Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

43results about How to "Avoid missed cuts" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Inserting cutting type variable diameter banana shaft removing and combing cutter self-adaptive to diameter of banana spike rod

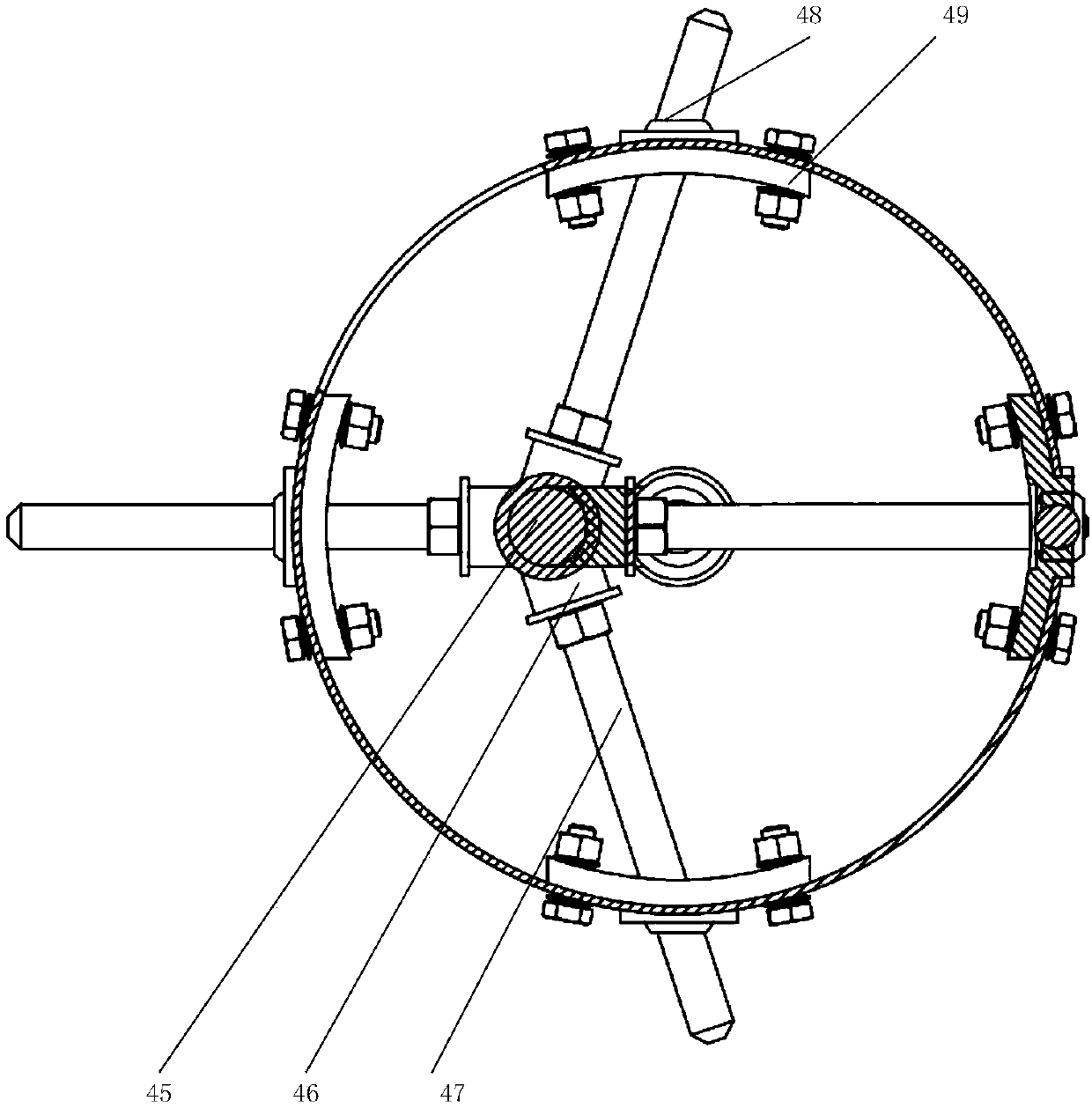

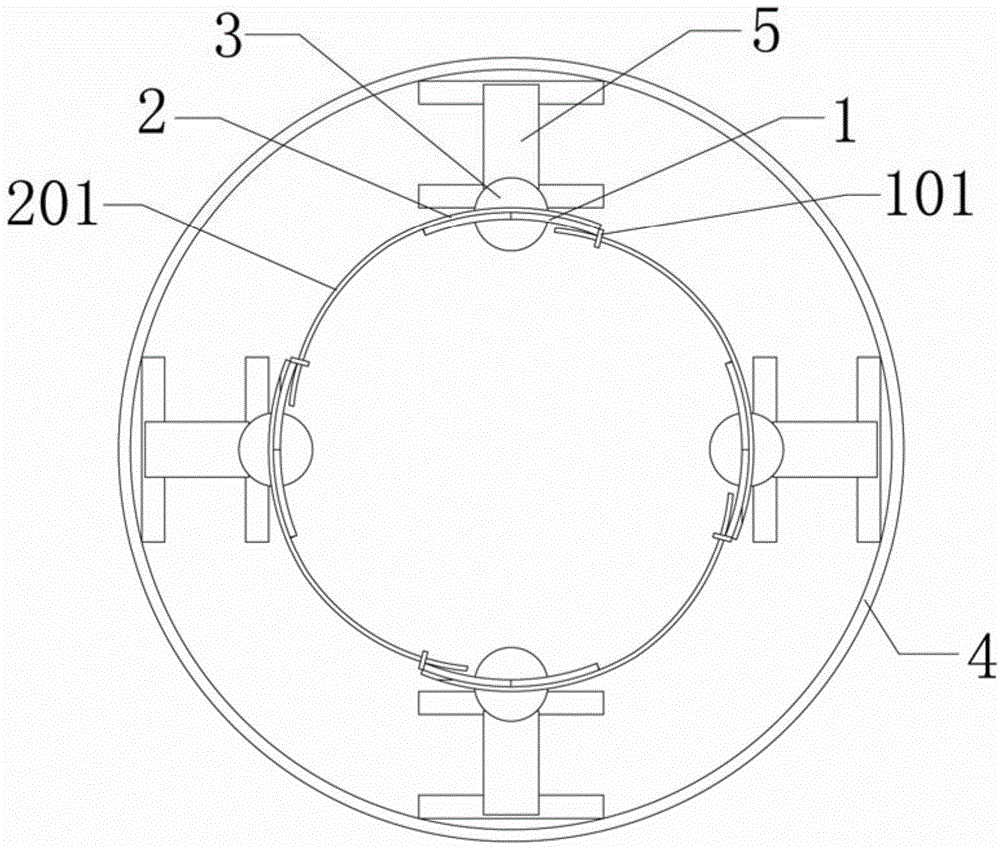

The invention discloses an inserting cutting type variable diameter banana shaft removing and combing cutter self-adaptive to the diameter of a banana spike rod. The cutter comprises hard combing blades, soft combing blades, universal ball bearings and a rack, wherein one side of each soft combing blade extends to form a cutter arm, and a limiting frame is arranged on each hard combing blade; the number of the hard combing blades and the number of the soft combing blades are plural, the body of one hard combing blade and the body of one soft combing blade are stacked to be combined into a combing blade set, a plurality of the hard combing blades and a plurality of the soft combing blades are combined into a plurality of combing blade sets arranged in the rack, the cutter arm of one combing blade set stretches into the limiting frame of the adjacent combing blade set, and the multiple combing blade sets are combined to form a circumferential cutting edge capable of wrapping the banana spike rod; each combing blade set is provided with one universal ball bearing, and a deformation structure is connected between each combing blade set and the rack. The cutter has the advantages of being light and small in overall structure, convenient to move, safe and labor-saving to operate, and suitable for mechanical banana combing.

Owner:SOUTH CHINA AGRI UNIV

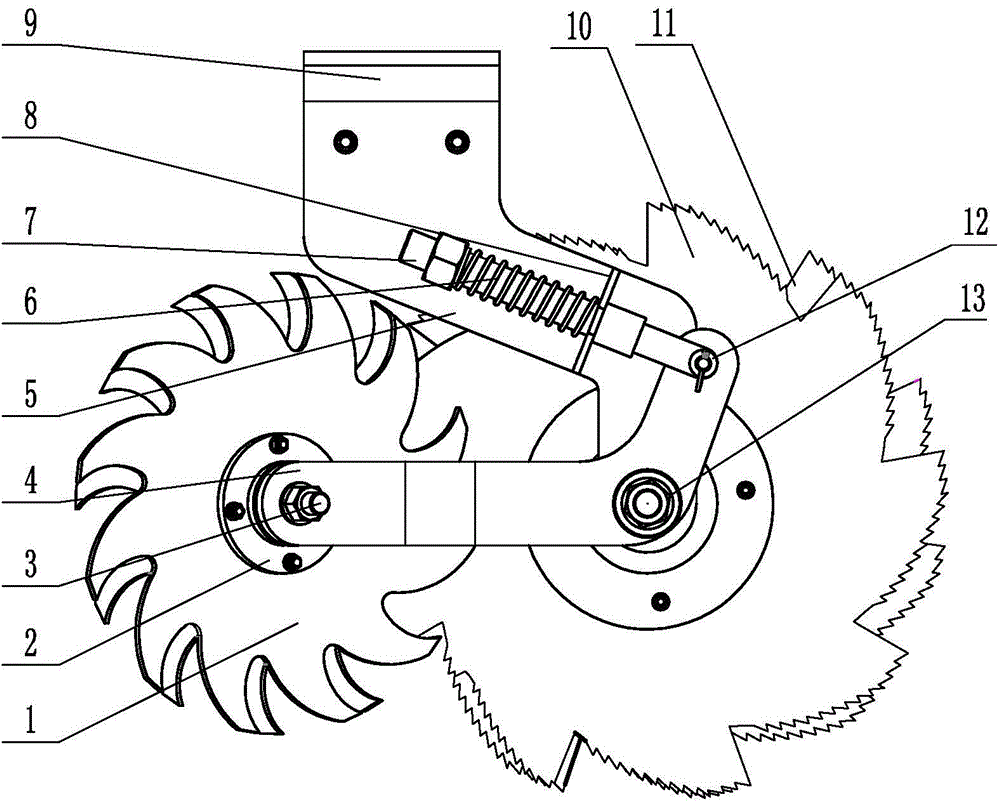

Cutting, shifting and blocking preventing device

InactiveCN104081898AAvoid missed cutsWork resistance is smallSpadesPloughsDevice formAgricultural machinery

The invention discloses a cutting, shifting and blocking preventing device, and belongs to the technical field of agricultural machinery. The cutting, shifting and blocking preventing device comprises a spindle, connecting sleeve plates, inclined plates, a breaking and cutting device and stubble shifting and blocking preventing devices, wherein the breaking and cutting device is mounted in the middle of the spindle, two groups of stubble shifting and blocking preventing devices are symmetrical about the breaking and cutting device and connected to two ends of the spindle, stubble shifting wheels of the stubble shifting and blocking preventing devices and breaking and cutting discs of the breaking and cutting device form deflection angles, and accordingly, the two symmetrical stubble shifting wheels are mounted on two sides of the end part of the breaking and breaking and cutting device in a splayed manner and simultaneously backwards shift stubble and laterally push stubble, straw and weeds; the connecting sleeve plates are symmetrically connected between the breaking and cutting device and the stubble shifting and blocking preventing devices on the spindle and are simultaneously connected with the stubble shifting and blocking preventing devices respectively; and during working, the two connecting sleeve plates are connected with a no-tillage planter for corn ridge culture respectively. The device can cut the stubble, straw and weeds, can shift the stubble, can throw the straw, the stubble and the weeds to the rear side and can push the straw, the stubble and the weeds to furrows on two sides, a clean seed bed is formed on a ridge, blocking is reduced, and the breaking and cutting quality is guaranteed.

Owner:SHENYANG AGRI UNIV

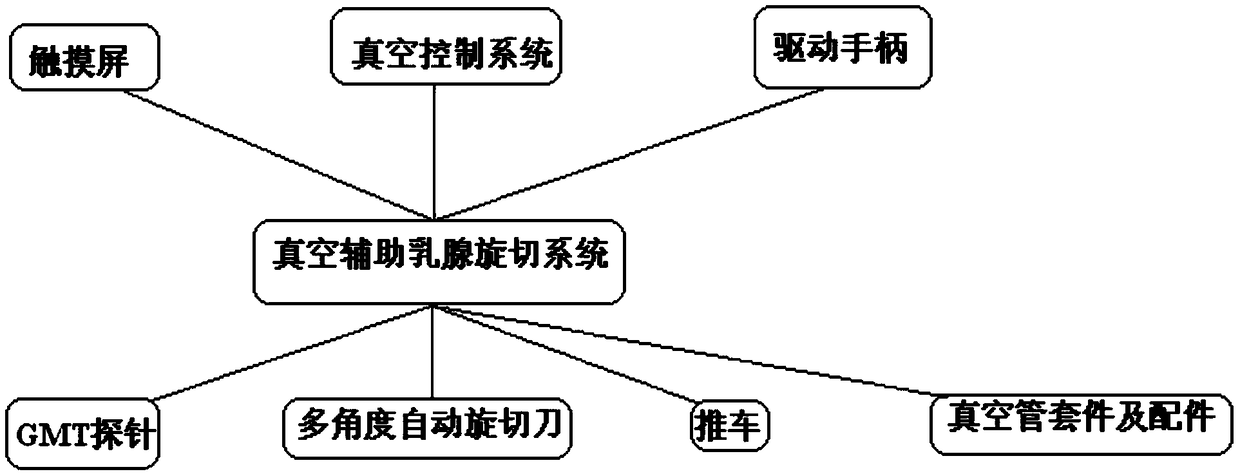

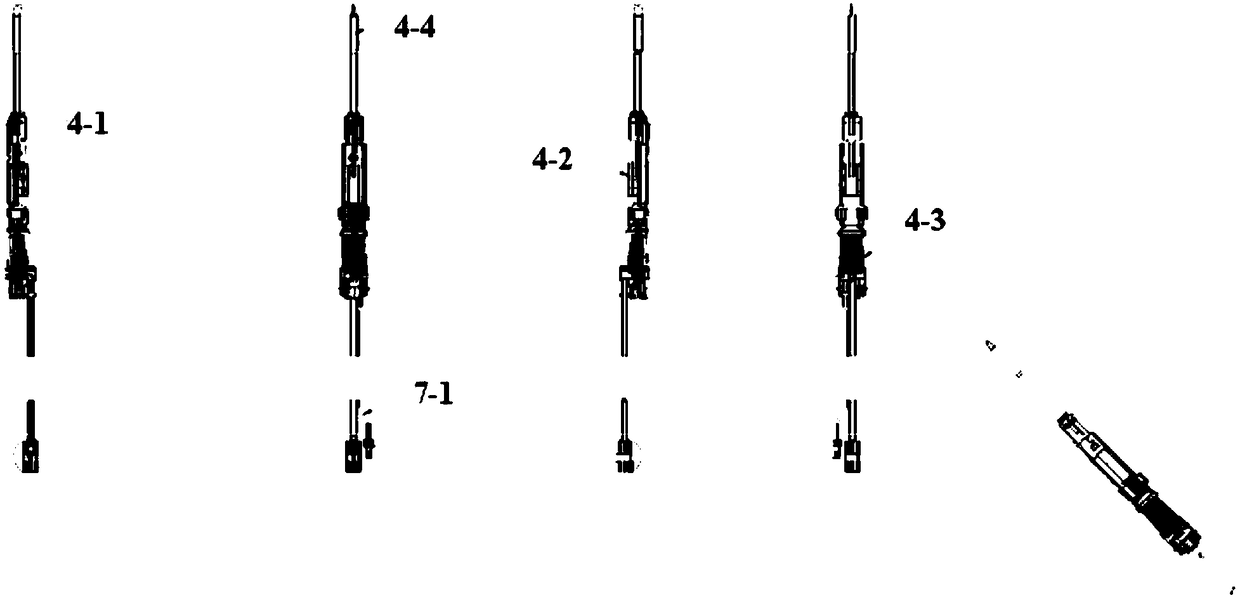

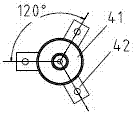

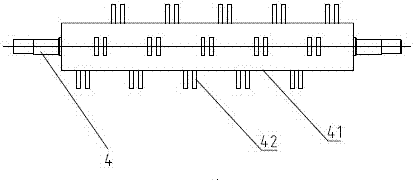

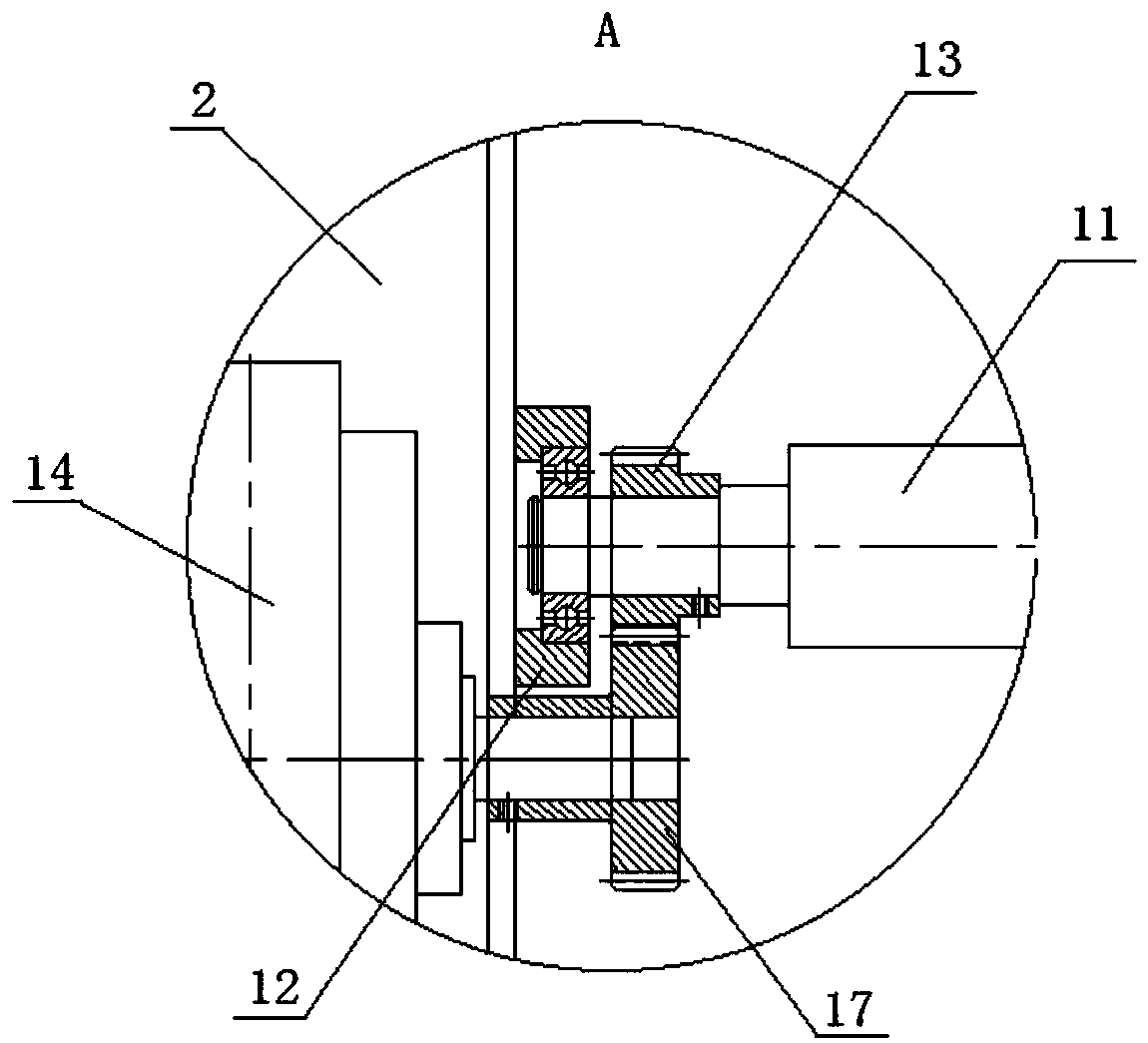

Vacuum-assisted mammary gland rotary cutting system and using method thereof

PendingCN108852424AReduce labor costsAvoid missed cutsSurgical needlesVaccination/ovulation diagnosticsVacuum assistedX-ray

The invention provides a vacuum-assisted mammary gland rotary cutting system. The system comprises a touch screen (1), a vacuum control system (2), a driving handle (3), GMT probes (4) and a multi-angle automatic rotary cutter (5), a trolley and vacuum tube kits and accessories; the touch screen (1) is provided with a touch screen data transmission port (1-1); the vacuum control system (2) provides vacuum pressure required for the entire system, drives a handle interface, controls the rotary cutting speed and identifies the probes, and tissue is sucked into a cutter groove through downward vacuum and sucked and conveyed through backward vacuum; the driving handle (3) comprises a handle driving connecting line (3-1), and a biopsy stent guided under X rays is arranged; the GMT probes (4) comprise the 7G puncture rotary cutting needle, the 10G puncture rotary cutting needle and the 12G puncture rotary cutting needle, and each GMT probe comprises a probe assembly (4-1), a rotary cutting puncture needle shell (4-2), a sample collection box assembly (4-3) and a probe protection sleeve (4-4), and the GMT probes (4) are compatible with various images; the multi-angle automatic rotary cutter (5) has 60-degree, 180-degree, 240-degree and 360-degree automatic rotary cutting modes preset by a program. The invention further provides a corresponding use method.

Owner:GERMAN MEDICAL TECH BEIJING

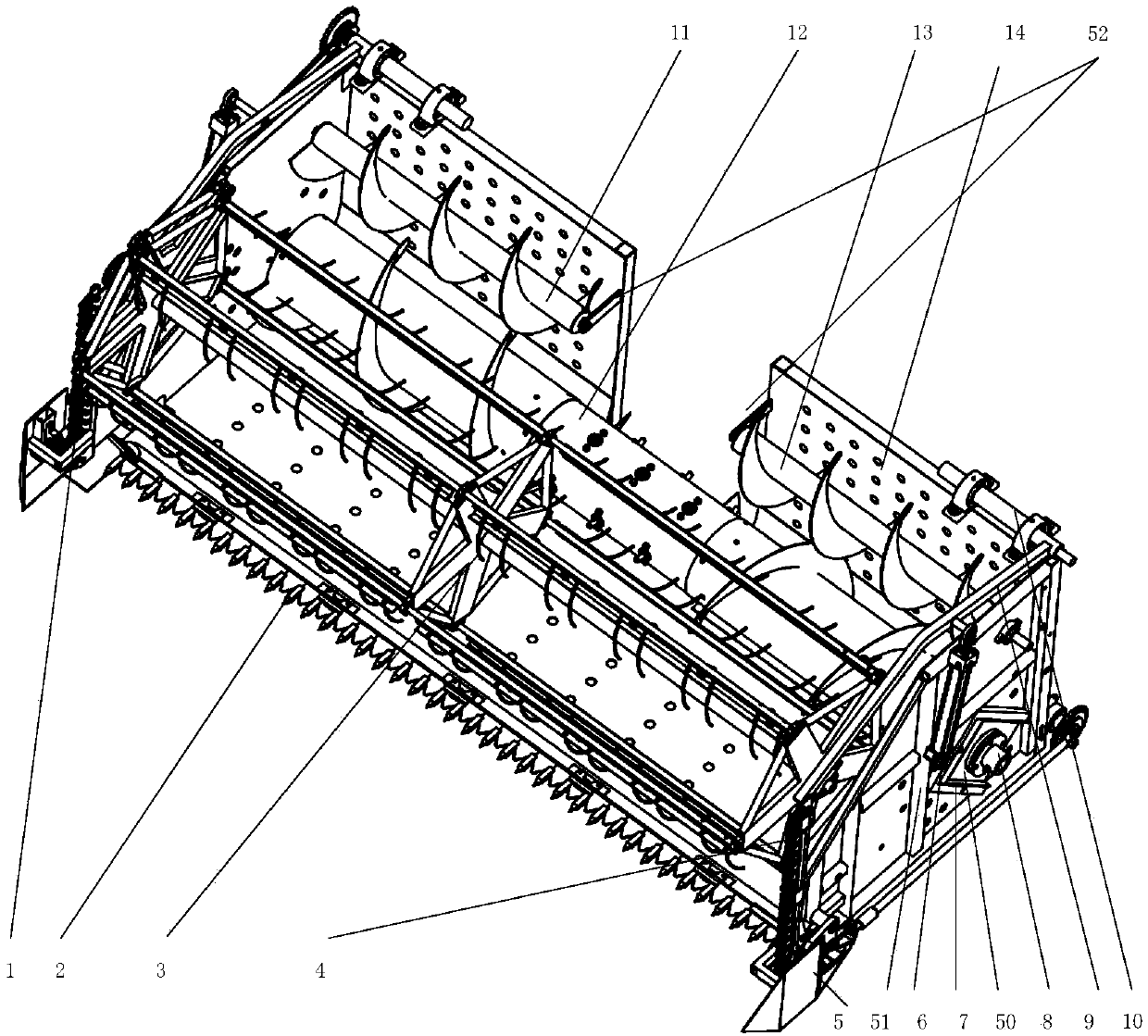

Stubble collecting and returning machine

The invention relates to the technical field of agricultural machinery and provides a stubble collecting and returning machine. The machine comprises a gear box, a tripod, a stander, a stubble collecting device knife pivot, a stubble collecting device knife bed, a stubble collecting knife, a stubble chopping knife, a returning device knife pivot, a returning knife bed, a returning knife, a fixed knife, a case and a copying sliding plate, wherein the gear box is mounted on the stander; the tripod is mounted on the stander by a suspension loop; the stubble collecting device knife pivot is horizontally mounted on the stander; the stubble collecting device knife bed is welded on the stubble collecting device knife pivot according to helix arrangement for mounting the stubble collecting knife and the stubble chopping knife; the returning device knife pivot is horizontally mounted on the stander; the returning knife bed is welded on the returning device knife pivot according to helix arrangement for mounting the returning knife; the case is mounted outside the returning device; the fixed knife is welded at the inner side of the front of the case; and the copying sliding plate is mounted on the case. When the machine works, the stubble collecting device collects the stubbles and throws the stubbles together with the straws into the returning device and the returning device crushes and returns the stubbles and the straws, thus realizing that the machine and the tools enter into the field once and carry out straw stubble collecting and returning operations simultaneously.

Owner:SHANDONG UNIV OF TECH

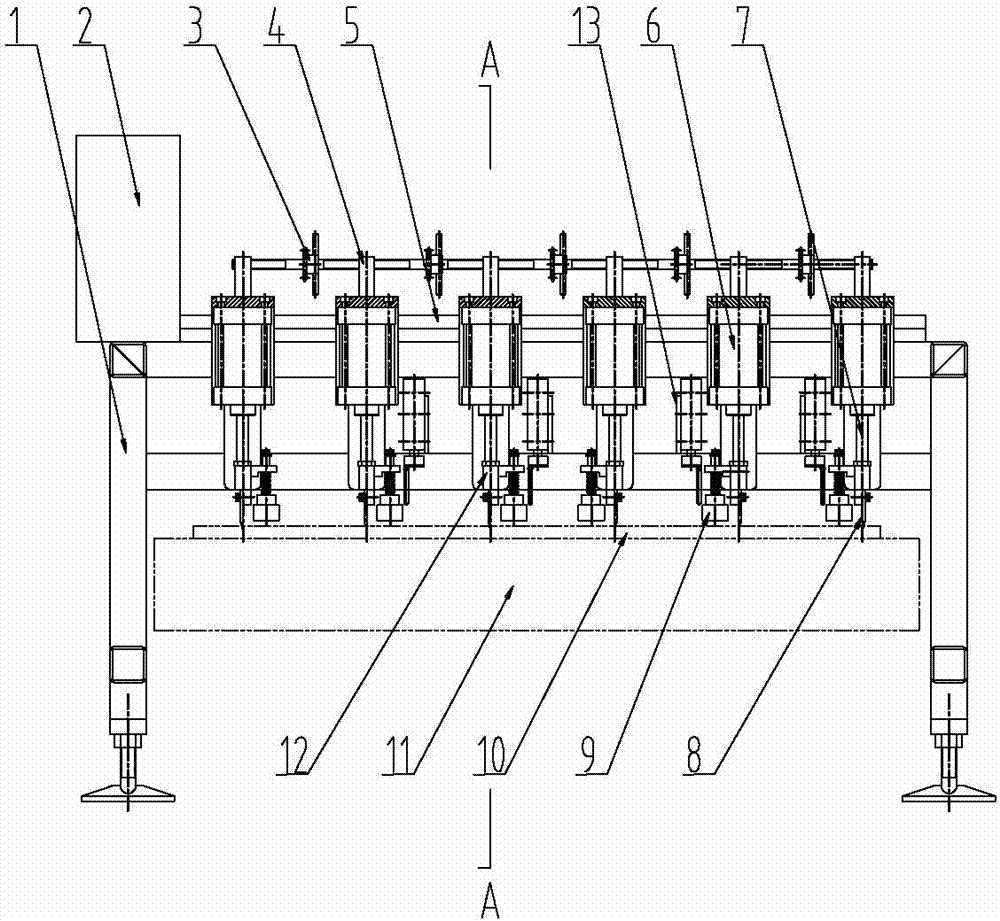

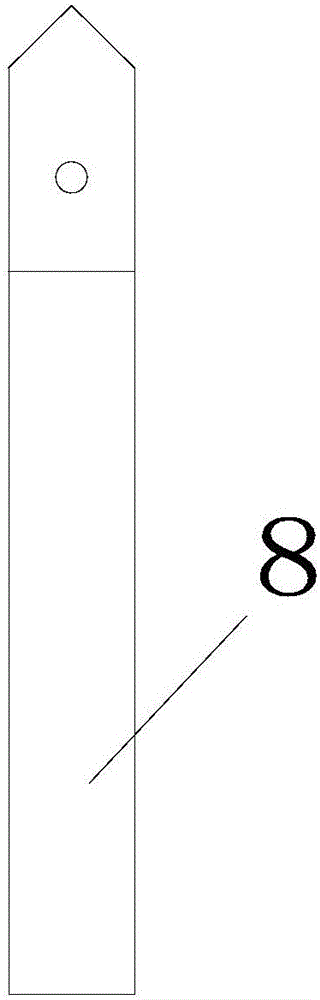

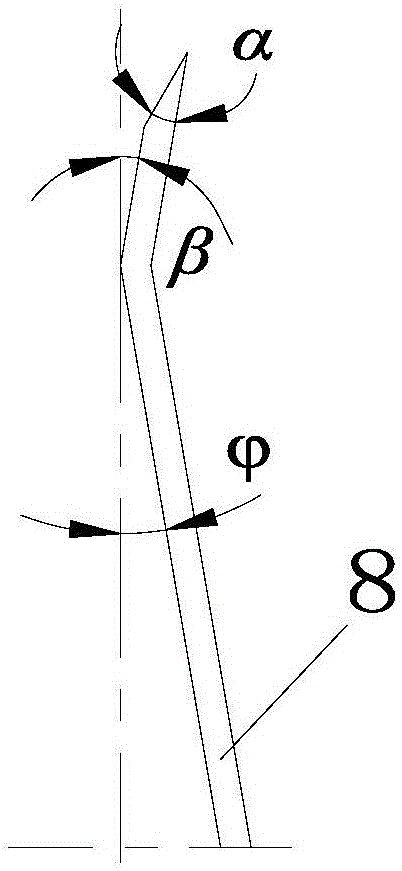

Fine dried noodle cutting machine

The invention discloses a fine dried noodle cutting machine which has a simple structure and can reduce food contamination. The fine dried noodle cutting machine comprises a machine frame (1), wherein a conveying belt (11) used for conveying long noodles (10) is arranged on the machine frame (1). The fine dried noodle cutting machine is characterized in that an electric control mechanism (2) and one to twelve cutting knife holders (4) are arranged on the machine frame (1), wherein one to twelve knife holders (12) driven by cylinders are arranged on the cutting knife holders (4); noodle cutting knives (8) and noodle pressing mechanisms (9) are arranged on the knife holders (12); and through sequentially controlling the cylinders by using the electric control mechanism (2), the long noodles (10) are cut into noodle sections of finished fine dried noodle length. The fine dried noodle cutting machine with a simple structure has the advantages that by adopting the cylinders to drive the noodle cutting knives, moving parts do not need to be lubricated, so that food contamination is avoided; and meanwhile, phenomena of cutting missing and repeated cutting are avoided when the noodles are adjacently cut for two times, so that phenomena of noodle breakage are decreased, the production cost is reduced, the lengths of fine dried noodles are uniform and the packaging quality is improved.

