Intelligent filling equipment and filling method thereof

A filling equipment and intelligent technology, which is applied in the field of intelligent filling equipment and its filling, can solve the problems that the filling accuracy and product qualification rate cannot be guaranteed, the size requirements of the transition conveyor belt are very strict, and the space occupied by the equipment increases. Guaranteed filling pass rate, improved accuracy and product pass rate, and simplified actions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

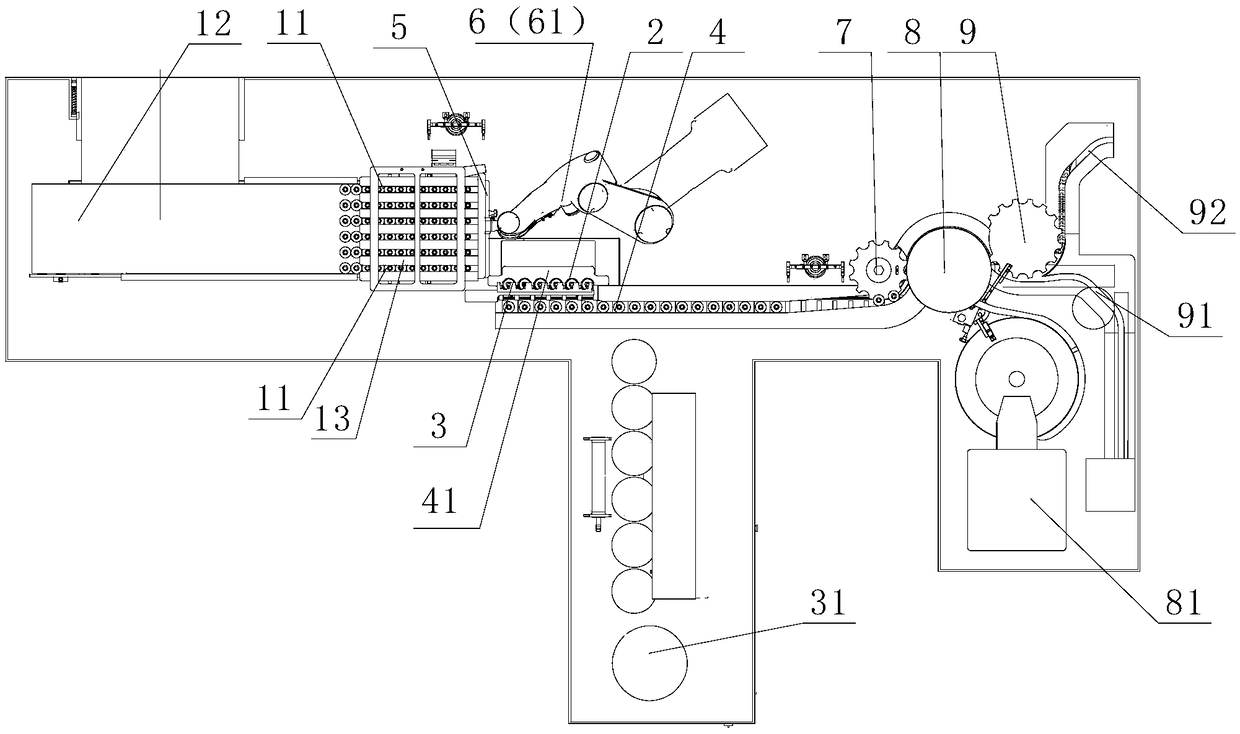

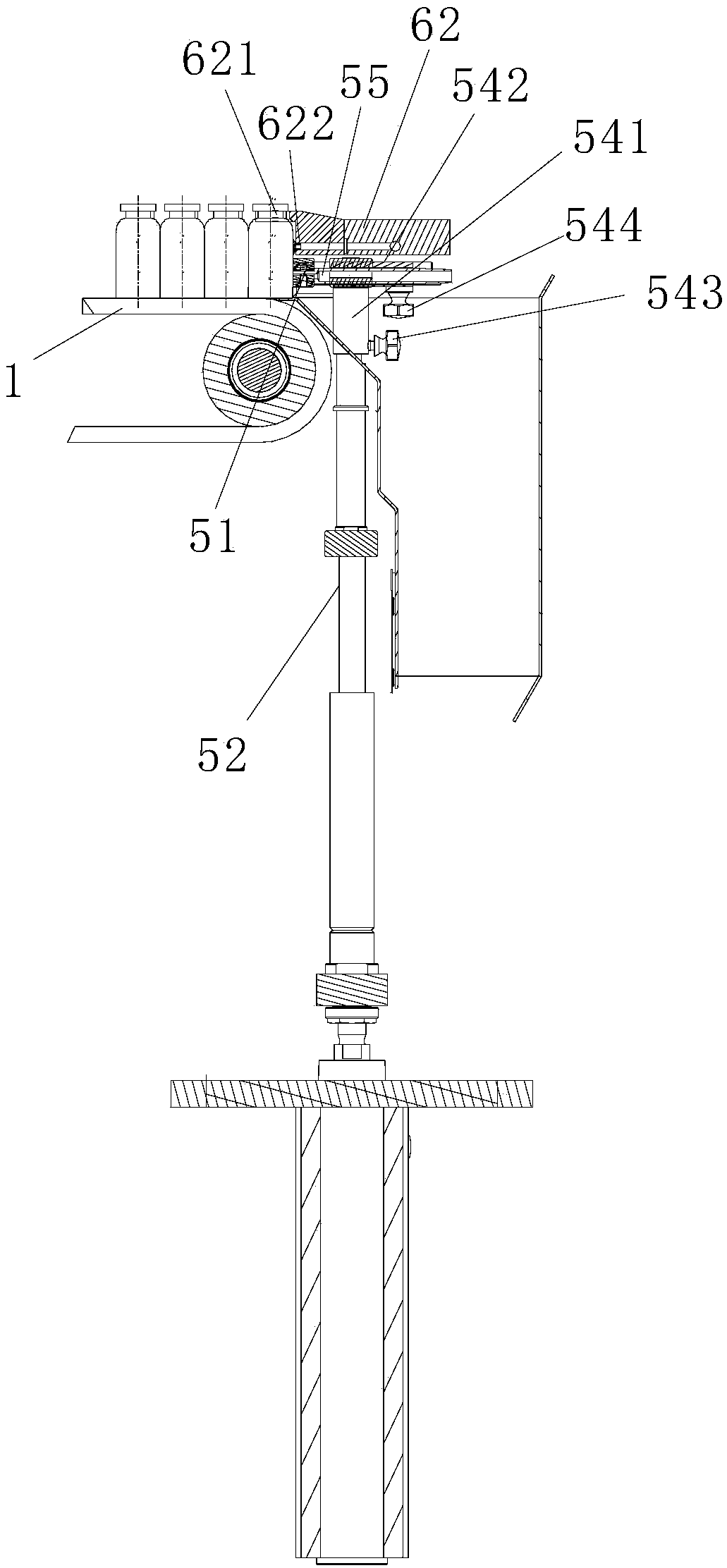

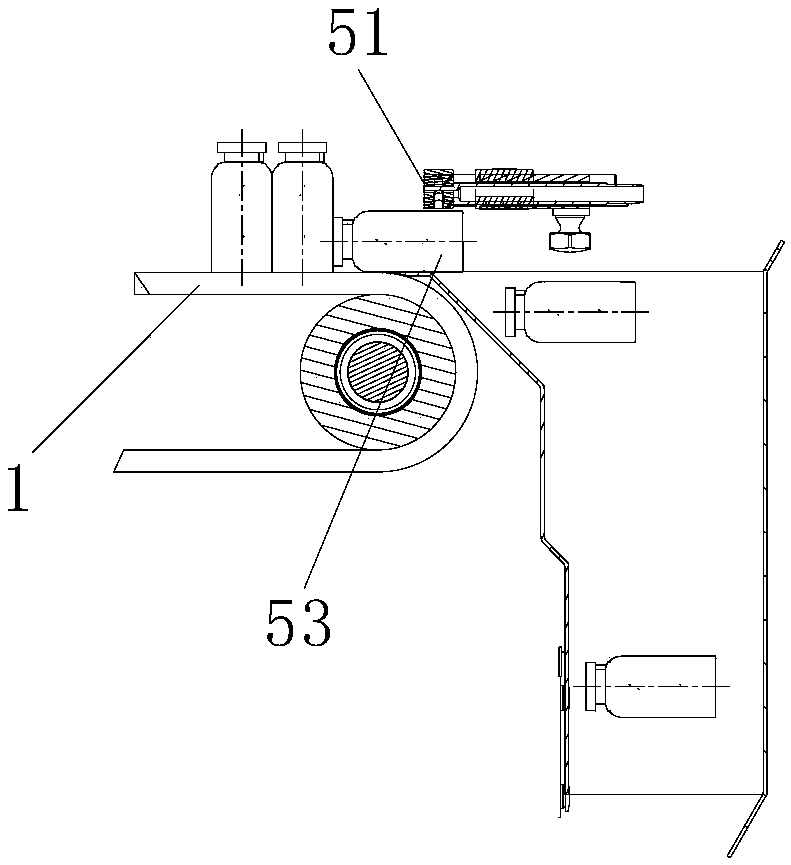

[0035] Figure 1 to Figure 5 An embodiment of the intelligent filling equipment and its filling method according to the present invention is shown. The intelligent filling equipment of this embodiment includes a bottle feeding mechanism 1, a weighing component 2, a needle filling component 3, and a bottle discharging mechanism 4 , also includes a transfer mechanism 6 for transferring the medicine bottle on the bottle-in mechanism 1 to the weighing part 2 and the medicine bottle on the weighing part 2 to the bottle-out mechanism 4, and the weighing part 2 is arranged on the bottle-out mechanism 4, the needle filling part 3 is arranged above the weighing part 2, and the bottle outlet mechanism 4 is equipped with a buffer platform 41, and the bottle inlet end of the bottle outlet mechanism 4 and the buffer platform 41 are relatively arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com