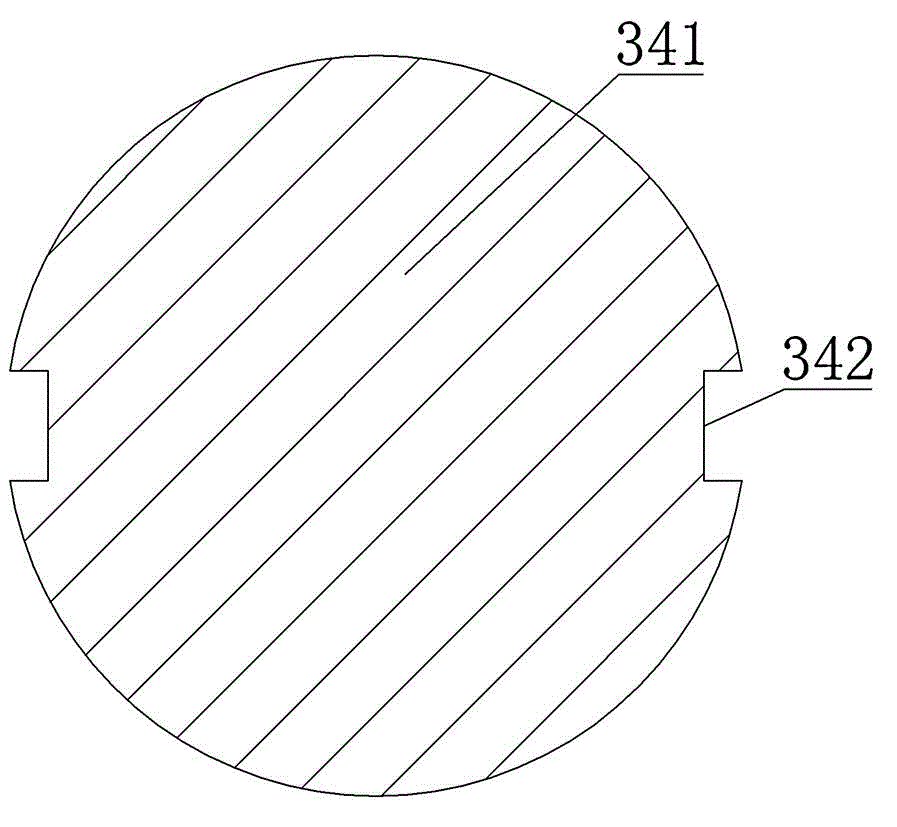

Continuous conduit type coring equipment

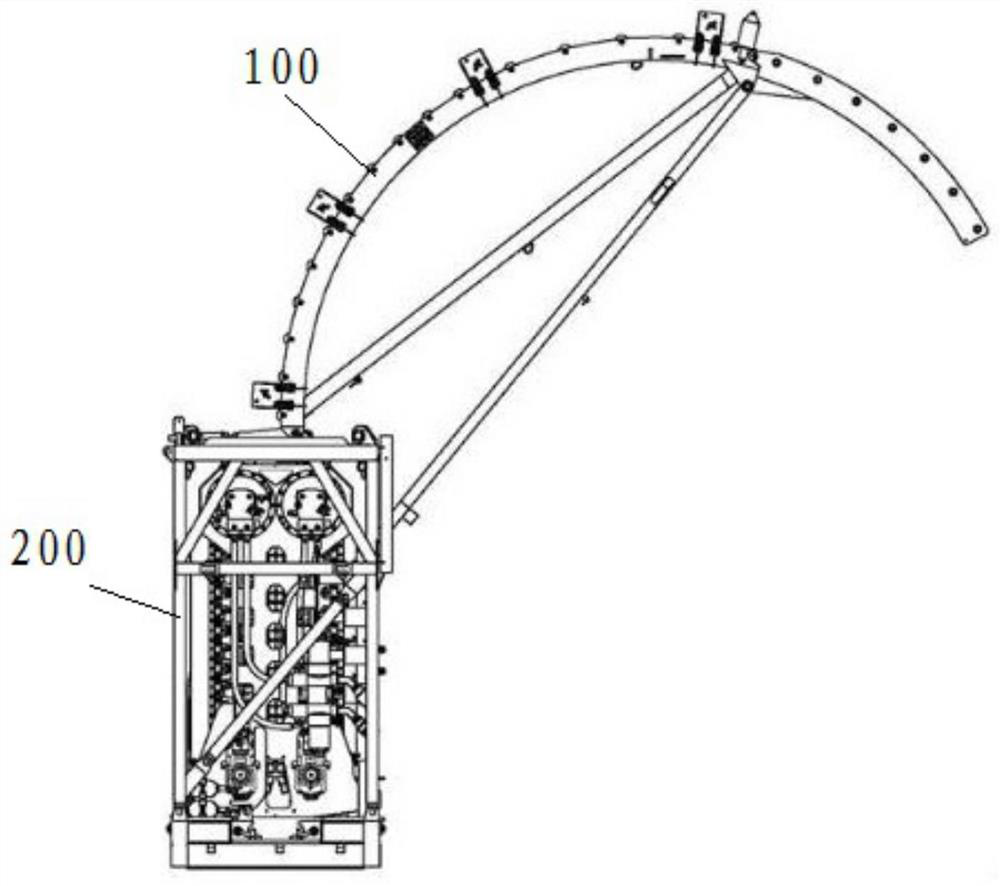

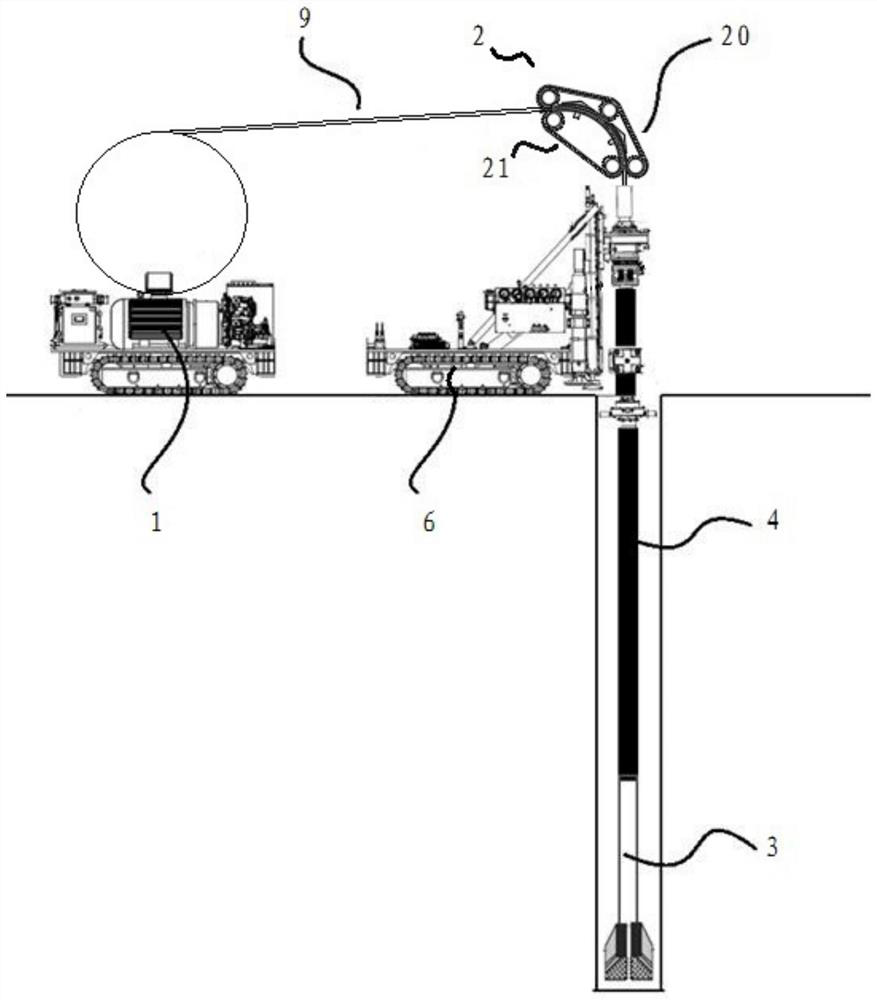

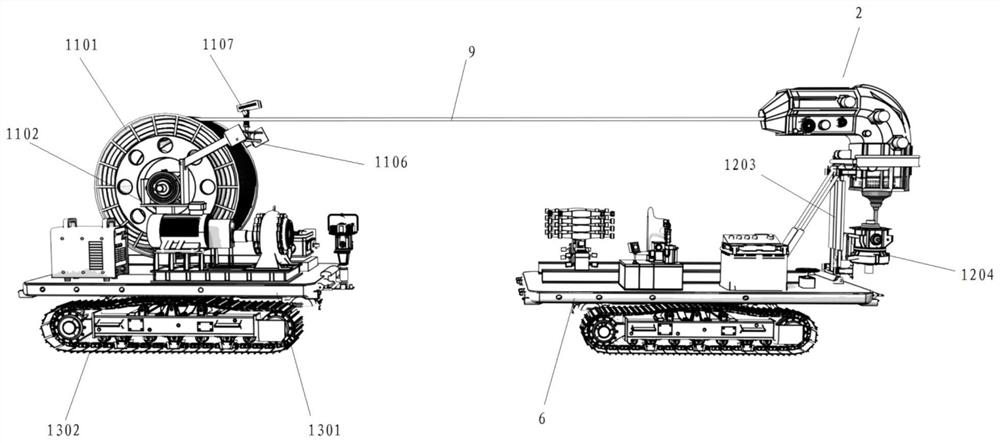

PendingCN111810072AReal-time measurementPlay the role of "rope"Drilling rodsDrilling casingsCable transmissionControl signal

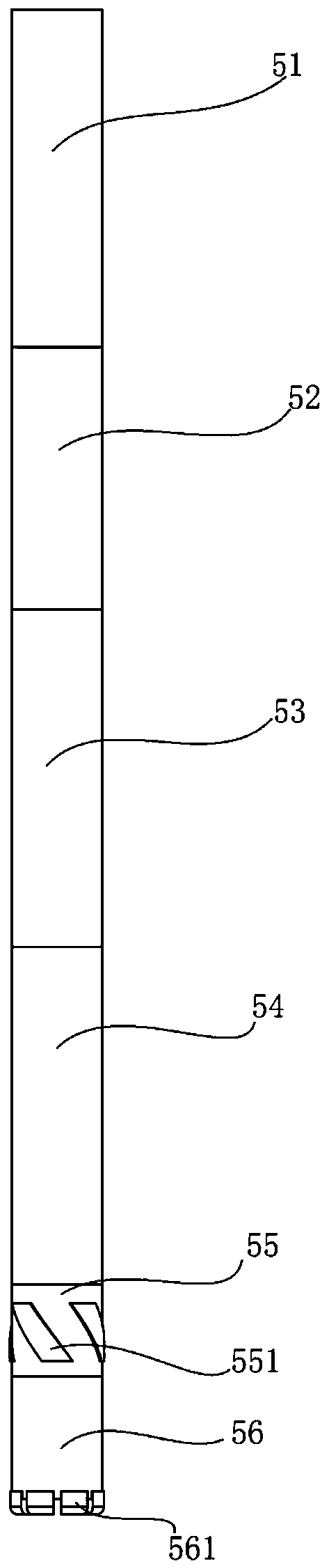

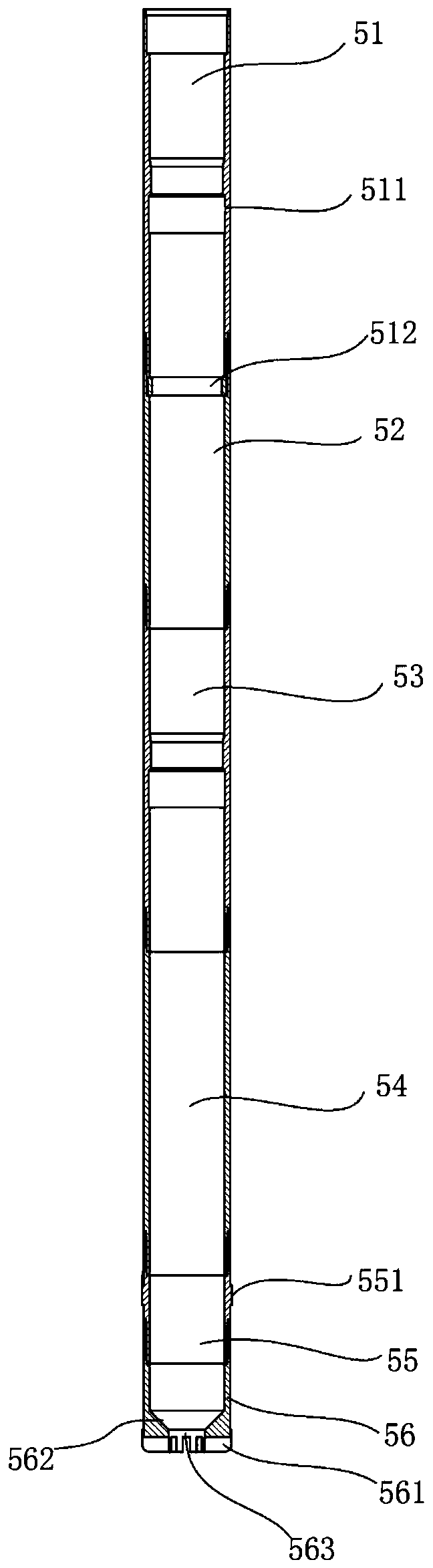

The invention relates to continuous conduit type coring equipment which comprises a coring device and a continuous conduit operation device. The coring device comprises an inner pipe assembly and an outer pipe assembly, and the inner pipe assembly can be connected with the outer pipe assembly in a clamping manner; the outer pipe assembly comprises an outer pipe and a drill bit arranged on the outer pipe, and the inner pipe assembly comprises an inner pipe component and a central rod; the inner pipe component comprises a core inner cylinder, a core outer cylinder and a pressure retaining valvearranged at the bottom of the core outer cylinder; and the continuous conduit operation device comprises a continuous conduit and a guiding and injecting integrated mechanism capable of pulling the continuous conduit down or out, wherein the continuous conduit is used for lowering and lifting the inner pipe assembly. The pressure maintaining coring device is lifted up and lowered by using the continuous conduit operation device, a cable can penetrate in the continuous conduit conveniently transmit measurement and control signals, and real-time measurement of hole bottom parameters is facilitated; the guiding and injecting integrated mechanism integrates a guiding function and an injecting function, a guide gooseneck can be omitted, and the height of the equipment can be effectively reduced; and the equipment is particularly suitable for operation environments with the limited space height.

Owner:SICHUAN UNIV

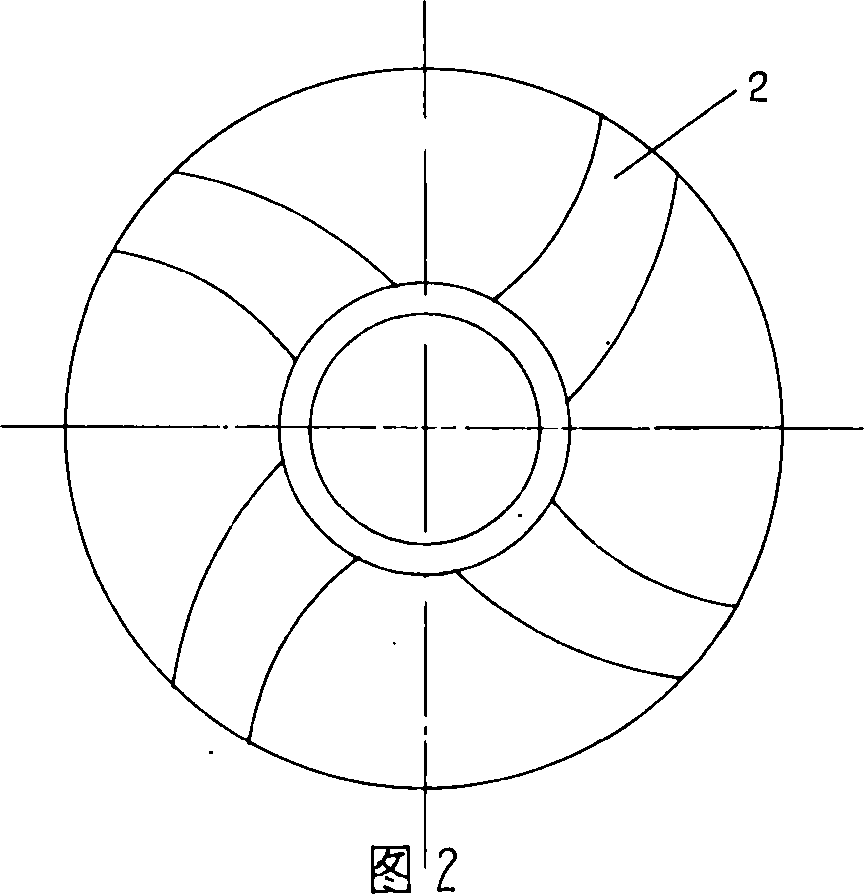

Die pressing plastic and steel fan impeller production process and special mould

The invention relates to a method for producing molded plastic steel fan blade wheel, and relative special mould, wherein it mainly comprises: producing integrated skeleton, producing base middle element, molding, and demoulding; the special mould comprises the upper and lower moulds and the overflow structure. The invention has the advantages that: it has high producing efficiency, high quality and high accuracy; the inventive blade wheel has light weight, high strength, high accuracy and stable operation.

