Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Flexible and convenient positioning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

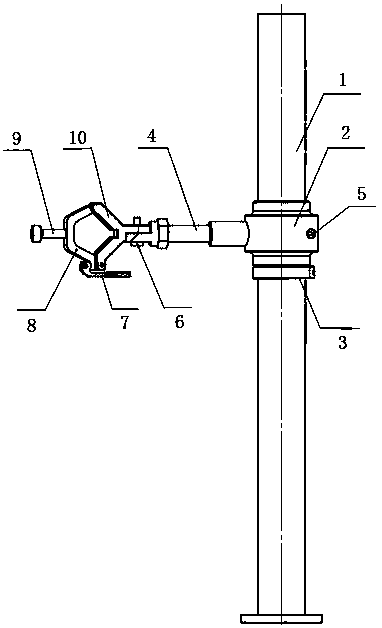

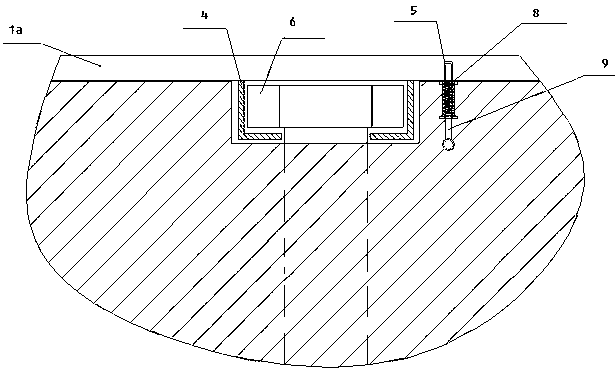

Natural gas pipe construction support device

ActiveCN107830243AFlexible and convenient positioningPrevent slipping outPipe laying and repairTrolley cranesInstabilityPipe support

The invention discloses a natural gas pipe construction support device. The natural gas pipe construction support device comprises a cross beam, a longitudinal beam, a longitudinal beam driving motor,a lifter receiving groove, a lifter, a lifting hanging hook, a support leg, a pipe positioning sleeve and a pipe. The pipe positioning sleeve with a belt wheel base is provided to realize free rotating movement of pipes with different diameters during lifting when the natural gas pipe support device supports and positions the pipes; and the positioning instability caused by reverse driving of bagsleeves due to shaking of the pipes by friction between the bag sleeves for wrapping the pipes and the pipes during adjusting the positions of the pipes is not generated.

