Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36results about How to "Easy to pre-fix" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Power distribution cabinet illuminating device

InactiveCN110513639AAvoid exposureEasy to operateNon-electric lightingPoint-like light sourceLED lampEngineering

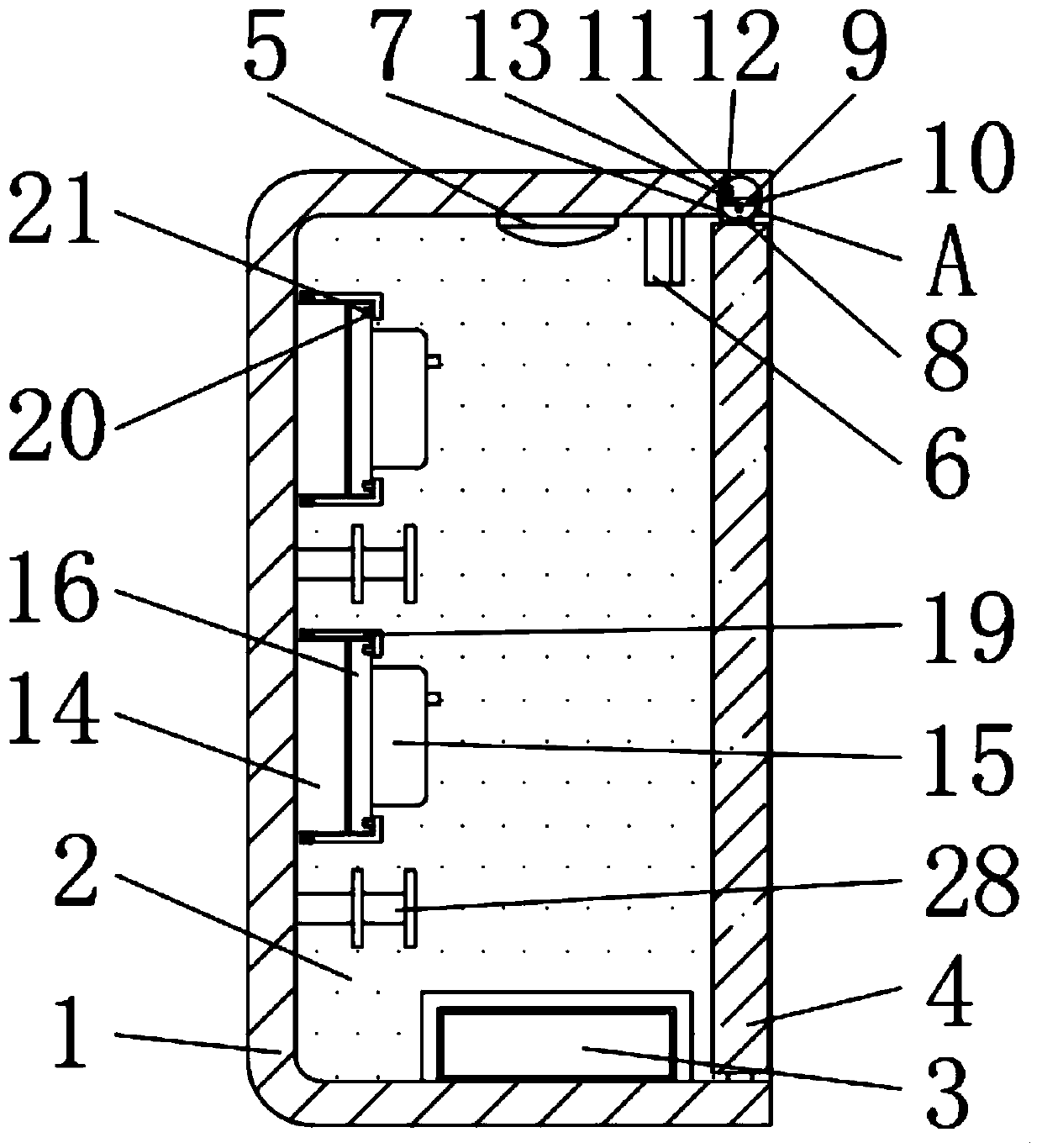

The invention discloses a power distribution cabinet illuminating device. The power distribution cabinet illuminating device comprises a cabinet body, a first spring, a fixed rod and a second spring;an installation groove is formed in the cabinet body; a storage battery is installed at the bottom of the installation groove; a cabinet door is rotationally connected to the opening side of the cabinet body, close to the installation groove; an LED lamp is installed at the top of the installation groove; a light shielding plate is fixed on one side, close to the LED lamp, of the cabinet body; anelastic switch groove is formed in the top of the cabinet body, close to the cabinet door; and an elastic switch is rotationally connected in the elastic switch groove. According to the power distribution cabinet illuminating device, the light shielding plate is arranged, the length of the light shielding plate is larger than the outer diameter of the LED lamp, and the horizontal height of the bottom of the light shielding plate is larger than the horizontal height of the bottom of the LED lamp, so that the light shielding plate can completely cover the outer side of the LED lamp; when the cabinet door is opened and the LED lamp is turned on, light is prevented from being irradiated to the eyes of a worker; and meanwhile, the LED lamp is used for illuminating the installation groove, so that the worker can operate a power distribution cabinet conveniently.

Owner:江宏友

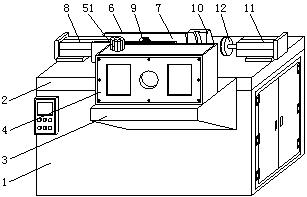

Assembly device of radiator bracket of refrigeration equipment

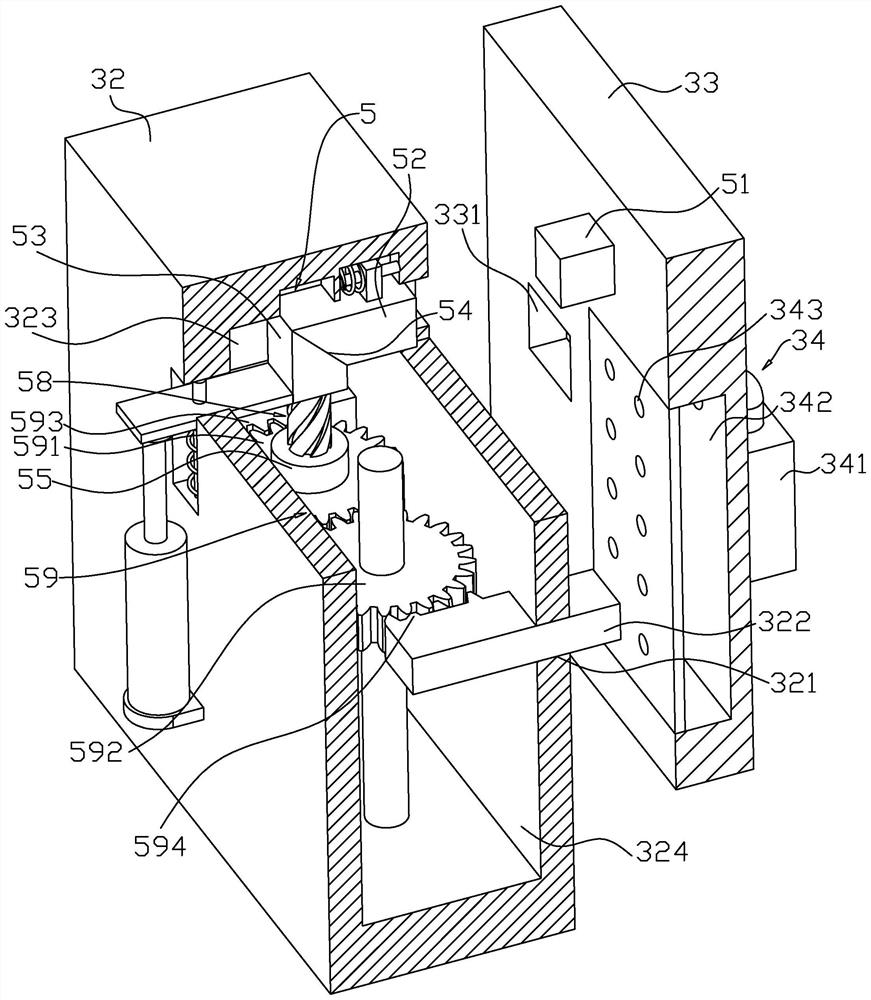

ActiveCN111571217AImprove assembly efficiencyImprove assembly accuracyOther manufacturing equipments/toolsEngineeringRefrigeration

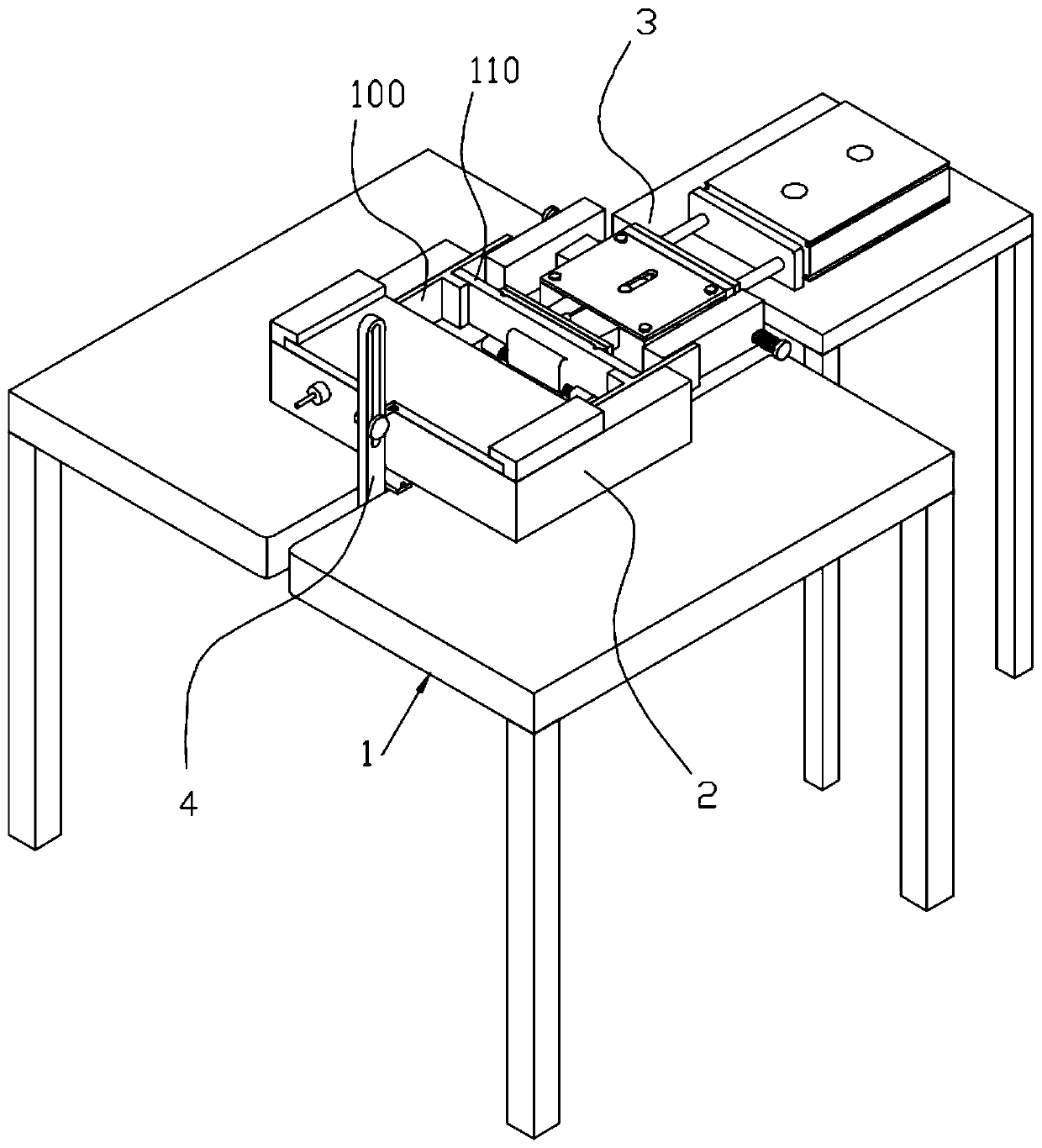

The invention discloses an assembly device of a radiator bracket of refrigeration equipment, and relates to the technical field of refrigeration equipment accessory processing. The device comprises aworkbench, a fixing seat, an assembly mechanism and a limiting mechanism, wherein the fixing seat is arranged on the workbench and is used for placing a bracket body, a negative electrode conductive head is arranged at the front end of the fixing seat, the assembly mechanism is positioned at one side of the fixing seat, the assembly mechanism is used for welding and fixing a rib plate on the bracket body and carrying out flanging treatment on two extended ends of the bracket body, and the limiting mechanism is connected with the assembly mechanism and is used for limiting the bracket body before the rib plate is welded. According to the device, the assembly mechanism can carry out flanging treatment on the bracket body while realizing welding assembly of the rib plate, and the two traditional independent working procedures are integrated together, so that the assembly efficiency is obviously improved, and the assembly precision is also improved due to adoption of mechanized operation.

Owner:DONG GUAN JIN FENG TECH CO LTD

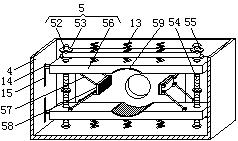

Waste collection box with intelligent classifying function

The invention discloses a waste collection box with an intelligent classifying function. The waste collection box with the intelligent classifying function comprises a base. The top end of the base isprovided with a waste collection box. A fire extinguishing assembly is arranged in the waste collection box. The waste collection box with the intelligent classifying function is scientific and reasonable in structure and safe and convenient to use. Due to the arrangement of the fire extinguishing assembly and functions of a top plate, a connecting column, a water tank, a connecting pipe and a fixing block, the water tank can be fixed in advance conveniently so as to be conveniently installed, and the installation difficulty is reduced. Through the functions of a spray head and a water flow guide plate, when a fire occurs in the waste collection box, fire extinguishing work is convenient to carry out, the fire is extinguished in time, greater losses caused by the spread of the fire are avoided, and meanwhile, water flow can be conveniently guided to comprehensively carry out fire extinguishing work in the waste collection box, and the fire extinguishing effect is improved. Through thefunctions of a water inlet pipe, an external connection hole and a shielding plate, water sources can be conveniently filled into the water tank through an external connection water pipe by workers,and better use convenience is realized.

Owner:XUZHOU WONDERFUL INFRASTRUCTURE MFG

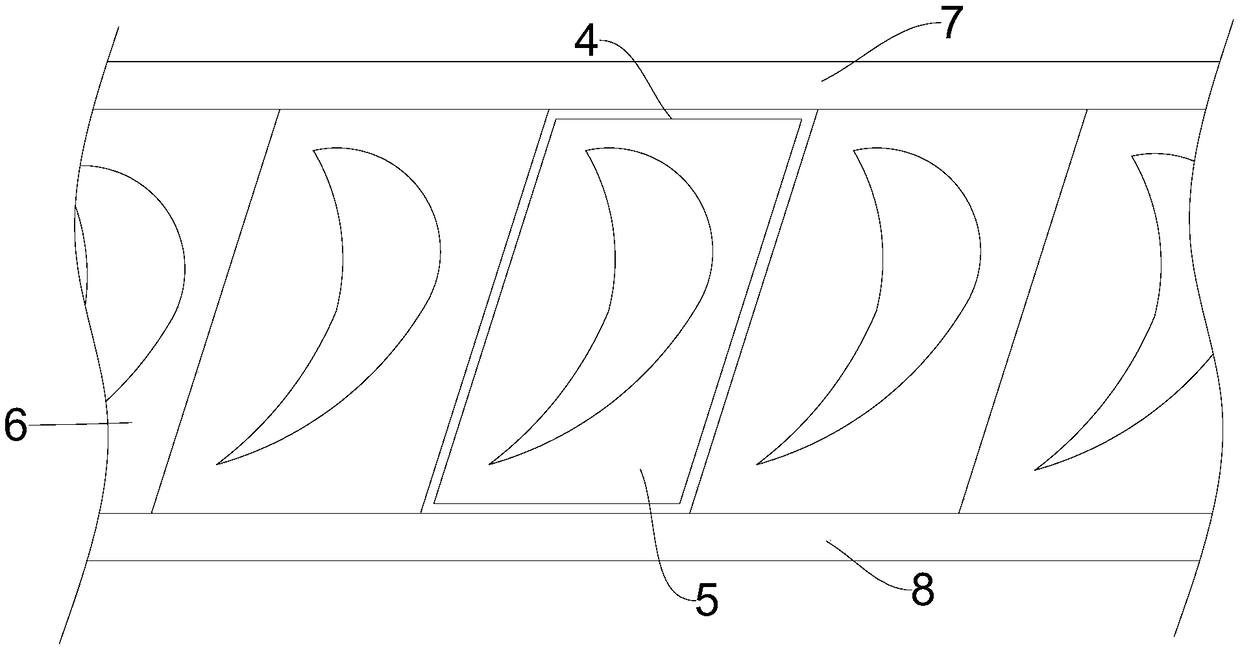

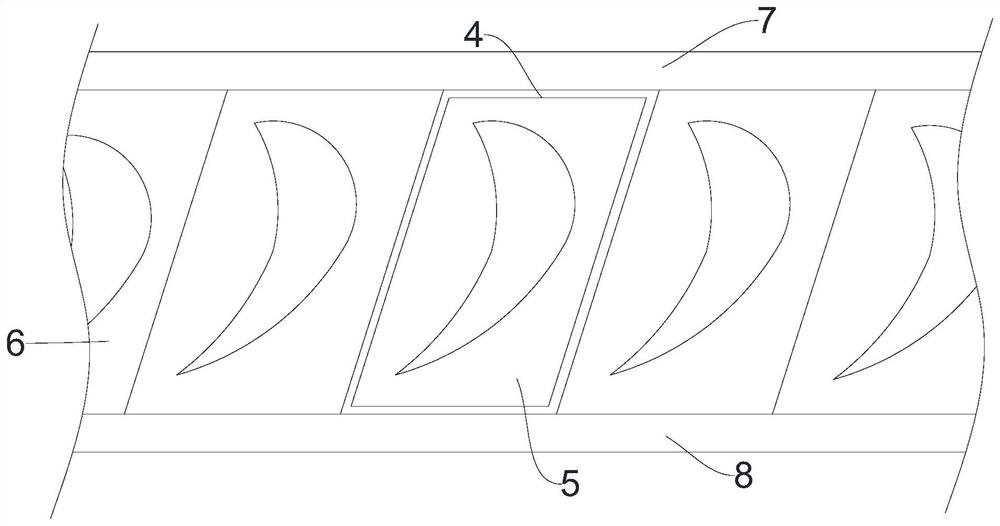

Fabric rolling drum with pressing plate provided with V-shaped clamping hooks

The invention discloses a fabric rolling drum with a pressing plate provided with V-shaped clamping hooks. Fabric scraps can be conveniently prefixed to a reel through matching of the pressing plate arranged on the reel and a pressing groove, and the pressing plate can be better matched with the pressing groove through the V-shaped clamping hooks arranged on one side of the pressing plate at the same time; then the reel is driven to rotate through a rotary handle arranged at one end of the reel so as to make the fabric scraps be rolled to the reel and be tightly squeezed with sawteeth on the side walls of a long groove, so that the contact area between the fabric scraps and the reel is increased, the fabric scraps are pressed effectively and tightly, and slipping is prevented; and finally the rotary handle is locked. The structure is convenient to operate; fabric rolling is stable and reliable; slipping is avoided; time and labor are saved.

