Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

43results about How to "Guaranteed filling accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

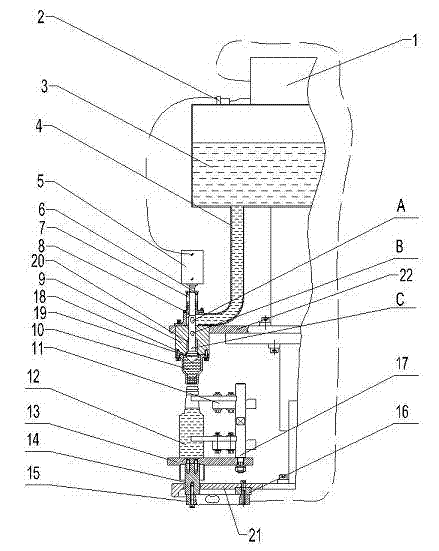

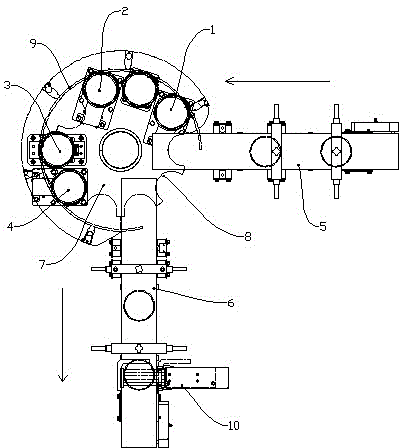

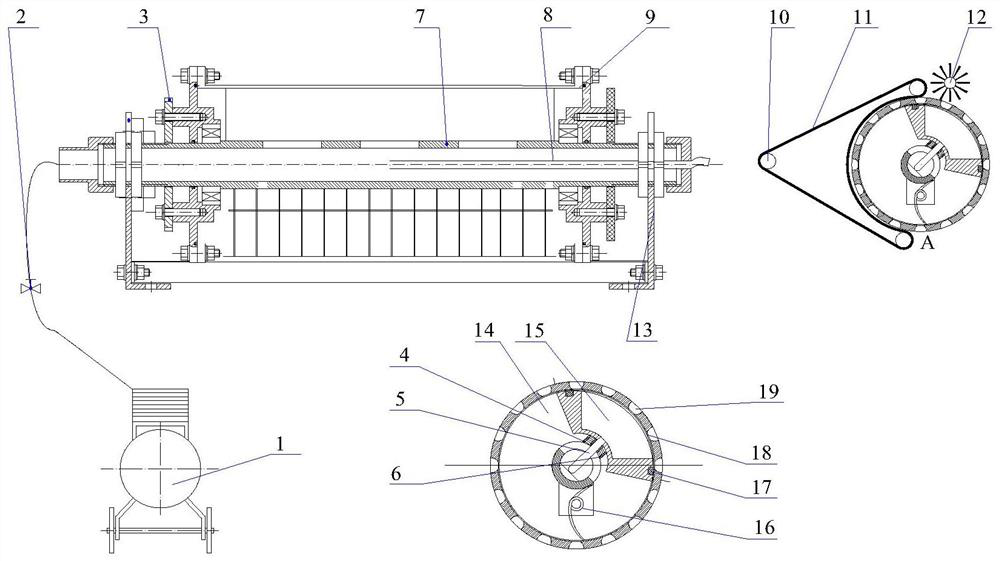

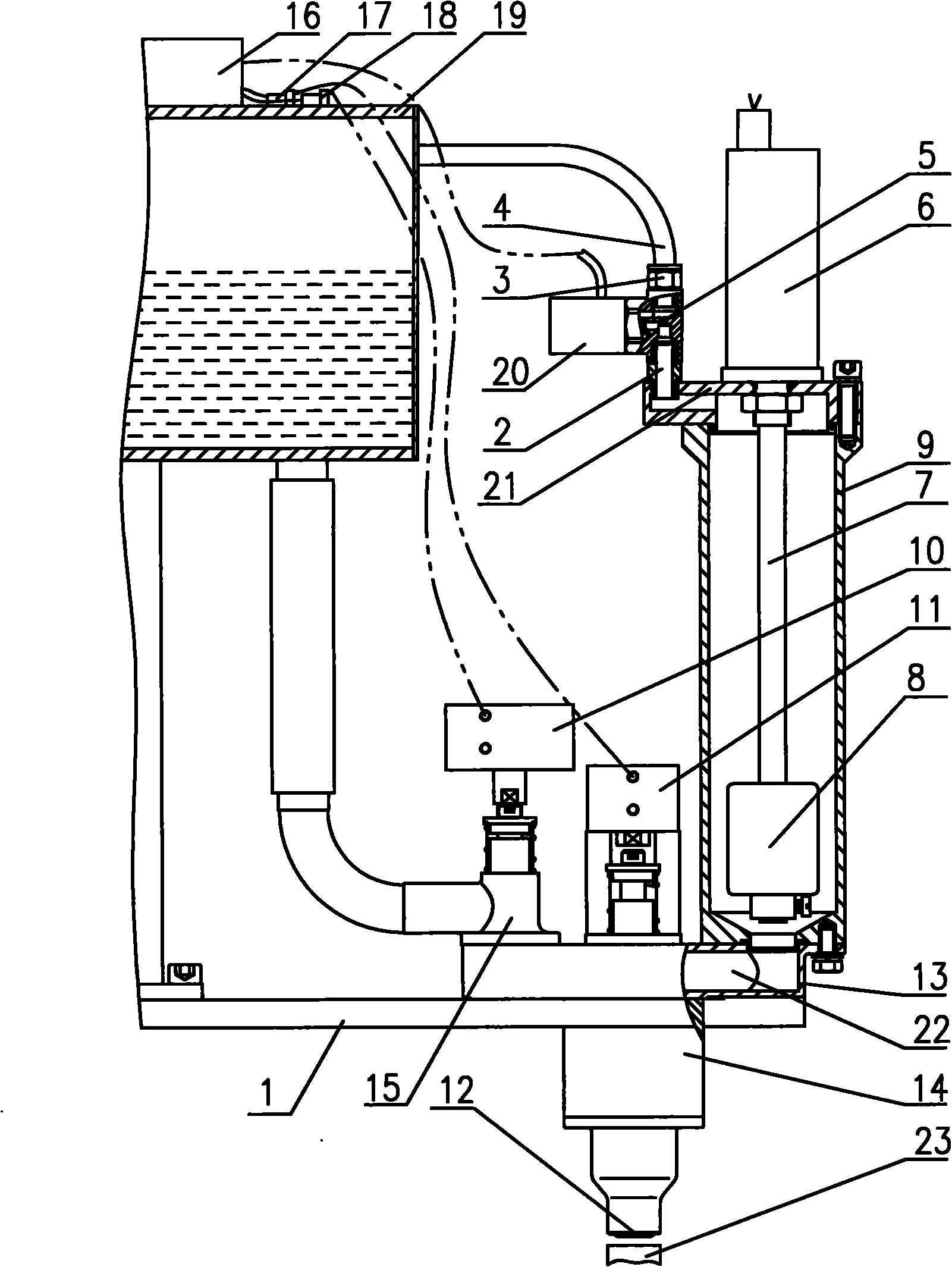

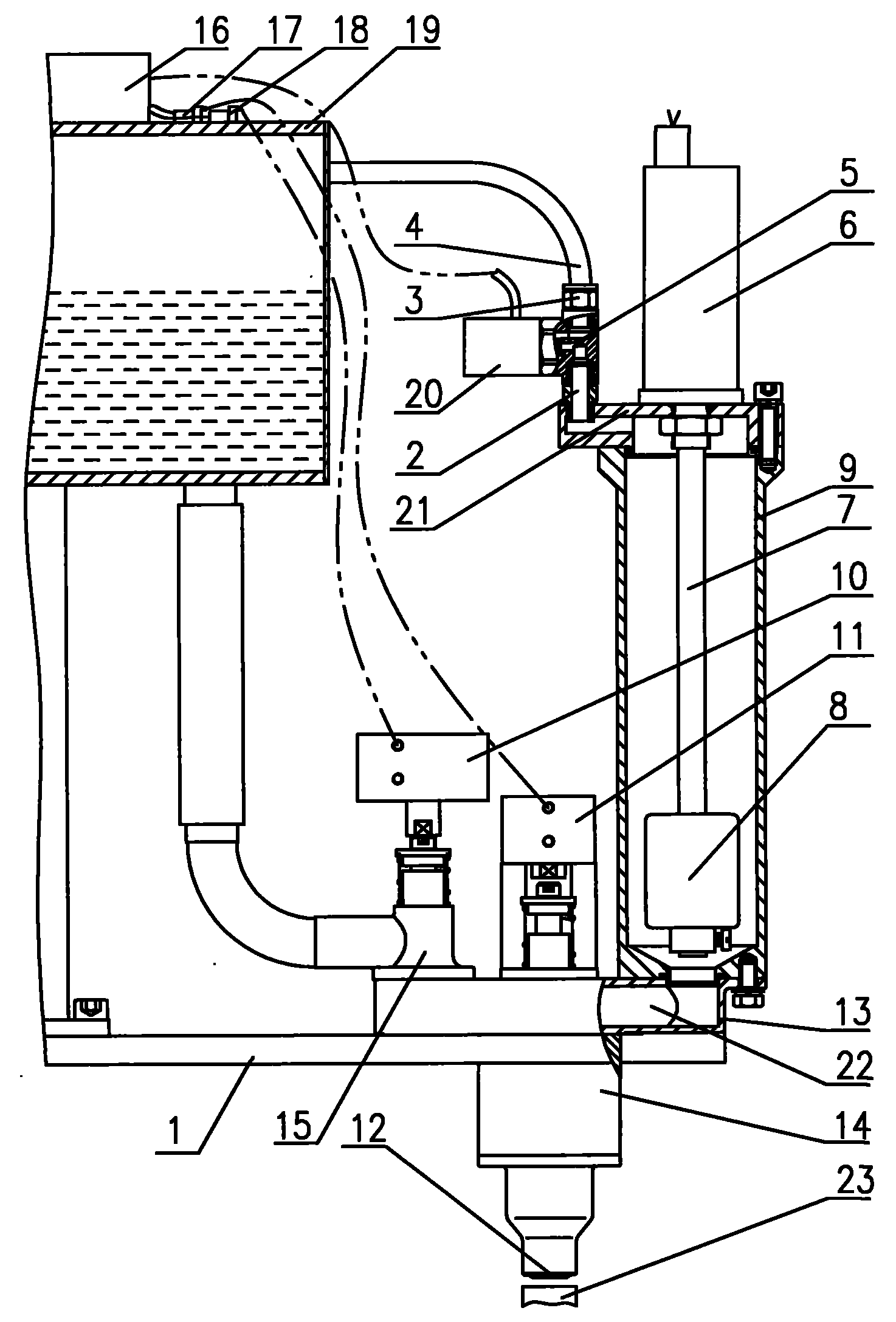

Electronic-weighing flow-rate-variable filling device

ActiveCN102765500ASolving undetectableRealize dual flow rate fillingLiquid materialMagnetic valveWorking environment

Owner:安丘市鼎正机械设备有限公司

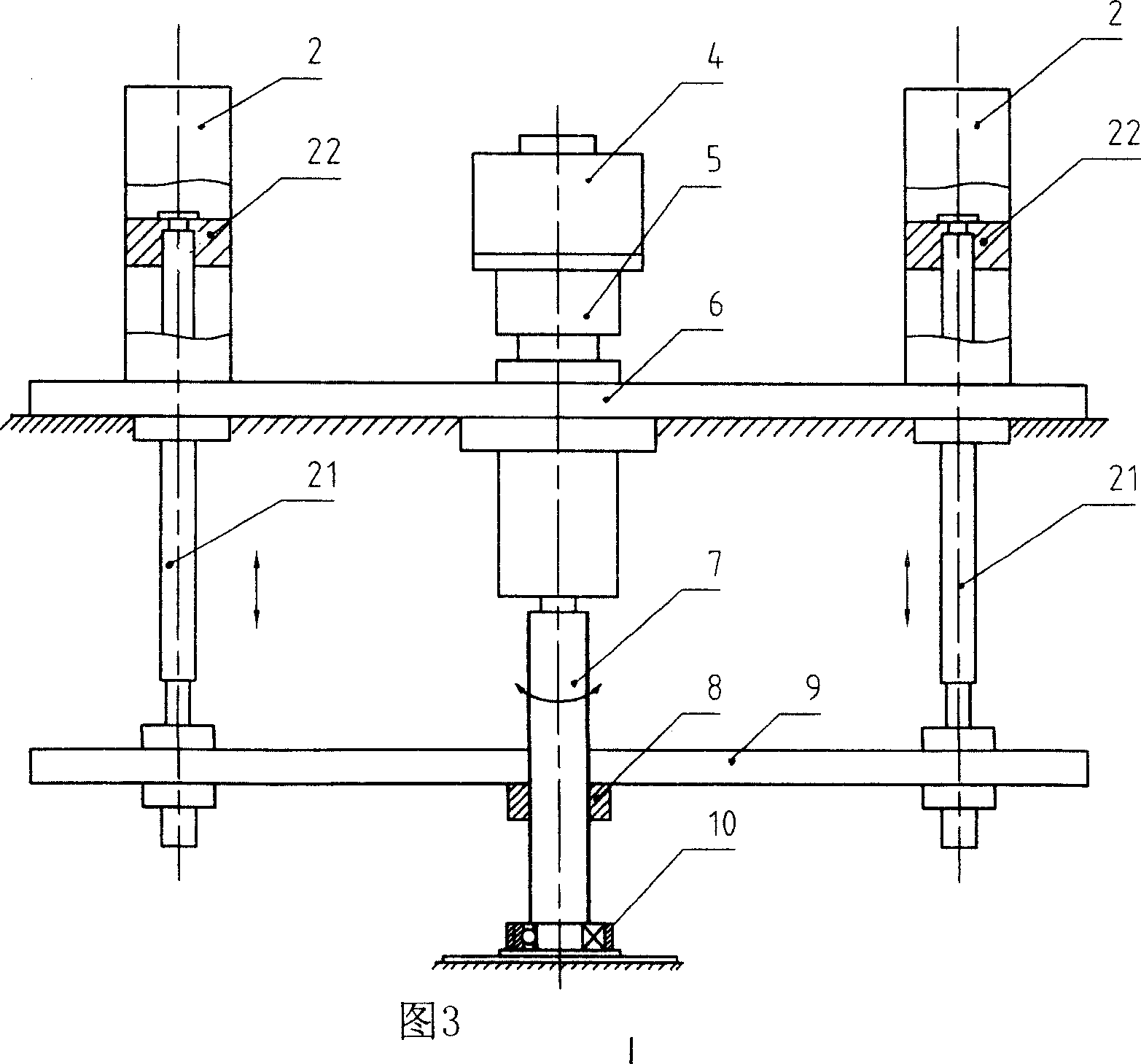

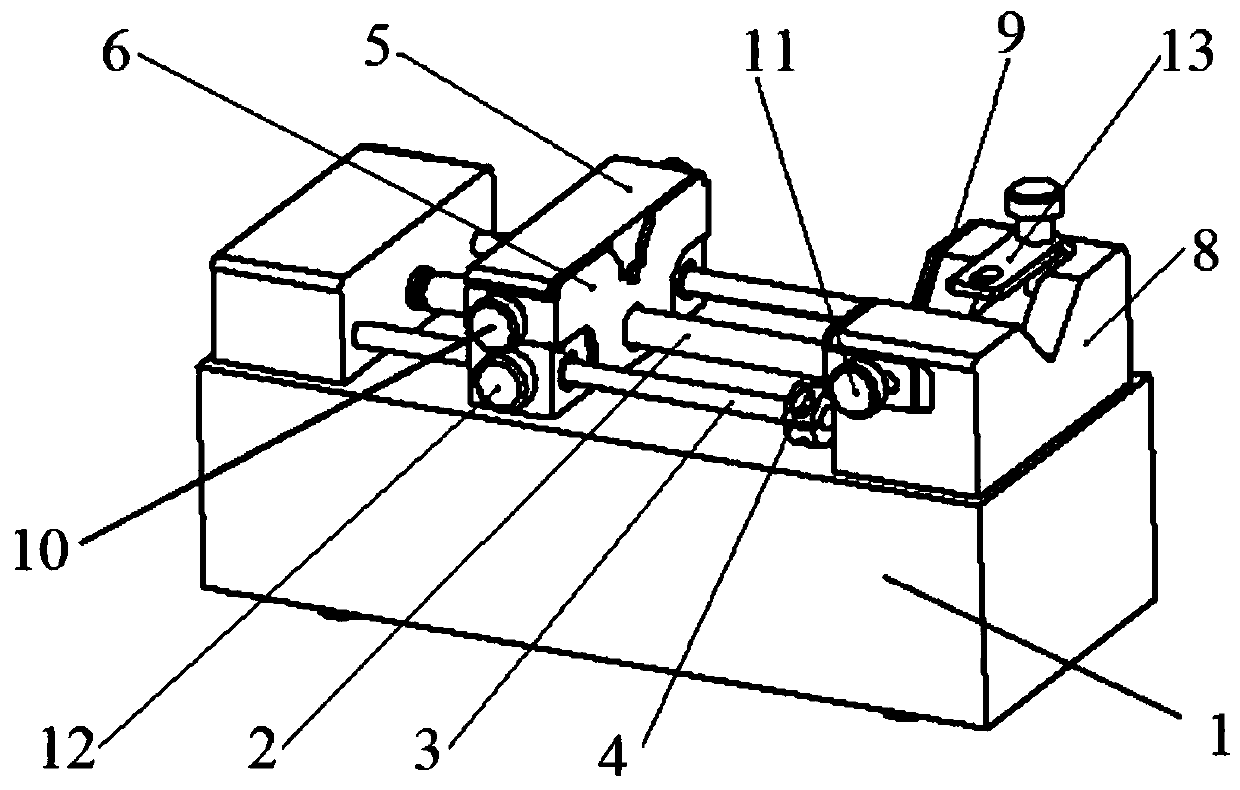

Filling apparatus for liquid bottle filler

The invention discloses a filling device of liquid bottler, which comprises the following parts: servo motor, declaration motor, fixing board, screw rod, nut and two bottle cylinders, wherein two bottle cylinders and declaration machine are set on the fixed board on two sides of declaration symmetrically, which is assembled on the rack, the bottom of piston rod of bottle cylinder is fixed on the elevation board, the servo motor connects declaration machine, the upper end of screw rod connects output shaft of declaration machine, the lower end of screw rod is set in the bearing seat through bearing, the bearing seat is fixed on the rack with nut on the elevation board to connect screw rod rotatably.

Owner:房国荣

Canned product weighing and filling device

InactiveCN104554901ARealize weighing one by oneSlow downSolid materialPackaging automatic controlEngineeringMachining

The invention relates to packaging equipment for canned products, in particular to a canned product weight and filling device for use in a canning production pipeline. The device comprises a conveying device capable of driving packaging cans to move in sequence, wherein an empty can weighing work station on which empty cans can be weighted in sequence, a rough machining weighing work station on which materials can be filled rapidly to a required weight and can be weighed, a fine machining filling work station on which the materials can be filled rapidly to a required weight, and a finished product weighing work station on which the filled canned products can be weighted in sequence are arranged in sequence on the conveying travel of the conveying device. According to the canned product weighting and filing device, the empty can weighing work station and the rough-machining weighting work station are separated, and previous-stage empty cans can be weighted in a rough machining filling process, so that empty cans can be weighted one by one; meanwhile, the running speed of the production line is not lowered, the filling accuracy is ensured, and higher running efficiency is achieved.

Owner:JOYEA CORP

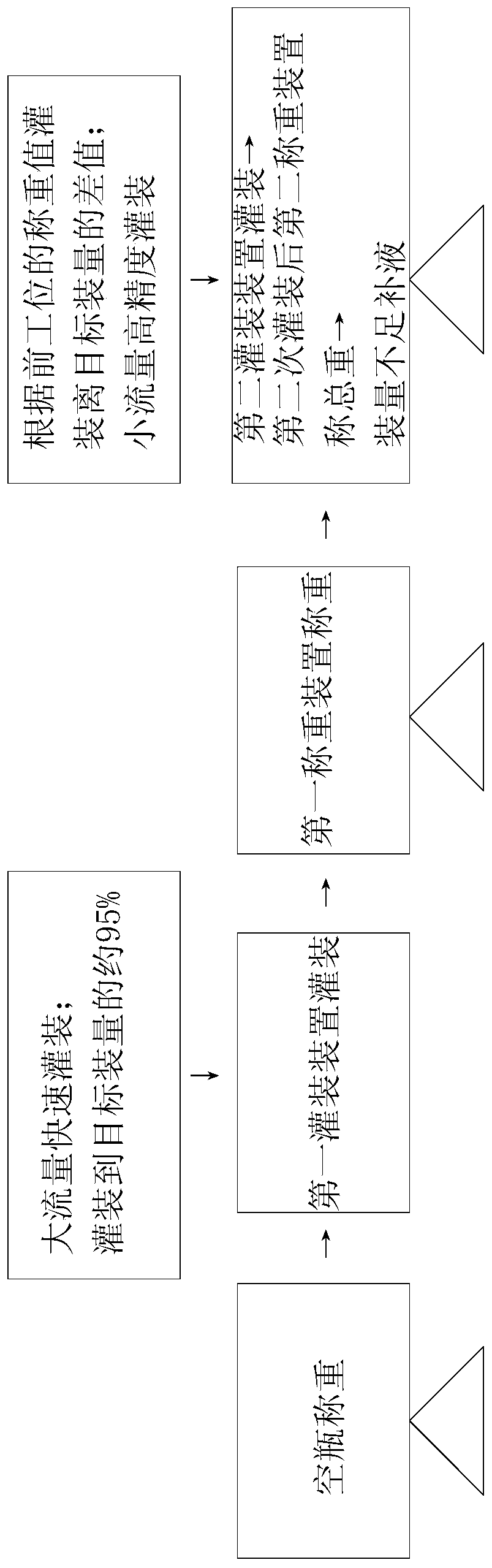

Filling method and system

PendingCN110467142AShorten the production cycleIncrease productivityLiquid materialLiquid bottlingBottleDevice breakage

The invention discloses a filling method, comprising the following steps: S1, weighing an empty bottle; S2, filling the empty bottle for the first time according to the set filling amount; S3, weighing the bottle after the first filling; S4, filling the bottle for the second time after the first filling; and S5, weighing the bottle after the second filling. The invention further discloses a filling system, comprising a first weighing station, a first filling station, a second filling station and a conveying device, wherein the first filling station is provided with a first filling device, a second weighing station is arranged between the first filling station and the second filling station, the second filling station is provided with a second filling device and a third weighing station, and the diameter of a filling pipeline of the first filling device is larger than that of the filling pipeline of the second filling device. The filling method and system have the advantages of facilitating both the production efficiency and the filling precision and avoiding damage to the equipment.