Owner:KEMEN NOODLE MFG CO LTD

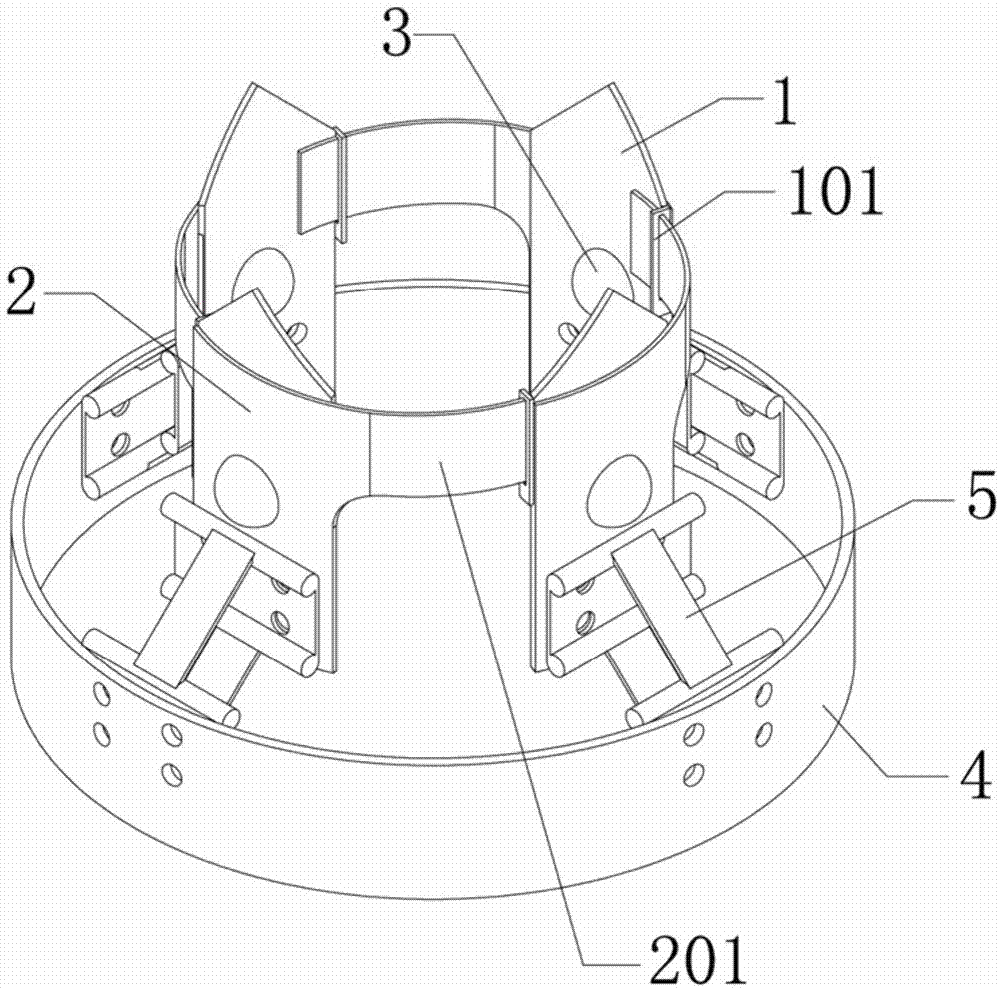

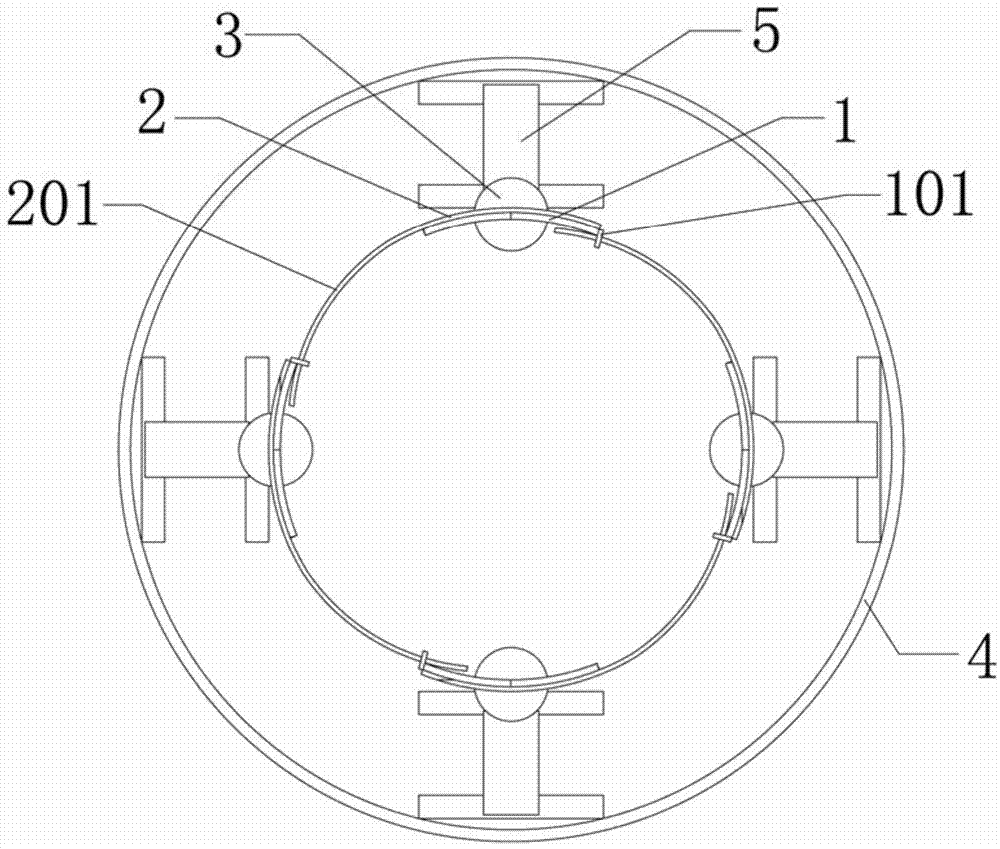

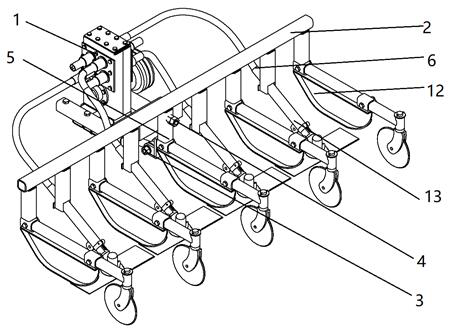

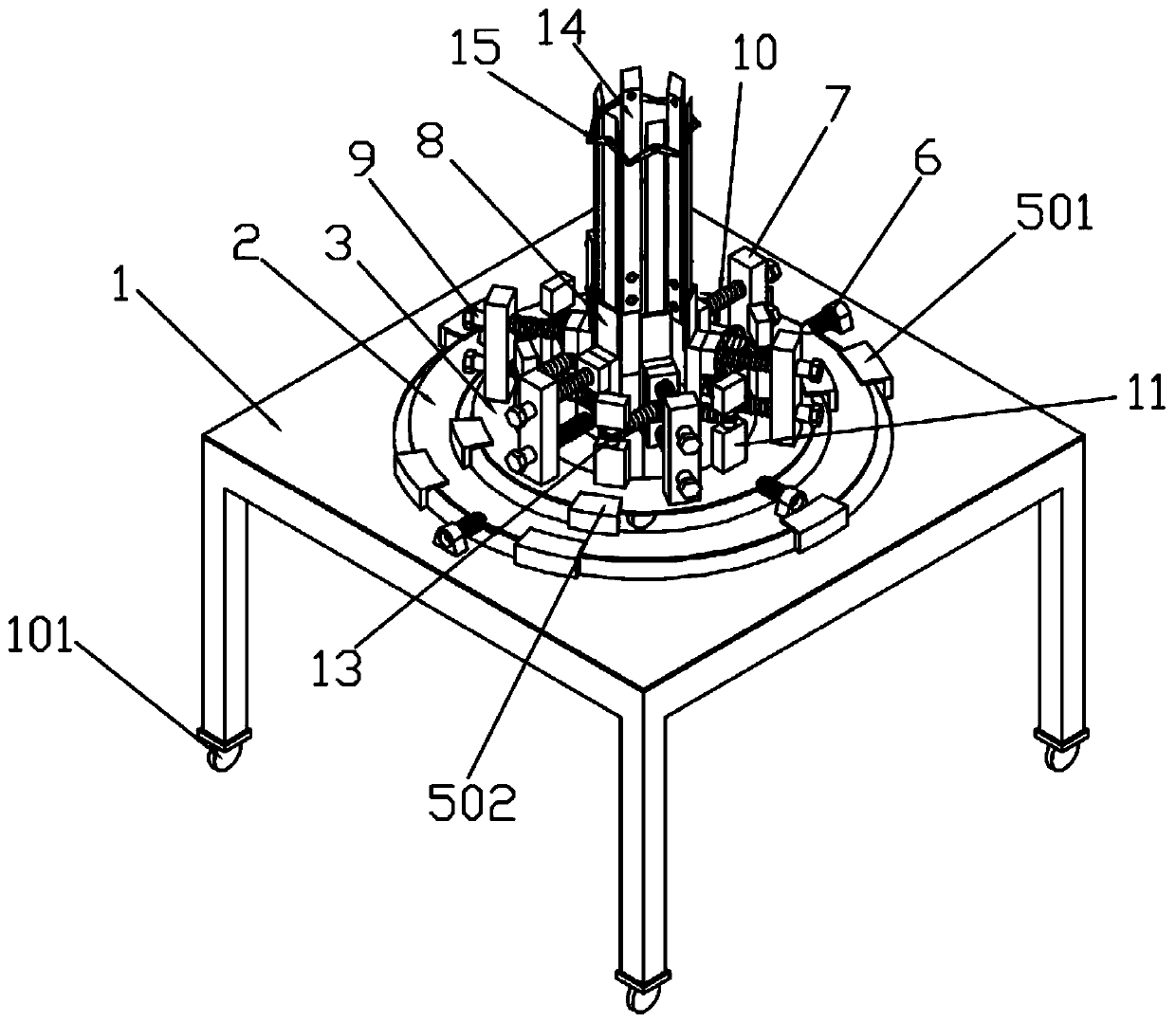

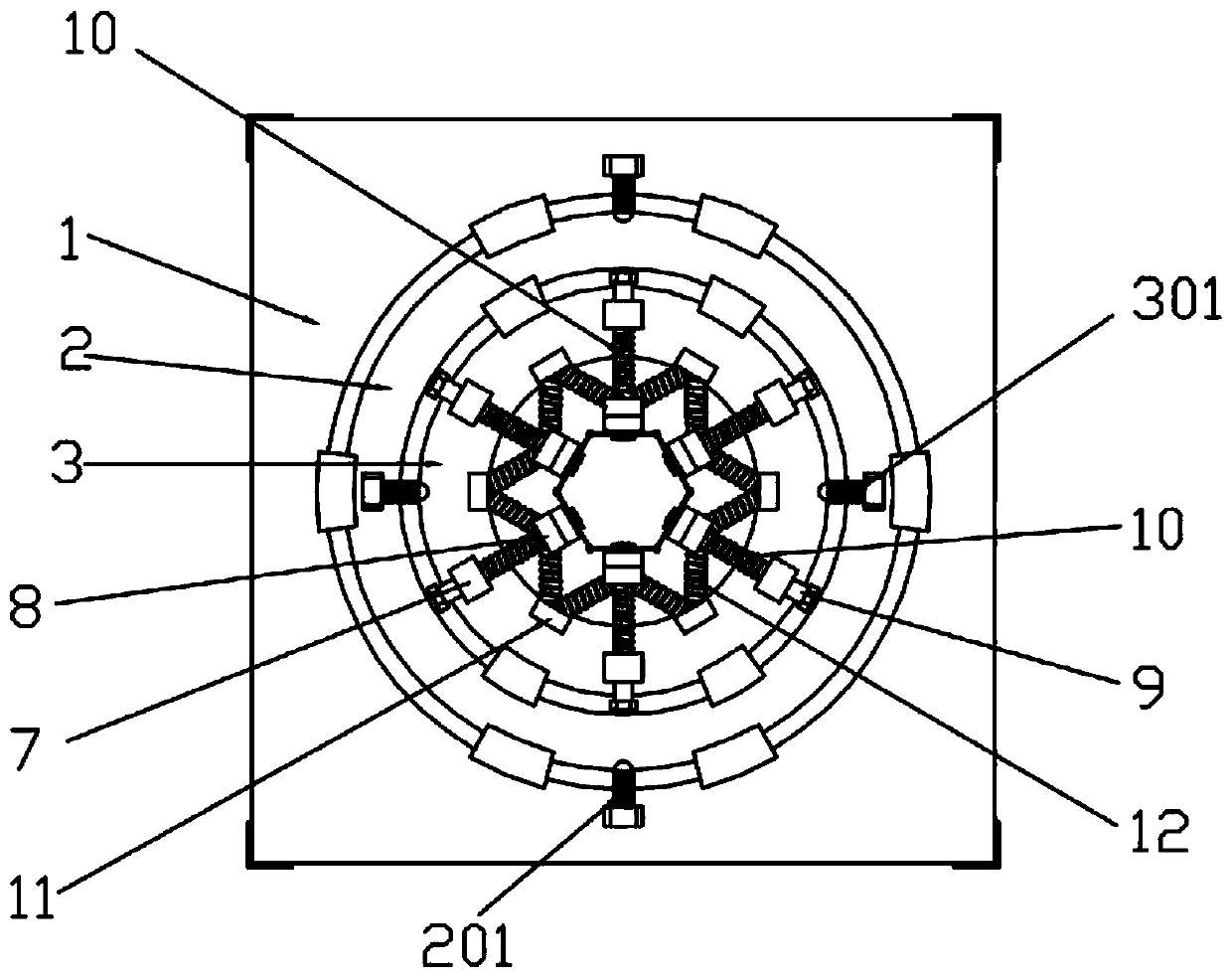

Inserting and cutting type banana combing device capable of surrounding banana stems in self-adaptive manner

The invention discloses an inserting and cutting type banana combing device capable of surrounding banana stems in a self-adaptive manner. The inserting and cutting type banana combing device comprises a machine frame, a power source, a cutter head, a gear set, connecting rods, a plurality of linear guide rails, L-shaped sliding blocks, springs, hard blade mounting frames, hard blades and soft blades, wherein the gear set is arranged between the cutter head and the table board of the machine frame, and consists of a driving gear and a driven gear; the linear guide rails are annularly arrayed on the cutter head; each L-shaped sliding block is mounted on the corresponding linear guide rail in a sliding manner; each connecting rod is arranged between every two linear guide rails; one ends ofthe connecting rods are hinged to the edge of a center hole of the driven gear, and the other end of the corresponding connecting rod is hinged to the horizontal edge of the corresponding L-shaped sliding block; each hard blade mounting frame is connected with the corresponding L-shaped sliding block through bolts; the springs sleeve the bolts; each hard blade is mounted on the corresponding hardblade mounting frame; each soft blade group is riveted to the outer side of the corresponding hard blade; and every two soft blade groups are riveted to form an annular enveloping structure which canenvelope the banana spike rods. The inserting and cutting type banana combing device disclosed by the invention has the advantages of being light and small in integral structure, convenient to move, safe and labor-saving to operate, self-adaptive to the banana spikes and rods and the like.

Owner:SOUTH CHINA AGRI UNIV

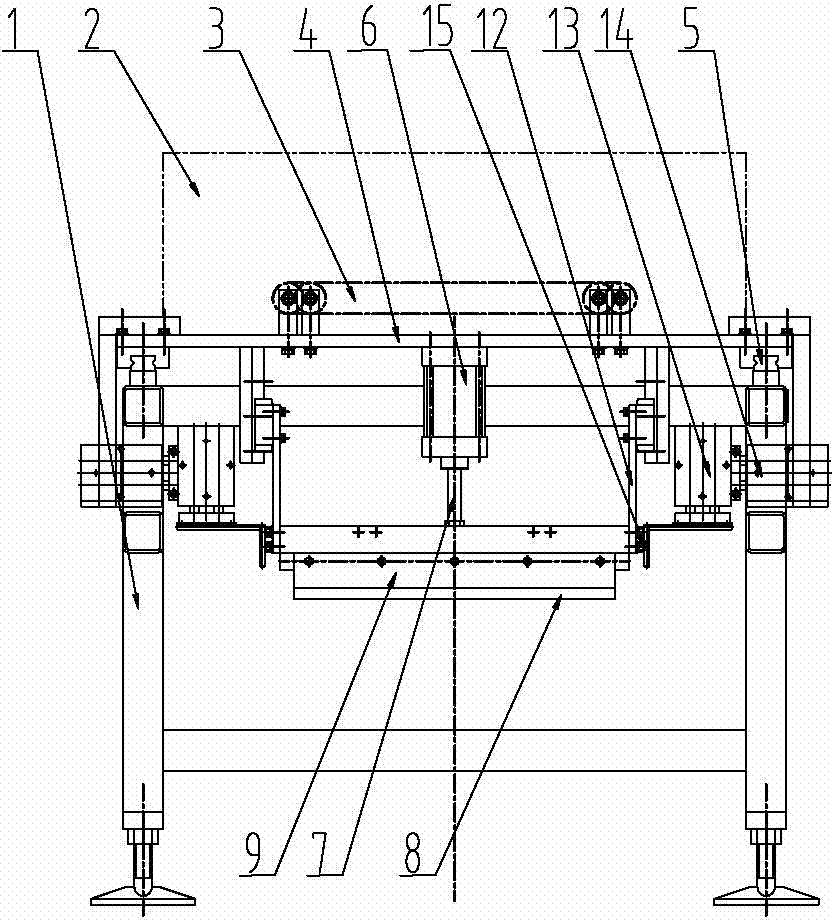

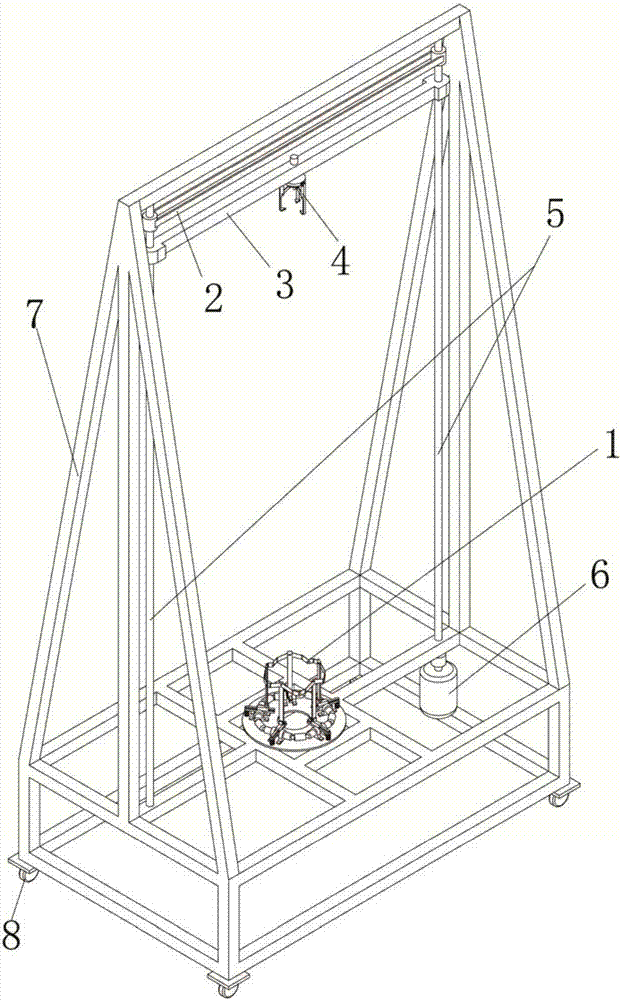

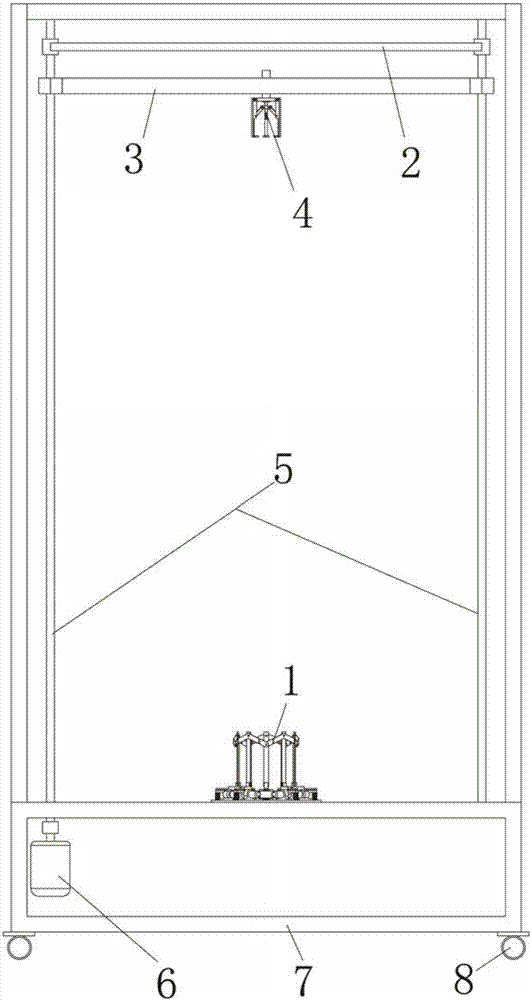

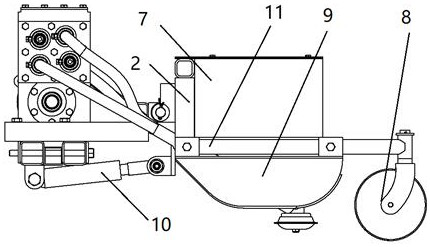

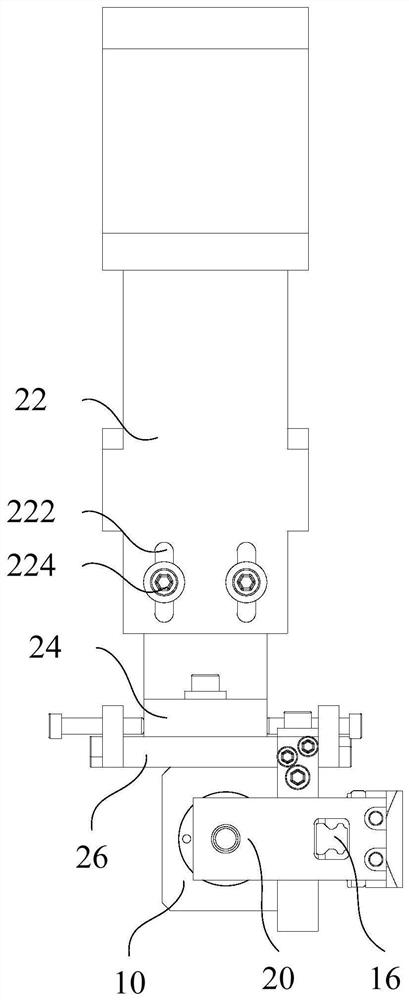

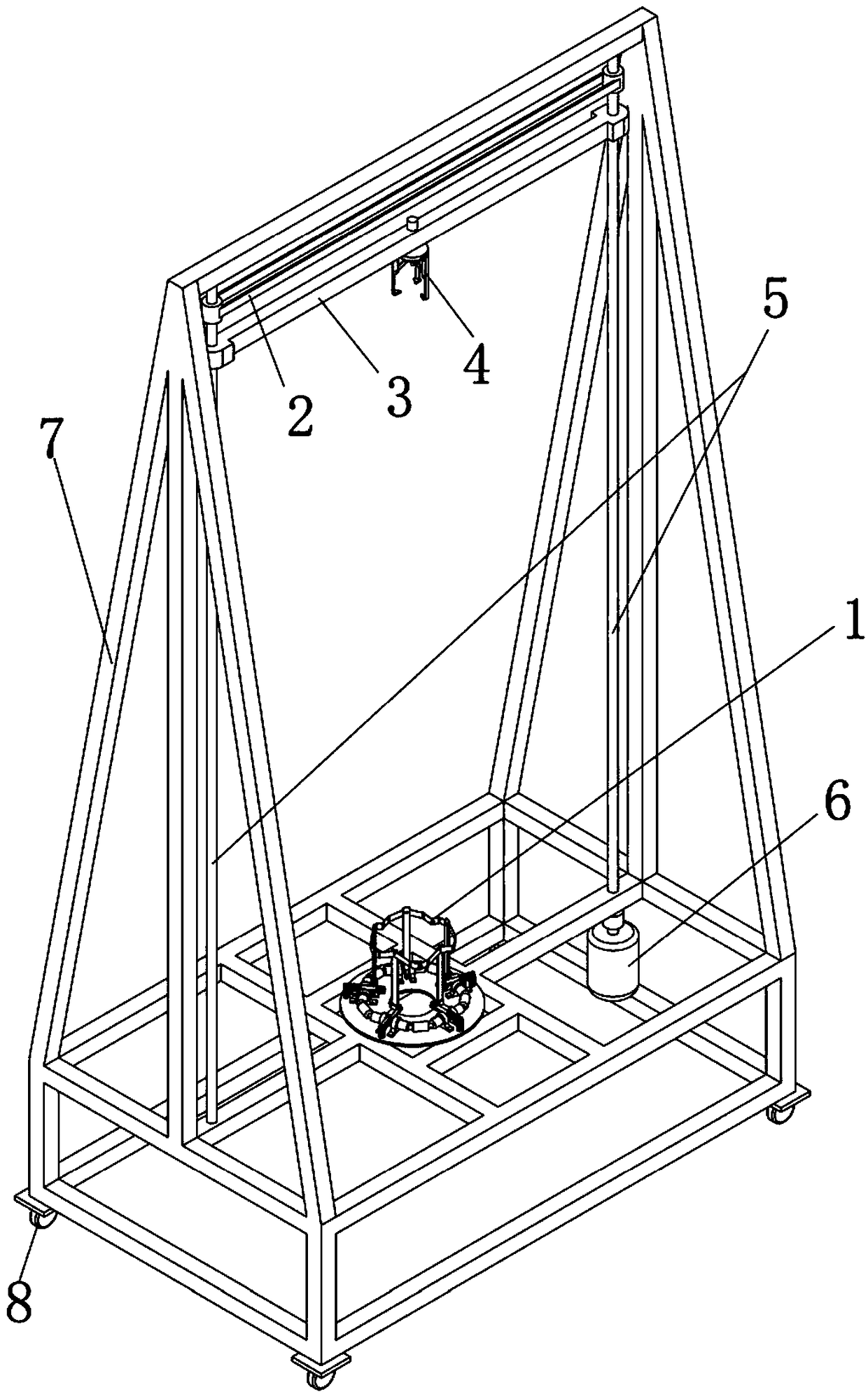

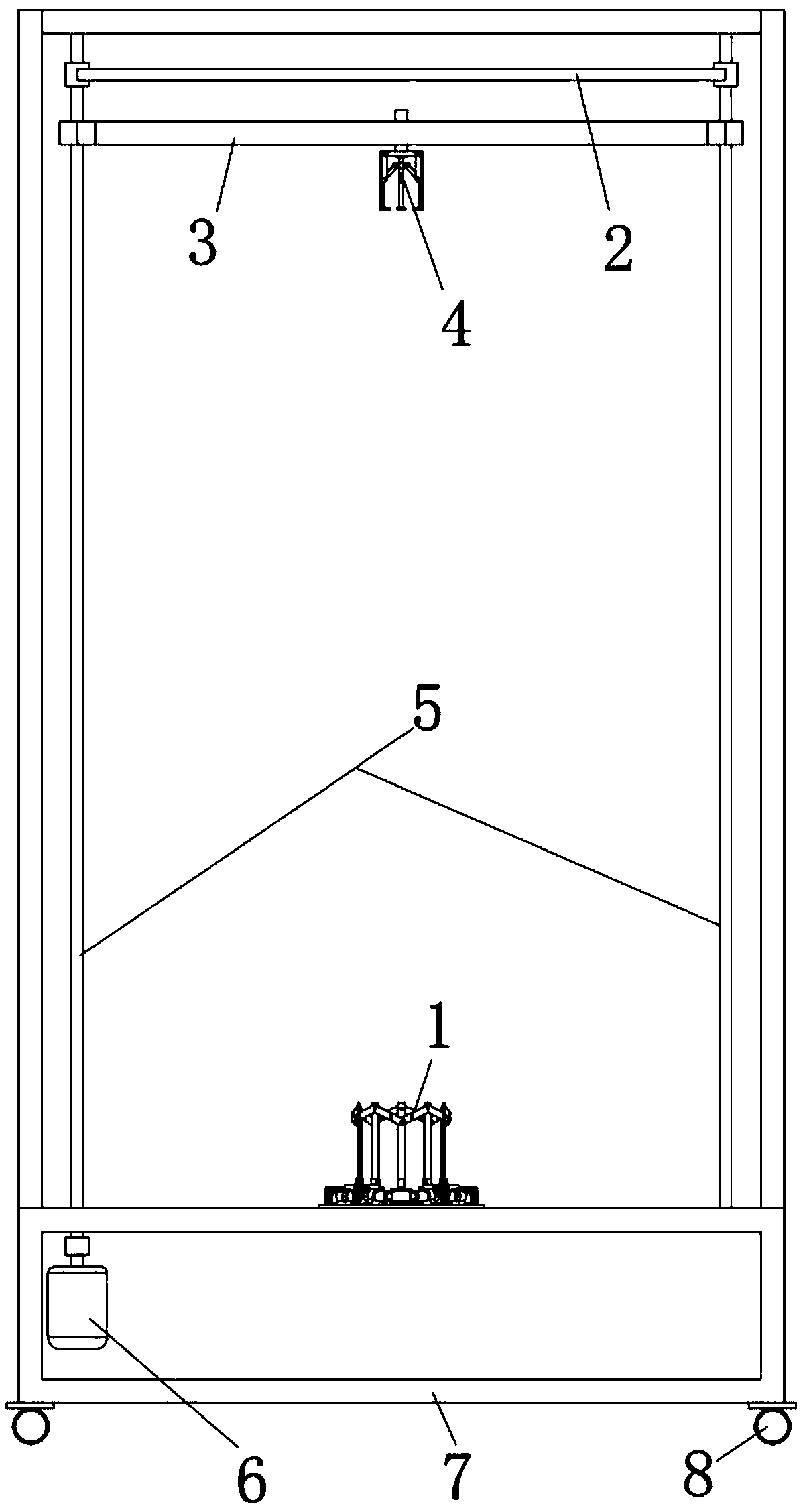

Inserting-cutting type banana crown cutting device

ActiveCN107048446AAutomatic diameter adjustmentAchieving diameter adaptationFood treatmentBall screwSelf locking

