Rotating shaft locking device of transmission mechanism

A transmission mechanism and locking device technology, applied in the direction of electromechanical devices, rotating shafts, electric components, etc., can solve the problems of high power of the drive motor, low efficiency of the transmission chain, interference with the turntable, etc., and achieve high locking precision, lock High reliability and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

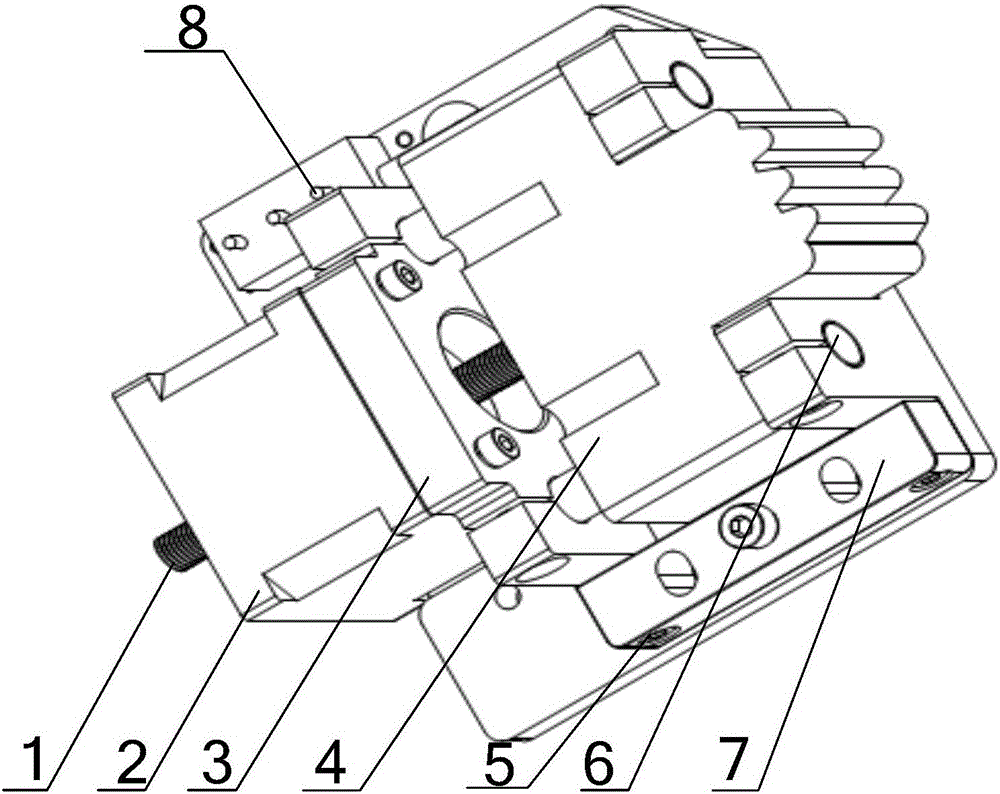

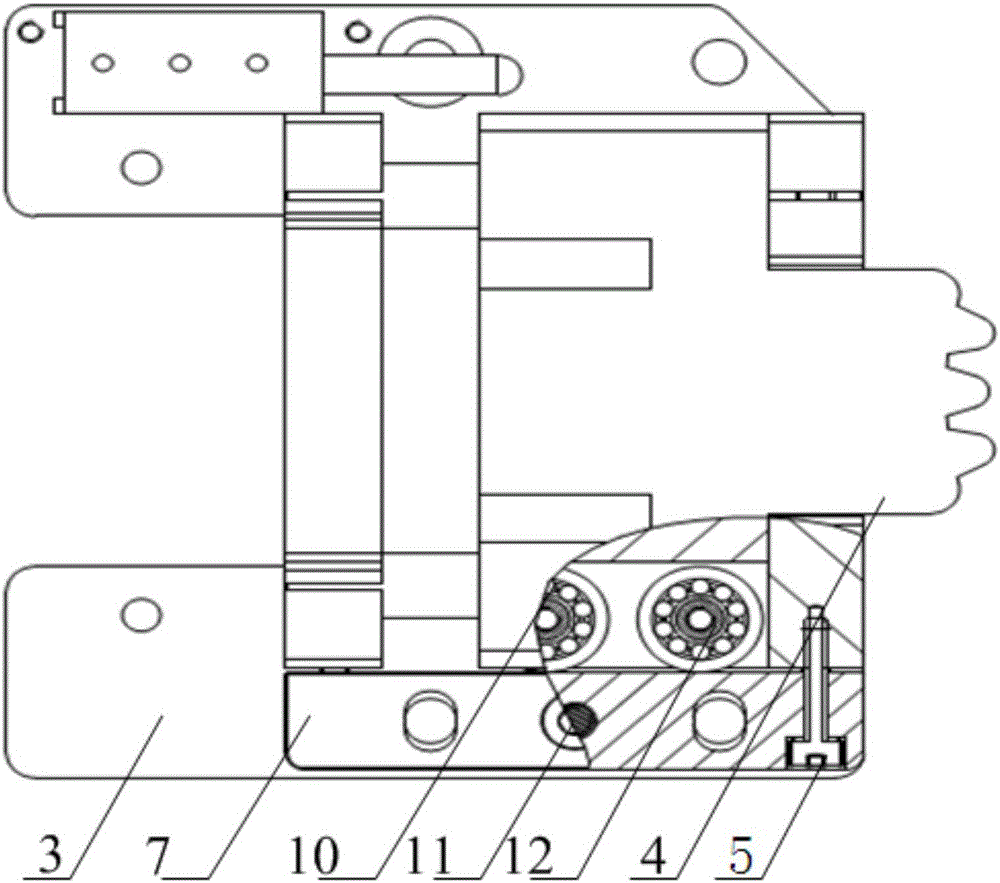

[0029] The rotating shaft locking device of the transmission mechanism of the present invention controls the movement of the locking block 4 by using a linear motor with a self-locking function, and relies on the front teeth of the locking block 4 to be inserted into the locking gear connected to the rotating shaft so that the two teeth mesh with each other. Realize the locking of the rotating shaft, so as to realize the locking of the transmission mechanism such as the turntable connected with the rotating shaft; when unlocking, control the motor to disengage the front teeth of the locking mechanism from the locking gear, and rely on the screw nut pair of the linear stepping motor Self-locking ability to maintain locking force and locking accuracy.

[0030] Specifically, such as figure 1 As...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com