Filling control device and control method thereof

The technology of a filling device and control method is applied in the field of filling control device and its control, which can solve the problems of low filling accuracy, inability to set recipes, inconvenient adjustment of liquid level module detection methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Embodiments of the present invention are described in detail below:

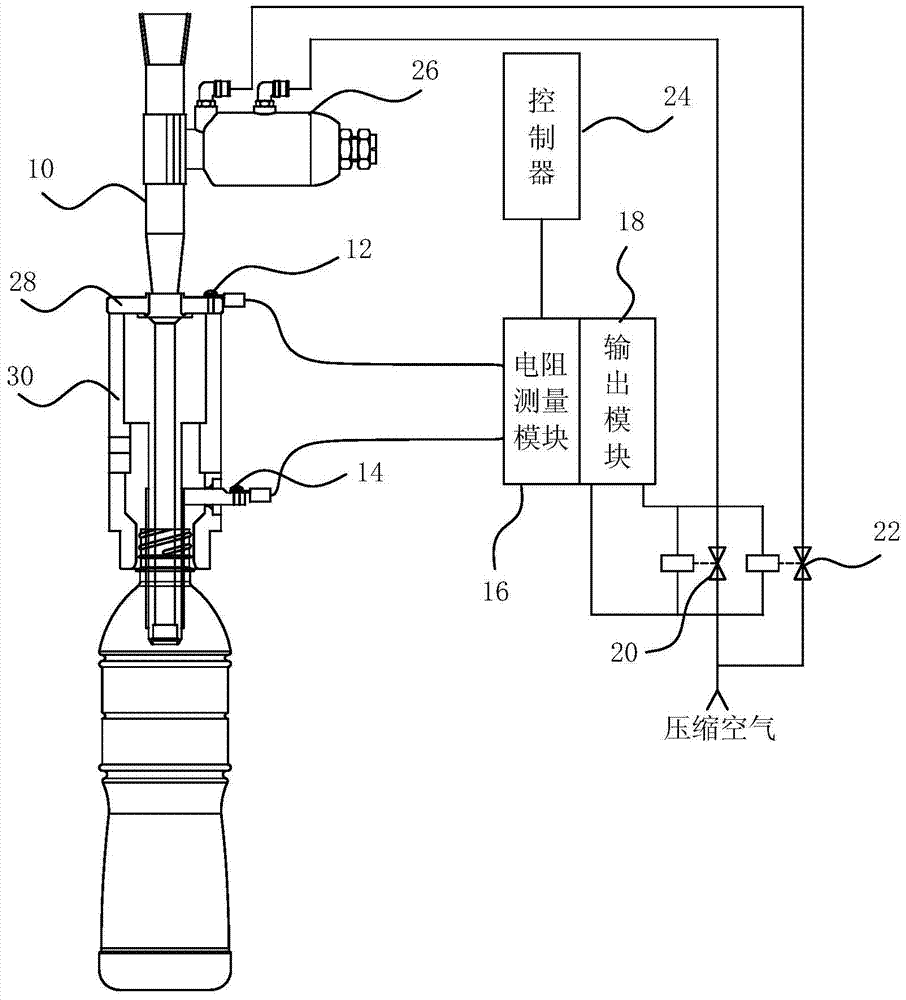

[0029] Such as figure 1 As shown, a probe-type filling device includes a feeding tube 10, a resistance measurement module 16 and a controller 24. The feeding tube 10 is equipped with a first probe 12 and a second probe 14 distributed up and down. , the first probe 12 on the upper part is connected to the feeding pipe 10, the second probe 14 is insulated from the feeding pipe 10, and when the second probe 14 is in contact with the material, the first A probe 12 communicates with a second probe 14 to form a detection loop, the first probe 12 and the second probe 14 are both connected to the resistance measurement module 16, and the resistance measurement module 16 is connected to the controller 24;

[0030] It also includes a two-stage diaphragm valve 26, an output module 18, a first solenoid valve 20 and a second solenoid valve 22, the two-stage diaphragm valve 26 is connected with compressed air, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com