Die pressing plastic and steel fan impeller production process and special mould

A fan impeller and production process technology, which is applied in the field of molded plastic steel fan impeller production technology and its special mold, can solve the problem that the production method of FRP hand lay-up impeller cannot be qualitatively improved, and restricts the progress and development of anti-corrosion fan time wheel, fan The impeller does not meet the strength requirements and other problems, and achieves the effects of light weight, good twist resistance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

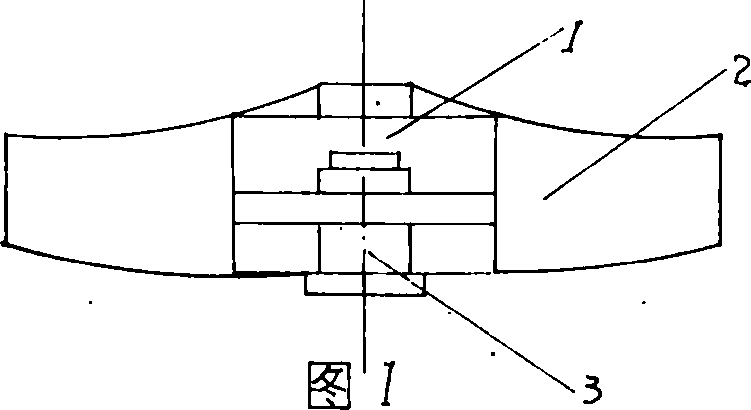

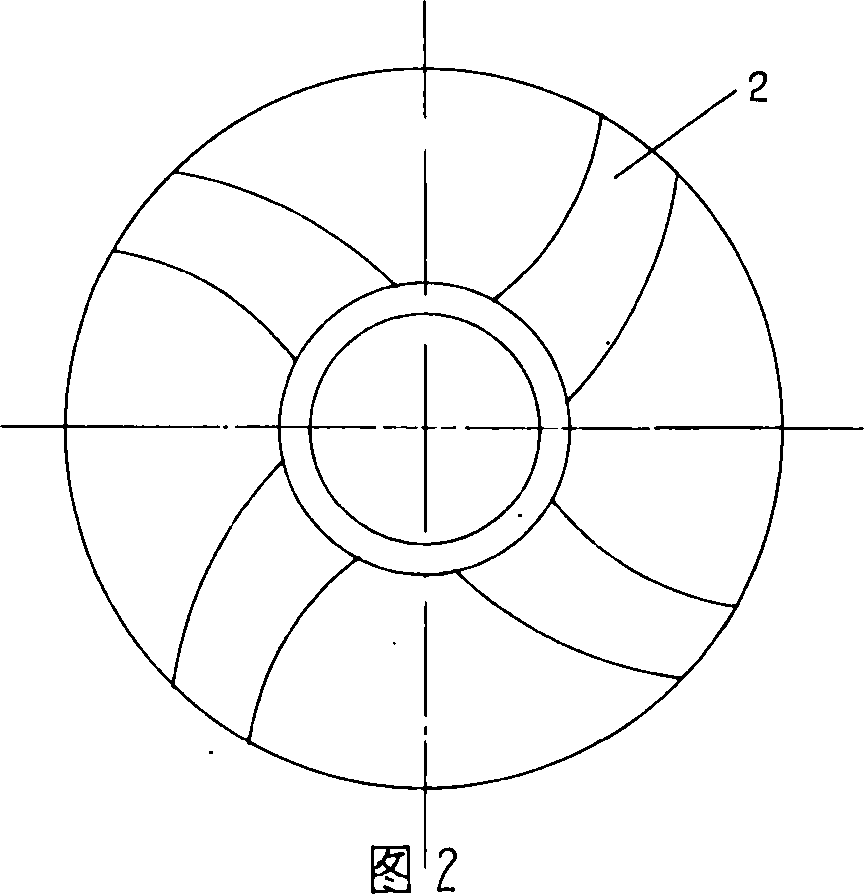

[0025] 1. Description of the centrifuge impeller process embodiment:

[0026] 1. Material selection: Bisphenol A structure and vinyl ester resin materials with excellent corrosion resistance and corrosion-resistant glass fiber reinforced materials are used as base materials.

[0027] 2. Ingredients: ingredients: 30-40% resin, 30-50% reinforced glass fiber, the rest are auxiliary materials such as plasticizers and fillers: use a kneader or a sheet machine to mix until it becomes agglomerated DMC or SMC for later use.

[0028] 3. Skeleton production: Weld several stamped special-shaped parts or centrifuge impeller-shaped metal skeleton (the rear disc and impeller are integrated, the front disc can be manufactured separately, and the two are pre-embedded with connecting screws and nuts, and then pressed separately. assembly).

[0029] 4. Making prototype intermediates. Attach the above-mentioned group or sheet to the metal skeleton, wrap it with a certain thickness, and wrap it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com