Industrial robot absolute precision calibration system and calibration method

An industrial robot, absolute precision technology, applied in manipulators, manufacturing tools, program-controlled manipulators, etc., can solve the problem of limited reliability of calibration results, inability to calibrate the exact position of the robot base coordinate system, and inability to accurately calibrate the robot base coordinate system, etc. problems, to achieve the effect of improving absolute positioning accuracy, reliable measurement accuracy and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

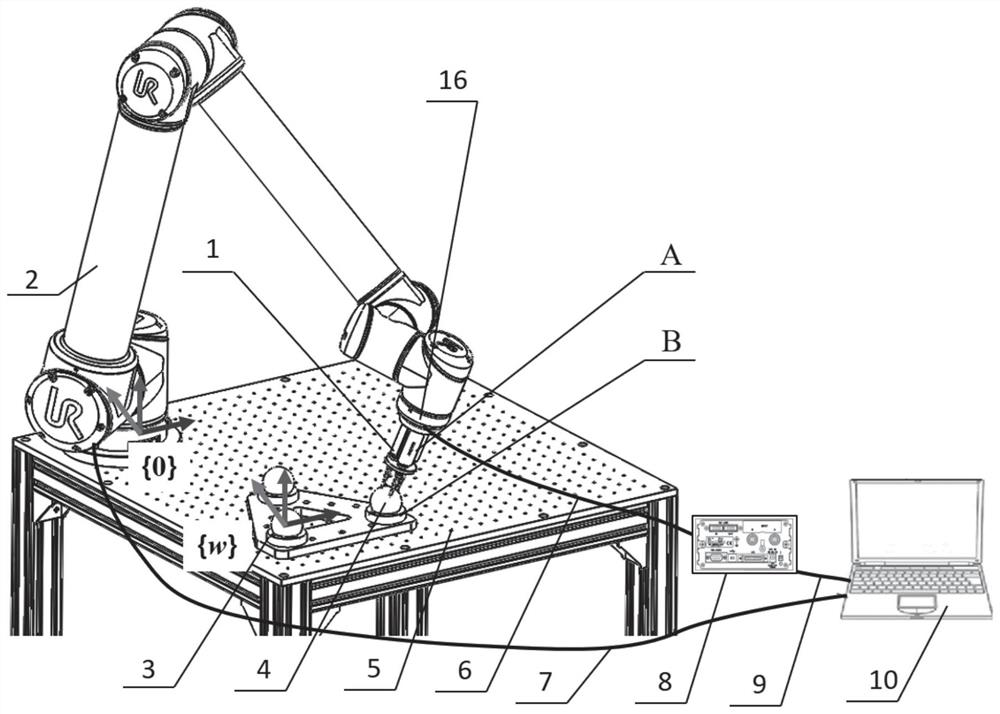

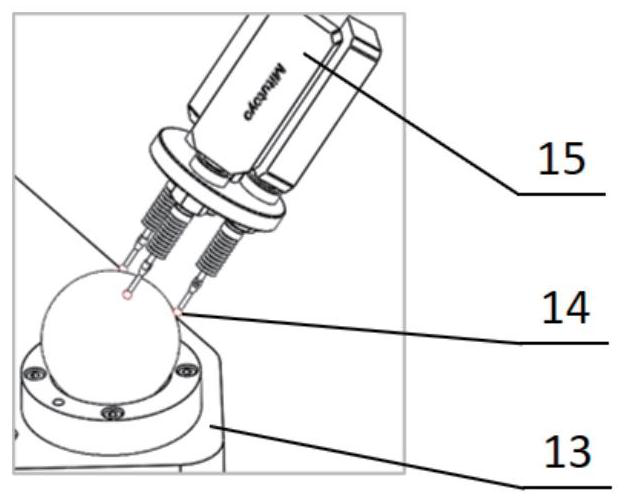

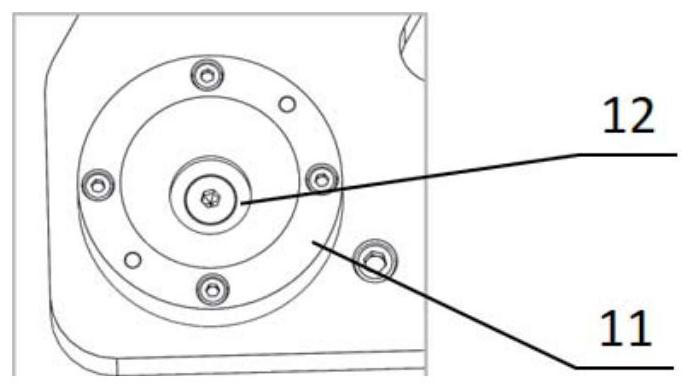

[0045] As mentioned above, in view of the shortcomings of the existing technology, such as the expensive and heavy measuring equipment used in the existing robot calibration method, and the inability to calibrate the pose of the robot base coordinate system, the inventors of the present application have achieved A robot absolute precision calibration system with the advantages of portability, low cost, reliable accuracy, and convenient operation is proposed, as well as an absolute calibration method with the functions of robot kinematics parameter calibration and robot base coordinate system pose calibration.

[0046] The present invention is described in further detail below in conjunction with embodiment and accompanying drawing, it should be pointed out that following embodiment is intended to facilitate understanding of the present invention, and it does not have any limiting effect.

[0047] like Figure 1a-Figure 1c As shown, an embodiment of the present invention provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com