Owner:WUXI XINGLIN DYEING ENVIRONMENTAL PROTECTION EQUIP

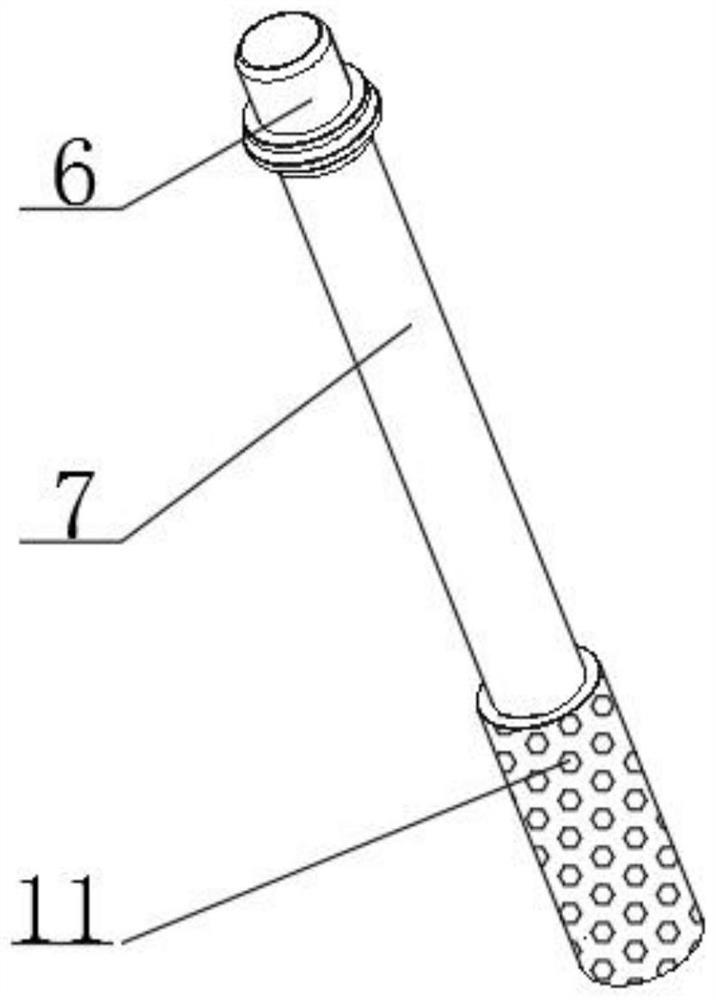

PCB drilling mechanism

InactiveCN112265060AIncrease flexibilityEasy to weldMetal working apparatusDrill holeStructural engineering

The invention relates to a PCB drilling mechanism. The PCB drilling mechanism comprises a drill rod main shaft, a liquid cavity mechanism, a clamping ring mechanism, a pressing rod mechanism, a starting mechanism, a fan cylinder and a metal ring, wherein four notches are formed in the middle of the drill rod main shaft, limiting plates are arranged in the notches, limiting balls are arranged on the outer walls of the limiting plates, the clamping ring mechanism comprises a clamping ring arranged in the middle of the drill rod main shaft in a sleeving mode, an annular cavity formed in the innerside of the clamping ring and a limiting hole formed in the inner wall of the clamping ring and used for being clamped on the limiting balls, four arm rods are welded to the outer wall of the clamping ring, and the pressing rod mechanisms are further inserted into the four arm rods. In this way, a glue solution is smeared in a drill hole, components can be fixed in advance and welded convenientlyafter being inserted, functionality is improved again, an inserting hole type connecting plate is arranged at the top of the liquid cavity mechanism, the connecting plate can be detached from a drillrod main shaft switch according to needs, which is suitable for occasions where the liquid cavity mechanism does not need to be filled with the glue solution, and the application is more flexible.

Owner:江苏洲旭电路科技有限公司

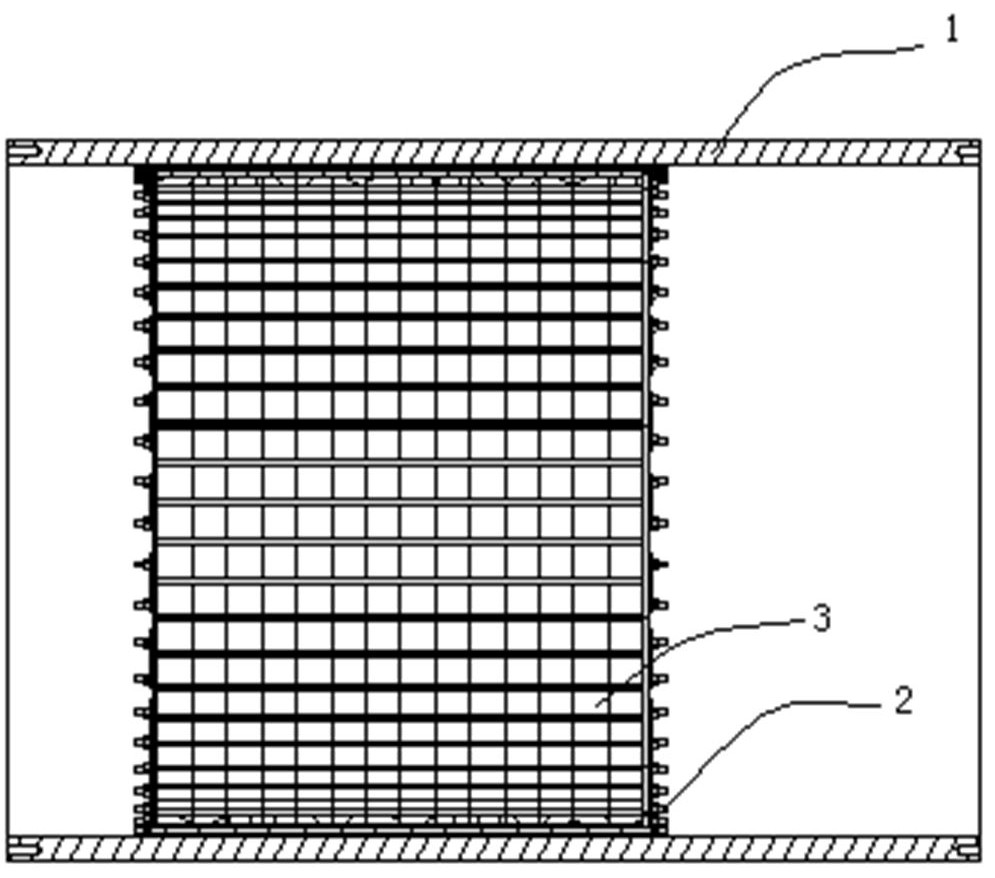

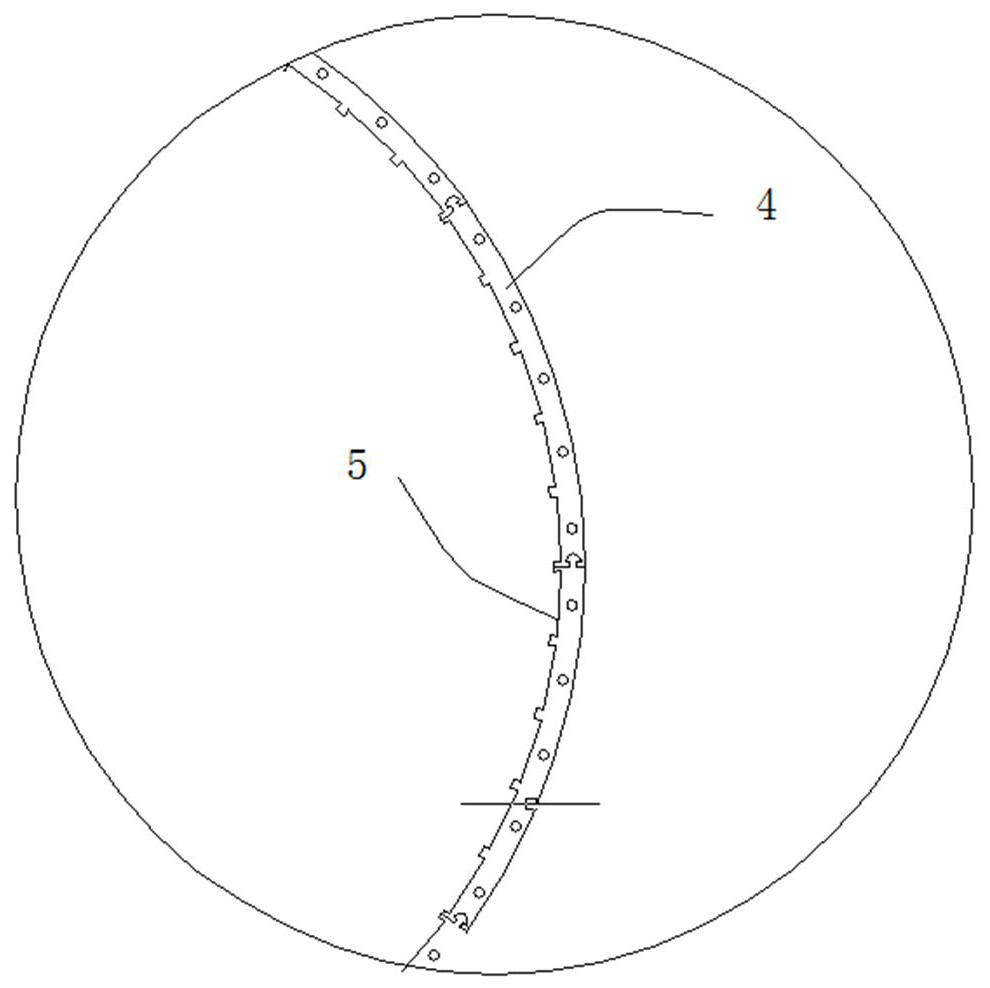

Fabricated formwork structure and construction process thereof

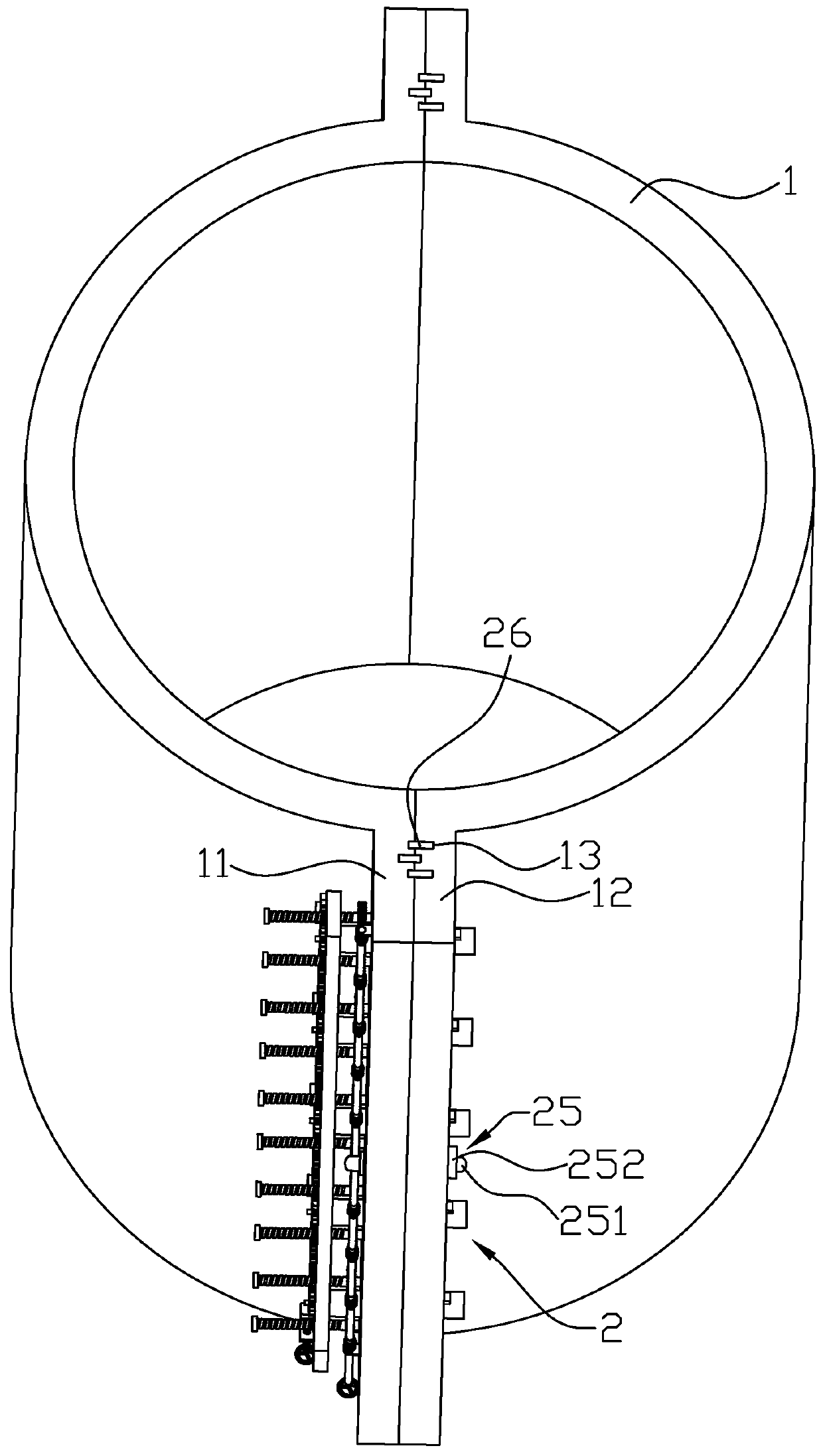

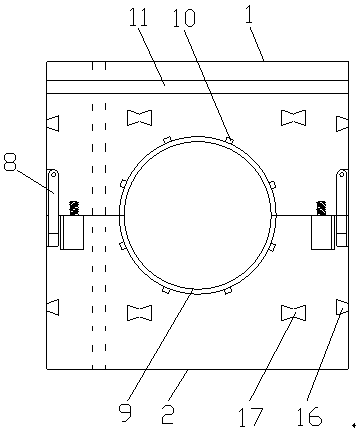

The invention relates to a fabricated formwork structure and a construction process thereof. The fabricated formwork structure comprises two semi-arc-shaped formworks, two first connecting frames andtwo second connecting frames; a fixing device is arranged between the first connecting frames and the second connecting frames and comprises a pre-fixing assembly, a plurality of first through holes,a plurality of second through holes, a movable plate and a plurality of connecting pipes, and sealing strips are arranged between the first connecting frames and the second connecting frames; drivingmechanisms are arranged on one sides of the first connecting frames, limiting mechanisms are arranged each connecting pipes, each of the limiting mechanism comprises a plurality of limiting blocks, adriving block and a screw rod, the opposite inner sides of each limiting block and each driving block are provided with inclined surfaces correspondingly, and the driving blocks are in threaded connection with the screw rods; and reset assemblies are arranged on the inner walls of the connecting pipes, and a transmission mechanism is arranged on one side of the movable plate. According to the fabricated formwork structure and the construction process thereof, by arranging the fixing device, the two semi-arc-shaped formworks can be conveniently fixed so that the labor intensity of operators canbe reduced.

Owner:CHONGQING TUO DA CONSTR GRP

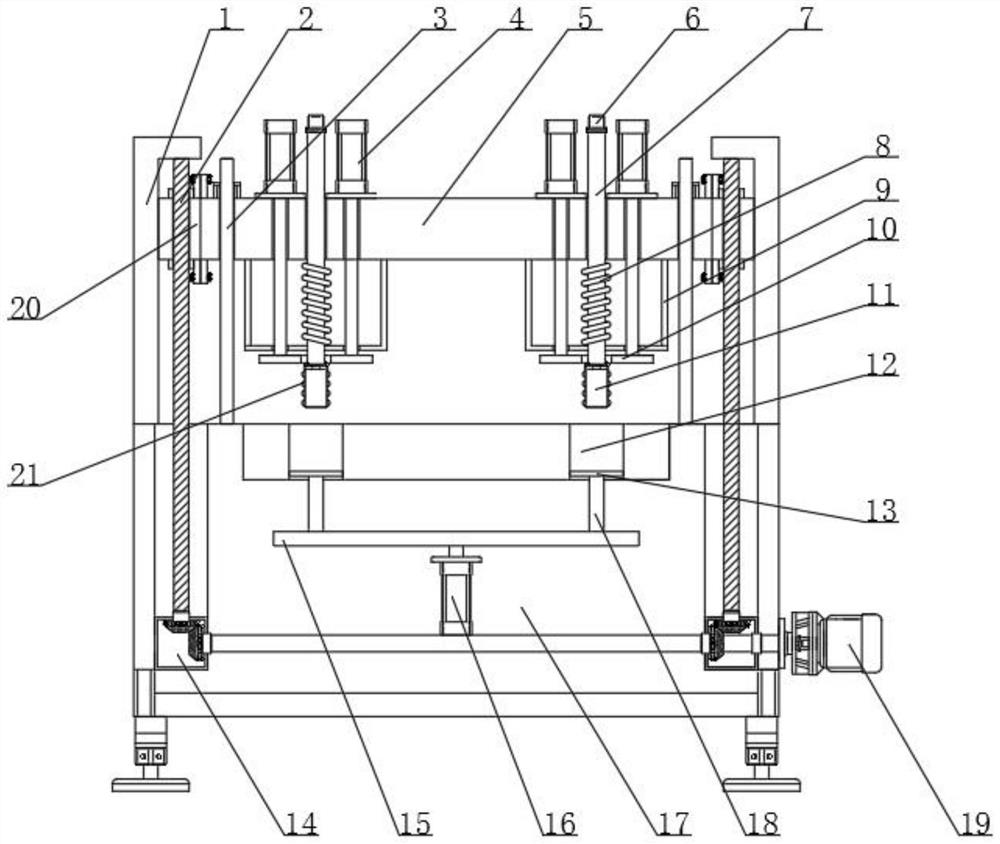

Asphalt waterproof coiled material tearing performance detection method

ActiveCN112577815AReduce the likelihood of sheddingEasy to fixMaterial strength using tensile/compressive forcesBituminous waterproofingStructural engineering