Owner:邢台天宏祥燃气有限公司 +1

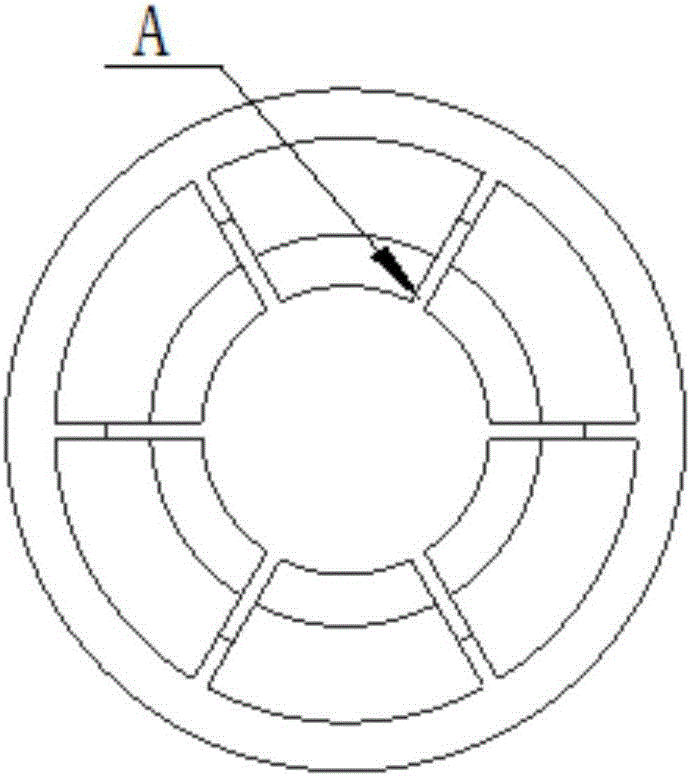

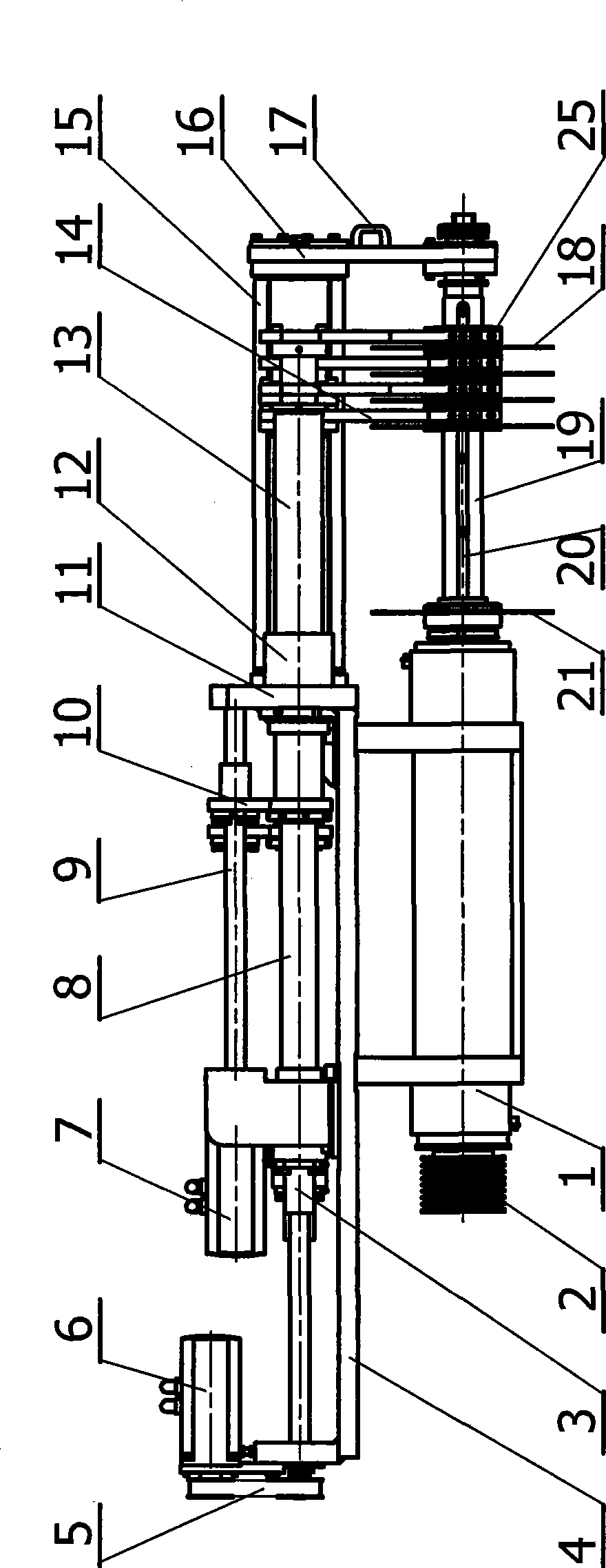

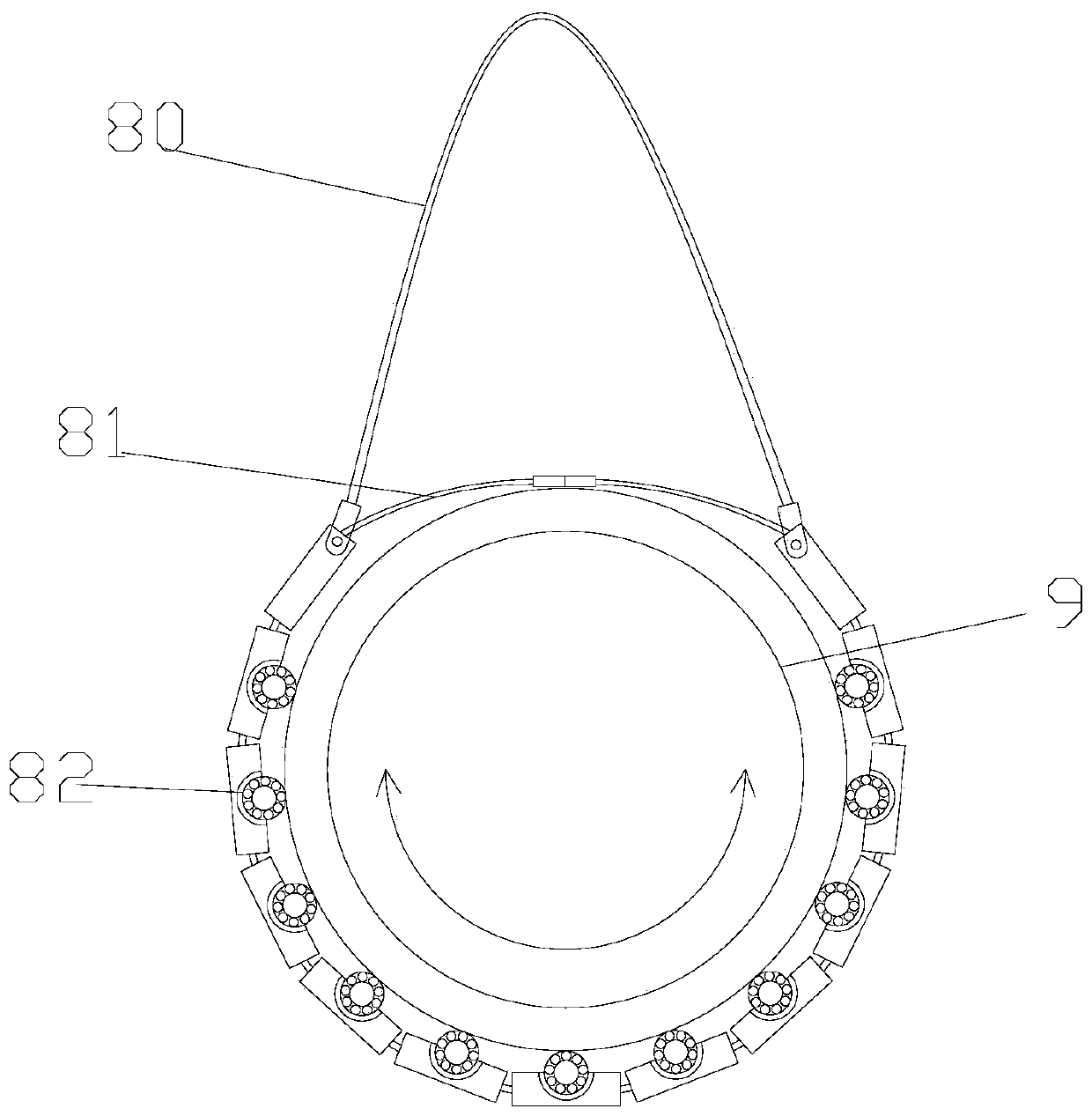

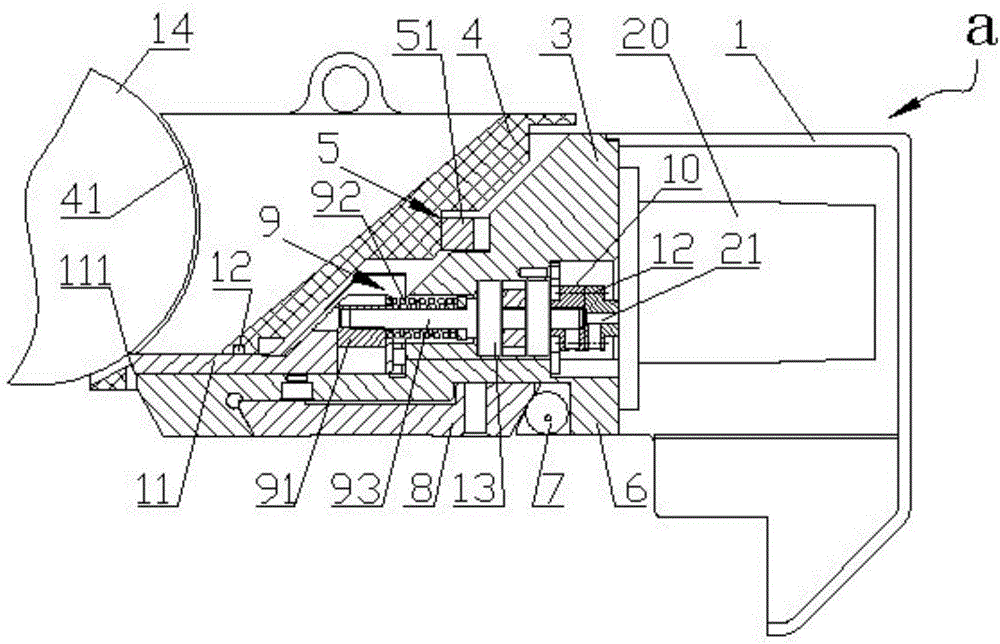

Assembling, disassembling and locking mechanism for shear-resistance blocks of ultrahigh pressure large diameter deep sea environment simulating device

InactiveCN103216616AEasy to use and flexibleImprove work efficiencyPressure vesselsLocking mechanismEngineering

The invention relates to an assembling, disassembling and locking mechanism for shear-resistance blocks of an ultrahigh pressure large diameter deep sea environment simulating device. The assembling, disassembling and locking mechanism for the shear-resistance block of the ultrahigh pressure large diameter deep sea environment simulating device comprises a pressure barrel, a close cover is arranged on the top of the pressure barrel, a shear groove is formed in the inner ring surface of the upper portion of the pressure barrel, the shear-resistant blocks are mounted on the close cover and is connected to the shear groove which is formed in the pressure barrel in a clamping mode, the shear-resistant blocks comprise oblique shear-resistant blocks and straight shear-resistant blocks, the oblique shear-resistant blocks and the straight shear-resistant blocks are mounted on the top of the close cover alternately and form a circle, and a bearing pedestal in mounted on the middle portion of the close cover. The assembling, disassembling and locking mechanism for the shear-resistance blocks of the ultrahigh pressure large diameter deep sea environment simulating device further comprises a hydro-cylinder base, a hydro-cylinder is mounted on the hydro-cylinder base, the hydro-cylinder base and the bearing pedestal are assembled into a whole through a bearing, and thus a shear-resistant block assembling and disassembling device is formed. The assembling, disassembling and locking mechanism for the shear-resistance blocks of the ultrahigh pressure large diameter deep sea environment simulating device is flexible and reliable in use and high in work efficiency.

