Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

69results about How to "Improve absolute positioning accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

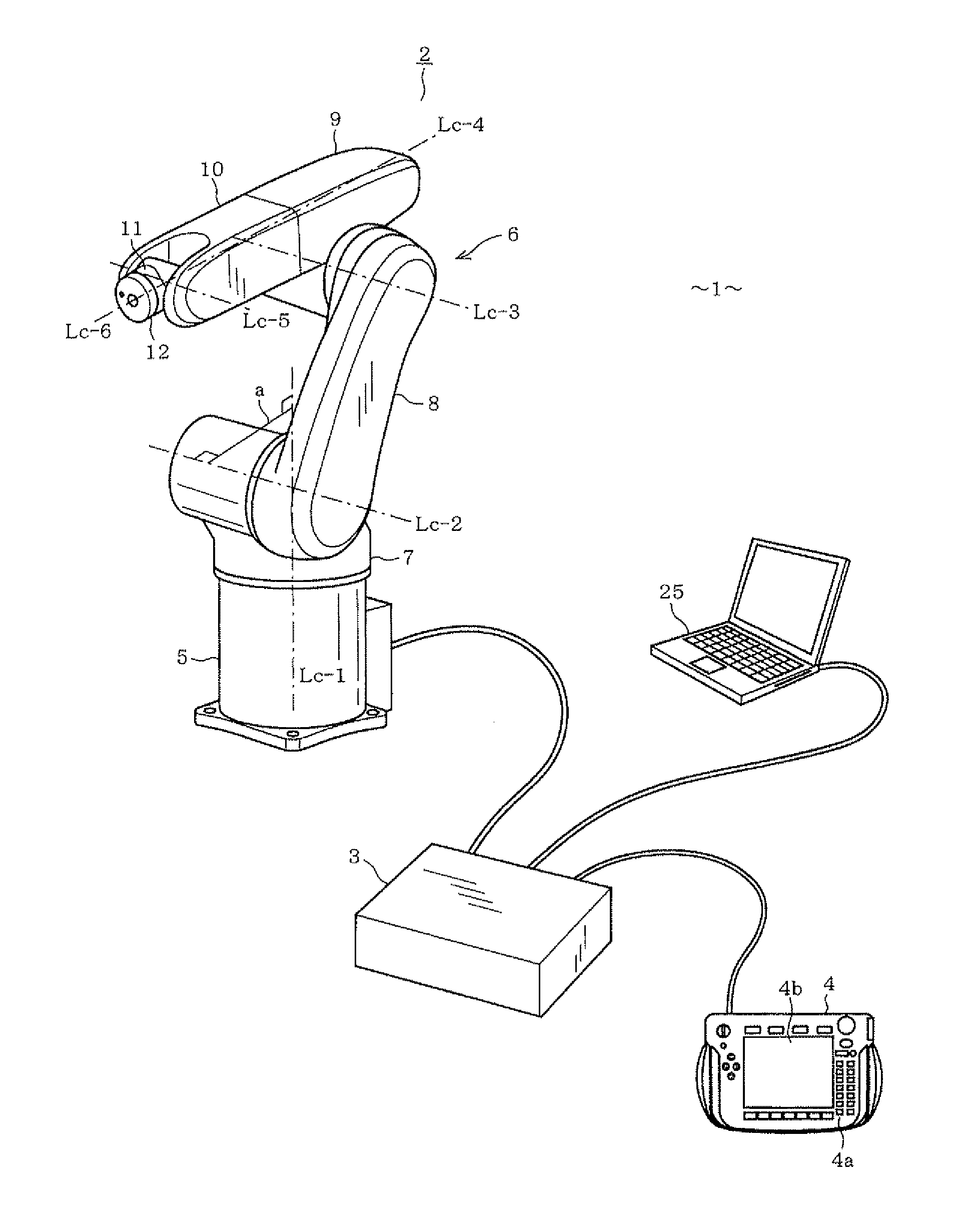

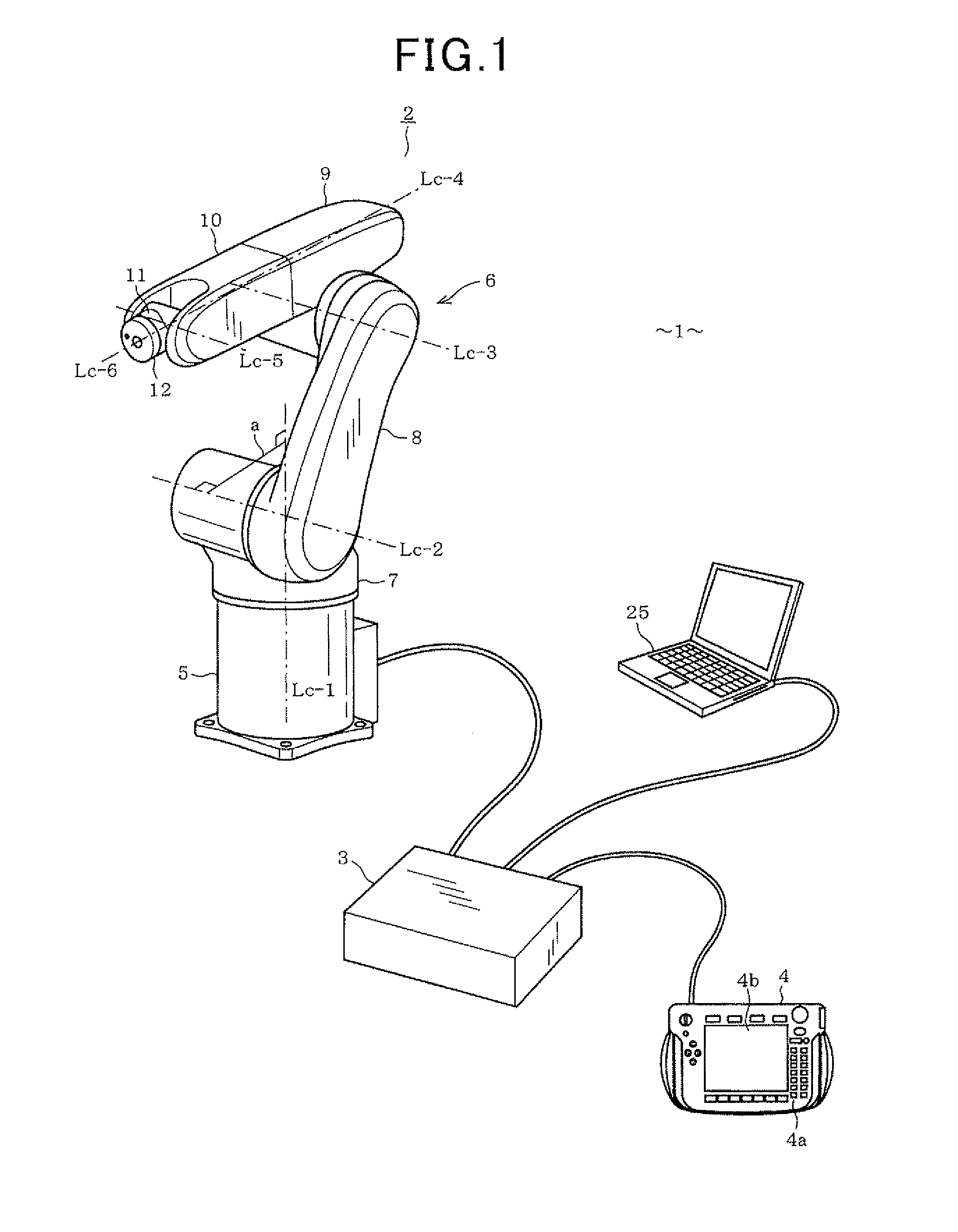

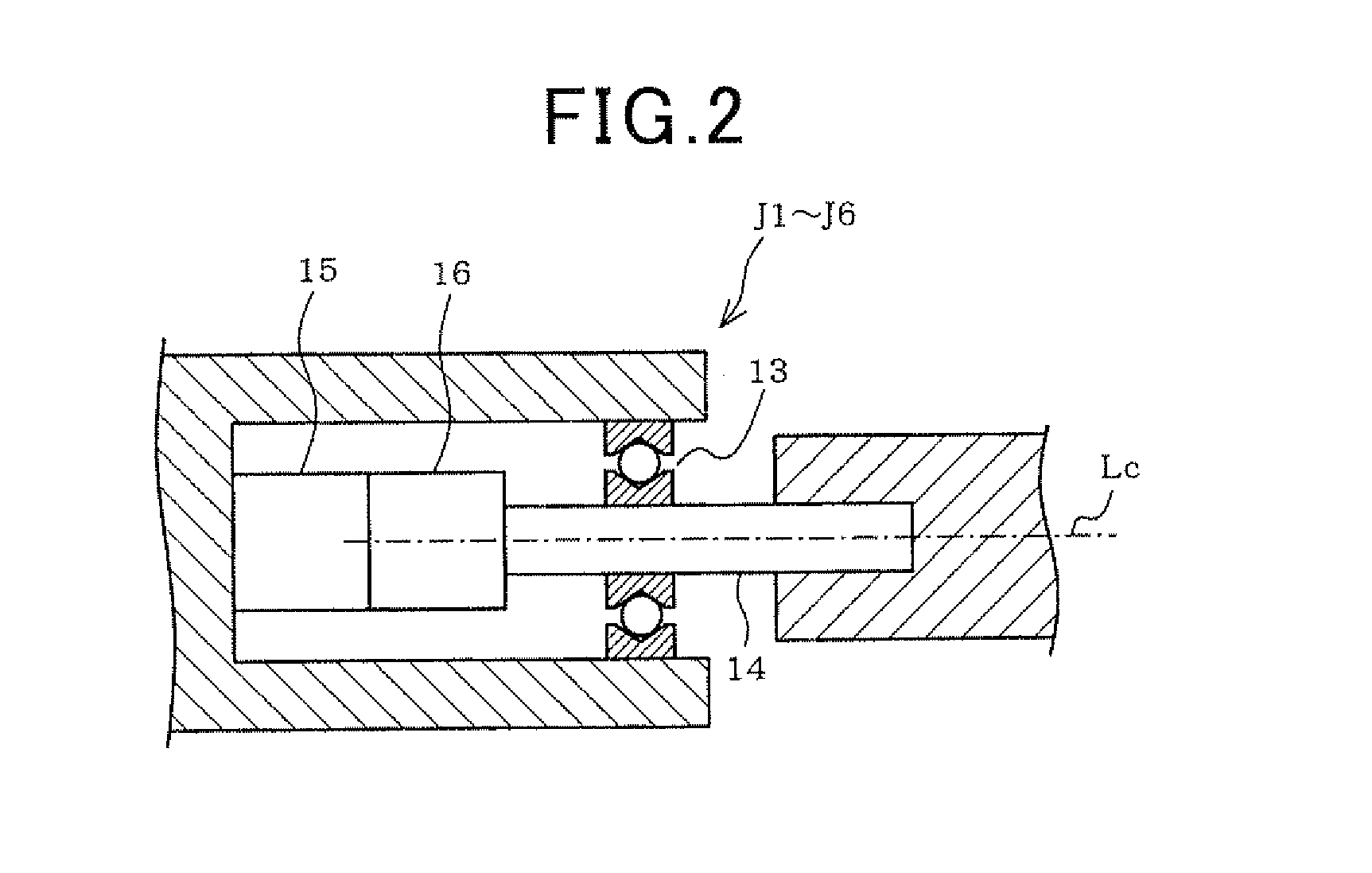

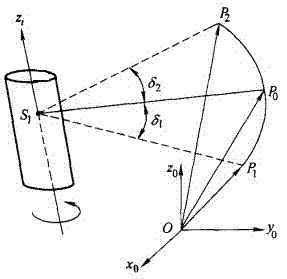

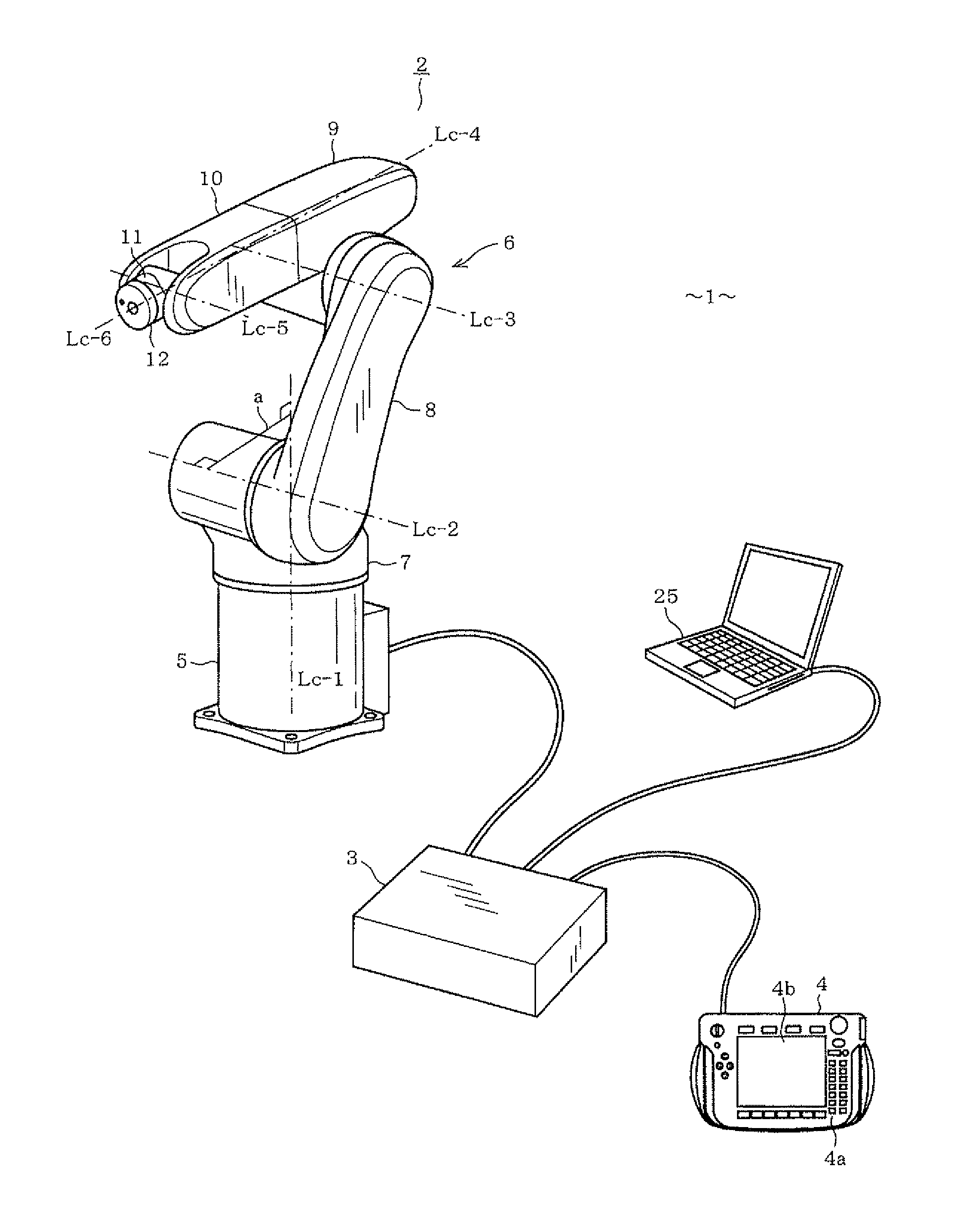

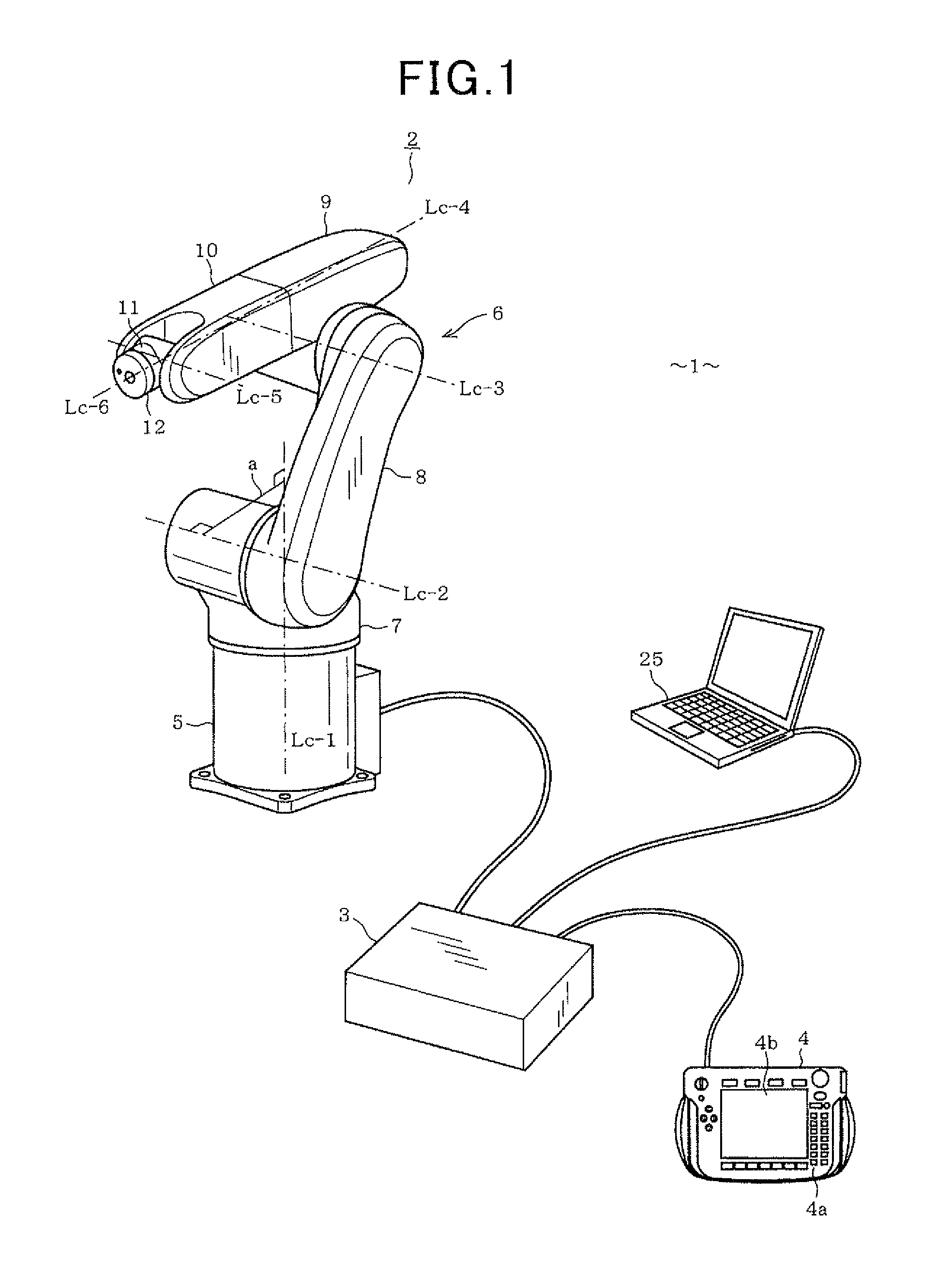

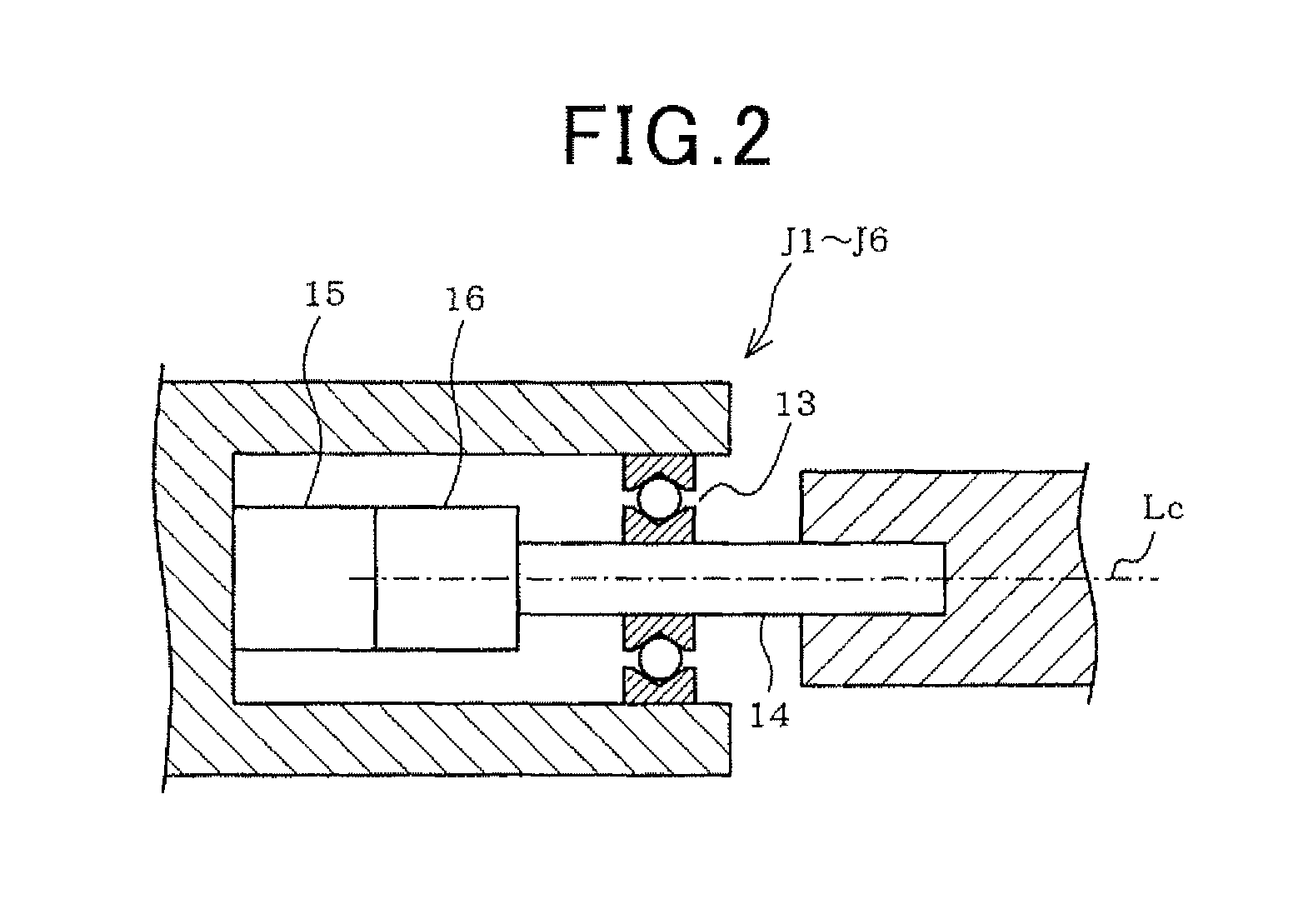

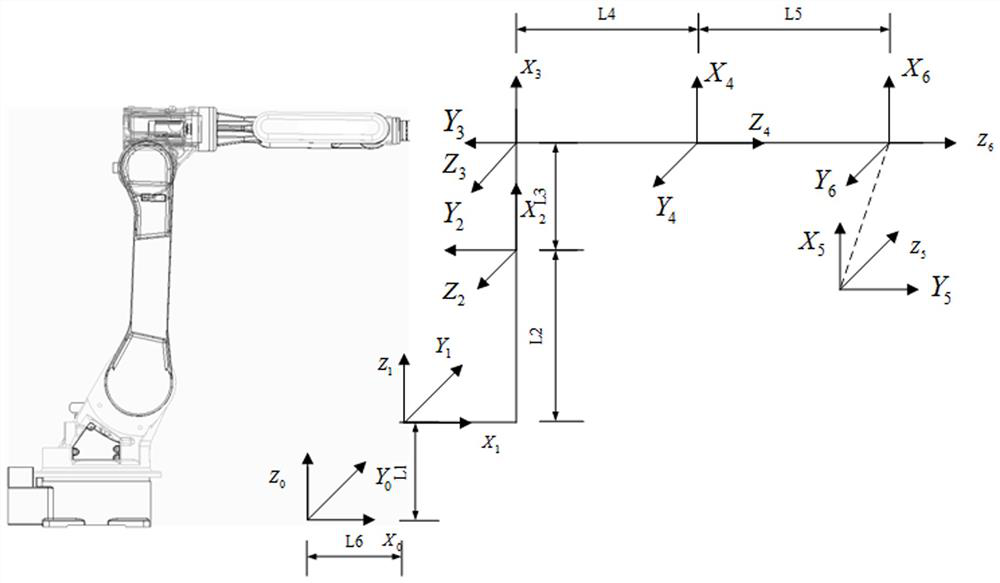

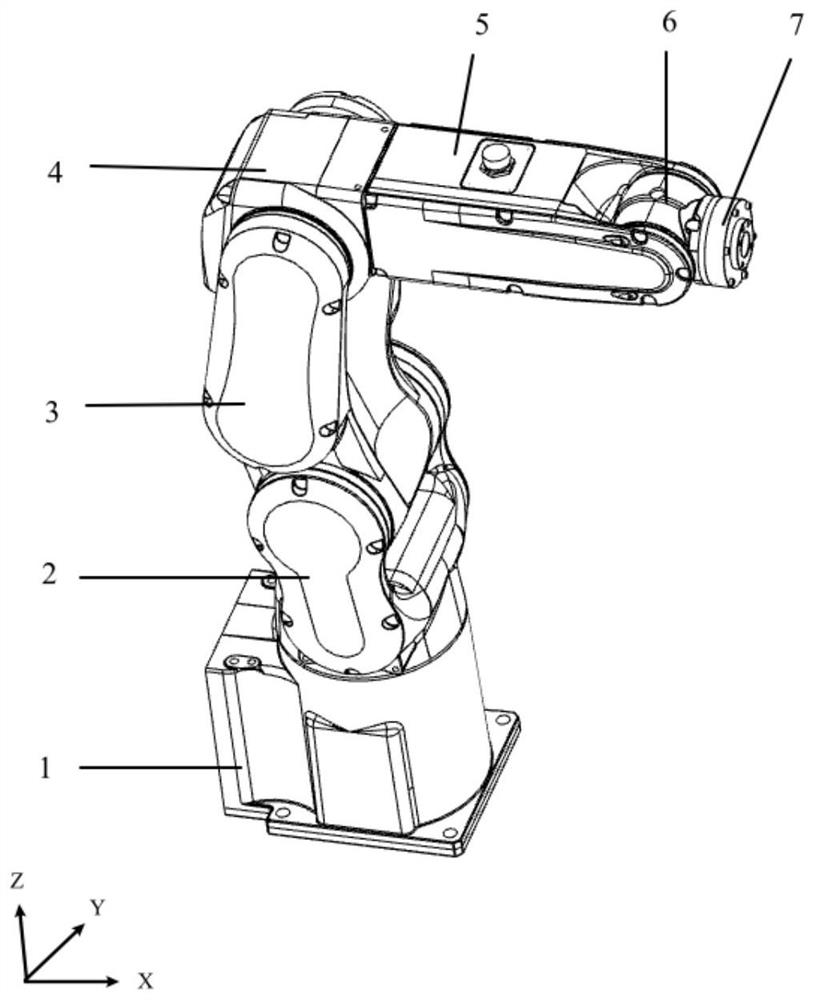

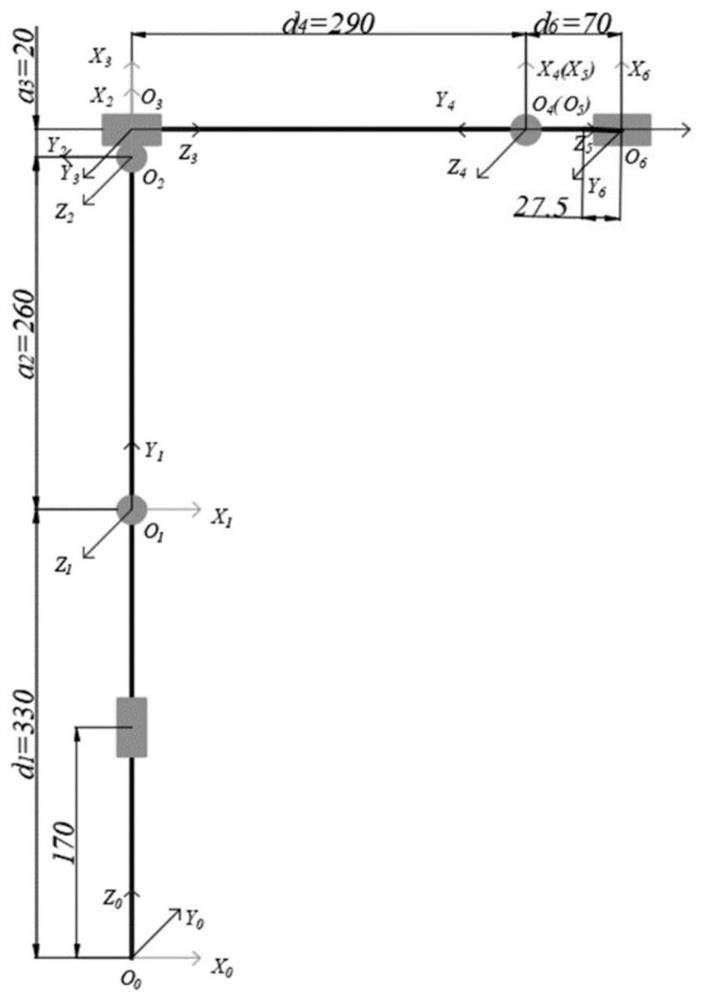

Method of detecting an inter-axis offset of 6-axis robot

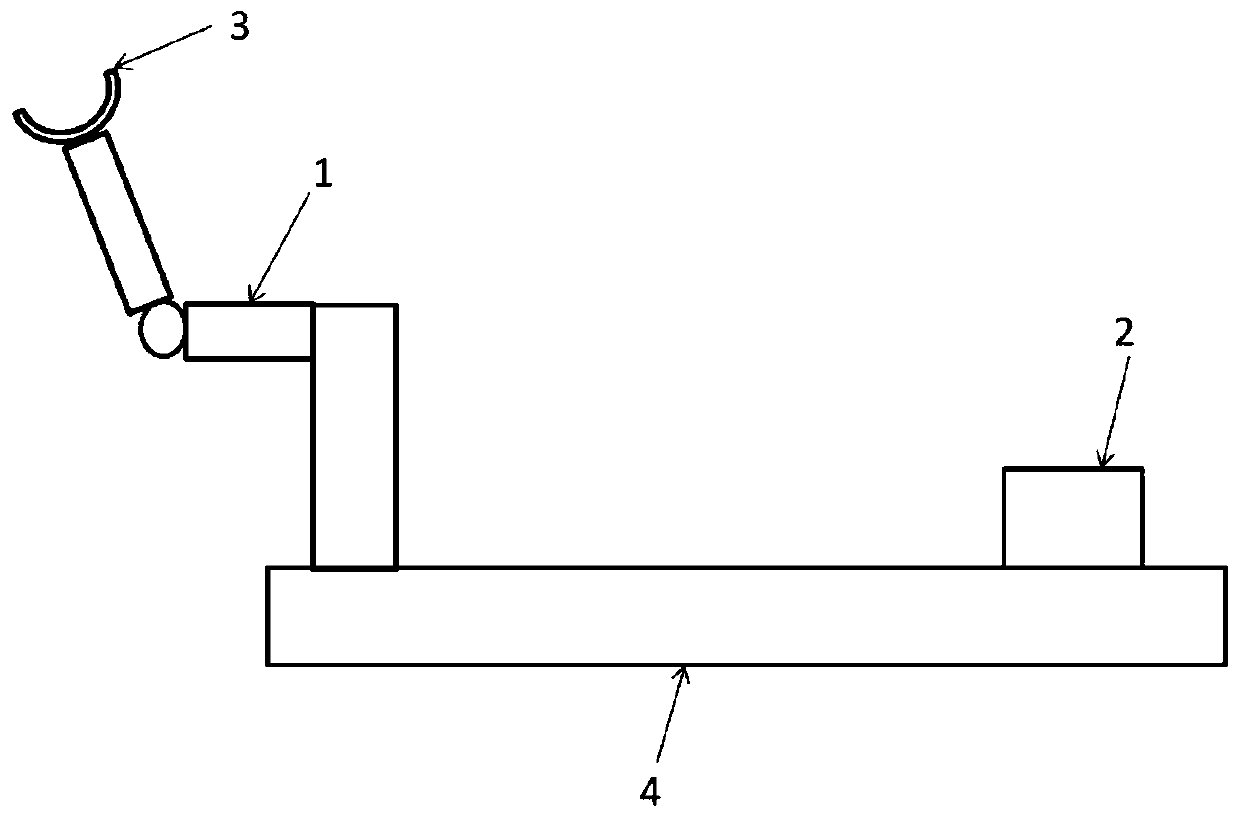

ActiveUS20120239194A1Improve absolute positioning accuracyHigh positioning accuracyProgramme-controlled manipulatorComputer controlEngineeringActuator

In a 6-axis robot, as an example, an inter-axis offset can be measured and calibrated. A light emitting diode is installed on an end effector, and the end effector is located on a plurality of target positions of movement on the axis X (Xb) of a robot coordinate. Then, the position of the light emitting diode is measured by a three-dimensional gauge, and an inter-axis offset F is detected based on an error between the target positions of movement and actually moved positions. For the inter-axis offset F, DH parameters are calibrated.

Owner:DENSO WAVE INC

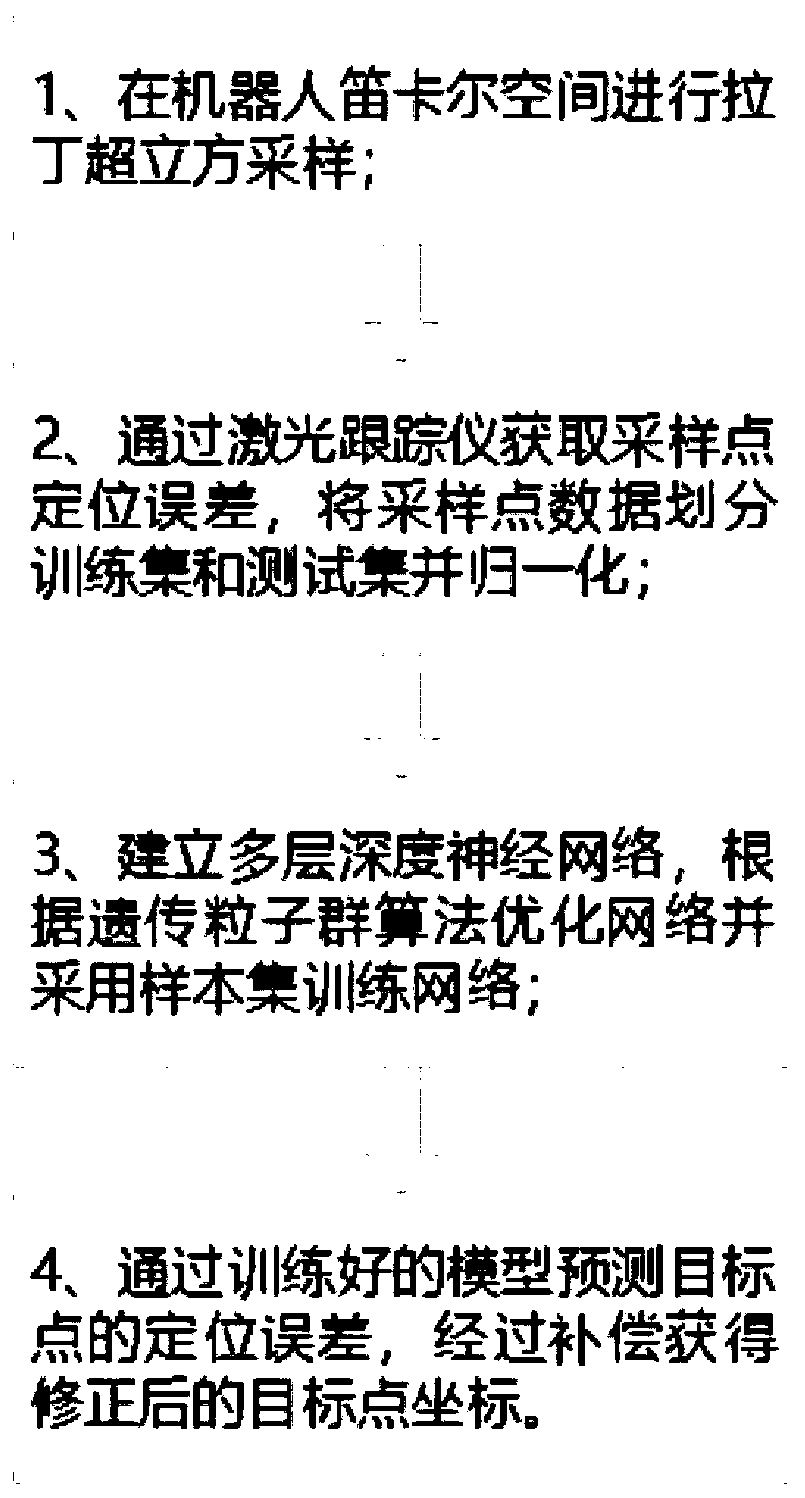

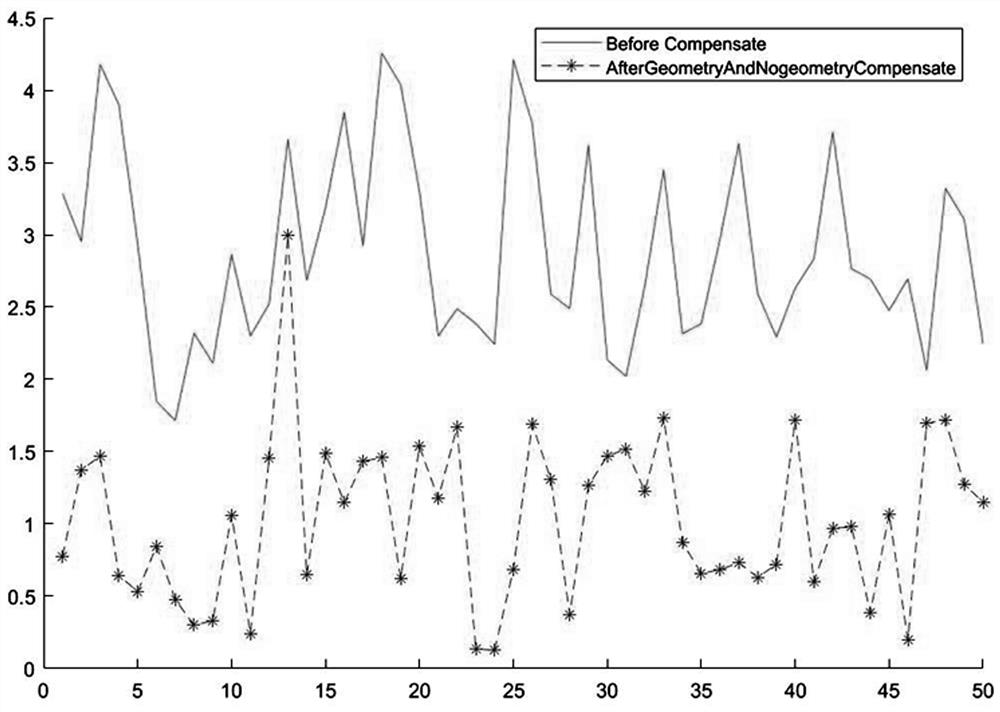

Method for compensating positioning errors of robot based on deep neural network

ActiveCN110385720AImprove absolute positioning accuracyAccurate predictionProgramme-controlled manipulatorPattern recognitionAbsolute positioning

The invention discloses a method for compensating positioning errors of a robot based on a deep neural network. The method comprises the following steps: taking theoretical coordinate data of each sampling point and corresponding actual positioning errors as one group of sample data; constructing a robot positioning error prediction model, and training and testing the robot positioning error prediction model by adopting the sample