Aquatic weed cutting, conveying and bundling system and ship

A technology of aquatic plants and cutters, which is applied in the direction of harvesting platforms, harvesters, agricultural machinery and implements, etc., can solve the problem of not being able to cut underwater and collecting and transporting aquatic plants to the water surface, unable to collect aquatic plants on both sides of the hull, and increasing Hull grass storage volume and other issues, to achieve the effect of convenient transshipment, convenient maintenance, and weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

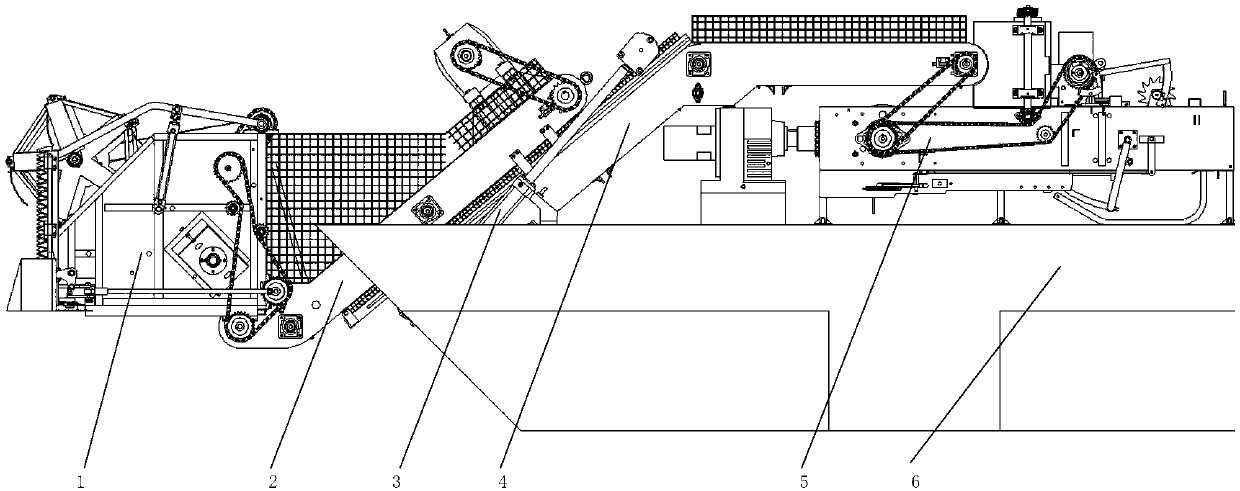

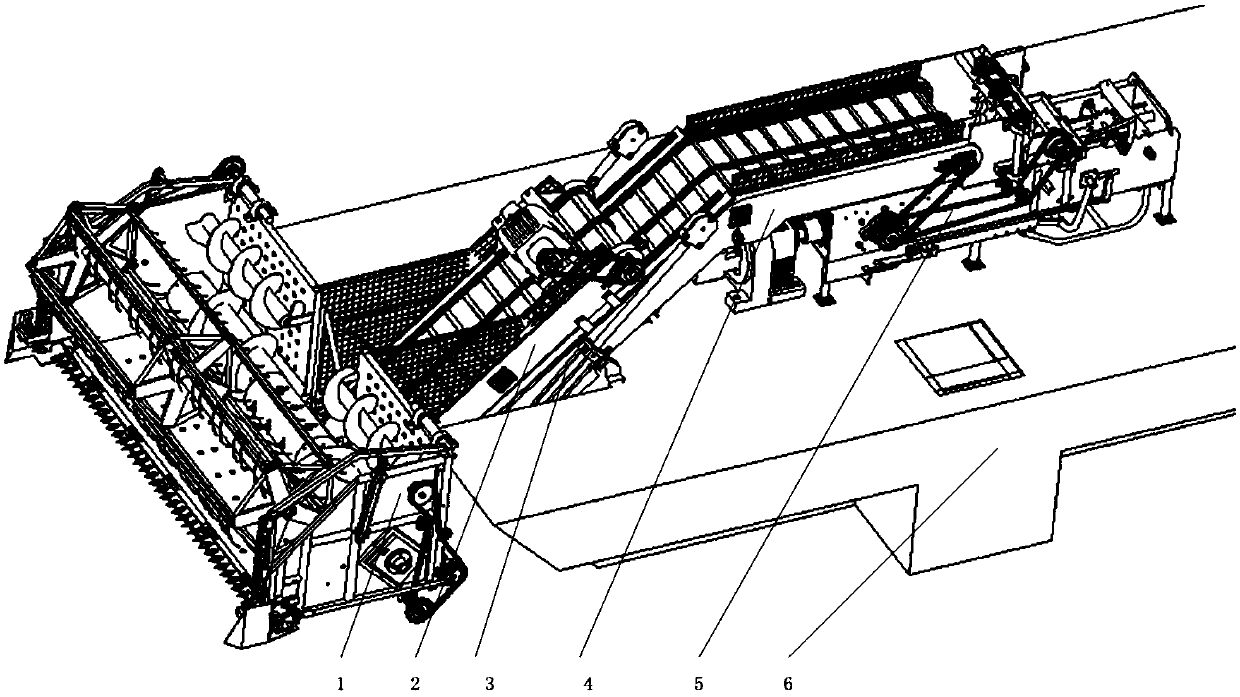

[0057] Such as figure 1 , 2 Shown is an embodiment of the aquatic plant cutting, conveying and bundling system, which includes a header assembly 1, a primary conveying assembly 2, a cutting depth adjustment system 3, and a secondary conveying assembly 4. Compression and bundling system 5, power transmission system and hydraulic control circuit; the front part of the primary conveying assembly 2 is connected with the header assembly 1, and the rear part is connected with the secondary conveying assembly The front sliding connection into 4; The power transmission system is respectively connected with the header assembly 1 , the primary conveying assembly 2 , the secondary conveying assembly 4 and the compression and bundling system 5 .

