Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "Clamping force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

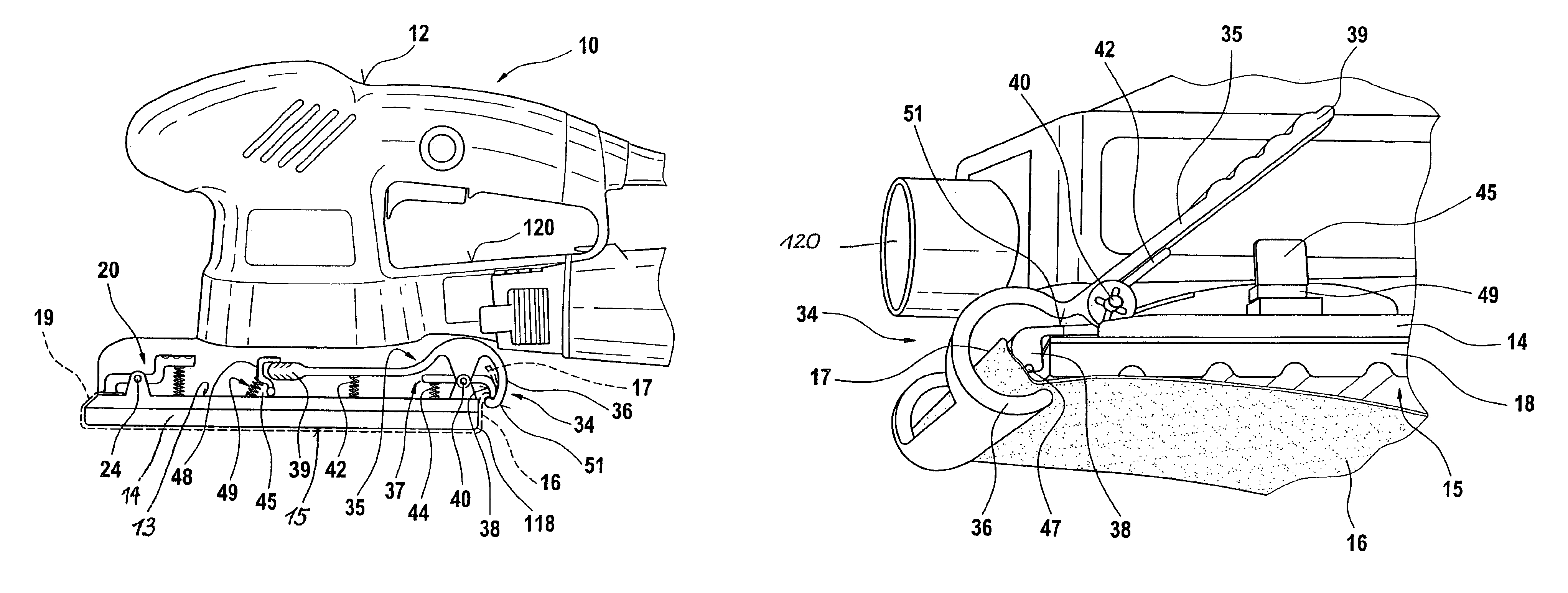

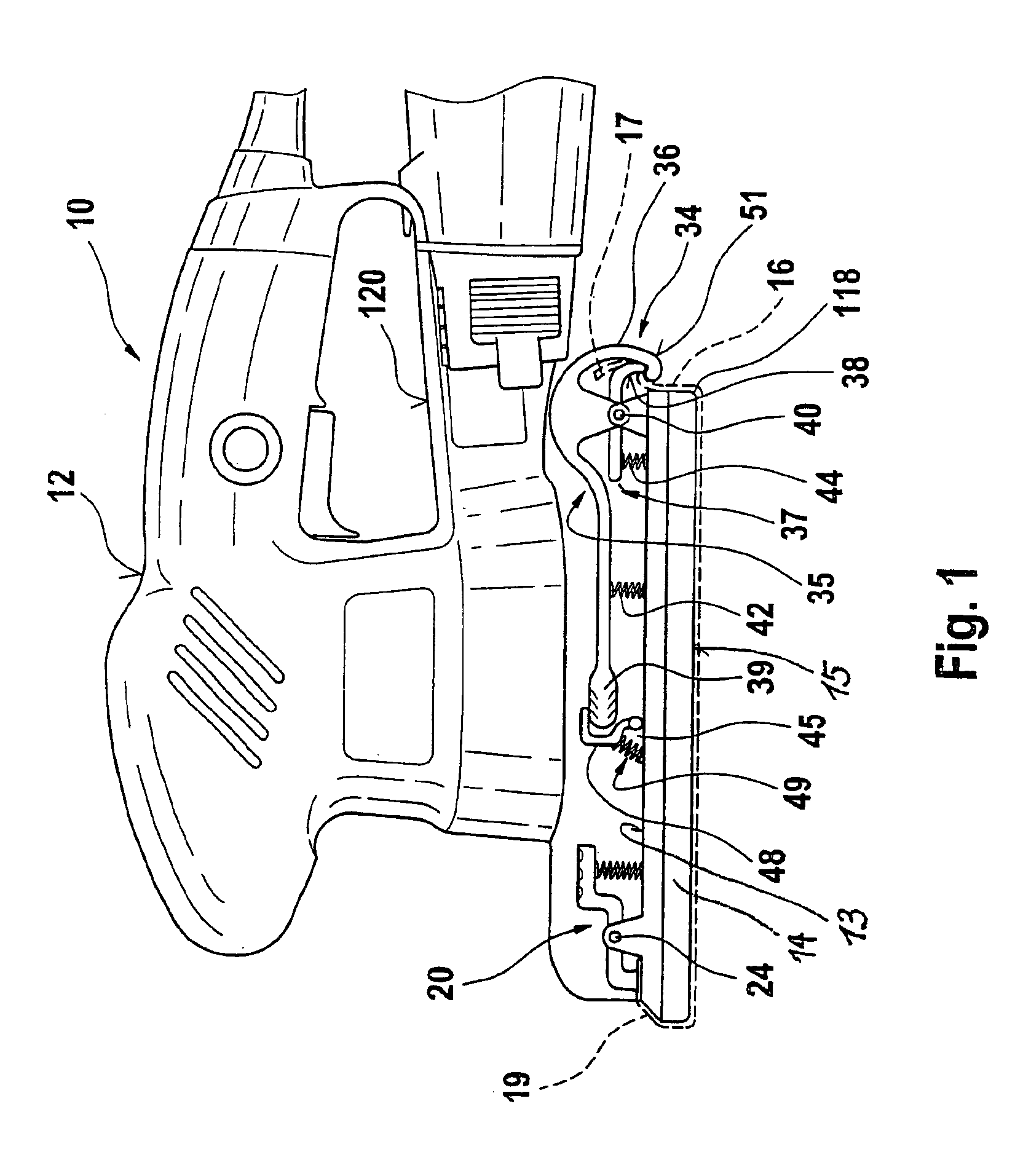

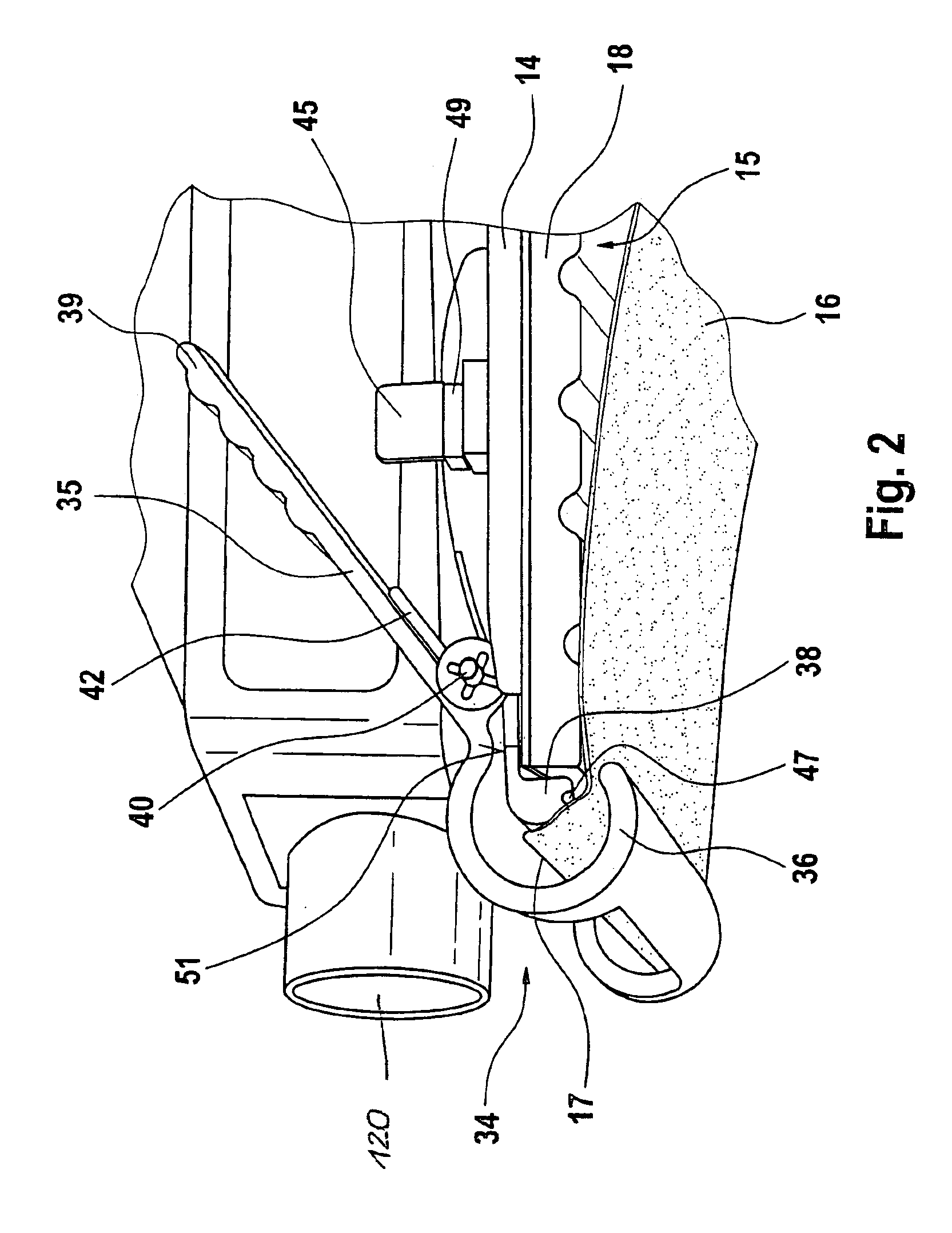

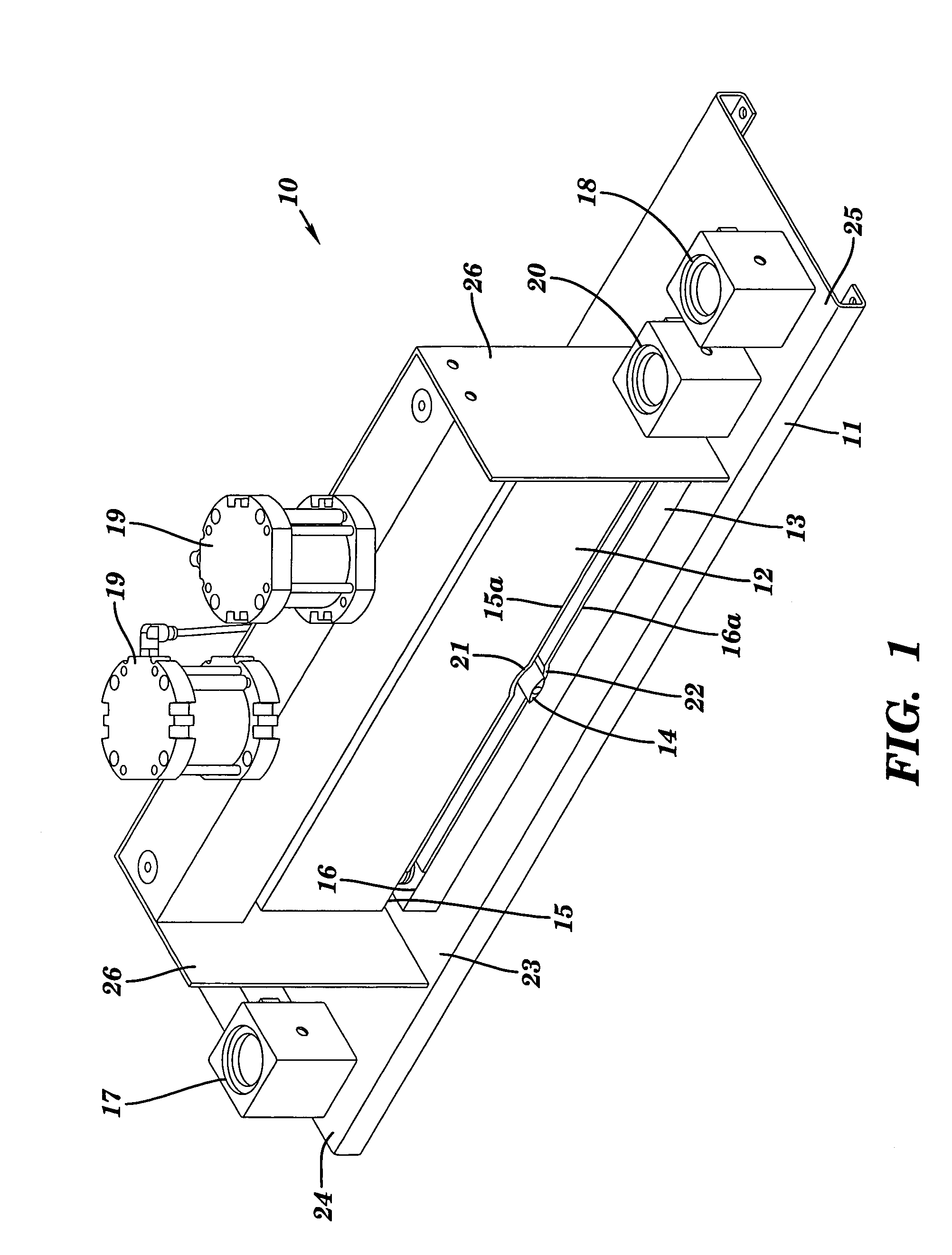

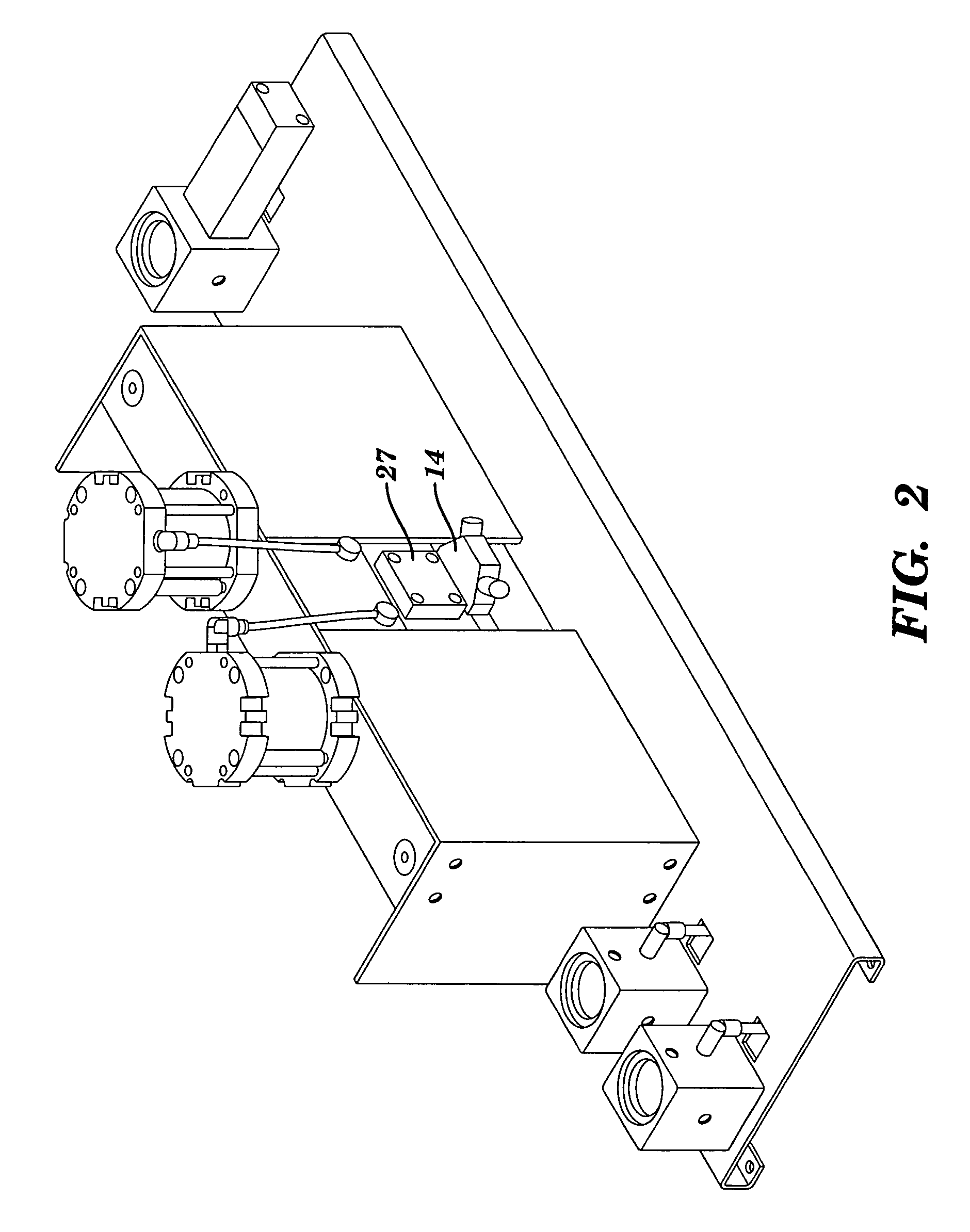

Abrasive strip carrier and hand sander

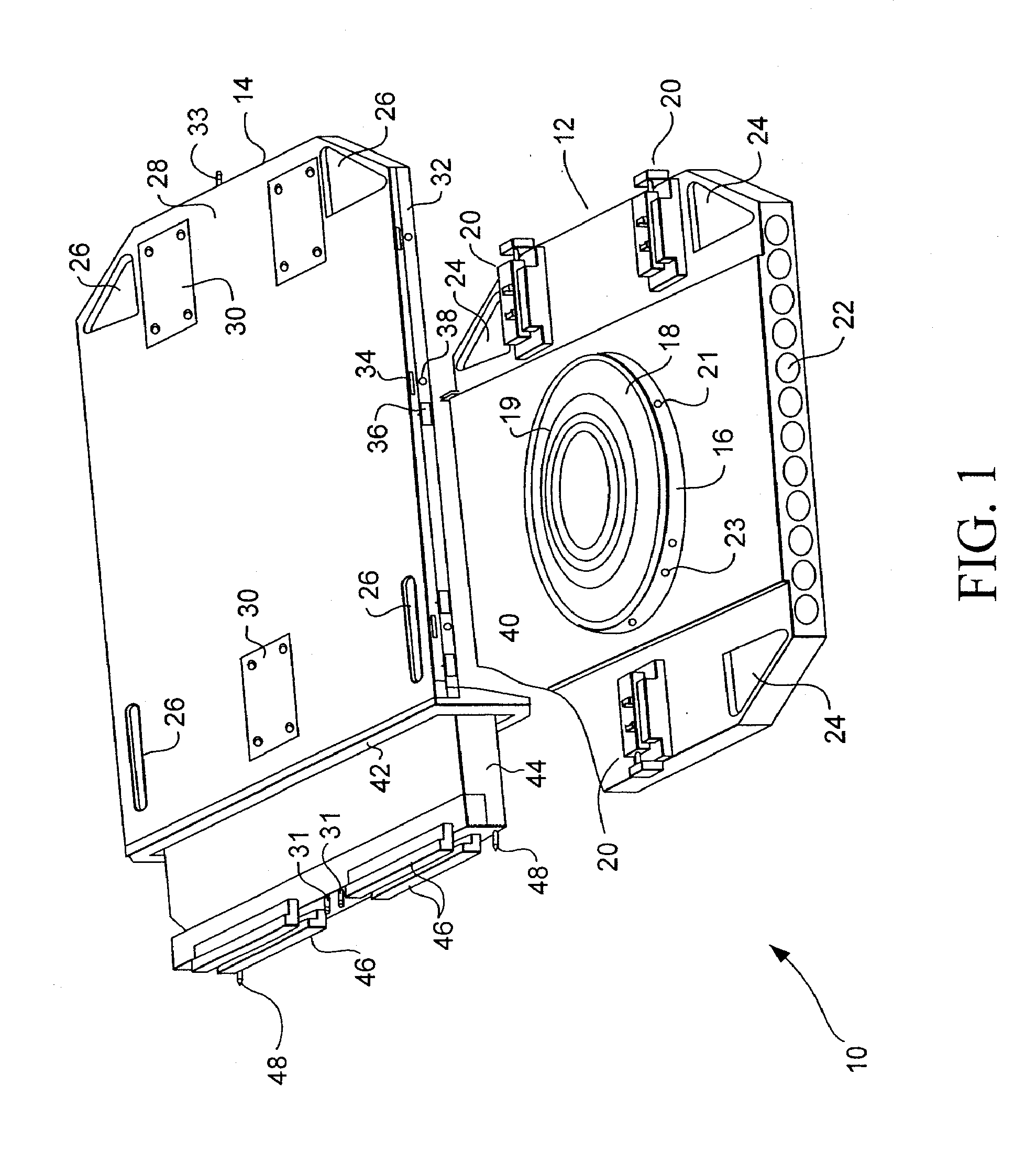

InactiveUS6857948B2Improve grinding effectImprove efficiencyPortable grinding machinesGrinding/polishing hand toolsSanderEngineering

A power grinder, in particular an oscillating grinder (10), having a housing (12) and a grinding sheet holder (14), on whose working face (15) a grinding sheet (16) to be received is braced, and its reception is effected by means of clamping means (20, 23) that lock opposite grinding sheet ends (17, 19) to the grinding sheet holder (14), is made easier to operate, and its machining capacity is improved, by providing that for equipping it with the grinding sheet, the clamping means (20, 23) are movable jointly with a grinding sheet end (17) clamped to them away from the opposite, likewise clamped grinding sheet end (19), so that the latter is locked, while under tensile stress.