data, wherein the robot positioning error prediction model is used for predicting positioning errors of an inputted target point to obtain a positioning error prediction value; and inputting theoretical pose data to the robot positioning error prediction model to obtain prediction errors and compensating and correcting target point coordinates. According to the method disclosed by the invention, the influence of the position and the pose of a positioning point on the positioning errors is comprehensively considered; and a complex mapping relation between theoretical pose and actual positioning errors of a robot is expressed by using the deep neural network to predict the positioning errors of the target point and compensate the errors. By use of the method disclosed by the invention, absolute positioning precision of the robot can be remarkably improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

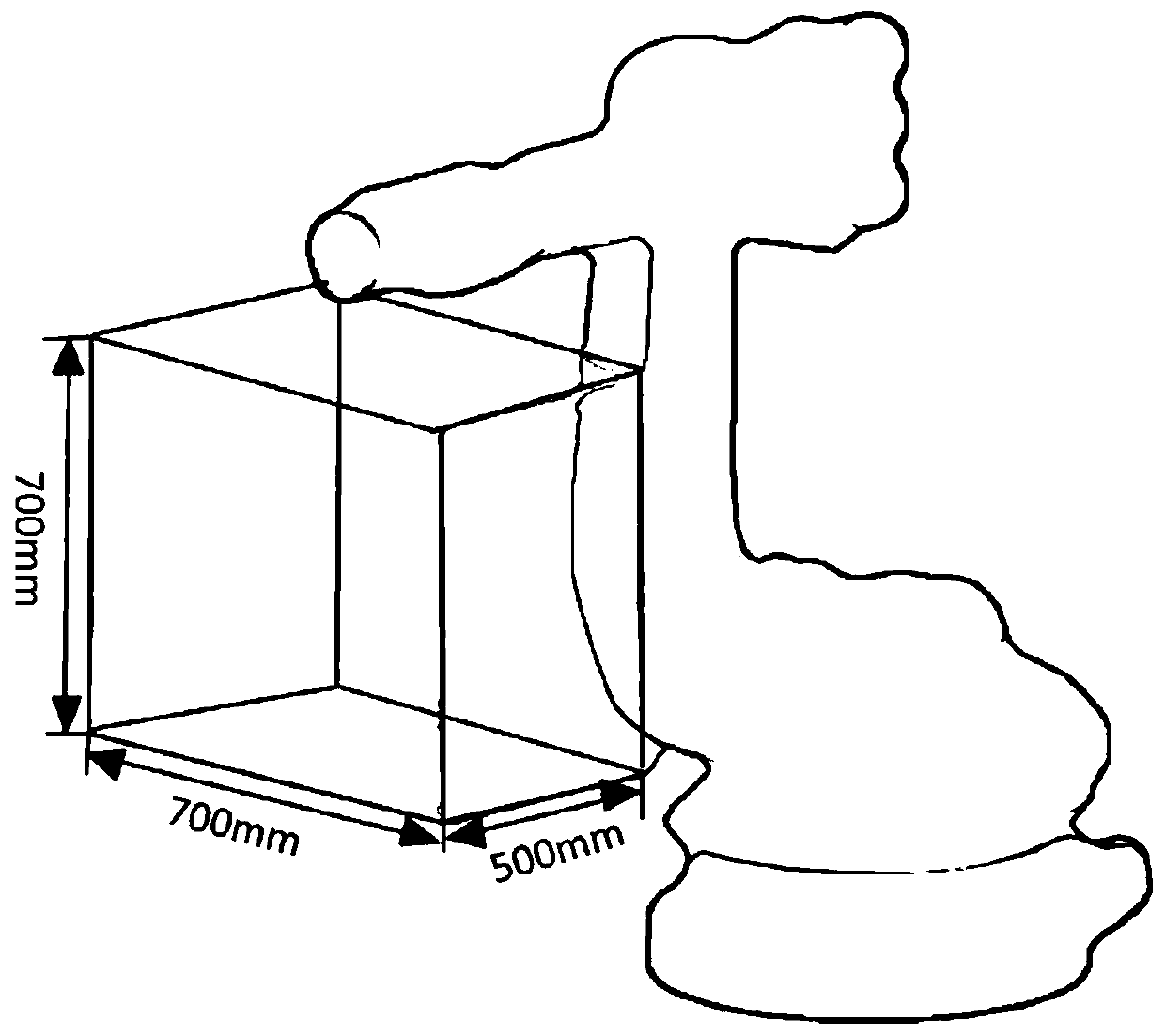

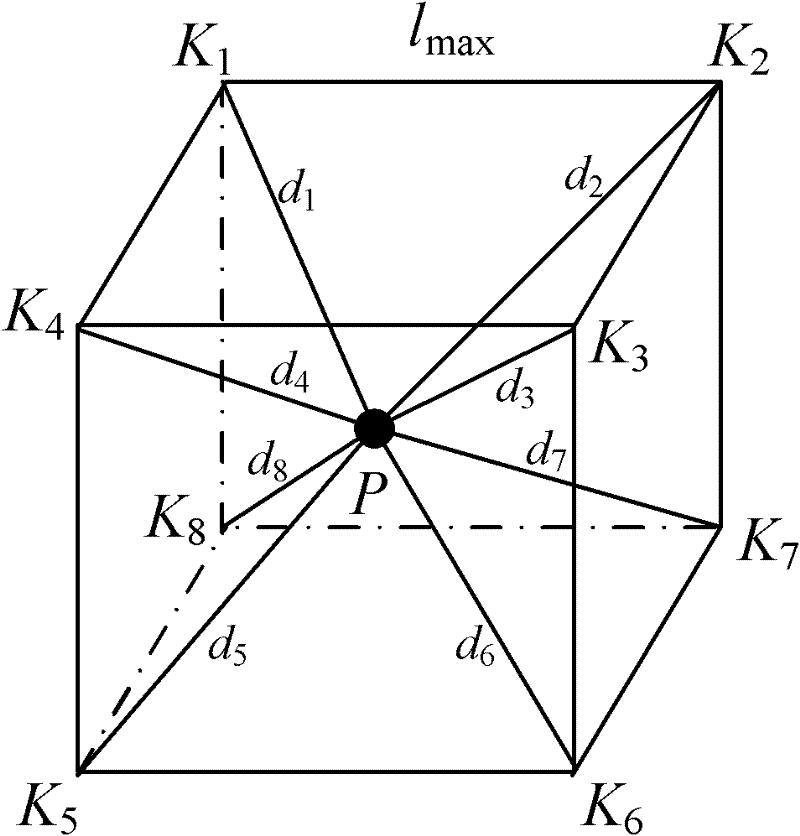

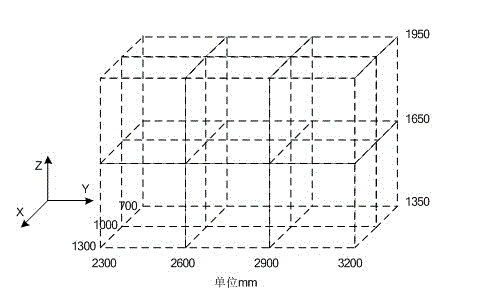

Three-dimensional grid precision compensation method for industrial robot

ActiveCN102230783AQuickly put into applicationReduce workloadUsing optical meansSimulationLaser tracker

The invention discloses a three-dimensional grid precision compensation method for an industrial robot and belongs to the technical field of inverse calibration of industrial robots. In the method, by taking advantage of the characteristic that the industrial robot has relatively high reposition accuracy and establishing the relationship between theory coordinates and actual positioning coordinates by a laser tracker, the theoretical coordinates of any one point in a certain cubic grid divided in an enveloping space of the robot can be corrected by a spatial interpolation process, so that the absolute position precision compensation of the robot at the point is accomplished. In the method, the calculation procedure is simple and fast; the absolute position precision of the robot can be obviously improved, and the robot can be suitable for a wider application range.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +1

