Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

183results about How to "High locking reliability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

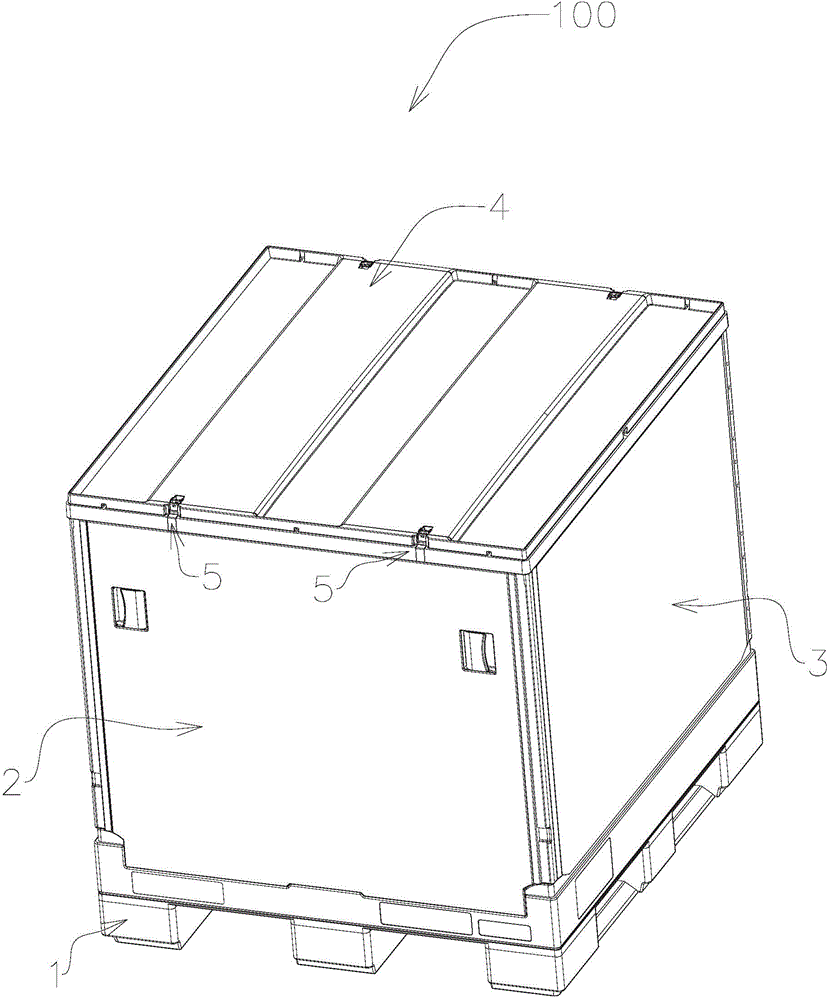

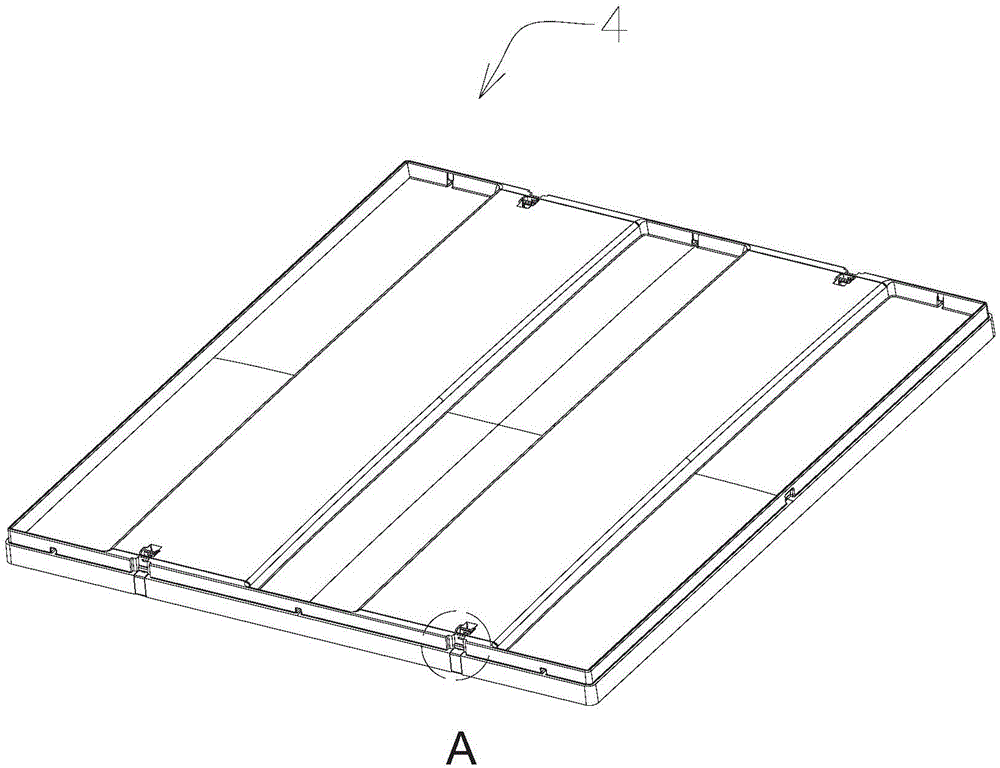

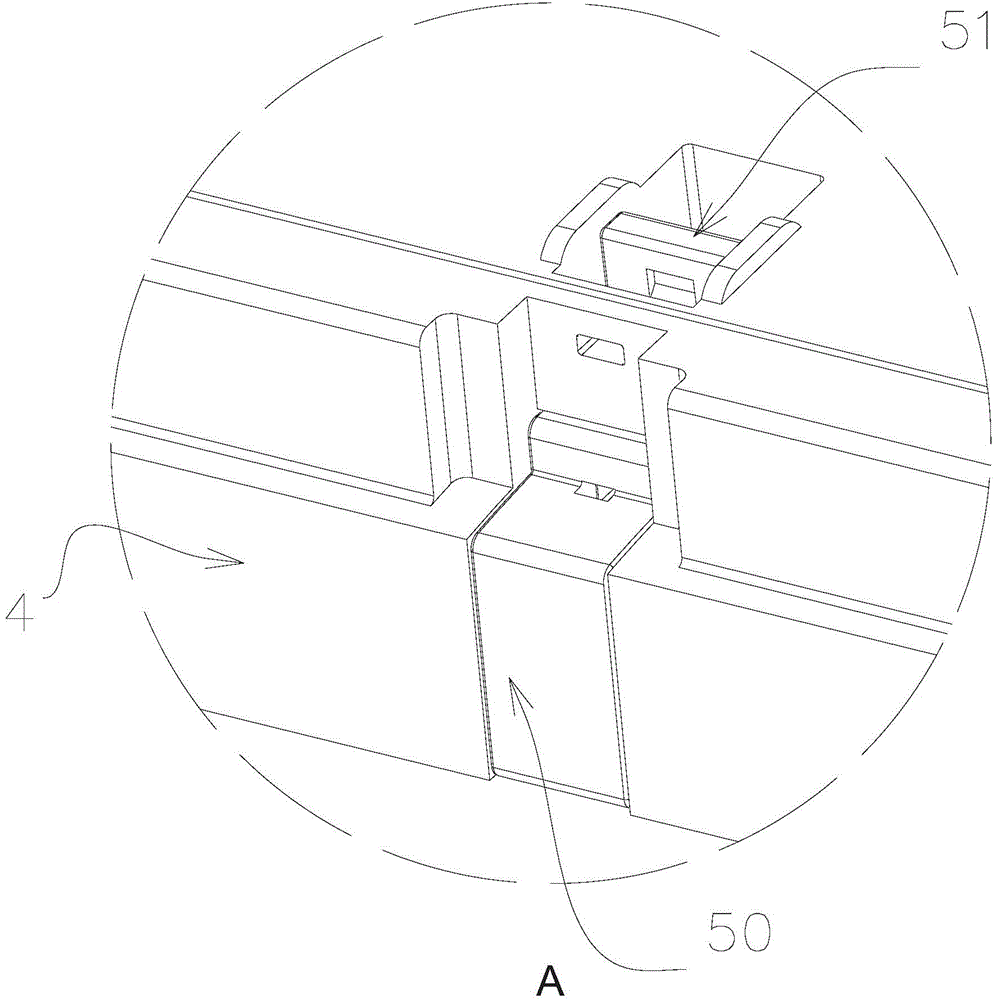

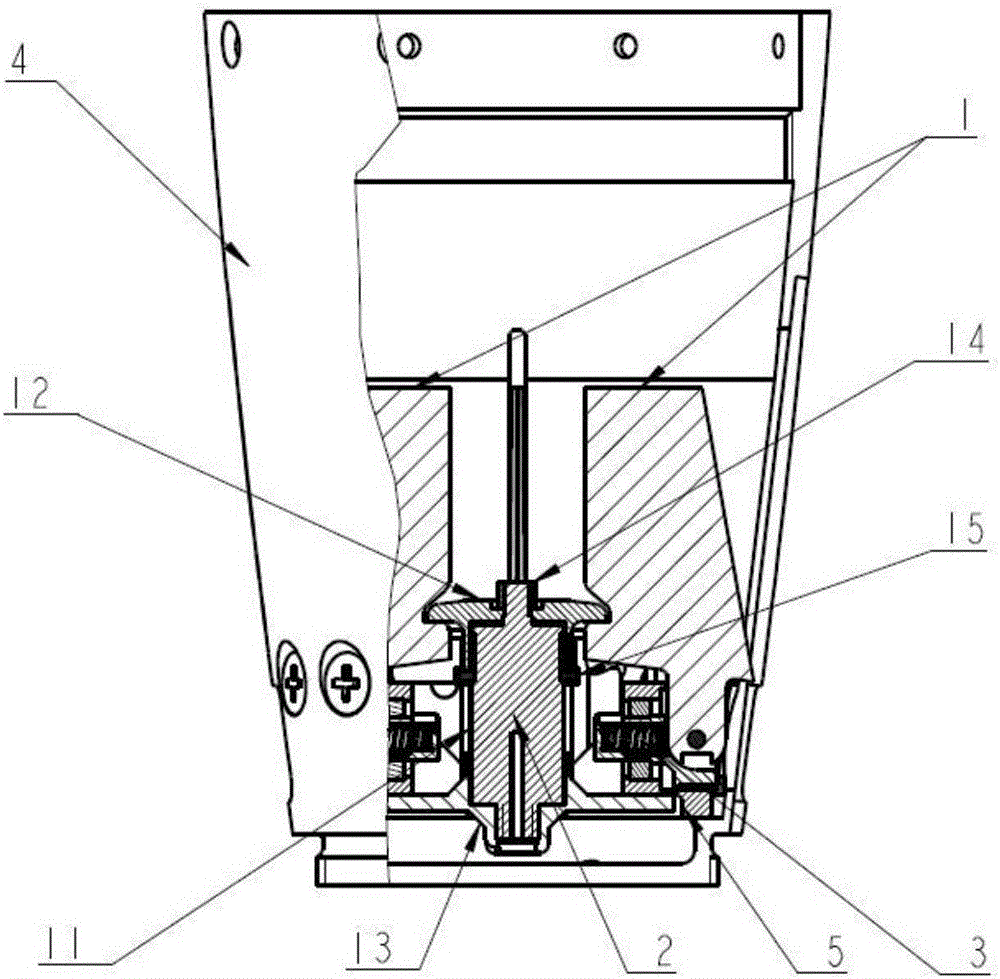

Container and locking mechanism thereof

ActiveCN104590787AReduce accumulated altitudeReduce laborLarge containersRigid containersLocking mechanismEngineering

The invention discloses a locking mechanism which is used for locking an upper cover of a container on a container side plate. The container comprises a base, the upper cover and side plates, wherein the upper cover is provided with a safe edge. The locking mechanism comprises a locking piece, a driving piece, a resetting piece, lock holes and a groove, wherein the lock holes are formed in the outer side of at least one side plate, and the groove is formed in the upper cover; one end of the locking piece is arranged in the groove, and the other end of the locking piece is provided with a lock head; the lock head penetrates through the safe edge and can extend into one of the lock holes along a direction vertical to the corresponding side plate, so that the upper cover is locked to the corresponding side plate; the driving piece is arranged in the groove and is used for driving the locking piece to perform unlocking, and the resetting piece is arranged in the groove and is used for resetting the driving piece after unlocking is finished. According to the container and the locking mechanism, the transportation cost and the storage cost can be lowered and the labor intensity of operators is alleviated.

Owner:SHANGHAI HONGYAN RETURNABLE TRANSIT PACKAGINGS CO LTD

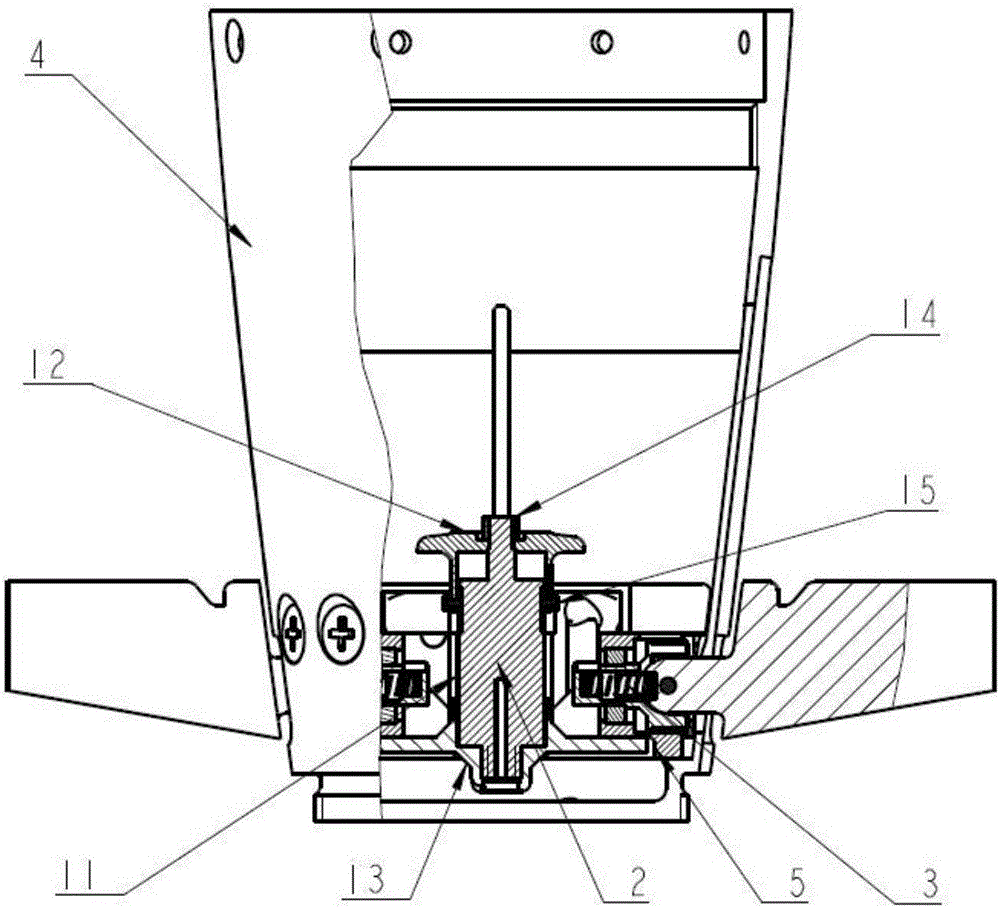

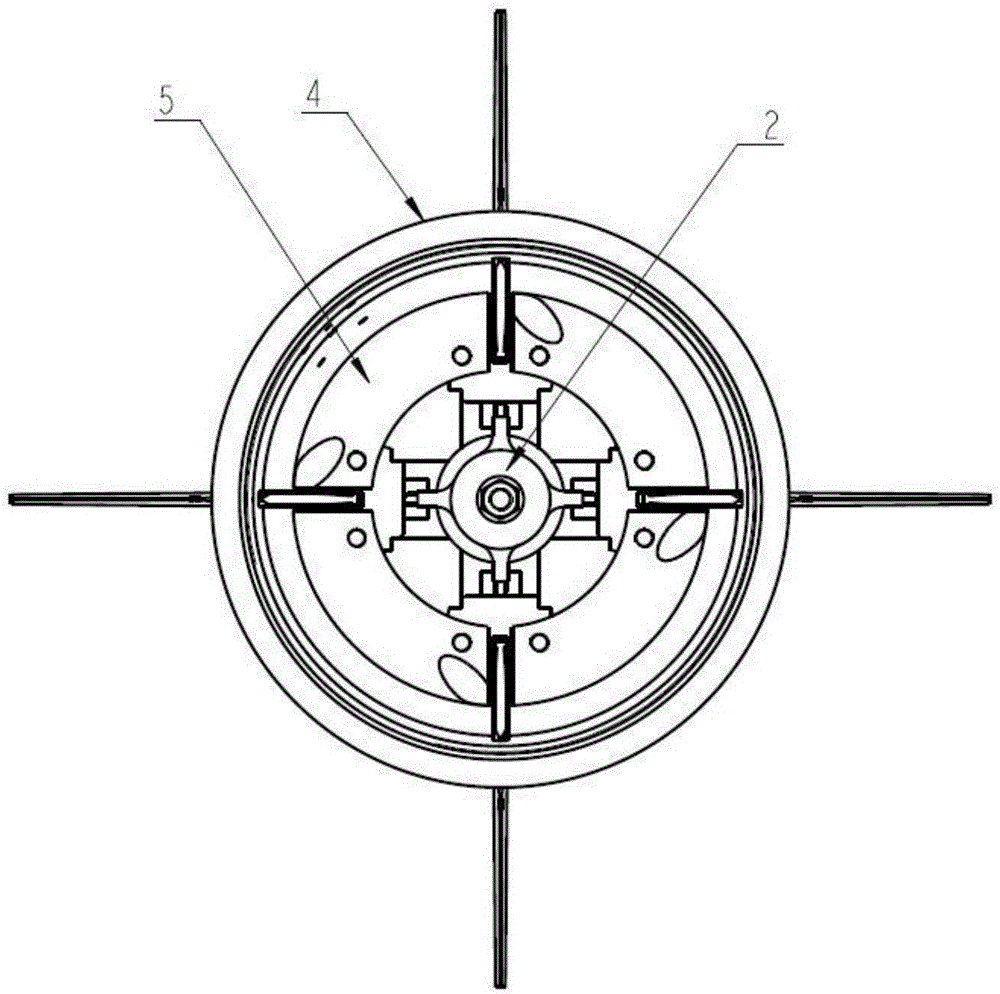

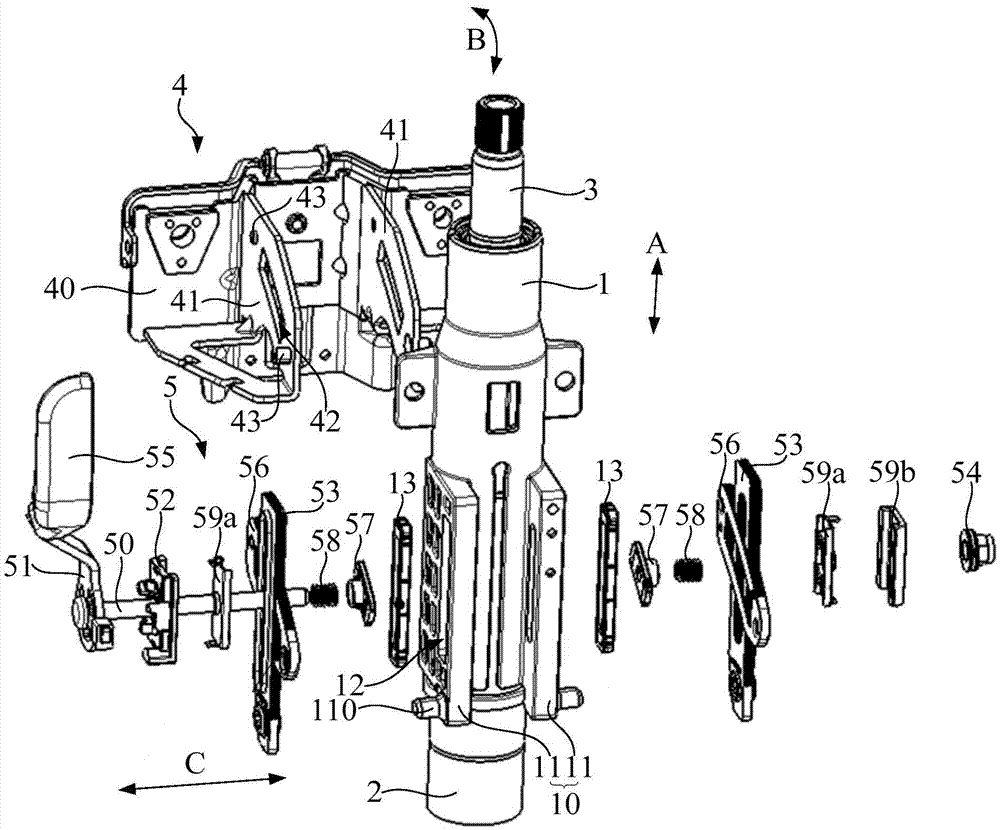

Missile-borne rudder wing spreading locking mechanism based on pin pusher actuation

A scheme that a rudder system with a wing spreading locking function pushes rudder sheets to spread simultaneously and lock the rudder sheets is adopted by the invention. After a rocket projectile is launched, the rudder system is powered by a missile-borne controller; after a rudder spreading command is emitted, the rudder system controller receives the rudder spreading command of the missile-borne control system; current amplification is performed after the rudder system controller receives a rudder spreading command signal, so that a pin pusher is started, and a pushing disc is pushed to spread the four rudder sheets simultaneously; after spreading angles reach 90 degrees, limiting is performed through the locking mechanism, and the whole wing spreading locking function is finished; and then, the missile-borne controller gives a rudder deflecting command, so that a rudder engine is controlled to drive the rudder sheets to swing, and a servo control function is realized. Meanwhile, for ensuring that the sailing posture of the rocket projectile is not affected, the spreading time of the four rudder sheets is very short and the asynchronism of spreading is very low.

