Operation method for tunnel pressure-keeping coring equipment

A technology for equipment and tunnels, applied in the direction of undisturbed core extraction devices, earthwork drilling, drilling equipment, etc., can solve the problems of complex structure, complex working principle, difficult operation, etc., and achieve simple structure of the device, good operability, and good anti-rotation effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

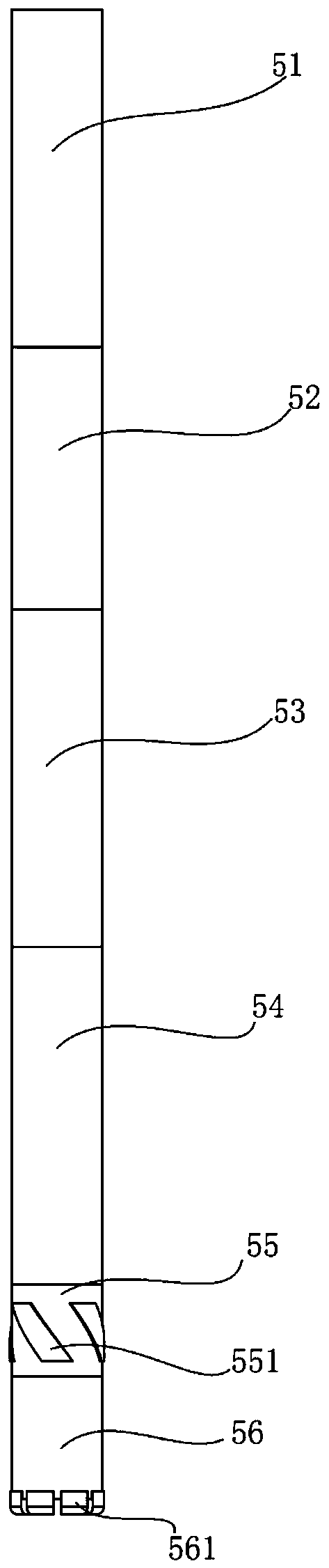

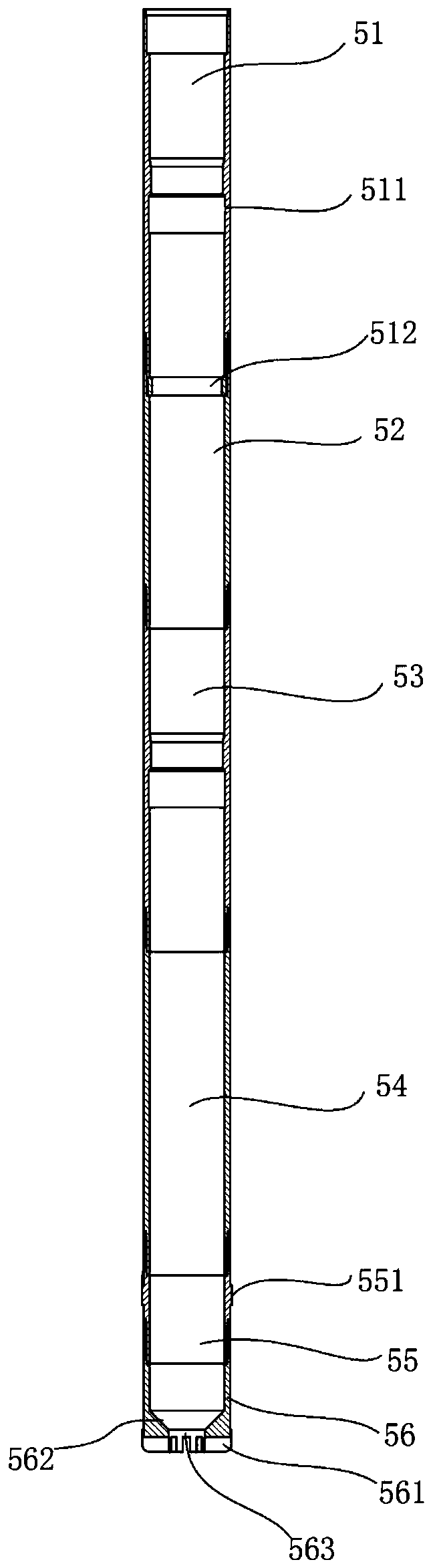

[0069] In order to make the purpose, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings, wherein the temperature sensor 101, the pressure sensor 102, the pressure sensor 103, and the signal cable 104 are not in the Figure 4 marked in the Figure 5 Marked out.