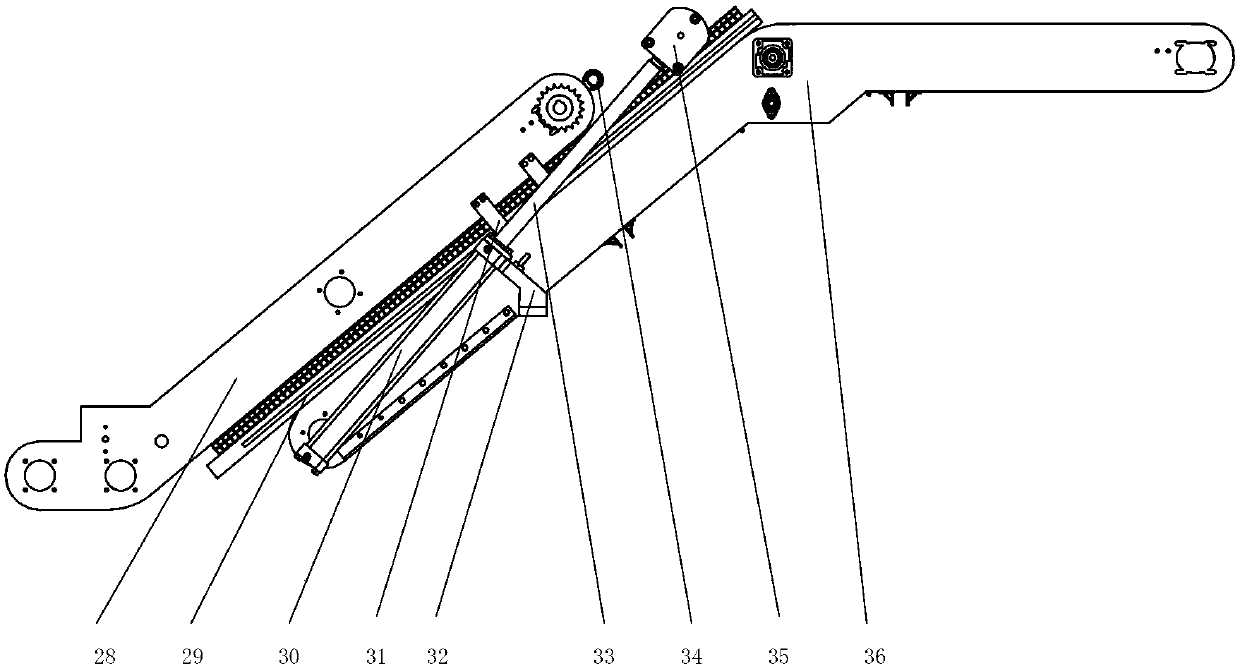

[0058] Preferably, the front part of the primary conveying assembly 2 is parallel to the rear part of the secondary conveying assembly 4; the rear part of the primary conveying assembly 2 and the front part of the secondary conveying assembly ...

Embodiment 2

[0084] An aquatic weed harvesting ship, comprising the aquatic weed harvesting platform described in Embodiment 1. Therefore, it has all the beneficial effects described in Embodiment 1, which will not be repeated here.

[0085] Preferably, the aquatic grass harvesting ship is an amphibious ship.

[0086] Such as figure 1 and 2 As shown, the compression and bundling system 5 is arranged on the deck surface in the middle of the hull 1, a hydraulic motor is arranged under the front end of the system to provide power for the system, and the front half of the secondary conveying assembly 4 is fixedly installed on the slope surface in the middle of the front end of the hull 6 , the second half is parallel to the deck surface, the second half of the primary conveying assembly 2 is parallel to the second half of the secondary conveying assembly 4, and the front half is arranged above it, and is connected with the pulley assembly through the slideway to achieve relative sliding, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com