Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "High calcium tolerance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing polyacrylate-2-acrylamide-2-methyl propane sulfonic acid

The invention discloses a method for preparing polyacrylic acid-2-acrylamide-2-methyl propanesulfonic acid. The method mainly comprises the following steps: 5 to 30 mass percent of crylic acid, 1 to 15 mass percent of 2-acrylamide-2-methyl propanesulfonic acid, 0.5 to 6 mass percent of persulfate, 0.2 to 3 mass percent of sodium sulfite, 0.05 to 3 mass percent of L-ascorbic acid, 0.5 to 9 mass percent of ethanol, 0.5 to 3 mass percent of dodecyl mercaptan and 50 to 85 mass percent of water are mixed to have polymerization reaction for not less than one hour at a temperature of between 35 and 60 DEG C to obtain the polyacrylic acid-2-acrylamide-2-methyl propanesulfonic acid. The method has the advantages the polyacrylic acid-2-acrylamide-2-methyl propanesulfonic acid with low molecular weight is synthesized once, has low starting reaction temperature, less energy consumption, rapid reaction speed, high utilization efficiency of equipment, a simple process and convenient operation.

Owner:娄底市裕德科技有限公司

Method for descaling steel-making turbid circulation water

InactiveCN1749185ASo as not to damageGood descaling effectWater softeningWater/sewage treatment by flocculation/precipitationSodium carbonateChemistry

The method of descaling steel-making turbid circulation water includes precipitation and separation of turbid circulation water in sedimentation tank, in which are added sodium carbonate to lower calcium hardness of water, descaling dispersant for descaling and dispersion, and flocculant to lower water turbidity. The present invention has high descaling effect and no damage to production equipment, can decrease calcium ion of water to eliminate scale radically, and has the advantages of low cost, easy cleaning, etc.

