A container intelligent filling and sealing system and method

A container and intelligent technology, which is applied in the field of pharmaceutical packaging equipment and food, can solve the problems of high filling accuracy and the need to detect the filling volume of each filling container, so as to improve the filling pass rate and filling volume Accurate, position-accurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

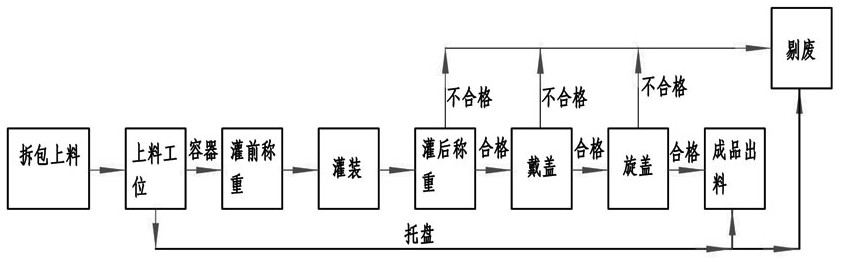

[0029] figure 1 An embodiment of the container intelligent filling and sealing system of the present invention is shown. The container intelligent filling and sealing system of this embodiment includes a first conveying track 1, and the first conveying track 1 is sequentially provided with a feeding station and a container along the conveying direction. Transfer station, finished product sorting station and finished product collection platform 3, the side of the first conveying track 1 is provided with weighing device 4, capping device 5 and capping device 6, weighing device 4, capping device 5 and rotary capping device The cover device 6 is equipped with a second conveying track 8, and the filling device 7 is arranged above the weighing device 4. The first conveying track 1 is provided with a container carrier 9 upstream of the container transfer station and placed at the finished product sorting station. The upstream is provided with a finished product carrier 18, the contai...

Embodiment 2

[0038] figure 2 An embodiment of the potting method of the container intelligent potting system of the present invention is shown. The potting method of this embodiment includes the following steps:

[0039] S1. Unpacking and loading: unpack at the loading station and load the container carrier 9 with the container onto the first conveying track 1 (that is, when packaging, the container is first placed on the container carrier 9, and then Pack again; when unpacking, after unpacking the packaging box, the container is directly loaded together with the container carrier 9 as a whole, and the container is transported on the first conveying track 1 by means of the container carrier 9), and the first conveying track 1 carries the container The tool 9 is transported to the container transfer station, and the first material blocking device 12 blocks the container carrier 9;

[0040] S2. Container transfer: the container transfer manipulator 10 takes the container in the container c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com