Owner:TRUKING TECH LTD

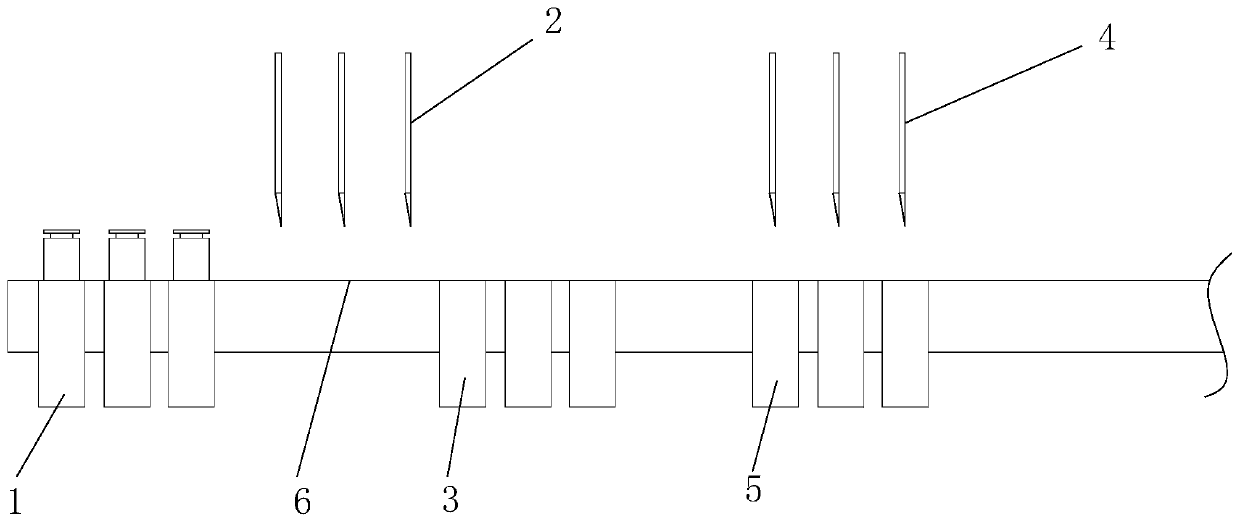

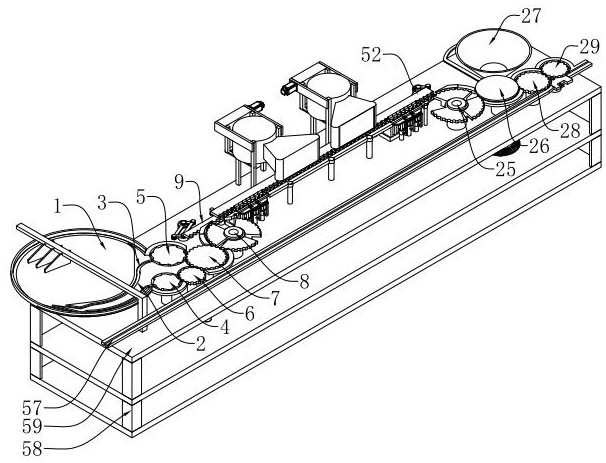

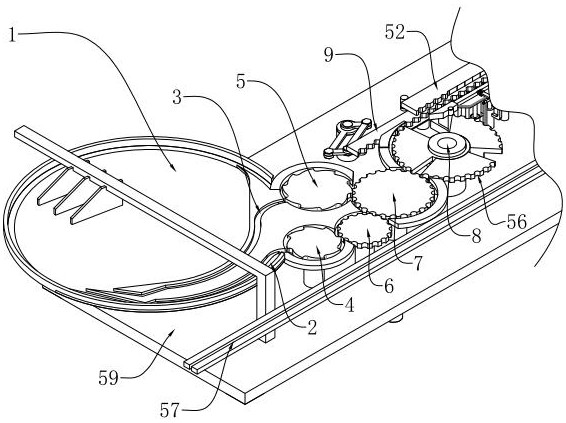

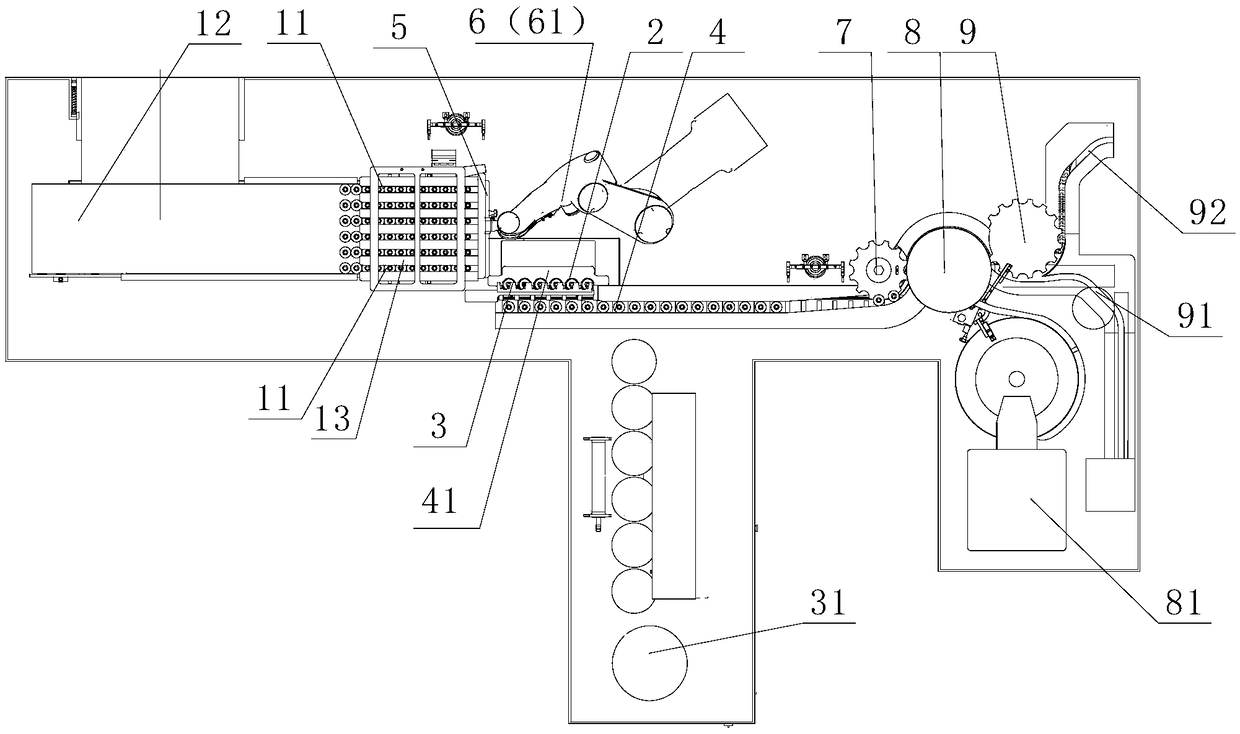

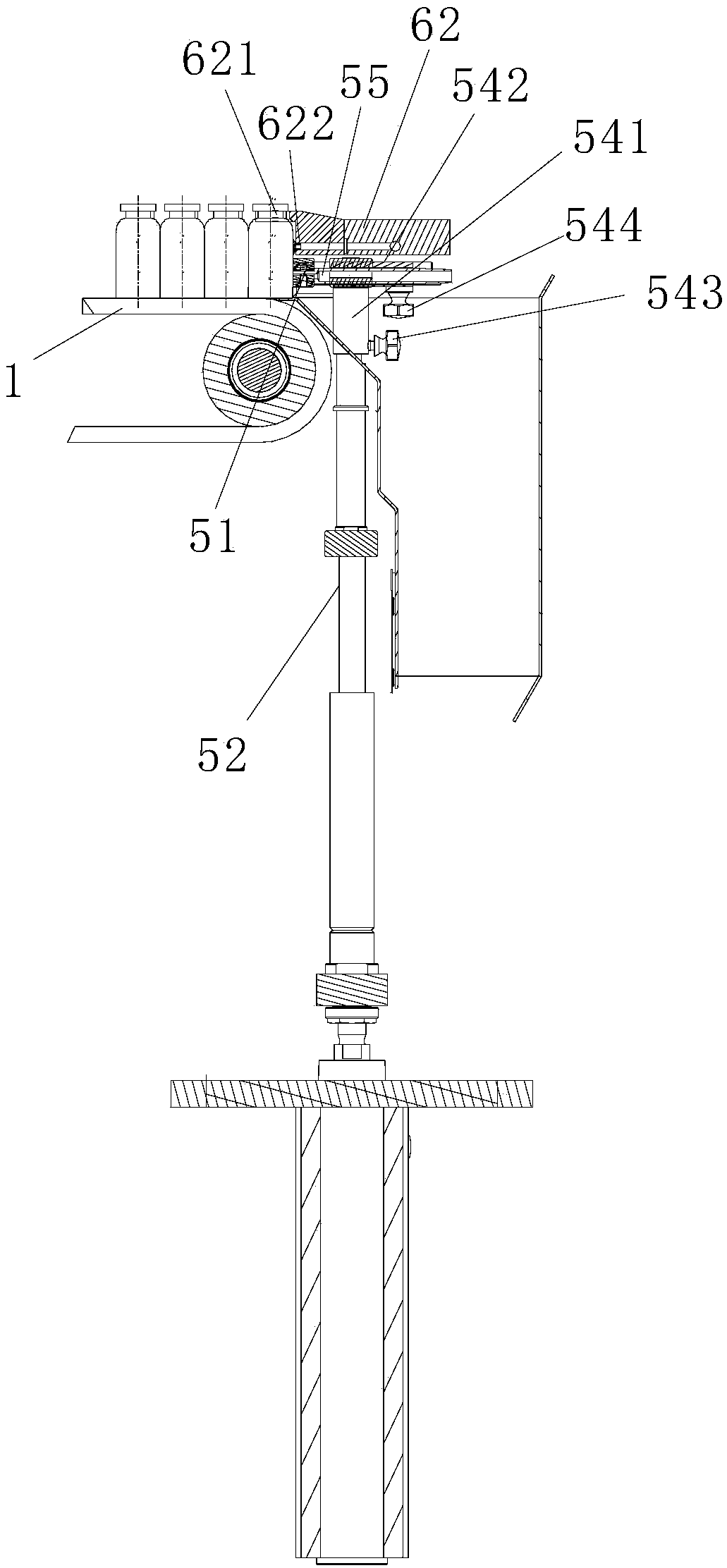

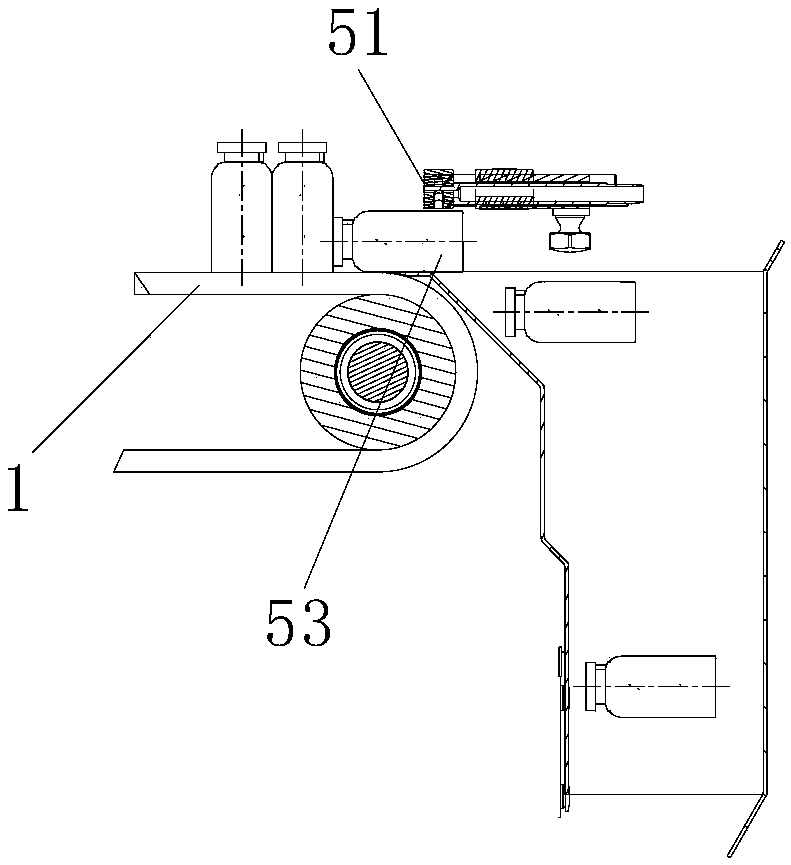

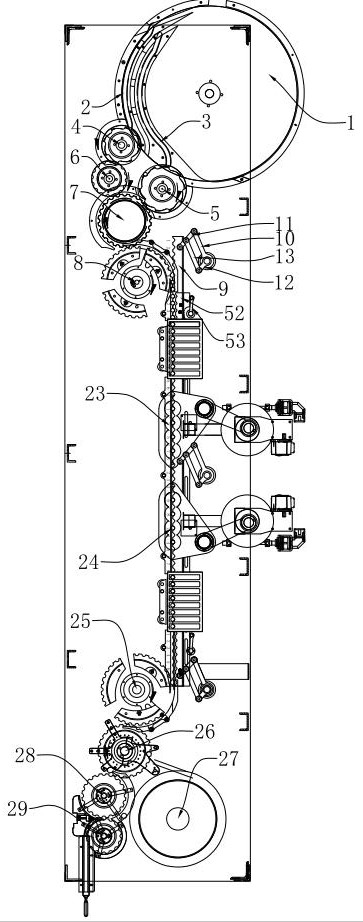

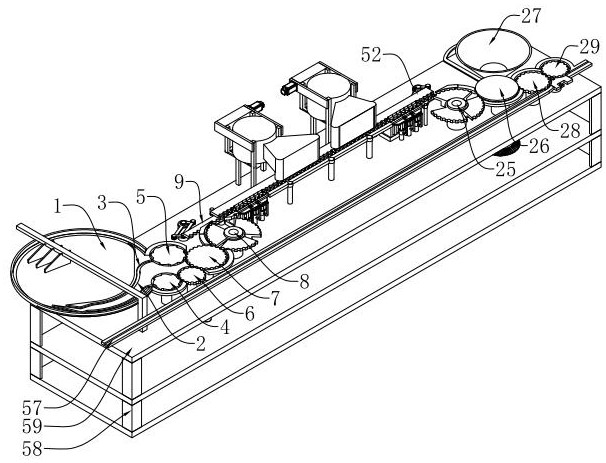

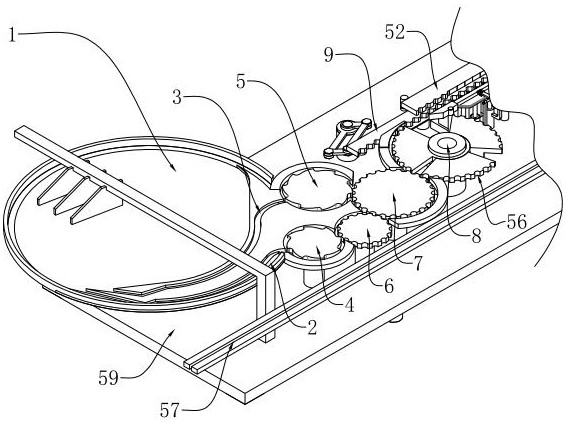

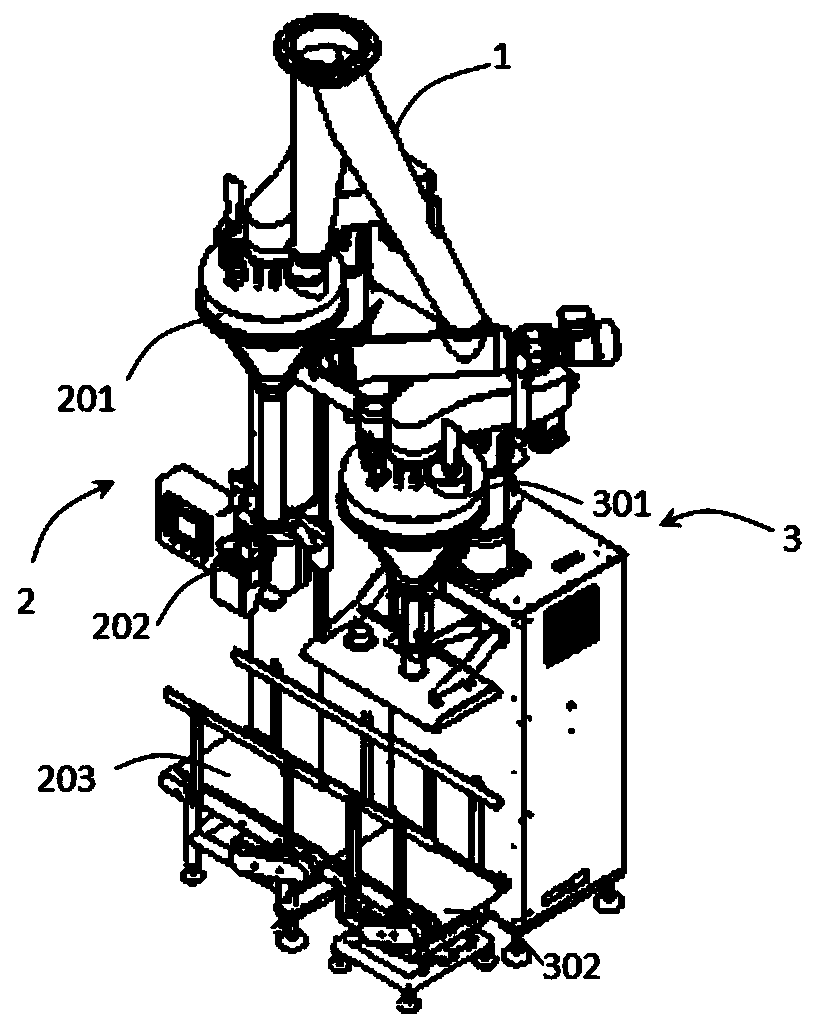

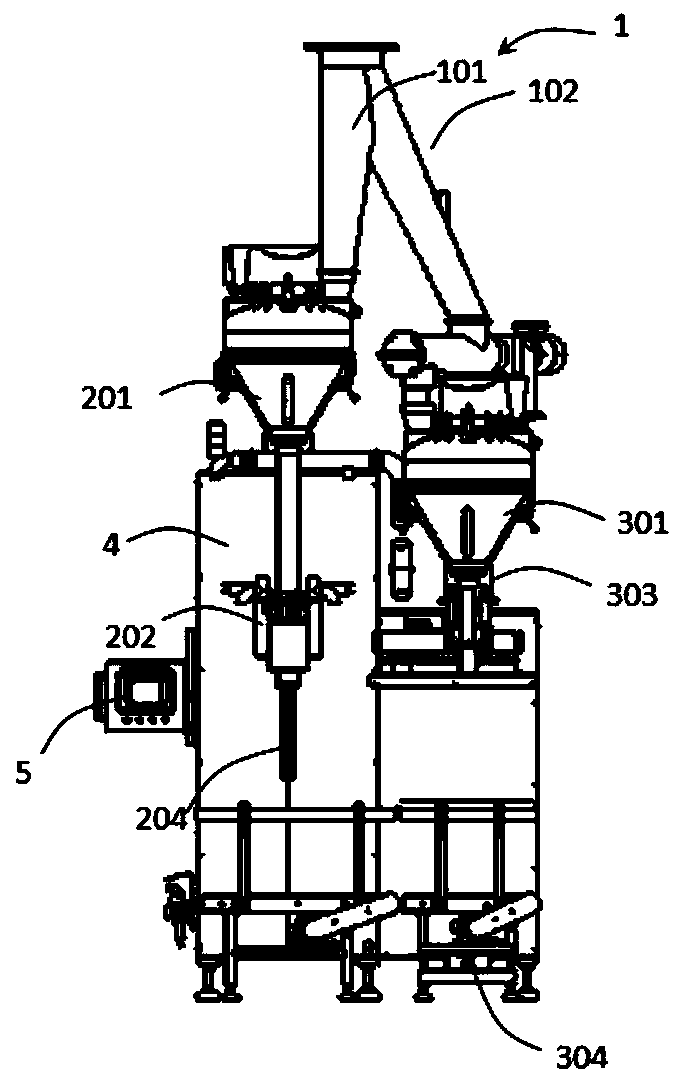

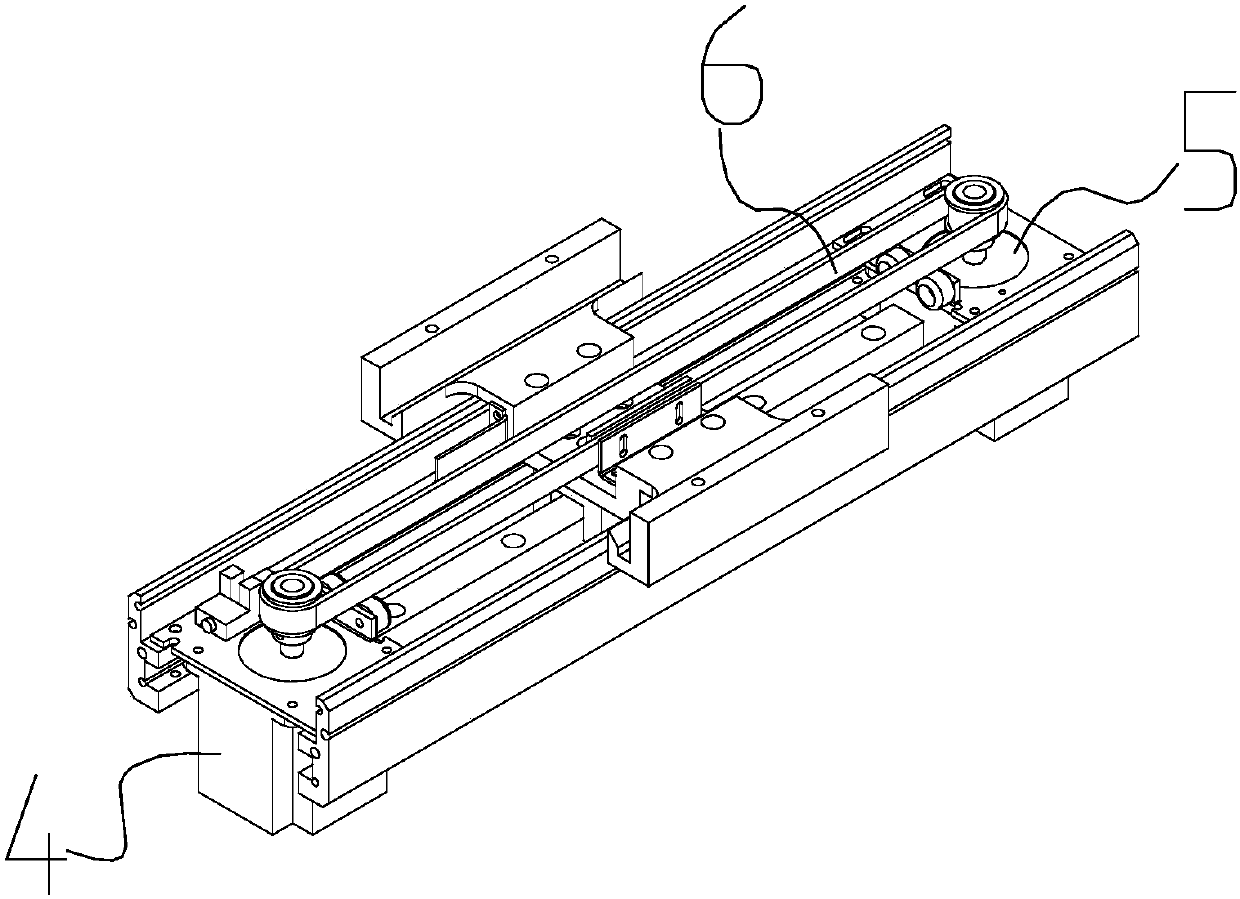

Online full-automatic screw powder filling machine with correction and inspection-free functions