Owner:张世忠

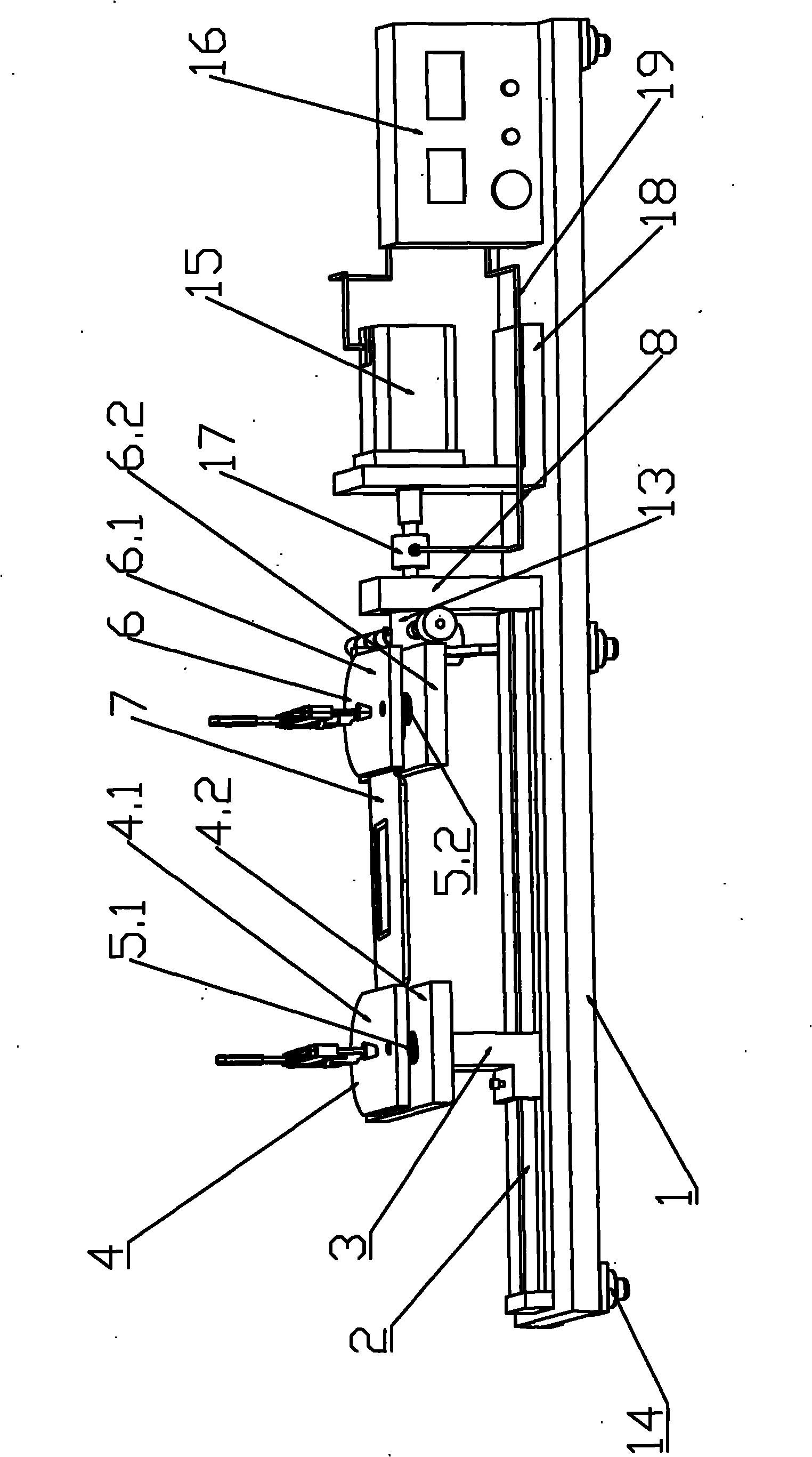

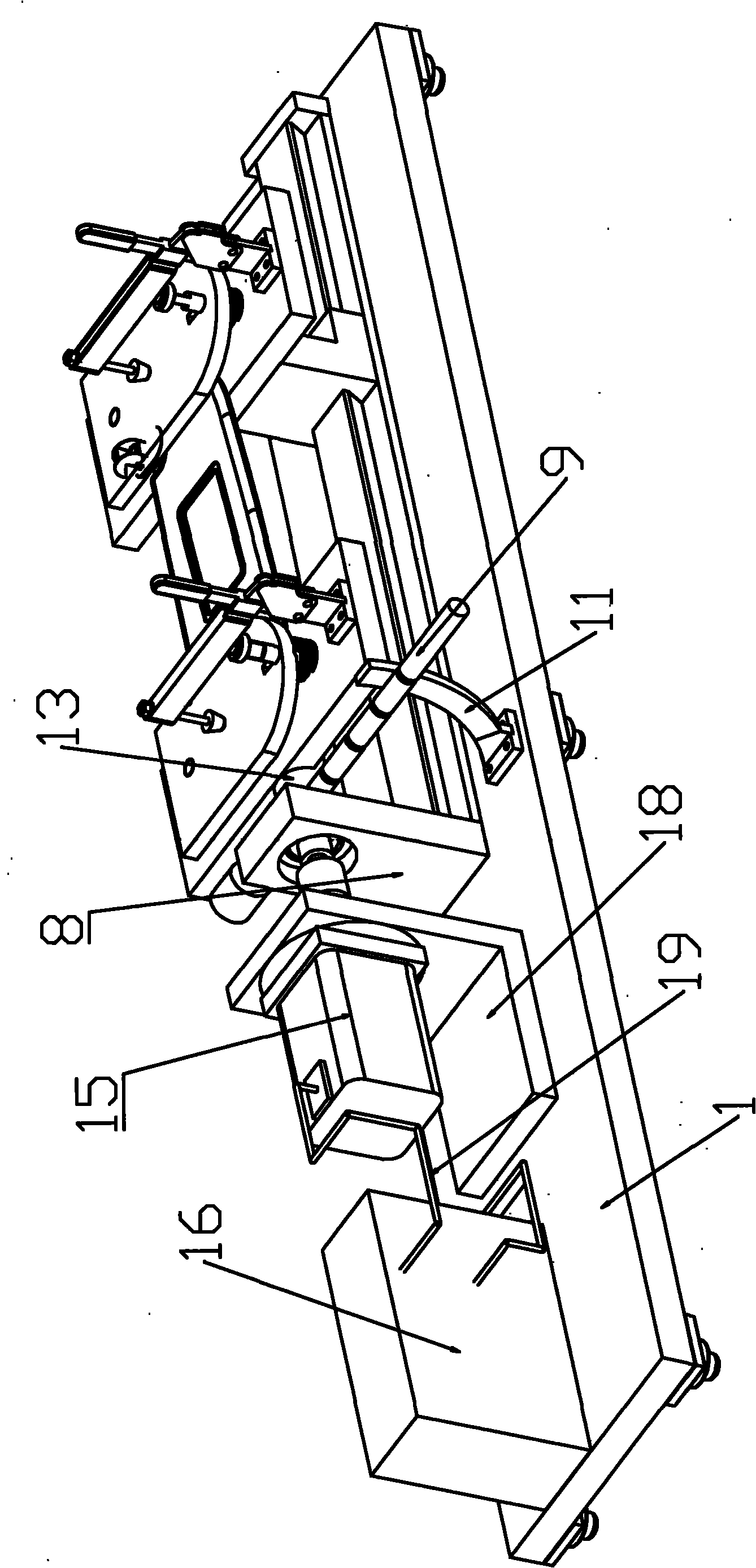

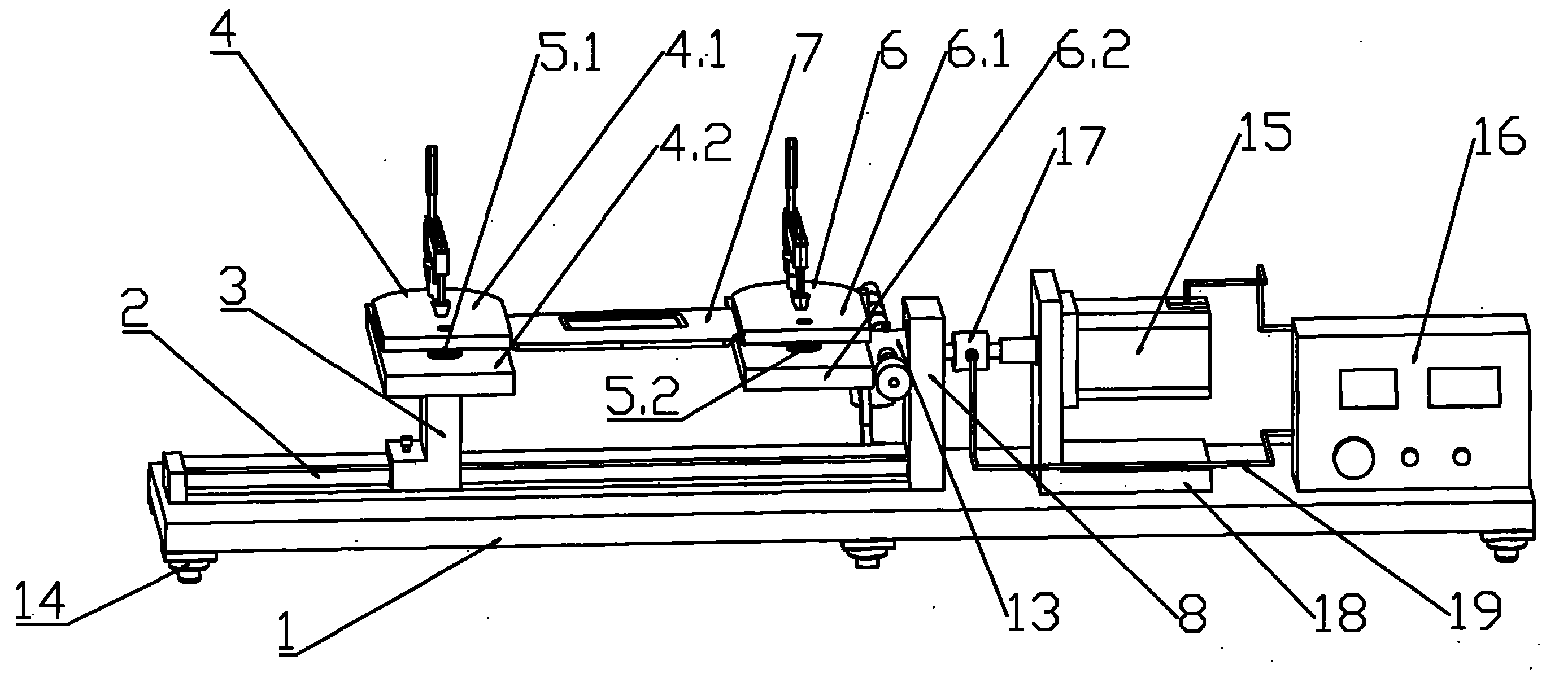

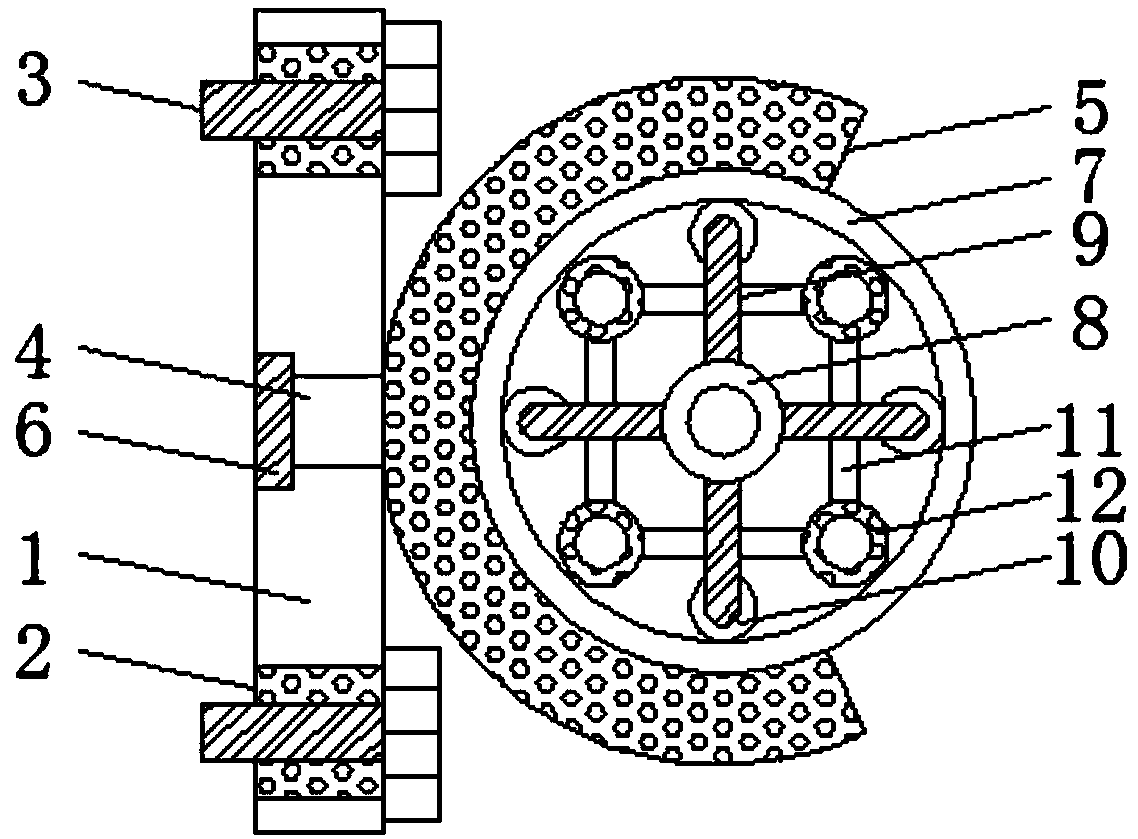

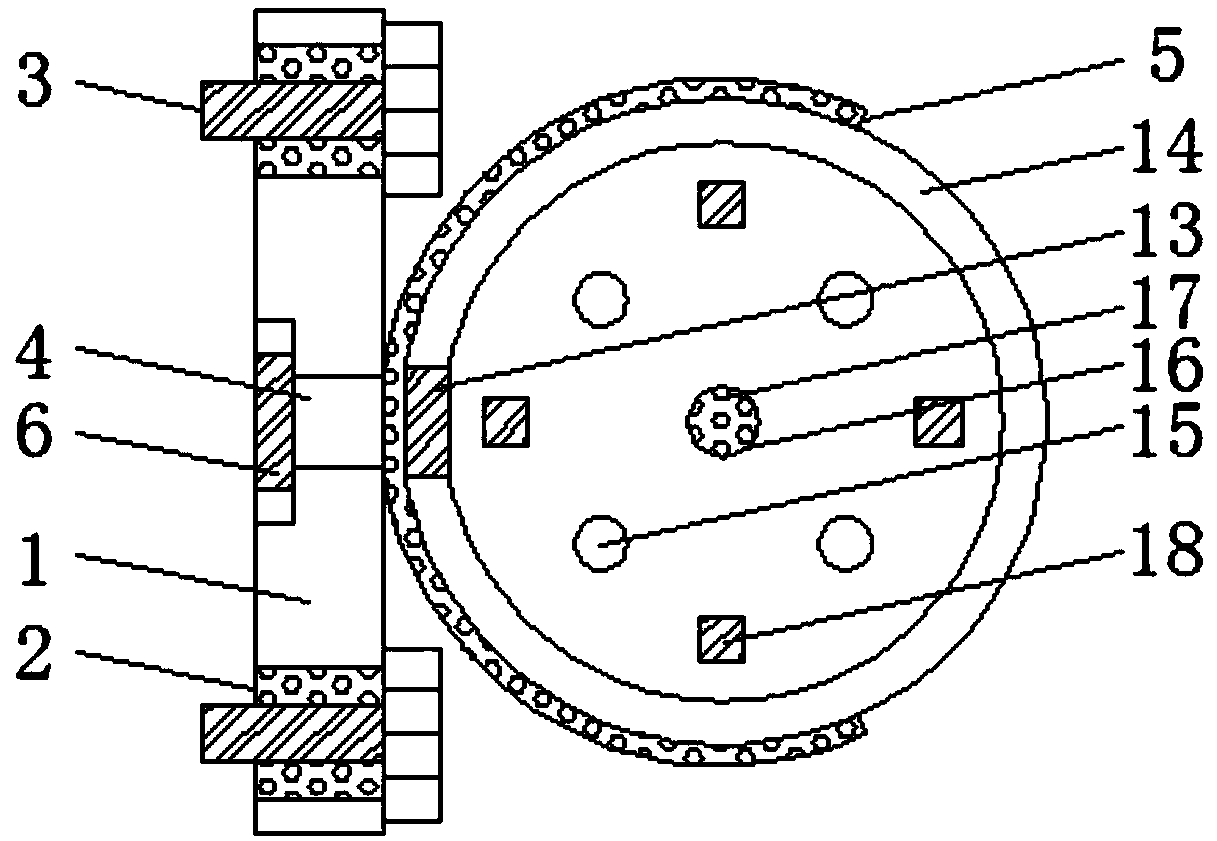

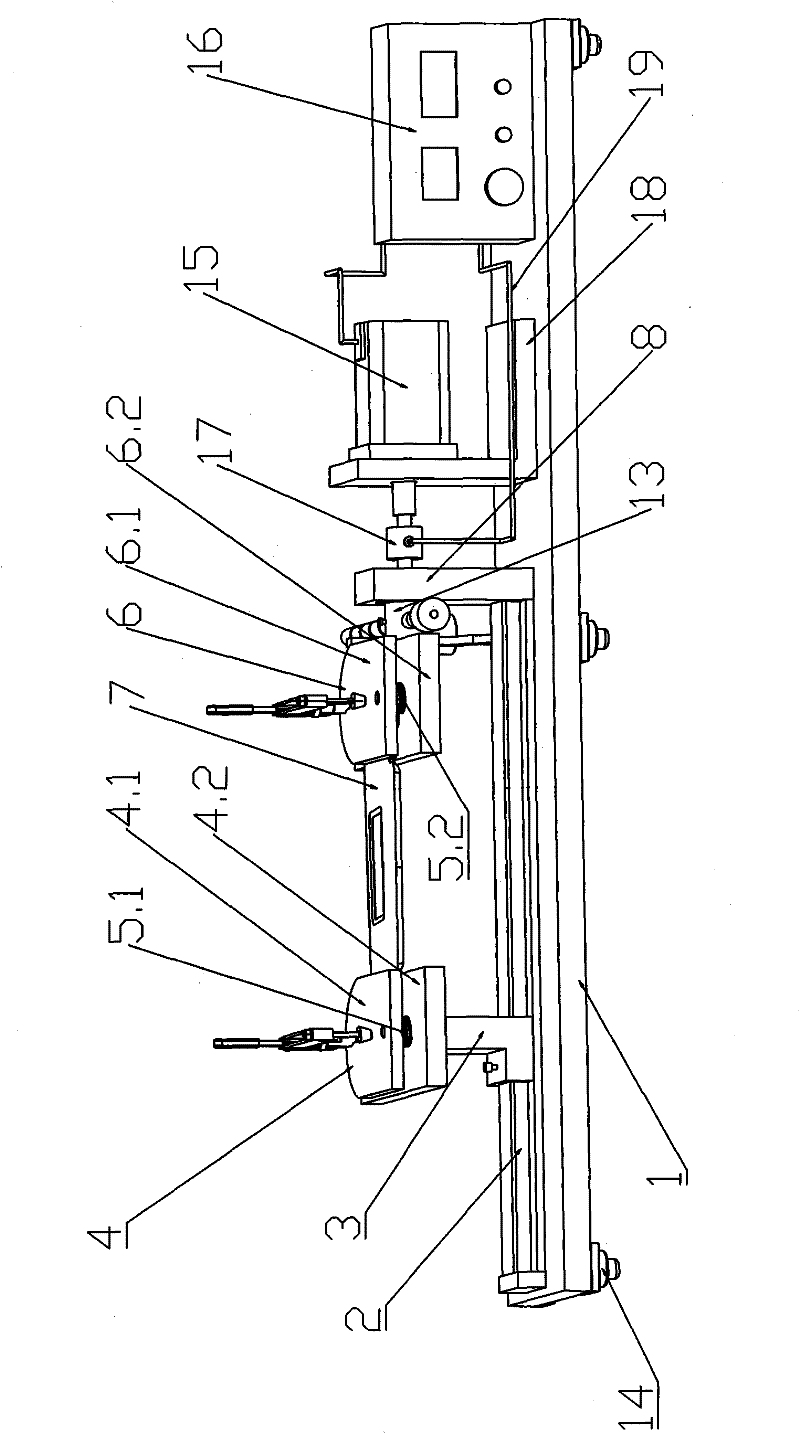

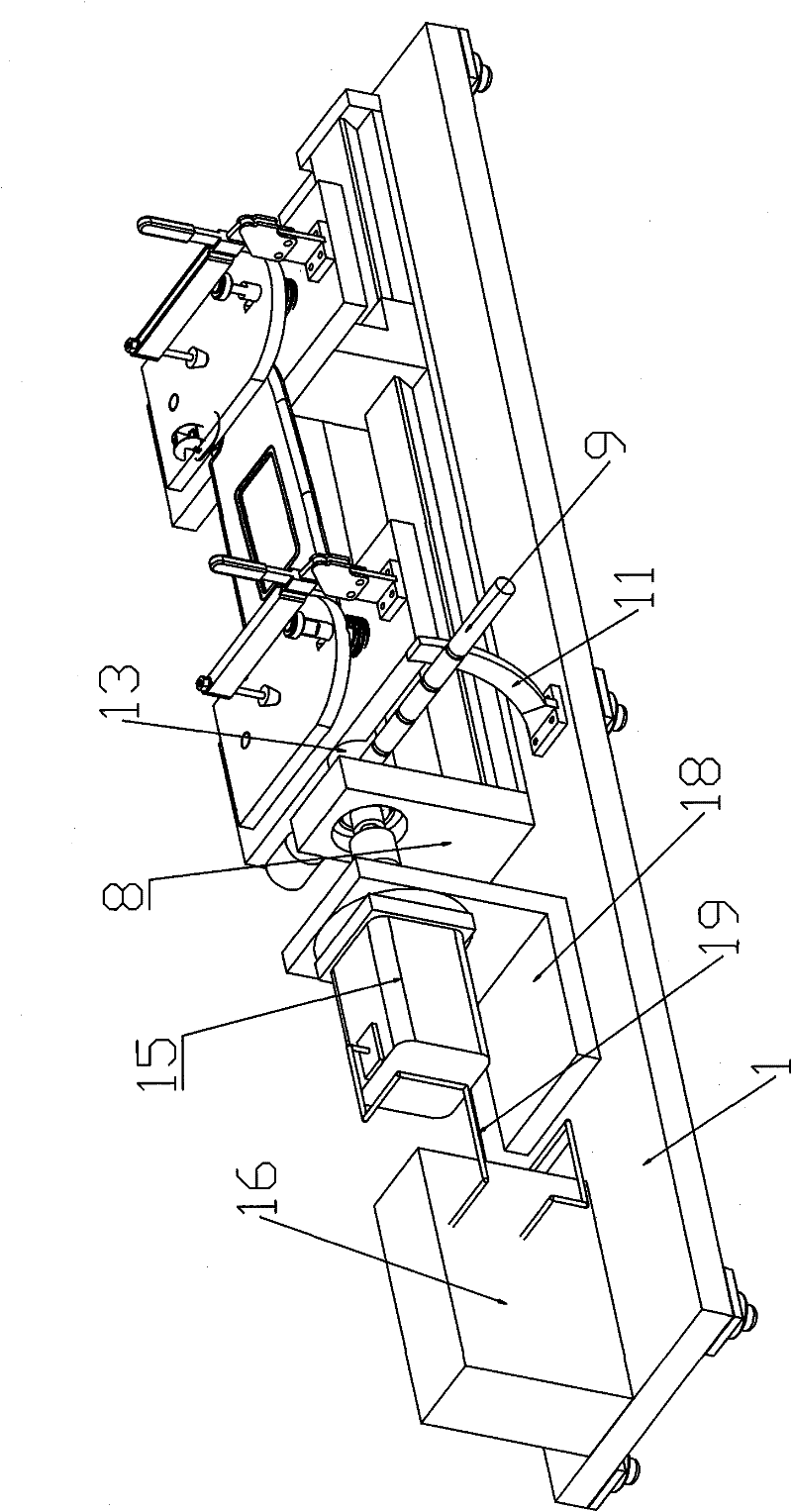

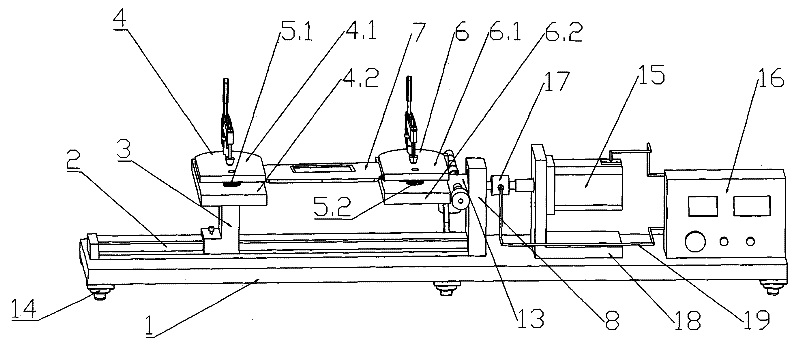

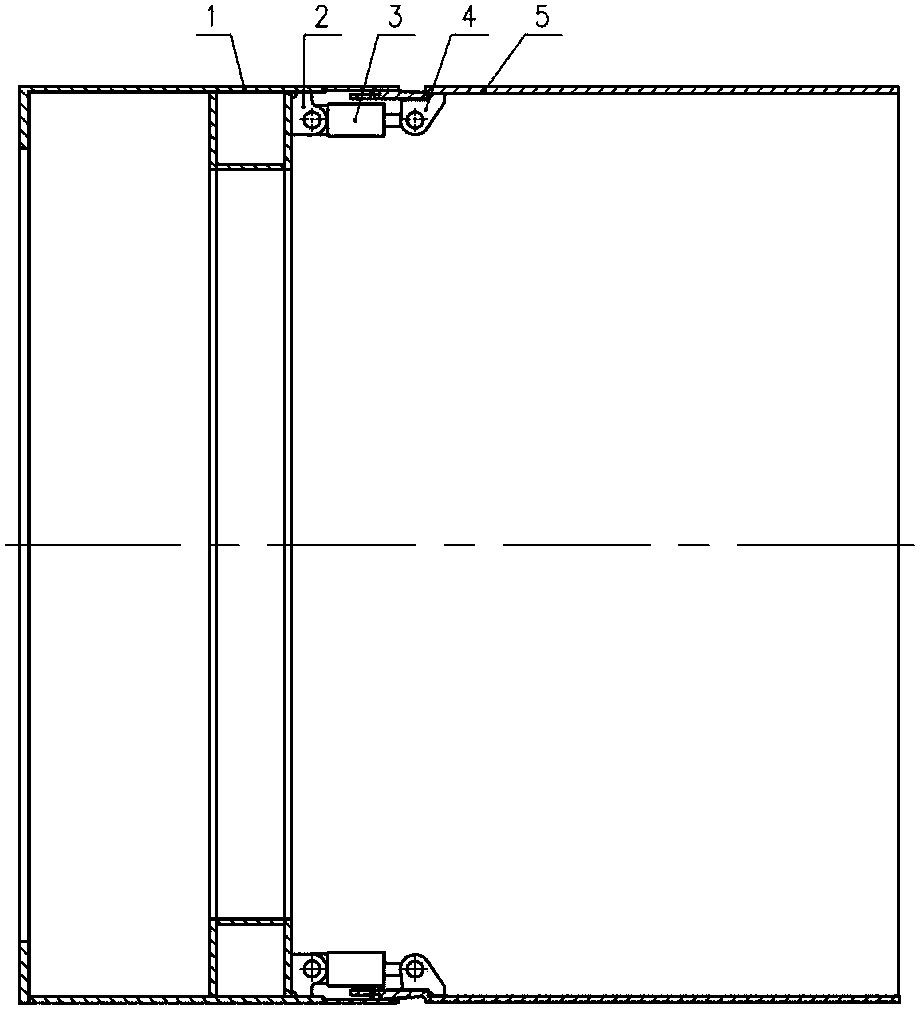

Automobile sunshade plate distortion test device

ActiveCN102072813AImprove anti-twist performanceEasy to operateMachine part testingFixed frameDrive shaft

The invention discloses an automobile sunshade plate distortion test device. The device comprises a base 1, a first fixed frame 3, a second fixed frame 8, a first clamp 4, a second clamp 6, a transmission shaft 13, a lever 9, an angle calibrated scale 11, a servo motor 15, a torque sensor 17 and a motor controller 16. The automobile sunshade plate distortion test device is convenient to operate and simple in test, and can conveniently test the distortion resistance of an automobile sunshade plate.

