Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

42results about How to "Achieve vertical placement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

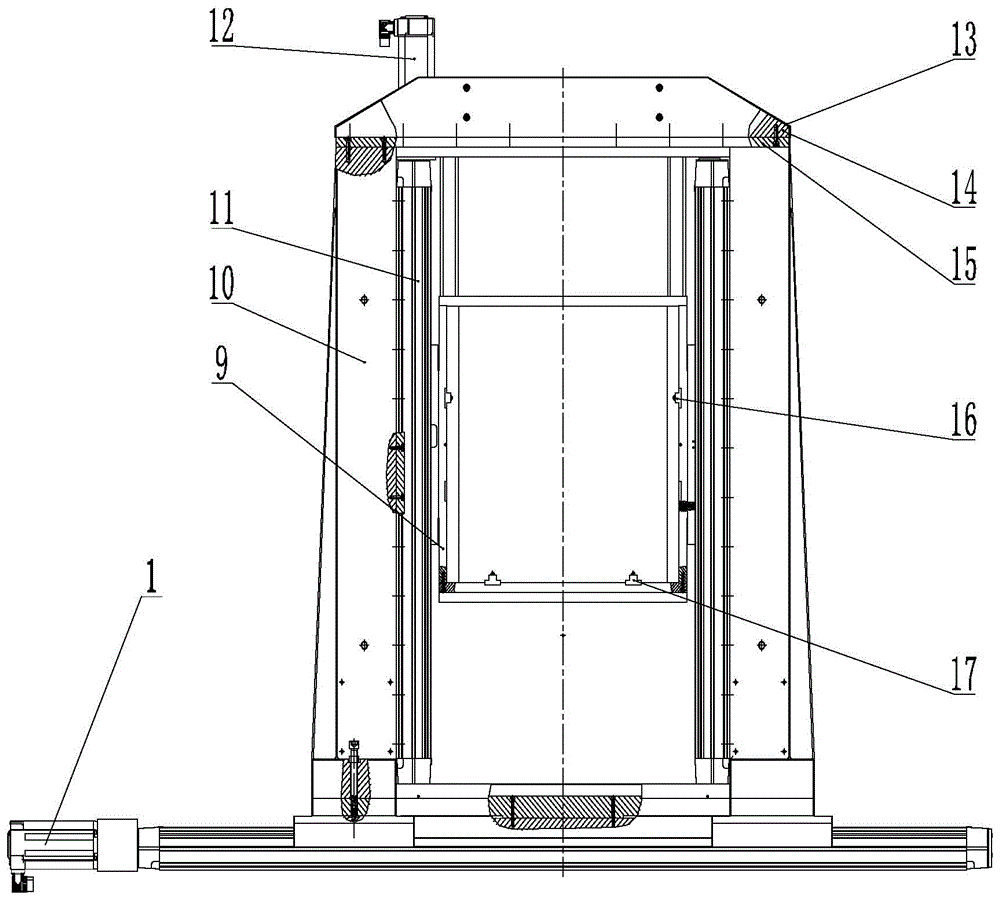

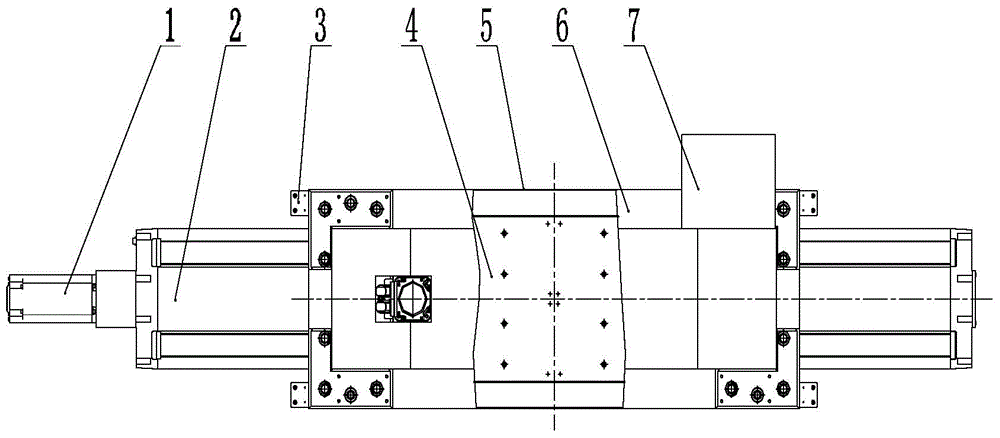

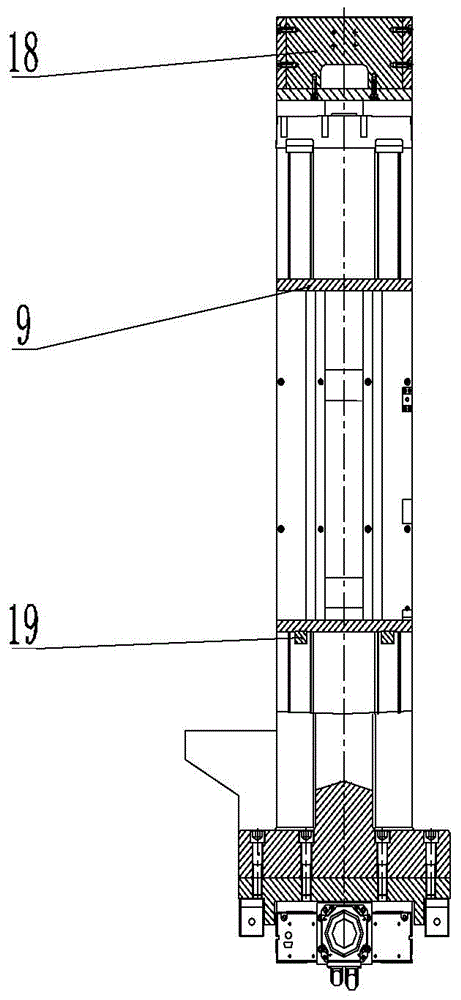