ActiveCN112722351AFilling dose reductionImprove efficiencySolid materialPackaging automatic controlPenicillinControl system

The invention relates to an online full-automatic screw powder filling machine with correction and inspection-free functions. The online full-automatic screw powder filling machine comprises a non-constant-speed bottle feeding assembly, a primary online weighing assembly, a front filling set, a rear filling set, a secondary online weighing assembly, a non-constant-speed bottle discharging assembly, a plug adding assembly and a sampling and waste removing assembly which are sequentially arranged in the conveying direction of penicillin bottles. The online full-automatic screw powder filling machine further comprises a middle bottle pulling assembly, a power mechanism used for driving all the assemblies to operate, a conveying rail matched with all the assemblies, a PLC control system achieving the inspection-free function and a rack bearing all the assemblies. The online full-automatic screw powder filling machine has the beneficial effects of being high in efficiency, low in noise and compact in structure, each penicillin bottle can be directly weighed on an original rail before and after filling, and the defects of original manual weighing are overcome; and meanwhile, filling data of a filling head are corrected in real time, the qualified requirement of next-time filling is met, the filling precision is ensured, the filling speed is increased, the automation degree of the whole machine is high, manual intervention of operators is reduced, and pollution to medicine is reduced.

Owner:SHANDONG PENGLAI PHARMA MACHINERY FACTORYCO +1

Intelligent filling equipment and filling method thereof

PendingCN109110713ASimple actionHigh precisionSafety device in filling machineryEngineeringTransfer mechanism

The invention provides intelligent filling equipment. The intelligent filling equipment comprises a bottle feeding mechanism, weighing parts, needle filling parts and a bottle discharging mechanism, and further comprises a transferring mechanism, wherein the weighing parts are arranged at a bottle feeding end of the bottle discharging mechanism; the needle filling parts are arranged above the weighing parts; the bottle discharging mechanism is provided with a buffering platform; the bottle feeding end of the bottle discharging mechanism and the buffering platform are symmetrically distributedat two sides of the weighing parts. The invention further discloses a filling method of the intelligent filling equipment; the filling method comprises the following steps: S1, feeding bottles; S2, taking the bottles; S3, pushing the bottles and placing the bottles; S4, filling: carrying out next time bottle taking through the transferring mechanism; after separating the transferring mechanism from the bottle body on the weighing parts, weighing the weight of the empty bottle body firstly, and then starting to fill; keeping weighing until the filling amount reaches a target value; after filling is finished, carrying out next time bottle pushing and bottle placement through the transferring mechanism; S5, repeatedly carrying out step S4 until the filling of all medicine bottles is finished.The intelligent filling equipment is compact in structure and has the advantages of improving the filling precision and the product yield.

Owner:TRUKING TECH LTD

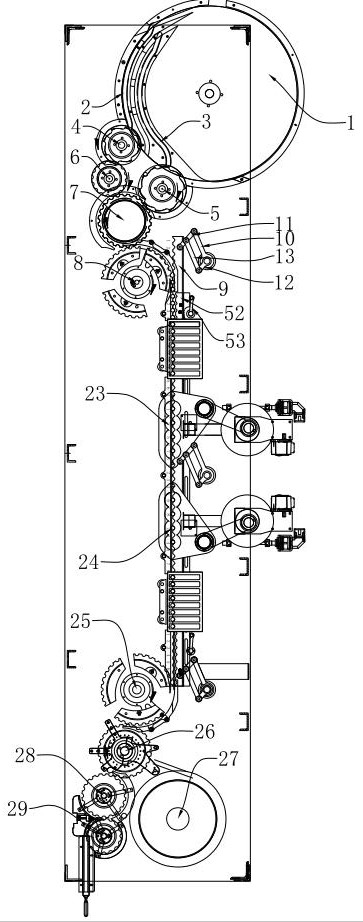

An online automatic screw powder filling machine with correction and inspection-free function

ActiveCN112722351BFilling dose reductionImprove efficiencySolid materialPackaging automatic controlLow noiseControl system

The invention relates to an online full-automatic screw powder filling machine with the function of correction and inspection-free, which comprises a non-uniform-speed bottle feeding component, a primary online weighing component, a front filling group and a rear filling group arranged in sequence along the conveying direction of vials , secondary on-line weighing component, variable speed bottle output component, stoppering component, sampling and rejecting component, and also includes the center pull bottle component, the power mechanism for driving each component, the transmission track that is suitable for each component, and The PLC control system that realizes the inspection-free function and the frame that carries each component. The present invention has the characteristics of high efficiency, low noise and compact structure. It can directly weigh each vial before and after filling on the original track, avoiding original The defect of manual weighing, at the same time, correct the filling data of the filling head in real time, so that the next filling can meet the qualified requirements, ensure the filling accuracy, improve the filling speed, and the whole machine has a high degree of automation, reducing the manual intervention of the operator , reducing the pollution of medicines.

Owner:SHANDONG PENGLAI PHARMA MACHINERY FACTORYCO +1

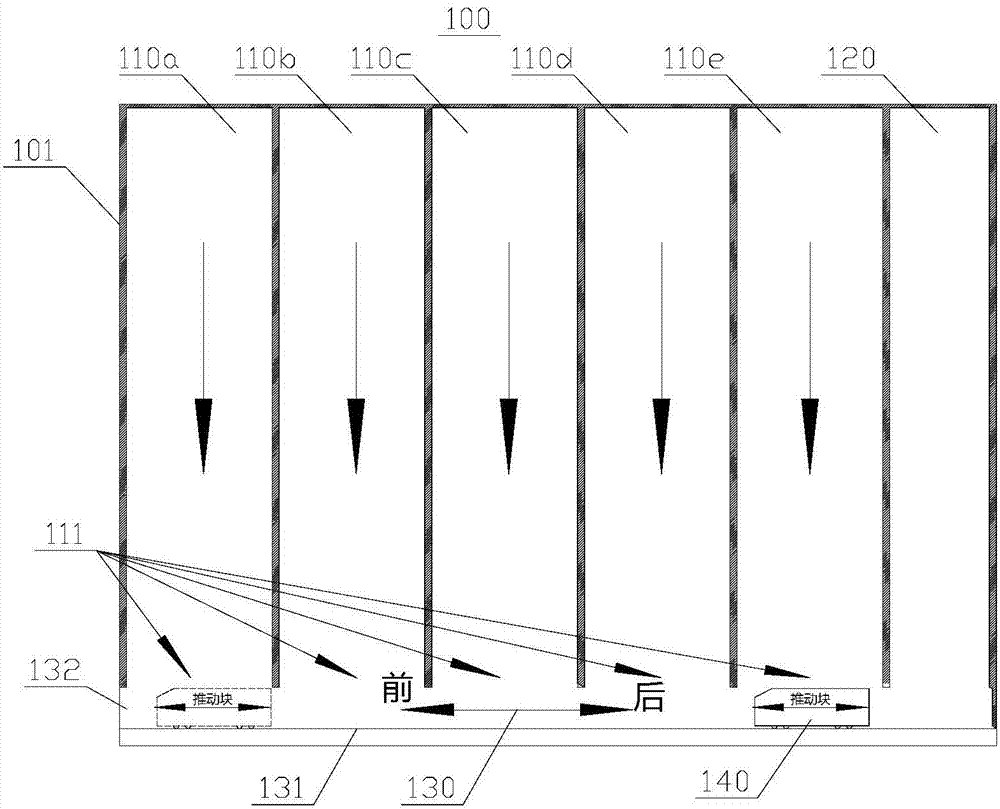

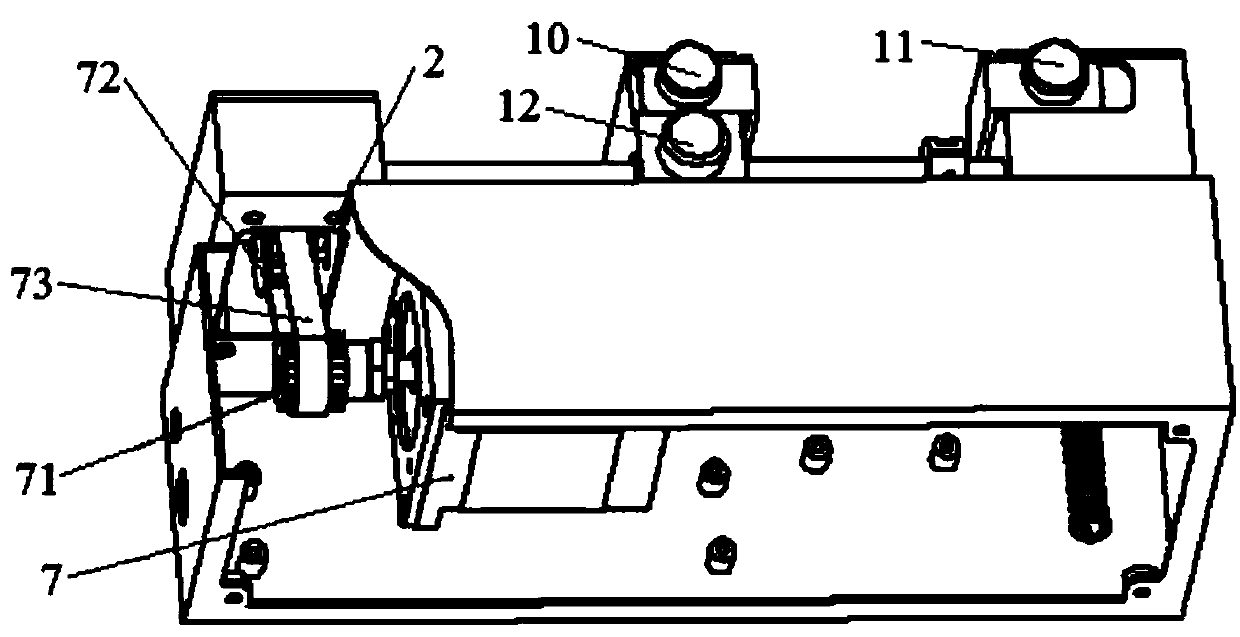

Vending machine and automatic goods discharging device

PendingCN107886630AImprove adaptabilityImprove replenishment efficiencyCoin-freed apparatus detailsApparatus for dispensing discrete articlesEngineeringMechanical engineering

The automatic vending machine and its automatic delivery device provided by the present invention include a housing, a push block and a controller; a delivery channel and a plurality of storage channels are formed in the housing; the delivery channel has a moving The track surface; the storage channel is used to store goods, and corresponds to one of the delivery channels; the controller controls the push block to reciprocate along the moving track surface; in the direction perpendicular to the moving track surface, the The distance between the storage outlet and the moving track surface is greater than the maximum size of the pushing block. The automatic delivery device can prevent the goods from being dropped or damaged from a high place, and improve the adaptability of the vending machine; it does not need to be filled at the vending machine site, which can improve the efficiency of replenishment; it does not need to set up a lot from bottom to top The driving device can make full use of the space in the casing and reduce the manufacturing cost of the automatic vending machine.

Owner:上海跃众文化传媒有限公司

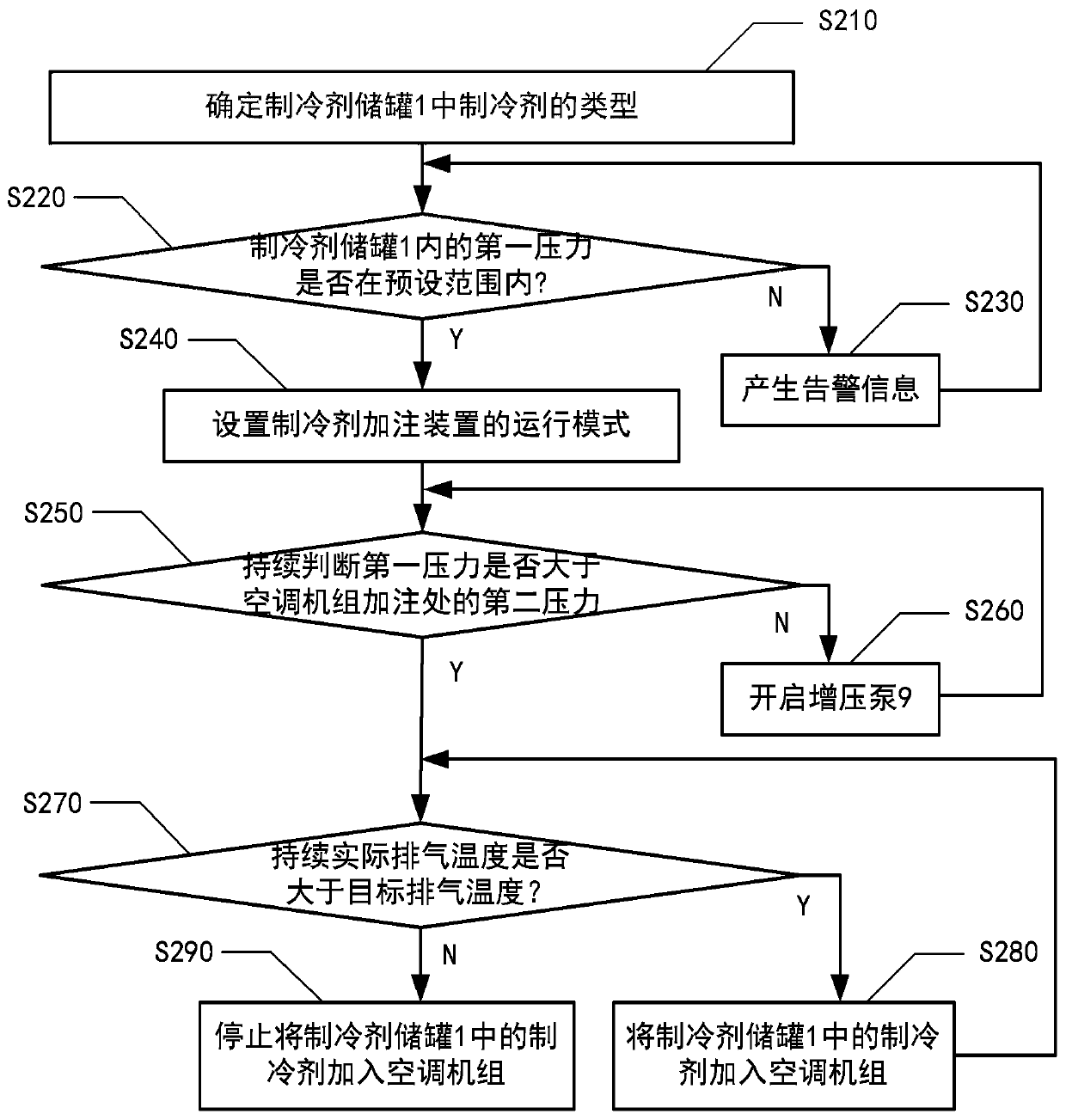

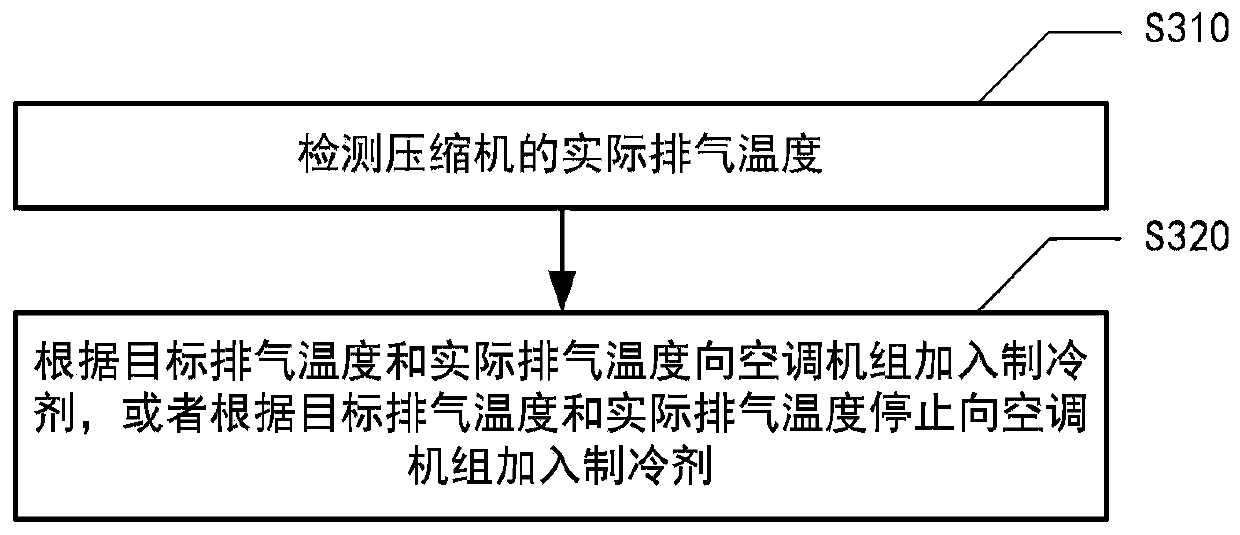

Refrigerant filling device and refrigerant filling method

InactiveCN111023412AReduce volumeReduce weightMechanical apparatusSpace heating and ventilation safety systemsAutomatic controlEngineering

The invention provides a refrigerant filling device and a refrigerant filling method. The refrigerant filling device comprises a refrigerant storage tank (1), a first temperature sensor (2), a controller (3) and an electromagnetic valve (4), wherein the refrigerant storage tank (1) is used for storing a refrigerant; the first temperature sensor (2) is used for detecting an actual exhausting temperature of a compressor; the controller (3) is used for generating a control command according to a target exhausting temperature and the actual exhausting temperature; and the electromagnetic valve (4)is used for adding the refrigerant into an air conditioning unit according to the control command or stopping adding the refrigerant into the air conditioning unit according to the control command. By controlling filling of the refrigerant automatically according to the exhausting temperature, the size and weight of the filling device can be reduced while the filling precision is guaranteed.