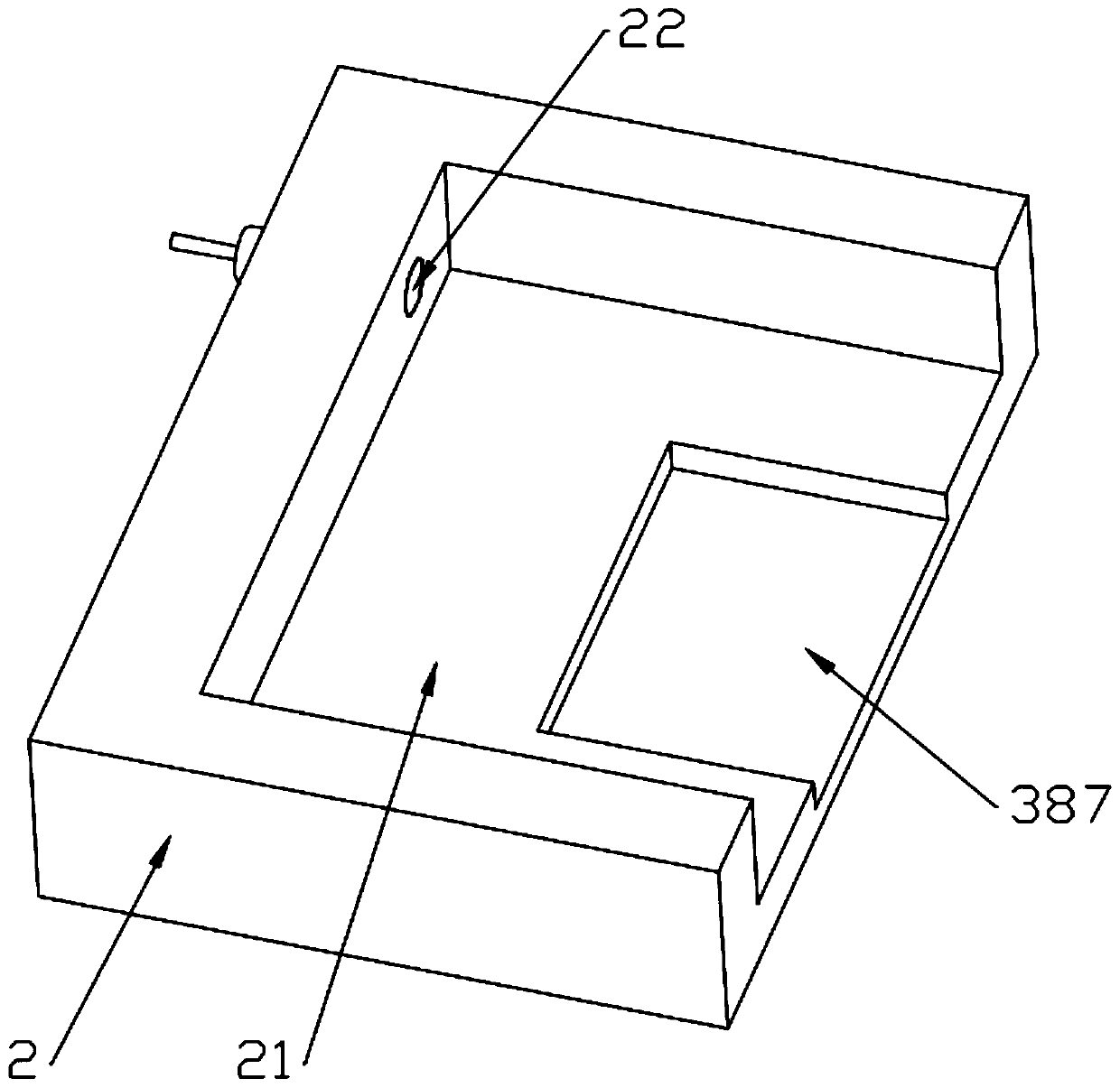

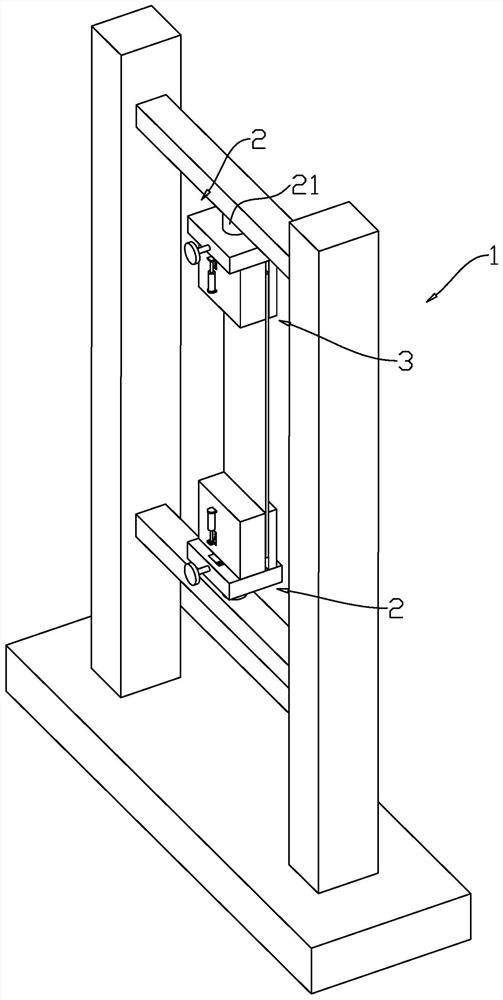

The invention relates to an asphalt waterproof coiled material tearing performance detection method, which comprises the following steps of: S1, mounting two sets of clamping structures, wherein the two sets of clamping structures are oppositely arranged, each set of clamping structure comprises a connecting block and a clamping device, and the connecting blocks are fixed on the asphalt waterproofroll tearing performance detection machine, so that the clamping structure can be mounted; S2, mounting an asphalt waterproof coiled material, namely putting one end of the asphalt waterproof coiledmaterial on one side, close to the movable plate, of the fixed plate, then pre-fixing the end of the asphalt waterproof coiled material through a pre-fixing assembly, then driving the movable plate tomove in the direction close to the fixed plate through a driving mechanism, so that one end of the asphalt waterproof coiled material can be mounted, and mounting the other end of the bituminous waterproof sheet material in the above manner; and S3, carrying out a test, which is implemented by testing the asphalt waterproof coiled material through an asphalt waterproof coiled material tearing performance detection machine. According to the asphalt waterproof coiled material tearing performance detection method, the possibility that the asphalt waterproof coiled material falls off during detection can be reduced.