Owner:BEIJING RES INST OF PRECISE MECHATRONICS CONTROLS

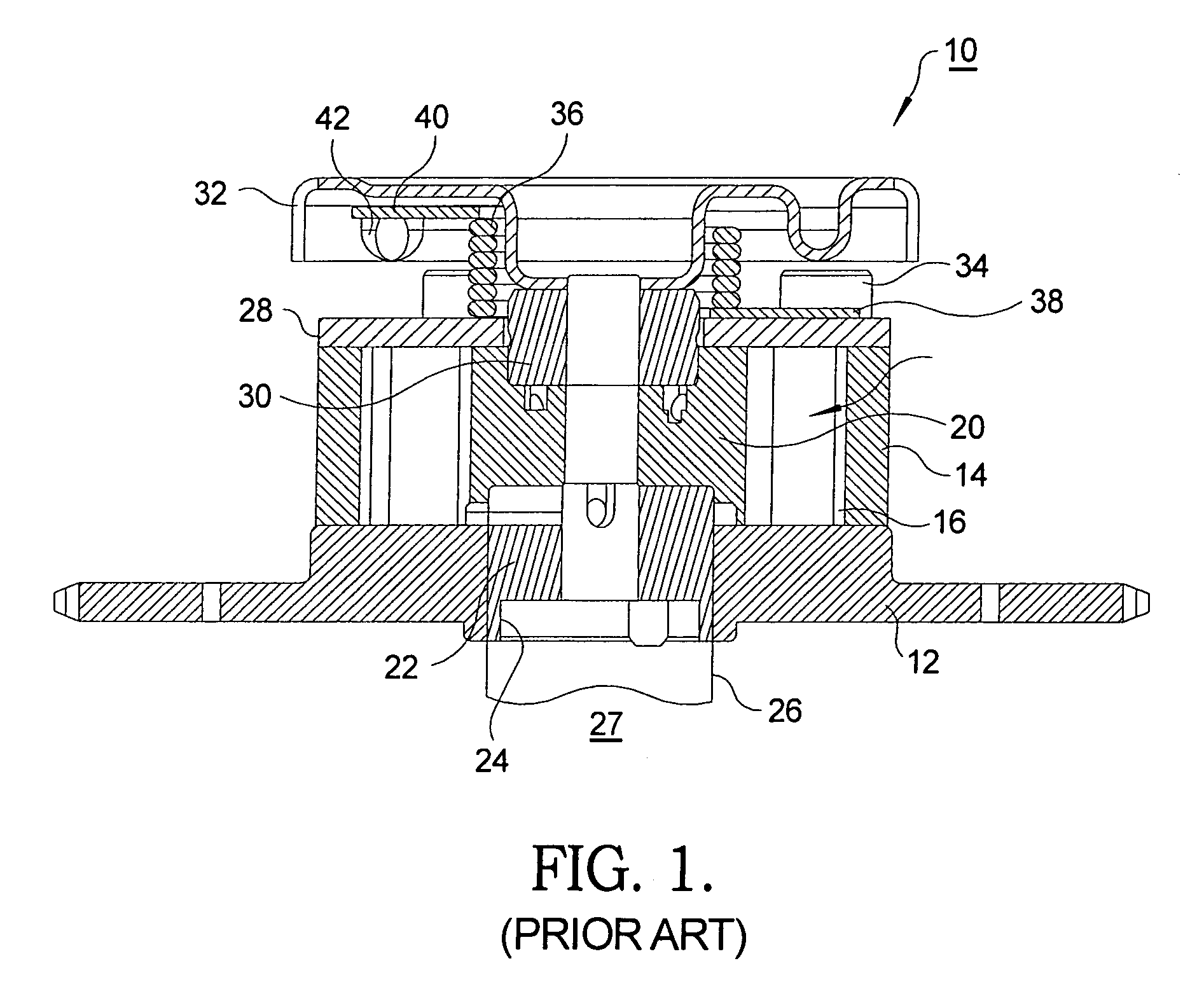

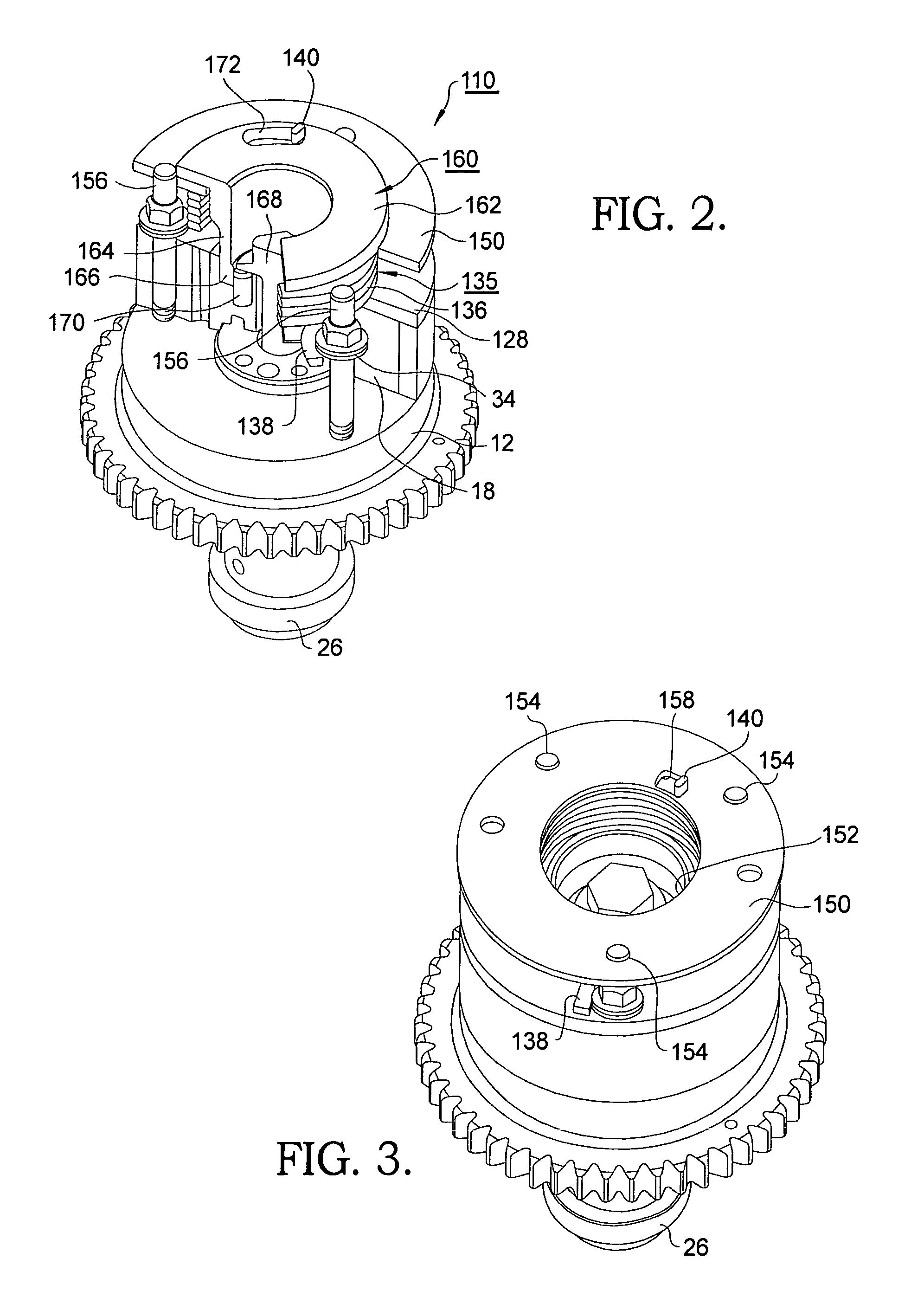

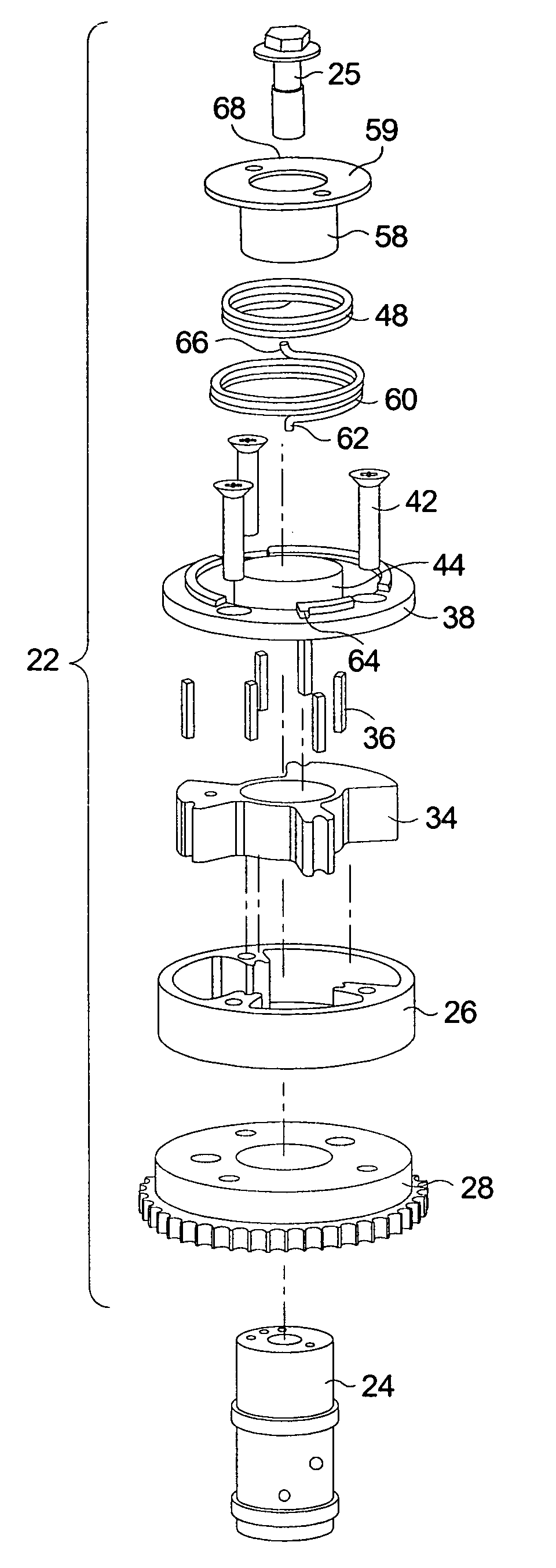

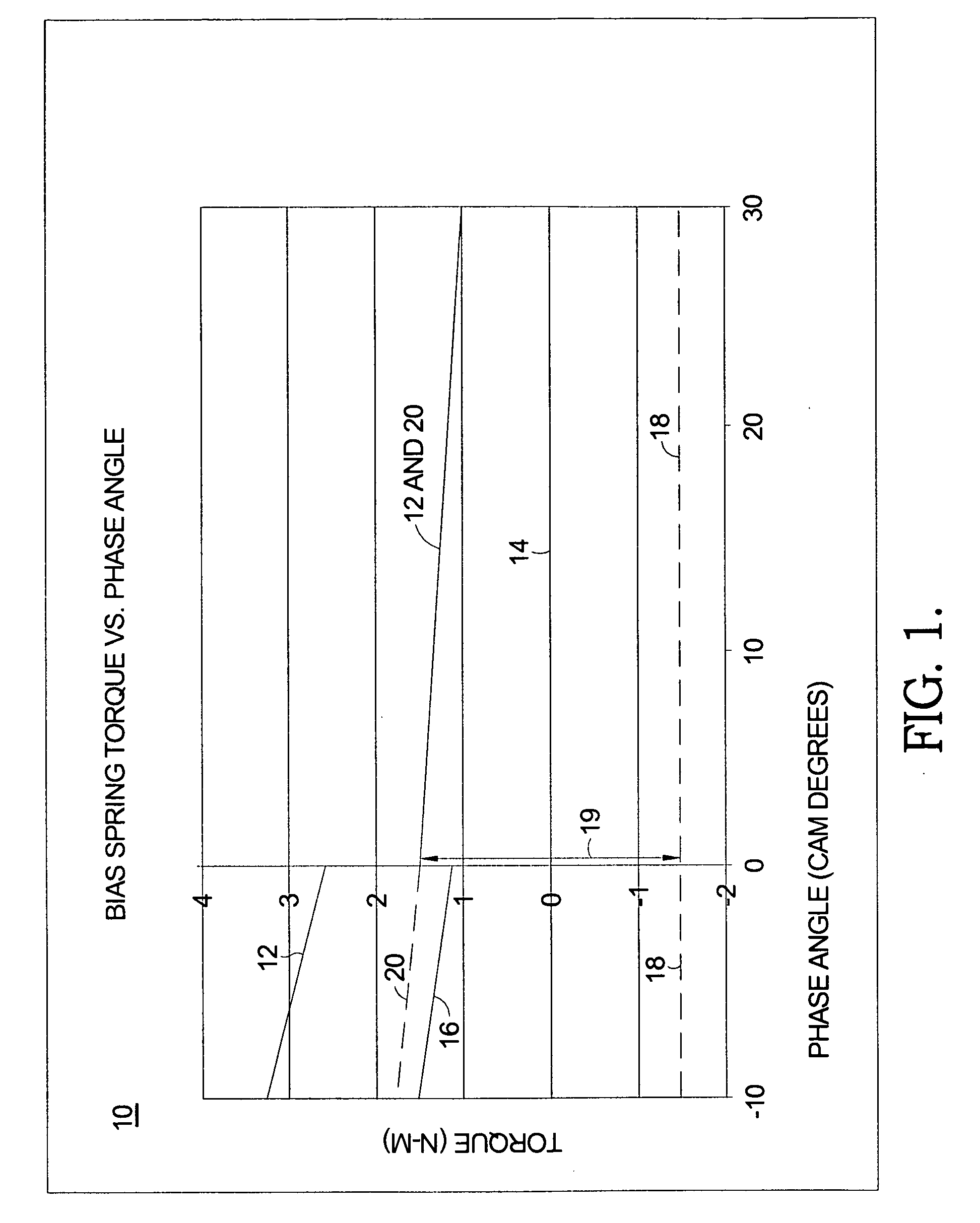

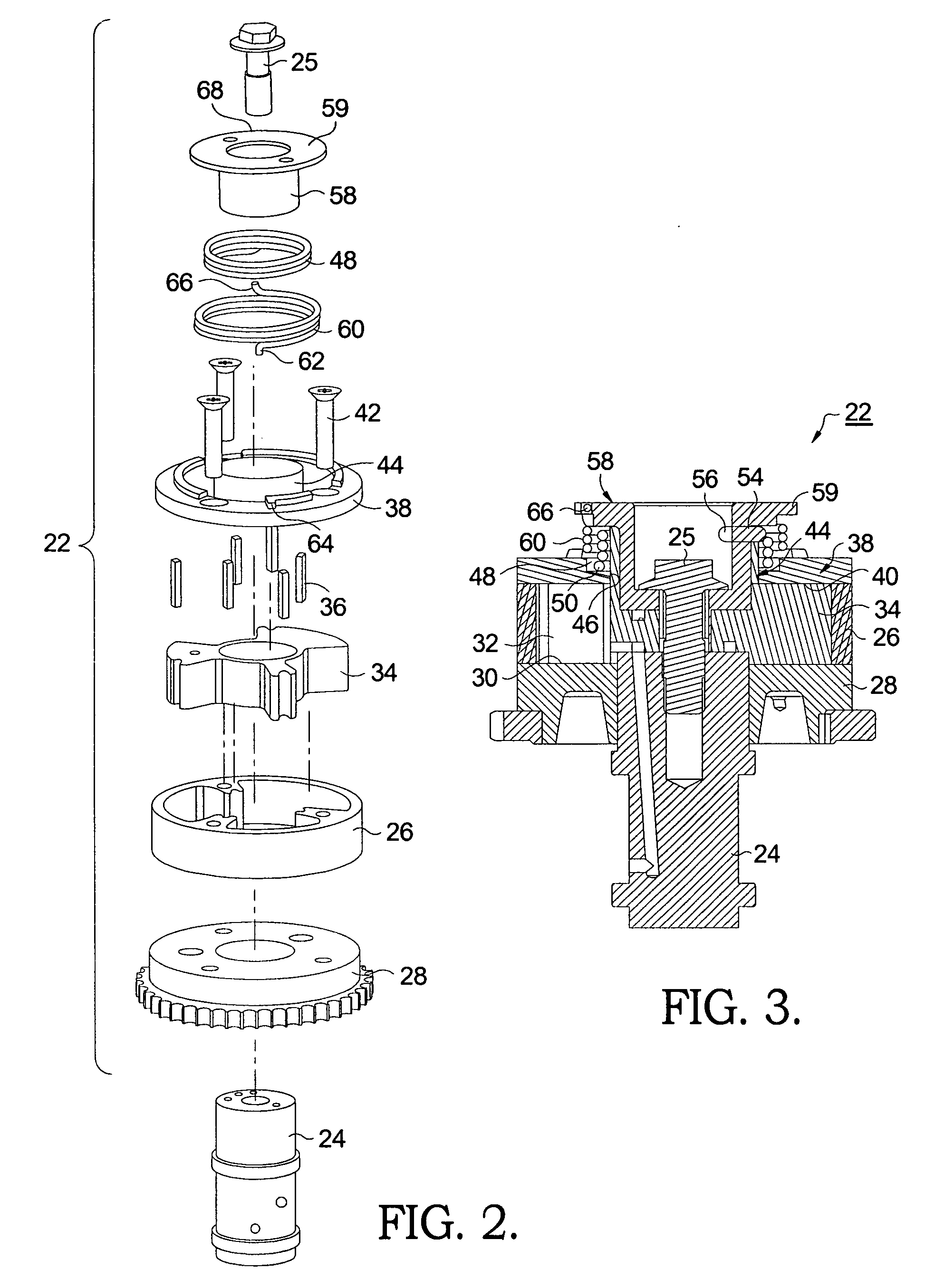

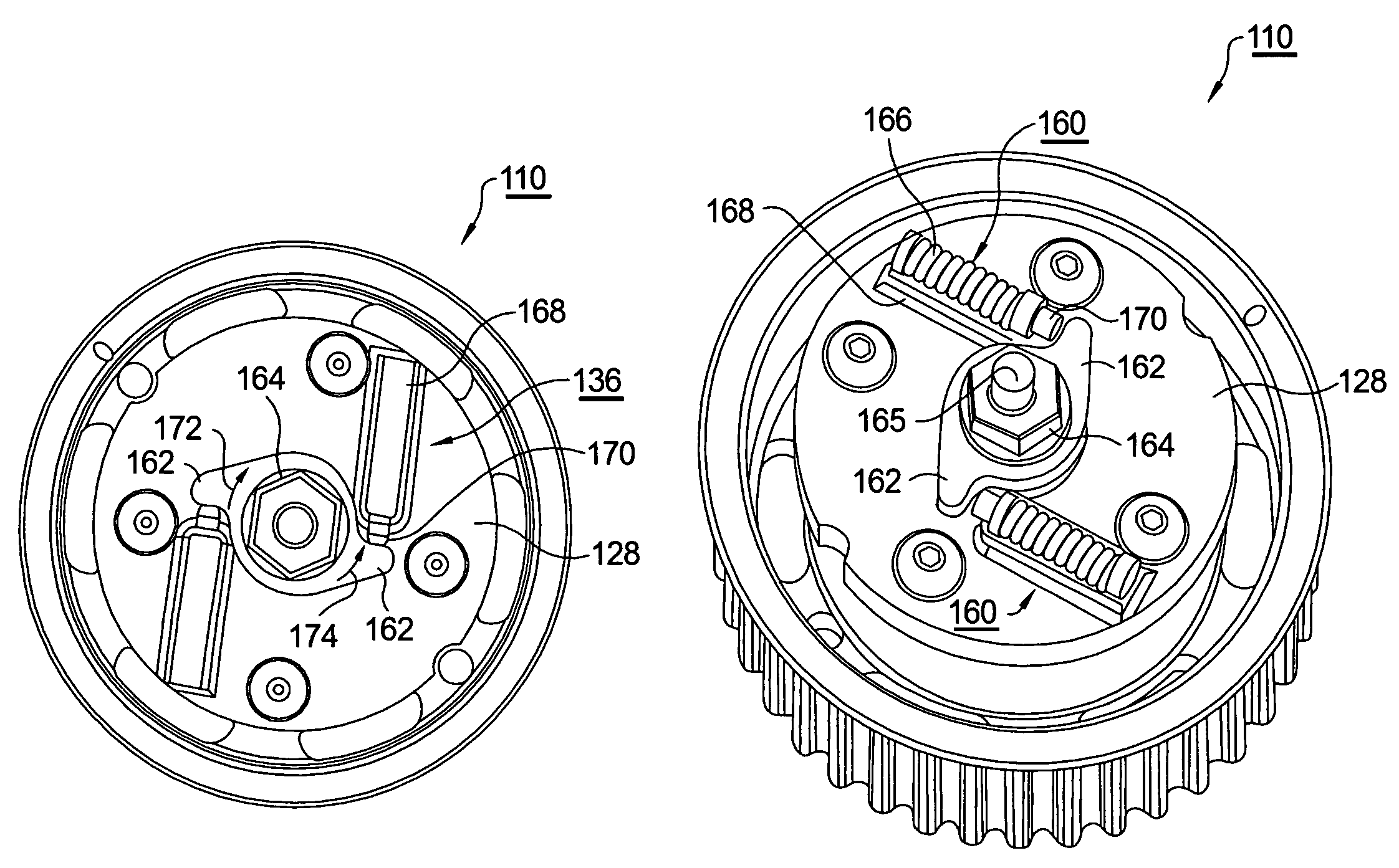

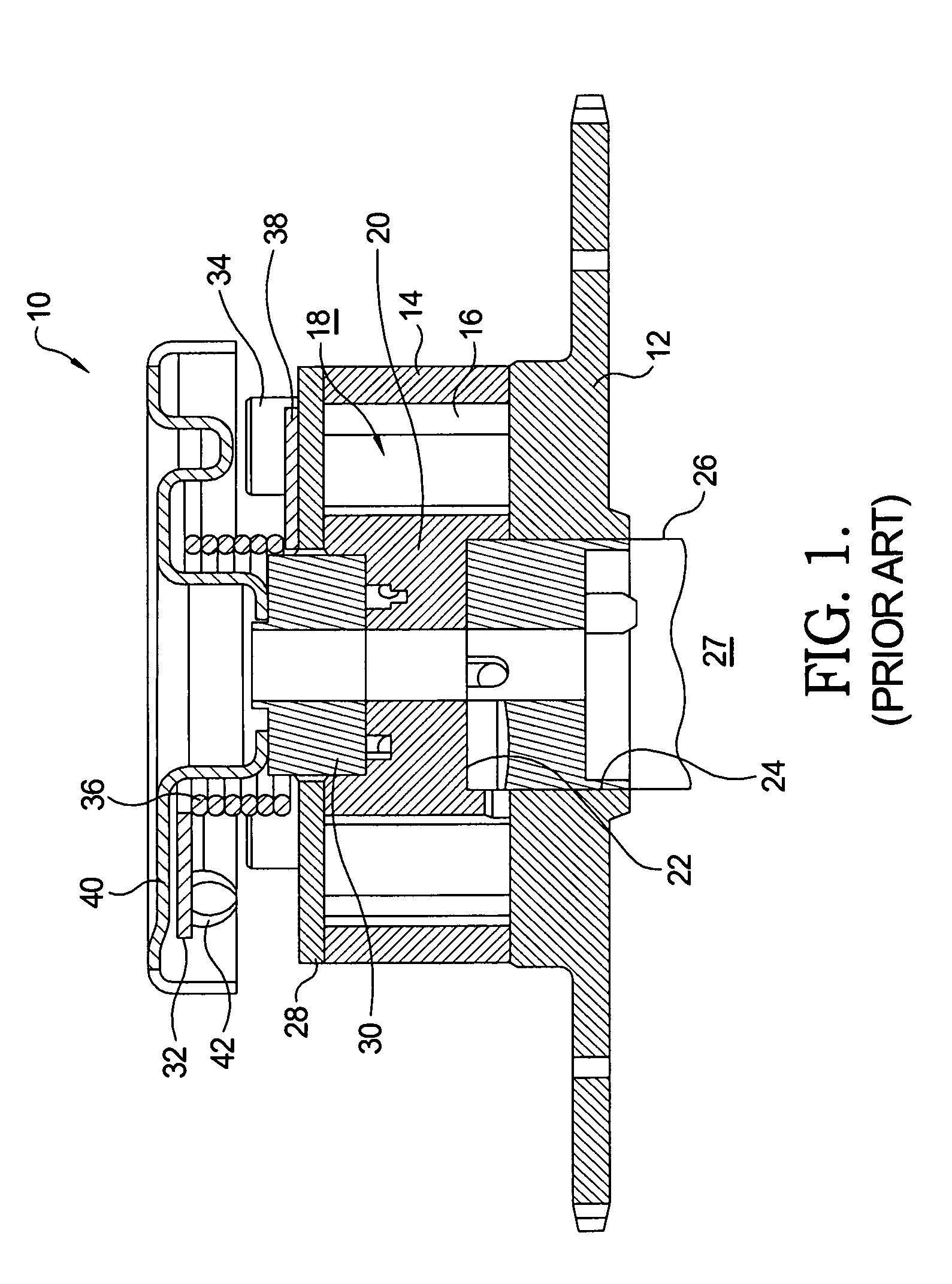

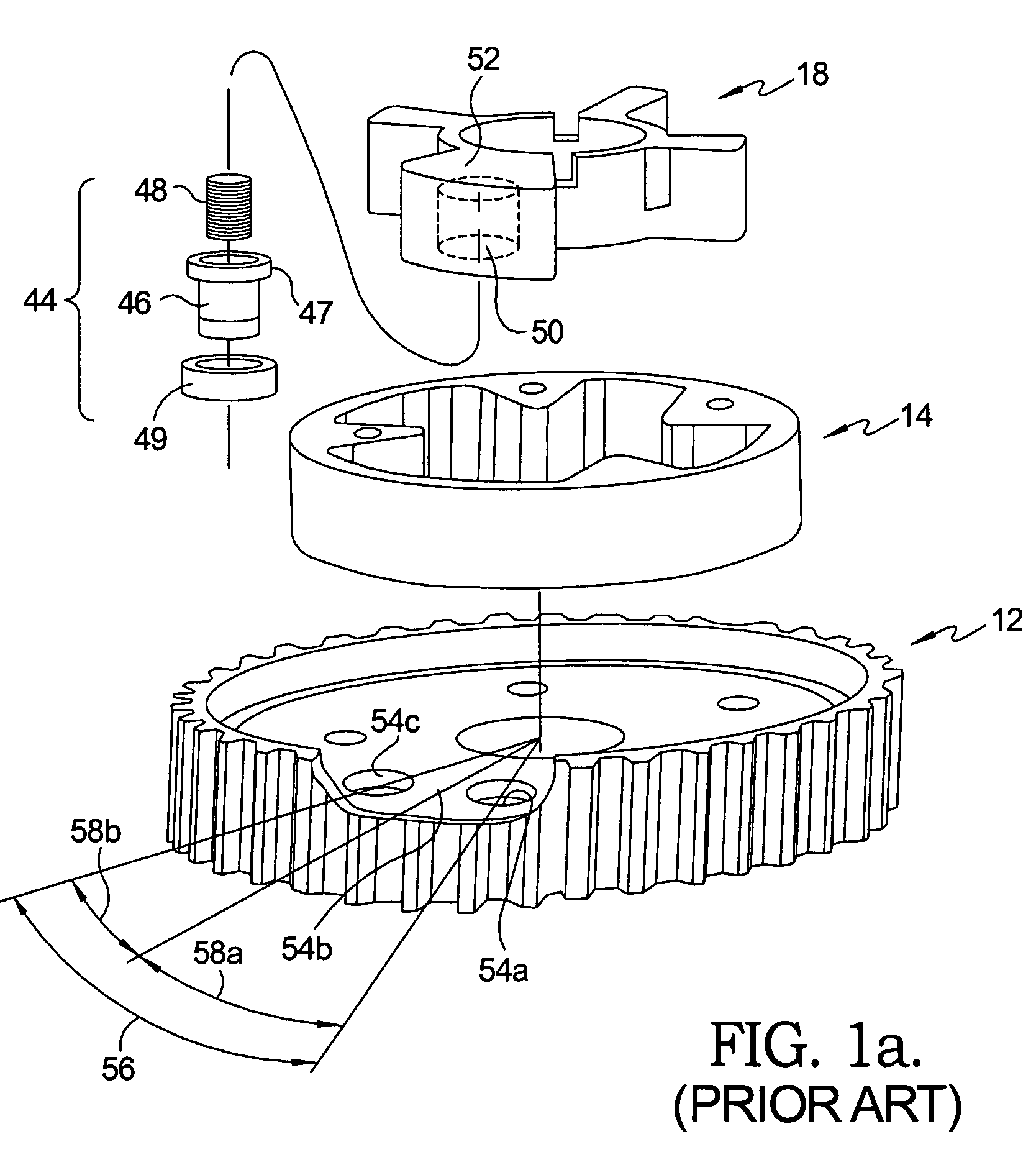

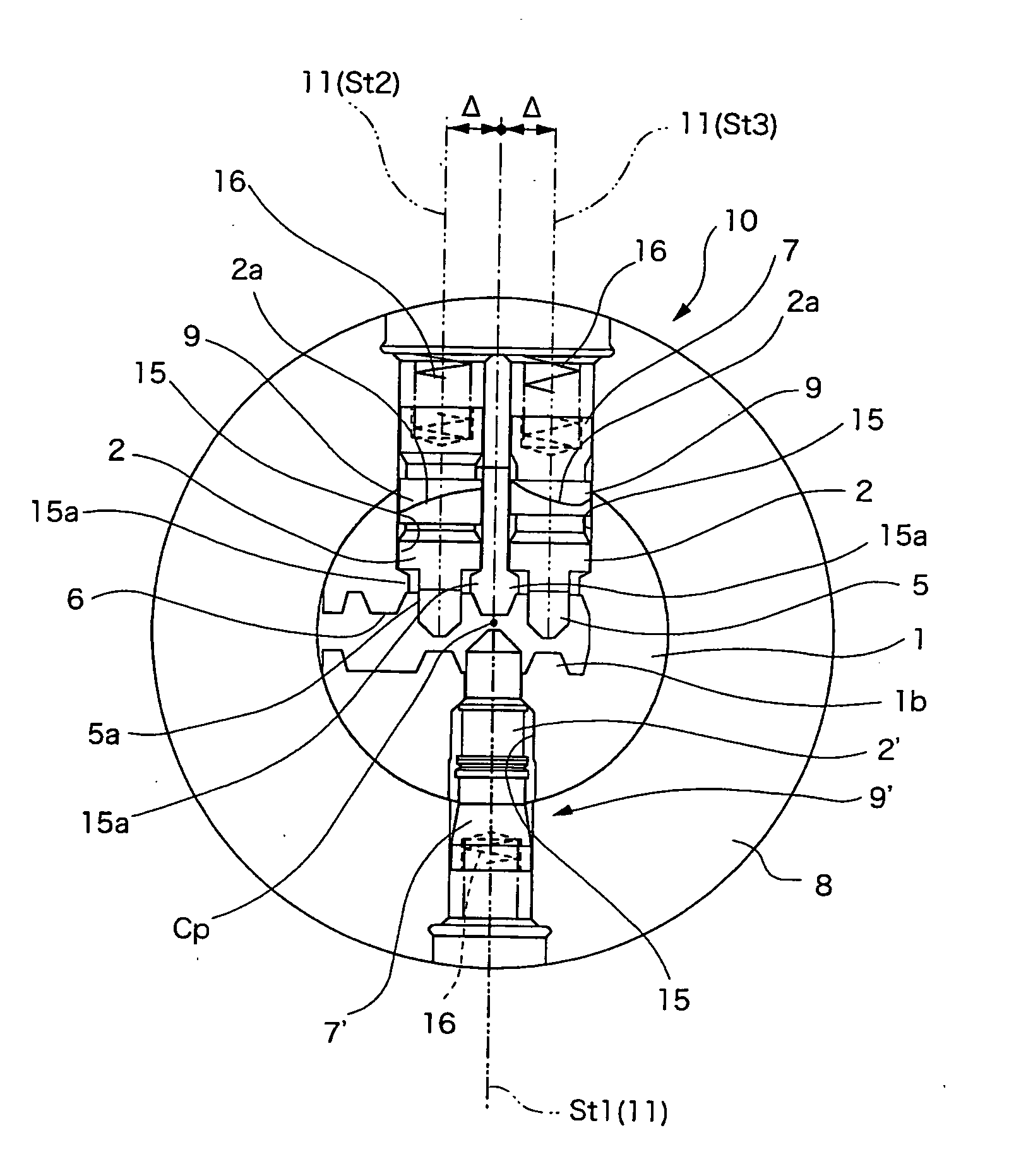

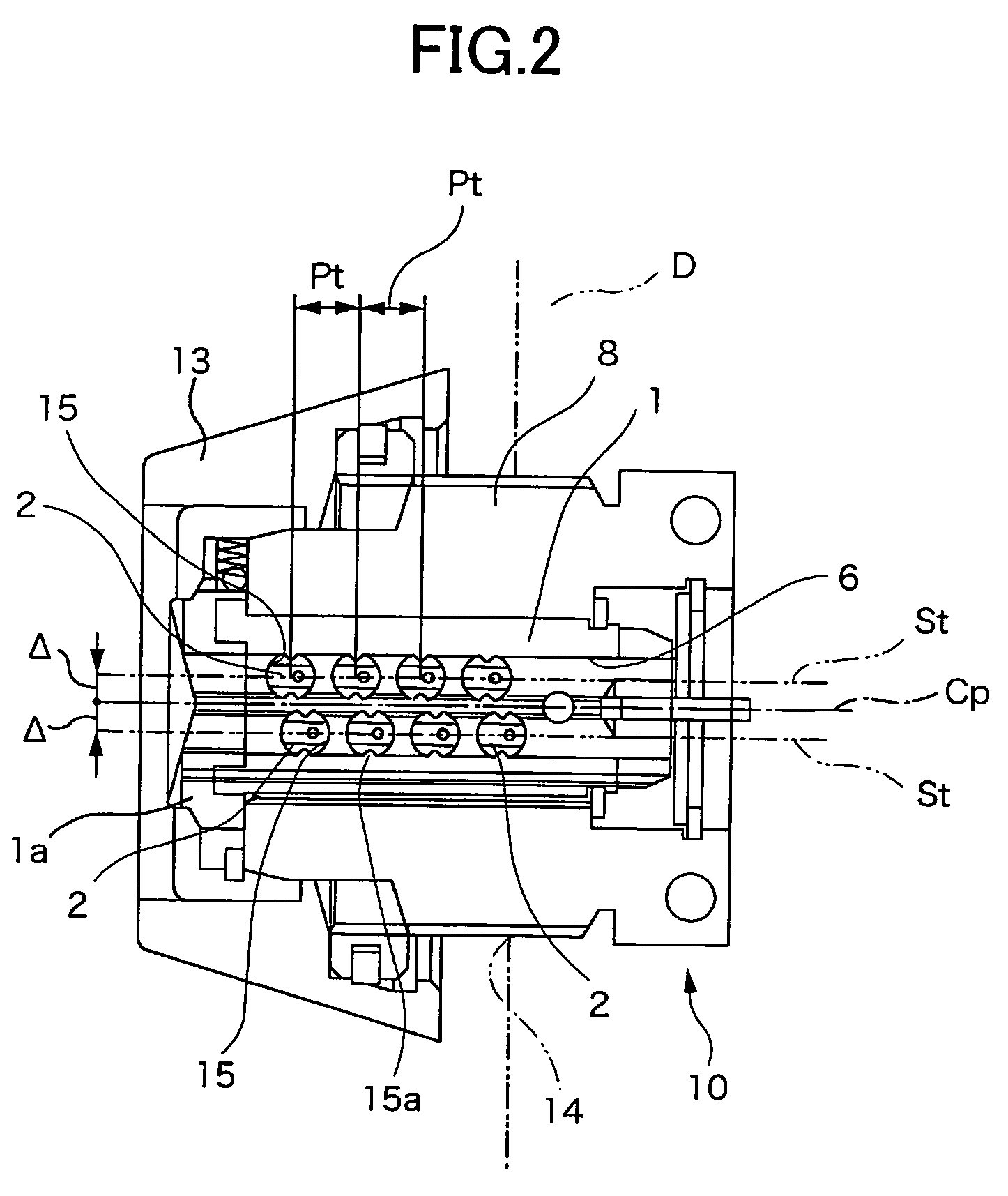

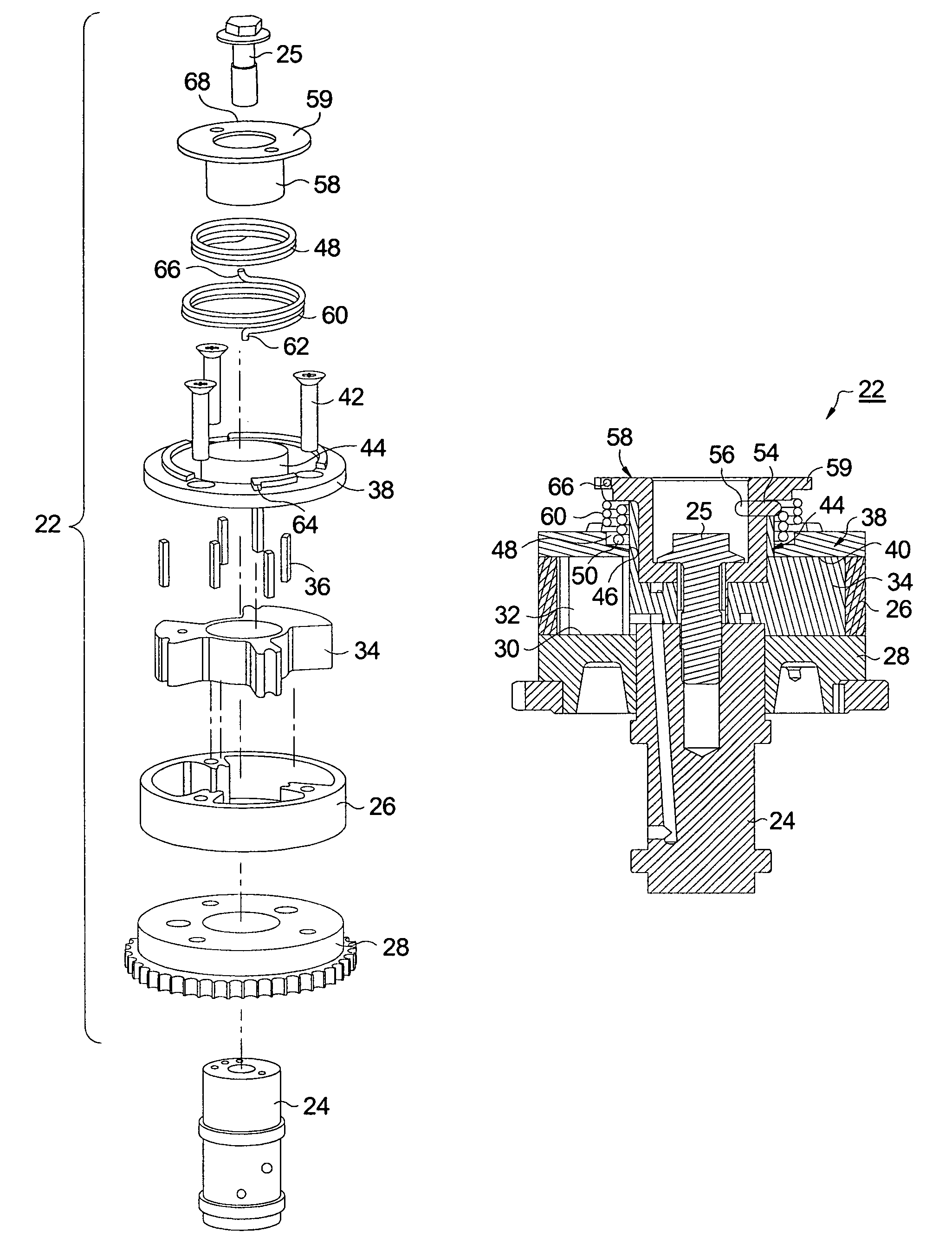

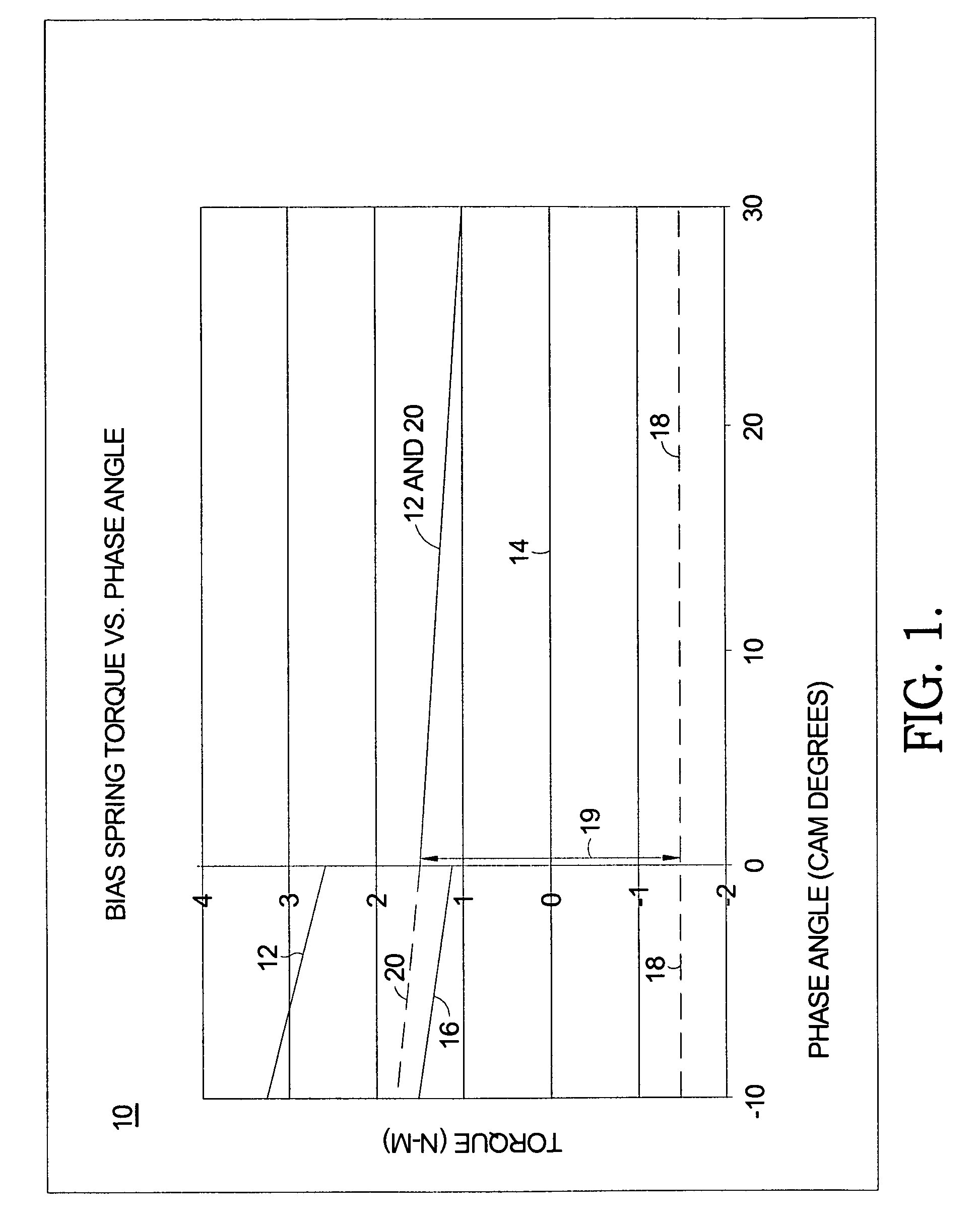

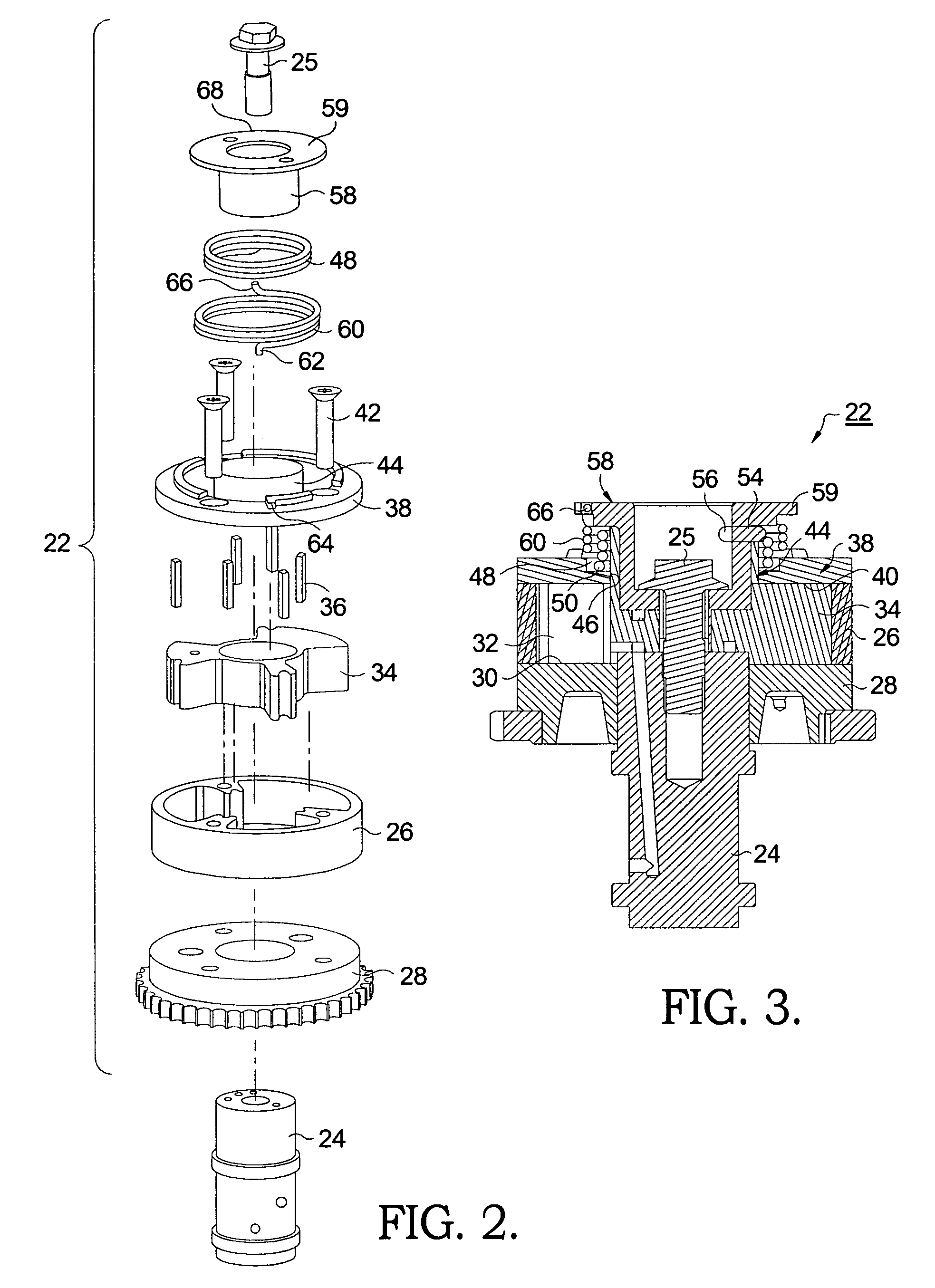

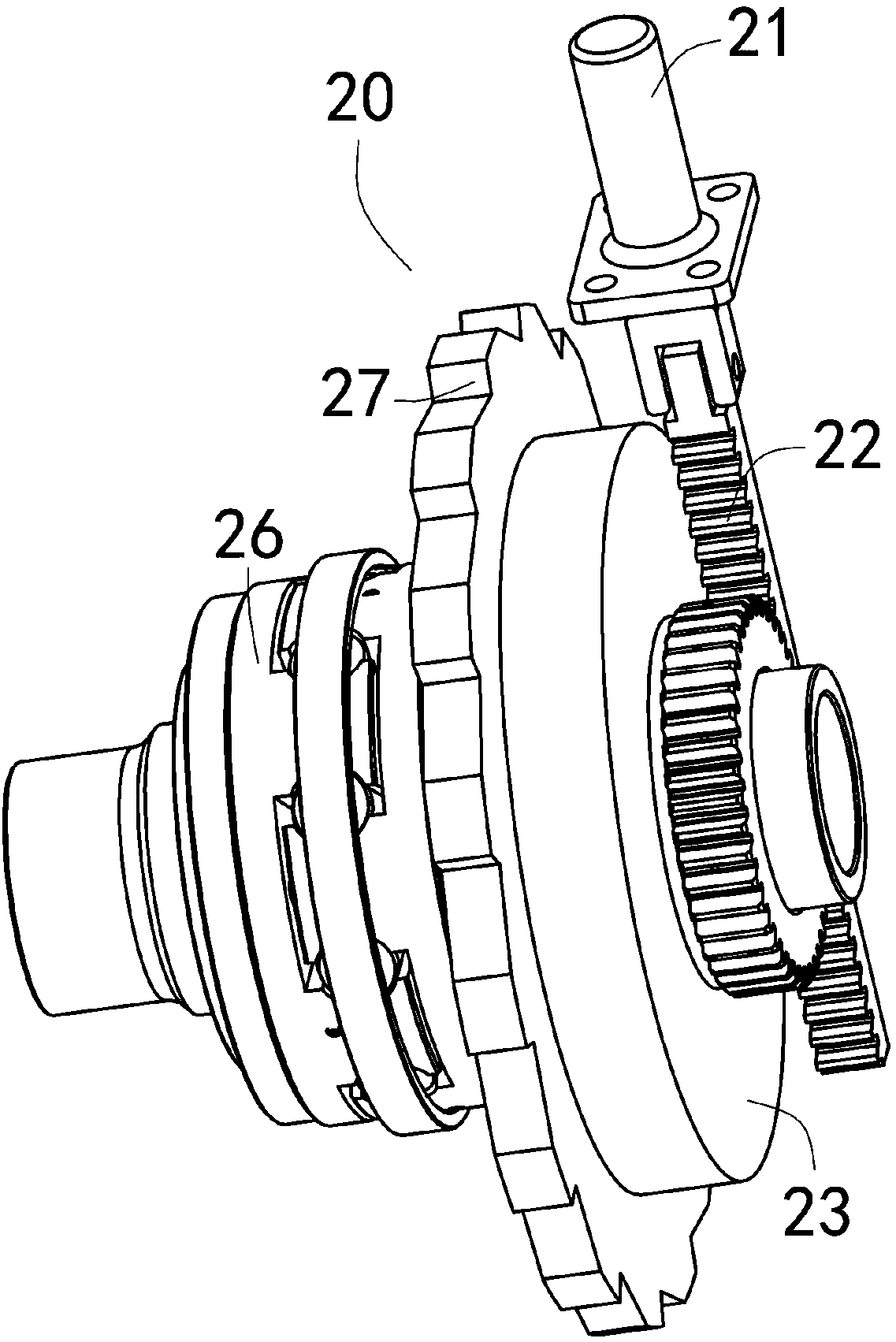

Vane-type cam phaser having bias spring system to assist intermediate position pin locking

ActiveUS7363897B2High locking reliabilityValve drivesMachines/enginesSprocketInternal combustion engine

Owner:DELPHI TECH IP LTD

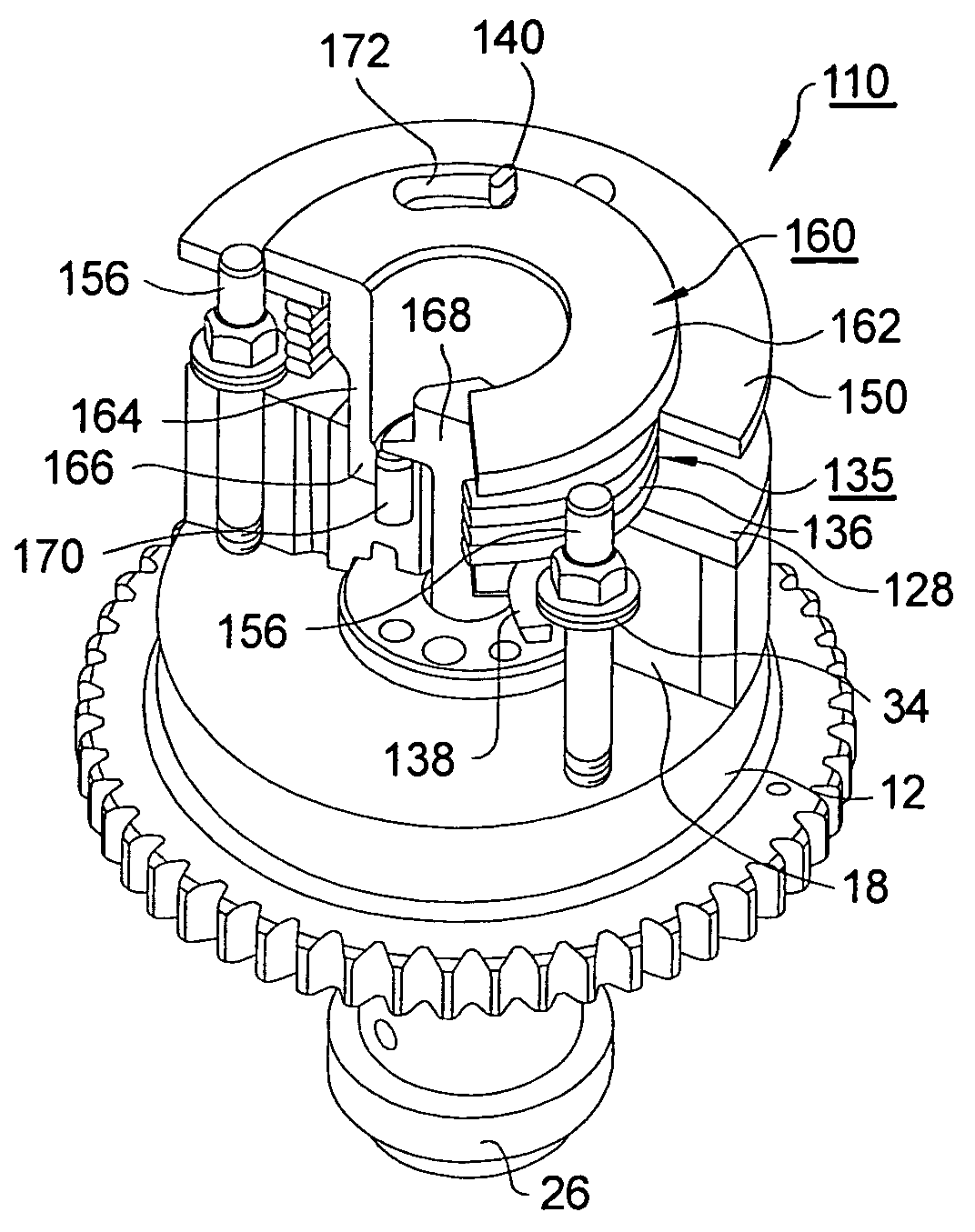

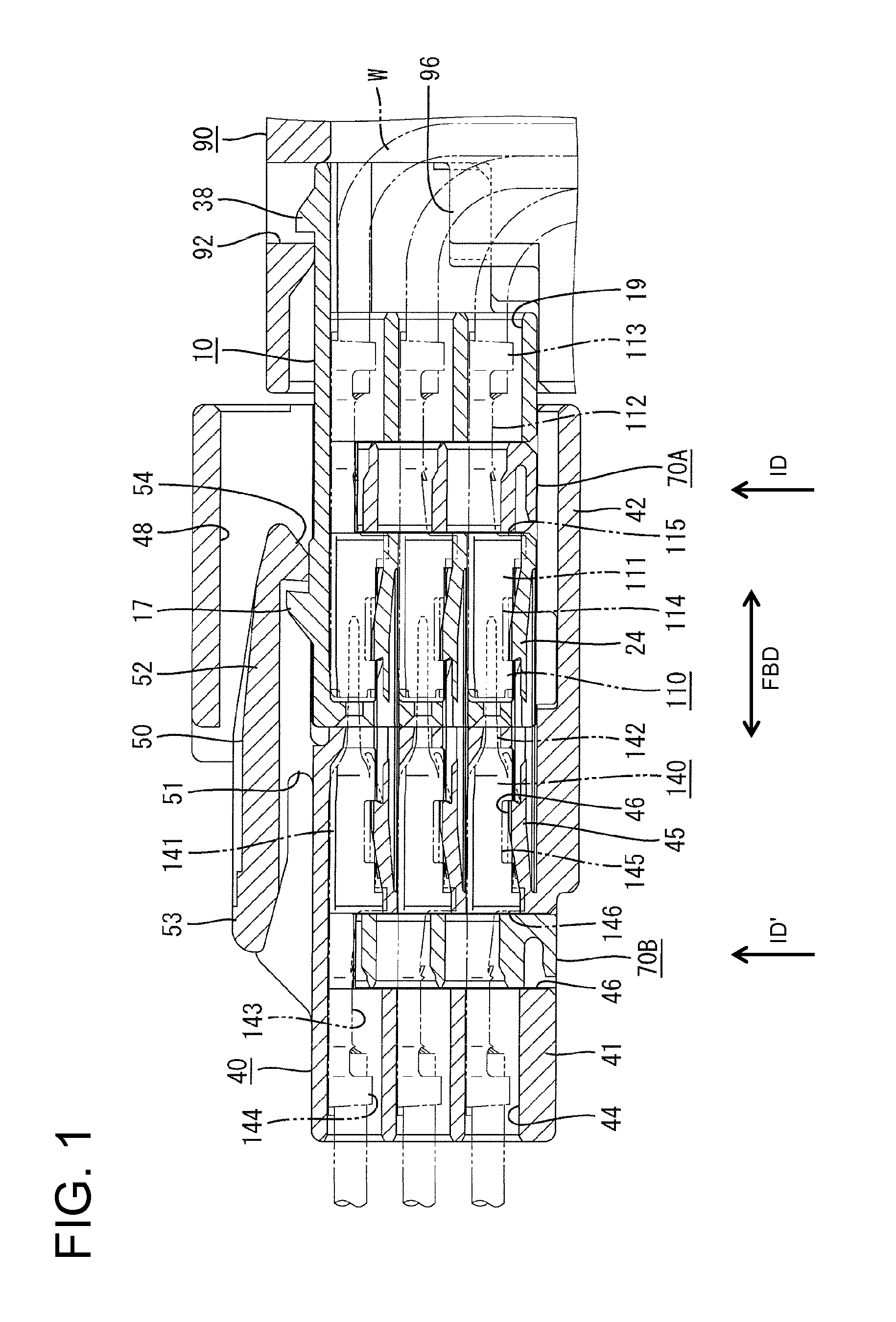

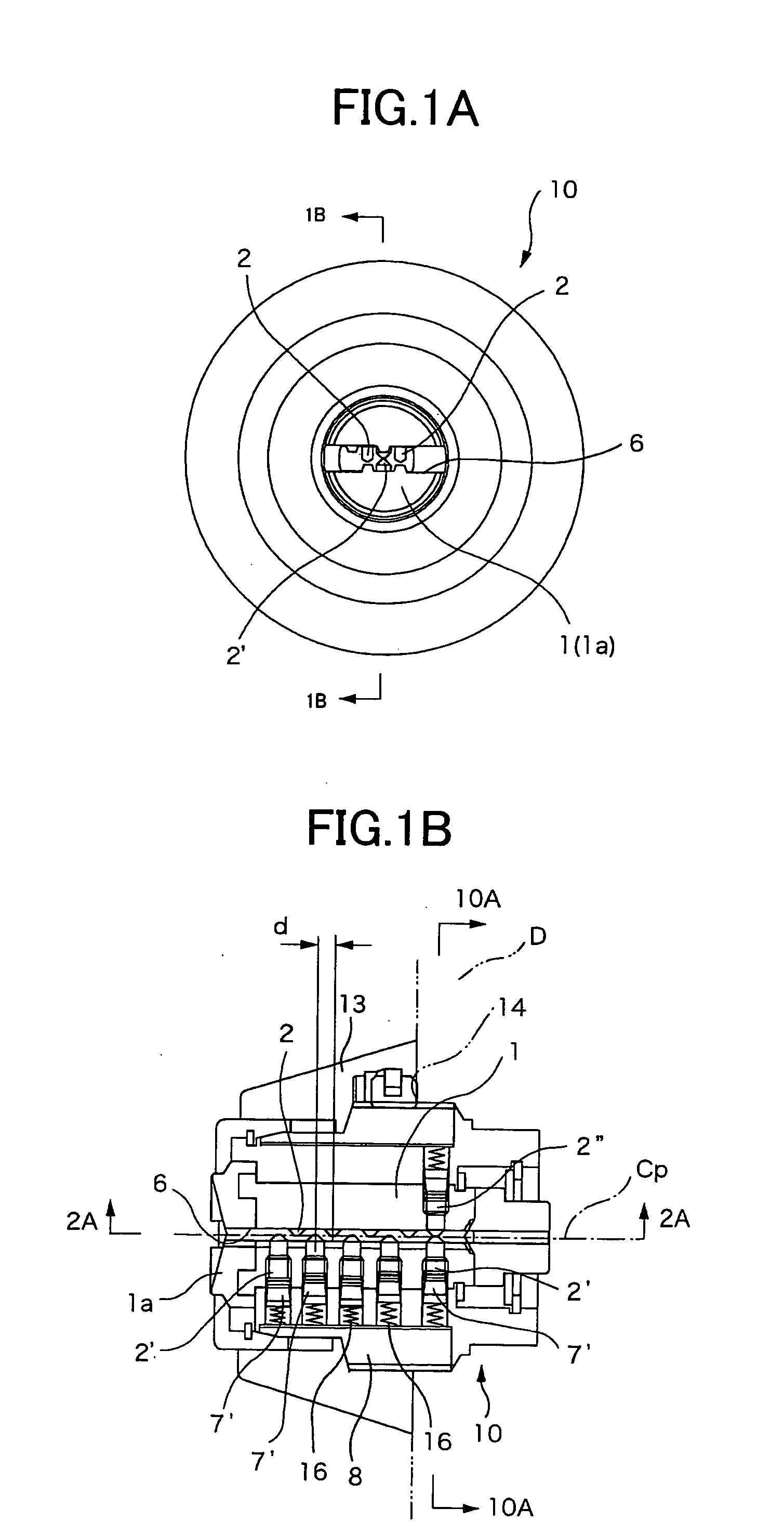

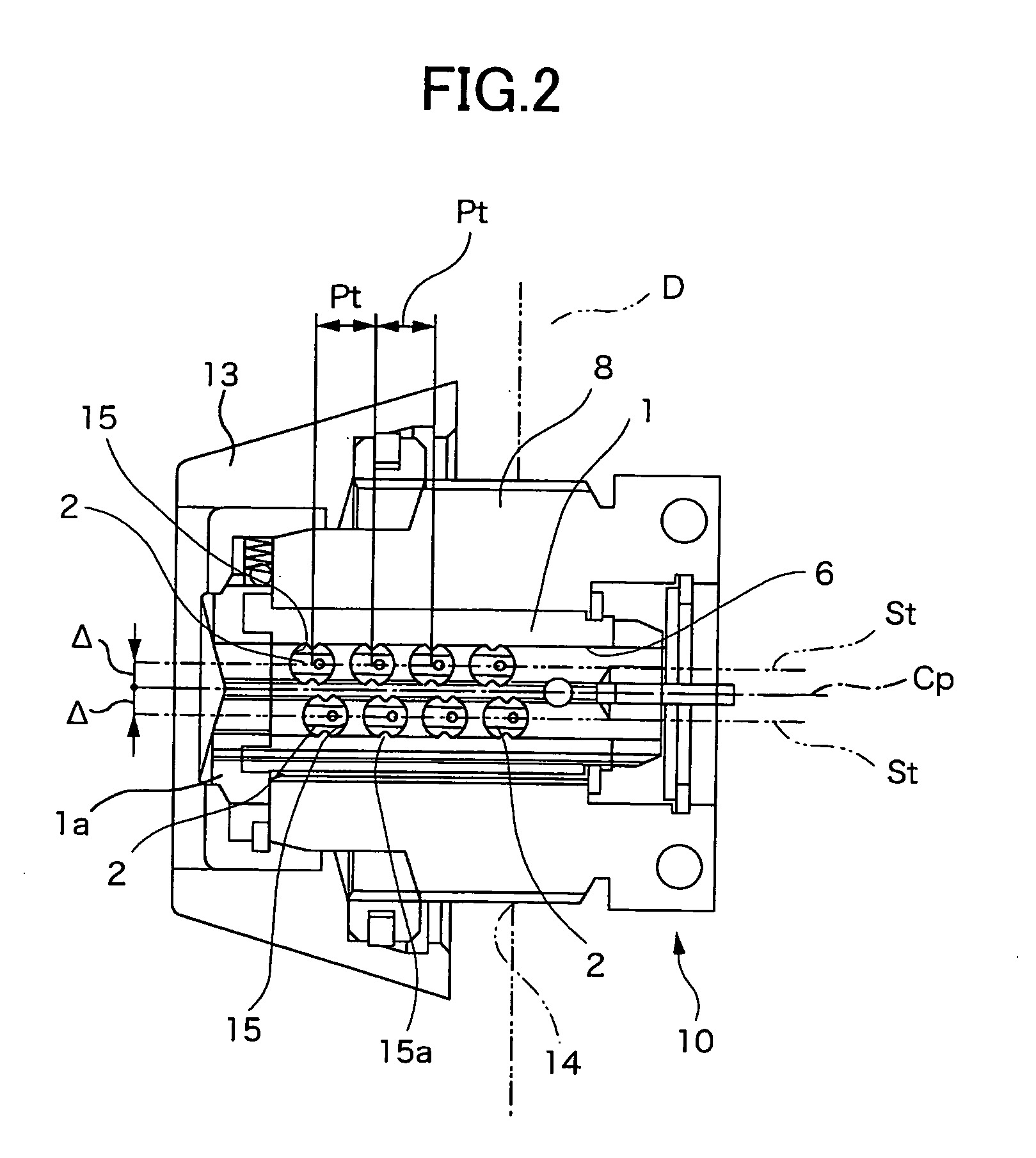

Vane-type cam phaser having dual rotor bias springs

ActiveUS20090235884A1High locking reliabilityAvoid distortionValve arrangementsYielding couplingCamTorsion spring

A vane-type camshaft phaser for varying the timing of combustion valves including a first torsional bias spring disposed on a cover plate spring guide and grounded to the cover plate and to a slot in a spring retainer to urge the rotor toward an intermediate locking position from any position retarded of the locking position. A second torsional bias spring also anchored to the cover plate and spring retainer urges the rotor in the advance direction over the full range of phaser authority to compensate for added camshaft torque loads imposed by non-valve actuating functions such as driving a mechanical fuel pump.

Owner:DELPHI TECH IP LTD

Vane-type cam phaser having bias spring system to assist intermediate position pin locking

ActiveUS7614370B2High locking reliabilityEasy to installYielding couplingCouplings for rigid shaftsEngineeringSprocket