Owner:ROBERT BOSCH GMBH

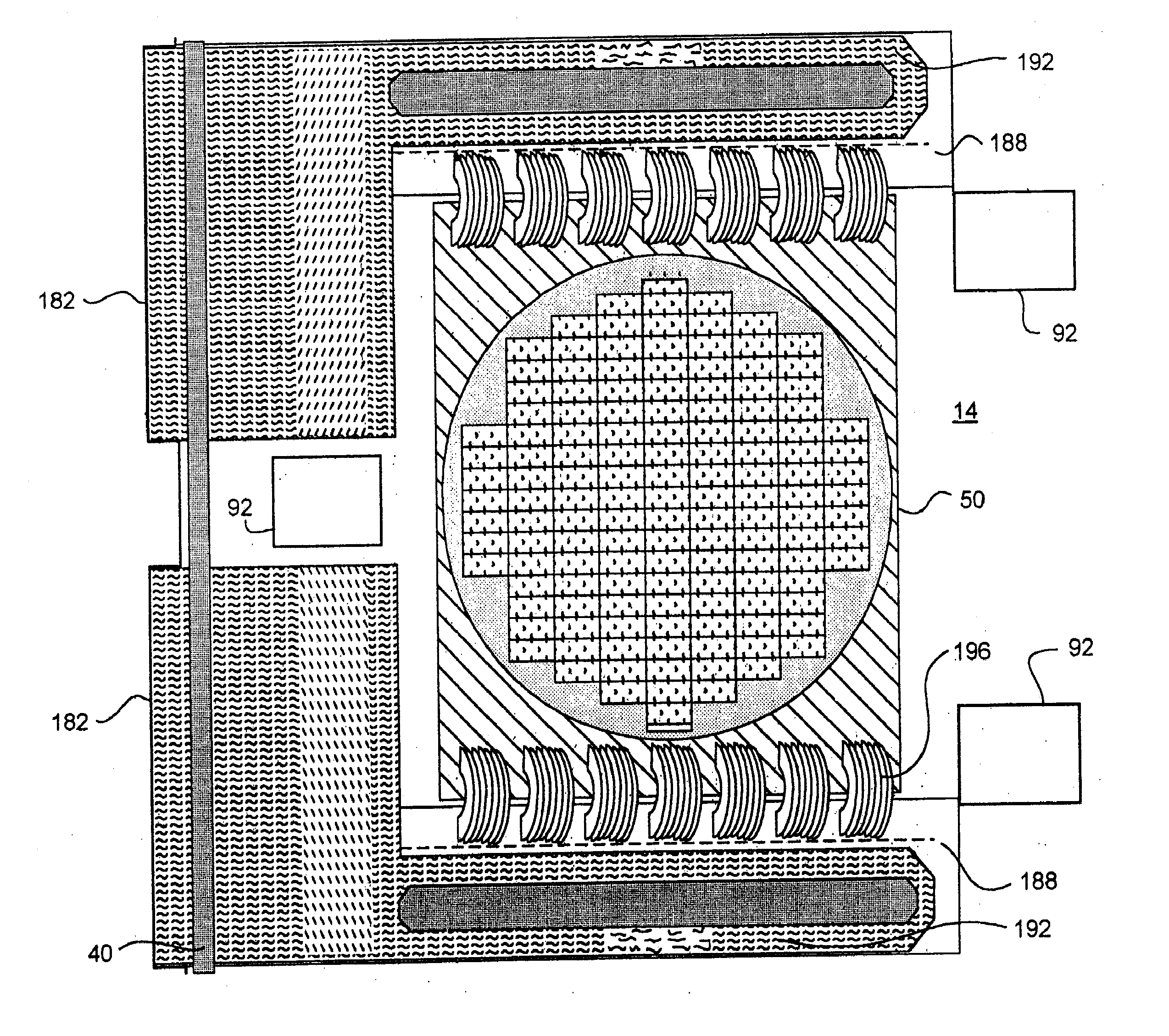

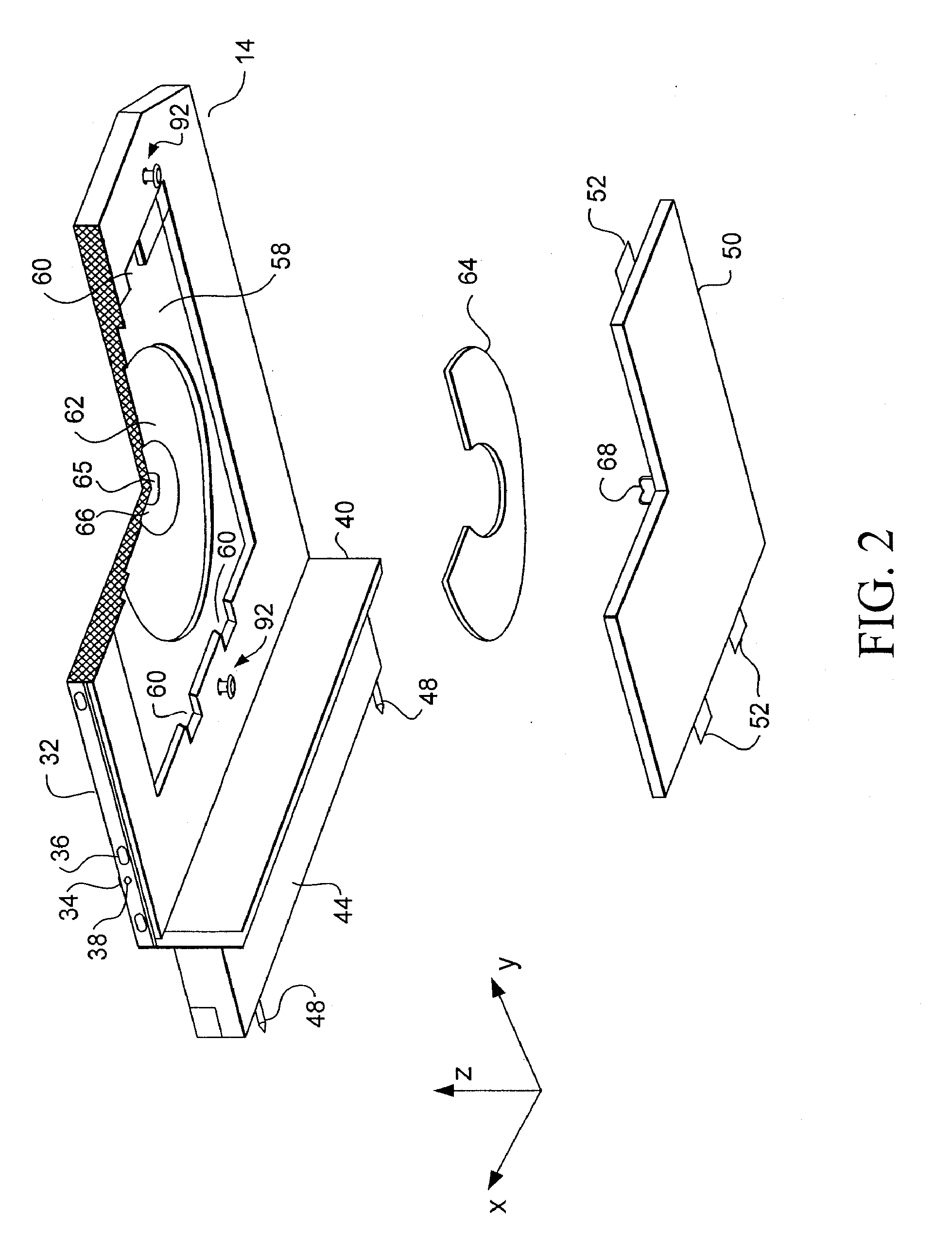

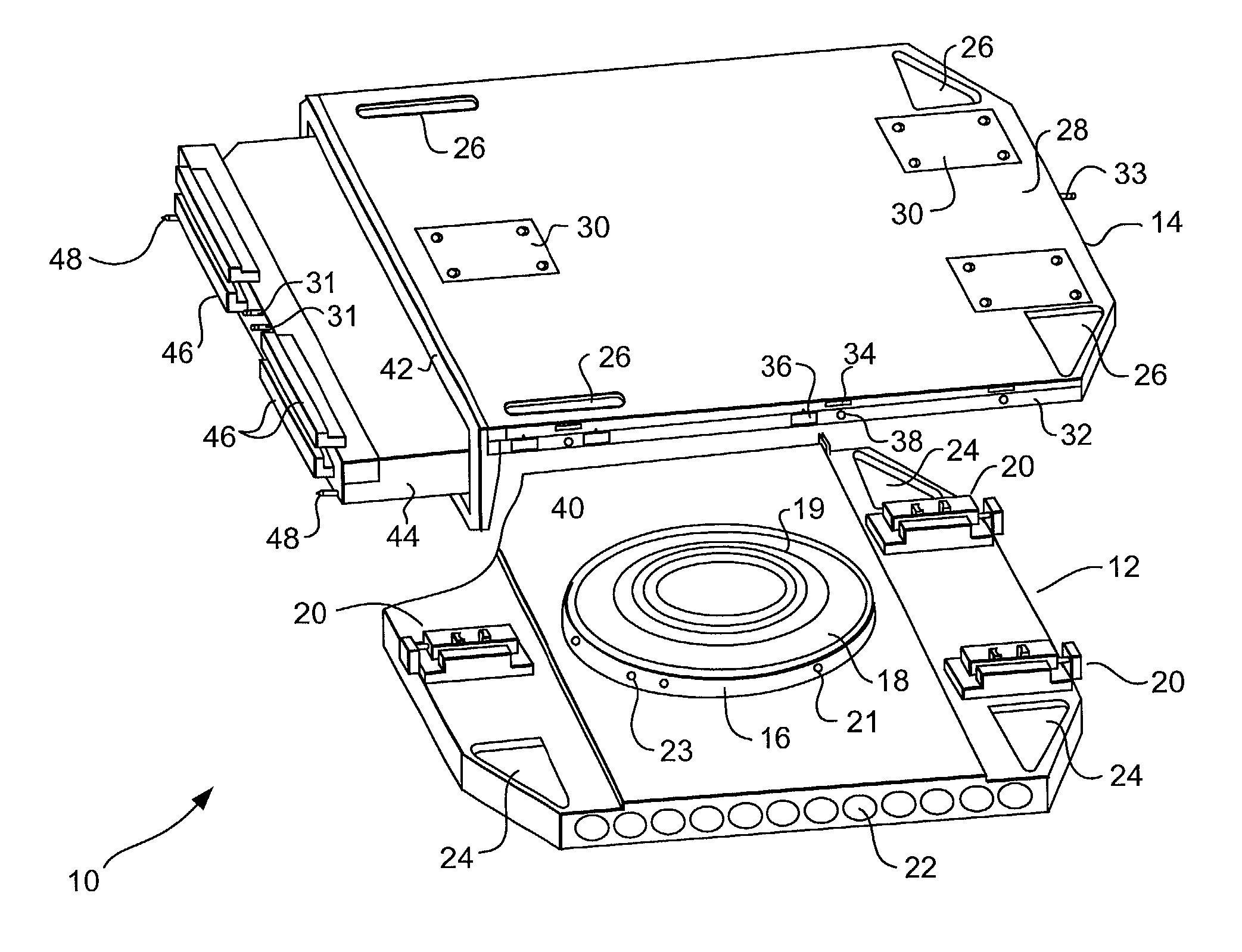

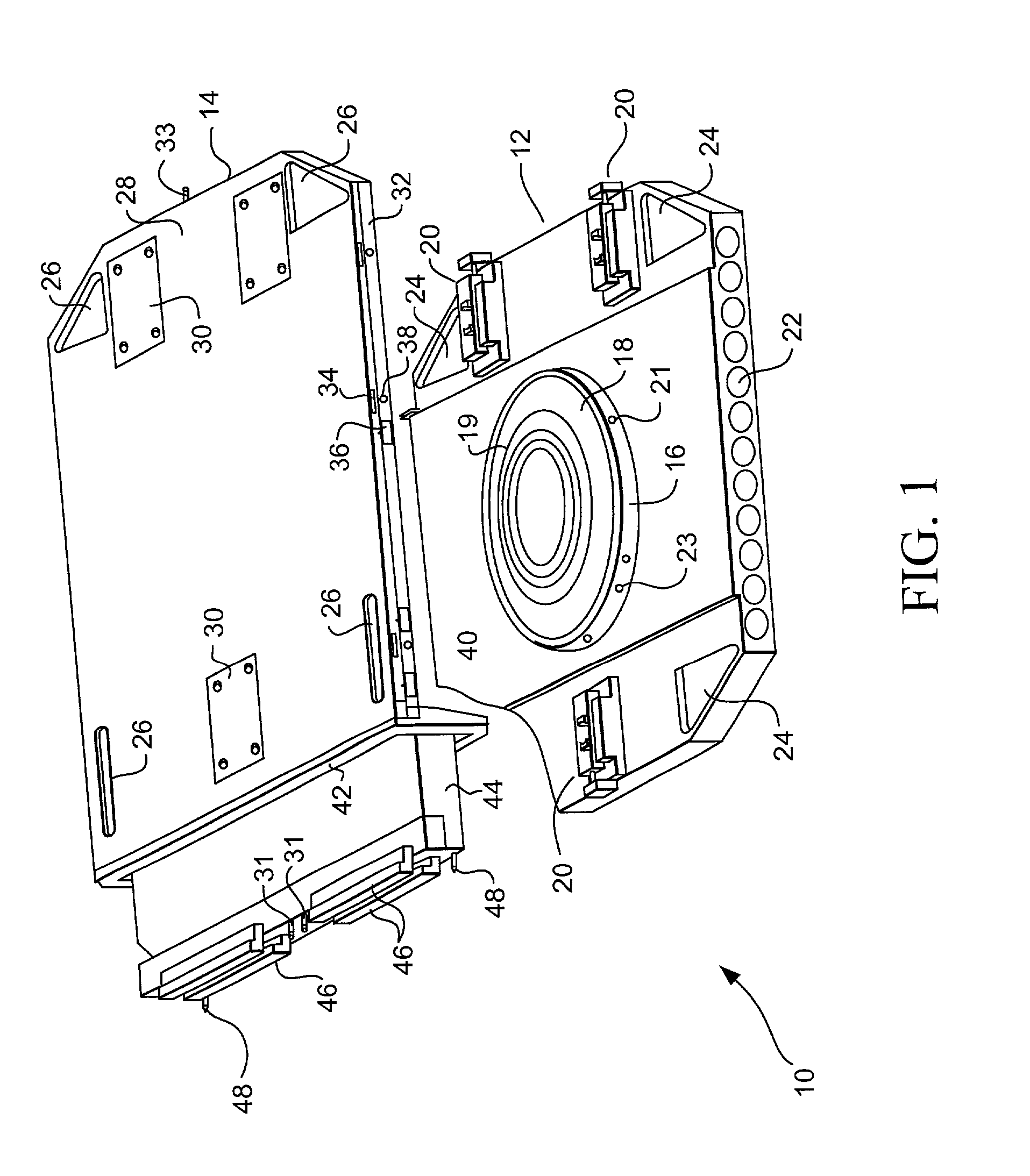

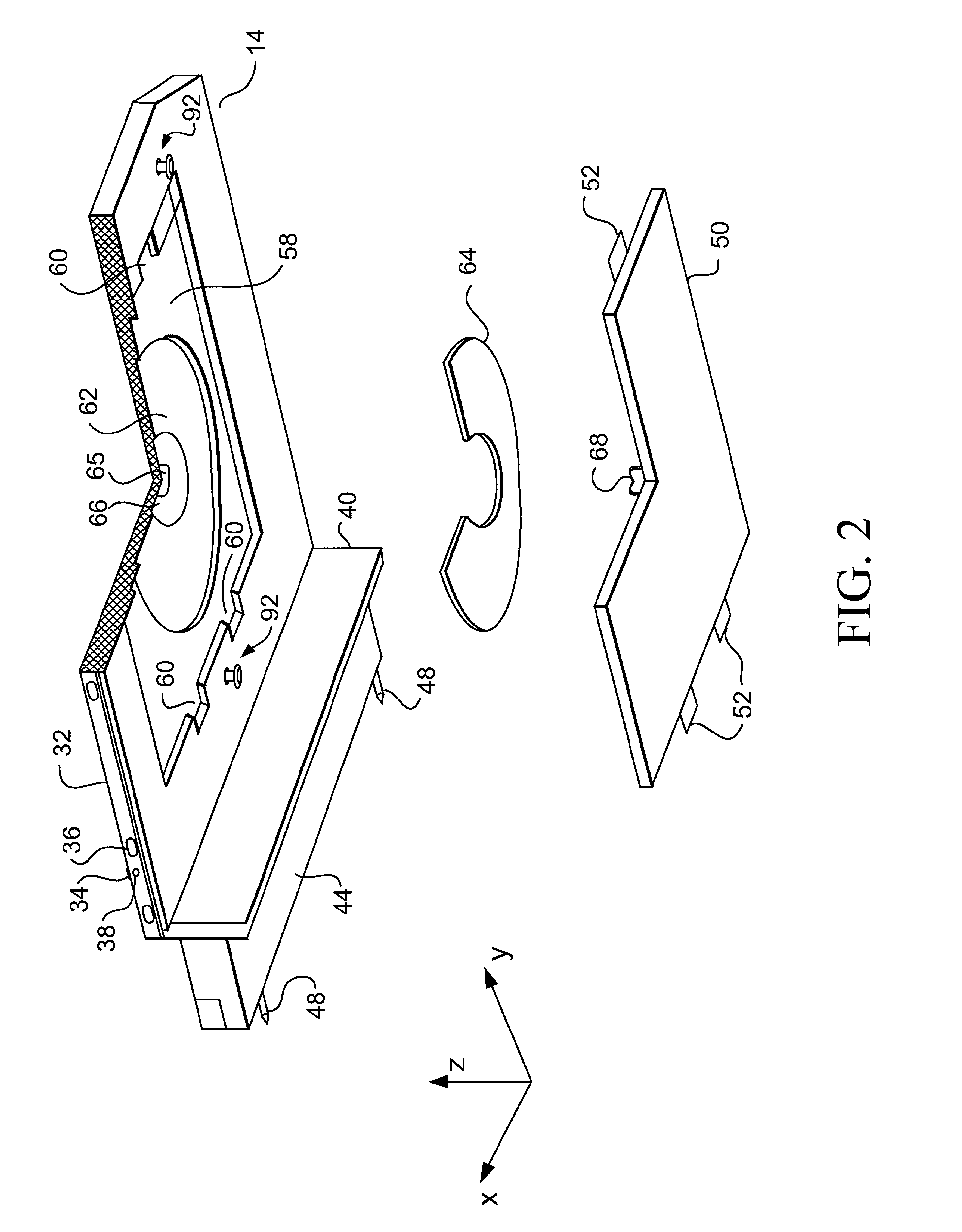

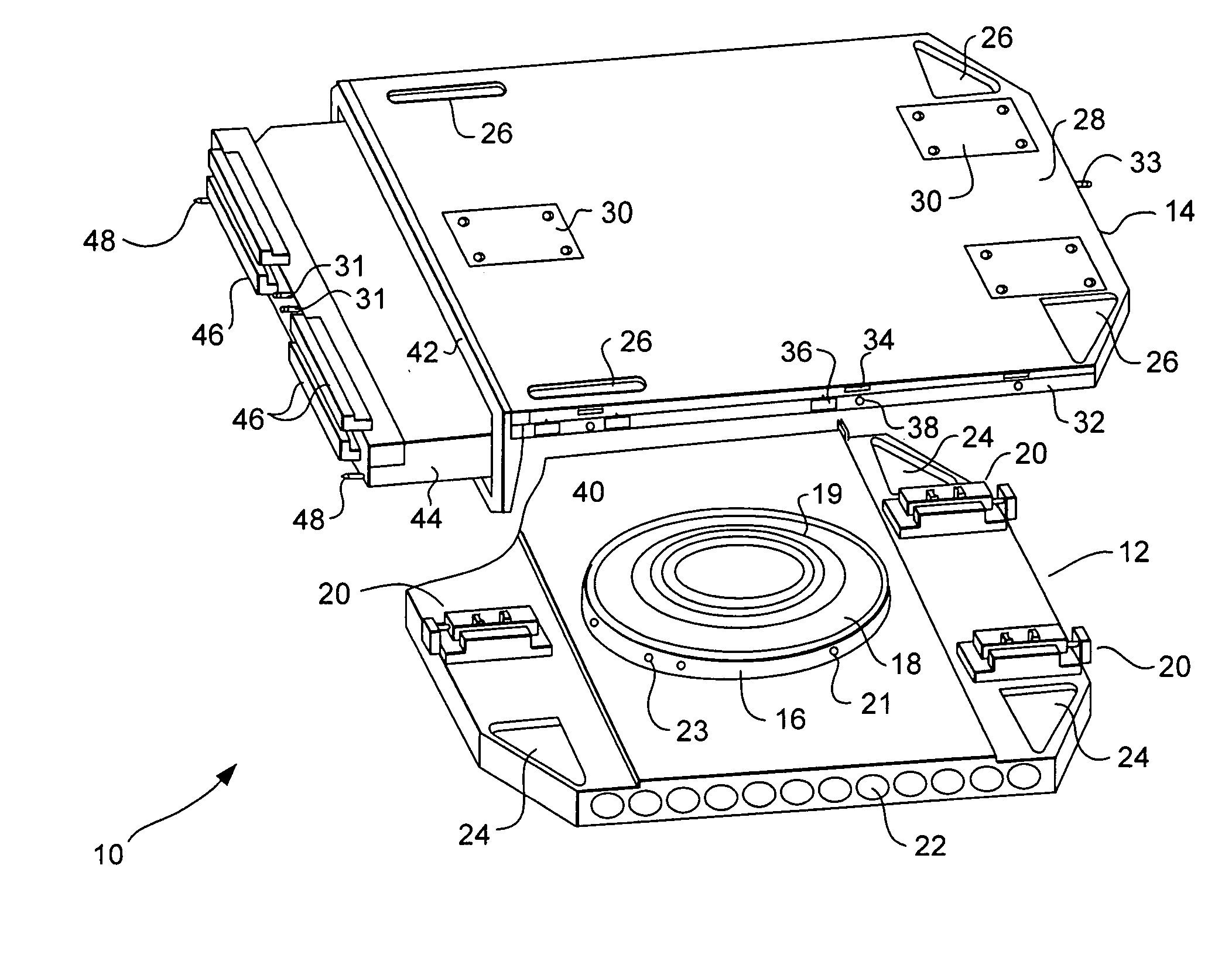

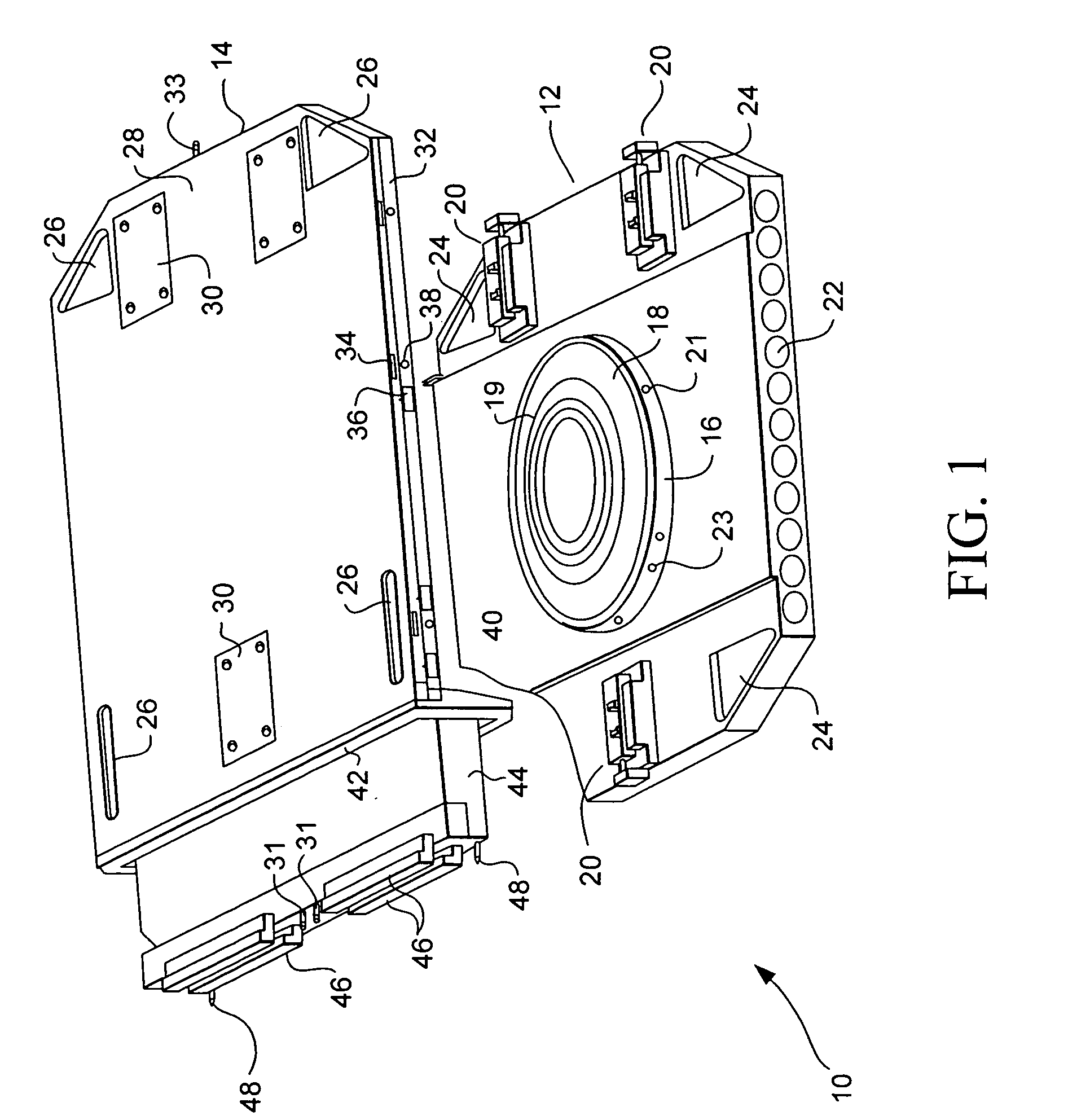

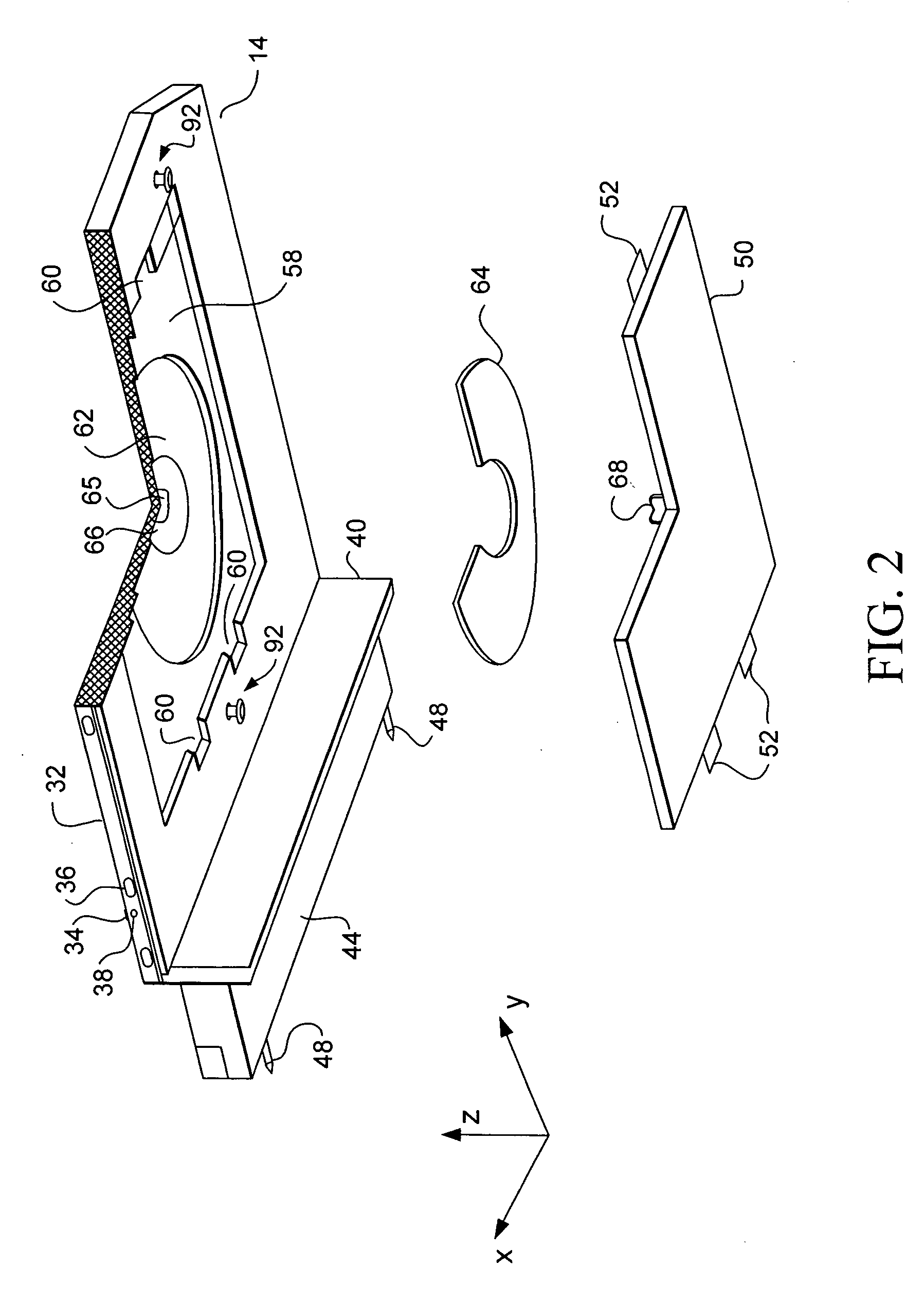

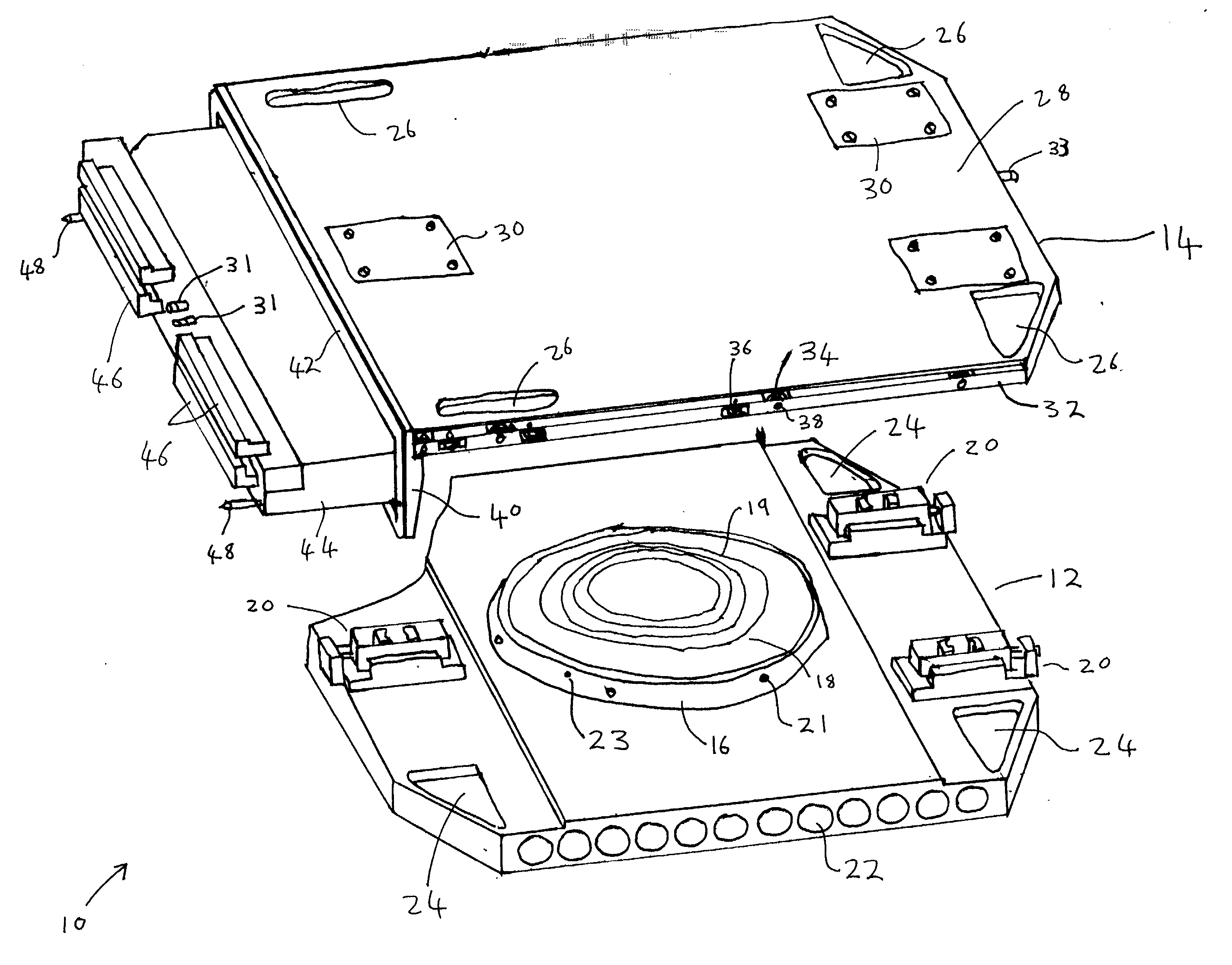

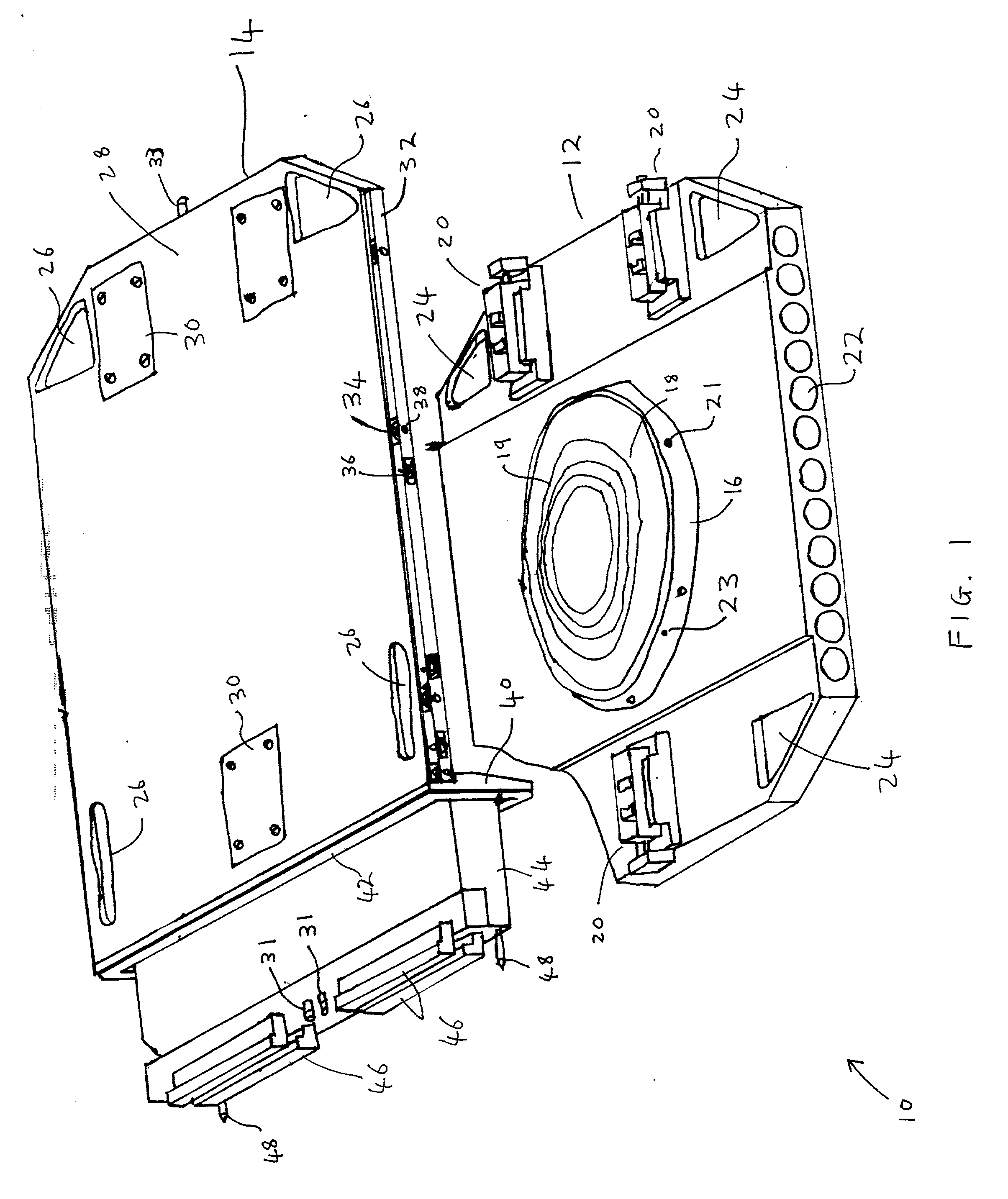

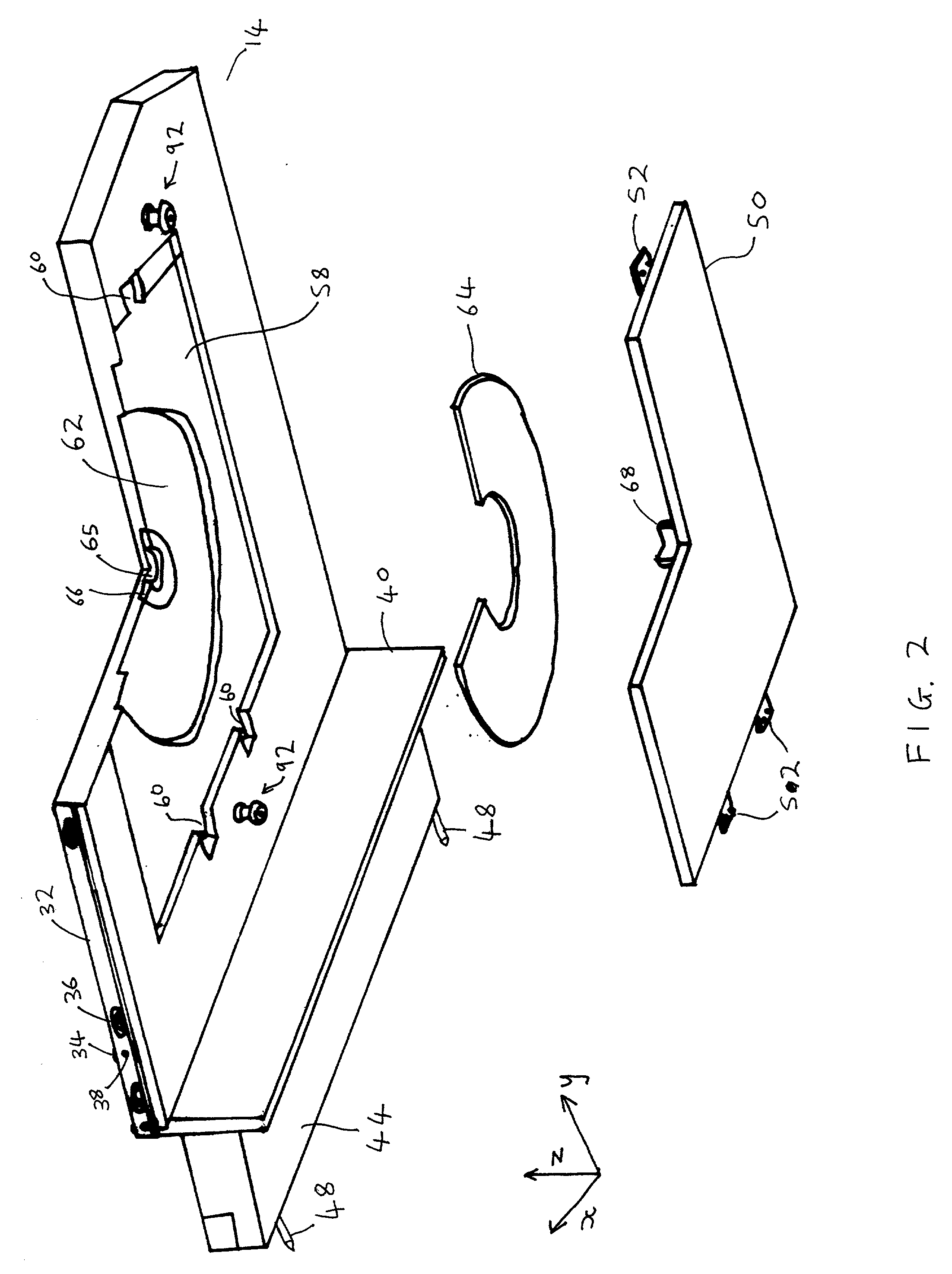

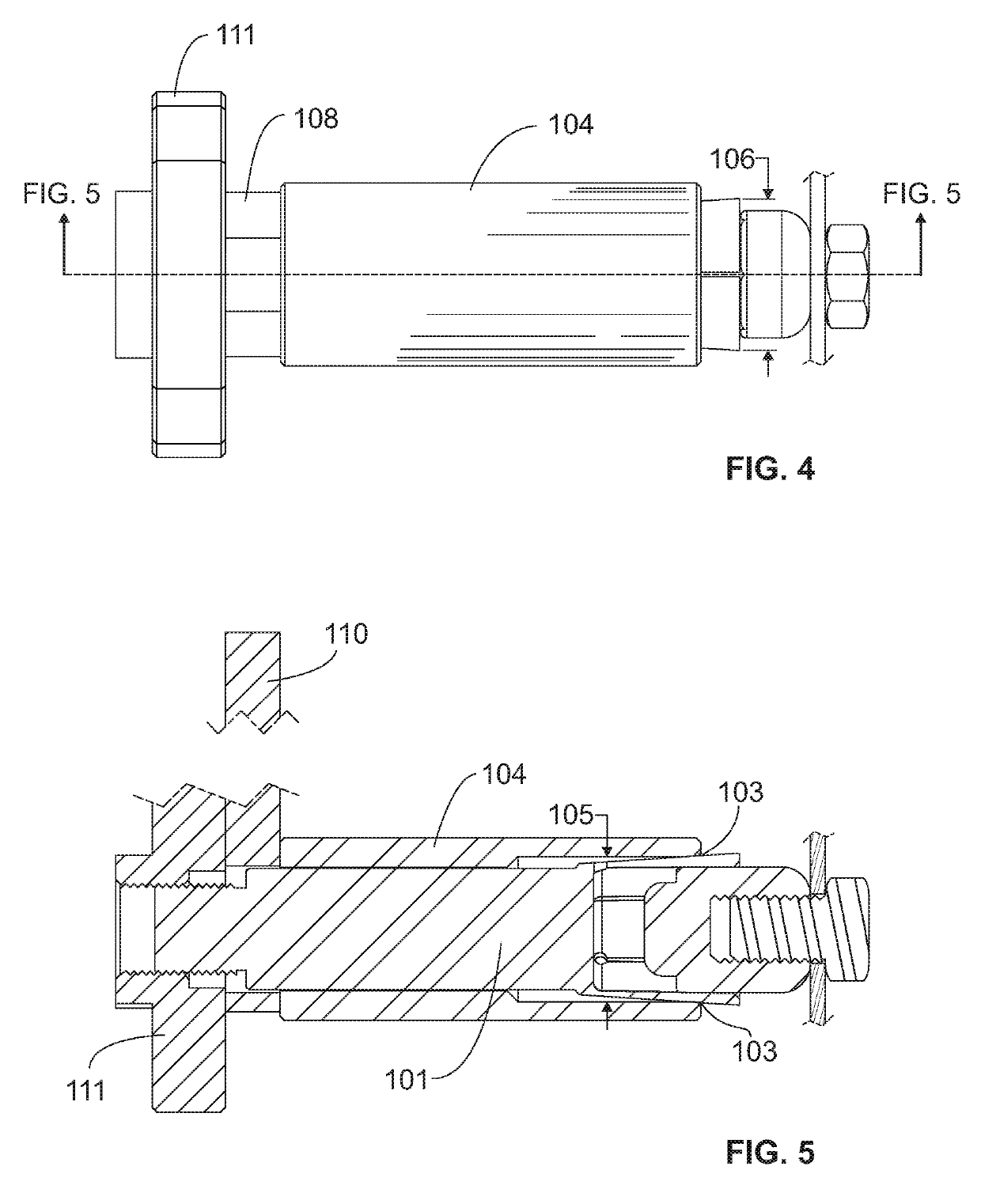

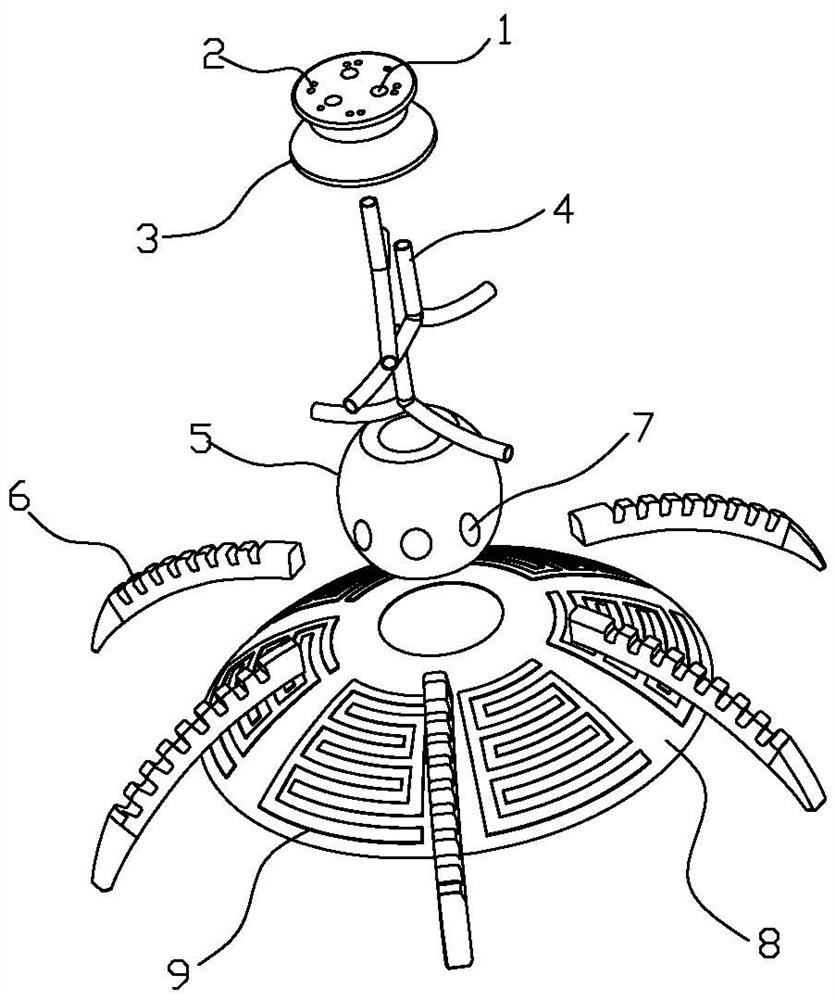

Wafer Burn-In and Test Employing Detachable Cartridge

InactiveUS20060132154A1Clamping forcePrevent exitElectronic circuit testingElectrical measurement instrument detailsKinematic couplingProbe card

A cartridge (10) includes a chuck plate (12) for receiving a wafer (74) and a probe plate (14) for establishing electrical contact with the wafer. In use, a mechanical connecting device (90) locks the chuck plate and the probe plate fixed relative to one another to maintain alignment of the wafer and the probe plate. Preferably, electrical contact with the wafer is established using a probe card (50) that is movably mounted to the probe plate by means of a plurality of leaf springs (52.) The mechanical connecting device is preferably a kinematic coupling including a male connector (94) and first and second opposed jaws (122, 124.) Each of the jaws is pivotable from a retracted position in which the male connector can be inserted between the jaws and an engaging position in which the jaws prevent withdrawal of the male connector from between the jaws. The male connector is movable between an extended and a retracted position, and is biased towards the retracted position. This provides a positive clamping force that pulls the chuck and probe plates together when the mechanical connecting device is engaged. To load a wafer into the cartridge, the wafer is placed on the chuck plate, the probe plate is aligned with the wafer, and the chuck plate and the probe plate are locked together. The cartridge can then be removed from the alignment device and placed in a burn-in or test chamber that does not itself require means for aligning the wafer or for providing a probe actuation force.

