Tools for Tapping Group Threaded Holes

A threaded hole and group technology, applied in manufacturing tools, metal processing equipment, tangent devices, etc., can solve the problems affecting the normal progress of scientific research tasks, low efficiency of tapping process, laborious and time-consuming operation, etc. Simple operation and manufacturing process, and the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with embodiment.

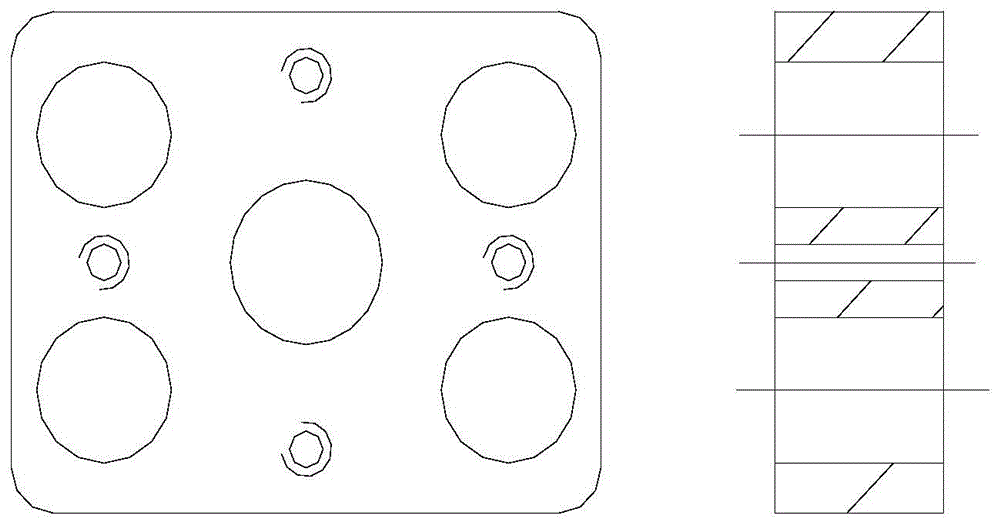

[0031] see figure 1 The present invention comprises a drill formwork 1 and a baffle plate 3 arranged on the drill formwork 1, the shapes of the drill formwork 1 and the baffle plate 3 are consistent, four guide holes are provided on the drill formwork 1 and the baffle plate 3, and the drill formwork 1 and the baffle plate 3 are provided with four guide holes. The guide holes of the baffle plate 3 correspond to each other, and the position of the guide hole corresponds to the position of the bottom hole of the boss that needs to be tapped in the casing. A corresponding middle hole is opened in the middle position of the drill template 1 and the baffle plate 3. The drill template 1 and the baffle plate 3 A guide sleeve 2 is provided in the guide hole of the plate 3, and the guide sleeve 2 is arranged as an intermediate step structure, and the step position is located between the drilli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com