Owner:中国船舶重工集团公司第七〇二研究所

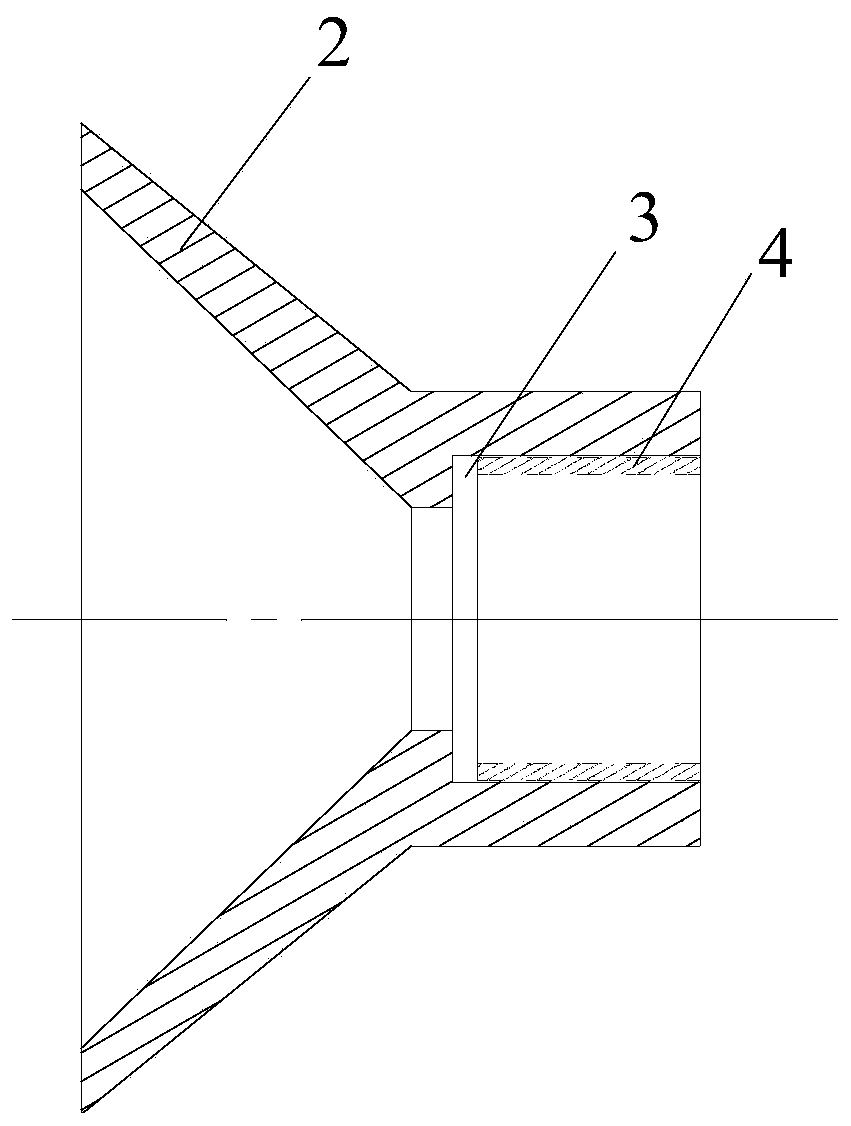

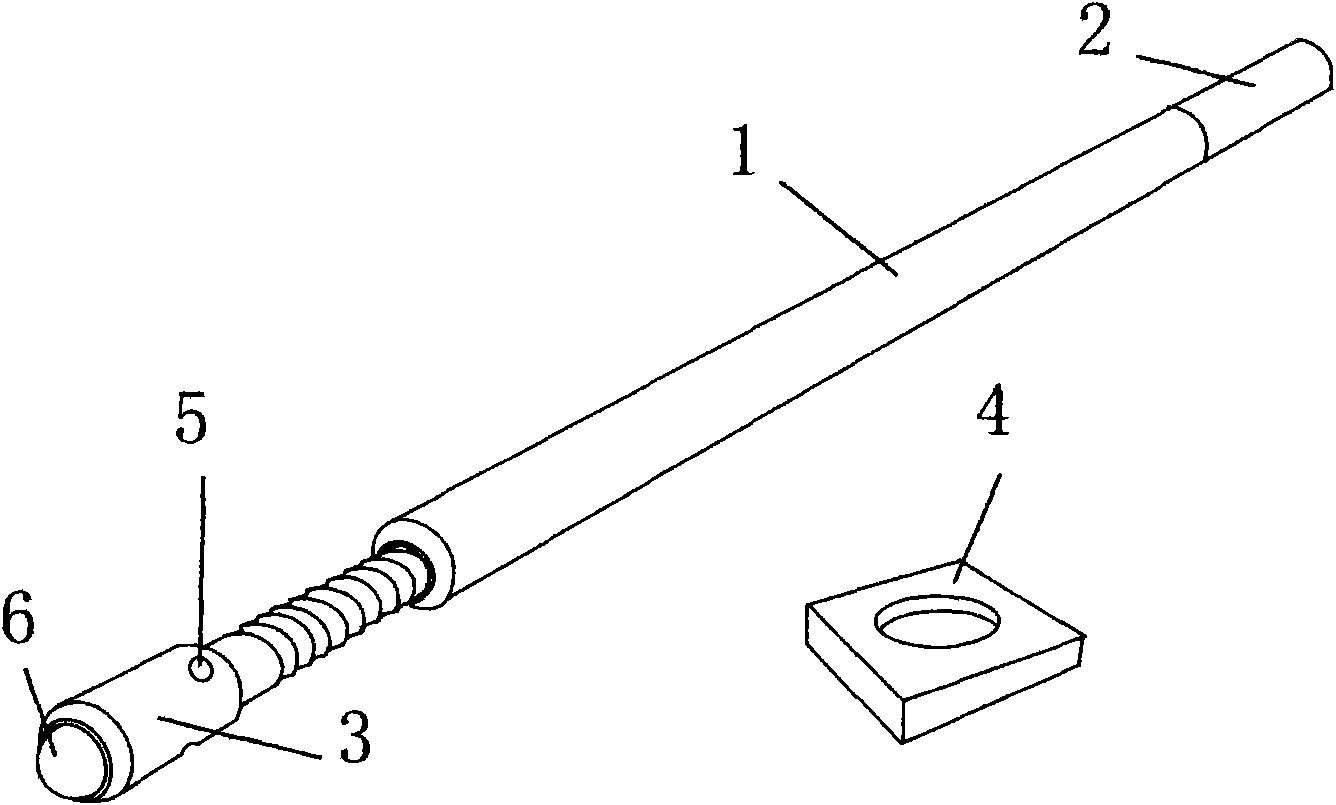

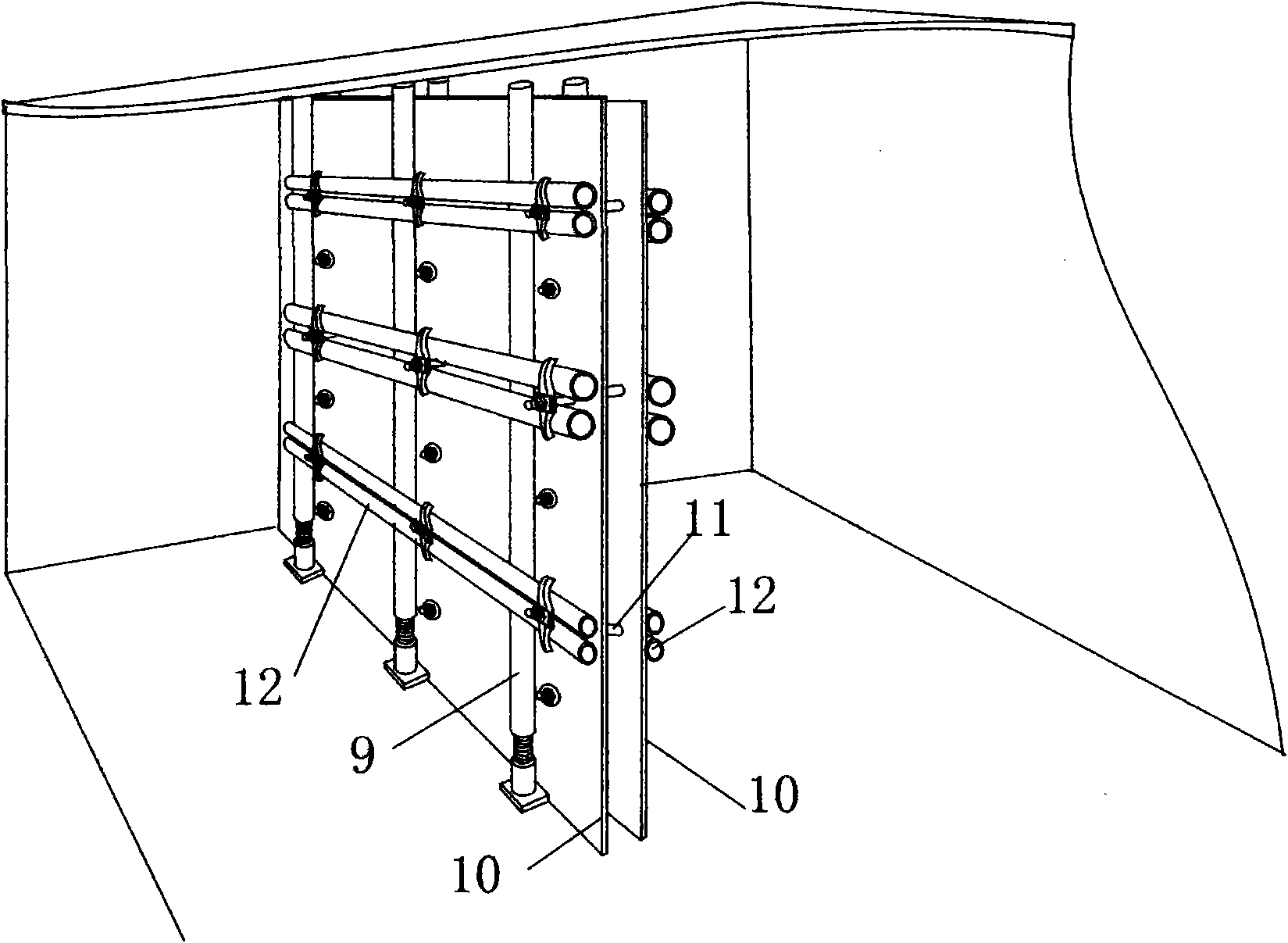

Longitudinal positioning and connecting device for support arch frame of underground project and construction method

ActiveCN106522998AEnable connectivityAchieve positioningUnderground chambersTunnel liningEngineeringScrew thread

The invention discloses a longitudinal positioning and connecting device for a support arch frame of an underground project and a construction method. The longitudinal positioning and connecting device comprises a connecting rod, a first fixing device and a second fixing device, wherein one end of the connecting rod is a spherical round head, and a first threaded hole is formed in the spherical round head; the other end of the connecting rod is of a swelling structure; the first fixing device is used for providing a clamping structure for clamping and fixing the swelling structure, and the inner diameter of the clamping structure is smaller than the outer diameter of the swelling structure; and the second fixing device is of a hollow structure formed by surrounding of a shell, the end part of the hollow structure is opened, a second threaded hole matched with the first threaded hole is formed in the shell, and the diameter of the spherical round head is larger than the inner diameter of the end part of the hollow structure and smaller than the inner diameter of a main body part of the hollow structure. The longitudinal positioning and connecting device has the beneficial effects that the positioning is convenient and flexible, and the construction period is shortened. By utilizing the device, the longitudinal connection and accurate positioning of the support arch frame can be realized by only moving the arc frame, aligning the arc frame and inserting the arc frame into the first fixing device, so that the construction time is greatly saved, and the construction safety is improved.