Owner:姚可佩

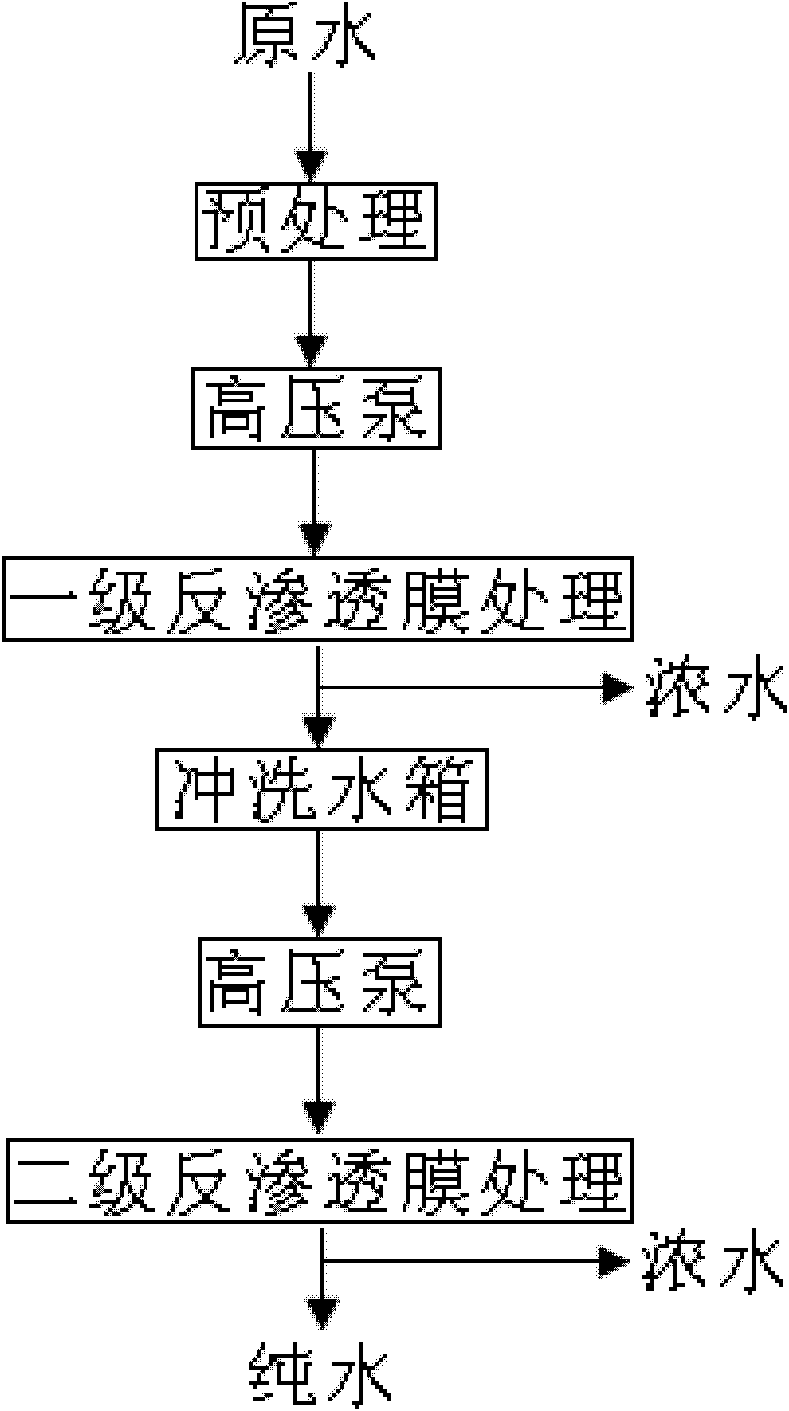

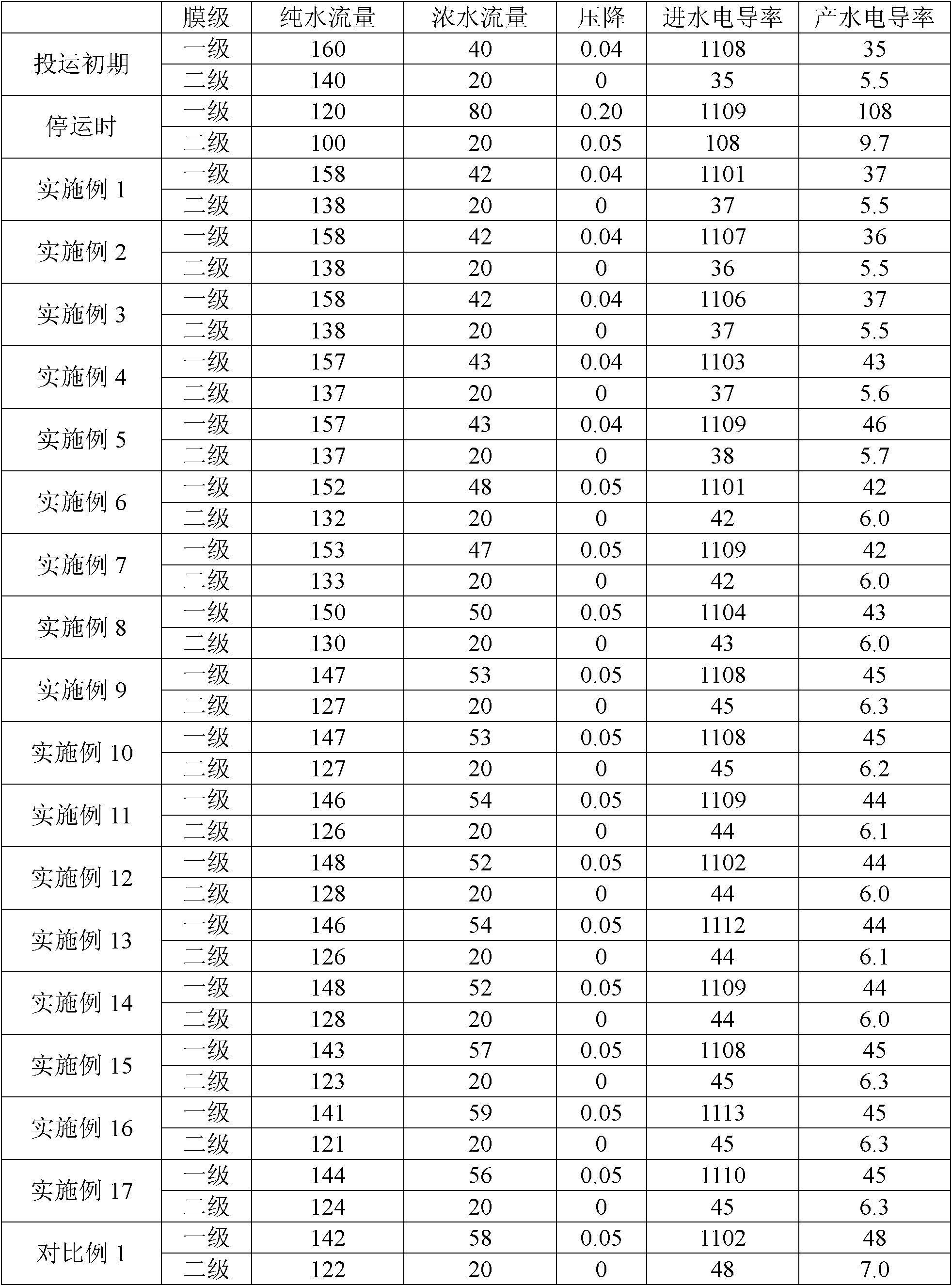

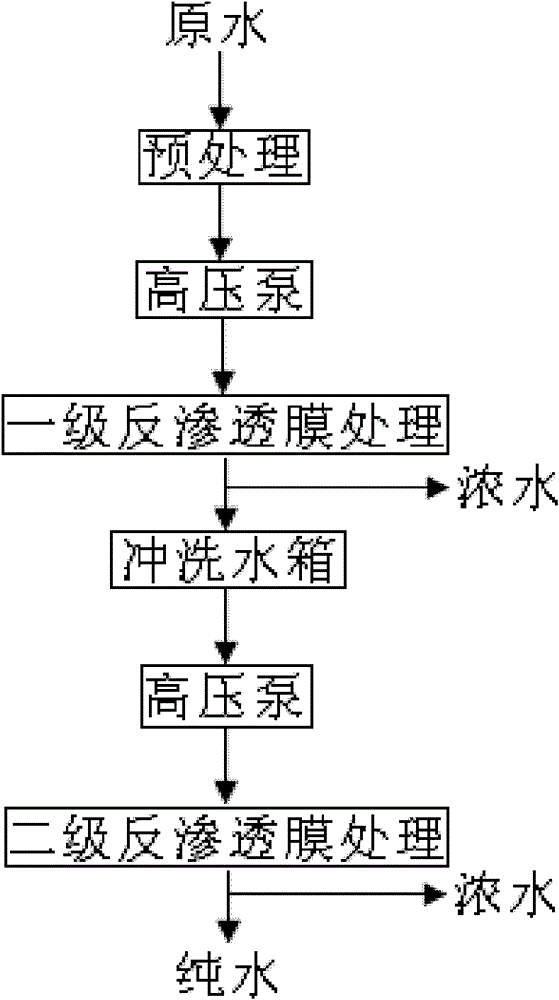

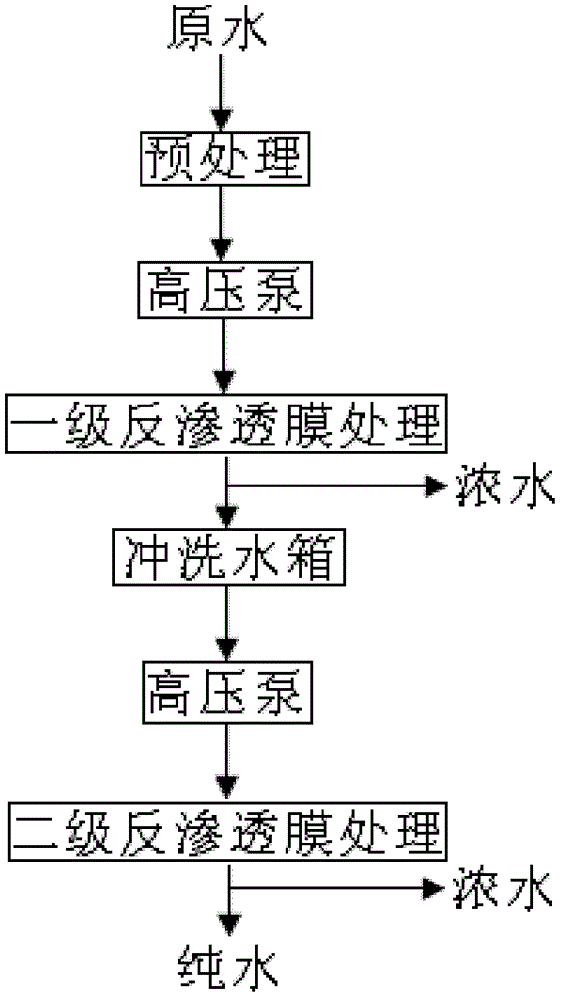

Cleaning agent composition and cleaning method for reverse osmosis membrane

ActiveCN103143263AGood dissolution and removal effectImprove solubilitySemi-permeable membranesReverse osmosisTRISODIUM NITRILOTRIACETATE

The invention relates to a cleaning agent composition, comprising citric acid, hydrochloric acid, trisodium nitrilotriacetate and a dispersing agent. The dispersing agent is selected at least one from an organic phosphonic acid, a poly-aspartic acid, a polyepoxysuccinic acid and a co-polymer and / or a homopolymer obtained by polymerization of at least one of an unsaturated organic acid, an unsaturated organic acid ester and an unsaturated organic acid anhydride, wherein the organic phosphonic acid comprises one or more of hydroxyls, amino groups, carboxyls and sulfonyls. The invention also relates to a method for cleaning a reverse osmosis membrane by using the above cleaning agent composition. The method comprises the steps of preparing the cleaning agent composition into a cleaning liquid with a pH value of 2.5-3.5 and cleaning the reverse osmosis membrane by using the cleaning liquid. The cleaning liquid prepared by the cleaning agent composition can clean the reverse osmosis membrane effectively, makes water yield of a reverse osmosis system restore basically, and can significantly reduce front-and-back pressure difference of the reverse osmosis membrane and reduce conductivity of produced water.

