Filling method and system

A filling system and filling device technology, used in packaging, bottle filling, liquid bottling, etc., can solve problems such as difficulty in achieving filling accuracy, reducing filling efficiency, and damage to load cells, and ensuring filling accuracy. , The effect of shortening the production cycle and avoiding equipment damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

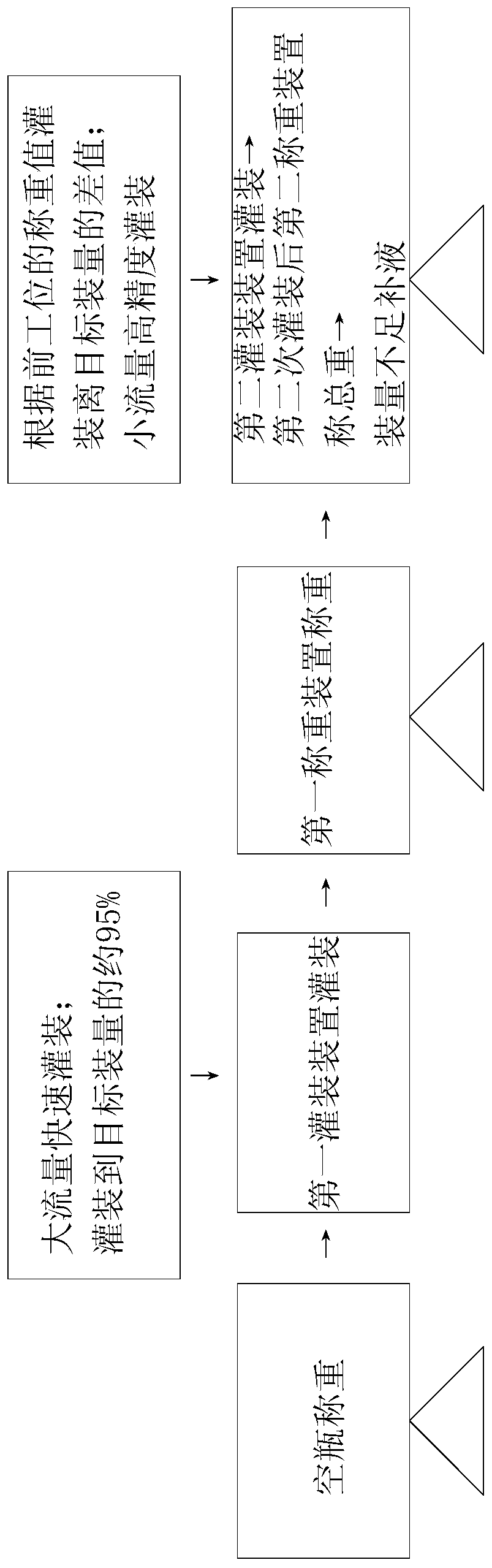

[0031] figure 1 An embodiment of the filling method of the present invention is shown, the filling method of the present embodiment comprises the following steps:

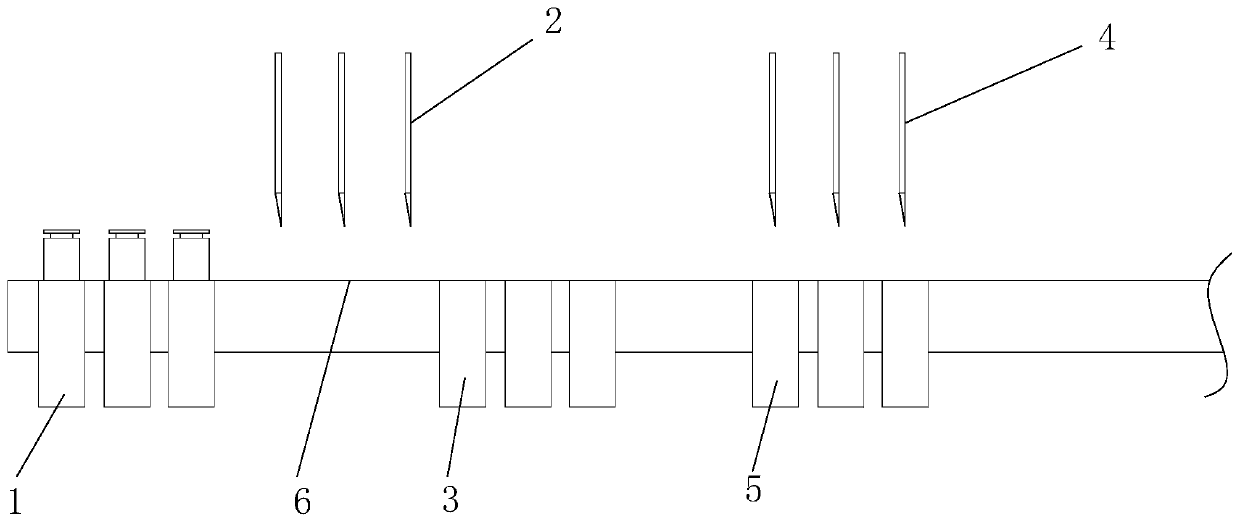

[0032] S1, the first weighing station 1 weighs the empty bottle;

[0033] S2. The first filling device 2 fills the empty bottle for the first time according to the set filling volume;

[0034] S3, the second weighing station 3 weighs the bottle body after the first filling;

[0035] S4. The second filling device 4 fills the bottle body after the first filling for the second time. The flow rate of the second filling device 4 is less than the flow rate of the first filling device 2. If the target filling volume is K , The actual filling volume of the first filling of the bottle measured in S3 is K1, and the set filling volume of the second filling is K2, then K2=K-K1;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com