Filling machine with online weighing function

The technology of a filling machine and a weighing device, which is applied in the fields of medical machinery and food, can solve the problems of reducing production efficiency, scrapping medicine bottles, and wasting medicines, and achieves the effects of reducing material loss, improving filling accuracy, and reducing unqualified products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

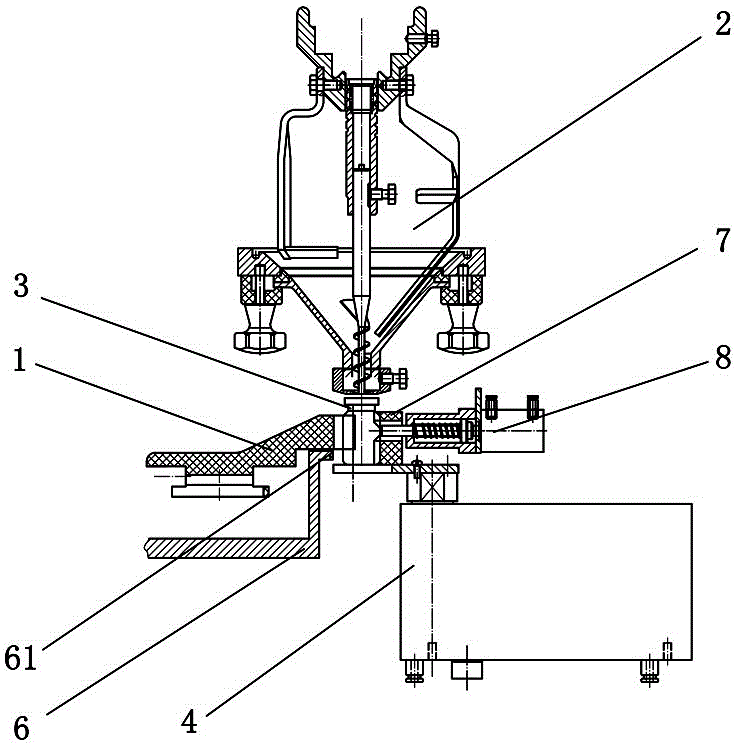

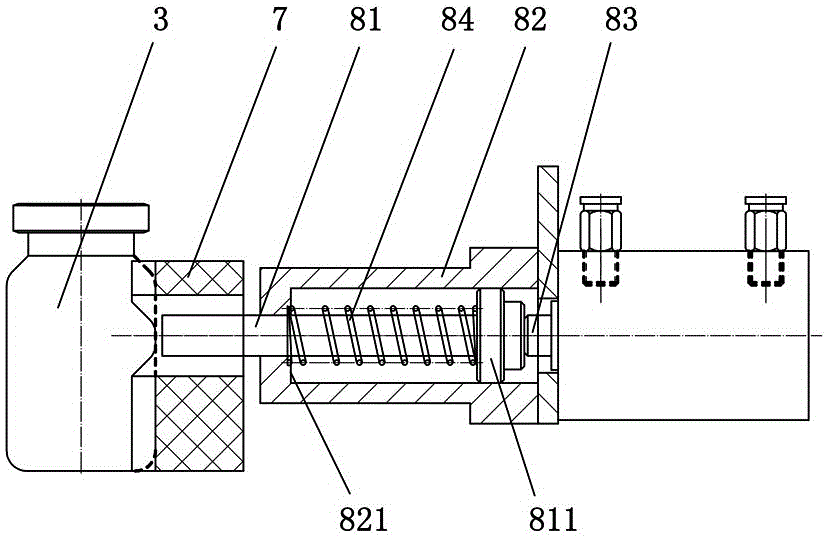

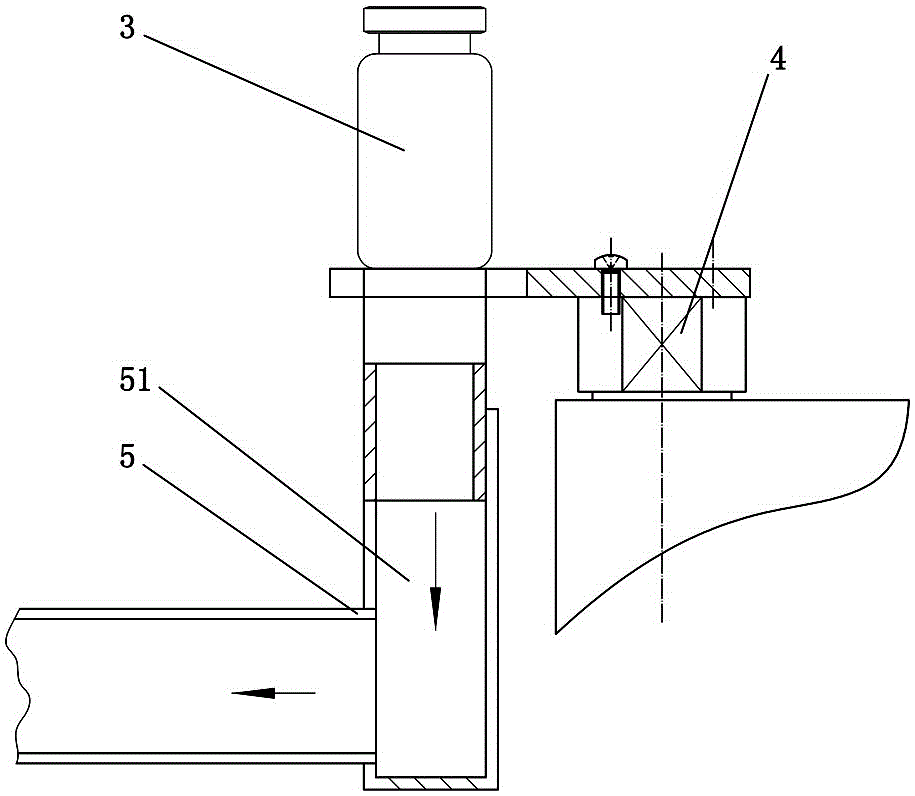

[0024] Figure 1 to Figure 4 Shown is an embodiment of the dispensing machine with online weighing function of the present invention, the dispensing machine with online weighing function includes a bottle-moving mechanism 1 and at least one sub-packing station, and the bottle-moving mechanism 1 can place medicine bottles 3 Transported to the subpackaging station, each subpackaging station is equipped with a weighing device 4 that resets the weight of the empty medicine bottle 3 before subpackaging and weighs the medicine bottle 3 in real time during subpackaging, and the weighing device 4 It is connected with the dispensing device of the dispensing machine through the control assembly. The sub-packaging device includes a plurality of sub-packaging mechanisms 2, and each sub-packaging station is provided with a sub-packaging mechanism...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com