Owner:NINGBO SUNLIGHT MOTOR PARTS

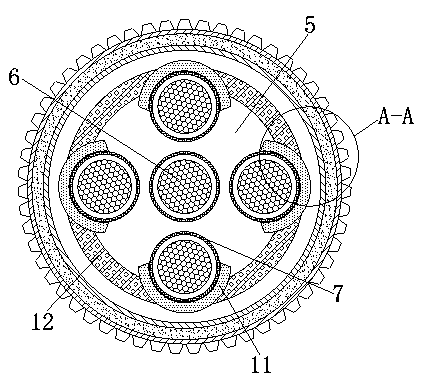

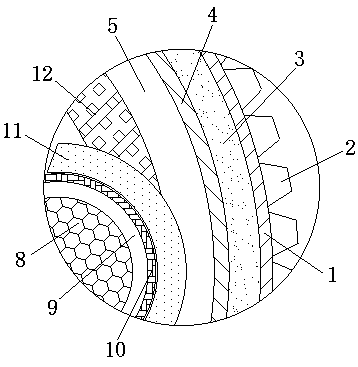

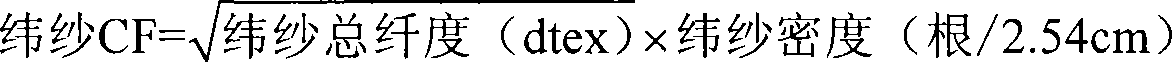

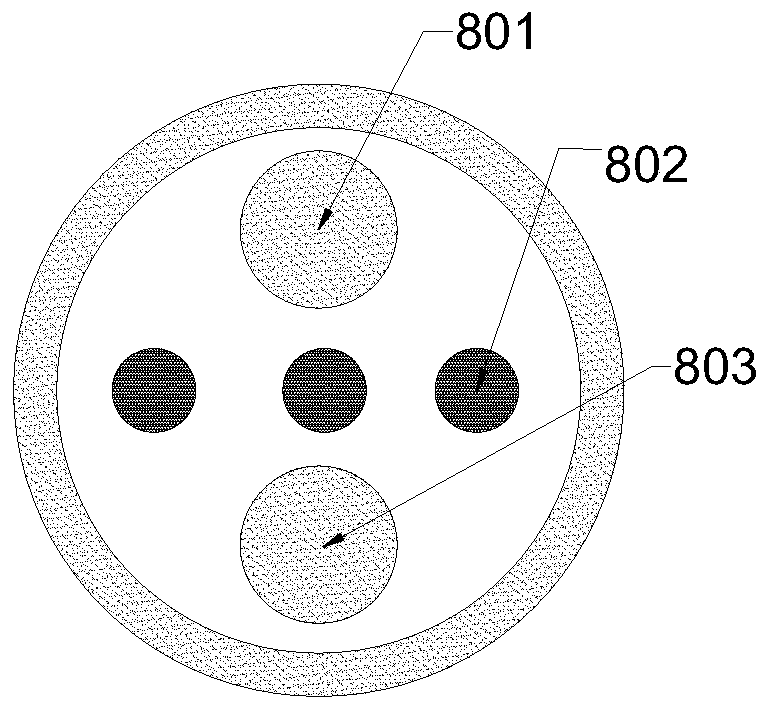

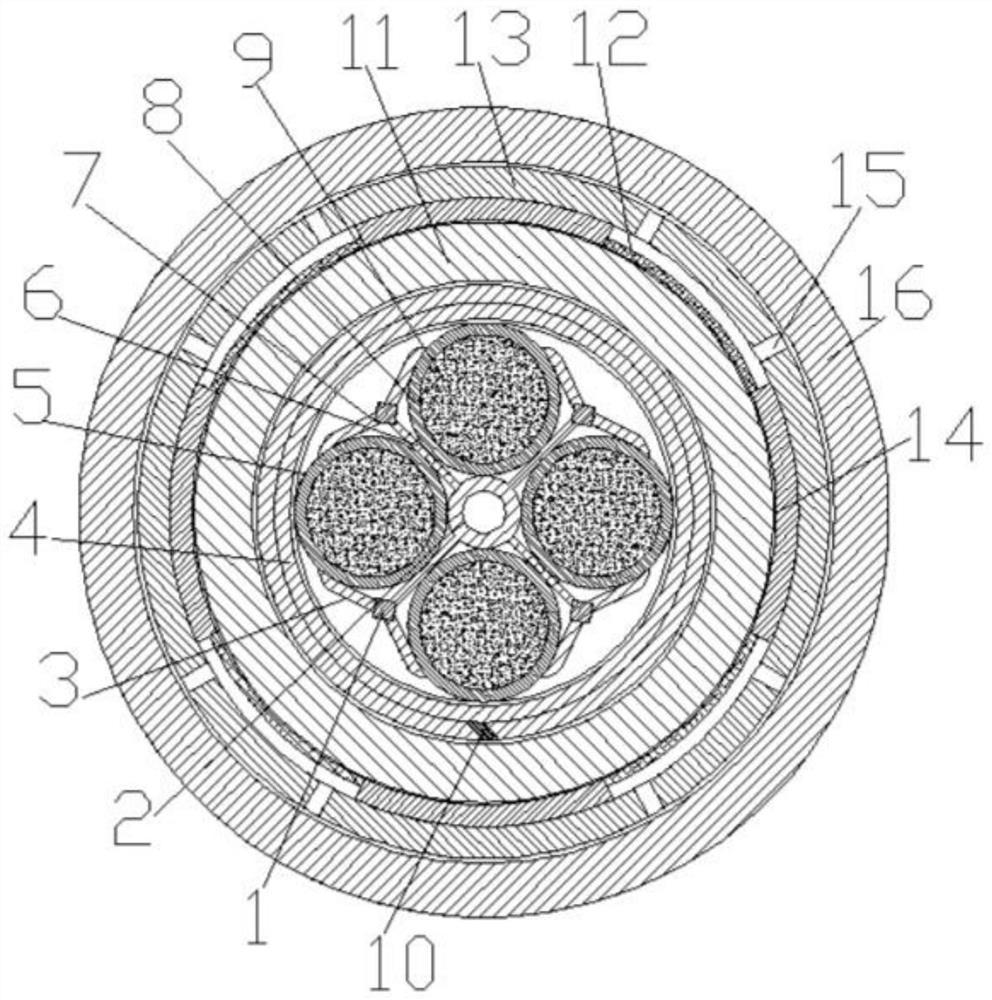

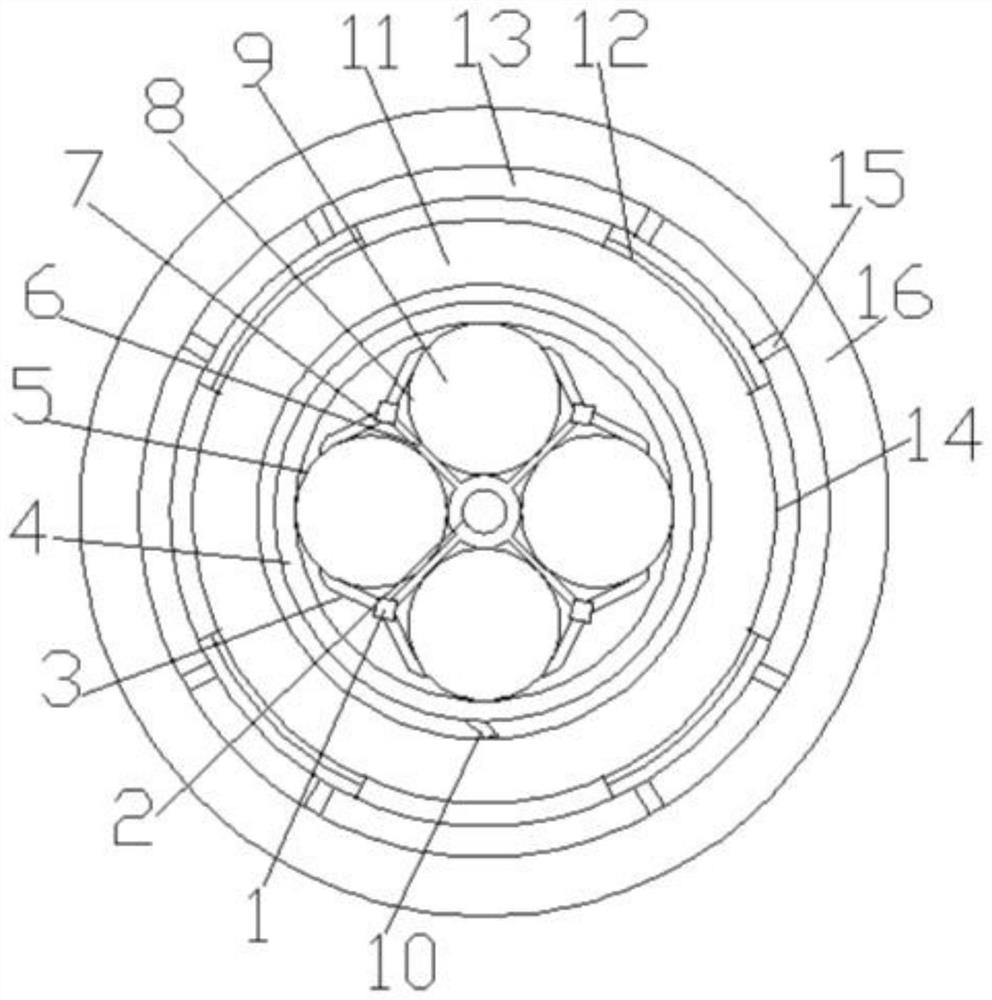

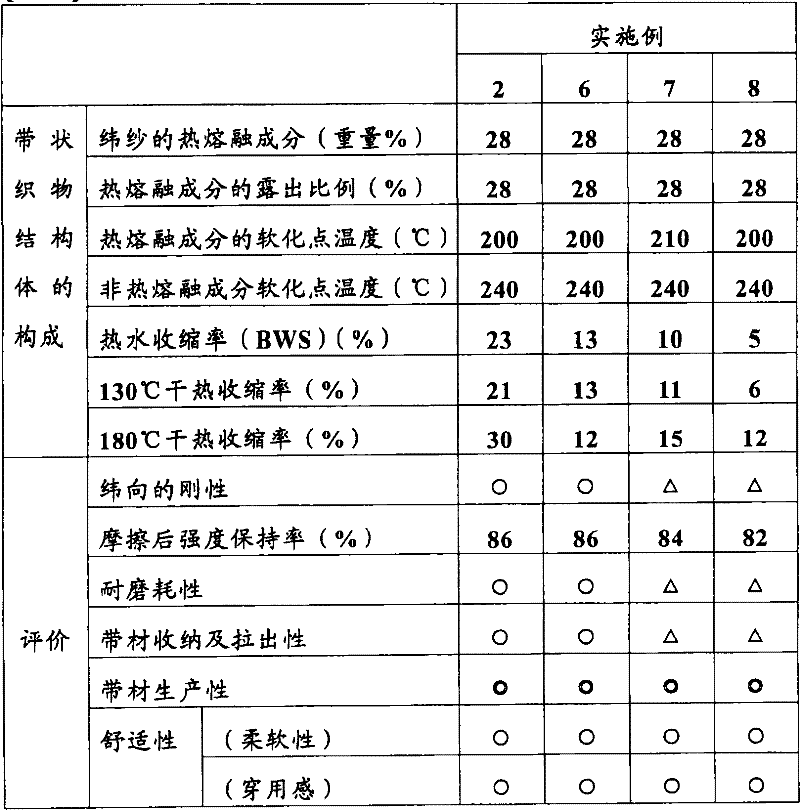

A waterproof and twist-proof cable for wind power generation

ActiveCN108962466AImprove insulation performanceEffective waterproof protectionInsulated cablesPower cablesCopper wireEngineering

The invention discloses a waterproof and twist-proof cable for wind power generation. The cable comprises an outer insulating layer; the surface of the outer insulating layer is fixedly connected withrubber protrusions; and an outer waterproof layer is adhered to the inner wall of the outer insulating layer; a silicone layer is adhered to the inner wall of the outer waterproof layer; and a filling layer is adhered to the inner wall of the silicone layer; a main conductive wire is arranged at the center of the inside portion of the filling layer; secondary conductive wires are arranged in portions, at the top and left and right sides of the main conductive, inside the filling layer; and the four secondary conductive wires are arranged to encircle the main conductive wire at the center. Themain conductive and the secondary conductive wires each comprise a copper core, wherein the copper core is formed by twisting 23 bundles of wires, and each bundle is formed by twisting 102 copper wires with a diameter of 0.2 mm. The waterproof and twist-proof cable for wind power generation is simple in structure, low in cost, effectively avoids occurrence of cable twisting-off or water seepage,can realize continuous conveying of electric energy, reduces cost of circuit setting and completely satisfies demands of usage.

Owner:宝胜(宁夏)线缆科技有限公司

Wire-distributing and arrangement device for multiple wire bundles

InactiveCN108725347AEasy inspection and maintenanceImprove usabilityElectrical apparatusElectric/fluid circuitDistortionEngineering

The invention discloses a wire-distributing and arrangement device for multiple wire bundles in the technical field of wire bundles. A wire bundling drum is arranged in an inner cavity of an elastic clamp groove and comprises a drum body. The front and back end surfaces of the drum body are both equipped with four groups of mounting holes. A rotary groove is arranged in the middle of an inner cavity of the drum body. A bearing is arranged at the center of an inner cavity of the wire bundling drum. Four groups of support rods are uniformly arranged on the outer wall of the bearing. One ends, departing from the bearing, of the support rods are equipped with universal wheels. The center of a cover plate is equipped with a heat radiating hole matching the bearing. A dustproof filter screen isarranged in an inner cavity of the heat radiating hole. According to the application demand, the same number of wire distributing pipes is installed by the wire arrangement device. Therefore, detection and maintenance are convenient to carry out. Meanwhile, the wire-arrangement device can conveniently and quickly adjust directions of the elastic clamp groove and the wire bundling drum according towire bundle direction. Additionally, the wire-arrangement device has good anti-distortion performance. Service lifetime of wire bundles is greatly prolonged. Safety performance of the wire bundles isimproved. The application demand is met.

Owner:徐州市永拓机械科技有限公司

Operation method for tunnel pressure-keeping coring equipment

The invention discloses an operation method for tunnel pressure-keeping coring equipment. An inner tube assembly of a corer is placed into a coring position by using a continuous conduit; meanwhile, the continuous conduit and a hollow rod are of hollow structures; a signal cable and a power cable are placed into the hollow structures; the continuous conduit is matched with a multiple anti-rotationmechanism of the inner tube assembly to prevent a core barrel from rotating; and the rock barrel is further provided with a deadweight valve for keeping pressure and keeping truthiness. The operationmethod is high in operation performance, and can prevent the core barrel from rotating in the coring process, keep a rock core pure, and facilitate separation of the inner tube assembly from an outertube assembly.

Owner:SICHUAN UNIV

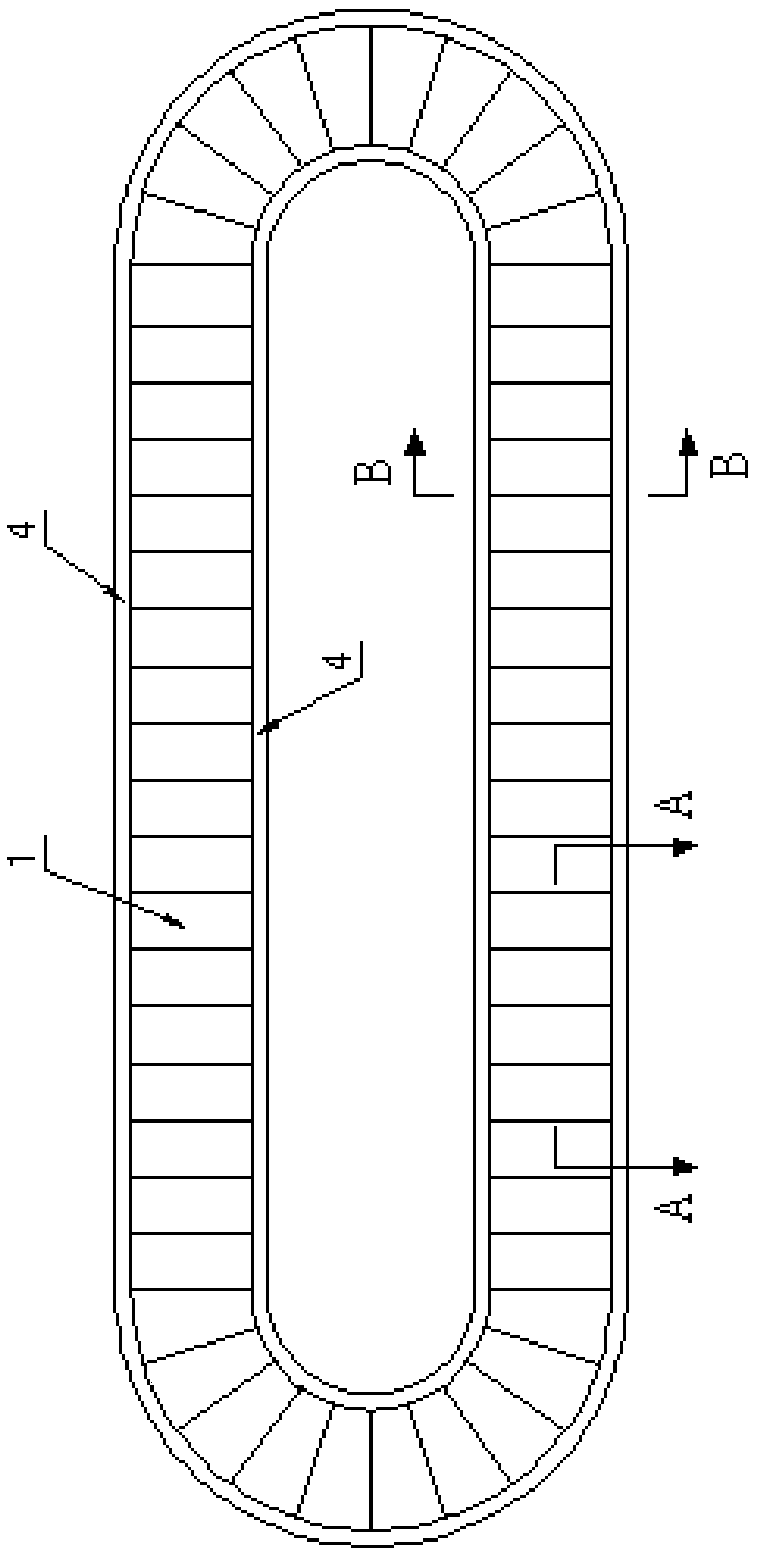

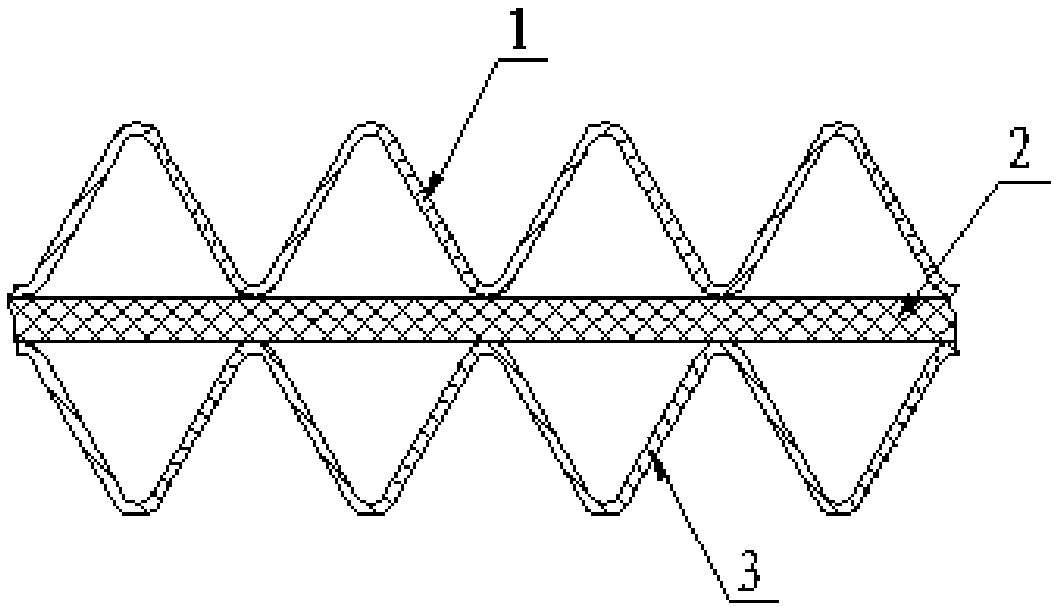

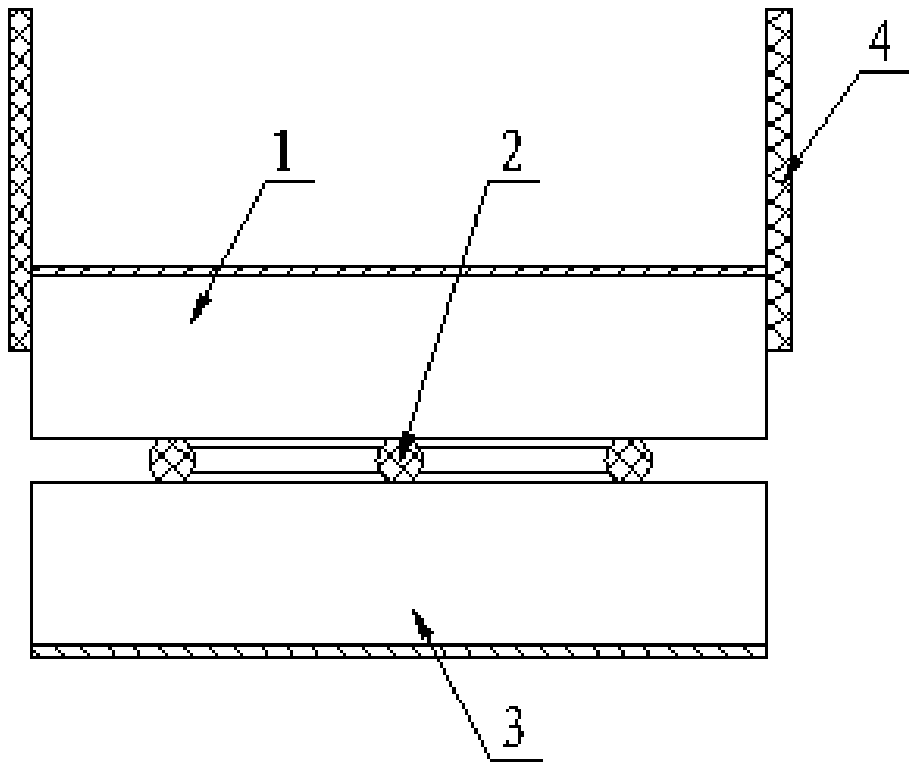

Integral annular conveying belt

Owner:ZHANGJIAGANG HUASHEN INDAL RUBBER PRODS

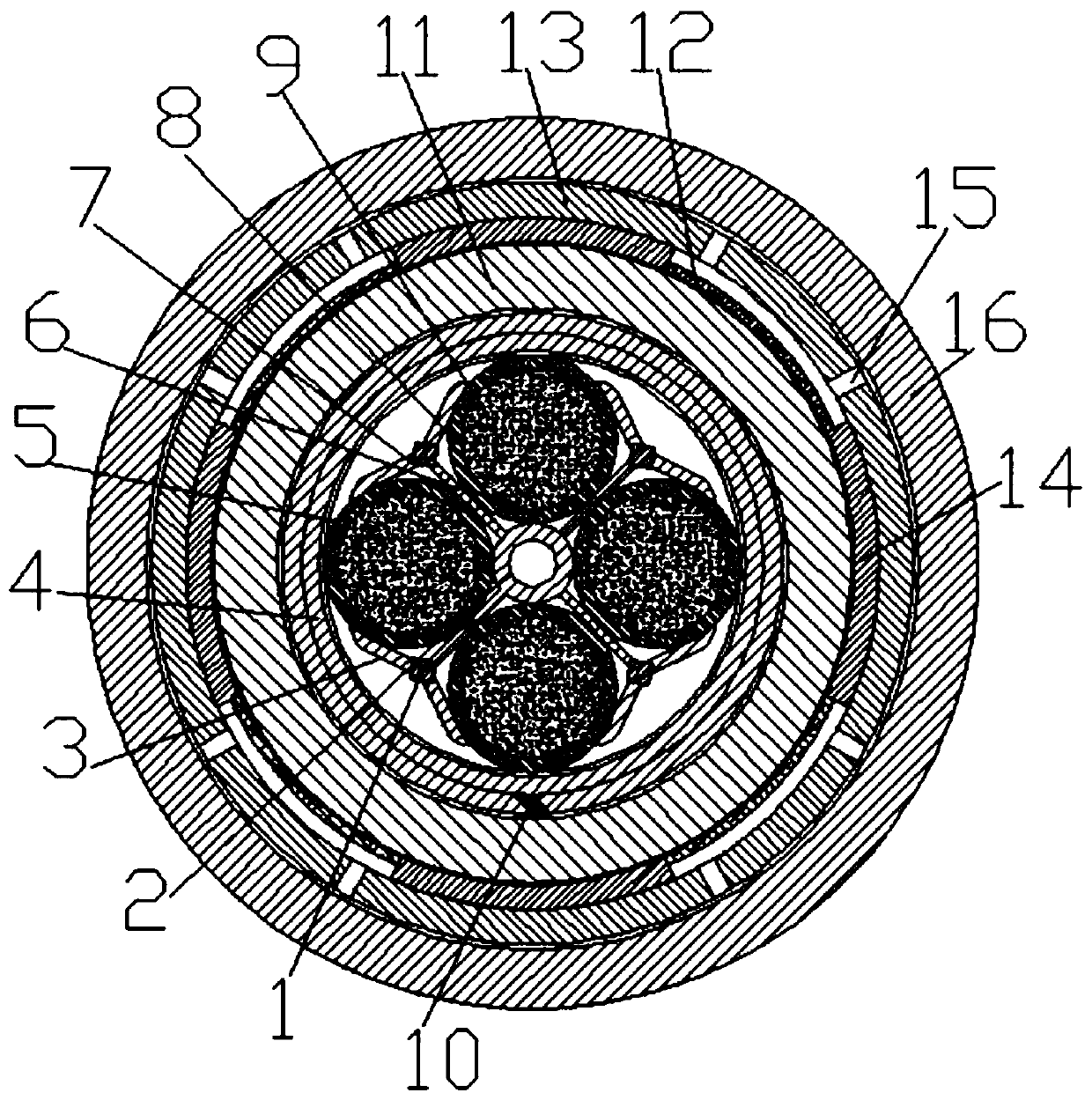

A waterproof and anti-twisting cable for wind power generation

InactiveCN108986980AImprove anti-twist performanceEasy to twistClimate change adaptationInsulated cablesDistortionWind force

The invention discloses a waterproof and anti-twisting cable for wind power generation. The cable includes a cable core, the surface of the cable core is fixedly connected with a protective layer, Thetop and bottom of the protective layer are fixedly connected with a first shock absorbing device, the left and right sides of the protective layer are fixedly connected with a second shock absorbingdevice, two first shock absorbing devices are fixedly connected with one side of the two second shock absorbing devices away from the protective layer through a buffer layer, and the surface of the buffer layer is fixedly connected with a waterproof layer. As that first shock absorb device and the second shock absorbing device are arrange, the cable realizes a suspension cable for wind power generation with good anti-distortion effect, In the use process, the twisting force generated by the collision of the cables when the blower rotates continuously can be effectively overcome, so the damagecaused by the collision is prevented, the service life of the cables is greatly prolonged, the resources are saved, and the hidden danger caused by the cable damage is avoided.