Owner:AEHR TEST SYST

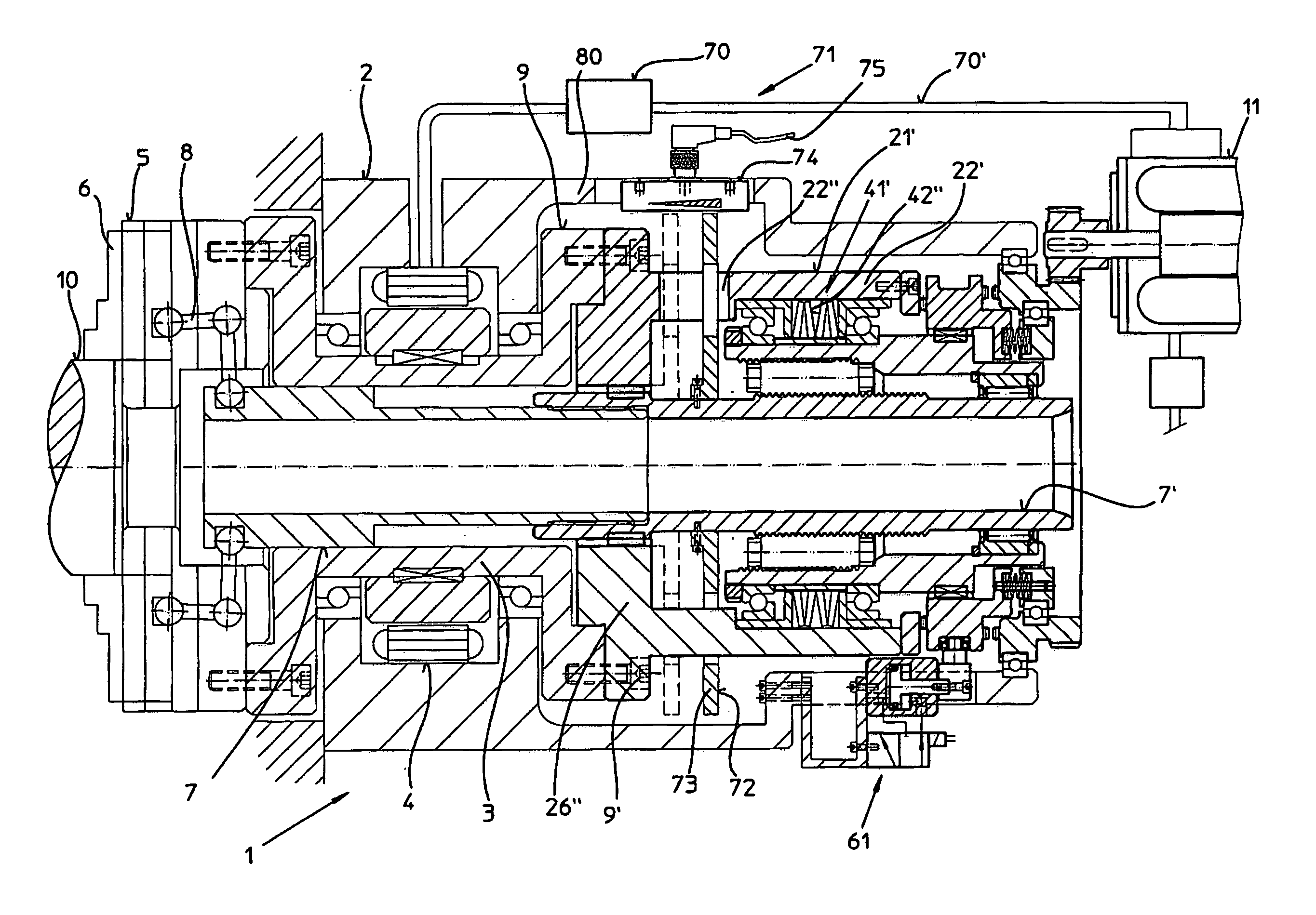

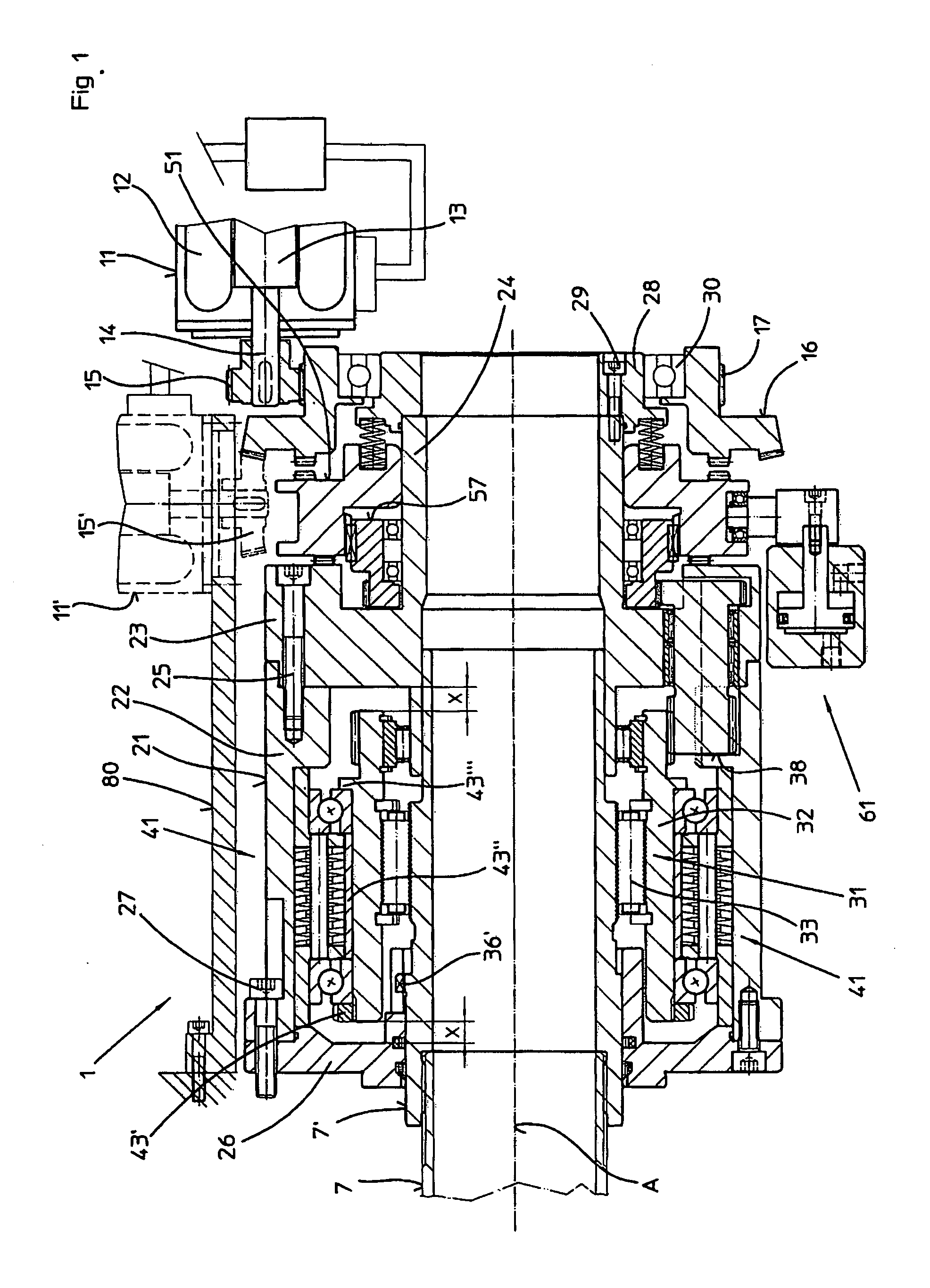

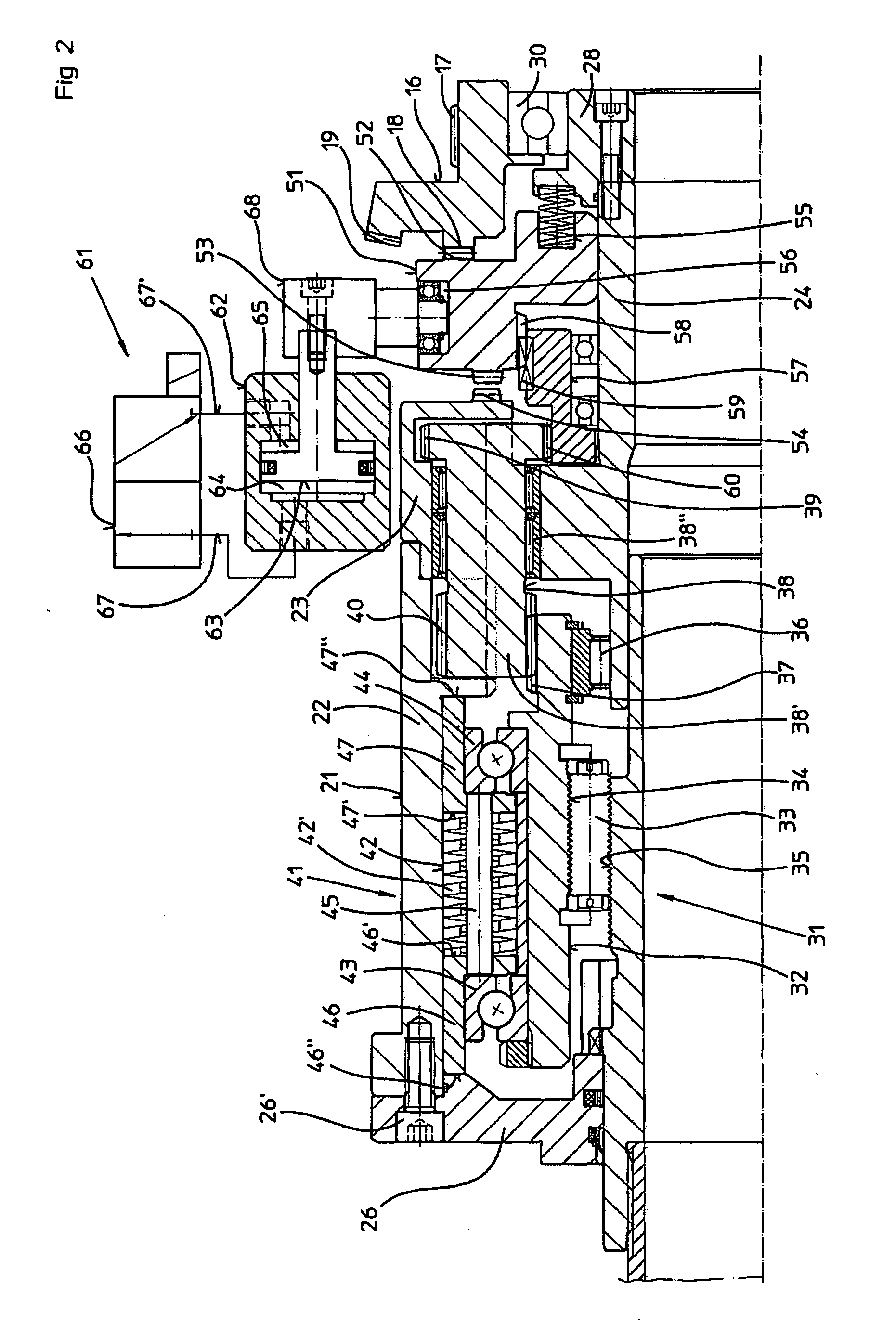

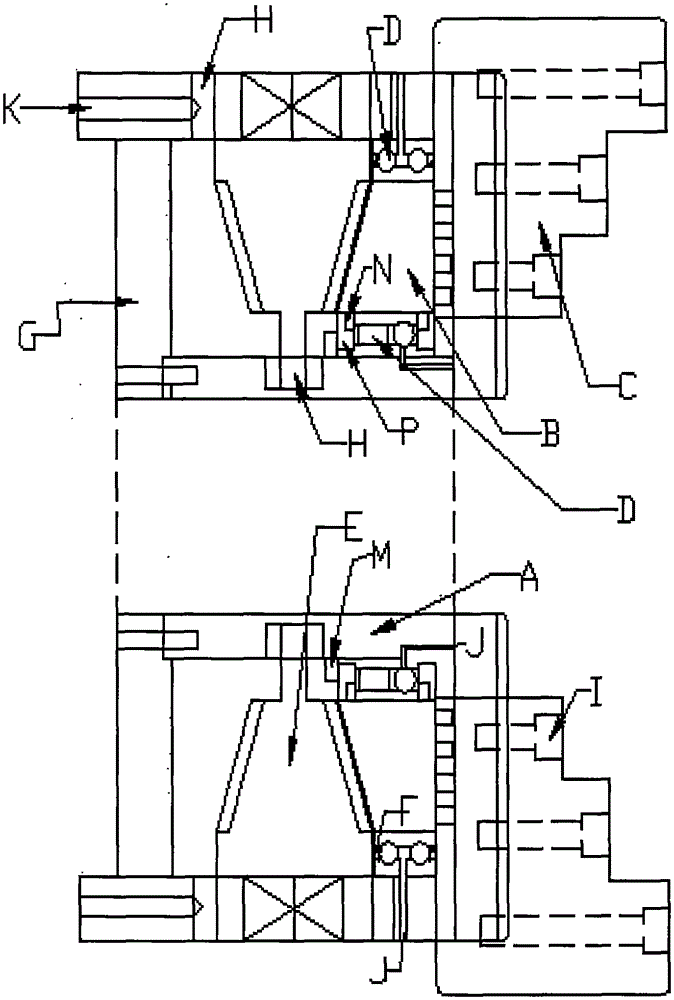

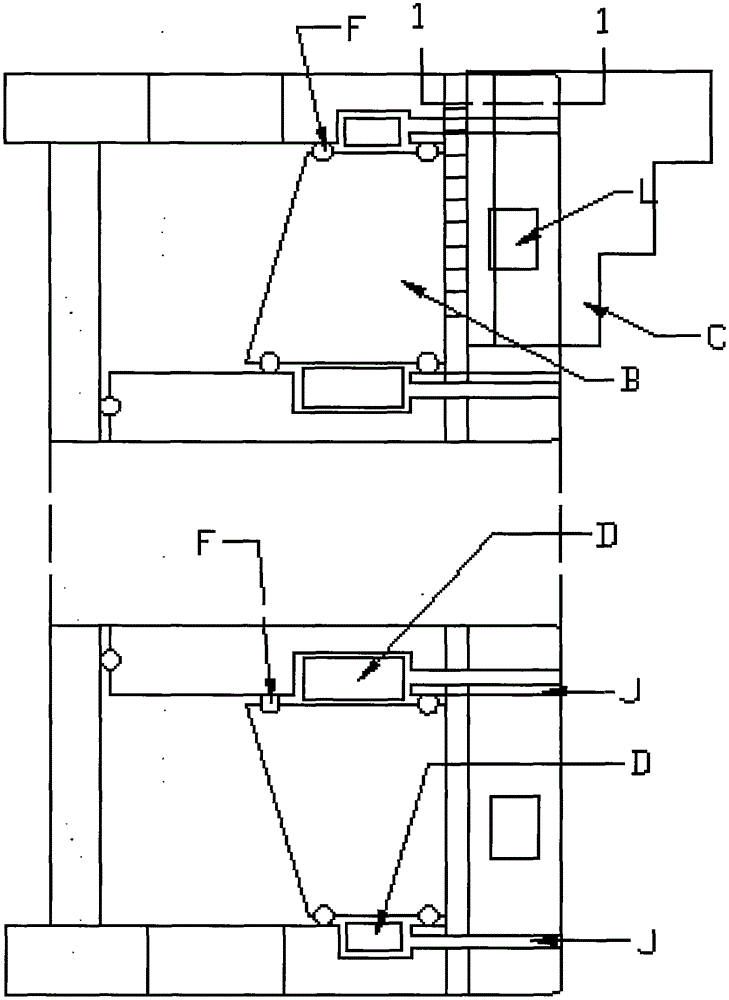

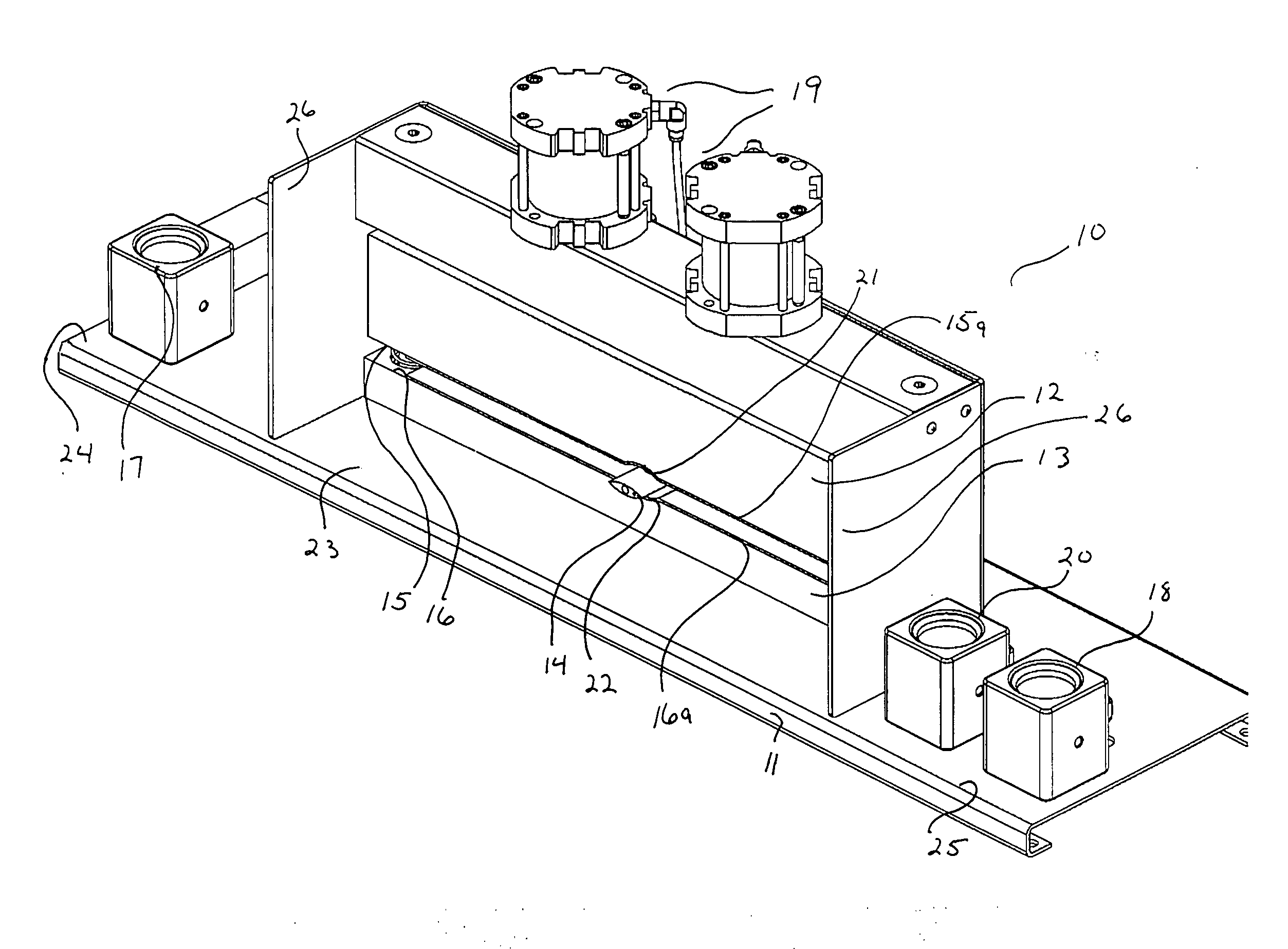

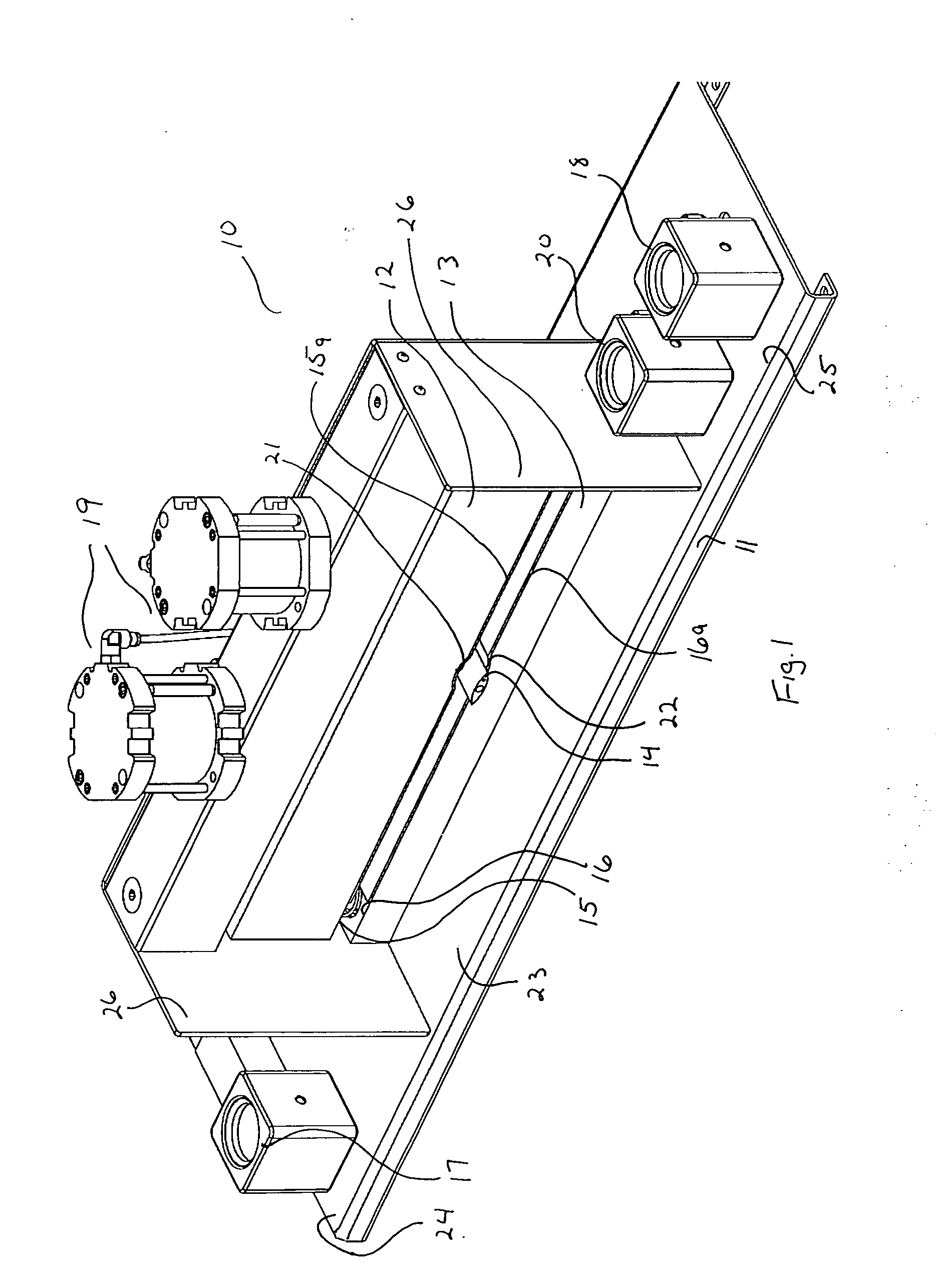

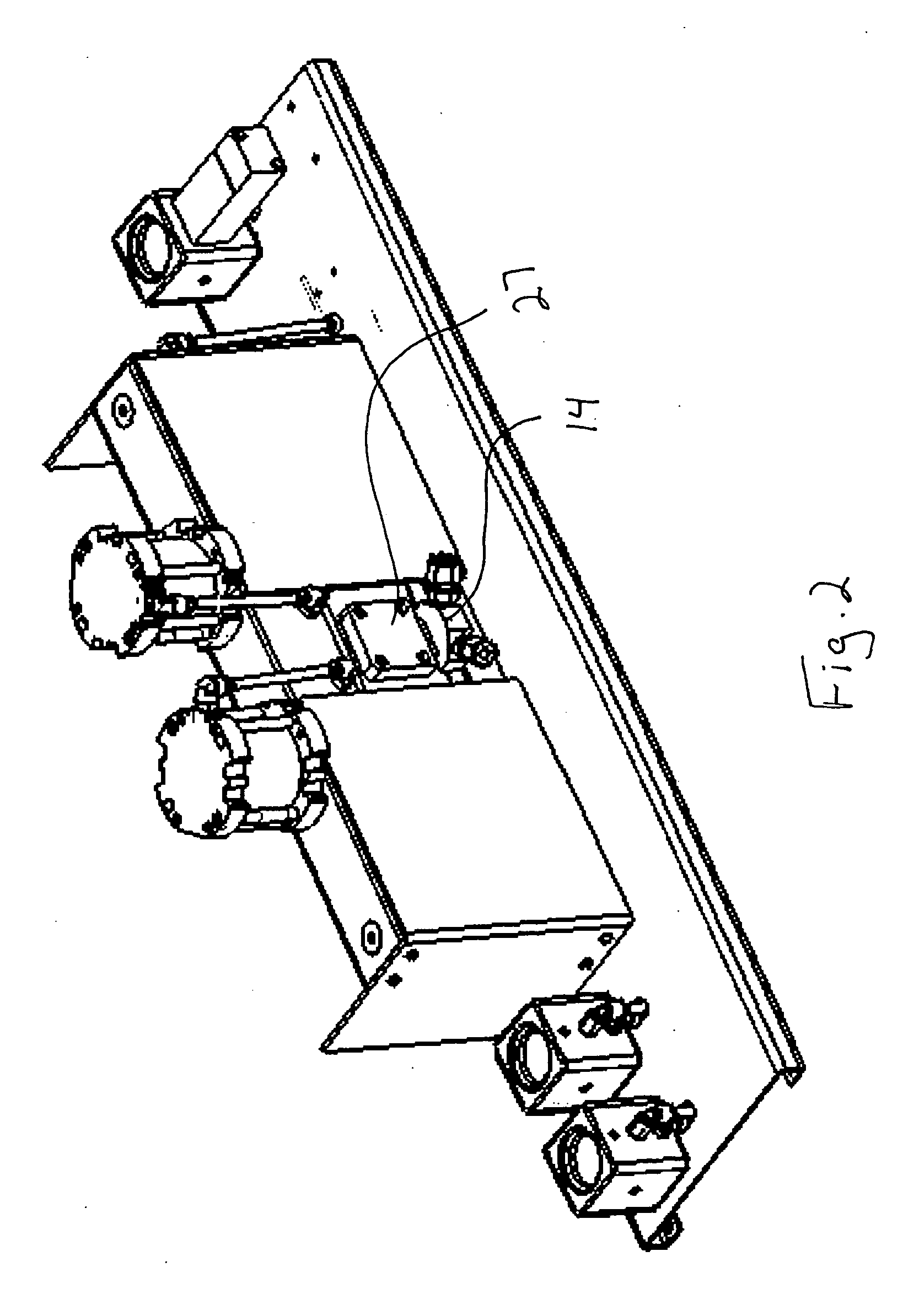

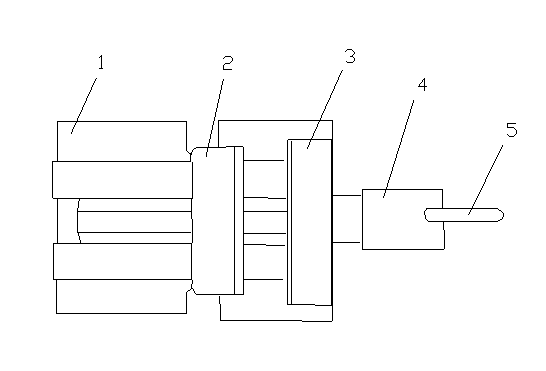

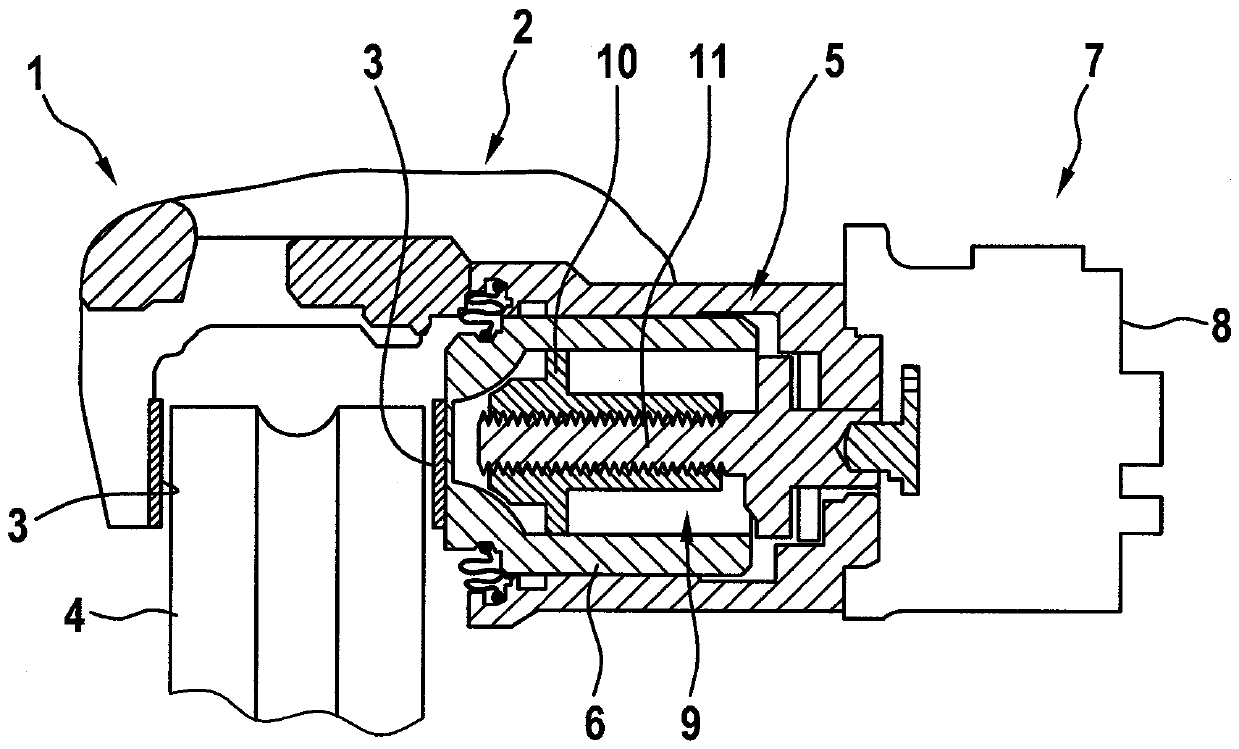

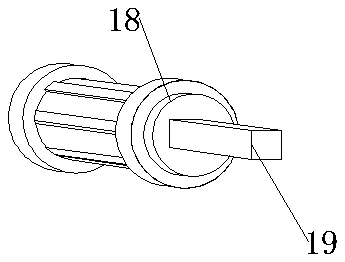

Clamping device

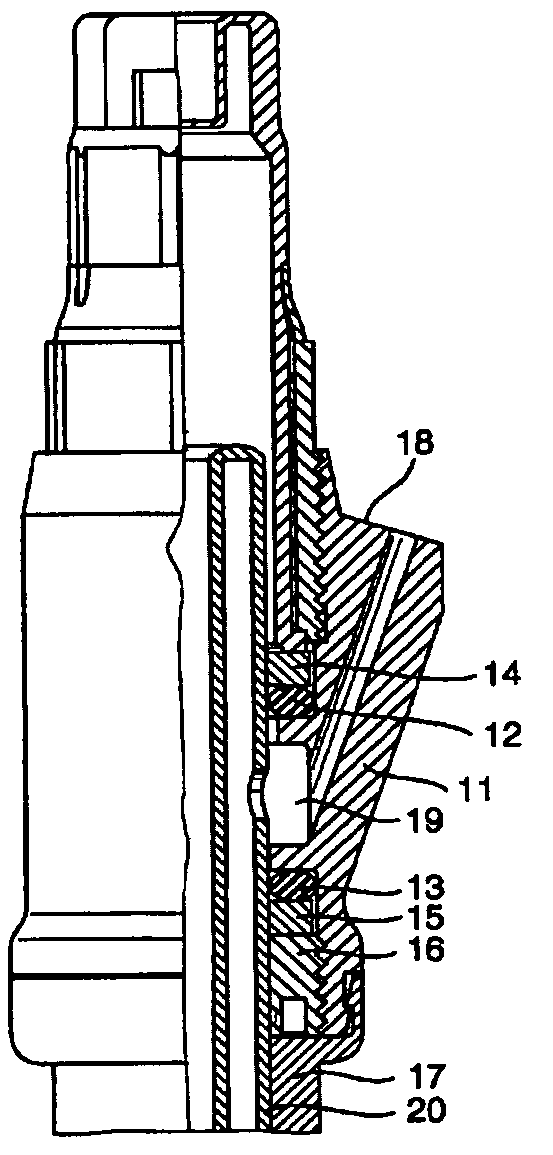

InactiveUS20110272898A1Clamping forceReduce energy consumptionSleeve/socket jointsMeasurement/indication equipmentsEngineeringPower transmission

A clamping device for machine tools is provided with a chuck, the clamping jaws of which are actuated by a draw rod, the clamping device having of a servomotor, a movement converter and a force accumulator, the servomotor is connectable to the movement converter for triggering clamping movements. The movement converter and the force accumulator are disposed in a housing connectable to the machine spindle, and in clamping position of the clamping device, the sliding sleeve can be decoupled from the servomotor, and the housing can be connected to the movement converter by means of the sliding sleeve.The servomotor is operated only to clamp and unclamp a workpiece, and is in a driving connection with the clamping device in operating conditions. All components of the clamping device involved in power transmission are in driving connection with the machine spindle during the machining of the workpiece.