Owner:JIANGSU SANYANG CONSTR ENG DETECTION

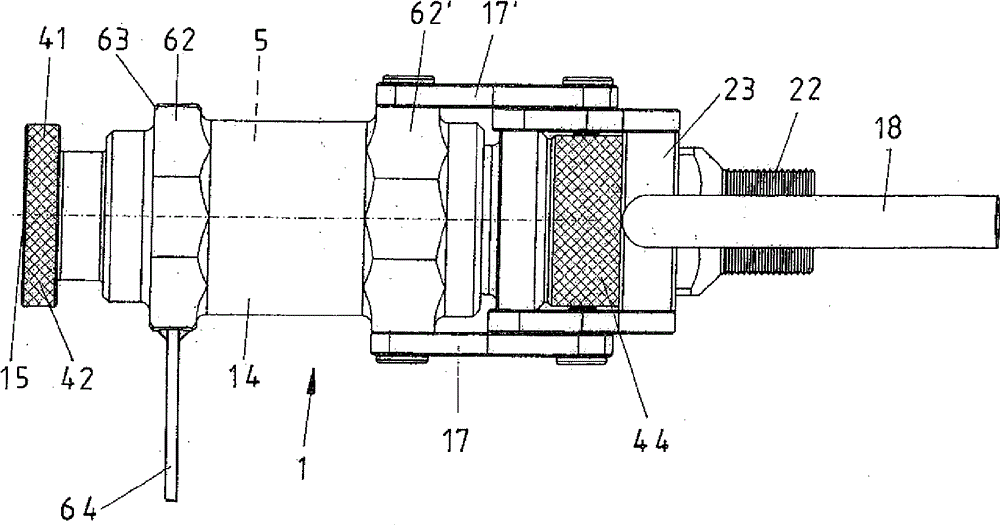

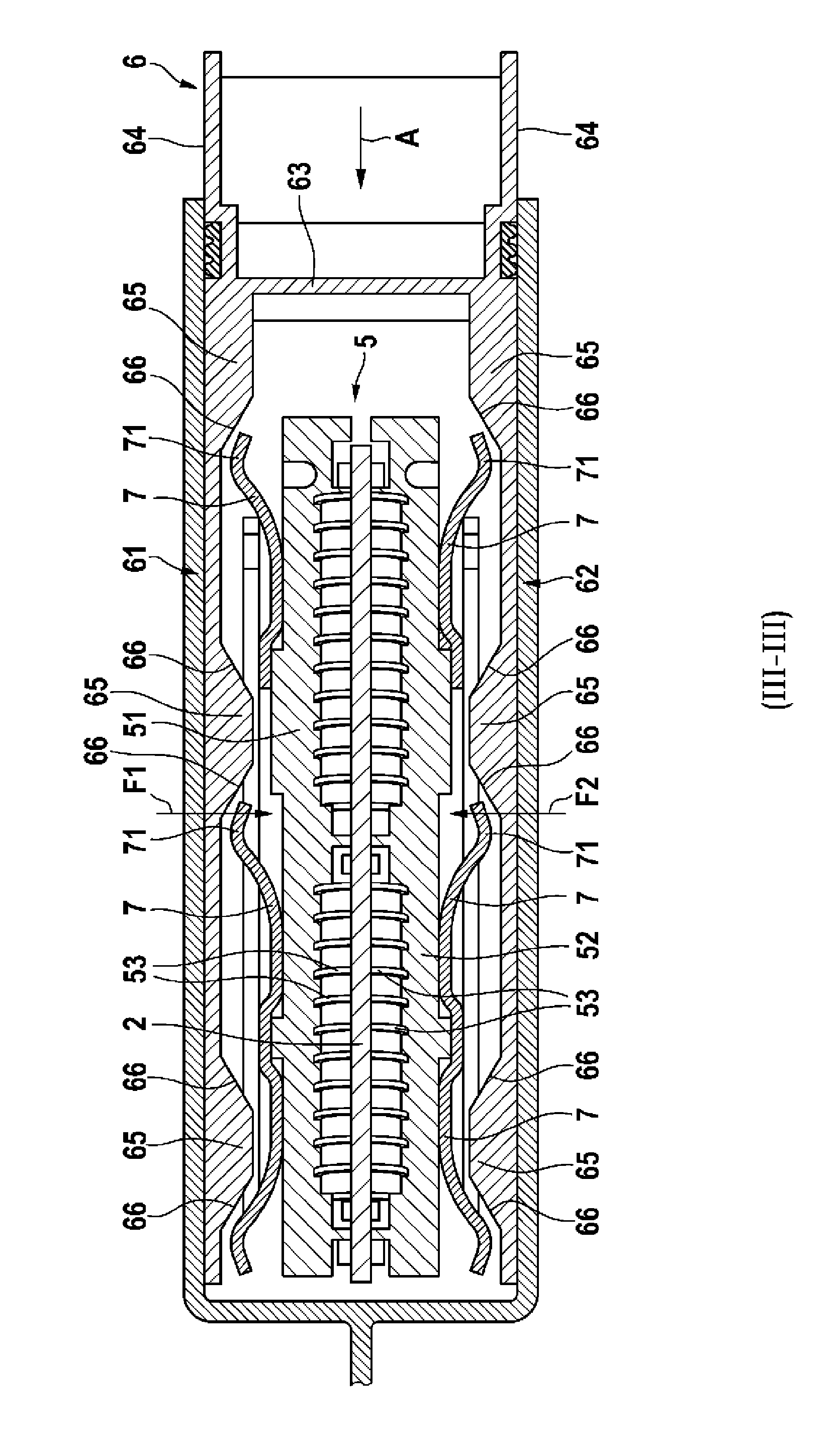

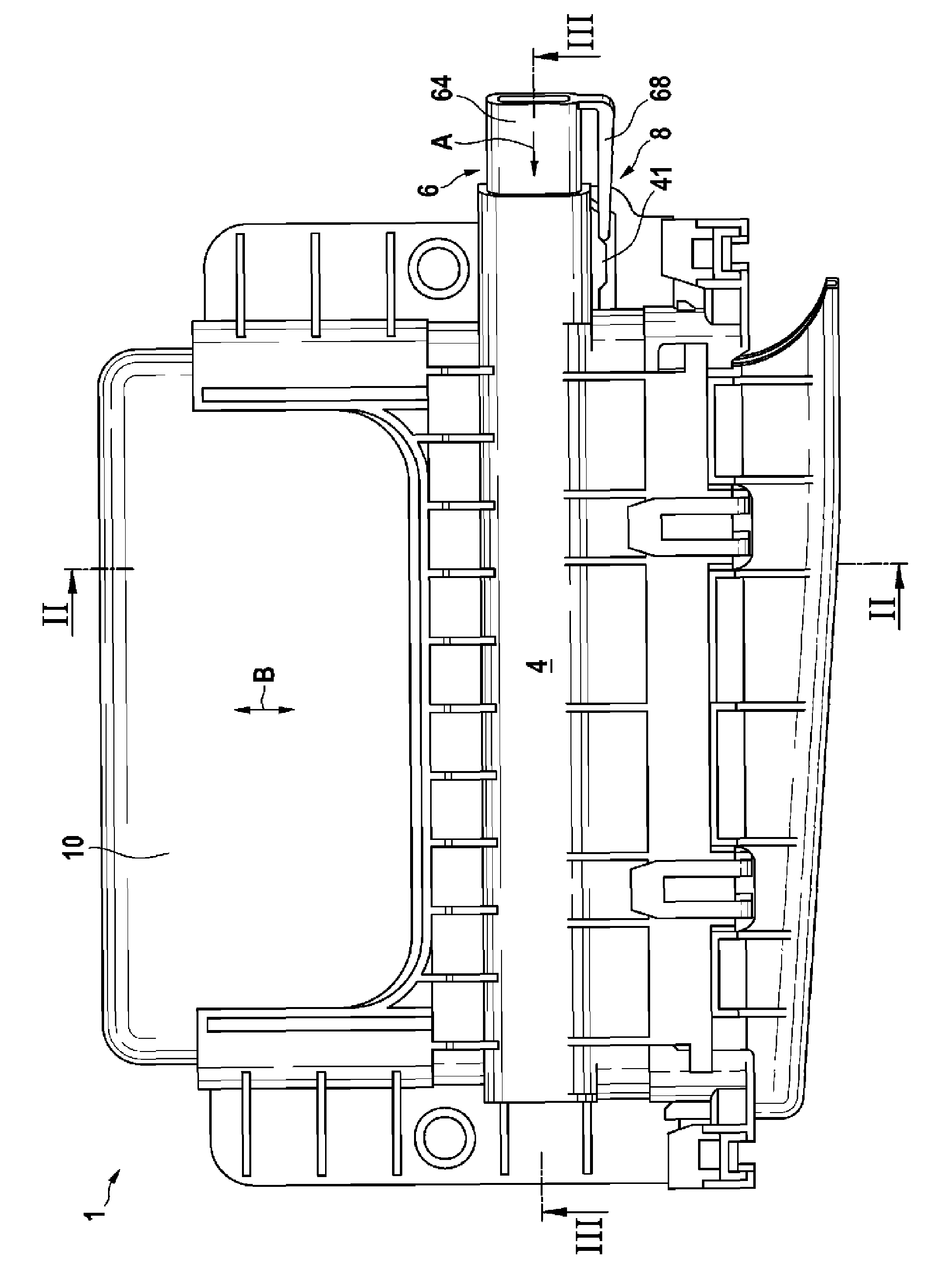

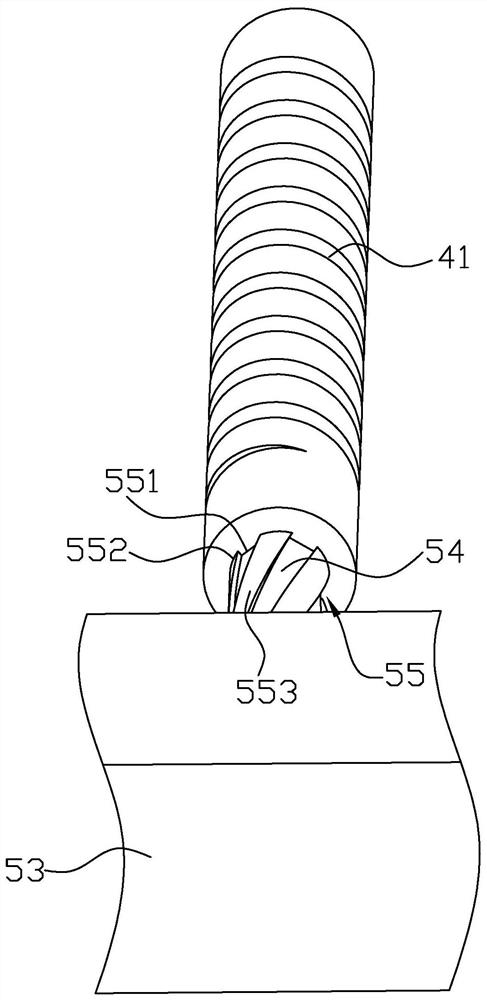

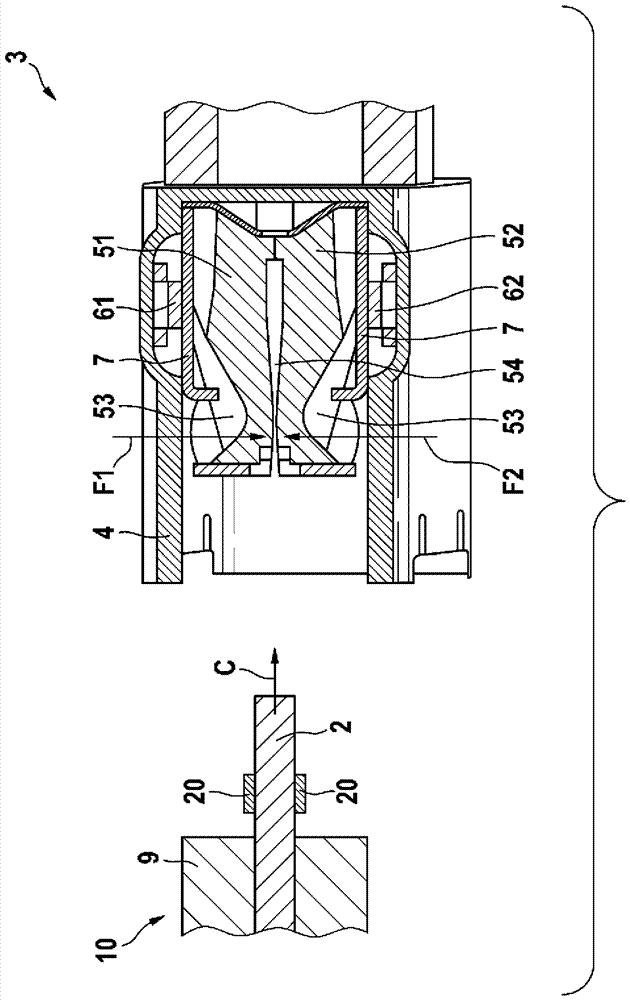

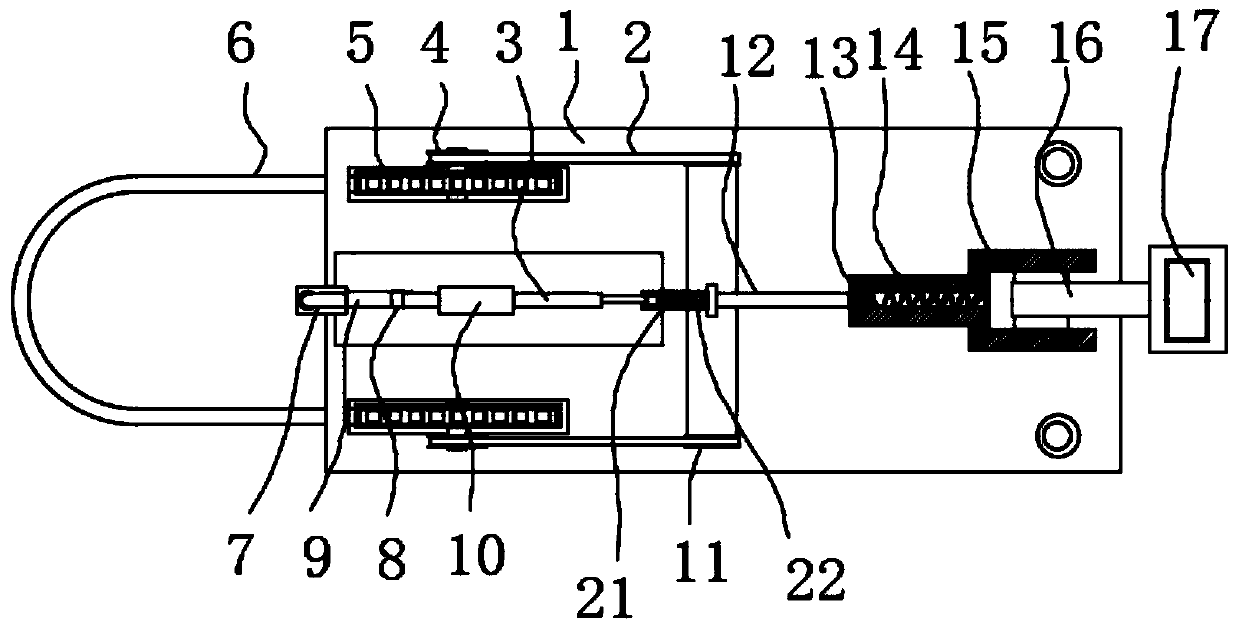

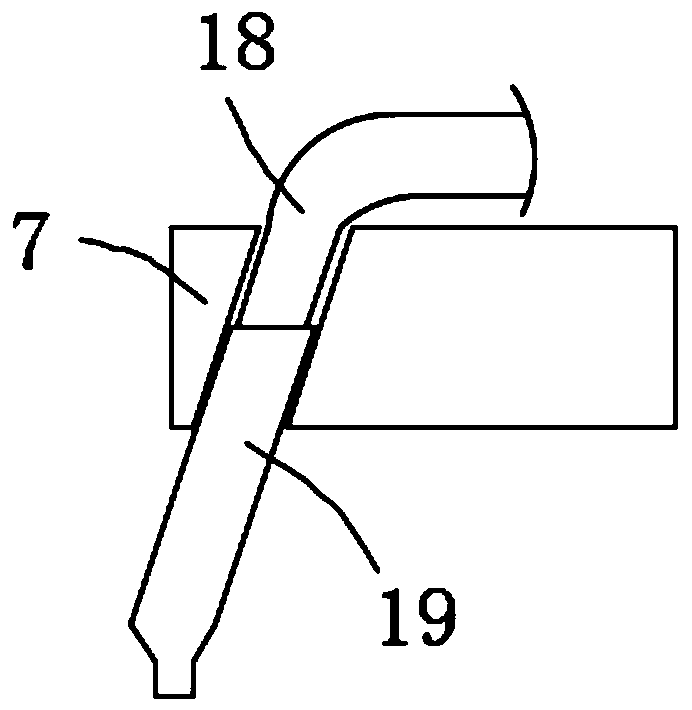

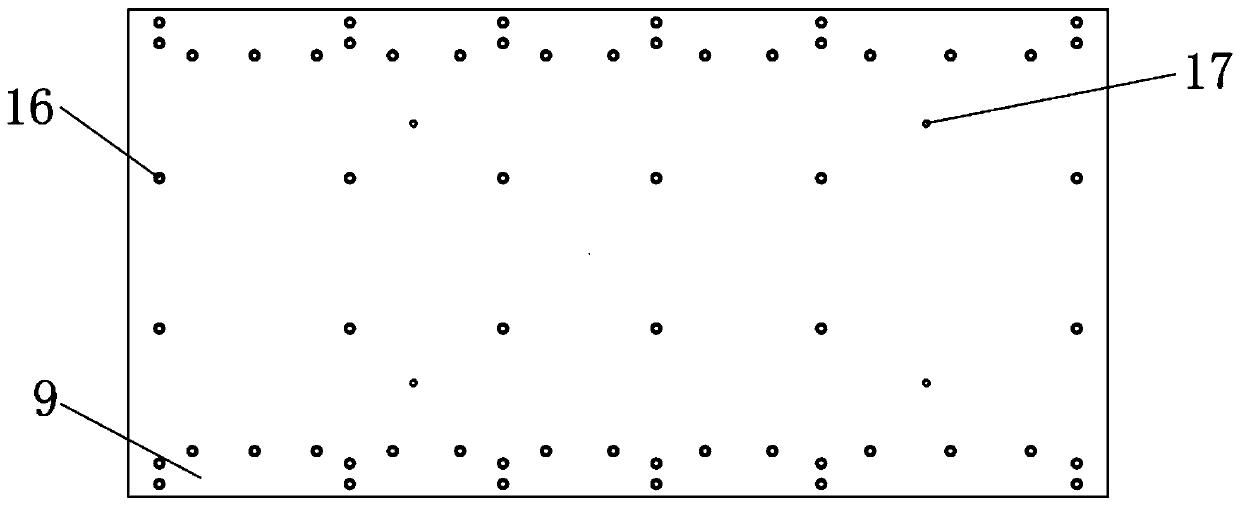

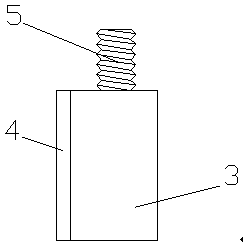

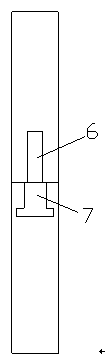

Lance holder with protector for curved lances, in particular curved oxygen lances

ActiveCN103333989AAchieve first fixationDifficult turning processMelt-holding vesselsCharge manipulationEngineeringOxygen

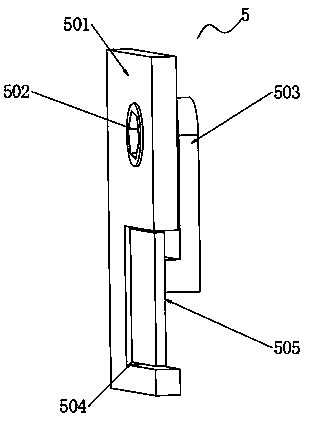

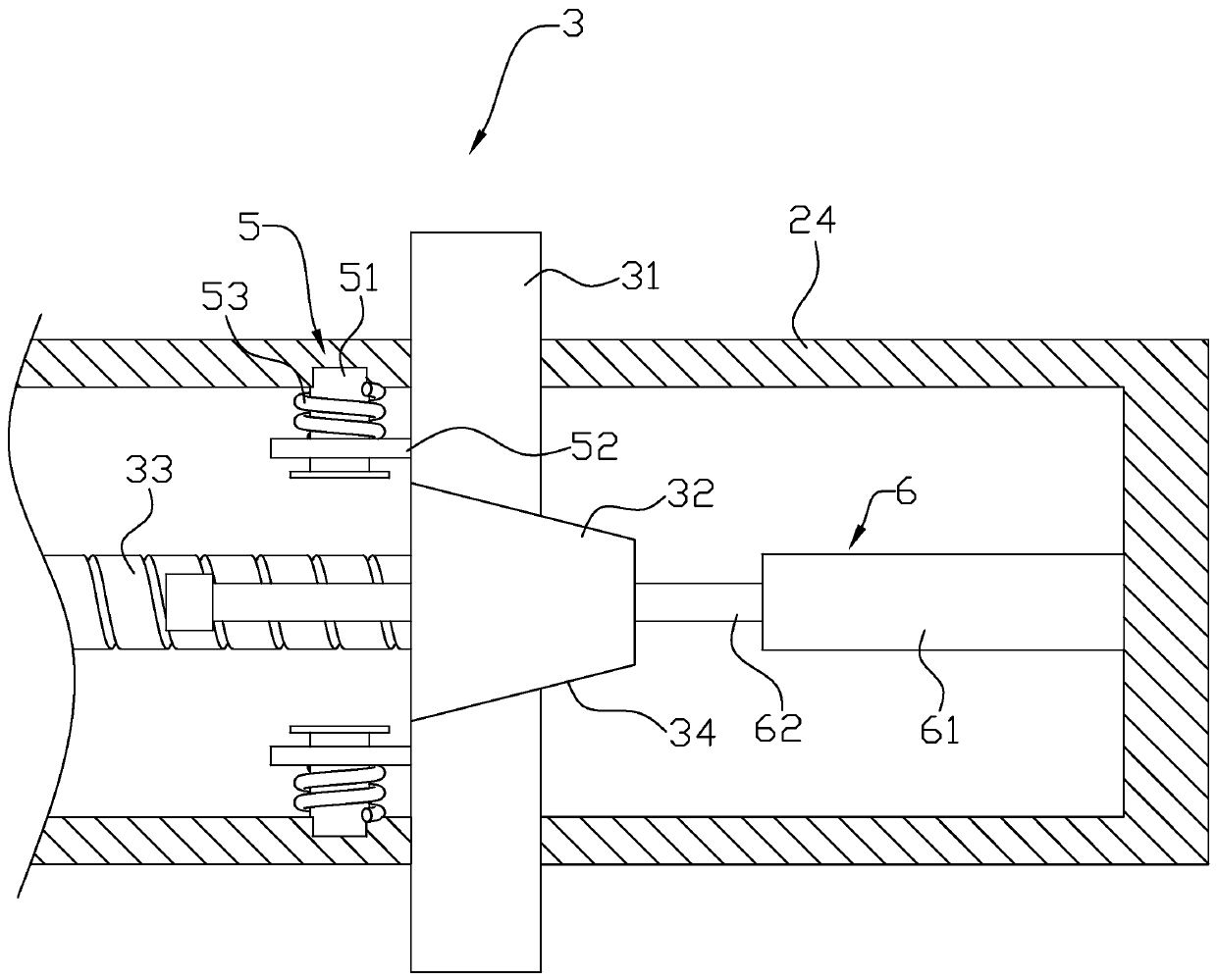

The invention refers to a lance holder with a protector for curved lances, in particular curved oxygen lances. Besides a clamping head 5 with a fixing member 6 and a clamping 7, the lance holder 1 used for an effuse 2, in particular for an oxygen lance is also provided with a prefixing member 15 responsible for fixing in advance the effuse 2 to be guided to the lance holder 1 such that when curved, the effuse 2 can not slide and in particular can not rotate in a center clamping member 31. In addition, the lance holder 1 has an output valve 53 and a non-return valve 11 of special types, and a column springs 10 or a non-return spring is arranged in a sealed member so as to avoid influence by gas. In addition, a necessary burn-back protective device 9 is taken out of a movement path of the effuse 2 to be inserted so as to be profitably arranged by protected areas.

Owner:BEDA OXYGENTECHNIK ARMATUREN GMBH

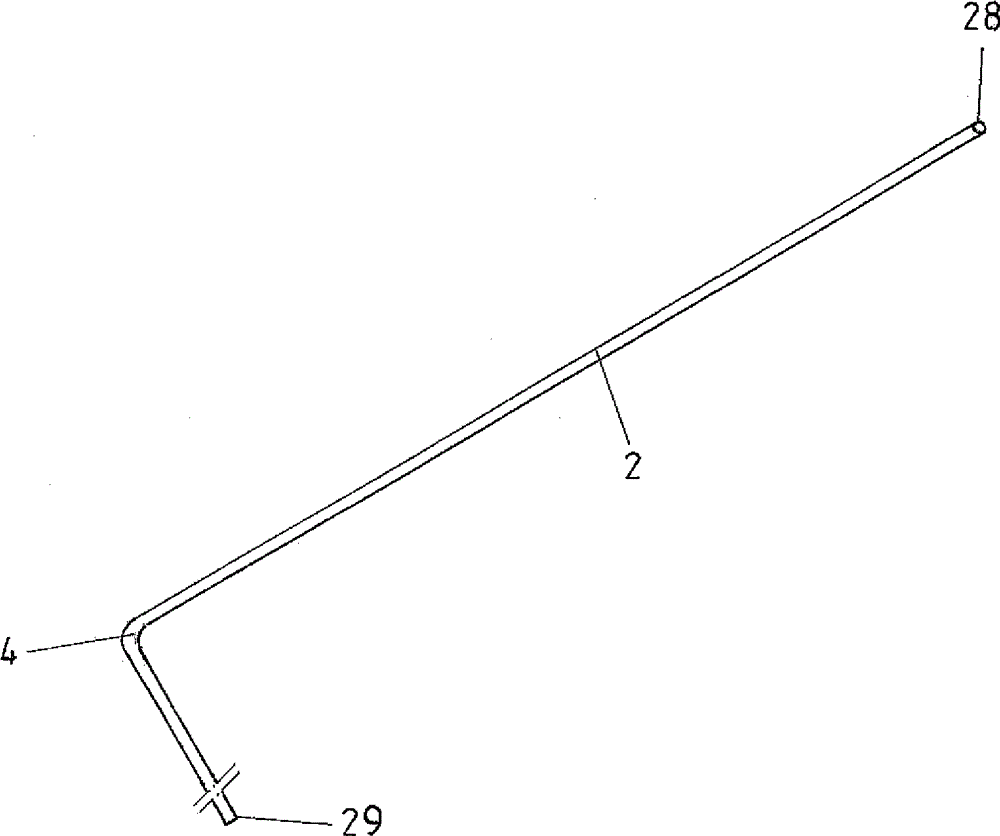

Method for replacing blades of aircraft engine

The invention relates to a method for replacing blades of an aircraft engine. The method comprises the following steps: cutting off the blades on a low-pressure turbine guider welding assembly; modifying the shape of the replacement blades according to the shape of the welding assembly; assembling the modified replacement blades into the cut low-pressure turbine guider welding assembly to performwelding and positioning; after the replacement blades are completely welded and fixed on the low-pressure turbine guider welding assembly, performing a turn-milling on the end face of the boss of thereplacement blades, and performing a location hole finish machining on the replaced blades; after the location hole finish machining is completed, polishing the parts of the replacement blades which are welded with the front piece and the tail piece of an upper edge plate and a flow deflector until the metal luster is exposed; welding the flow deflector, the front piece, and the tail piece to theupper edge plate of the replacement blades by using a point welding machine. According to the method for replacing blades of the aircraft engine, targeted replacement can be performed on the guide blades of an aero-engine, and the maintenance cost of the engine is reduced.

Owner:CHINA HANGFA GUIZHOU LIYANG AVIATION POWER CO LTD

Fabric rolling drum with reel provided with evenly distributed annular grooves

The invention discloses a fabric rolling drum with a reel provided with evenly distributed annular grooves. Fabric scraps can be conveniently prefixed to the reel through a sticking layer arranged on the reel; then the reel is driven to rotate through a rotary handle arranged at one end of the reel so as to make the fabric scraps be rolled to the reel provided with the annular grooves and be tightly squeezed with sawteeth on the side walls of a long groove, so that the contact area between the fabric scraps and the reel is increased, the fabric scraps are pressed effectively and tightly, and slipping is prevented; and finally the rotary handle is locked. The structure is convenient to operate; fabric rolling is stable and reliable; slipping is avoided; time and labor are saved.

Owner:WUXI XUEJIANG ENVIRONMENT ENG EQUIP

Fixing plate for orthopedic medical treatment

The invention discloses a fixing plate for orthopedic medical treatment. The fixing plate comprises a fixing plate body, wherein a moving mechanism is arranged at the bottom of an inner cavity of thefixing plate body, an extension plate is movably connected to the top of the moving mechanism, the top of the extension plate penetrates through the fixing plate body and is in bolted connection witha baffle, and the bottom of the baffle is movably connected with the top of the fixing plate body. Through cooperation of a lead screw, a rotary knob, a threaded sleeve, a limiting block and a containing groove, a user drives the lead screw to rotate through the rotary knob, so that the threaded sleeve drives the extension plate to move upwards, the length of the fixing plate body is increased, the user can conveniently, rapidly and perfectly support the injured part of a patient as required, and the situation that the user needs to replace the fixing plate body repeatedly to be matched with the injured part of the patient is avoided; and through cooperation of a second mounting block, a clamping block, a clamping groove, a first bolt and elastic bands, the user can conveniently fix the fixing plate body and the body of the patient in advance through the elastic bands.