Owner:东方鑫盛线缆有限公司

Vinylidene fluoride resin monofilament and process for producing the same

InactiveUS20070009734A1High knot strengthImprove anti-twist performanceLinesConjugated synthetic polymer artificial filamentsChemistryFluoride salt

A monofilament obtained by smelt-spinning and stretching of a vinylidene fluoride resin is subjected to a high-temperature relaxation treatment for an extremely short period of 0.05-0.5 sec. within a high-temperature heating oil bath at a temperature of 140-175° C., thereby producing a vinylidene fluoride resin monofilament, which comprises a vinylidene fluoride resin having an inherent viscosity of at least 1.40 dl / g, and has a knot strength (JIS L1013) of at least 600 MPa and excellent anti-twist property represented by a twist index of at least 0.90 when measured after the monofilament being subjected to application for 1 minute of a tensile load equal to approximately 50% of a maximum tensile load (JIS K7113), removal of the load, and standing for 3 hours.

Owner:KUREHA KAGAKU KOGYO KK

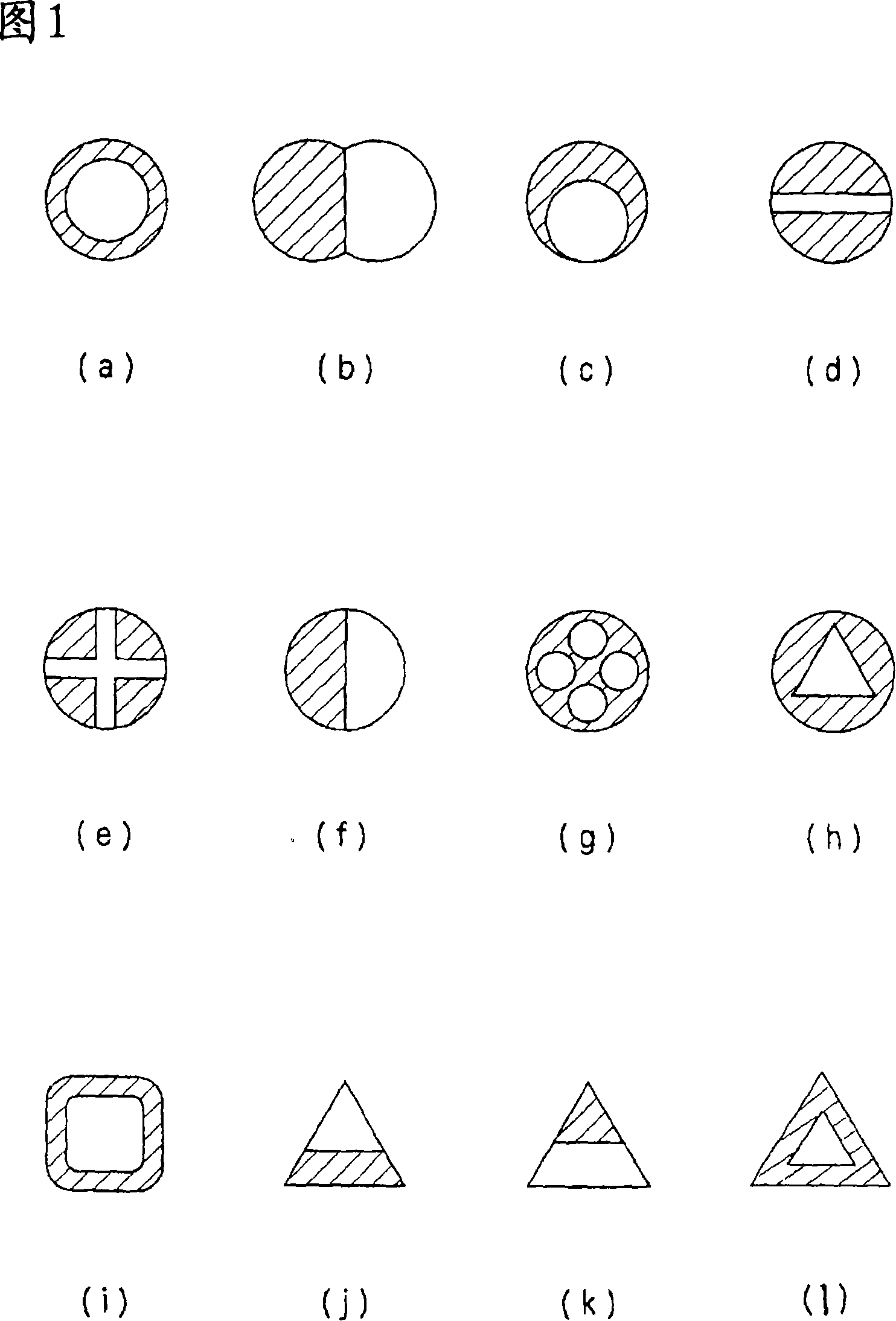

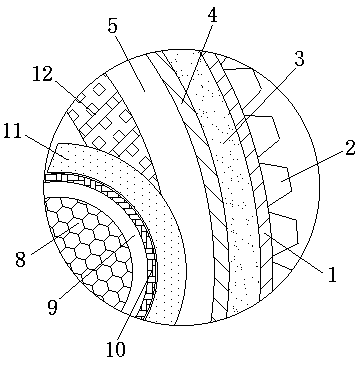

Distortion-resistance-type butterfly-shape optical cable

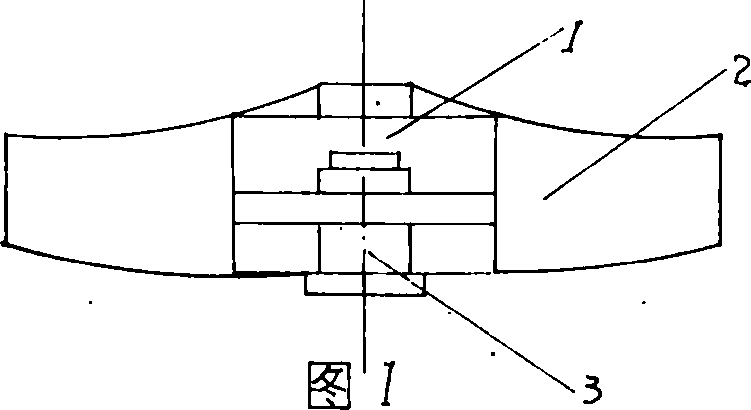

InactiveCN103353654AReduces natural cracking problemsImprove anti-twist performanceFibre mechanical structuresEngineeringDistortion

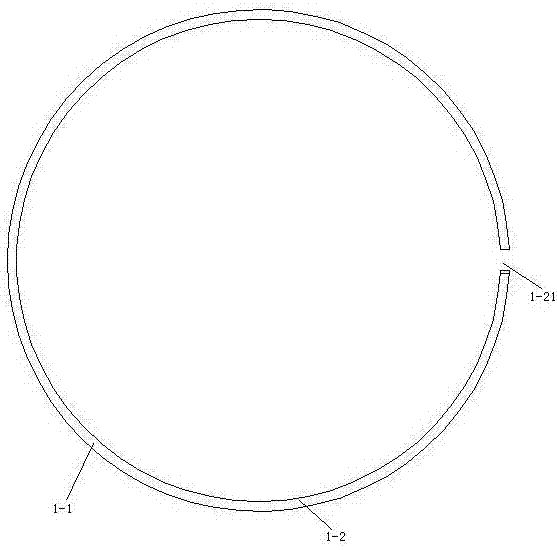

The invention relates to a distortion-resistance-type butterfly-shape optical cable. The optical cable comprises reinforcement components (1), optical fibers (2) and a sheath (4). A center position of the sheath (4) is provided with the plurality of optical fibers (2). A cross section of the sheath (4) is a butterfly structure. The two reinforcement components (1) are arranged in the sheath (4) and are distributed on two sides of the optical fibers and are symmetrical about the optical fibers. Left and right sides of the optical fibers (2) are provided with two tearing ports (3). The tearing ports (3) are in a trapezoidal shape. A center connection line of the reinforcement components (1) is mutually parallel to a bottom line of the tearing ports (3). The optical fibers (2) are distributed on the two sides of the center connection line of the reinforcement components (1). The reinforcement components (1), the optical fibers (2) and the tearing ports (3) are not contacted with each other. The optical cable of the invention has the advantages that distortion-resistance performance is good; optical cable performance is stable; a service life is long; construction and laying are easy.

Owner:成都亨通光通信有限公司

Watchband and its joint used therein

InactiveCN1788644AAdjustable lengthEasy connection/disassemblyBraceletsWrist-watch strapsBiomedical engineering

The present invention discloses one kind of metal catapult watch band and its joints. Each of the joints includes one first assembly, one second assembly and a casing. The second assembly has a bottom barrel with connecting part connected to the first short fork and the second short fork in the first assembly, and the casing has a cavity buckled to a casing barrel and buckled to the first and the second casing buckle tab. The first assembly in a joint has a long fork capable of being inserted into the flute of the second assembly of the next joint for connection or separated from the flute for detaching. The watch band may be detached fast and conveniently and has low cost and wide use range.

Owner:陈志垣

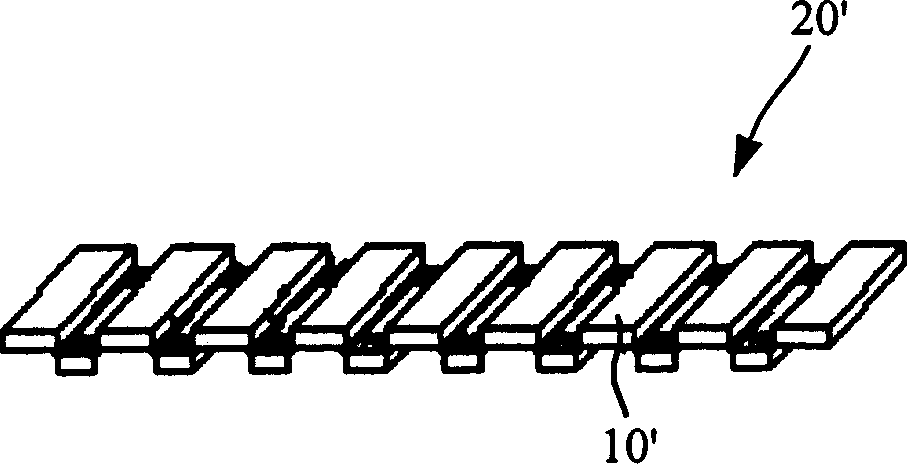

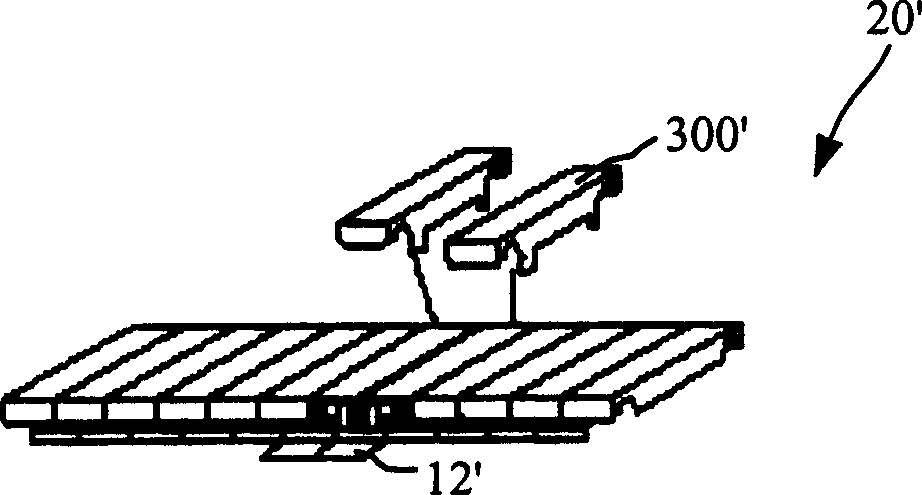

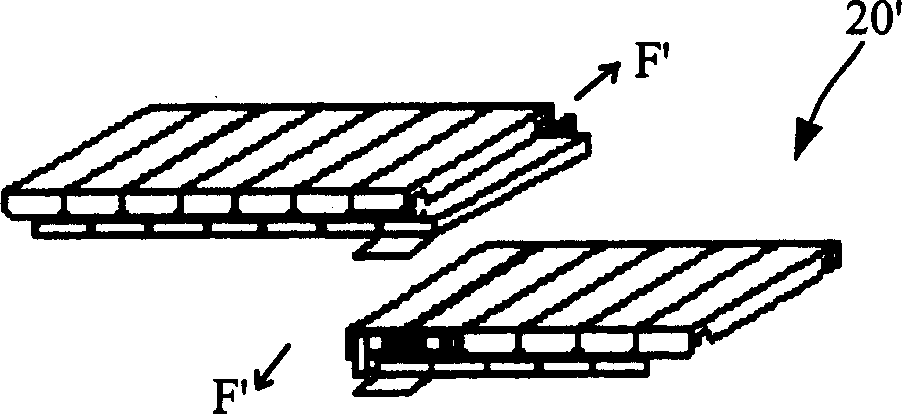

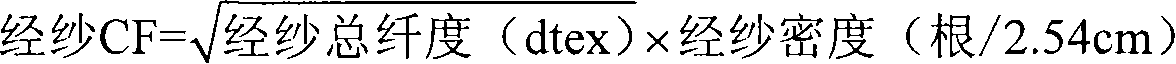

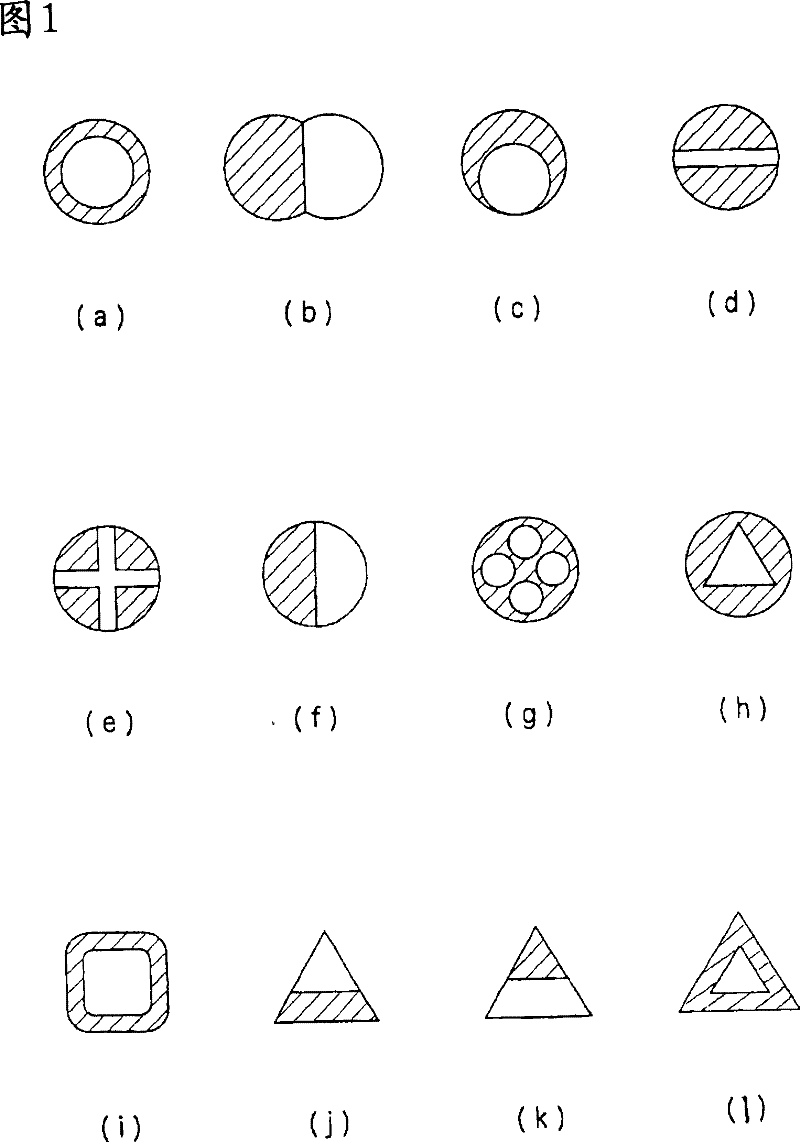

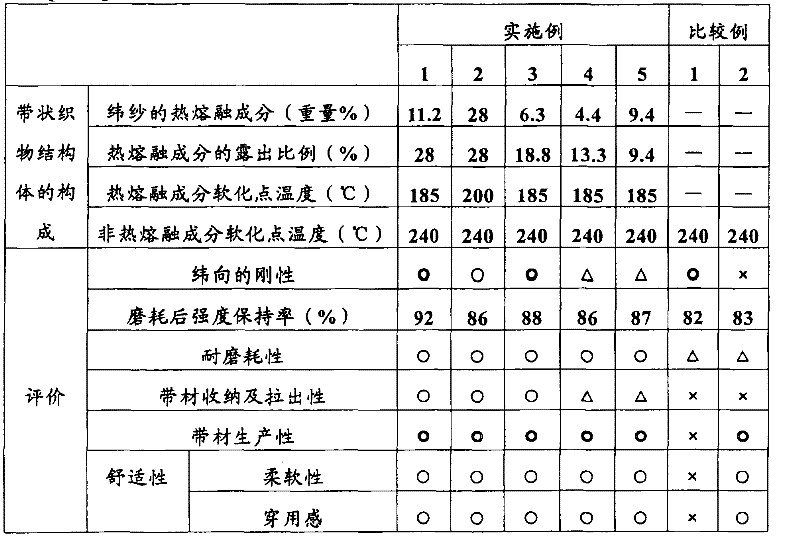

Woven structure of belt form and method for production thereof

ActiveCN101107390ANot easy to twistAvoid distortionOther accessoriesWoven fabricsPolymer scienceBand shape

A band-form woven-fabric structure which is formed by weaving from non-fusion-bondable synthetic fibers and fusion-bondable synthetic fibers including in the fiber surface a fusion-bondable ingredient having a softening point lower by at least 30 DEG C than that of the non-fusion-bondable synthetic fibers, wherein the fusion-bondable synthetic fibers are used as at least part of the weft in the woven-fabric structure and have undergone a heat treatment at a temperature not lower than the softening point of the fusion-bondable ingredient, whereby the fusion-bondable synthetic fibers have been fusion-bonded to themselves or to the non-fusion-bondable synthetic fibers. According to this woven-fabric structure, a band-form woven-fabric structure, e.g., a webbing for seat belts, can be efficiently produced which, even when used repeatedly, retains the weft-direction rigidity over long and is less apt to twist and which is soft and easy to handle.