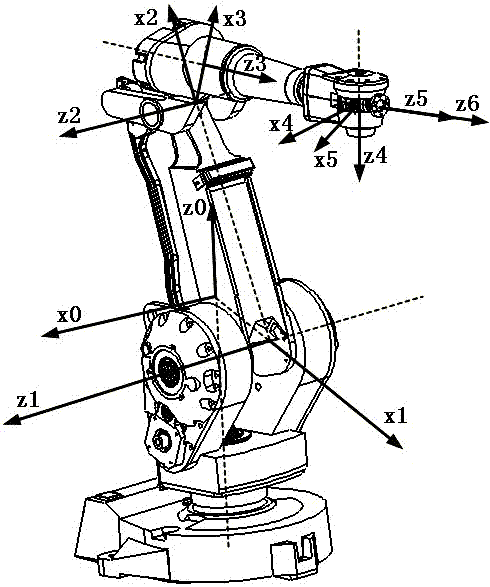

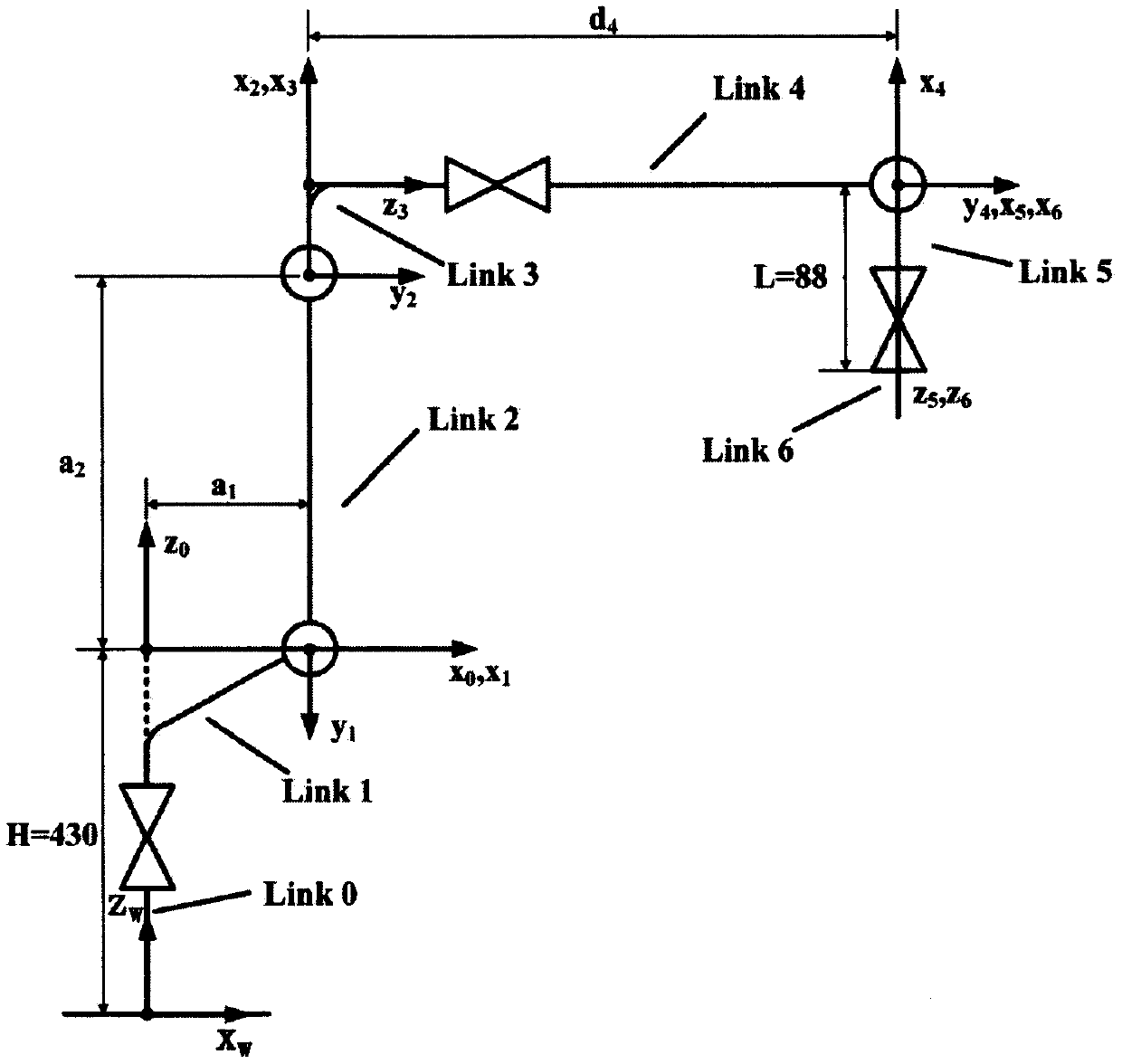

Industrial robot positioning precision calibration method

InactiveCN102692873AImprove absolute positioning accuracyImprove performanceAdaptive controlKinematics equationsEngineering

The invention relates to an industrial robot positioning precision calibration method used for improving robot absolute positioning precision. The method comprises the steps that: a robot kinetics model is established; a rotary joint equation is established by using a circumferential method; joint torsion angle parameter values are calculated; the actual pose of a robot end is measured accurately by utilizing a laser tracker; D-H algorithm inversion kinetics equation is improved to obtain geometrical structural parameters; calibration of joint distance parameter values and calibration of joint offset are realized, and thereby first calibration is completed. Error correction is carried out on D-H parameters based on first calibration results, and if positioning precision can not meet requirements, second calibration can be carried out by substituting parameter correction values, instead of theoretical parameter values, into the kinetics equation. Absolute positioning precision of the robot is improved with the calibration method, which is proved in experiments. According to the invention, the calibration method is advantaged in that the method is simple and practical and introduces small external errors.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

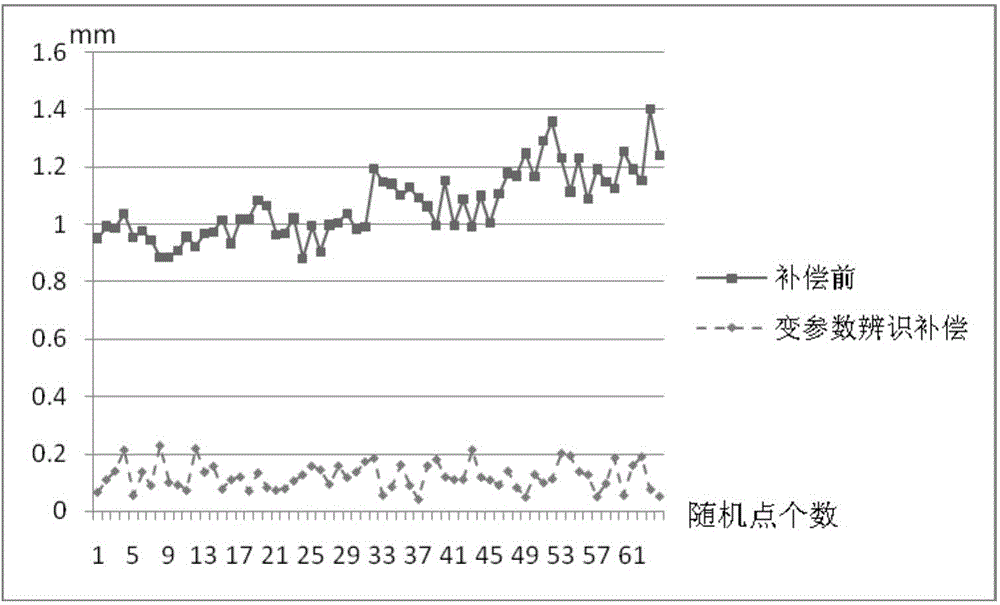

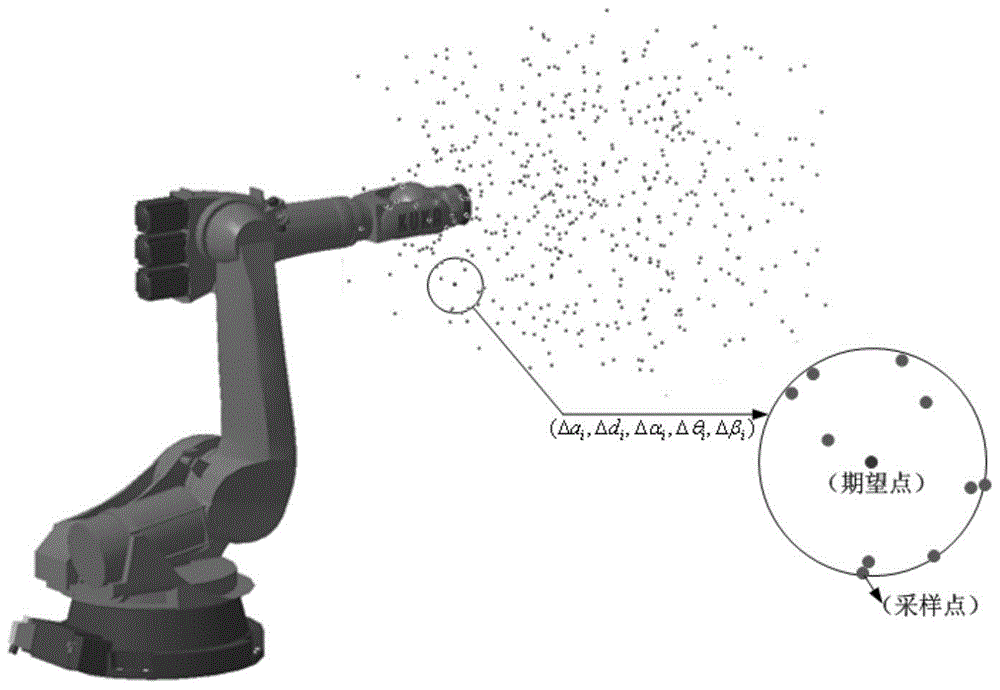

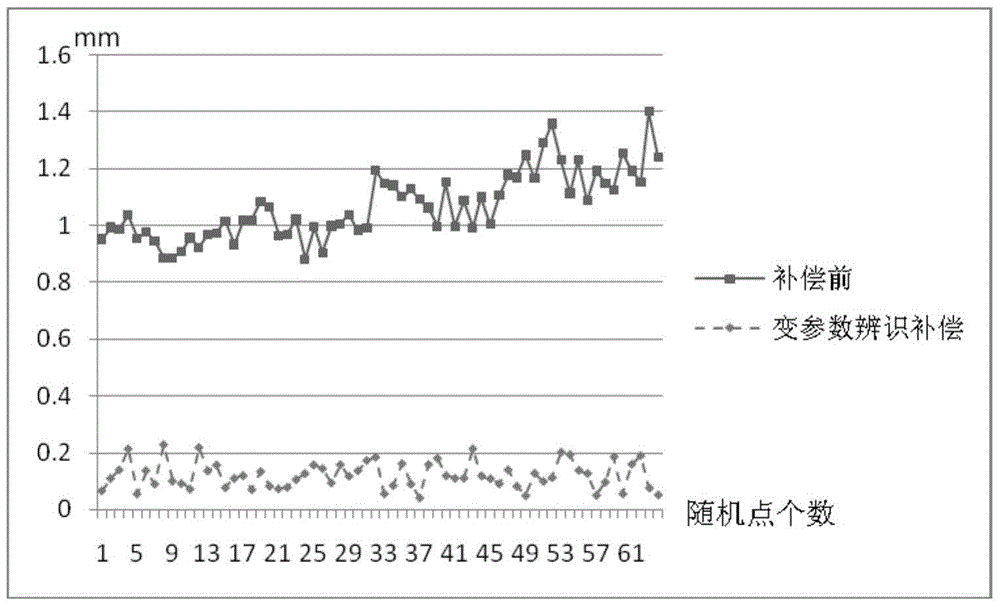

Robot precision compensation method for variable-parameter error recognition

ActiveCN104535027AImprove absolute positioning accuracyFind global convergent solutionNavigational calculation instrumentsLaser trackerInverse kinematics

The invention discloses a robot precision compensation method for variable-parameter error recognition and belongs to the technical field of robot inverse calibration. A variable-parameter error module is provided, errors of pose points of a robot in different spaces are sampled through a laser tracker, a plurality of points which are closest to an expected pose point are sought in the near area range according to the space where the expected pose point is located, and an improved Levenberg-Marquardt damp iterative least square method algorithm is used for solving the global convergent solution of the parameter error corresponding to the expected pose point, and therefore the practical parameter of the expected pose point is solved. The pose point at which the robot should arrive practically is solved through the practical parameter of the expected pose point and through inverse kinematics of the expected pose point, and the absolute positioning precision compensation of the robot at the pose point is achieved. The robot precision compensation method can obviously improve the absolute positioning precision of the robot and can be applied to the field where the requirement for robot precision is high.

Owner:江苏航鼎智能装备有限公司

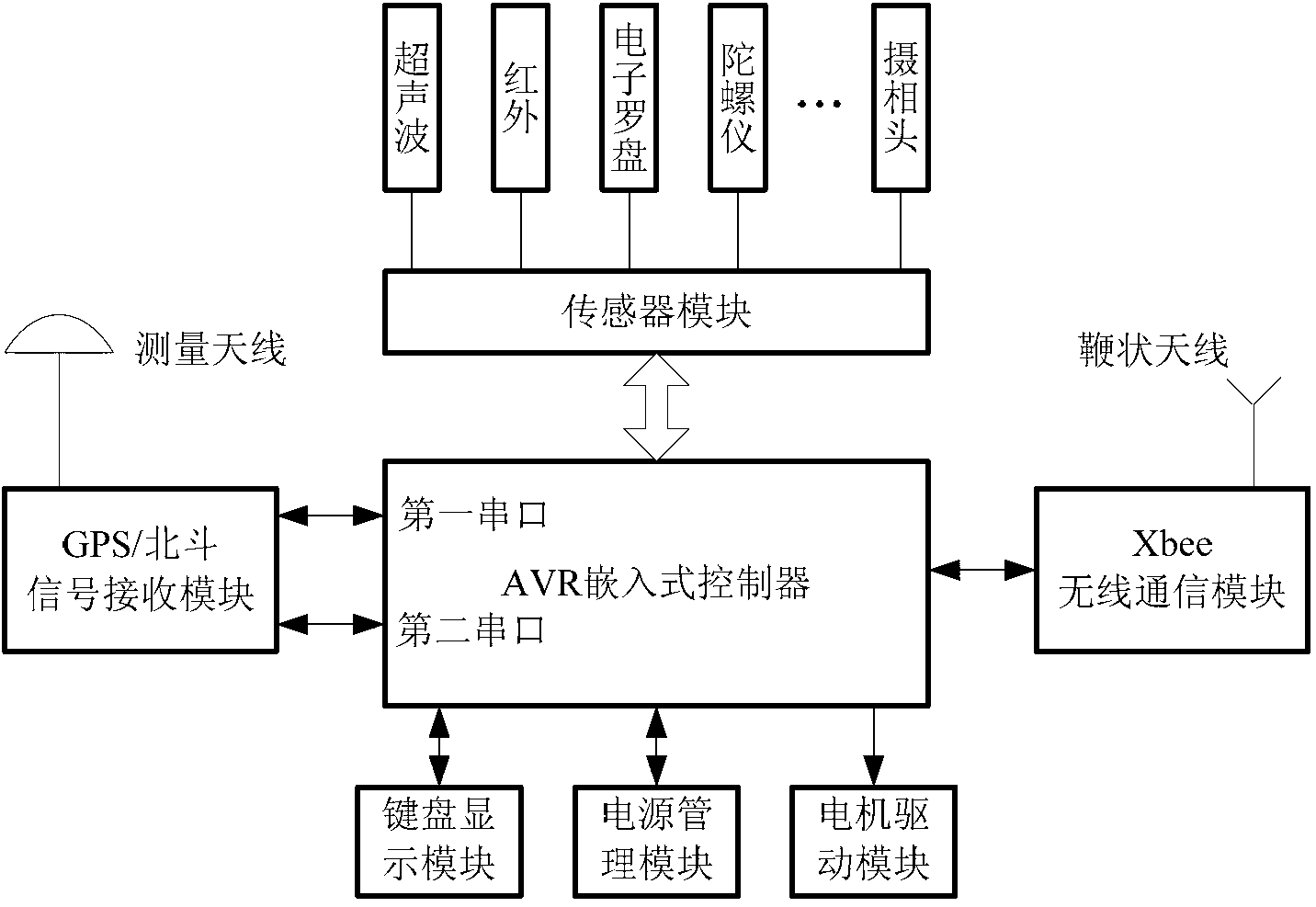

Control system and control method of outdoor micro ground swarm robot

ActiveCN103235595AImprove co-location accuracySimple designTotal factory controlProgramme total factory controlControl systemDifferential correction

The invention discloses a control system and a control method of an outdoor micro ground swarm robot. The control system comprises a differential positioning base station, an upper monitoring computer and a plurality of individual robots, wherein the individual robots form a swarm robot system; the differential positioning base station is used for receiving a positioning signal in real time, performing pseudo-range differential calculation with a given base station reference coordinate, and then sending a differential correction number to the individual robots in the swarm robot system through a wireless communication module; the individual robots are used for receiving the positioning signal in real time and the differential correction number sent by the base station and obtaining a position coordinate after performing pseudo-range differential calculation; and the upper monitoring computer is used for receiving the position information of the individual robots through the wireless communication module and sending a command to control the running of the individual robots. By the control system and the control method, the positioning precision of the individual robots can be improved, and complex tasks, such as coordinate control and combined target search of the swarm robots are realized.

Owner:湖南睿图智能科技有限公司

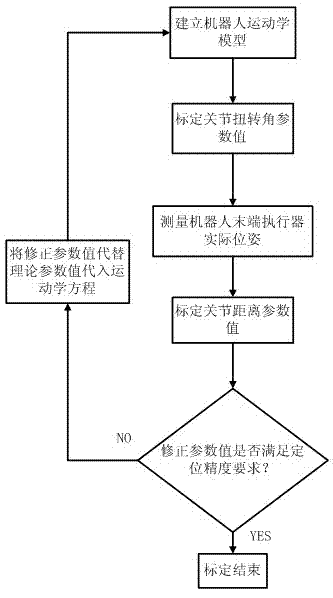

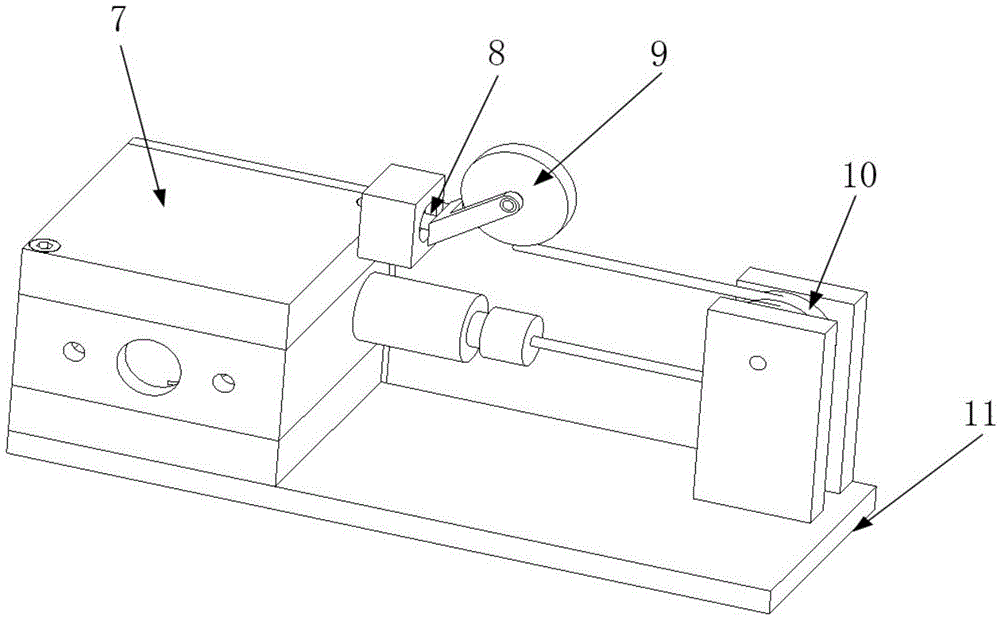

Pull-cord encoder based calibration method of industrial robot

InactiveCN104890013AImprove absolute positioning accuracyHigh precisionManipulatorSimulationStructural error

The invention discloses a pull-cord encoder based calibration method of an industrial robot. The method includes: calculating an error model of the robot according to a kinematic model of the robot and the structure of a pull-cord robot; allowing structural errors of the robot to fully affect rules of an end effector to demonstrate the robot; according to a command of a demonstration program, allowing the robot to move a specified position, and acquiring distances of the pull-cord encoder when the robot is at different positions; according to the acquired measurement data and end positional data of the robot, calculating a reference position of the pull-cord encoder; by means of the calculated reference position and the error model built, calibrating structural parameters of the robot; according to structural errors obtained in the calibration process, correcting the structural parameters of the robot; repeating the steps from five to seven until that the precision is satisfactory. The method is easy to implement and convenient to operate.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Serial robot kinematics parameter calibration method based on vision

The invention provides a serial robot kinematics parameter calibration method based on vision. The optical axis of a camera serves as virtual straight line constraint, and a kinematics error model based on straight line constraint is built; a fixed point is selected from a calibration plate fixed to the tail end of a robot to serve as a feature point, motion of a mechanical arm is controlled through a visual control method based on images, and the feature point is made to arrive at the optical axis; according to joint angular data of the robot, the forward kinematics is used for calculating the nominal position of the feature point and the alignment error matrix; and the kinematics parameter error is estimated through the iterative least squares algorithm, and the actual kinematics parameter is calculated according to the nominal kinematics parameter. According to the serial robot kinematics parameter calibration method based on vision, the optical axis of the camera serves as virtualconstraint, calibration can be completed through only the joint angular data of the robot, the cost is low, operation is easy, expensive high-precision measuring equipment is not needed, and the method has the universality for serial robot calibration and can be widely applied to industrial, space and underwater environments to improve the absolute positioning precision of the mechanical arm.

Owner:HARBIN ENG UNIV

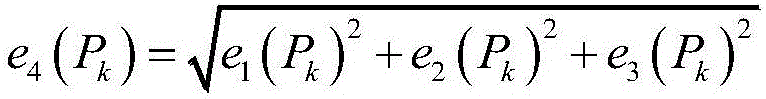

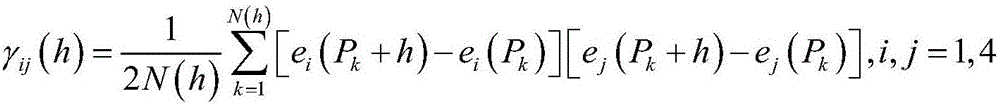

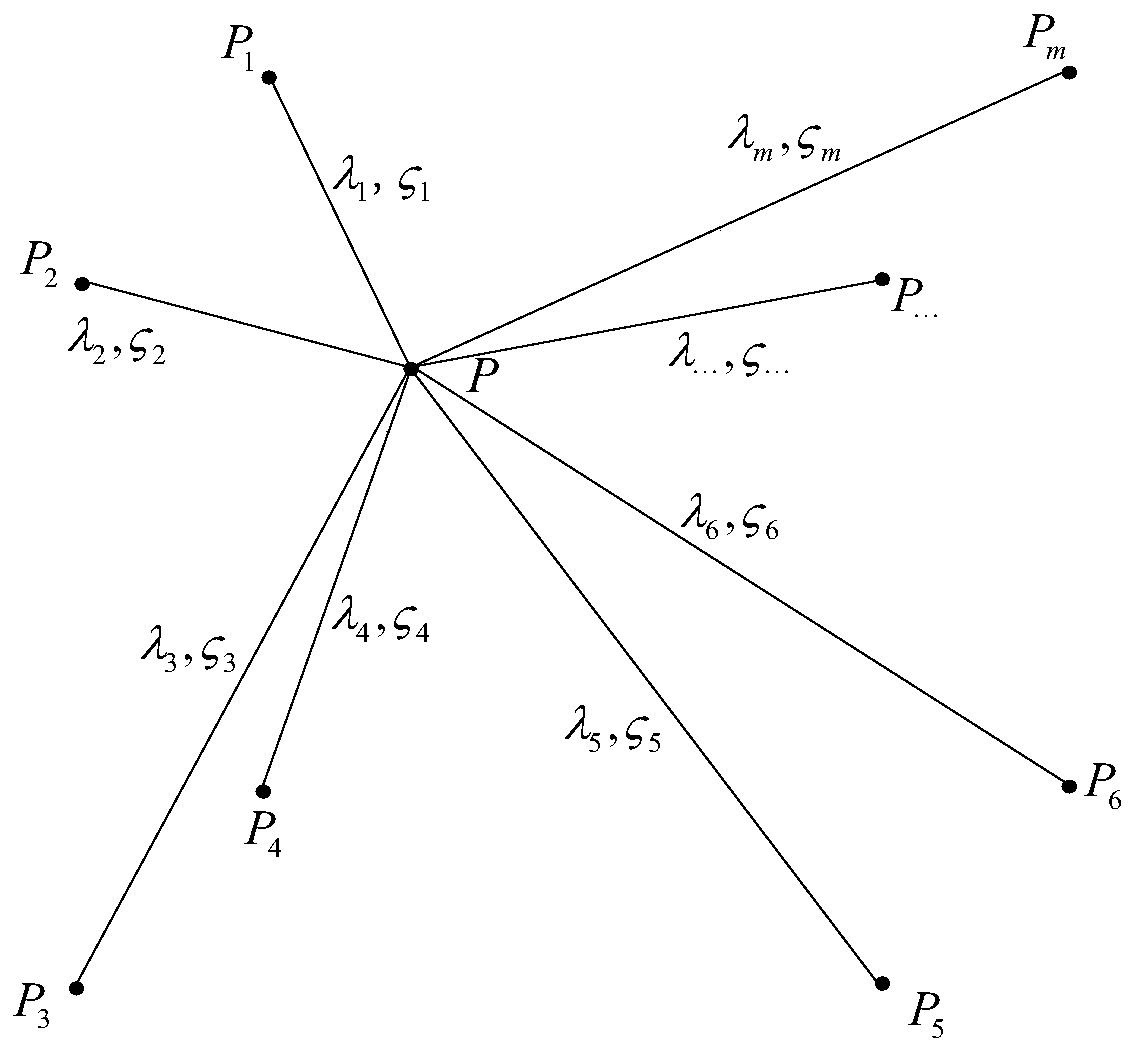

CoKriging-based absolute positioning error estimation method of mechanical arm

InactiveCN106595485AImprove absolute positioning accuracyUsing optical meansEstimation methodsOpen source

The invention, which belongs to the technical field of the robot, discloses a CoKriging-based absolute positioning error estimation method of a mechanical arm. Equipment used by the method consists of an industrial mechanical arm, a laser tracker and a target sphere. The target sphere is pasted to a flange at the tail end of the mechanical arm and is used as a central point of the tool. According to the method, the laser tracker measures practical positions of some points; position errors of theoretical positions and practical positions of the points are obtained; CoKriging interpolation processing is carried out on position errors in X, Y and Z directions and a position error model; and then position error estimation of points in mechanical arm moving space in the X, Y and Z directions is carried out, so that absolute positioning error estimation is realized. The method is independent of the kinematic model of the mechanical arm; the absolute positioning precision of the mechanical arm can be improved; and modification of internal parameters of the non-open-source controller of the mechanical arm can be avoided.