Owner:NINGBO AUX ELECTRIC

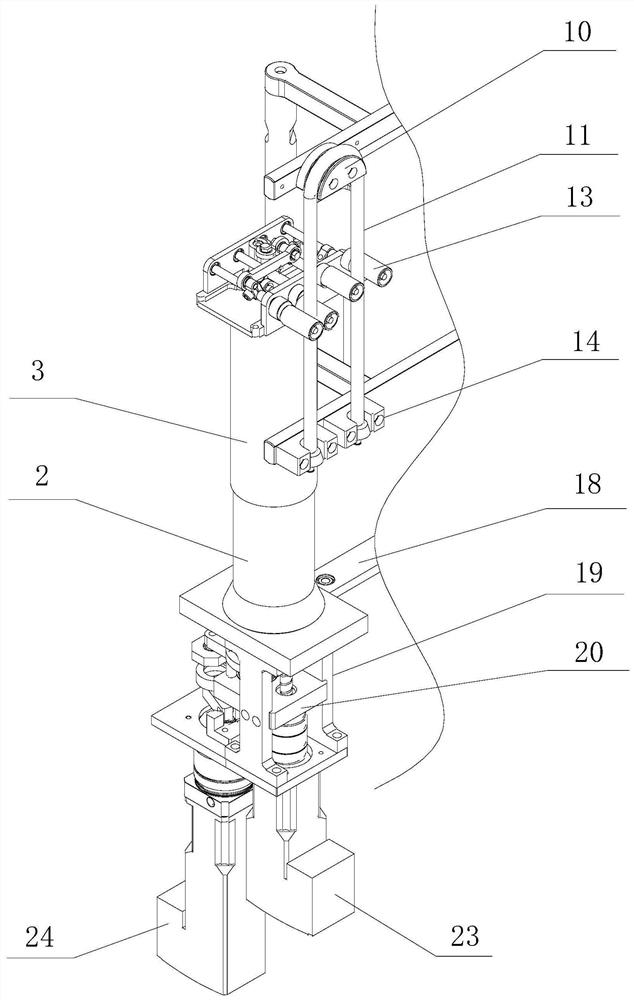

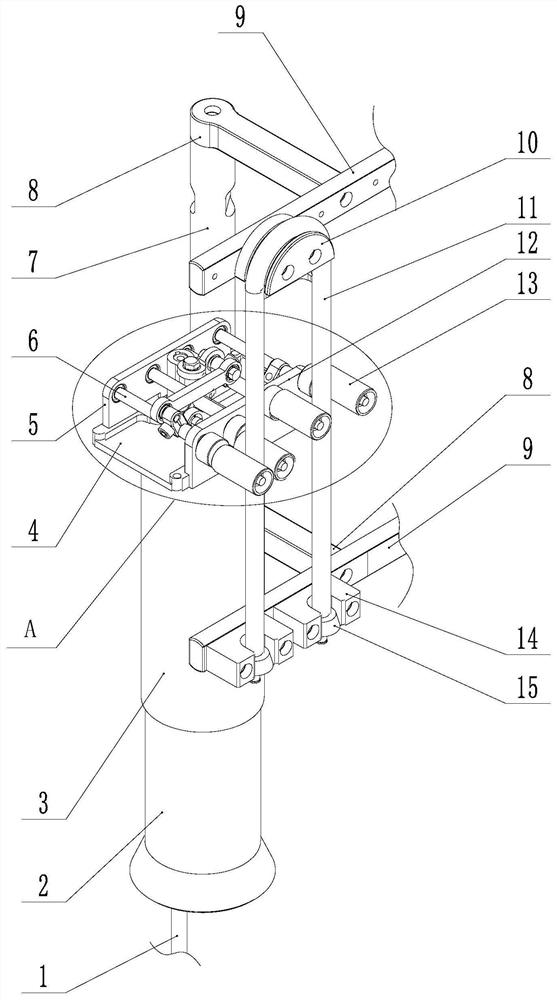

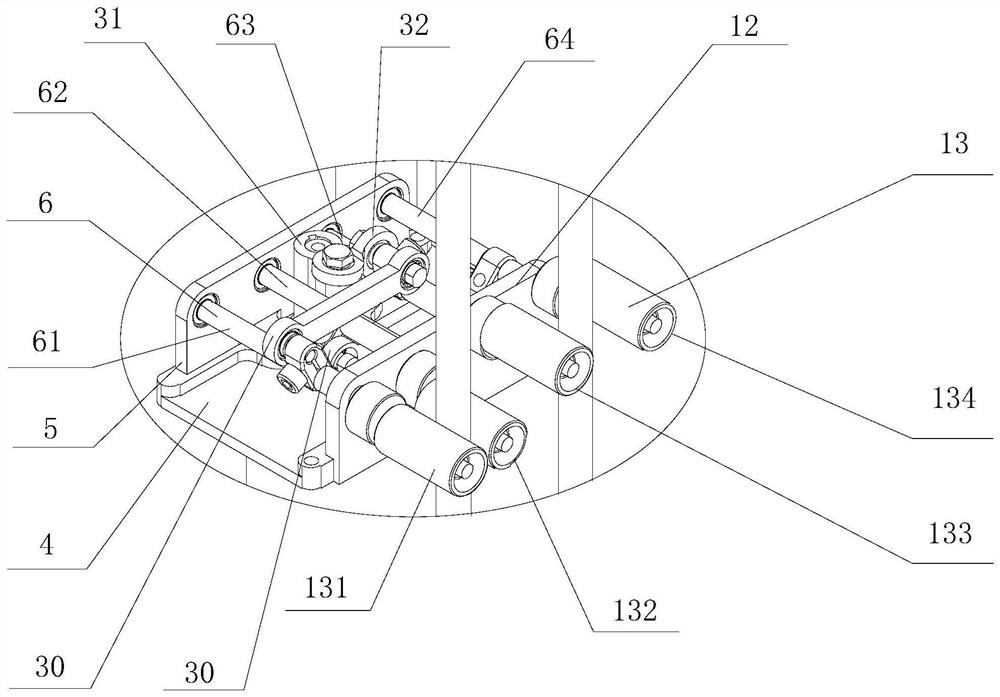

Pneumatic combined rice seed metering device

PendingCN111758343AReduce wasteAchieve cleaning effectSeed depositing seeder partsMechanical engineeringOryza sativa

The invention relates to a pneumatic combined rice seed metering device. 15 rows of 12 hemispherical indents in each row are uniformly arranged on the outer surface of a roller, the position, oppositeto the centers of the indents, of the inner surface of the roller is provided with 15 annular grooves, the indents are machined in the outer surface of the roller, the annular grooves are formed in the inner surface of the roller, the indents and the annular grooves penetrate through each other to form long and thin rectangular narrow slits, and the effect of adsorbing rice bud seeds is achievedthrough the internal and external pressure difference of the annular grooves. When the roller indents are filled with seeds, firstly, seed filling is completed under the combined action of self-filling of the gravity of the seeds and the pressure difference between the two ends of the narrow slits, and the purpose of ensuring stable seed filling is achieved; before the bud seeds are carried by theroller indents and conveyed to a seed discharging position, the pressure difference between the two ends of the narrow slits disappears, and the conveying process is completed completely with the help of the protection effect of a seed protection belt; and when the roller discharges seeds to a growing tray, the seeds can be separated from the roller and sown on the growing tray due to the gravityof bud seeds and the action of force generated by outward release of potential energy of seed bouncing steel wires, the seed bouncing steel wires penetrate through the narrow slits to complete the cleaning effect on suction holes, the seed suction capacity of the seed metering device is recovered, and the seed metering device can continuously and stably work. Therefore, the designed seed meteringdevice can adapt to the existing 15-row 25-column type rice growing soft trays to carry out high-precision operation.

Owner:CHANGCHUN AGRI MACHINERY

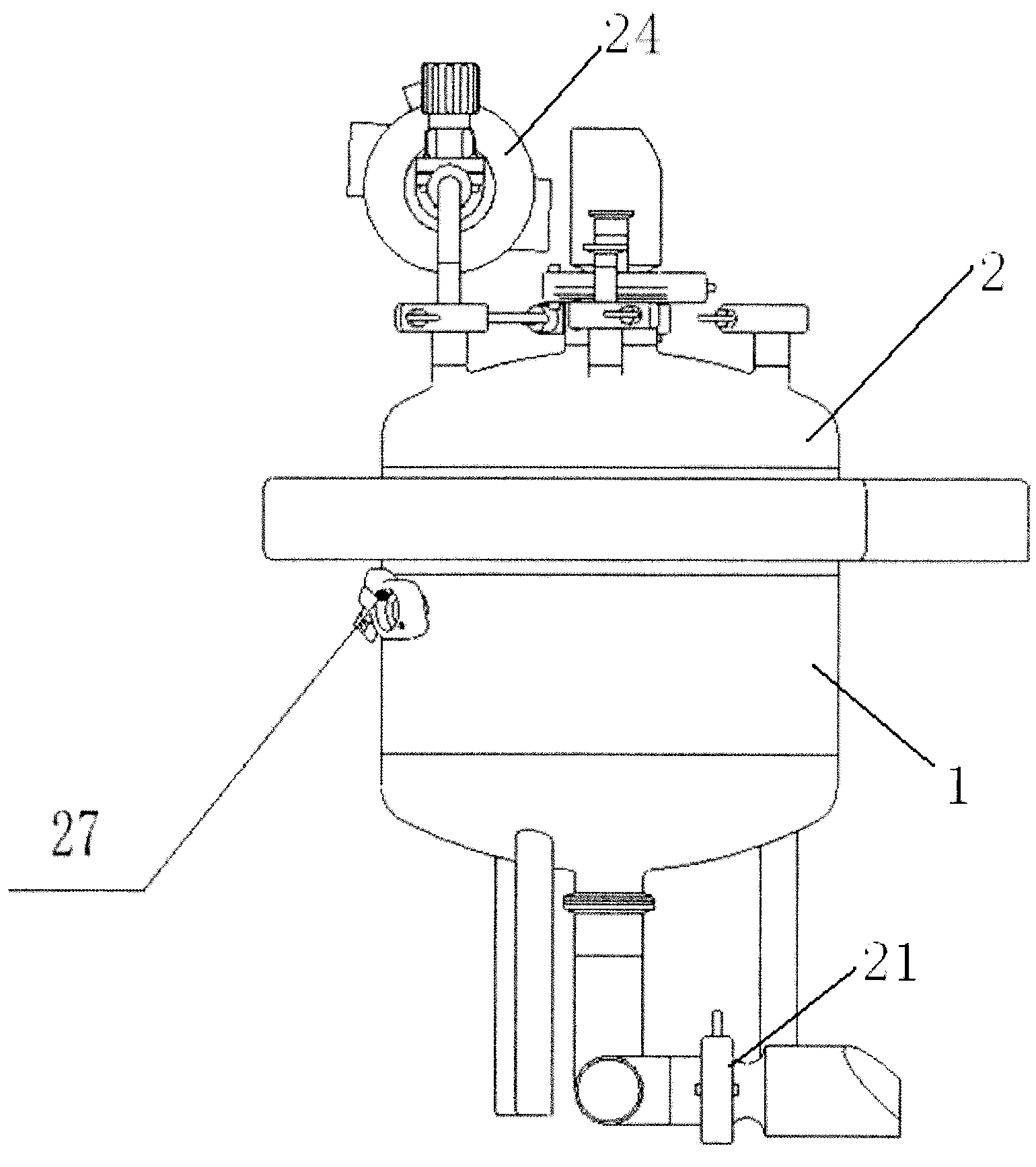

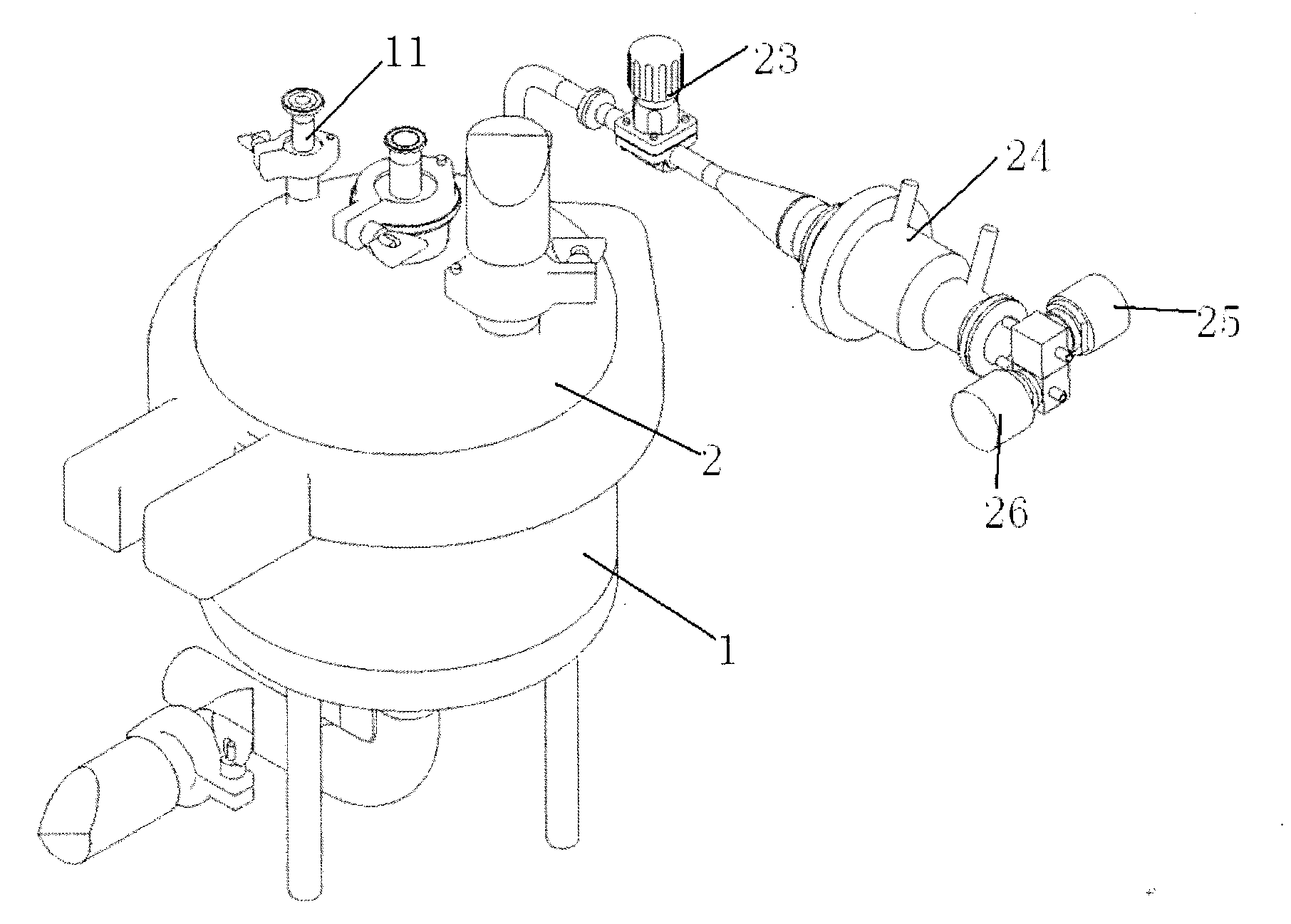

Constant pressure device

InactiveCN103318824AHigh precisionLittle change in filling pressureLiquid bottlingBuffer tankBiochemical engineering

The invention relates to a constant pressure device, and the device comprises a buffer tank and a pressure-supplementing and pressure-discharging component. The constant pressure device is characterized in that, the buffer tank comprises a lower tank arranged below and an upper tank arranged above, and the lower tank and the upper tank are connected together in a butt joint way, forming a tank body via a lathedog; a sealing ring is disposed on the butt joint surface of the lower tank and the upper tank; one end of a fluid-supplementing tube is inserted into the tank body, and the other end sticks out of the tank body; a spray apparatus is disposed in the upper tank, and an inlet of the spray apparatus sticks out of the tank body; the upper tank is communicated with the pressure-supplementing and pressure-discharging component, and the bottom of the lower tank is communicated with a filling tube; and a filling pressure transducer for obtaining filling pressure is disposed at the filling tube. The constant pressure device of the invention has the advantages of: simple structure, easy disassembly and assembly, high stability, and SOP / SIP compatibility.

Owner:SHANGHAI TOFFLON SCI & TECH CO LTD

Geometric modeling method for soybean seeds

ActiveCN110457818AReduce the numberGuaranteed filling accuracySpecial data processing applicationsGeometric modelingRate change

The invention discloses a geometric modeling method for soybean seeds, which comprises the following steps: 1, selecting a plurality of soybean seeds of a variety to be modeled, respectively detectingthe characteristic size of each soybean seed, and respectively calculating the spherical rate phi i of each soybean seed to obtain the average spherical rate of the variety to be modeled; 2, equallydividing the spherical rate range interval of the soybean seeds into a first spherical rate change interval, a second spherical rate change interval and a third spherical rate change interval of whichthe spherical rates are decreased; 3, determining interval range to which average spherical rate belongs. The spherical rate [phi]I of the to-be-modeled grain is calculated by detecting the feature size of the soybean grain, and the filling model is determined according to the range interval where the spherical rate is located. On the premise that the filling precision is guaranteed, the number of filling balls is small, and the simulation calculation efficiency can be improved.

Owner:JILIN UNIV

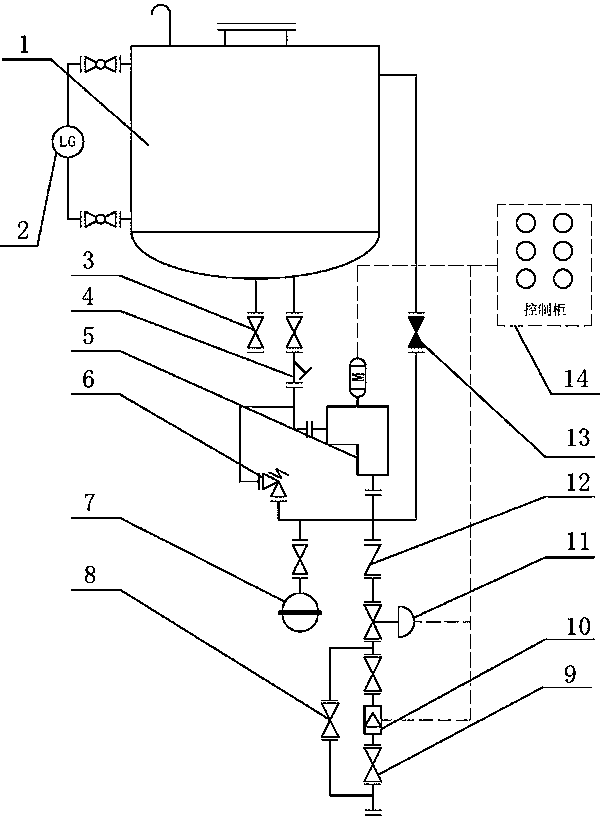

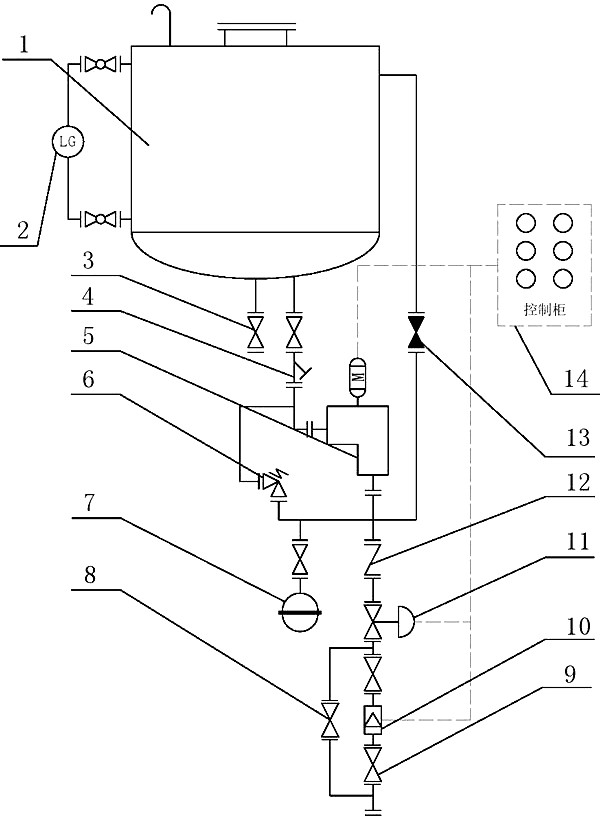

Method for realizing small-flow high-precision metering and filling of conventional metering pump

ActiveCN110410674AStable structureImprove efficiencyPipeline systemsPump controlEngineeringMetering pump

The invention discloses a method for realizing small-flow high-precision metering and filling of a conventional metering pump. According to the method, a control device for realizing small-flow high-precision metering and filling is included, the control device comprises a Y-shaped filter, a safety valve, a buffer with a pressure gauge, a bypass ball valve, an isolation ball valve, a flow meter, asmall flow regulating valve, a check valve, a throttling valve and a control cabinet, under the general force support of the flow meter, the small flow regulating valve, the buffer with the pressuregauge, the control cabinet and other accessories, a conventional metering pump can achieve the control precision of 10% or below, the accumulative errors are reduced, the purpose of accurate meteringis achieved, the control device has the characteristics of being reliable in structure, high in efficiency and low in cost, the filling precision of a fluid material at the flow rate of 10% or below is ensured, and the reinvestment is saved.

Owner:LUOYANG LVCHAO ENVIRONMENTAL PROTECTION TECH

Double-station filling machine

The invention relates to the technical field of filling machines, and discloses a double-station filling machine. The double-station filling machine comprises a material distributing system, a first filling system and a second filling system. The first filling system comprises a first screw scale, a clamping device and a first conveying device, wherein the top of the first screw scale is connectedwith the material distributing system, the bottom of the first screw scale is connected with the clamping device, and the first conveying device is located below the clamping device. The second filling system comprises a second screw scale and a second conveying device. The top of the second screw scale is connected with the material distributing system. The second conveying device is located below the second screw scale. The second conveying device is in butt joint with the first conveying device and is used for conveying articles on the first conveying device. The double-station filling machine has the characteristics of high filling efficiency and high precision.