Owner:SHANDONG UNIV

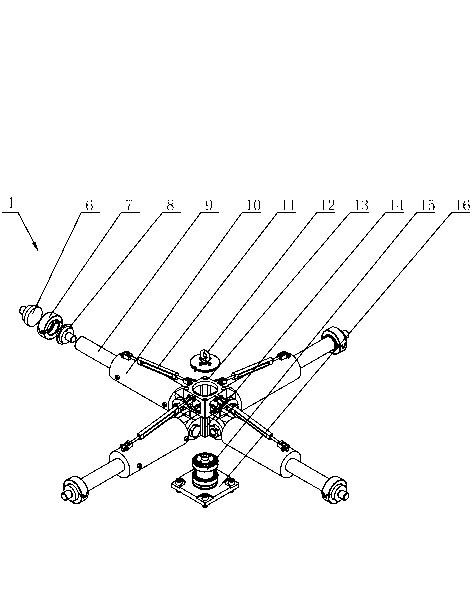

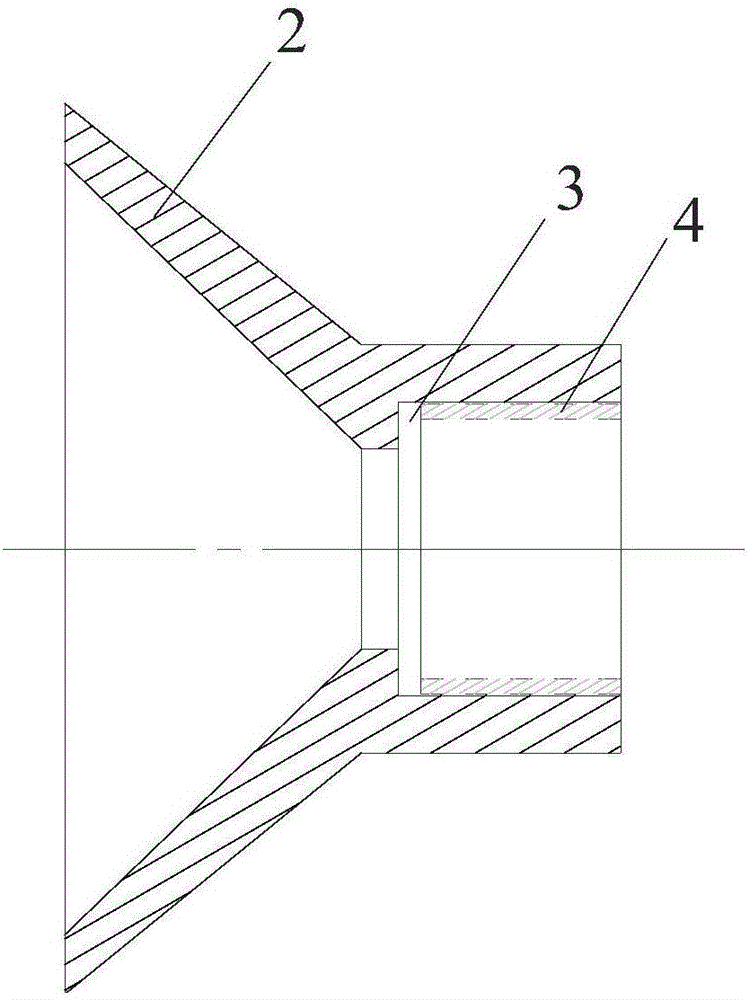

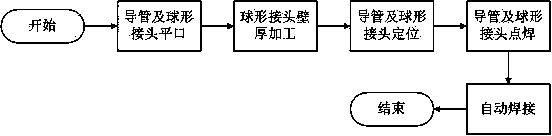

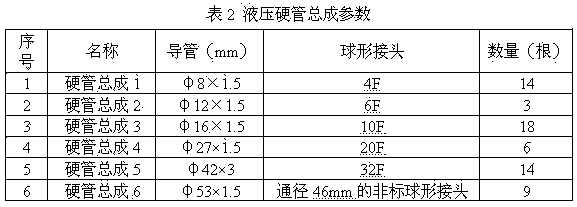

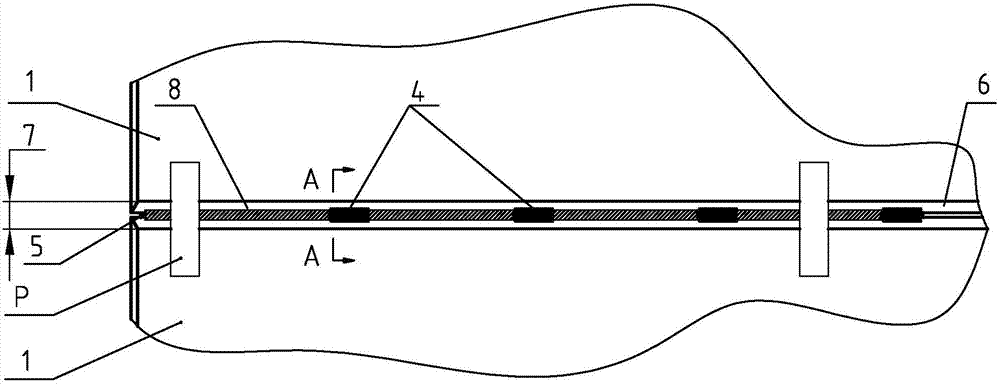

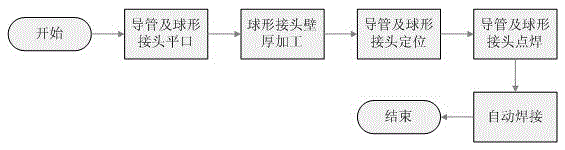

Automatic welding method for hydraulic hard tube assembly

ActiveCN103962684AMeet welding wall thickness requirementsPrecise dockingWelding/cutting auxillary devicesAuxillary welding devicesButt jointEngineering

The invention belongs to the technical field of welding and relates to a welding technology for a hydraulic hard tube, in particular to an automatic welding method for a hydraulic hard tube assembly. By the adoption of the automatic welding method for the hydraulic hard tube assembly, the welding ratio of automatic welding is high, and the welding quality is stable when the hydraulic hard tube assembly is welded. According to the technical scheme, the automatic welding method for the hydraulic hard tube assembly comprises the following steps that firstly, a welding groove of a guide tube and a welding groove of a spherical joint in the hydraulic hard tube assembly are machined to be plain ends; secondly, the guide tube and the spherical joint of the hydraulic hard tube assembly generated after the first step are grouped, and the inner diameter and the outer diameter of the position, where the spherical joint and the guide tube are grouped, of the spherical joint are machined to be equal to the inner diameter and the outer diameter of the guide tube respectively; thirdly, the guide tube and the spherical joint of the hydraulic hard tube assembly generated after the second step are in butt joint with each other and located; fourthly, spot welding is conducted on the guide tube and the spherical joint of the hydraulic hard tube assembly generated after the third step; fifthly, automatic welding is conducted on the guide tube and the spherical joint of the hydraulic hard tube assembly generated after the fourth step.

Owner:CHANGZHI QINGHUA MACHINERY FACTORY +1

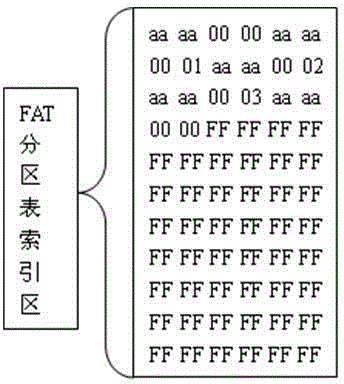

File system FAT (file allocation table) partition table management method based on NOR FLASH

InactiveCN102945274AImprove securityImprove reliabilitySpecial data processing applicationsComputer scienceFile allocation table

The invention provides a file system FAT (file allocation table) partition table management method based on NOR FLASH, which is characterized in that a region in NOR FLASH is allocated and is used as an FAT partition table management region, the region is further divided into two parts, i.e. an FAT partition table index region and an FAT partition table region, wherein the FAT partition table region can be used for storing a plurality of FAT partition tables, firstly the region in the NOR FLASH is allocated and is used as the FAT partition table management region, the FAT partition table management region comprises the FAT partition table index region and a plurality of FAT partition tables, a current valid FAT partition table is obtained according to an index number in the FAT partition table index region, the FAT partition table next to the current valid FAT partition table is only required to be erased when the FAT partition table is required to be modified for file operation, and index numbers in the FAT partition table index region are cyclically increased.

Owner:LANGCHAO ELECTRONIC INFORMATION IND CO LTD

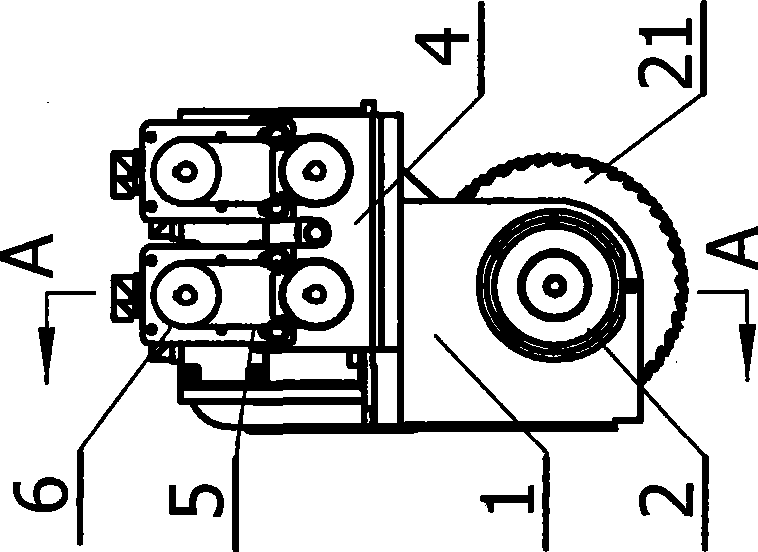

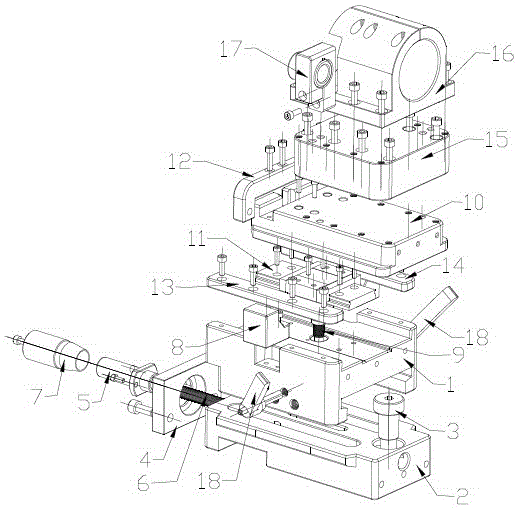

Built-in fine adjustment slipway motion mechanism

ActiveCN103692226AEasy to locateReduce structural wearLarge fixed membersMetal working apparatusEngineering

The invention discloses a built-in fine adjustment slipway motion mechanism. The built-in fine adjustment slipway motion mechanism comprises a slipway fixed seat, a fine adjustment slipway main body, a motion mechanism loading main platform, a driving mechanism main body component, wherein the fine adjustment slipway main body is arranged on the slipway fixed seat; the motion mechanism loading main platform is arranged on the fine adjustment slipway main body; the driving mechanism main body component is arranged on the motion mechanism loading main platform; the slipway fixed seat is internally provided with a fine adjustment device; the fine adjustment device can realize fine adjustment motion of the slipway main body on the slipway fixed seat. Through the above scheme, the built-in fine adjustment slipway motion mechanism disclosed by the invention is used for positioning repeated motion needing accurate alignment fine adjustment, so that the positioning is more flexible and convenient; the built-in fine adjustment slipway motion mechanism is particularly suitable for high-speed cutting main shafts and pneumatic main shafts (high processing precision is needed and impact is prevented), and can effectively reduce the noises caused by motion and the structural abrasion caused by the impact, thus greatly promoting the precision during repeated positioning; the blank on the structural aspect in the prior art is solved.