Owner:HIESTAND KARL

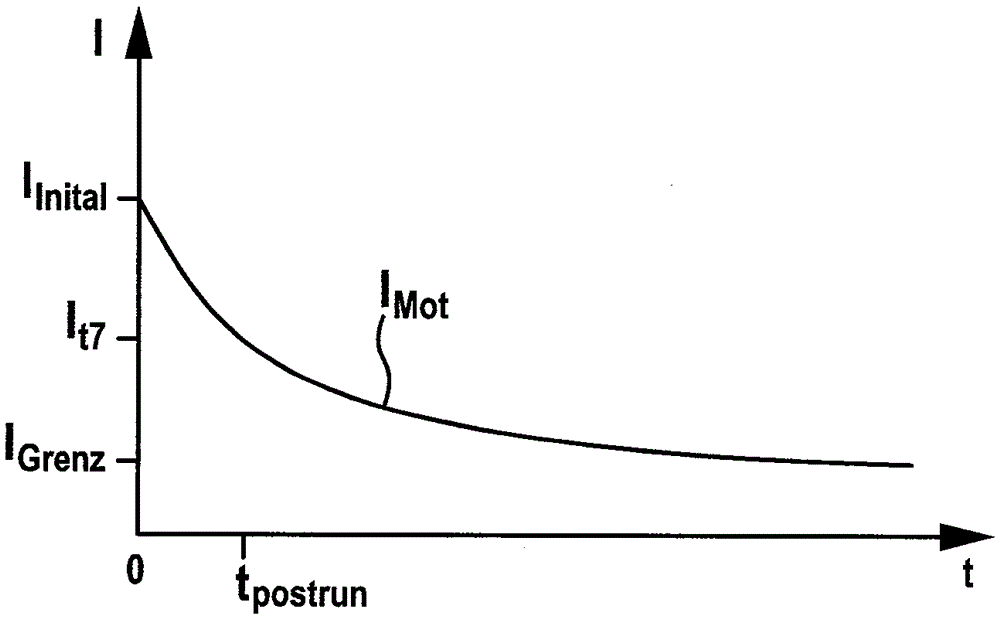

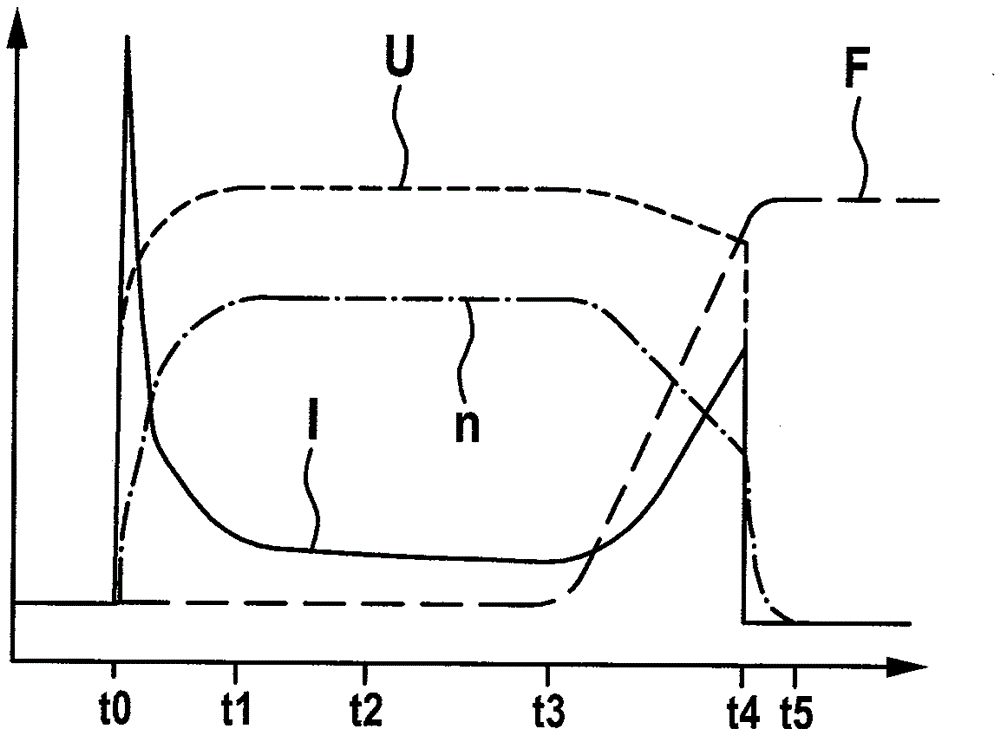

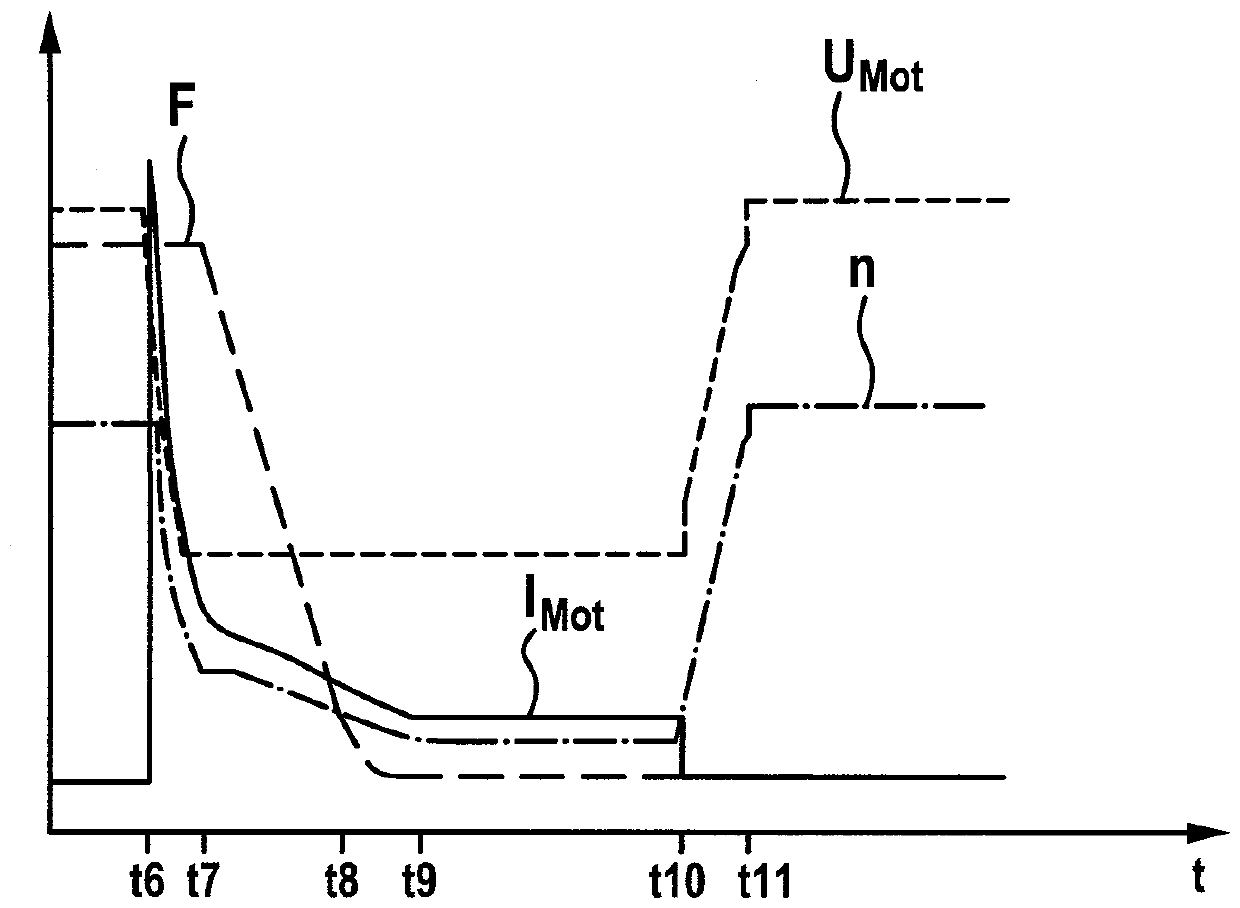

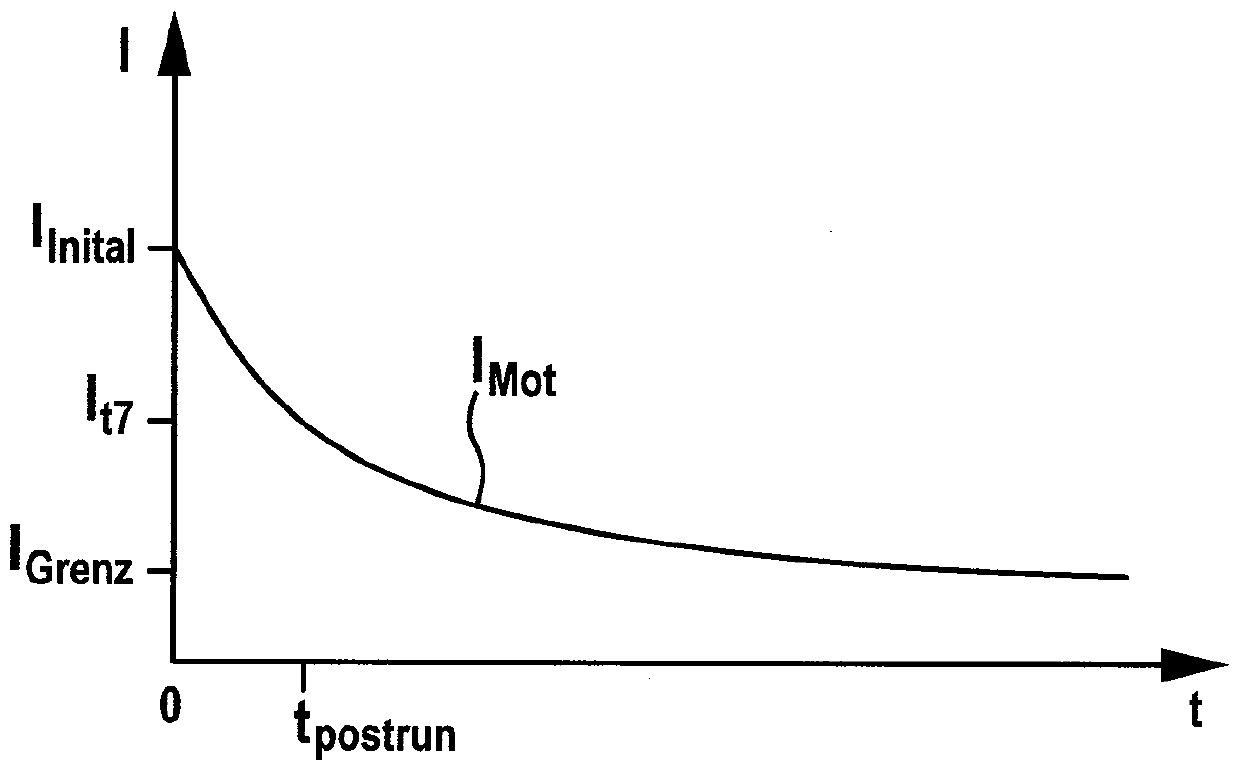

Method and Apparatus for Operating a Braking Device, Braking Device

ActiveCN105711575AReduce the impact of miscalculationsReduce loadAxially engaging brakesBraking action transmissionActuatorControl theory

A method is used for operating a braking device (1) of a vehicle, in particular a parking brake device. The braking device (1) comprises an electromotive actuator (7) that displaces an actuator element (10) either into a clamping position for subjecting a brake disk (4) to a clamping force or into a release position for releasing the brake disk (4). A brake disk temperature is determined in order to activate the actuator (7) depending on the determined brake disk temperature. The brake disk temperature is determined depending on at least one actuator current value.

Owner:ROBERT BOSCH GMBH

Wafer burn-in and test employing detachable cartridge

InactiveUS20020030502A1Clamping forcePrevent exitElectrical measurement instrument detailsFault location by increasing destruction at faultKinematic couplingProbe card

A cartridge (10) includes a chuck plate (12) for receiving a wafer (74) and a probe plate (14) for establishing electrical contact with the wafer. In use, a mechanical connecting device (90) locks the chuck plate and the probe plate fixed relative to one another to maintain alignment of the wafer and the probe plate. Preferably, electrical contact with the wafer is established using a probe card (50) that is movably mounted to the probe plate by means of a plurality of leaf springs (52.) The mechanical connecting device is preferably a kinematic coupling including a male connector (94) and first and second opposed jaws (122, 124.) Each of the jaws is pivotable from a retracted position in which the male connector can be inserted between the jaws and an engaging position in which the jaws prevent withdrawal of the male connector from between the jaws. The male connector is movable between an extended and a retracted position, and is biased towards the retracted position. This provides a positive clamping force that pulls the chuck and probe plates together when the mechanical connecting device is engaged. To load a wafer into the cartridge, the wafer is placed on the chuck plate, the probe plate is aligned with the wafer, and the chuck plate and the probe plate are locked together. The cartridge can then be removed from the alignment device and placed in a burn-in or test chamber that does not itself require means for aligning the wafer or for providing a probe actuation force.

Owner:AEHR TEST SYST

Wafer burn-in and test employing detachable cartridge

InactiveUS20040046578A1Clamping forcePrevent exitElectronic circuit testingElectrical measurement instrument detailsKinematic couplingProbe card

A cartridge (10) includes a chuck plate (12) for receiving a wafer (74) and a probe plate (14) for establishing electrical contact with the wafer. In use, a mechanical connecting device (90) locks the chuck plate and the probe plate fixed relative to one another to maintain alignment of the wafer and the probe plate. Preferably, electrical contact with the wafer is established using a probe card (50) that is movably mounted to the probe plate by means of a plurality of leaf springs (52.) The mechanical connecting device is preferably a kinematic coupling including a male connector (94) and first and second opposed jaws (122, 124.) Each of the jaws is pivotable from a retracted position in which the male connector can be inserted between the jaws and an engaging position in which the jaws prevent withdrawal of the male connector from between the jaws. The male connector is movable between an extended and a retracted position, and is biased towards the retracted position. This provides a positive clamping force that pulls the chuck and probe plates together when the mechanical connecting device is engaged. To load a wafer into the cartridge, the wafer is placed on the chuck plate, the probe plate is aligned with the wafer, and the chuck plate and the probe plate are locked together. The cartridge can then be removed from the alignment device and placed in a burn-in or test chamber that does not itself require means for aligning the wafer or for providing a probe actuation force.

Owner:AEHR TEST SYST

Kinematic coupling

InactiveUS20020002008A1Clamping forcePrevent exitEngagement/disengagement of coupling partsElectronic circuit testingKinematic couplingEngineering

A kinematic coupling includes a male connector (94) and first and second opposed jaws (122, 124.) Each of the jaws is pivotable from a retracted position in which the male connector can be inserted between the jaws and an engaging position in which the jaws prevent withdrawal of the male connector from between the jaws. The male connector is movable between an extended and a retracted position, and is biased towards the retracted position. This provides a positive clamping force when the kinematic coupling is engaged.

Owner:AEHR TEST SYST

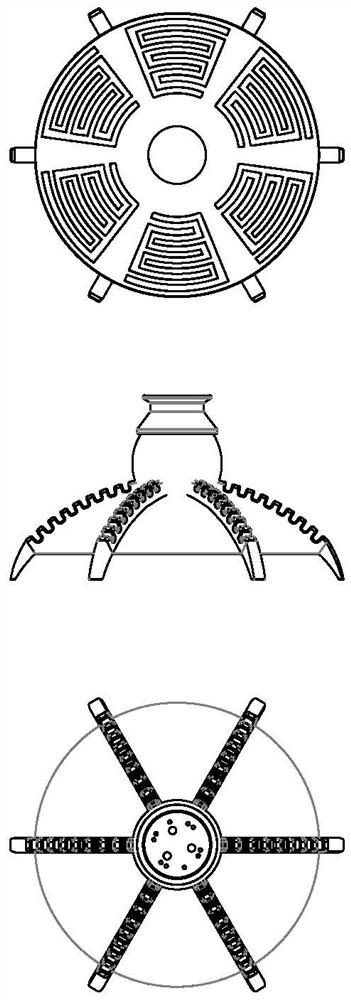

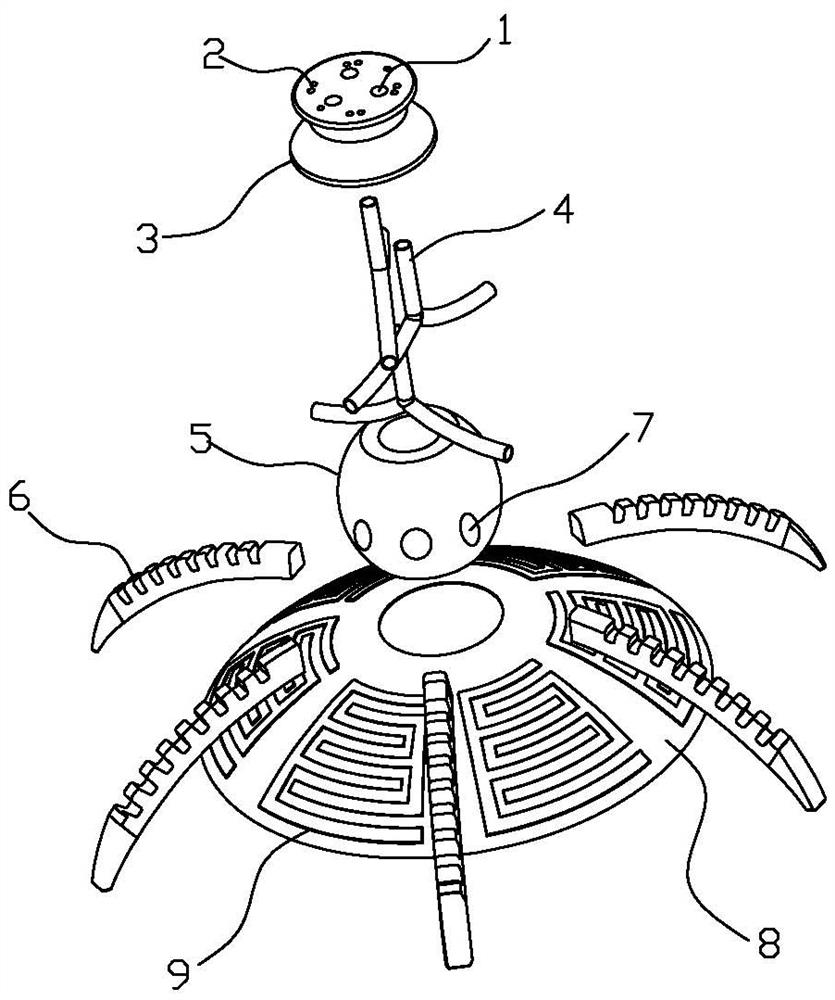

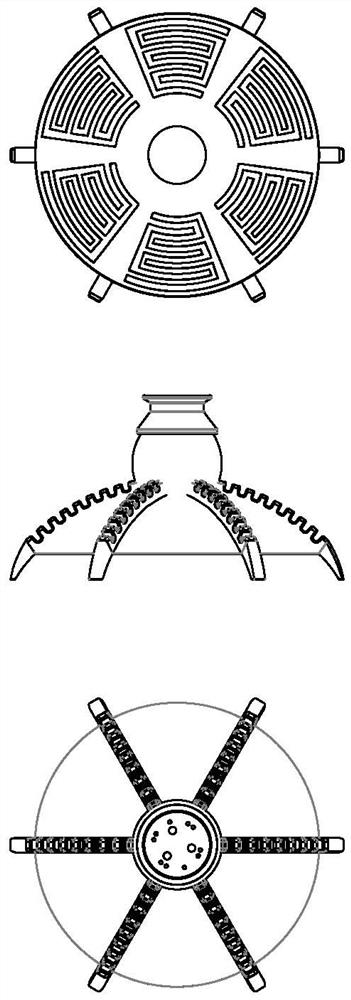

Soft electrostatic adhesion coating type bionic octopus manipulator

The invention relates to a soft electrostatic adhesion coating type bionic octopus manipulator. The soft electrostatic adhesion coating type bionic octopus manipulator comprises a connecting base, a main cavity and claw fingers, wherein the connecting base is in a hollow circular truncated cone shape, the lower end of the connecting base is open, and through inflating holes are formed in the upper end face of the connecting base; the main cavity is in a hollow drum shape, the upper end of the main cavity is open, and the main cavity is connected with the lower end of the connecting base; the periphery of the main cavity is provided with a plurality of connecting holes which are through from inside to outside; the multiple claw fingers are in a pneumatic network type; the claw fingers are hollow, the front ends of the claw fingers are inclined wedge-shaped, and the rear ends of the claw fingers are communicated with the connecting holes; the inflating holes are connected with the connecting holes through air pipes; the soft electrostatic adhesion coating type bionic octopus manipulator further comprises a flexible covering film; the covering film is disc-shaped, and the center of the top surface of the covering film is connected with the bottom of the main cavity; and a plurality of electrodes are arranged in the covering film. According to the soft electrostatic adhesion coating type bionic octopus manipulator, the clamping force is effectively increased, the clamping force borne by a target object can be equally divided, and the damage risk of the target object is reduced; and meanwhile, multiple grabbing modes are achieved, so that the clamping range is enlarged, and the use requirement can be fully met.