Owner:杭州加一包装技术有限责任公司

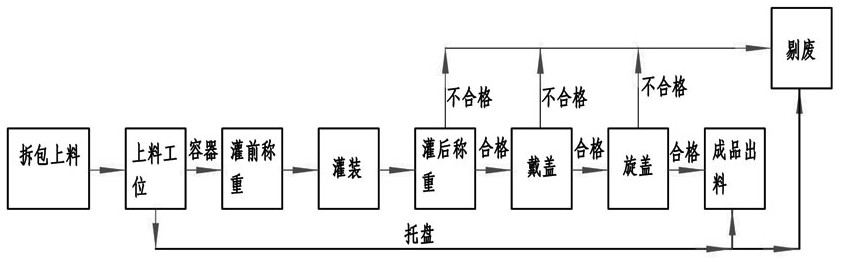

A container intelligent filling and sealing system and method

ActiveCN109592628BAccurate locationEasy to detectThreaded caps applicationSynchronising machinesRobot handCap device

The invention discloses an intelligent encapsulating system. The intelligent encapsulating system comprises a first conveying rail, wherein a loading station, a container transfer station, a finishedproduct sorting station and a finished product collecting platform are sequentially arranged in a conveying direction; the side of the first conveying rail is equipped with a weighing device, a capping device and a cap screwing device, which are equipped with a second conveying rail in a matched mode, wherein a filling device is arranged above the weighing device, a container carrier and a finished product carrier are separately arranged on the first conveying rail, the container transfer station is equipped with a first blocking device and a container transfer mechanical hand for transferringthe container on the container carrier onto the weighing device and transferring the container on the weighing device to a loading end of the second conveying rail; and the finished product sorting station is equipped with a second blocking device, and a sorting mechanical hand which is used for transferring a finished product at the unloading end of the second conveying rail onto the finished product carrier. The method comprises the following steps: loading; transferring the container; filling and weighing; capping and performing cap screwing; sorting; and collecting the finished product. The intelligent encapsulating system has the advantages of being simple in structure, suitable for transferring the container by virtue of a carrying tool, high in filling precision requirement, and the like.

Owner:TRUKING TECH LTD

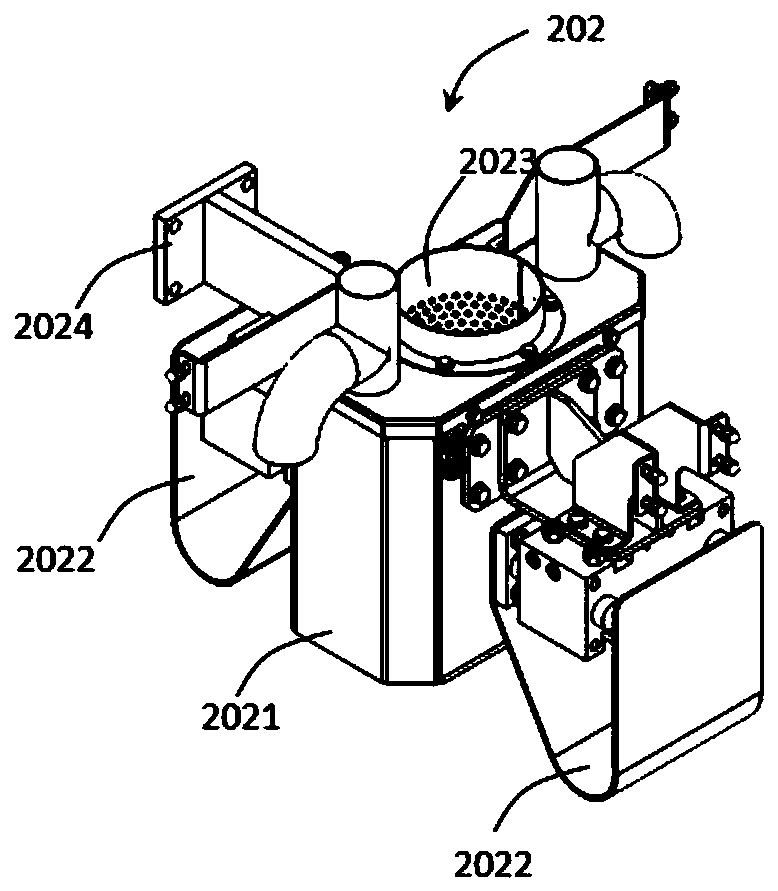

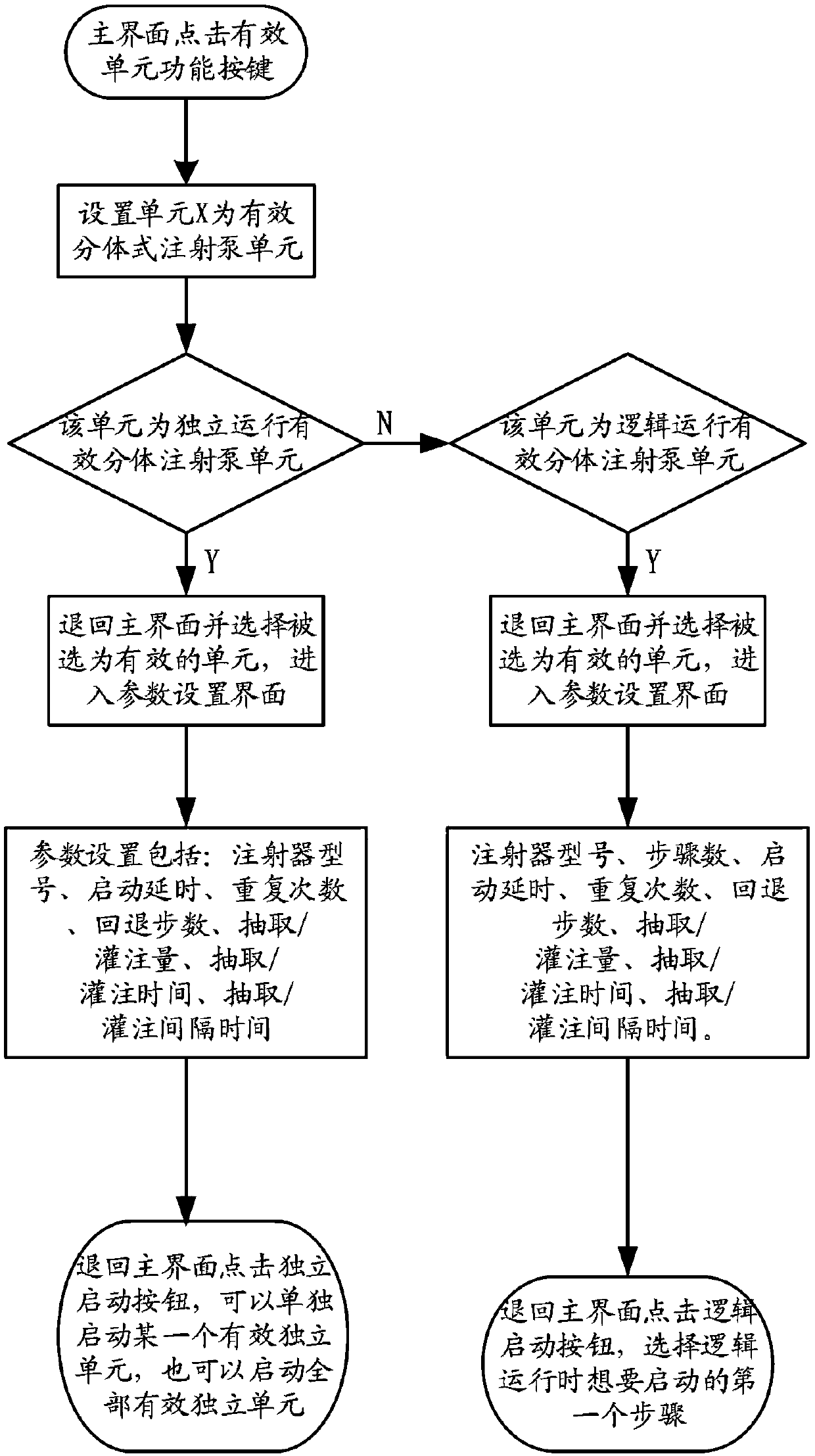

Control system and control method of split type injection pump

InactiveCN111166969ARich use requirementsLow costAutomatic syringesMedical devicesControl systemControl engineering

The invention discloses a control system and a control method of a split type injection pump. The system can control a plurality of split type injection pump units at the same time, and different working modes are set for different split type injection pump units respectively. The split type injection pump units work independently, do not influence one another, can also work according to the logicrelation sequence, and can meet diversified use requirements of customers so as to reduce the user cost. The system further has a calibration function, the filling amount is automatically calibratedbefore production, the filling precision is ensured, the online fine adjustment function is achieved, and fine adjustment can be conveniently conducted on all units in the production process.

Owner:BAODING SHENCHEN PUMP IND

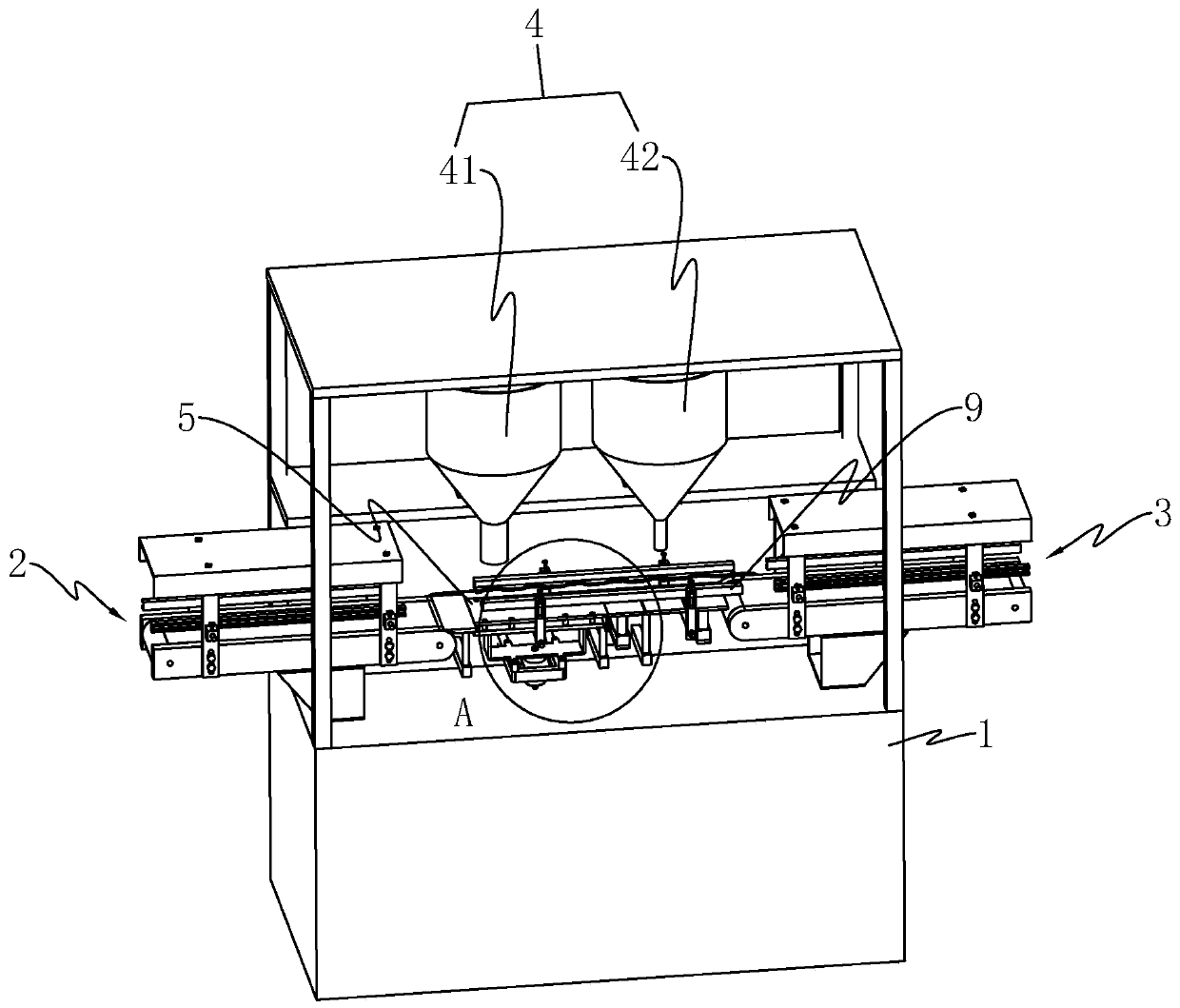

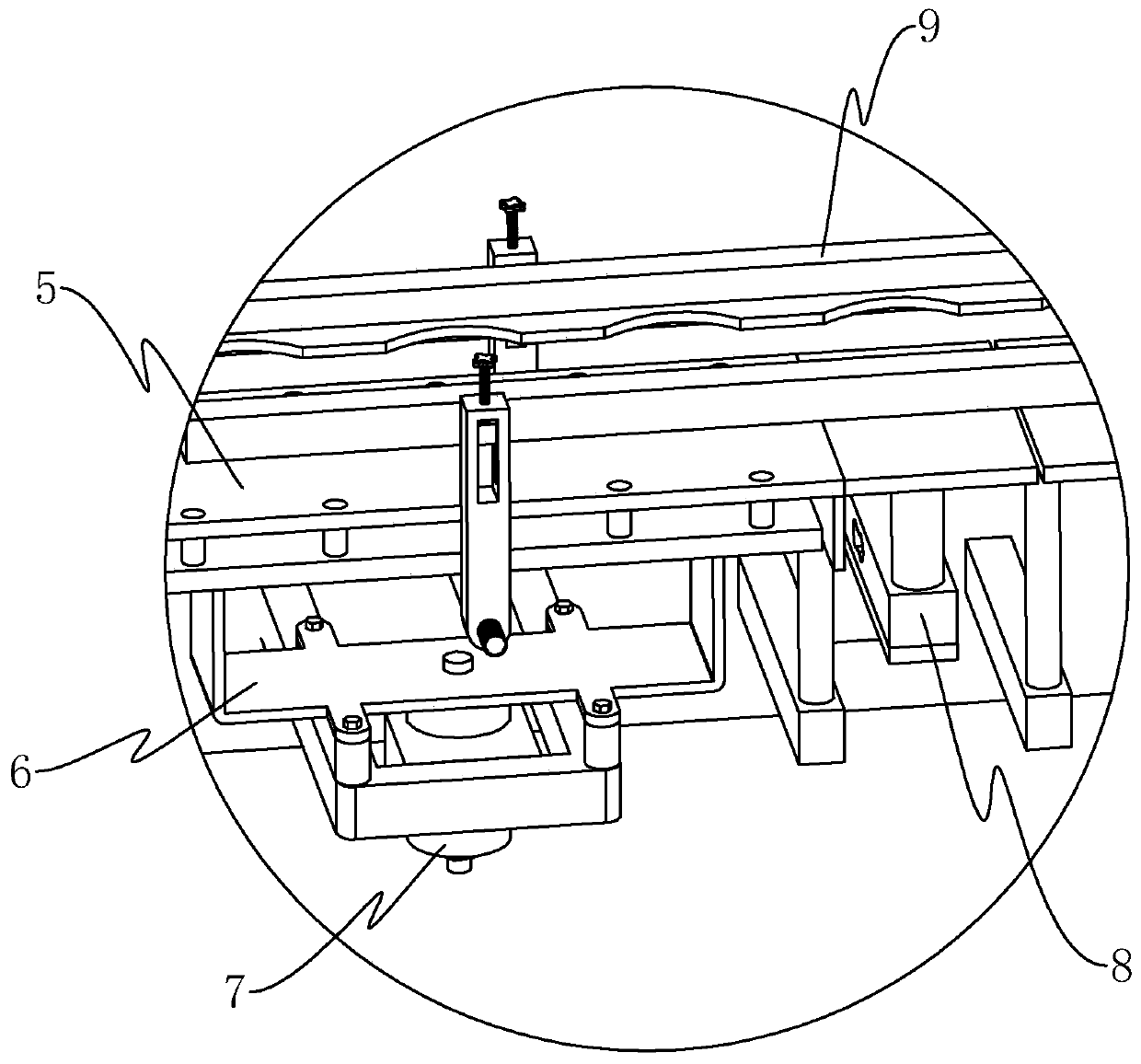

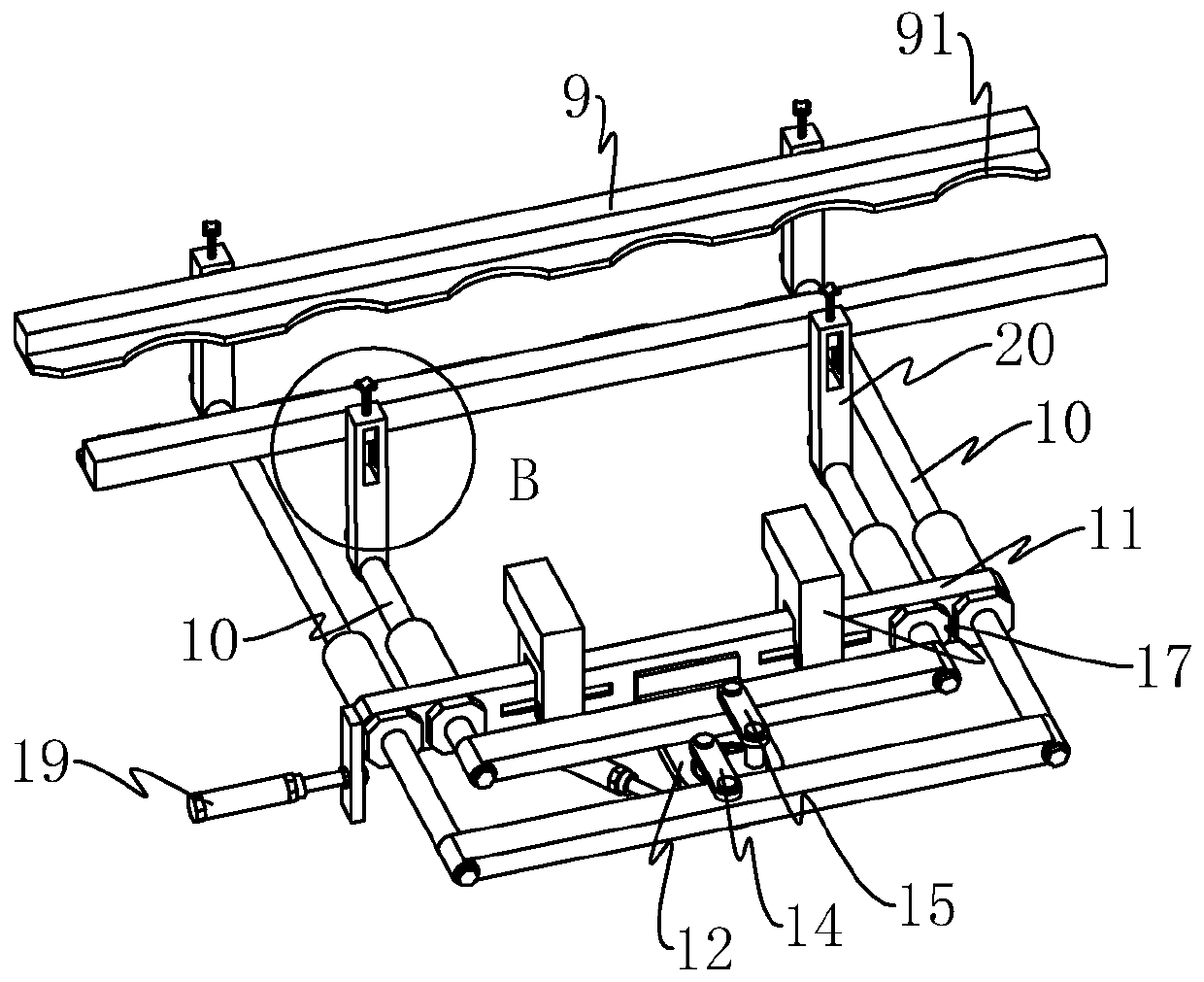

a filling machine

ActiveCN108382657BAvoid interferenceGuaranteed fillingLiquid materialMechanical equipmentEngineering

The invention discloses a filling machine and belongs to the field of packaging mechanical equipment. The filling machine comprises a rack, a hopper, a conveyor belt group and a weighing device; the conveyor belt group comprises a front conveyor belt and a back conveyor belt; a supporting plate is erected between the front conveyor belt and the back conveyor belt; clamping plates are arranged on the two sides of the supporting plate in a width direction respectively; the rack is provided with a clamping power component and a feeding power component; the clamping power component comprises a moving bracket, a rotation bracket, a first transmission rod, a second transmission rod and a clamping cylinder; the feeding power component comprises a linkage frame, a supporting frame and a feeding cylinder; the hopper comprises a first hopper and a second hopper; and the first hopper and the second hopper are arranged in a length direction of the supporting plate at an interval. The invention provides the filling machine which is fully automatic and is stable in work, convenient and rapid to operate and very high in both filling efficiency and filling accuracy of a product.

