Continuous conduit type coring equipment

A catheter and equipment technology, which is applied in the field of continuous catheter coring equipment, can solve the problems of actual error of coring components, high height, unsuitable working environment with limited space and height, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

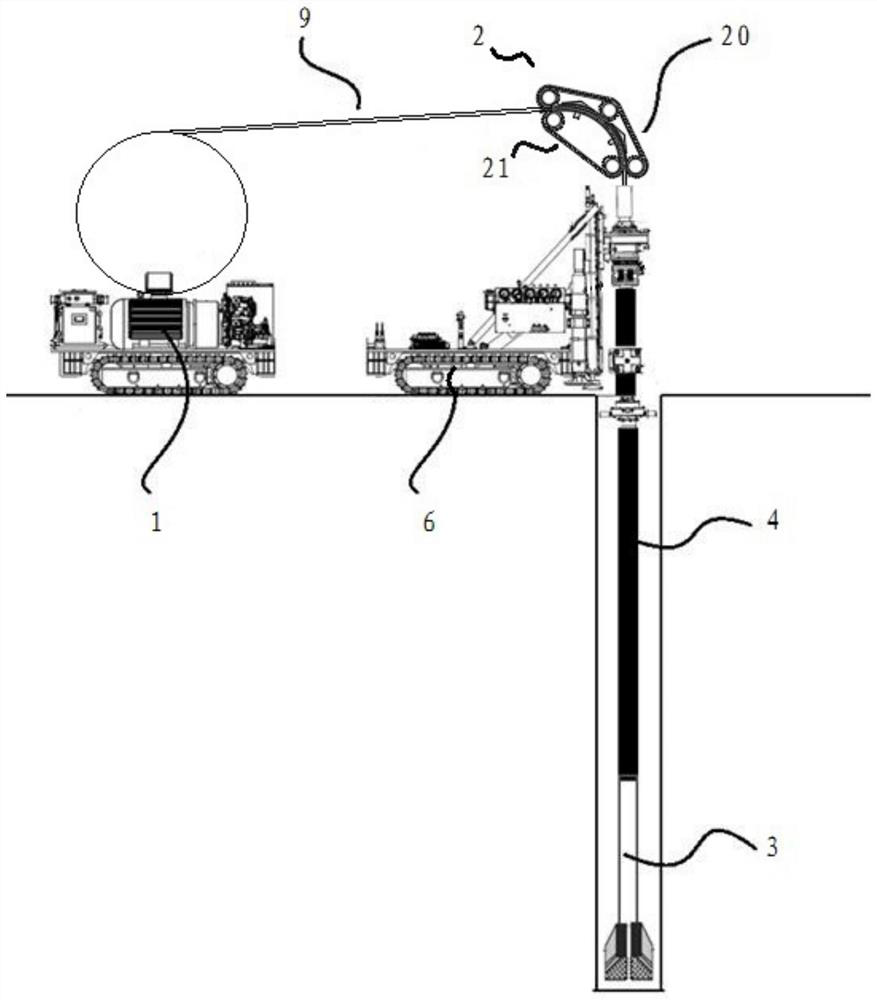

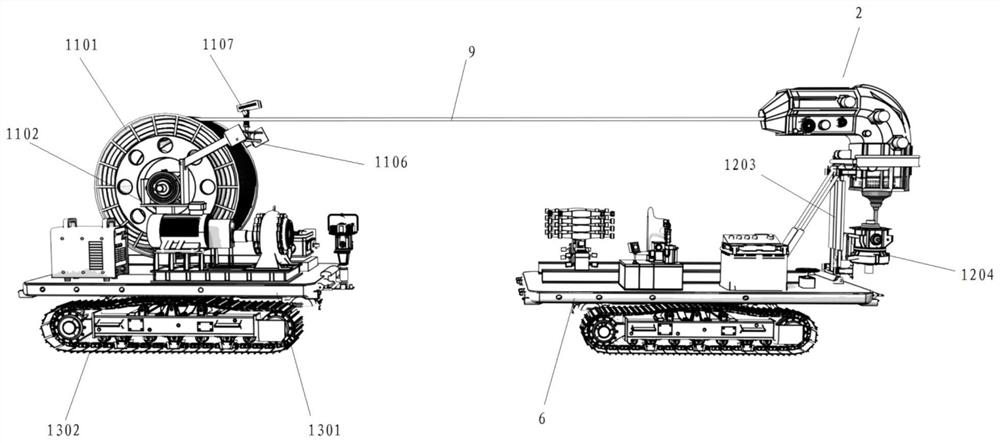

[0061] like figure 2 As shown, the continuous conduit type coring equipment disclosed in this embodiment includes a continuous conduit operation device, a tunnel drilling machine 6 and a core extractor 3 .