Owner:NANJING AGRICULTURAL UNIVERSITY

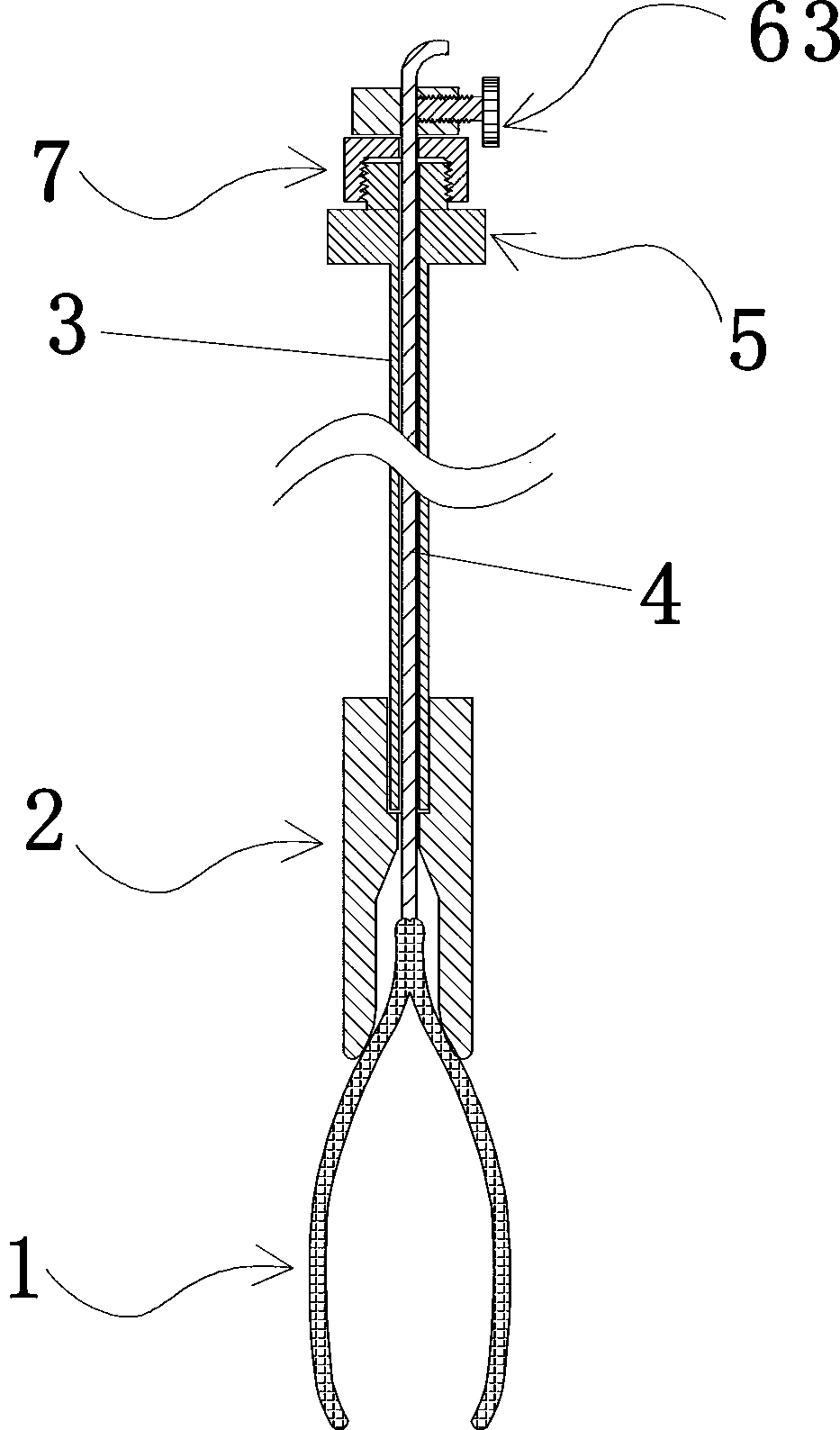

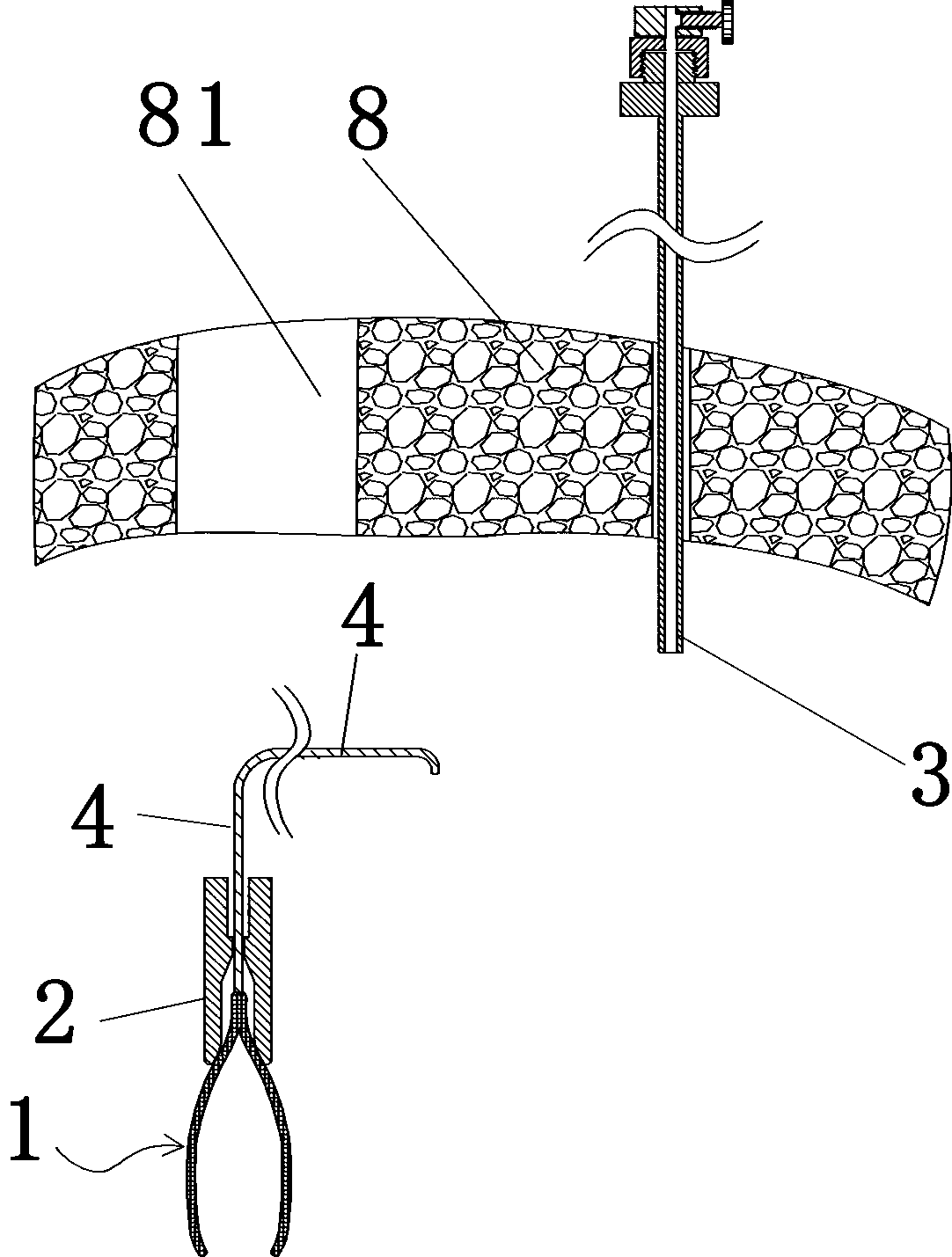

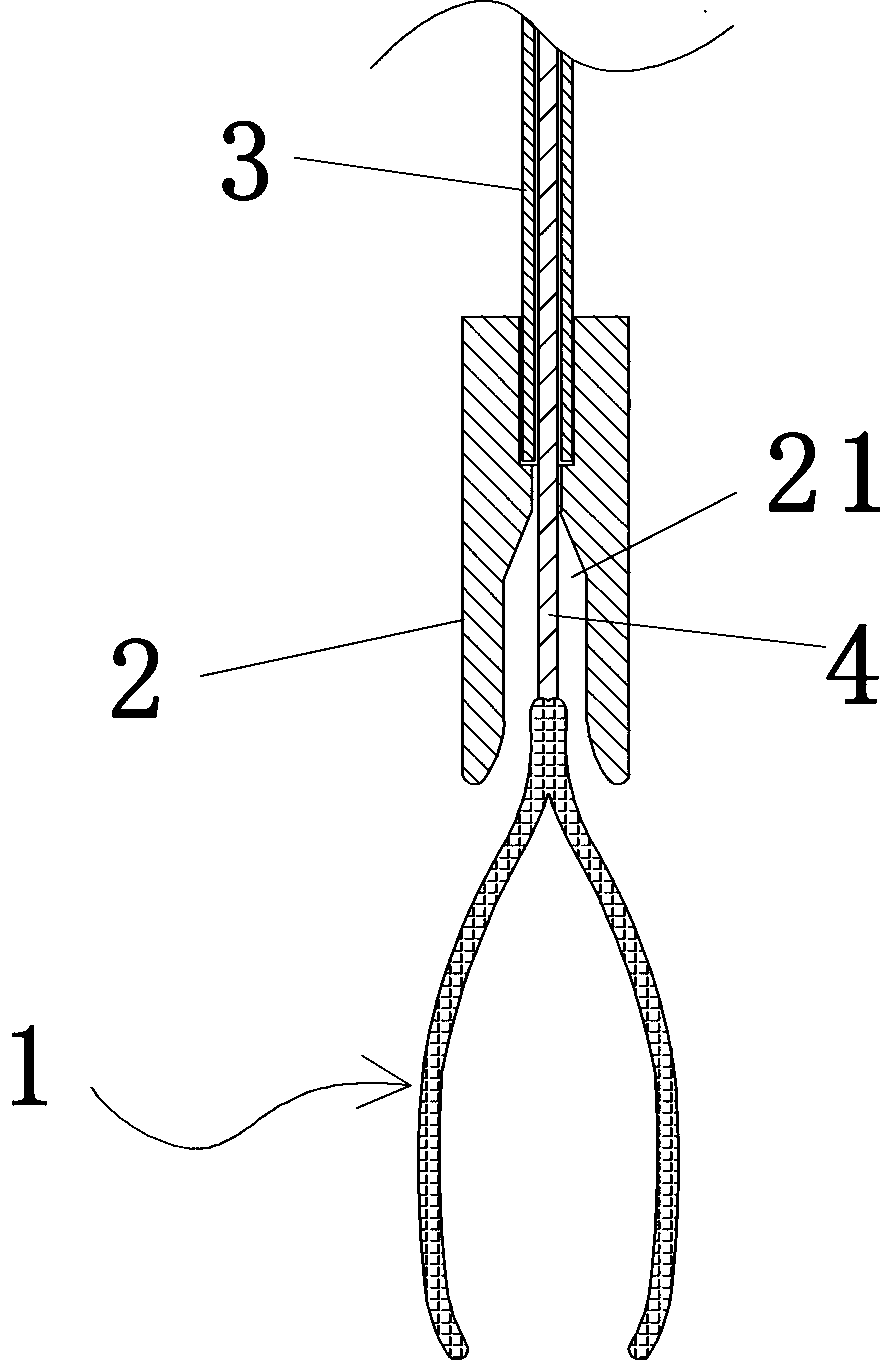

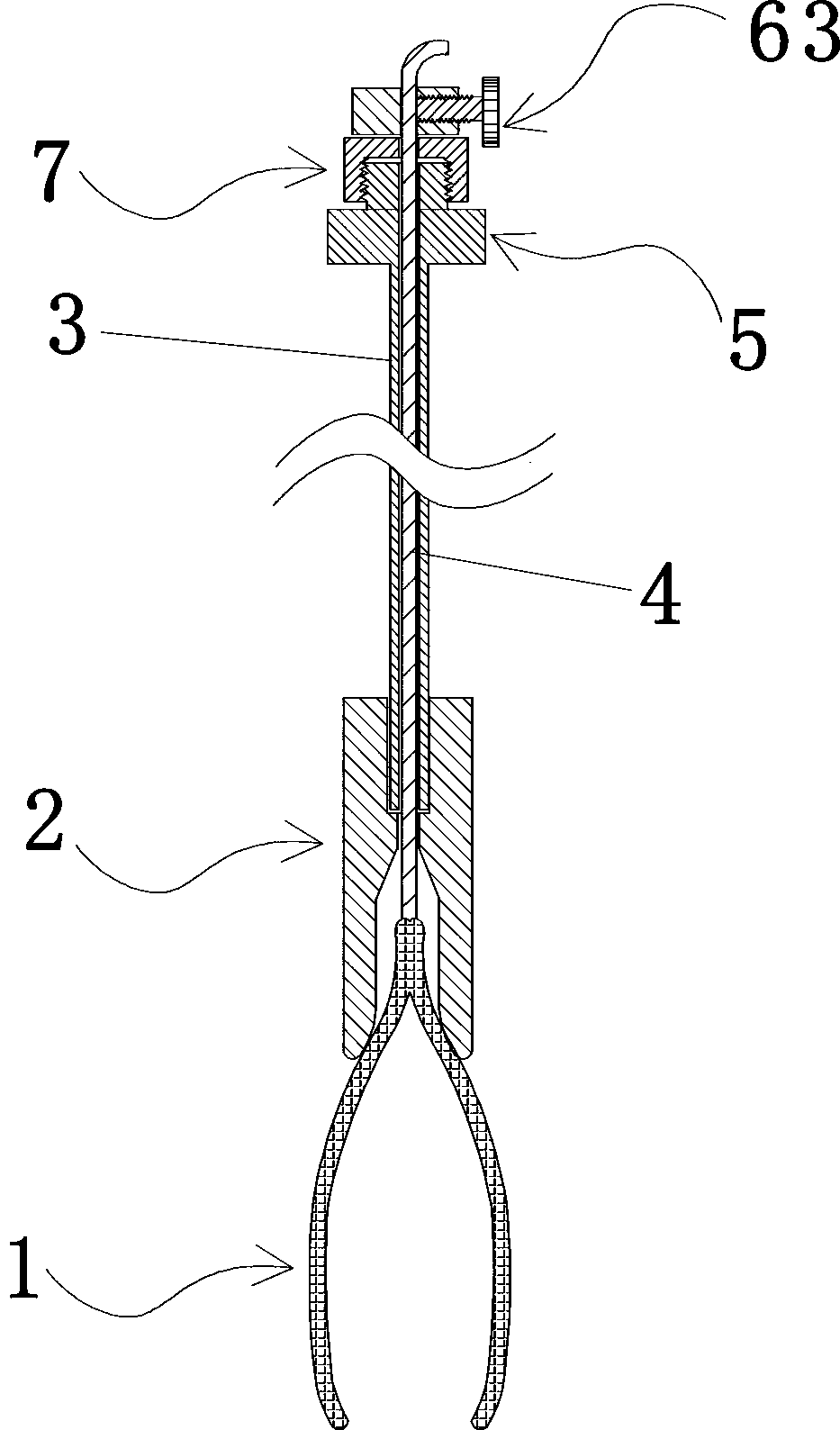

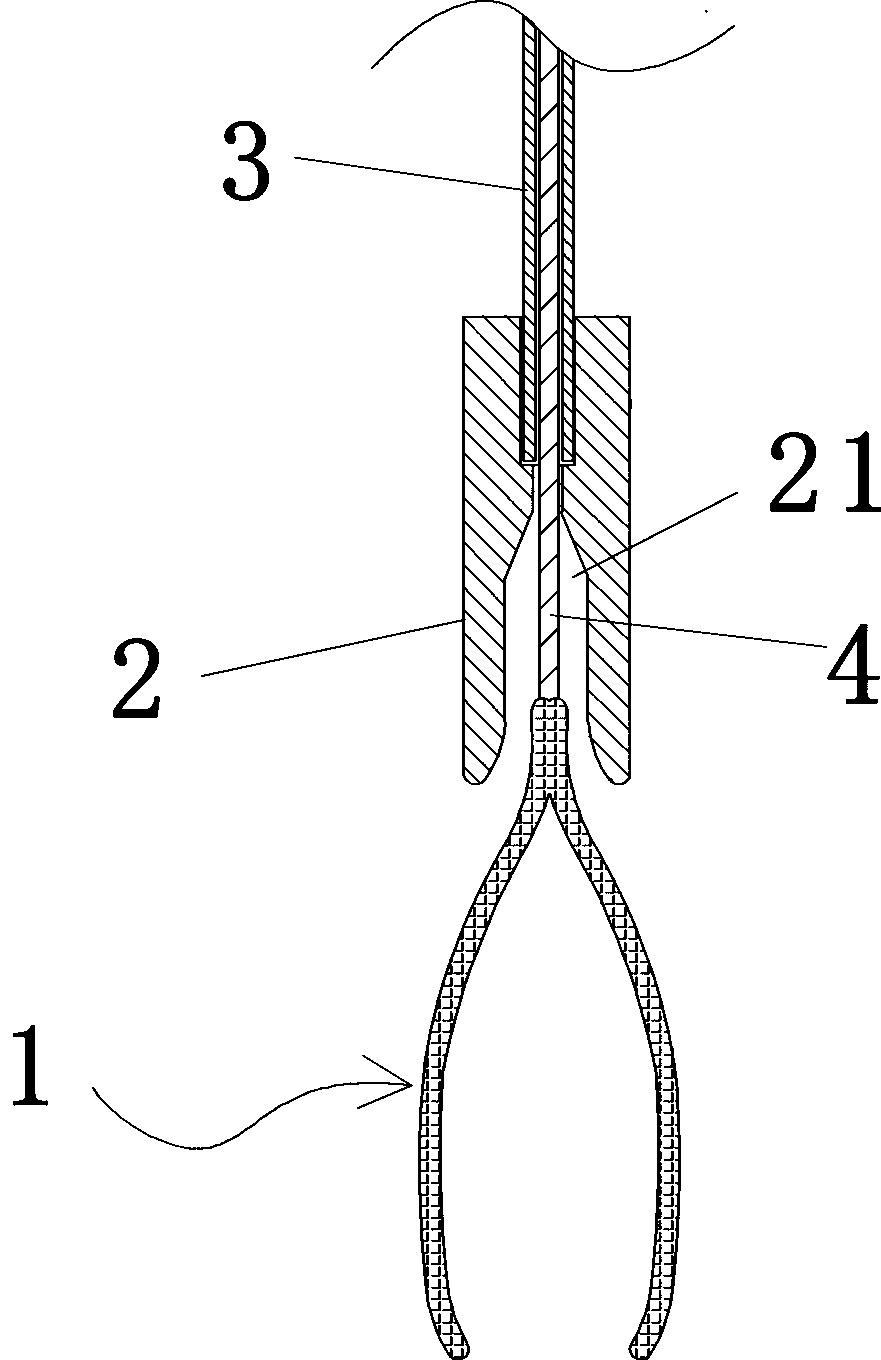

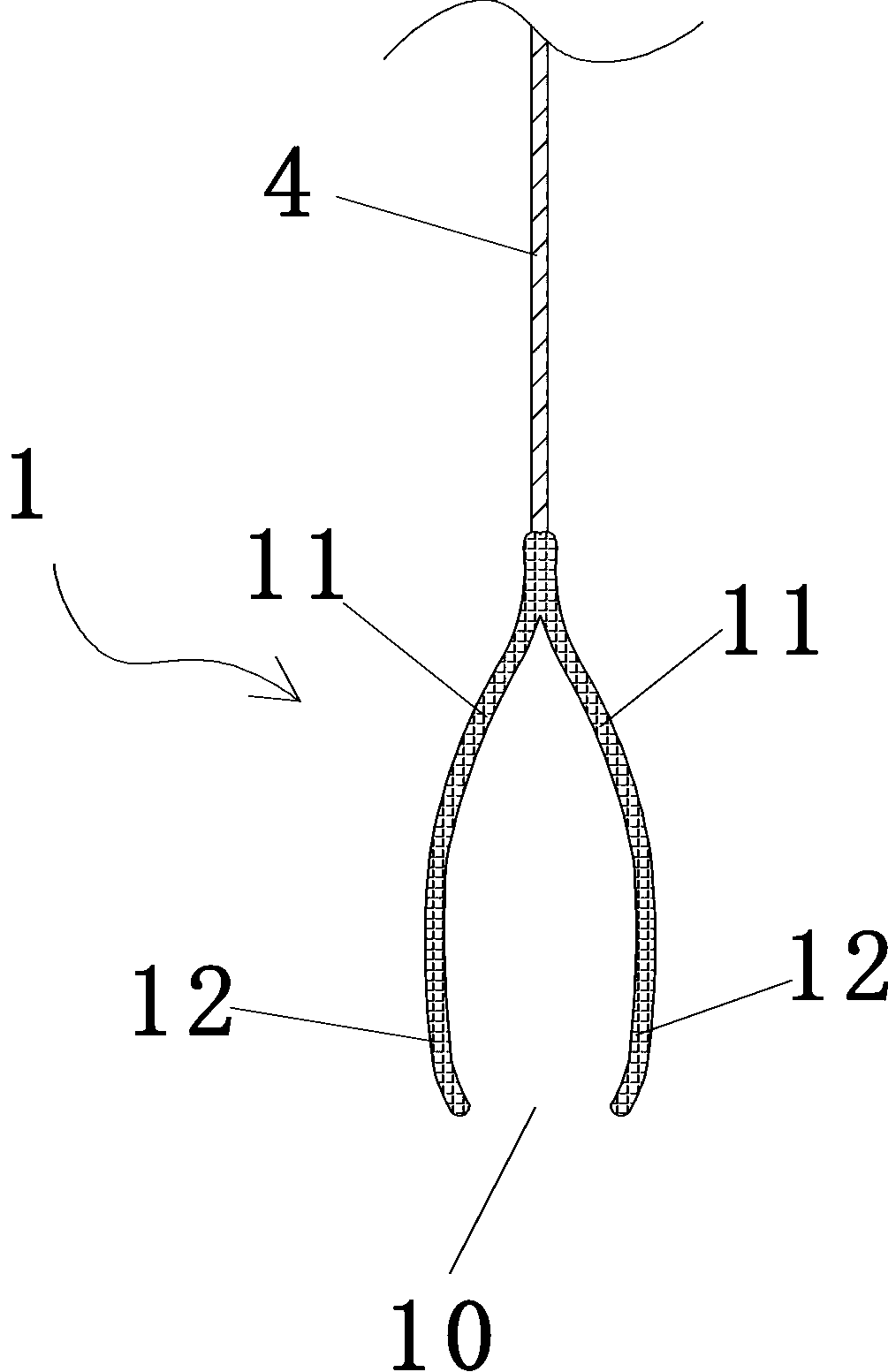

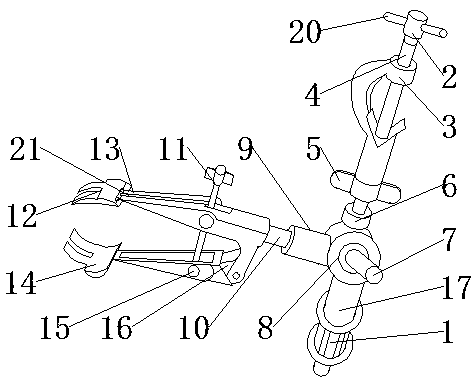

Minimally invasive surgery clamp for abdominal cavity

The invention provides a minimally invasive surgery clamp for the abdominal cavity. The minimally invasive surgery clamp for the abdominal cavity comprises an elastic clamp body and a metal wire, wherein the inner end of the metal wire is fixedly connected with the rear end of the elastic clamp body; the minimally invasive surgery clamp is further provided with a hollow round metal sleeve and an auxiliary control block, a through hole running through the axial full length is formed in the middle of the auxiliary control block, the through hole comprises a clamp body accommodating section, a necking down section and a metal sleeve accommodating section, the front end part of the clamp body accommodating section is in the shape of a horn mouth with the large front part and the small rear part, the hole diameter of the metal sleeve accommodating section allows the insertion of the inner end of the round metal sleeve, and the hole diameter of the necking down section is greater than the diameter of the metal wire and smaller than the outer diameter of the round metal sleeve. For the minimally invasive surgery clamp for the abdominal cavity, the needed size of an operation hole is freeof the limitation of the size of clamp arms of the clamp body, the needed hole diameter of the operation hole is small, the clamping of the clamp arms is powerful, and the operation is simple and convenient.

Owner:汕头市颂美恩生物科技有限公司

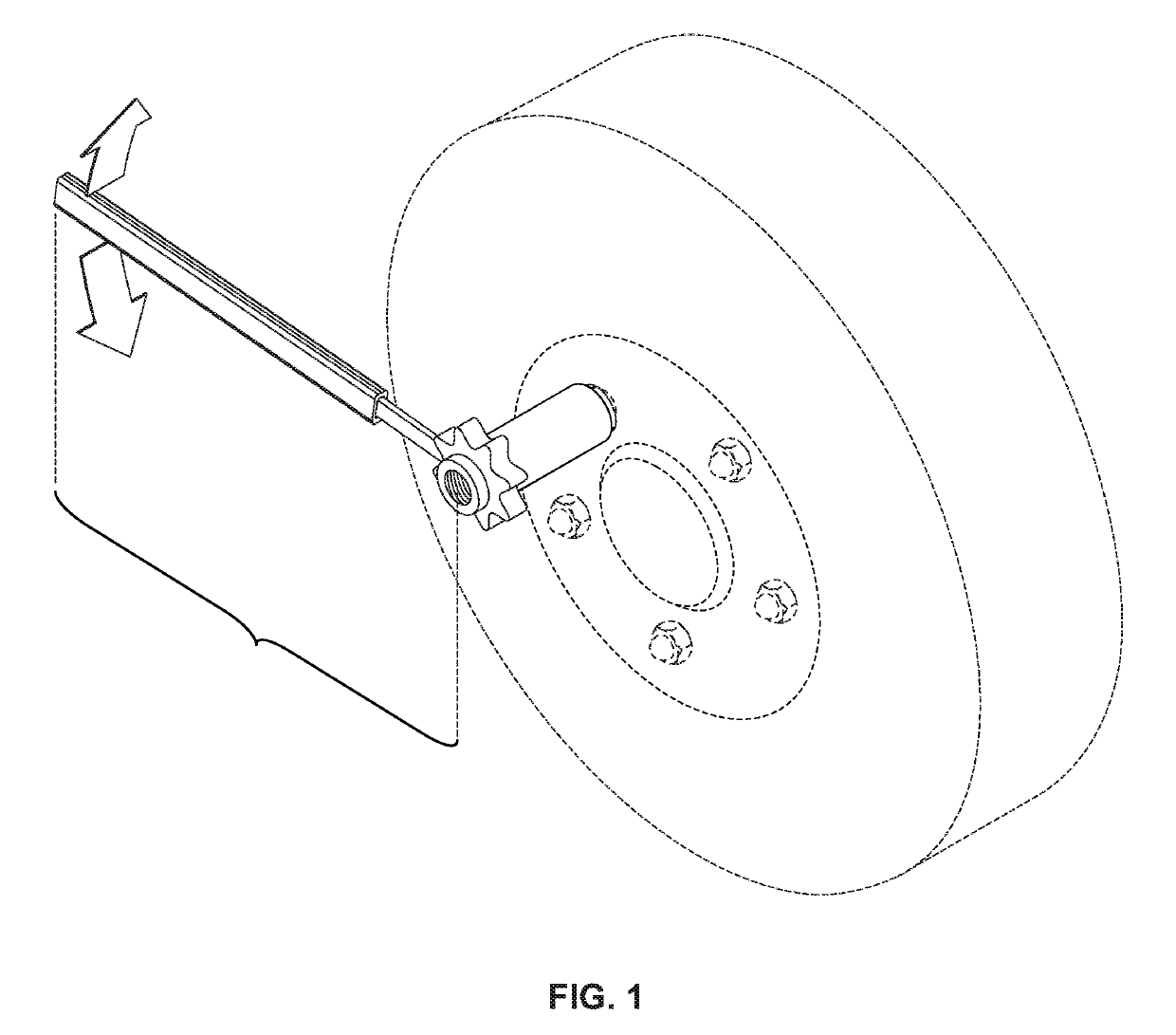

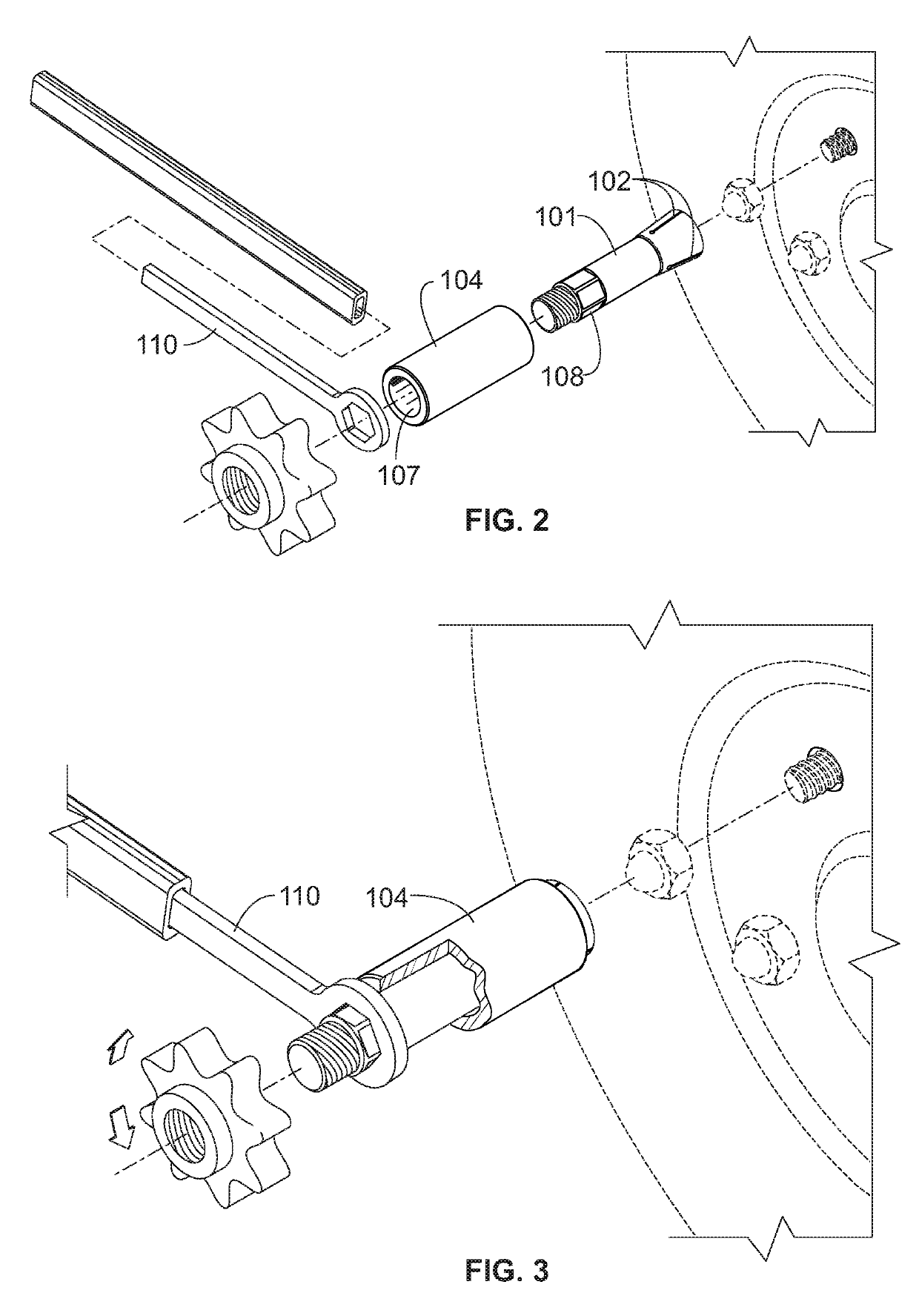

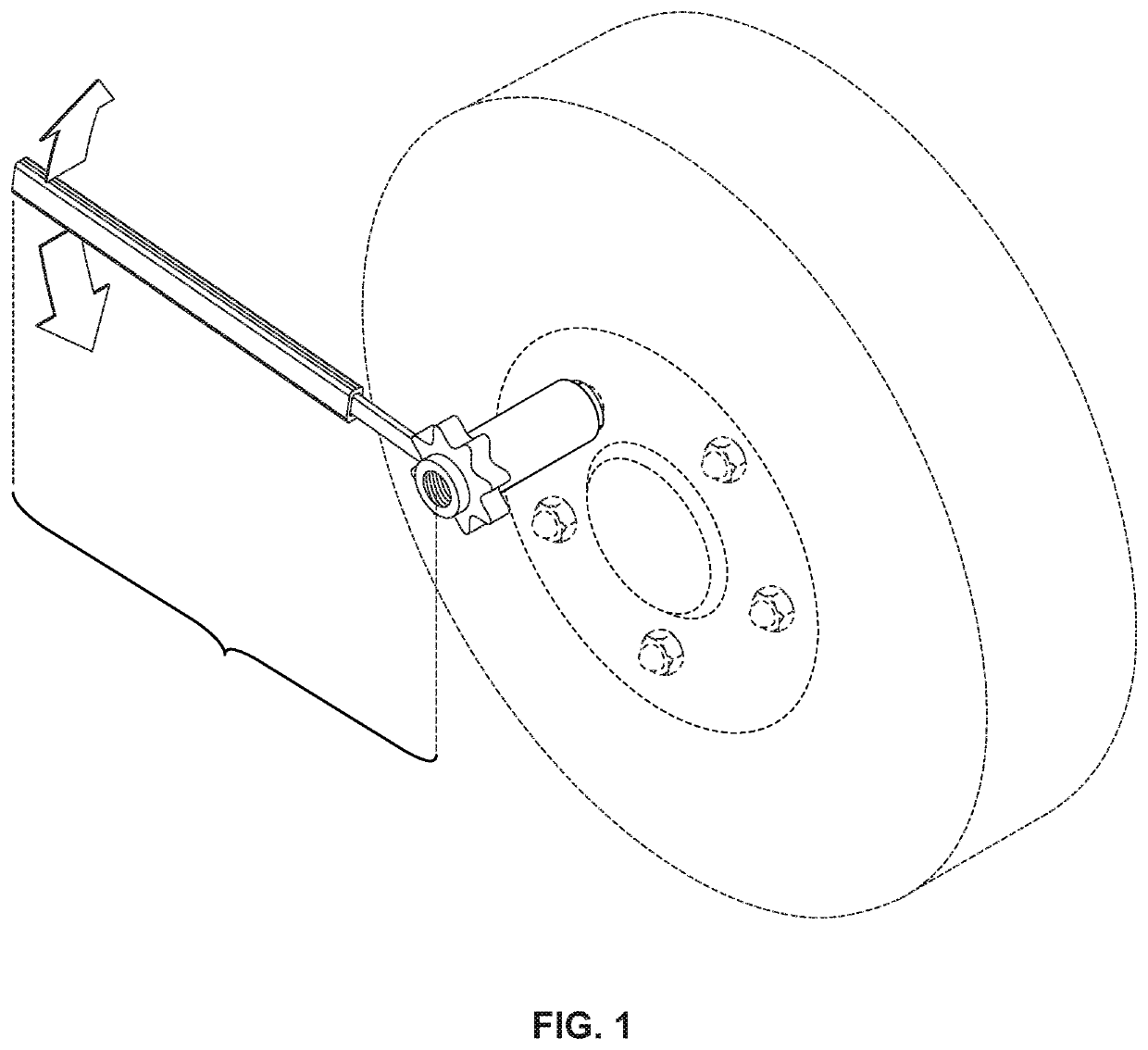

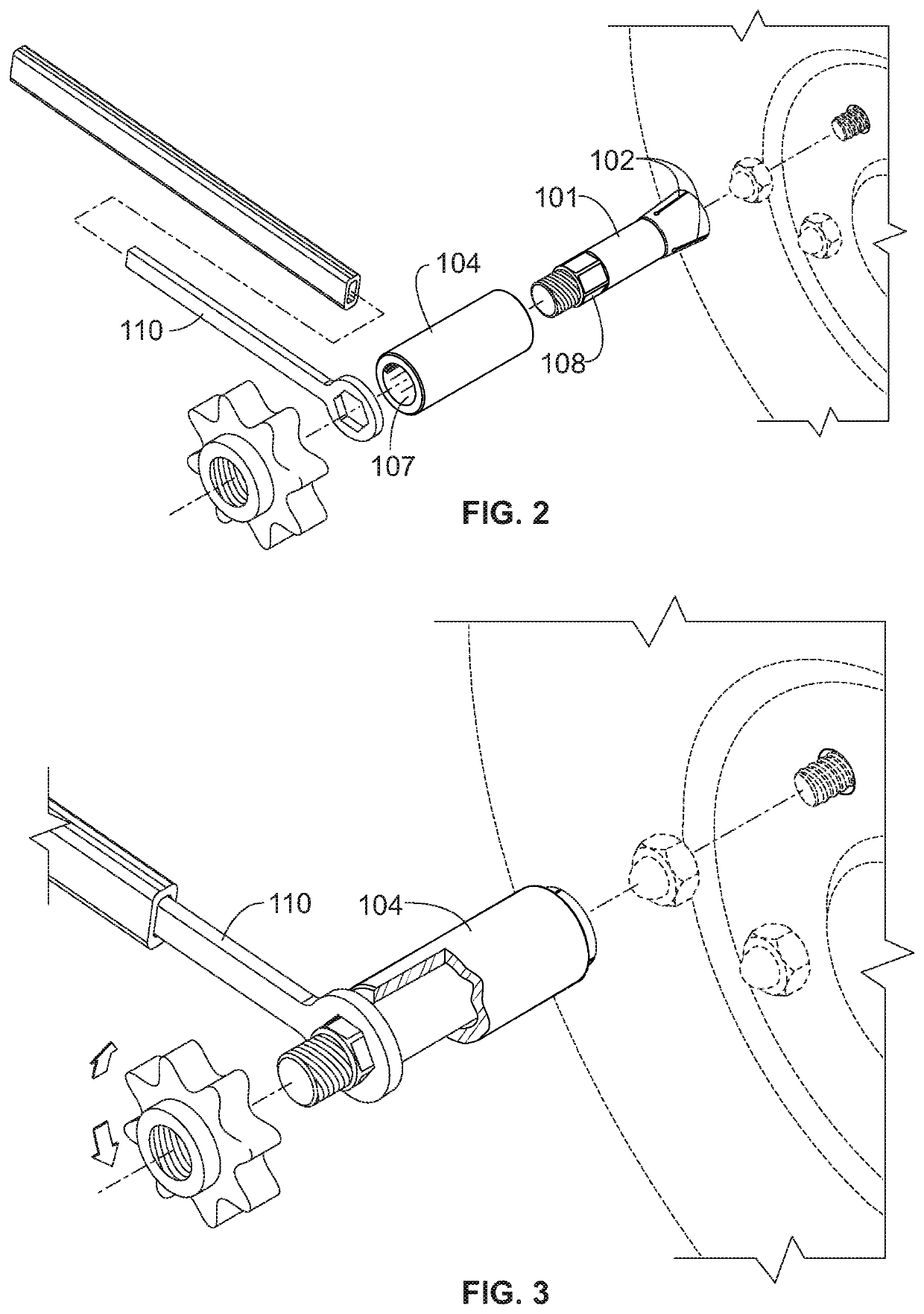

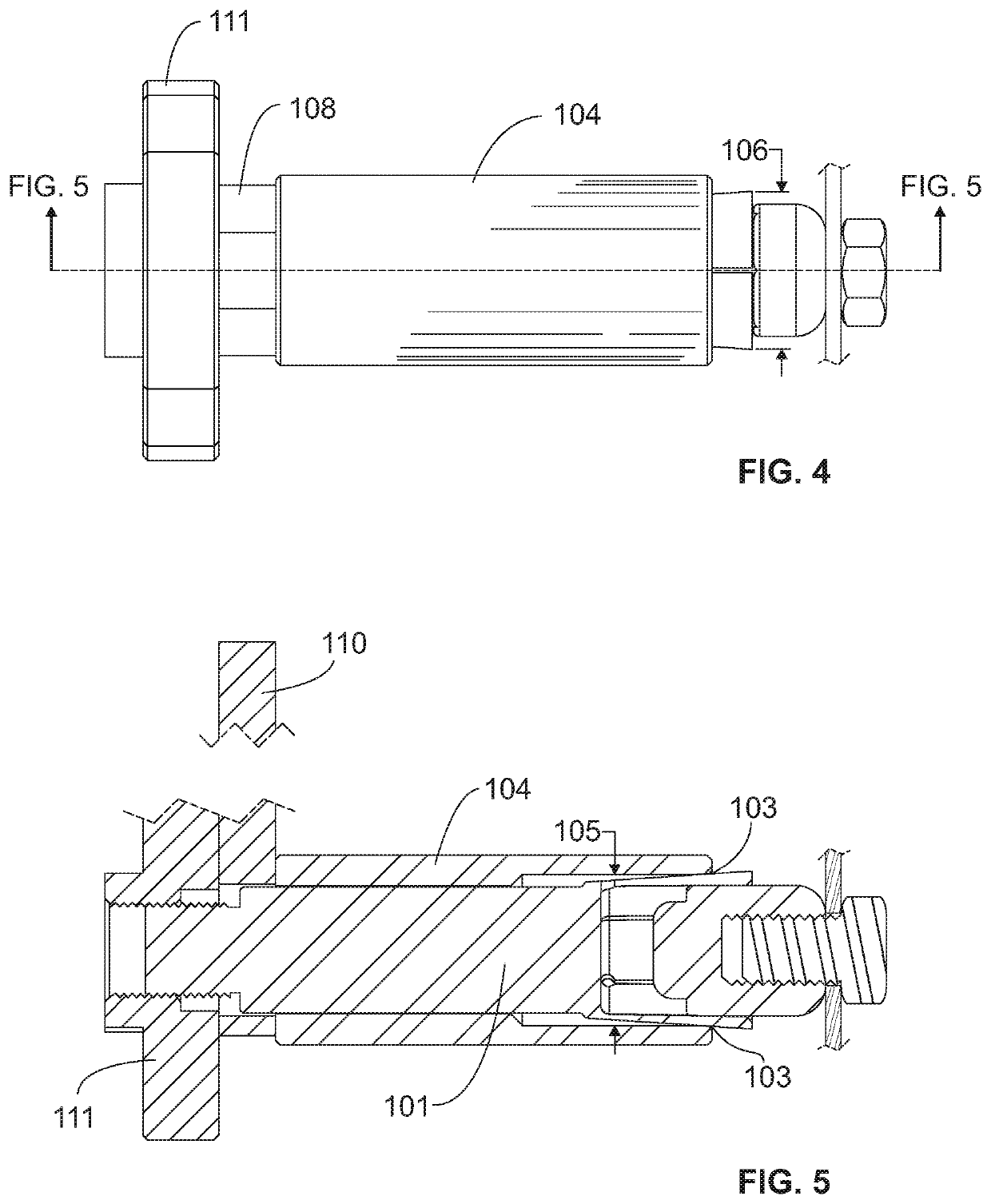

Lug wrench with secure clamping mechanism

A lug wrench apparatus comprising a collet-type assembly whereby the socket clamps to the lug nut in a manner similar to the way a collet clamps a router bit. The clamping mechanism can be provided either by a screw-compression, or an eccentric cam compression. Arbitrarily large amounts of torque can be applied by means of an extension which fits over the arm of a wrench that is clamped to the shaft of the collet.

Owner:BOWDEN SR FREDERICK L

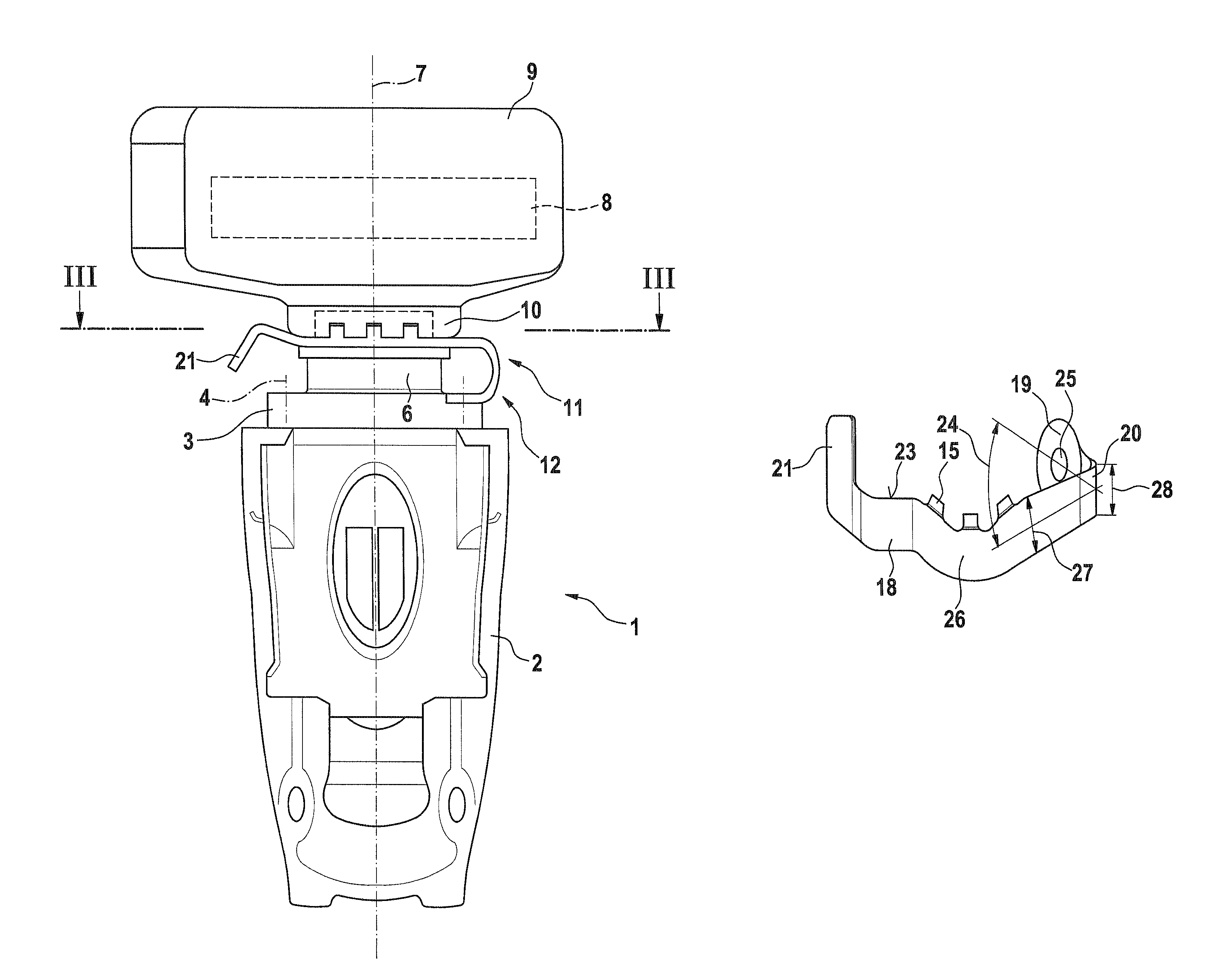

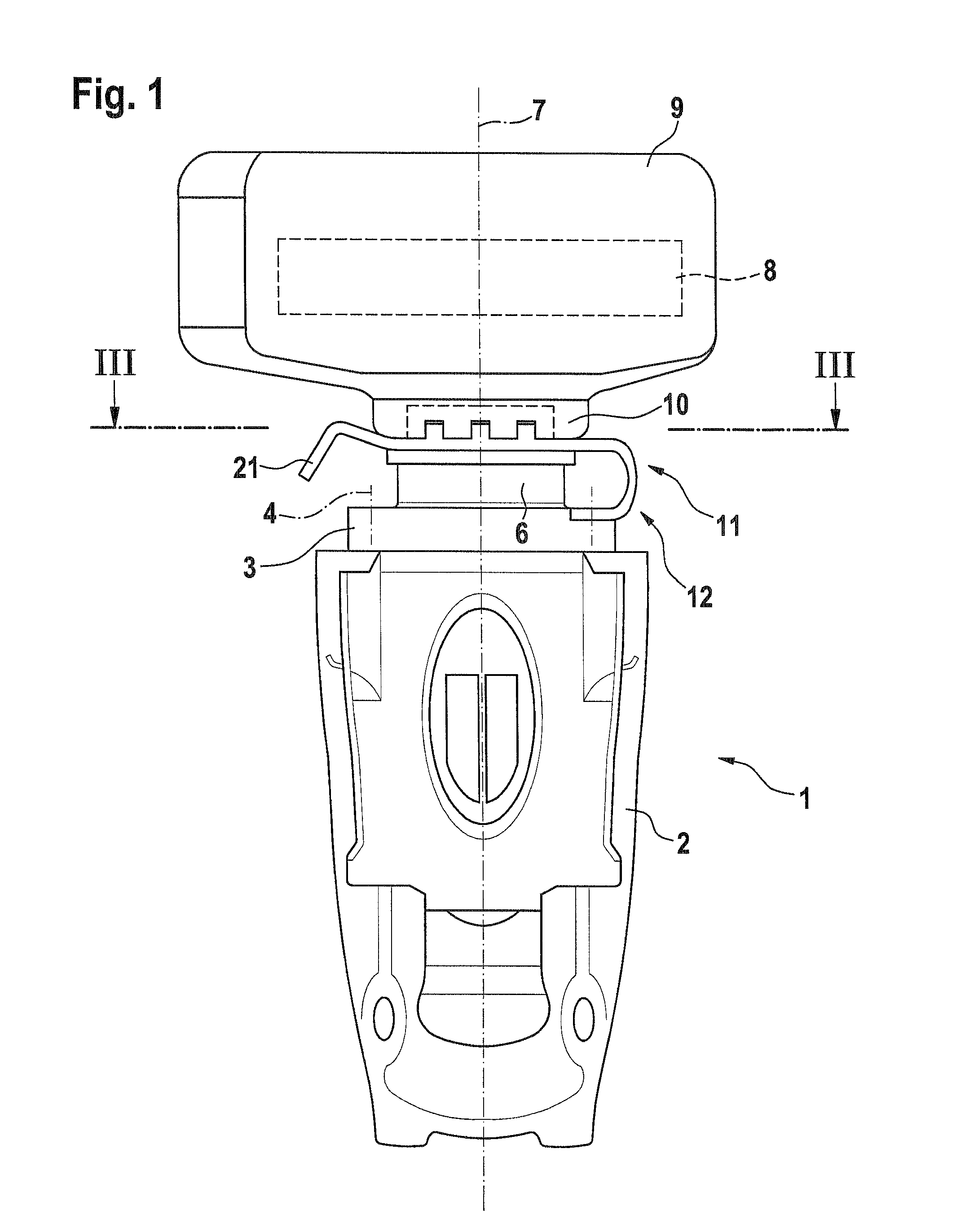

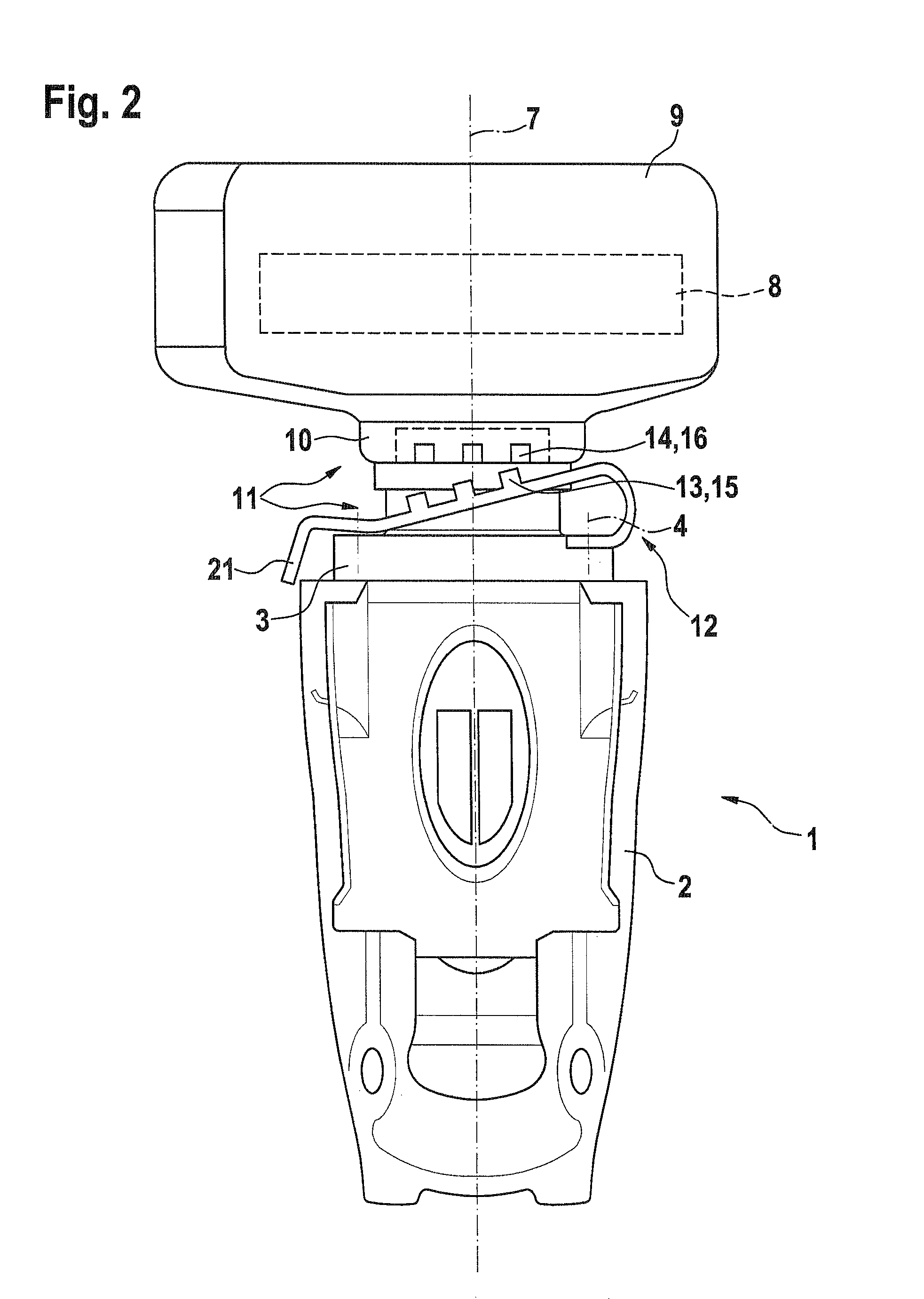

Hand-held power tool, in particular hand-guided grinding machine

ActiveUS8512104B2Clamping forceInfluenced in intensityPortable grinding machinesGrinding/polishing safety devicesLocking mechanismHand held

A protective guard is provided for a hand-held power tool, in particular a hand-guided grinding machine. According to the invention, the tool is at least partially covered by the protective guard. The guard is supported in an elastically flexible fashion in the circumference direction of the bearing journal by means of a spring means that prestress locking elements of a locking mechanism in their engaged positions.