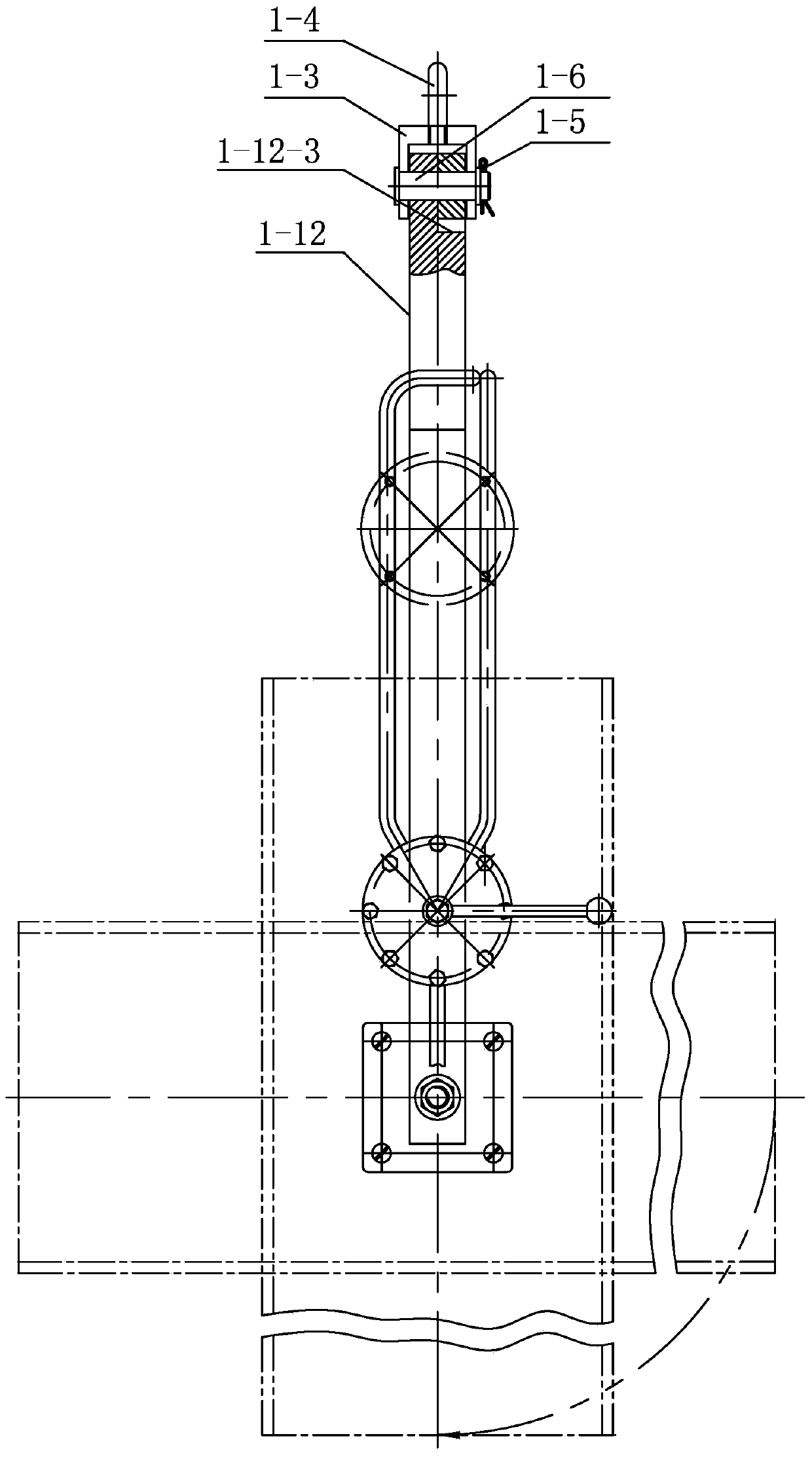

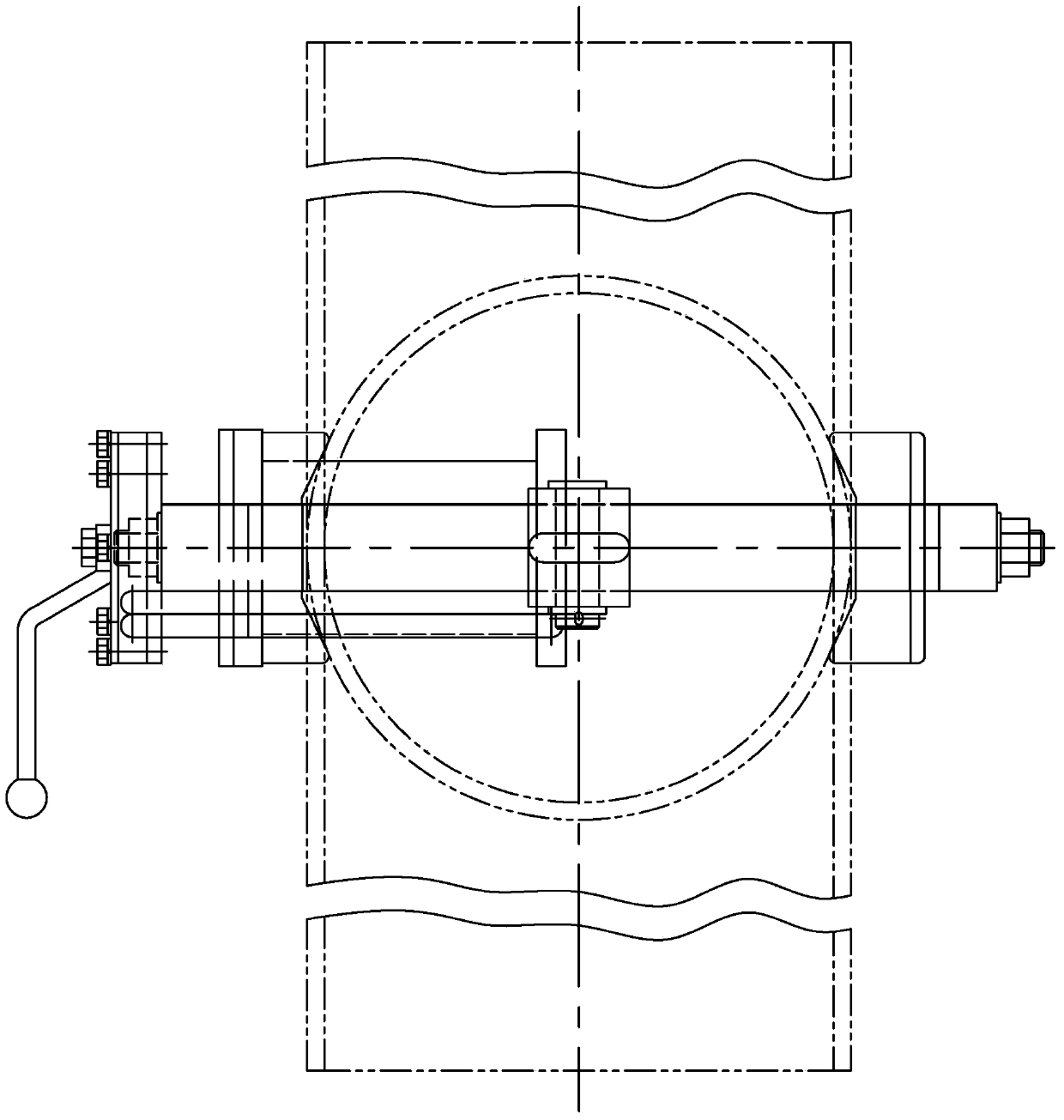