A vane-type camshaft phaser for varying the timing of combustion valves in an internal combustion engine includes a seat formed in the sprocket at the appropriate position of intermediate rotation and a locking pin slidably disposed in a vane of the rotor for engaging the seat to lock the rotor at the intermediate position. A bias spring system disposed on a cover plate urges the rotor toward the locking position from any position retarded of the locking position. A first spring system embodiment comprises a pair of compression spring assemblies. A second spring system embodiment comprises an internal torsion spring. In each embodiment, the phaser may be assembled without having the spring system coupled to the rotor, thereby overcoming a rotor cocking problem inherent in prior art phasers, assuring reliable mounting of an assembled phaser onto an engine camshaft.

Owner:DELPHI TECH IP LTD

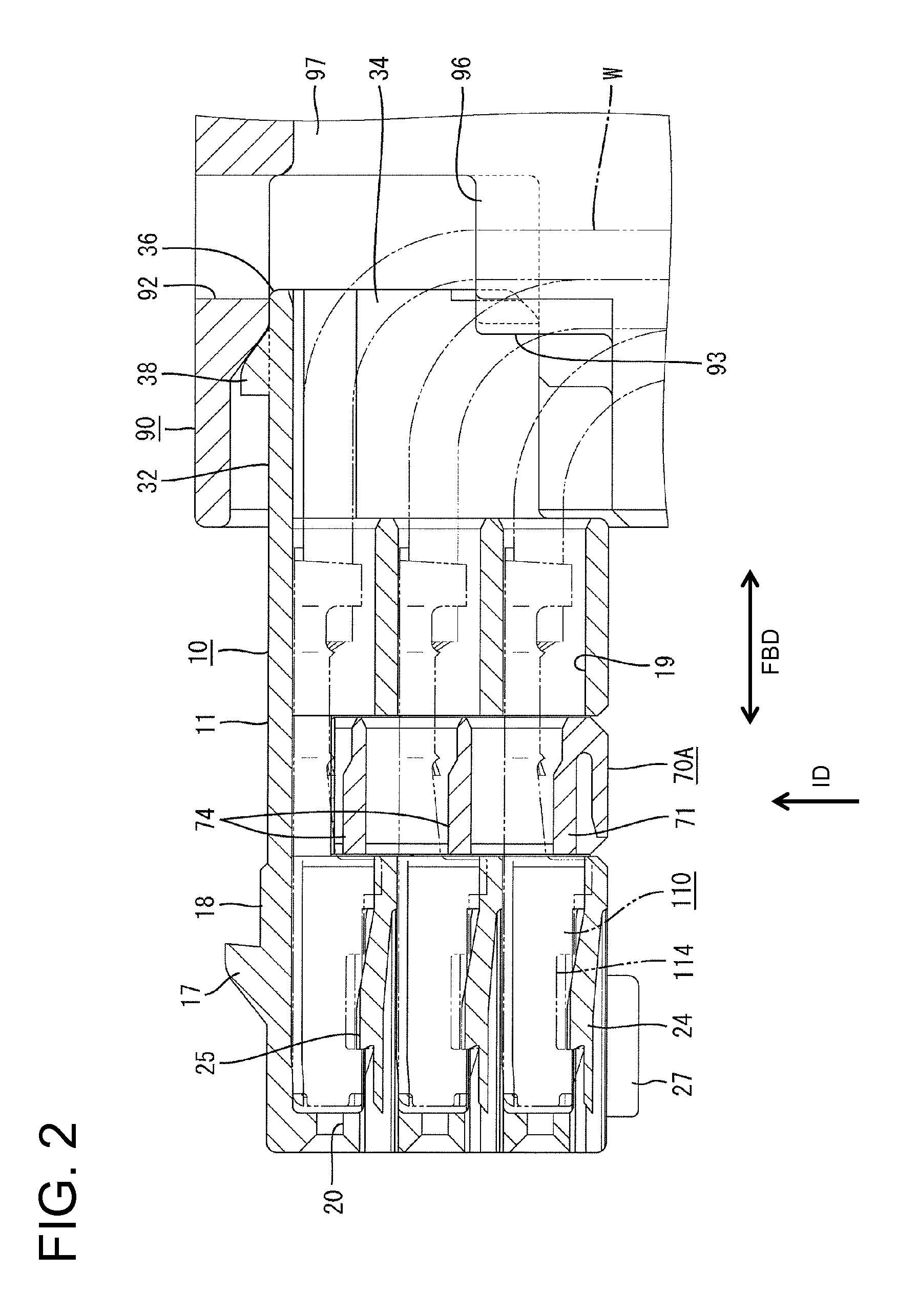

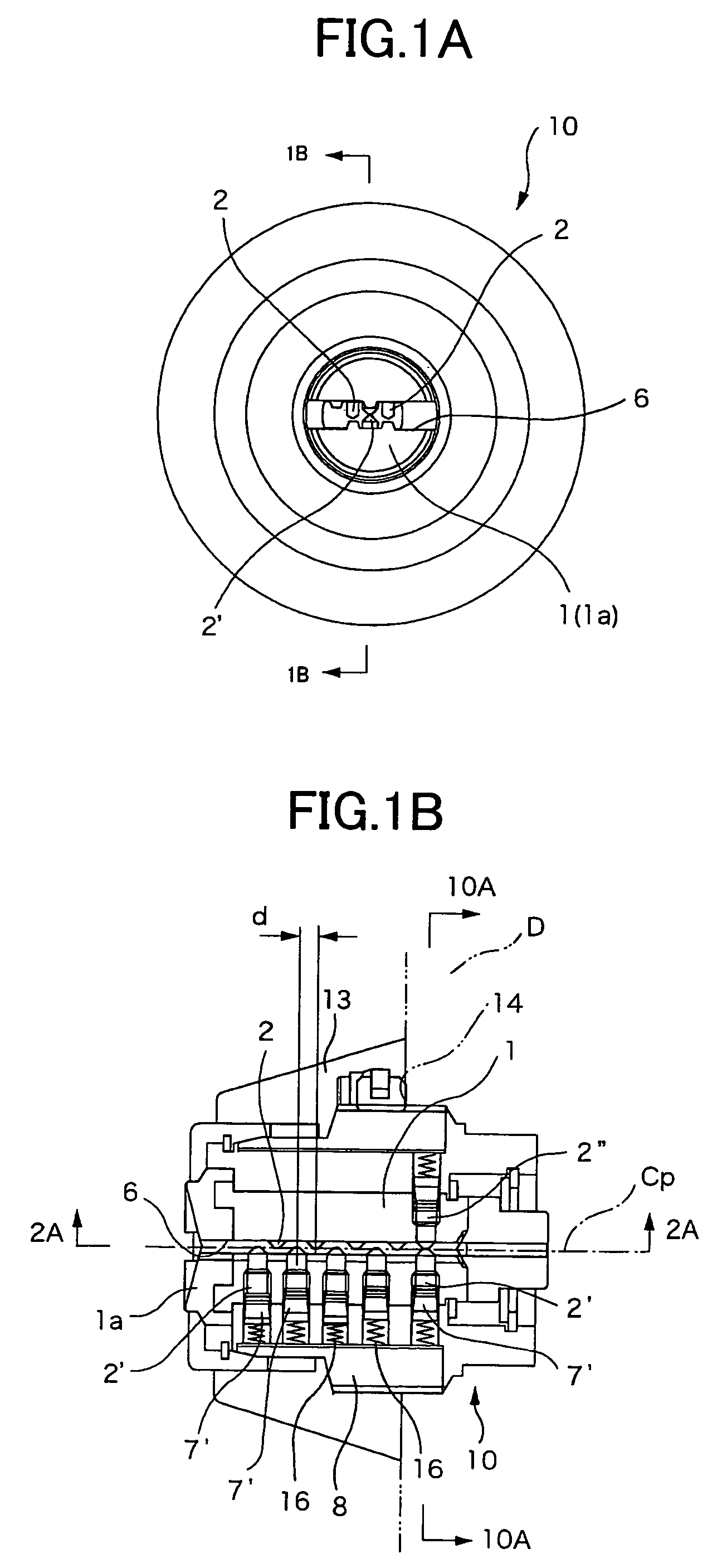

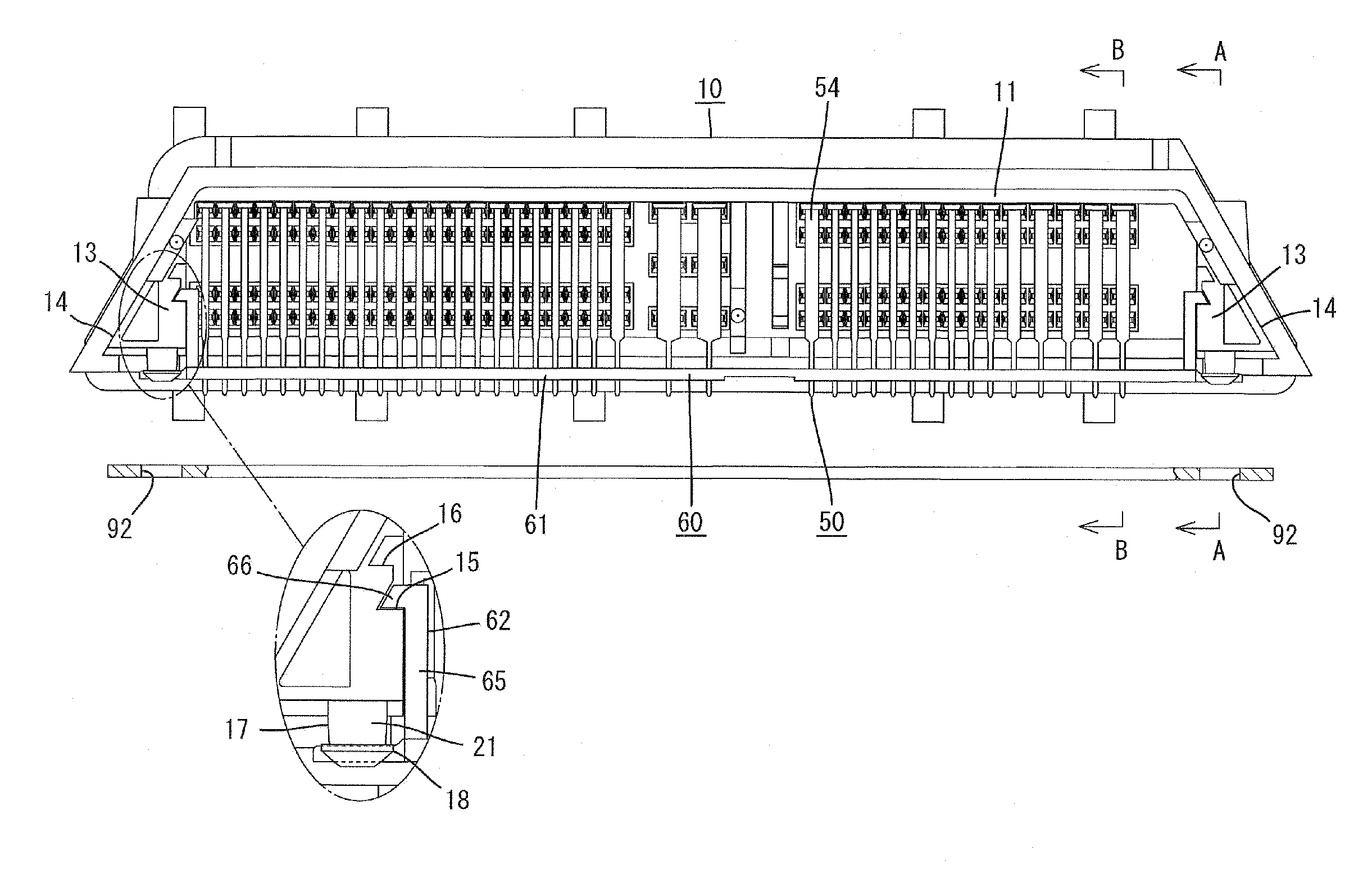

Connector

ActiveUS8052489B2Reduce volumeAvoid misconnectionVehicle connectorsIncorrect coupling preventionEngineeringMechanical engineering

A connector is provided with a pair of female and male housings (10, 40) connectable with each other. The female housing (10) includes a block-shaped housing main body (11) and the male housing (40) includes a receptacle (42) having an inner surface shape conforming to outer surfaces of the housing main body (11). Corners on the outer surface of the housing main body diagonal to each other are bevels (14, 15) with different shapes. The bevels (14, 15) include moderately inclined portions (14) located at the opposite ends of the upper surface of the housing main body (11) and inclined at a relatively large angle with respect to a height direction and steeply inclined portions (15) located at the opposite ends of the lower surface of the housing main body (11) and inclined at a relatively small angle with respect to the height direction.