Owner:昆山鸿富洋科技有限公司

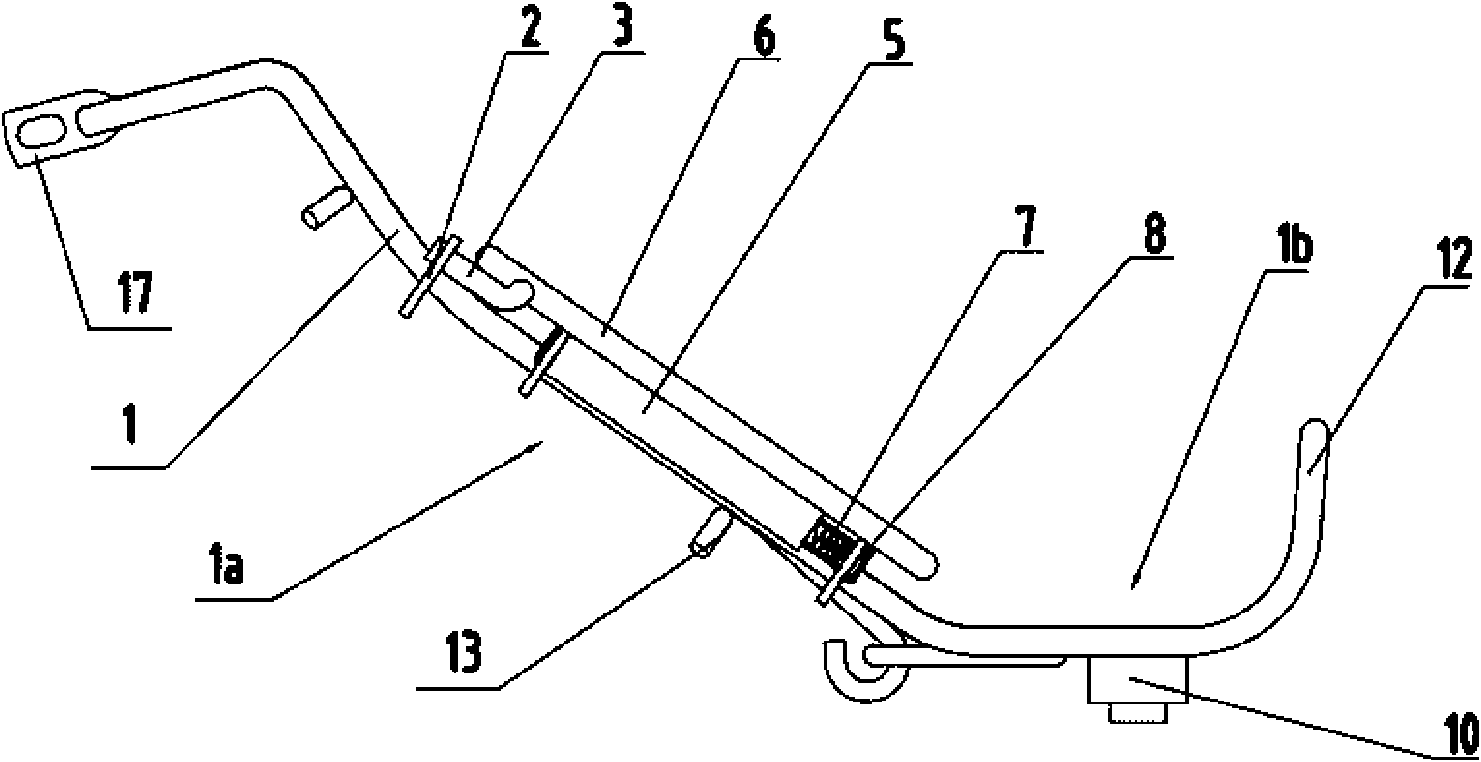

Middle rack mounted on camber beam of motorcycle

InactiveCN101580086ADoes not affect the shapeSmall load areaLuggage carriersEngineeringSupport plane

The invention discloses a middle rack mounted on a camber beam of a motorcycle. The middle rack comprises a main rack which is formed by bending and provided with an inclined front carrying part and a horizontal back carrying part. The front end of the front carrying part is provided with two mounting supports; the back carrying part is provided with mounting holes; the tail end of the back carrying part is provided with an upward guard rail; the left side and the right side of the front carrying part of the main rack are respectively provided with a multi-angle-positioned turning sub-rack which can be folded inwards and unfolded outwards; and the turning sub-racks turn relative to the front carrying part of the main rack by virtue of a spring hinge mechanism and form a fixed turning angle by virtue of a multi-angle positioning mechanism. By taking advantage of the turning sub-racks arranged at two sides of the main rack, a carrying supporting structure of the middle rack is caused to change according to the needs, thereby not only forming a smaller carrying supporting plane, but also forming a larger carrying supporting plane and forming also a basket-shaped rack capable of containing articles; and the middle rack has a plurality of article carrying functions and is flexibly and conveniently used.

Owner:CHONGQING LONCIN MOTOR

Novel shipbuilding assembly method and steel plate leveling device

InactiveCN104259681AAvoid damageSave human effortWelding/cutting auxillary devicesVessel partsManufacturing technologyWeld seam

The invention discloses a novel hull erection method and belongs to the technical field of shipbuilding. The method includes the steps such as cutting grooves, grinding the grooves, assembling, leveling steel plates, applying pads, welding priming weld seams required for the production of positioning weld seams, welding the positioning weld seams, welding transition weld seams, welding erection weld seams, and polishing the erected whole. The novel hull erection method has the advantages that clamp plates are replaced with the positioning weld seams, the steps of welding the clamp plates and cutting the clamp plates are omitted, manpower and material resources and raw materials are greatly saved, less damage is caused to a hull, cost of polishing before and after welding is saved, and the basis for automated welding is laid.

Owner:宋广科

Mandrel structure of circular saw machine for preferably cutting timber in longitudinal direction

The present invention discloses a saw shaft structure of optimized longitudinal cutting circular sawing machine, which comprises a saw shaft and a saw shaft base that is used for supporting the saw shaft. The saw shaft is at least sleeved with a sawblade sliding sleeve which can move along the axial direction and rotate along with the saw shaft. The sawblade sliding sleeve is at least fixedly installed with a movable circular saw blade which is movably connected with a circular saw blade shifting fork. The circular saw blade shifting fork is connected with a screw pair. The saw shaft is at least fixedly installed with a fixed circular saw blade and is at least fixedly installed with a saw shaft driving key. The shaft hole of sawblade sliding sleeve is at least internally provided with a driving key groove that is corresponding with the saw shaft driving key. The saw shaft structure can realize the axial sliding adjustment to the circular saw blade conveniently and flexibly. Longitudinally material cutting can be executed according to an optimal cutting plan. The saw shaft structure also has higher material yielding rate and production efficiency, and is widely used in various multi-blade circular sawing machine.

Owner:JIANGSU JIANGJIA MACHINERY

Lifting type office table

InactiveCN102987724AFlexible and convenient positioningEasy to operateSuspended tablesWall tablesComputer science

Owner:TIANJIN HELI OIL & GAS TECH

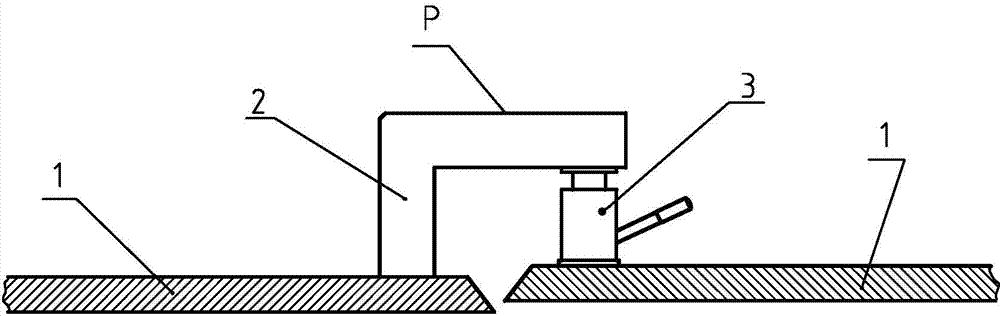

Punching machine with quick positioning function

PendingCN109079014AEasy to operateFlexible and convenient to moveMetal-working feeding devicesPositioning devicesPunch pressEngineering

The invention provides a punching machine with a quick positioning function. The punching machine with the quick positioning function comprises a punching machine body, wherein a punch chip is arranged on the punching machine body, a worktable is arranged below the punch chip, and a workpiece to be punched is placed on the worktable; and a laser sight is arranged on the punching machine body, an aiming light spot emitted by the laser sight falls on the upper surface of the workpiece at the position directly below the punch chip, and the punching position on the surface of the workpiece is directly positioned through the laser sight. According to the punching machine with the quick positioning function, operators can flexibly and conveniently move the workpiece to a pre-punching position under the punch chip, and accurate punching work can be completed without using a complex positioning mechanism; and the whole device has the advantages of rapid positioning and convenient operation bythe operators.

Owner:江苏吉野电气有限公司

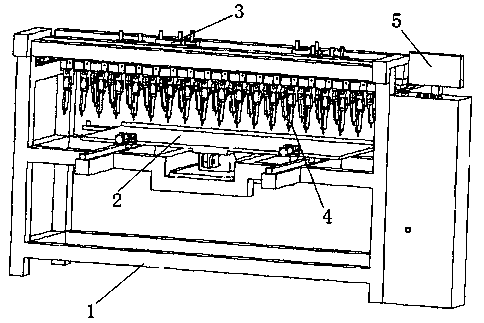

Ink piece device

ActiveCN104191812AEasy to clean and maintainReduce consumptionPrinting press partsPrinting pressPiece Unit

The invention relates to an ink piece device which is arranged on a printing machine. The ink piece device comprises an ink roller (14) and a plurality of ink piece units (1), wherein the ink piece units (1) are arranged on one side of the ink roller in the direction of an ink roller shaft and can slide in the axial direction of the ink roller (14). A plurality of independent ink supply areas corresponding to the ink roller (14) are formed. According to the ink piece device, the ink piece device is arranged to be a combined body composed of the intelligent ink piece units, independent ink supply for same-roller and different-ink-color sub areas is achieved, only the areas required to be inked is supplied with the oil ink, and oil ink consumption is reduced; the sub areas are convenient to adjust, and the ink piece units are independent relatively, so that assembly and disassembly are quick in speed, and flexible and convenient positioning is achieved; if one ink piece is damaged in the using process, only local replacement is needed, and use cost can be reduced; the ink piece units are arranged on a track, so that assembly and disassembly are convenient, the printing device can be repaired quickly, and meanwhile, the parts prone to damage can be replaced conveniently and the ink piece can be maintained and cleaned conveniently.