Owner:CHINA PETROLEUM & CHEM CORP +1

Special scale inhibitor for reverse osmosis membrane water treatment system

InactiveCN106830188AIncrease the concentration factorGood acid and alkali resistanceSemi-permeable membranesSpecific water treatment objectivesCompound organicWater production

The invention relates to a special scale inhibitor for a reverse osmosis membrane water treatment system. The special scale inhibitor is prepared from the following components in parts by mass: 1 to 5 parts of hydroxyethanediphosphonic acid, 1 to 9 parts of 2-phosphonobutane-1,2,4-tricarboxylic acid, 1 to 3 parts of acrylic acid-2-acrylamido-2-methyl propyl sulfonic acid copolymer, and 5 to 15 parts of water. The scale inhibitor has the advantages that the scaling of inorganic matters at the membrane surface is effectively controlled, the water production rate and water production quality of the membrane system are effectively improved, the cleaning frequency of the membrane system is reduced, the service life of the membrane is prolonged, and the operation cost of the membrane system is reduced; the special scale inhibitor for reverse osmosis is mainly formed by compounding organic phosphine and low-molecular polycarboxylic acid, and contains functional groups of carboxylic groups, hydroxyl groups, phosphonic groups, sulfonic groups and amide groups, so that the secondary scaling of calcium phosphate is prevented, and the precipitation of adhering particles due to exceeding of critical concentration caused by change of water quality can be effectively inhibited.

Owner:云南天朗环境科技有限公司

Self-emulsifying hydrophobic association type polyacrylamide grafted guanidine gum, preparation method thereof and application thereof in oil field

PendingCN111320723AHigh calcium toleranceGood scale resistanceDrilling compositionAcryditeCross linker

The invention discloses a self-emulsifying hydrophobic association type polyacrylamide grafted guanidine gum and a preparation method and application thereof in an oil field, and the preparation method comprises the following steps: 1) mixing paraffin, a compound emulsifier and hexadecanol to prepare an oil phase; adding guanidine gum to obtain a reversed-phase emulsion; 2) adding the reversed-phase emulsion into an acrylamide solution, a sodium 2-acrylamido dodecanesulfonate solution and an N-n-dodecyl acrylamide solution; 3) adding an initiator solution, stirring under the condition of introducing nitrogen, and stopping introducing the nitrogen into the sealing device for reaction; 4) after the reaction is finished, demulsifying with ethanol, performing suction filtration, washing and drying to obtain a crude product; 5) extracting the crude product, and 6) adding a borax cross-linking agent into the grafted guanidine gum solution to prepare the self-emulsifying hydrophobic association type polyacrylamide grafted guanidine gum fracturing fluid. The salt resistance of the guanidine gum fracturing fluid is improved, and the temperature resistance and salt resistance of the copolymer grafted guanidine gum fracturing fluid are improved.

Owner:甘肃智仑新材料科技有限公司

Cleaning agent composition and cleaning method for reverse osmosis membrane

ActiveCN103143261AImprove lipophilicityReduce foamingSemi-permeable membranesReverse osmosisEthylene Homopolymers

The invention relates to a cleaning agent composition, comprising an A agent and a B agent. The A agent and the B agent are stored independently. The A agent comprises a non-ionic surfactant and a dispersing agent, wherein the non-ionic surfactant is a fatty alcohol-polyoxyethylene ether; and the dispersing agent is selected at least one from an organic phosphonic acid, a poly-aspartic acid, a polyepoxysuccinic acid and a co-polymer and / or a homopolymer obtained by polymerization of at least one of an unsaturated organic acid, an unsaturated organic acid ester and an unsaturated organic acid anhydride. The B agent contains a foaming agent. The invention also relates to a method for cleaning a reverse osmosis membrane by using the above cleaning agent composition. A cleaning liquid prepared by the cleaning agent composition can clean the reverse osmosis membrane effectively, makes water yield of a reverse osmosis system restore basically, and can significantly reduce front-and-back pressure difference of the reverse osmosis membrane and reduce conductivity of produced water.

Owner:CHINA PETROLEUM & CHEM CORP +1

Solid corrosion and scale inhibitor and processing method thereof

ActiveCN111219168AEasy to useEvenly dispersedScale removal and water softeningCleaning apparatusFungicideO-Phosphoric Acid

The invention relates to a solid corrosion and scale inhibitor and a processing method thereof, and belongs to the technical field of oil-water well scale prevention. The solid corrosion and scale inhibitor comprises the following components in parts by weight: 30 to 35 parts of imidazoline quaternary ammonium salt, 8 to 10 parts of organic phosphoric acid, 1-3 parts of fungicide, 0.5-1 part of dispersant, and 20-30 parts of water. The processing method comprises the following step of evenly dispersing the imidazoline quaternary ammonium salt, the organic phosphoric acid and the fungicide in the dispersant of the network structure to form a solid block. A long-acting slow-release mechanism is that the dissolution rate of an oil-soluble slow-release regulator with a network structure achieves slow and stable release, so that the imidazoline quaternary ammonium salt and the organic phosphoric acid are uniformly dispersed in an oil-water mixture in a shaft to form the scale inhibitor withcomprehensive effects of slow release, scale inhibition and sterilization, and the user performance is high..

Owner:刘辉

Cleaning agent composition and cleaning method for reverse osmosis membrane

ActiveCN103143264AImprove wettabilityImprove washing effectSemi-permeable membranesReverse osmosisEthylene Homopolymers

The invention relates to a cleaning agent composition, comprising a non-ionic surfactant and a dispersing agent, wherein the non-ionic surfactant is a fatty alcohol-polyoxyethylene ether; and the dispersing agent is a (methyl)acrylic homopolymer and / or a (methyl)acrylic acid copolymer. The invention also relates to a method for cleaning a reverse osmosis membrane by using the above cleaning agent composition. The method comprises the steps of preparing the cleaning agent composition into a cleaning liquid with a pH value of 10.5-11.5 and cleaning the reverse osmosis membrane by using the cleaning liquid. The cleaning liquid prepared by the cleaning agent composition can clean the reverse osmosis membrane effectively, makes water yield of a reverse osmosis system restore basically, and can significantly reduce front-and-back pressure difference of the reverse osmosis membrane and reduce conductivity of produced water.

Owner:CHINA PETROLEUM & CHEM CORP +1

Negative ion air purification solution and preparation method thereof

InactiveCN110227334AHigh content of negative ion mother liquorHigh calcium toleranceGas treatmentDispersed particle separationTectorial membranePhysical chemistry

The invention discloses a negative ion air purification solution, which comprises the following components by weight: 80-96 parts of a negative ion mother liquor, 0.2-1 part of a dispersant, 3-10 parts of a weakly alkaline additive, 0.5-3 parts of a film-forming agent and 0.1-0.7 part of a film-forming additive. The negative ion air purification solution has pH of 6.0-7.2 and a negative ion concentration of 2000-30000 / cubic centimeter. The negative ion air purification solution is added with the dispersant and weakly alkaline additive, the dispersant has high calcium tolerance and can effectively prevent the deposition of various salts, and the weakly alkaline additive can neutralize the acidity of the negative ion mother liquor and make the pH of the negative ion air purification solutionapproach or reach neutral. The negative ion air purification solution does not corrode metal parts during use, and does not require constructors to wrap metal parts with a protective film in advance,thus saving labor and being safe.