Owner:BEIHANG UNIV

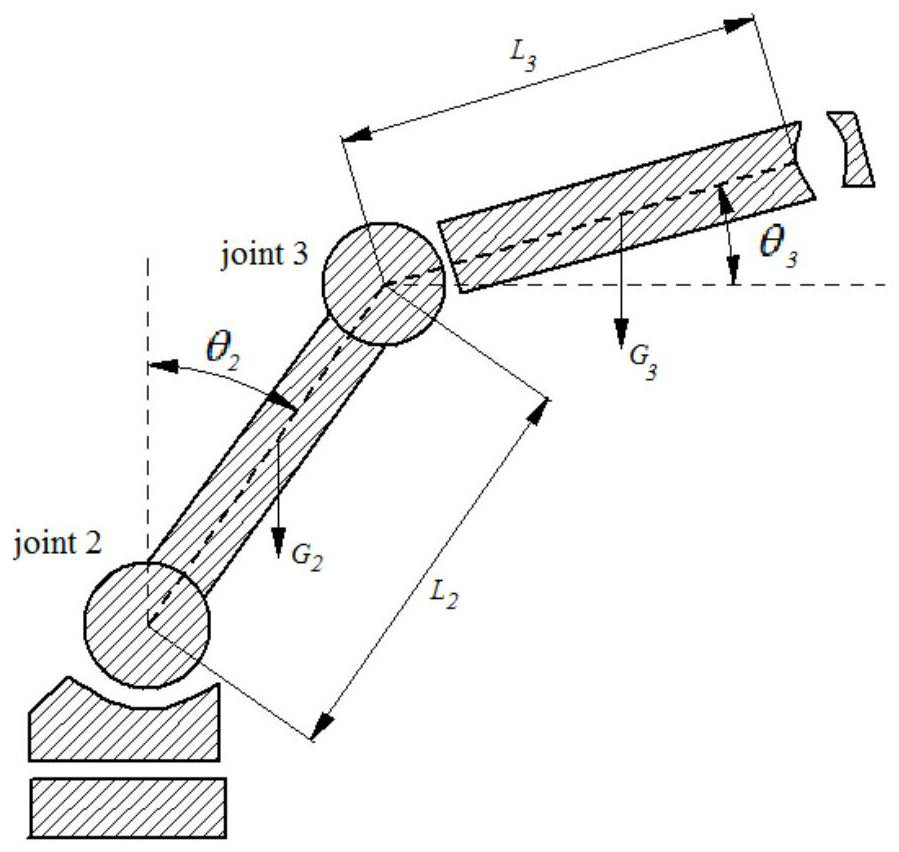

Dead weight and load deformation compensation based robot calibration method and system

ActiveCN108406768AImprove absolute positioning accuracyProgramme-controlled manipulatorKinematicsKinematic calibration

The invention discloses a dead weight and load deformation compensation based robot calibration method and a system. The method comprises the following steps that original nominal joint angles corresponding to each calibration point position are compensated to obtain compensation joint angles on the basis of joint angle deformation caused by the dead weight and load of the robot; according to theactual measured position obtained when a tool installed the tail end of the robot reaches each calibration point position at the tail end and compensation joint angles, to-be-identified parameters arecorrected. According to the method and the system, the original nominal joint angles corresponding to each calibration point position are compensated based on the joint angle deformation caused by the dead weight and load of the robot, the compensation joint angles are adopted instead of the non-original nominal joint angles in the calibration process, so that the calibration process reduces theinfluence on absolute positioning precision caused by the dead weight and load of the robot; and compared with a kinematic calibration algorithm, the absolute positioning precision of the robot can begreatly improved, and the absolute positioning precision of an industrial robot can be greatly improved.

Owner:汇川技术(东莞)有限公司

Method of detecting an inter-axis offset of 6-axis robot

ActiveUS8918210B2Improve absolute positioning accuracyHigh positioning accuracyProgramme-controlled manipulatorComputer controlEngineeringActuator

Owner:DENSO WAVE INC

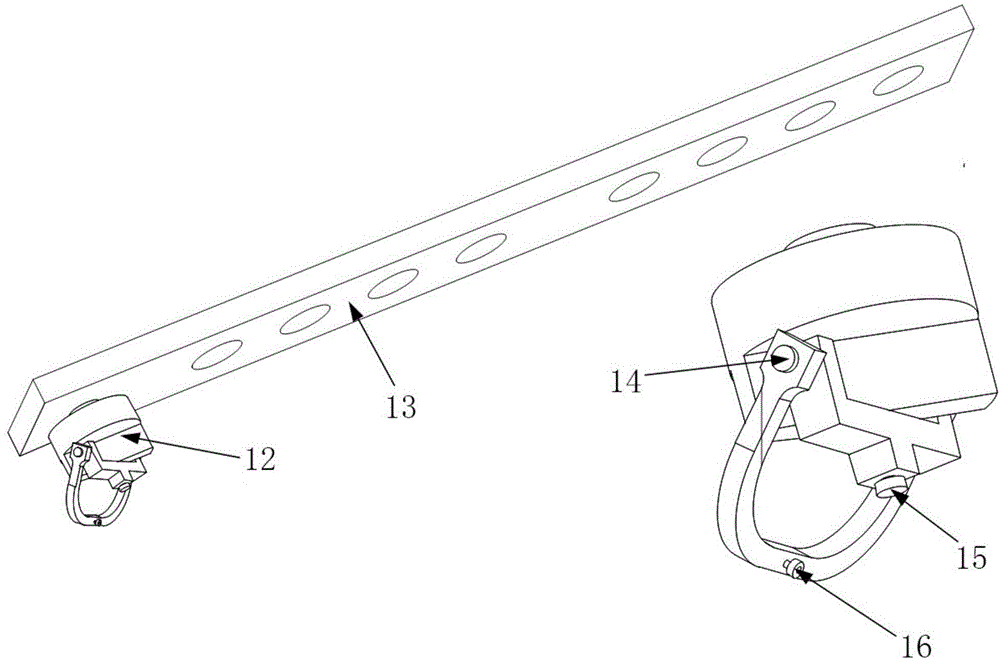

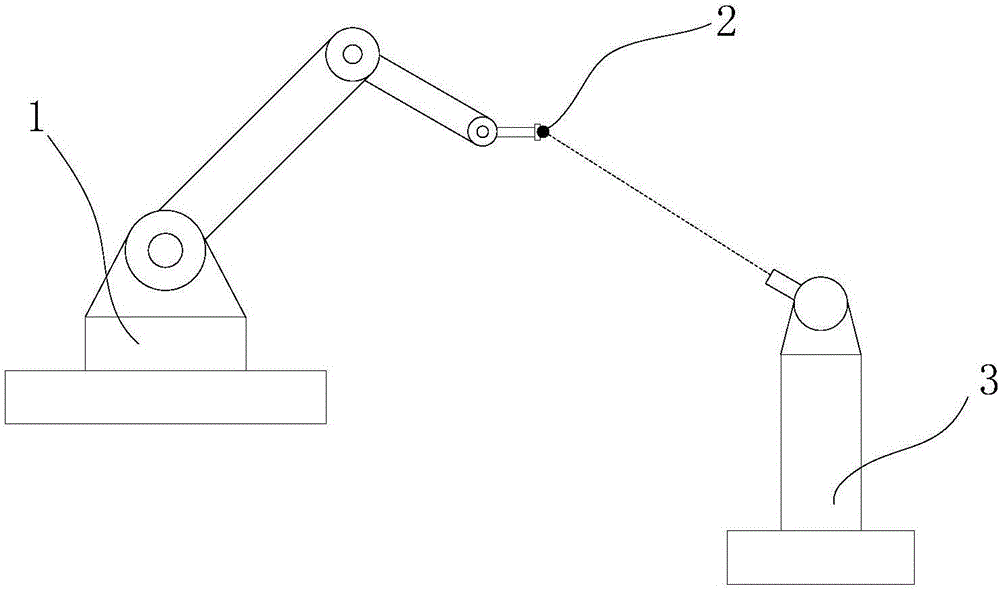

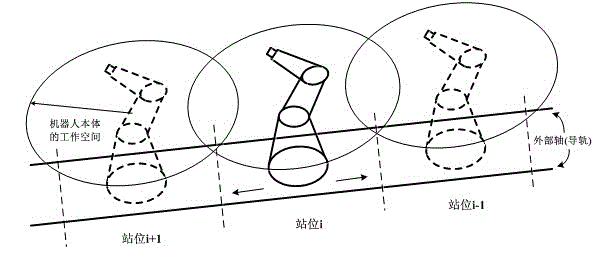

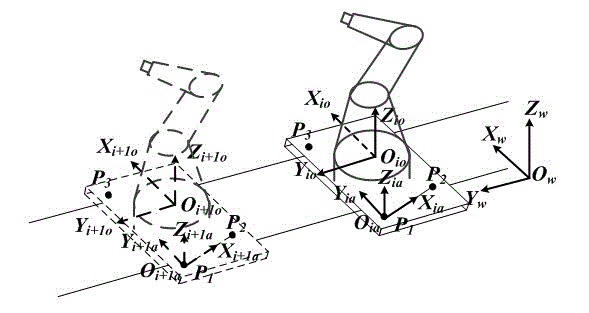

Substation type precision compensation for robot system with additional external shaft

ActiveCN103144109AExpand the scope of workImprove work adaptabilityProgramme-controlled manipulatorRobotic systemsLaser tracker

The invention discloses a substation type precision compensation for a robot system with an additional external shaft, belongs to the technical field of industrial robot reverse calibration, and aims to solve the difficulty in compensating the error of the external shaft (guide rail) of the industrial robot. According to the method, based on a robot envelope line, the guide rail is divided into a plurality of substations and substation type compensation is performed. The method comprises the steps: a laser tracker is adopted to measure and recognize the error of the external shaft (guide rail) and the robot, and the compensation for the tail end error of the robot is completed through inputting corrected control commands into the robot. During measurement and recognition of the error of the external shaft, an auxiliary coordinate system is introduced so as to allow the measuring process to be simple and quick, and meanwhile to ensure the precision. Through test verification, the method can greatly improve the absolute positioning precision of the robot with the additional external shaft, so as to allow the robot to be suitable for wider applications.

Owner:江苏航鼎智能装备有限公司

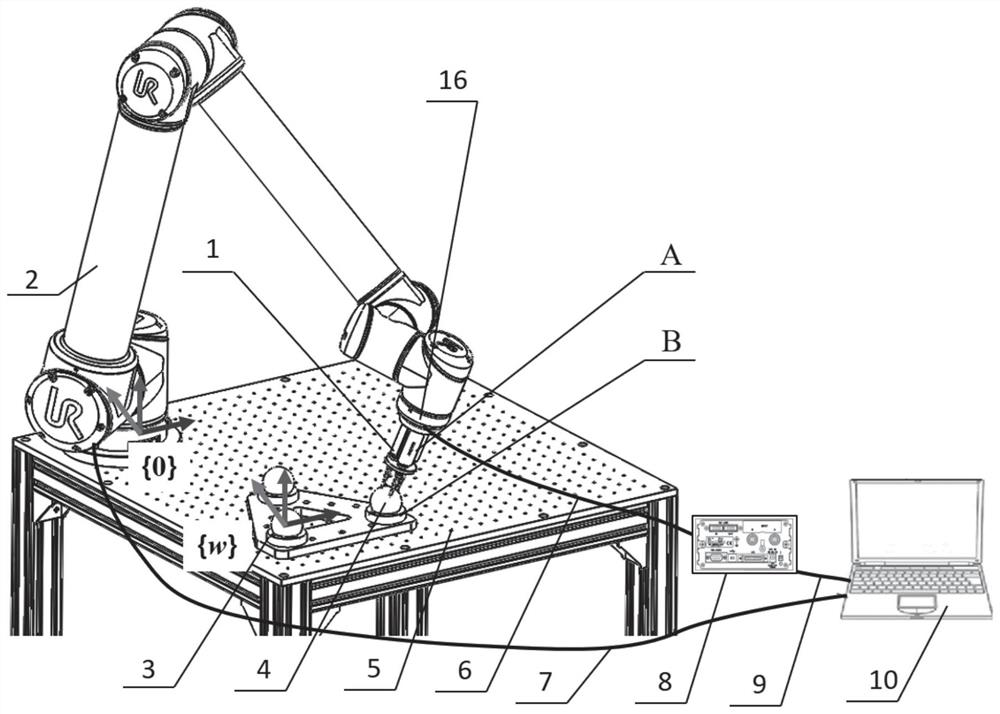

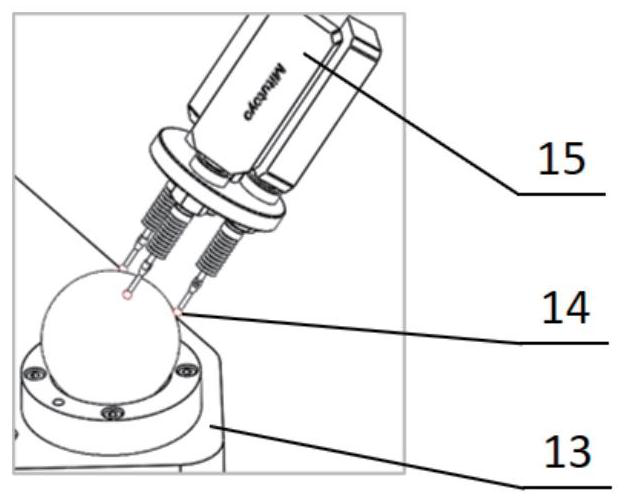

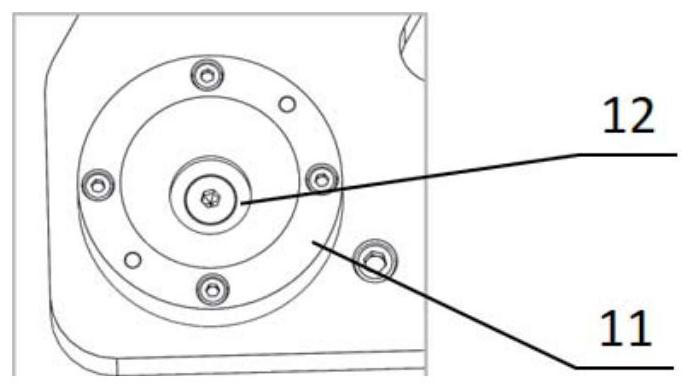

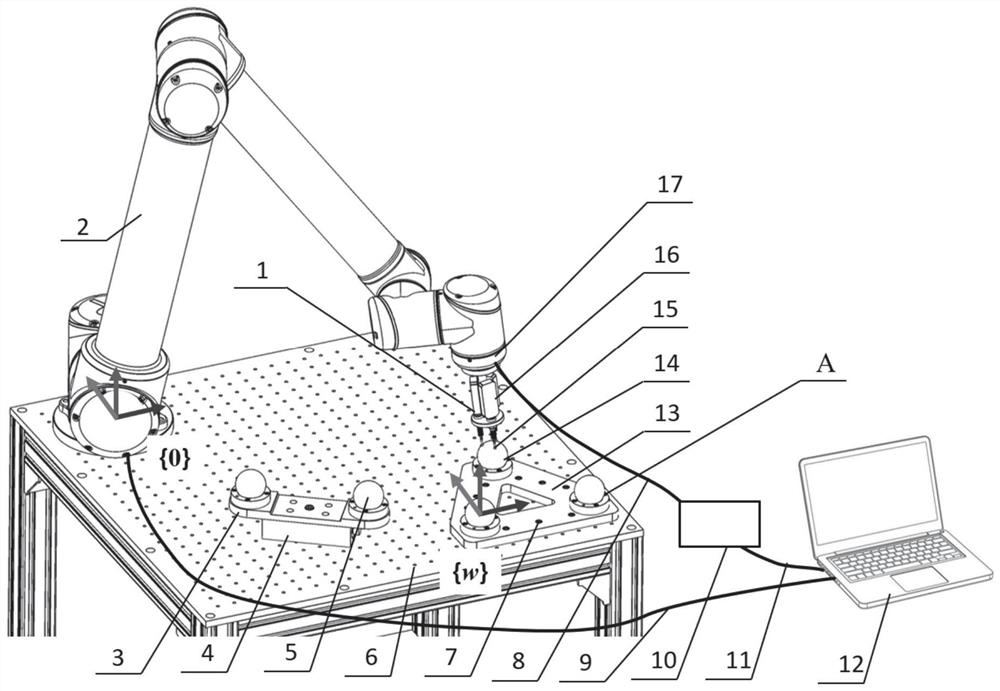

Industrial robot absolute precision calibration system and calibration method

The invention discloses an industrial robot absolute precision calibration system and calibration method. The calibration system comprises a three-ball base device, an end measuring device, a robot, acommunication cable, a computer and the like, and the calibration method comprises the steps that the fixed three-ball base device is used for building a world coordinate system used for describing arobot base coordinate system; the end measuring device mounted on a robot flange is used for measuring robot end position error information; the computer is used for reading position error data and robot joint angle data; and finally, all measured data are substituted into an absolute accuracy calibration algorithm of the computer to carry out iterative computation, and an exact kinematic model describing the world coordinate system is obtained. The calibration system and the calibration method are used, the posture of the robot base coordinate system and robot kinematics parameters can be accurately calibrated, and the robot absolute positioning precision can be improved.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

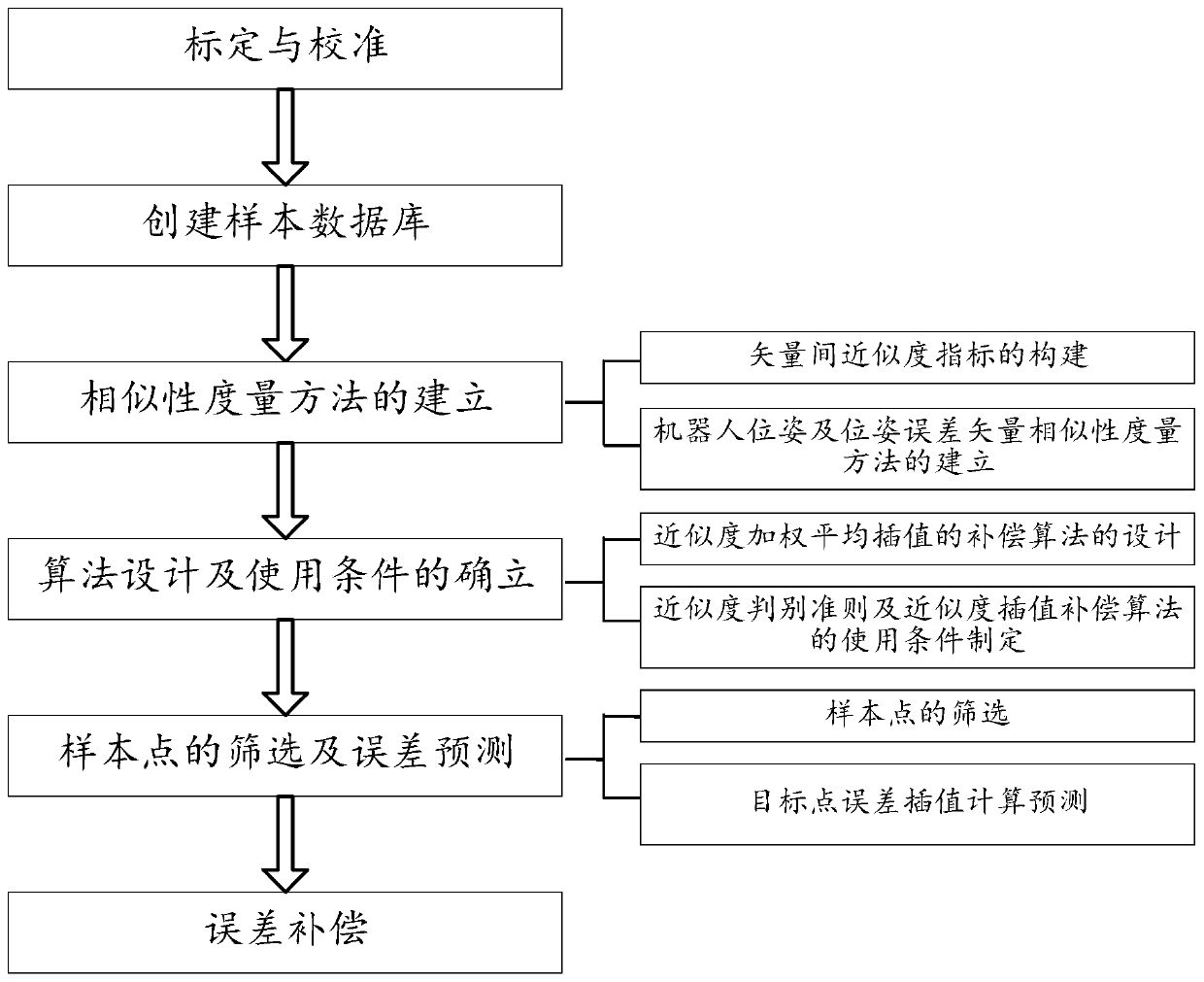

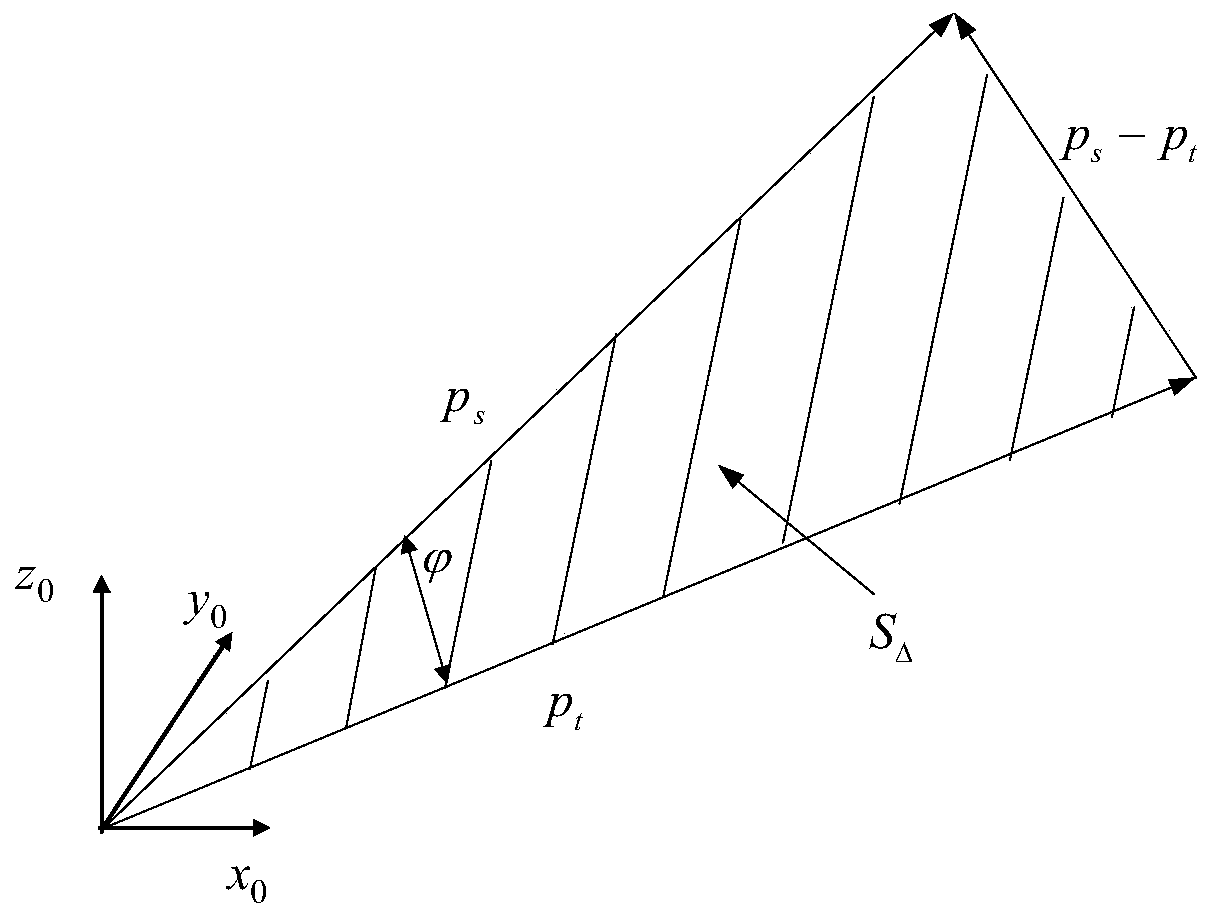

Robot precision compensation method based on approximate degree weighted average interpolation algorithm

ActiveCN110421566AAchieve precise compensationRealize precision compensationProgramme-controlled manipulatorGeometric errorPattern recognition

The invention discloses a robot precision compensation method based on approximate degree weighted average interpolation algorithm. The method comprises the following steps of, aiming at any target point, selecting sample points within the neighborhood of the target point in a sample database, and carrying out further selection on the basis of a judgment rule of similarity as well as using conditions of similar and close vector interpolation algorithm; and then determining influence weighted value of all the sample points on the target point according to a similarity index between the vectorswhen it is judged that the pose vector of the target point and pose vectors of a plurality of sample points within the neighborhood of the target point share sufficient similarity on the basis of thejudgment rule of similarity as well as the using conditions of similar and close vector interpolation algorithm; and adopting approximate degree weighted average interpolation algorithm for carrying out interpolation prediction on pose errors of the target point. According to the robot precision compensation method based on approximate degree weighted average interpolation algorithm, absolute positioning precision of a robot can be significantly improved, and the defect that high precision compensation of same effects in a whole working space cannot be realized through a traditional calibration method is effectively overcome, and therefore the robot precision compensation method is applicable to non-geometric error compensation of the robot, and can be effectively applied to the field where high precision is required for the robot.