Owner:江苏科思机电工程有限公司

Compressor shell cover preassembled flatness detecting and adjusting mechanism

ActiveCN109655018AGuarantee product qualityIncrease productivityUsing optical meansWater flowAgricultural engineering

The invention discloses a compressor shell cover preassembled flatness detecting and adjusting mechanism and belongs to the technical field of compressor assembling. The mechanism comprises a water flowing platform, water flowing platform positioning mechanisms, photoelectric sensors, a detecting mechanism, an adjusting mechanism, an upper cover plate, a plurality of uprights and a tray, the uppercover plate is arranged above the water flowing platform through the uprights, the detecting mechanism and the adjusting mechanism are arranged on the upper cover plate and positioned on one side close to the water flowing platform, the water flowing platform positioning mechanisms for positioning the tray are arranged at positions, below the detecting mechanism and the adjusting mechanism, of the water flowing platform, and one photoelectric sensor is arranged on one side of each water flowing platform positioning mechanism. The compressor shell cover preassembled flatness detecting and adjusting mechanism is high in detecting accuracy, capable of realizing automatic detecting and automatic adjusting of compressor shell cover preassembled flatness and accurate in adjusting, detecting andadjusting processes are integrated, convenience is brought to streamlined production operation, and compressor production efficiency is improved effectively.

Owner:EAST CHINA JIAOTONG UNIVERSITY

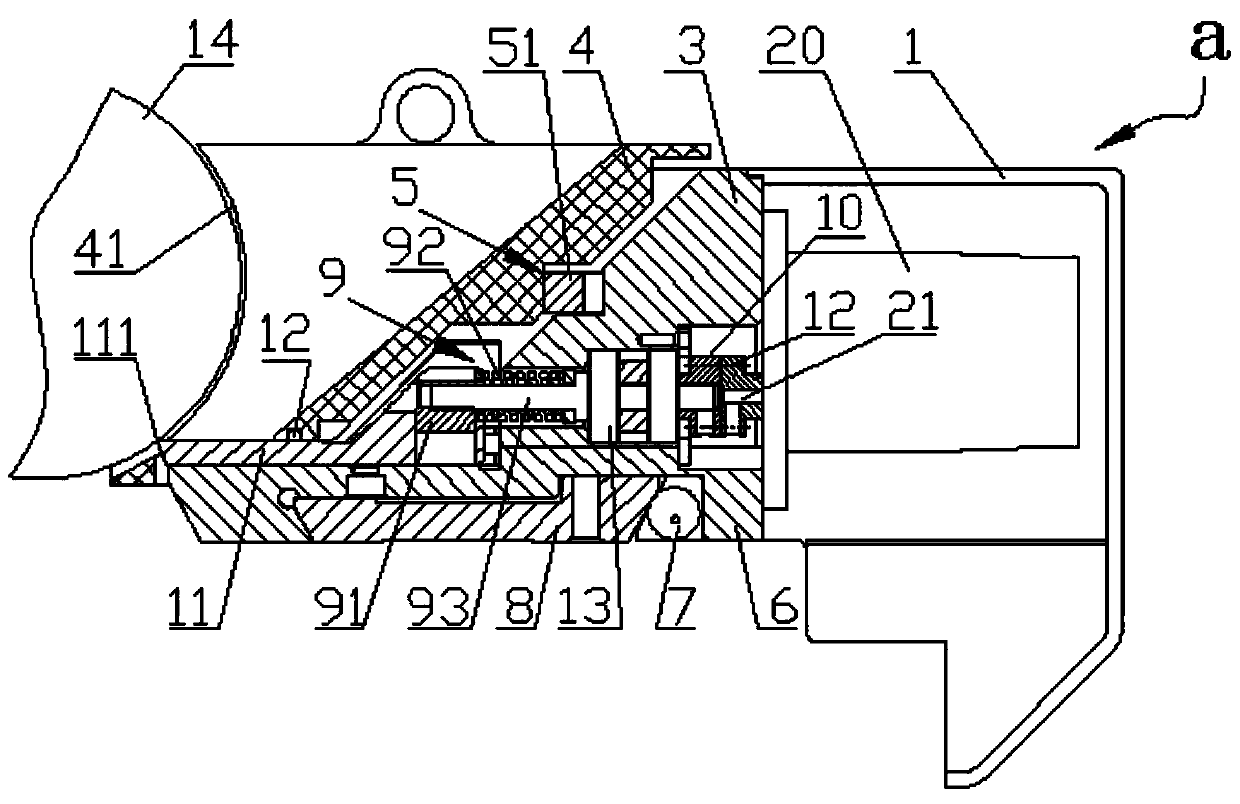

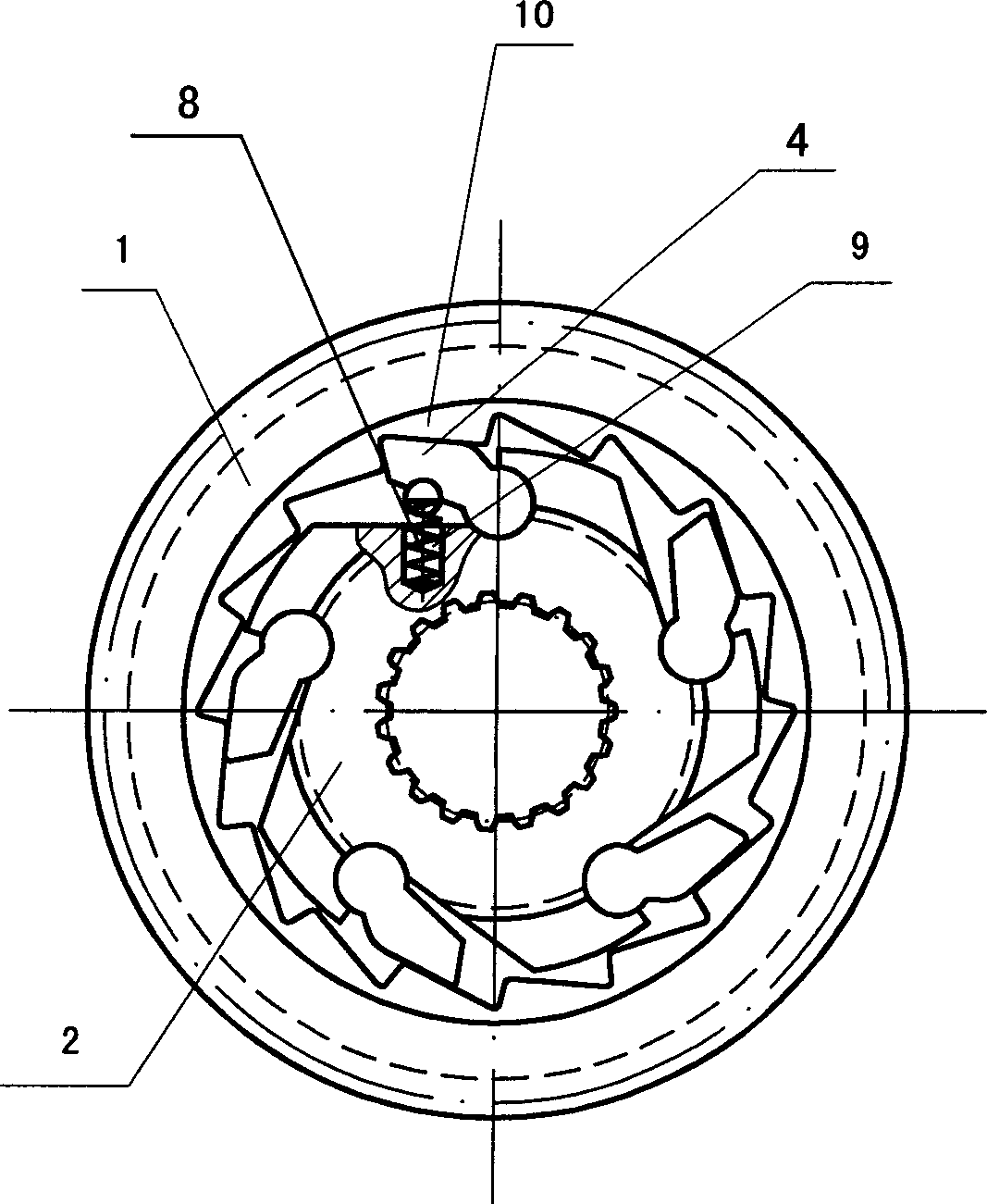

Motorcycle fuel-saving one-way engage switch

InactiveCN1477318AImprove positioning reliabilityFast clutch actionRoad transportFreewheel clutchesEngineeringMechanical engineering

The present invention relates to a fuel-saving one-way gear meshing device for motorcycle. The gear meshing device includes ratchet wheel toothed ring and inner core, the periphery of the inner core is equipped with recessed groove, in the recessed groove the stay tooth is mounted, and the stay tooth is correspondent to the click being in the ratchet wheel toothed ring, the ratchet wheel toothed ring and inner core are divided into two section axially, one section is the click and stay tooth matched section, between stay tooth and inner core a pressure spring is set, and another section is the relative freely rotation matching section between ratchet wheel toothed ring and inner core, and between the ratchet wheel toothed ring and inner core and bearing is mounted.

Owner:魏衍昌

A kind of automatic welding method of hydraulic hard pipe assembly

ActiveCN103962684BMeet welding wall thickness requirementsPrecise dockingWelding/cutting auxillary devicesAuxillary welding devicesButt jointEngineering

The invention belongs to the technical field of welding and relates to a welding technology for a hydraulic hard tube, in particular to an automatic welding method for a hydraulic hard tube assembly. By the adoption of the automatic welding method for the hydraulic hard tube assembly, the welding ratio of automatic welding is high, and the welding quality is stable when the hydraulic hard tube assembly is welded. According to the technical scheme, the automatic welding method for the hydraulic hard tube assembly comprises the following steps that firstly, a welding groove of a guide tube and a welding groove of a spherical joint in the hydraulic hard tube assembly are machined to be plain ends; secondly, the guide tube and the spherical joint of the hydraulic hard tube assembly generated after the first step are grouped, and the inner diameter and the outer diameter of the position, where the spherical joint and the guide tube are grouped, of the spherical joint are machined to be equal to the inner diameter and the outer diameter of the guide tube respectively; thirdly, the guide tube and the spherical joint of the hydraulic hard tube assembly generated after the second step are in butt joint with each other and located; fourthly, spot welding is conducted on the guide tube and the spherical joint of the hydraulic hard tube assembly generated after the third step; fifthly, automatic welding is conducted on the guide tube and the spherical joint of the hydraulic hard tube assembly generated after the fourth step.

