Method for realizing small-flow high-precision metering and filling of conventional metering pump

A metering pump, small flow technology, applied in the direction of pump, pump control, liquid variable capacity machinery, etc., can solve the problems of high cost, high manufacturing difficulty, and reduced filling volume, so as to ensure the filling accuracy and save waste. The effect of investment, structure and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

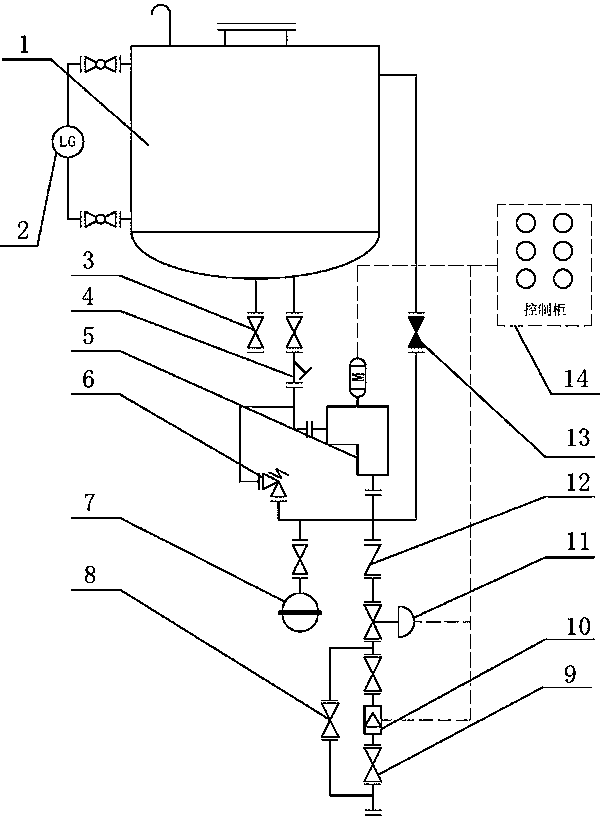

[0023] The invention is a method for conventional metering pumps to realize small-flow and high-precision metering and filling. When the conventional metering pump is adjusted within the flow range of 10-100%, its metering accuracy can reach ±1%. If the flow rate is below 10%, it will The flow control accuracy is low, the cumulative error is large, and the problem of accurate measurement cannot be achieved. The problem to be solved by the method of the present invention is, which configuration of the conventional metering pump can realize the control accuracy of the flow rate below 10%, reduce the cumulative error and can achieve precise measurement.

[0024] full text combination figure 1 For most industries that need to transport fluid materials, the conventional metering pump (5) is used to measure the flow of fluid materials transported by the dosing tank. One side of the dosing tank (1) is equipped with a liquid level gauge (2). The upper and lower ends are connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com