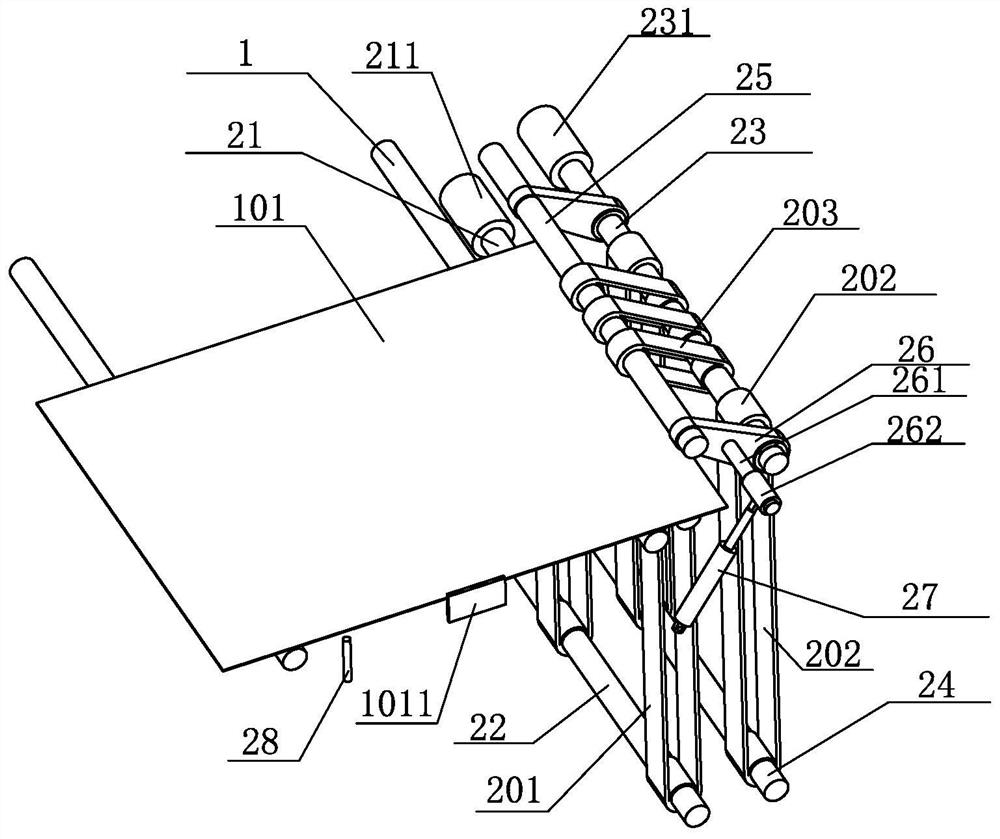

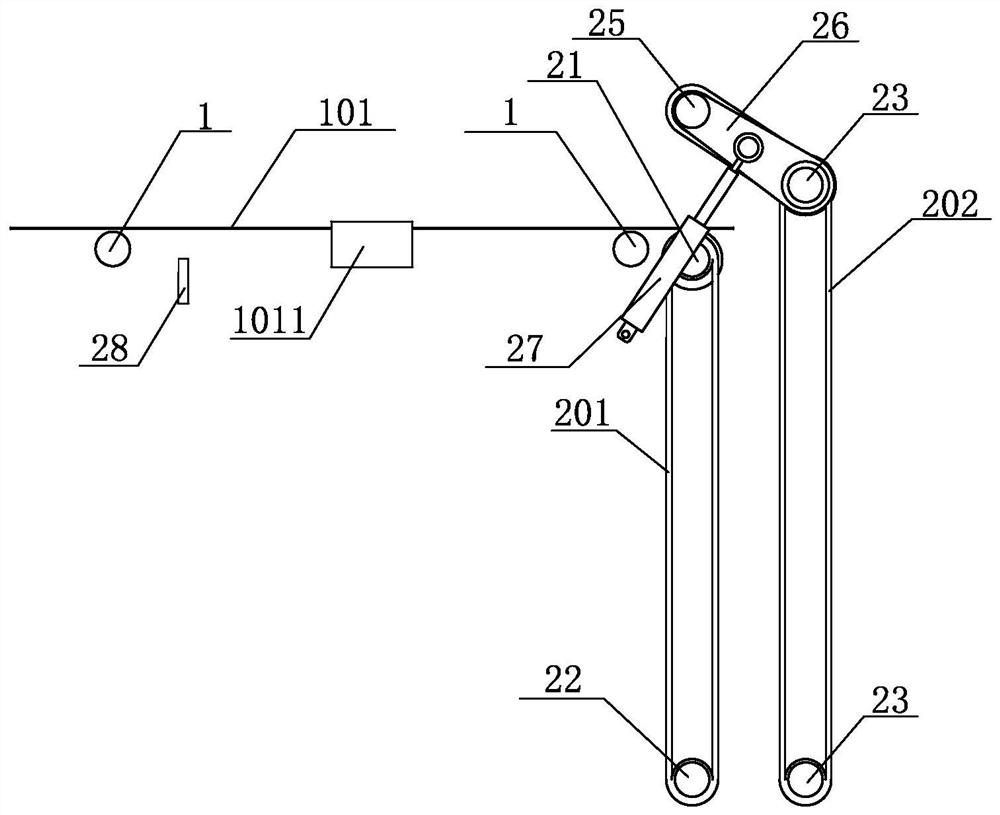