Owner:SUMITOMO WIRING SYST LTD

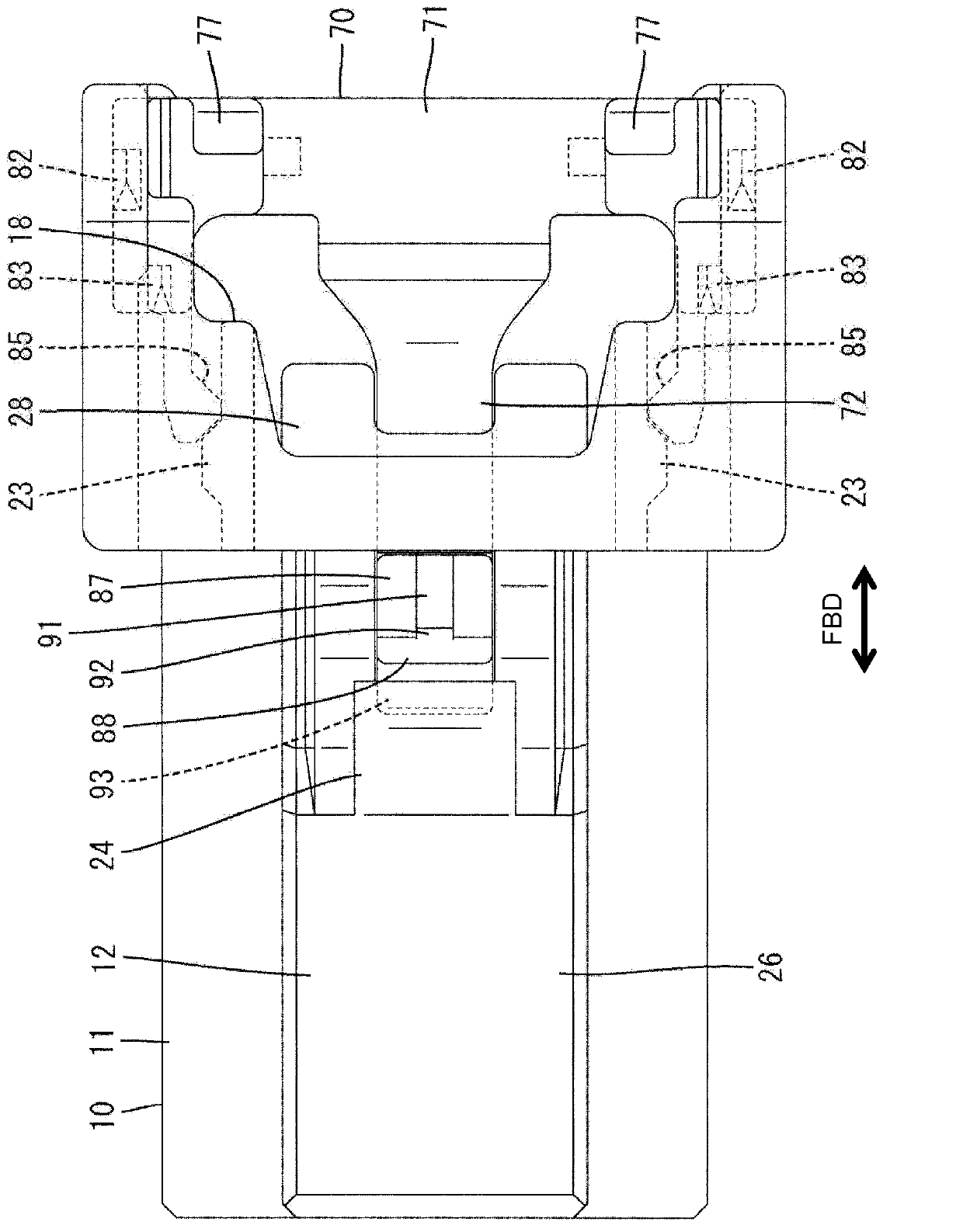

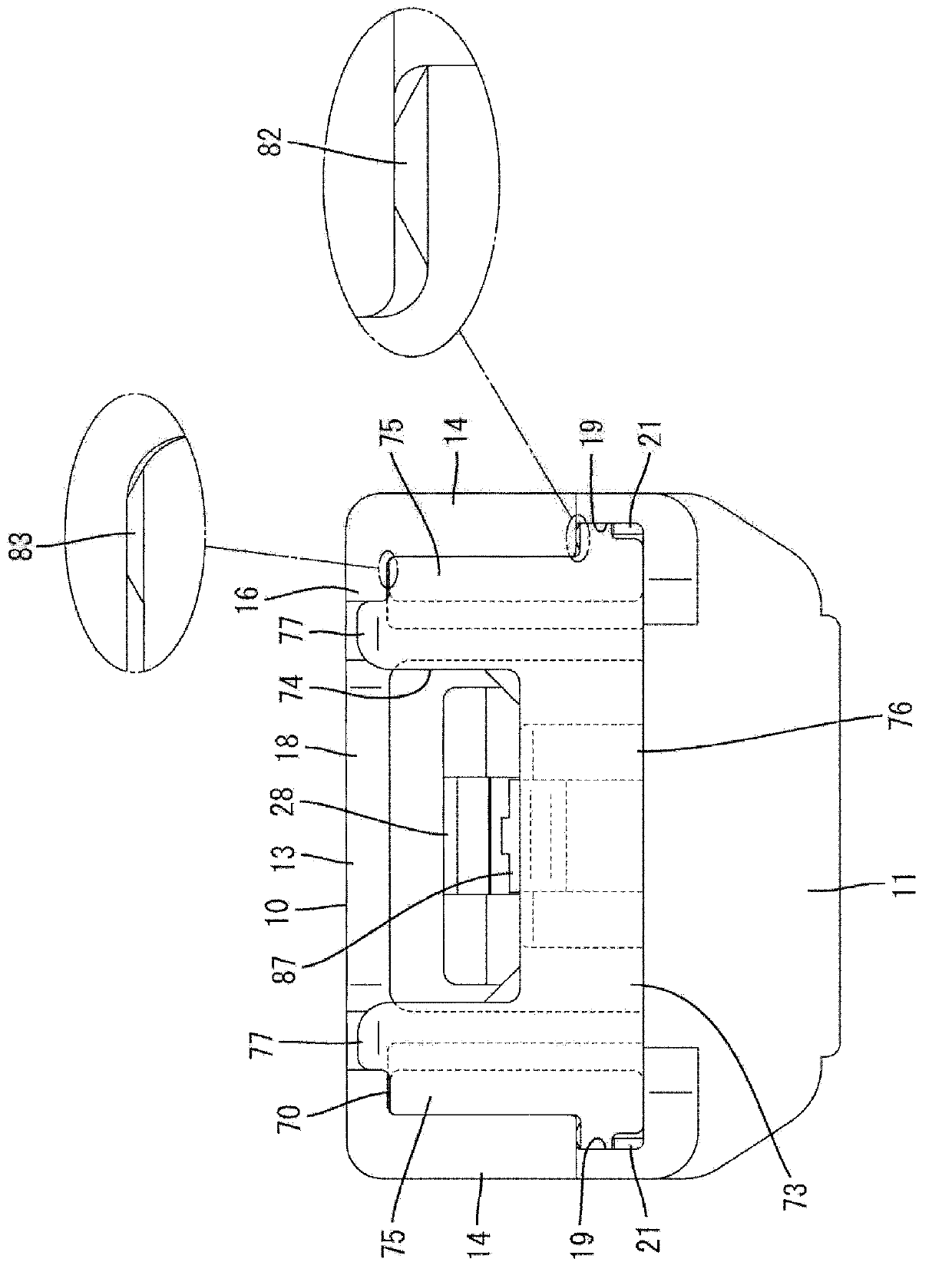

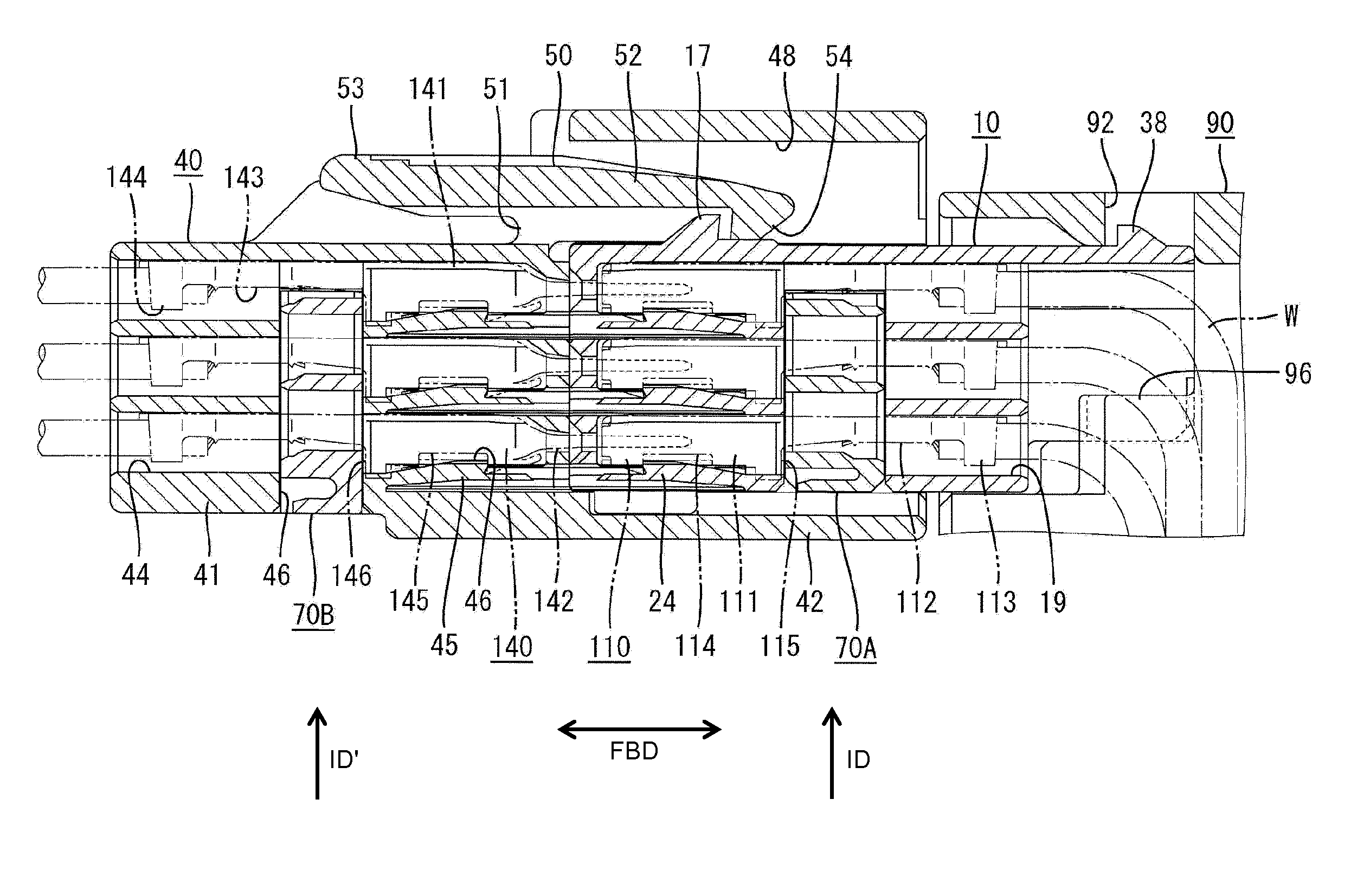

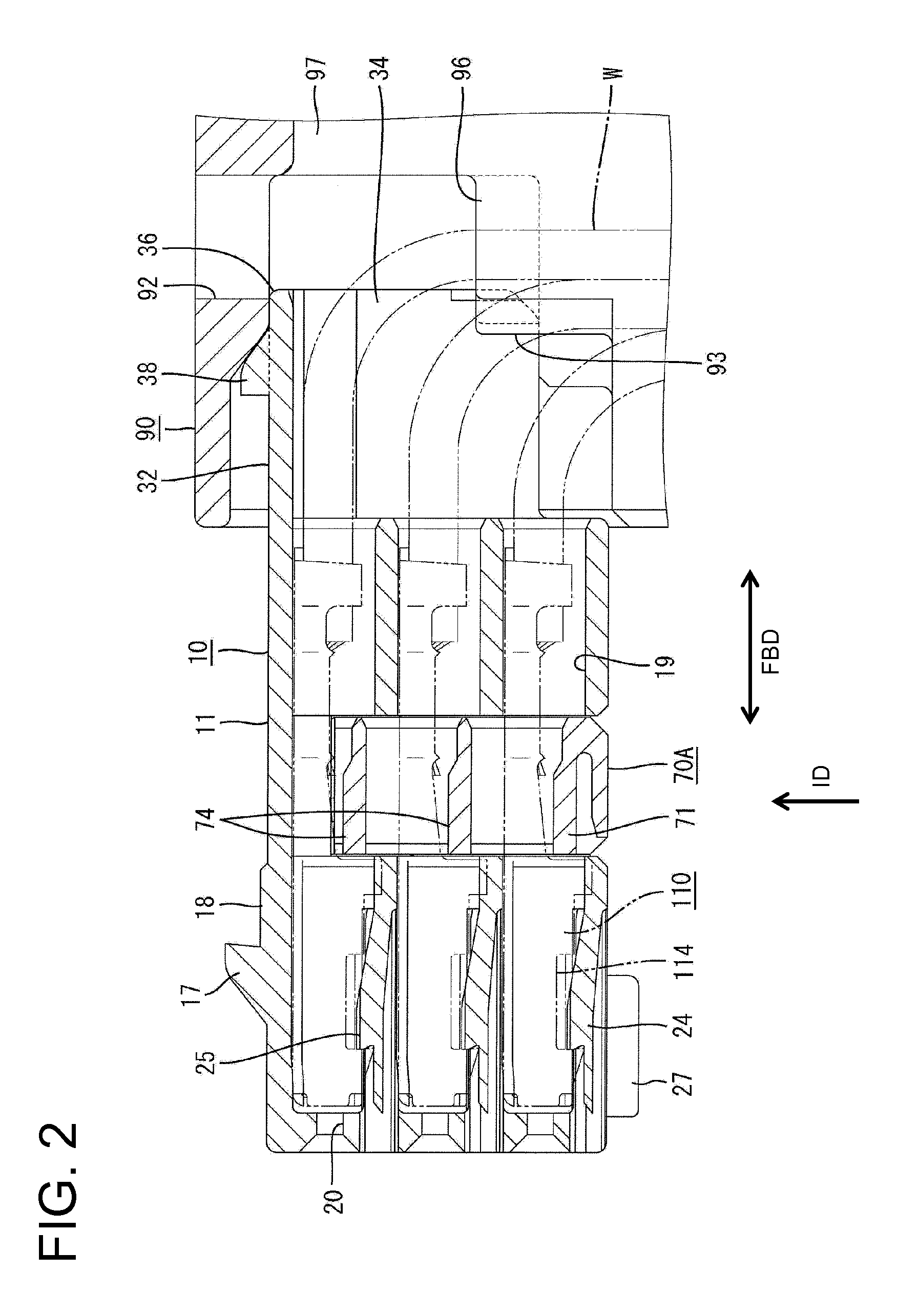

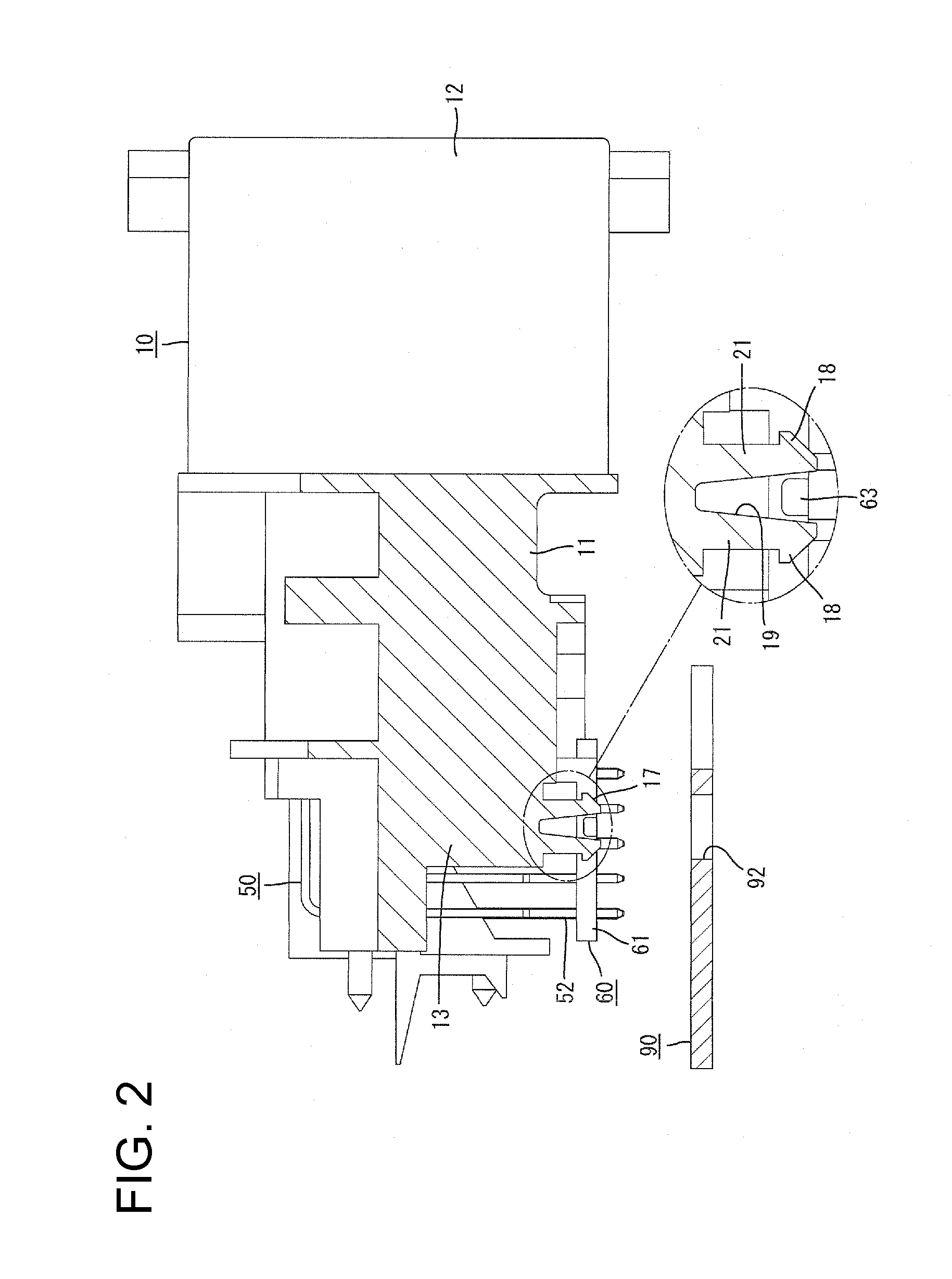

Connector, connector assembly and assembling method therefor

ActiveCN103311730AHigh locking reliabilityCoupling device engaging/disengagingCoupling device detailsCantileverMechanical engineering

An object of the present invention is to improve locking reliability. A lock arm 12 extends backward in a cantilever manner from a front end part of a housing main body 11. The lock arm 12 includes an accommodating recess 31 which is open toward a deformation space 25 therefor and toward the back. When the housing main body 11 is properly connected to a mating housing 50 and a detecting member 70 is pushed from a standby position to a detection position, a part of the detecting member 70 is inserted into the accommodating recess 31.

Owner:SUMITOMO WIRING SYST LTD

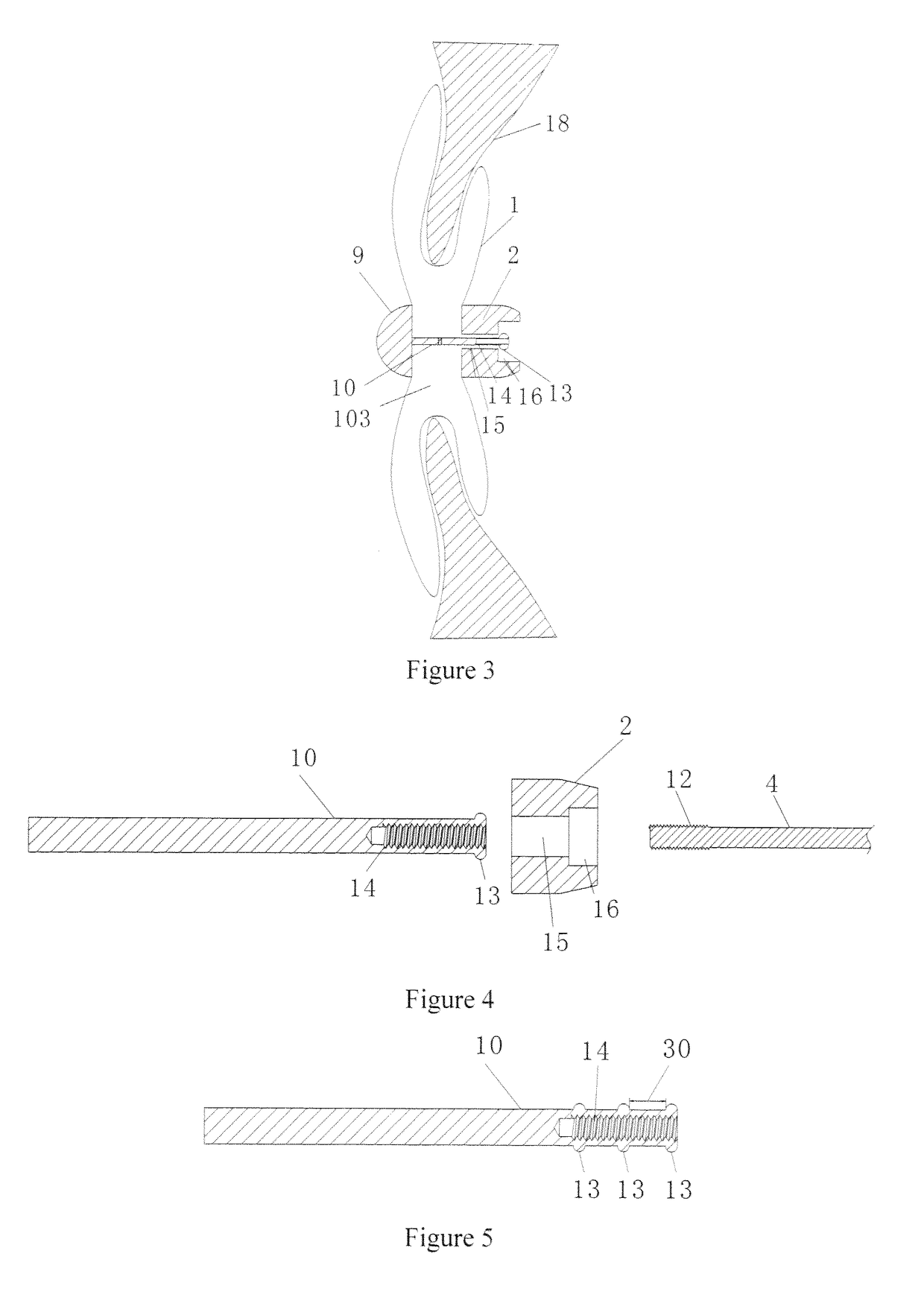

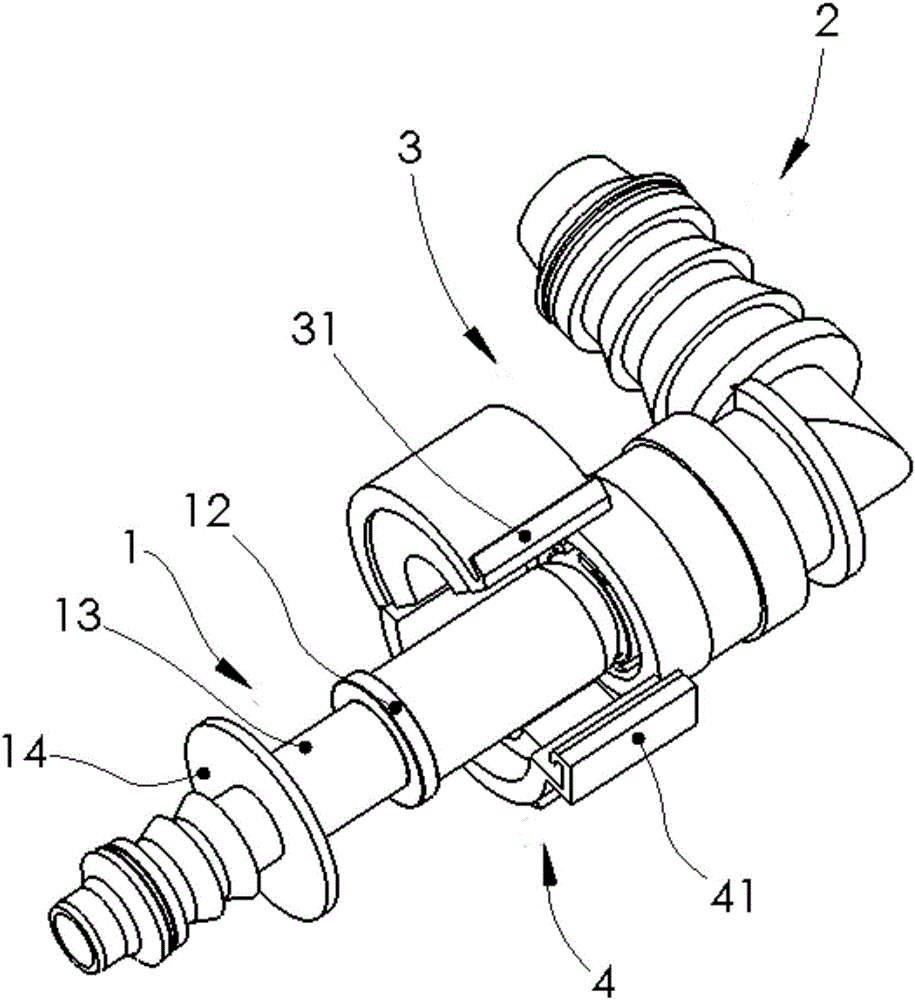

Occluder and Occlusion Device

The present invention relates to an occluder (100), comprising a meshed occlusion body (I) provided with a cavity (103), and a proximal hub (2), as well as a locking member (10) and a stopping member (13) both of which are located in the cavity (103). The distal end of the locking member (10) is connected to the distal end of the occlusion body (1). The stopping member (13) is disposed at the proximal end of the locking member (10). The proximal occluder head (2) is provided with a locking hole (15) in communication with the cavity (103). The radial size of the stopping member (13) is slightly larger than the diameter of the locking hole (15). The radial size of the locking member (10) is smaller than the diameter of the locking hole (15), and at least one of the proximal occluder head (2) and the stopping member (13) is an elastic member. An occlusion device comprises the occluder (100), a hollow delivery mechanism (200) and a traction member (4). The distal end of the traction member (4) is detachably connected to the proximal end of the locking member (10) of the occluder (100) after extending through the distal end of the delivery mechanism (200). The occlusion device has a simple locking structure, and simplifies the manufacturing process and the locking operation.

Owner:LIFETECH SCIENTIFIC (SHENZHEN) CO LTD

Cylinder lock device

InactiveUS20060042335A1Increase different lock codeIncreasing different locking codeKeysCylinder locksEngineeringConical surface

Tumbler pins 2 are movably housed in a plug 1. A locked / unlocked state is determined by the turning position on the moving direction center axes of the tumbler pins 2. An unlocking key 4 to be inserted into the plug 1 is provided with unlocking code forming recesses 3 for determining the turning positions of the tumbler pins at code decision positions. The tumbler pins 2 are provided at their leading end portions with drive portions 5, which have slope sides of conical faces gradually reduced in diameter toward the leading ends and having rotational centers offset from the moving direction center axes. The side wall faces of the unlocking code forming recesses 3 are formed of conical faces having rotational centers substantially aligned with those of the conical faces forming the slope sides of the drive portions 5. At code decision positions, the slope sides of the drive portions 5 are forced to contact with the side wall faces of the unlocking code forming recesses 3 thereby to determine the turning positions of the tumbler pins2.

Owner:ALPHA

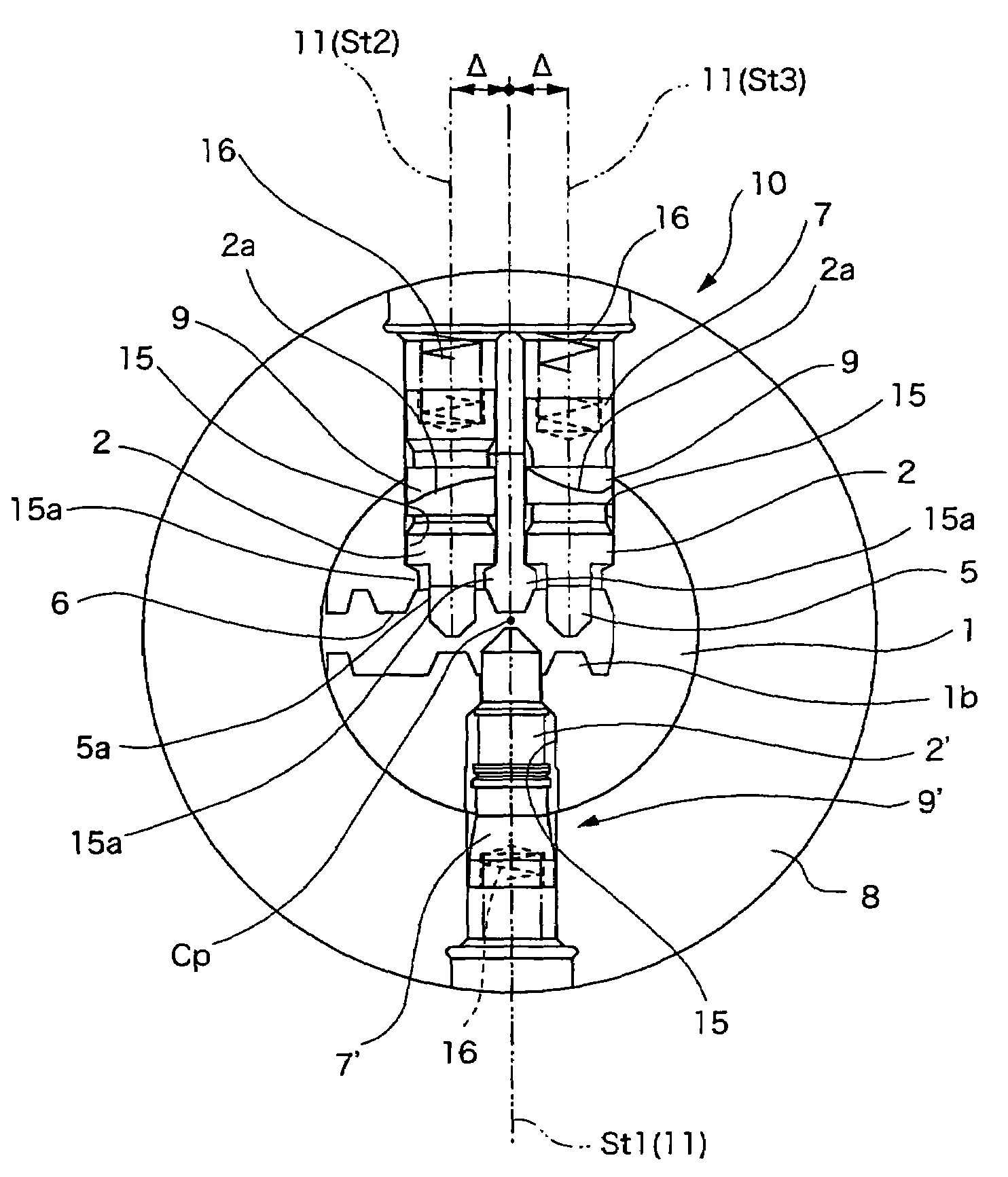

Connector

ActiveUS20100136819A1Small thicknessLess rigidEngagement/disengagement of coupling partsVehicle connectorsEngineeringSurface shape

A connector is provided with a pair of female and male housings (10, 40) connectable with each other. The female housing (10) includes a block-shaped housing main body (11) and the male housing (40) includes a receptacle (42) having an inner surface shape conforming to outer surfaces of the housing main body (11). Corners on the outer surface of the housing main body diagonal to each other are bevels (14, 15) with different shapes. The bevels (14, 15) include moderately inclined portions (14) located at the opposite ends of the upper surface of the housing main body (11) and inclined at a relatively large angle with respect to a height direction and steeply inclined portions (15) located at the opposite ends of the lower surface of the housing main body (11) and inclined at a relatively small angle with respect to the height direction.