Owner:GUANGZHOU NANENG ENVIRONMENTAL PROTECTION TECHCAL DEV CO LTD

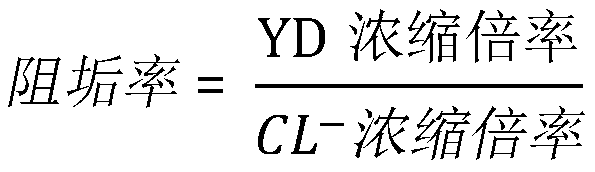

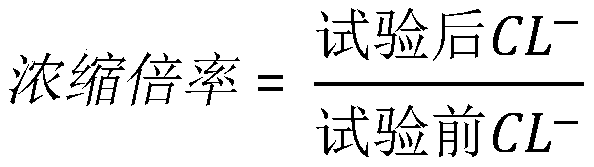

Anti-scaling agent of reverse osmosis membrane, and application thereof

ActiveCN102397753AImprove work efficiencyHigh calcium toleranceSemi-permeable membranesScale removal and water softeningReverse osmosisCarboxylic acid

The invention relates to a composite anti-scaling agent of a reverse osmosis membrane, and an application thereof. The composite anti-scaling agent comprises a component a and a component b, wherein the component a comprises at least one selected from methylene phosphonic carboxylic acid, the general formula of the component a is RCH(COOH)N(CH2PO3H2)2, the RCH(COOH)N is selected from an amino acid, the component b comprises at least one material selected from an organic phosphonic acid polymer and / or an organic carboxylic acid polymer. With adopting the composite anti-scaling agent of the present invention to carry out water treatment for a reverse osmosis system, the problems of CaCO3 deposition and CaSO4 deposition on the reverse osmosis membrane can be solved, the membrane pollution due to the CaCO3 deposition and the CaSO4 deposition can be eliminated, the work efficiency of the reverse osmosis system can be improved, the service lives of the reverse osmosis membrane and the reverse osmosis equipment can be prolonged, and the reverse osmosis cost can be reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Super-branched chain reverse osmosis scale inhibitor with net structure as well as preparation method and application of super-branched chain reverse osmosis scale inhibitor

ActiveCN109592746AHigh calcium toleranceGood dispersion performanceWater/sewage treatment bu osmosis/dialysisOrganic acid2-Acrylamido-2-methylpropane sulfonic acid

The invention provides a super-branched chain reverse osmosis scale inhibitor with a net structure. The super-branched chain reverse osmosis scale inhibitor is characterized by being prepared from substances containing the following components: the mass ratio of an acrylic acid-2-acrylamido-2-methylpropane sulfonic acid copolymer to a mixture of polyamino polyether methylene phosphonate and organic phosphine derivatives to tricarboxylic acid is (2-2.5):1:(0.5-1); the mass of water is 1-1.5 times as much as the sum of masses of the acrylic acid-2-acrylamido-2-methylpropane sulfonic acid copolymer, the mixture of polyamino polyether methylene phosphonate and organic phosphine derivatives and tricarboxylic acid; the mass of a crosslinking agent is 0.5-1% of the mass of the water; and the concentration of an organic acid catalyst in the water is 0.5-1 mol / L. A scale inhibitor is capable of effectively preventing carbonate, sulfate, metal oxide and silicon dioxide from blocking a reverse osmosis membrane and effectively realizing sterilization.

Owner:SHANGHAI FENGXIN ENVIRONMENTAL PROTECTION TECH

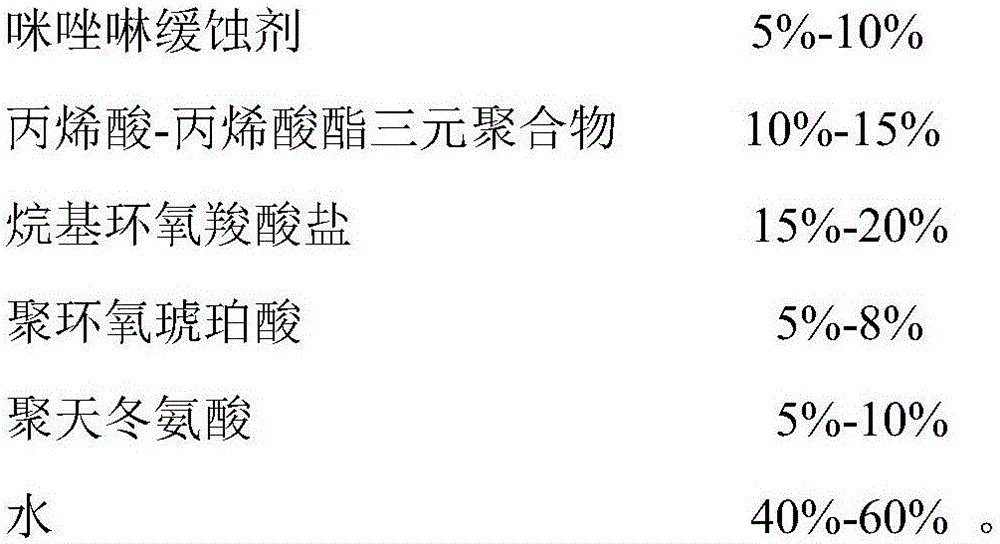

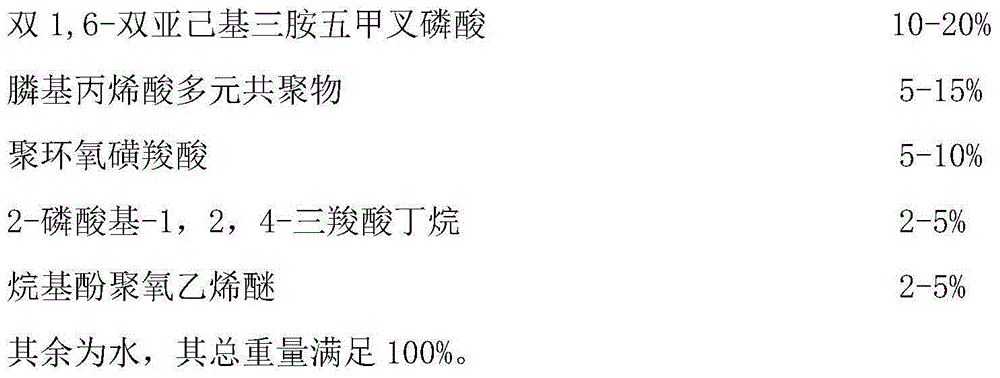

Novel multifunctional scale inhibitor for leachate deep treatment

InactiveCN106673215ANo irritating smellImprove thermal stabilityScale removal and water softeningContaminated groundwater/leachate treatmentEpoxyCarboxylic salt

The invention discloses a novel multifunctional scale inhibitor for leachate deep treatment. The novel multifunctional scale inhibitor comprises the following ingredients in percentage by mass: 3 to 15 percent of imidazoline corrosion inhibitors, 5 to 20 percent of acrylic acid- acrylic ester ternary polymers, 10 to 25 percent of alkyl epoxy carboxylate, 3 to 10 percent of polyepoxysuccinic acid, 3 to 15 percent of polyaspartic acid and 30 to 70 percent of water. The novel multifunctional scale inhibitor is invented by specially aiming at the characteristics of high hardness, high alkalinity, high heavy metal pollution concentration of the landfill leachate wastewater; ingredients with certain scale inhibition, dispersion and corrosion inhibition effects are compounded; the synergistic interaction effect is achieved. The novel multifunctional scale inhibitor has the advantages that the price is low; the cost is low; the good effects are achieved on the corrosion inhibition of the metal pipeline in the leachate deep treatment and the scale inhibition of a reverse osmosis membrane.