Owner:EAST CHINA JIAOTONG UNIVERSITY

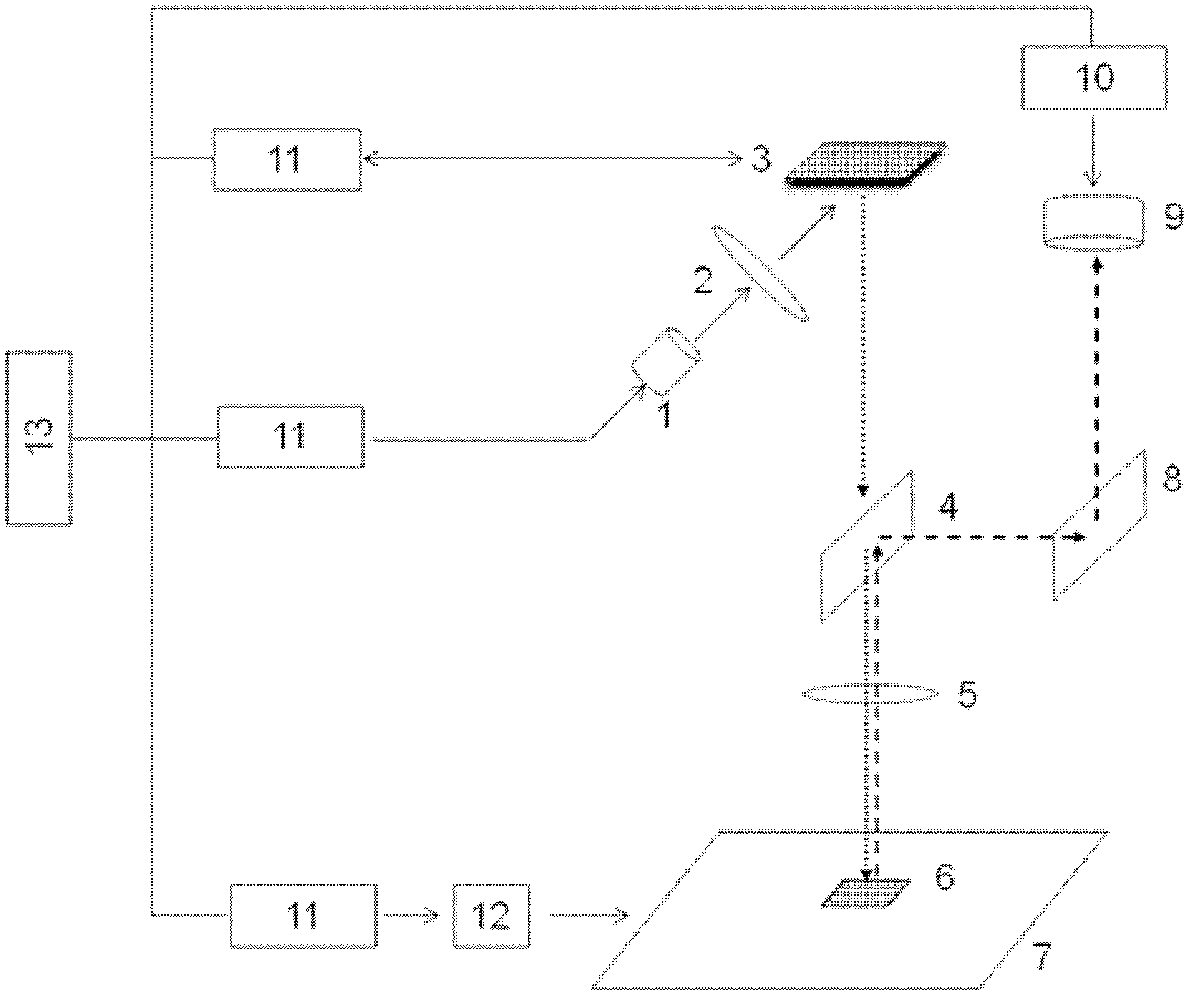

Method for measuring time delay by synchronous signal trigger sweep

ActiveCN102681359AImprove absolute positioning accuracyPhotomechanical exposure apparatusMicrolithography exposure apparatusSpatial light modulatorDelay Duration

The invention discloses a method for measuring time delay by synchronous signal time sweep. Pulse signals are equidistantly triggered at different speeds along a positive direction of a precise mobile platform to a spatial light modulator which exposes two frames different in sizes at the same center position to imaging on a substrate surface, the time delay from the outputting of synchronous signals to the image displaying of the spatial light modulator is calculated by measuring a positional deviation of the exposed frames, then the exposure can be compensated according to the time delay. The method for measuring time delay by synchronous signal time sweep can accurately expose the image to a designated position, absolute positioning accuracy of the exposed image is improved, and absolute positioning accuracy error of the exposed image caused by different exposure speeds is avoided simultaneously.

Owner:中夏芯基(上海)科技有限公司

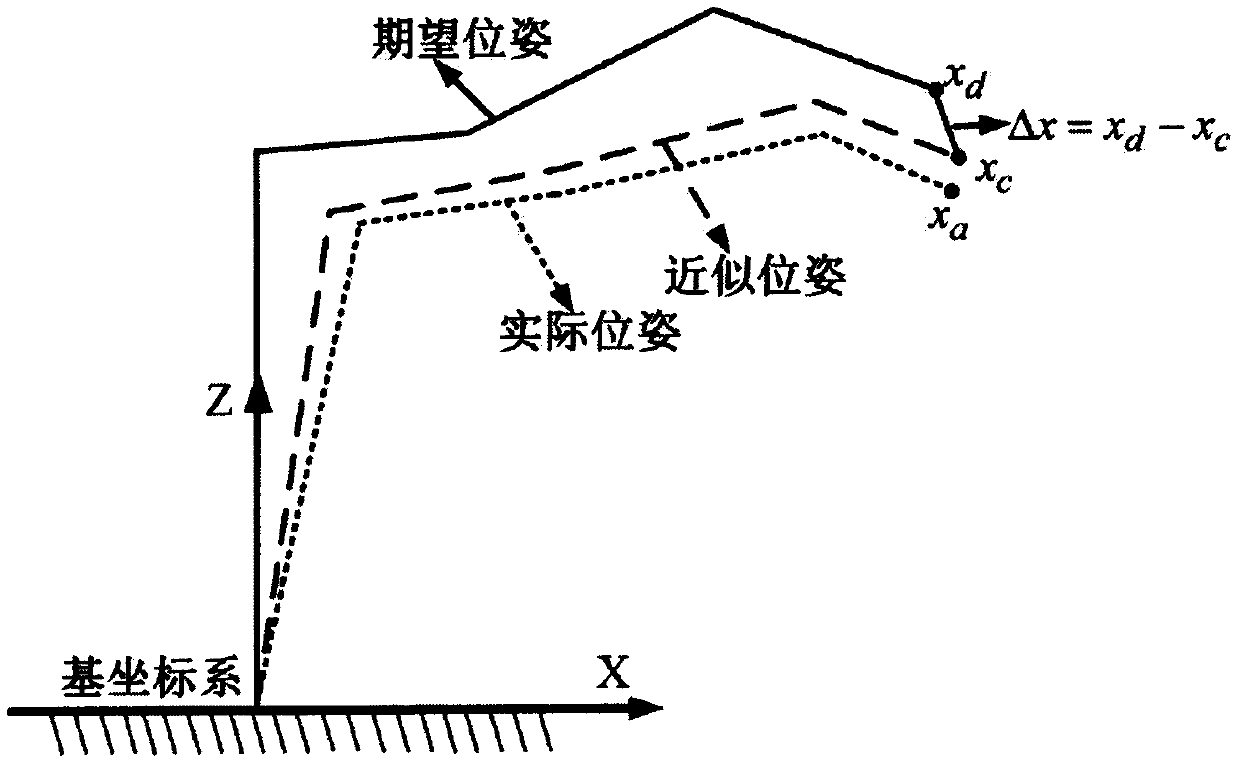

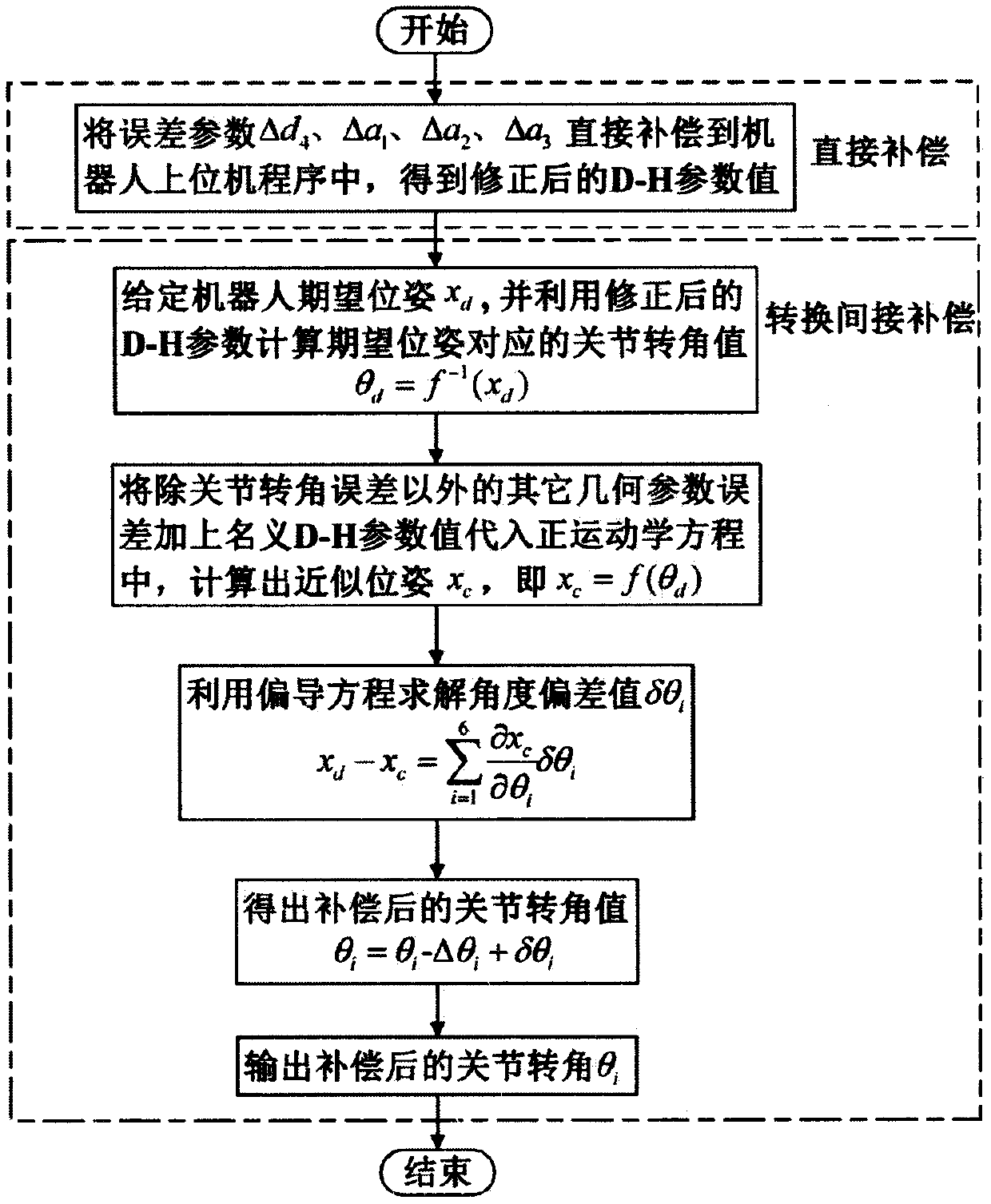

Two-step error compensation method for robot

ActiveCN111055273AReduce end position errorImprove absolute positioning accuracyProgramme-controlled manipulatorLeast squaresDifferential kinematics

The invention discloses a two-step error compensation method for a robot. The method comprises the steps of: (1) establishing a robot positioning error model based on a corrected D-H method and differential kinematics; (2) solving all geometric parameter errors by utilizing a least squares iteration estimation, and directly compensating the directly compensatable geometric parameter errors into D-H configuration parameters of the robot; and (3) converting the non-directly compensatable geometric parameter errors into a joint rotation angle compensation value, and correcting the rotation anglevalue of each joint of the robot to realize indirect compensation. According to the method, robot error compensation is divided into two steps, direct compensation of geometric parameter errors solvedby a robot inverse kinematics algorithm cannot be affected, and residual geometric parameter errors are indirectly compensated to robot joint rotation angles. According to the method, existing robotinverse kinematics algorithm does not need to be modified, robot tail end position errors can be effectively reduced, robot tail end absolute positioning precision is improved, and the method can be widely applied to the technical field of robot error compensation.

Owner:GUANGXI UNIV

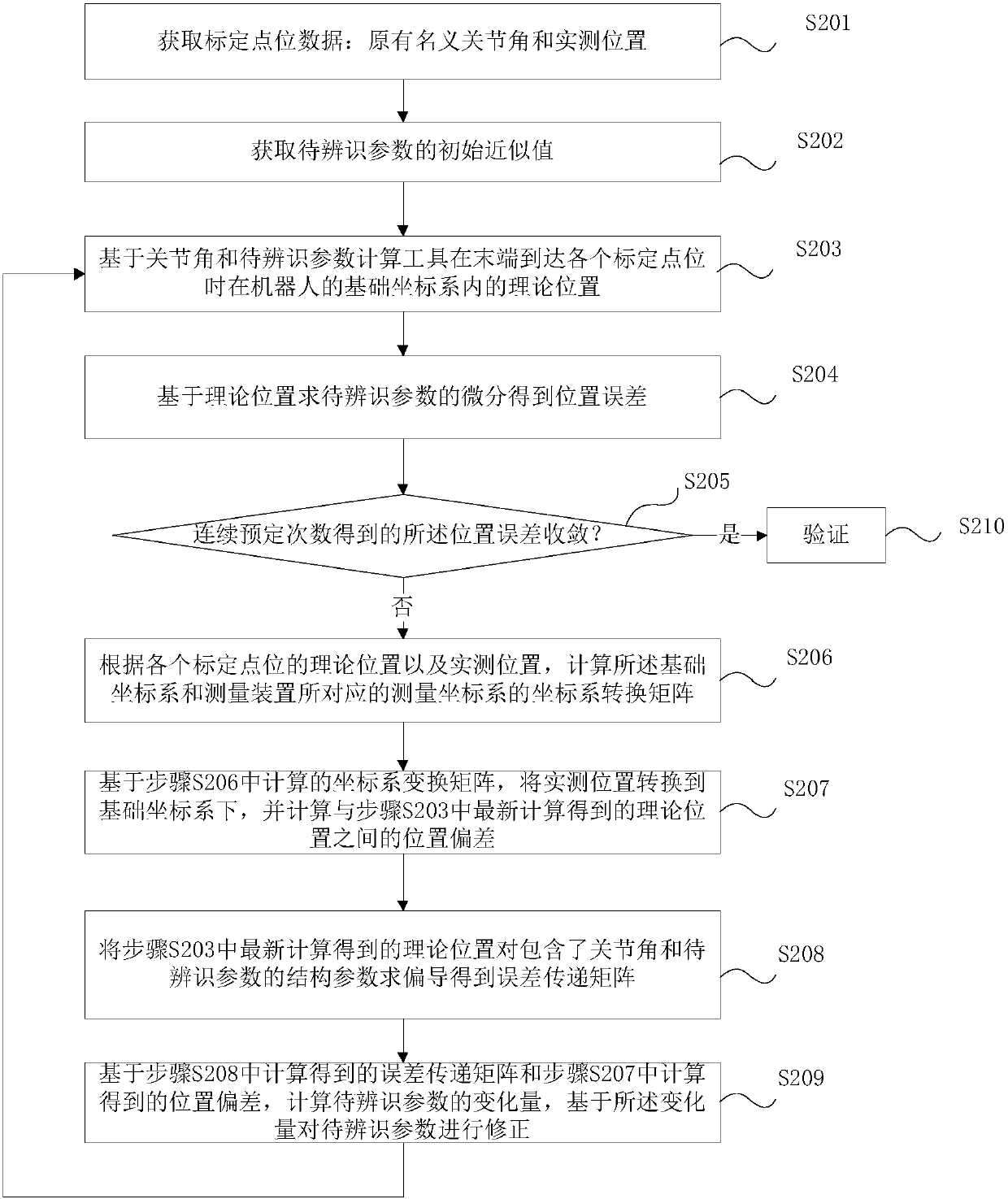

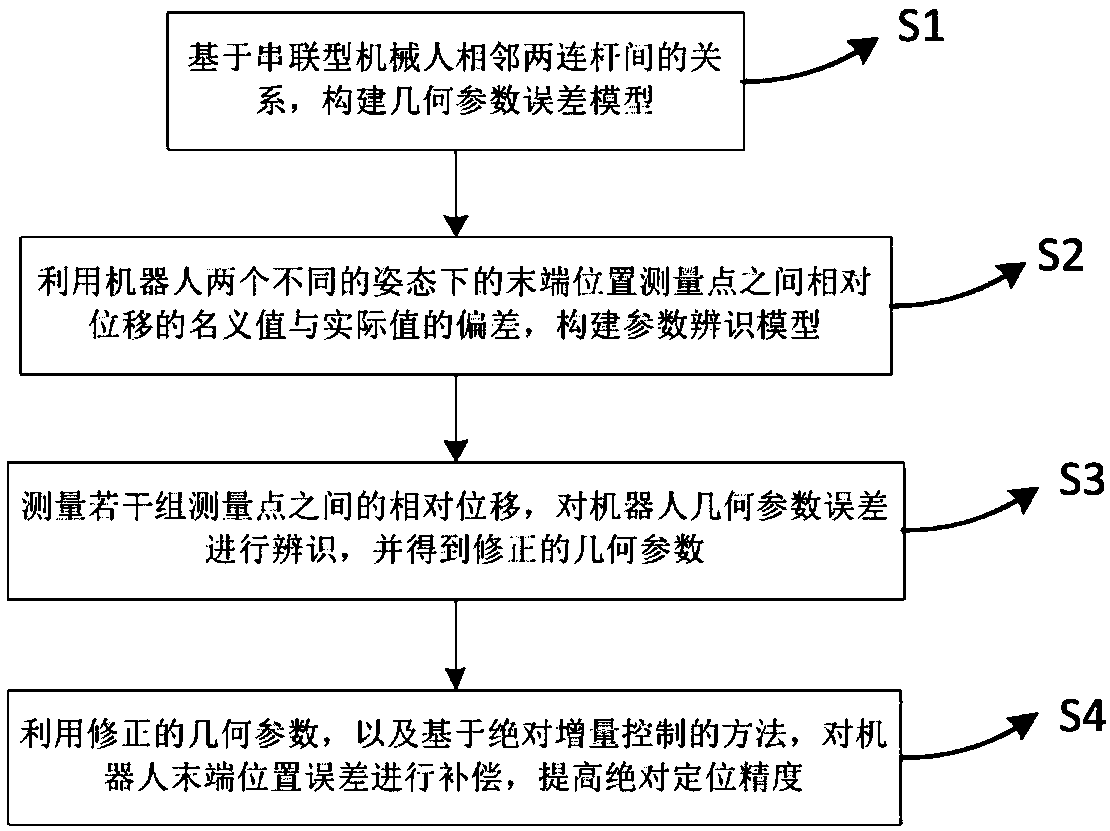

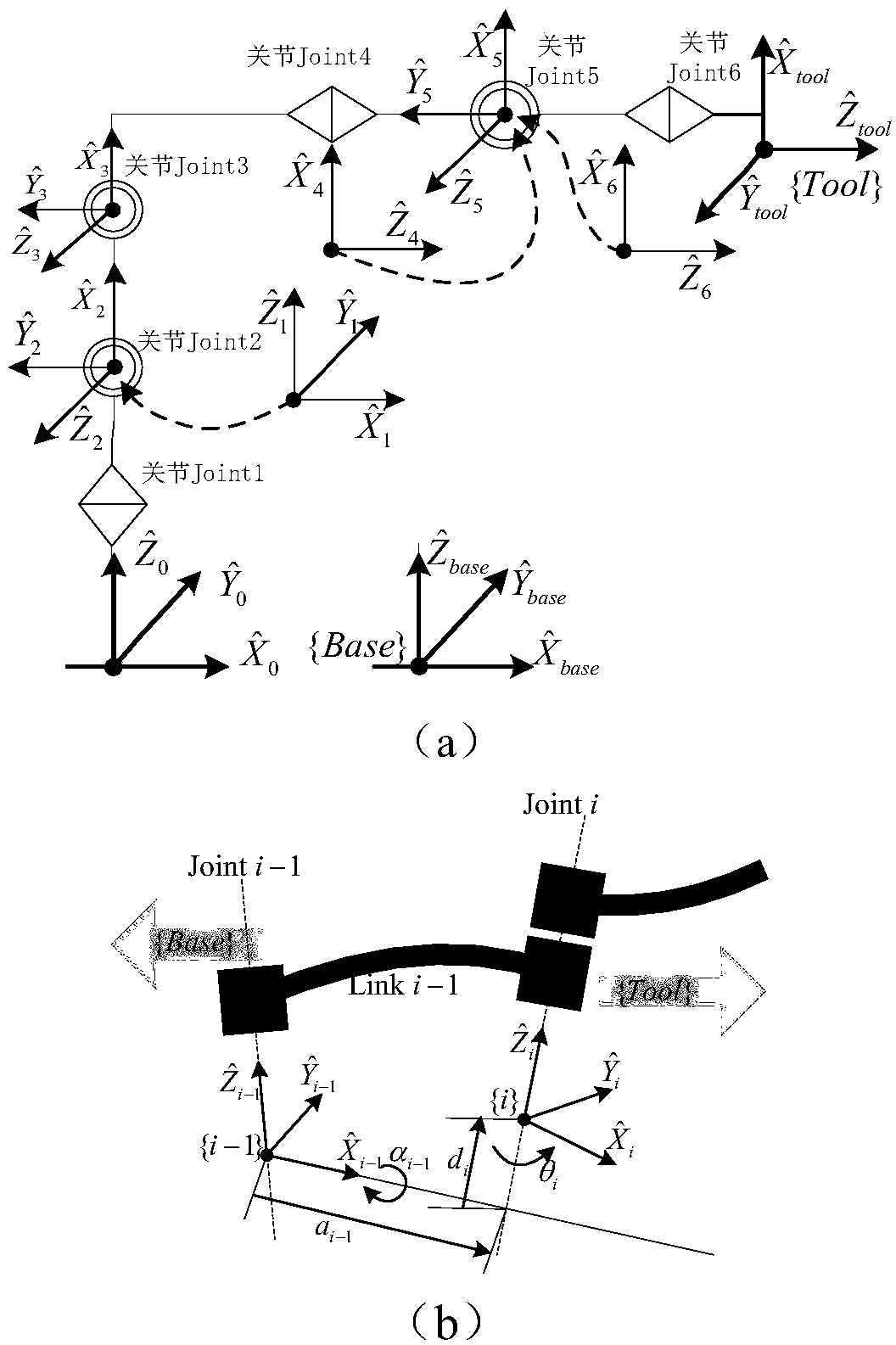

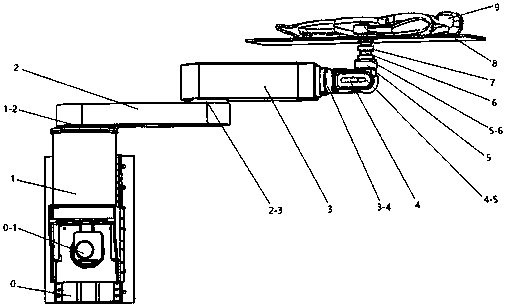

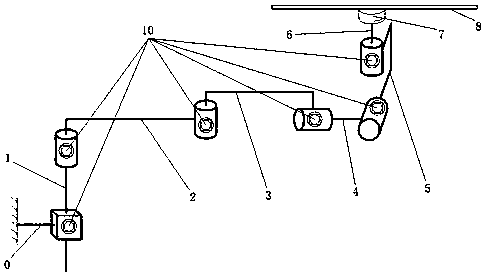

Serial robot kinematic calibration method and system

InactiveCN109176531AImprove absolute positioning accuracyReduce calibration timeProgramme-controlled manipulatorRelative displacementPosition error

The embodiment of the invention provides a serial robot kinematic calibration method and system. The method comprises the steps of S1, establishing a geometrical parameter error model based on the relationship of two adjacent connecting rods of a serial robot; S2, establishing a parameter identification model according to the difference of the nominal value and the actual value of relative displacement between measuring points of tail end positions of the robot under two different postures; S3, measuring relative displacement between a plurality of sets of measuring points and conducting identification on the geometrical parameter error of the robot to obtain a corrected geometrical parameter; and S4, compensating for the errors of the tail end positions of the robot according to the corrected geometrical parameter and on the basis of an absolute increment control method to improve the absolute positioning accuracy. Through the technical scheme, the calibration time can be saved, and the calibration process is more flexible. The kinematic parameters are accurately identified by establishing the parameter identification model, and through cooperation with the error compensation algorithm, the trajectory planning accuracy is improved.