The present invention discloses an inserting-cutting type banana crown cutting device comprising an inserting-cutting type crown cutter, a synchronous belt transmission mechanism, a movable beam, a linkage self-locking clamping jaw, ball screw mechanisms, a motor and a bracket. The inserting-cutting type crown cutter is fixed on a lower holder of the bracket. The two sets of ball screw mechanisms are vertically arranged on the holder on both sides of the inserting-cutting type crown cutter, respectively, wherein one set of the ball screw mechanism is driven by the motor and synchronous movement of the two sets of ball screw mechanisms is realized by the synchronous belt transmission mechanism. The movable beam is arranged on the two sets of ball screw mechanisms, located above the inserting-cutting type crown cutter, and driven by the two sets of ball screw mechanisms to realize up-down linear movement. The linkage self-locking clamping jaw is arranged on the movable beam, used for clamping banana stalk and matched with the inserting-cutting type crown cutter, and cutting bananaes crown by crown from the stalk is realized. The banana crown cutting device disclosed by the present invention has the advantages of compact overall structure and light weight, and is convenience in transportation, safe and labor-saving in operation and the like, and is applicable to the mechanization of banana crown cutting.

Owner:SOUTH CHINA AGRI UNIV

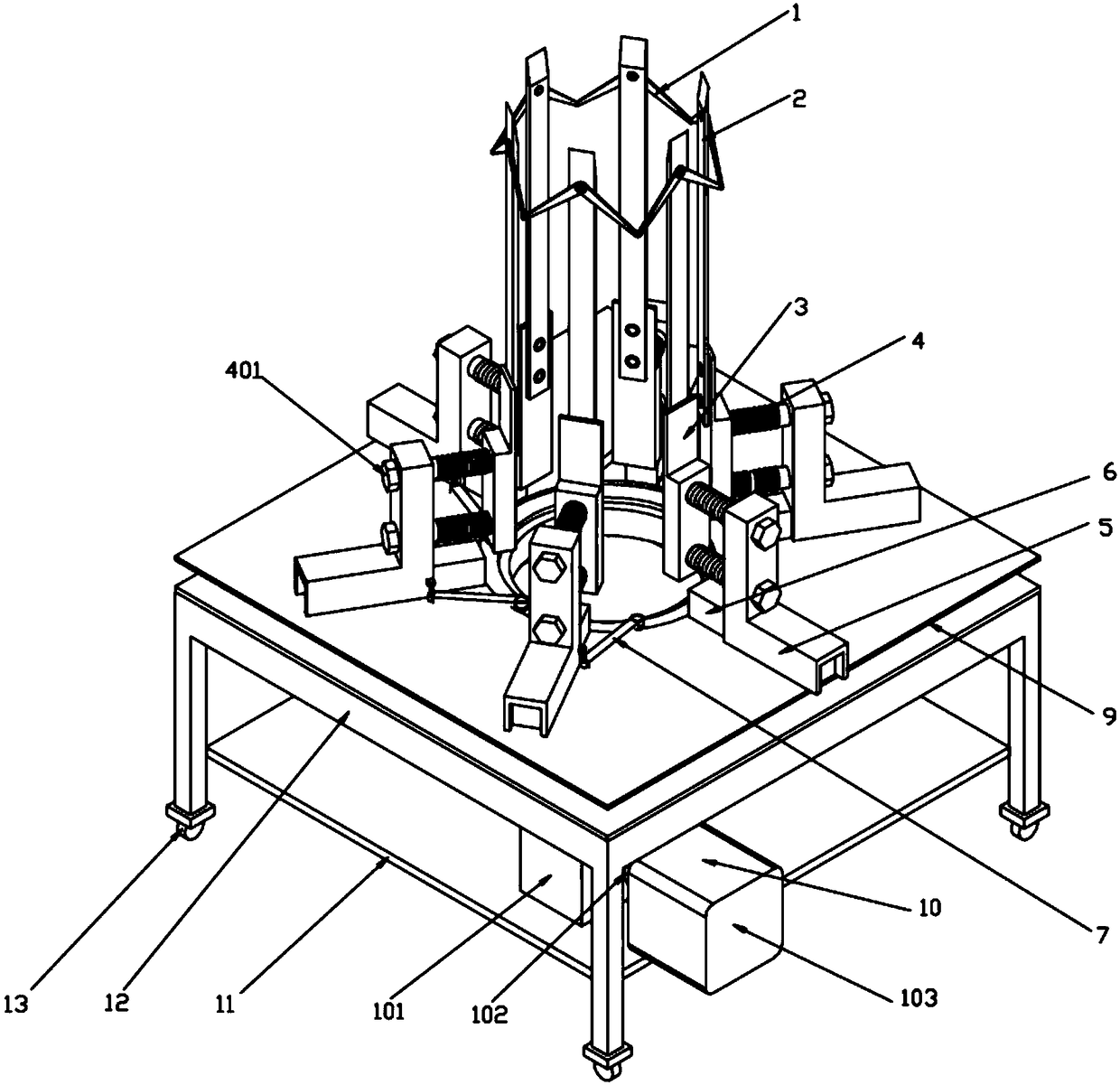

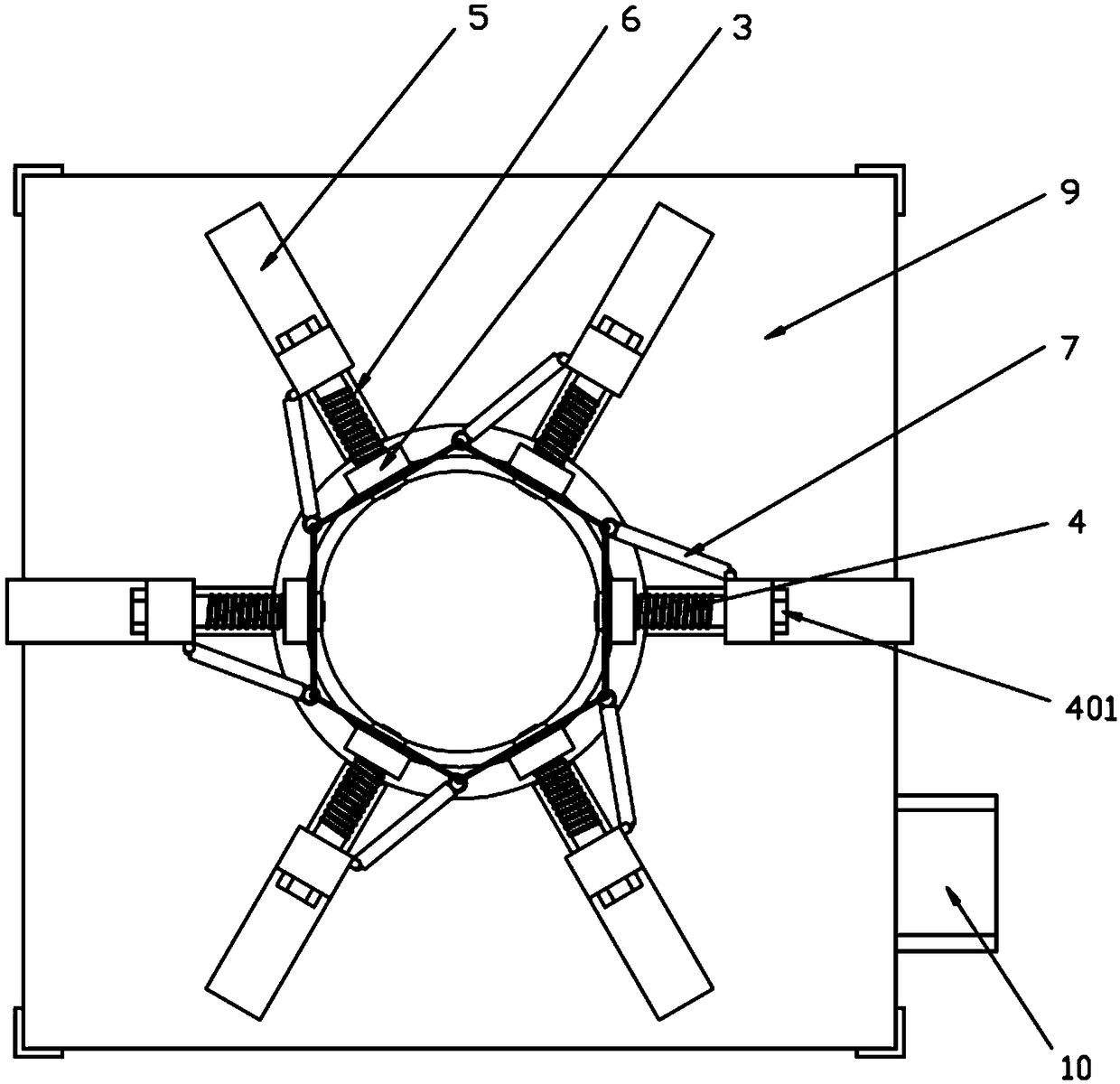

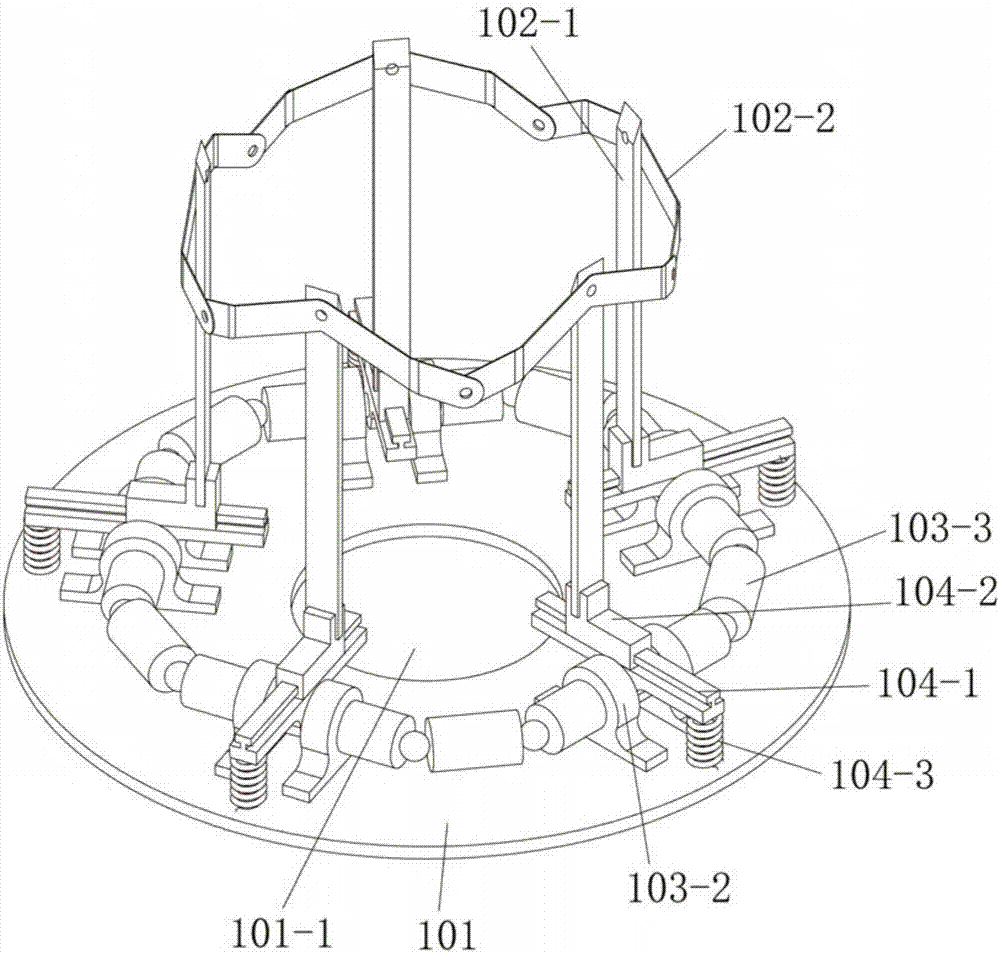

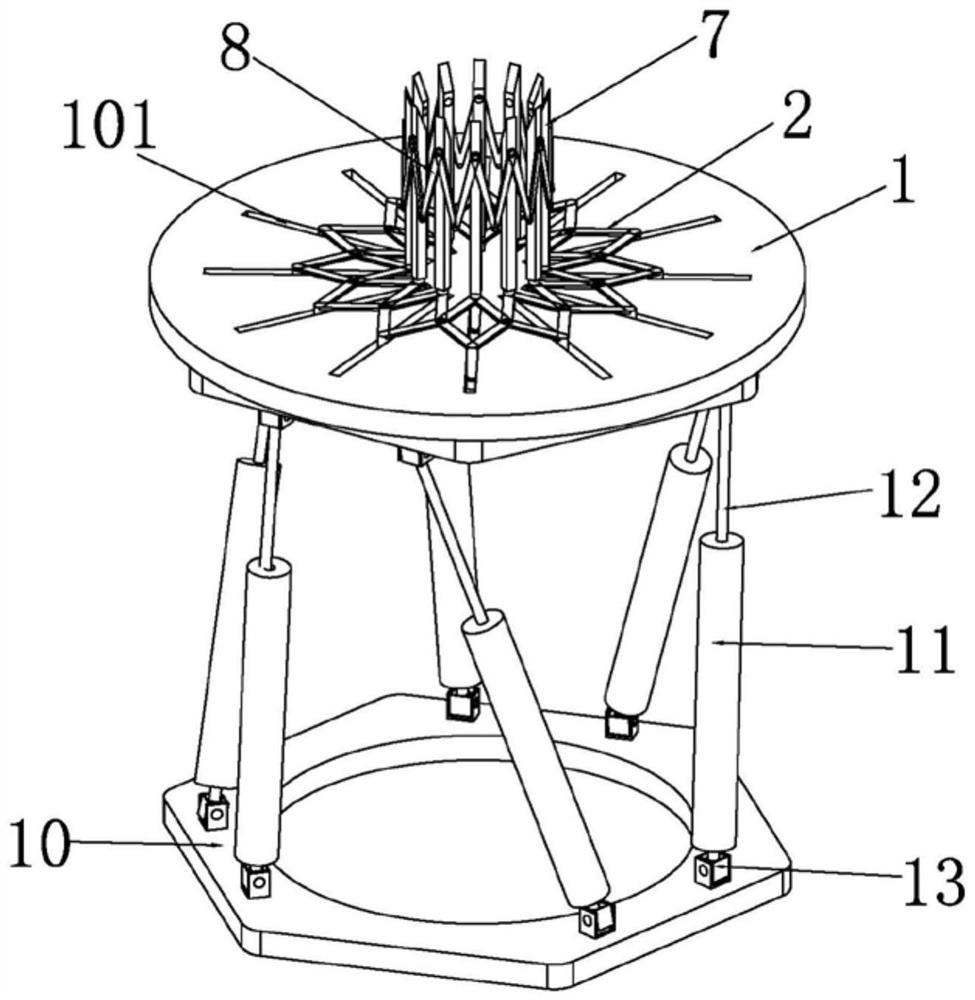

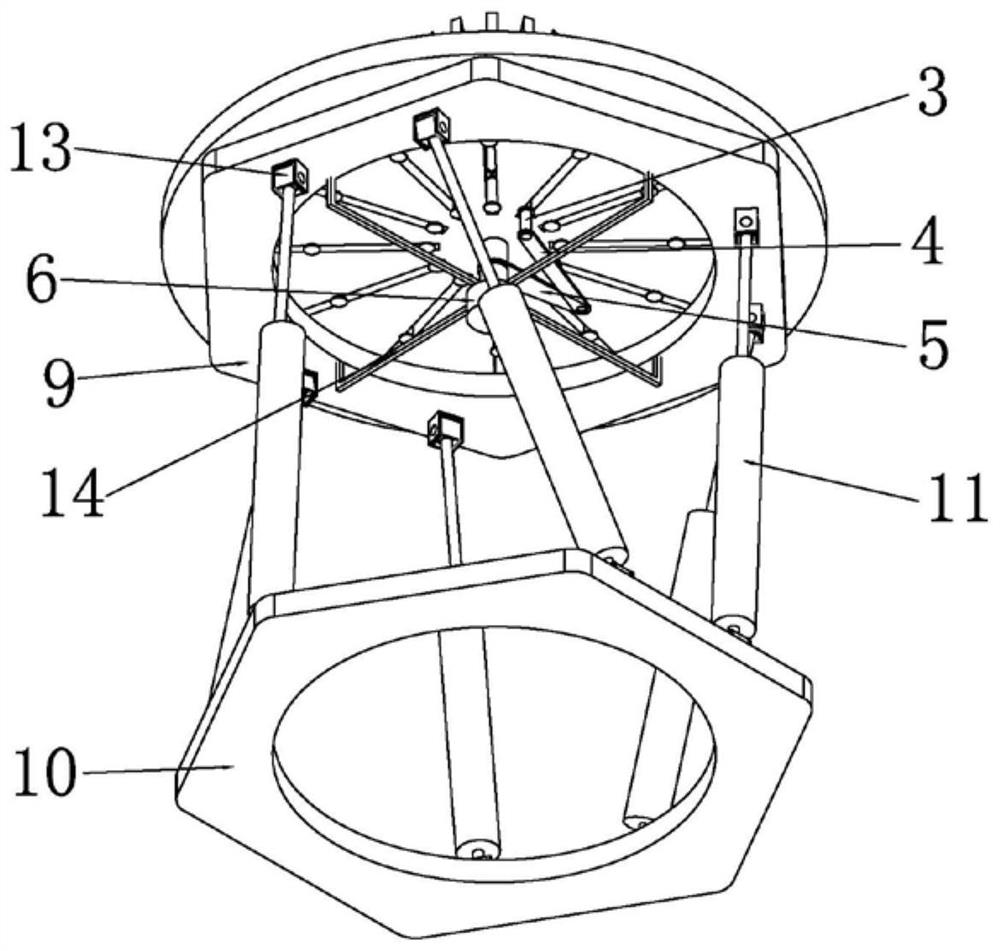

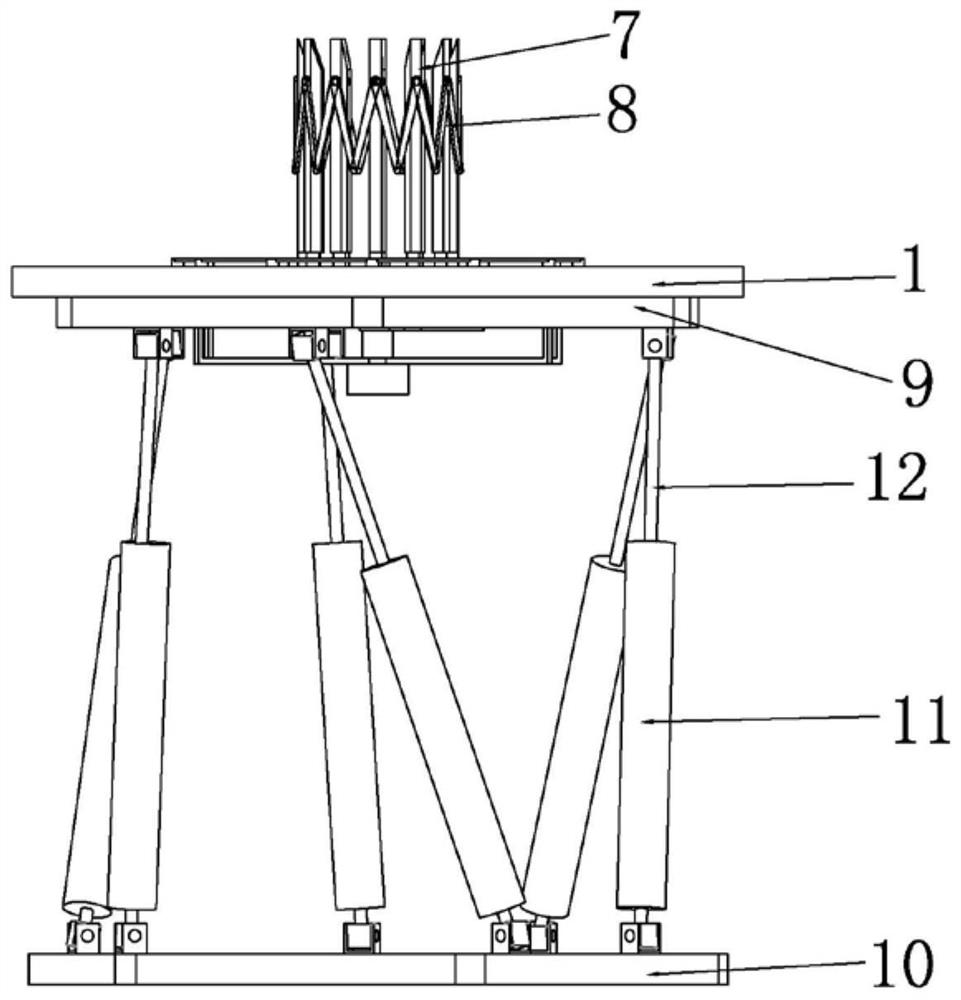

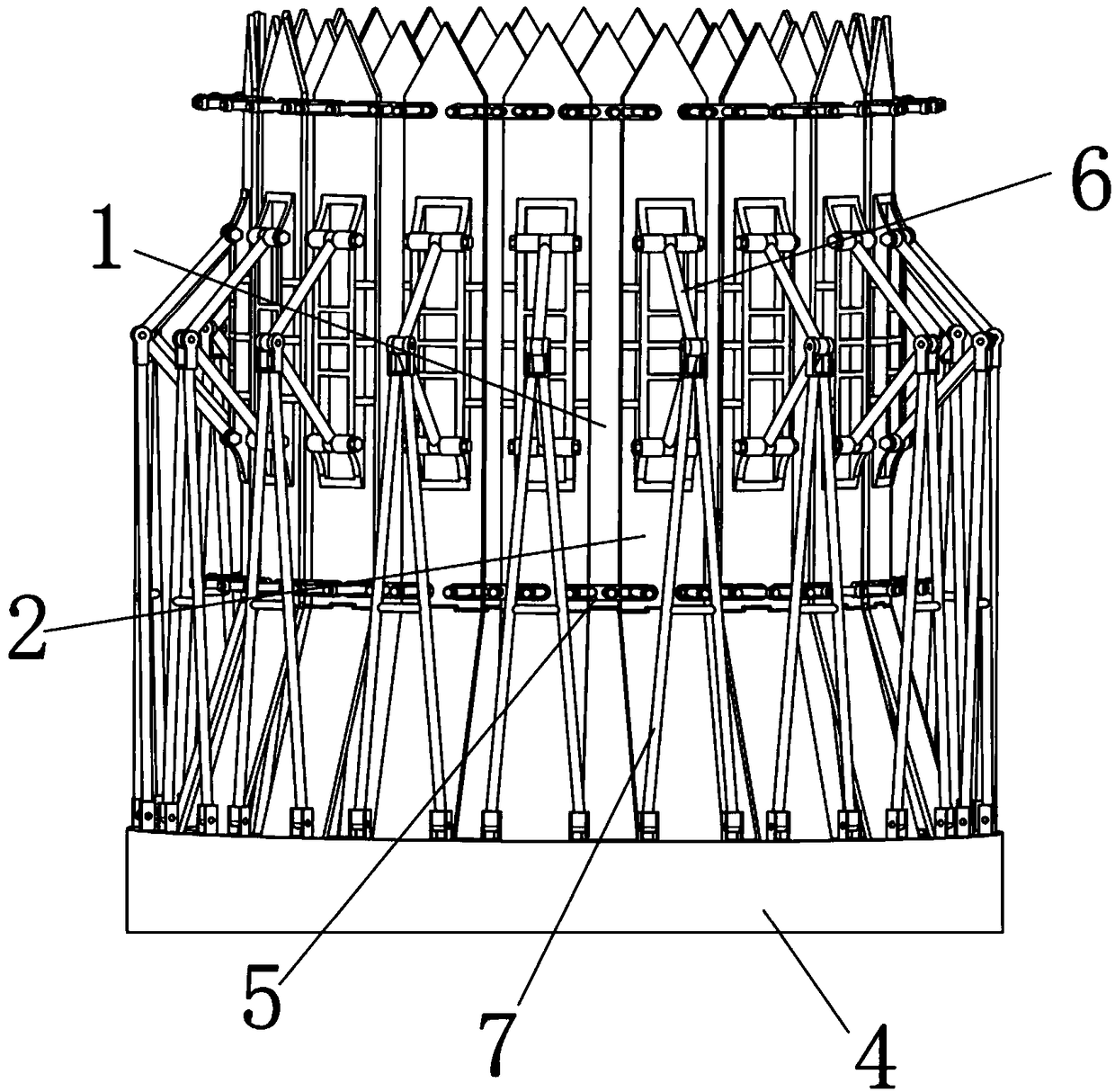

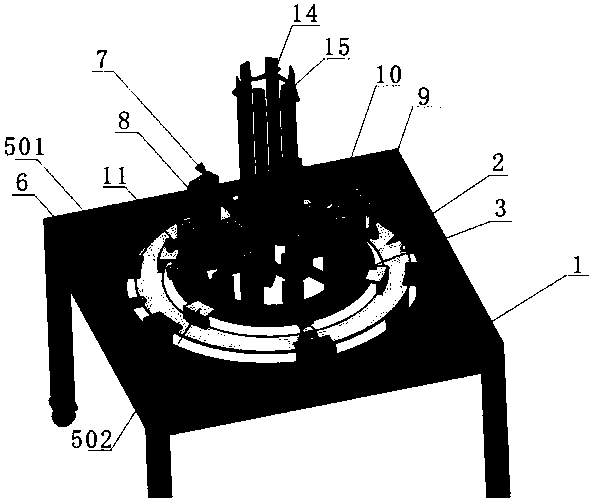

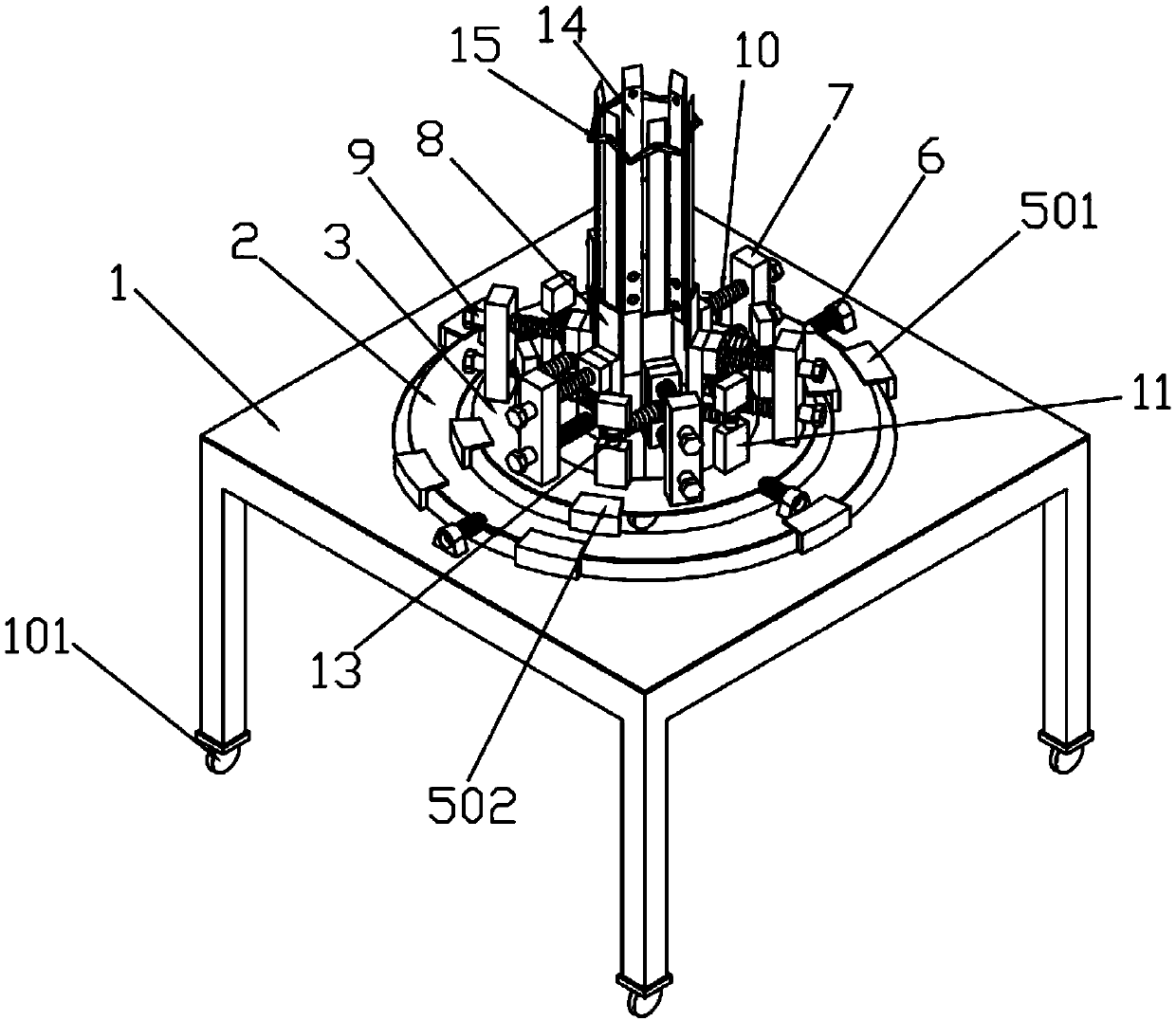

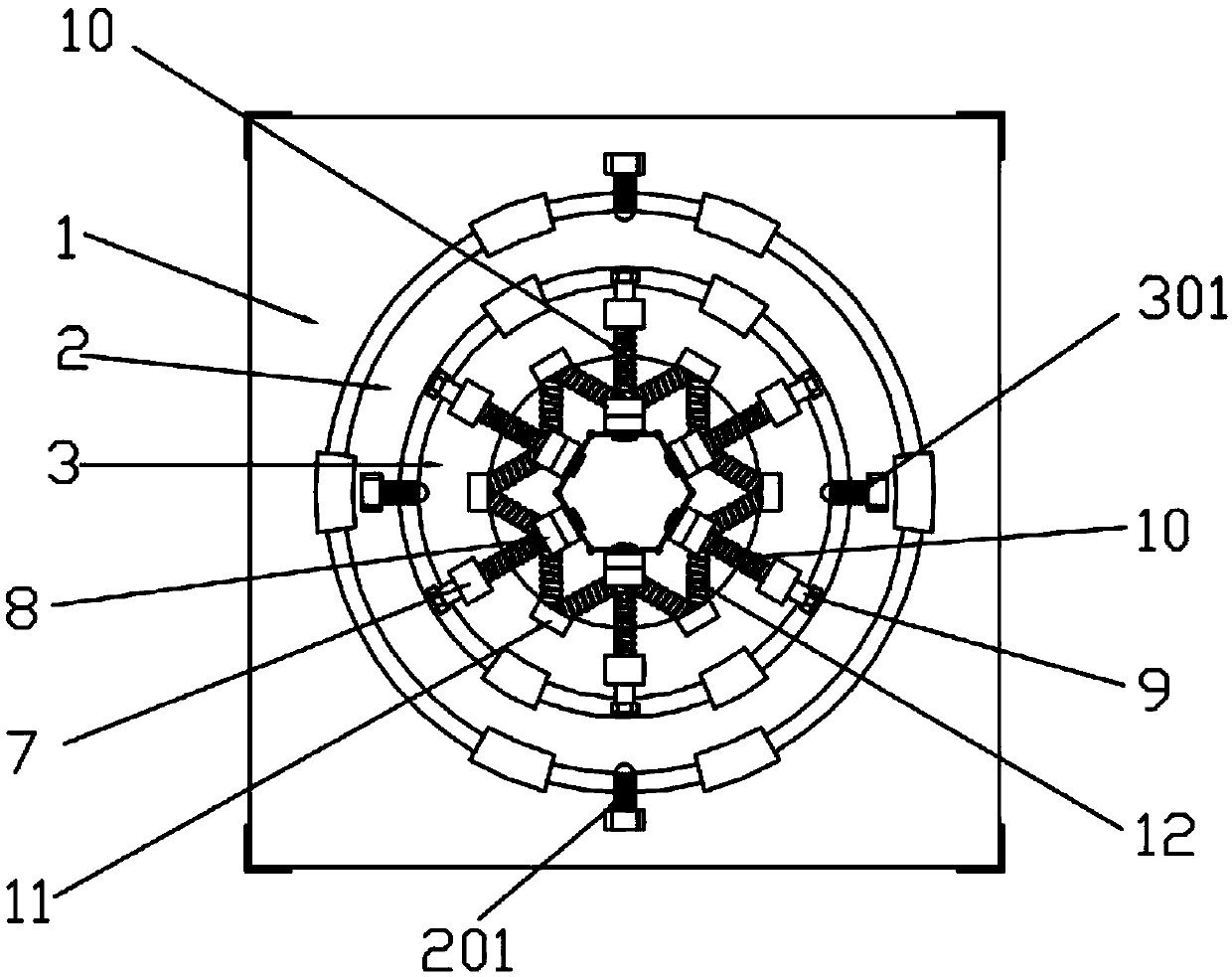

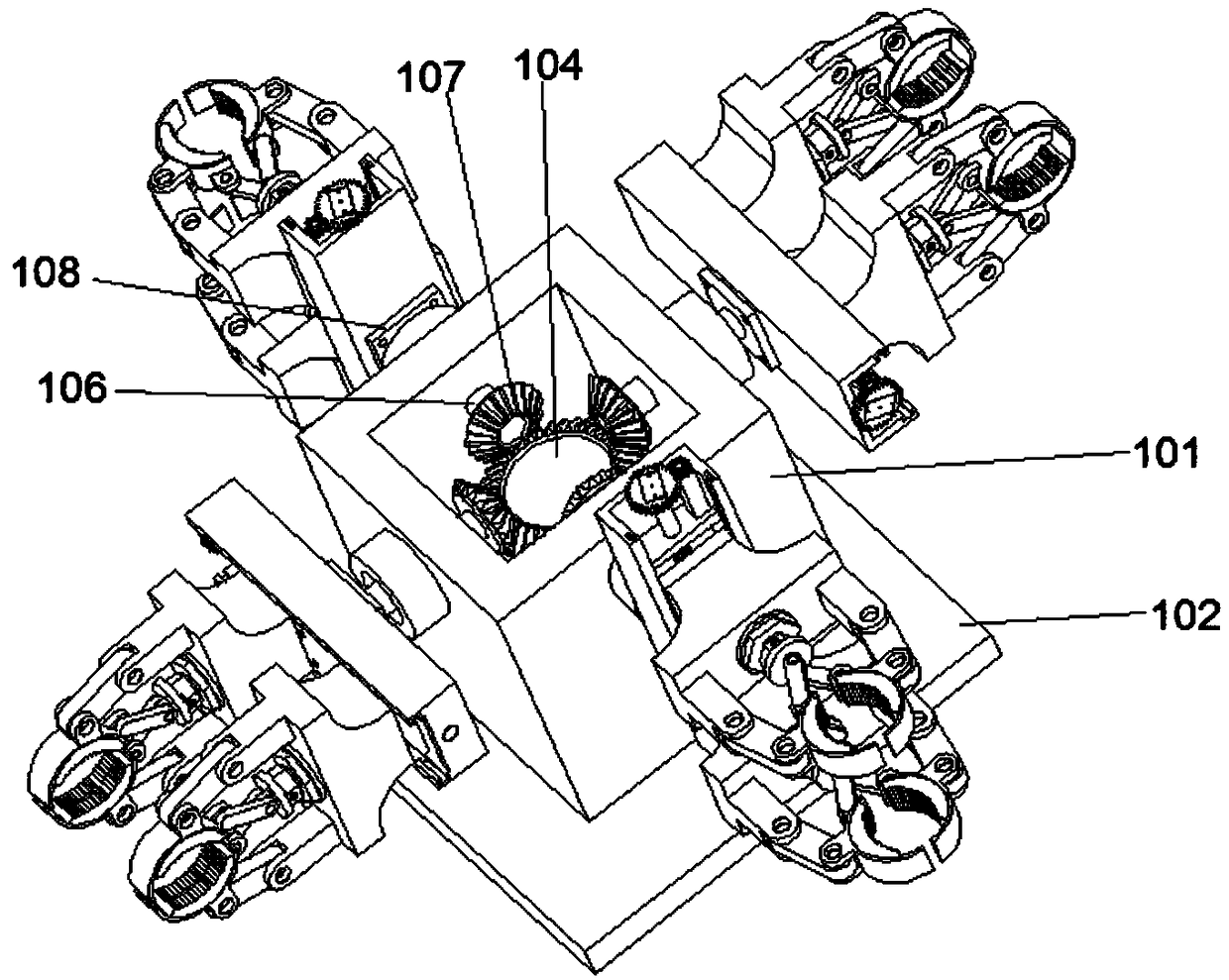

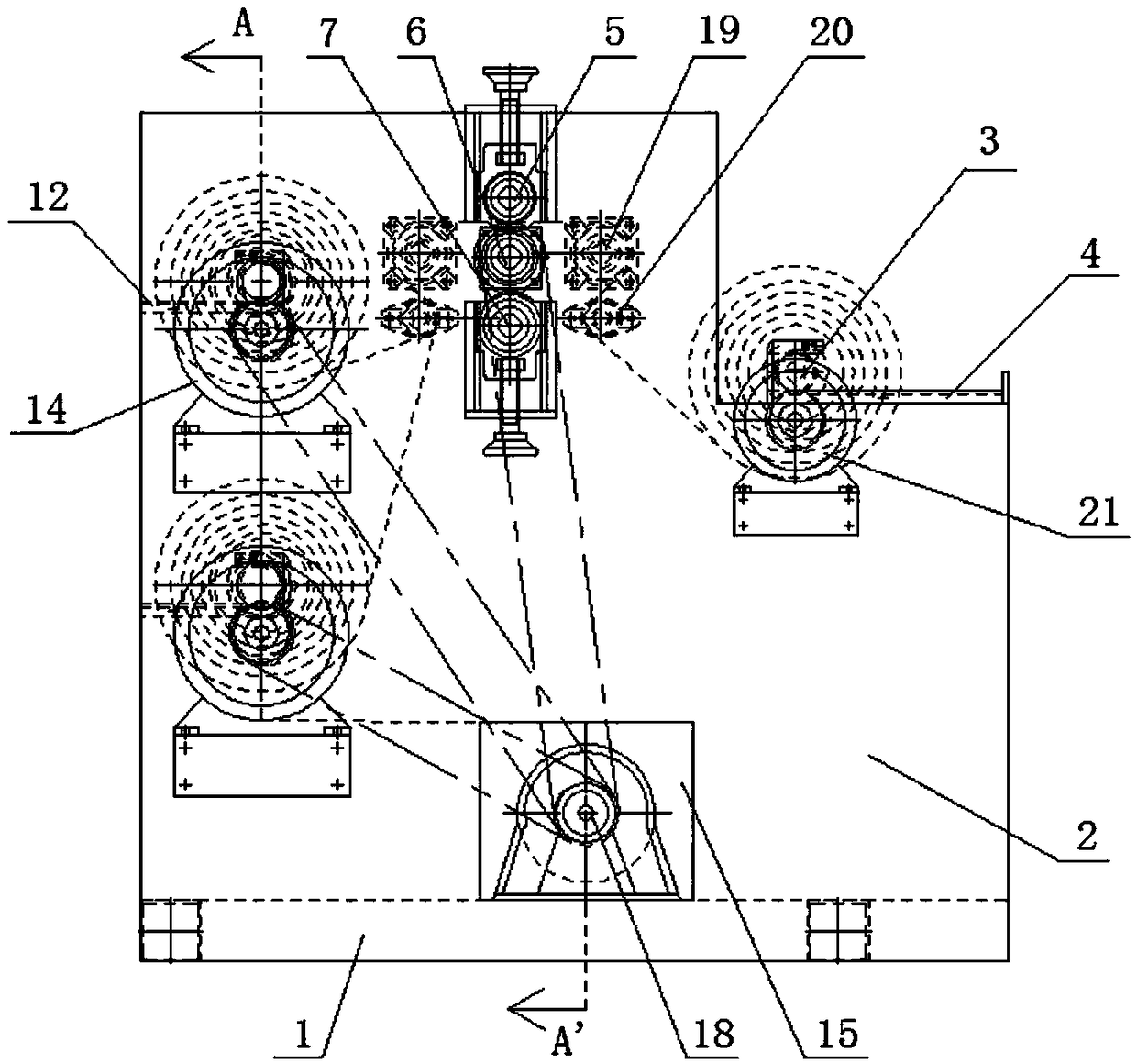

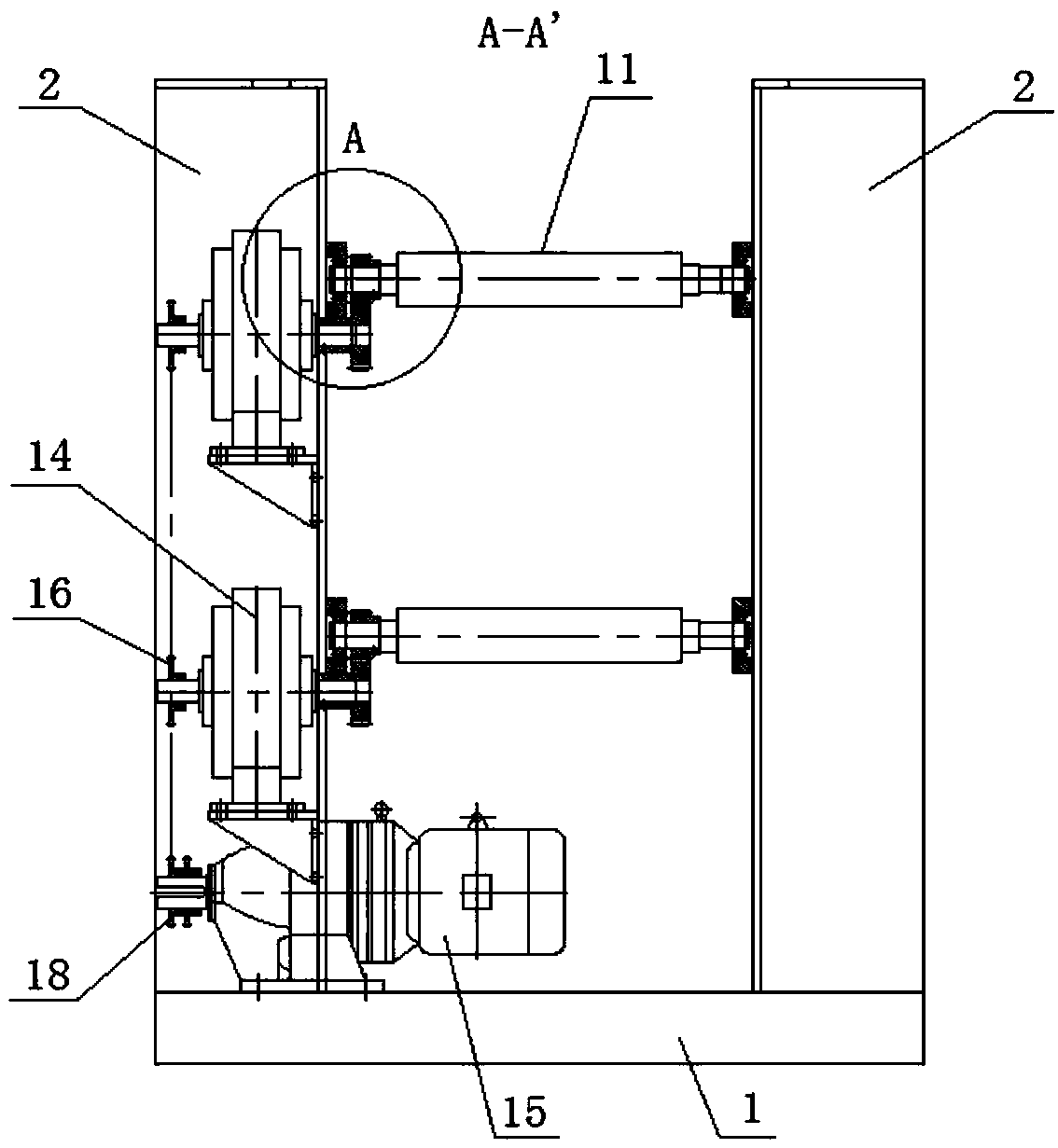

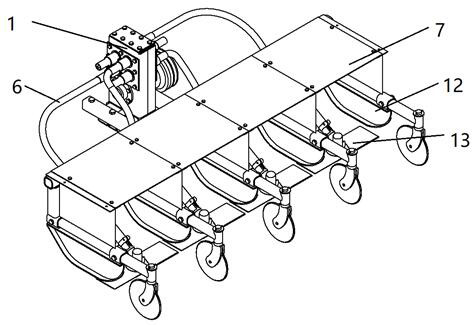

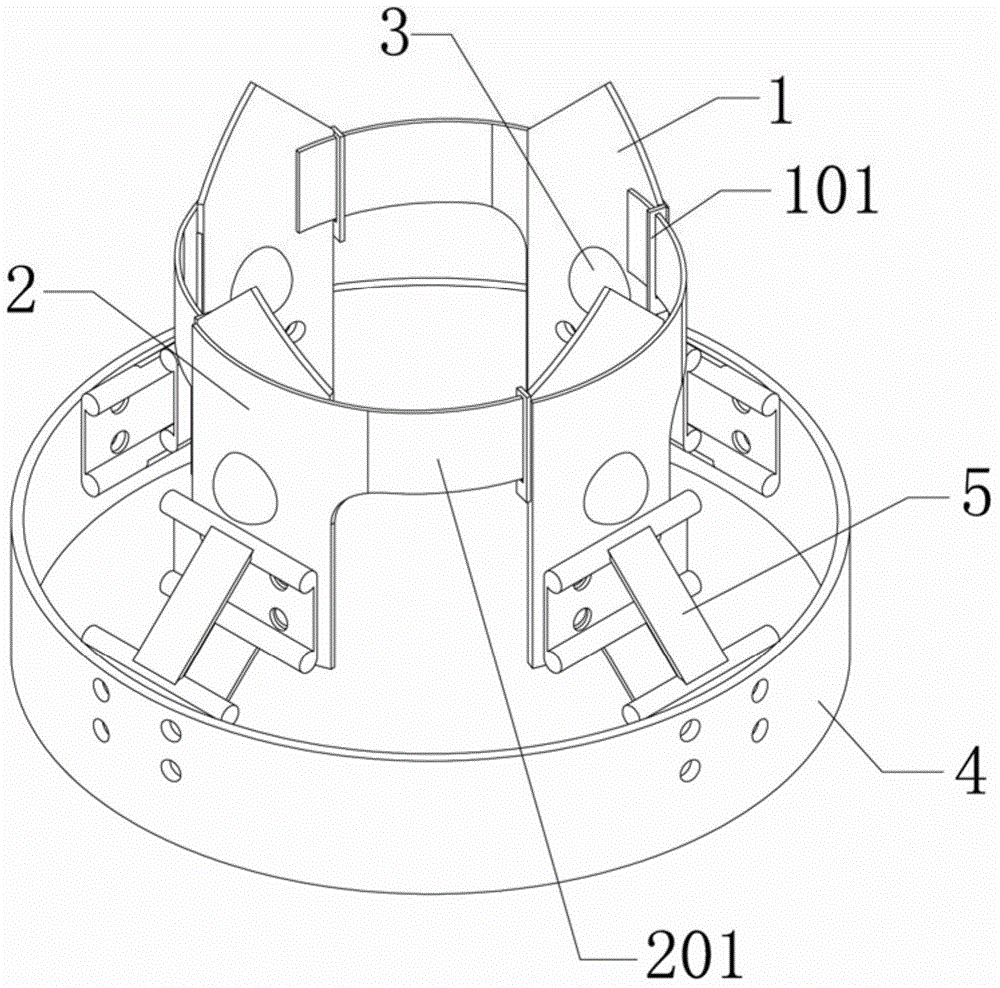

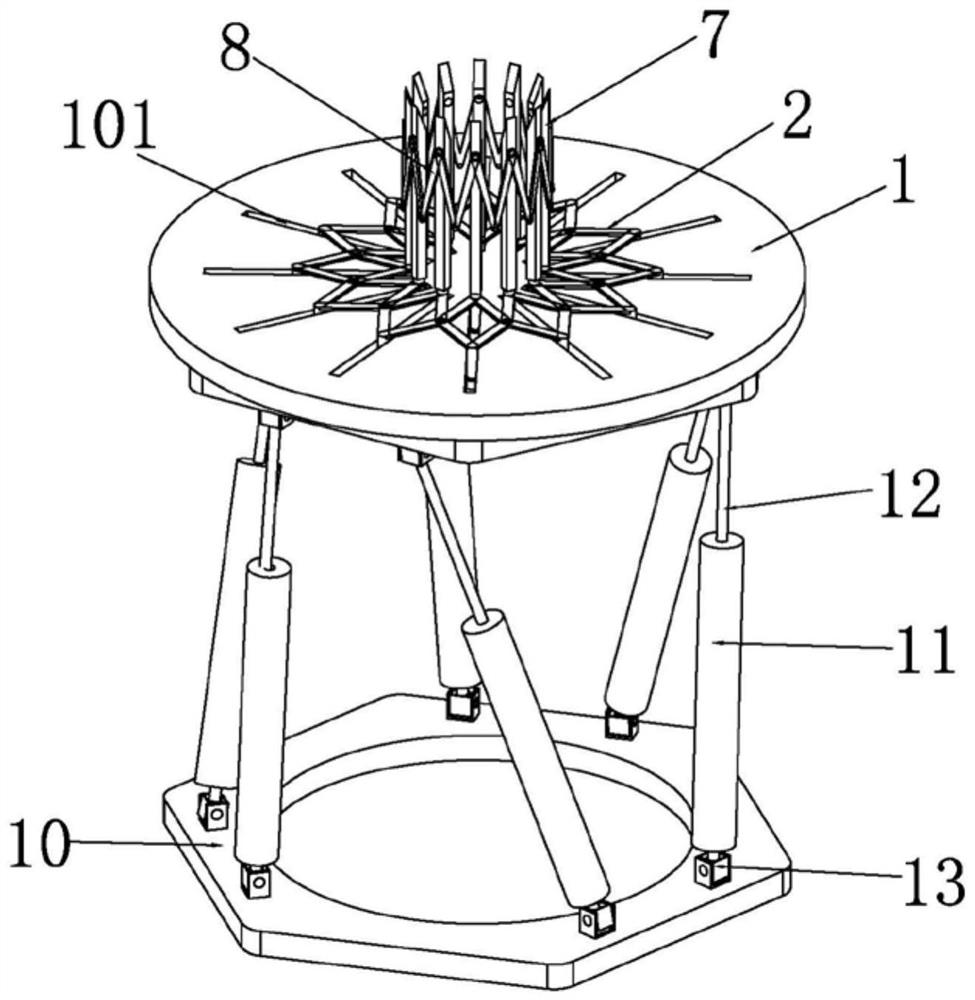

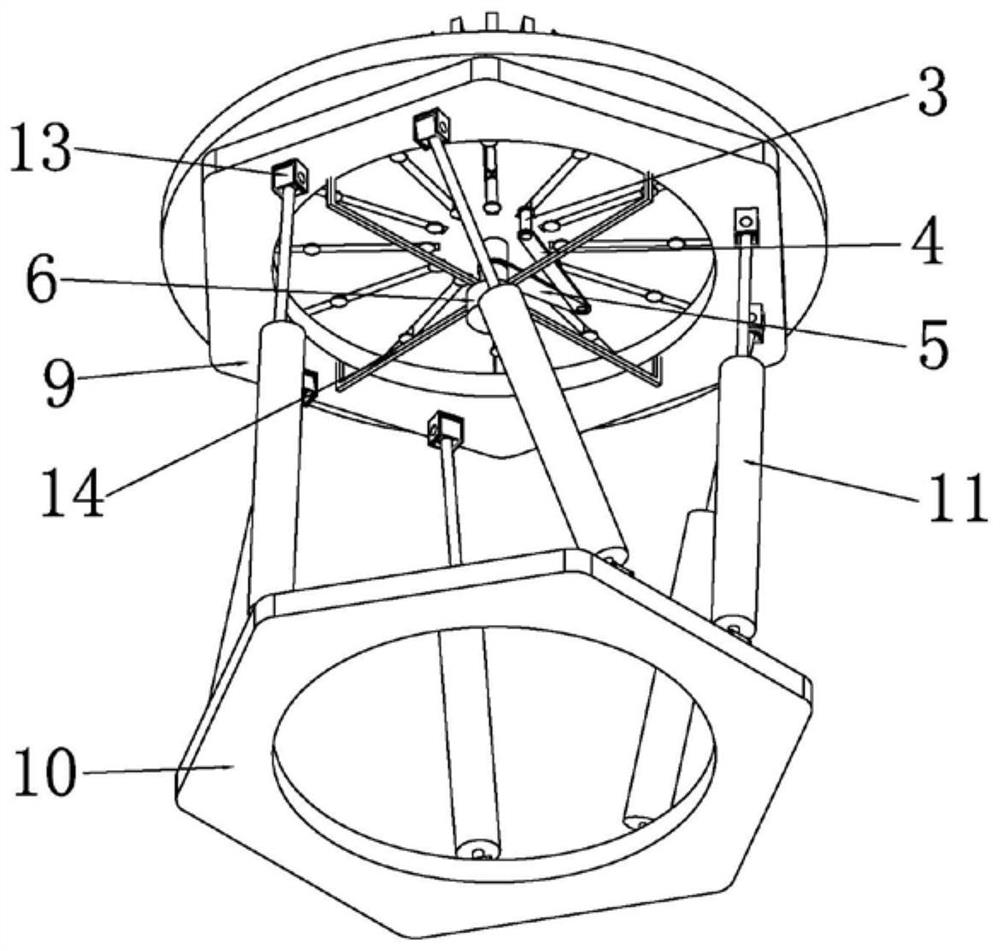

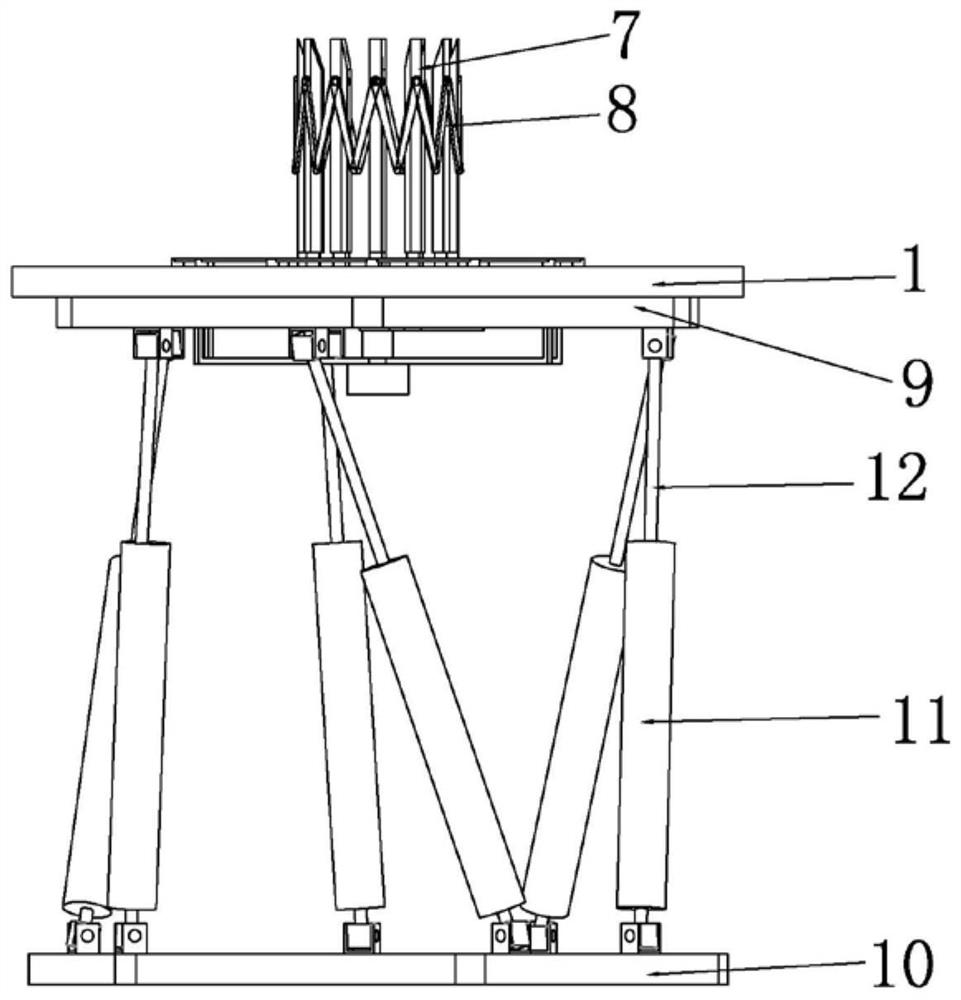

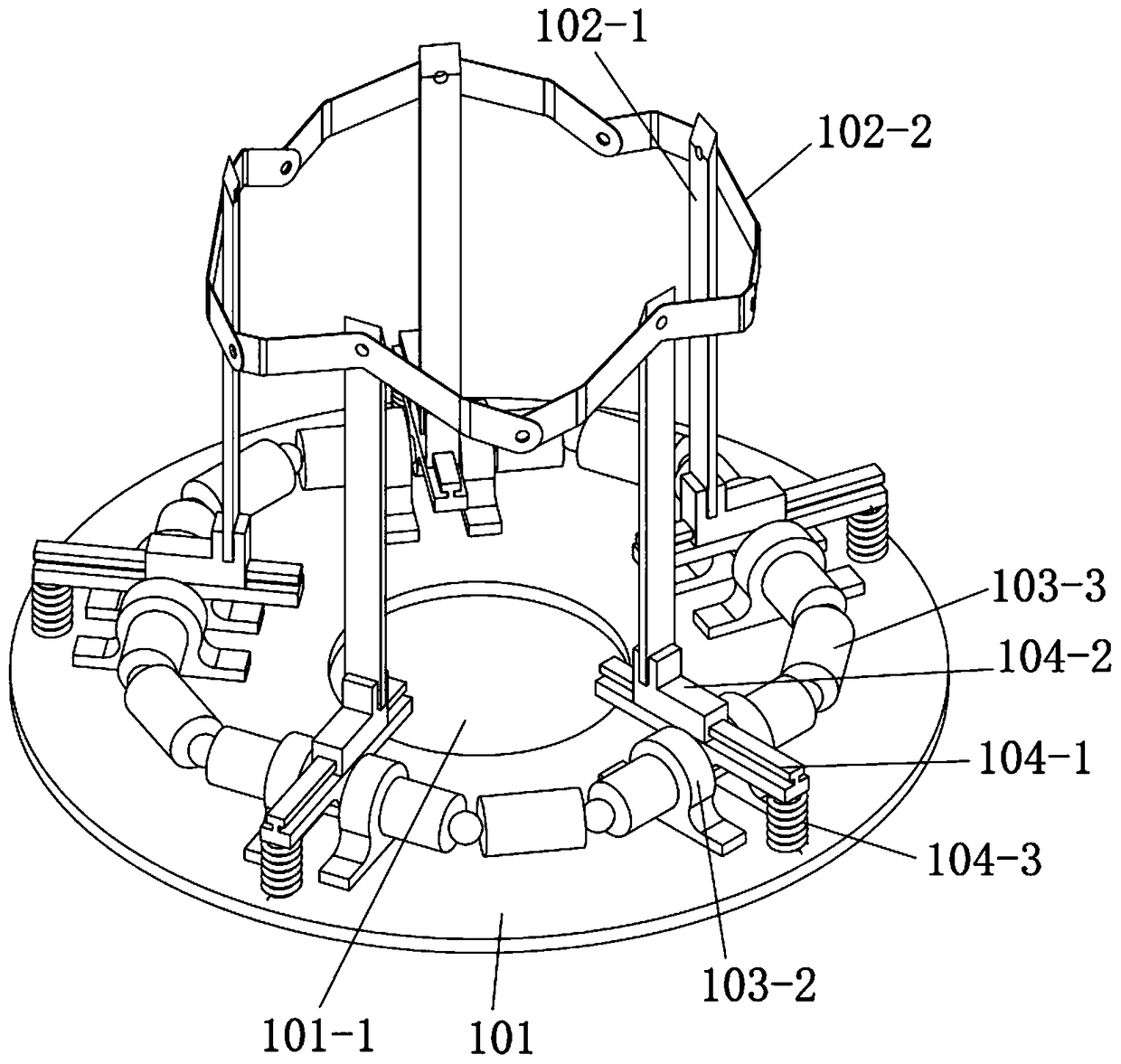

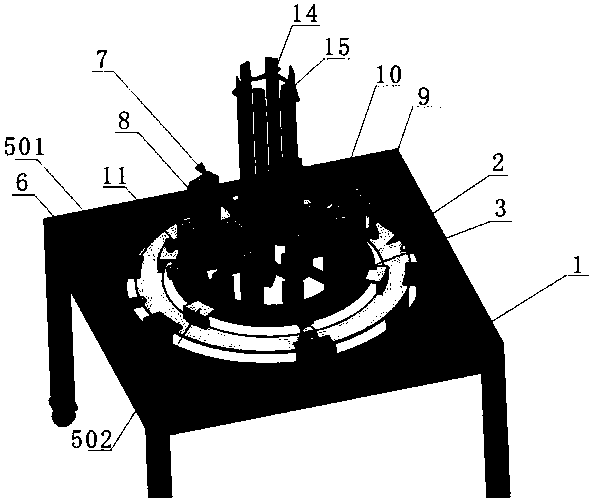

Banana combing platform based on rigid-flexible coupling parallel mechanism

ActiveCN112244333AImproved Adaptive Envelope performanceAvoid Missing Banana Comb HandlesFood treatmentPhysicsEngineering

The invention discloses a banana combing platform based on a rigid-flexible coupling parallel mechanism. The banana combing platform comprises a combing cutter disc, parallel four-bar linkages, a guide rod, connecting rods, a crank, a power source, an annular enveloping cutter, a top plate, a bottom plate and the rigid-flexible coupling parallel mechanism. A plurality of guide grooves are formed in the combing cutter disc in the circumferential direction of the combing cutter disc. Each guide groove is correspondingly provided with one parallel four-bar linkage. The multiple parallel four-barlinkages form an annular diameter-variable extensible mechanism. The annular enveloping cutter is arranged on the