Cooling forming device for wet tissue tube production

A technology of cooling forming and wet tissue, applied in the direction of coating, etc., can solve the problems of inconvenient removal, inconvenience and direct immersion into cooling liquid, etc., to avoid the effect of position shaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

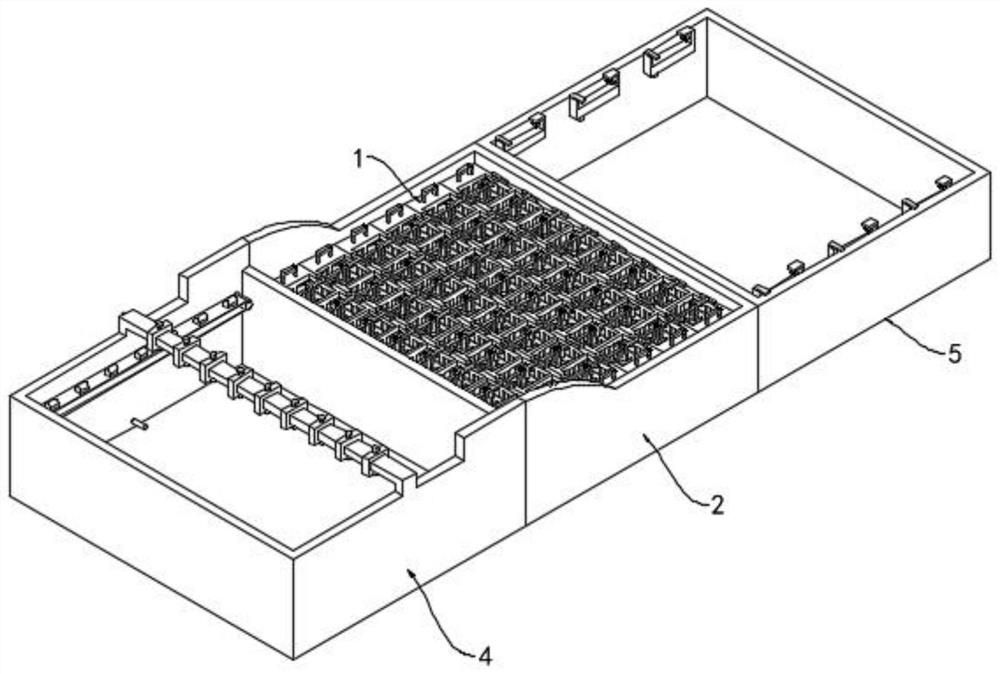

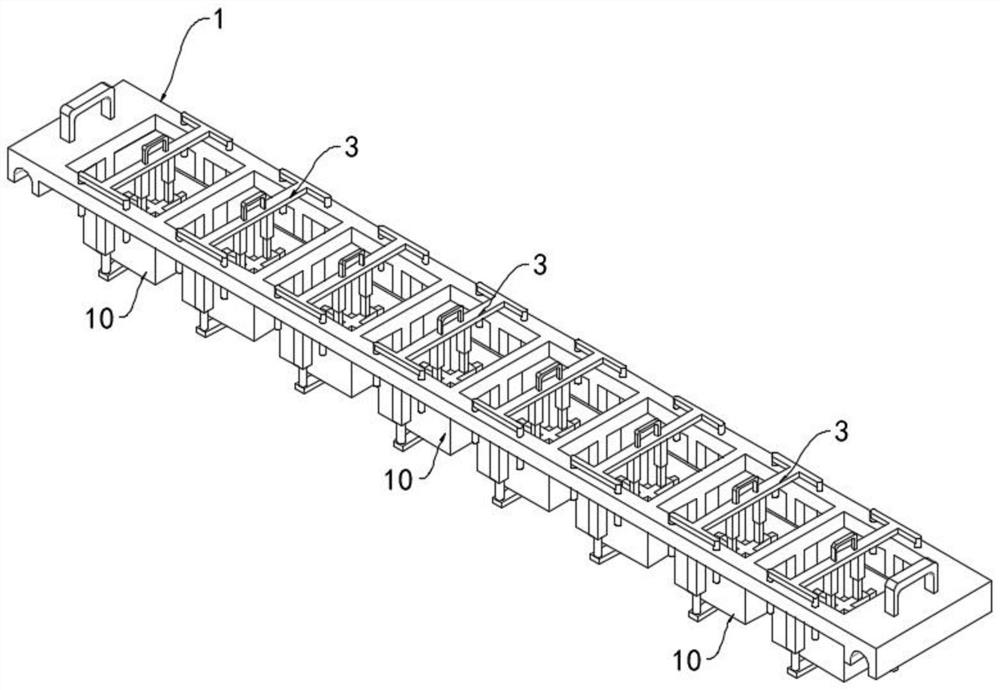

[0027] A cooling and forming device for the production of wet tissue cylinders: comprising a cooling tank 2 for cooling the wet tissue cylinder 10, an adding tank 4 for injecting cooling liquid into the wet tissue cylinder 10, and a bottom through pipeline The pouring tank 5 communicated with the adding tank 4; also includes a fixing frame 1 for fixing the wet tissue cartridge 10, and the fixing frame 1 can be arbitrarily placed in the cooling tank 2, the adding groove 4 and the pouring groove 5 during use; the fixing frame 1 includes A pair of supporting longitudinal beams 11 arranged in parallel, a number of parallel supporting beams 12 are arranged between the two supporting longitudinal beams 11, and are separated by the supporting beams 12 to form a number of space units for placing the wet tissue cartridge 10; located in any space A first telescopic rod 13 is provided on the bottom side of the two supporting longitudinal beams 11 at the unit, and a "cross"-shaped bottom p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com