Owner:BEIJING INST OF RADIO MEASUREMENT

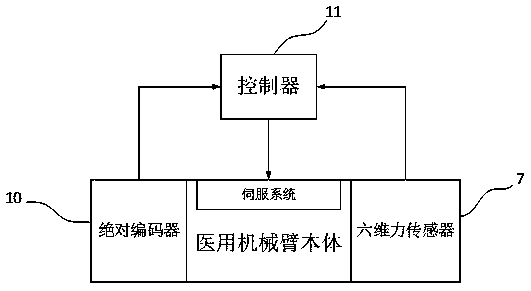

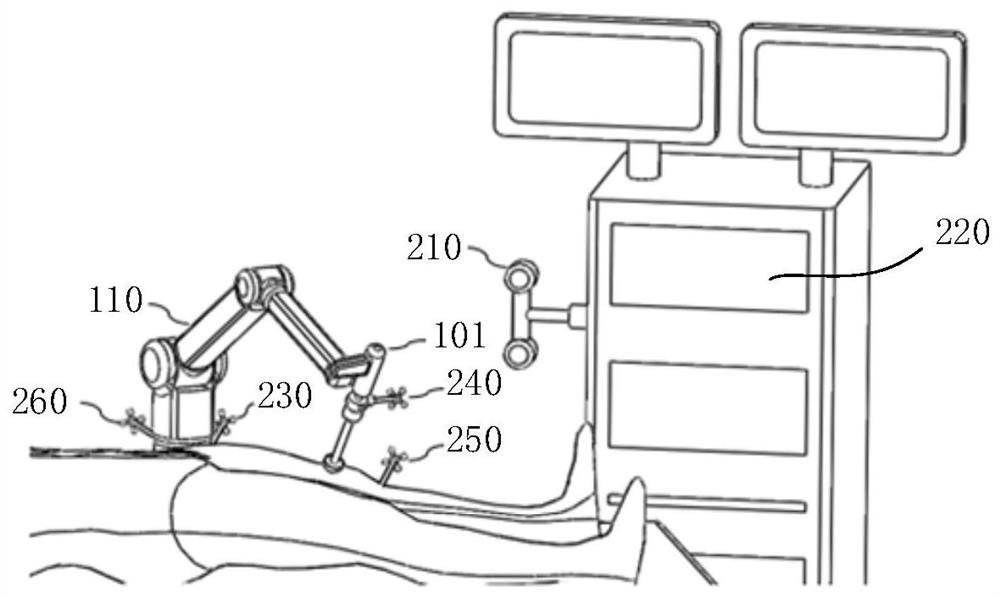

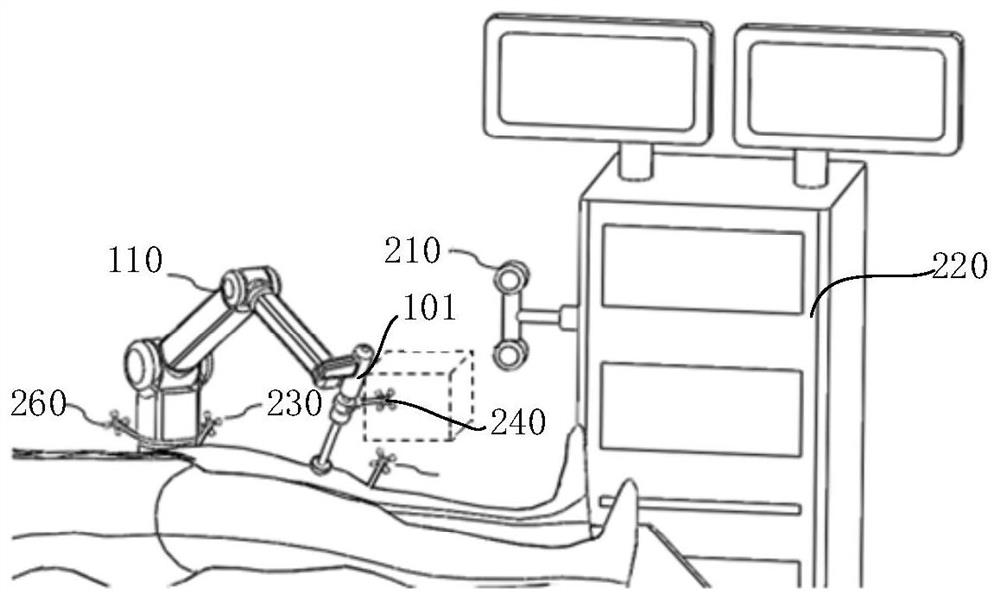

Patient-carrying medical mechanical arm error compensation system and method

InactiveCN110152211AImprove absolute positioning accuracyReal-time updateProgramme-controlled manipulatorX-ray/gamma-ray/particle-irradiation therapyGravity centerControl theory

The invention discloses a patient-carrying medical mechanical arm error compensation system and method. The compensation system comprises a medical mechanical arm body, an absolute encoder, a six dimensional force sensor and a controller; by using the six dimensional force sensor for detecting the gravity size and centre-of-gravity position of a patient, the terminal pose error of the medical mechanical arm is worked out through a flexibility error model, the method is rapid and efficient, and automatic error compensation is easy to achieve; in the flexibility error model calculation in the error compensation method, average flexural rigidity and average torsional rigidity are introduced, the influence of a variable cross section bar structure on the flexibility error of the medical mechanical arm is considered, and the mechanical arm pose error calculation precision can be further improved.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

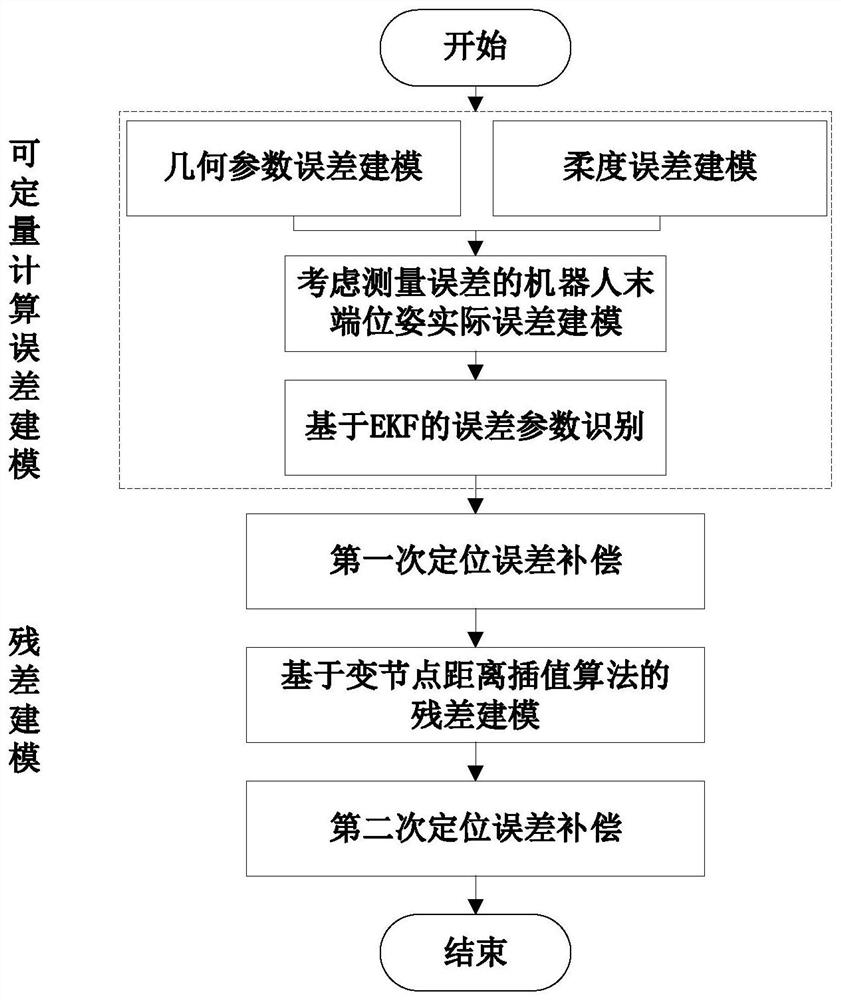

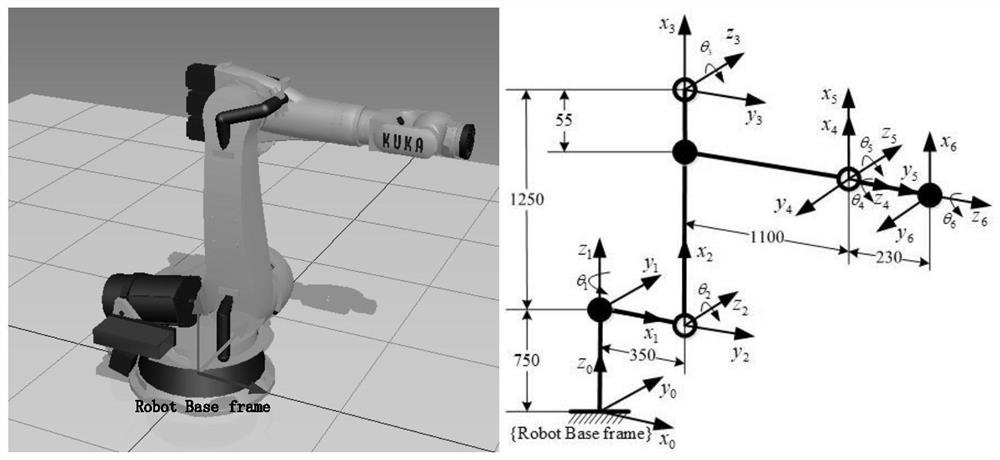

Robot absolute positioning precision calibration method based on kinematics and spatial interpolation

ActiveCN112873199AImprove absolute positioning accuracyImprove recognition accuracyProgramme-controlled manipulatorRobot positionComputer vision

The invention discloses a robot absolute positioning precision calibration method based on kinematics and spatial interpolation, and belongs to the field of robot control methods. The method comprises the following steps: firstly, respectively establishing a robot geometric parameter error model and a flexibility error model to obtain a quantitative calculation error delta V; then, measuring an actual tail end pose of the robot to obtain identification experiment data, adopting an EKF algorithm for robot quantitative calculation error delta V parameter identification, correcting robot nominal geometric parameters through robot error parameters obtained through identification, thereby accomplishing first-time positioning error compensation of the robot and remaining robot positioning residual errors; constructing a robot positioning residual error model; carrying out secondary positioning error compensation on the robot; and finally obtaining an expected position of the robot. A variable-node distance interpolation algorithm considering joint influence degree is established, so that absolute positioning precision of the robot can be effectively improved, and defects of an existing method and technology in precision are overcome.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Industrial robot step-by-step calibration system and method

PendingCN112847341ALow costLarge measuring rangeProgramme-controlled manipulatorTotal factory controlSimulationKinematic calibration

The invention discloses an industrial robot step-by-step calibration system and method. The calibration system comprises a tail end measuring device arranged on a robot flange, as well as a movable double-ball device, a fixed three-ball-seat device, a counter, a computer and the like which are matched with a robot. The calibration method comprises first-step calibration: calibrating kinematics parameters of the robot by using a wide-area distance error; and second-step calibration: based on the result of the first-step calibration, calibrating the pose of a robot-based coordinate system by using a position error. Furthermore, the calibration method can also comprise the following steps: firstly, calibrating the measurement error of the tail end measurement device; and then carrying out the first-step calibration and the second-step calibration. The calibration system has the advantages of being portable, low in cost and the like; meanwhile, the calibration method improves the precision and reliability of kinematics calibration, calibration of the robot-based coordinate system is achieved, then the absolute positioning precision of the robot is improved, and the application range of the robot in precision manufacturing is widened.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

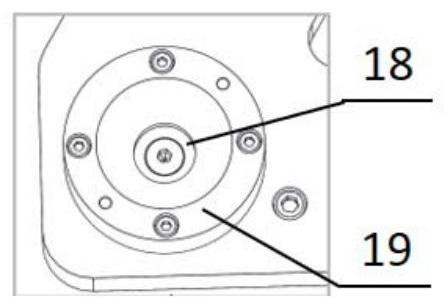

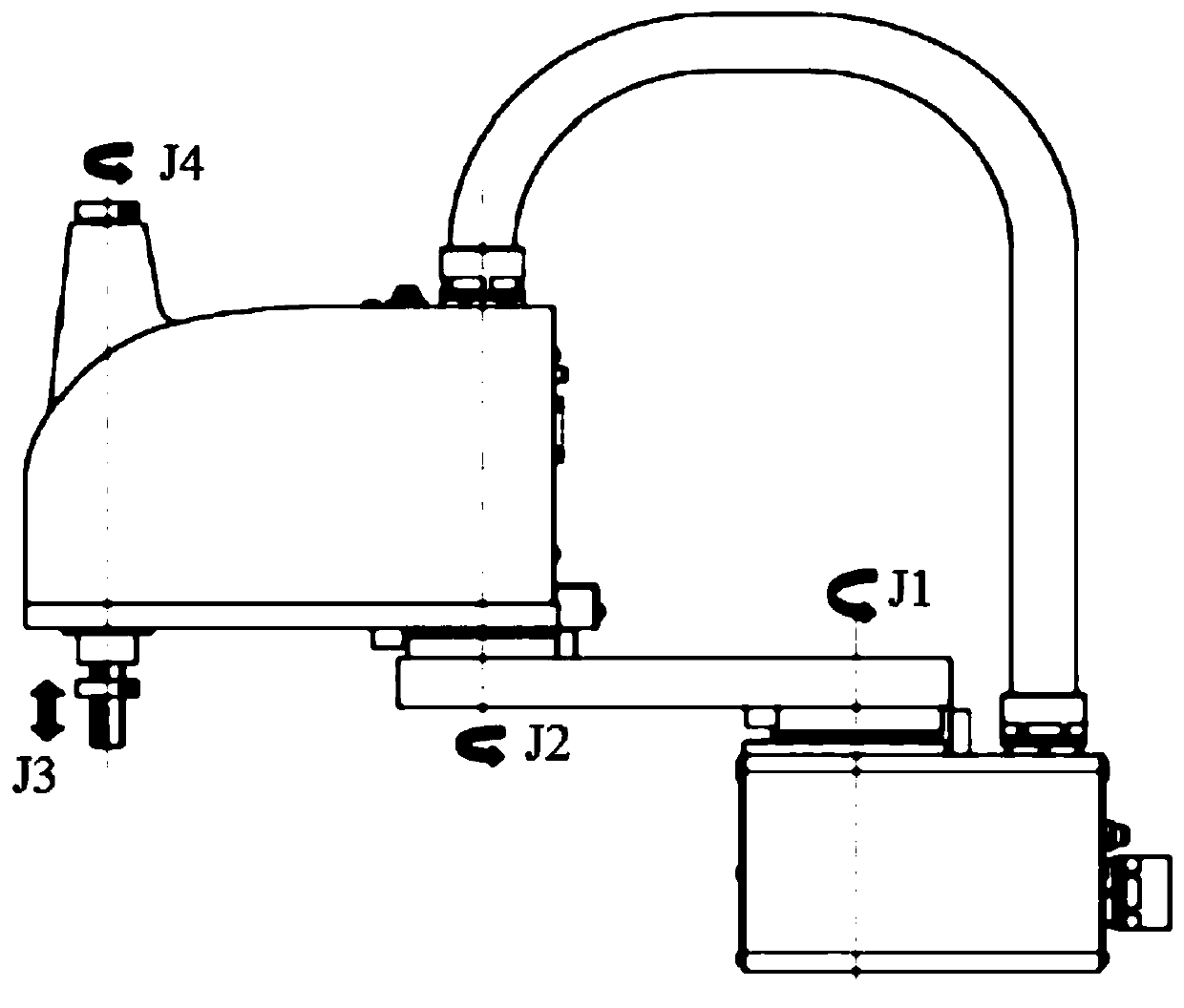

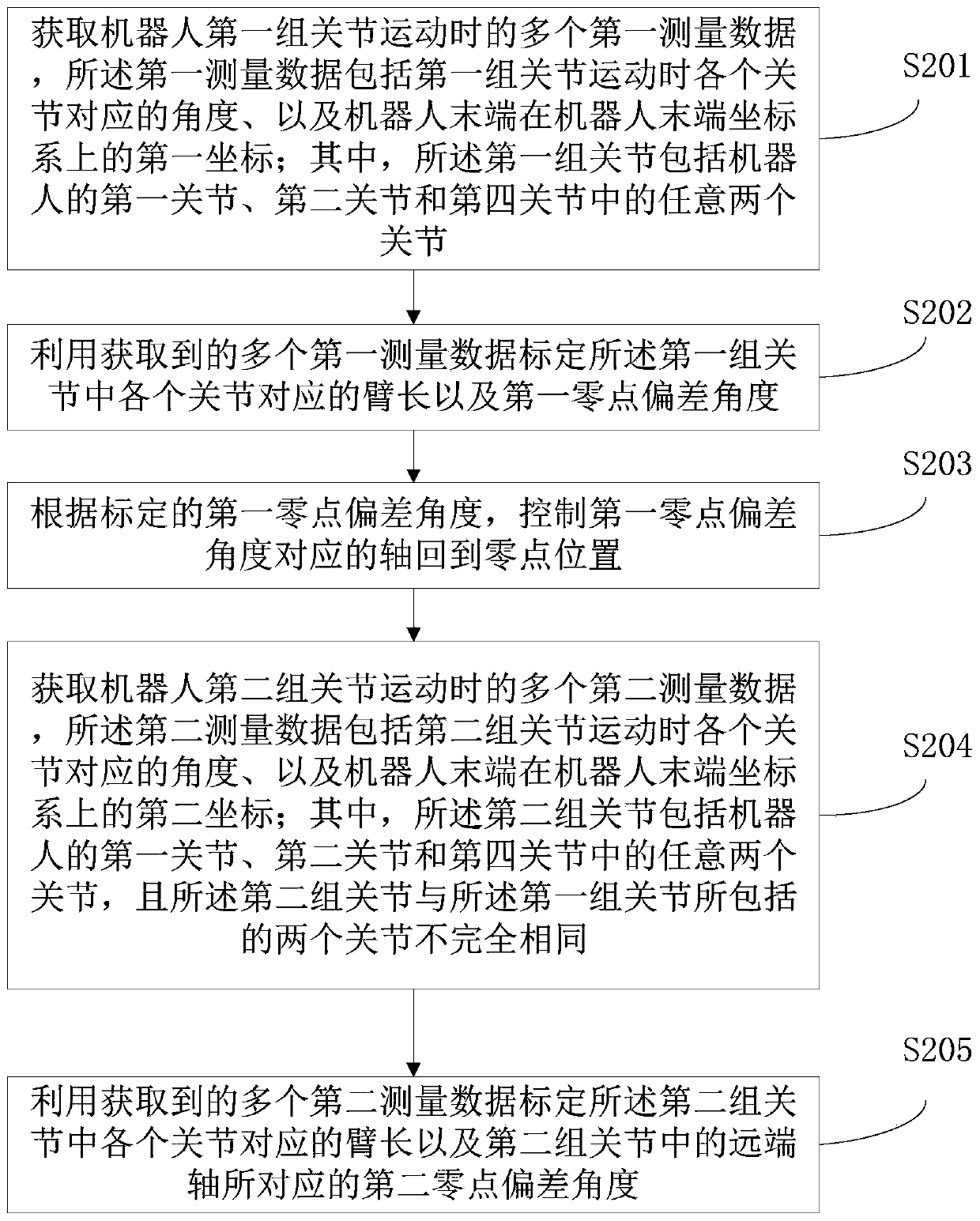

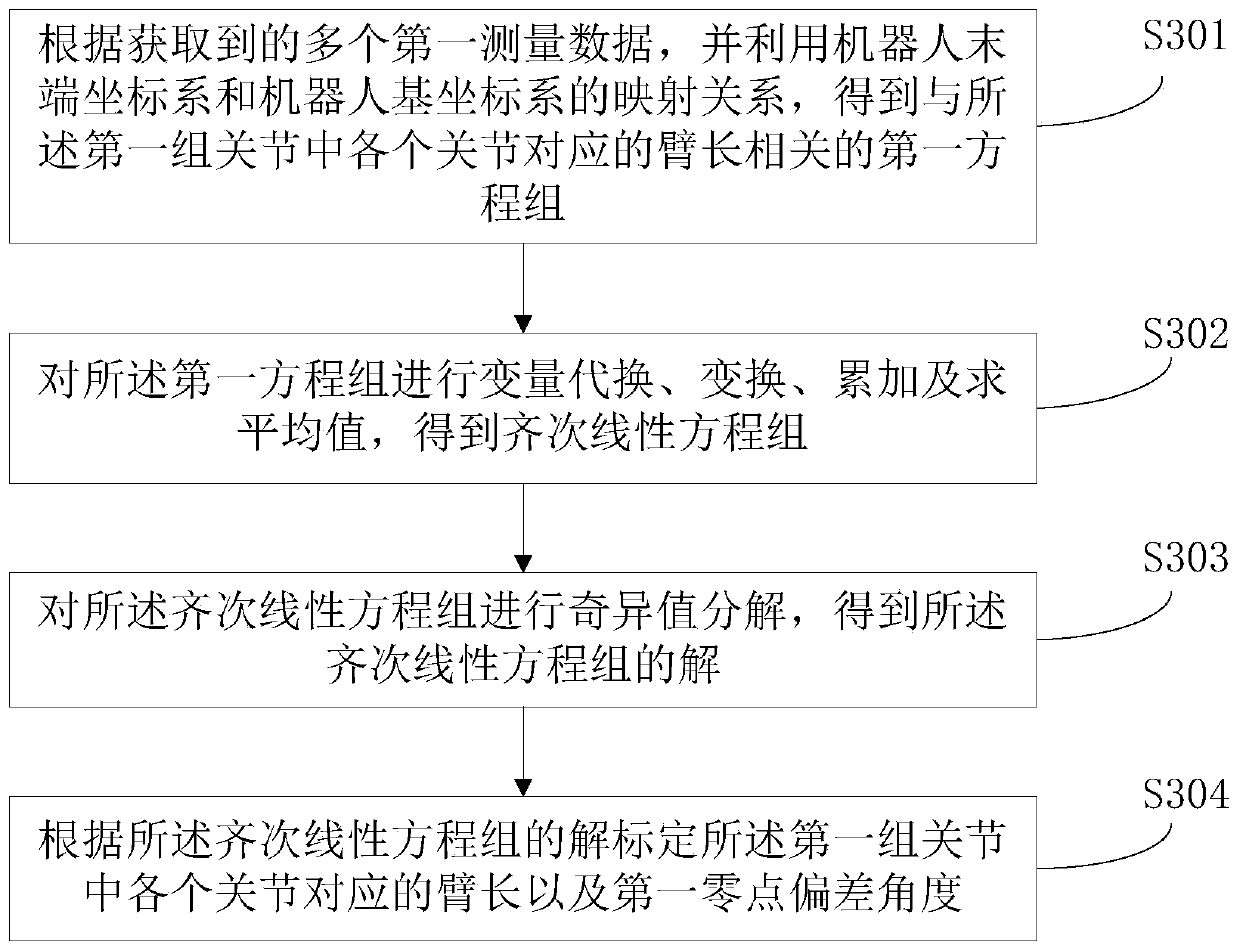

Method and device for calibrating mechanical parameters of SCARA robot and SCARA robot

ActiveCN111113419AImprove absolute positioning accuracyAvoid affecting calibration accuracyProgramme-controlled manipulatorSimulationClassical mechanics

The invention is suitable for the technical field of robots, and provides a method and device for calibrating mechanical parameters of an SCARA robot and the SCARA robot. By acquiring a plurality of first measurement data and second measurement data, the angle corresponding to each joint when a first group of joints and a second group of joints move, a first zero point deviation angle and a secondzero point are respectively calculated by adopting a multi-point method, so that the calibration precision of the arm length and the zero point is improved, and the calibration precision of the arm length and the zero point affects the absolute positioning precision of the SCARA robot, so that the absolute positioning precision of the SCARA robot is also improved.