Owner:SEIREN CO LTD

Movable anti-aging cable for stacker-reclaimer

ActiveCN110828046AImprove integrityPlay the role of extrusion clamping and fixingInsulated cablesInsulated conductorsEngineeringStructural engineering

The invention discloses a movable anti-aging cable for a stacker-reclaimer. The movable anti-aging cable comprises a fixation tough pipe, a tin cladding layer, a flame-retardant layer, a tensile layerand an oxygen barrier layer. The fixation tough pipe comprises a hollow pipe and a rubber pressing block. The fixation tough pipe is arranged in the tin cladding layer and fixedly connected with theouter surfaces of conductor bodies in a clamped mode; a cavity channel is formed in the middle of a hollow pipe; and the outer surface of the hollow pipe is fixedly connected with the rubber pressingblock perpendicularly. The fixation tough pipe and the conductor bodies form an integrated structure with deformation resistance, so that the overall pressure resistance is enhanced; and the separatedintegrated fixation mode can reduce the material torsion and stretching conditions caused by different deformation amounts due to the internal and external deformation offset of each layer of the cable caused by working movement. Besides, through the control of the tin cladding layer on the internal temperature, the strong flame-retardant property of the flame-retardant layer, the good torsion resistance of the tensile layer, and the thermal aging resistance of the oxygen barrier layer, the aging resistance of the whole cable is improved.

Owner:安徽省飞翔特种电缆有限公司

Vinylidene fluoride resin monofilament and process for producing the same

InactiveUS20090295038A1High knot strengthImprove anti-twist performanceLinesConjugated synthetic polymer artificial filamentsHeating oilFluoride

A monofilament obtained by smelt-spinning and stretching of a vinylidene fluoride resin is subjected to a high-temperature relaxation treatment for an extremely short period of 0.05-0.5 sec. within a high-temperature heating oil bath at a temperature of 140-175° C., thereby producing a vinylidene fluoride resin monofilament, which comprises a vinylidene fluoride resin having an inherent viscosity of at least 1.40 dl / g, and has a knot strength (JIS L1013) of at least 600 MPa and excellent anti-twist property represented by a twist index of at least 0.90 when measured after the monofilament being subjected to application for 1 minute of a tensile load equal to approximately 50% of a maximum tensile load (JIS K7113), removal of the load, and standing for 3 hours.

Owner:HASHIMOTO +3

Photovoltaic cable for solar equipment

InactiveCN107118558AReduced deformabilityImprove anti-interference abilityRubber insulatorsFlexible cablesElastomerCross-link

The invention discloses a photovoltaic cable for solar equipment. The photovoltaic cable comprises a cable core and an outer sheath, wherein the cable core is wrapped by the outer sheath; the outer sheath comprises the following raw materials in parts by weight: 40-60 parts of silicon rubber, 5-15 parts of polytetrafluoroethylene, 1.5-2.5 parts of a plasticizer, 1-2 parts of POE (Polyolefin Elastomer) plastic, 0.1-0.6 part of polyether-ether-ketone, 30-50 parts of a bamboo powder compound, 1-5 parts of stearic acid, 5-10 parts of nano calcined kaolin, 2-6 parts of dicyandiamide phosphate, 2.5-3.5 parts of a cross-linking agent, 1-2 parts of m-isopropenyl-2,2-dimethyl benzoyl isocyanate, 0.2-1.2 parts of a silane coupling agent Si69 and 2-4 parts of tri(dioctyl pyrophosphoryl oxo) titanium isopropoxide. The photovoltaic cable is good in elasticity, excellent in distortion resistance and good in interference resistance and reciprocation bending property, and in addition, due to formed high-temperature resistant chemical bands, a fire hazard is not easily caused even if the photovoltaic cable is in a high-temperature harsh environment, and cable short circuits can be also avoided.

Owner:ANHUI ELECTRIC GRP SHARES

Multidirectional spraying device for garden

InactiveCN110547175AExtended service lifeNo overheatingWatering devicesCultivating equipmentsMechanical engineeringHydraulic pressure

The invention discloses a multidirectional spraying device for a garden. The device comprises a main spraying device body, an adjuster and an inner spraying groove, a fixing bolt is arranged at the top of a pressurizer and fixedly connected with the pressurizer, and a rotation disc is arranged at the top of the fixing bolt and fixedly connected with the fixing bolt; the adjuster is arranged at thetop of the rotation disc and fixedly connected with the rotation disc, a limit block is arranged at the top of the adjuster and fixedly connected with the adjuster, and an annular spraying device isarranged at the top of the limit block and fixedly connected with the limit block; the inner spraying groove is formed in the middle of the annular spraying device and fixedly connected with the annular spraying device, and a cylindrical structure is adopted for the annular spraying device. The device can keep hydraulic pressure, does not need to consume energy and has an anti-explosion function,the cylindrical structure is evenly stressed, the device is small in structure and low in weight, through rotation, small dense holes are formed in the surface, multidirectional spraying is conductedduring rotation, and the device is suitable for the technical field of spraying and has far-reaching significance in the future.

Owner:杨常清

Anti-corrosion sewage pipeline material and preparation method thereof

The invention discloses an anti-corrosion sewage pipeline material which contains the following raw materials in parts by weight: 10-30 parts of polybutylene, 20-40 parts of polypropylene, 3-10 parts of an unsaturated polyester resin, 3-7 parts of brucite, 2-4 parts of liquid acrylonitrile-butadiene rubber, 1-5 parts of calcium lignosulphonate, 1-2 parts of dipentaerythritol diphosphite, 2-15 parts of fatty alcohol-polyoxyethylene ether, 5-15 parts of di-iso-decylphthalate, 3-9 parts of a nonionic surfactant, 2-4 parts of a plasticizer and 2-10 parts of a preservative. The anti-corrosion sewage pipeline material disclosed by the invention is capable of conveying sewage and preventing pipelines from corrosion, the unsaturated polyester resin is used as one of the raw materials, the unsaturated polyester resin is a thermoplastic synthetic resin with excellent properties and has characteristics of being small in specific gravity, free of toxin and easy to process, and thus a pipeline is good in impact resistance and torsion resistance.

Owner:HEFEI ANLI ELECTRIC POWER ENG CO LTD

Automobile sunshade plate distortion test device

ActiveCN102072813BImprove anti-twist performanceEasy to operateMachine part testingDrive shaftMotor controller

The invention discloses an automobile sunshade plate distortion test device. The device comprises a base 1, a first fixed frame 3, a second fixed frame 8, a first clamp 4, a second clamp 6, a transmission shaft 13, a lever 9, an angle calibrated scale 11, a servo motor 15, a torque sensor 17 and a motor controller 16. The automobile sunshade plate distortion test device is convenient to operate and simple in test, and can conveniently test the distortion resistance of an automobile sunshade plate.

Owner:NINGBO SUNLIGHT MOTOR PARTS

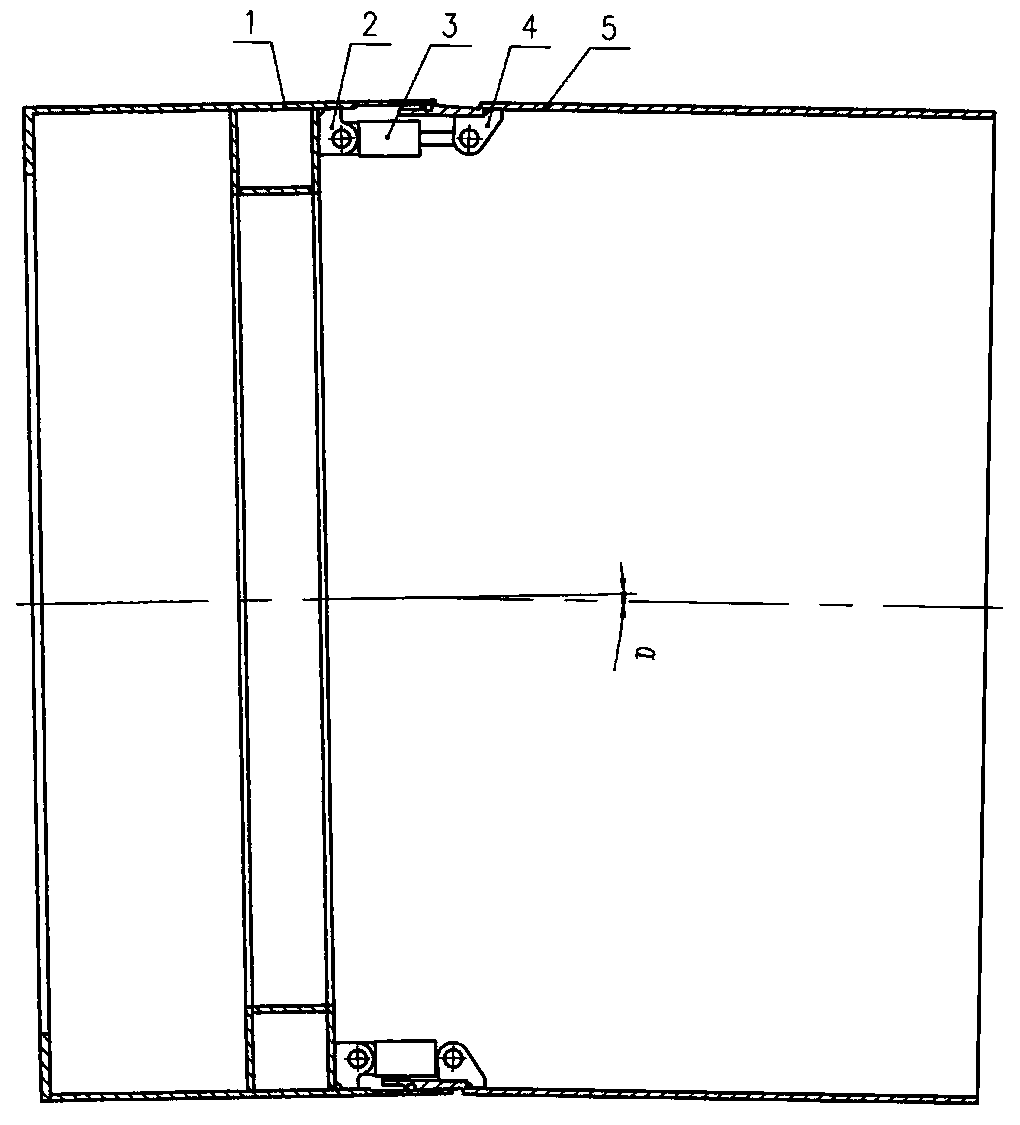

Radial type shield body torsionproof device

A radial type shield body torsionproof device is provided according to the invention, wherein the radial type shield body comprises a middle shield and a shield tail connected with each other through an articulated hydrocylinder. The middle shield comprises a middle shield support ring, a middle shield back support ring board and a middle shield articulated base arranged on the middle shield back support ring board. The shield tail comprises a shield tail connecting ring and a shield tail articulated base arranged on the shield tail connecting ring. The articulated hydrocylinder is connected between the middle shield articulated base and the shield tail articulated base. The torsionproof device comprises a torsionproof frame and a U-shaped baffle board, wherein the torsionproof frame is arranged on the middle shield support ring and the middle shield back support ring board and is arranged inside the articulated hydrocylinder radially with torsionproof ends, and the U-shaped baffle board is formed on the shield tail articulated base in a one-piece manner so that the torsionproof ends are contained in the inner cavity of the baffle board. Therefore, the torsionproof frame does not occupy the mounting position of the articulated hydrocylinder so that more articulated hydrocylinders can be arranged between the middle shield and the shield tail, and greater dragging force for the shield tail is provided to ensure successful shield construction.