Owner:广州富玛医药科技股份有限公司

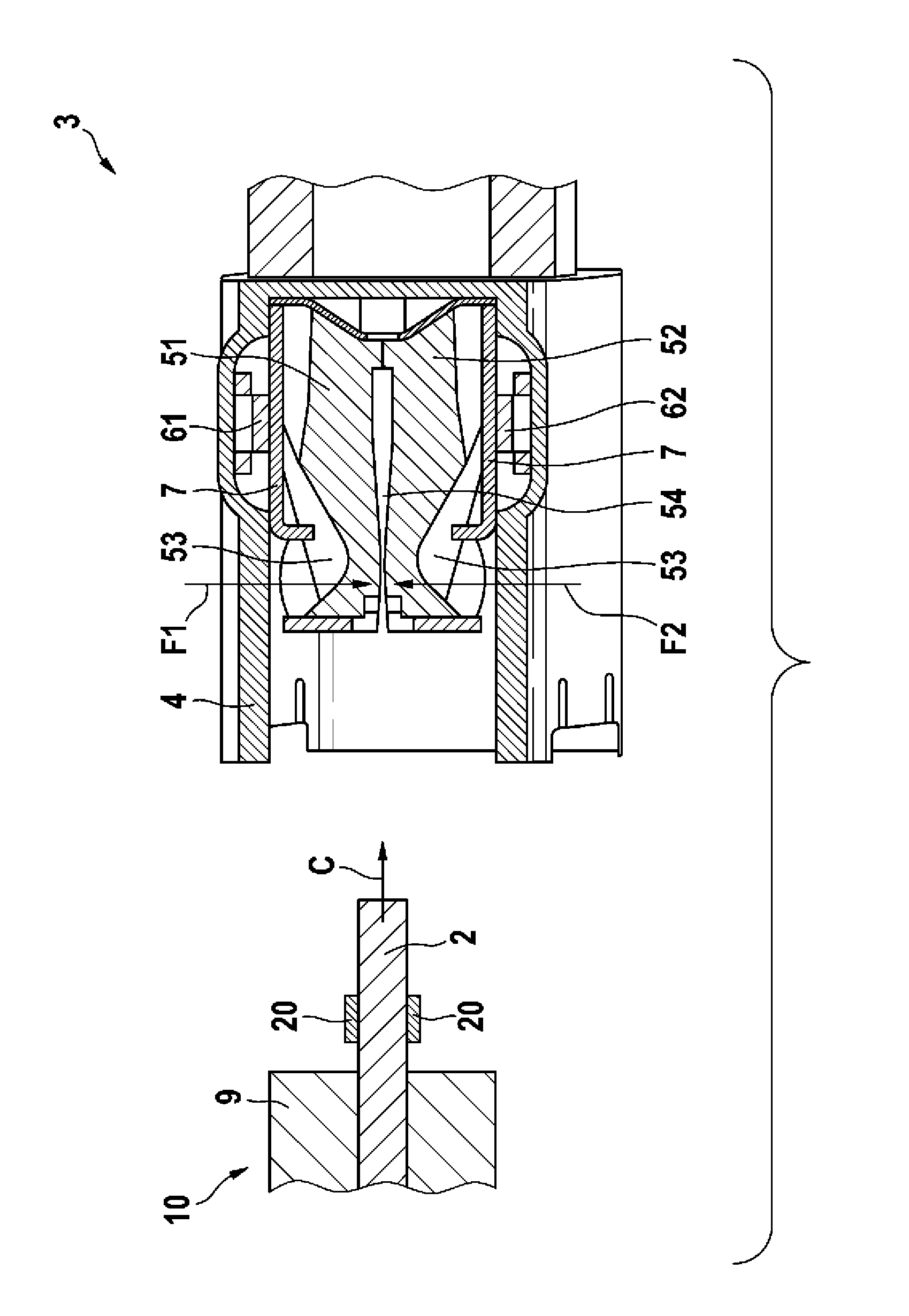

Direct plug element, in particular for vehicle control devices

ActiveCN103430385AEasy to pre-fixCoupling device detailsElectrical apparatus casings/cabinets/drawersMechanical engineeringVehicle control

Owner:ROBERT BOSCH GMBH

Improved method for prefixing and adhering parts

The invention relates to a method for prefixing and adhering two parts T1 and 12, having the steps of: a) providing a single-component moisture-curing adhesive K and an accelerator composition B whichcontains between 10 and 80 wt.% of water; b) producing an accelerated adhesive KB1 by mixing the adhesive K with a water-containing accelerator composition B in order to form the accelerated adhesiveKB1, said accelerated adhesive KB1 containing between 5 and 20 vol.% of the accelerator composition B, and subsequently applying the accelerated adhesive KB1 onto the first part T1; c) producing an optionally accelerated adhesive KB2 by optionally mixing the adhesive K with the water-containing accelerator composition B in order to form the optionally accelerated adhesive KB2, said optionally accelerated adhesive KB2 containing less than 5 vol.% of the accelerator composition B, and subsequently applying the optionally accelerated adhesive KB2 onto the first part T1; wherein the steps b) andc) can be carried out in any order, and the amount of the accelerated adhesive KB1 applied onto the first part T1 is less than the amount of the optionally accelerated adhesive KB2 applied onto the first part T1; and d) joining the second part T2 with the adhesive point such that a composite joint T12 is produced which connects the two parts T1 and T2 via the accelerated adhesive KB1 and the optionally accelerated adhesive KB2. The method according to the invention allows parts which are to be adhered to be prefixed and adhered using a single adhesive without requiring an additional prefixingprocess and without adversely affecting the resulting adhesion due to a cured mechanically inhomogeneous adhesive. Thus, a faster and better adhesion process is facilitated which can additionally be carried out with less effort.

Owner:SIKA TECH AG

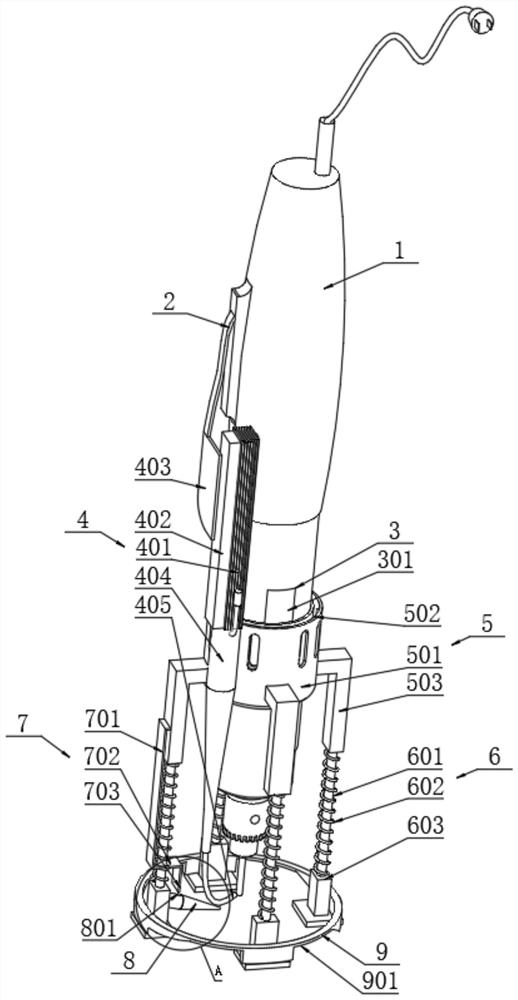

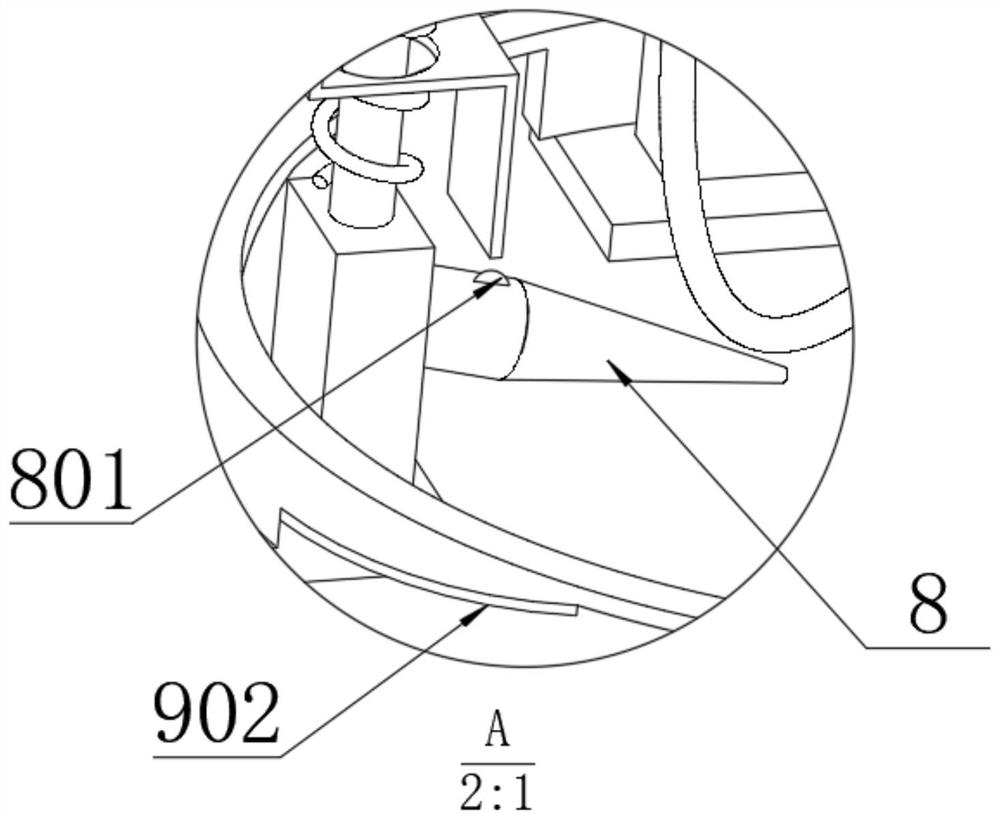

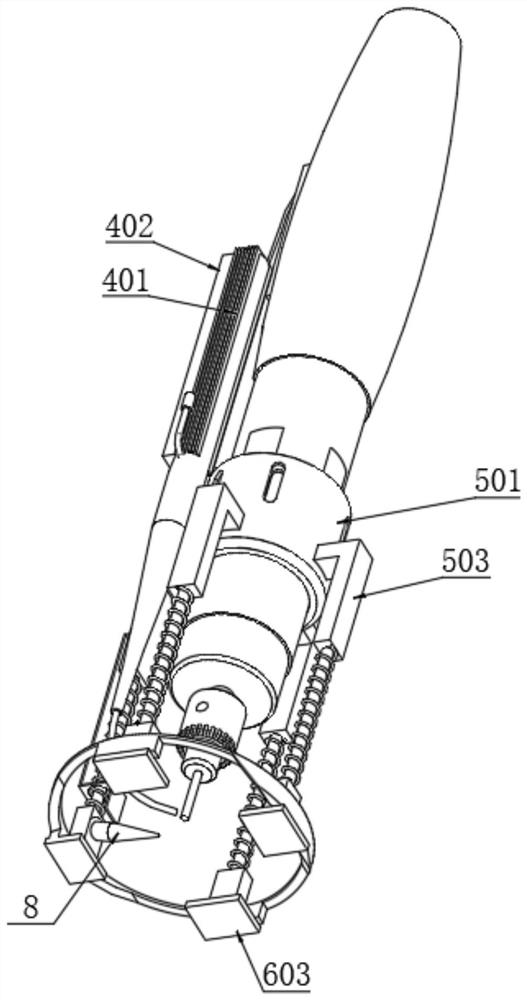

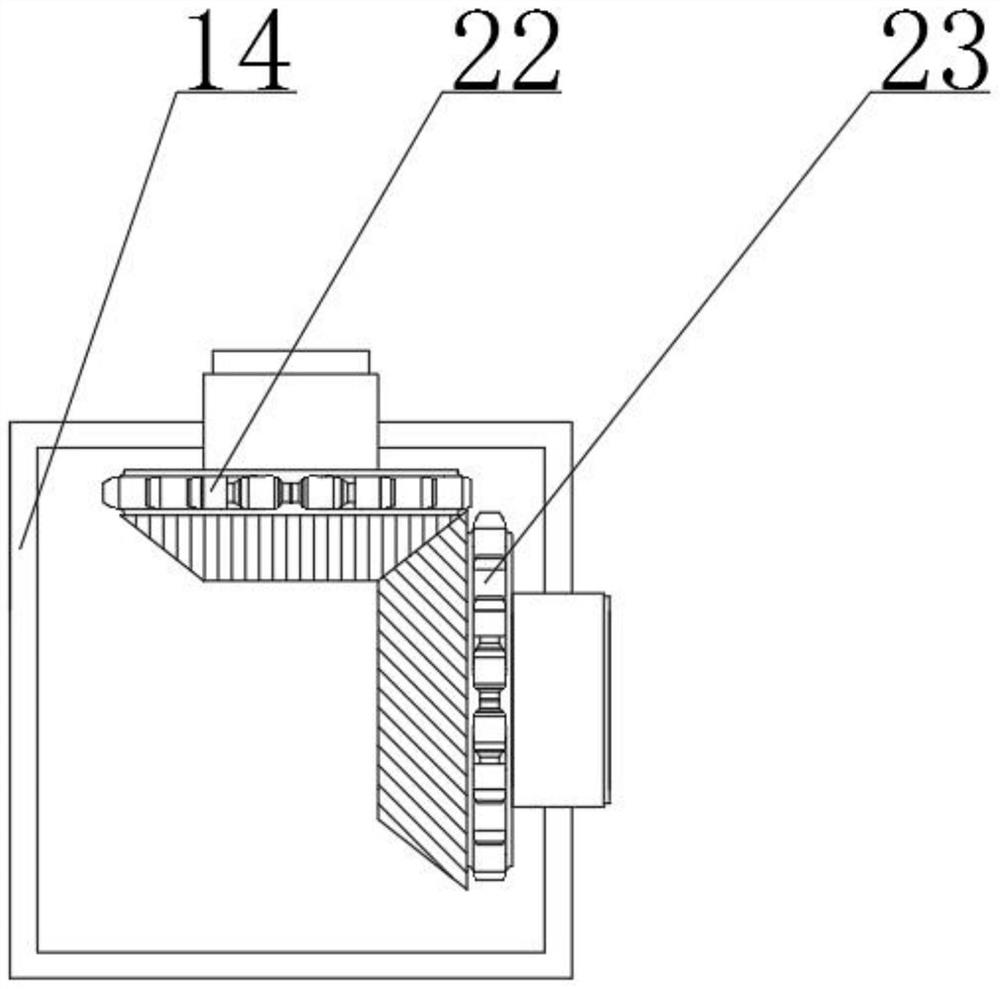

Pressure sensor inner core bushing press-fit tool with positioning mechanism and use method

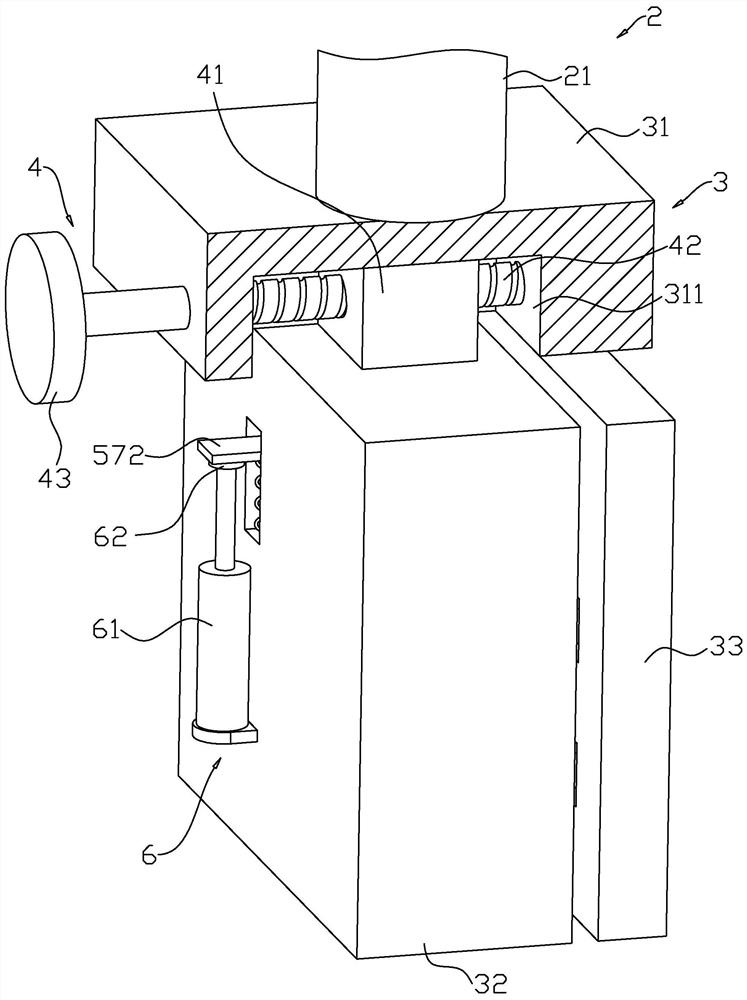

The invention discloses a pressure sensor inner core lining press-fit tool with a positioning mechanism and a using method, the pressure sensor inner core lining press-fit tool comprises a stand column and a base, transmission boxes are symmetrically arranged on the two sides of the interior of the base, driven bevel gears are arranged on the upper portions of the interiors of the two transmission boxes, and the driven bevel gears are arranged on the upper portions of the interiors of the two transmission boxes; the two driven bevel gears are rotationally connected with the transmission box, stand columns are arranged on the upper portion of the base, lead screws are arranged in the two stand columns, the two lead screws are connected with the driven bevel gears, and sliding rods are symmetrically arranged on the portions, on one sides of the two lead screws, of the base. The device is provided with an air guide pipe, a fixing rod, bubbles and a connector, an inner core lining is conveniently pre-fixed by the device, the problems that the inner core lining deviates during installation, consequently, press fitting is not in place, and a defective product is formed through press fitting are solved, in addition, an electric cylinder, a transmission plate, a connecting rod and a top plate are used in cooperation, discharging of the device is facilitated, and the working efficiency is improved. And the working efficiency of the device is improved.

Owner:安徽勒森传感科技有限公司

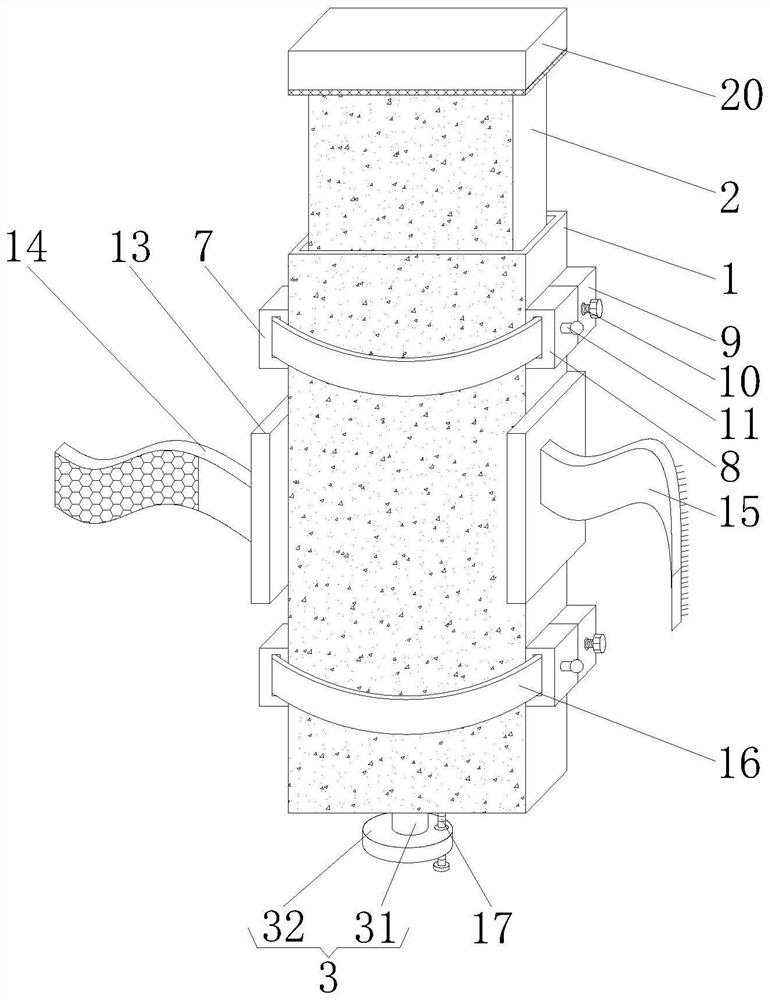

Rubber bushing device for automatic automobile shock absorber production

The invention discloses a rubber bushing device for automatic automobile shock absorber production. The rubber bushing device comprises a base, a workbench is connected to the top of the base in a bolted mode, a first air cylinder and a fixing seat are connected to the left side of the top of the workbench in sequence from left to right in a bolted mode, and a containing groove is formed in the top of the fixing seat. Through the cooperation of a moungting seat and an arc-shaped groove, a user can conveniently pre-fix the top of a shock absorber, the stability of the shock absorber is improved, through cooperation of a motor, a first positive and negative threaded rod, a driving wheel, a second positive and negative threaded rod, a driven wheel, clamping plates, movable rods, limiting plates and clamping grooves, the user can conveniently drive the clamping plates to move inwards at the same time through the motor, so that the top and the bottom of the shock absorber can be quickly limited by the clamping grooves, meanwhile, the clamping plates move towards the inner side at the same time, so that the movable rods can drive the limiting plates to move towards each other quickly, and therefore the user can limit the two sides of the shock absorber quickly and conveniently.