Owner:SHENZHEN YUEJIANG TECH CO LTD

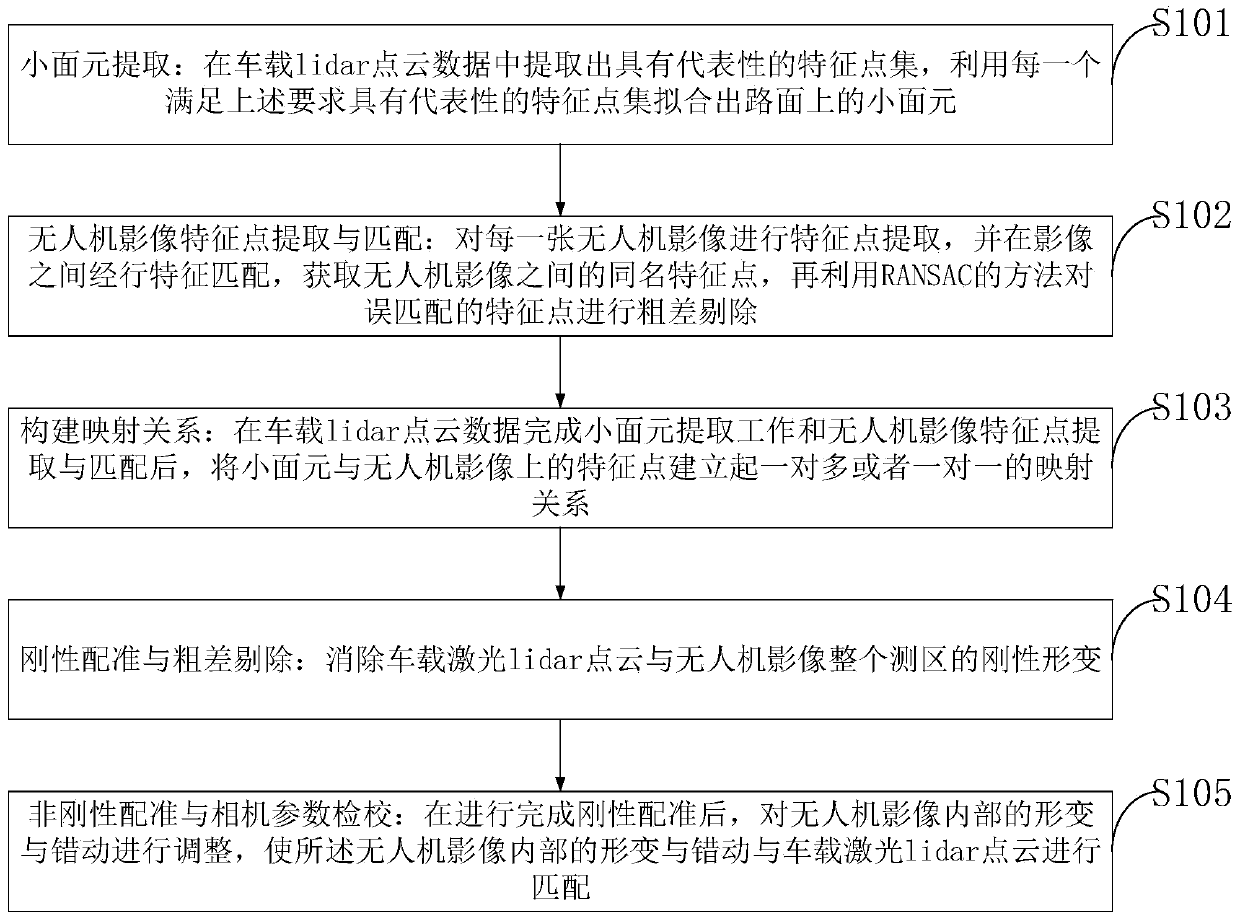

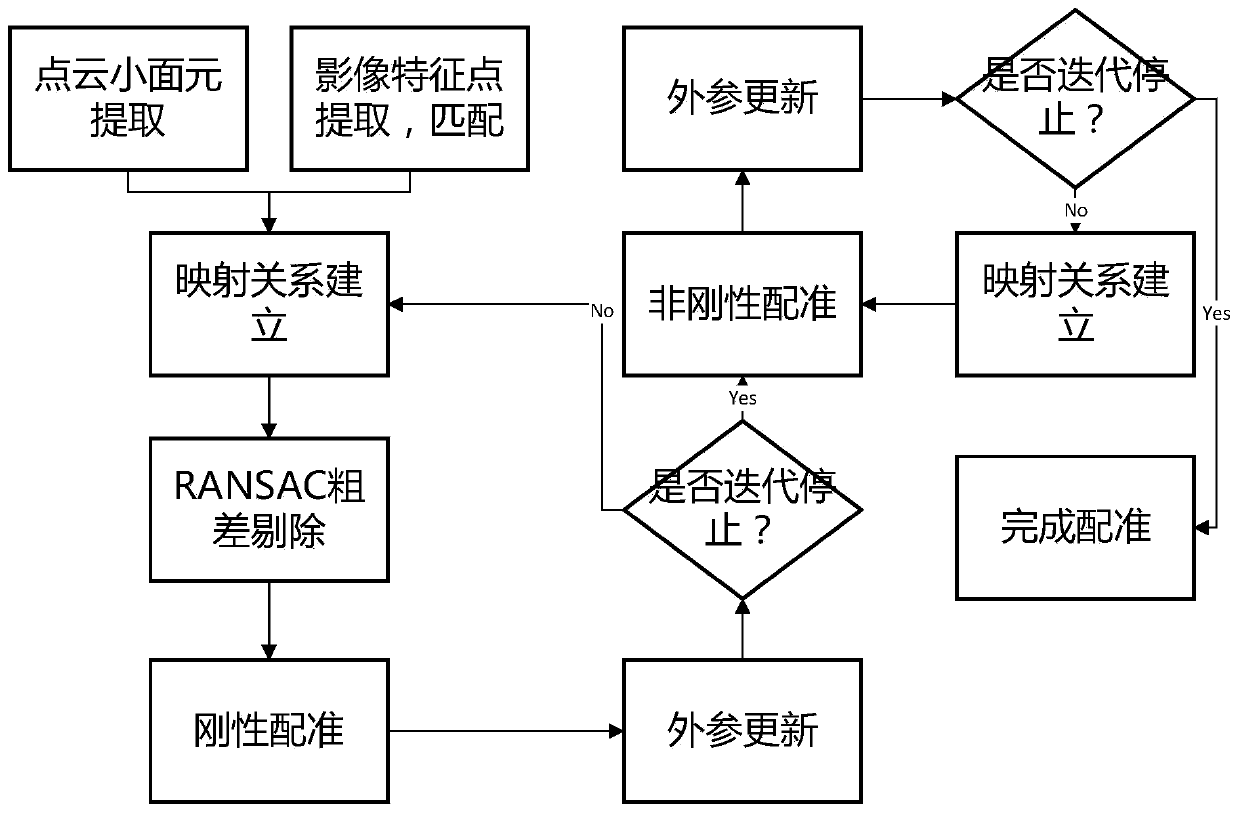

High-precision mapping and positioning method utilizing combination of vehicle-mounted Lidar and unmanned aerial vehicle

ActiveCN111457930AReduce rigid deformationHigh precisionInstruments for road network navigationElectromagnetic wave reradiationIn vehicleUncrewed vehicle

The invention belongs to the technical field of spatial data processing and positioning and discloses a high-precision mapping and positioning method based on the combination of a vehicle-mounted Lidar and an unmanned aerial vehicle. The method comprises the following steps of: acquiring a control surface element, performing feature point extraction on unmanned aerial vehicle images subjected to initial orientation processing, performing feature matching between the images, acquiring homonymous feature points between the unmanned aerial vehicle images, and performing gross error elimination onmismatched points by utilizing a robust estimation method; establishing a one-to-many or one-to-one mapping relationship between feature surface elements and feature points on the unmanned aerial vehicle images; and performing refining calculation on the unmanned aerial vehicle images and camera external parameters through bundle adjustment iteration so as to obtain high-precision azimuth elements and parameters. The method is high in speed and high in precision; the absolute positioning precision of the method is improved to be within the plane of 5cm and the elevation of 10cm through outfield control point checking; and a low-cost technical solution is provided for obtaining a high-precision map through the combination of the unmanned aerial vehicle and the Lidar.

Owner:WUHAN ZHONGHAITING DATA TECH CO LTD +1

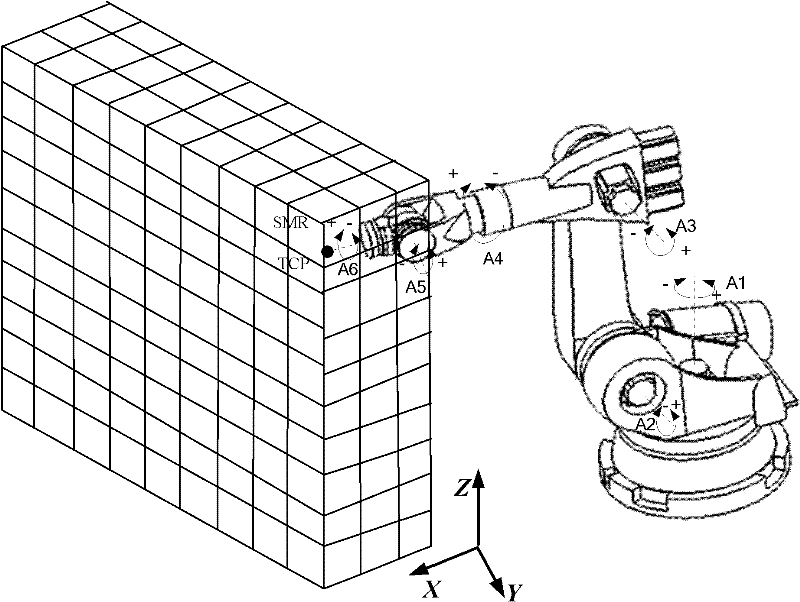

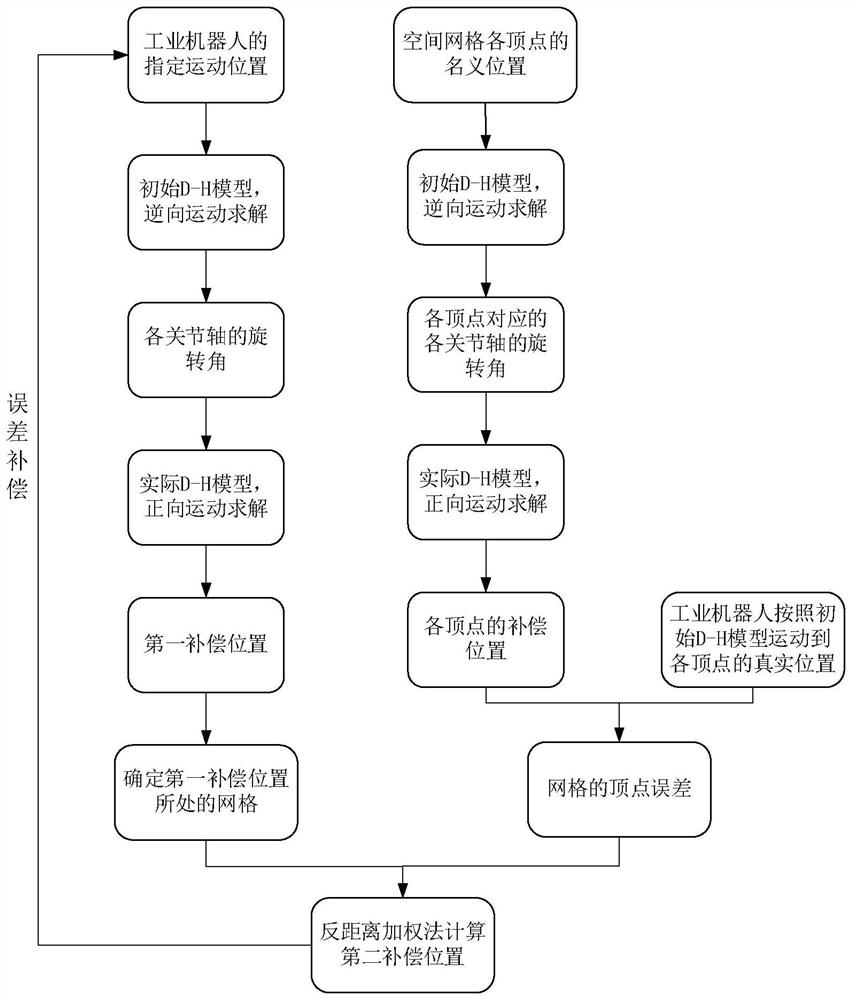

Error compensation method for industrial robot

PendingCN114161425AReduce mistakesImprove the level of flexibilityProgramme-controlled manipulatorRobot kinematicsIndustrial robotics

The invention relates to an error compensation method for an industrial robot, and belongs to the technical field of industrial robots. The error compensation method comprises the following steps: inputting a specified motion position into an initial robot kinematics model, and solving a rotation angle of each joint shaft by utilizing inverse motion; inputting the obtained rotation angle of each joint shaft into an actual robot kinematics model, and solving by utilizing forward motion to obtain a first compensation position corresponding to the specified motion position; the method comprises the following steps: carrying out grid division on a motion space of an industrial robot, determining a grid where a first compensation position is located, obtaining an error at the first compensation position in the grid by utilizing a spatial interpolation method according to each vertex error of the grid, and further obtaining a second compensation position by combining the first compensation position and the error of the point; and performing error compensation according to the second compensation position. The method combines an axis measurement method and a space grid method to carry out error compensation on the industrial robot, and the absolute positioning precision of the robot is effectively improved.

Owner:PLA STRATEGIC SUPPORT FORCE INFORMATION ENG UNIV PLA SSF IEU

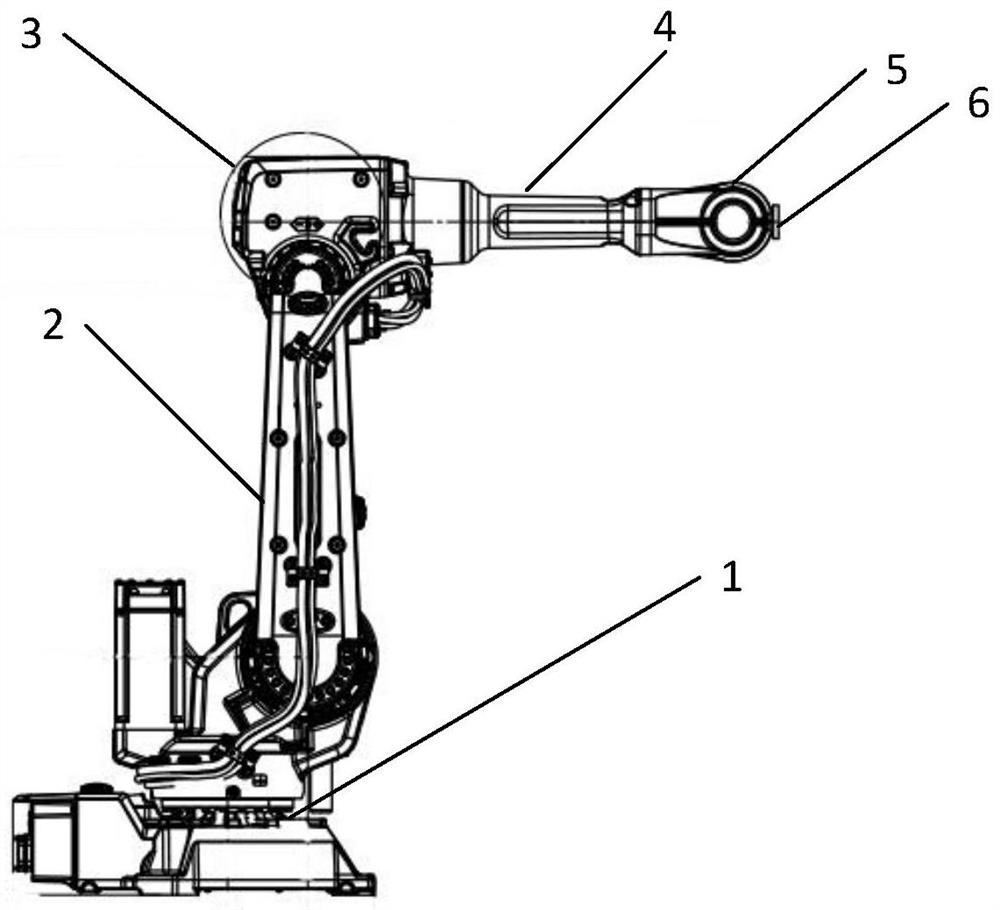

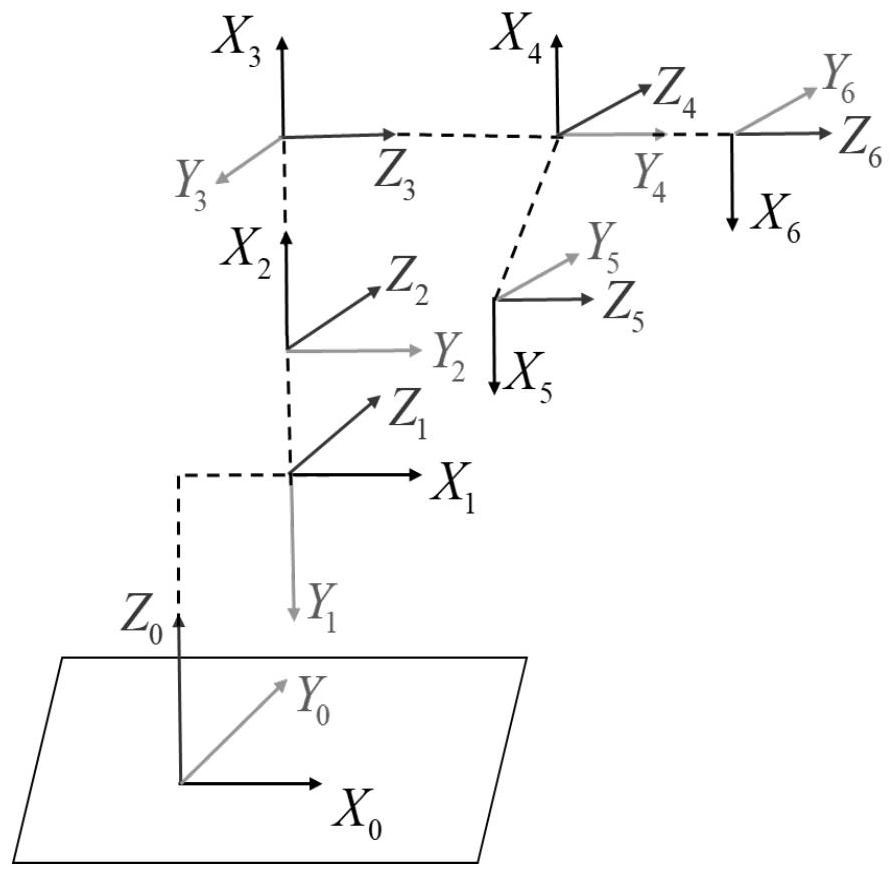

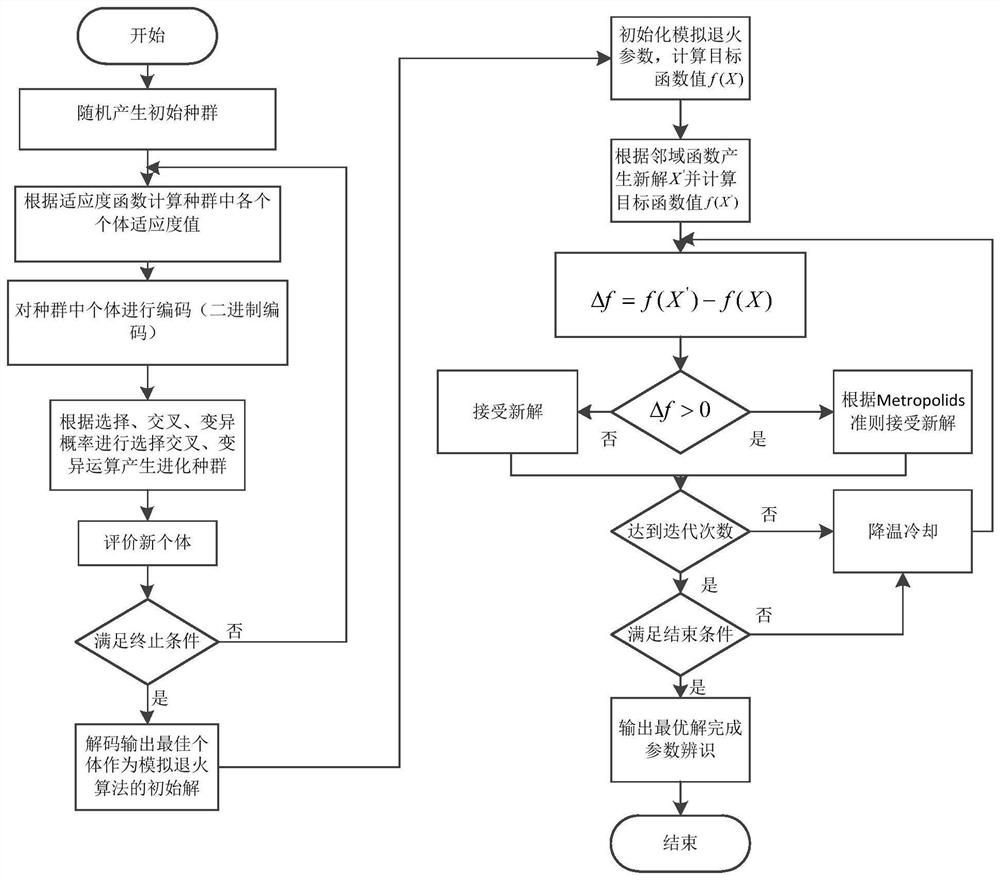

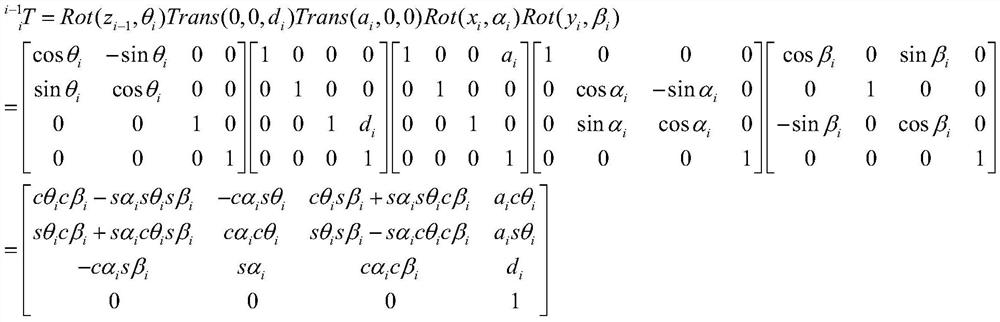

Robot kinematics parameter identification method based on hybrid genetic simulated annealing algorithm

InactiveCN112091950AAccurate identificationImprove absolute positioning accuracyProgramme-controlled manipulatorJointsPattern recognitionLocal search (optimization)

The invention discloses a robot kinematics parameter identification method based on a hybrid genetic simulated annealing algorithm. According to the method, a kinematics model of a robot and an errormodel of the robot are constructed, and performance advantages of a genetic algorithm and a simulated annealing algorithm are utilized and mixed together to be used; accurate identification of model errors is achieved through the global search capacity of the genetic algorithm and the local search capacity of the simulated annealing algorithm, and therefore various parameters of the robot models can be corrected, and the absolute positioning precision of the tail end of the robot is improved; and an optimal solution obtained by the genetic algorithm is directly input into the simulated annealing algorithm, and therefore the global optimization capacity is achieved, a local optimal solution can be omitted, and error model parameters are accurately identified.