extensible mechanism. The top plate is arranged on the bottom face of the combing cutter disc. The bottom plate is arranged under the top plate and connected with the top plate through the rigid-flexible coupling parallel mechanism. The annular enveloping cutter can rotate or move in space according to bending change of banana fruit spike shafts through the rigid-flexible coupling parallel mechanism, and the annular enveloping cutter can adapt to bending of the banana fruit spike shafts in a self-adaptation manner. The banana combing platform can effectively solve the problems that an existing mechanical combing device is poor in self-adaptation enveloping effect on the bananafruit spike shafts, and the profiling attachment degree is not high.

Owner:SOUTH CHINA AGRI UNIV

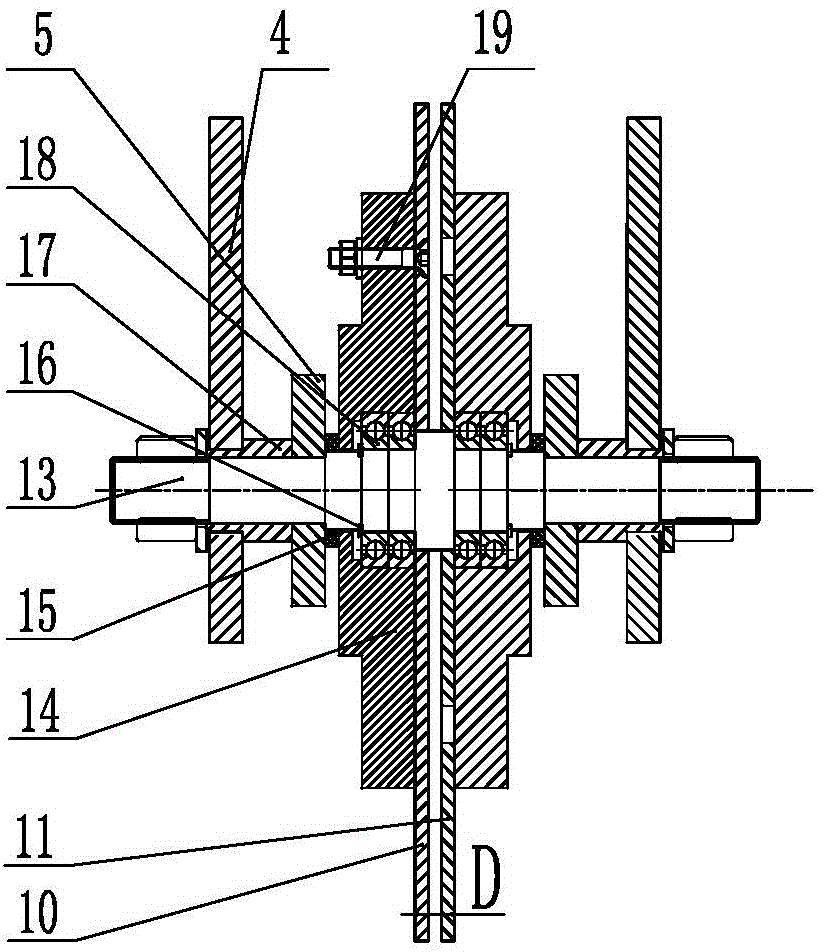

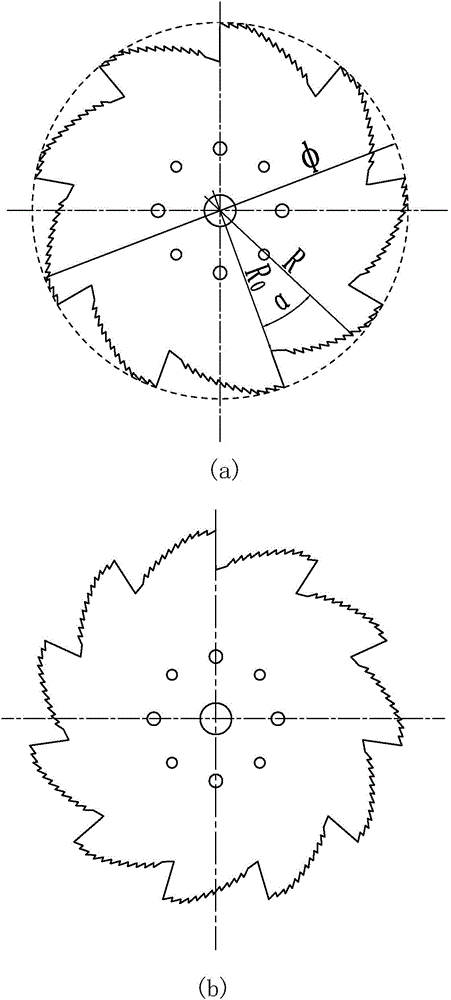

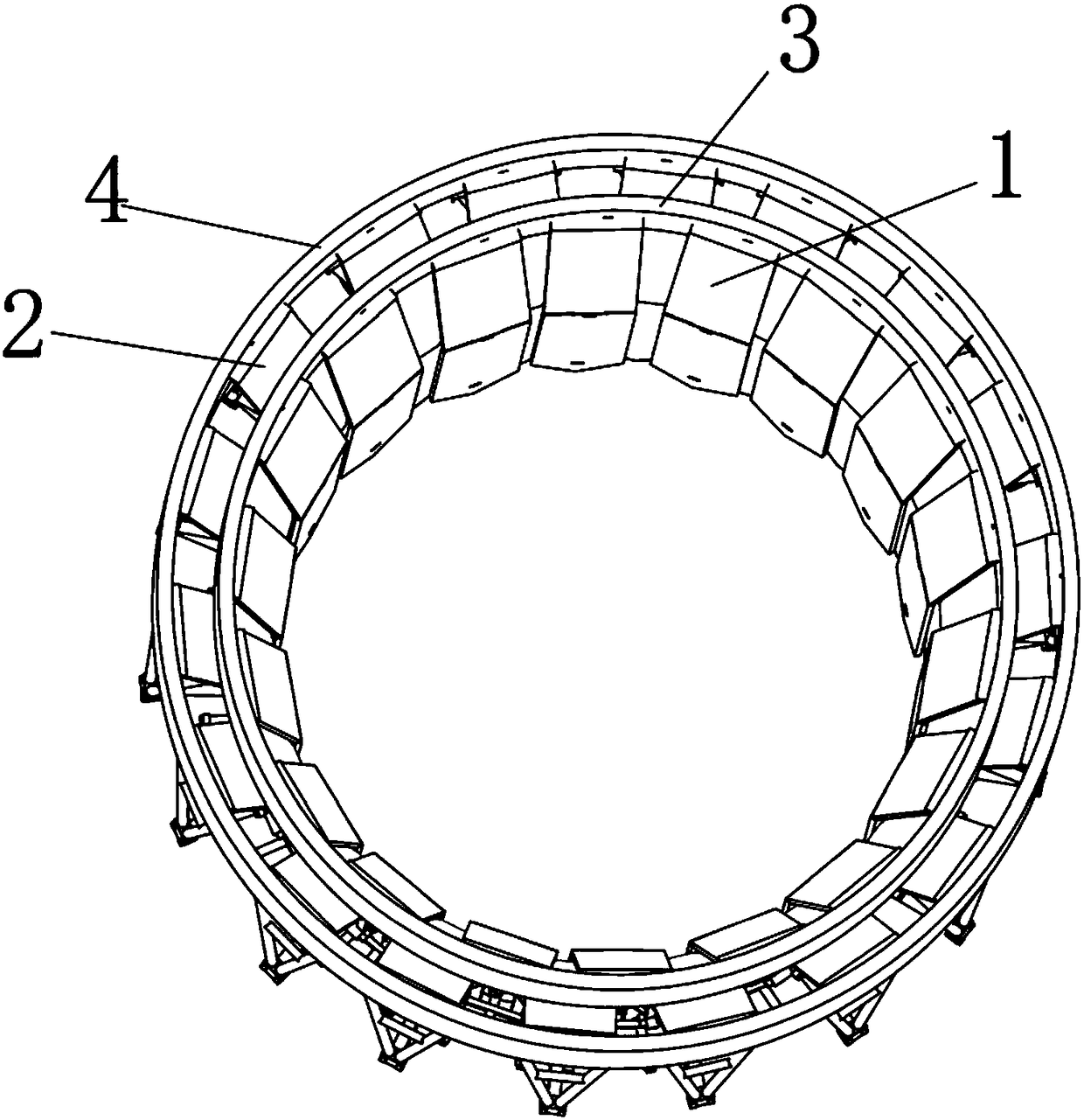

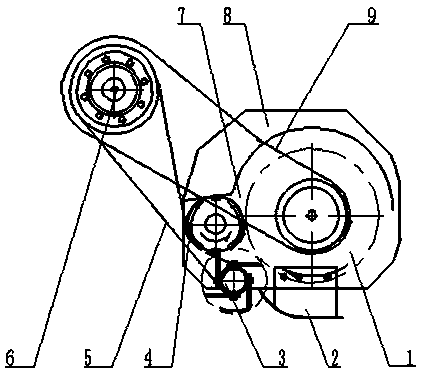

Variable-diameter self-adaptive rotary cutting type banana bunch cutter

ActiveCN108576877AAutomatic adjustment of diameter sizeRealize comb-by-comb deshaft combingFood treatmentSelf adaptiveDouble edge

The invention discloses a variable-diameter self-adaptive rotary cutting type banana bunch cutter. The variable-diameter self-adaptive rotary cutting type banana bunch cutter comprises double-edged internal cutting blades, double-edged external cutting blades, an internal annular blade carrier, an external annular blade carrier, connecting parts, two-section connecting link mechanisms and A-shapeddrag link mechanisms, wherein the internal annular blade carrier and the external annular blade carrier have the same center of circle; a plurality of double-edged internal cutting blades are mountedon the internal annular blade carrier and form an internal annular envelope structure; a plurality of double-edged external cutting blades are mounted on the external annular blade carrier and form an external annular envelope structure; the double-edged internal cutting blades and the double-edged external cutting blades are in staggered arrangement; every two double-edged external cutting blades are connected by the connecting parts; the double-edged internal cutting blades are connected with the corresponding connecting parts by pins; the two-section connecting link mechanisms are movablyhinged with the outer sides of the double-edged external cutting blades; two ends of the bottom parts of the A-shaped drag link mechanisms are hinged with the external annular blade carrier; and the top ends of the A-shaped drag link mechanisms are hinged with the hinge parts of two sections of connecting links of the two-section connecting link mechanisms. The variable-diameter self-adaptive rotary cutting type banana bunch cutter has the advantages of compact structure, light mass, convenient moving, safety in operation, labor saving and the like.

Owner:SOUTH CHINA AGRI UNIV

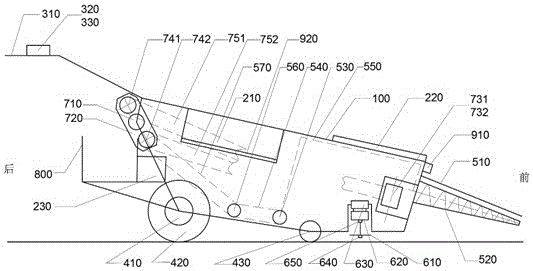

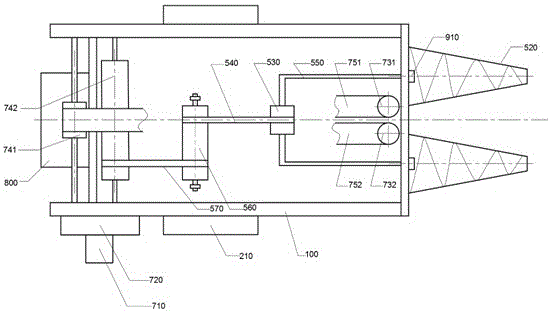

Automatic Chinese chive harvester

InactiveCN106134629ALightweight operation structureHigh degree of automationMowersRenewable energy machinesVideo monitoringChinese Chive