Owner:CHINA RAILWAY CONSTR HEAVY IND

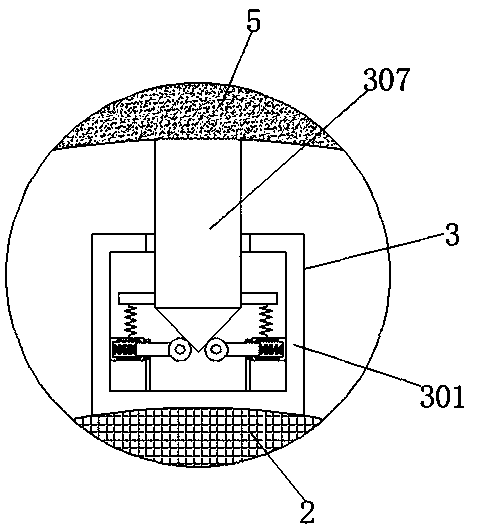

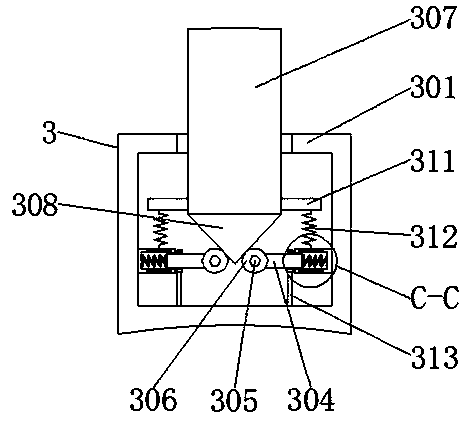

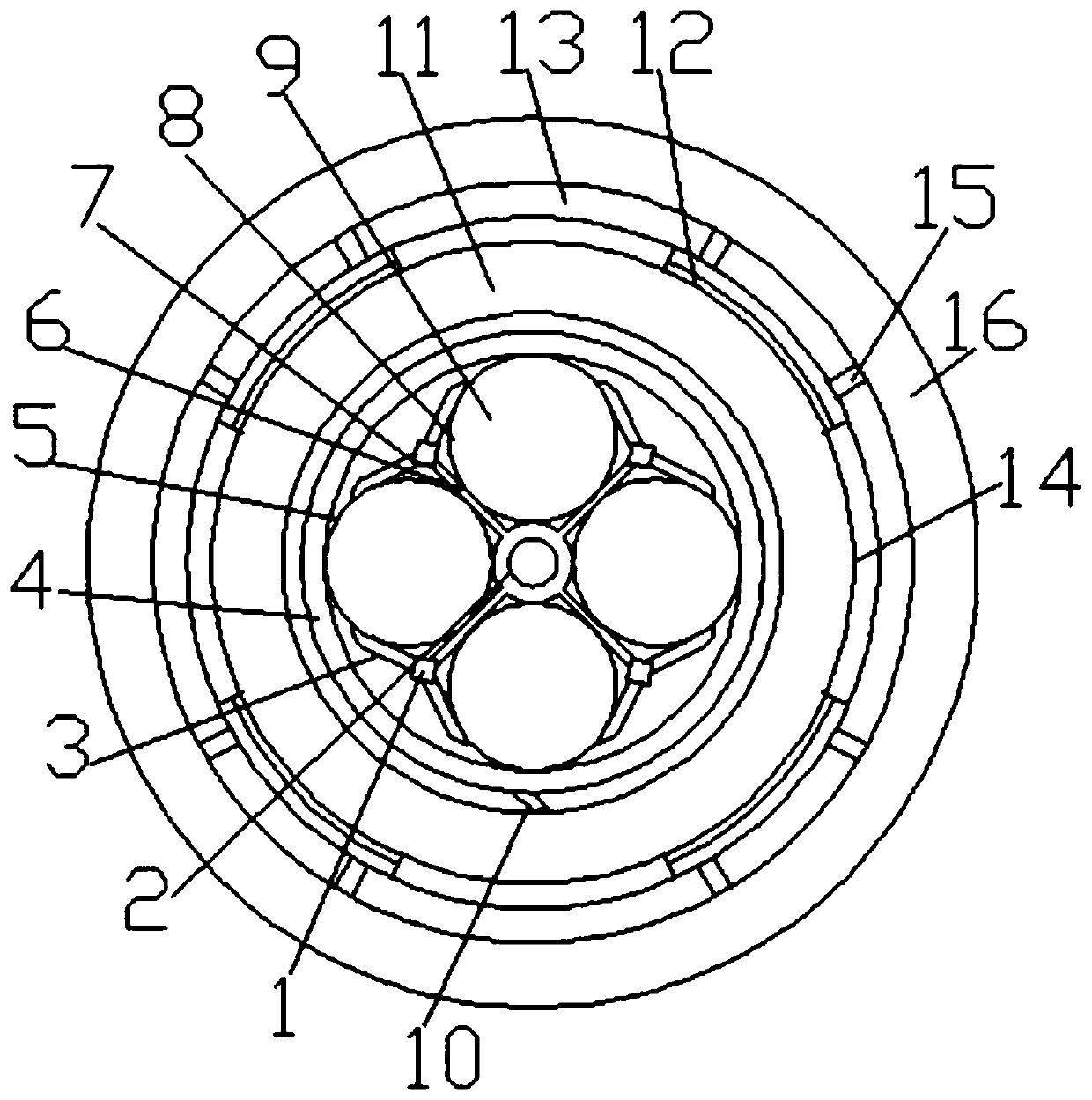

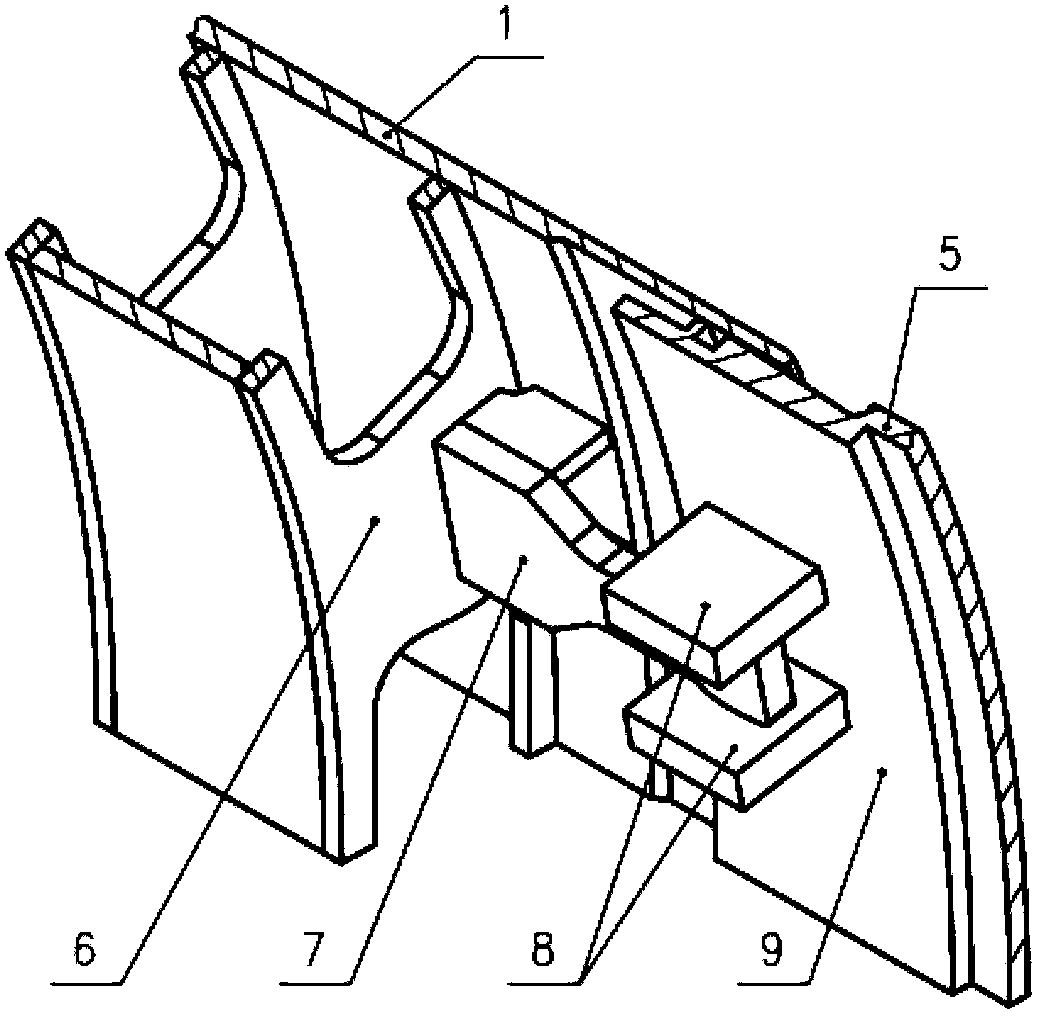

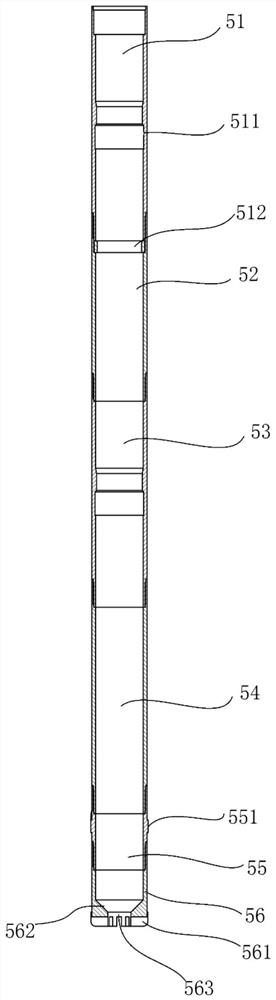

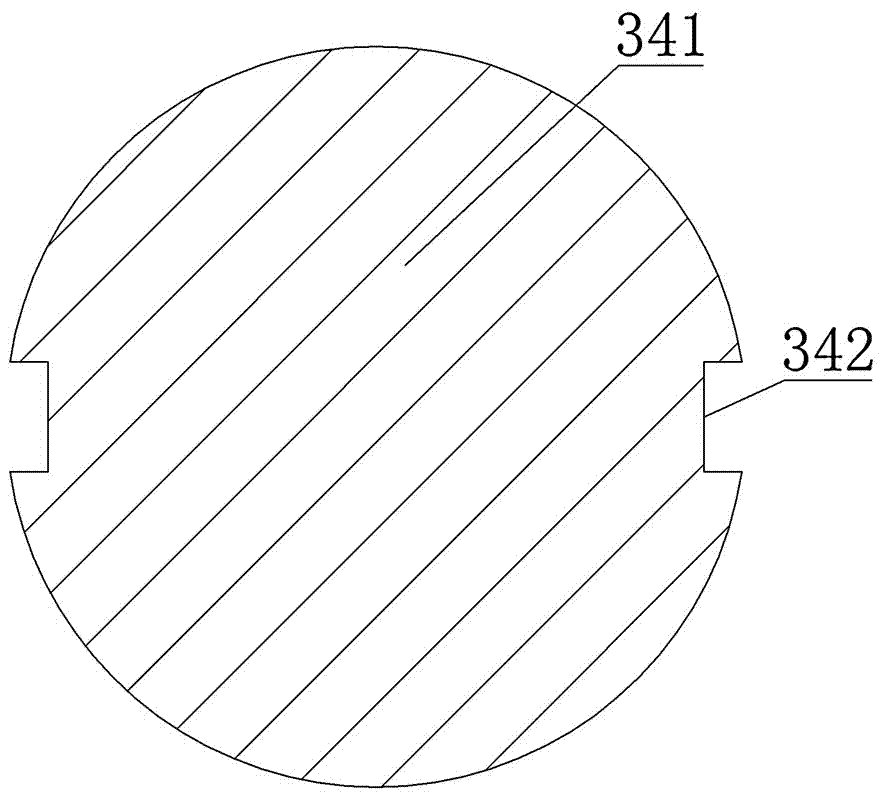

Multi-anti-rotating coring device

PendingCN111550207AReduce external distractionsReduce mistakesCore removalBall (bearing)Structural engineering

The invention discloses a multi-anti-rotating coring device. The device comprises an outer pipe assembly and an inner pipe assembly, and the inner pipe assembly is connected with the outer pipe assembly in a clamped mode; the inner pipe assembly comprises an inner pipe assembly and a center assembly, and a composite bearing set is arranged between the inner pipe assembly and the center assembly; the composite bearing set comprises a base, the base is in the form of a thrust bearing, the base is arranged in the inner pipe assembly, and a ball recess in an annular shape is formed in the inner wall of the base; and multiple ball holes are formed in the middle of a positioning pipe section in the circumferential direction, spherical rollers are arranged in the ball holes, and the protruding parts of the spherical rollers are matched with the ball recess. According to the device, a coring barrel can be prevented from rotating, the external interference is reduced, and errors between the coring component and real conditions are reduced.

Owner:SHENZHEN UNIV

Torsion-resistant automobile axle and its processing method

ActiveCN104875551BImprove anti-twist performanceReduce weightAxle unitsDistortionAutomotive engineering

Owner:YANGZHOU DONGSHENG AUTOMOTIVE CO LTD

A working method of tunnel pressure maintaining coring equipment

The invention discloses an operation method for tunnel pressure-holding coring equipment. By using a continuous conduit, the inner tube assembly of the core remover is placed in the coring position, and the continuous conduit and the central rod are hollow structures, and the signal cable and power The cable is placed in the hollow structure, and the continuous conduit cooperates with the multiple anti-rotation mechanisms of the inner tube assembly to prevent the rotation of the core barrel, and the core barrel is also equipped with a self-gravity valve for pressure maintenance. The invention has good operation performance, can prevent the core cylinder from rotating during the coring process, keeps the rock core pure, and the inner pipe assembly and the outer pipe assembly are easily separated.

Owner:SICHUAN UNIV

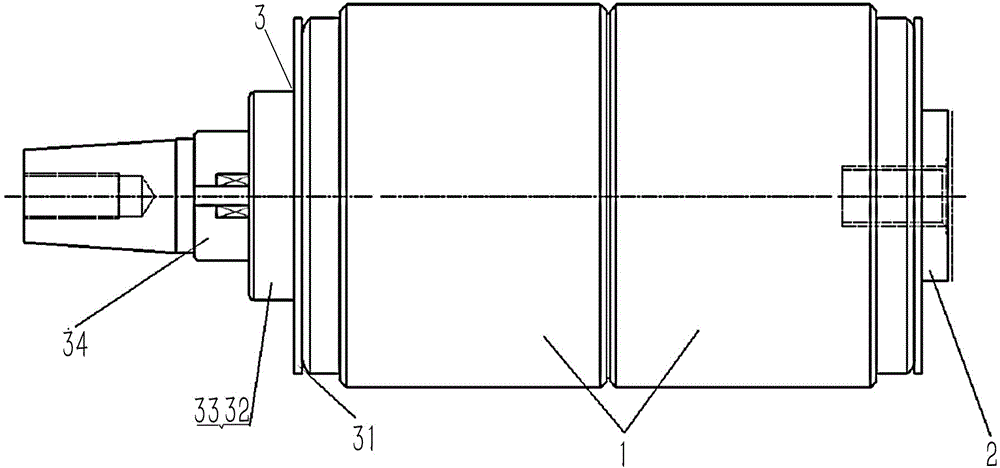

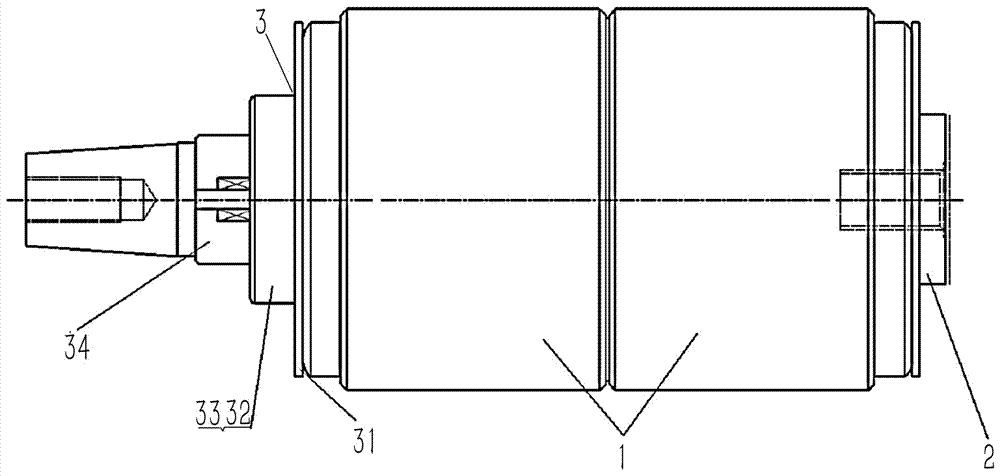

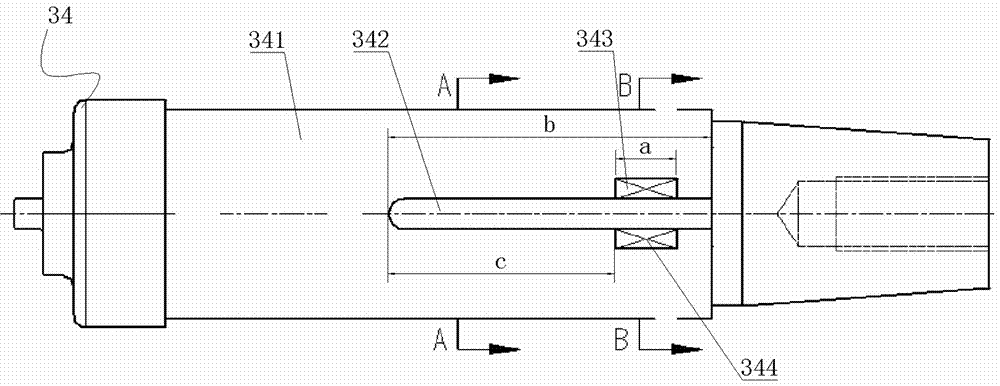

Dynamic conducting rod, dynamic end assembly with dynamic conducting rod and arc extinguish chamber

ActiveCN104795271AEasy to useEasy to assembleHigh-tension/heavy-dress switchesAir-break switchesEngineeringScrew thread

The invention discloses a dynamic conducting rod, a dynamic end assembly with the dynamic conducting rod and an arc extinguish chamber. Wrenching concave portions are formed in the peripheral surface of a guide column section of the dynamic conducting rod, the inwards concave bottom surfaces of the wrenching concave portions serve as wrenching profiles, and therefore when threaded connection between the dynamic conducting rod and other devices is conducted, a wrench can be installed on the wrenching concave portions of the guide column section, the wall surfaces of a jaw of the wrench can be matched with the wrenching profiles of the wrenching concave portions in a rotation-preventing mode. When the dynamic conducting rod is normally used, the purpose that the dynamic conducting rod conducts guiding movement in the front-and-rear direction relative to a guide sleeve is achieved through guiding matching between rotation-preventing key grooves and rotation-preventing convex ribs, the rotation-preventing concave ribs can prevent the dynamic conducting rod from rotating relative to the guide sleeve in the movement process of the dynamic conducting rod so as to achieve the effect of torsion resistance through key transmission, and therefore the dynamic conducting rod can be easily assembled and reliably used.

Owner:TIANJIN PINGGAO INTELLIGENT ELECTRIC +3

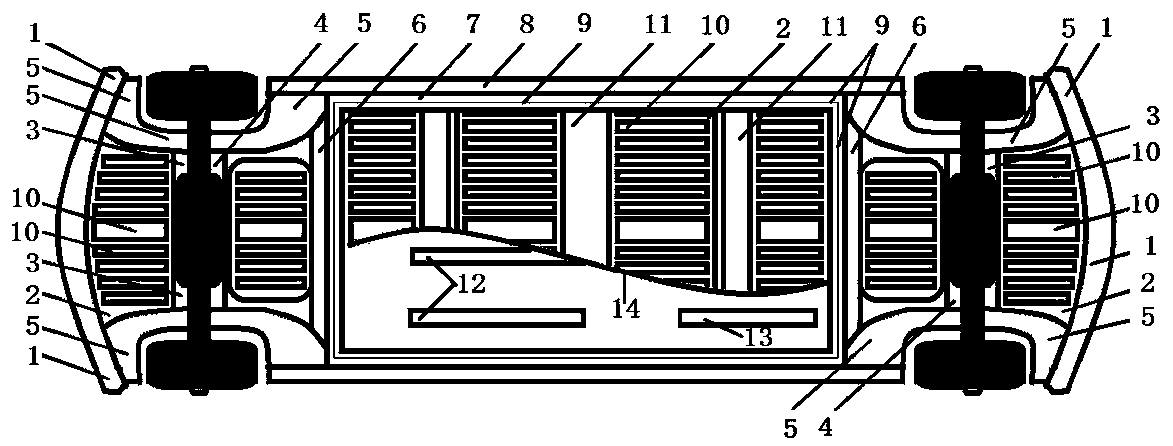

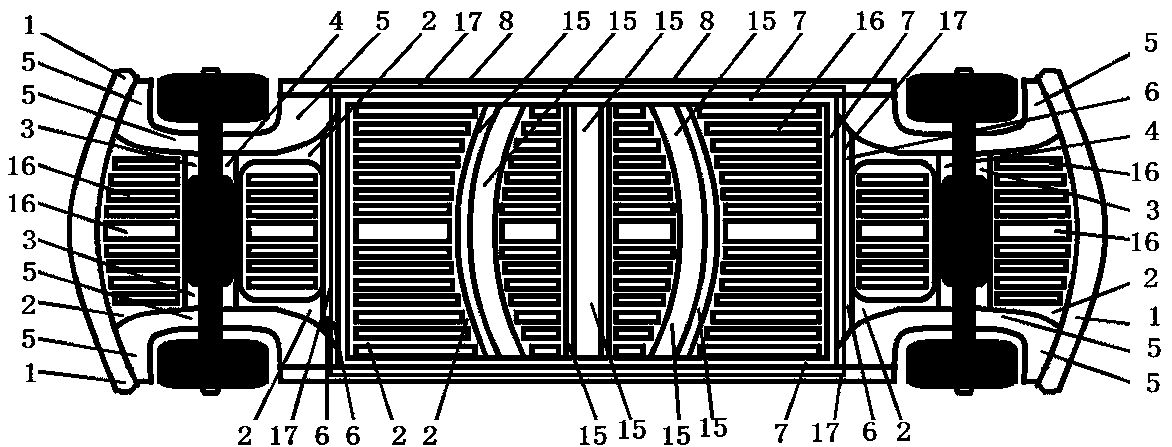

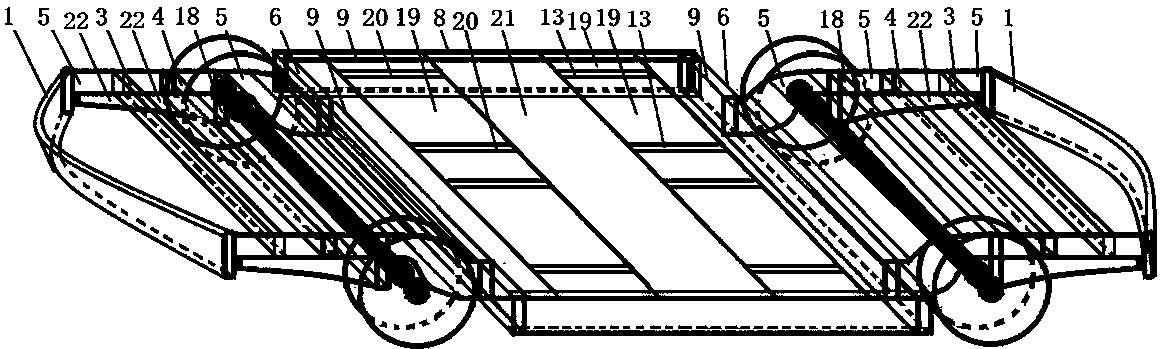

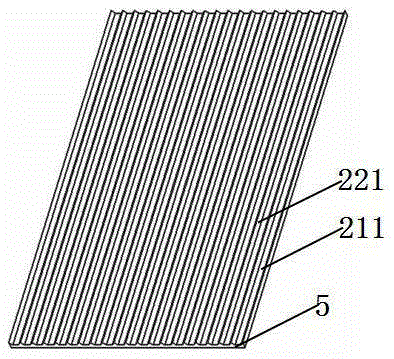

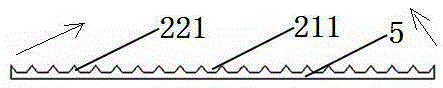

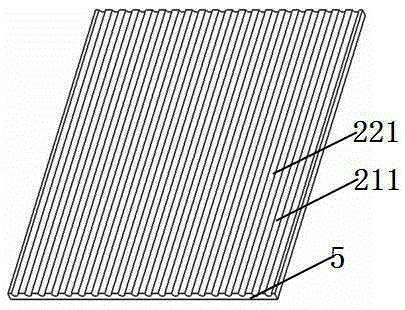

Load-bearing car body and car body covering part for light passenger car

PendingCN108688729AHigh tensile strengthIncreased durabilitySuperstructure subunitsMonocoque constructionsProduction lineWire mesh