Owner:SUMITOMO WIRING SYST LTD

Cylinder lock device

InactiveUS7421869B2Increasing different locking codeIncrease height differenceKeysCylinder locksEngineeringConical surface

Tumbler pins 2 are movably housed in a plug 1. A locked / unlocked state is determined by the turning position on the moving direction center axes of the tumbler pins 2. An unlocking key 4 to be inserted into the plug 1 is provided with unlocking code forming recesses 3 for determining the turning positions of the tumbler pins at code decision positions. The tumbler pins 2 are provided at their leading end portions with drive portions 5, which have slope sides of conical faces gradually reduced in diameter toward the leading ends and having rotational centers offset from the moving direction center axes. The side wall faces of the unlocking code forming recesses 3 are formed of conical faces having rotational centers substantially aligned with those of the conical faces forming the slope sides of the drive portions 5. At code decision positions, the slope sides of the drive portions 5 are forced to contact with the side wall faces of the unlocking code forming recesses 3 thereby to determine the turning positions of the tumbler pins 2.

Owner:ALPHA

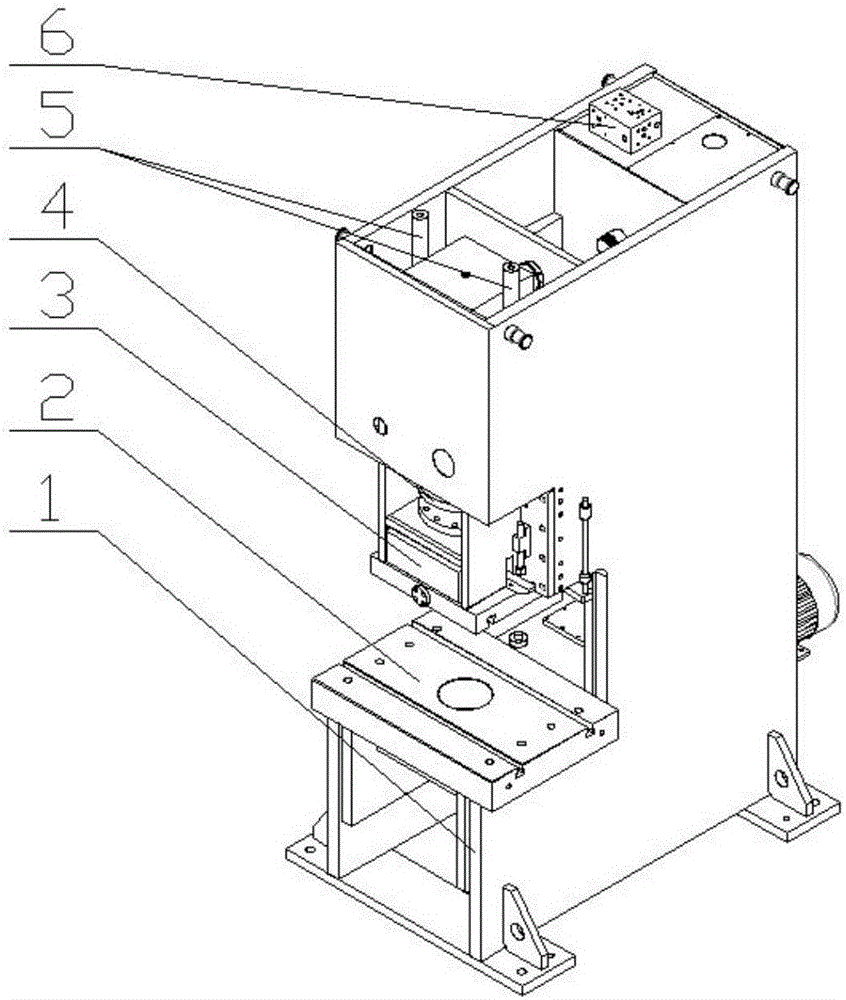

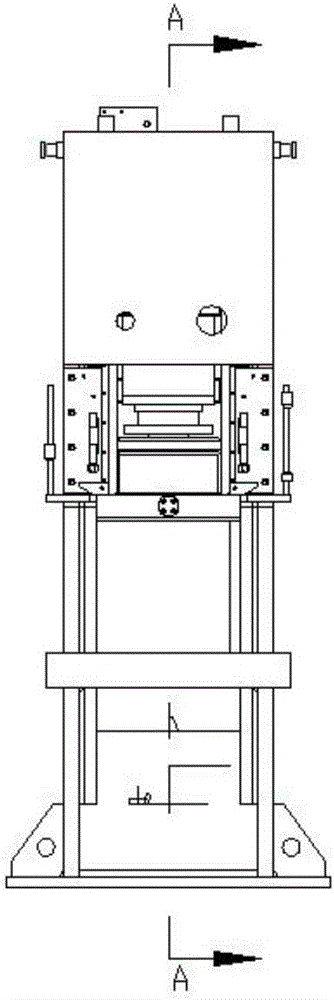

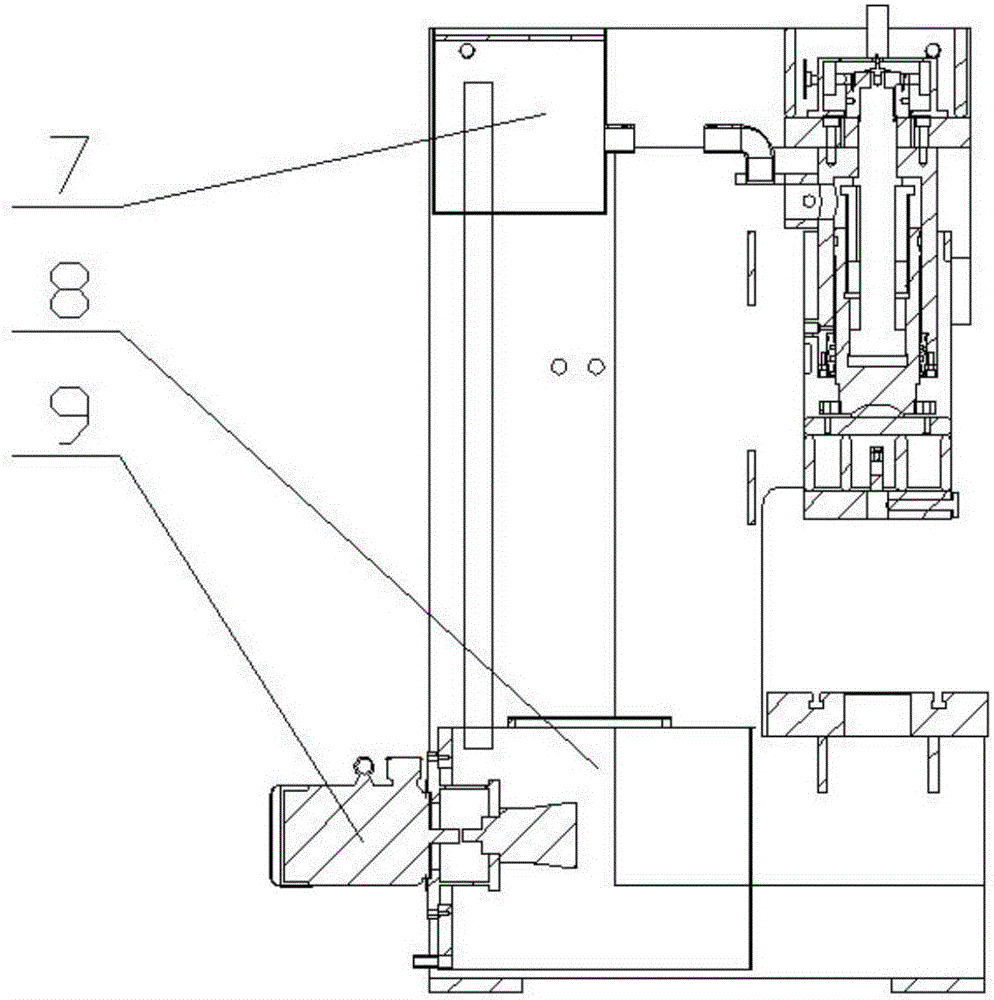

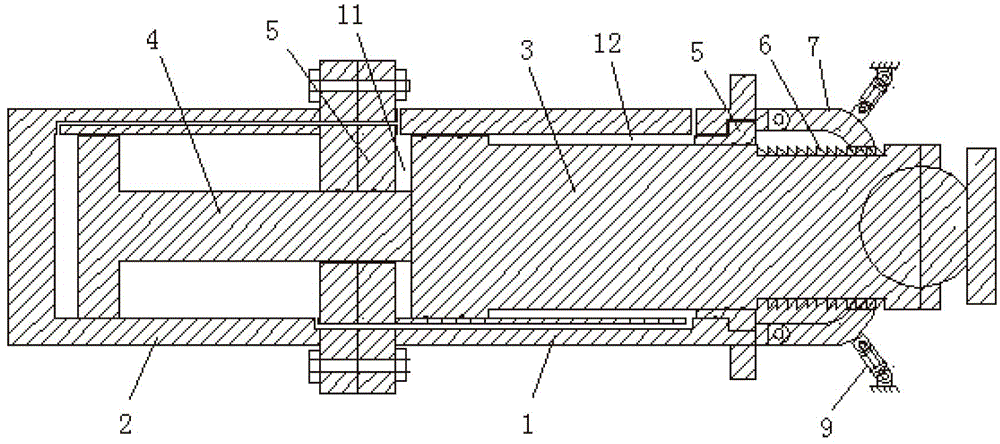

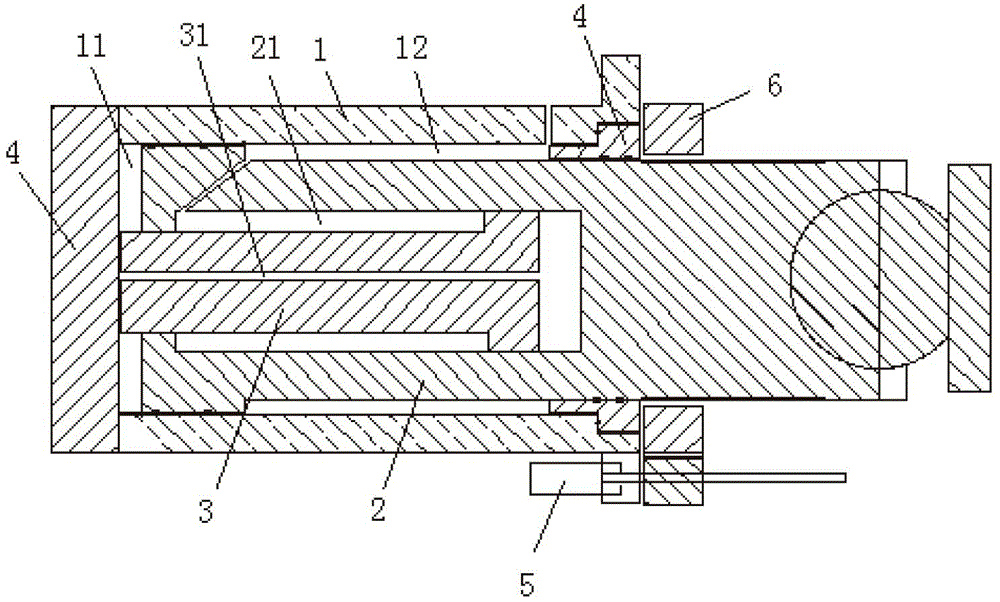

Stroke regulation built-in precise fast press machine, and oil cylinder and use method thereof

The invention discloses a stroke regulation built-in precise fast press machine, and an oil cylinder and a use method thereof, belongs to the field of a hydraulic press machine, and solves the problems of low production efficiency, high cost and complicated structure of a slide block regulating mechanism of the existing hydraulic press machine. The oil cylinder provided by the invention comprises a main cylinder piston rod and a main cylinder body, wherein one end of the main cylinder piston rod extends into the main cylinder body; one end extending into the main cylinder body is provided with a cavity; a regulating screw nut is arranged at the upper part of the inner wall of the cavity; the regulating screw nut and the inner wall of the cavity are connected through screw threads; a regulating screw rod is also arranged in the cavity; the lower end of the regulating screw rod extends into the cavity; the middle end passes through the regulating screw nut; the upper end extends out of the main cylinder body; the upper end, extending out of the main cylinder body, of the regulating screw rod is fixedly provided with a worm wheel; the middle end, penetrating through the regulating screw nut, of the regulating screw rod is provided with a key slot; a guide key is arranged on the corresponding regulating screw nut. The press machine, the oil cylinder and the use method have the advantages that the cost can be reduced; the production efficiency is improved; the applicability to various processing processes can be realized.

Owner:YANGZHOU ENG MACHINERY CO LTD

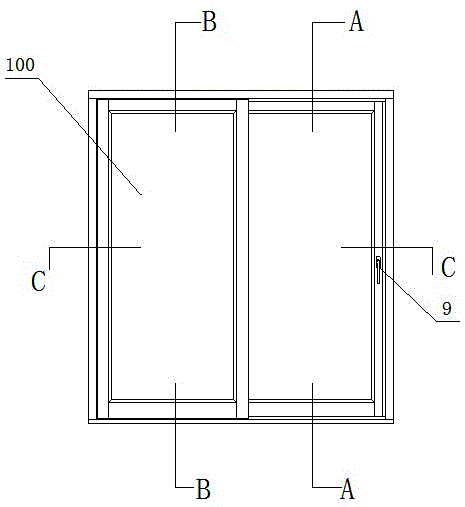

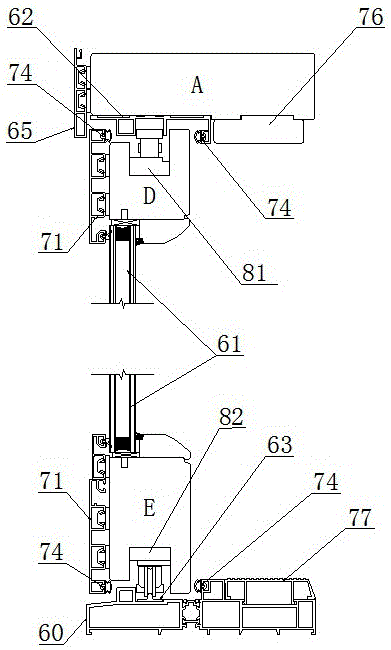

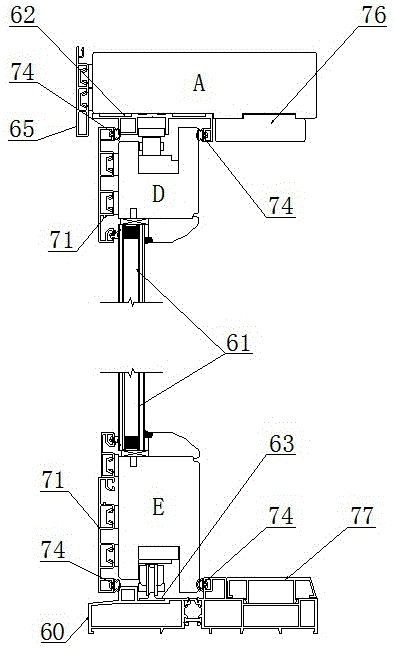

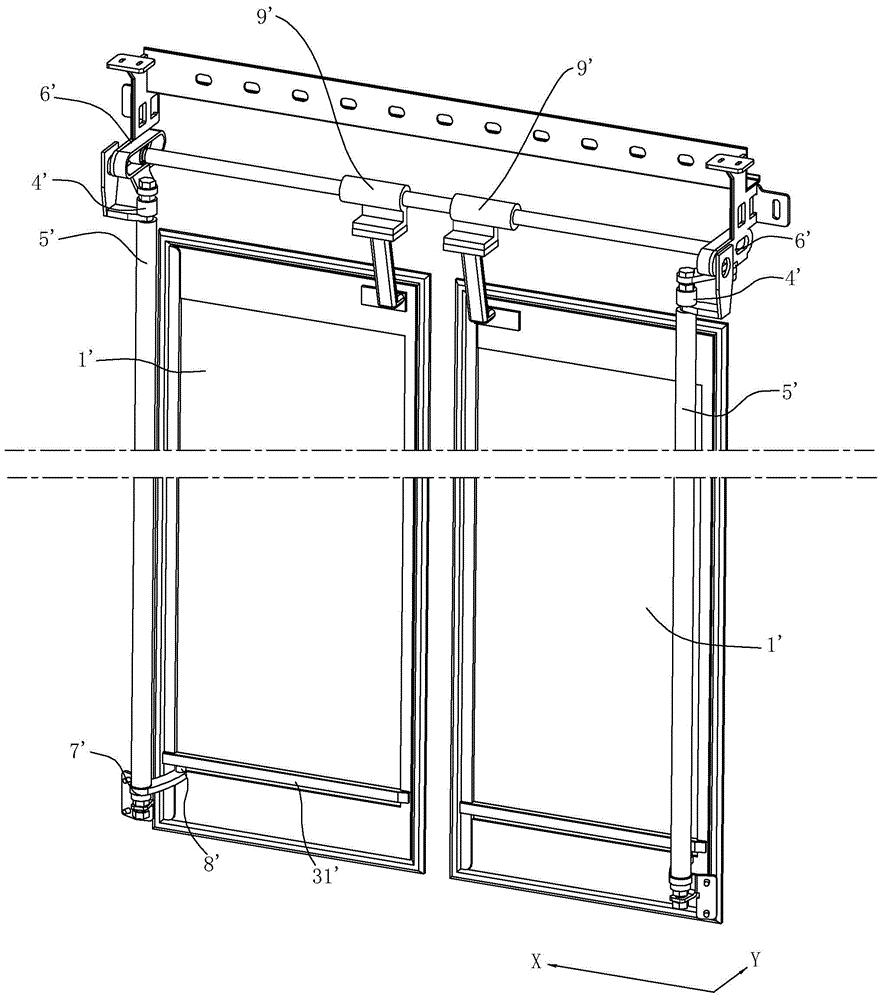

Pressing sliding door

ActiveCN105134021AImprove sealingImprove airtightnessBuilding locksSealing arrangementsSteering angleEngineering

The invention discloses a pressing sliding door. Sealing rubber strips are fixed to the lap joint gap of a sliding sash and a fixed sash and the contact gap of the sliding sash and a door frame. An upper set of drive hardware enables two or more sash hook locks, one steering angle driver, two or more upper pulley blocks, another steering angle driver and an upper lock head to be connected in series and then fixed to a handle driver through a drive batten. A lower set of drive hardware enables two or more lower pulley blocks, a third steering angle driver and a lower lock head to be connected in series and then fixed to the handle driver through a drive batten. Rotating handles and the two sets of drive hardware move in the handle direction. An upper sliding rail, a lower sliding rail, lock hooks of the sash hook locks and the lock heads are moved indoors from the outside of a room, so that the sliding sash tightly presses the sealing rubber strips located between the sliding sash and the fixed sash, between the sliding sash and an upper frame body or a lower frame body and between the sliding sash and a right frame body or a left frame body making contact with the sliding sash, and the lock hooks of the sash hook locks tightly hook locking blocks. The pressing sliding door is good in sealing effect, water tightness and air tightness are greatly improved, locking reliability is high and the service life is long.

Owner:HEBEI ORIENT SUNDAR WINDOW

Vehicle, steering system of vehicle, and adjustable steering column of vehicle

ActiveCN106976475ALarge locking forceHigh locking reliabilitySteering columnsSteering columnSteering system

The invention relates to a vehicle, a steering system of the vehicle, and an adjustable steering column of the vehicle. The adjustable steering column comprises a mounting support, an upper column tube and a locking and releasing control assembly, wherein the mounting support is used for being fixed to a vehicle body and is provided with clamping arms which are provided with first through holes; a fixing support is fixedly arranged on the outer wall of the upper column tube, used for being fixed to the clamping arms and provided with second through holes; the locking and releasing control assembly comprises a supporting rod penetrating through the first through holes and the second through holes, first adjusting pieces, second adjusting pieces, first friction pieces and limiting pieces, and the supporting rod is sequentially sleeved with the first adjusting pieces, the second adjusting pieces, the first friction pieces and the limiting pieces in the axial direction; the first adjusting pieces are fixed to the supporting rod, the supporting rod is sleeved with the second adjusting pieces and the first friction pieces in a spaced mode, the first friction pieces are provided with third through holes where the supporting rod can penetrate, and the limiting pieces are static relative to the supporting rod in the axial direction; and the clamping arms and the fixing support are oppositely arranged in the axial direction and located between the first friction pieces and the limiting pieces in the axial direction. Locking force of the adjustable steering column in the locked state is increased, and locking reliability of the steering column is improved.

Owner:SAIC MOTOR

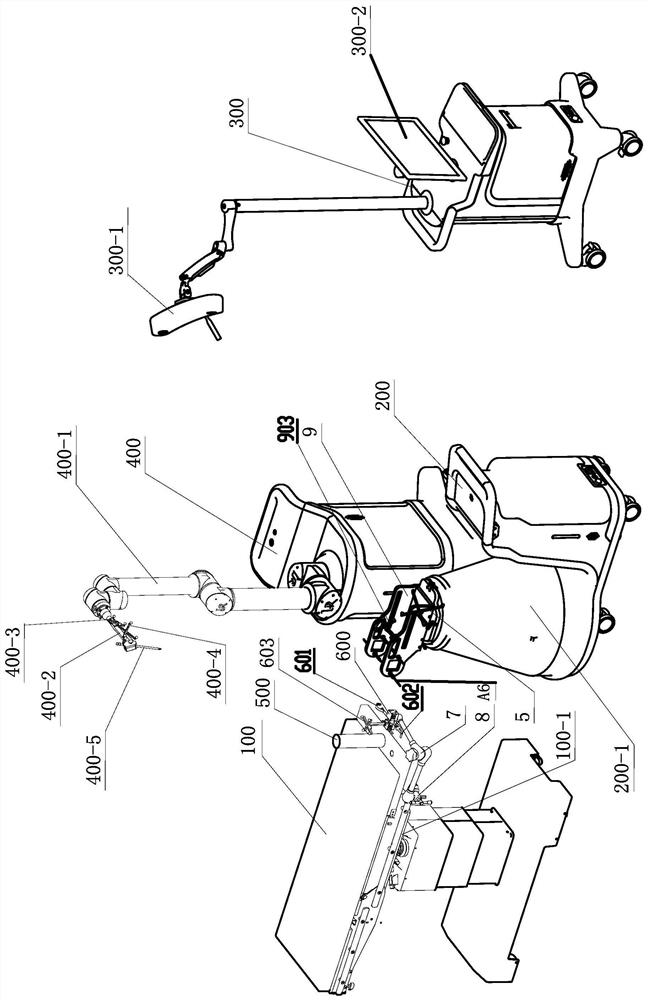

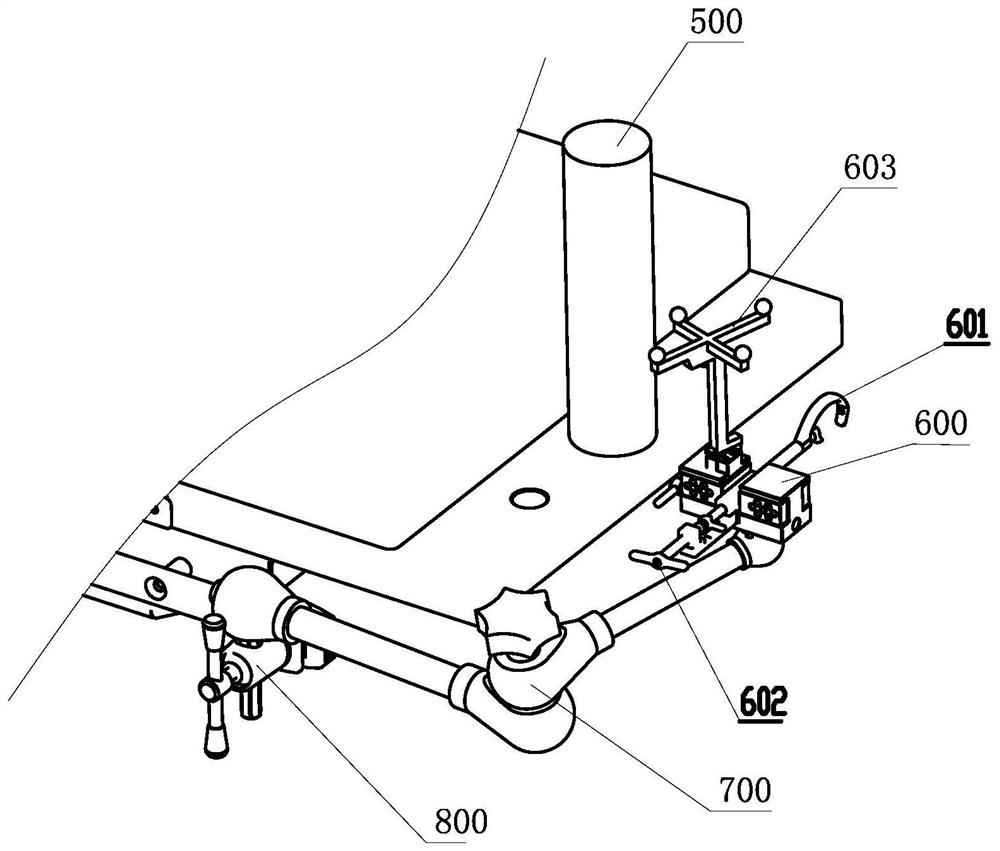

Orthopedic department reset positioning robot

ActiveCN112716603AAchieve positioningRealize resetInternal osteosythesisSurgical navigation systemsOrthopedics surgeryPhysical medicine and rehabilitation

The invention relates to an orthopedics department reset positioning robot, which solves the technical problem that an existing orthopedics department operation robot is low in reset precision during an operation and comprises a reset robot body, a navigation robot and a positioning robot body, the reset robot body comprises a reset platform, a far-end fixator and a far-end reference frame, and the far-end reference frame is fixed to the far-end fixator; the far-end fixator comprises a connecting base plate, a movable connecting plate, a first locking device, a reference frame, a first connecting side plate, a second connecting side plate, a first fixed sleeve, a second fixed sleeve, a fixing plate, a first fixed needle, a second fixed needle, a third fixed sleeve, a fourth fixed sleeve, a third fixed needle and a fourth fixed needle. The invention is widely applied to orthopedic surgery.