The invention discloses an automatic Chinese chive harvester. The automatic Chinese chive harvester comprises a Chinese chive harvester body, a cockpit, a flat car, a power supply system, a walking mechanism, a drawing-in mechanism, a harvesting mechanism, a conveying mechanism, a collecting mechanism and a lighting system. The Chinese chive harvester body is a self-propelled rack. The cockpit is arranged on the rear of the Chinese chive harvester body in a connected mode and comprises a cab and a control system. The control system comprises a rudder, an operating switch, a control unit and a video monitoring unit. The flat car is arranged on the rear of the cockpit and connected with the Chinese chive harvester body through a movable buffer rod. An upper roll shaft at the rear end and a lower roll shaft at the rear end are driven by a conveying motor installed at the right rear end of the self-propelled rack and a speed reducer attached to the conveying motor respectively, and therefore conveying belts are driven to achieve Chinese chive conveyance. The automatic Chinese chive harvester is easy to operate and learn, light in structure, high in automation degree, capable of achieving stepless speed adjustment, single-person operation and self-propelling and good in working reliability.

Owner:盐城市新明悦机械制造有限公司

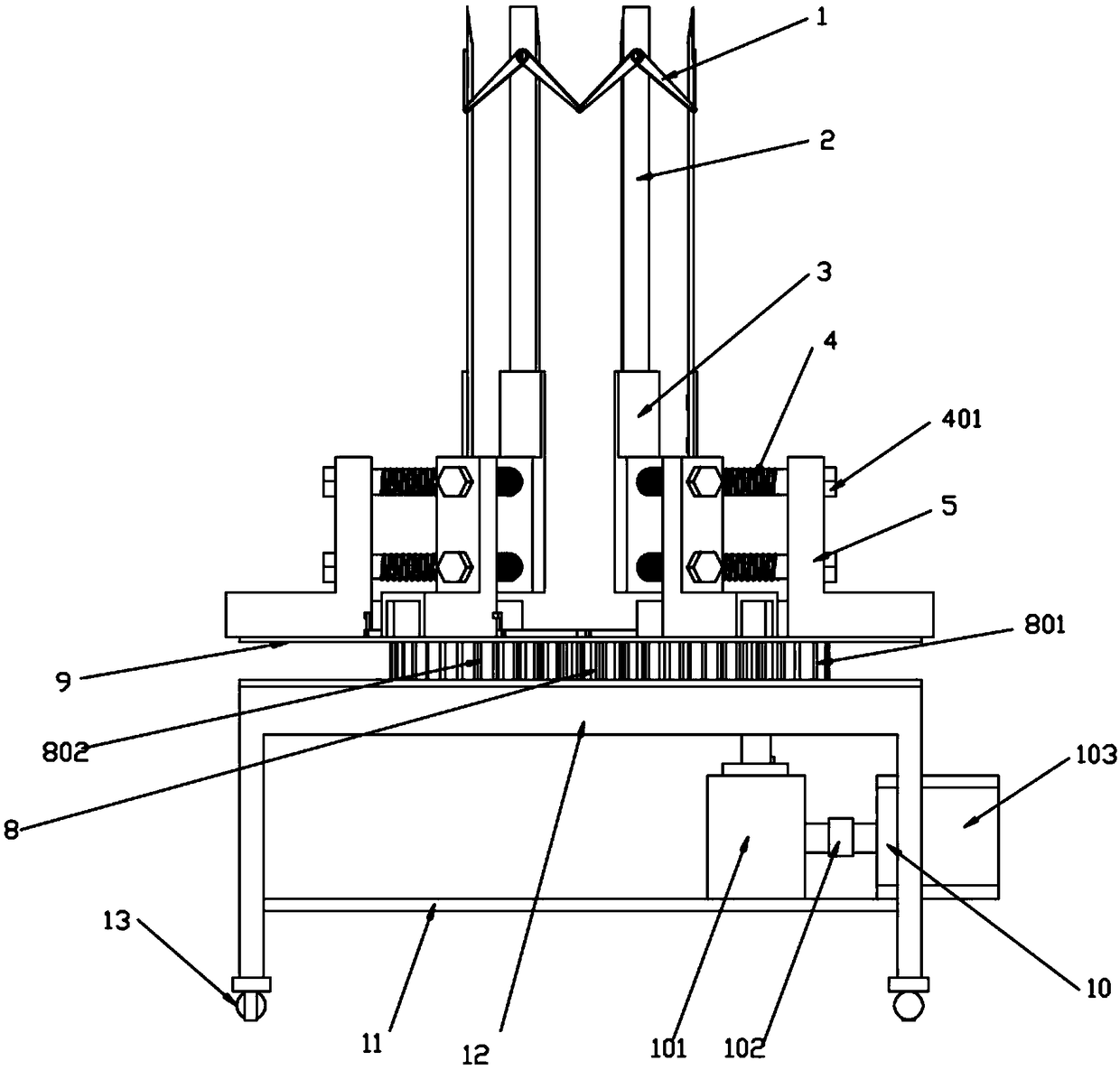

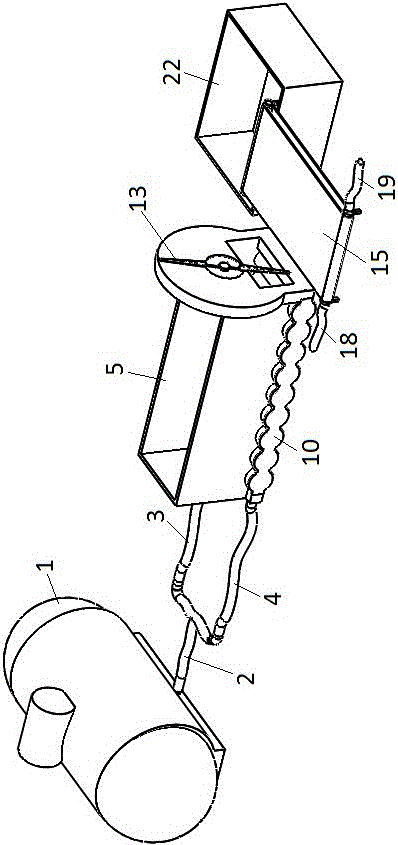

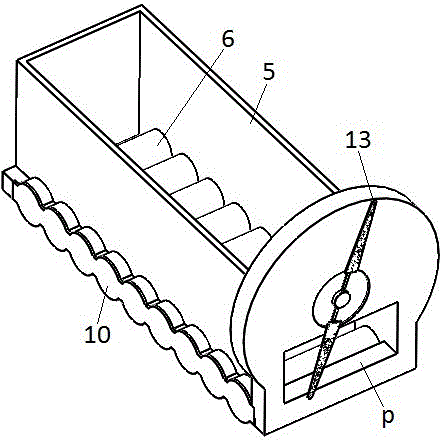

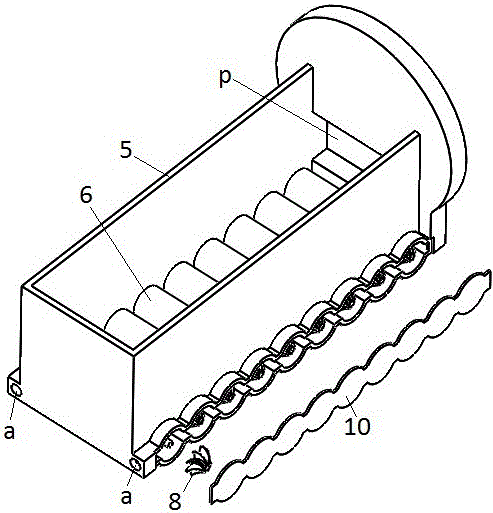

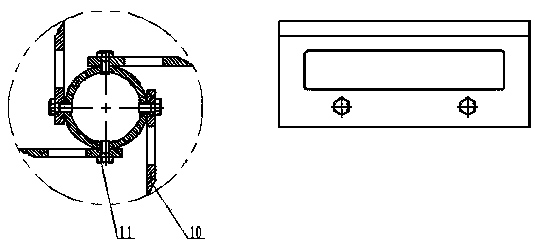

Constant force mechanism based banana harvesting device capable of automatically adapting to banana tree stem

ActiveCN109527622ASmooth and reliable rotationReduce rigid impactFood treatmentConstant forceEngineering

The invention discloses a constant force mechanism based banana harvesting device capable of automatically adapting to the banana tree stem. The device comprises a frame, an outer cutter head, an inner cutter head, a first fixed shaft, a second fixed shaft, a first elevating stop block, a second elevating stop block, a torsional spring, a fixed rack, a hard blade installation rack, a movable guiderod, a horizontal compression spring, a public column, an inclined compression spring, a hard blade, and a soft blade. The annular inner cutter head and the outer cutter head can rotate around the axes of the inner cutter head and the outer cutter head and sequentially arranged on the through hole of the frame. Multiple annular arrays of the fixed rack are arranged on the inner cutter head. The fixed rack and the hard blade installation rack are connected by the movable guide rod. The horizontal compression spring sleeves the movable guide rod. The public column is connected to the hard bladeinstallation rack through the inclined compression spring. The hard blade is mounted on the hard blade installation rack. The soft blade is rivetingly arranged on the external side of the hard bladeso as to form an annular enveloping structure that envelopes a banana spike. The provided device has the advantages that the device can automatically adapt to the banana tree stems and in a certain constant force displacement range, the clamping force is constant.