Owner:SOUTH CHINA UNIV OF TECH

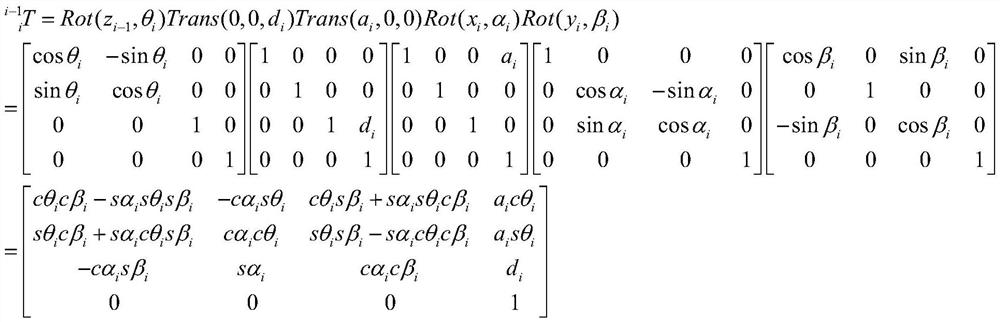

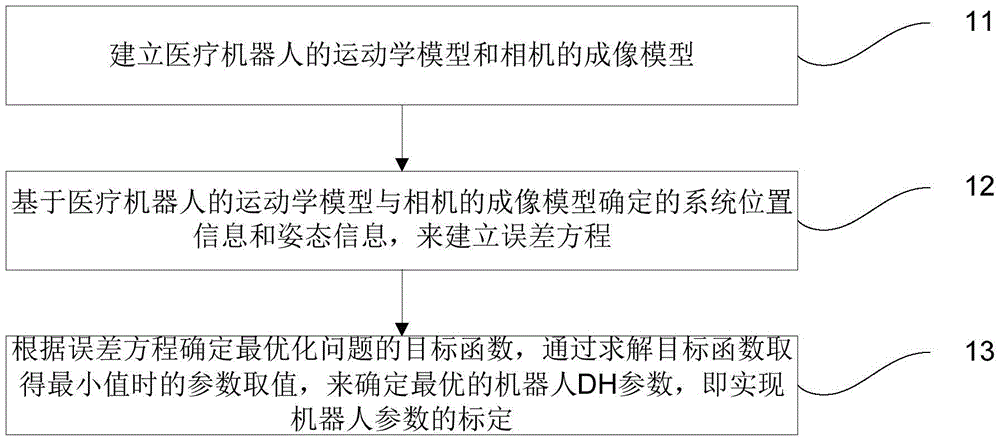

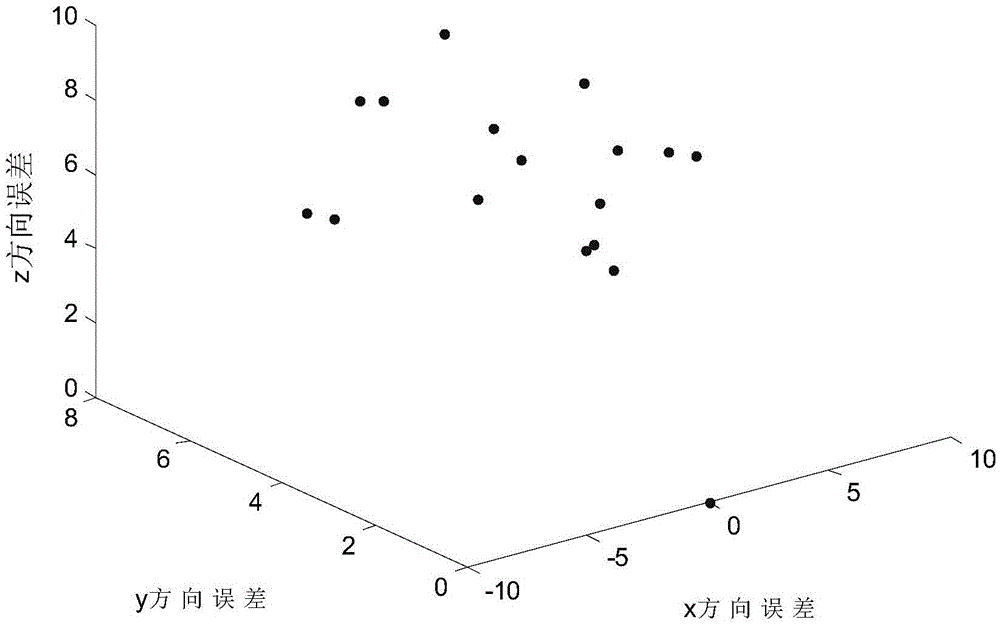

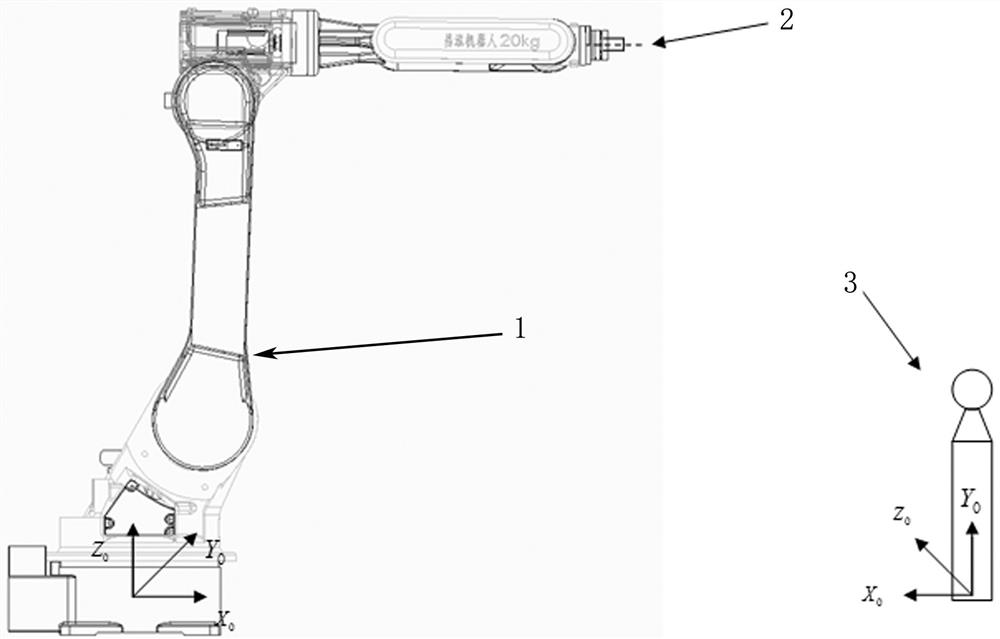

Medical robot DH parameter calibrating method

The invention discloses a medical robot DH parameter calibrating method, comprising: establishing the kinetic model of a medical robot and the imaging model of a camera; establishing an error equation according to the system position information and attitude information determined based on the kinetic model of a medical robot and the imaging model of a camera; and determining the objective function of an optimization problem according to the error equation, and solving the objective function to calibrate medical robot DH parameters. The method has the characteristics of simple operation and lower cost, and can effectively improve absolute positioning precision.

Owner:BEIJING BAIHUI WEIKANG SCI & TECH CO LTD

Method for improving absolute positioning precision based on six-degree-of-freedom series mechanical arm

ActiveCN113134837AAccurate calculationImprove absolute positioning accuracyProgramme-controlled manipulatorComputational physicsSix degrees of freedom

The invention relates to the field of self-adaptive control, in particular to a method for improving absolute positioning precision based on a six-degree-of-freedom series mechanical arm. The method comprises the following steps of, firstly, acquiring tail end target spot information through a laser tracker, and preprocessing to carry out coordinate conversion between the mechanical arm and the laser tracker; then, establishing an exponential product model of the mechanical arm by applying Lie Groups and Lie Algebras, fusing the exponential product model with a method for solving a global minimum value through a sequential quadratic programming algorithm, and compensating tail end geometric errors generated by joint parameter deviation of the mechanical arm; and finally, solving an inverse kinematics solution through an actual point location obtained by the laser tracker and the exponential product model, carrying out model training by using a Gaussian process regression algorithm, carrying out compensation prediction on a non-geometric motion error, and inputting a predicted compensated angle value into a demonstrator. According to the method, the actual kinematics model parameters of the mechanical arm can be calculated more accurately, and the tail end point position error is reduced so as to improve the absolute positioning precision of the mechanical arm.

Owner:ZHEJIANG UNIV

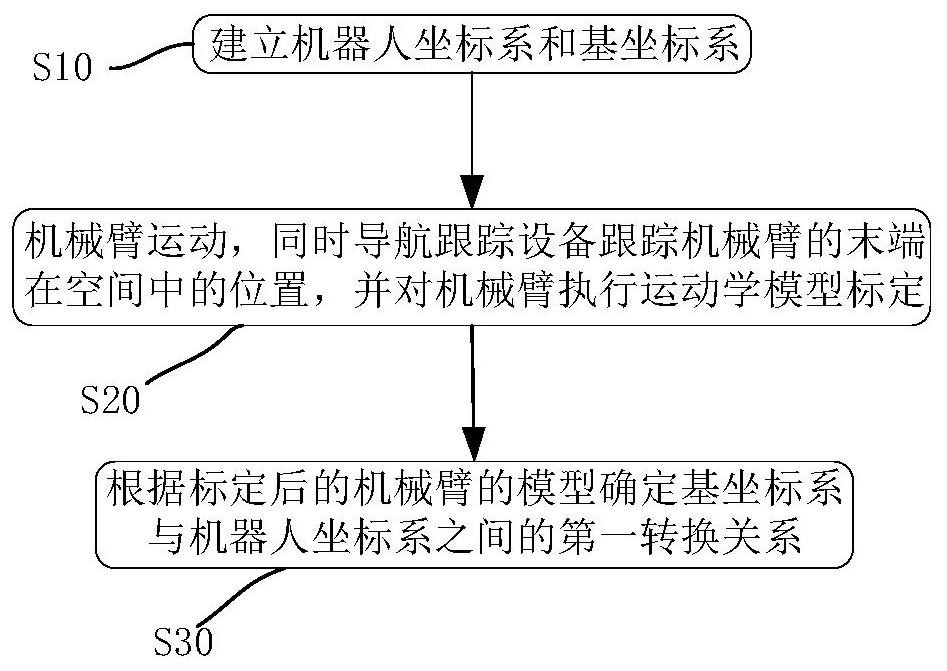

Navigation operation system, registration method thereof and computer readable storage medium

PendingCN112618018AImprove absolute positioning accuracyImprove positioning accuracyImage analysisSurgical navigation systemsRobotic systemsControl engineering

The invention provides a navigation operation system, a registration method thereof and a computer readable storage medium. The navigation operation system comprises a robot system, a navigation system and a control unit which are in communication connection, wherein the robot system comprises a mechanical arm and is provided with a robot coordinate system established on the mechanical arm; the navigation system comprises navigation tracking equipment; and the navigation system is provided with a base coordinate system which can be identified by the navigation tracking equipment. The navigation operation system is configured as follows: the navigation tracking equipment tracks the position of the tail end of the mechanical arm in space; and the control unit executes kinematic model calibration on the mechanical arm according to the position of the tail end of the mechanical arm in the space, and obtains a first conversion relationship between the base coordinate system and the robot coordinate system according to the calibrated model of the mechanical arm. The navigation operation system can improve the positioning accuracy of the mechanical arm and improve the operation precision.

Owner:SUZHOU MICROPORT ORTHOBOT CO LTD

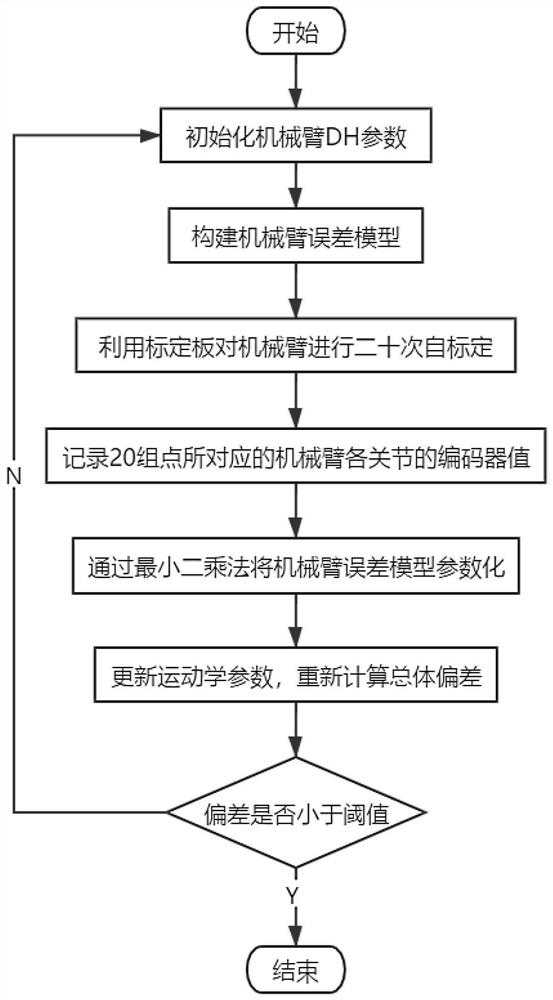

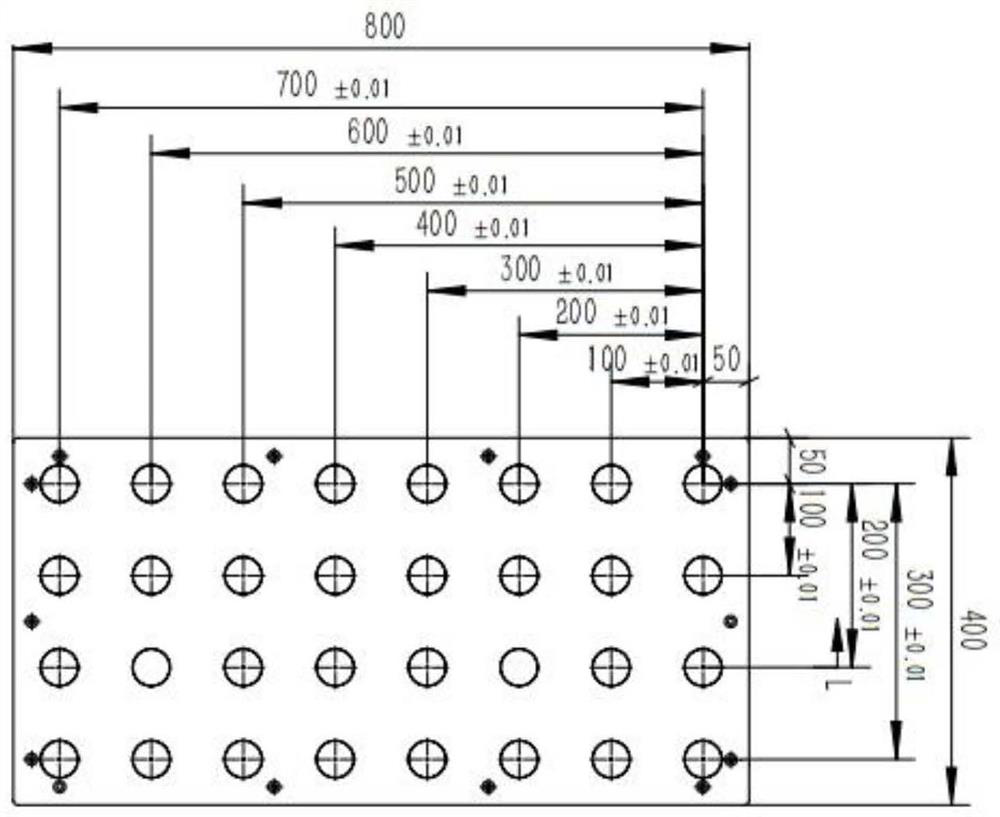

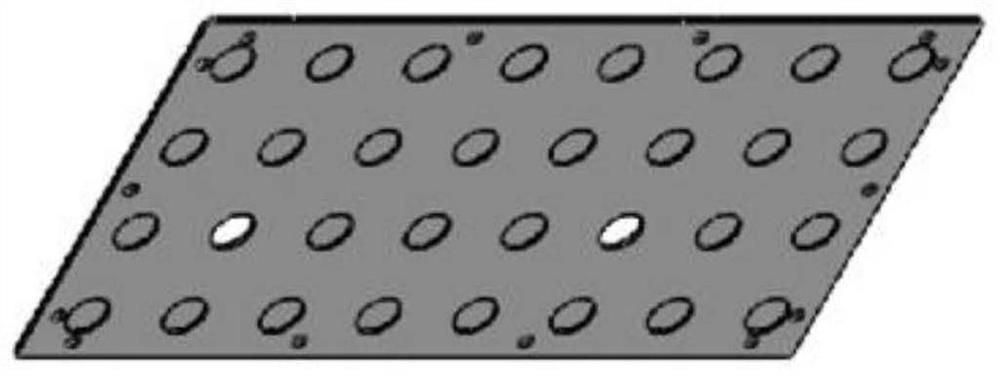

Mechanical arm DH parameter identification method based on least square method

ActiveCN112894814AImprove absolute positioning accuracyLow costProgramme-controlled manipulatorClassical mechanicsMechanical engineering

The invention discloses a mechanical arm DH parameter identification method based on a least square method. The method comprises the steps: determining the initial DH parameters of a mechanical arm according to the configuration and structural parameters of the mechanical arm, and constructing a mechanical arm error model according to a differential motion principle; based on the initial DH parameters of the mechanical arm, conducting self-calibration on the mechanical arm through a calibration plate, and recording encoder values of all joints, corresponding to all sets of points, of the mechanical arm; parameterizing the mechanical arm error model through the least square method in combination with the encoder values; according to the parameters of the mechanical arm error model and the initial DH parameters of the mechanical arm, obtaining the tail end position of each set of points, and calculating the difference value between each tail end position and the absolute position of a fixed point; and identifying the parameters of the mechanical arm error model by comparing the difference values with a set threshold value. According to the method, parameter identification is carried out by constructing the error model and through self-calibration of the calibration plate, the absolute positioning precision of the mechanical arm is effectively improved, and the cost can be reduced.

Owner:INST OF INTELLIGENT MFG TECH JITRI

A Robot Accuracy Compensation Method for Variable Parameter Error Identification

ActiveCN104535027BImprove absolute positioning accuracyFind global convergent solutionNavigational calculation instrumentsLaser trackerInverse kinematics

Owner:江苏航鼎智能装备有限公司

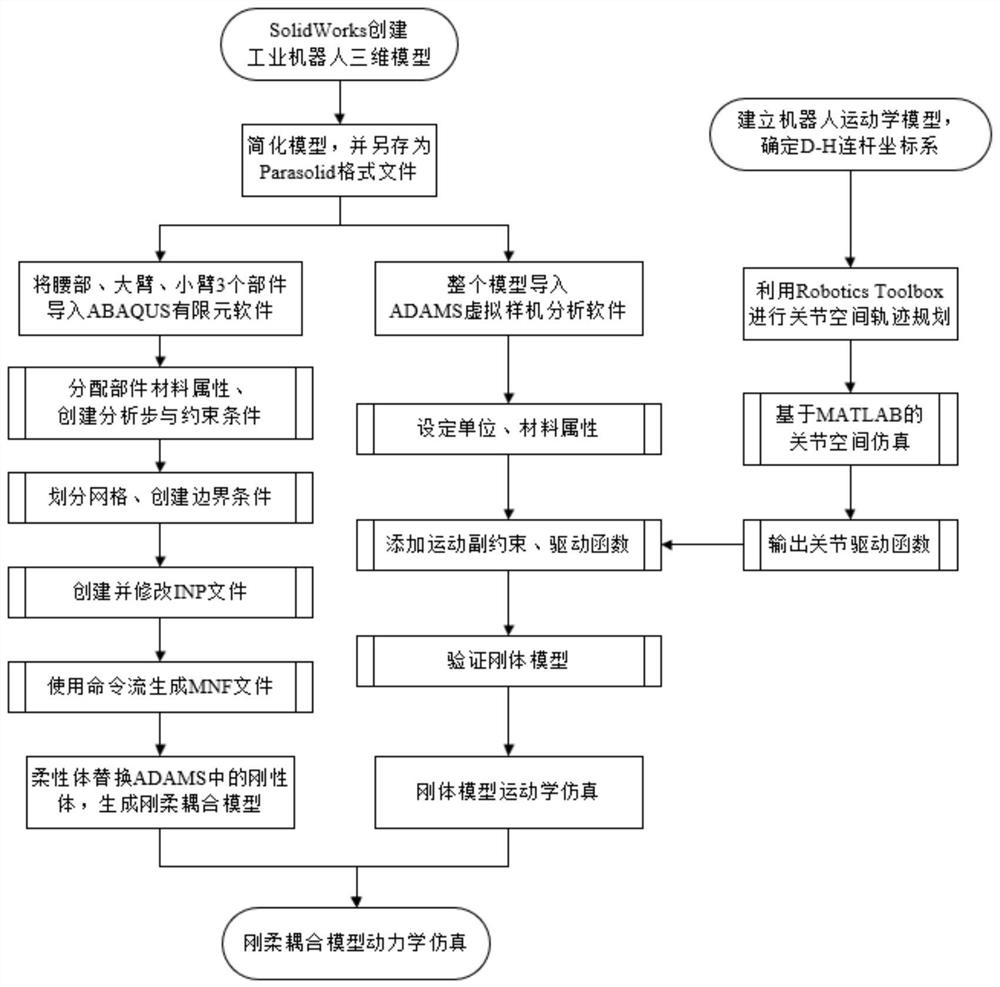

Rigid-flexible coupling model modeling simulation method for six-degree-of-freedom industrial robot

PendingCN112307578AReduced simulation timeImprove analysis efficiencyGeometric CADDesign optimisation/simulationKinematic pairTrajectory planning

The invention provides a six-degree-of-freedom industrial robot rigid-flexible coupling model modeling simulation method. The method comprises the steps: establishing an industrial robot rigid body model; importing the rigid body model into ADAMS, and setting unit attributes and material attributes; according to a kinematics model modeling method, performing trajectory planning on the robot in thejoint space based on an MATLAB robot toolbox, and outputting a joint driving function; adding kinematic pair constraints and joint driving functions into the ADAMS, and carrying out the kinematic simulation; importing the key component into ABAQUS, distributing component material attributes, creating analysis steps and constraint conditions, and establishing a modal neutral file after the key component is softened as a flexible body component; replacing corresponding parts in the rigid body model with the flexible body parts to generate a rigid-flexible coupling model of the industrial robot,and carrying out dynamic simulation on the rigid-flexible coupling model. The method is convenient for comprehensive research of change rules of kinematics and kinetic parameters of the tail end of the robot, simulation time is saved, and efficiency is improved.

Owner:JIANGSU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com