Owner:WEIHAI WEIGAO ORTHOPEDIC SURGICAL ROBOT CO LTD

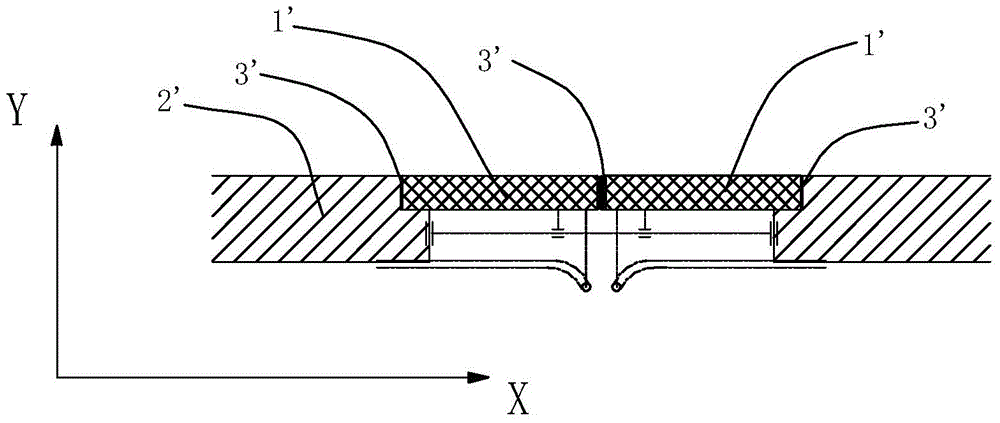

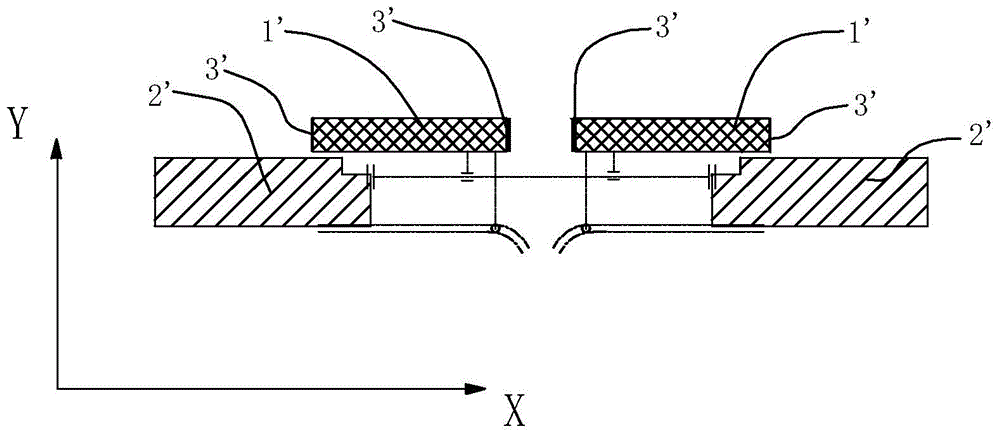

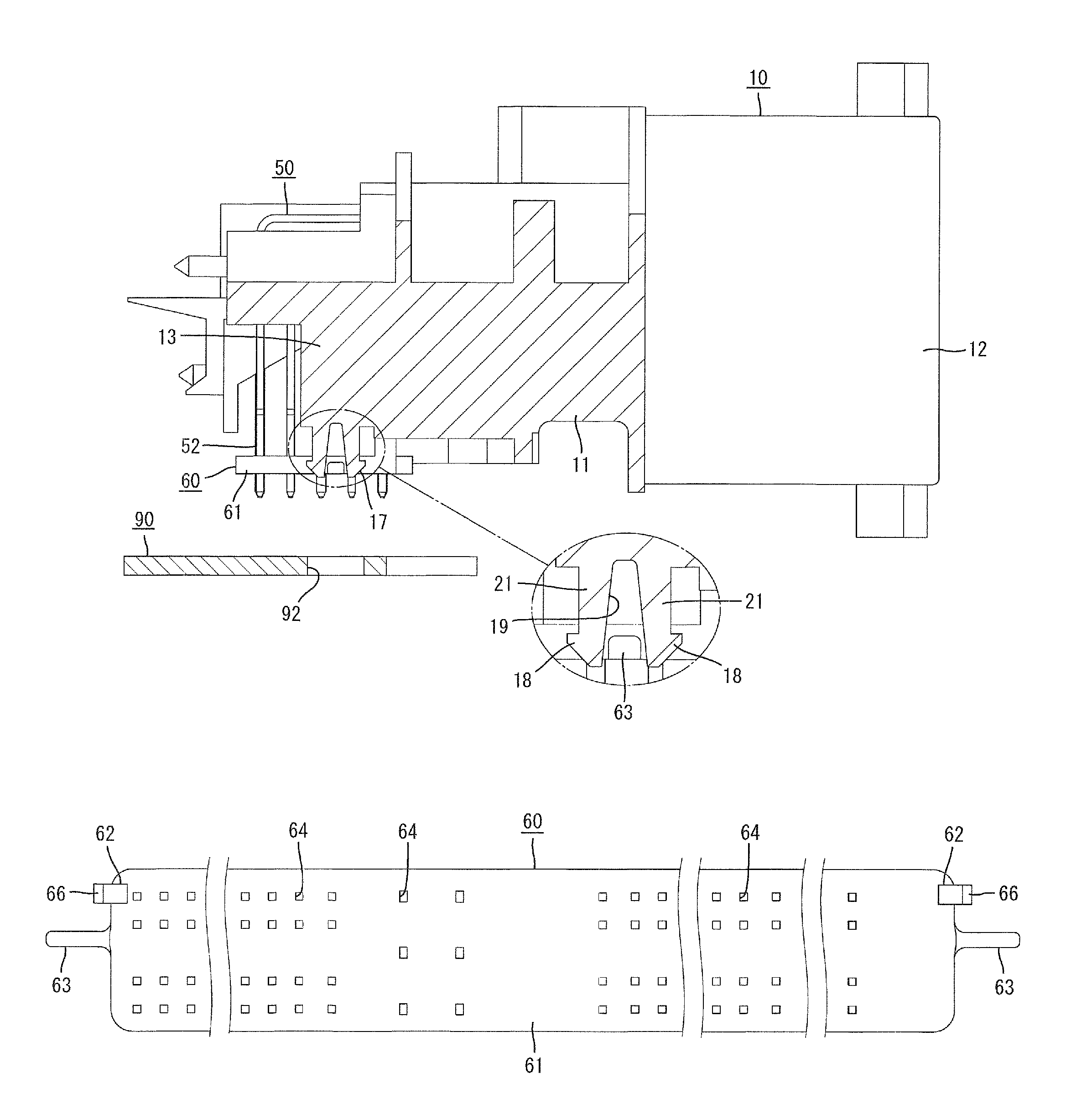

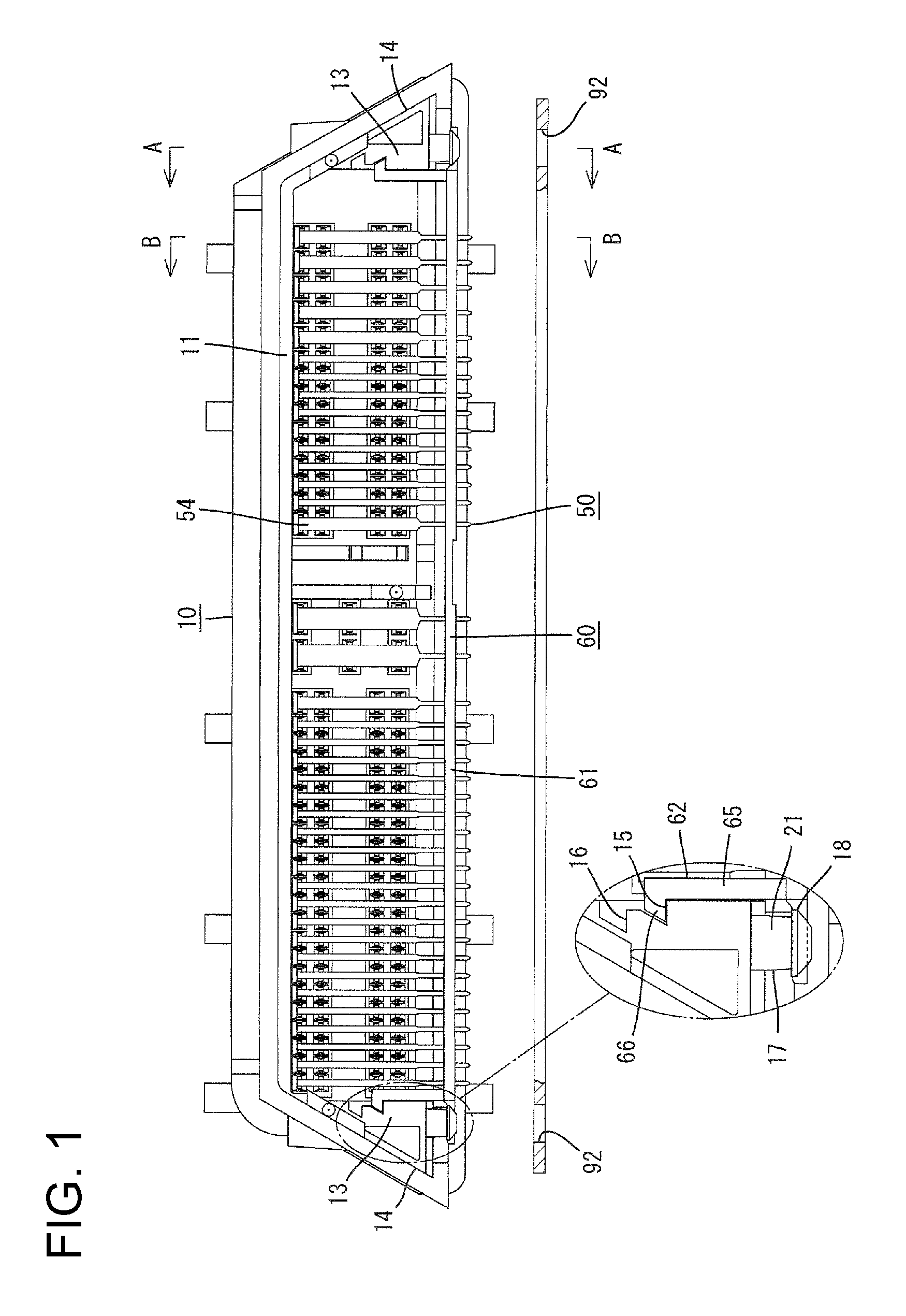

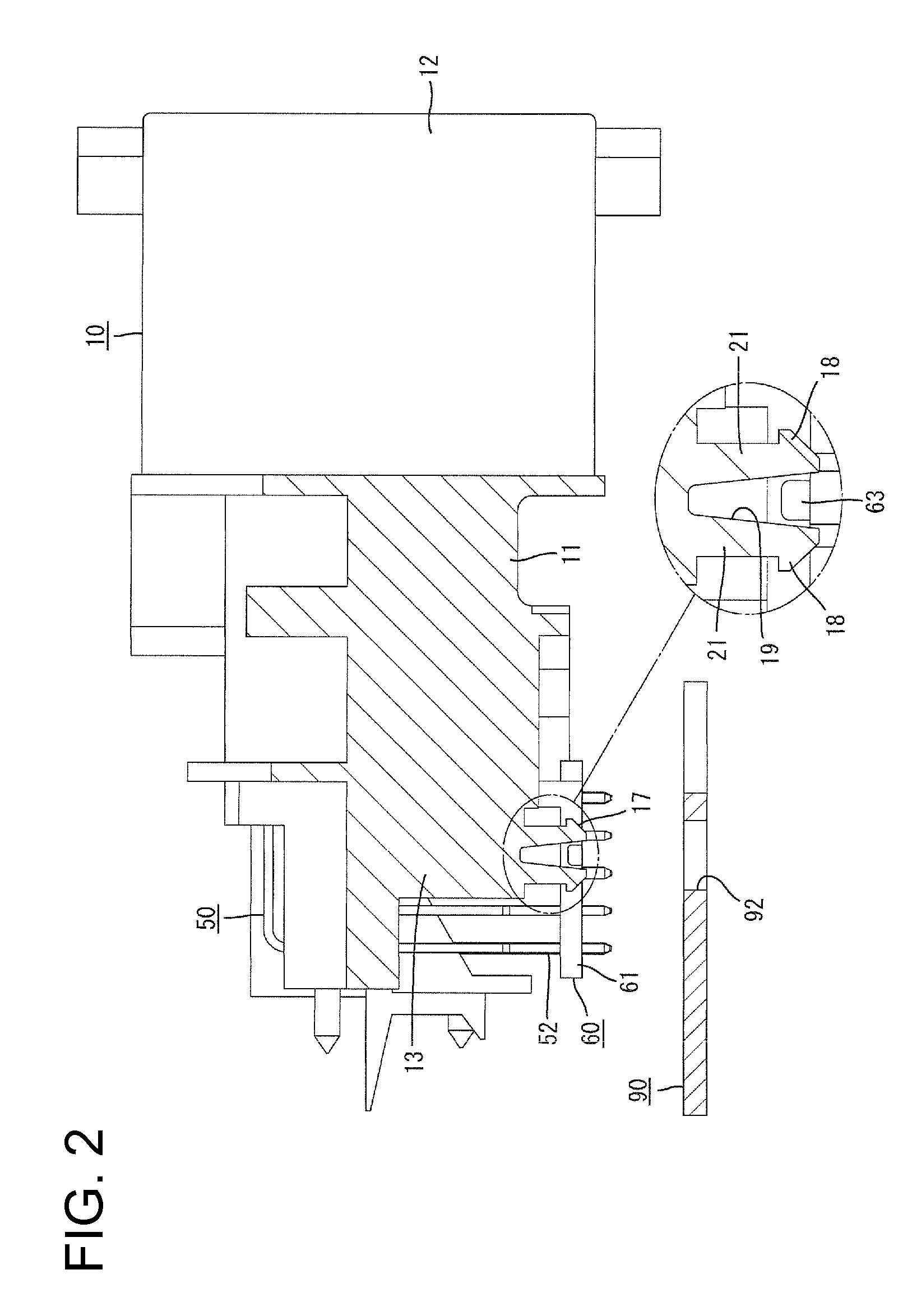

Board connector and method of mounting it

InactiveUS20110281462A1Avoid elastic deformationIncrease insertion spaceSecuring/insulating coupling contact membersPrinted circuitsEngineeringMechanical engineering

Owner:SUMITOMO WIRING SYST LTD

Combined-type self-locking-ratchet hydraulic oil cylinder

InactiveCN104100596AReliable lockingHigh outputFluid-pressure actuatorsPulp and paper industrySelf locking

The invention relates to the technical field of hydraulic power equipment, in particular to a combined-type self-locking-ratchet hydraulic oil cylinder, and aims to solve the technical problem that an existing oil cylinder is poor in locking reliability and low in output force. The combined-type self-locking-ratchet hydraulic oil cylinder comprises a main cylinder barrel, an auxiliary cylinder barrel, a main piston and an auxiliary piston, the main cylinder barrel and the auxiliary cylinder barrel are in left-right abutting connection, the main piston and the auxiliary piston are arranged in the main cylinder barrel and the auxiliary cylinder barrel respectively, inner cavities of the main cylinder barrel and the auxiliary cylinder barrel are separated by a left cylinder cover of the main cylinder barrel in a left-right manner, the right end of the main piston extends outside the main cylinder barrel, ratchet strips are formed on the periphery of the right portion of the main piston, ratchets matched with the ratchet strips are arranged on the main cylinder barrel in a pivoted manner, and the auxiliary piston is coaxial with the main piston and closely abutted against the left end of the same. The combined-type self-locking-ratchet hydraulic oil cylinder is reliable in locking and high in output force.

Owner:SHANGHAI HORIZON EQUIP ENG

Split vehicle fuel pipe quick joint

The invention discloses a split vehicle fuel pipe quick joint. The split vehicle fuel pipe quick joint comprises a male joint and a female joint; the male joint is a top-bottom communicated hollow structure; the female joint includes a female joint connecting pipe, a latch structure and a second hose connecting part; the latch structure is arranged at the front end of the female joint connecting pipe, and includes an upper cover body, a lower cover body, an upper latch and a lower latch; the upper cover body and the lower cover body are both semicircular, and are buckled with each other; the lower cover body is fixedly mounted at the front end of the female joint connecting pipe; a rotating shaft is arranged at the left end of the upper cover body, and is rotationally mounted at the left end of the lower cover body; the upper latch is arranged at the right end of the upper cover body; the lower latch is arranged at the right end of the lower cover body; and the upper latch is clamped in the lower latch. The split vehicle fuel pipe quick joint, provided by the invention, is convenient for installation, reliable in locking, reasonable in structure and low in cost.

Owner:ZHEJIANG UNIV OF TECH

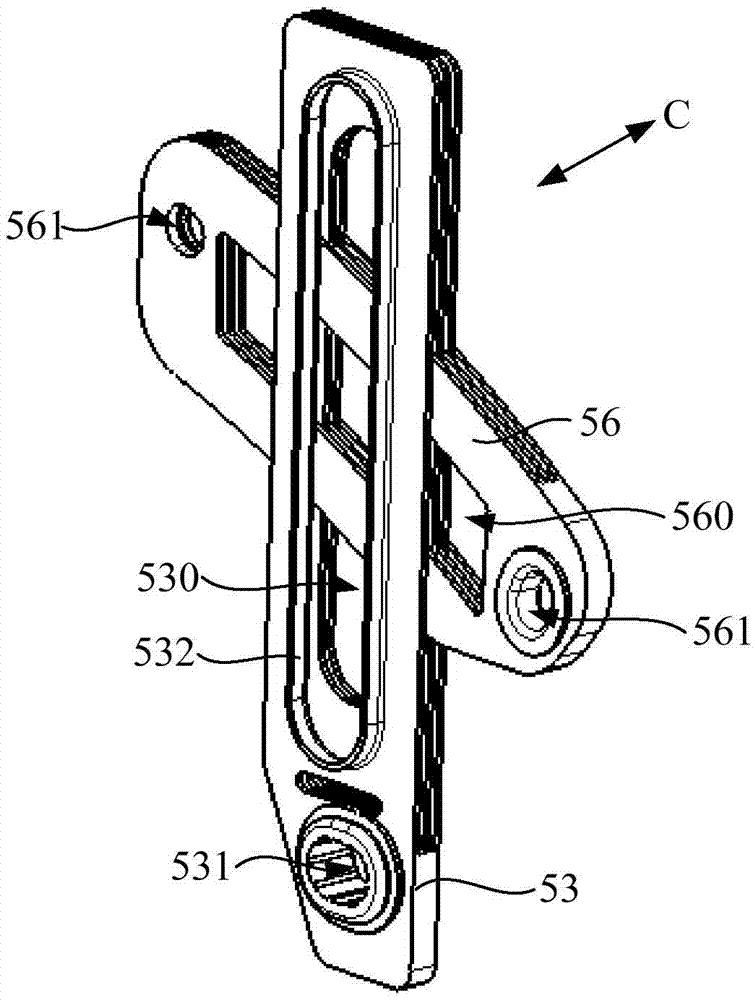

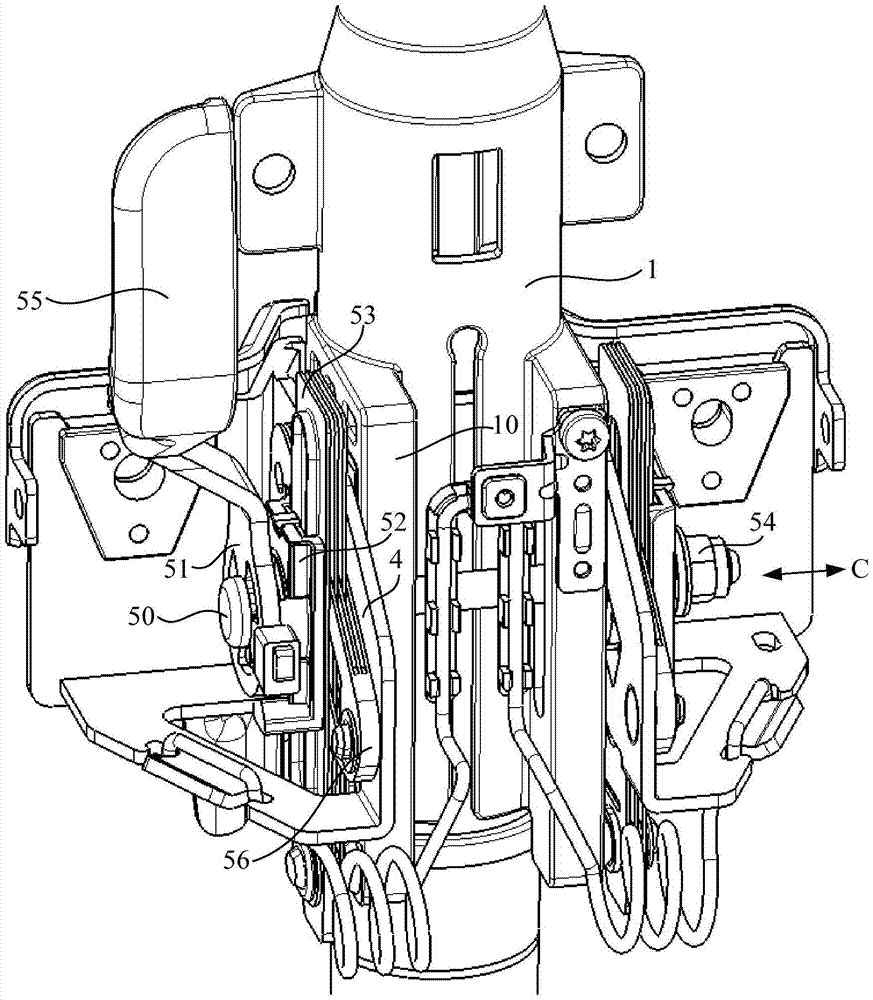

Anti-collision structure for road vehicle sliding-plug door system

InactiveCN105735795APrevent squeezeHigh locking reliabilityWing fastenersInterior spaceVehicle frame

The invention discloses an anti-collision structure for a road vehicle sliding-plug door system. The anti-collision structure comprises a door body with two folio door leaves which can perform translational motion mutually, and further comprises a first restraining mechanism and a second restraining mechanism, wherein the first restraining mechanism is arranged above the side, close to a vehicle door frame, of the door body; the second restraining mechanism is arranged below the door body; when the door body is closed, the first restraining mechanism connects the door body to the vehicle door frame, while when the door body is opened, the first restraining mechanism separates the door body from the vehicle door frame; and the second restraining mechanism always connects the door body to the vehicle body frame. By adoption of the anti-collision structure, not only can the door body be prevented from being opened due to a collision when being closed and can the rigidity and strength of the door body be improved, but also the door body can be guided and restrained in a multi-point manner when being opened and closed, so that smooth opening / closing action can be realized, vertical column mechanisms on the two sides of the door body are eliminated, and then the interior space of a road vehicle is larger.