Owner:上海达和荣艺包装机械有限公司

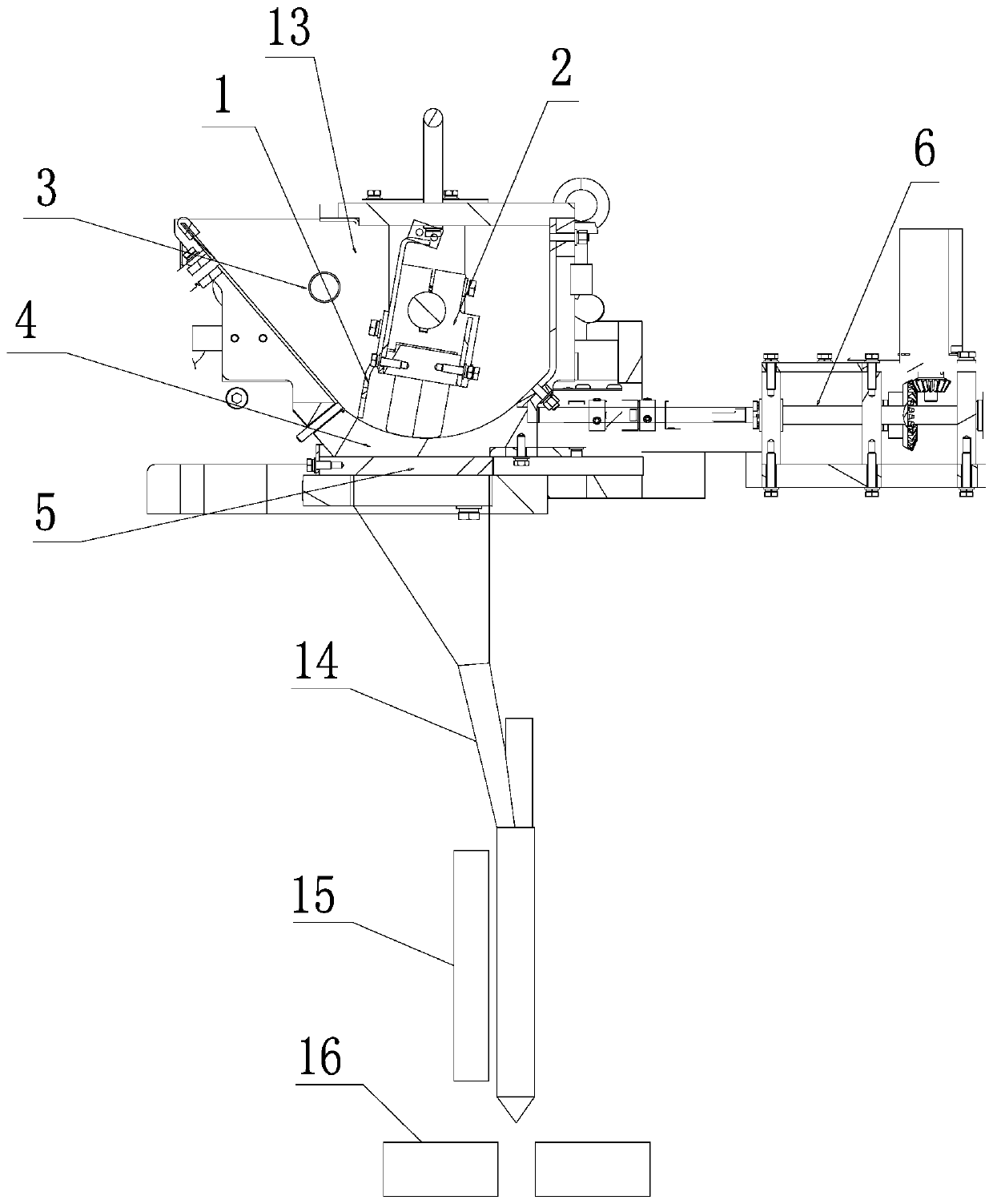

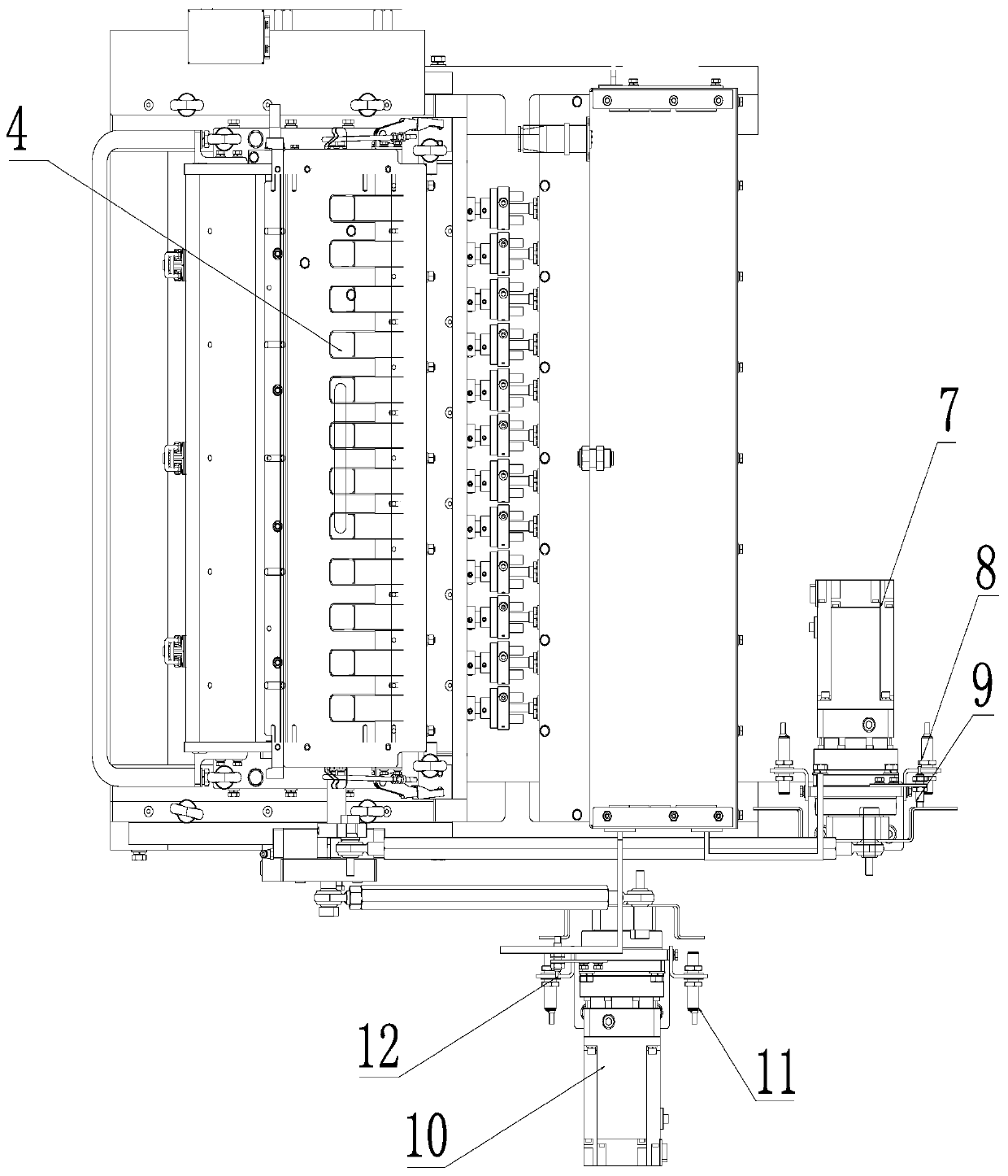

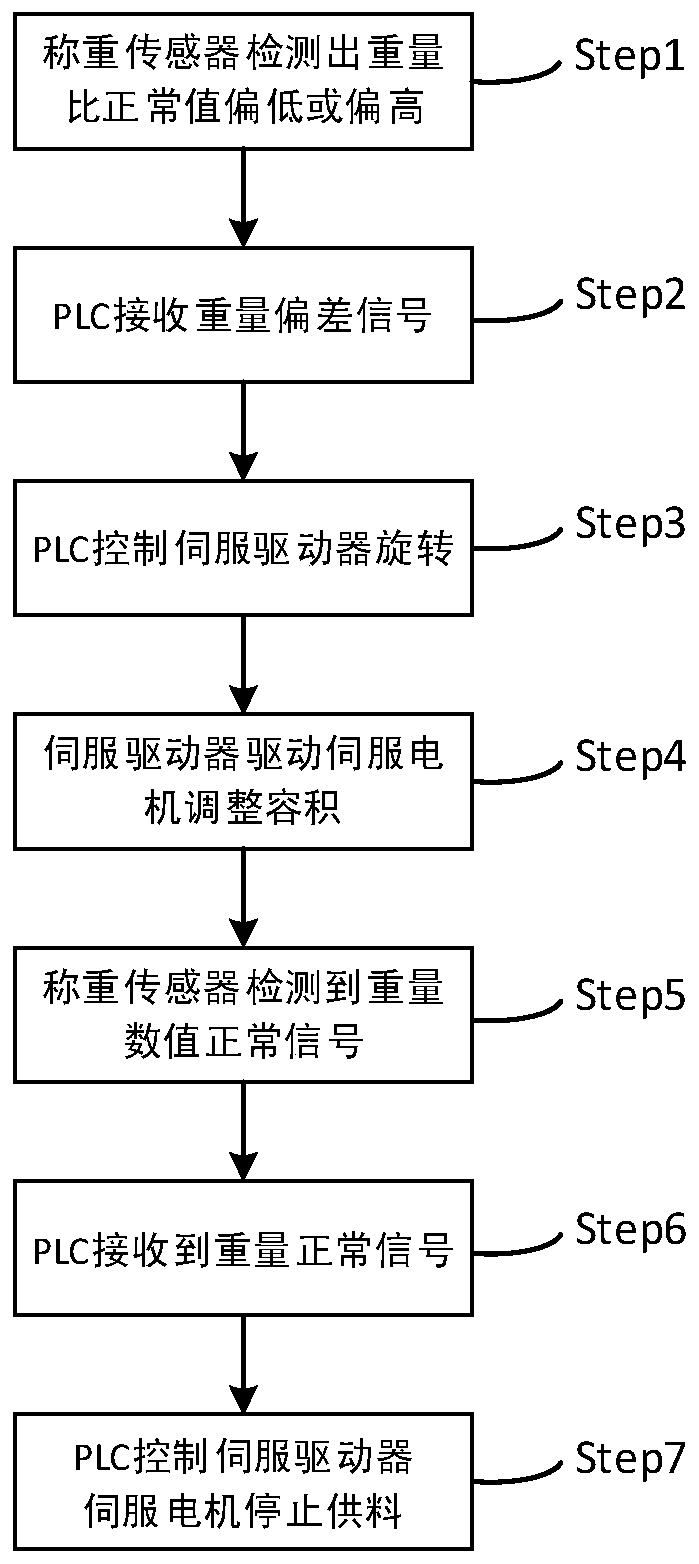

High-speed metering filling device, material supply method and feedback control method

ActiveCN109941533AFast filling speedShort filling timePackaging automatic controlSolid materialBlade plateEngineering

The invention relates to a high-speed metering filling device, a material supply method and a feedback control method. The high-speed metering filling device comprises a metering filling mechanism anda volume feedback adjusting mechanism. The volume feedback adjusting mechanism is used for controlling and adjusting the filling amount of the metering filling mechanism. The metering filling mechanism comprises a material bin, a scraping plate, an auxiliary scraping plate, a material level detection sensor, a metering box, a tool plate, a scraping plate drive servo motor and a tool plate drive servo motor. The volume feedback adjusting mechanism comprises a volume feedback adjusting device, a scraping plate limiting detection sensor, a scraping plate original point detection sensor, a tool plate limiting detection sensor and a tool plate original point detection sensor. The device further comprises a material falling forming assembly, a longitudinal sealer and a transverse sealer. The feedback control method and the material supply method are synchronously controlled and run; and through the material supply method and the feedback control method, the volume of the metering box and the material supply material level height in the material bin can be controlled and adjusted in a feedback manner through the volume feedback adjusting device.

Owner:JOYEA CORP

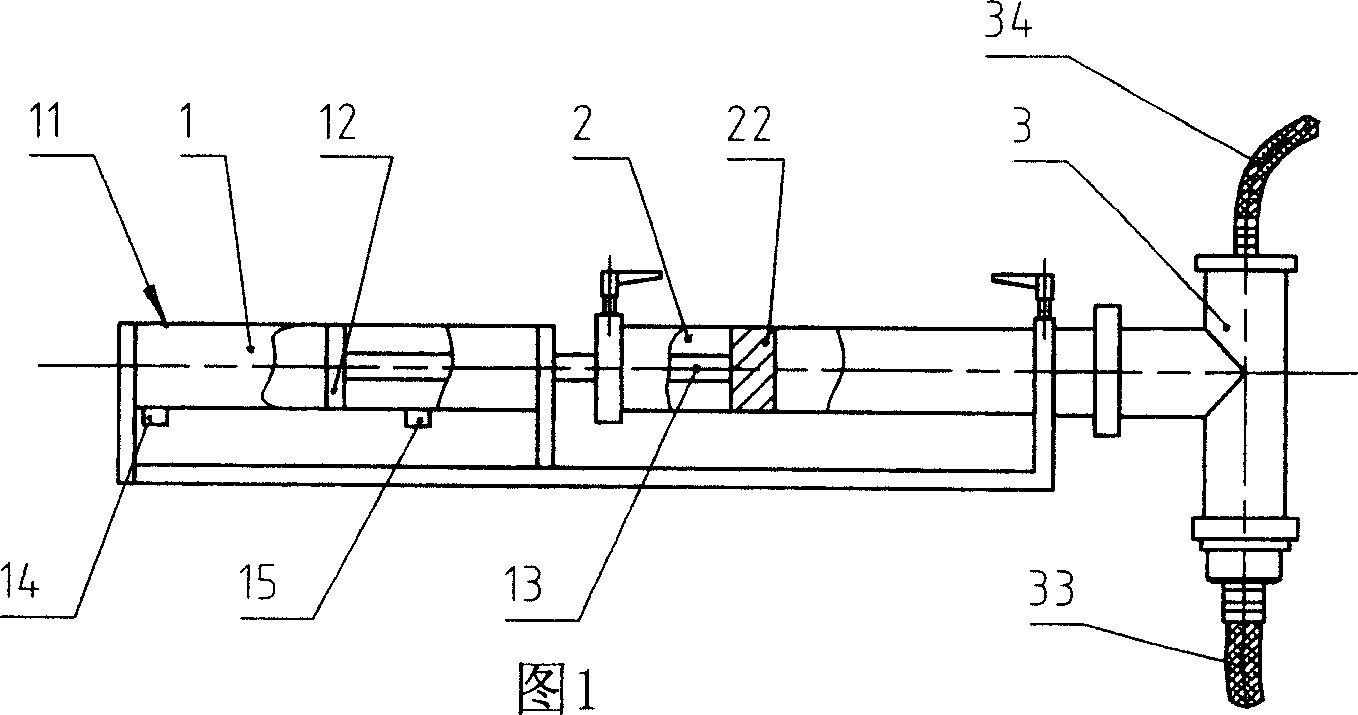

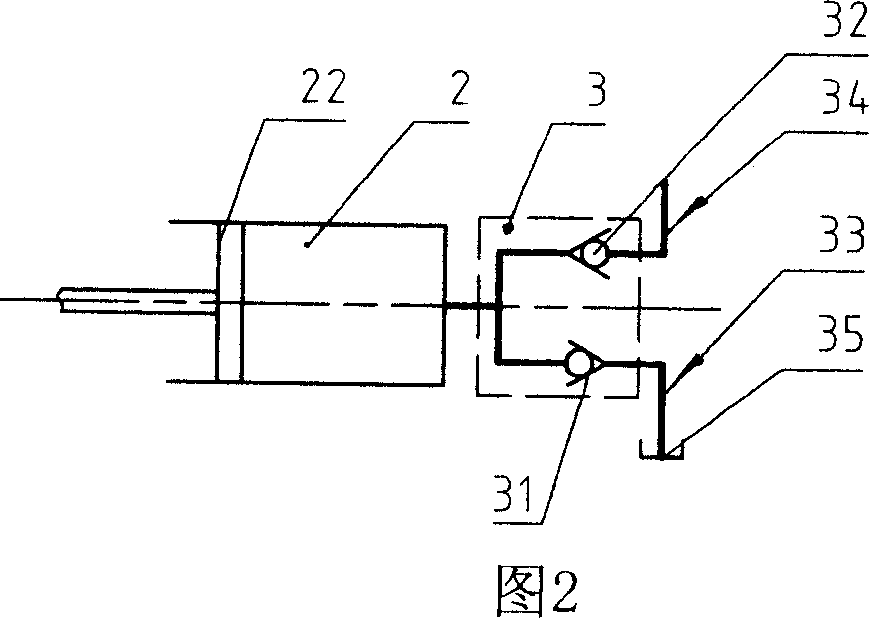

Loading controlling device and controlling method

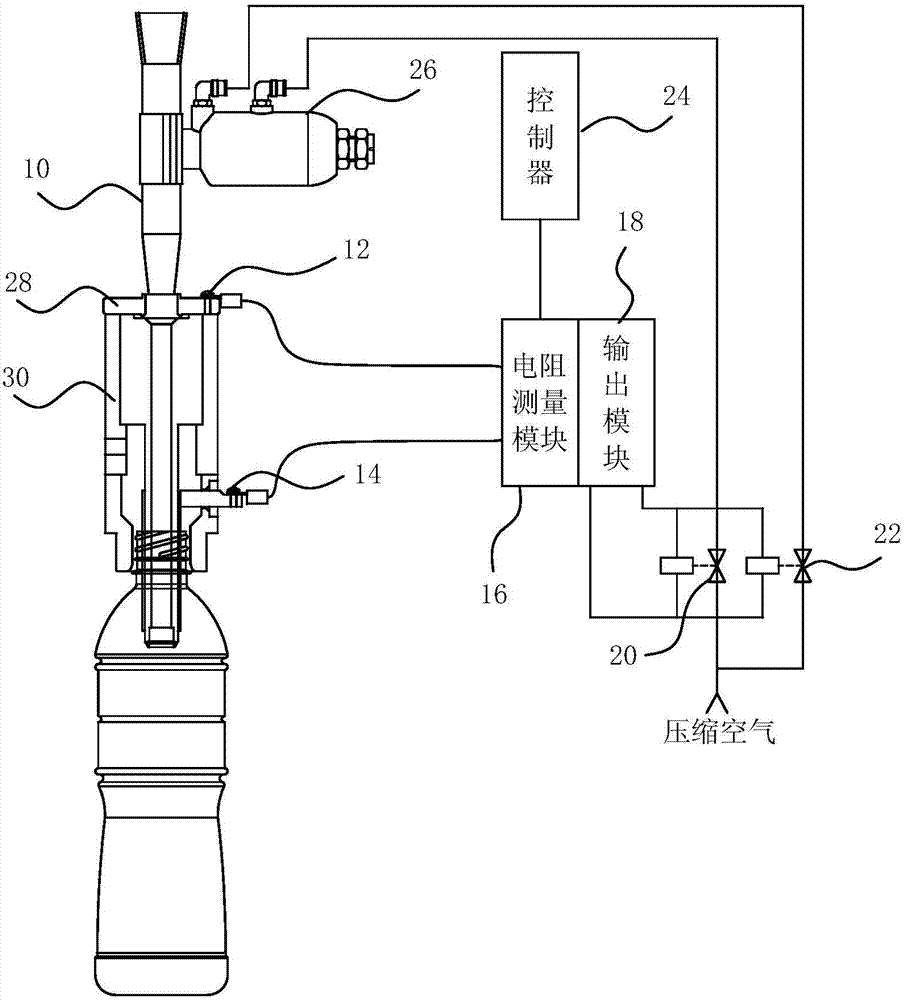

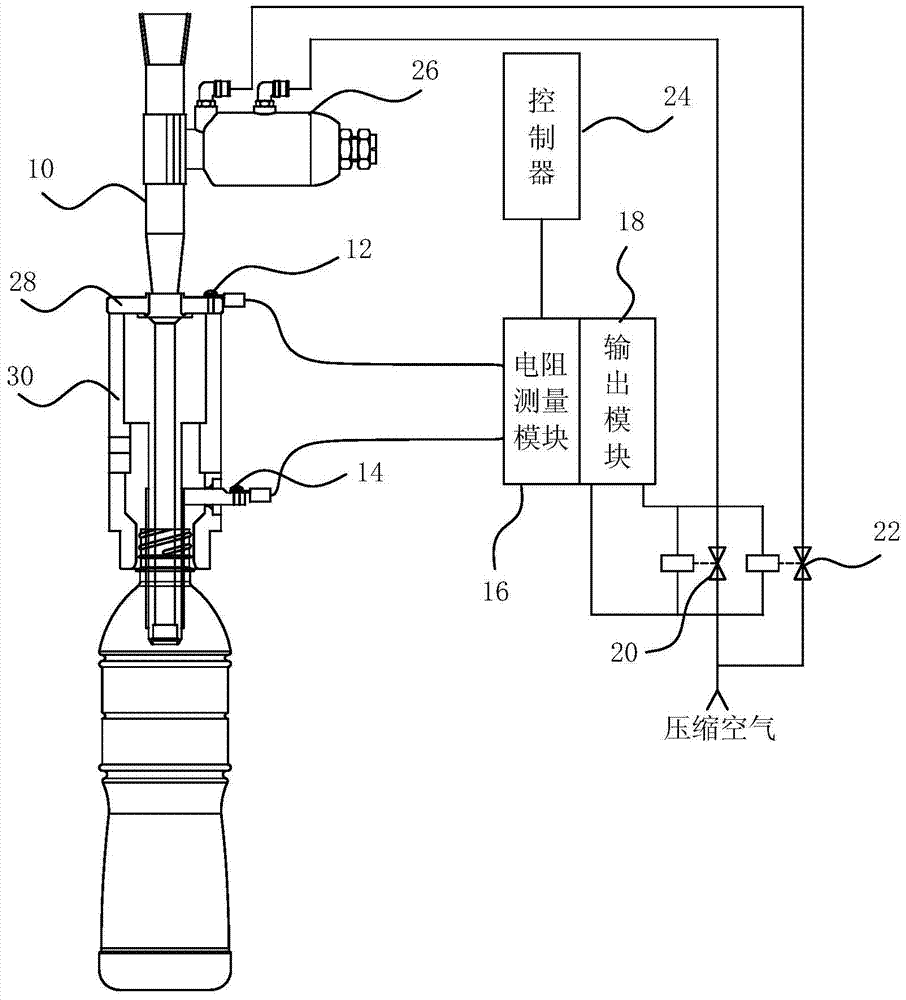

ActiveCN104495731AEliminate distractionsGuaranteed filling accuracyLiquid bottlingProbe typeSolenoid valve

The invention discloses a probe type loading device and a controlling method, the loading apparatus comprises a blanking tube, a resistor measure module and a controller, a first probe and a second probe distributed up and down are arranged on the blanking tube, the first probe positioned at upper portion is connected to the blanking tube, the second probe and the blanking tube are insulated, the first probe and the second probe are connected to the resistor measure module, and the resistor measure module is connected to the controller. The flow of a two stage diaphragm valve can be controlled by a first solenoid valve and a second solenoid valve, loading with two stage flow velocity of the material can be carried out, when the material in a bottle is loaded to a certain amount and contacted to the blanking tube, the material and the first probe are conducted, and continuous loading is carried out until the material and the second probe are conduced; the resistor measure module measures the resistance value between the first probe and the second probe, when the resistance value is less than a set resistance value, the two stage diaphragm valve is closed by controlling the solenoid valve, and then loading is finished.