Owner:东莞市正通机电设备设计有限公司

A method for replacing aircraft engine blades

The invention relates to a method for replacing blades of an aircraft engine. The method comprises the following steps: cutting off the blades on a low-pressure turbine guider welding assembly; modifying the shape of the replacement blades according to the shape of the welding assembly; assembling the modified replacement blades into the cut low-pressure turbine guider welding assembly to performwelding and positioning; after the replacement blades are completely welded and fixed on the low-pressure turbine guider welding assembly, performing a turn-milling on the end face of the boss of thereplacement blades, and performing a location hole finish machining on the replaced blades; after the location hole finish machining is completed, polishing the parts of the replacement blades which are welded with the front piece and the tail piece of an upper edge plate and a flow deflector until the metal luster is exposed; welding the flow deflector, the front piece, and the tail piece to theupper edge plate of the replacement blades by using a point welding machine. According to the method for replacing blades of the aircraft engine, targeted replacement can be performed on the guide blades of an aero-engine, and the maintenance cost of the engine is reduced.

Owner:CHINA HANGFA GUIZHOU LIYANG AVIATION POWER CO LTD

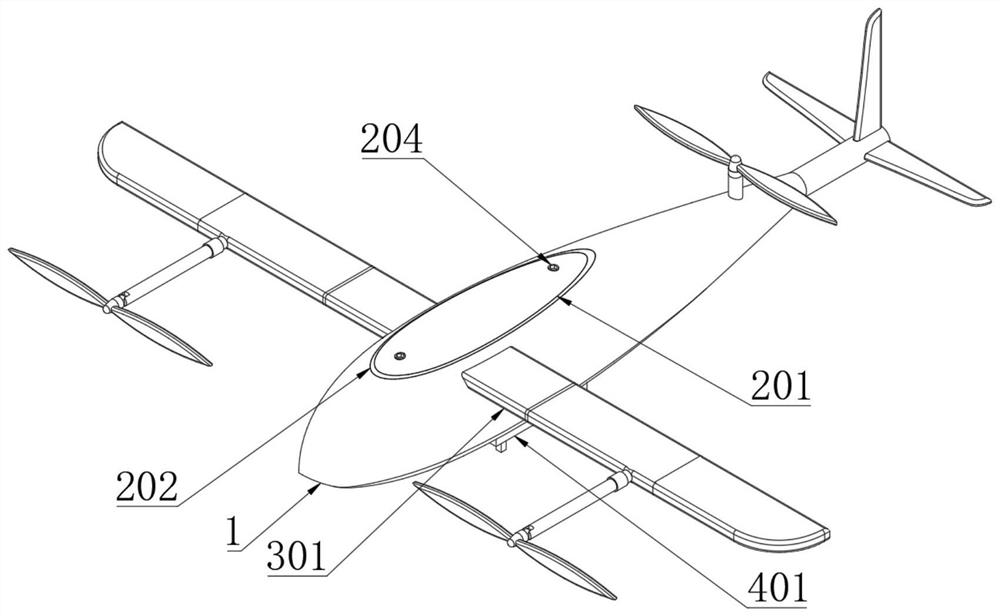

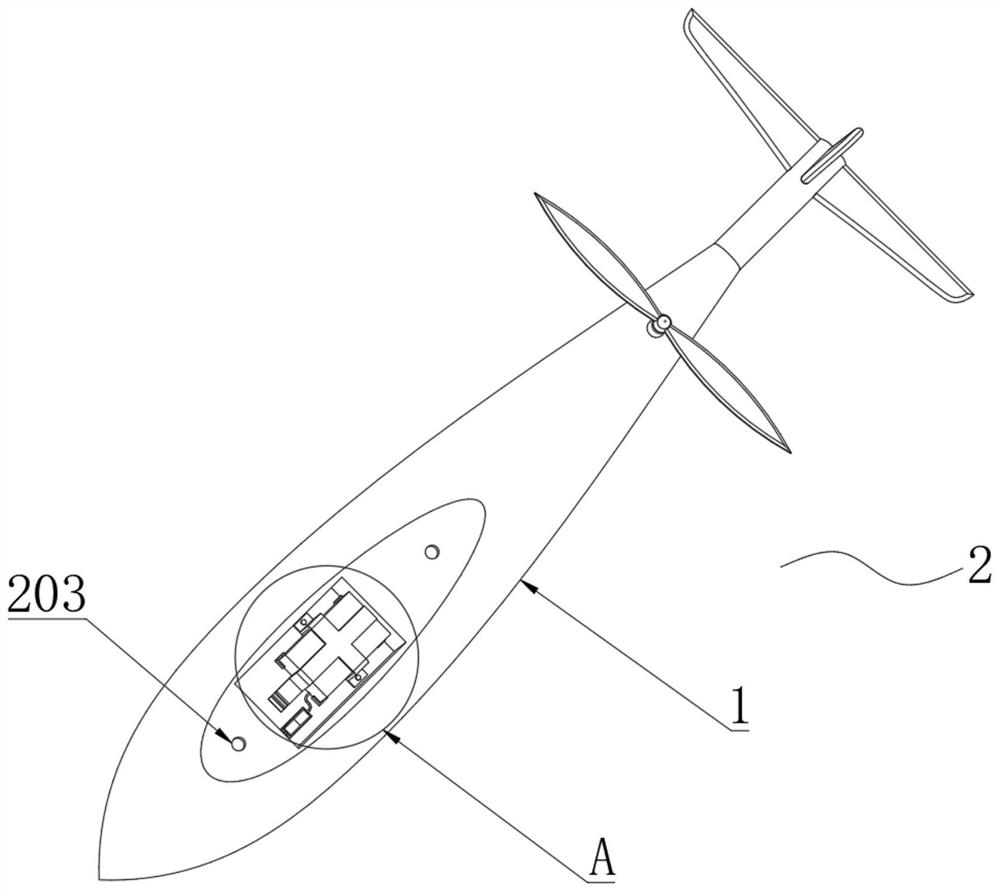

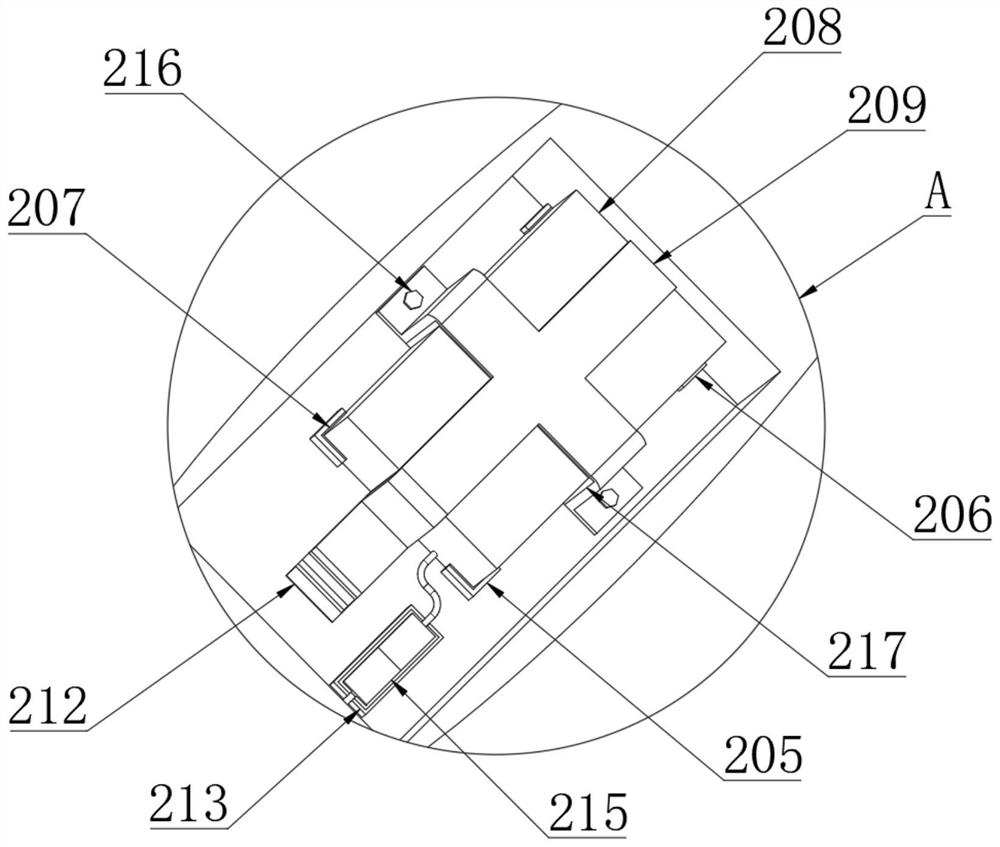

Tilting composite wing unmanned aerial vehicle with battery convenient to replace

ActiveCN112224399AEasy to disassembleEasy to installCell component detailsAlighting gearElectrical batteryUncrewed vehicle

The invention discloses a tilting composite wing unmanned aerial vehicle with battery convenient to replace. The tilting composite wing unmanned aerial vehicle comprises a vehicle body, a mounting mechanism is mounted in the vehicle body, and the mounting mechanism comprises a sealing cover, a sealing ring, a threaded groove, an inner hexagon bolt, an L-shaped plate, a limiting plate, a rubber pad, a storage battery, a cross-shaped frame, a groove, a limiting groove, a positioning block, a fixing frame, a limiting block, a buckle and a fixing bolt; and the sealing cover is installed in the middle of the top of the body. By means of the mounting mechanism, a worker can conveniently dismount and mount the sealing cover, so that the worker can conveniently replace a storage battery in the later period; meanwhile, the worker can conveniently pre-fix the position of the storage battery; therefore, position deviation of the storage battery in the fixing process of the storage battery by workers is avoided, the difficulty of replacing and installing the storage battery by the workers is reduced, and the workers can conveniently limit the position of the buckle of the storage battery and the buckle of the unmanned aerial vehicle after the buckle is buckled.

Owner:北京卫通新科测控技术有限公司

A metal curtain wall structure

The invention discloses a metal curtain wall structure, which relates to the technical field of curtain walls. The key point of the technical solution is to include a fixing plate and a plurality of metal curtain wall panels, a fixing device is installed on the fixing plate, and the fixing device includes a vertical plate and a plurality of rows of slots; each The row of slots includes two slots, both slots are plugged with inserts, and the inserts are fixed to the metal curtain wall panels; two sets of first fixing mechanisms are installed in the vertical plates; each set of first fixing mechanisms includes a second A chute, lead screw and slider; one end of the lead screw is fixedly connected with a spline, the spline is slidably connected with a connecting rod, one end of the connecting rod is provided with a relief groove, and a keyway is provided in the relief groove; One side of the block is provided with a threaded hole, and one end of the connecting rod is threadedly connected to the threaded hole; a pushing component is installed on the slider; a driving mechanism is installed in the vertical plate. The invention facilitates the installation of the metal curtain wall panels by setting the fixing device.

Owner:武汉凌翔建筑装饰工程有限公司

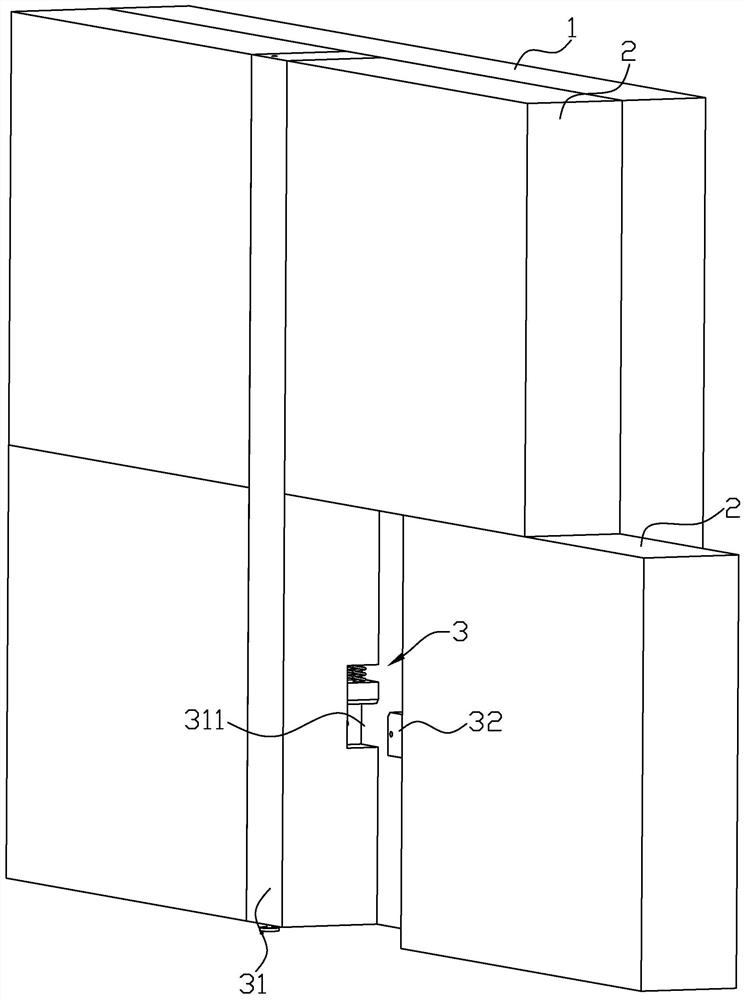

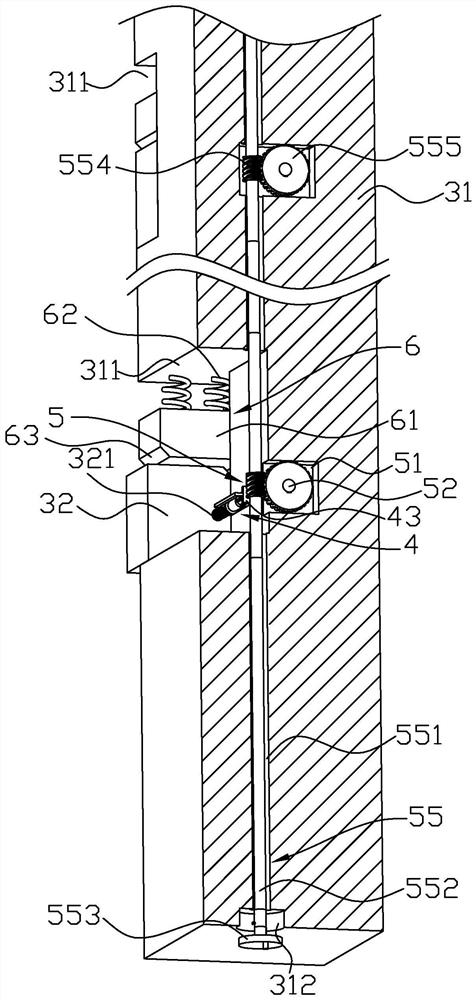

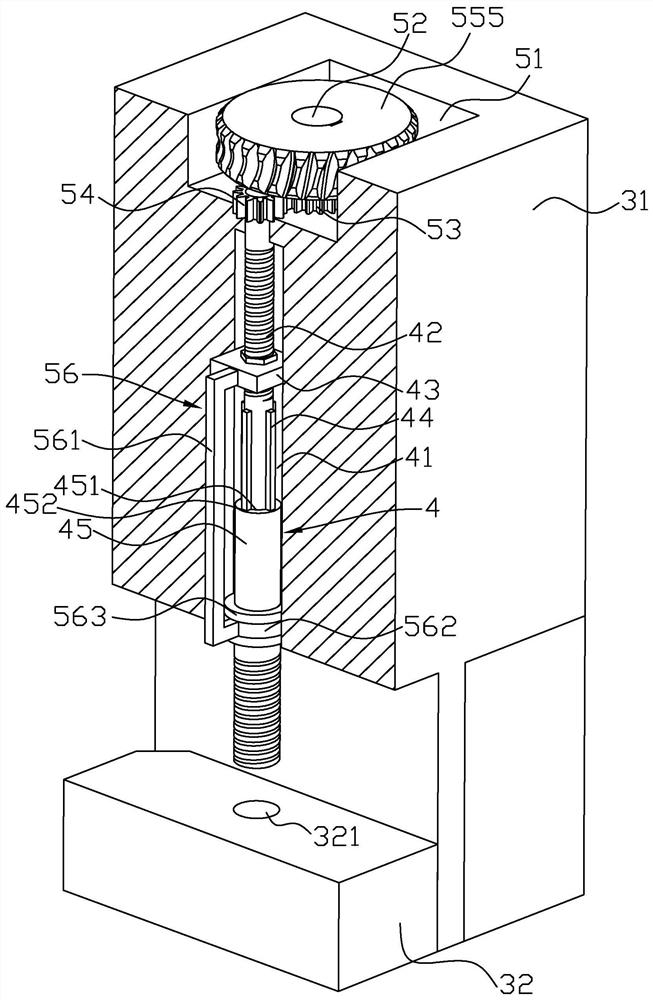

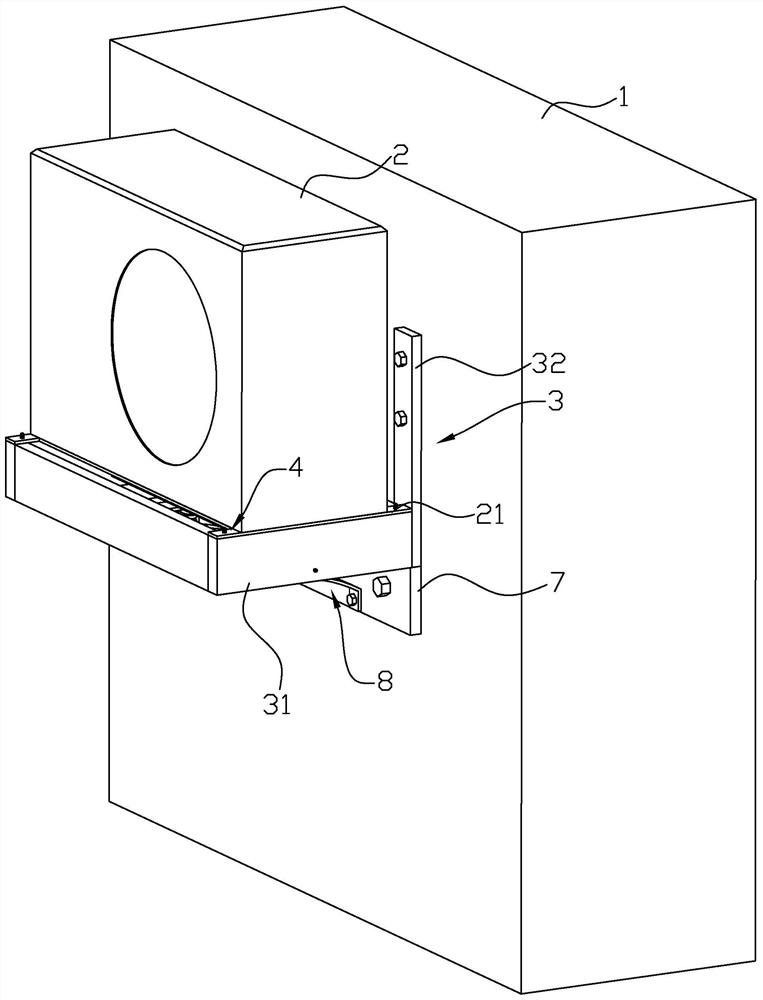

Air conditioner installation structure and installation method

ActiveCN111059646BImprove shock absorptionReduces the possibility of looseningLighting and heating apparatusAir conditioning systemsEngineeringMachine

The invention relates to an installation structure and installation method of an air conditioner, which includes a mounting frame, the mounting frame includes a frame and two vertical rods; Both ends are provided with a plurality of second through holes, and the first through holes and the second through holes are set in one-to-one correspondence; each second through hole is equipped with a shock absorber, and the shock absorber includes a first lead screw, a first The slider, the first connecting rod vertically fixed on the top of the first slider and the first spring sleeved on the first connecting rod; the top of the first connecting rod is set through the first through hole and is threaded with a nut; the second A sinking groove is opened on the top of the through hole, the top of the first spring abuts against the bottom of the base, and the bottom of the first spring abuts against the bottom of the sinking groove; the bottom of the frame is equipped with a drive for driving a plurality of first lead screws to rotate. device. The present invention can reduce the possibility of loosening of the mounting frame by providing the shock absorbing device.