Owner:SHANGHAI FENGXIN ENVIRONMENTAL PROTECTION TECH

Coal chemical industry grey water scale inhibitor

PendingCN112194261AImprove thermal stabilityReduce decompositionSpecific water treatment objectivesScale removal and water softeningMeth-Greywater

The invention discloses a coal chemical industry grey water scale inhibitor, and belongs to the technical field of grey water scale inhibitors. The coal chemical industry grey water scale inhibitor comprises the following components by weight: 10-15 parts of water; 20-35 parts of polyamino polyether methylene phosphonic acid; 32-47 parts of an acrylic acid-2-acrylamide-2-methyl propanesulfonic acid copolymer; 17-28 parts of an acrylic acid-acrylate copolymer; 2-8 parts of a compounding agent; 1-3 parts of a stabilizer; and 2-5 parts of a passivation solution. The scale inhibitor of the invention has the advantages of being stable at high temperature, high in scale inhibition rate and good in corrosion inhibition.

Owner:上海鲁昕化工科技有限公司

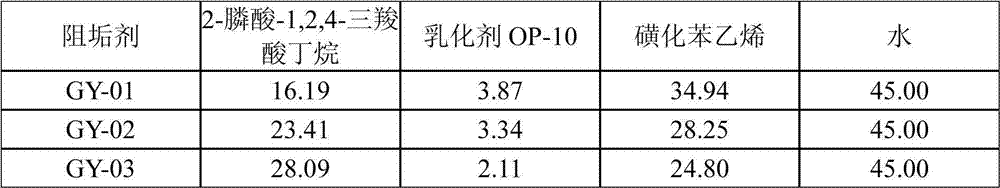

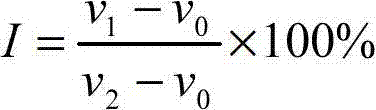

Antiscalant agent for water-in-oil system in high-temperature oilfield environment, its preparation method and application

ActiveCN104370379BEnhanced inhibitory effectDiffusion uniqueWaste water treatment from quariesWater treatment compoundsEpoxyEnvironment water

Owner:CNOOC TIANJIN CHEM RES & DESIGN INST +1

Method for preparing polyacrylate-2-acrylamide-2-methyl propane sulfonic acid

The invention discloses a method for preparing polyacrylic acid-2-acrylamide-2-methyl propanesulfonic acid. The method mainly comprises the following steps: 5 to 30 mass percent of crylic acid, 1 to 15 mass percent of 2-acrylamide-2-methyl propanesulfonic acid, 0.5 to 6 mass percent of persulfate, 0.2 to 3 mass percent of sodium sulfite, 0.05 to 3 mass percent of L-ascorbic acid, 0.5 to 9 mass percent of ethanol, 0.5 to 3 mass percent of dodecyl mercaptan and 50 to 85 mass percent of water are mixed to have polymerization reaction for not less than one hour at a temperature of between 35 and60 DEG C to obtain the polyacrylic acid-2-acrylamide-2-methyl propanesulfonic acid. The method has the advantages the polyacrylic acid-2-acrylamide-2-methyl propanesulfonic acid with low molecular weight is synthesized once, has low starting reaction temperature, less energy consumption, rapid reaction speed, high utilization efficiency of equipment, a simple process and convenient operation.

Owner:娄底市裕德科技有限公司

Anti-scaling agent of reverse osmosis membrane, and application thereof

ActiveCN102397753BImprove work efficiencyHigh calcium toleranceSemi-permeable membranesScale removal and water softeningReverse osmosisCarboxylic acid

The invention relates to a composite anti-scaling agent of a reverse osmosis membrane, and an application thereof. The composite anti-scaling agent comprises a component a and a component b, wherein the component a comprises at least one selected from methylene phosphonic carboxylic acid, the general formula of the component a is RCH(COOH)N(CH2PO3H2)2, the RCH(COOH)N is selected from an amino acid, the component b comprises at least one material selected from an organic phosphonic acid polymer and / or an organic carboxylic acid polymer. With adopting the composite anti-scaling agent of the present invention to carry out water treatment for a reverse osmosis system, the problems of CaCO3 deposition and CaSO4 deposition on the reverse osmosis membrane can be solved, the membrane pollution due to the CaCO3 deposition and the CaSO4 deposition can be eliminated, the work efficiency of the reverse osmosis system can be improved, the service lives of the reverse osmosis membrane and the reverse osmosis equipment can be prolonged, and the reverse osmosis cost can be reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

A composite non-phosphorus corrosion and scale inhibitor

InactiveCN105800802BGood water solubilityPromote degradationSpecific water treatment objectivesTreatment using complexing/solubilising chemicalsSolubilitySulfate

The invention discloses composite type phosphorous-free corrosion and scale inhibitor.The composite type phosphorous-free corrosion and scale inhibitor is composed of, by weight, 20-30 parts of S-carboxyalkylthiosuccinic acid (CETSA), 10-15 parts of sodium gluconate, 5-8 parts of sodium benzoate, 10-20 parts of hydroxy-propyl acrylate (HPA), 5-10 parts of zinc sulfate and 35-45 parts of water.CETSA is good in water solubility and biodegradability and has good corrosion and scale inhibition performance within a wide pH range, and particularly after CETSA is compounded with sodium gluconate, hydroxy-propyl acrylate (HPA), Zn salt and the like, the corrosion inhibiting rate is remarkably raised.Under the conditions that the temperature is 45 DEG C and the mass fraction is 20 micrograms / g, the corrosion inhibiting rate of the composite type phosphorous-free corrosion and scale inhibitor can reach 93.2%, and the scale inhibiting rate reaches 98.5%.

Owner:中山市瑞龙环保工程服务有限公司

Scale and corrosion inhibitor for high-alkalinity and high-hardness water

ActiveCN103819012BLow in phosphorusHigh calcium toleranceTreatment using complexing/solubilising chemicalsAlkalinityCarboxylic salt

The invention discloses a scale and corrosion inhibitor composition with relatively low phosphorus content, which is special for high-alkalinity and high-hardness water. The composition comprises fatty alcohol-polyoxyethylene ether carboxylate, an organic phosphine scale and corrosion inhibitor, zinc salt and the balance of deionized water. The scale and corrosion inhibitor can be used for a cooling water system with high pH value, alkalinity, hardness and concentration multiple, and has a good corrosion inhibition effect on carbon steel.

Owner:SHANDONG TAIHE WATER TREATMENT TECH CO LTD

Oil field scale inhibitor as well as preparation method and application thereof

ActiveCN102703047BImprove thermal stabilityHigh calcium toleranceDrilling compositionBorehole/well accessoriesTricarboxylic acidThermal stability

Owner:PETROCHINA CO LTD

Hyperbranched reverse osmosis antiscalant with network structure, preparation method and application thereof

ActiveCN109592746BGood scale resistanceHigh calcium toleranceWater/sewage treatment bu osmosis/dialysisPolymer sciencePtru catalyst

The invention provides a hyperbranched reverse osmosis scale inhibitor with a network structure, which is characterized in that it is prepared from the following components: acrylic acid-2-acrylamide-2-methylpropanesulfonic acid copolymer, poly The mixture of amino polyether group methylene phosphonic acid and organic phosphine derivatives, the mass ratio of tricarboxylic acid is 2~2.5:1:0.5~1; the quality of water is acrylic acid-2-acrylamide-2-methyl 1 to 1.5 times the mass of propanesulfonic acid copolymer, mixture of polyamino polyether group methylene phosphonic acid and organic phosphine derivatives, and tricarboxylic acid; the mass of the crosslinking agent is 0.5 of the mass of water ~1%; the concentration of inorganic acid catalyst in water is 0.5~1mol / L. The scale inhibitor can effectively prevent the fouling of the reverse osmosis membrane by carbonate, sulfate, metal oxide and silicon dioxide, and the scale inhibitor can effectively kill bacteria.