Owner:ROBERT BOSCH GMBH

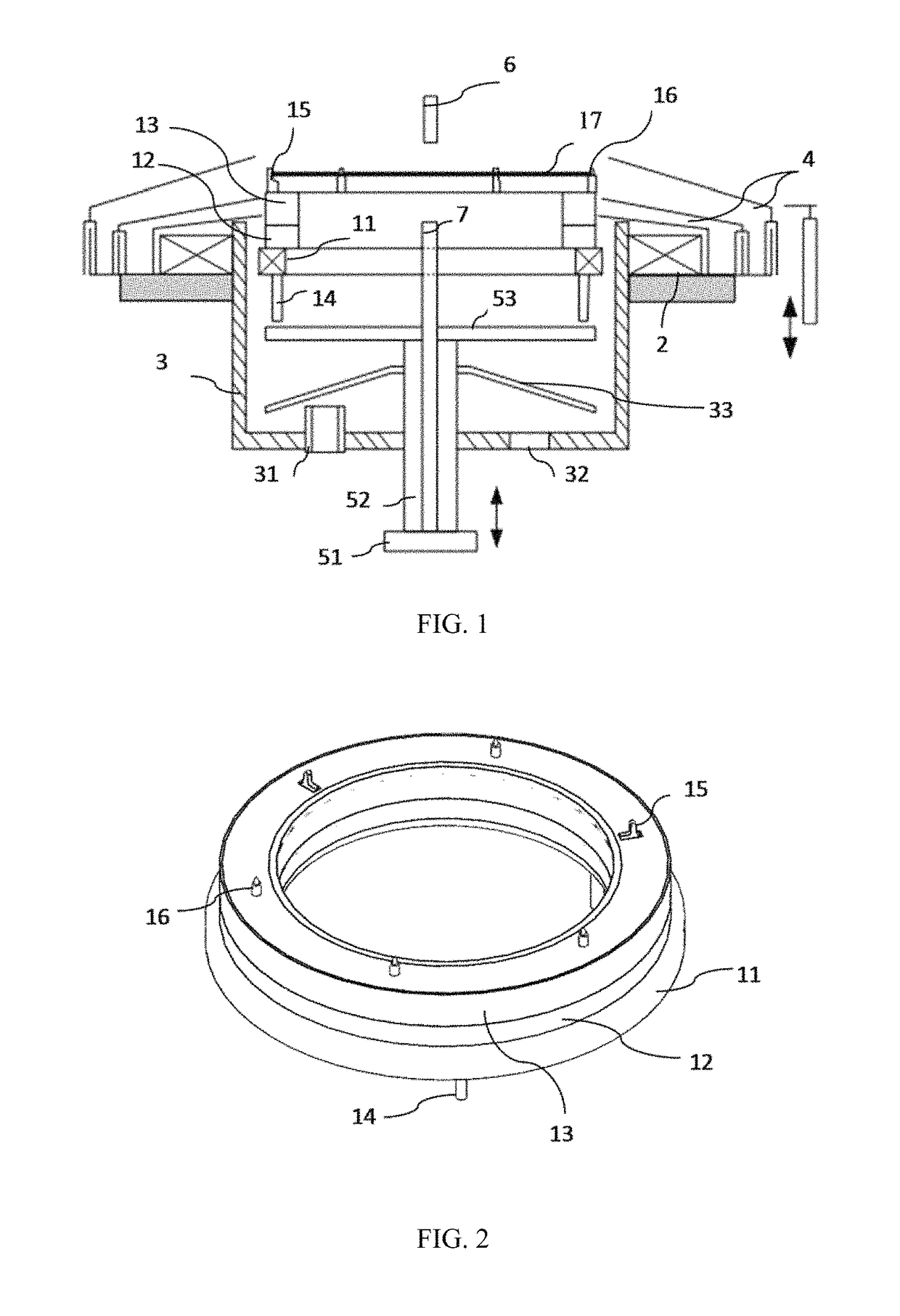

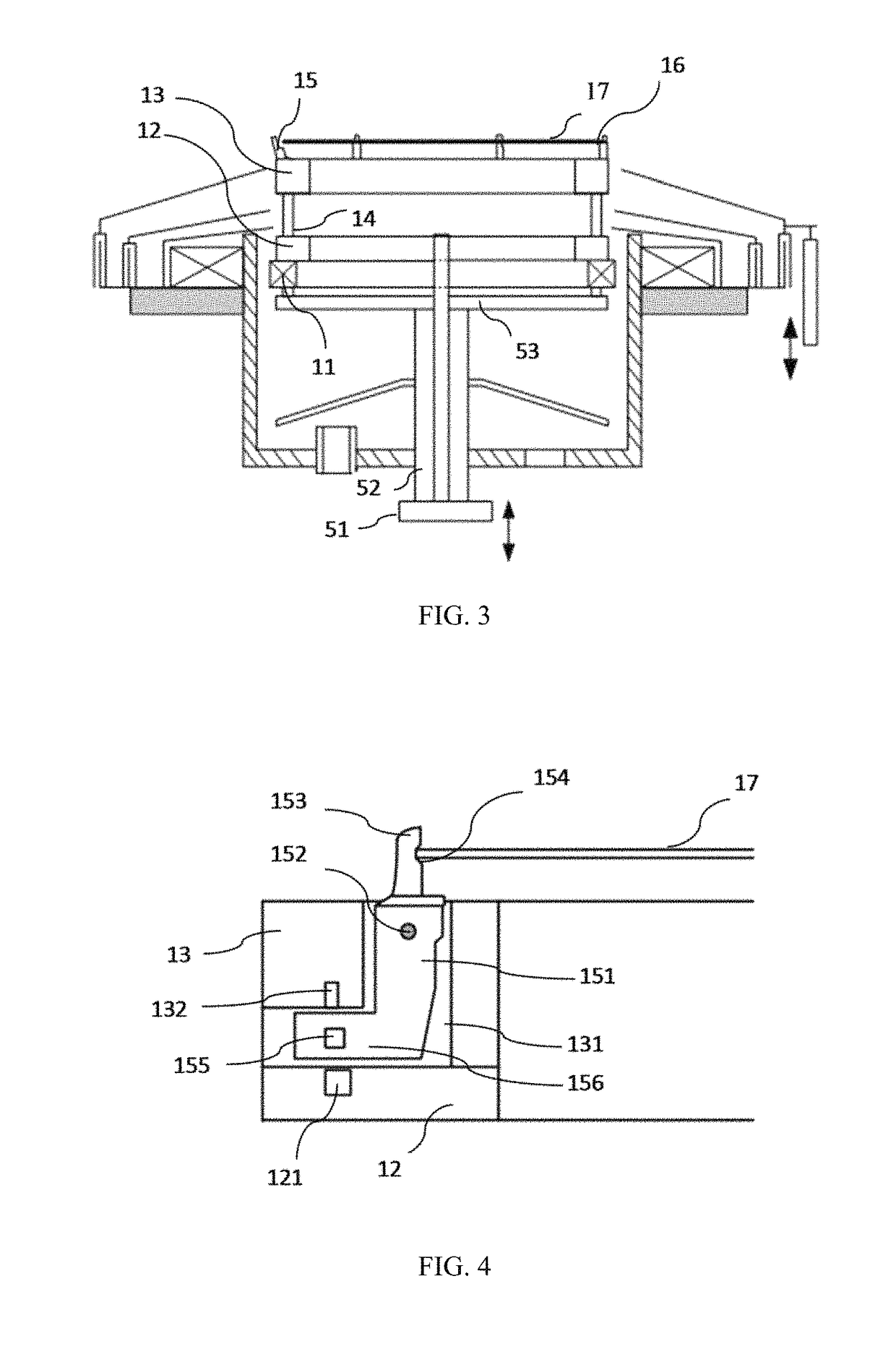

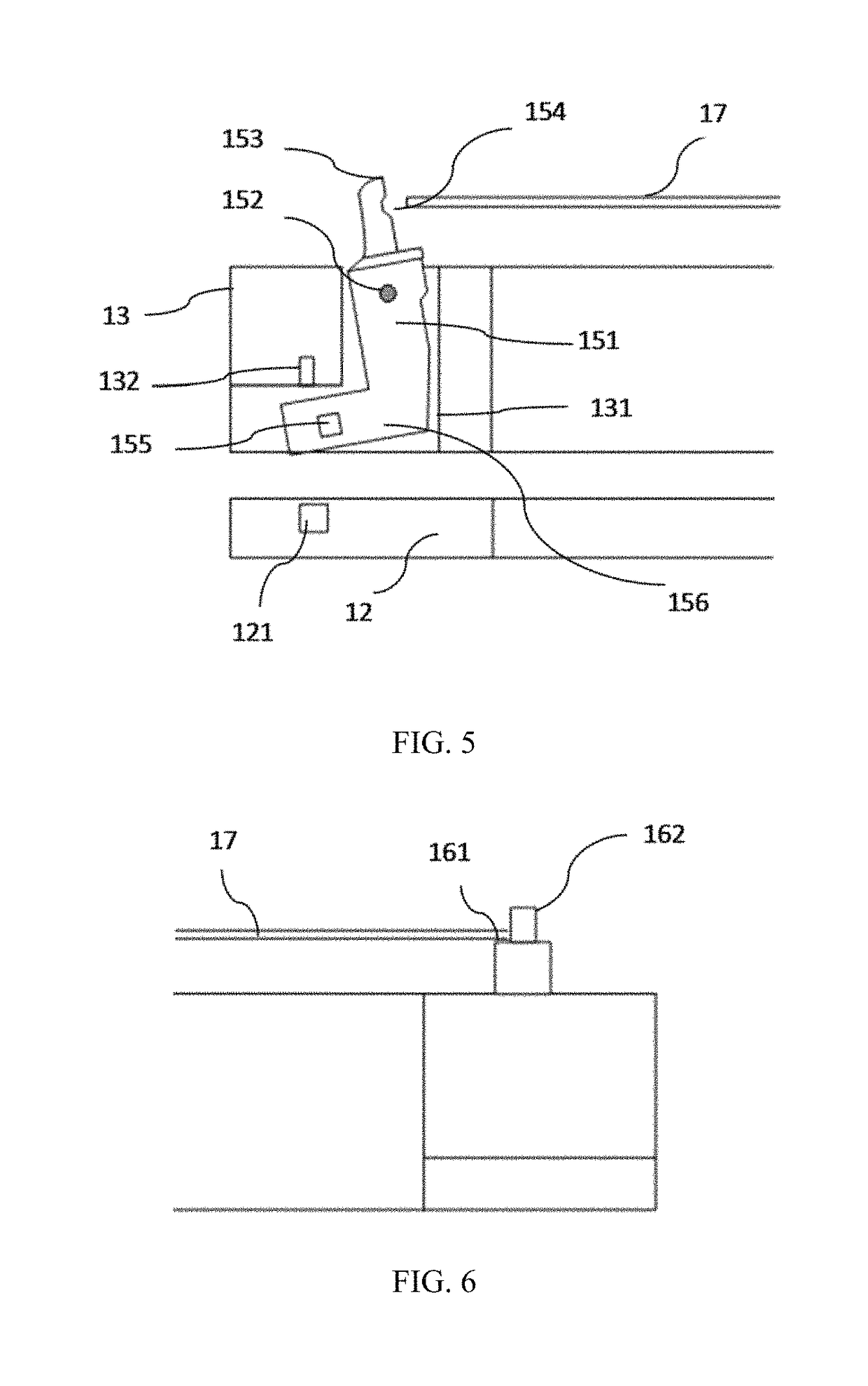

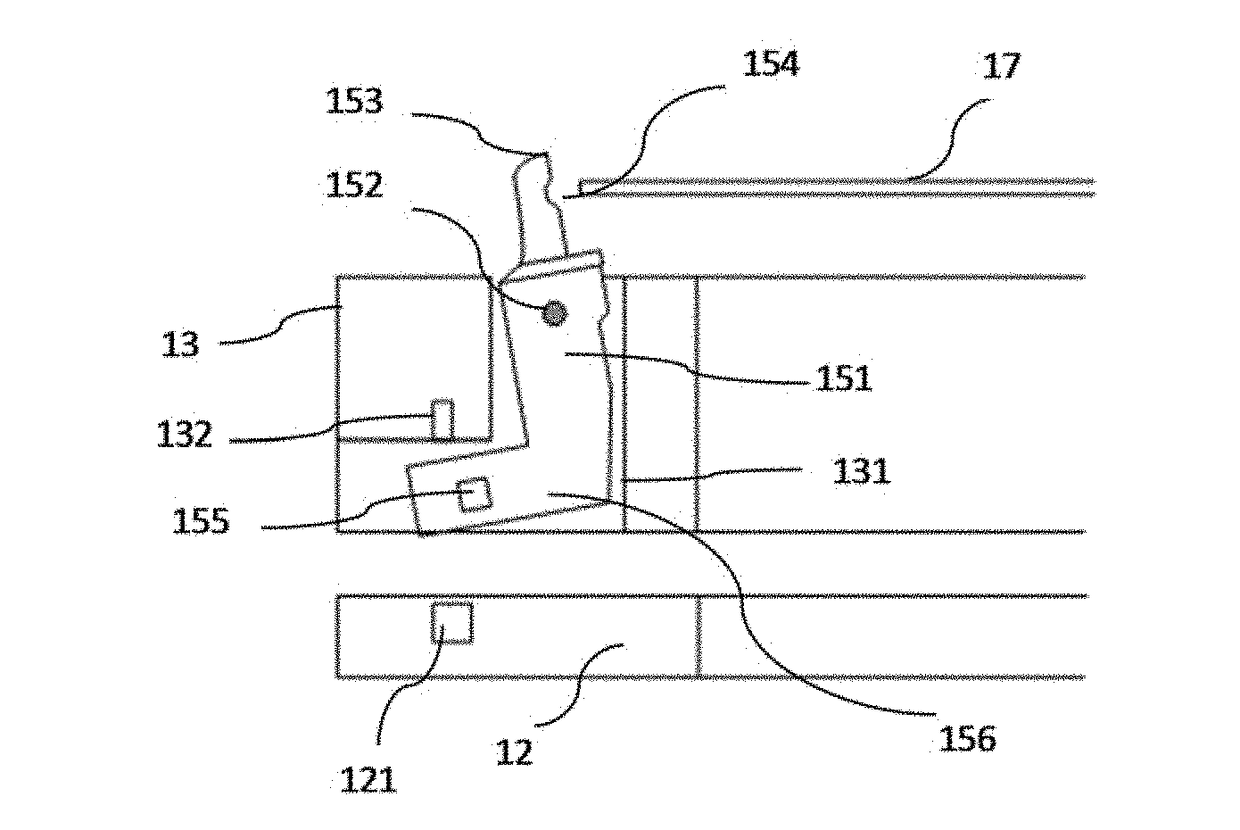

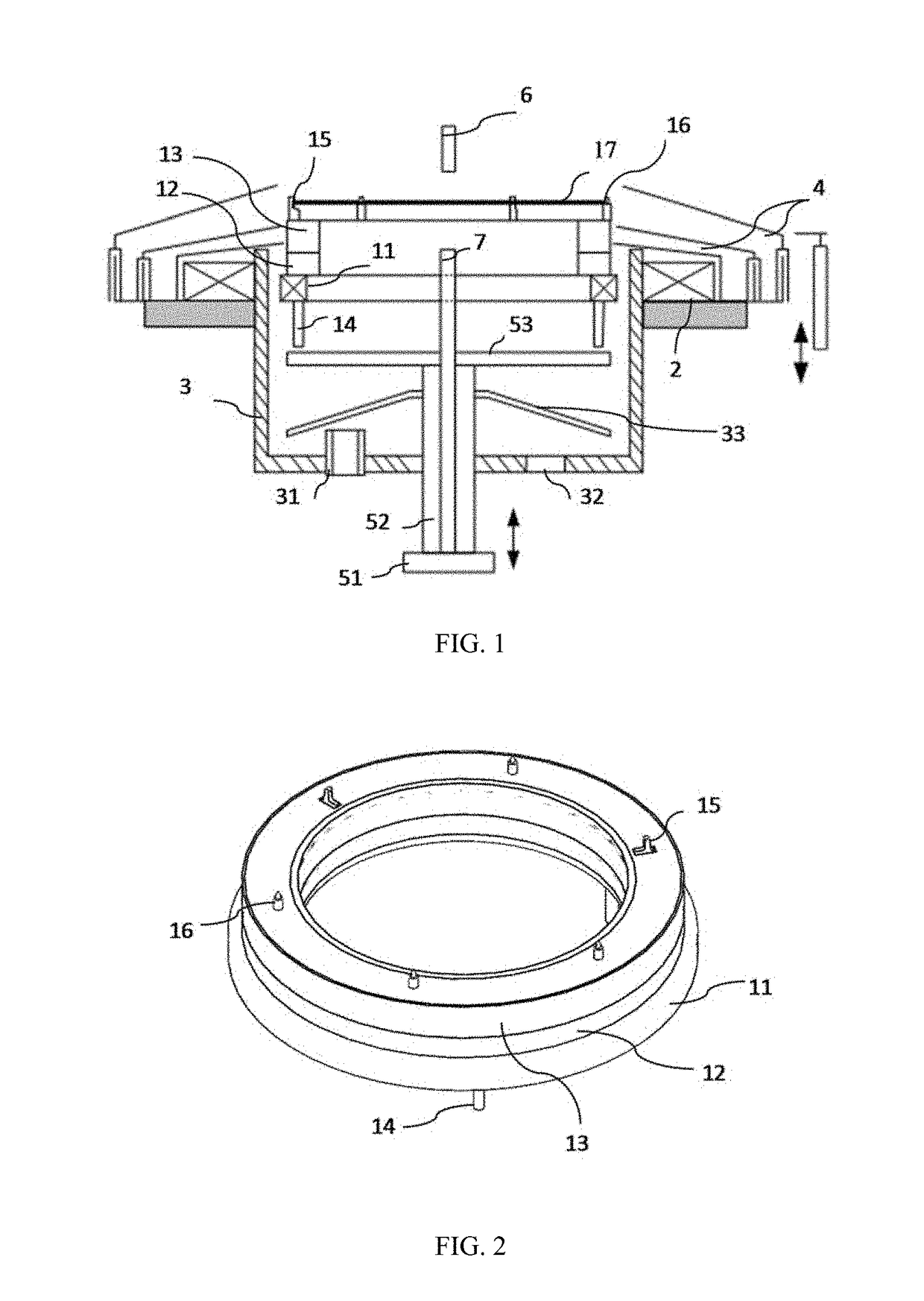

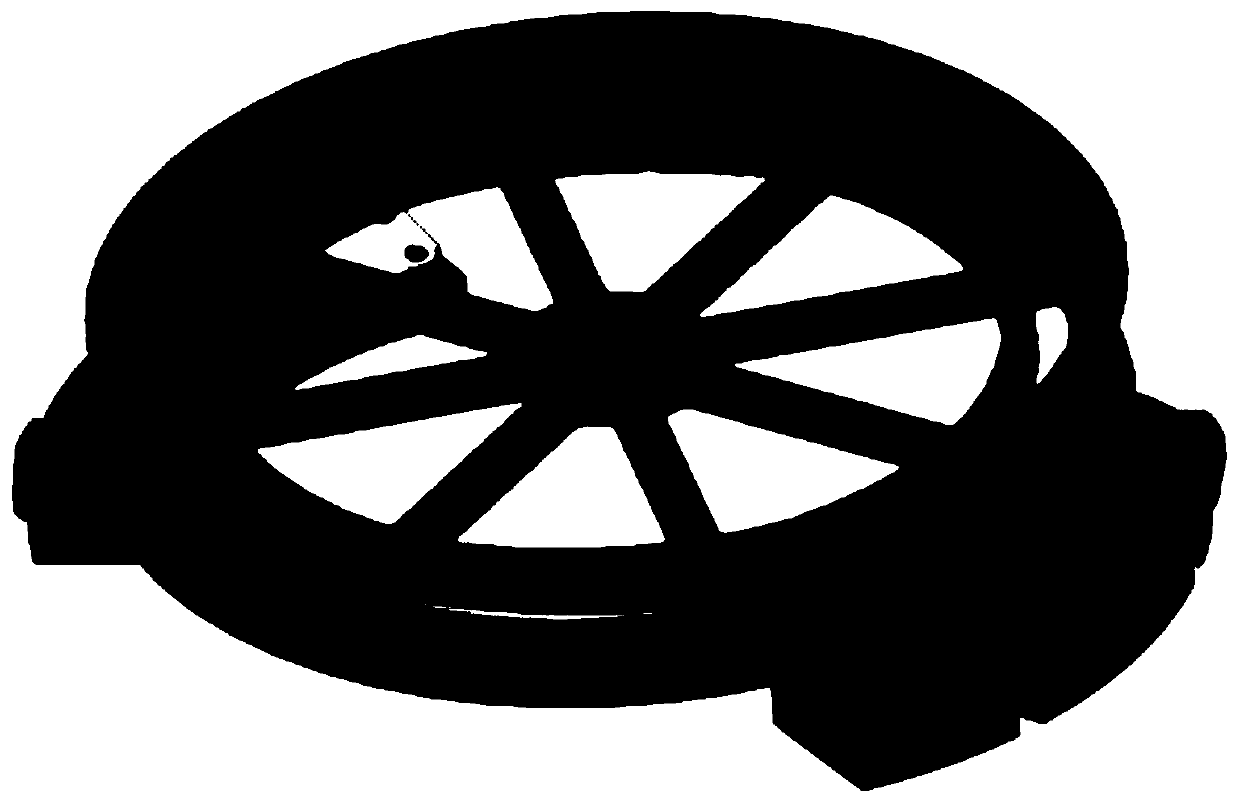

Device for holding and rotating plate shaped article

ActiveUS10204818B2Simple structureEasy and reliable motion controlSemiconductor/solid-state device manufacturingBody positionsEngineering

A device for holding and rotating a plate shaped article comprises a group of fixed pins and a group of pivot pins arranged along the circumference of the movable base in a manner that each pivot pin opposites a fixed pin, and also comprises magnetic bodies positioned within and outside two opposing sides of the pivot pins. Each of the pivot pins can be driven to rotate around its pivot back and forth under the magnetic repulsive force between two adjacent magnetic bodies, so as to release or clamp the plate shaped article. The present invention has advantages of simple structure, convenient and reliable action control, controllable clamping force and good compatibility with various processing chambers.

Owner:BEIJING SEVENSTAR ELECTRONICS CO LTD

Device for holding and rotating plate shaped article

ActiveUS20170358480A1Small space occupationSimple structureSemiconductor/solid-state device manufacturingPhysicsEngineering

A device for holding and rotating a plate shaped article comprises a group of fixed pins and a group of pivot pins arranged along the circumference of the movable base in a manner that each pivot pin opposites a fixed pin, and also comprises magnetic bodies positioned within and outside two opposing sides of the pivot pins. Each of the pivot pins can be driven to rotate around its pivot back and forth under the magnetic repulsive force between two adjacent magnetic bodies, so as to release or clamp the plate shaped article. The present invention has advantages of simple structure, convenient and reliable action control, controllable clamping force and good compatibility with various processing chambers.

Owner:BEIJING SEVENSTAR ELECTRONICS CO LTD

Lug wrench with secure clamping mechanism

ActiveUS10780738B2Clamping forceExert clamping forceWheel mounting apparatusSpannersClassical mechanicsEngineering

A lug wrench apparatus comprising a collet-type assembly whereby the socket clamps to the lug nut in a manner similar to the way a collet clamps a router bit. The clamping mechanism can be provided either by a screw-compression, or an eccentric cam compression. Arbitrarily large amounts of torque can be applied by means of an extension which fits over the arm of a wrench that is clamped to the shaft of the collet.

Owner:BOWDEN SR FREDERICK L

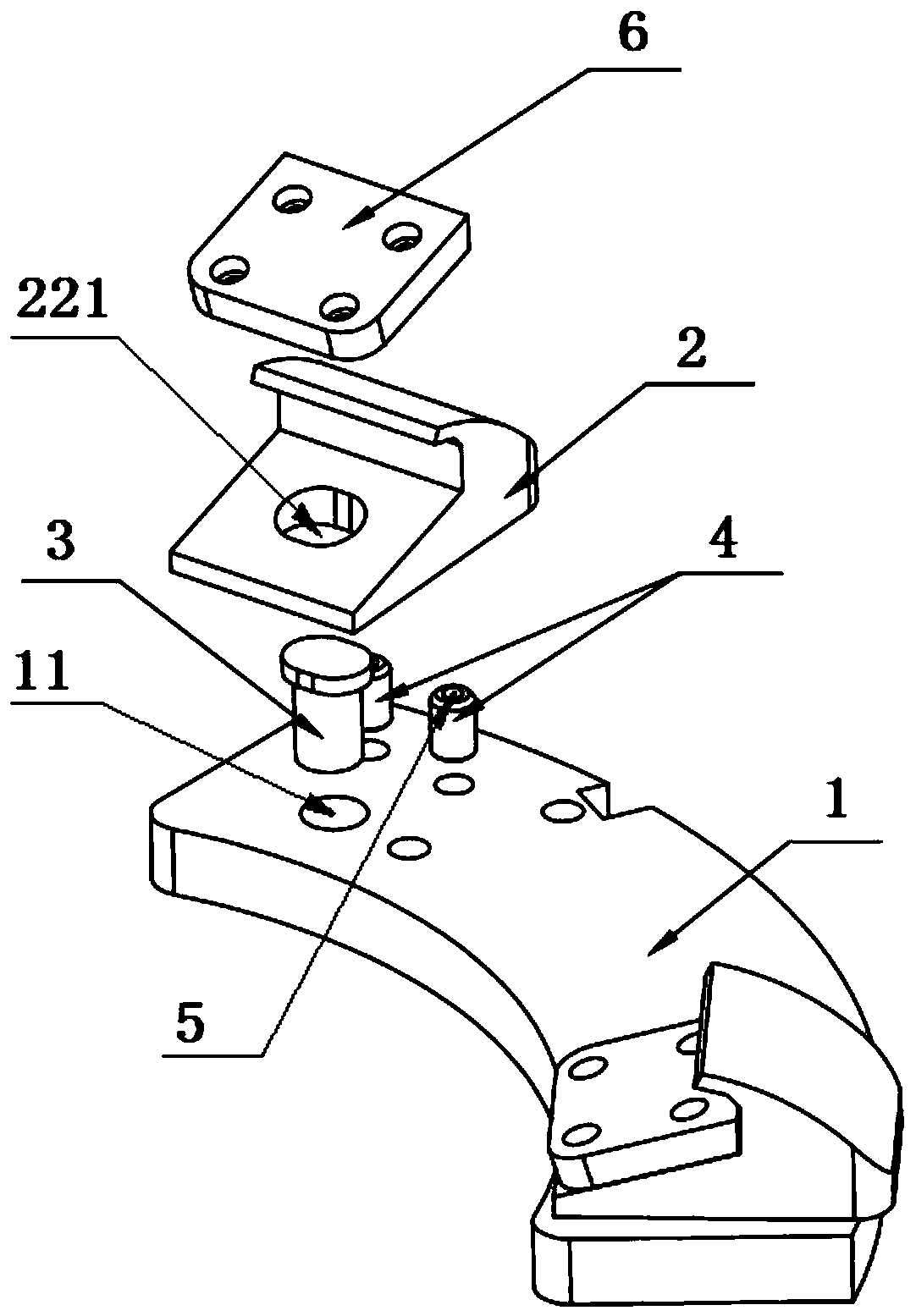

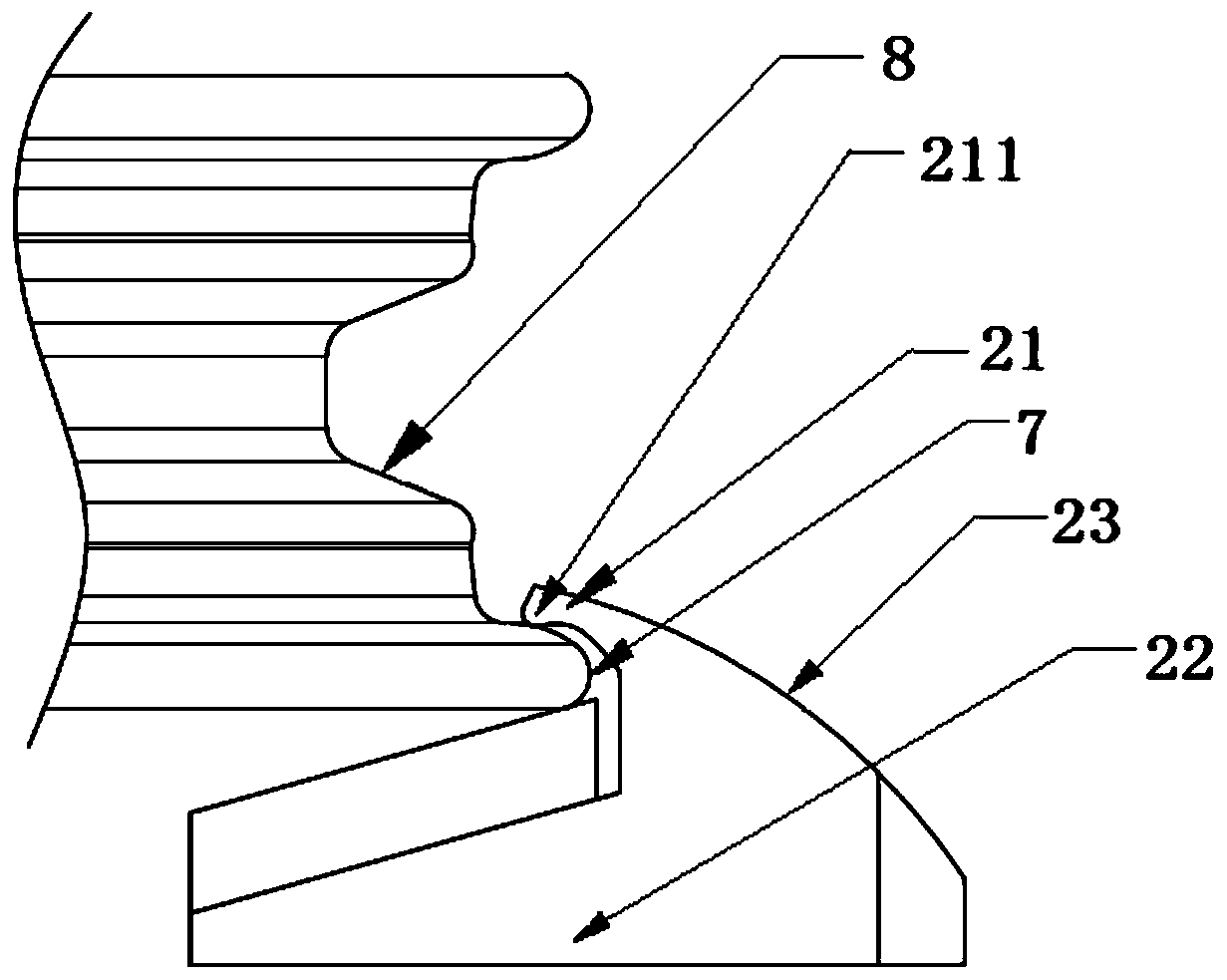

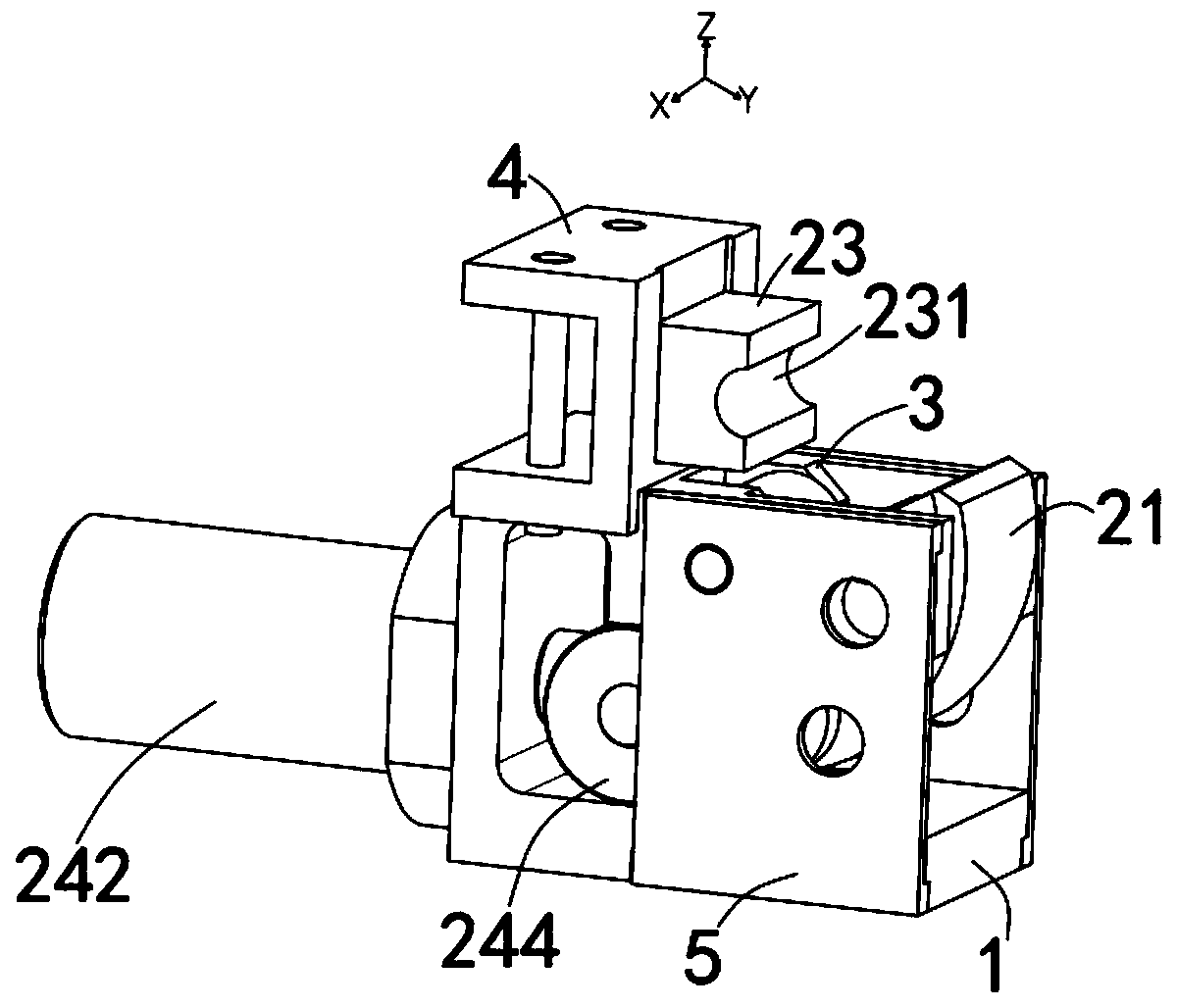

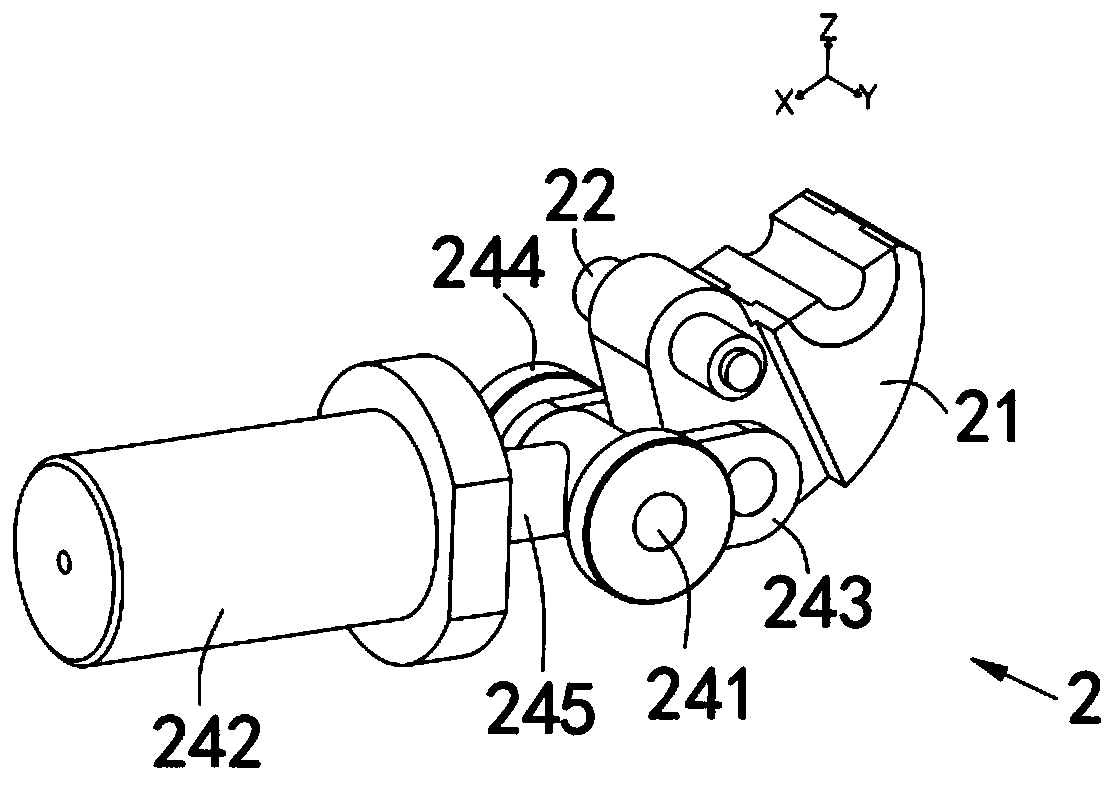

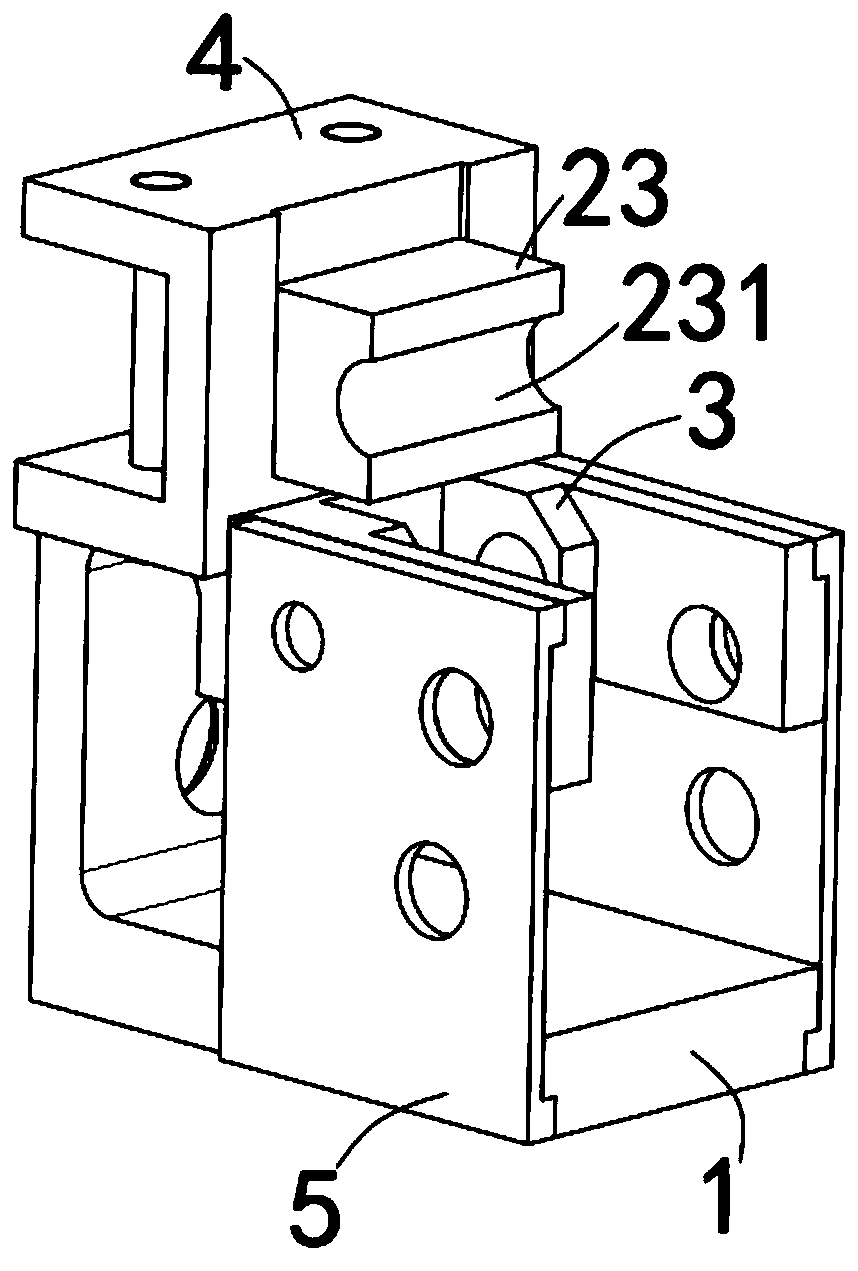

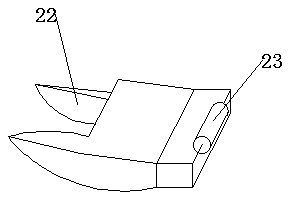

Hub positioning clamp

PendingCN110370203ANot to be scratchedWill not affect the tire loading processWork holdersBiomedical engineering