Owner:GUANGZHOU TECH LONG PACKAGING MACHINERY CO LTD

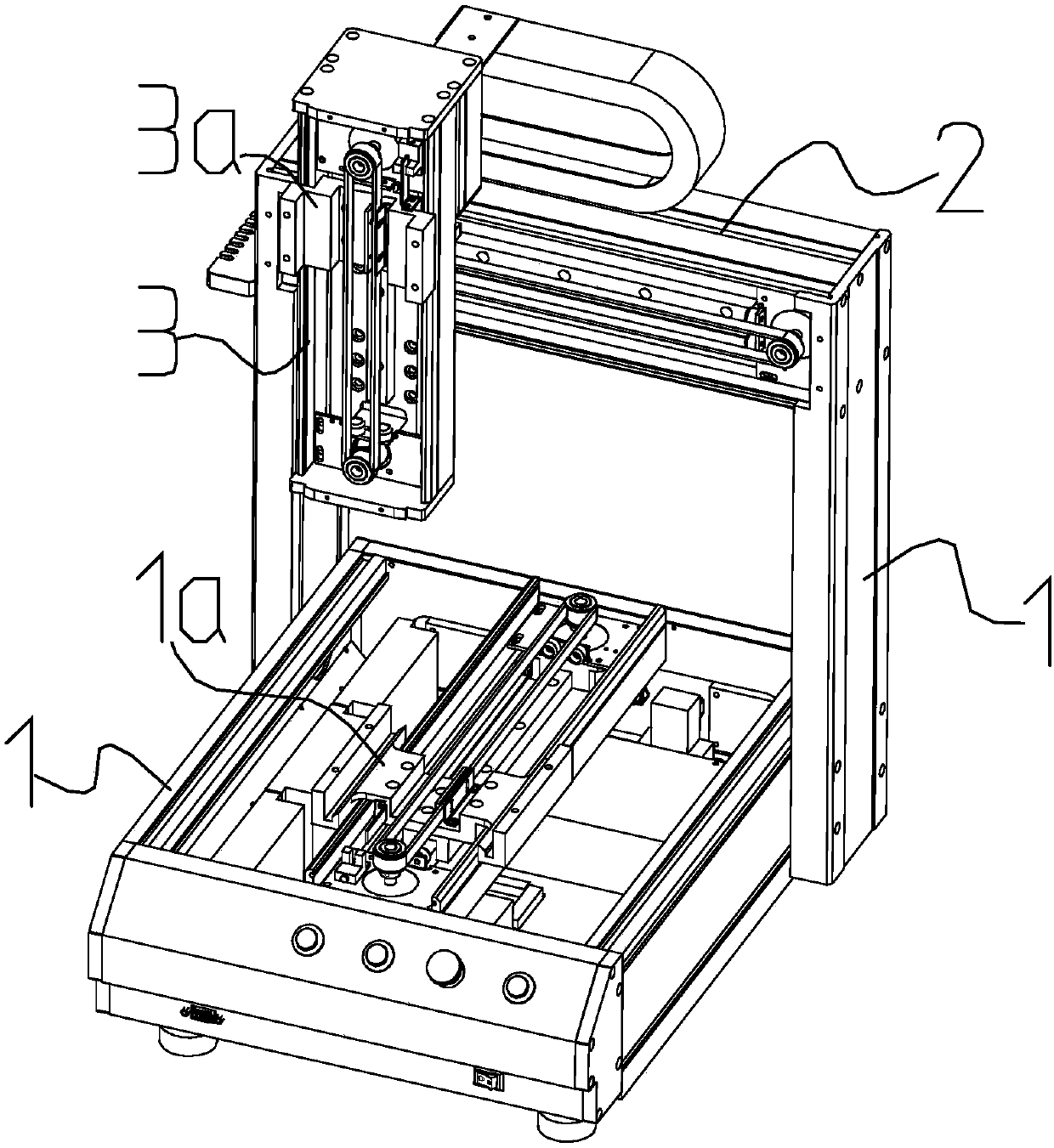

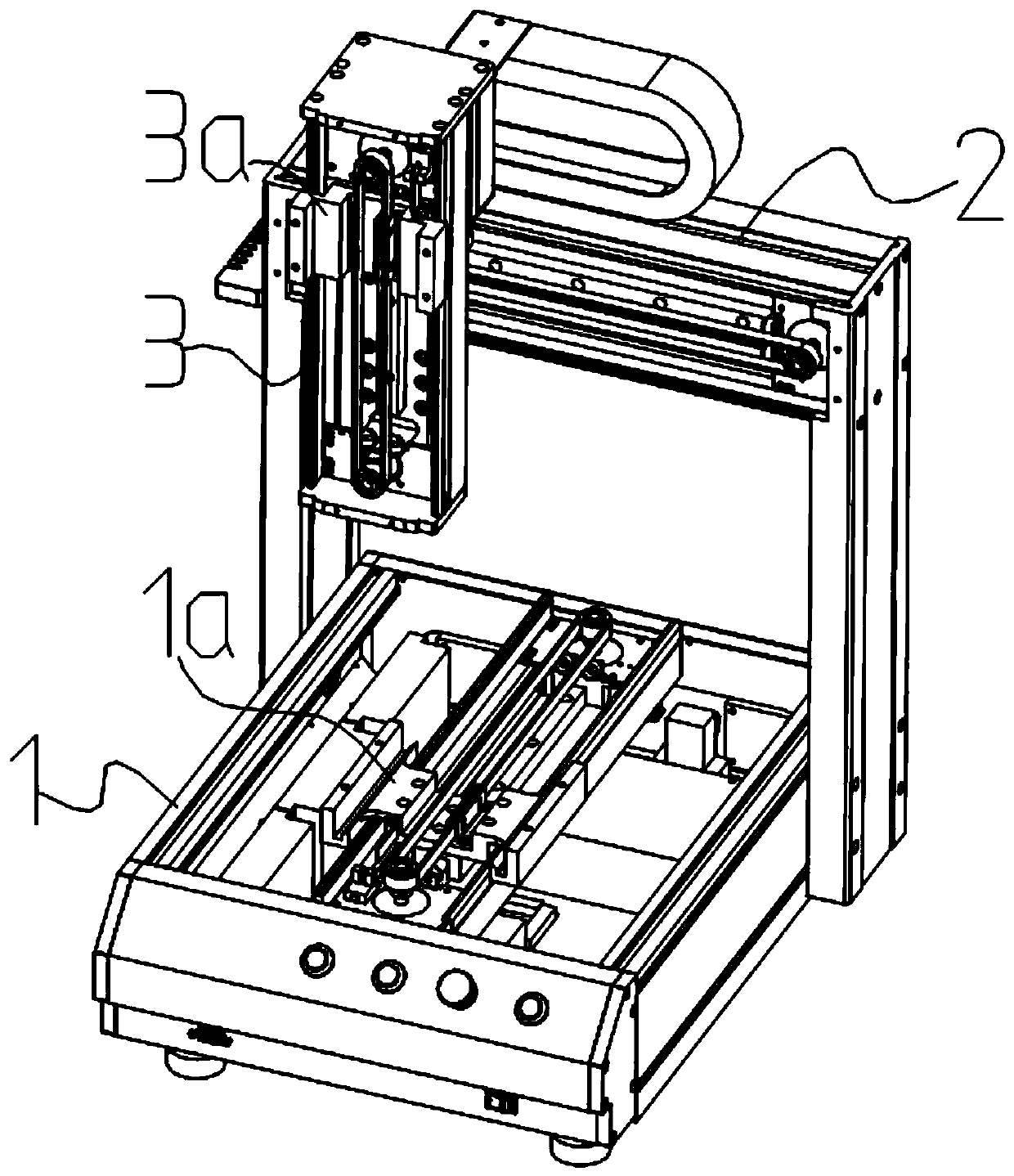

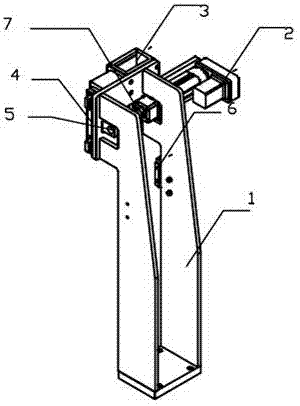

High-precision automatic filling device

The invention discloses a high-precision automatic filling device. The high-precision automatic filling device comprises a horizontal sliding shell, a transverse supporting shell and a vertical supporting shell, and further comprises a transmission pump used for driving liquid transmission, wherein a sliding tray capable of longitudinally sliding in the front-back direction of a reserved longitudinal guide rail is arranged on the horizontal sliding shell; a transverse sliding block capable of transversely sliding in the left-right direction of an inner cavity of the transverse supporting shellis arranged in the transverse supporting shell; a vertical sliding block capable of vertically sliding in the up-down direction of an inner cavity of the vertical supporting shell is arranged in thevertical supporting shell; one linear driving unit is arranged in each of the horizontal sliding shell, the transverse supporting shell and the vertical supporting shell; the linear driving units areused for driving the corresponding sliding blocks to linearly slide along the guide rails; and liquid transmission pipes of the transmission pump are fixed in reserved clamping holes of clamping blocks. The high-precision automatic filling device has various operation modes, automatically operates according to preset program, and is intelligently controlled, the automation degree is high, liquidsare transferred at high precision, and working efficiency is greatly improved.

Owner:BAODING SHENCHEN PUMP IND

Polyurethane resin filling equipment

InactiveCN110775925ASame contentGuaranteed filling accuracyBarrels/casks fillingPolymer scienceEngineering

The invention relates to the technical field of polyurethane resin production, and discloses polyurethane resin filling equipment. The polyurethane resin filling equipment comprises a machine frame and a barreling mechanism which is movably arranged at the lower end of the machine frame. A storage tank is arranged at the upper end of the machine frame, a feed port is formed in the upper end of thestorage tank, a plurality of discharge ports are formed in the lower end of the storage tank, and each discharge port is provided with a quantitative tank. The barreling mechanism comprises a devicetrolley, and a plurality of collecting barrels are arranged on the trolley in one-to-one correspondence with the multiple quantitative tanks. According to the polyurethane resin filling equipment, thequantitative tanks are arranged at the discharge ports, the content of polyurethane resin in each quantitative tank is the same, so that it is ensured that the content of polyurethane resin from thequantitative tanks to the collecting barrels is the same, and thus the tank filling accuracy is ensured. Meanwhile, the multiple quantitative tanks are arranged at the lower end of the storage tank, so that multiple tanks can be filled at one time, and the filling efficiency is improved. The polyurethane resin filling equipment is simple in structure, good in use effect and easy to promote and use.

Owner:QINGYUAN FANYI POLYURETHANE CO LTD

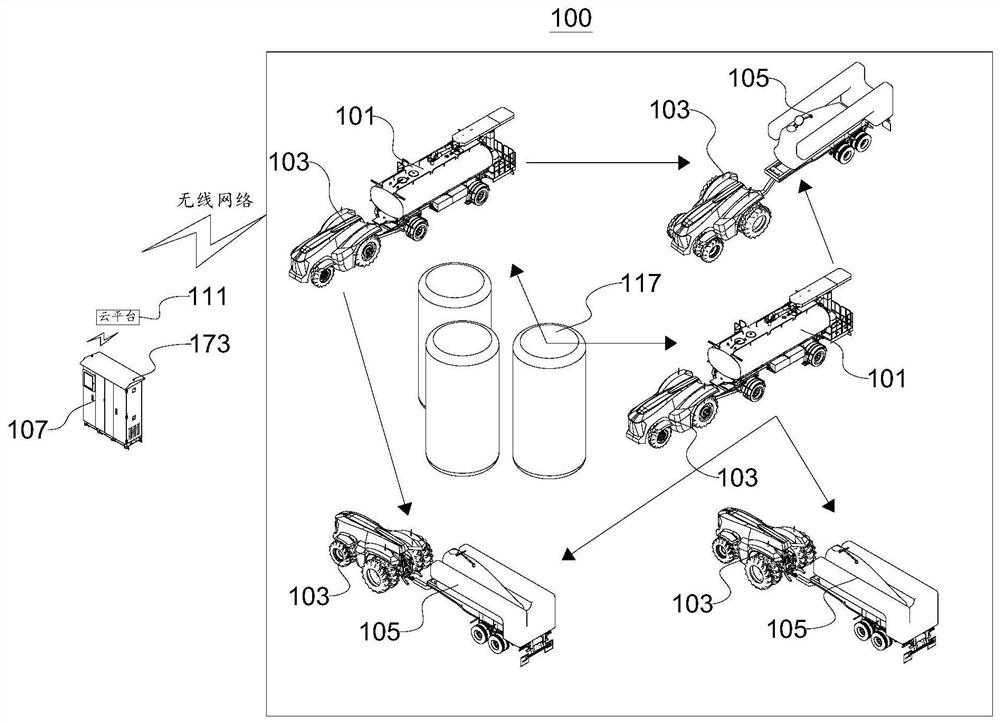

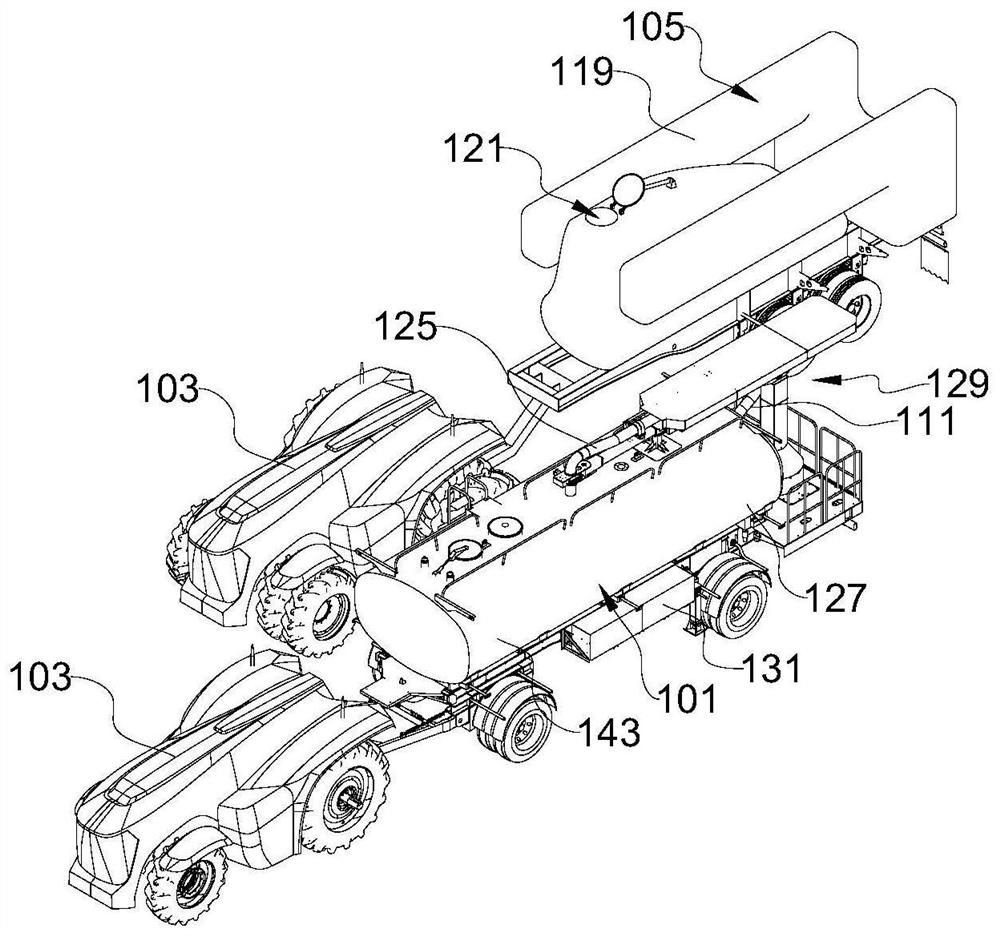

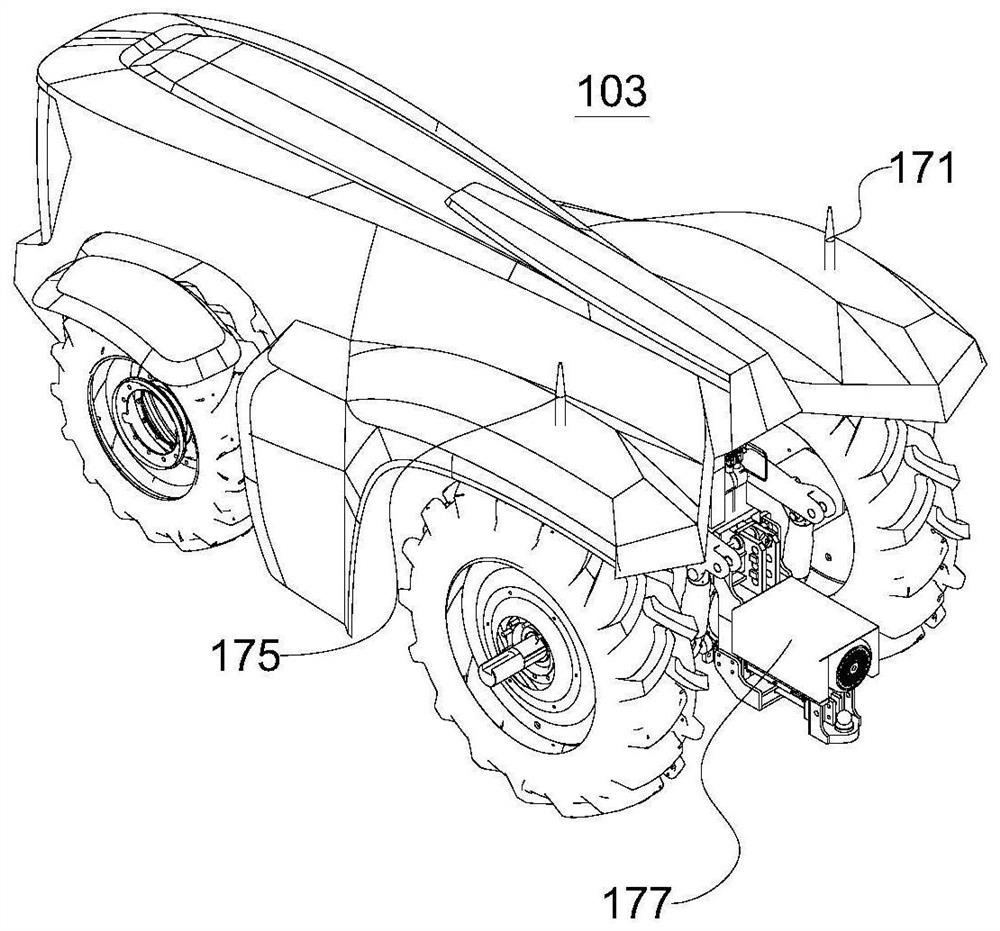

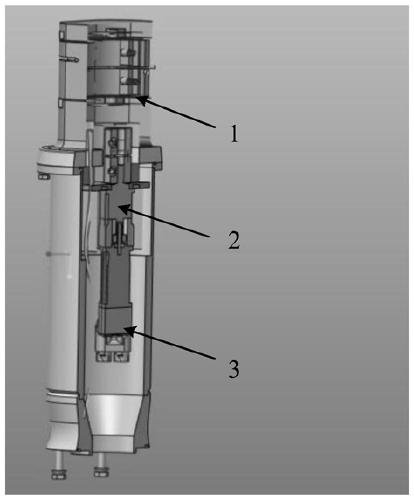

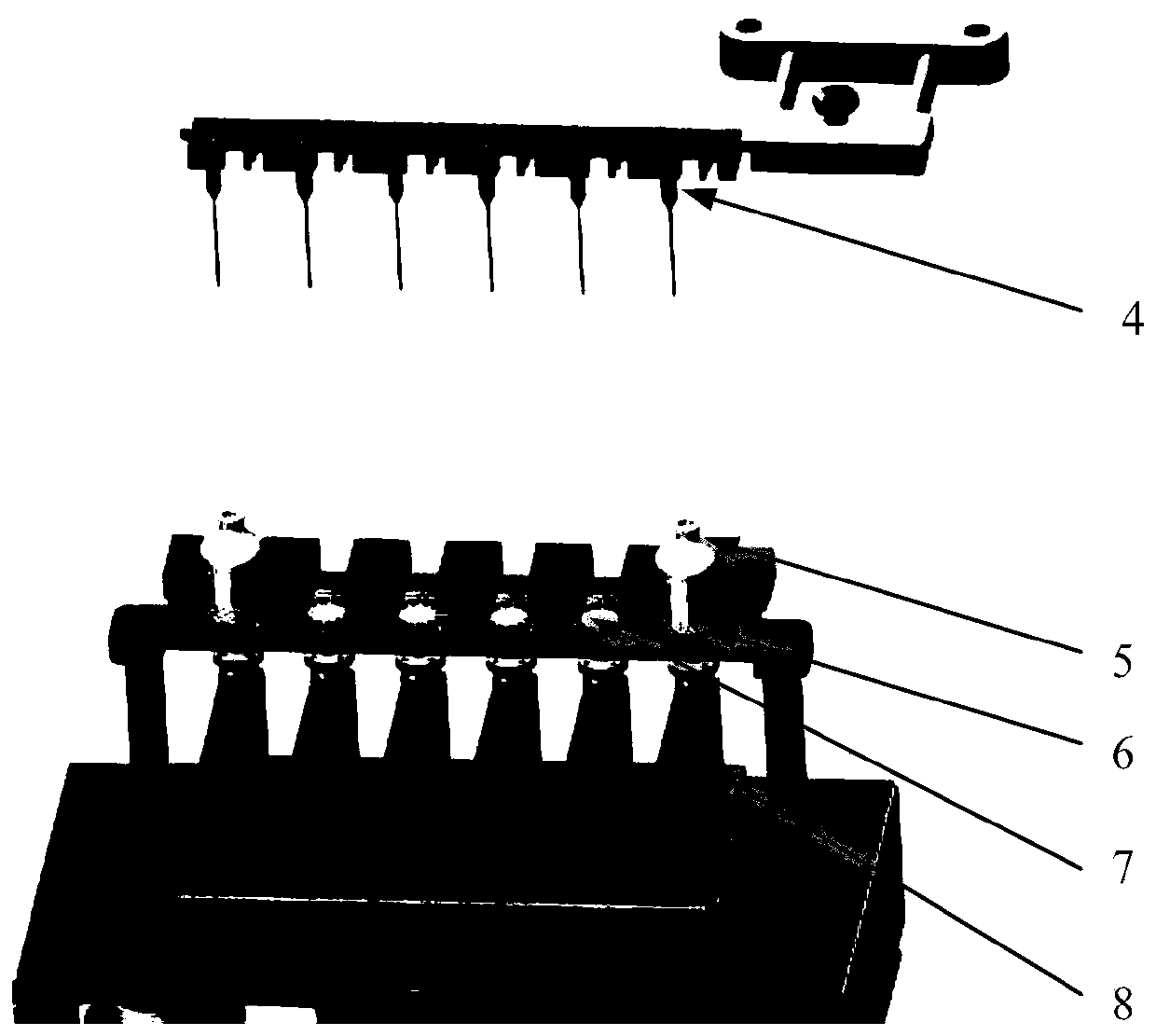

Liquid filling system

PendingCN114394569AGuaranteed reliabilityGuaranteed stabilityLiquid transferring devicesAutomationAutomotive engineering

The invention discloses a liquid filling system, and relates to the technical field of automatic liquid filling. The liquid filling system is used for filling a filled vehicle with liquid and comprises a filling vehicle, driving equipment and master control equipment, the filling vehicle is used for filling liquid for the filled vehicle; the driving equipment comprises a positioning device and is used for driving the filling vehicle and the filled vehicle to move; and the master control equipment is in communication connection with the filling vehicle and the driving equipment, and is used for controlling the driving equipment to drive the filling vehicle and the filled vehicle to move to a filling destination according to a preset route according to the positioning information of the positioning device, and controlling the filling vehicle to inject liquid into the filled vehicle after the filling vehicle and the filled vehicle move to the filling destination. The liquid filling system is high in automation and intelligence degree, the burden of manual filling can be relieved, multi-directional and multi-destination liquid filling can be achieved, the liquid filling range is wider, and the filling and supplying efficiency can be effectively improved.