Owner:SHANGHAI FENGXIN ENVIRONMENTAL PROTECTION TECH

Cleaning agent composition and cleaning method for reverse osmosis membrane

ActiveCN103143261BImprove lipophilicityReduce foamingSemi-permeable membranesFoaming agentReverse osmosis

Owner:CHINA PETROLEUM & CHEM CORP +1

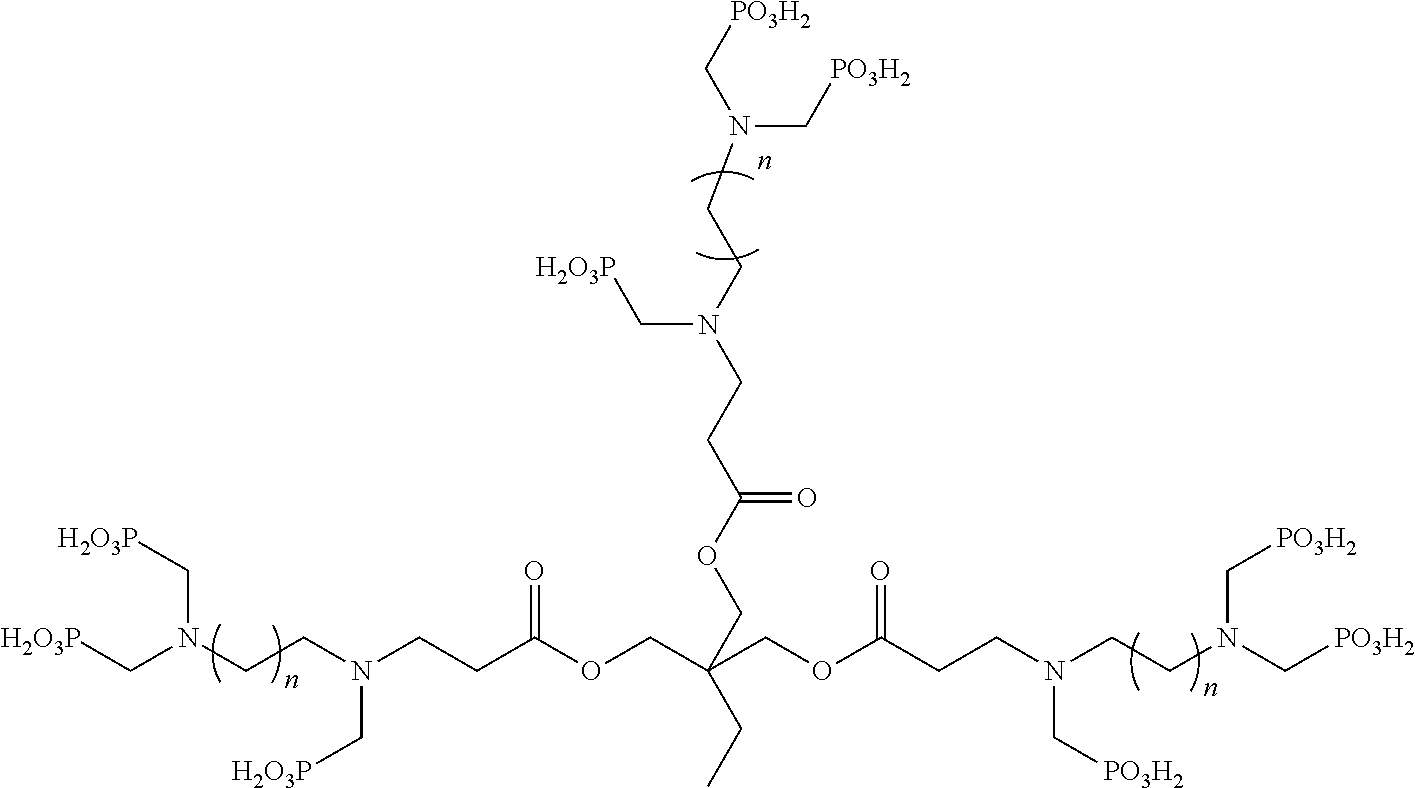

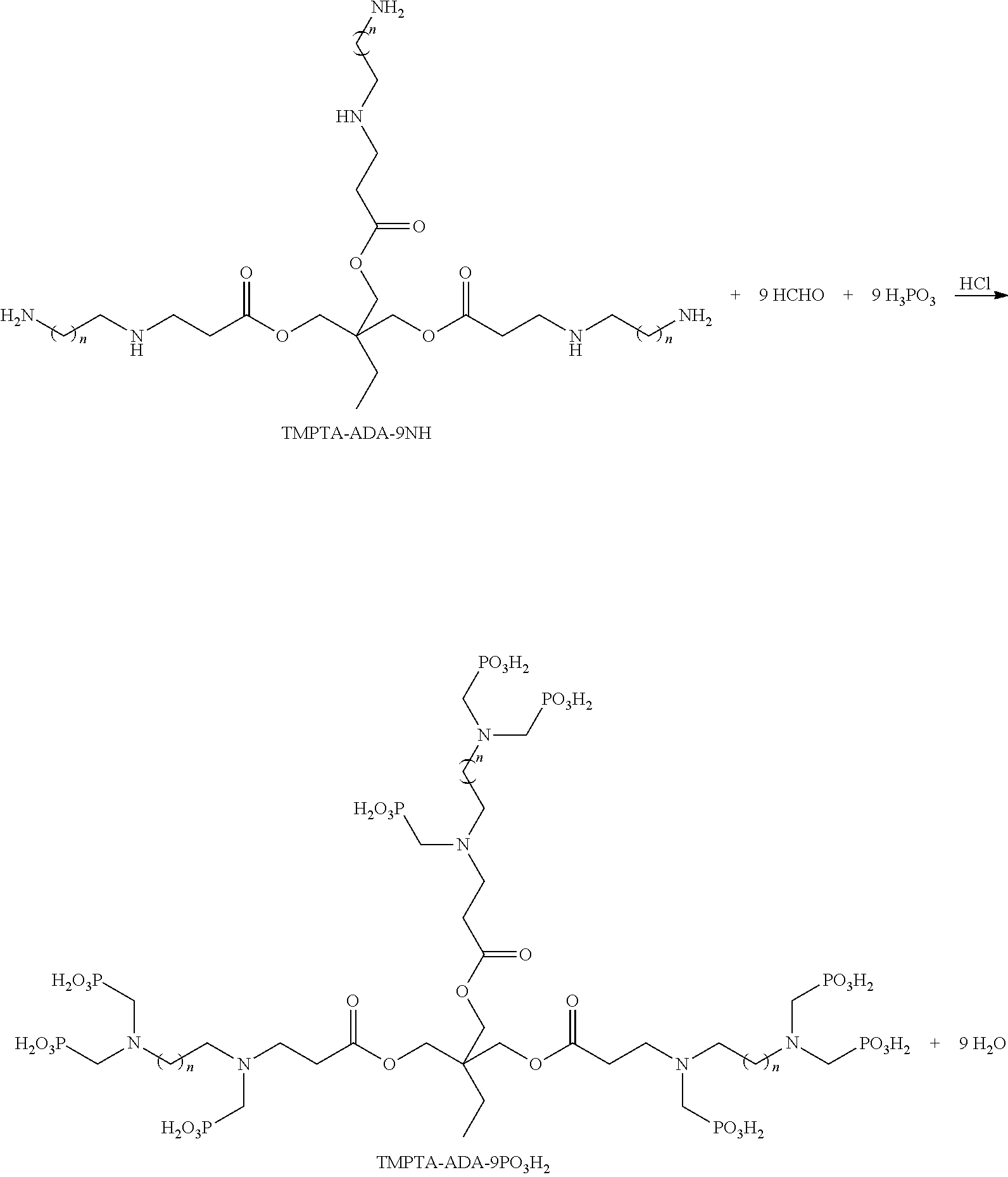

Trimethylolpropane core, phosphonic acid terminated dendrimer and its preparation method