The invention discloses a hub positioning clamp. The hub positioning clamp comprises a clamp base (1) and two clamp claws (2) installed at the two ends of the clamp base (1); and the clamp claws (2) comprise supporting ends (22), claw tail parts (23) and clamping ends (21), wherein arc-shaped bulges (211) are arranged at the top ends of the clamping ends (21), the supporting ends (22) are providedwith first holes (221), the two ends of the clamp base (1) are correspondingly provided with second holes (11), first pins (3) penetrate through the first holes (221) and the second holes (11) to beused for installing the clamp claws (2) on the clamp base (1), and the clamp claws (2) can rotate on the clamp base (1) by taking the first pins (3) as axes. According to the hub positioning clamp, the slot-shaped positioning method is adopted, and the clamp claws can rotate in all directions, so that the clamp is suitable for hubs with different sizes, and no influence is generated on a tire assembling process; and in addition, the structure of the clamp is further improved so that the hub cannot be scratched.

Owner:皮休车轮科技(台州)有限公司

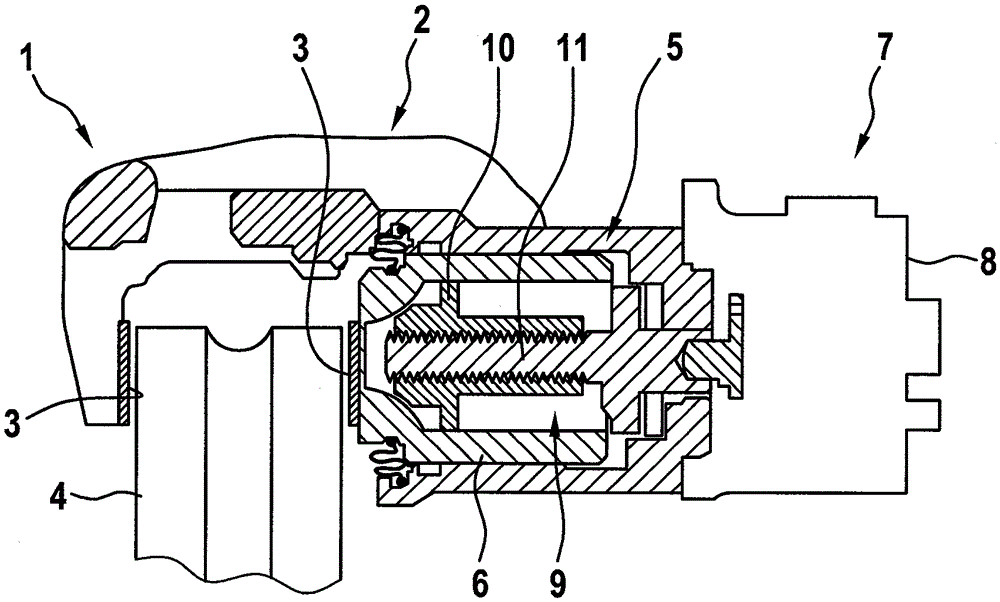

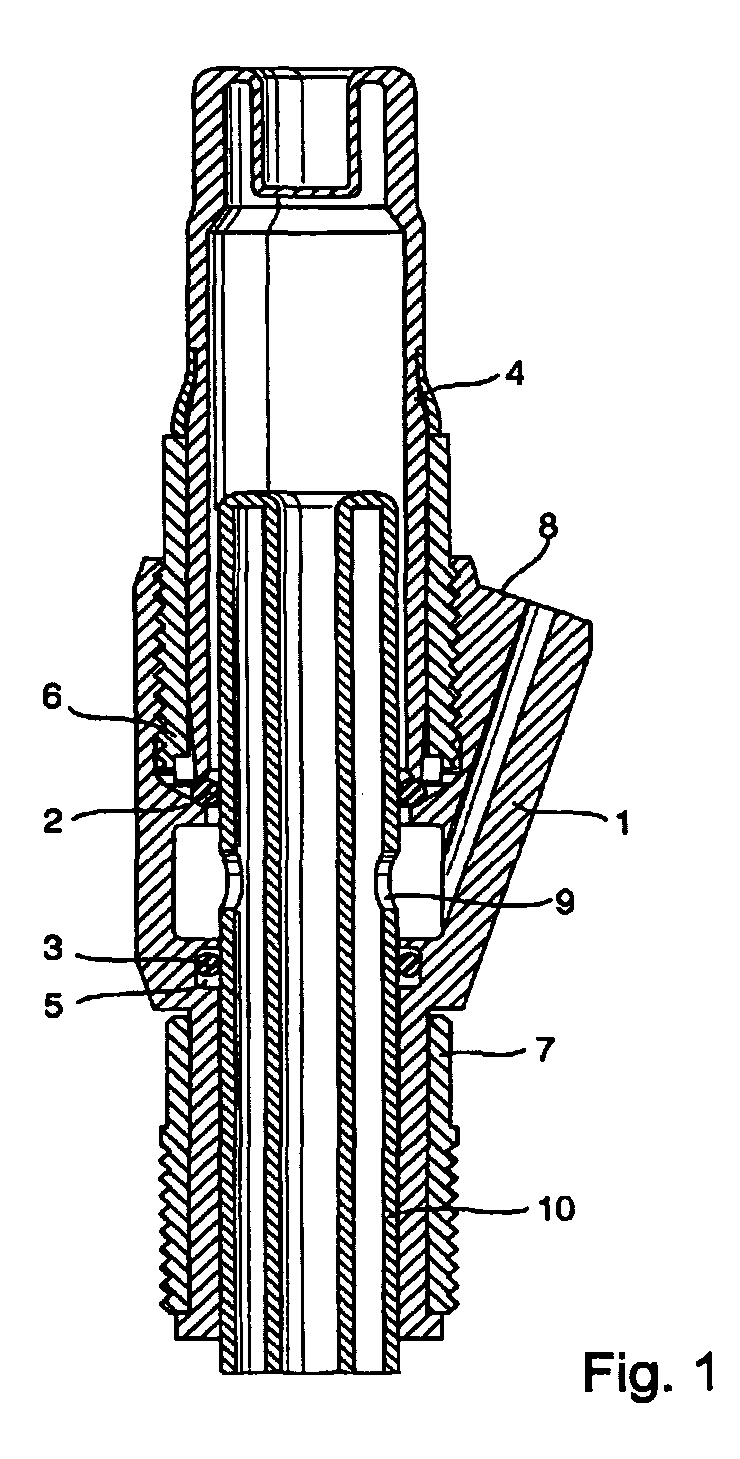

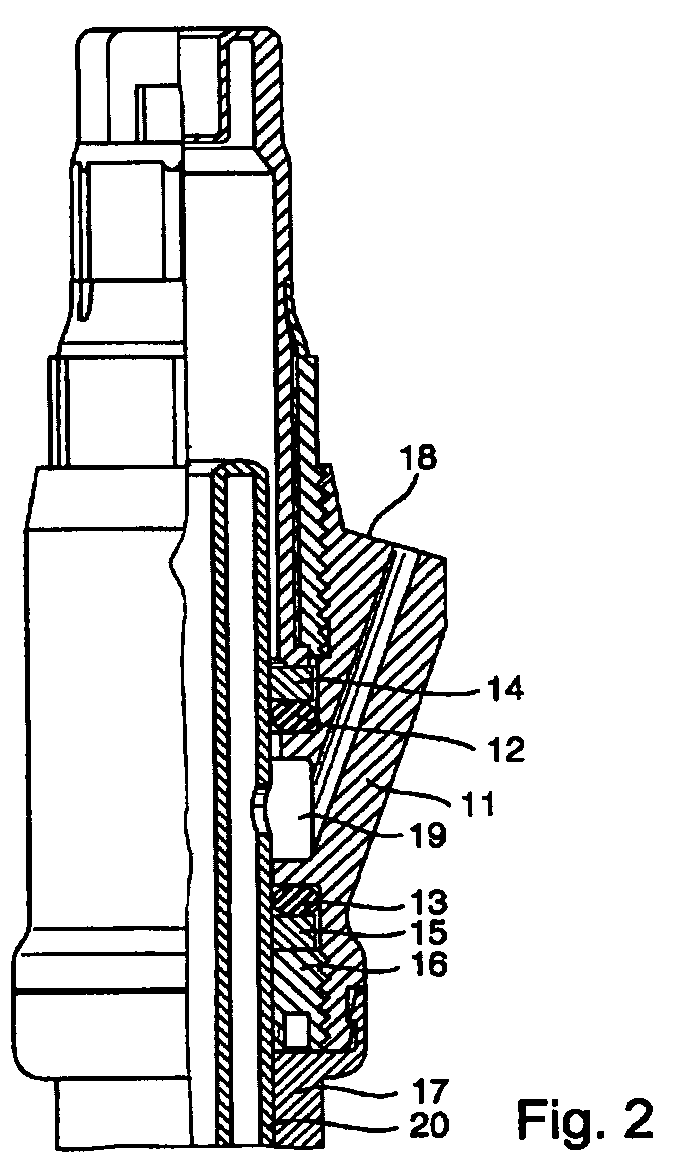

Adapter for supplying electrolyte to a potentiometric sensor

InactiveUS7880471B2Clamping forceAvoid loadMaterial electrochemical variablesEngineeringMechanical engineering

An adapter for a potentiometric sensor having a sensor shaft, which has a reference liquid opening in its exterior surface. The adapter comprises an annular chamber member having a sensor opening for receiving the sensor shaft. Arranged in the sensor opening are first and second sealing rings for the sensor shaft. The axial position of the reference liquid opening lies between the first and second sealing rings. Formed between the sealing rings and the sensor shaft is an annular chamber, which is in communication with the reference liquid opening. The annular chamber member further includes a duct extending between the annular chamber and a reference feed opening. The adapter further includes a process connection member having a process connection opening, which surrounds the sensor shaft, and whose axis is aligned with the axis of the sensor opening. The axial position of the process connection member is fixed relative to the annular chamber member, and the process connection member is freely rotatable relative to the annular chamber member.

Owner:ENDRESS HAUSER CONDUCTA GESELLSCHAFT FUER MESS UND REGELTECHNIK MBH CO KG

Wear-resistant high-precision self-centering chuck

The invention discloses a wear-resistant high-precision self-centering chuck which comprises chuck bodies, bevel gears mounted in the chuck bodies, wire coiling bodies, garbage baffles, sealing rings or sealing tapes, lubricating pieces and magnetic blocks, wherein the multiple types of rolling or combined type rolling guide rails are arranged at both ends of the bevel gears, the inner and outer diameter parts (the inner diameter parts and the outer diameter parts) and the end surfaces of the wire coiling bodies, or on the chuck bodies; the lubricant passage ways or a lubricating oil is arranged at friction parts as well as parts, provided with the rolling guide rails, of the chuck bodies; multiple types of sliding guide rails which are super large in contact area and convenient in precision repair and claws which are convenient in precision repair are arranged on the end surfaces of the chuck bodies; the garbage baffles have sealing property; the sealing rings or sealing tapes are arranged at the inner and outer diameter parts of the chuck bodies or at the garbage baffles; the lubricating pieces are arranged in the guide rails arranged on the end surfaces of the chuck bodies; the magnetic blocks are arranged on the claws and capable of easily clamping disc parts to be flat. The wear-resistant high-precision self-centering chuck has the advantages that the wear precision can be conveniently repaired, the cost is low, the precision is high, high durability is achieved, the production cost is reduced, the production efficiency is improved, and the original generation chuck can be replaced, therefore the chuck is an ideal wear-resistant high-precision self-centering chuck.

Owner:赵恒源

Tin soldering device for I-shaped inductor processing

InactiveCN110948077AAvoid pinchingPrevent the phenomenon of false weldingWelding/soldering/cutting articlesMetal working apparatusEngineeringInductor

The invention discloses a tin soldering device for I-shaped inductor processing. The device comprises a baseplate, wherein four supports are disposed at a fixed interval on the top of the baseplate; alead screw is disposed horizontally and horizontally disposed inside the supports in a rotatable manner; lead screw nuts are disposed at an interval on the lead screw; a supporting table is fixedly disposed on a side end of the lead screw nuts; a lifting air cylinder is disposed at the center of the upper surface of the supporting table; a telescopic end of the lifting air cylinder passes throughthe supporting table downwards and is fixedly connected to a lifting table; and a clamping mechanism is disposed on the lower surface of the lifting table. The device disclosed by the invention has the beneficial effects that tin soaking can be conducted on multiple I-shaped inductors at a time; during material fetching, clamping damage to the I-shaped inductors can be effectively prevented; processing quality and production efficiency are increased; and insufficient soldering caused by decrease of a soldering flux or a tin liquid can be prevented.

Owner:湖南碧建精密机械有限公司

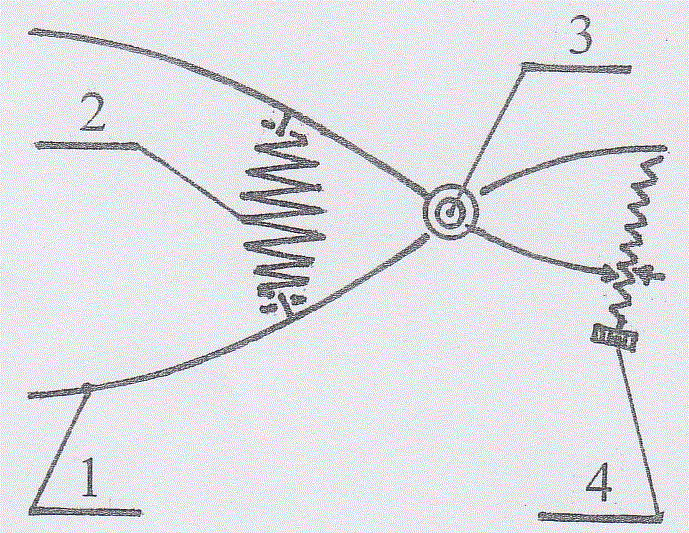

Self-tensioning clamp for assembling and disassembling meter

The invention discloses a self-tensioning clamp for assembling and disassembling a meter, and belongs to the technical field of instruments and meters. The self-tensioning clamp consists of two half clamps 1, a pressure spring 2, a hinge shaft 3 and an opening nail 4, wherein the two half clamps 1 are hinged together through the hinge shaft 3; the pressure spring 2 is arranged at positions, close to the hinge shaft 3, on claw sections of the two half clamps 1; under a normal use state, the two half clamps 1 are opened. The opening nail 4 for adjusting the openness of the clamp is arranged on the closed section of one half clamp 1. The opening nail 4 is adjusted to make the openness of the two half clamps 1 clamp an element to be assembled or disassembled; then a user pinches the two half clamps 1 to enable the clamp to clamp for assembly or disassembly of the element. The self-tensioning clamp is high in clamping force, convenient for assembling and disassembling, time-saving, labor-saving and good in effect, and is used for assembling and disassembling an instrument or a meter.

Owner:STATE GRID CORP OF CHINA +1

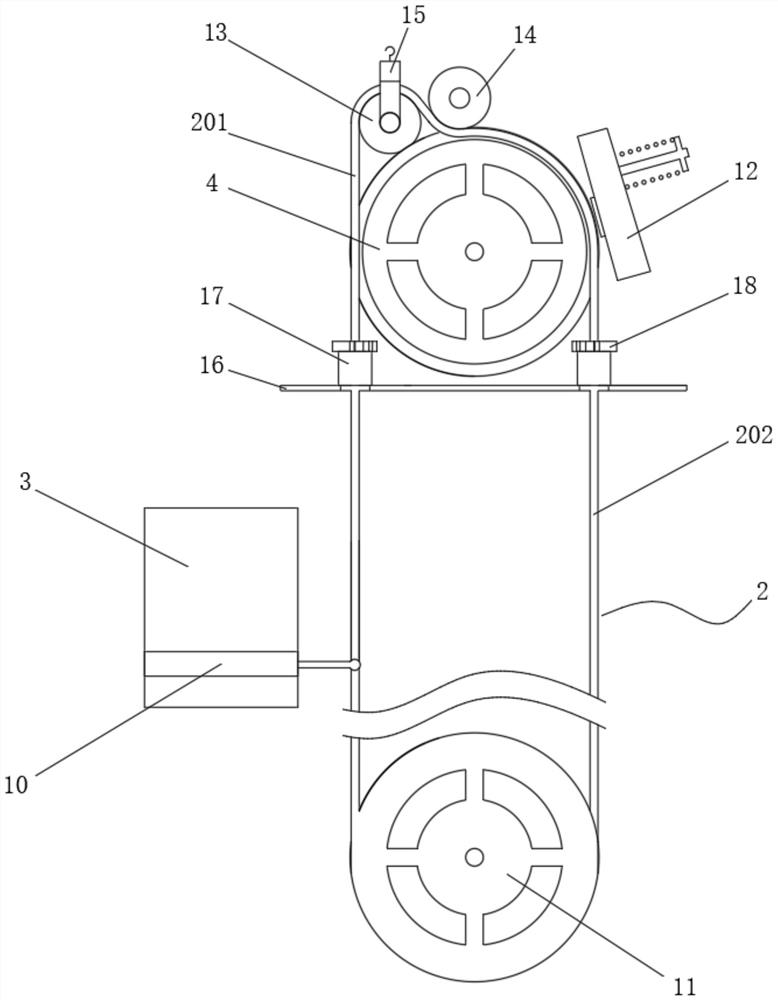

Online detection method and device for elevator safety device

The invention relates to an online detection device and method for an elevator safety device. Acting force is applied to a steel wire rope through a rope lifting device so that the steel wire rope can be separated from a speed limiter rope wheel; when the speed limiter rope wheel reaches a certain speed, a steel wire rope clamping device acts to clamp the steel wire rope, and the instantaneous action speed of a speed limiter is detected; the section a of the steel wire rope between the steel wire rope clamping device and safety tongs is pulled to act on the safety tongs, and whether the elevator safety device is linked or not is judged by observing whether the safety tongs act or not. The online detection device can directly perform linkage test of the speed limiter and the safety tongs on an elevator in a static or low-speed running state in an elevator shaft, so that the detection work of the elevator can be met, and irreversible damage to the elevator can be avoided.

Owner:河南大亘计量检测研究院有限公司

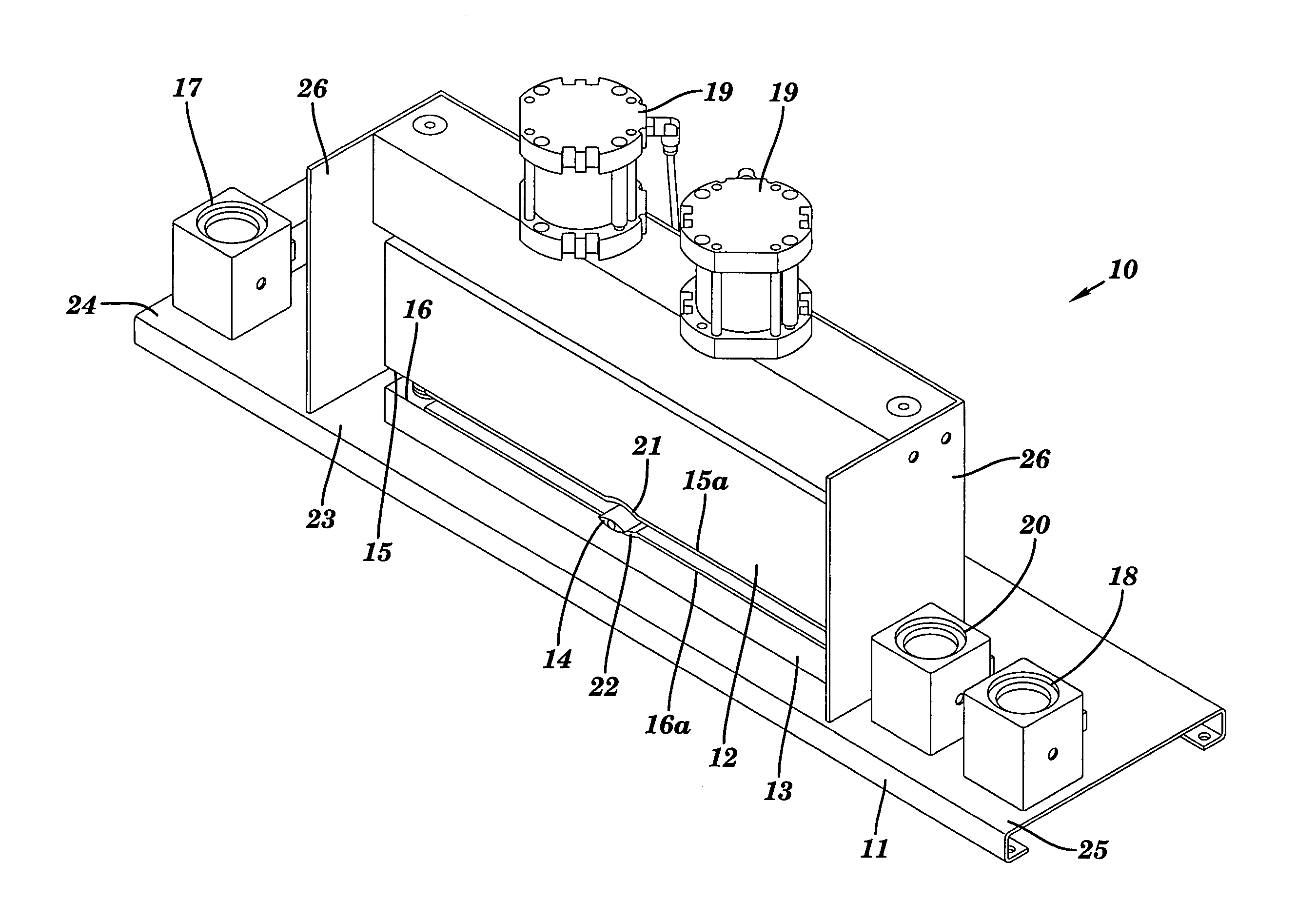

Open package test fixture

ActiveUS20050204801A1Improve sealingClamping forceDetection of fluid at leakage pointMeasurement of fluid loss/gain ratePackage testingEngineering

The test fixture of the present invention comprises a pair of clamping bars / jaws, matched to accommodate an inflation port, or a pressure supply / sensing nozzle. The clamping jaws further comprise a layer of leak proof crushable material, for helping retain the item being tested. When the jaws are activated, the jaws and leak proof crushable material serve to effectively seal the package on the remaining side, and about the pressure supply / sensing nozzle.