Owner:SOUTH CHINA AGRI UNIV

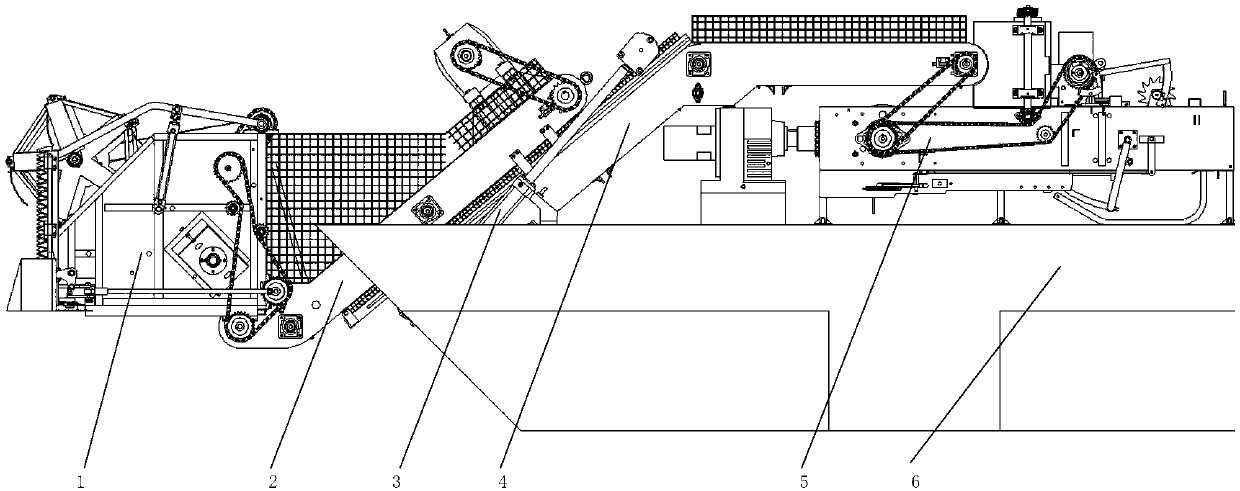

A small-size fragrant-flowered garlic harvester

InactiveCN106068911ALightweight operation structureHigh degree of automationHarvestersRenewable energy machinesDrive wheelMotor drive

The invention provides a small-size fragrant-flowered garlic harvester comprising a fragrant-flowered garlic harvester body, a power supply system, a control system, a walking mechanism, a closing mechanism, a harvesting mechanism, a conveying mechanism, a collection mechanism and a lighting system. The body employs accumulators for power supply and employs a solar power generation device and a small-size generator unit as auxiliary power sources; with a hub motor driving a rear drive wheel, self-walking and stepless speed regulation can be realized; via the different-direction rotation of spiral closing devices, fragrant-flowered garlic can be centralized and guided; a conveying motor installed on the right rear end of the self-walking frame and a speed reducer attached thereto drive a rear end upper roll shaft and a rear end lower roll shaft, so that conveying belts are driven to convey fragrant-flowered garlic. The operation of the small-size fragrant-flowered garlic harvester is simple and easy to learn; the small-size fragrant-flowered garlic harvester is light in structure and high in degree of automation, realizes stepless speed regulation, single-man operation and self-walking, and is great in work reliability.

Owner:盐城市新明悦机械制造有限公司

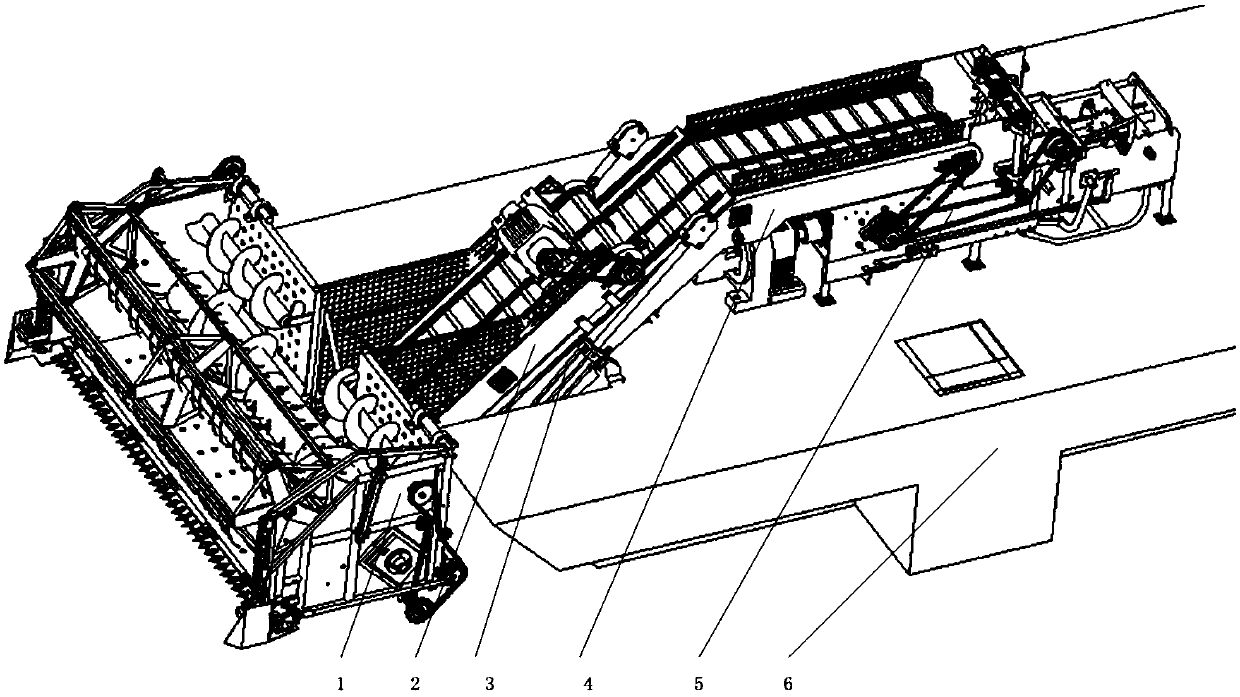

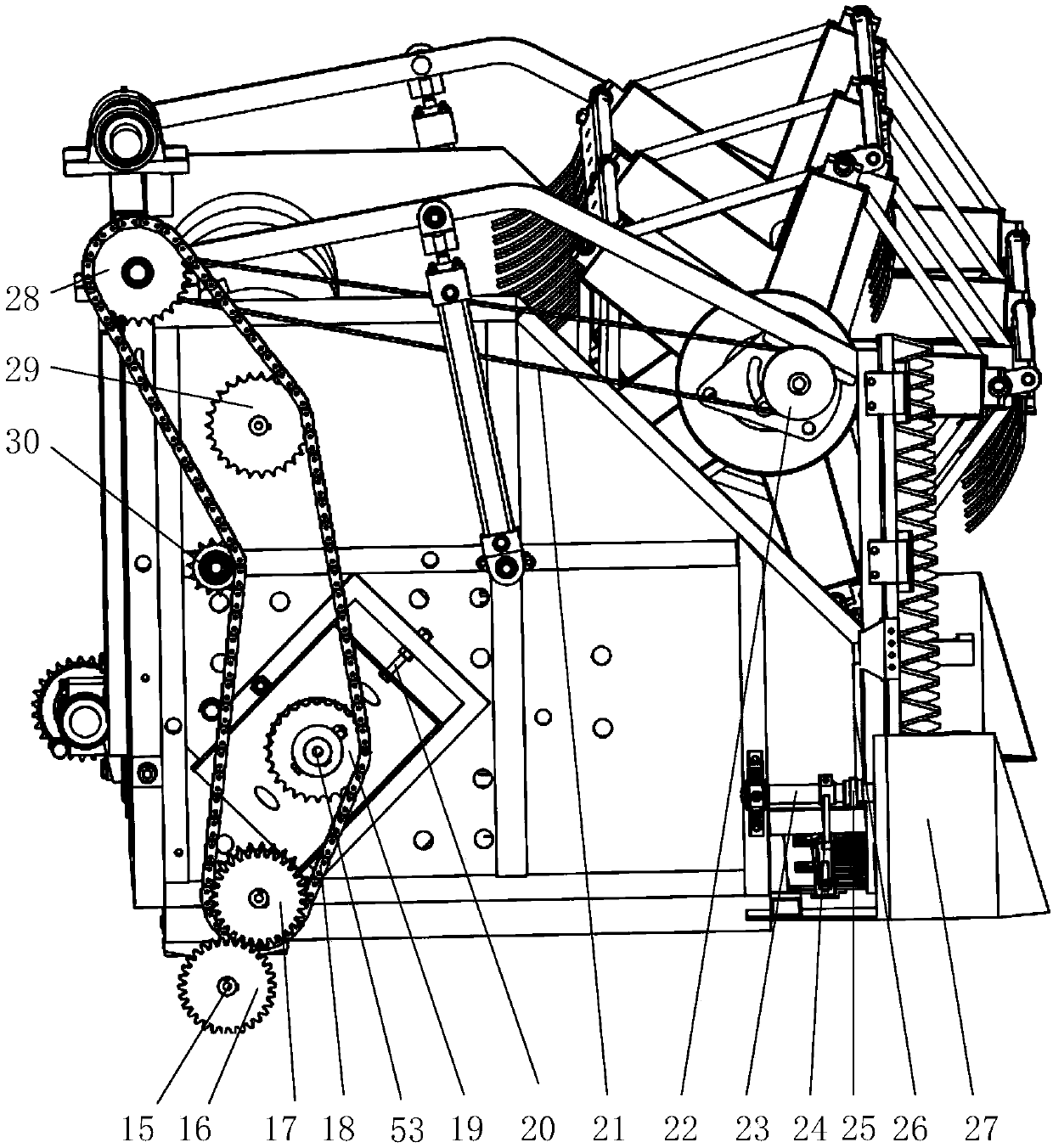

Aquatic weed cutting, conveying and bundling system and ship

The invention provides an aquatic weed cutting, conveying and bundling system and a ship. The system comprises a cutting table assembly, a primary conveying assembly, a cutting depth adjustment system, a secondary conveying assembly and a compressing and bundling system; the front portion of the primary conveying assembly is connected with the cutting table assembly, and the rear portion of the primary conveying assembly is in sliding connection with the front portion of the secondary conveying assembly through the cutting depth adjustment system; the compressing and bundling system is installed at the tail end of the rear portion of the secondary conveying assembly. The system can serve as a working part carried on the amphibious ship to effectively control water grass pollution in rivers, lakes and main canals. When the ship drives on land, the primary conveying assembly and a front-end cutting platform are stored through a hydraulic oil cylinder, and the occupied space of a hull isreduced; when the ship works in water, the primary conveying assembly and a cutting platform are put down through the hydraulic oil cylinder to adjust the cutting depth, and the aquatic weed cutting,conveying and bundling functions are achieved. The cutting table assembly of the aquatic weed cutting, conveying and bundling system can push aquatic weeds on the upper portion and the lower portion of the two sides to a cutting table notch for conveying the conveying parts behind, and thus efficient harvesting of the aquatic weeds can be achieved.

Owner:泰州市力鼎机械设备有限公司

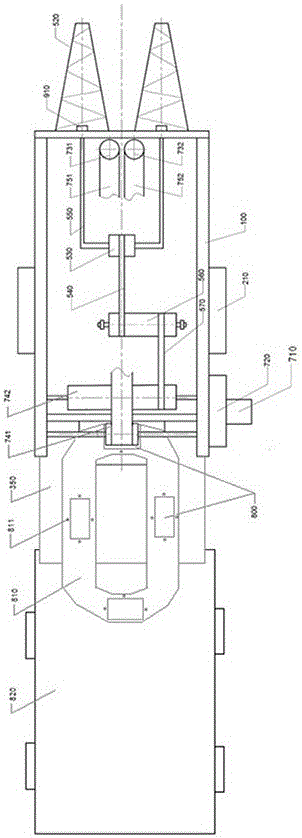

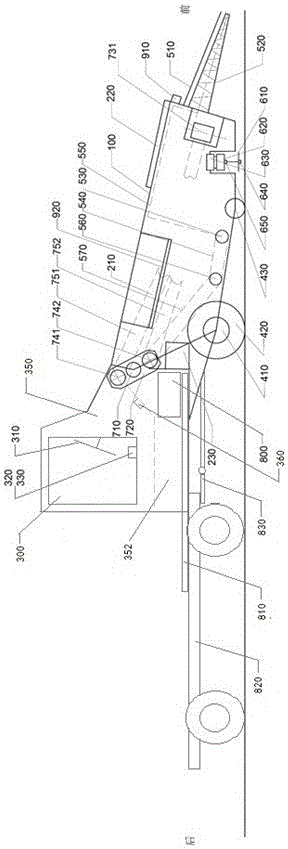

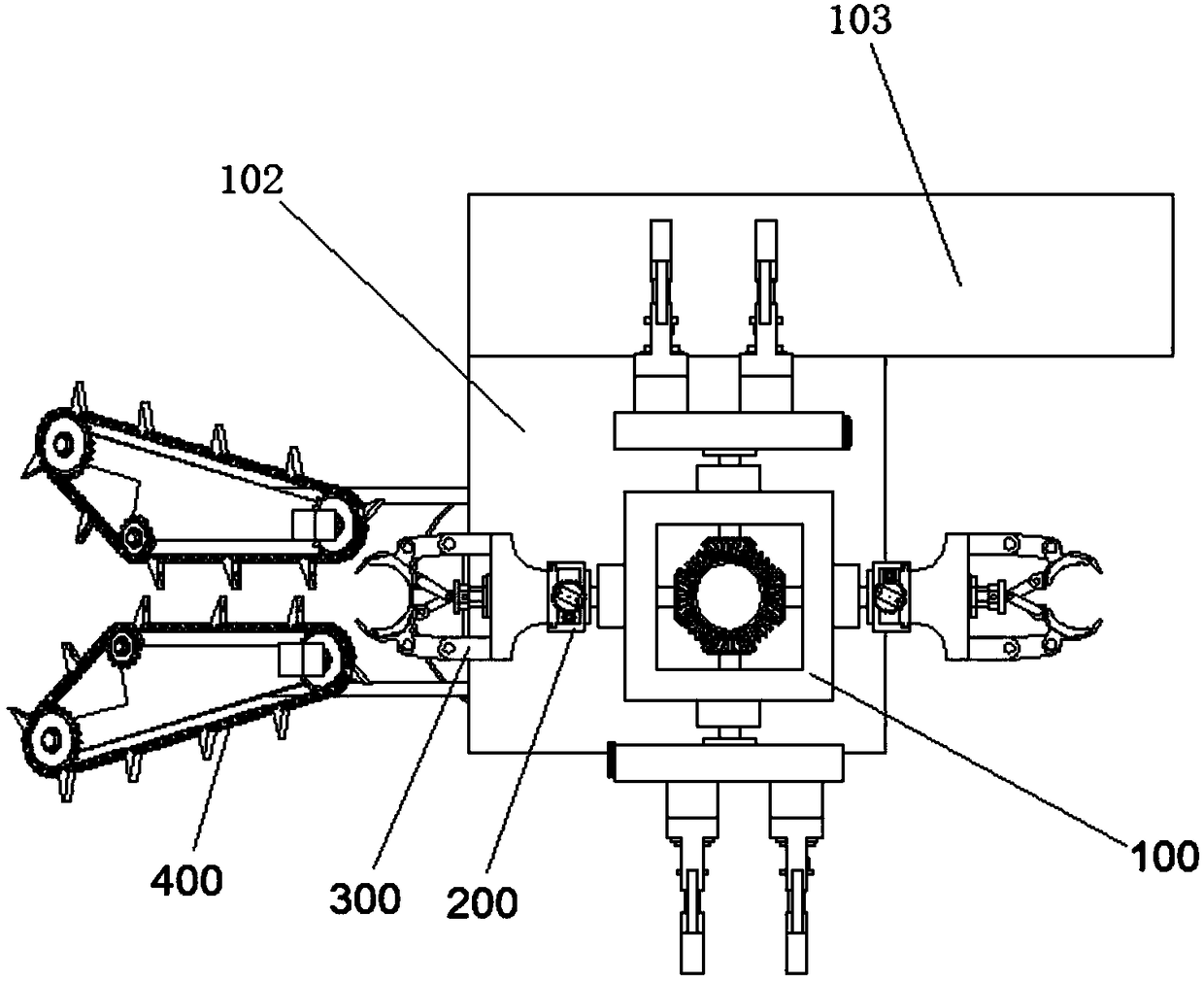

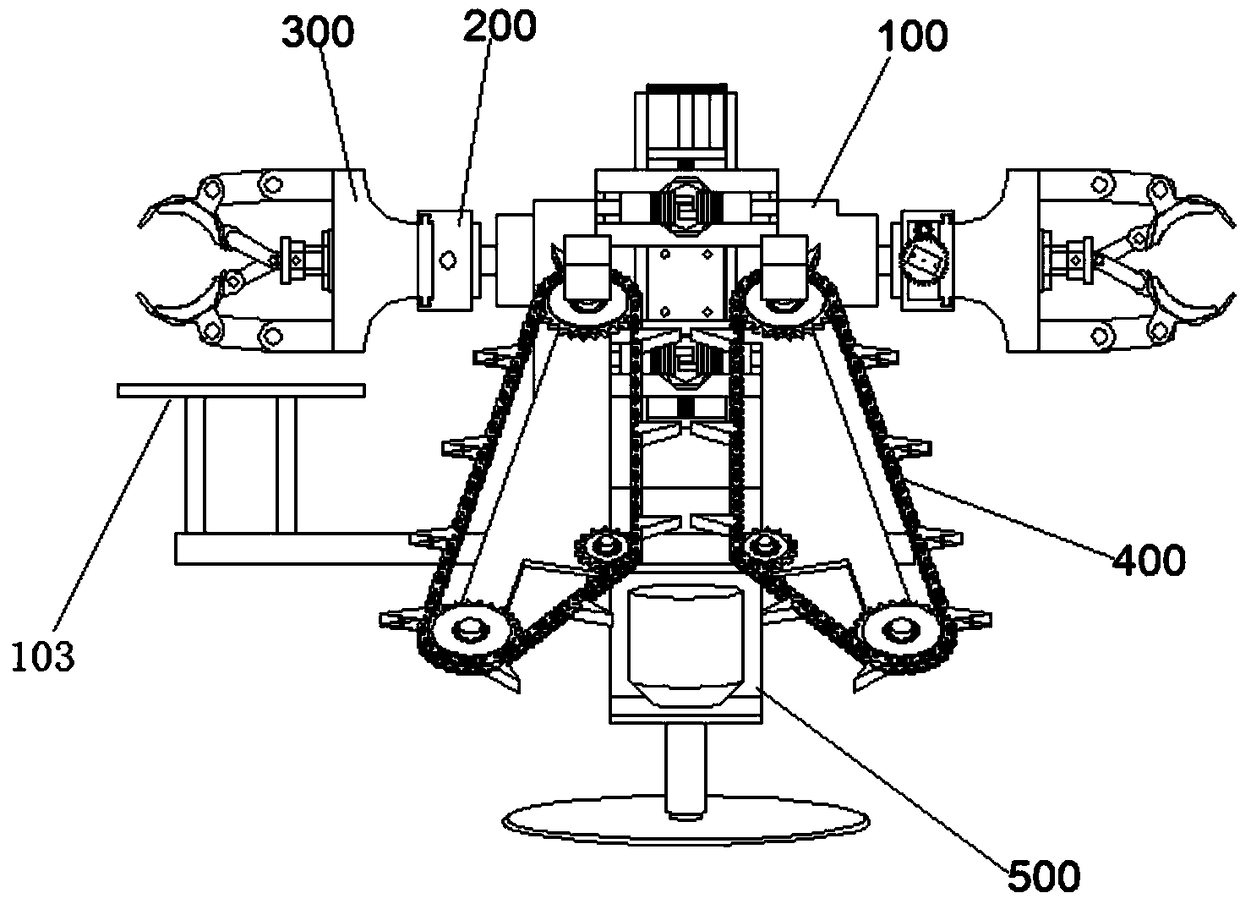

Intelligent fetching harvesting device for sugarcane harvester and using method of intelligent fetching harvesting device

ActiveCN109429701AAccurate clamping positionImprove efficiencyHarvestersAgricultural lifting devicesEngineeringSecondary growth

The invention discloses an intelligent fetching harvesting device for a sugarcane harvester and a using method of the intelligent fetching harvesting device. The intelligent fetching harvesting devicecomprises a hollow rotary mechanism, arm lifting mechanisms, fetching arms, sugarcane supporting devices and a cutting device, wherein the sugarcane supporting devices convey sugarcane into the cutting area, the sugarcane is cut and separated, then the sugarcane is lifted by the arm lifting mechanisms, the hollow rotary mechanism rotates to make the sugarcane conveyed into a collection area, andfinally, the sugarcane is put down by the fetching arms. Compared with the prior art, in the intelligent fetching harvesting device for the sugarcane harvester and the using method of the intelligentfetching harvesting device, the fetching arms synchronously work, and the work efficiency is high. During cutting, the sugarcane is in a fixed state, the cuts of the sugarcane are regular, secondary growth of the sugarcane is not affected, the work efficiency is improved, and the labor force is liberated.

Owner:YANCHENG INST OF TECH

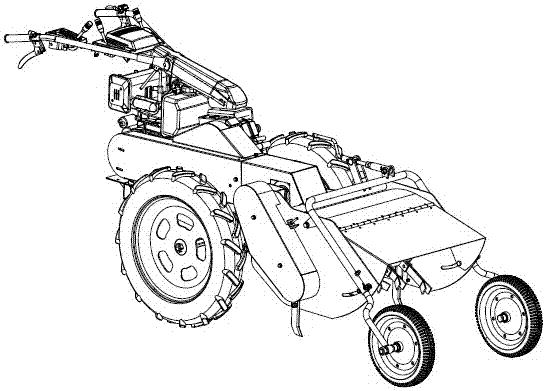

Leakproof multi-purpose walking sweet potato vine crusher

PendingCN106900285AToss to ensureAvoid missed cutsCrop conditionersMowersHelical lineAgricultural engineering

The invention relates to a leakproof multi-purpose walking sweet potato vine crusher, and belongs to the technical field of agricultural harvesters. A gearbox of the crusher is fixedly connected with an installation plate and an engine installation frame; the installation plate and the engine installation frame extend out forwards and backwards separately; the gearbox extends out of an operating rod towards the upper back part; the installation plate is connected with a vine cutting mechanism through a suspension frame; the vine cutting mechanism comprises knife rolls of cutting knives which are axially arranged at intervals and extend along the radial direction; a housing is arranged on each knife roll; tool aprons which are distributed along a helical line and extend out along the radial direction are axially distributed on a knife shaft of each knife roll at intervals; the tool aprons are hinged with the inner ends of the corresponding cutting knives; when the knife shafts rotate, tip rotating envelope surfaces of the cutting knives are matched with a ridge; a channel formed by intervals between the housings and the tip rotating envelope surfaces is in a necking form which is convergent from the front part to the middle part and is divergent from the middle part to the back part; and an inverted V splitter plate is arranged at the rear part of each housing. According to the leakproof multi-purpose walking sweet potato vine crusher, sweet potato vine leakage cutting can be effectively avoided, the cutting effect is improved and the condition that cut vines are thrown to furrows is ensured.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

Konjak dicing and sorting assembly line equipment

PendingCN106722522AAvoid missed cutsConvenient placement and orientationConveyorsMetal working apparatusImpellerEngineering

The invention provides konjak dicing and sorting assembly line equipment. The konjak dicing and sorting assembly line equipment is mainly divided into a power part, a konjak conveying part, a dicing part, a konjak slice conveying part, and a cooking part, wherein the entire power part adopts pneumatic driving; the konjak conveying part is used for conveying konjak blocks in the manner that impellers rotate to drive rollers to rotate; and air holes are formed in a cutting knife of the dicing part, the dicing part can separate the konjack slices while being used for dicing, the konjak slices fall into the konjak slice conveying part, and then the konjak slices are directly conveyed to a dehydrating and cooking groove through a conveyer belt for cooking. The konjak dicing and sorting assembly line equipment can be convenient to use in konjak food processing industry, overcomes the special characteristics of konjak being difficult to process, and greatly reduces the labor cost. The konjak dicing and sorting assembly line equipment is safe, practical and reliable.

Owner:NINGDE VOCATIONAL & TECHN COLLEGE

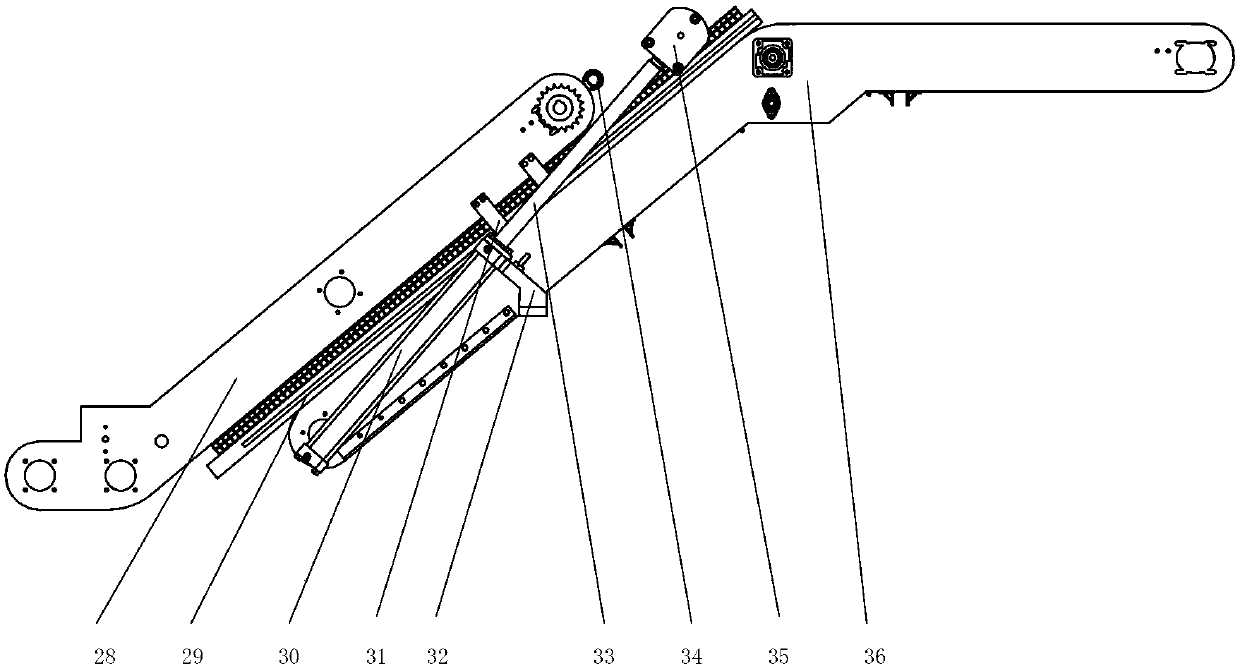

Aquatic weed harvesting table and harvester

PendingCN109566076AEfficient HarvestingAvoid the situation of missed cutting in deep waterHeadersEngineeringAquatic weeds

The invention provides an aquatic weed harvesting table and a harvester. The aquatic weed harvesting table comprises a cutting table frame, a cutter, a first auger, a second auger, a third auger, a transmission mechanism and a reel; a rear plate of the cutting table frame is provided with a notch; the cutter is installed at the front end of the cutting table frame; the two ends of the reel are mounted on two side plates of the cutting table frame and located behind the cutter; the two ends of the first auger are mounted on the two side plates of the cutting table frame and located behind the reel; the second auger and the third auger are installed on the two sides of the notch of the cutting table frame respectively; the transmission mechanism is connected with the cutter, the reel, the first auger, the second auger and the third auger separately. The first auger and the small augers of the aquatic weed harvesting table gather aquatic weeds on the two sides of the upper portion and thelower portions to the notch behind the cutting table separately, the phenomenon of deep water miss cutting is avoided, and efficient harvesting of the aquatic weeds can be achieved.

Owner:泰州市力鼎机械设备有限公司

Multi-cutter dividing and cutting machine for sawtooth decorative ribbon

ActiveCN108555997AAvoid compression deformationAvoid deformationMetal working apparatusWebs handlingHigh pressureConductor Coil

The invention provides a multi-cutter dividing and cutting machine for a sawtooth decorative ribbon. The machine comprises a machine frame, the machine frame comprises a supporting base and supports symmetrically arranged on the front side and the rear side of the top face of the supporting base, the support on the front side is provided with a driving mechanism, and an unwinding mechanism, a tooth edge dividing and cutting mechanism and a winding mechanism are sequentially arranged between the two supports from right to left. The unwinding mechanism comprises an unwinding gas expansion shaft.The tooth edge dividing and cutting mechanism comprises a tooth cutter roller, a nylon roller and a carrier roller which are sequentially arranged from top to bottom in the vertical direction. The winding mechanism comprises two winding gas expansion shafts which are horizontally arranged up and down. The driving mechanism comprises a first magnetic powder clutch and a winding motor. The multi-cutter dividing and cutting machine has the advantages that multi-cutter sawtooth dividing and cutting for raw materials is achieved through high pressure of the tooth cutter roller and the nylon roller, the sawtooth decorative ribbon with the needed specification is obtained through one working procedure, waste is avoided, the problems that machining is tedious and complex and the efficiency is loware effectively solved, the two winding gas expansion shafts are adopted after dividing and cutting to achieve the staggered winding effect, and two adjacent sawtooth decorative ribbons are preventedfrom being intertwined during winding.