ActiveUS9403853B2Prevent scalingHigh calcium toleranceWaste water treatment from quariesSemi-permeable membranesDendrimerReverse osmosis

A trimethylolpropane core, phosphonic acid terminated dendrimer and its preparation method are provided, And a preparation method thereof comprises steps of processing Michael addition reaction on trimethylolpropane triacrylate (CH3CH2C(CH2OCOCH2═CH2)3) and alkylidene diamine (NH2CH2(CH2)nNH2), wherein n is an integer from 1 to 5, so as to obtain trimethylolpropane core, amino group terminated dendrimer, and modifying the amino group by methylene phosphonic acid to obtain the trimethylolpropane core, phosphonic acid terminated dendrimer having a chemical formula of CH3CH2C[CH2OCOCH2CH2N(CH2PO3H2)CH2(CH2)nN(CH2PO3H2)2]3, wherein n is an integer from 1 to 5. The trimethylolpropane core, phosphonic acid terminated dendrimer has high calcium tolerance, and excellent inhibiting efficiency of calcium carbonate, calcium sulfate and barium sulfate, which is applied in inhibiting the formation and deposition in industrial water systems of circulating cooling water, oilfield flooding and reverse osmosis, and particularly suitable for water treatment with high calcium tolerance.

Owner:TONGJI UNIV

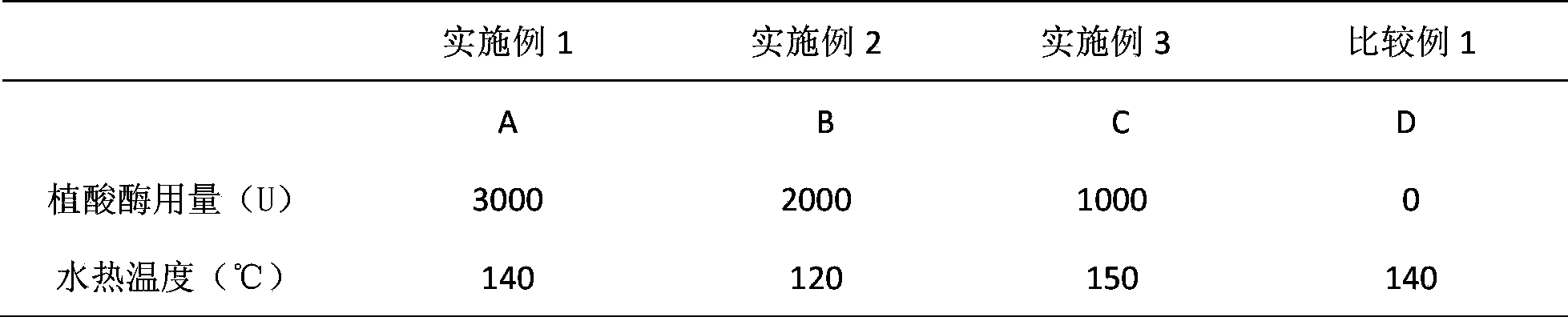

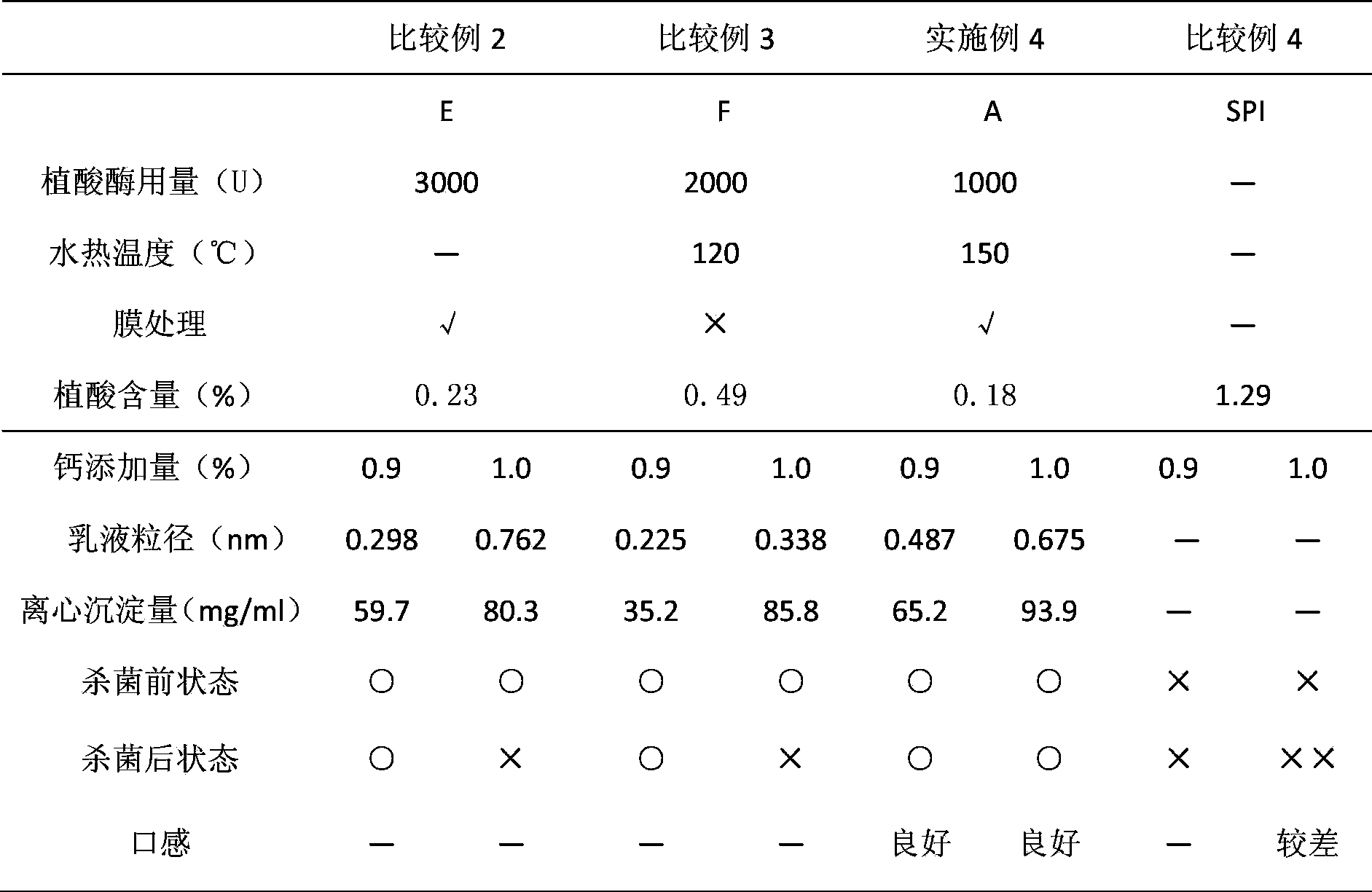

A kind of preparation method of low phytic acid calcium-tolerant soybean protein

ActiveCN103053786BHigh calcium toleranceHigh in sugarProtein composition from vegetable seedsProtein solutionPhytase