Owner:武汉问鼎机电工程有限公司

Especially direct plug-in elements for vehicle controllers

InactiveCN103430385BEasy to pre-fixCoupling device detailsElectrical apparatus casings/cabinets/drawersMechanical engineering

Owner:ROBERT BOSCH GMBH

Cooling forming device for wet tissue tube production

Owner:铜陵鸿亿新材料科技有限公司 +1

River point welding auxiliary device

InactiveCN111468870AEasy to repair weldingUse environmental protection and scienceWelding/cutting auxillary devicesAuxillary welding devicesAgricultural engineeringStructural engineering

The invention discloses a river point welding auxiliary device which comprises a base with the transverse cross section shaped like a Chinese character 'ao'. A transversely-arranged limiting groove isformed in the base. A first spring is fixedly connected to one side wall of the limiting groove. A movable sleeve is fixedly connected to one end of the first spring. A positioning pin is inserted into the movable sleeve. A Y-shaped block is fixedly connected to one side of the positioning pin. A driving device is arranged on the Y-shaped block. Due to the mutual effect of a corrugated pipe, a point welding pipe and other structures, when a column just makes contact with a beam, preliminary welding is achieved, workers can achieve follow-up repair welding, the device relies on river as motivepower, and use is more environmentally friendly and scientific.

Owner:周兵

Sealing device for carton packaging

PendingCN114872996AImprove work efficiencyPrevent rotationPackage recyclingWrapper twisting/gatheringAdhesive beltCarton

The invention provides a sealing device for carton packaging, and relates to the technical field of carton packaging, the sealing device comprises a device base, a plurality of conveying roller ways are arranged at the two ends of the device base, a plurality of conveying belts are arranged between the conveying roller ways at the two ends, and a telescopic fixing rod is arranged at the end, close to the conveying belts, of the device base; a movable sliding column is arranged at the end, away from the conveying belts, of the telescopic fixing rod, a sealing mechanism is arranged between the upper end of the movable sliding column and the two conveying belts, a rotating mechanism is arranged on the surface of one end of the sealing mechanism, and an adhesive tape placing platform is arranged at one end of the rotating mechanism. And when idle time occurs, the adhesive tape is replaced on the adhesive tape placing platform of which the adhesive tape is used up, so that the working efficiency during carton packaging and sealing is improved.

Owner:重庆市国盛包装有限责任公司

Left side plate

PendingCN111570622AStable structureEasy to assembleShaping toolsStructural engineeringMechanical engineering

The invention discloses a left side plate which comprises a lower support plate and a top rod; a lower cushion block is fixed to the upper end of the lower support plate; a lower die holder is fixed to the side, far away from the lower support plate, of the lower cushion block; a lower backing plate is fixed to the side, far away from the lower cushion block, of the lower die holder; a stop baffleis arranged on the top of the lower backing plate; an upper clamping plate is fixed above the stop baffle; an upper die holder is fixed to the side, far away from the stop baffle, of the upper clamping plate; an upper cushion block is fixed to the top of the upper die holder; and an upper support plate is mounted on the side, far away from the upper die holder, of the upper cushion block. The left side plate is provided with the lower support plate and the upper support plate; the lower support plate, the lower cushion block, the lower die holder, the lower backing plate, the stop baffle, theupper clamping plate, the upper die holder, the upper cushin block and the upper support plate are fixedly connected through a first bolt groove, a second bolt groove, a third bolt groove and a fourth bolt groove to form the left side plate, so that the left side plate is steadier in structure and can be assembled and rapidly changed.

Owner:青岛创王智能科技有限公司

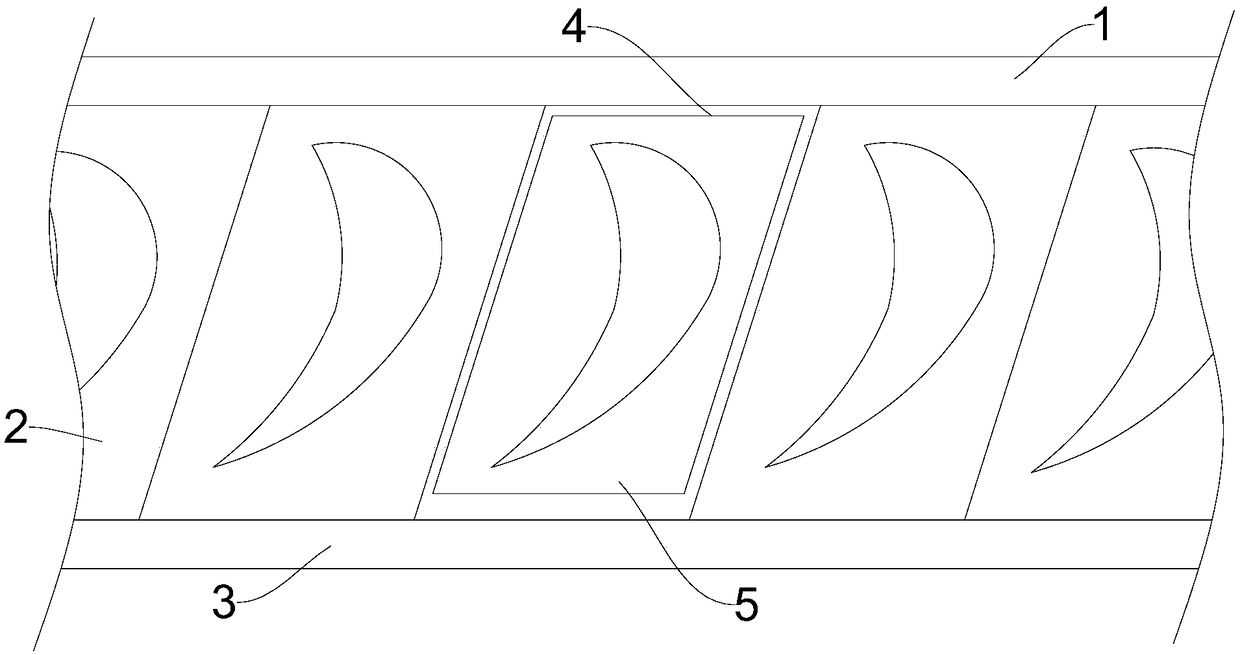

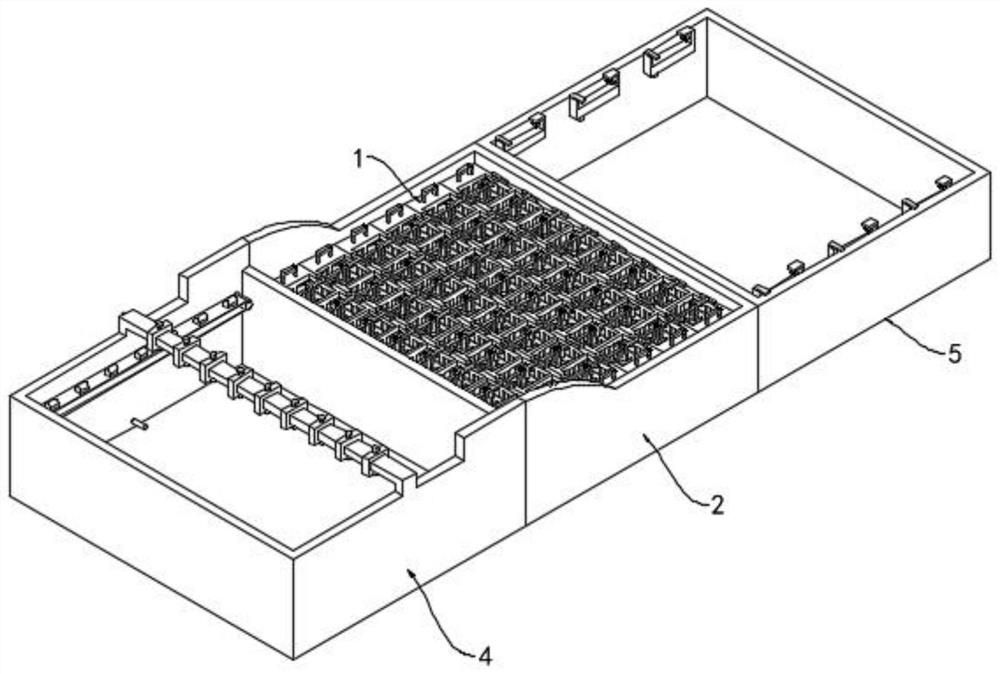

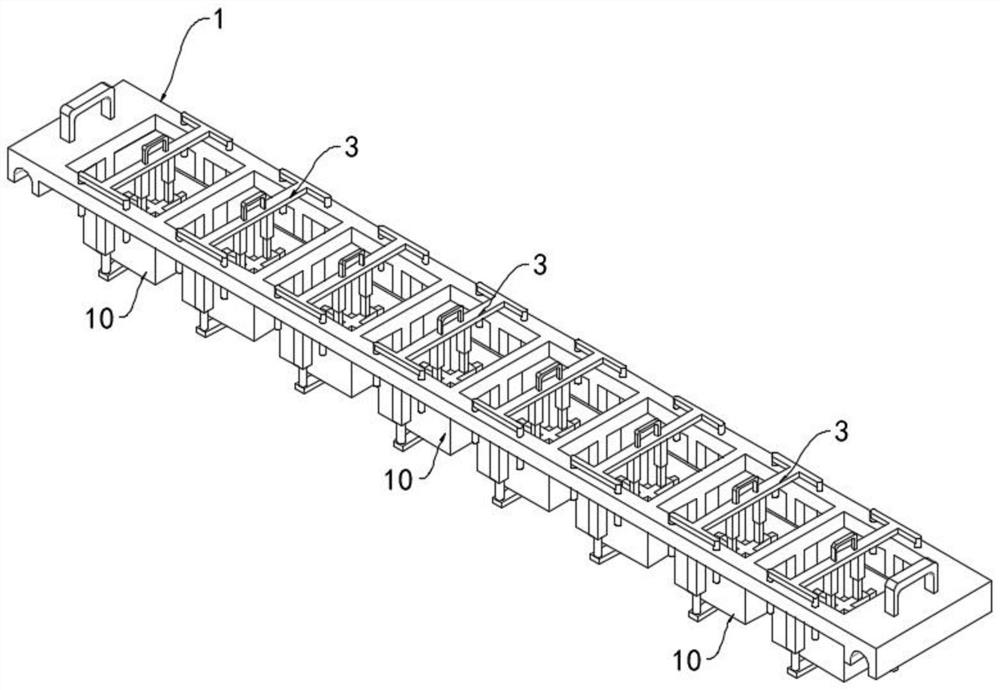

A rapid assembly process of surface-mounted magnetic steel for permanent magnet motors

ActiveCN113612359BEasy to pre-fixPrevent the glue from falling offManufacturing stator/rotor bodiesElectric machineAdhesive

The invention discloses a rapid assembly process for surface-mounted magnetic steel of a permanent magnet motor, including a heating process, a set process, a measurement process, a dust removal and cooling process, and a surface-mounted process. The method can not only solve the problem of adhesive failure and magnetic steel falling off; but also avoid bolt installation, reduce rotor eddy current loss, and improve motor performance; use mixed structural adhesive for bonding, improve the magnetic steel assembly efficiency of permanent magnet motor, and improve the performance of the motor. Product performance permanent magnet motor magnet assembly process.