Owner:CHANGZHI QINGHUA MACHINERY FACTORY +1

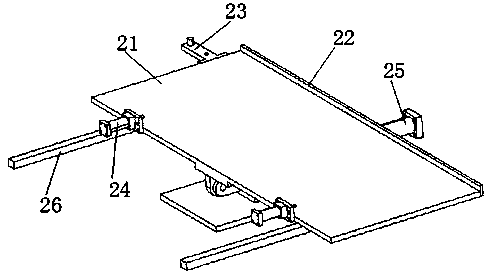

Method for edge decoration and boundary of a membrane material

ActiveCN109318630BFlexible and convenient positioningPrevent movementWriting boardsSupport surfaceContact plane

The invention discloses a decorating and limiting method for membrane material edges. The decorating and limiting method is realized through a magnetic edge strip and is characterized in that steps are arranged on the contact surfaces of the magnetic edge strip and a membrane and the contact surfaces of the magnetic edge strip and the magnetic supporting surface of the membrane; the thin step surface of the magnetic edge strip is combined with the membrane; the thick step surface of the magnetic edge strip is combined with the supporting surface of the magnetic membrane; the fall of the stepsis just matched with the thickness of the membrane; and the area of the magnetic supporting surface is larger than that of the membrane material. According to the method, the steps are arranged on thecontact surfaces of the magnetic edge strip, so that the edge strip cannot move toward an erasable writing board; edge strips are positioned by moving the edge strips to the membrane material until the edge strips cannot be moved, and assembly is finished instantly; tedious work of aligning vertically and laterally is omitted; the decoration of the magnetic supporting surface is carried out and the erasable writing area is expanded at will, and the effect is remarkable; meanwhile, the membrane material and the magnetic edge strips can be positioned, moved and changed at will on the large-areamagnetic supporting surface simultaneously; by adopting the magnetic edge strip in the technical scheme, bounding of materials, areas, changing and assembly of edge strips and frames in the prior artis broken through; and the magnetic edge strip is a new favorite for use and choice of advertising, decorating, exhibiting, teaching and product discussing.

Owner:广州新莱福磁材有限公司 +1

A device and method for automatically dispensing paste solder

ActiveCN108608086BStable structureGuaranteed accuracySolder feeding devicesSoldering auxillary devicesAutomatic controlControl system

The invention relates to a device and method for automatically dispensing cream solder. The device comprises a rack, a workbench device, a positioning regulation and control device, a cream solder dispensing device and an automatic control device. The method comprises the steps that a product to be dispensed with cream solder is fixed to a work panel of the workbench device, rough adjustment and fine adjustment are conducted on a cream solder dispensing operation area so as to figure out an accurate cream solder dispensing operation area, and cream solder dispensing operation is conducted on aspecific position of the surface of the product. The device is firm and stable in structure; the method adopts a PLC control system for automatic operation in the whole course, positioning is simpleand accurate, and cream solder consumption is stable; and operation quality can be effectively ensured, the cost is reduced, and the production efficiency is improved.

Owner:JIANGXI AVONFLOW HVAC TECH CO LTD

Natural gas pipeline laying calibration device

InactiveCN114060609APrevent slippingFlexible and convenient positioningPipe supportsPipe laying and repairEngineeringStructural engineering

The invention discloses a natural gas pipeline laying calibration device which structurally comprises a supporting platform, a rotating shaft rod, a rotating shaft sleeve, clamping plates, a connecting sleeve, a height adjusting device and a height fixing device. The rotating shaft sleeve is located at the central axis of the supporting platform, the rotating shaft rod penetrates through a rotating shaft round hole in the rotating shaft sleeve, the left clamping plate and the right clamping plate are connected in a staggered mode through the rotating shaft rod, the height adjusting device is fixedly connected to the surface of the supporting platform and exerts stress on a cross-shaped nut to drive a lifting threaded rod to move up and down, further, a jacking and extruding device is driven to move, rotation angles of the clamping plates are changed, and the height of the jacking and extruding device is locked through the height fixing device. According to the natural gas pipeline laying calibration device, a pipeline can be fixedly supported, the height and angle of the pipeline can be adjusted, operation is convenient, and the natural gas pipeline laying calibration device is suitable for laying of the natural gas pipeline and pipe opening assembly in site construction.

Owner:SOUTHWEST PETROLEUM UNIV

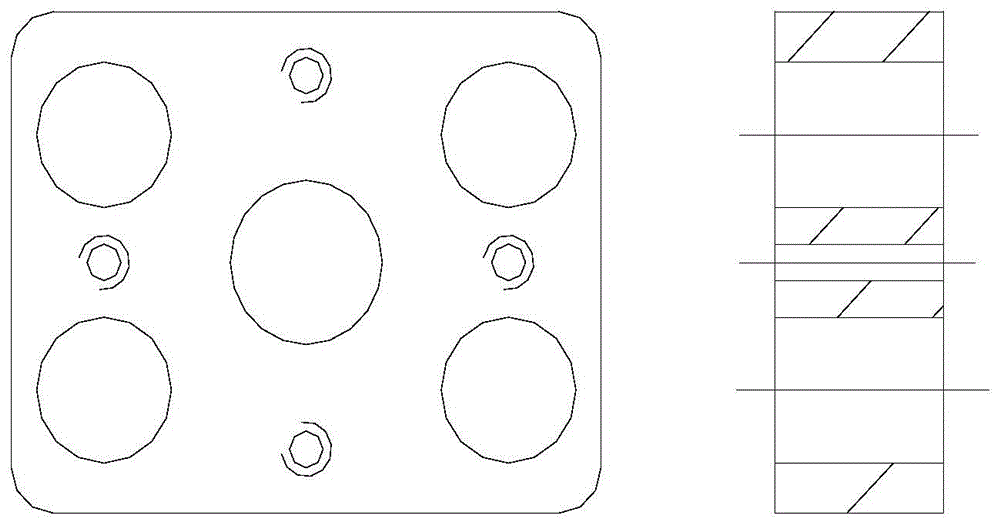

Tools for Tapping Group Threaded Holes

ActiveCN104475884BGuaranteed verticalityEliminate position deviationThread cutting machinesEngineeringUltimate tensile strength

The invention discloses a tapping tool for grouped threaded holes, and aims to reliably position and press, reduce the labor intensity and improve the tapping efficiency. The adopted technical scheme is that the tool comprises a drill plate and a baffle plate, wherein the drill plate and the baffle plate have consistent shapes and are both provided with guide holes and middle holes; a guide sleeve is arranged in the guide holes and is provided with an axial through hole; the position of the through hole corresponds to the position of a bottom hole of a case; the guide sleeve can move horizontally in the guide holes; a bolt is arranged in the through hole of the guide sleeve; one end of the bolt extends into the bottom hole of a boss of the case, and the other end of the bolt extends out of the through hole of the guide sleeve; a step-shaped positioning pin is arranged in the middle holes; a small end of the positioning pin extends into the middle holes, and big end of the positioning pin can be inserted into the positioning hole in a boss surface of the case and is axially provided with a pressing plate; the positioning pin and the pressing plate are provided with axial threaded holes; a bolt is arranged in the threaded holes and penetrates through the threaded holes of the positioning pin and the middle holes of the baffle plate; the entire device can be positioned and tightly pressed on the case through the nut.

Owner:AECC AVIATION POWER CO LTD

A 3D digital modeling method based on dome video stream

ActiveCN108830925BFlexible and convenient positioningPrecise positioningImage enhancementImage analysisPattern recognitionPoint cloud

The invention relates to a three-dimensional digital modeling method based on dome video streams. It includes the following steps: S handheld dome camera shoots video according to the route required by the user; S2 obtains the handheld dome camera video stream; S3 automatically extracts key frames from the video stream; S4 uses a super-resolution algorithm to improve the image quality of key frame images. ;S5 tracks the pixels on the key frame image to obtain a dense point cloud; S6 selects and tracks stable pixels and uses the PnP algorithm to estimate the camera motion trajectory, thereby determining the camera position and orientation; the stable pixels are located in the middle area of the key frame image points and the number of continuous tracking frames is greater than 10 frames; S7 performs three-dimensional modeling based on the dense point cloud obtained in step S5 and the camera position and orientation obtained in step S6. The invention provides a three-dimensional digital modeling method that does not require fixed-point shooting, has high stability in establishing a three-dimensional model, and has high visual effect fluency.

Owner:CHINA GERMANYZHUHAIARTIFICIAL INTELLIGENCE INST CO LTD +2

A support device for natural gas pipeline construction

InactiveCN107830243BFlexible and convenient positioningPrevent slipping outPipe laying and repairTrolley cranesInstabilityPipe support

The invention discloses a natural gas pipe construction support device. The natural gas pipe construction support device comprises a cross beam, a longitudinal beam, a longitudinal beam driving motor,a lifter receiving groove, a lifter, a lifting hanging hook, a support leg, a pipe positioning sleeve and a pipe. The pipe positioning sleeve with a belt wheel base is provided to realize free rotating movement of pipes with different diameters during lifting when the natural gas pipe support device supports and positions the pipes; and the positioning instability caused by reverse driving of bagsleeves due to shaking of the pipes by friction between the bag sleeves for wrapping the pipes and the pipes during adjusting the positions of the pipes is not generated.