Owner:CARLETON TECH

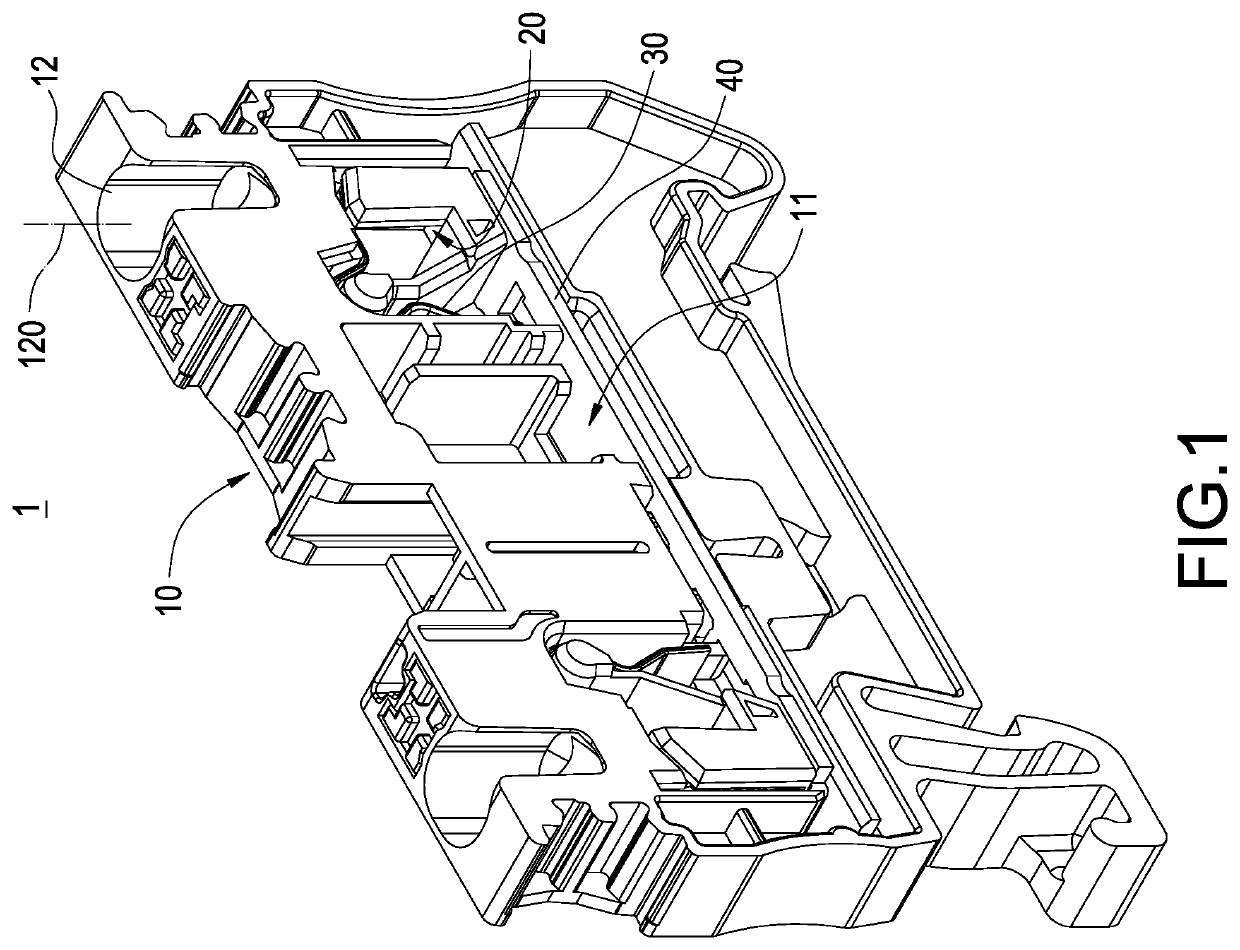

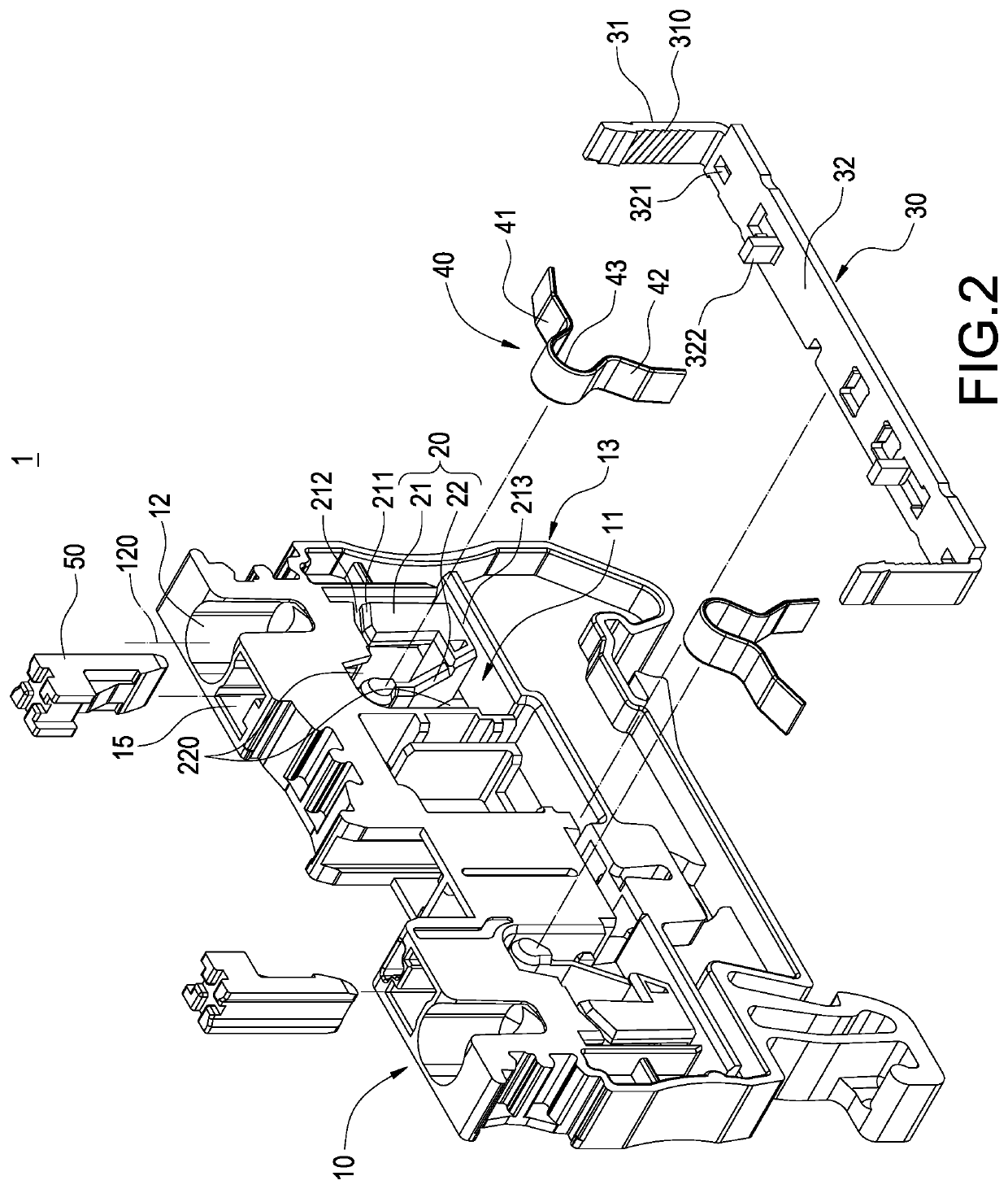

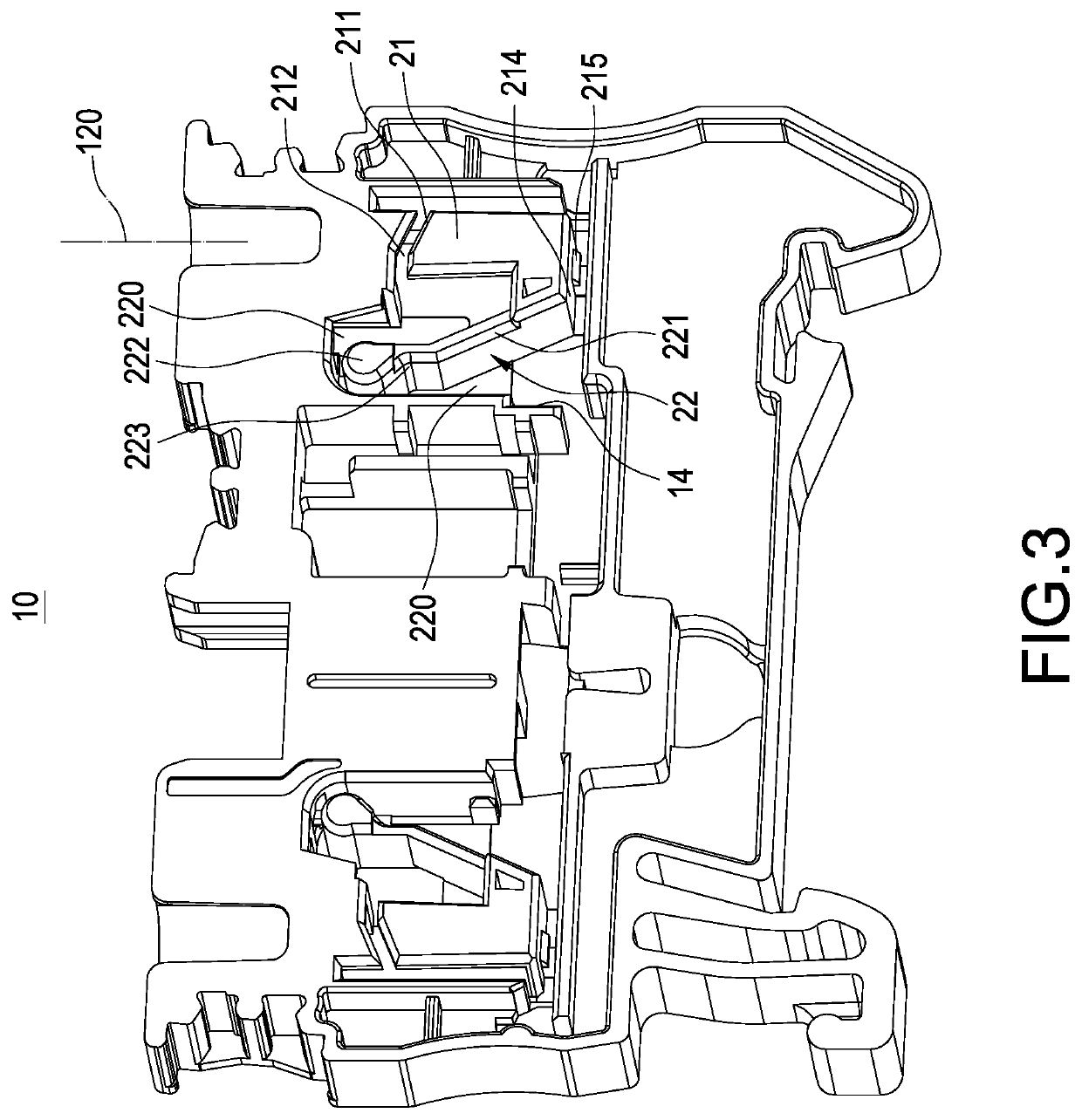

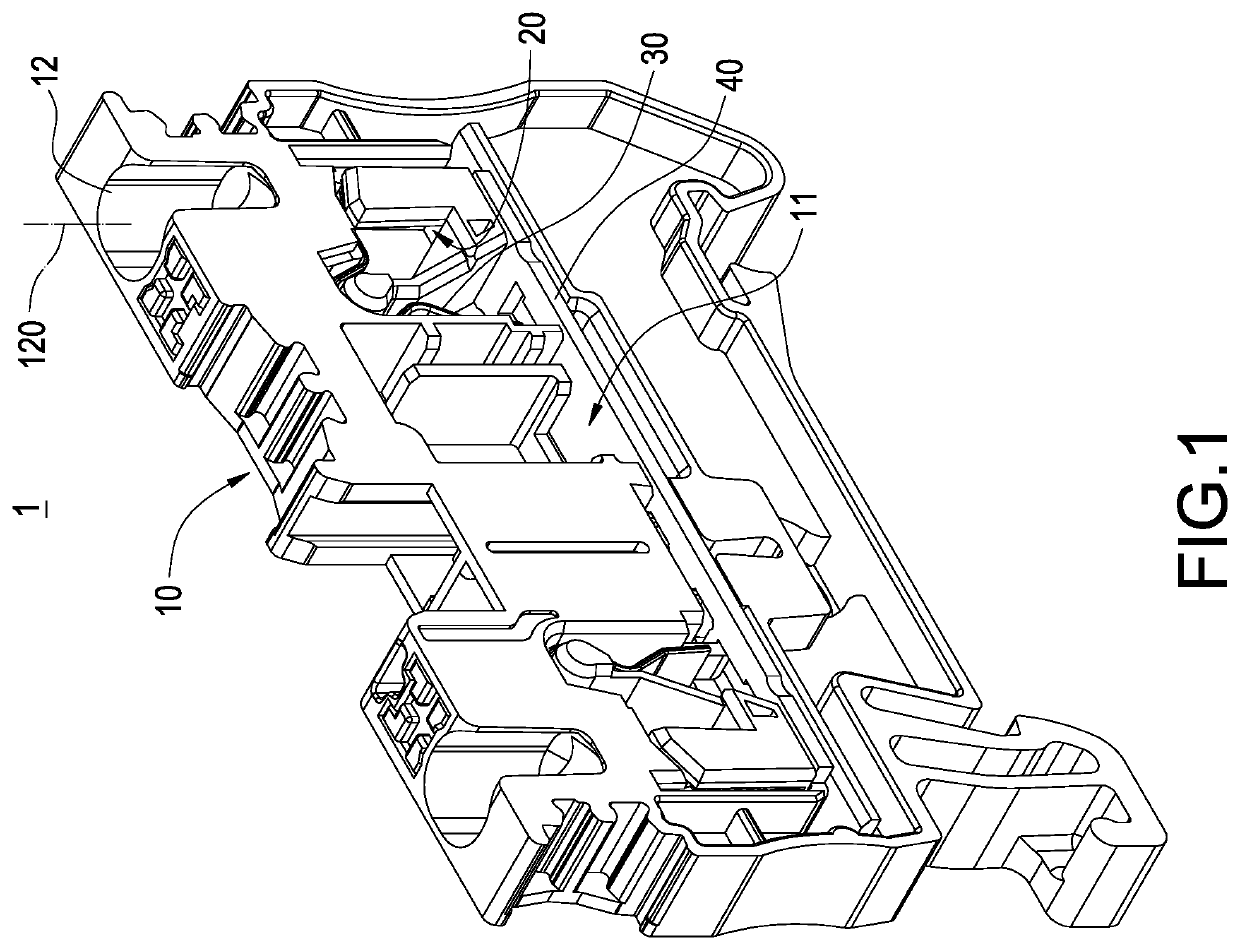

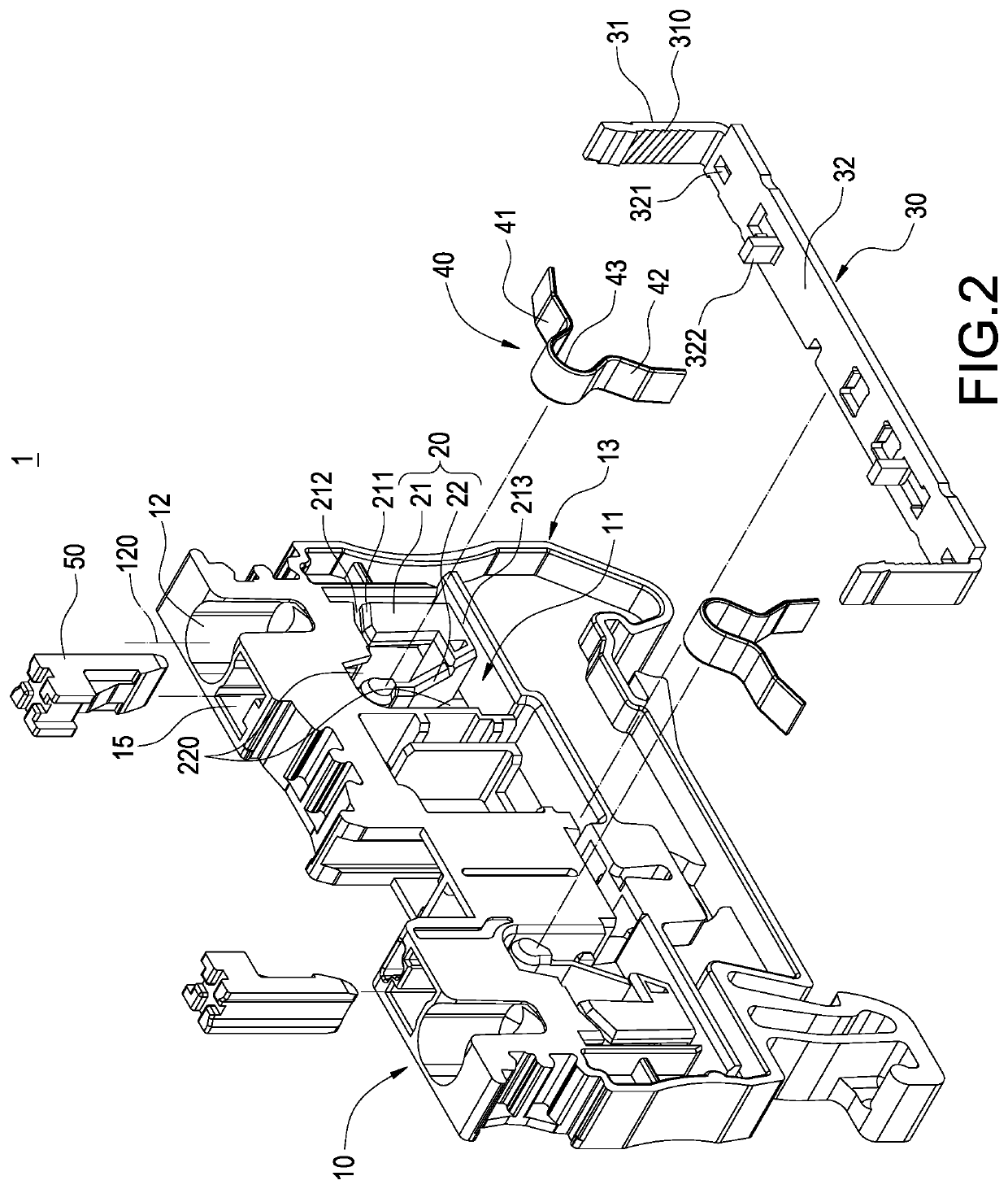

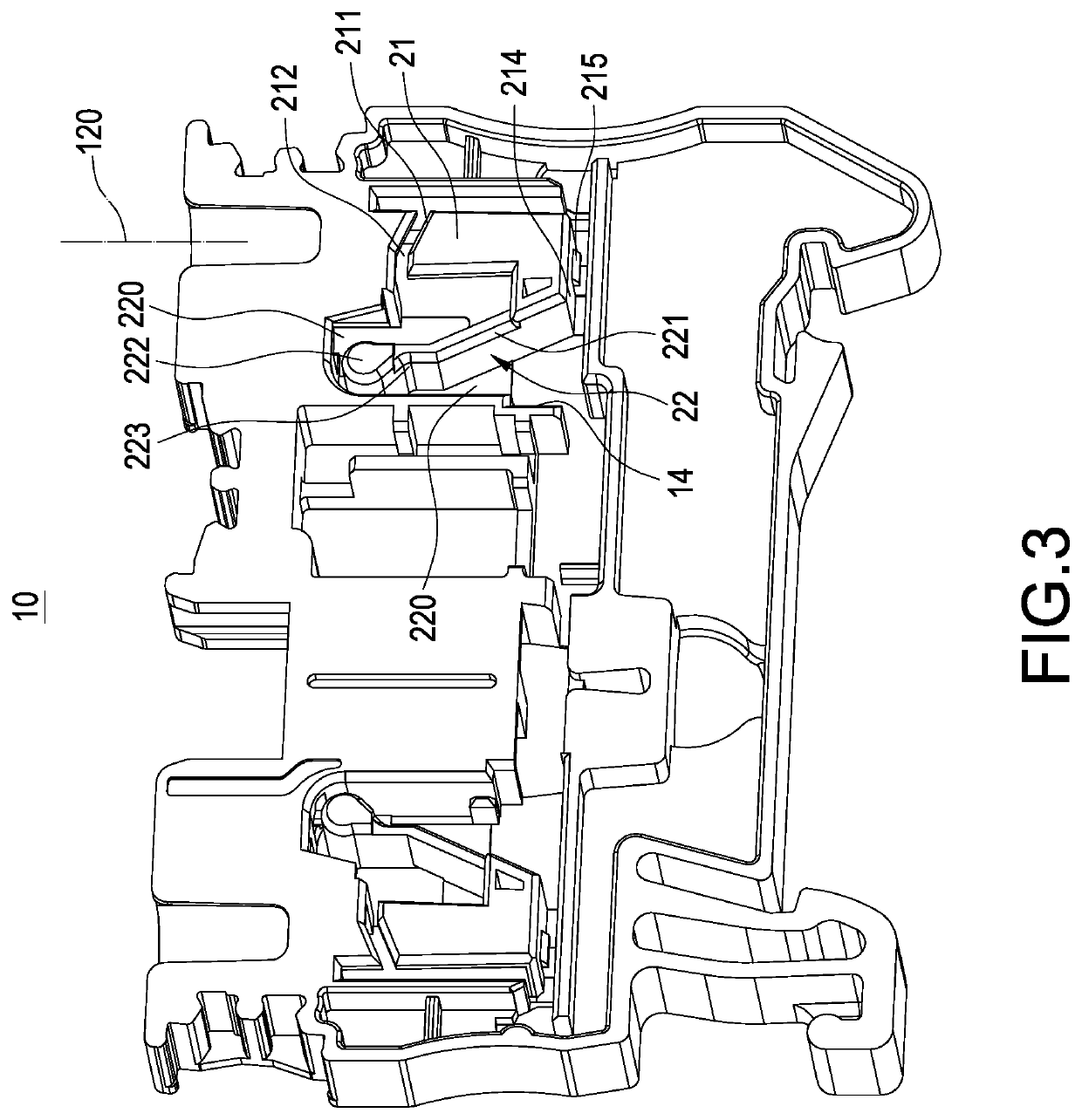

Terminal block with integral guiding structure

ActiveUS11444395B1Easy to assembleClamping forceElectrically conductive connectionsCoupling contact membersStructural engineeringMechanical engineering

This disclosure is a terminal block. An insulative base includes an accommodating space and an insertion hole. The insulative base includes a lateral opening. A guiding structure is disposed in the accommodating space and includes a guiding plate and a guiding arm. A passing space is formed between the insulative base and the guiding plate. An L-shaped space is formed between the guiding plate and the insulative base. A U-shaped space is formed between the guiding arm and the insulative base. A conducting terminal is positioned in the L-shaped space. An elastic strip includes an abutting section, a positioning section and a U-shaped section connected therebetween. The elastic strip is inserted to the passing space and the U-shaped space to be connected with the guiding arm.

Owner:DINKLE ENTERPRISE CO LTD +1

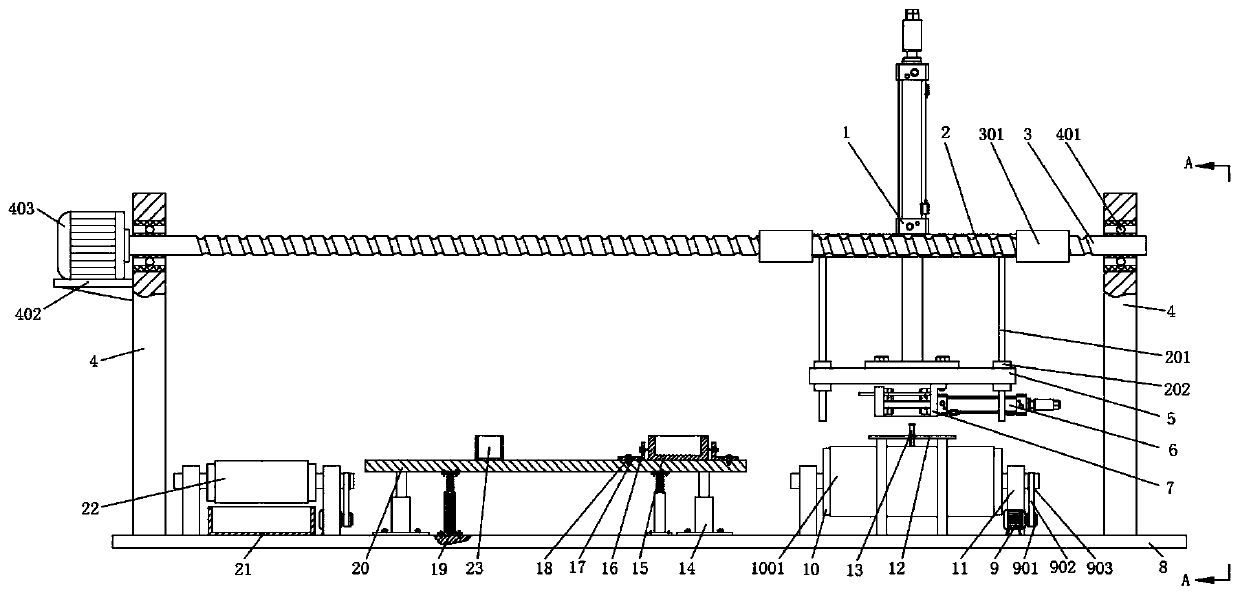

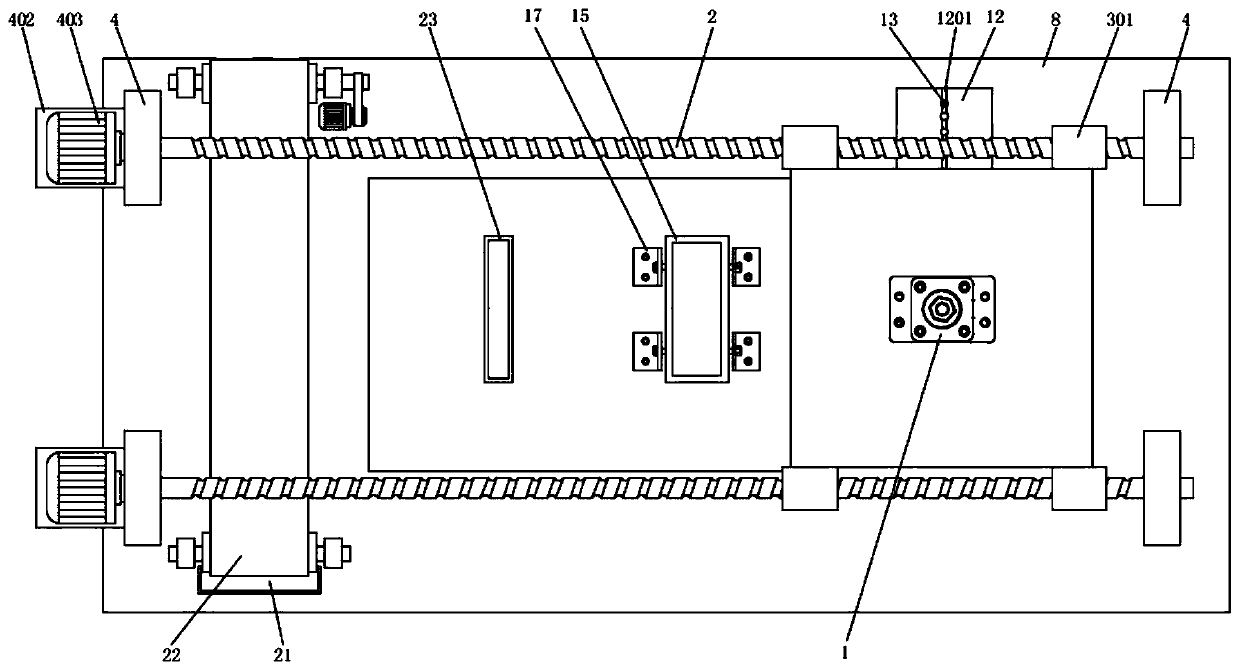

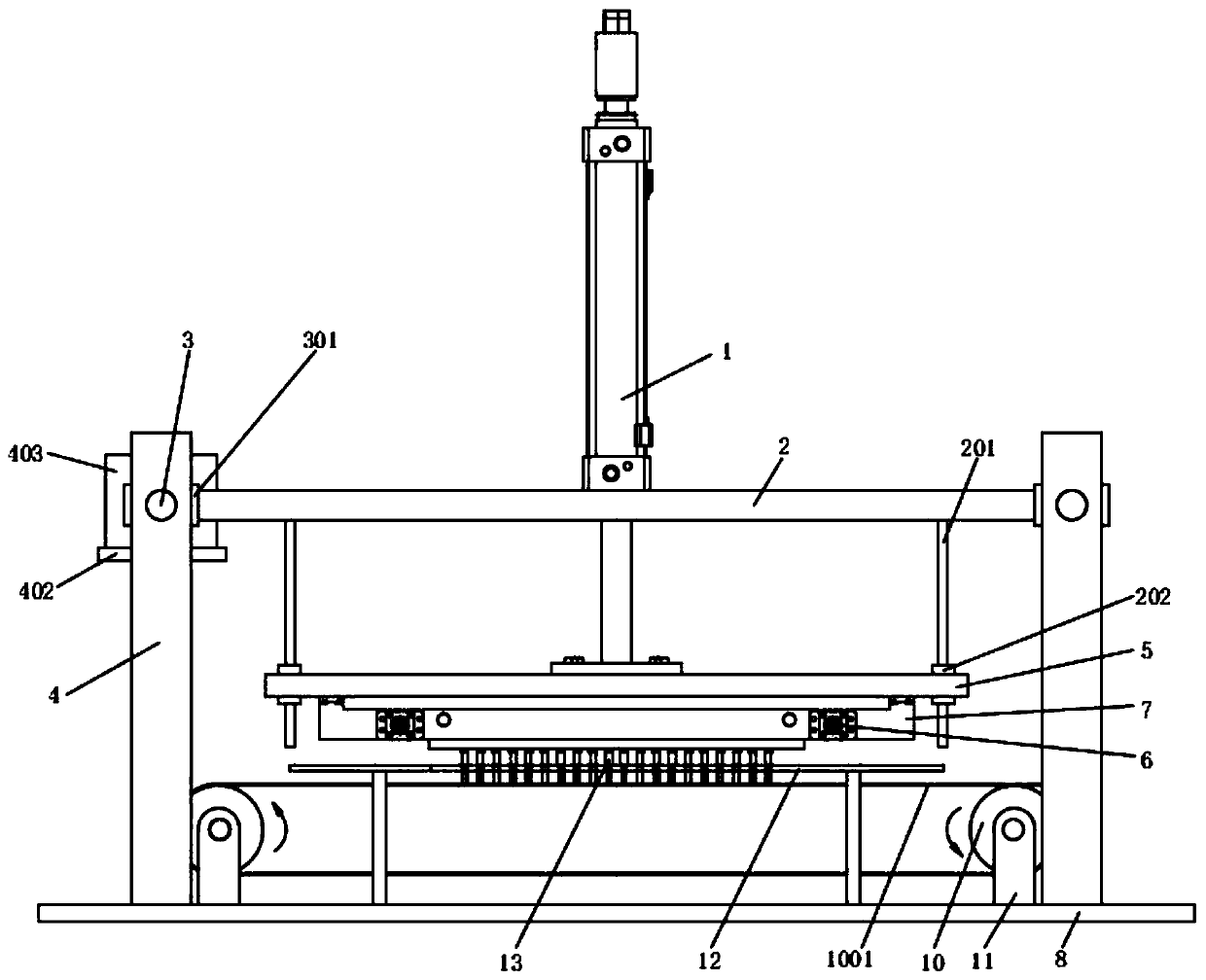

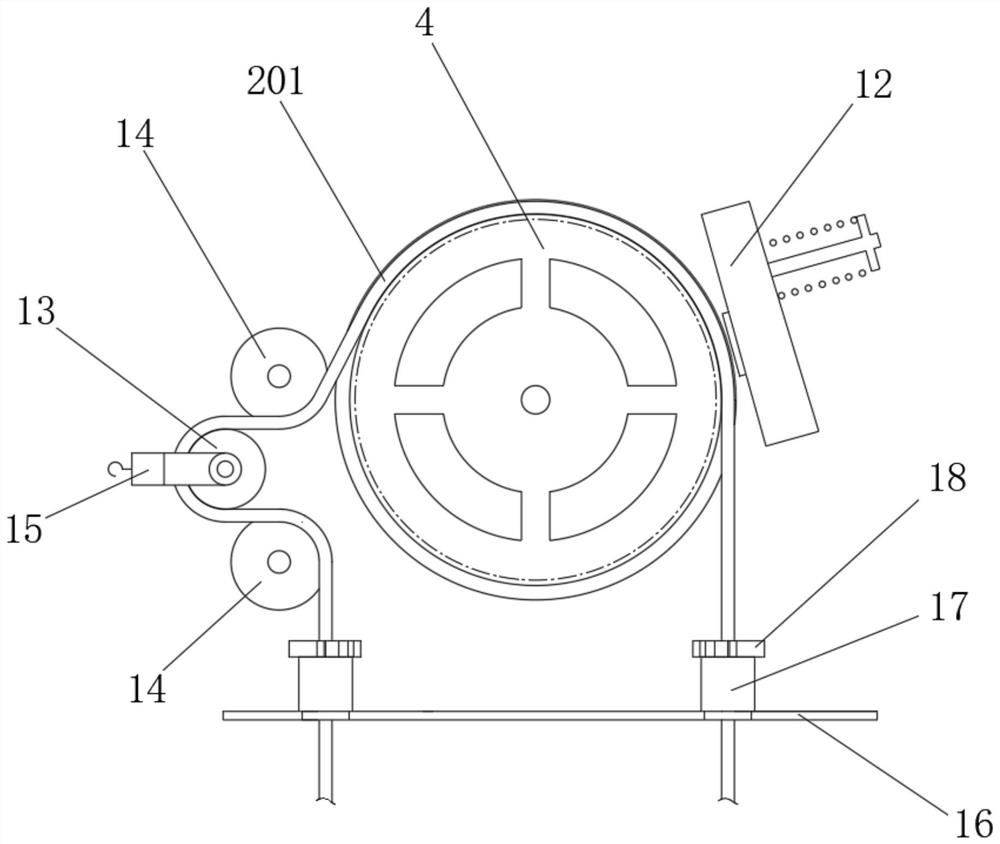

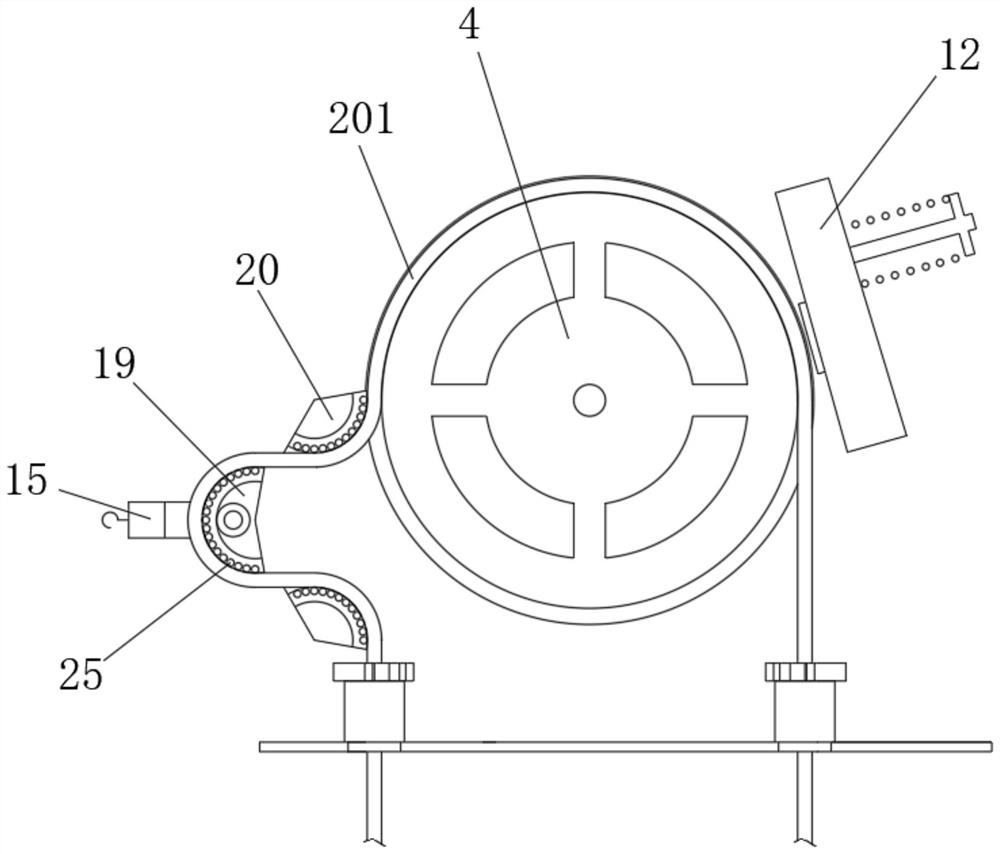

Top pier holding device for numerical-controlled pipe bending machine

The invention discloses a top pier holding device for a numerical-controlled pipe bending machine. The top pier holding device comprises a support frame and a convolution type clamping structure, wherein the support frame is at least provided with two openings, and the two openings are adjacent; the convolution type clamping structure is rotatably connected to an inner cavity of the support frameand comprises a pushing collet, a fixed clamping block, a fixed shaft and a pushing component, wherein a first semicircle groove is formed in the fixed clamping block; a shaft fixing block is fixedlyconnected to the inner wall of the support frame, and the shaft fixing block is symmetrically arranged on two sides of the inner part of the support frame; the end of the fixed shaft is fixed to the shaft fixing block; and the pushing collet sleeves the fixed shaft, and besides, the pushing collet performs circumferential rotation around the fixed shaft. According to the top pier holding device disclosed by the invention, the whole equipment is simple in structure, large in clasping force and small in occupied area; after pipe bending is completed, all structural members of the top pier holding device are lower than the lower surface of a pipe; and according to the size of the pipe bending radius, the whole equipment can adjust the axial position of the pushing collet.

Owner:SHANGHAI HAODE THERMAL POWER TECH CO LTD

Abdominal minimally invasive surgery clamp

The invention provides a minimally invasive surgery clamp for the abdominal cavity. The minimally invasive surgery clamp for the abdominal cavity comprises an elastic clamp body and a metal wire, wherein the inner end of the metal wire is fixedly connected with the rear end of the elastic clamp body; the minimally invasive surgery clamp is further provided with a hollow round metal sleeve and an auxiliary control block, a through hole running through the axial full length is formed in the middle of the auxiliary control block, the through hole comprises a clamp body accommodating section, a necking down section and a metal sleeve accommodating section, the front end part of the clamp body accommodating section is in the shape of a horn mouth with the large front part and the small rear part, the hole diameter of the metal sleeve accommodating section allows the insertion of the inner end of the round metal sleeve, and the hole diameter of the necking down section is greater than the diameter of the metal wire and smaller than the outer diameter of the round metal sleeve. For the minimally invasive surgery clamp for the abdominal cavity, the needed size of an operation hole is freeof the limitation of the size of clamp arms of the clamp body, the needed hole diameter of the operation hole is small, the clamping of the clamp arms is powerful, and the operation is simple and convenient.

Owner:汕头市颂美恩生物科技有限公司

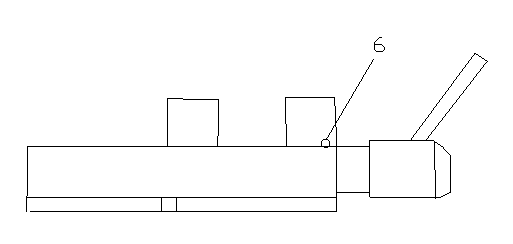

Instrument bench vice

InactiveCN102717267ACompact structureFashionablePositioning apparatusMetal-working holdersEngineeringInstrument table

The invention discloses an instrument bench vice. The bench vice comprises a seat, a movable block, a fixed block, a leading screw, a handle and a positioning pin, wherein the fixed block is fixed on the seat, the positioning pin is arranged on the fixed block to prevent the fixed block from moving, the movable block is mounted on the seat, the rotatablely movable leading screw is fixed on the seat, the handle is fixed on the leading screw, and a V-shaped groove and a spigot groove mutually perpendicular are provided on the movable block. The instrument bench vice provided by the invention enables improvement in strength and service life of small bench vices, and additions in functions of small bench vices.

Owner:GAOYOU LIBO MACHINE TOOL ACCESSORIES FACTORY

Terminal block with integral guiding structure

ActiveUS20220320763A1Easy to assembleClamping forceElectrically conductive connectionsCoupling contact membersStructural engineeringMechanical engineering

This disclosure is a terminal block. An insulative base includes an accommodating space and an insertion hole. The insulative base includes a lateral opening. A guiding structure is disposed in the accommodating space and includes a guiding plate and a guiding arm. A passing space is formed between the insulative base and the guiding plate. An L-shaped space is formed between the guiding plate and the insulative base. A U-shaped space is formed between the guiding arm and the insulative base. A conducting terminal is positioned in the L-shaped space. An elastic strip includes an abutting section, a positioning section and a U-shaped section connected therebetween. The elastic strip is inserted to the passing space and the U-shaped space to be connected with the guiding arm.

Owner:DINKLE ENTERPRISE CO LTD +1

A Soft Electrostatic Adhesive Coated Bionic Octopus Manipulator

The invention relates to a soft electrostatic adhesion-coated bionic octopus manipulator, which includes a connection seat, a main chamber and claw fingers. Inflatable holes; the main chamber is hollow and drum-shaped, and its upper end is open, and is connected with the lower end of the connecting seat; the periphery of the main chamber is provided with a plurality of connecting holes connecting inside and outside; the claw fingers There are multiple, all of which are pneumatic network type; the claw finger is hollow, its front end is wedge-shaped, and its rear end communicates with the connection hole; the inflation hole is connected to the connection hole through a trachea; it also includes A flexible coating; the coating is disc-shaped, and the center of its top surface is connected to the bottom of the main chamber; multiple electrodes are arranged in the coating. The invention effectively increases the clamping force, and can evenly share the clamping force on the target object, reducing the risk of damage; meanwhile, it also has a variety of grasping modes, increases the clamping range, and can fully meet the use requirements.

Owner:NANJING AGRICULTURAL UNIVERSITY

Open package test fixture

ActiveUS7013710B2Improve sealingClamping forceDetection of fluid at leakage pointMeasurement of fluid loss/gain ratePackage testingEngineering

The test fixture of the present invention comprises a pair of clamping bars / jaws, matched to accommodate an inflation port, or a pressure supply / sensing nozzle. The clamping jaws further comprise a layer of leak proof crushable material, for helping retain the item being tested. When the jaws are activated, the jaws and leak proof crushable material serve to effectively seal the package on the remaining side, and about the pressure supply / sensing nozzle.

Owner:CARLETON TECH

Method and device for operating a braking device, braking device

ActiveCN105711575BGuaranteed loss of clamping forceReliable brakeAxially engaging brakesBraking action transmissionActuatorControl theory

The invention relates to a method for operating a brake system (1), in particular a parking brake system, of a vehicle, wherein the brake system (1) has an electric actuator (7), which The actuator element (10) can be moved selectively into a clamping position for applying a clamping force to the brake disc (4) or into a release position for releasing said brake disc (4), wherein the brake disc temperature is ascertained , in order to actuate the actuator (7) as a function of the determined brake disc temperature, characterized in that the brake disc temperature is determined as a function of at least one current value of the actuator (7).

Owner:ROBERT BOSCH GMBH

Mechanical clamp device

The invention discloses a mechanical clamp device comprising control force shaft. An arch-shaped force arm is arranged at the middle end of the control force shaft. The lower portion of the arch-shaped force arm is tightly connected with an adjusting shaft button. The lower end of the control force shaft is provided with a conversion bearing. The middle portion of the conversion bearing is provided with a connection branch shaft. The connection branch shaft is arranged in the conversion bearing in a penetrating manner. The lower end of the conversion branch shaft is fixedly connected with a gripper sleeve shaft. The lower end of the gripper sleeve shaft is fixedly connected with a rotating gripper. The left portion of the conversion bearing is fixedly connected with a clamping jaw sleeve shaft. The left end of the clamping jaw sleeve shaft is provided with a supporting force shaft. The supporting force shaft is embedded into the clamping jaw sleeve shaft. The control force shaft and the supporting force shaft are used as the main shafts to support the main structure of the mechanical clamp device, the connection branch shaft achieves reinforcement, so that the whole mechanical clamp device is stable, and the safety of the device is enhanced. Due to the arrangement of the conversion bearing and a rotating button shaft, the mechanical clamp device can freely rotate in corresponding directions, and the flexibility of the device is improved.

Owner:刘黄莹

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com