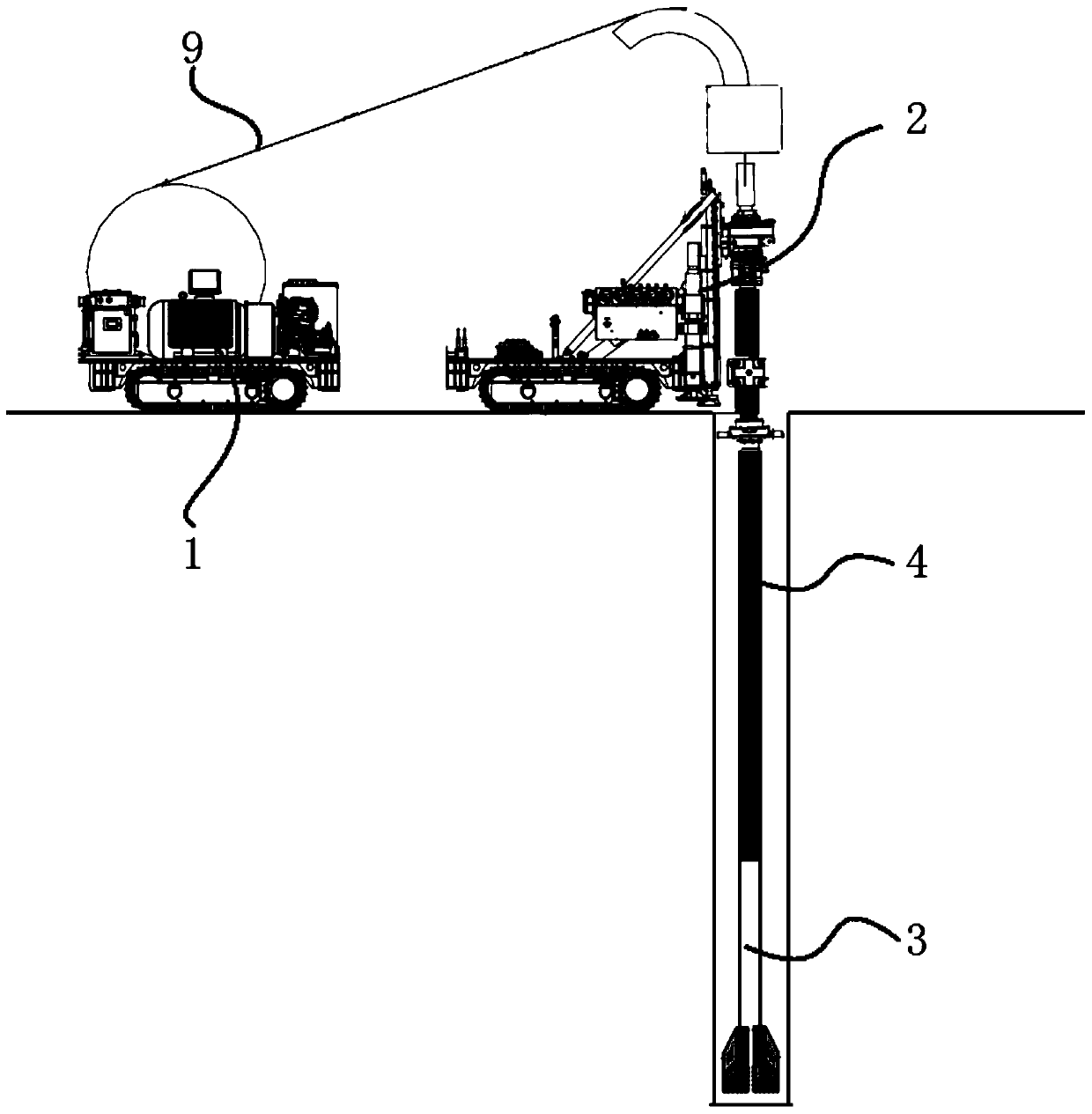

[0070] Such as Figure 1-19 As shown, the present invention discloses an operation method of tunnel pressure maintaining coring equipment, which includes continuous conduit operation equipment and a coring device 3 .

[0071] The continuous conduit operation equipment includes a reel device 1 and a transfer device 2. The reel device 1 and the transfer device 2 are both equipped with a mobile base 1301, and the mobile base 1301 is equipped with a crawler belt 1302.

[0072] The reel device 1 is used to accommodate the continuous conduit 9. The reel device 1 includes a reel 1101 and a reel hold...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com