Owner:邢台天宏祥燃气有限公司 +1

Ultrahigh pressure large-diameter anti-shear block loading, unloading and locking mechanism for simulator under deep ocean environment

ActiveCN103953728AEasy to use and flexibleImprove work efficiencyPressure vesselsUltra high pressureLocking mechanism

The invention relates to an ultrahigh large-diameter anti-shear block loading, unloading and locking mechanism for a simulator under the deep ocean environment. The anti-shear block loading, unloading and locking mechanism comprises a pressure drum; a sealing cover is arranged at the top of the pressure drum; a shearing slot is formed in the inner ring surface of the upper part of the pressure drum; anti-shear blocks are arranged and positioned on the sealing cover; the anti-shear blocks are clamped in the shearing slot formed on the pressure drum; the anti-shear blocks comprise oblique anti-shear blocks and straight anti-shear blocks which are arranged at the top of the sealing cover at intervals and encircle by one circle; a bearing block is arranged in the middle of the sealing cover; the mechanism also comprises an oil cylinder seat; an oil cylinder is arranged on the oil cylinder seat; the oil cylinder seat and the bearing block are integrally assembled by a bearing, so an anti-shear block loading and unloading device is formed. The anti-shear block loading, unloading and locking mechanism is flexible and reliable in use and high in work efficiency.

Owner:CHINA SHIPBUILDING IND CORP NO 702 RES INST

Longitudinal positioning connection device and construction method of underground engineering support arch

ActiveCN106522998BEnable connectivityAchieve positioningUnderground chambersTunnel liningEngineeringEngineering support

The invention discloses a longitudinal positioning and connecting device for a support arch frame of an underground project and a construction method. The longitudinal positioning and connecting device comprises a connecting rod, a first fixing device and a second fixing device, wherein one end of the connecting rod is a spherical round head, and a first threaded hole is formed in the spherical round head; the other end of the connecting rod is of a swelling structure; the first fixing device is used for providing a clamping structure for clamping and fixing the swelling structure, and the inner diameter of the clamping structure is smaller than the outer diameter of the swelling structure; and the second fixing device is of a hollow structure formed by surrounding of a shell, the end part of the hollow structure is opened, a second threaded hole matched with the first threaded hole is formed in the shell, and the diameter of the spherical round head is larger than the inner diameter of the end part of the hollow structure and smaller than the inner diameter of a main body part of the hollow structure. The longitudinal positioning and connecting device has the beneficial effects that the positioning is convenient and flexible, and the construction period is shortened. By utilizing the device, the longitudinal connection and accurate positioning of the support arch frame can be realized by only moving the arc frame, aligning the arc frame and inserting the arc frame into the first fixing device, so that the construction time is greatly saved, and the construction safety is improved.

Owner:SHANDONG UNIV

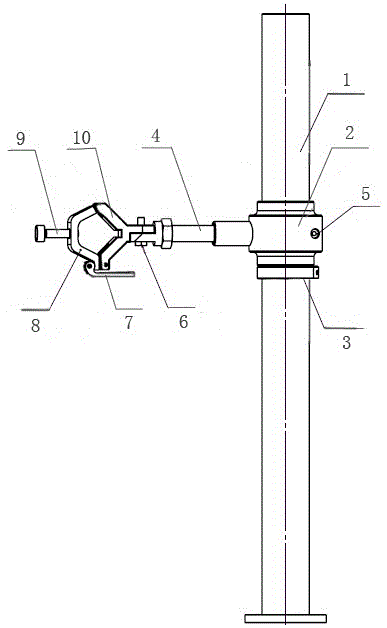

Trial stand for welder training

InactiveCN106781795AFlexible and convenient positioningEasy to operateCosmonautic condition simulationsSimulatorsEngineeringMechanical engineering

The invention discloses a trial stand for welder training. The trial stand for welder training comprises a fixed arm, a rotary arm, a plate clamping device and a pipe clamping device. The rotary arm is movably connected with the fixed arm through a first fastening screw, and the rotary arm can rotate around the fixed arm by 360 degrees. The plate clamping device and the pipe clamping device are movably connected with the rotary arm through a second fastening screw and a third fastening screw respectively. The plate clamping device and the pipe clamping device can rotate around the rotary arm by 360 degrees. According to the trial stand for welder training, a single mode of traditional trial stands is changed, training tests of plate samples and pipe samples can be both conducted, positioning is flexible and convenient, operation is easy, samples can rotate by 360 degrees, vertical height can be freely adjusted, quick positioning can be achieved based on positions, training assisting time is saved a lot, and working efficiency is improved.

Owner:泰州口岸船舶有限公司

A surgical positioning device and a robot surgical system

ActiveCN104083217BAvoid the problem of introducing systematic errorsAvoid the problem of limited application rangeSurgical robotsInstruments for stereotaxic surgeryEngineeringSystem error

The invention relates to an operation positioning device and method and a robot operation system. The operation positioning device comprises a positioning ruler, an upper computer and a series-connection mechanical arm with at least six degrees of freedom. The upper computer is connected with the series-connection mechanical arm, the positioning ruler comprises two opposite surfaces allowing X-rays to transmit, the two opposite surfaces are fixedly connected through a connecting surface allowing X-rays to transmit, the two opposite surfaces are respectively provided with a group of marks, each group of marks comprise at least four mark points which are not located on the same straight line, and the mark points are X-ray-proof components. Any opposite surface or the connecting surface is fixedly connected with a ruler handle, and the ruler handle is connected with the tail end of the series-connection mechanical arm through a port. The upper computer adjusts the position of the positioning ruler by controlling movement of the series-connection mechanical arm, space positioning calculation is conducted according to the mark points in collected images, and a planning path is obtained. The device can achieve perspective positioning at any angle, and can eliminate system errors caused when an operation path is calculated, increase working space and improve the operation positioning accuracy.

Owner:BEIJING TINAVI MEDICAL TECH

Mandrel structure of circular saw machine for preferably cutting timber in longitudinal direction

The present invention discloses a saw shaft structure of optimized longitudinal cutting circular sawing machine, which comprises a saw shaft and a saw shaft base that is used for supporting the saw shaft. The saw shaft is at least sleeved with a sawblade sliding sleeve which can move along the axial direction and rotate along with the saw shaft. The sawblade sliding sleeve is at least fixedly installed with a movable circular saw blade which is movably connected with a circular saw blade shifting fork. The circular saw blade shifting fork is connected with a screw pair. The saw shaft is at least fixedly installed with a fixed circular saw blade and is at least fixedly installed with a saw shaft driving key. The shaft hole of sawblade sliding sleeve is at least internally provided with a driving key groove that is corresponding with the saw shaft driving key. The saw shaft structure can realize the axial sliding adjustment to the circular saw blade conveniently and flexibly. Longitudinally material cutting can be executed according to an optimal cutting plan. The saw shaft structure also has higher material yielding rate and production efficiency, and is widely used in various multi-blade circular sawing machine.

Owner:JIANGSU JIANGJIA MACHINERY

Support mould upright post for cast wall bodies

InactiveCN101654955AImprove efficiencySimple structureAuxillary members of forms/shuttering/falseworksScrew threadIndustrial engineering

The invention belongs to the field of building equipment, in particular to a support mould upright post for cast wall bodies. The support mould upright post is characterized in that the support mouldupright post is provided with a lifting jack and consists of a support rod (1) on the upper part and the lifting jack on the bottom part, wherein the bottom end of the support rod(1) is in matched connection with the upper end of the lifting jack. The support rod (1) is also provided with a spiral fastener or a through hole matched with a mould plate through hole; the top end of the support rod (1) is provided with an insertion rod (2) which is matched with the support rod (1) by insertion or threads; and the lifting jack may be a spiral type lifting jack, a hydraulic type lifting jack, a lever type lifting jack, an inclined plane type lifting jack or an electric type lifting jack. The invention provides the support mould upright post, which has the advantages of simple structure, easy operation, labor and time conservation, low cost and high efficiency.

Owner:杨小平

A built-in fine-tuning sliding table movement mechanism

ActiveCN103692226BPrevent fallingNot hit directlyLarge fixed membersMetal working apparatusEngineeringFine-tuning

The invention discloses a built-in fine adjustment slipway motion mechanism. The built-in fine adjustment slipway motion mechanism comprises a slipway fixed seat, a fine adjustment slipway main body, a motion mechanism loading main platform, a driving mechanism main body component, wherein the fine adjustment slipway main body is arranged on the slipway fixed seat; the motion mechanism loading main platform is arranged on the fine adjustment slipway main body; the driving mechanism main body component is arranged on the motion mechanism loading main platform; the slipway fixed seat is internally provided with a fine adjustment device; the fine adjustment device can realize fine adjustment motion of the slipway main body on the slipway fixed seat. Through the above scheme, the built-in fine adjustment slipway motion mechanism disclosed by the invention is used for positioning repeated motion needing accurate alignment fine adjustment, so that the positioning is more flexible and convenient; the built-in fine adjustment slipway motion mechanism is particularly suitable for high-speed cutting main shafts and pneumatic main shafts (high processing precision is needed and impact is prevented), and can effectively reduce the noises caused by motion and the structural abrasion caused by the impact, thus greatly promoting the precision during repeated positioning; the blank on the structural aspect in the prior art is solved.

Owner:昆山鸿富洋科技有限公司

an ink device

ActiveCN104191812BEasy to clean and maintainReduce consumptionPrinting press partsPrinting pressPiece Unit

The invention relates to an ink piece device which is arranged on a printing machine. The ink piece device comprises an ink roller (14) and a plurality of ink piece units (1), wherein the ink piece units (1) are arranged on one side of the ink roller in the direction of an ink roller shaft and can slide in the axial direction of the ink roller (14). A plurality of independent ink supply areas corresponding to the ink roller (14) are formed. According to the ink piece device, the ink piece device is arranged to be a combined body composed of the intelligent ink piece units, independent ink supply for same-roller and different-ink-color sub areas is achieved, only the areas required to be inked is supplied with the oil ink, and oil ink consumption is reduced; the sub areas are convenient to adjust, and the ink piece units are independent relatively, so that assembly and disassembly are quick in speed, and flexible and convenient positioning is achieved; if one ink piece is damaged in the using process, only local replacement is needed, and use cost can be reduced; the ink piece units are arranged on a track, so that assembly and disassembly are convenient, the printing device can be repaired quickly, and meanwhile, the parts prone to damage can be replaced conveniently and the ink piece can be maintained and cleaned conveniently.

Owner:江苏科思机电工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com