Kinematic coupling

a kinematic coupling and coupling technology, applied in the direction of coupling device connection, instruments, manufacturing tools, etc., can solve the problems of circuits (ic's), ic's tend to fail early in their projected life, and loss of added packaging costs,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

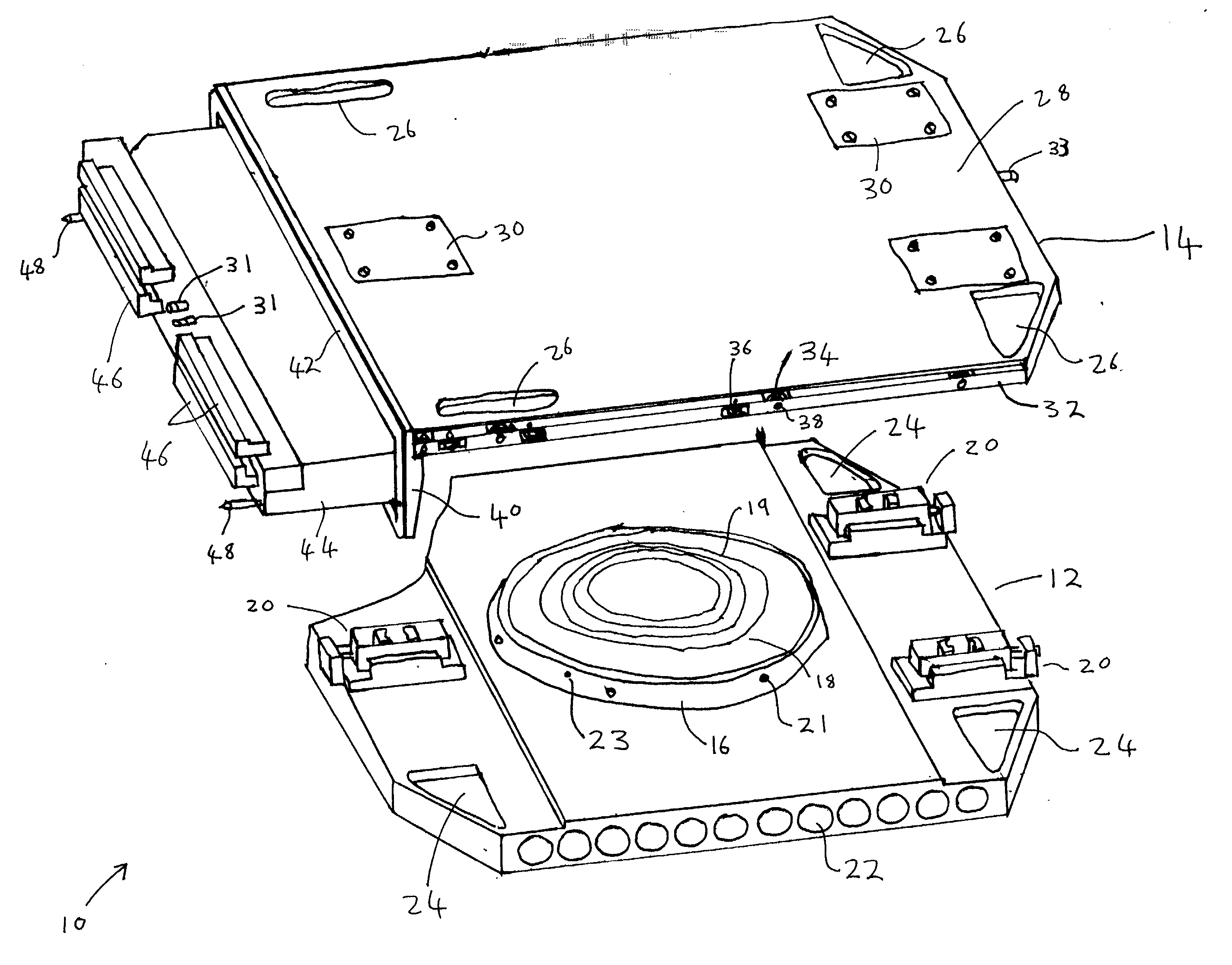

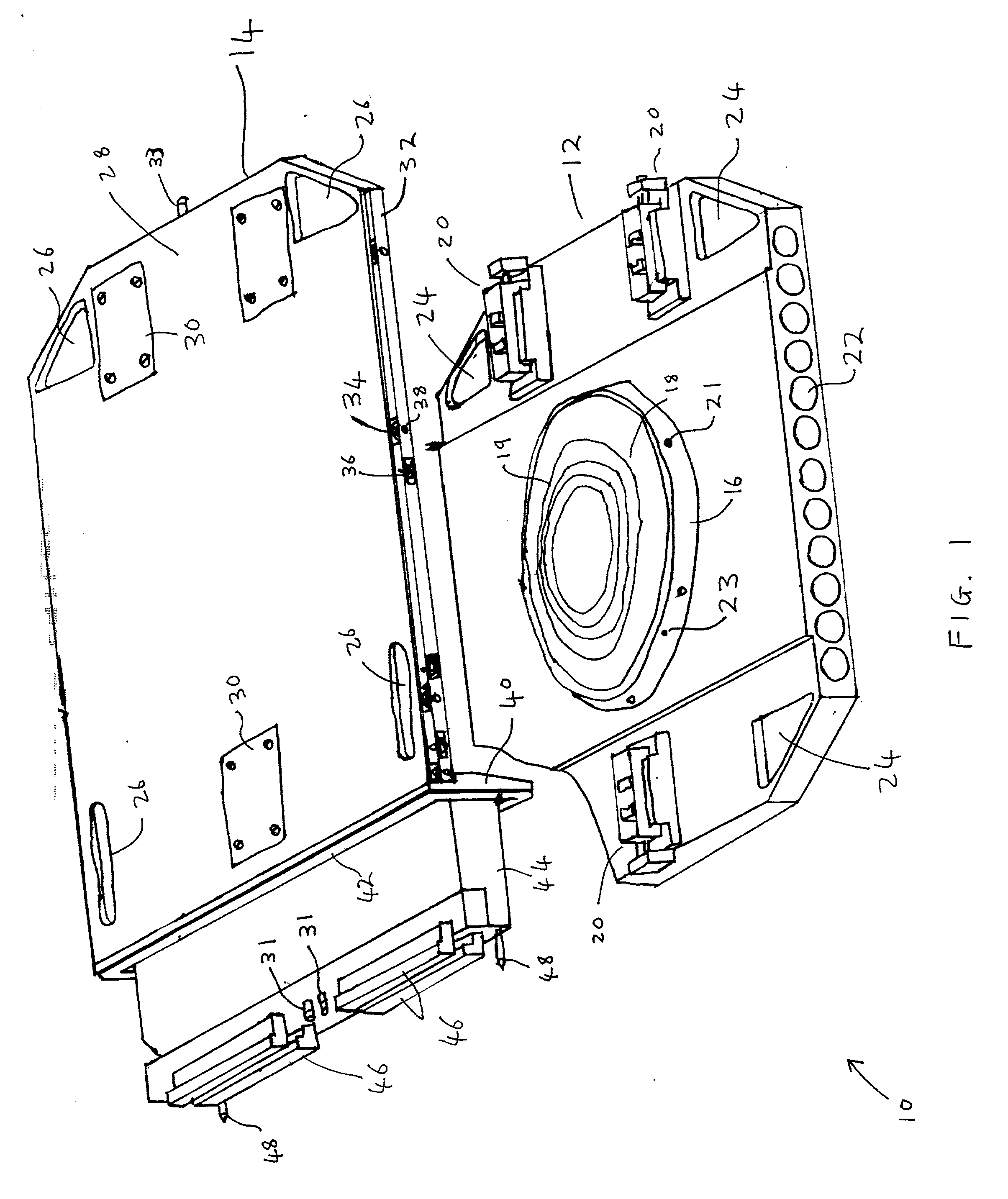

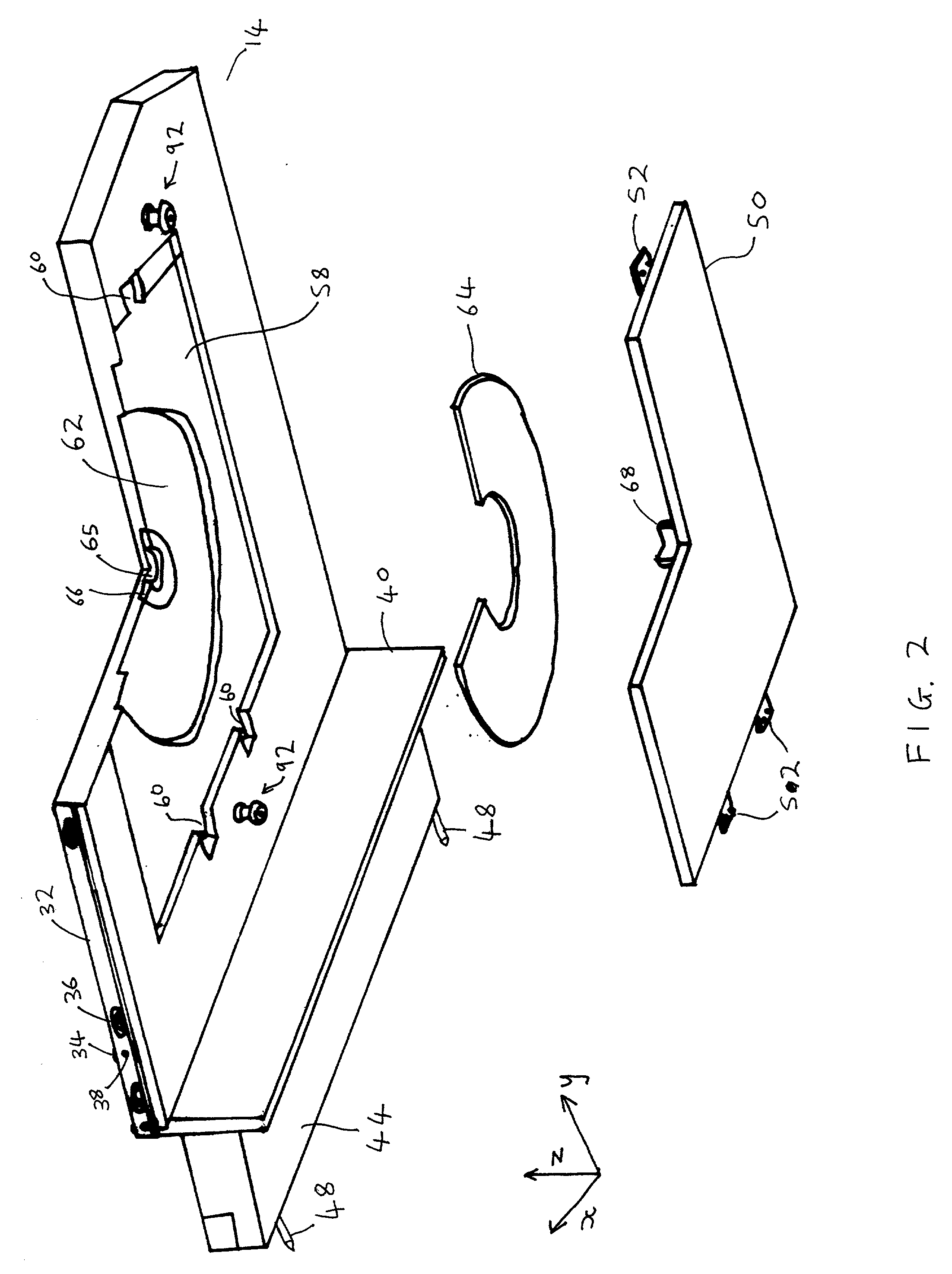

[0038] A wafer-level burn-in and test cartridge according to the invention is illustrated in FIG. 1. The cartridge, generally indicated by the reference numeral 10, comprises a chuck plate 12 and a probe plate 14. The chuck plate 12 and the probe plate 14 may be made of any suitable material. In the illustrated embodiment, the chuck plate 12 and the probe plate 14 are made of 6061 aluminum.

[0039] The chuck plate 12 is generally rectangular in shape, and includes a centrally-located raised pedestal 16. In use, a semiconductor wafer is placed on the upper surface 18 of the pedestal 16. Mounted to the upper surface of the chuck plate 12 are the lower halves 20 of three mechanical connecting devices that are used to lock the chuck plate 12 and the probe plate 14 together in use. In the illustrated embodiment, the mechanical connecting devices are kinematic couplings, which are discussed below in more detail with reference to FIGS. 6 to 12. Formed transversely through the chuck plate 12 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com