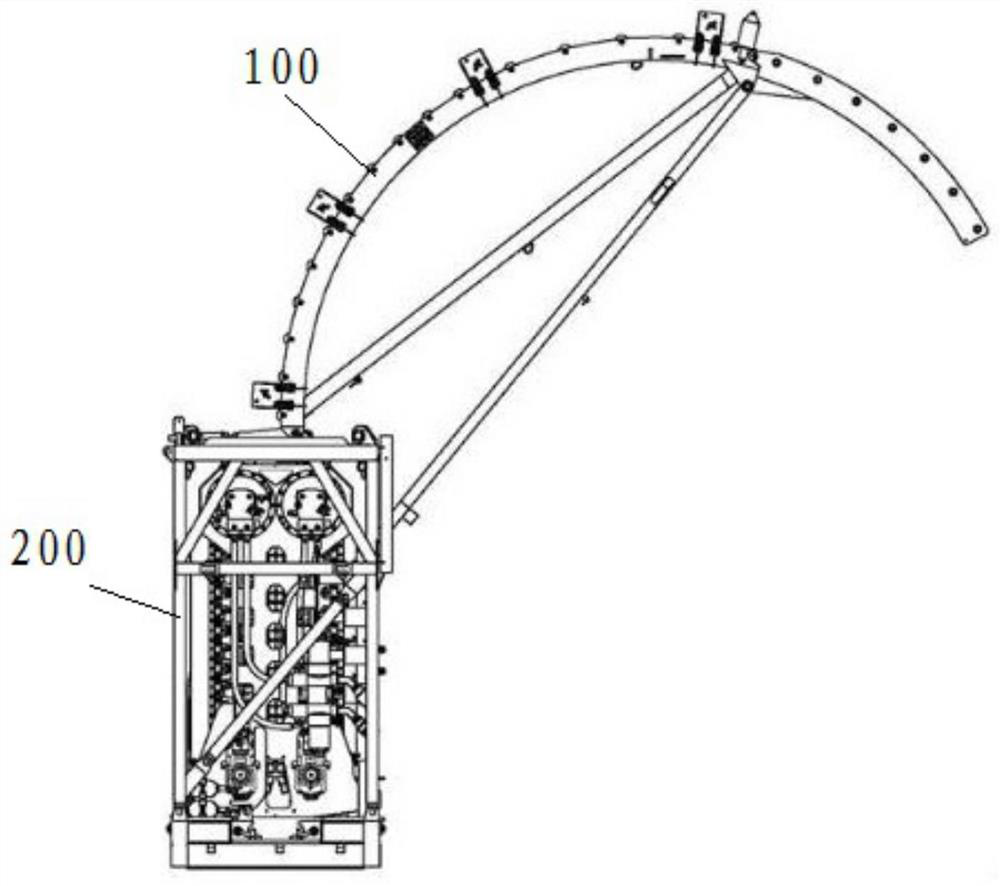

[0062] The continuous conduit operation device includes a reel device 1 , an operation vehicle, a continuous conduit 9 and an integrated guide and injection mechanism 2 .

[0063] like figure 2 , 3 , 4, 5, the reel device 1 is installed on the work vehicle for receiving the continuous conduit 9 . The reel device 1 includes a reel 1101 and a reel stand 1102. The reel 1101 is set on the reel stand 1102, and the reel stand 1102 is provided with a pipe arrangement assembly. The work vehicle includes a base 1301 and a crawler running mechanism 1302 , and the crawler running gear 1302 is arranged at the bottom of the base 1301 .

[0064] The pipe arrangement assembly includes a pipe support 1104 and a torque limiter. The pipe support 1104 is rotatably connected to the reel...

Embodiment 2

[0144] The difference between this embodiment and Embodiment 1 is that: Figure 19 As shown, the second sprocket chain clamping assembly 21 in this embodiment also includes a second tensioning pulley 24 engaged with the second chain 213, the second driving pulley 211, the second tensioning pulley 24 and the second driven pulley 212 Not in a straight line.

[0145] In this embodiment, an arc-shaped guide nipple 5 is provided at the entrance of the catheter guide passage, and the arc-shaped guide nipple 5 guides the continuous catheter 9 to enter the catheter guide passage more smoothly. The arc-shaped guide short joint 5 is concentric with the catheter guide channel and has the same radius.

[0146] The arc-shaped guide nipple 5 is located below the entrance of the guide channel of the guide tube, and has a certain supporting effect on the continuous guide tube 9 .

Embodiment 3

[0148] The difference between this embodiment and embodiment one or embodiment two is: as Figure 20 As shown, in this embodiment, the first push plate 205 is connected with a clamping driving device 22 for driving it to move in the radial direction.

[0149] The guiding and injecting integrated mechanism of the present invention integrates guiding and injecting functions, and adds a straightening device, which can ensure no increase in downhole wear while effectively reducing the height of the equipment. The invention is especially suitable for working environments with limited space and height, such as working in coal mine roadways.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com