Owner:NINGBO CRRC TIMES TRANSDUCER TECH CO LTD

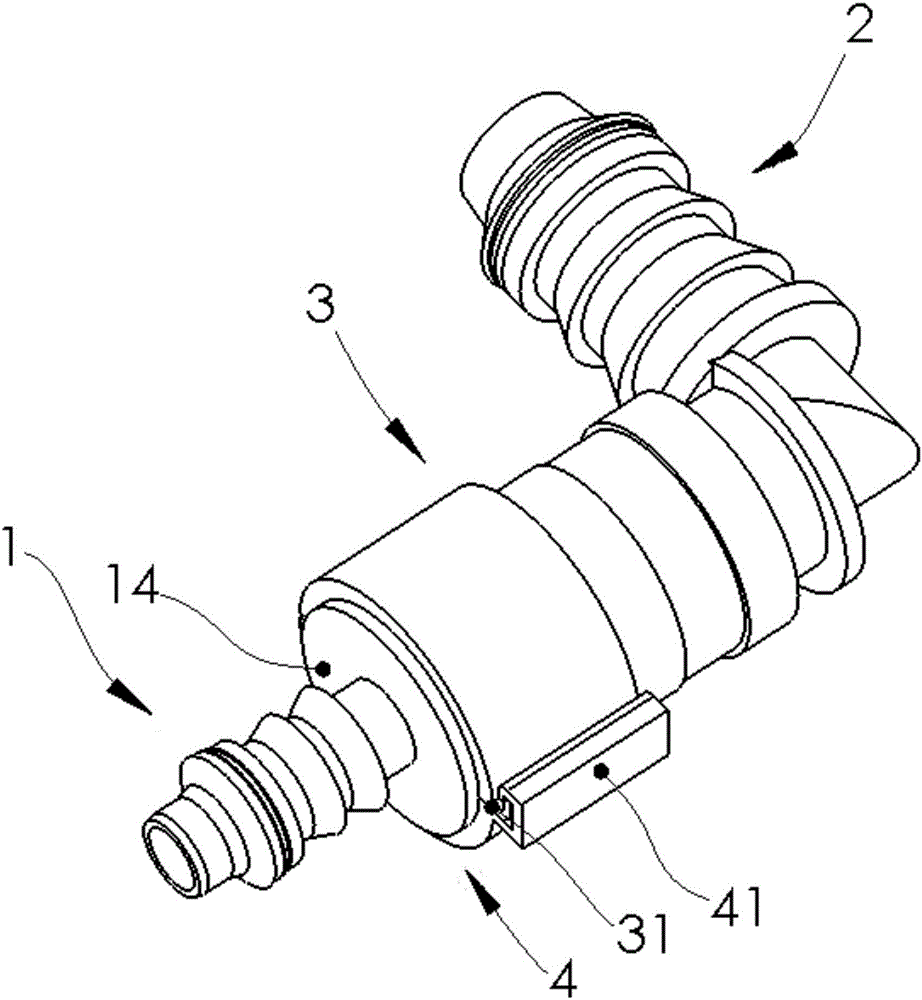

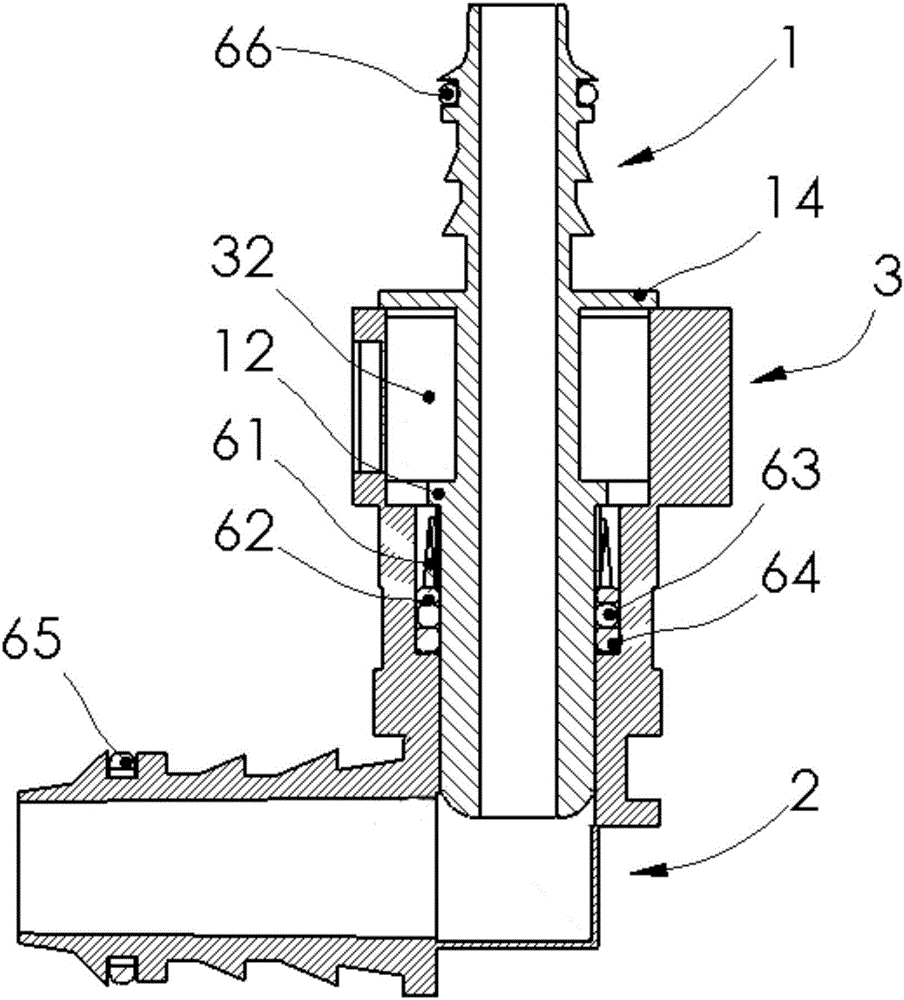

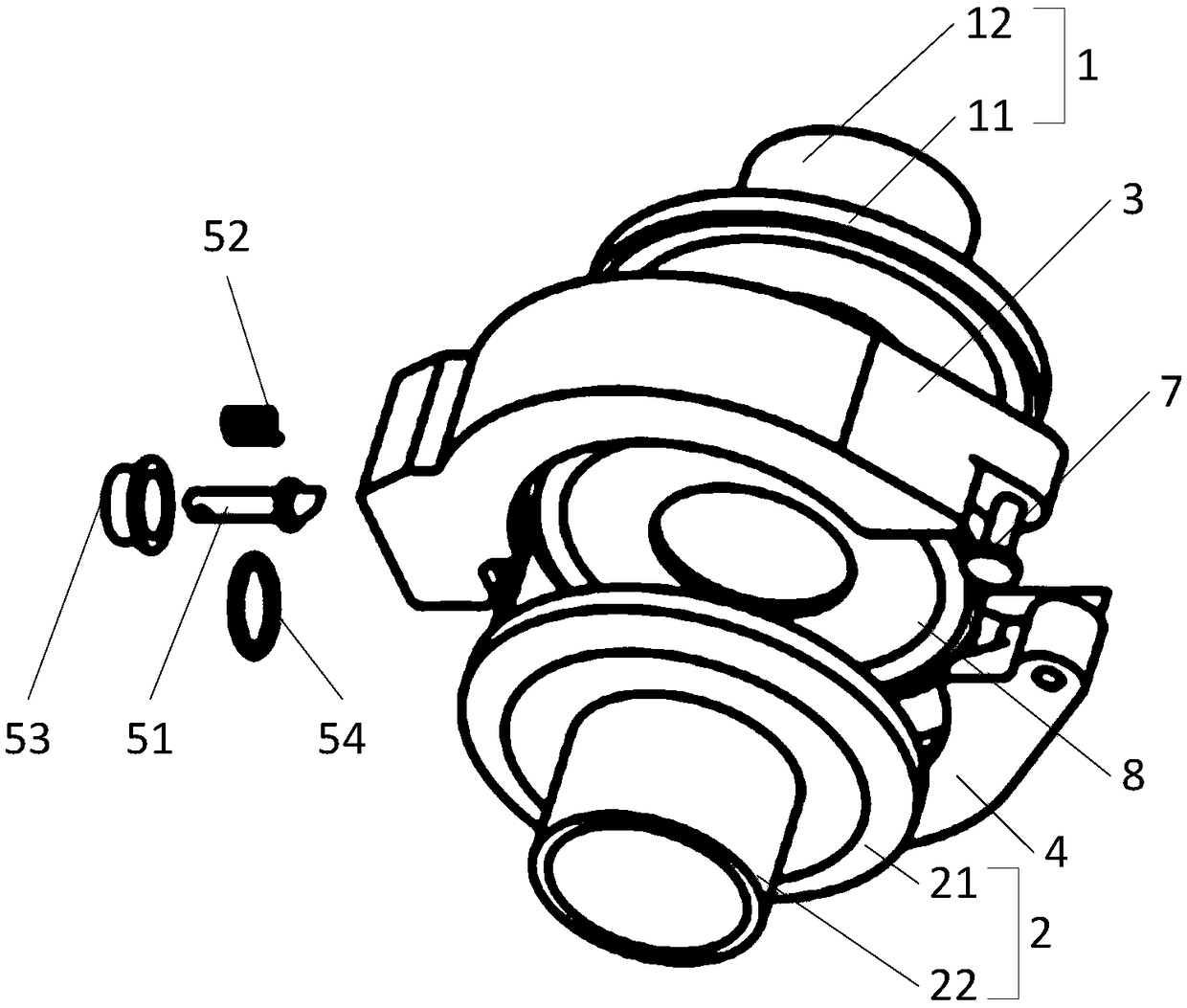

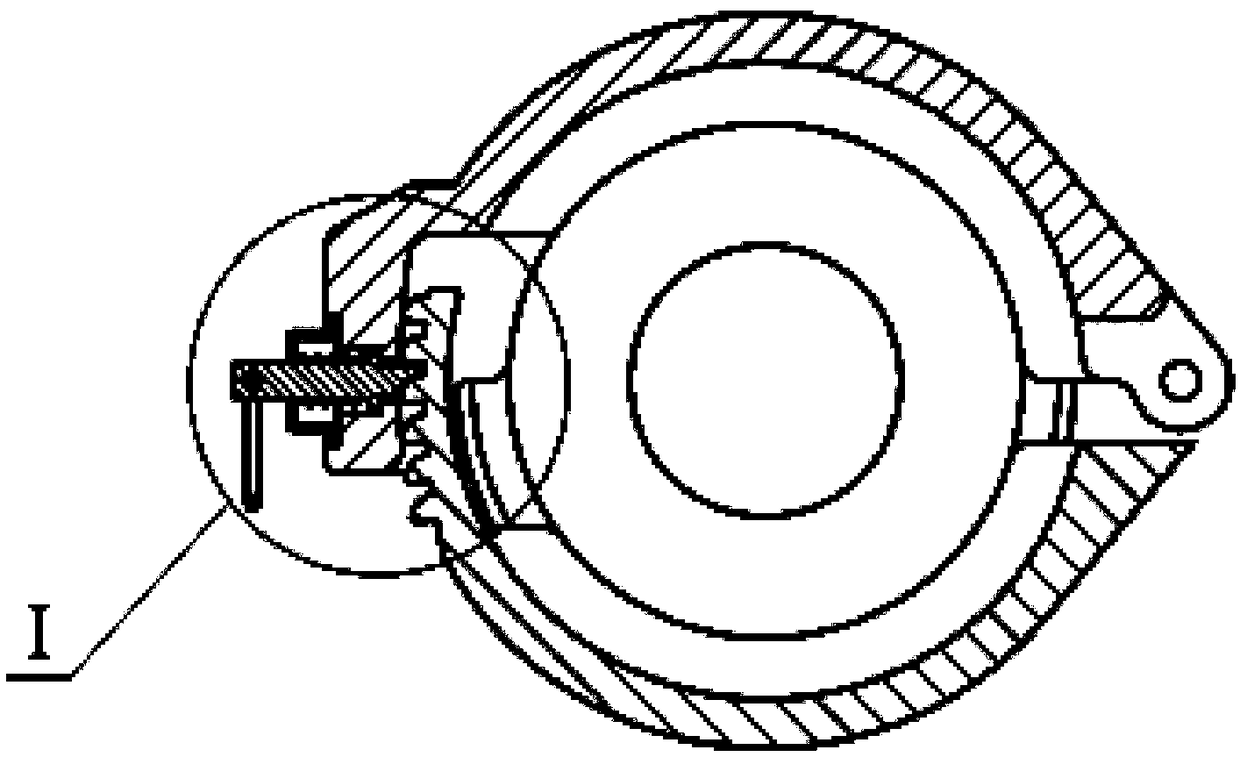

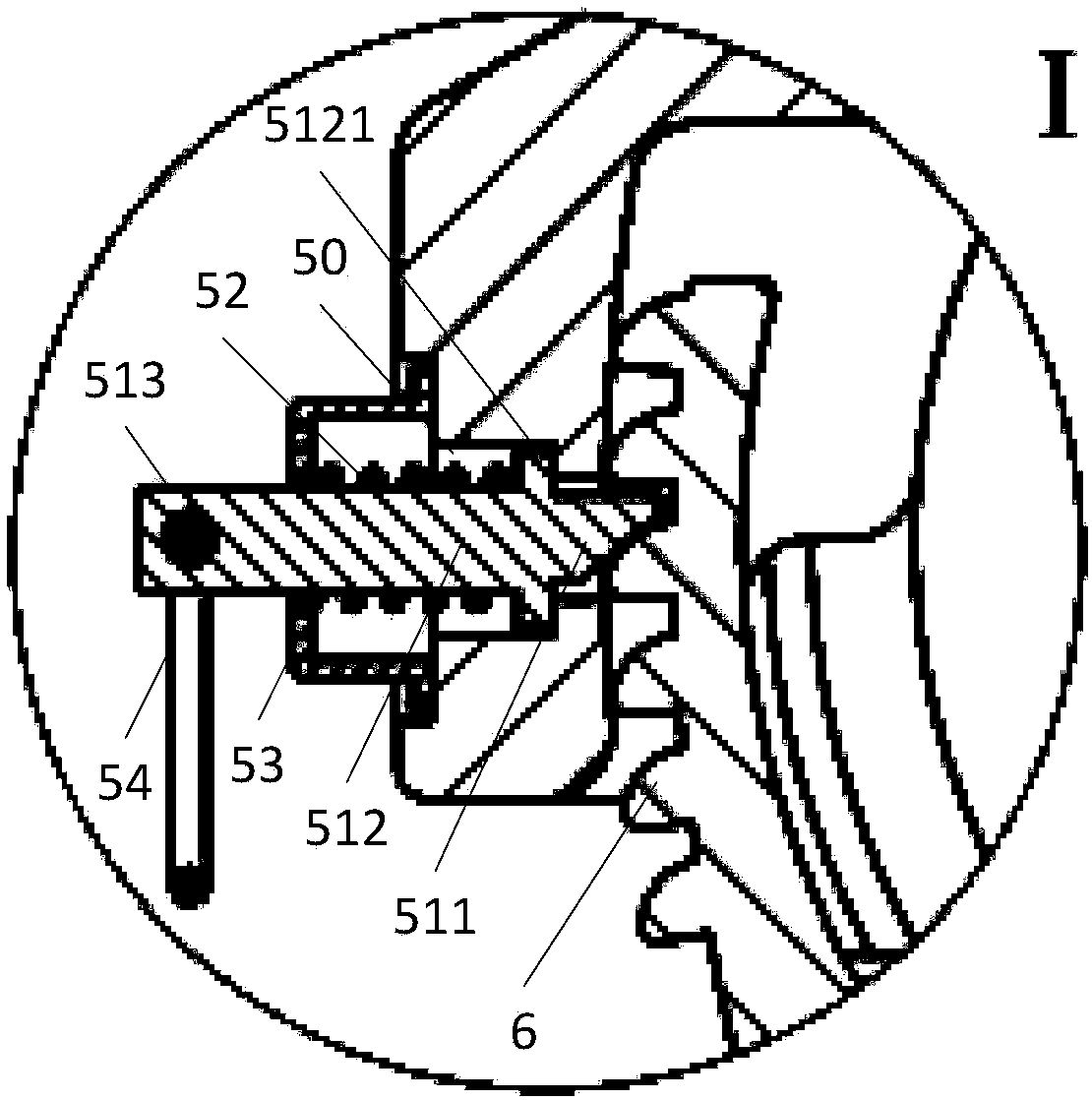

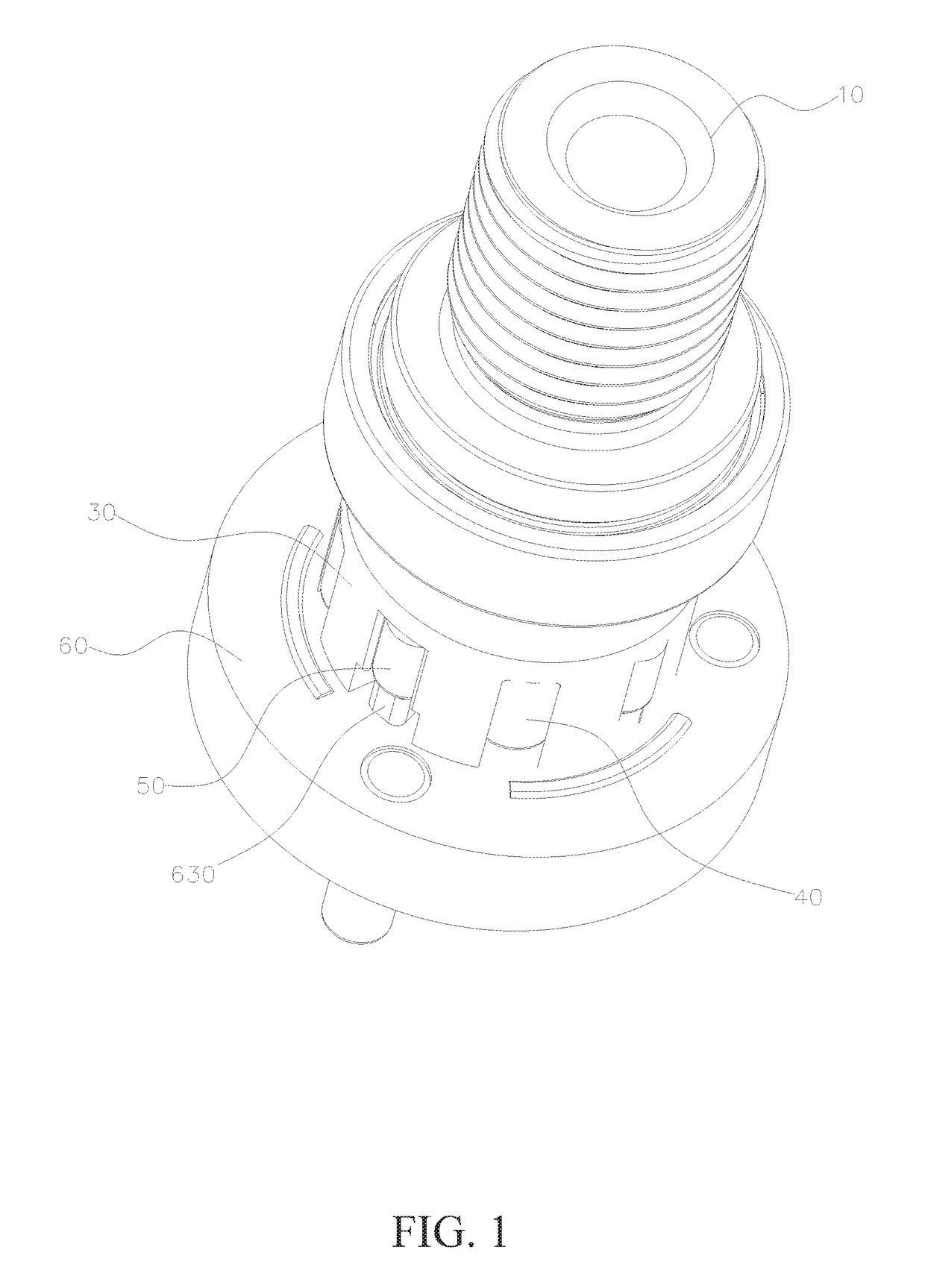

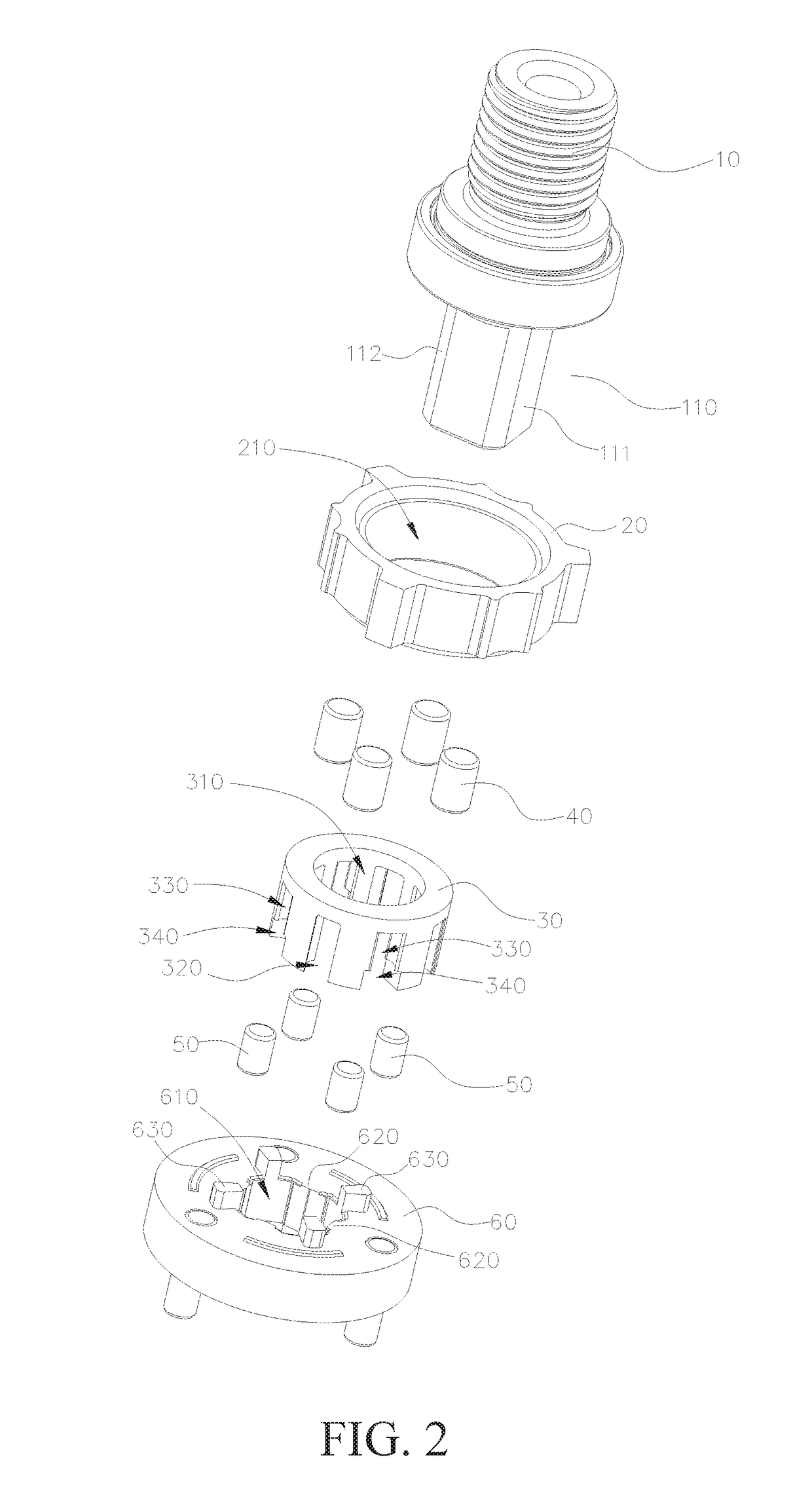

Locking device of water pipe joint

The invention discloses a locking device of a water pipe joint. The locking device comprises a first water pipe joint and a second water pipe joint; a first hoop and a second hoop are matched with thefirst water pipe joint and the second water pipe joint, and one end of the first hoop and one end of the second hoop are hinged in an axial direction; the other end corresponding to the first hoop extends outwards to form a first extending face, and the other end corresponding to the second hoop extends outwards to form a second extending face; the second extending face comprises a part corresponding to the first extending face; and a pawl assembly is arranged on the first extension face and a ratchet wheel is arranged on the second extension face, and the other end of the first hoop and theother end of the second hoop are locked cooperate through the pawl assembly and the ratchet wheel in a clamping mode. According to the device, the locking device of the water pipe joint is compact, simple in structure and low in cost, one end of each clamping hoop is hinged, the other end of each clamping hoop cooperate through the ratchet wheel and the pawl assembly so that the assembling or disassembling can be convenient, anti-leakage effect is good, locking reliability is high, maintenance is not needed.

Owner:BEIJING INST OF RADIO MEASUREMENT

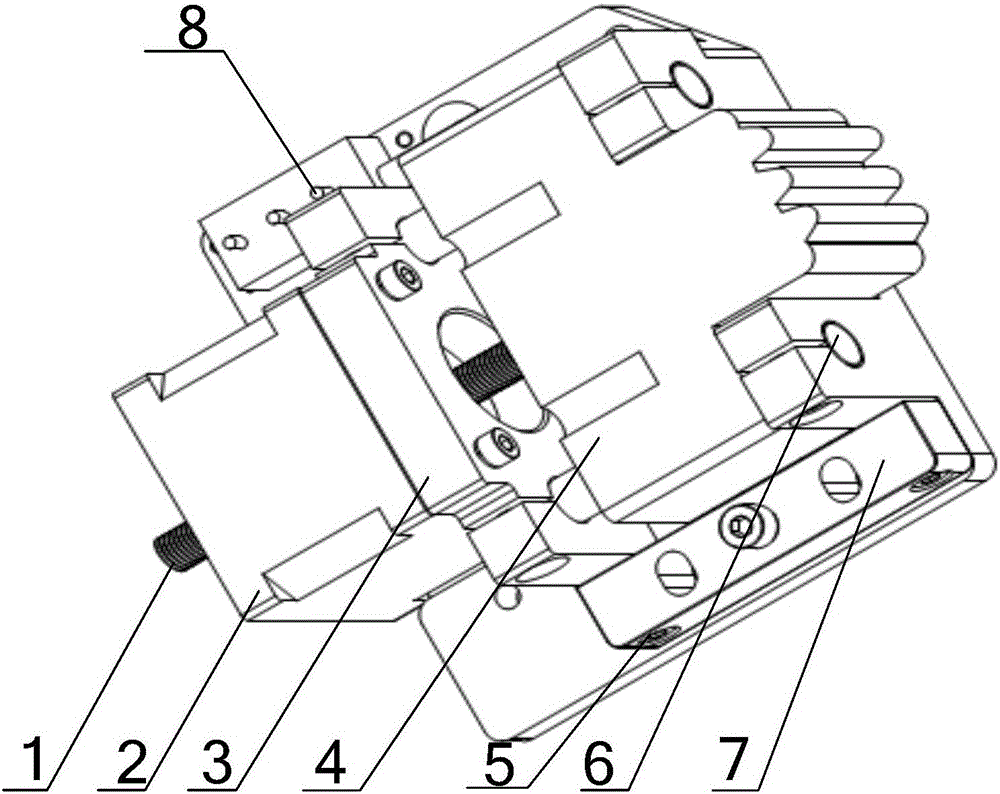

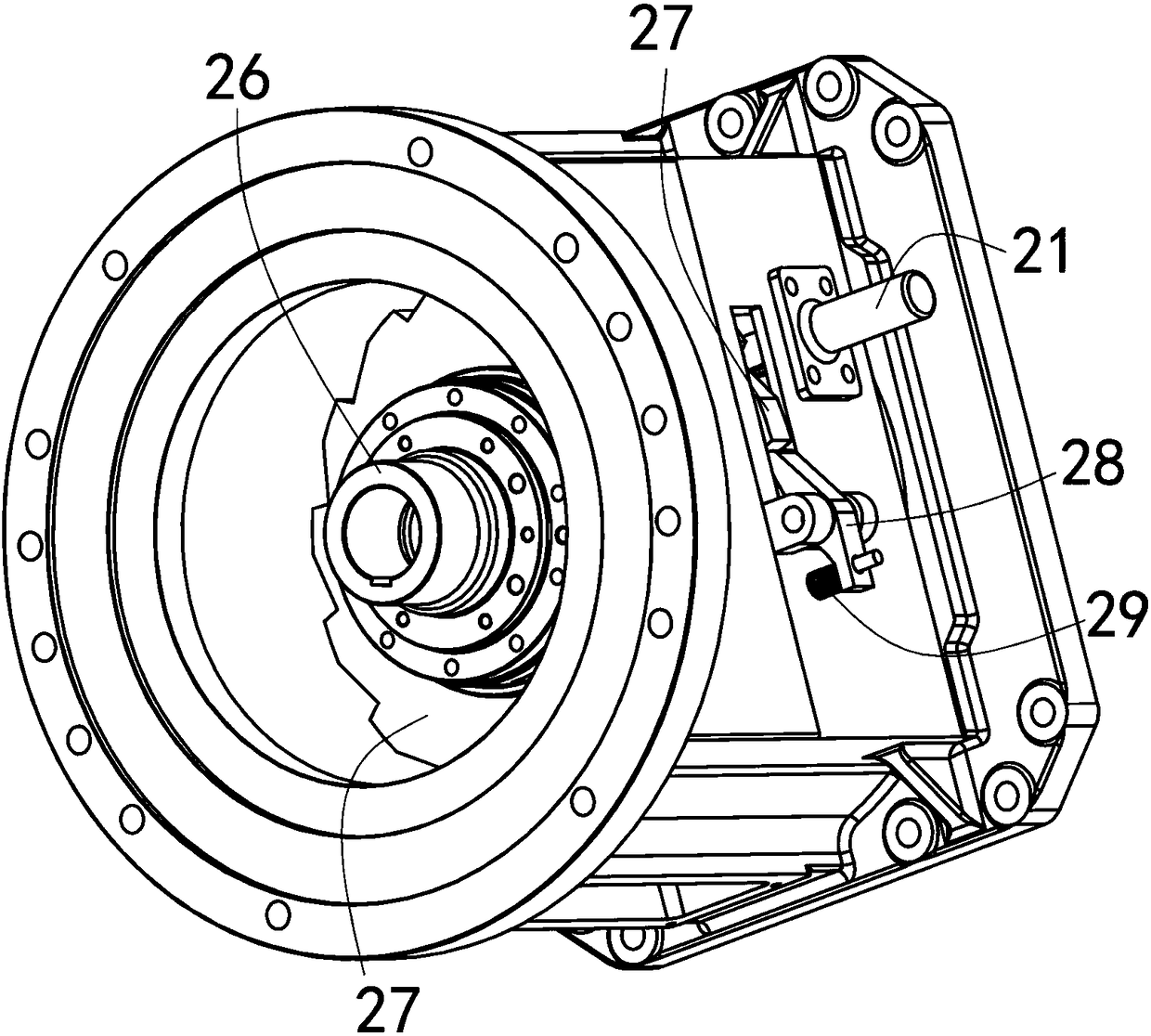

Locking device for spindle of electric tool

InactiveUS20190015962A1High locking reliabilityDifficult to assemblePortable power-driven toolsPortable drilling machinesPower toolEngineering

A locking device for a spindle of an electric tool comprises an output shaft, a fixing ring, a retainer, locking roller pins, bearing roller pins and a power output disc. When the power output disc is active, the power output disc drives the output shaft to rotate thus outputting torque and meanwhile driving the retainer to rotate synchronously; when the output shaft is active, the output shaft rotates to make the planes of the multi-surface shaft of the output shaft deflect and drives the locking roller pins to abut against the fixing ring so as to lock the spindle. In the locking process, under the supporting effect of the bearing roller pins, the spindle rotates in a balanced mode and is stressed uniformly, the locking reliability is high, and the overall structure assembling difficulty is low.

Owner:BEST SELECT IND SUZHOU CO LTD

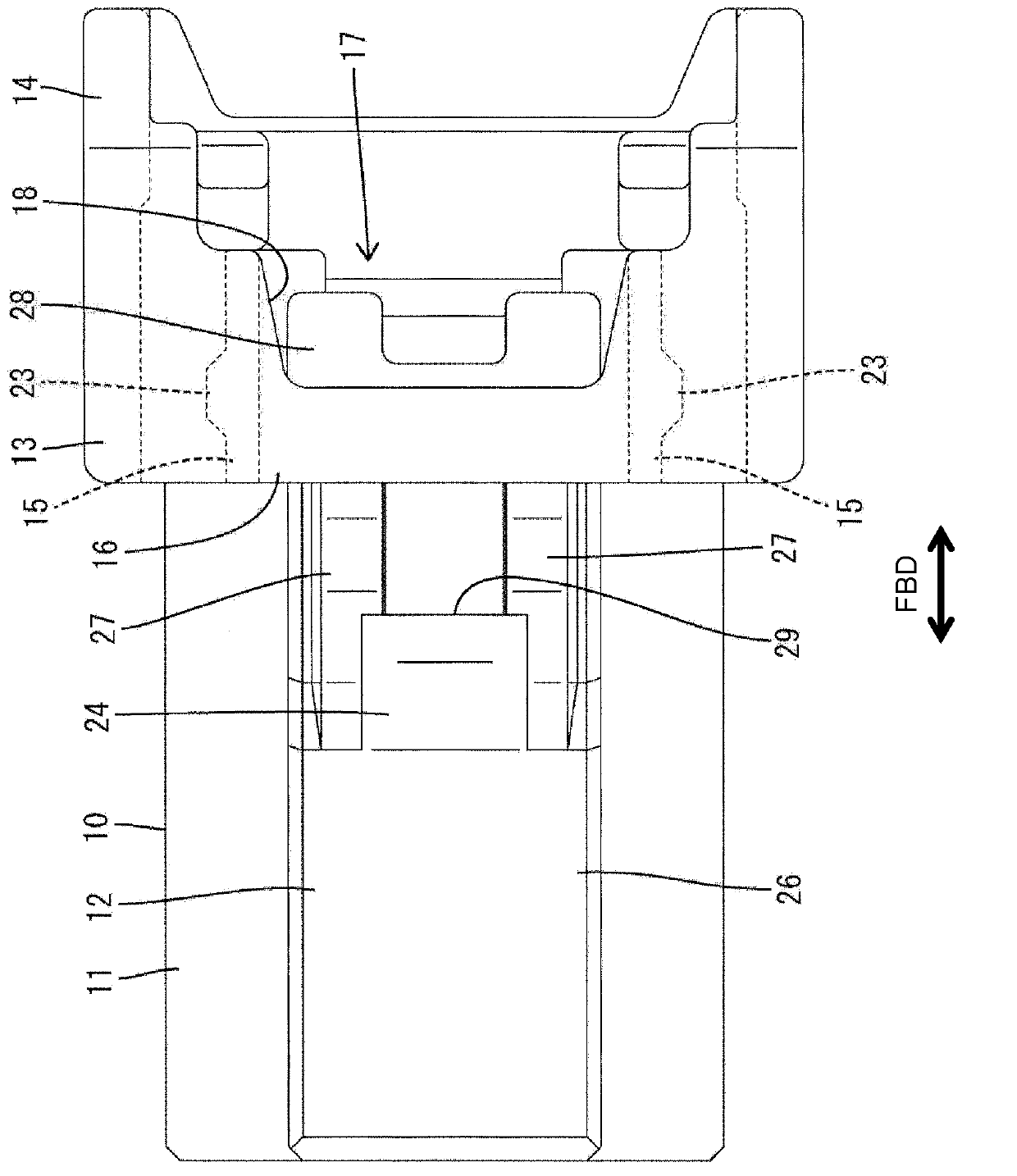

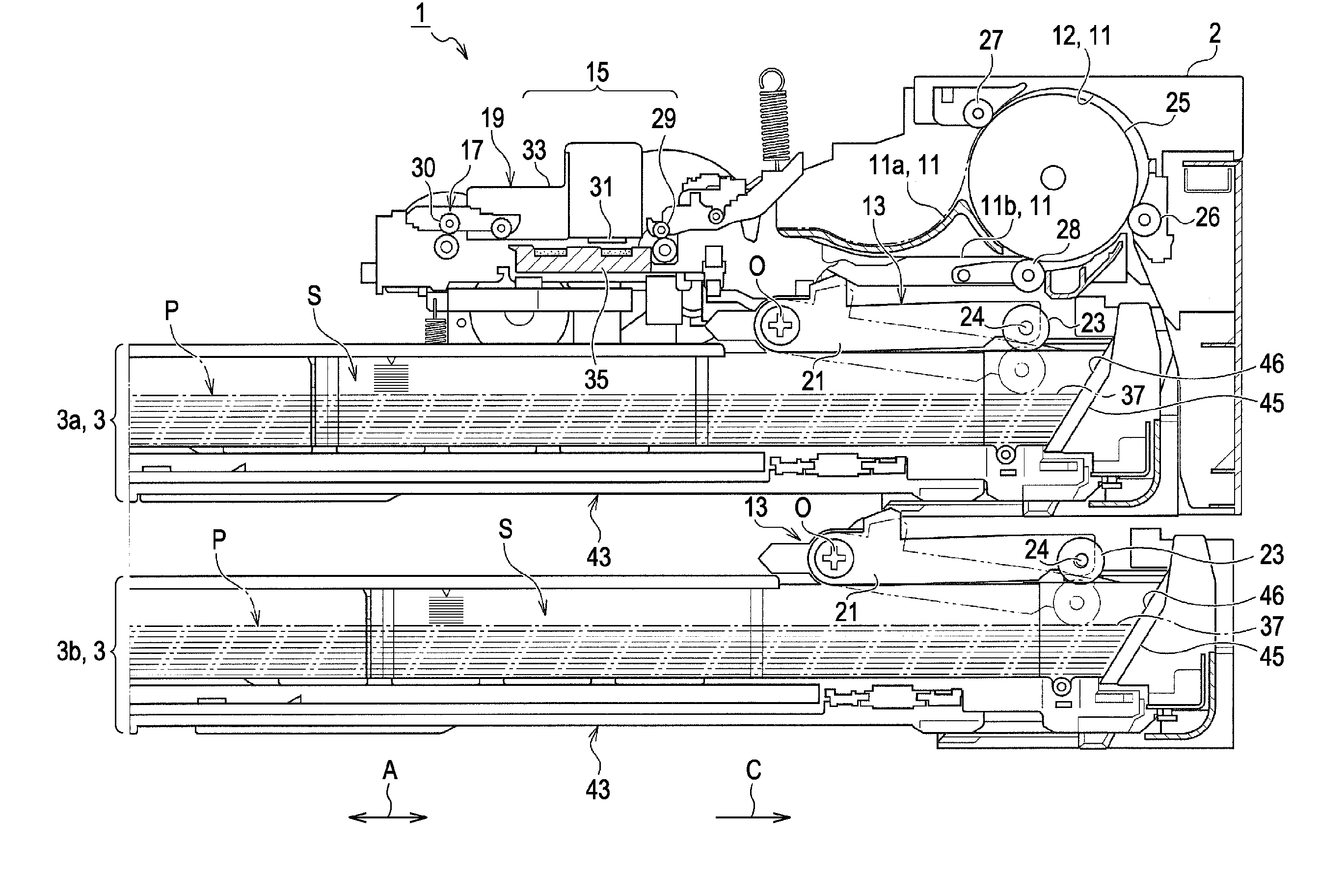

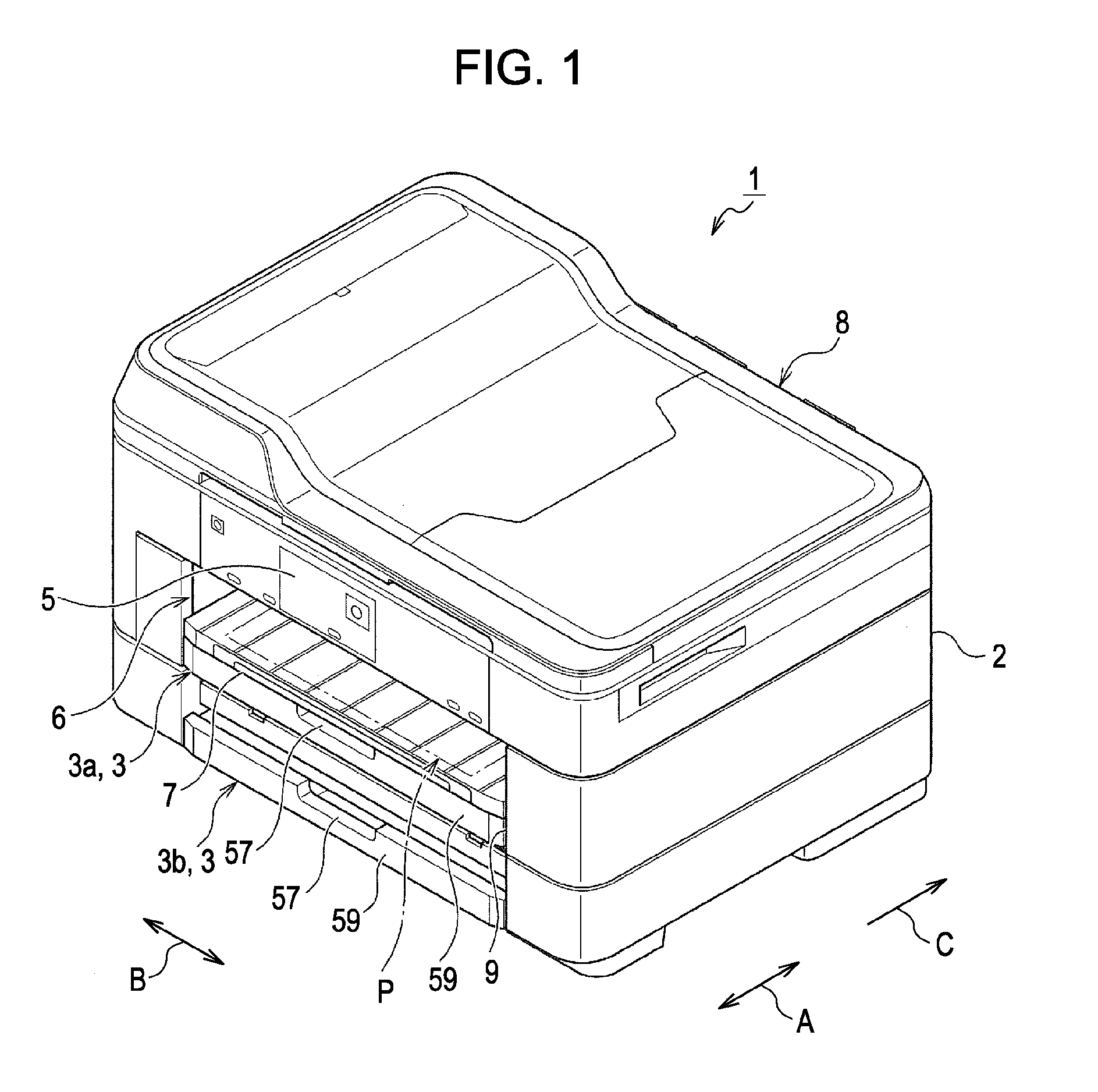

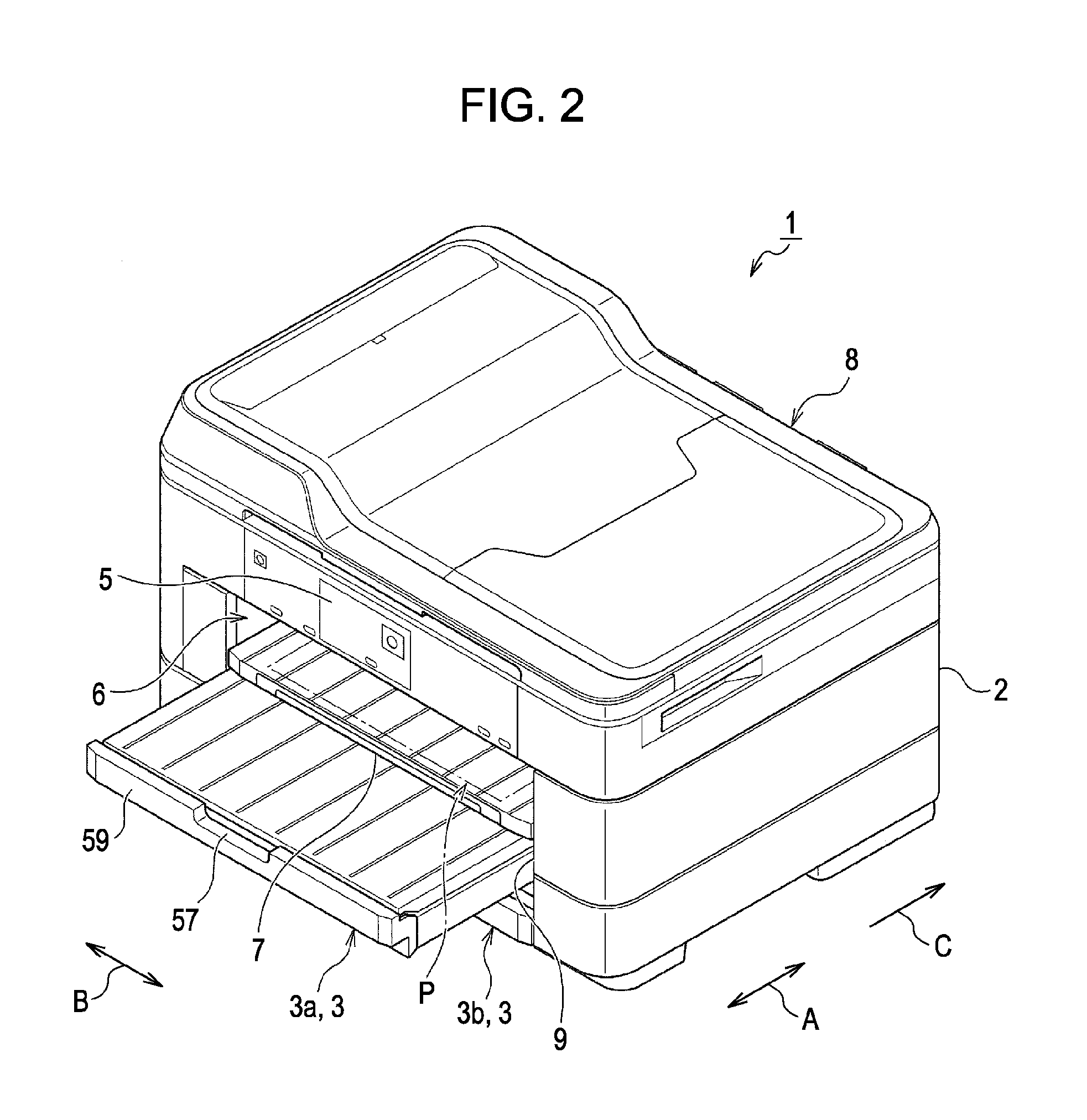

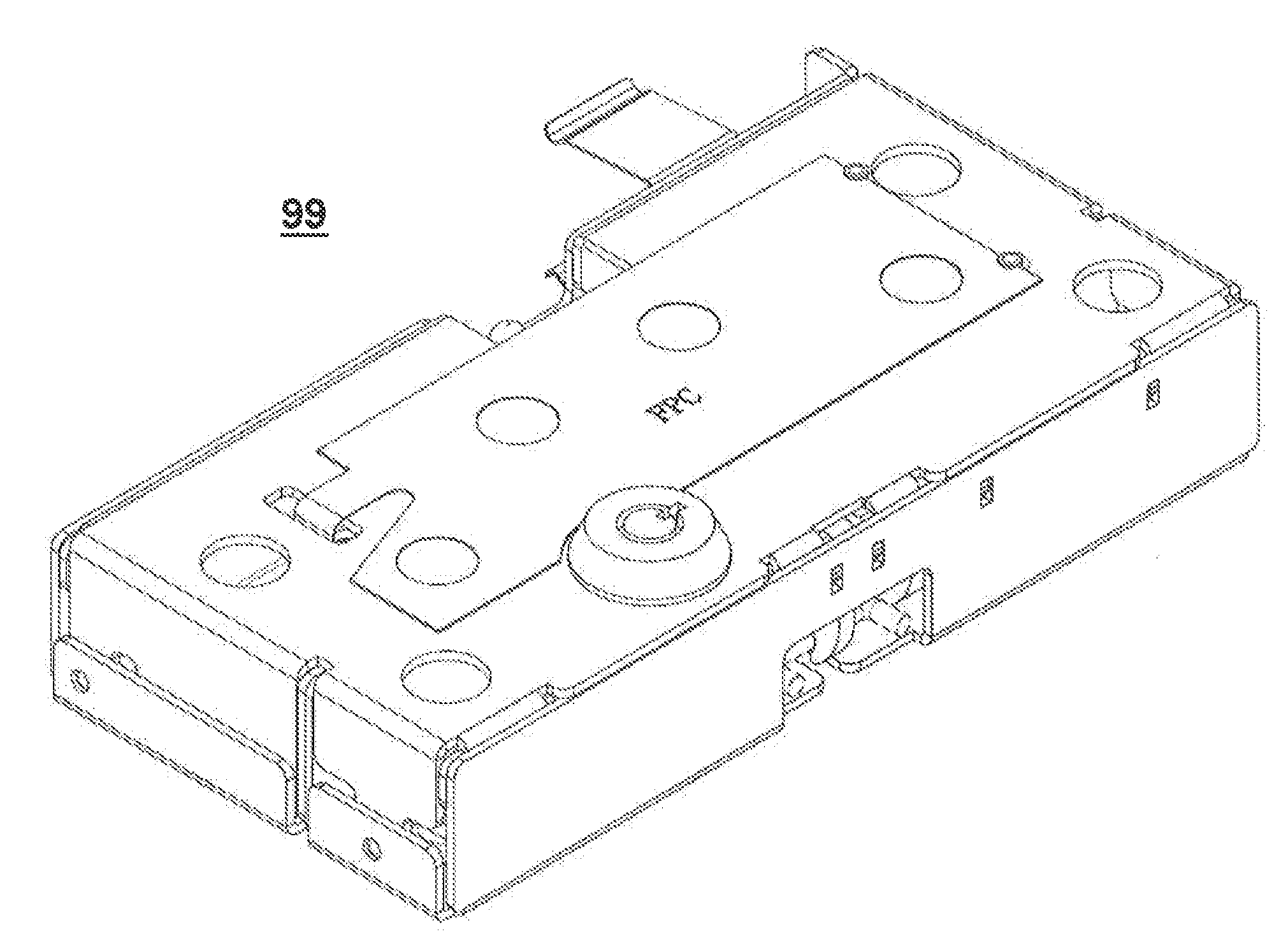

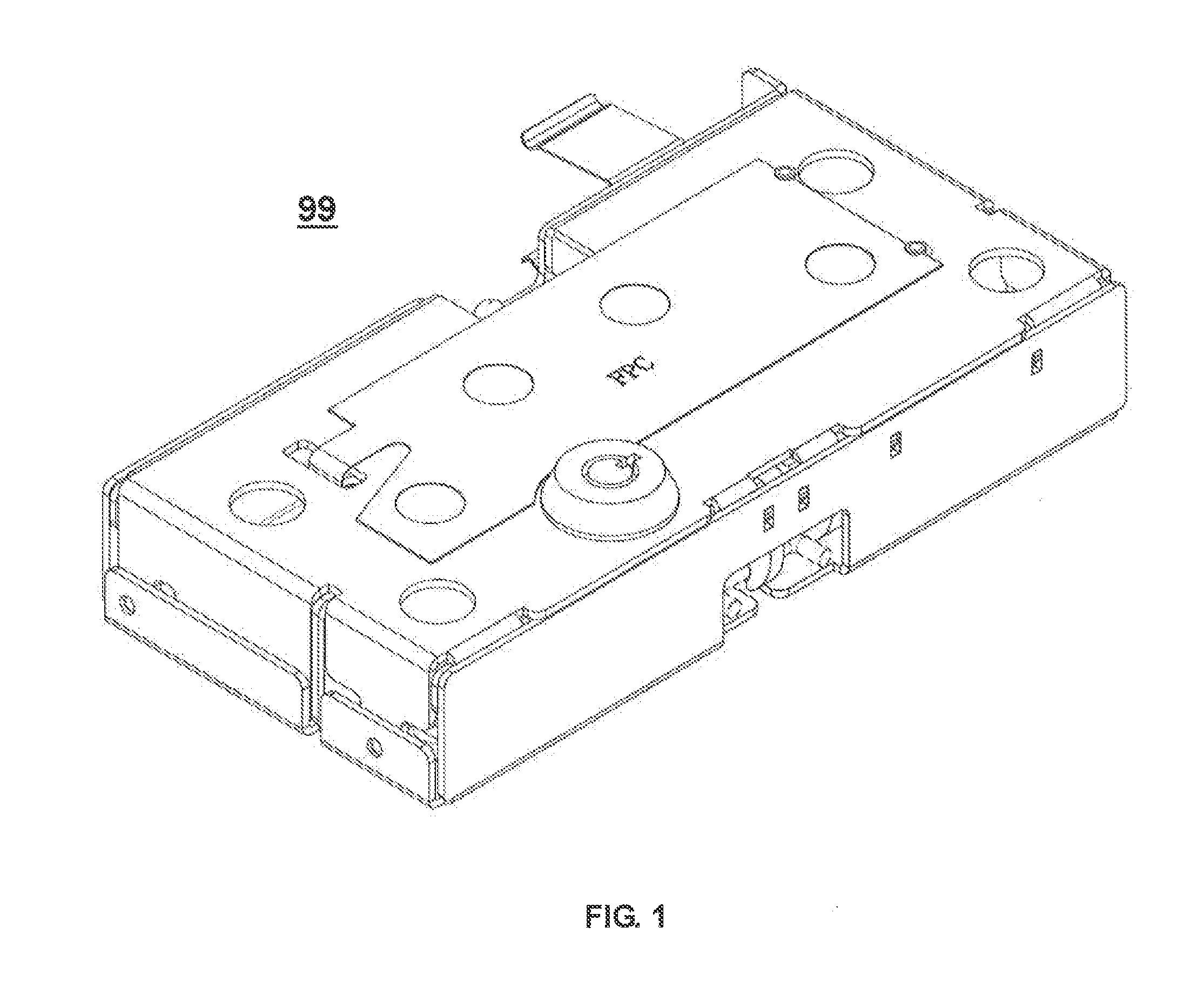

Recording material feed cassette and recording apparatus

ActiveUS20120235345A1High locking reliabilityProcess stabilityArticle feedersArticle separationLocking mechanismEngineering