Owner:YANCHENG XUHUA MACHINERY

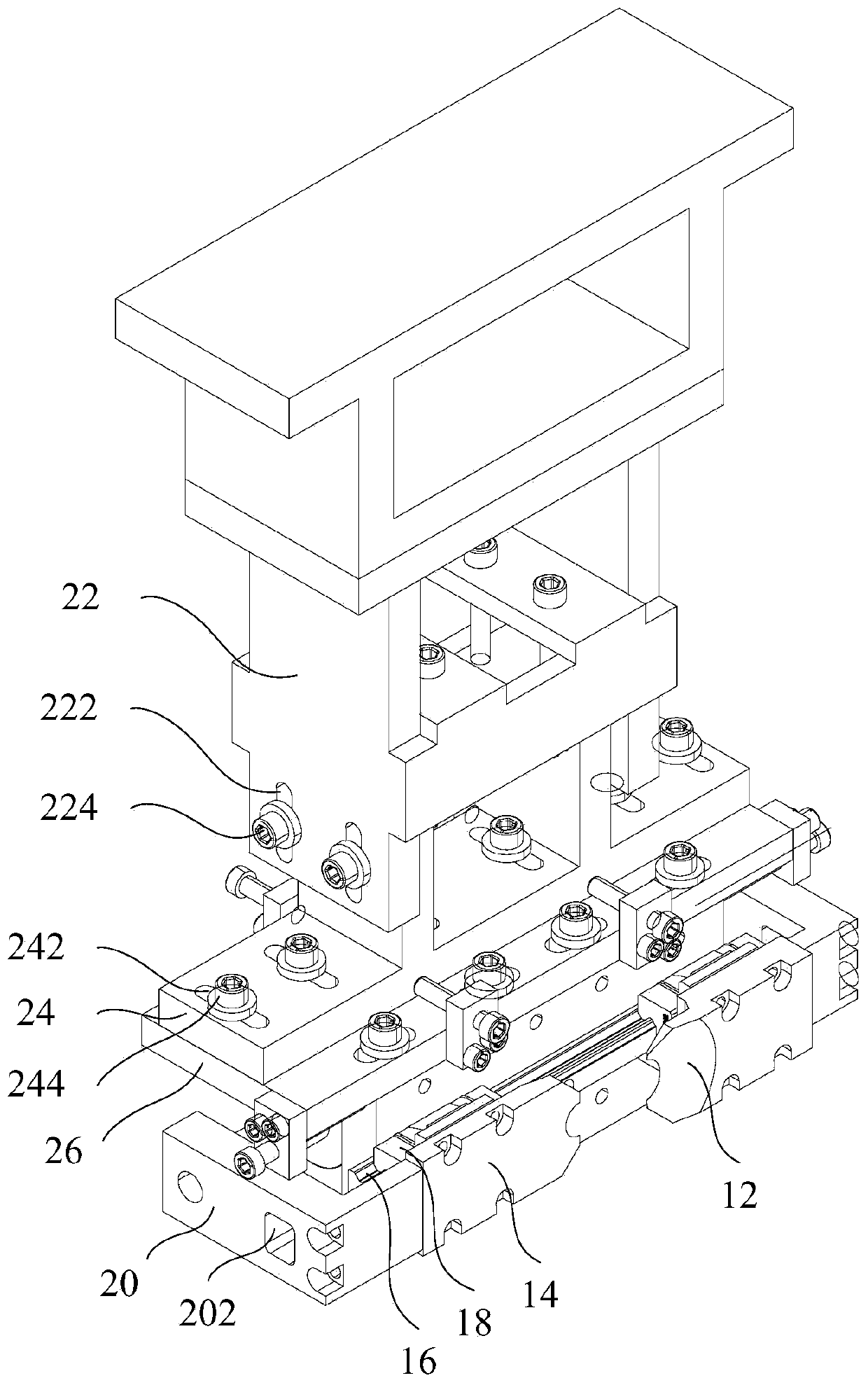

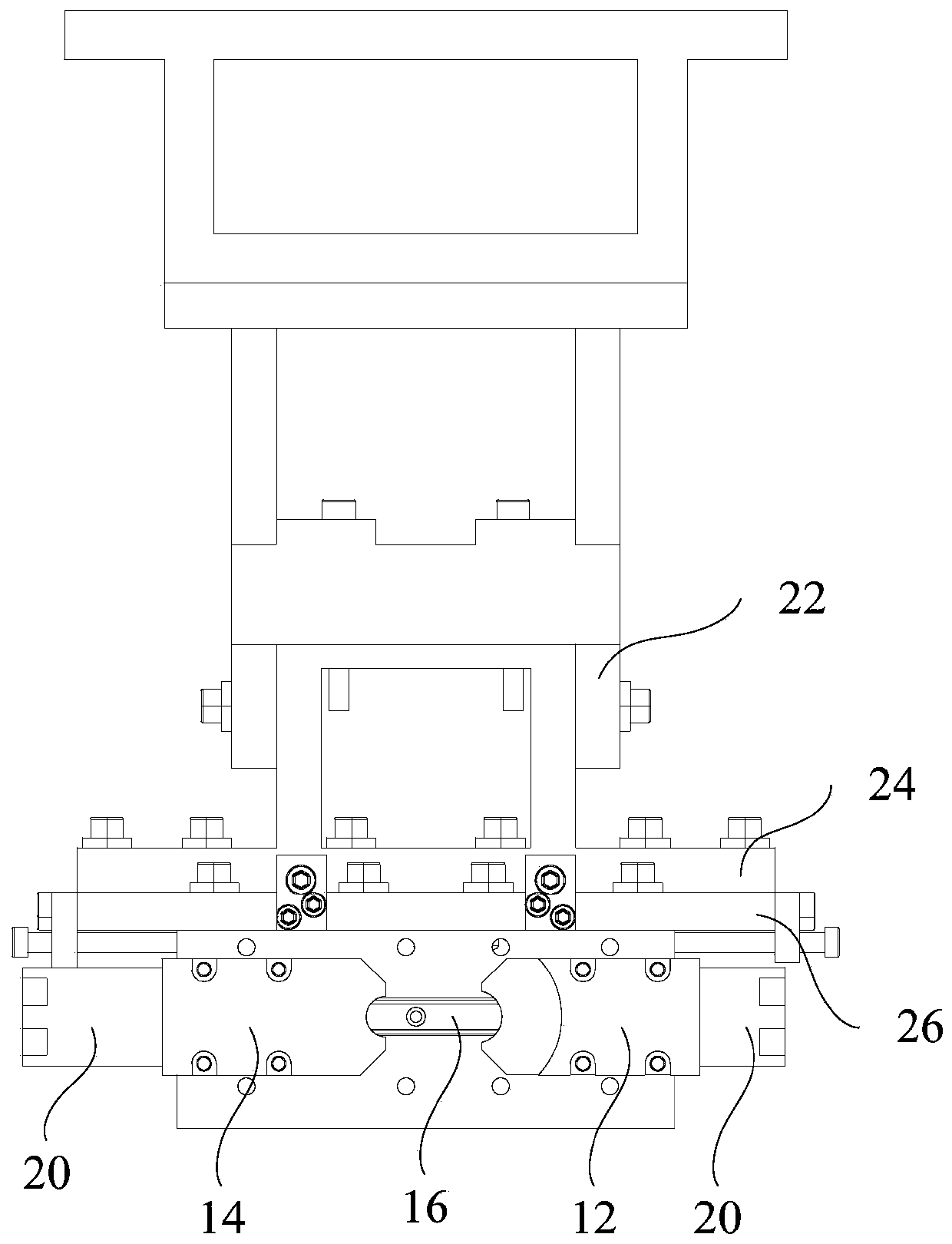

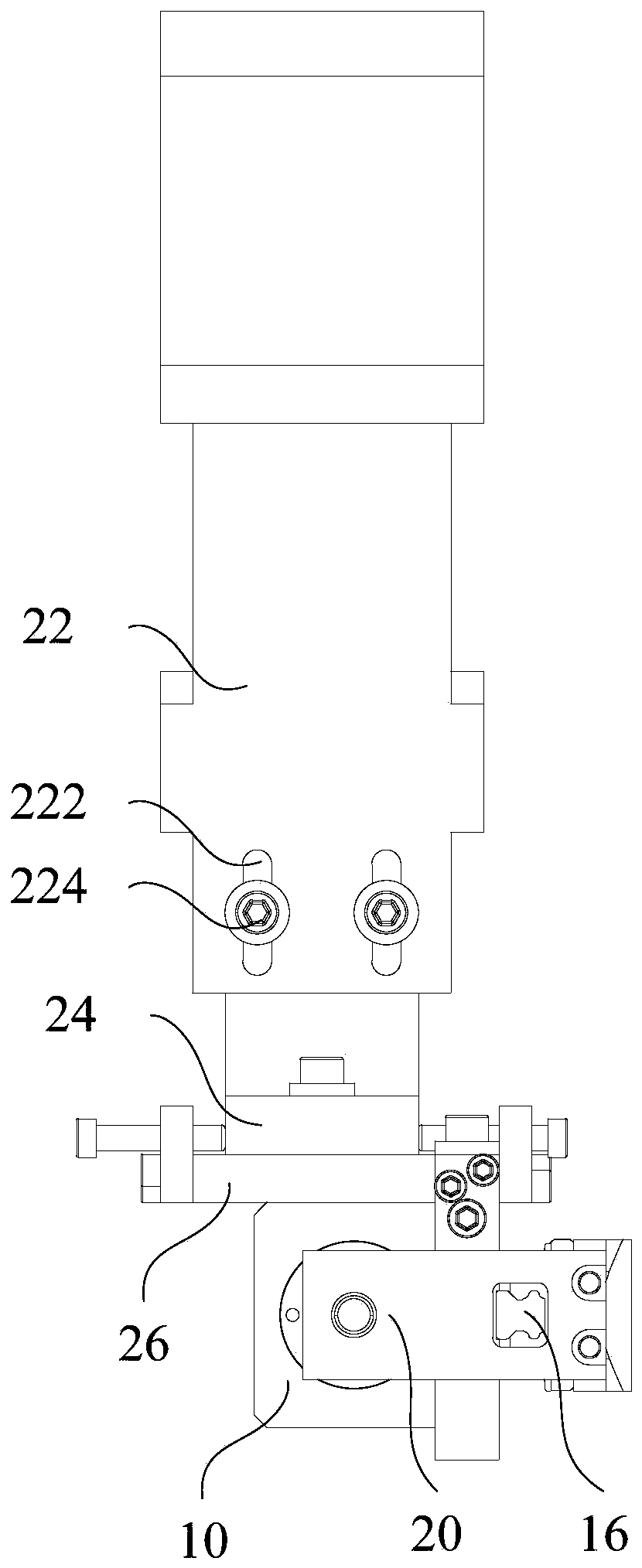

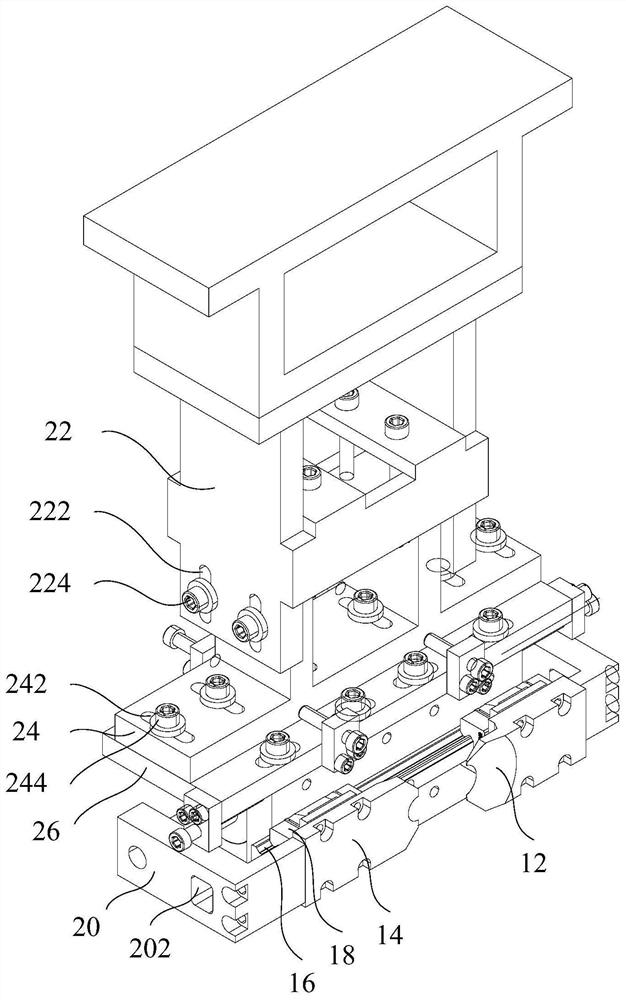

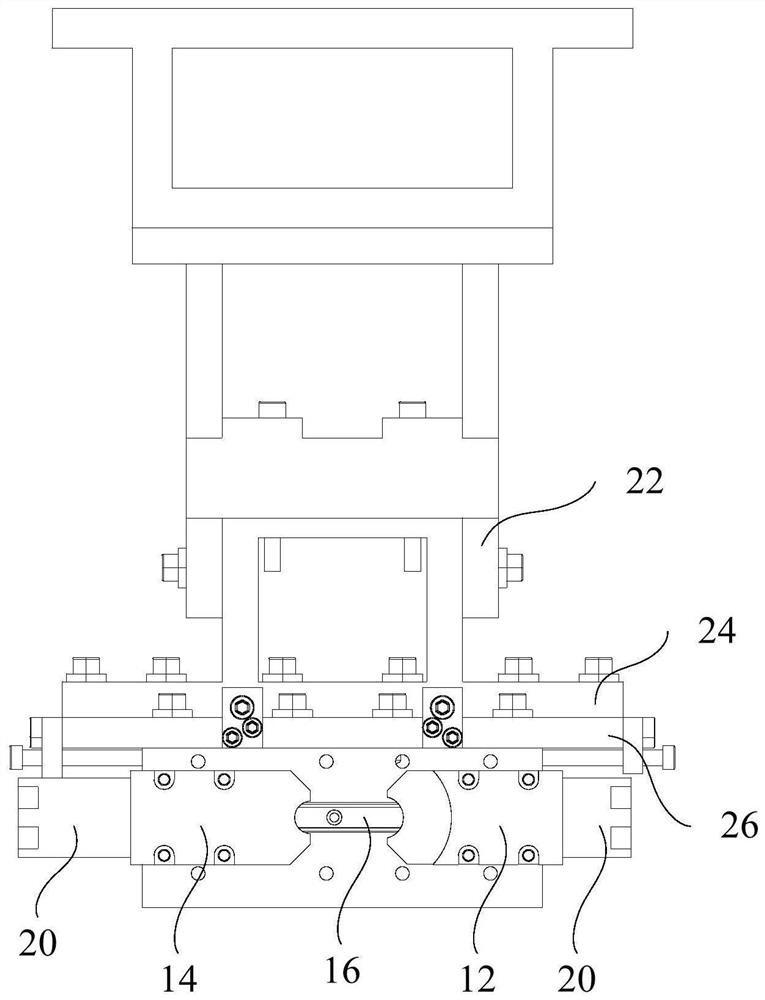

Cutting device, hole punching cutting device and control method of hole punching cutting device

ActiveCN109760130AReduce processing timeEasy to processMetal working apparatusEngineeringMechanical engineering

The invention provides a cutting device, a hole punching cutting device and a control method of the hole punching cutting device. The cutting device comprises a driving assembly, a cutting part connected with the driving assembly which is used for driving the cutting part to move, and an auxiliary cutting part connected with the driving assembly which is further used for driving the auxiliary cutting part to move; and after the auxiliary cutting part moves to be in abutting connection with a to-be-cut article, the driving assembly drives the cutting part to cut the to-be-cut article. Accordingto the cutting device, the cutting part is driven by the driving assembly to move so as to cut the to-be-cut article, automatic cutting can be achieved, cutting is convenient and fast, the conditionsthat cutting is not flat and the cut face is not flat due to the fact that cutting is performed manually by adopting a cutter are avoided, and the cutting effect is good. Besides, after the auxiliarycutting part moves to be in abutting connection with the to-be-cut article, the cutting part can be used for cutting the to-be-cut article, and it can be effectively avoided that the to-be-cut article bears the thrust effect of the cutting part, displacement is caused, and deflection is caused.

Owner:GUANGZHOU MIDEA HUALING REFRIGERATOR

Working head of a multi-blade horizontal weeder and leak-proof weeding method

ActiveCN110178523BSimple structureIncrease the weeding areaMowersStructural engineeringMechanical engineering

The invention relates to a working head of a multi-blade horizontal weeder, which includes a frame, the frame includes a beam, and several weeding mechanisms are arranged on the beam, and the weeding mechanism is fixedly connected with the beam. One side and / or both sides of each weeding mechanism also includes a guiding weeding mechanism, the guiding weeding mechanism is fixedly connected with the beam, and through the cooperative work of multiple weeding mechanisms and guiding weeding mechanisms, a larger The working area can effectively prevent missed cuts and improve the efficiency of weeding.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

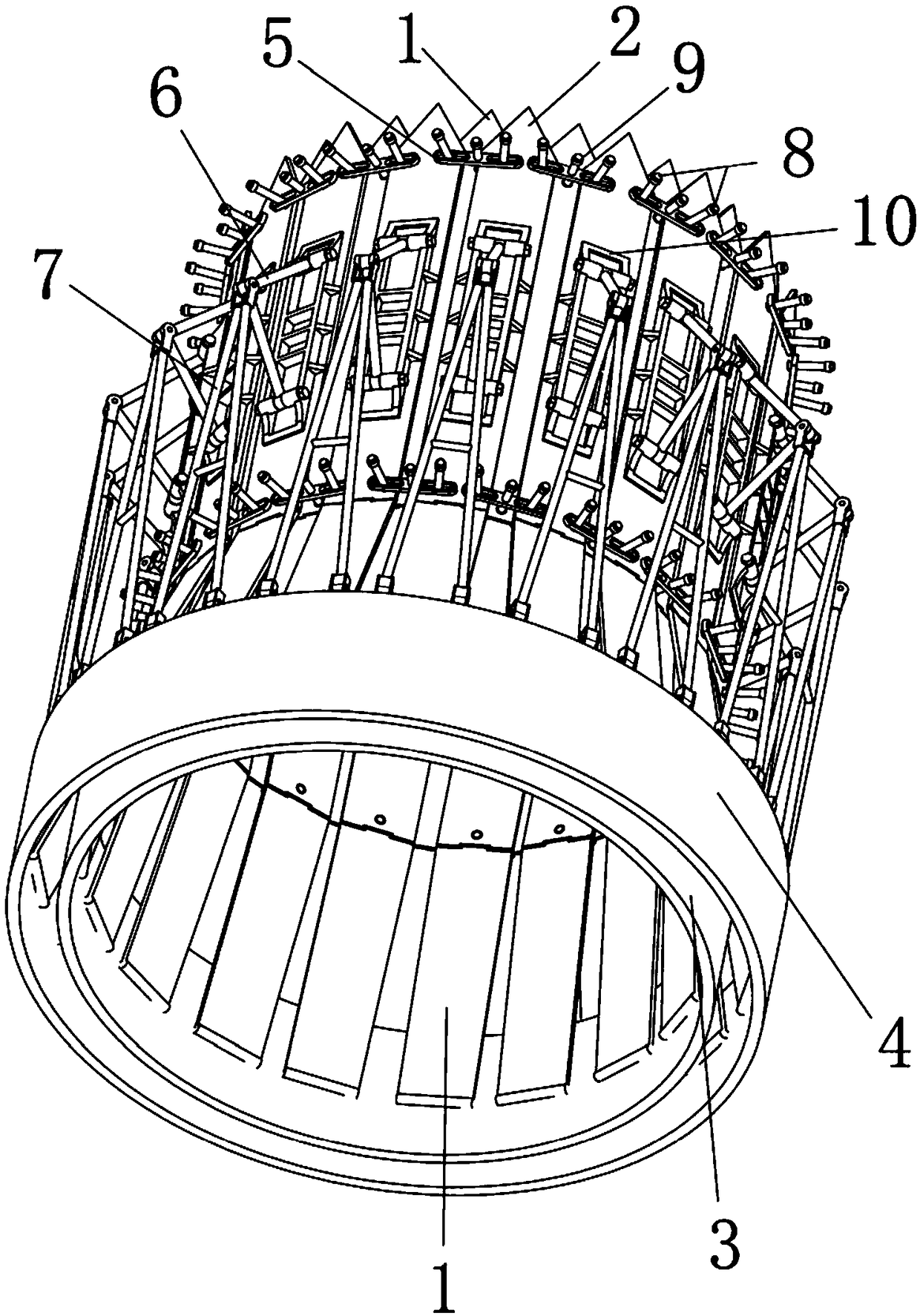

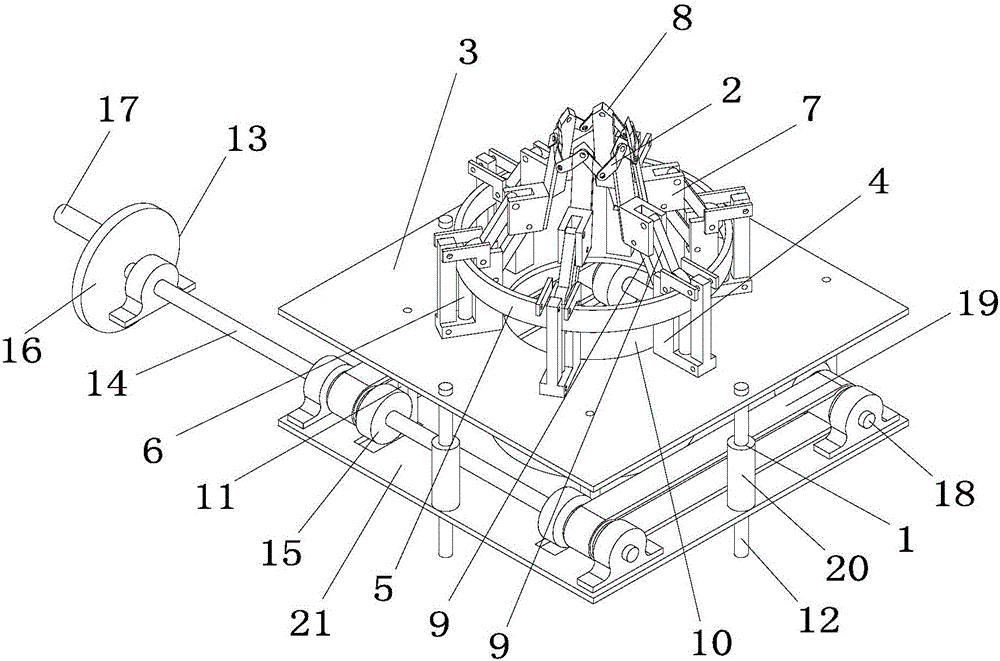

A ring-shaped banana drop-comb device with variable-diameter impact and plunge-cutting

The invention discloses a reducing impact insertion-cutting type annular banana comb cutting device. The reducing impact insertion-cutting type annular banana comb cutting device comprises a lifting frame and at least three cutting units, wherein the lifting frame is provided with a workbench and a lifting mechanism for lifting and lowering the workbench; the cutting units are annularly arranged on the workbench; the cutting units comprise parallelogram mechanisms, comb cutting knife groups and knife group synchronous controllers. The lifting mechanism of the banana comb cutting device has an impact effect. When fruit stems are in contact with hard blades or soft blades during banana comb cutting, insertion cutting of banana stems under the impact of the hard blades and the soft blades can be realized by controlling the revolving of runners, so that the aims of removing stalks and cutting combs are fulfilled, the cutting quality can be improved, the comb cutting time is shortened, and the efficiency is increased.

Owner:SOUTH CHINA AGRI UNIV

Cutting device, punching and cutting device and control method thereof

ActiveCN109760130BReduce processing timeEasy to processMetal working apparatusStructural engineeringMechanical engineering

The invention provides a cutting device, a hole punching cutting device and a control method of the hole punching cutting device. The cutting device comprises a driving assembly, a cutting part connected with the driving assembly which is used for driving the cutting part to move, and an auxiliary cutting part connected with the driving assembly which is further used for driving the auxiliary cutting part to move; and after the auxiliary cutting part moves to be in abutting connection with a to-be-cut article, the driving assembly drives the cutting part to cut the to-be-cut article. Accordingto the cutting device, the cutting part is driven by the driving assembly to move so as to cut the to-be-cut article, automatic cutting can be achieved, cutting is convenient and fast, the conditionsthat cutting is not flat and the cut face is not flat due to the fact that cutting is performed manually by adopting a cutter are avoided, and the cutting effect is good. Besides, after the auxiliarycutting part moves to be in abutting connection with the to-be-cut article, the cutting part can be used for cutting the to-be-cut article, and it can be effectively avoided that the to-be-cut article bears the thrust effect of the cutting part, displacement is caused, and deflection is caused.

Owner:GUANGZHOU MIDEA HUALING REFRIGERATOR

Corn stubble digging and stalk-stubble smashing device

InactiveCN102523767BSpeed does not decreaseSolve the real problemGatherer machinesEngineeringCombine harvester

A corn stubble digging and stalk-stubble smashing device comprises a stalk smashing device, a transmission system, a digging-type stubble cutting device, a stalk feeding beater, a power input device, a housing, a side board, a supporting plate, a cutter, a tubular shaft and the like. The corn stubble digging and stalk-stubble smashing device can be used in conjunction with a self-propelled or suspended corn combine harvester, or can be used in conjunction with a tractor singly. The profile modeling supporting plate can lead the digging-type stubble cutting device to dig up and cut off corn stubbles according to a certain depth, the stubbles and stalks are fed to the stalk feeding beater together under the action of the stalk feeding beater, and the stalks and the stubbles are cut up through a high speed revolution crushing cutter, so that stubble digging, stalk smashing and field return operation can be performed by one machine at the same time.

Owner:SHANDONG UNIV OF TECH

Plug-cut variable-diameter banana deshafting and combing knife that can adapt to the diameter of the banana stalk

The invention discloses an inserting cutting type variable diameter banana shaft removing and combing cutter self-adaptive to the diameter of a banana spike rod. The cutter comprises hard combing blades, soft combing blades, universal ball bearings and a rack, wherein one side of each soft combing blade extends to form a cutter arm, and a limiting frame is arranged on each hard combing blade; the number of the hard combing blades and the number of the soft combing blades are plural, the body of one hard combing blade and the body of one soft combing blade are stacked to be combined into a combing blade set, a plurality of the hard combing blades and a plurality of the soft combing blades are combined into a plurality of combing blade sets arranged in the rack, the cutter arm of one combing blade set stretches into the limiting frame of the adjacent combing blade set, and the multiple combing blade sets are combined to form a circumferential cutting edge capable of wrapping the banana spike rod; each combing blade set is provided with one universal ball bearing, and a deformation structure is connected between each combing blade set and the rack. The cutter has the advantages of being light and small in overall structure, convenient to move, safe and labor-saving to operate, and suitable for mechanical banana combing.