Owner:SHANDONG OURUIAN ELECTRIC

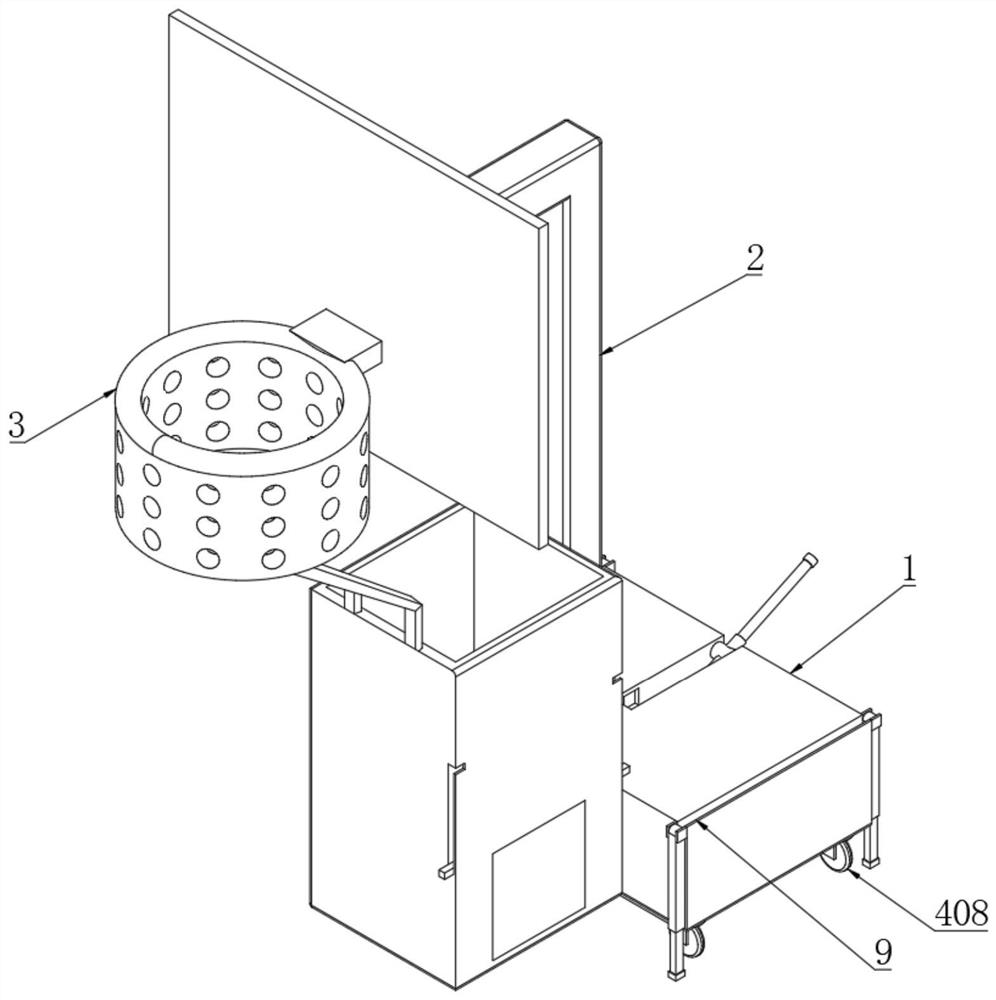

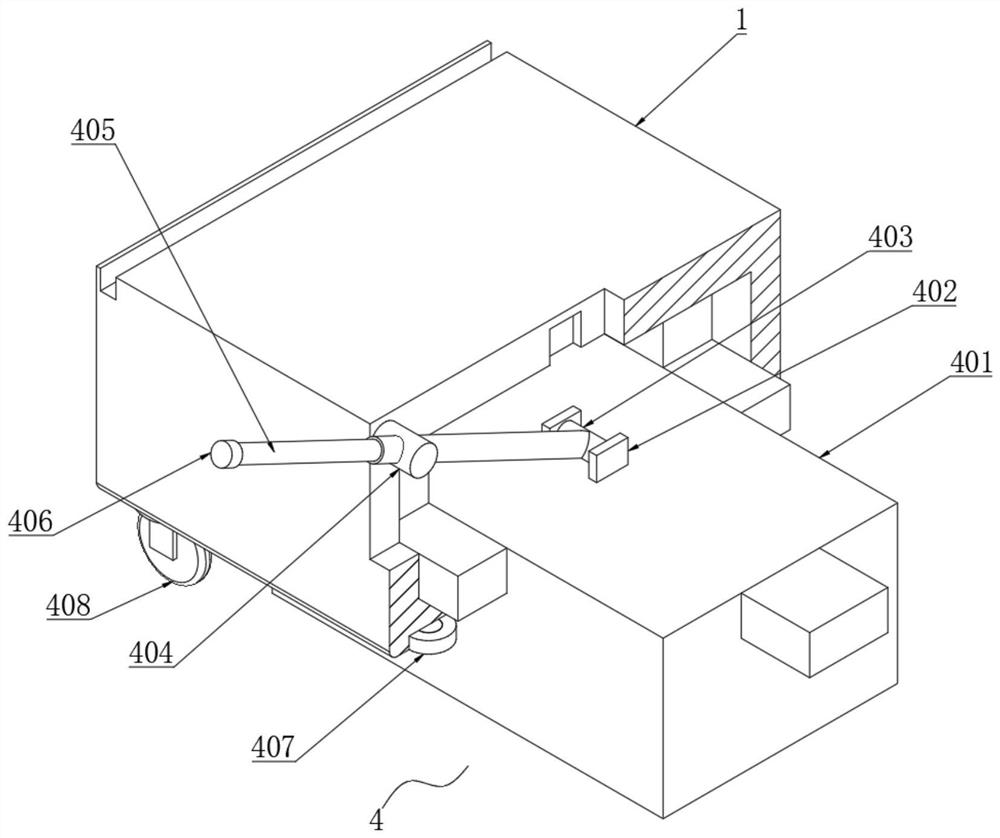

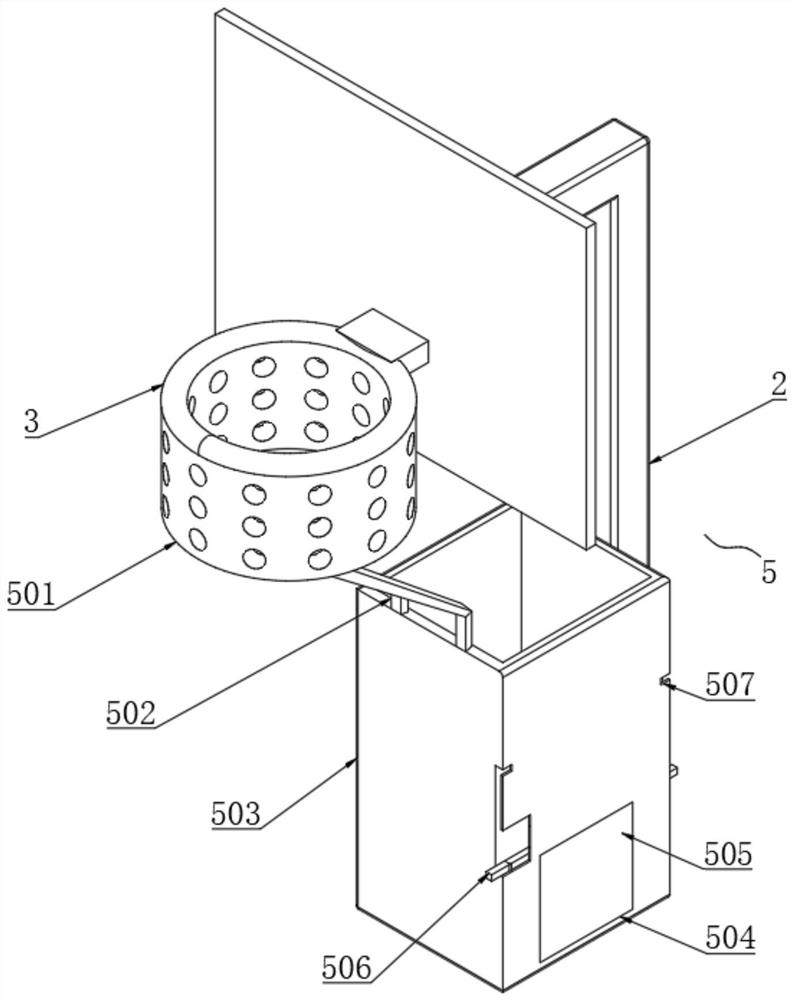

Throwing equipment for basketball training

The invention discloses a throwing equipment for basketball training, which comprises a fixed seat, a fixed rod is installed on the top edge of the fixed seat, a fixed frame is installed on the bottom of one side of the fixed rod, and a positioning stable frame is installed on the inner side of the fixed seat. mechanism, the positioning stabilization mechanism includes a counterweight, a fixed plate, a rotating rod, a rotating shaft, a connecting rod, a bump, a support plate and a universal wheel, and the inner side of the fixed seat is slidably connected with a counterweight. The mechanism is convenient for athletes to fix the position of the counterweight, so that it is convenient for the athlete to move the position of the fixed seat, and it is also convenient for the athlete to fix the position of the fixed seat after moving. At the same time, it can reduce the position of the center of gravity of the fixed seat after moving. Thereby, the stability of placing the fixed seat is improved, and the phenomenon of position shifting or tilting of the fixed seat during use is avoided, thereby improving the work efficiency of athletes moving the fixed seat.

Owner:盐城盐龙文化体育产业投资有限公司

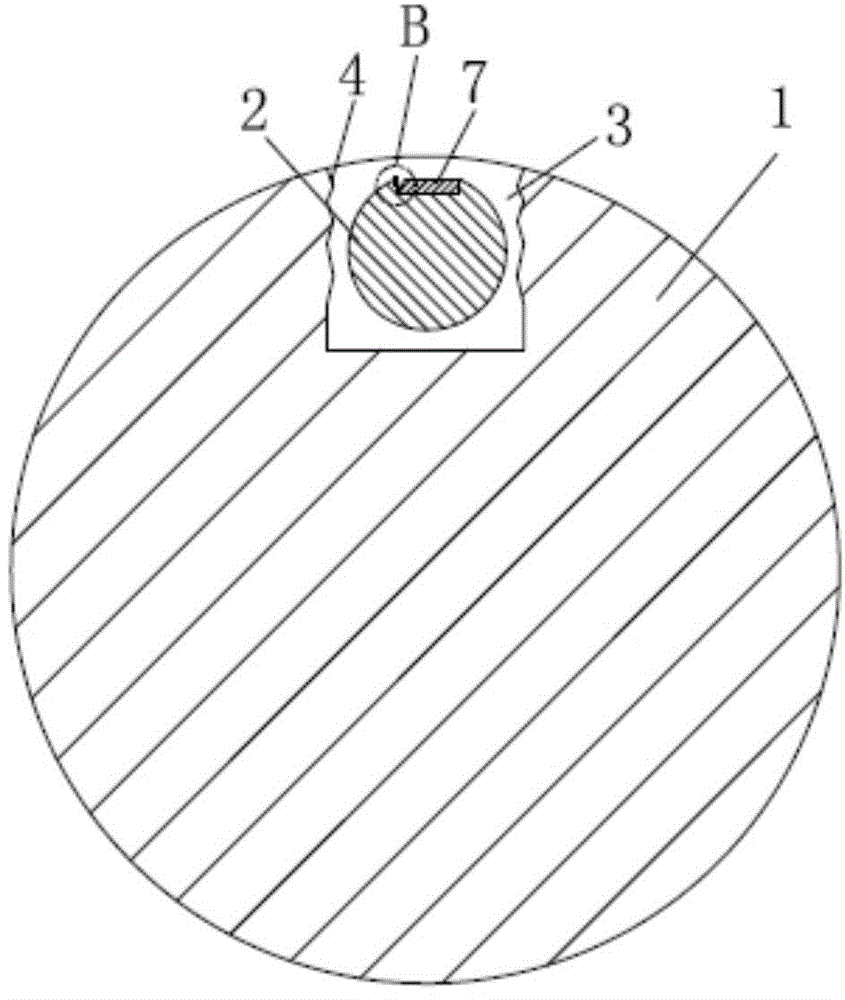

Stable tube pillow of electric force tube

ActiveCN109921369AReduce the burden onImprove reinforcementCable installations in underground tubesEngineeringElectric power

The present invention discloses a stable tube pillow of an electric force tube. The tube pillow comprises an upper pillow part and a lower pillow part, the upper pillow part and the lower pillow partare both provided with semicircular grooves, the upper pillow part is provided with an insertion body for pre-fixing, the lower pillow part is provided with an insertion groove paired with the insertion body, the insertion body comprises an insertion strip, a magnet block and a threaded rod, the insertion strip and the threaded rod are integrally arranged, the magnet block is located at one side of the insertion strip, the magnet block is fixedly connected with the insertion strip, the upper pillow part is provided with a screw hole paired with the threaded rod, the upper pillow part and the insertion strip are detachably connected through the threaded rod and the screw hole, the upper pillow part and the lower pillow part are respectively provided with a first receiving groove and a second receiving groove, and the two sides of the upper pillow part are both provided with metal connection parts paired with the first receiving groove and the second receiving groove. The stable tube pillow of the electric force tube is good in connection stability.

Owner:GUANGXI POWER GRID CO LTD NANNING POWER SUPPLY BUREAU

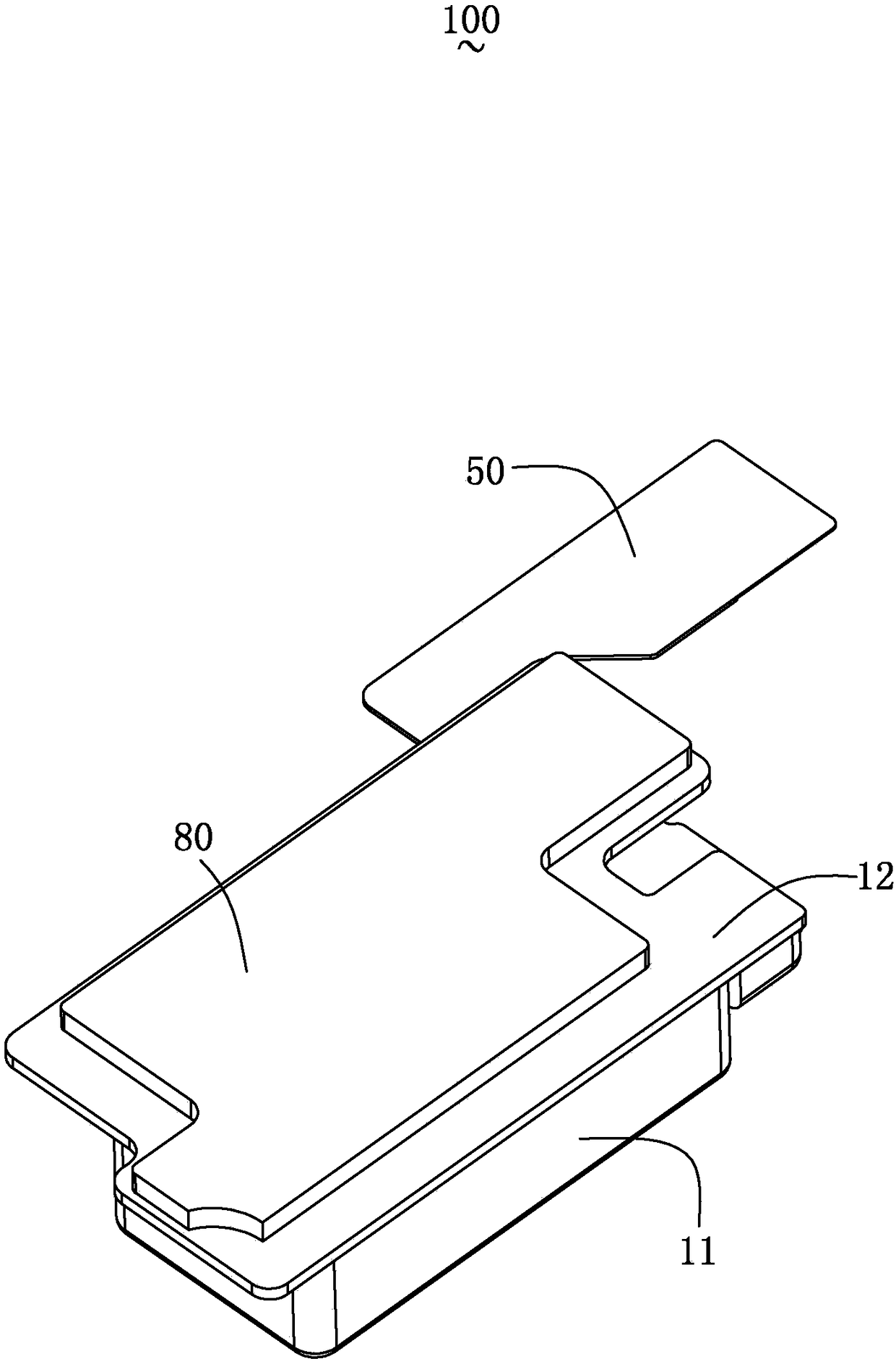

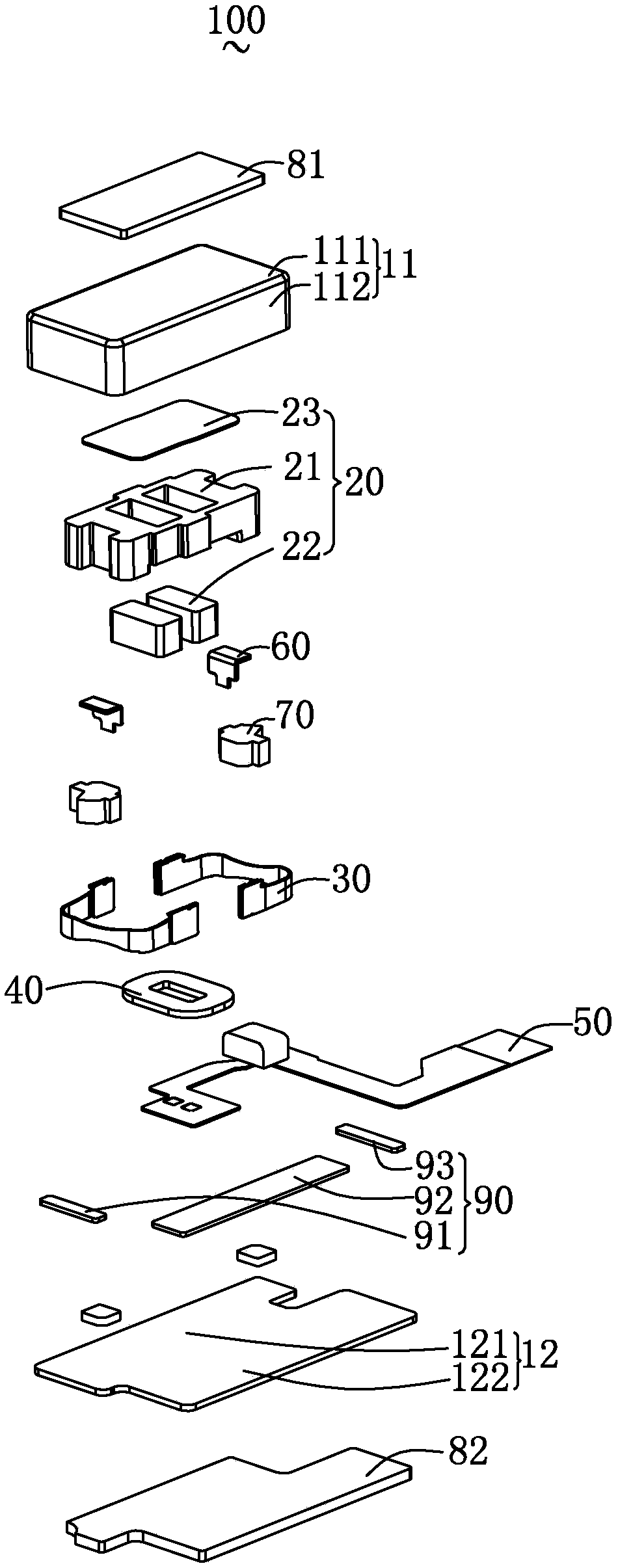

Linear vibration motor and mounting method thereof

InactiveCN109038914AImprove the fixed effectGood fixing performanceReciprocating/oscillating/vibrating magnetic circuit partsSupports/enclosures/casingsLinear vibrationAdhesive

A linear vibration motor which includes a housing having an accommodation space, a vibration unit accommodated in the accommodation space, an elastic member which suspends the vibration unit in the accommodation space and a driving unit which drives the vibration of the vibration unit, the housing comprises a casing and a cover plate arranged on the casing to enclose the accommodation space, the housing includes a bottom wall disposed opposite to the cover plate and a side wall surrounding the bottom wall, the cover plate includes a main body portion opposed to the bottom wall and an extensionportion extending from the edge of the main body portion to the outside of the casing, The linear vibration motor further comprises a first foam fixed on a side of the bottom wall remote from the accommodation space, a second foam fixed on a side of the cover plate remote from the accommodation space, and a double-sided adhesive fixed on a side of the extension portion close to the bottom wall. The linear vibration motor comprises a first foam fixed on a side of the bottom wall remote from the accommodation space, a second foam fixed on a side of the cover plate remote from the accommodationspace, and a double-sided adhesive fixed on a side of the extension portion close to the bottom wall. Compared with the related art, the linear vibration motor provided by the invention has better fixing effect.

Owner:AAC TECH PTE LTD

A tilting compound wing unmanned aerial vehicle with convenient battery replacement

ActiveCN112224399BEasy to disassembleEasy to installCell component detailsAlighting gearElectrical batteryUncrewed vehicle

The invention discloses a tilting compound-wing unmanned aerial vehicle which is convenient for battery replacement. It includes a fuselage, and a mounting mechanism is installed inside the fuselage. The mounting mechanism includes a sealing cover, a sealing ring, a thread groove, an inner hexagonal bolt, L-shaped plate, limit plate, rubber pad, battery, cross frame, groove, limit groove, positioning block, fixed frame, limit block, buckle and fixing bolt, and a sealing cover is installed in the middle part of the top of the fuselage, The invention facilitates the staff to dismantle and install the sealing cover through the installation mechanism, thereby facilitating the staff to replace the battery in the later stage, and at the same time, it is also convenient for the staff to pre-fix the position of the battery, thereby avoiding the process of staff fixing the battery The position of the middle battery is shifted, which reduces the difficulty for the staff to replace and install the battery, and facilitates the staff to limit the position of the buckle of the battery and the buckle of the drone.

Owner:北京卫通新科测控技术有限公司

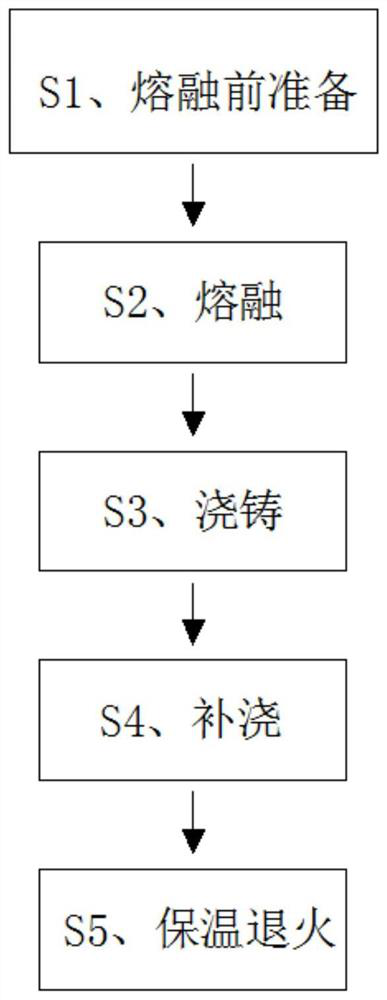

Zirconium corundum mullite brick for hazardous waste rotary kiln and preparation method

PendingCN114413619ALarge temperature differenceReduce widthRotary drum furnacesFurnace coolingBrickMullite

The invention relates to the technical field of fused alumina zirconia mullite bricks, and discloses a fused alumina zirconia mullite brick for a hazardous waste rotary kiln and a preparation method thereof.The preparation method comprises the steps that aluminum oxide, alkali powder, zircon sand and other raw materials are added into an electric furnace, the raw materials are subjected to high-temperature oxidation melting, oxygen is blown into melt, then the melt is directly poured into a casting mold from the electric furnace, and after casting of a casting is completed, the fused alumina zirconia mullite brick is obtained; after cold contraction for a period of time, the melt is fully cast in a shrinkage cavity, and the casting mold is cooled in advance before casting, so that the temperature difference between the casting and the casting mold is increased, the width of a solidification area of the casting from the surface to the inside is reduced, the solidification shrinkage speed of the casting is slowed down, and the possibility of hot cracking when the core part of the casting is finally solidified is reduced; meanwhile, in the casting process, the outside of the casting mold is cooled, so that the situation that the temperature of the casting mold rises, material components of the casting mold are decomposed and gasified and chemically react with molten liquid is avoided, and the possibility that a pore layer appears on a casting or insufficient casting occurs is reduced.

Owner:江苏朗耐德耐火材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com