Constant pressure device

A technology of constant pressure device and spray device, which is applied in cosmetics packaging equipment, food, and medicine fields, can solve the problems of low filling accuracy of small doses, fluctuations in filling pressure, and great difficulty, so as to prevent pollution and cross-contamination, The effect of small filling pressure change and ensuring filling accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the present invention more comprehensible, preferred embodiments are described in detail below with accompanying drawings.

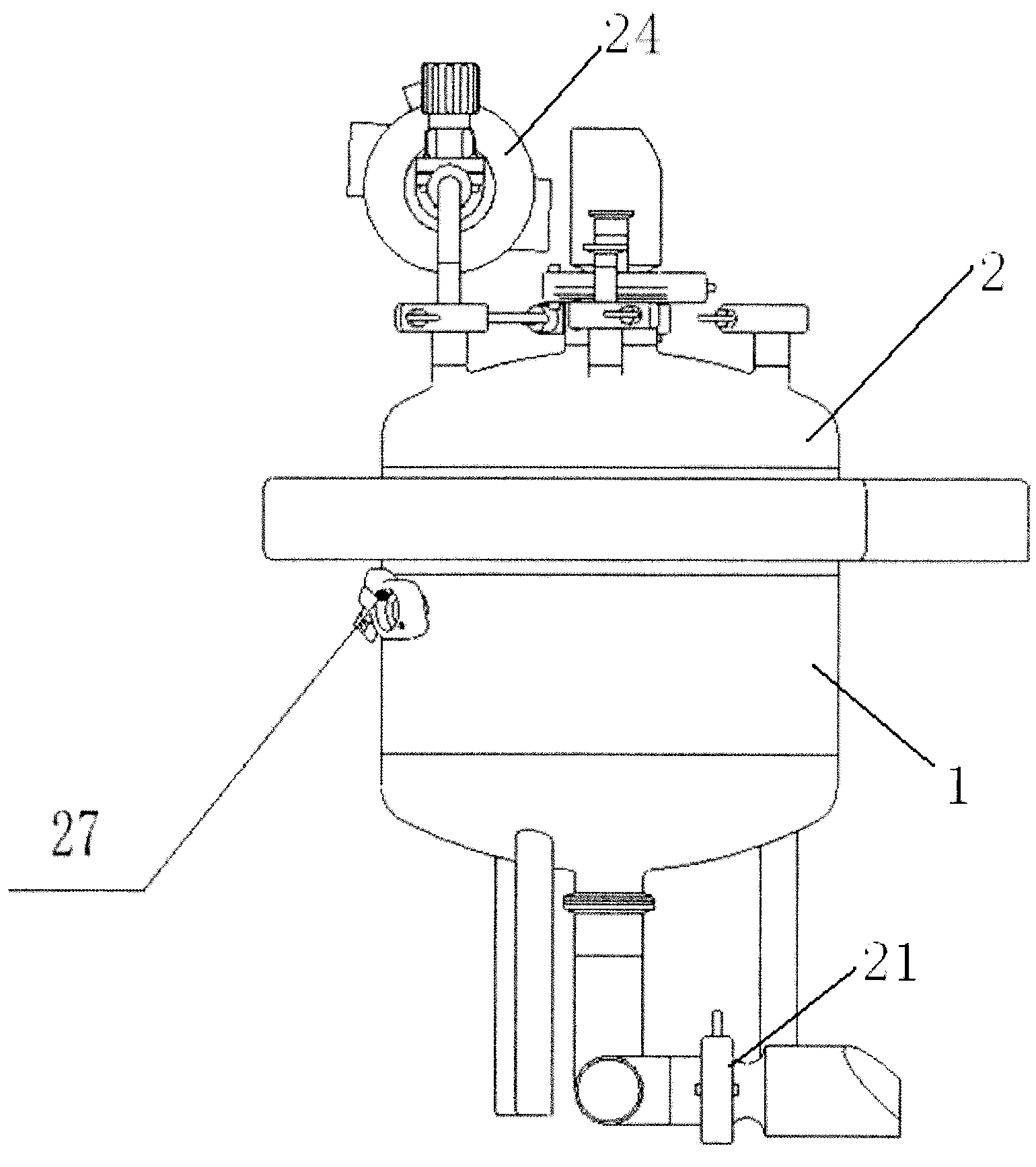

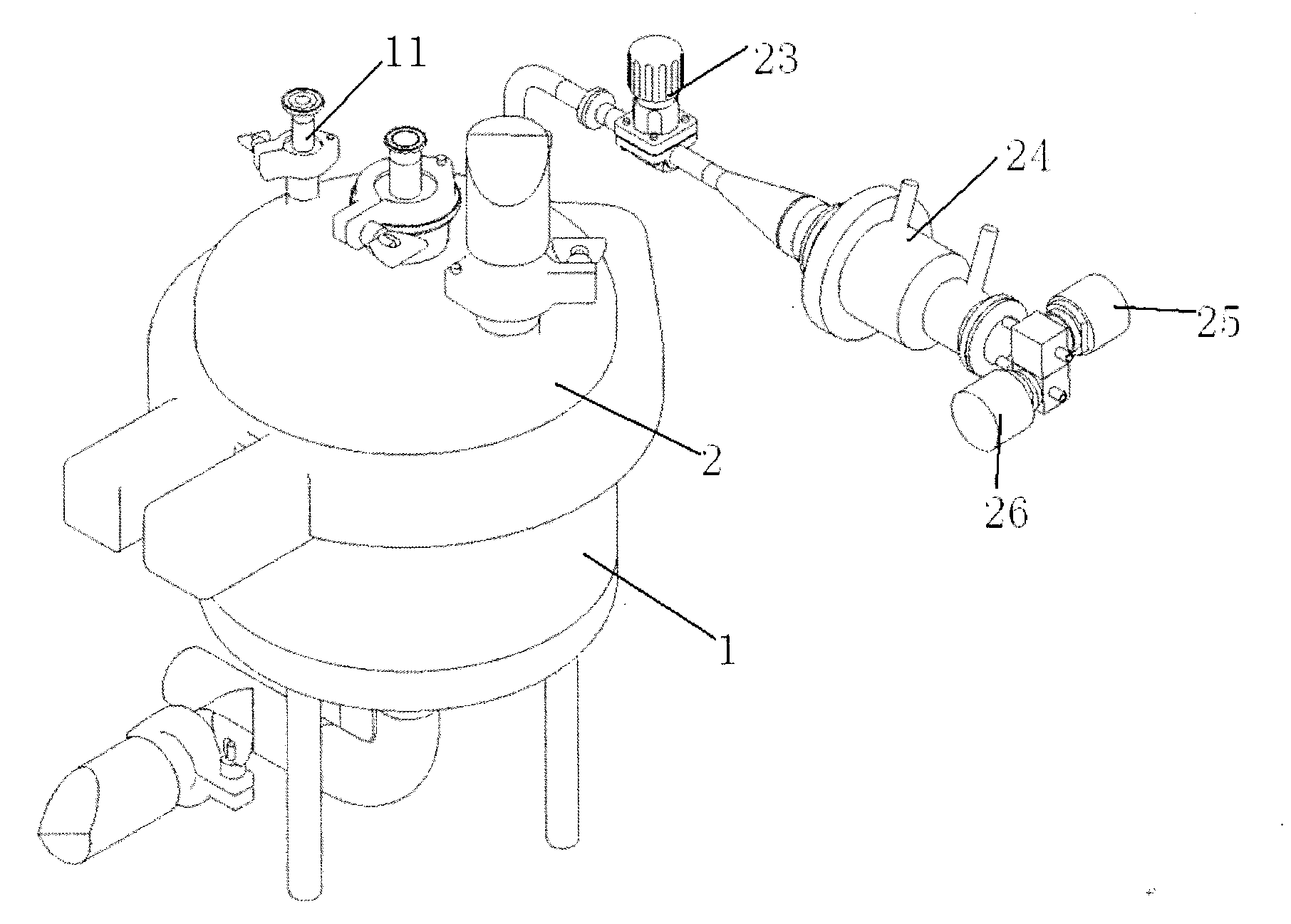

[0024] like Figure 1 to Figure 3 As shown, a constant pressure device provided by the present invention includes a buffer tank and pressure supplement and discharge components connected thereto. The buffer tank includes a lower tank body 1 and an upper tank body 2 arranged up and down, and the lower tank body 1 and the upper tank body 2 After docking, the tank body is formed by the clamp 4, and a sealing ring 3 is provided on the butt joint surface of the lower tank body 1 and the upper tank body 2. One end of the liquid replenishment pipe 11 stretches into the tank body. After passing through the upper tank body 2, it extends into the lower tank body 1. The liquid replenishment pipe 11 goes deep into the tank body to prevent splashing and foam generation in the liquid replenishment process. The other end of the liquid replenishm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com