Owner:SOUTH CHINA AGRI UNIV

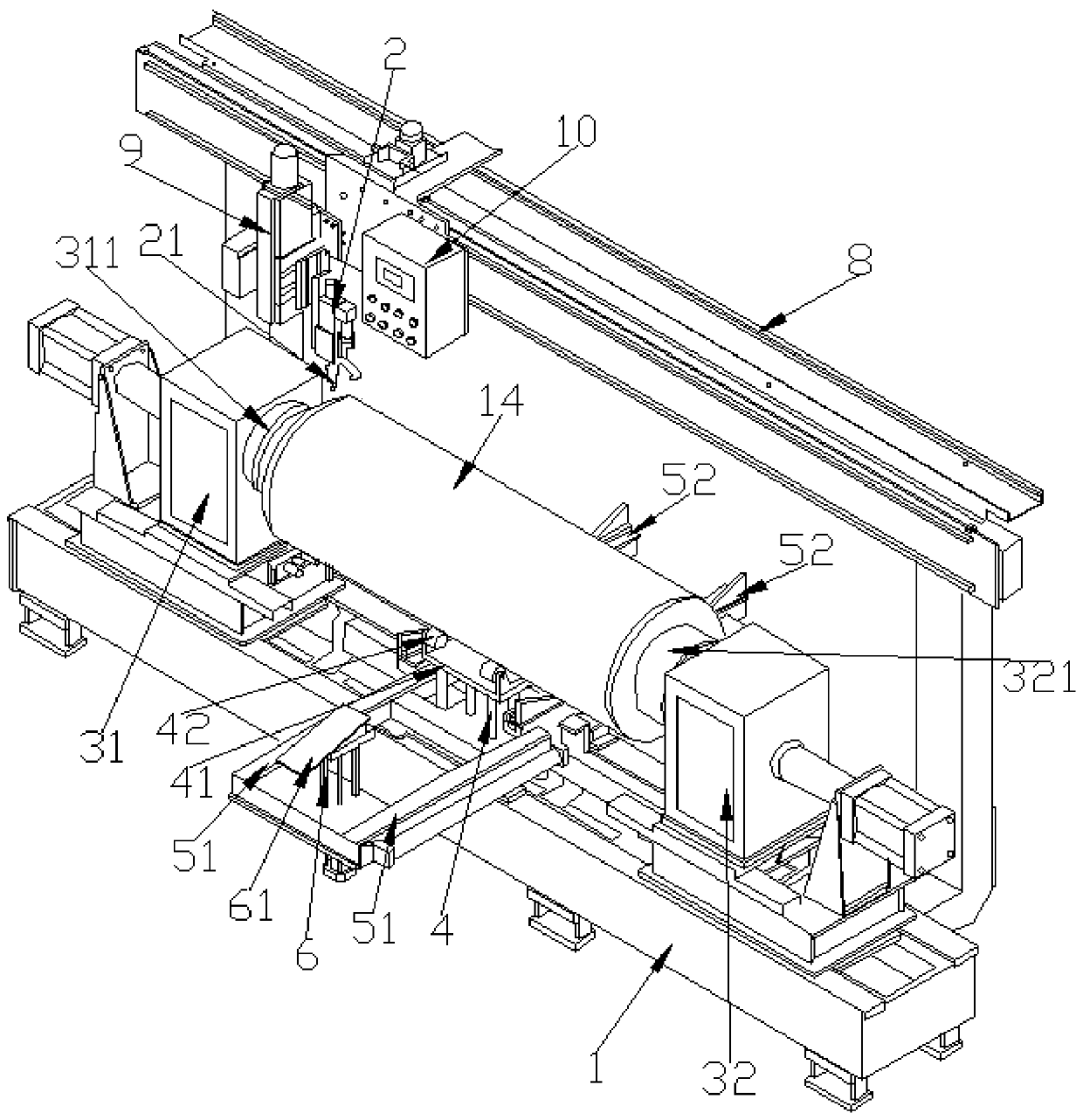

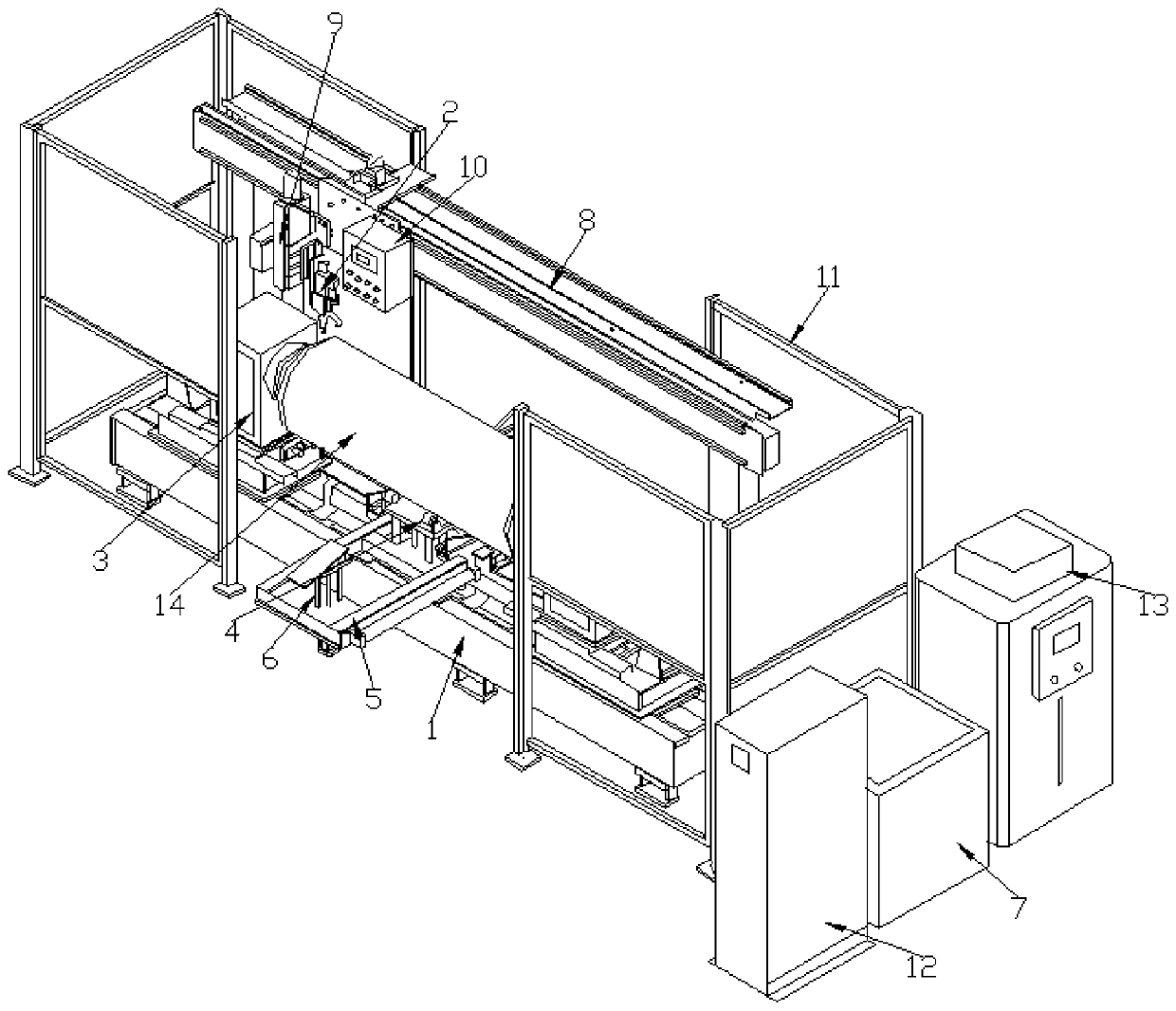

Run-on plate cutting device and cutting method

PendingCN111421246AAvoid uneven cuttingAvoid missed cutsLaser beam welding apparatusEngineeringStructural engineering

The invention provides a run-on plate cutting device and a cutting method and relates to the technical field of cutting devices. The technical problem that in the prior art, when a cutting machine ismanually held in hand to cut run-on plates at the positions of arc starting and arc extinguishing of straight welding of a water tank inner container, the potential safety hazard is relatively high issolved. The cutting device comprises a support, a cutting mechanism and a supporting and rotating mechanism, wherein the cutting mechanism and the supporting and rotating mechanism are supported on the support; the supporting and rotating mechanism is used for clamping the two ends of a to-be-machined piece and can drive the to-be-machined piece to rotate; the position of a cutting head on the cutting mechanism can be adjusted; and when the cutting head is adjusted to a preset position, the to-be-machined piece on the supporting and rotating mechanism is rotated so that the run-on plate on the to-be-machined piece can be subjected to cutting treatment. The run-on plate cutting device and the cutting method are used for achieving cutting on the run-on plates of straight welding of the water tank inner container, the accuracy and stability of cutting is improved, and safety is improved.

Owner:GREE ELECTRIC APPLIANCES WUHAN +1

A banana combing platform based on rigid-flexible coupling parallel mechanism

ActiveCN112244333BImproved Adaptive Envelope performanceAvoid missed cutsFood treatmentCrankEngineering

The invention discloses a banana combing platform based on a rigid-flexible coupling parallel mechanism, comprising a combing cutterhead, a parallel four-bar, a guide rod, a connecting rod, a crank, a power source, an annular envelope cutter, an upper base plate, and a lower base plate and a rigid-flexible coupling parallel mechanism; the combing cutter head is processed with a plurality of guide grooves along its circumferential direction; each guide groove is correspondingly provided with a parallel four-bar, and a plurality of parallel four-bar links form a ring-shaped variable diameter The expandable mechanism; the annular enveloping cutter is set on the expandable mechanism; the upper base plate is installed on the bottom surface of the comb cutter head, and the lower base plate is placed directly below the upper base plate, and is connected through a rigid-flexible coupling parallel mechanism connected with each other, through the rigid-flexible coupling parallel mechanism, the annular enveloping cutter can be rotated or moved in space according to the bending change of the banana cob, so that it can adapt to the bending of the banana cob. The invention can effectively solve the problems that the existing mechanical doffing device has poor self-adaptive enveloping effect on banana fruit cobs and low conforming degree of profiling.

Owner:SOUTH CHINA AGRI UNIV

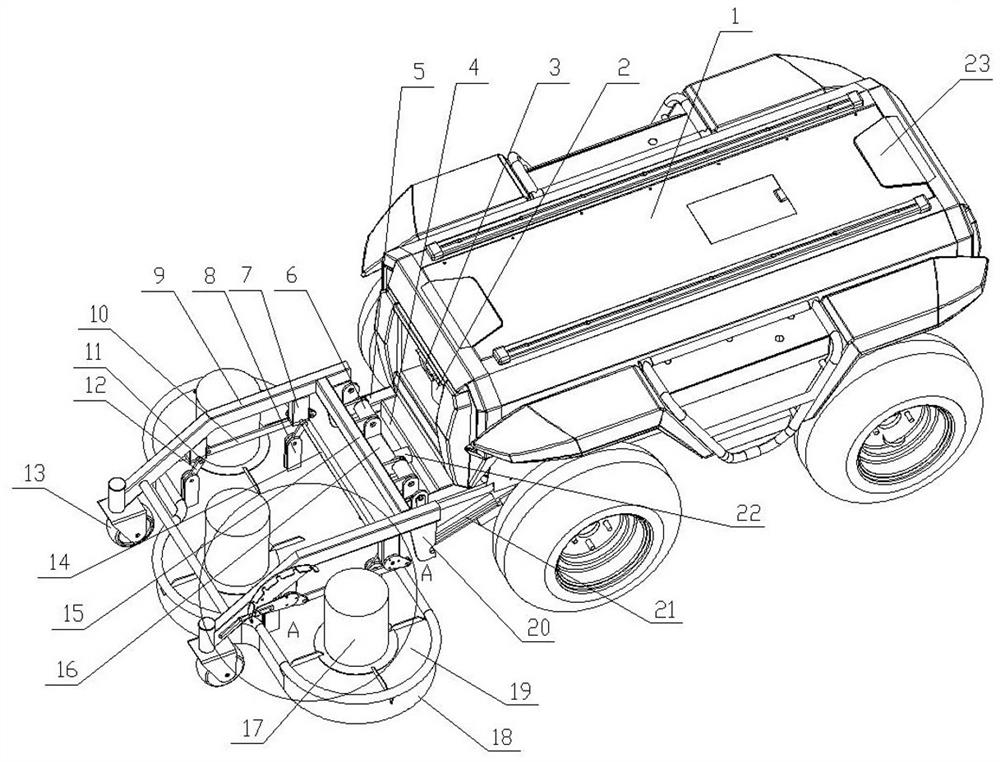

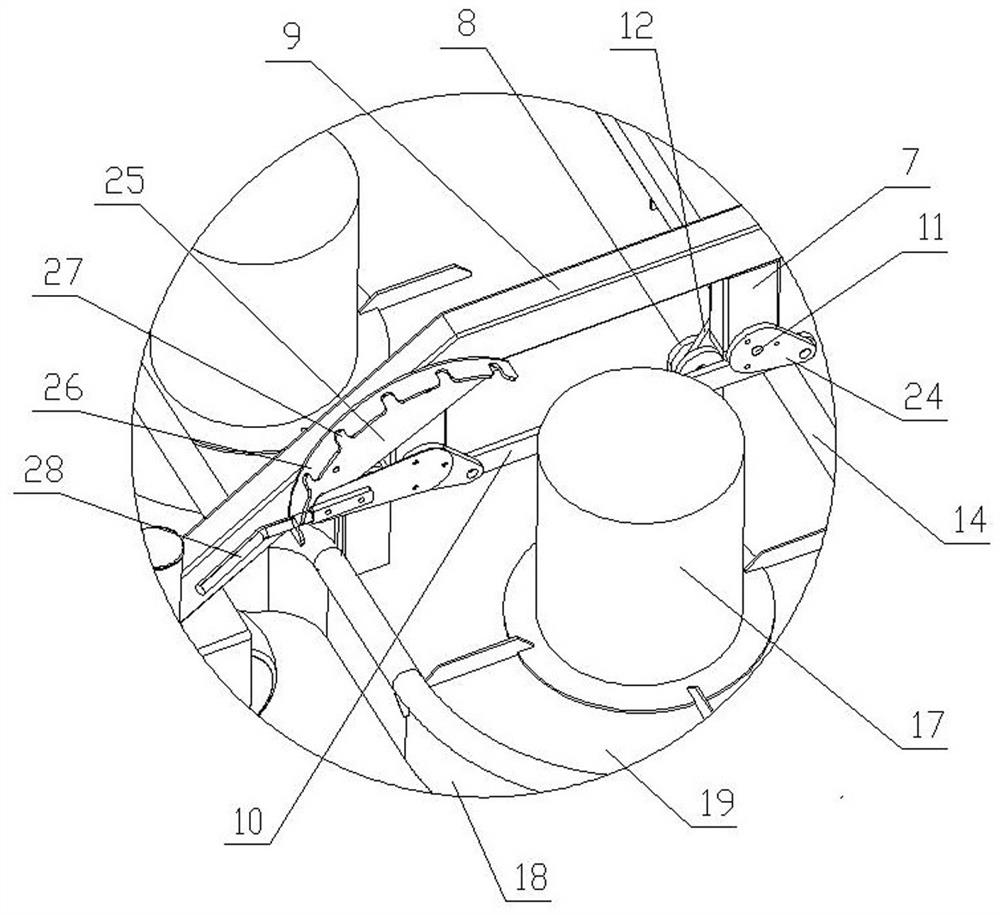

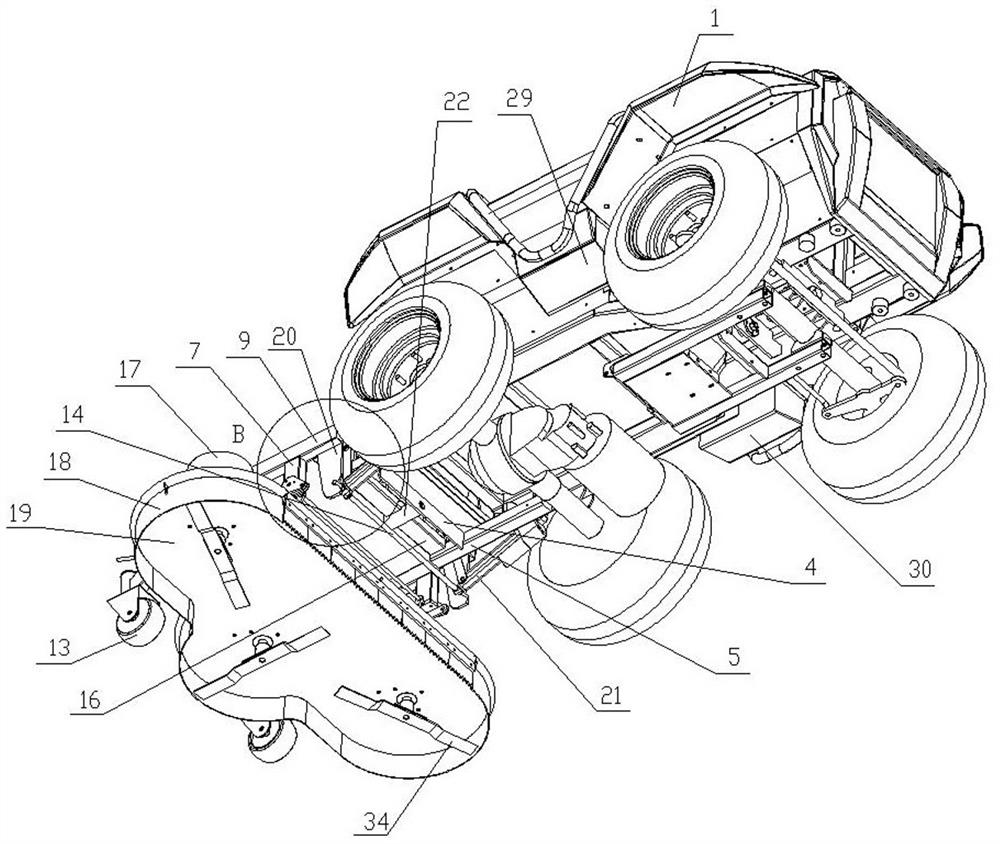

A four-wheel lawn mower with unmanned autonomous operation

ActiveCN113079805BAutomate operationsImprove work efficiencyMowersVehicular energy storageControl theoryLidar

The invention relates to a lawn mower, in particular to a four-wheel lawn mower with unmanned autonomous operation. It includes a four-wheel drive vehicle, the four-wheel drive vehicle has an electronic controller, and the front end of the four-wheel drive vehicle is connected to a mowing disc. It is characterized in that there is an intelligent controller on the four-wheel drive vehicle, a camera and a laser radar are arranged on the front end of the four-wheel drive vehicle, a GNSS positioning antenna is arranged on the top of the four-wheel drive vehicle, and the electronic controller, camera, laser radar and GNSS positioning antennas are electrically connected to the intelligent controller. The lawnmower can work automatically and has high working efficiency.

Owner:WUXI KALMAN NAVIGATION TECH CO LTD

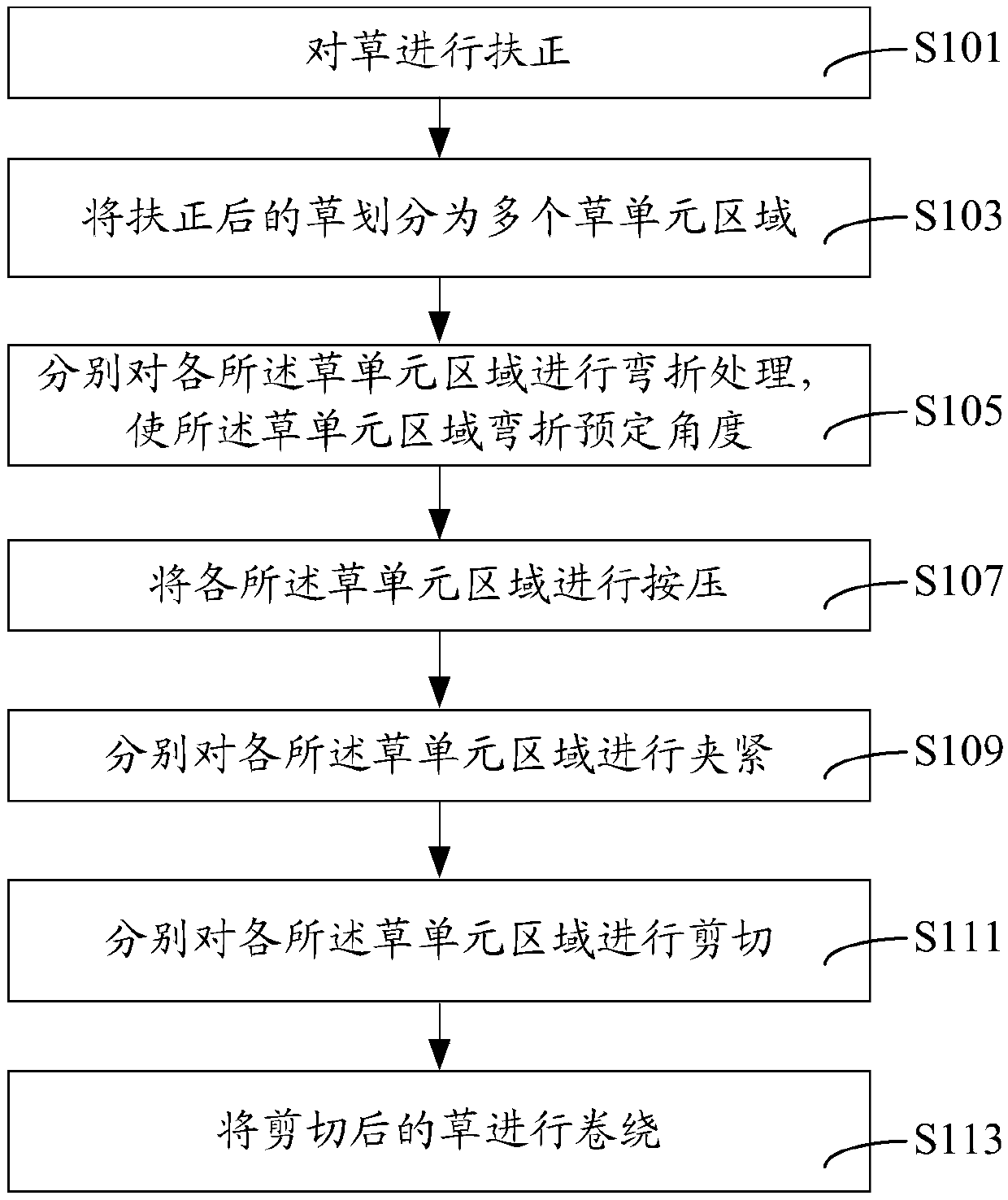

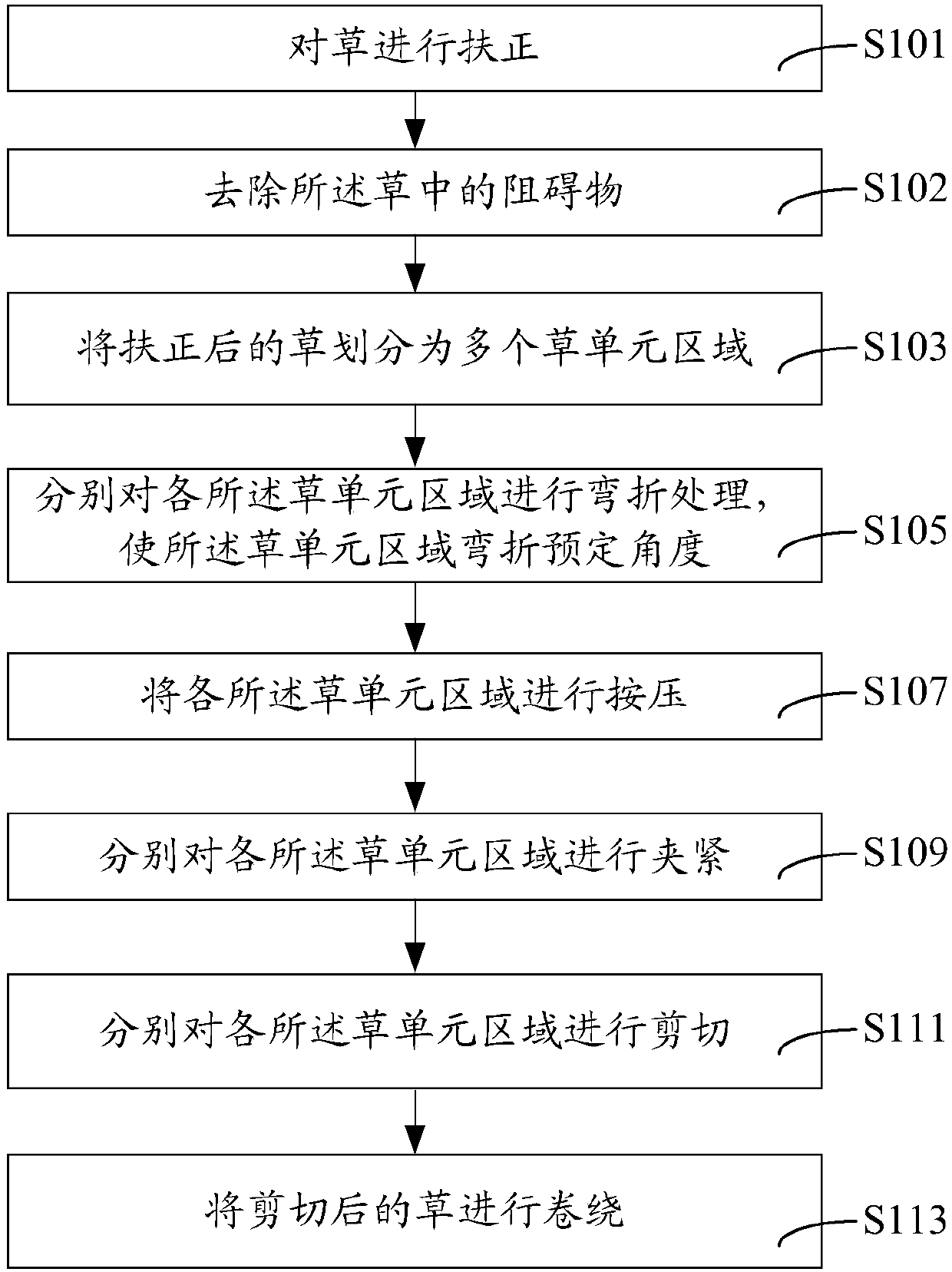

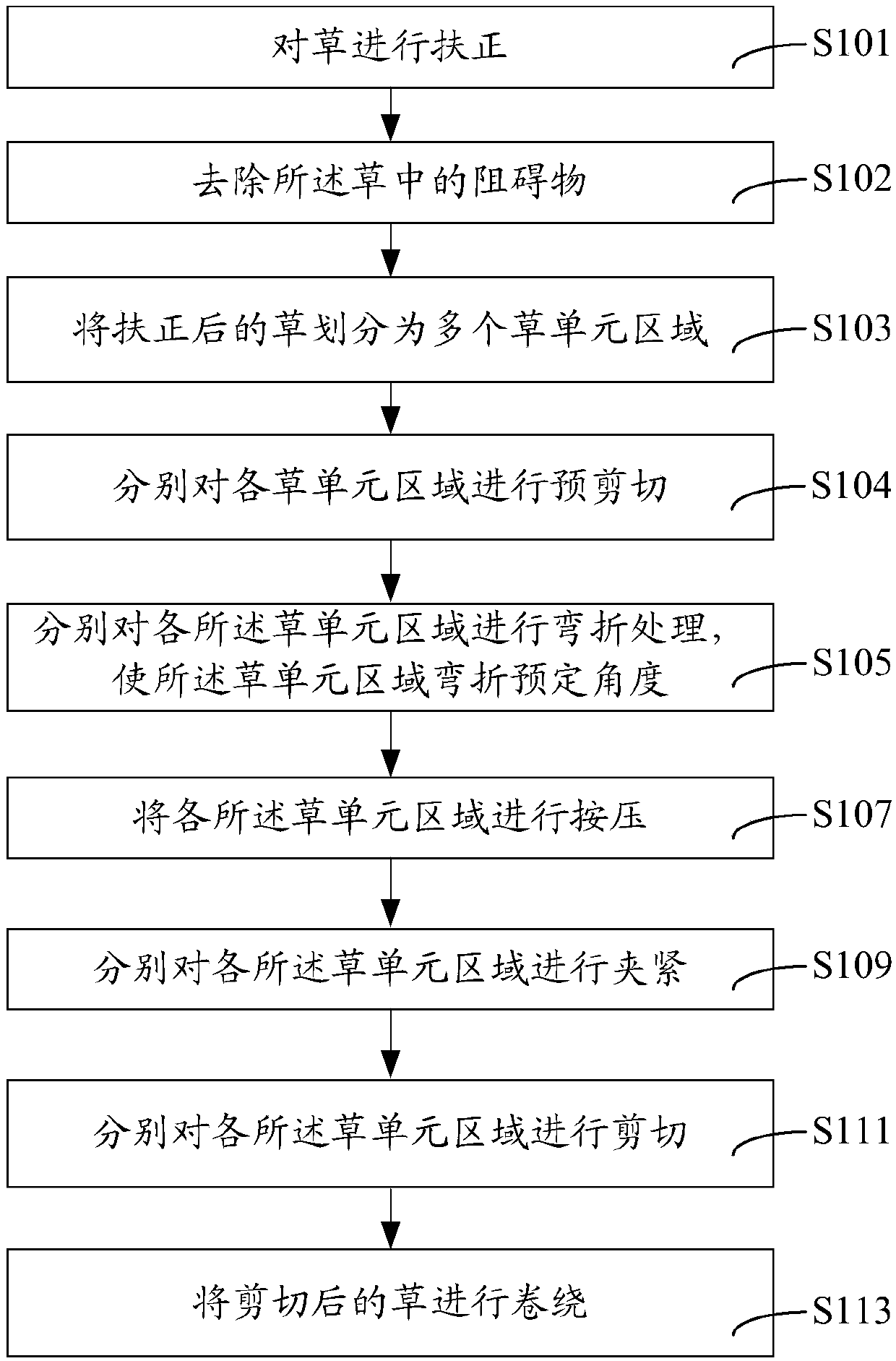

Grass cutting device and grass cutting method thereof

InactiveCN107750579ASolve the problem that the grass cannot be cutAvoid clutterMowersEngineeringUprighting

The invention relates to a grass cutting device and a grass cutting method thereof. The above-mentioned grass cutting method comprises the following steps: uprighting grass; dividing the uprighted grass into a plurality of grass unit areas; respectively subjecting the grass unit areas to bending treatment, and allowing each grass unit area to bend into a predetermined angle; pressing each grass unit area; respectively clamping the grass unit areas; respectively cutting the grass unit areas; and winding cut grass. The grass cutting device and the grass cutting method mentioned above have the following advantages: the grass unit areas are respectively cut, and the grass is divided into a plurality of grass unit areas for cutting, so excessive amount of the cut grass in a same cavity in a traditional grass cutting method is avoided, and the problem that a grass cutting device is incapable of cutting off the grass is solved; and the cut grass is winded, facilitates concentration and transportation and is avoided from scattering all around, so cutting of the grass is finally completed.

Owner:惠州市洛玛科技有限公司

A kind of cutting-type banana drop-comb device

ActiveCN107048446BAutomatic diameter adjustmentAchieving diameter adaptationFood treatmentBall screwEngineering

The present invention discloses an inserting-cutting type banana crown cutting device comprising an inserting-cutting type crown cutter, a synchronous belt transmission mechanism, a movable beam, a linkage self-locking clamping jaw, ball screw mechanisms, a motor and a bracket. The inserting-cutting type crown cutter is fixed on a lower holder of the bracket. The two sets of ball screw mechanisms are vertically arranged on the holder on both sides of the inserting-cutting type crown cutter, respectively, wherein one set of the ball screw mechanism is driven by the motor and synchronous movement of the two sets of ball screw mechanisms is realized by the synchronous belt transmission mechanism. The movable beam is arranged on the two sets of ball screw mechanisms, located above the inserting-cutting type crown cutter, and driven by the two sets of ball screw mechanisms to realize up-down linear movement. The linkage self-locking clamping jaw is arranged on the movable beam, used for clamping banana stalk and matched with the inserting-cutting type crown cutter, and cutting bananaes crown by crown from the stalk is realized. The banana crown cutting device disclosed by the present invention has the advantages of compact overall structure and light weight, and is convenience in transportation, safe and labor-saving in operation and the like, and is applicable to the mechanization of banana crown cutting.

Owner:SOUTH CHINA AGRI UNIV

Banana combing device with adaptive banana stem based on constant force mechanism

ActiveCN109527622BSmooth and reliable rotationReduce rigid impactFood treatmentConstant forceStructural engineering

The invention discloses a constant force mechanism based banana harvesting device capable of automatically adapting to the banana tree stem. The device comprises a frame, an outer cutter head, an inner cutter head, a first fixed shaft, a second fixed shaft, a first elevating stop block, a second elevating stop block, a torsional spring, a fixed rack, a hard blade installation rack, a movable guiderod, a horizontal compression spring, a public column, an inclined compression spring, a hard blade, and a soft blade. The annular inner cutter head and the outer cutter head can rotate around the axes of the inner cutter head and the outer cutter head and sequentially arranged on the through hole of the frame. Multiple annular arrays of the fixed rack are arranged on the inner cutter head. The fixed rack and the hard blade installation rack are connected by the movable guide rod. The horizontal compression spring sleeves the movable guide rod. The public column is connected to the hard bladeinstallation rack through the inclined compression spring. The hard blade is mounted on the hard blade installation rack. The soft blade is rivetingly arranged on the external side of the hard bladeso as to form an annular enveloping structure that envelopes a banana spike. The provided device has the advantages that the device can automatically adapt to the banana tree stems and in a certain constant force displacement range, the clamping force is constant.

Owner:SOUTH CHINA AGRI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com