Filling apparatus for liquid bottle filler

A filling device and filling machine technology, applied in liquid bottling, liquid processing, packaging, etc., can solve the problems of changing filling amount, changing, waste of filling materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

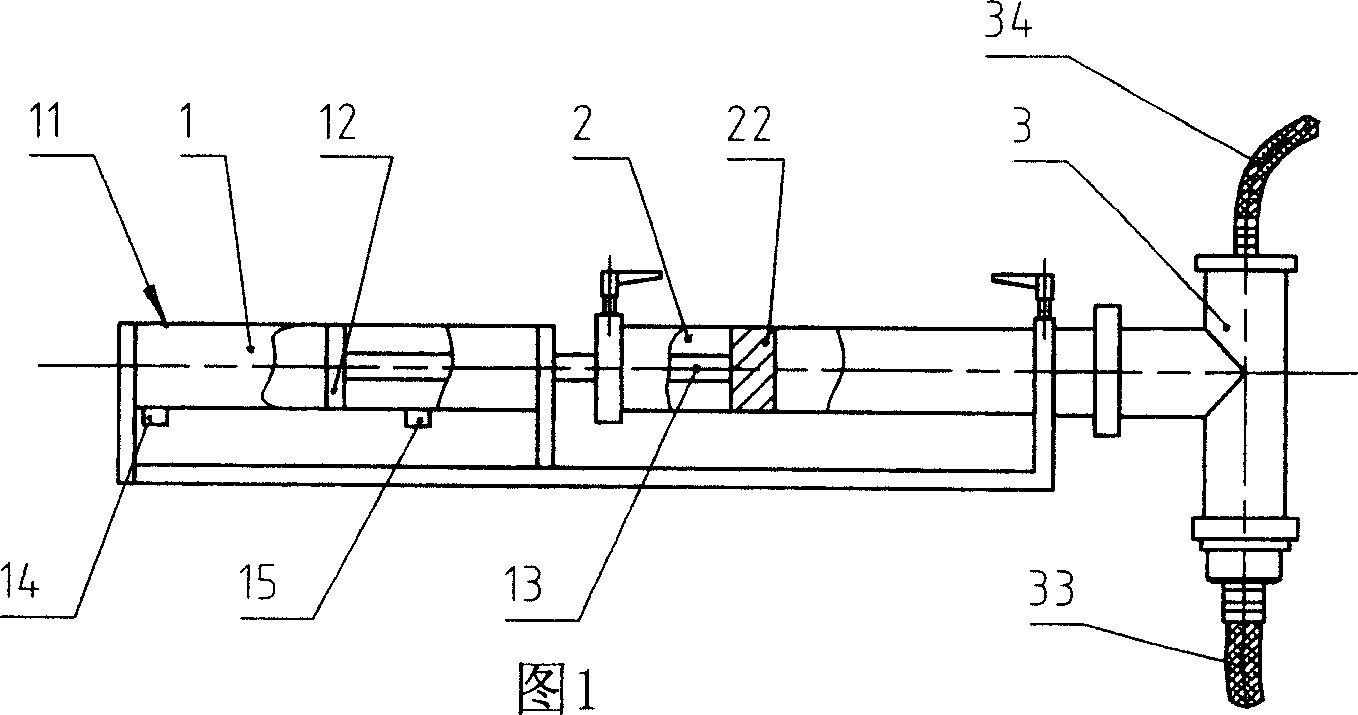

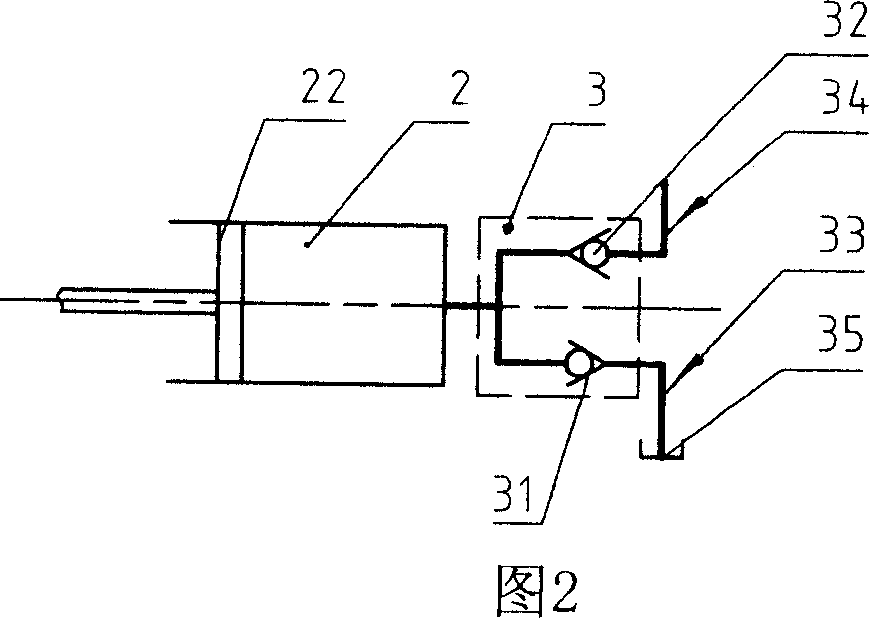

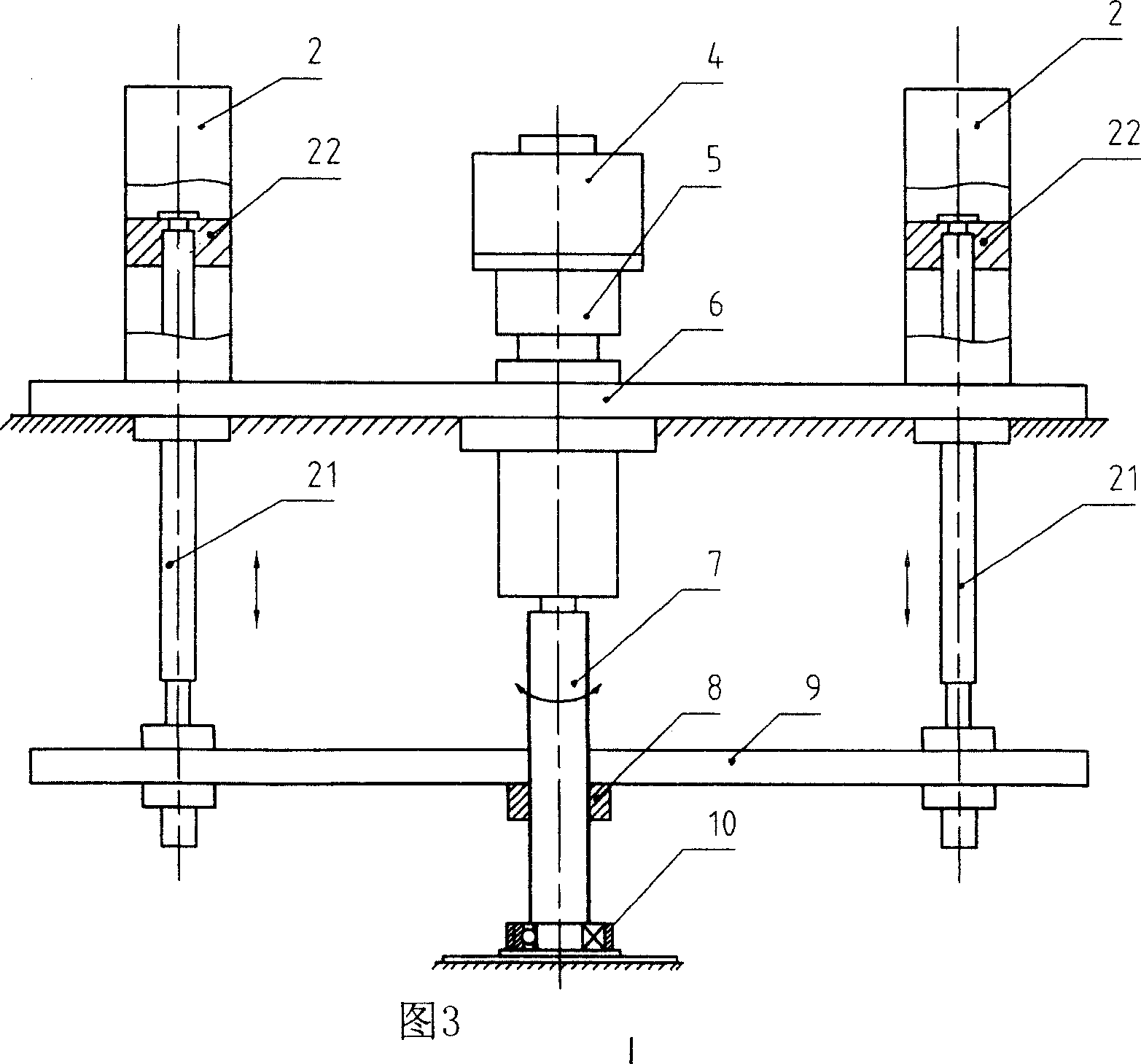

[0014] The filling device of the liquid filling machine of the present invention consists of a servo motor 4, a speed reducer 5, a fixed plate 6, a screw mandrel 7, a nut 8 and two filling cylinders 2, wherein the two filling cylinders 2 and the speed reducer 5 are both Installed on the fixed plate 6, the fixed plate 6 is fixedly installed on the frame, and two filling cylinders 2 are symmetrically distributed on both sides of the reducer 5, and the lower end of the piston rod 21 of the filling cylinder 2 is fixed on the lifting plate 9 Above, the servo motor 4 is directly connected to the reducer 5, the screw 7 is a ball screw, the upper end of the ball screw is connected to the output shaft of the reducer 5, and the lower end of the ball screw is installed in the bearing housing 10 through a bearing, The bearing seat 10 is fixed on the frame, and the nut 8 is screwed on the ball screw and fixed on the lifting plate 9 .

[0015] Although only two filling cylinders are include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com