The invention discloses a load-bearing car body and a car body covering part for a light automobile passenger car, and belongs to the technical field of automobile bodies. The load-bearing car body and the car body covering part for the automobile light passenger car mainly solve the problems that an existing steel passenger car body has large self-weight, and an aluminum alloy passenger car bodyhas poor strength and stiffness. The load-bearing car body and the car body covering part are mainly characterized in that an aluminum alloy beam plate lined with high-strength steel wire mesh of theload-bearing car body is formed by fusion high-strength steel wire mesh fusion compression moulding forming; a rubber-plastic plate lined with high-strength steel wire mesh of the car body covering part is formed by high-strength steel wire mesh fusion compression moulding forming, and the car body covering part belongs to a color surface plate load-bearing car body covering part of a one-time forming non-coating process and working procedure; and the pollution process of coating production line can be completely omitted, according to a conventional vehicle, weight can be reduced more than 50%, material can be saved, the cost is reduced by more than 30%, and the load-bearing car body and the car body covering part for the light passenger car can automatically restore prototypes due to light collision, are energy-saving and environmentally friendly, and are low in cost and light in weight.

Owner:王子齐

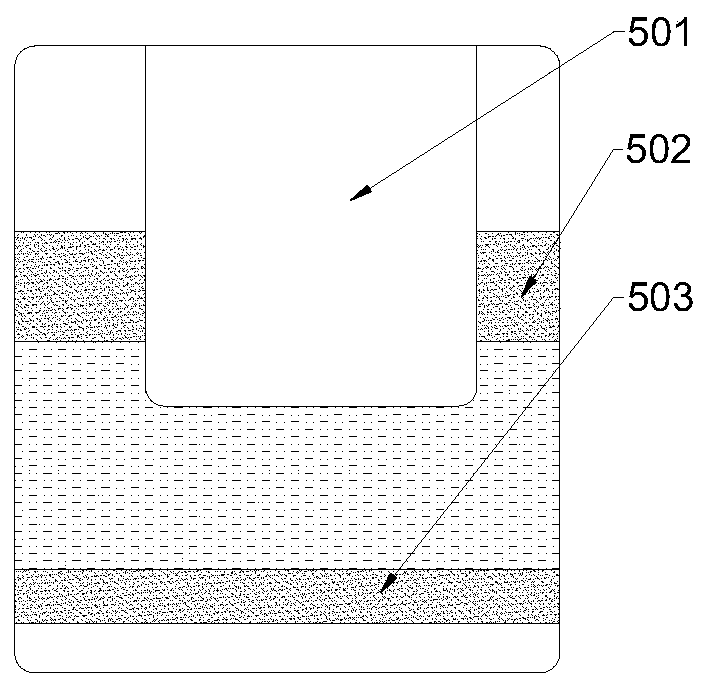

Manufacturing method of air-blowing pipeline

ActiveCN105372775AImprove anti-twist performanceGood effectOptical fibre/cable installationCoatingsMechanical engineeringIndustrial engineering

The invention belongs to the pipeline technical field and relates to a manufacturing method of an air-blowing pipeline. The manufacturing method comprises the following steps that: first step, a flat and straight air-blowing pipe body is folded, the air-blowing pipe body passes through an opening narrowing channel, and then passes through a hole in a shaping pipe, and further passes through a mold core hole, and the air-blowing pipe body is pulled, and a plunger is located inside the air-blowing pipe body, and the joint of two sides of the air-blowing pipe body at a shaping end is located at a shaping groove and is heated, so that a protruding rib can be formed; and second step, a plastic extruding machine is started, and plastic enters a space between the mold core and the mold sleeve of the head of the plastic extruding machine, and an upper outer pipe body is formed at the exterior of the air-blowing pipe body through extrusion, and a traction system pulls the outer pipe body to enter a cooling system, so that the air-blowing pipeline can be formed. According to the manufacturing method of the air-blowing pipeline, a system of an air-blowing pipeline for manufacturing cables is adopted. The manufacturing method adopts a simple system, is low in cost and is easy to master, and has simplicity. The air-blowing pipeline manufactured by adopting the method has excellent anti-torsion and anti-bending performance.

Owner:南通市水利勘测设计研究院有限公司

A mobile anti-aging cable for a stacker-reclaimer

ActiveCN110828046BImprove integrityPlay the role of extrusion clamping and fixingInsulated cablesInsulated conductorsEngineeringStructural engineering

Owner:安徽省飞翔特种电缆有限公司

A moving conductive rod, a moving end assembly and an arc extinguishing chamber using the moving conductive rod

ActiveCN104795271BEasy to useEasy to assembleHigh-tension/heavy-dress switchesAir-break switchesEngineeringScrew thread

The invention discloses a dynamic conducting rod, a dynamic end assembly with the dynamic conducting rod and an arc extinguish chamber. Wrenching concave portions are formed in the peripheral surface of a guide column section of the dynamic conducting rod, the inwards concave bottom surfaces of the wrenching concave portions serve as wrenching profiles, and therefore when threaded connection between the dynamic conducting rod and other devices is conducted, a wrench can be installed on the wrenching concave portions of the guide column section, the wall surfaces of a jaw of the wrench can be matched with the wrenching profiles of the wrenching concave portions in a rotation-preventing mode. When the dynamic conducting rod is normally used, the purpose that the dynamic conducting rod conducts guiding movement in the front-and-rear direction relative to a guide sleeve is achieved through guiding matching between rotation-preventing key grooves and rotation-preventing convex ribs, the rotation-preventing concave ribs can prevent the dynamic conducting rod from rotating relative to the guide sleeve in the movement process of the dynamic conducting rod so as to achieve the effect of torsion resistance through key transmission, and therefore the dynamic conducting rod can be easily assembled and reliably used.

Owner:TIANJIN PINGGAO INTELLIGENT ELECTRIC +3

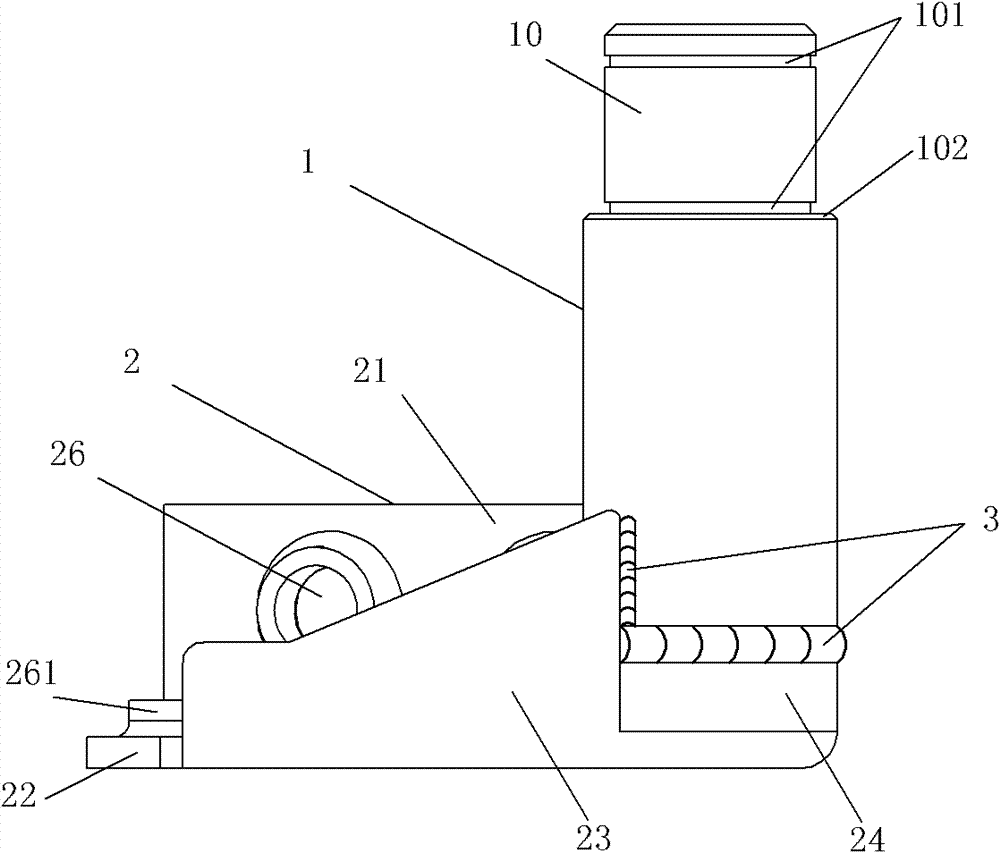

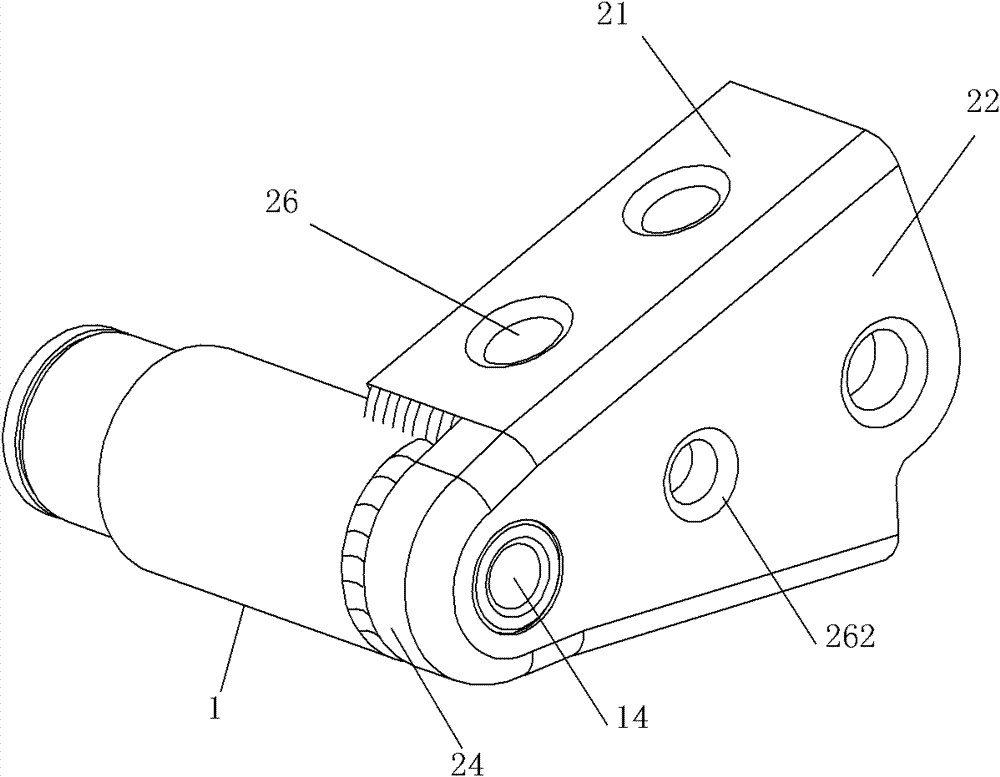

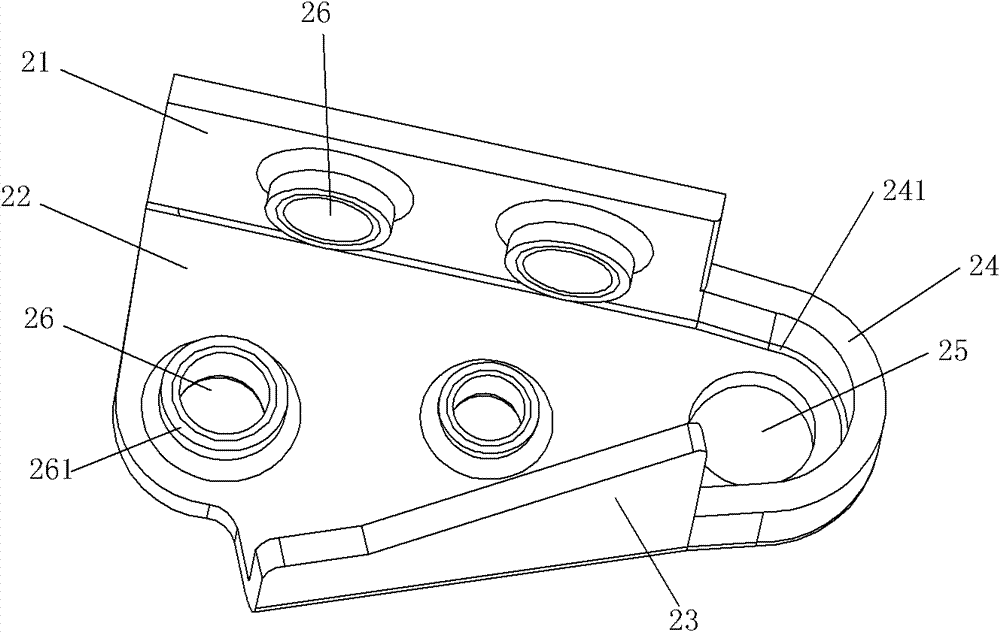

Welding-type jockey pulley base of stainless steel escalator step

ActiveCN101905837BHigh strengthMeet the requirements of safe operationEnergy efficiency in escalatorsEscalatorsEnergy consumptionMaterials science

The invention relates to a welding-type jockey pulley base of a stainless steel escalator step, belonging to the manufacturing field of escalators. The traditional structure is formed by casting integrally and has the problems of energy consumption, low percent of pass, high manufacturing cost and poor consistency. The welding-type jockey pulley base of the stainless steel escalator step comprises a jockey pulley shaft and a base body with a mounting hole, wherein the jockey pulley shaft and the base body are detachable members which are integrally welded and fixed; the jockey pulley shaft iscylindrical and comprises a jockey pulley mounting part on the upper part, a shaft lever in the middle part and a shaft base connection end on the lower part; the base body is a board stamping part comprising a triangular bottom face and a side wall which is perpendicular to the bottom face and provided with an opening at one end; a connection chamfer is arranged at the joint of the triangular bottom face and the side wall; and the vertex angle of the triangular bottom face is provided with a jockey pulley mounting hole in which the jockey pulley mounting part is inserted. The invention has the advantages of detachable production, convenient processing, low manufacturing cost, energy saving, light self weight and good strength, and is suitable for detachable-type stainless steel steps.

Owner:宁波昌隆机电有限公司

Woven structure of belt form and method for production thereof

ActiveCN101107390BNot easy to twistAvoid distortionOther accessoriesWoven fabricsPolymer scienceBand shape

A band-form woven-fabric structure which is formed by weaving from non-fusion-bondable synthetic fibers and fusion-bondable synthetic fibers including in the fiber surface a fusion-bondable ingredient having a softening point lower by at least 30 DEG C than that of the non-fusion-bondable synthetic fibers, wherein the fusion-bondable synthetic fibers are used as at least part of the weft in the woven-fabric structure and have undergone a heat treatment at a temperature not lower than the softening point of the fusion-bondable ingredient, whereby the fusion-bondable synthetic fibers have been fusion-bonded to themselves or to the non-fusion-bondable synthetic fibers. According to this woven-fabric structure, a band-form woven-fabric structure, e.g., a webbing for seat belts, can be efficiently produced which, even when used repeatedly, retains the weft-direction rigidity over long and is less apt to twist and which is soft and easy to handle.

Owner:SEIREN CO LTD

Waterproof and twist-proof cables for wind power generation

ActiveCN108962466BImprove insulation performanceEffective waterproof protectionInsulated cablesPower cablesEngineeringWind power generation

The invention discloses a waterproof and twist-proof cable for wind power generation. The cable comprises an outer insulating layer; the surface of the outer insulating layer is fixedly connected withrubber protrusions; and an outer waterproof layer is adhered to the inner wall of the outer insulating layer; a silicone layer is adhered to the inner wall of the outer waterproof layer; and a filling layer is adhered to the inner wall of the silicone layer; a main conductive wire is arranged at the center of the inside portion of the filling layer; secondary conductive wires are arranged in portions, at the top and left and right sides of the main conductive, inside the filling layer; and the four secondary conductive wires are arranged to encircle the main conductive wire at the center. Themain conductive and the secondary conductive wires each comprise a copper core, wherein the copper core is formed by twisting 23 bundles of wires, and each bundle is formed by twisting 102 copper wires with a diameter of 0.2 mm. The waterproof and twist-proof cable for wind power generation is simple in structure, low in cost, effectively avoids occurrence of cable twisting-off or water seepage,can realize continuous conveying of electric energy, reduces cost of circuit setting and completely satisfies demands of usage.

Owner:宝胜(宁夏)线缆科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com