A recording material feed cassette includes first and second cassette portions. The second cassette portion is assembled so as to be capable of extending / retracting relative to the first cassette portion and, along with the first cassette portion, contains a recording material. A locking mechanism fixes the position of the second cassette portion relative to the first cassette portion. The locking mechanism has a lock portion capable of moving in a first direction that is orthogonal to the extension / retraction direction so as to take on a locked position and an unlocked position, an operation portion that is capable of moving in a second direction that follows the extension / retraction direction, and a connection portion that connects the lock portion and the operation portion and that is capable of deforming as a result of the movement of the lock portion in the first direction.

Owner:SEIKO EPSON CORP

Combined type thread self-locking hydraulic oil cylinder

InactiveCN104088855AReliable lockingHigh outputFluid-pressure actuatorsHydraulic cylinderSelf locking

The invention relates to the technical field of hydraulic power equipment, in particular to a combined type thread self-locking hydraulic air cylinder. The technical problem that an existing oil cylinder is poor in locking reliability and low in output force is solved. The oil cylinder comprises a cylinder barrel, a main piston and an auxiliary piston. The main piston is arranged in an inner cavity of the cylinder barrel, the right end of the main piston stretches out of the cylinder barrel, and external threads with the central axis of the main piston as the spiral axis are formed on the right circumferential face of the main piston. A driving motor and an annular gear are arranged on the cylinder barrel, a power output shaft of the driving motor is meshed with the annular gear, and the annular gear is meshed with external threads on the right portion of the main piston through internal threads of an inner ring. The main piston is provided with an auxiliary cavity, the auxiliary piston is arranged in the auxiliary cavity and divides the auxiliary cavity into a left sub-cavity and a right sub-cavity, the left end of the auxiliary piston penetrates through the left end cavity wall of the auxiliary cavity to stretch into a rodless cavity, and the right sub-cavity of the auxiliary cavity is communicated with the rodless cavity of the cylinder barrel through a shaft hole formed in the auxiliary piston. The oil cylinder can achieve reliable locking and is high in output force.

Owner:SHANGHAI HORIZON EQUIP ENG

Vane-type cam phaser having dual rotor bias springs

A vane-type camshaft phaser for varying the timing of combustion valves including a first torsional bias spring disposed on a cover plate spring guide and grounded to the cover plate and to a slot in a spring retainer to urge the rotor toward an intermediate locking position from any position retarded of the locking position. A second torsional bias spring also anchored to the cover plate and spring retainer urges the rotor in the advance direction over the full range of phaser authority to compensate for added camshaft torque loads imposed by non-valve actuating functions such as driving a mechanical fuel pump.

Owner:DELPHI TECH IP LTD

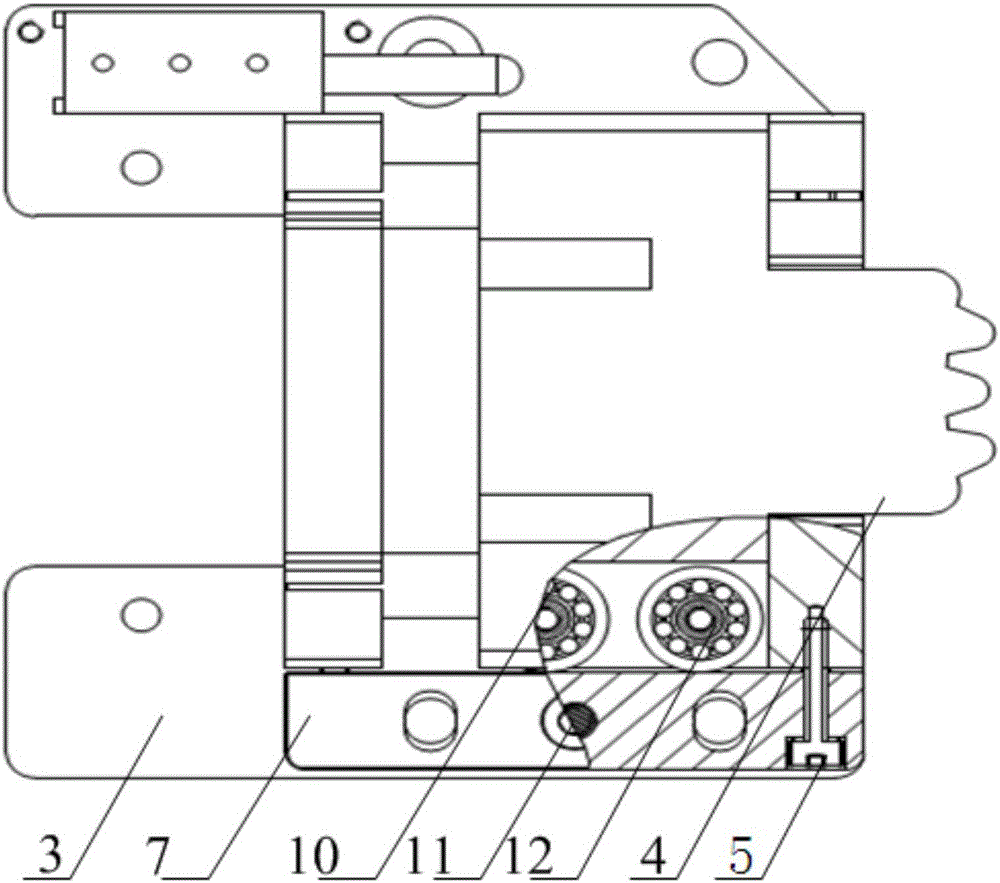

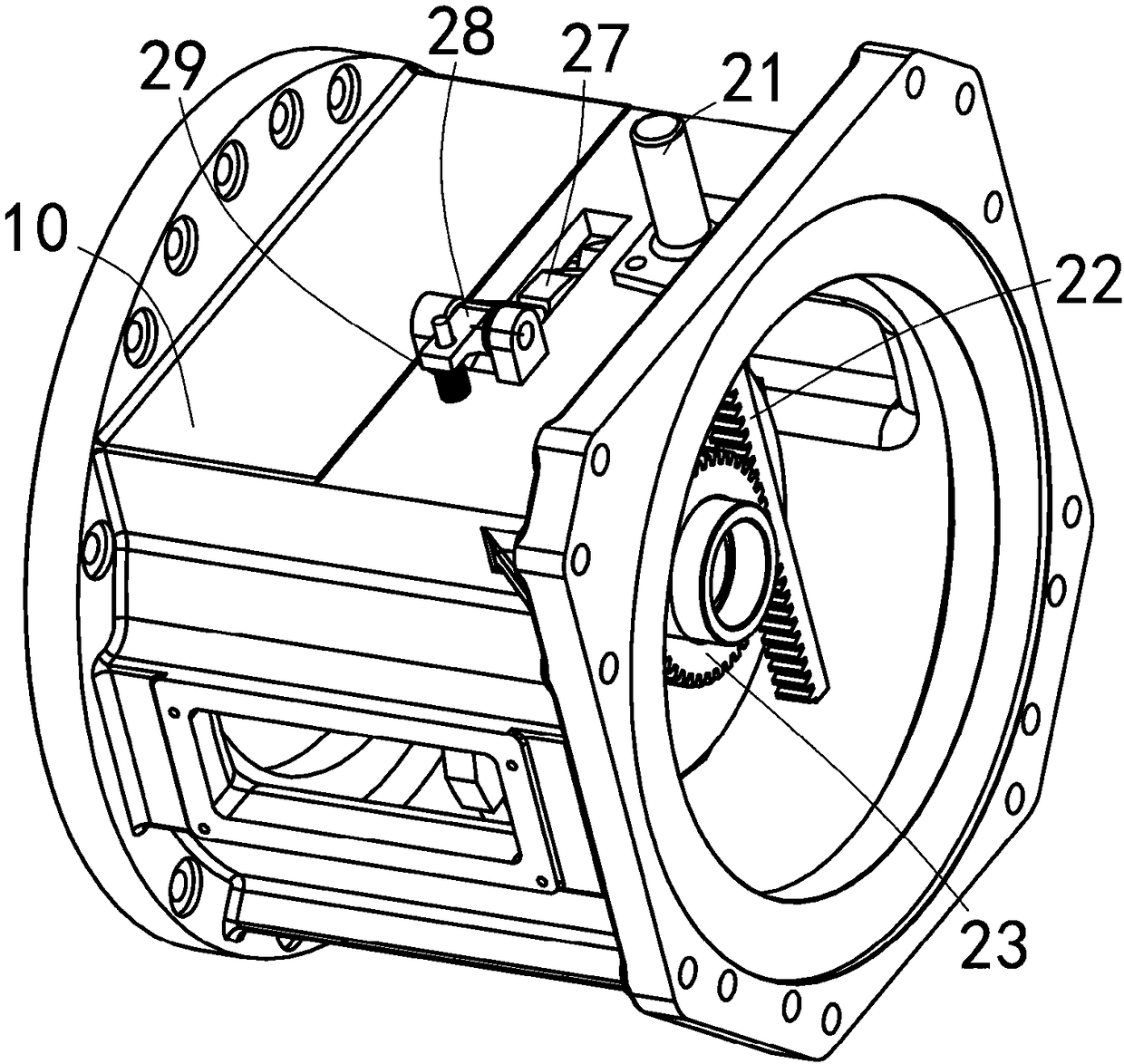

Rotating shaft locking device of transmission mechanism

ActiveCN105156451ASolve the automatic locking functionHigh locking reliabilityShaft for rotary movementMechanical energy handlingSelf lockingDrive motor

The invention discloses a rotating shaft locking device of a transmission mechanism. The rotating shaft locking device comprises a transmission locking device and a locking gear fixedly connected onto a rotating shaft of the transmission mechanism; the transmission locking device comprises a lead screw, a driving motor, a base, a locking block and guide rails which are parallelly fixed on the base; the two sides of the locking block sleeve the guide rails; one end of the locking block is provided with teeth meshed with the locking gear, and the other end of the locking block is connected with the driving motor which is fixed on the base through the lead screw; the driving motor drives the locking block to move along the guide rails to be meshed with the locking gear for locking or to be separated from the locking gear for unlocking through the lead screw; the driving motor is utilized for providing power for the locking block to ensure the insertion and the separation of the teeth; the automatic locking function of the rotating shaft is effectively solved; the locking force can be set by controlling the rotation speed of the driving motor and the backoff amount after locking; the maintenance of a locking load is realized through the self-locking ability of a screw-nut pair; the locking reliability is high; and the assembly is convenient.

Owner:NO 771 INST OF NO 9 RES INST CHINA AEROSPACE SCI & TECH

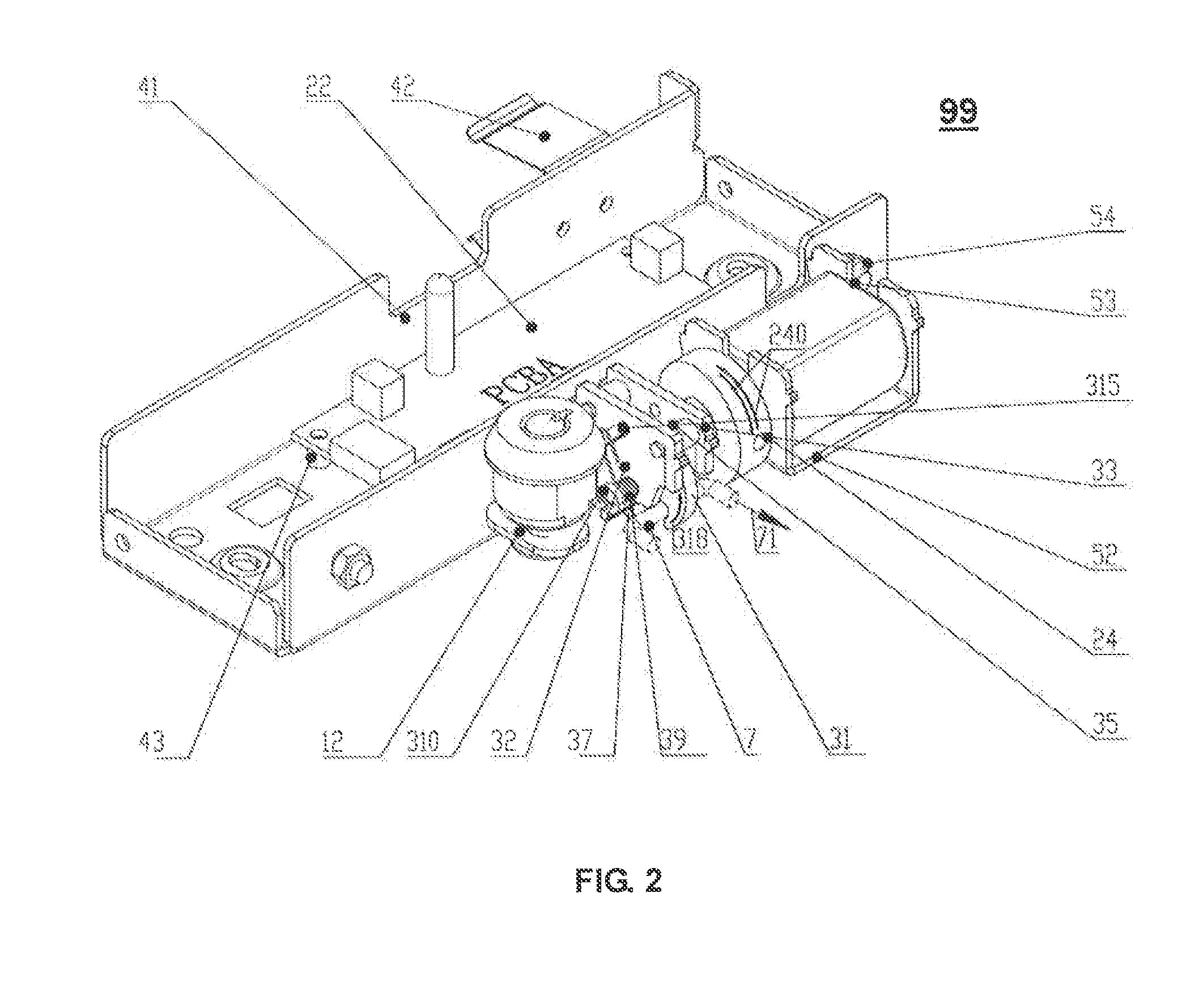

Modularly-designed fuse safety insurance mechanism

ActiveCN112525022AGuaranteed processing securityQuestions Guaranteed to AnswerAmmunition fuzesCantilevered beamExplosive train

The invention discloses a modularly-designed fuse safety insurance mechanism which is composed of three times of safety insurances, the first time of safety insurance is a recoil insurance; the secondtime of safety insurance is a centrifugal insurance; the third time of insurance is a long-distance insurance; and the three times of insurances and an explosion-proof sliding block form a main bodyof the safety insurance mechanism. At ordinary times, the explosion-proof sliding block is clamped by a recoil safety device composed of a cantilever beam mass block and a centrifugal safety device composed of a spring mass block, an explosion propagation sequence is separated, and the safety of a fuse is guaranteed. In the launching state, the safety insurance mechanism sequentially relieves thethree times of insurances by recognizing recoil force, centrifugal force and other environmental force, the explosive-proof sliding block relieves corresponding constraints, locking is completed, a detonating hole is aligned, and the safety insurance mechanism relieves the insurances. Based on the three-dimensional additive manufacturing technology, the size and the complexity of the safety insurance mechanism can be effectively reduced, the mechanism is convenient to assemble due to the modular design principle, and meanwhile the workload of optimization design of the mechanism in the futureis greatly reduced.

Owner:NANJING UNIV OF SCI & TECH

Electronic lock

InactiveUS20150089982A1High locking reliabilitySimple locking structureNon-mechanical controlsConstruction fastening devicesEngineeringCam

This invention discloses an electronic lock, including cam lock assembly, electronic control assembly, lock latch assembly and latch bolt assembly. The latch bolt assembly includes latch bolt, latch bolt bracket and latch shaft. The latch bolt mentioned is pivoted at the latch bolt bracket, while latch shaft is translational positioned at it. By the latch shaft, cam bolt and electronic control assembly can connect with latch bolt and latch component in sequence. The latch shaft is configured with reset and compression spring, while latch bolt is with torsion spring and latch mounting parts, then the latch is able to linkage connect through latch mounting parts. From stated above, we can know the invention is ingeniously designed to lock / unlock latch parts, having lock assembly and electronic control assembly sharing one set of lock bolt (latch bolt). It can be seen that the invention effectively simplifies the existing lock structure.

Owner:TRI STAR

Intermittent self-locking type chain fastening device for scraper machine and chain fastening method

PendingCN108217089APrecise working positionAdapt to the working environmentConveyorsHydraulic cylinderCoupling

The invention provides an intermittent self-locking type chain fastening device for a scraper machine. The intermittent self-locking type chain fastening device comprises a connecting hood barrel andan intermittent hydraulic chain fastening mechanism. The intermittent hydraulic chain fastening mechanism is installed in the connecting hood barrel. The hydraulic chain fastening mechanism comprisesa hydraulic cylinder, a rack, a ratchet-gear wheel, a first pawl, a first ratchet, a coupling, a second ratchet and a second pawl. One end of the rack is fixedly connected with one end of the hydraulic cylinder. The rack and the ratchet-gear wheel are engaged. According to the intermittent self-locking type chain fastening device, the hydraulic cylinder is adopted as a power part, and the intermittent self-locked type chain fastening device can better adapt to a downhole emulsified liquid working environment; the working position of the hydraulic cylinder is accurate, and the tensioning degreeof a chain can be controlled accurately; self-locking of the two sets of ratchets and pawls at any time is achieved , and locking reliability is high; the hydraulic cylinder is arranged to be perpendicular to the transmission direction of the power part, the sizes of the ratchet-gear wheel and the rack are adjusted conveniently, and the size of the chain fastening device can be reduced effectively; the ratchet and pawl structure is achieved, torque is large, and the transmission efficiency is high. The invention further provides a chain fastening method of the intermittent self-locking type chain fastening device for the scraper machine.

Owner:NINGXIA TIANDI BENNIU IND GRP +1

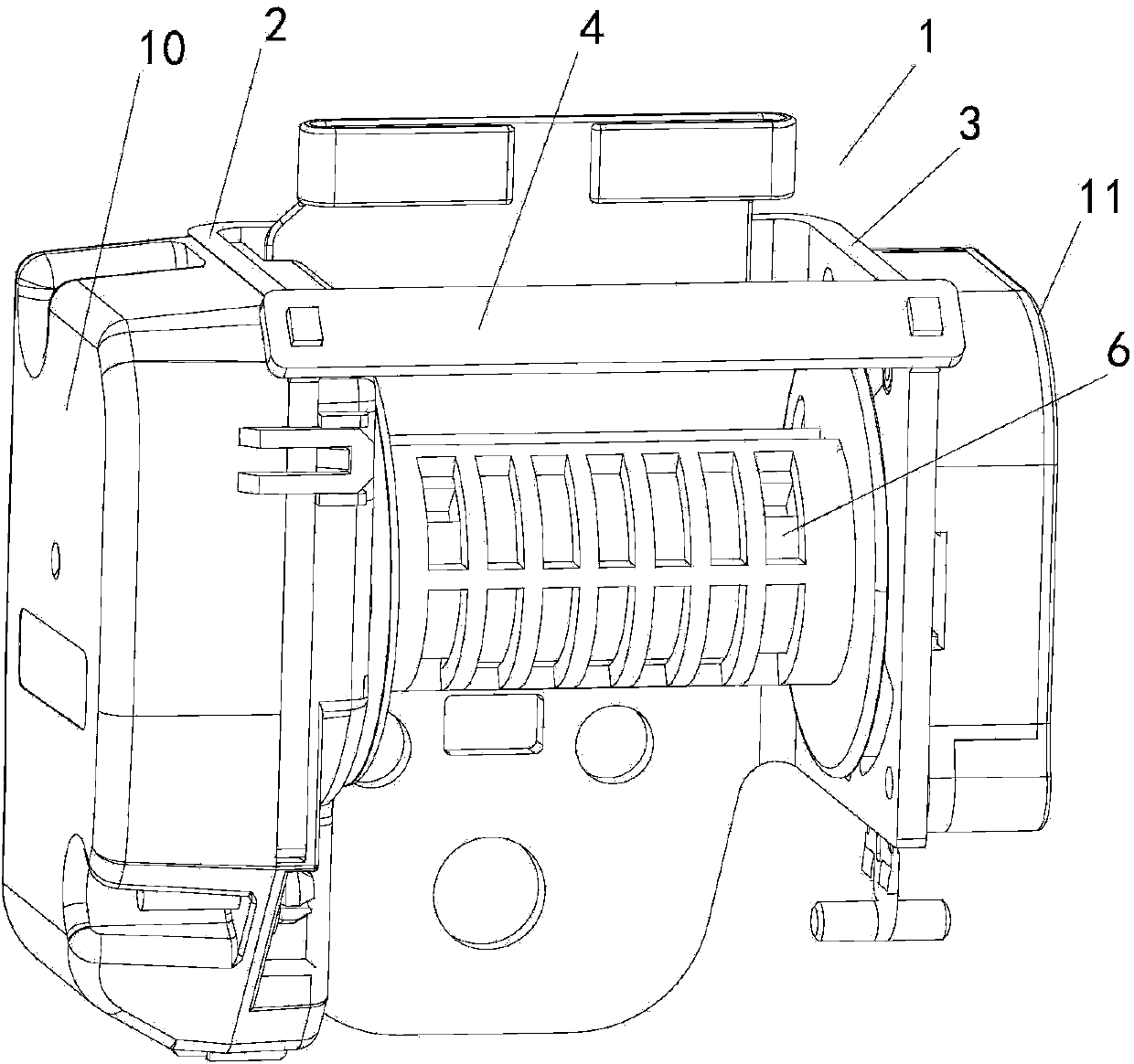

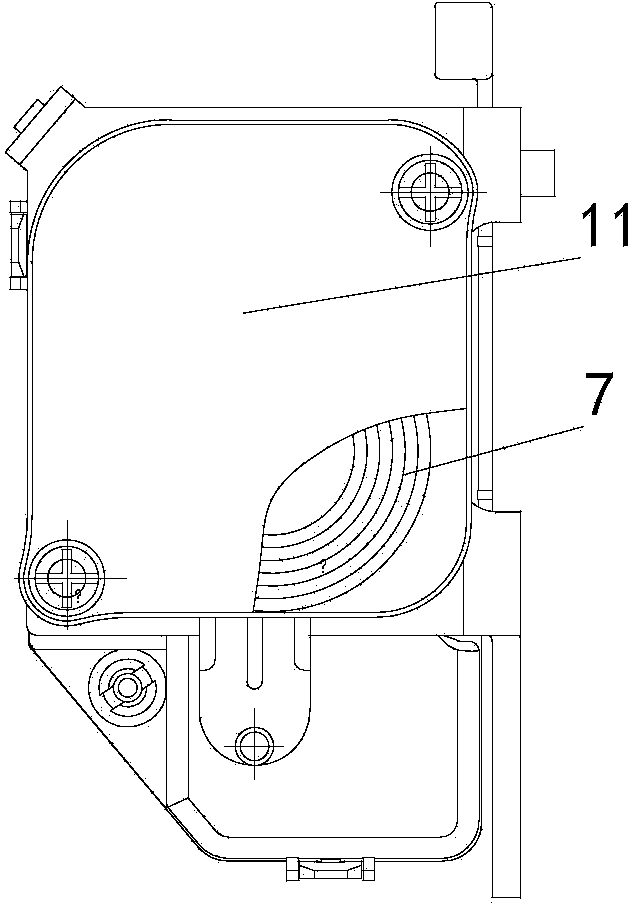

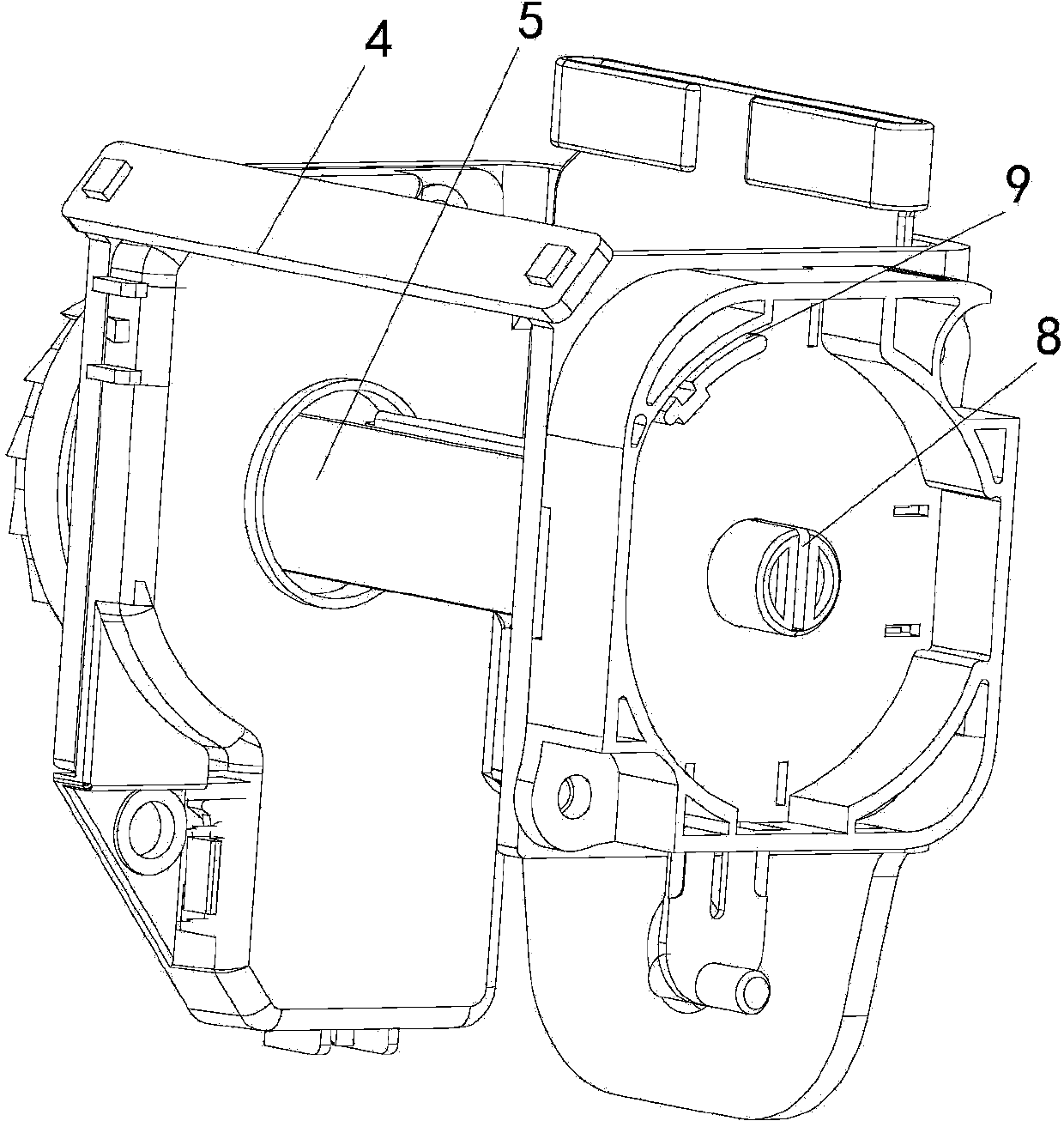

Safety belt winding device

ActiveCN104192092AReduce weightReasonable structural designBelt retractorsLocking mechanismCoil spring

The invention relates to the technical field of automobile passive safety, in particular to a safety belt winding device of automobile safety pieces. The safety belt winding device comprises a winding seat, a rotatable spindle arranged on the winding seat, a winding drum arranged on the spindle and rotating along with the spindle, and a coil spring mechanism arranged on the winding seat and used for driving the spindle to rotate forwards and backwards. A first fluted disc is arranged at one end of the spindle and rotates along with the spindle, teeth are arranged on the peripheral face of the first fluted disc, and locking mechanisms used for locking the teeth on the peripheral face of the first fluted disc are arranged on the winding seat. The safety belt winding device is designed according to the GB14166-2013 standard requirement, belongs to a composite sensitive type winder, is applied to an automobile safety belt, and is used for protecting life safety of passengers. When the corresponding locking mechanism reaches a certain response value, the safety belt can be automatically locked and opened, and life safety of the passengers can be effectively protected.

Owner:常州市东晨车辆部件有限公司

Board connector and method of mounting it

InactiveUS8435051B2Avoid elastic deformationIncrease insertion spaceSecuring/insulating coupling contact membersPrinted circuitsMechanical engineering

Owner:SUMITOMO WIRING SYST LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com