Owner:SOUTH CHINA UNIV OF TECH

A kind of preparation method and application of reverse osmosis phosphorus-free scale inhibitor with network structure

ActiveCN111302506BImprove toleranceGood scale resistanceSemi-permeable membranesScale removal and water softeningDiethylenetriamineReverse osmosis

Owner:SHANGHAI FENGXIN ENVIRONMENTAL PROTECTION TECH

Coal gasification grey water dispersing agent and preparation method thereof

PendingCN113816504AExcellent anti-scaling and dispersing effect at high temperatureMaintain scale inhibition dispersion rateSpecific water treatment objectivesScale removal and water softeningO-Phosphoric AcidBiopolymer

The invention discloses a coal gasification grey water dispersing agent and a preparation method thereof, the coal gasification grey water dispersing agent comprises 5%-15% of phosphoric acid tricarboxylic acid butane, 5%-15% of polymaleic anhydride, 5%-15% of acrylic acid-acrylamide sulfonate biopolymer and tap water, and the preparation method comprises the steps of material picking, feeding, standing and filtering. According to the present invention, the high-temperature scale inhibition dispersion effect is excellent, the scale inhibition dispersion rate of more than 80% at the high temperature of more than 200 DEG C is still maintained, the scale inhibition dispersion agent has been applied to a variety of gasification furnaces such as coal water slurry gasification, pulverized coal gasification and the like, can be used for a long enough period, can not be stopped for more than 6 months, and can ensure the continuous and stable operation of the device.

Owner:南京开广化工有限公司

Reverse osmosis scale inhibitor and preparation method thereof

PendingCN114159976AExcellent anti-scaling performance in concentrated waterGood anti-scaling effectSemi-permeable membranesMeth-Biopolymer

The invention discloses a preparation method of a reverse osmosis scale inhibitor. The reverse osmosis scale inhibitor comprises the following raw materials: 10-15 parts of amino trimethylene phosphonic acid, 10-15 parts of an acrylic acid-acrylate sulfonate biopolymer, 3-5 parts of citric acid, 5-8 parts of propyl methacrylamide, 3-6 parts of sodium hydrogen sulfite and 60-70 parts of tap water. The preparation method comprises the following steps: feeding: sucking tap water into a reaction kettle, keeping the temperature at 30-40 DEG C, and starting stirring; adding amino trimethylene phosphonic acid into the reaction kettle; adding citric acid into the reaction kettle; sucking the acrylic acid-acrylate sulfonate binary copolymer into the reaction kettle; after stirring for 3 to 5 minutes, adding propyl methacrylamide and sodium hydrogen sulfite into the reaction kettle; continuously stirring for 20-40 minutes, and uniformly mixing; standing: after standing for 20-40 minutes, cooling to normal temperature, sampling and checking to ensure that no precipitate is separated out; and filtering: after filtering, sub-packaging to obtain a finished product.

Owner:南京开广化工有限公司

Cleaning agent composition and cleaning method for reverse osmosis membrane

ActiveCN103143263BGood dissolution and removal effectImprove solubilitySemi-permeable membranesReverse osmosisTRISODIUM NITRILOTRIACETATE

The invention relates to a cleaning agent composition, comprising citric acid, hydrochloric acid, trisodium nitrilotriacetate and a dispersing agent. The dispersing agent is selected at least one from an organic phosphonic acid, a poly-aspartic acid, a polyepoxysuccinic acid and a co-polymer and / or a homopolymer obtained by polymerization of at least one of an unsaturated organic acid, an unsaturated organic acid ester and an unsaturated organic acid anhydride, wherein the organic phosphonic acid comprises one or more of hydroxyls, amino groups, carboxyls and sulfonyls. The invention also relates to a method for cleaning a reverse osmosis membrane by using the above cleaning agent composition. The method comprises the steps of preparing the cleaning agent composition into a cleaning liquid with a pH value of 2.5-3.5 and cleaning the reverse osmosis membrane by using the cleaning liquid. The cleaning liquid prepared by the cleaning agent composition can clean the reverse osmosis membrane effectively, makes water yield of a reverse osmosis system restore basically, and can significantly reduce front-and-back pressure difference of the reverse osmosis membrane and reduce conductivity of produced water.

Owner:CHINA PETROLEUM & CHEM CORP +1

Cleaning agent composition and cleaning method for reverse osmosis membrane

ActiveCN103143264BImprove wettabilityImprove washing effectSemi-permeable membranesEthylene HomopolymersCleansing Agents

The invention relates to a cleaning agent composition, comprising a non-ionic surfactant and a dispersing agent, wherein the non-ionic surfactant is a fatty alcohol-polyoxyethylene ether; and the dispersing agent is a (methyl)acrylic homopolymer and / or a (methyl)acrylic acid copolymer. The invention also relates to a method for cleaning a reverse osmosis membrane by using the above cleaning agent composition. The method comprises the steps of preparing the cleaning agent composition into a cleaning liquid with a pH value of 10.5-11.5 and cleaning the reverse osmosis membrane by using the cleaning liquid. The cleaning liquid prepared by the cleaning agent composition can clean the reverse osmosis membrane effectively, makes water yield of a reverse osmosis system restore basically, and can significantly reduce front-and-back pressure difference of the reverse osmosis membrane and reduce conductivity of produced water.

Owner:CHINA PETROLEUM & CHEM CORP +1

High temperature resistant composite water treatment agent and preparation method thereof

ActiveCN103466814BImprove pollutionDoes not cause breedingScale removal and water softeningHeat stabilityHigh-temperature corrosion

The invention provides a composite water treatment agent which is used for industrial recycling cooling water treatment, has an excellent CaCO3 scale inhibiting function and good corrosion inhibiting ability, and is particularly applicable to high temperature conditions as well as a preparation method of the composite water treatment agent. The composite water treatment agent provided by the invention is mainly prepared from raw materials such as organic polybasic phosphonic acid, hydrolytic polymaleic anhydride or acrylic acid-maleic anhydride, an inorganic salt corrosion inhibitor and an organic salt corrosion inhibitor. Compared with the prior art, the composite water treatment agent provided by the invention is very high in chemical stability and heat stability, and the scale inhibiting effect under the high temperature condition is guaranteed. The product, namely the composite water treatment agent provided by the invention, aiming at an industrial water system which is high in content of scale-forming ions and higher in medium temperature, can effectively prevent generation of calcium carbonate scales, permit higher operating temperature and bear considerably high total salt content and content of scale-forming ions, and is safe in production and implementation processes, and raw materials are easily obtained.

Owner:SHANDONG TIANQING TECH DEV

Method for descaling steel-making turbid circulation water

InactiveCN1328189CReduce hardnessReduce turbidityWater softeningWater/sewage treatment by flocculation/precipitationTurbidityHardness

The method of descaling steel-making turbid circulation water includes precipitation and separation of turbid circulation water in sedimentation tank, in which are added sodium carbonate to lower calcium hardness of water, descaling dispersant for descaling and dispersion, and flocculant to lower water turbidity. The present invention has high descaling effect and no damage to production equipment, can decrease calcium ion of water to eliminate scale radically, and has the advantages of low cost, easy cleaning, etc.

Owner:姚可佩

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com