Owner:广东皓耘科技有限公司

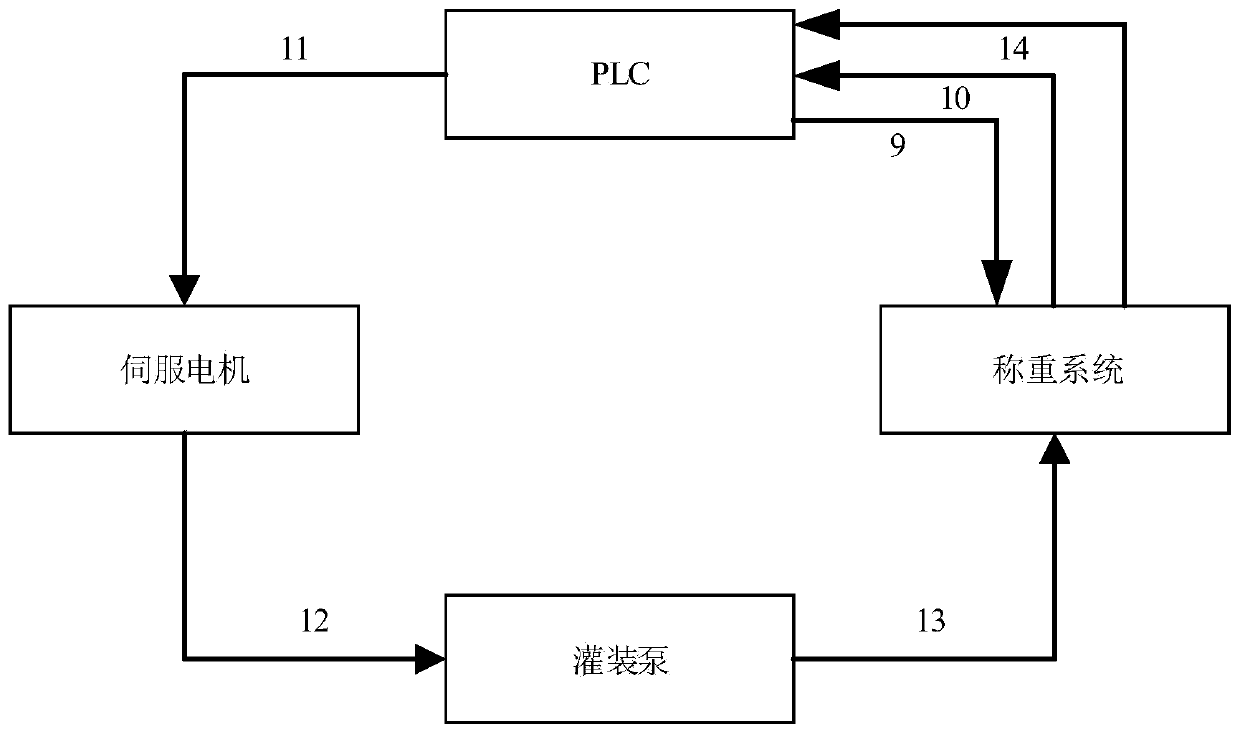

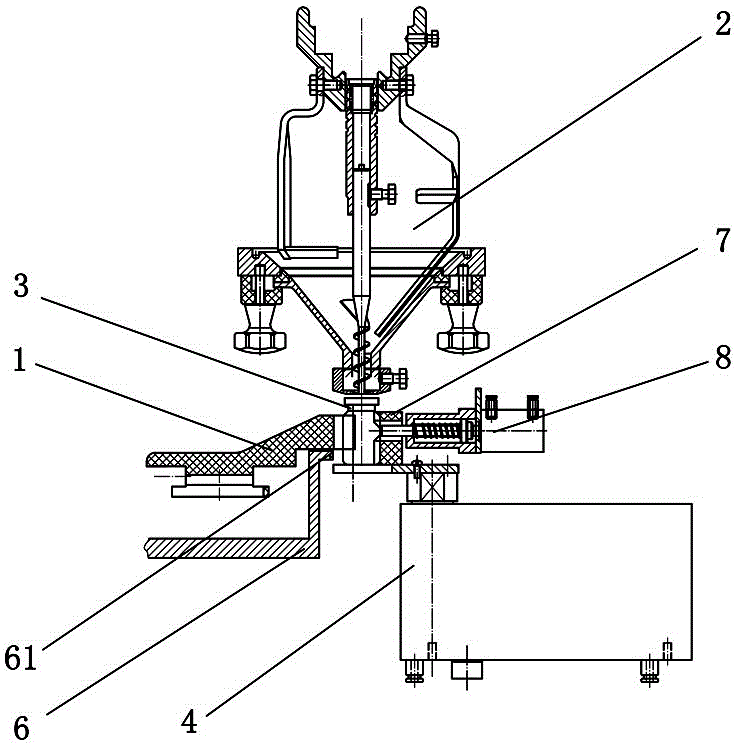

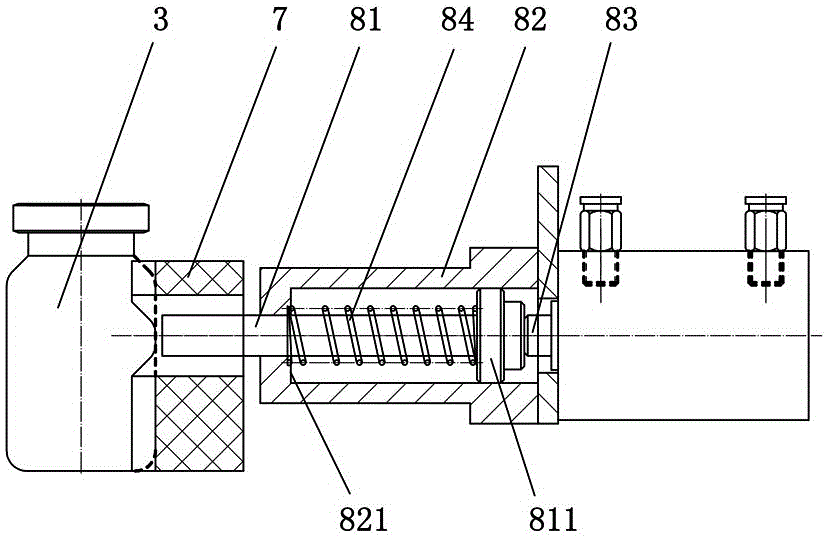

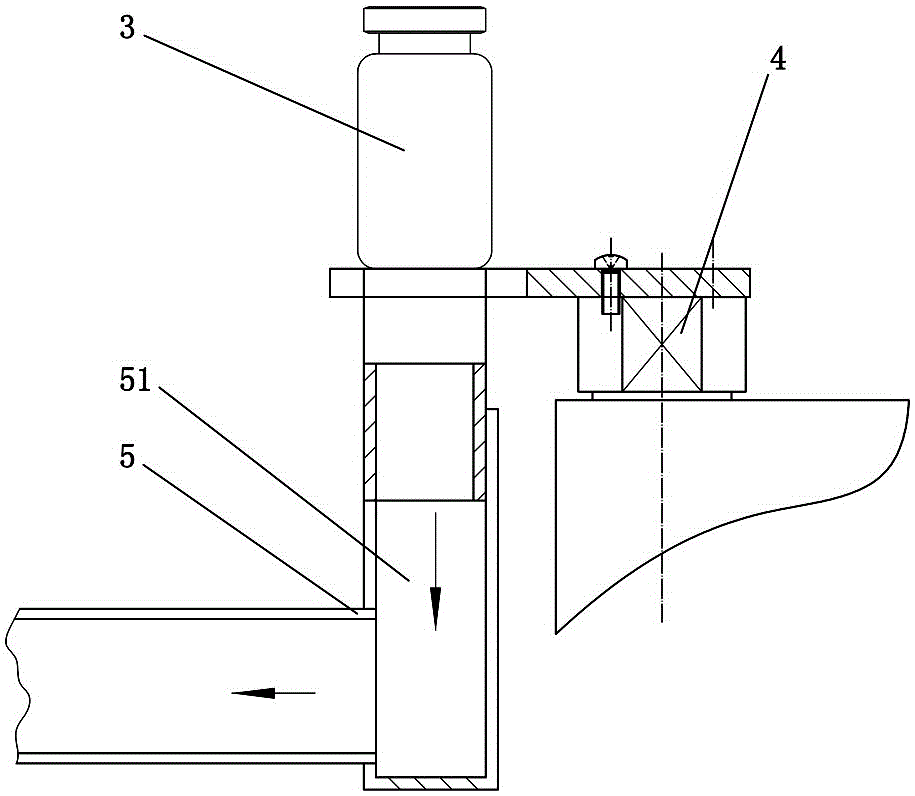

A method and device for controlling filling accuracy

ActiveCN109592095BAvoid interferenceGuaranteed production speedLiquid materialControl engineeringMechanical engineering

The invention provides a method and equipment for controlling filling accuracy. By using a controlling method including a system initiation stage, a rough filling stage, a refined filling stage and aclosing stage, the filling accuracy is controlled; in the refined filling stage, low-speed filling is carried out by using a filling pump; after second predetermined time T16, the weight of liquid isdetected in real time until the weight reaches a second predetermined value G2 and then the detection is stopped; and the size of the second predetermined value G2 is determined according to a difference value between target weight G1 of a container and the weight of a less amount of surplus liquid which does not flow into the container during closing of the filling pump. According to the method and equipment for controlling the filling accuracy disclosed by the invention, rough filling and refined filling are separately carried out and sectional control is carried out, the rough filling is used for ensuring the production speed and the refined filling is used for ensuring the filling accuracy; the pump-rear pipe storage amount is taken into consideration between a refined filling value and a predetermined value; and through calibrating the matching of the refined filling value and the pump-rear pipe storage amount in real time, the situation that the final filling amount is almost consistent with the predetermined value is ensured.

Owner:TRUKING TECH LTD

Filling machine with online weighing function

ActiveCN105173252BReduce residual powderAvoid wastingPackaging automatic controlSolid materialEngineeringMedicine bottles

The invention discloses a subpackaging machine with the online weighing function. The subpackaging machine with the online weighing function comprises a bottle travelling mechanism and at least one subpackaging station. The bottle travelling mechanism can convey medicine bottles to the subpackaging stations. Each subpackaging station is provided with a weighing device for performing zero clearing on the weight of the empty medicine bottles before subpackaging and performing real-time weighing on the medicine bottles in the subpackaging process. The weighing devices are connected with a subpackaging device of the subpackaging machine through a control assembly. The subpackaging machine has the beneficial effects of being simple in structure, high in subpackaging precision, low in cost, capable of improving production efficiency and the like.

Owner:TRUKING TECH LTD

A high-precision automatic filling device

The invention discloses a high-precision automatic filling device. The high-precision automatic filling device comprises a horizontal sliding shell, a transverse supporting shell and a vertical supporting shell, and further comprises a transmission pump used for driving liquid transmission, wherein a sliding tray capable of longitudinally sliding in the front-back direction of a reserved longitudinal guide rail is arranged on the horizontal sliding shell; a transverse sliding block capable of transversely sliding in the left-right direction of an inner cavity of the transverse supporting shellis arranged in the transverse supporting shell; a vertical sliding block capable of vertically sliding in the up-down direction of an inner cavity of the vertical supporting shell is arranged in thevertical supporting shell; one linear driving unit is arranged in each of the horizontal sliding shell, the transverse supporting shell and the vertical supporting shell; the linear driving units areused for driving the corresponding sliding blocks to linearly slide along the guide rails; and liquid transmission pipes of the transmission pump are fixed in reserved clamping holes of clamping blocks. The high-precision automatic filling device has various operation modes, automatically operates according to preset program, and is intelligently controlled, the automation degree is high, liquidsare transferred at high precision, and working efficiency is greatly improved.

Owner:BAODING SHENCHEN PUMP IND

Measuring cup with automatic filling volume adjustment function

InactiveCN107499548AEasy to adjust the filling volumeEasy to replaceSolid materialEngineeringMeasuring cup

The invention relates to a measuring cup, in particular to a measuring cup which can automatically adjust the filling volume. The measuring cup for automatically adjusting the filling volume of the present invention includes a measuring cup, a measuring cup telescopic block, a stepping electric cylinder, a control panel and a bracket, wherein the measuring cup, the control panel and the stepping electric cylinder are fixed to the bracket by fixing screws Above, the side wall of the measuring cup is provided with an opening, the telescopic block of the measuring cup penetrates into the side wall of the measuring cup through the opening, and one end of the stepping electric cylinder is connected with a transmission rod, and the telescopic block of the measuring cup passes through the telescopic block The fixing device is fixed on the transmission rod; the control panel is located under the stepping electric cylinder, and is used to control the stepping electric cylinder to drag the telescopic block of the measuring cup to move horizontally. The invention can freely adjust the size of the measuring cup according to the products produced, so that the equipment can be compatible with more products; the assembly process of replacing the measuring cup is canceled, the replacement process is simplified, and the production efficiency is improved.

Owner:青岛怡口智能科技有限公司

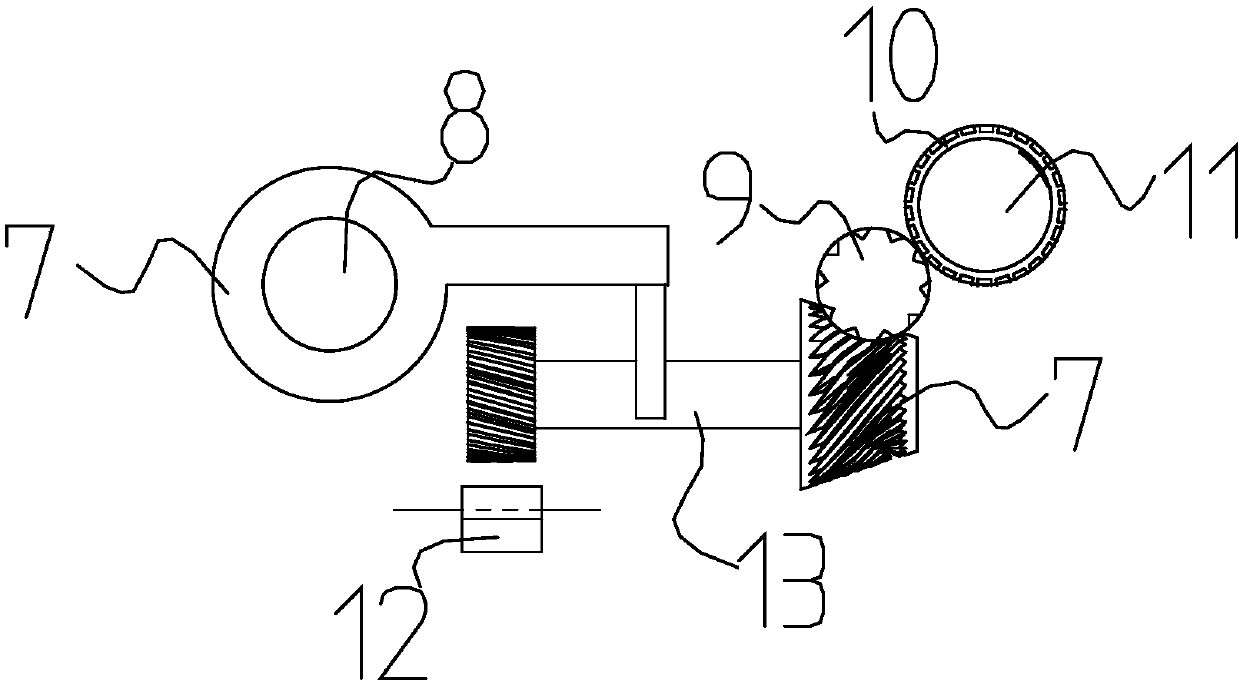

Variable flow rate intelligent sense filling valve

ActiveCN101746701BFast filling speedImprove filling efficiencyLiquid bottlingHydraulic cylinderEngineering

The invention discloses a variable flow rate intelligent sense filling valve which comprises a valve body, wherein the valve body is provided with a feeding valve which is communicated with a hydraulic cylinder pipeline filled with a filling liquid, the lower part of the valve body is provided with a discharging valve, the valve body is provided with a valve cylinder, a cylinder cavity of the valve cylinder is communicated with a valve cavity of the valve body, and the valve cylinder is provided with a liquid level sensing device and an air inlet control device. The invention realizes double-flow rate filling, improves the filling speed and ensures the filling precision, does not produce excessive bubbles so that the filling liquid can not overflow, saves the filling liquid, and improves the filling efficiency.

Owner:安丘市鼎正机械设备有限公司

Filling control device and control method thereof

ActiveCN104495731BEliminate distractionsGuaranteed filling accuracyLiquid bottlingElectrical resistance and conductanceProbe type

Owner:GUANGZHOU TECH LONG PACKAGING MACHINERY CO LTD

Linear continuous filling peristaltic pump

PendingCN113775513AContinuous filling achievedIncrease fill volumePositive displacement pump componentsFlexible member pumpsPeristaltic pumpReciprocating motion

The invention discloses a linear continuous filling peristaltic pump. The linear continuous filling peristaltic pump comprises a pump body assembly, a pipeline assembly, a pipe pressing assembly and a linear reciprocating motion assembly, wherein, the pipeline assembly comprises a hose and a hose support assembly, the hose support assembly is arranged on the side portion of a pump body, the hose is hung at one end of the hose support assembly, the input end and the output end of the hose are fixed to the other end of the hose support assembly, and the hose hanging portion and the two ends are linearly arranged; the linear reciprocating motion assembly and the pipe pressing assembly are both installed on the pump body assembly, and the linear reciprocating motion assembly is used for driving the pipe pressing assembly to do linear reciprocating motion; and in one cycle of reciprocating motion of the pipe pressing assembly, the pipe pressing assembly extrudes or loosens the hose from the hose input end to the hose hanging portion and from the hose hanging portion to the hose output end, so that continuous filling and metering of materials are achieved. The linear continuous filling peristaltic pump has the advantages of compact structure, high filling efficiency, stable metering and the like, and continuous material filling of the linear peristaltic pump is realized.

Owner:CHANGSHA ZENITHSUN INTELLIGENCE QUANTITATIVE TECH CO LTD

A method for conventional metering pumps to realize small flow and high-precision metering and filling

ActiveCN110410674BStable structureImprove efficiencyPipeline systemsPump controlControl theoryMetering pump

The invention discloses a method for realizing small-flow high-precision metering and filling of a conventional metering pump. According to the method, a control device for realizing small-flow high-precision metering and filling is included, the control device comprises a Y-shaped filter, a safety valve, a buffer with a pressure gauge, a bypass ball valve, an isolation ball valve, a flow meter, asmall flow regulating valve, a check valve, a throttling valve and a control cabinet, under the general force support of the flow meter, the small flow regulating valve, the buffer with the pressuregauge, the control cabinet and other accessories, a conventional metering pump can achieve the control precision of 10% or below, the accumulative errors are reduced, the purpose of accurate meteringis achieved, the control device has the characteristics of being reliable in structure, high in efficiency and low in cost, the filling precision of a fluid material at the flow rate of 10% or below is ensured, and the reinvestment is saved.

Owner:LUOYANG LVCHAO ENVIRONMENTAL PROTECTION TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com