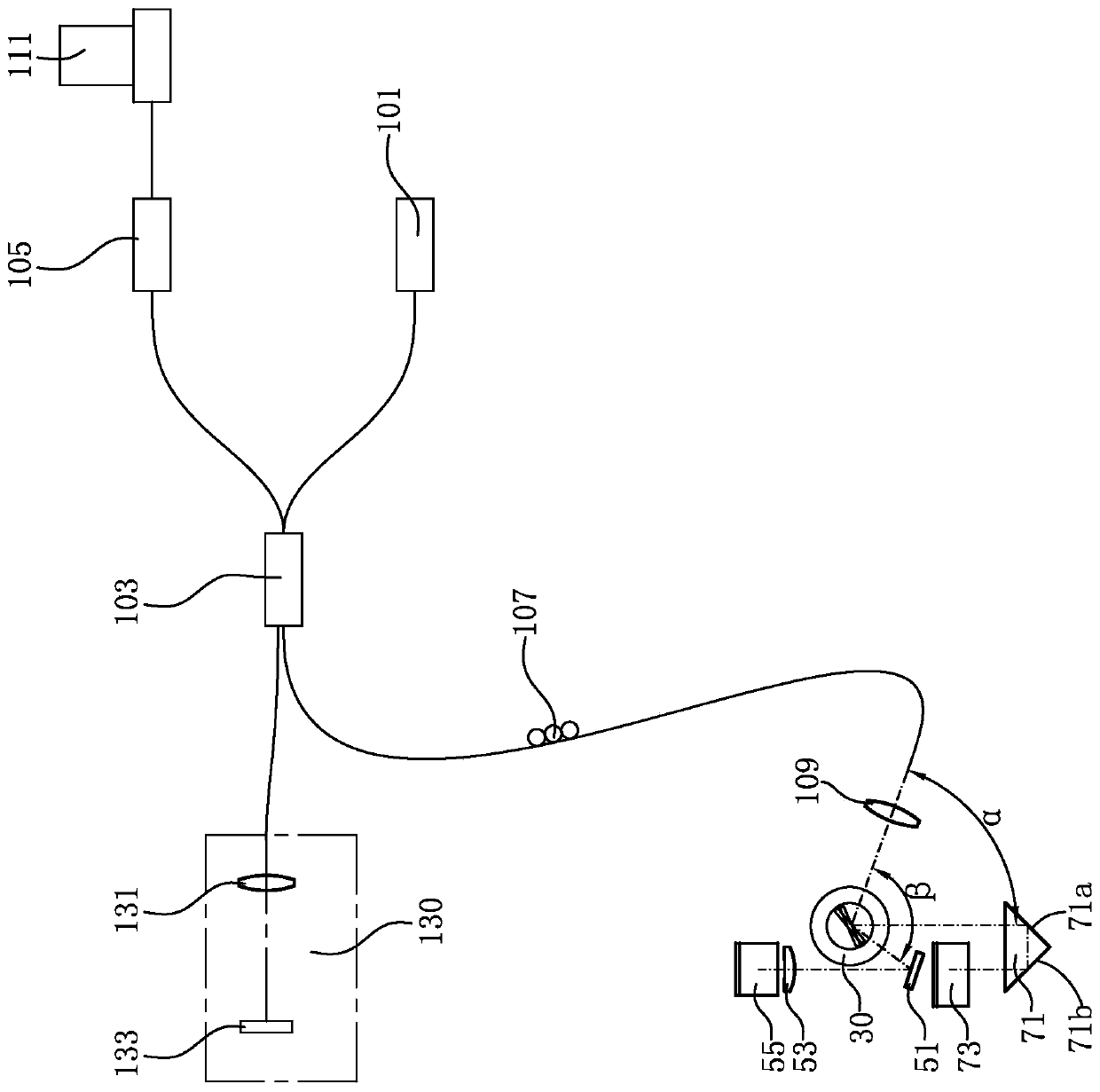

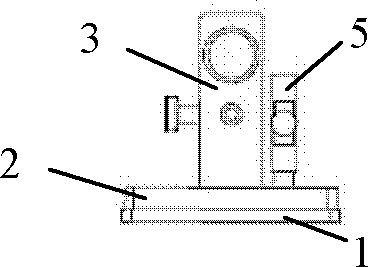

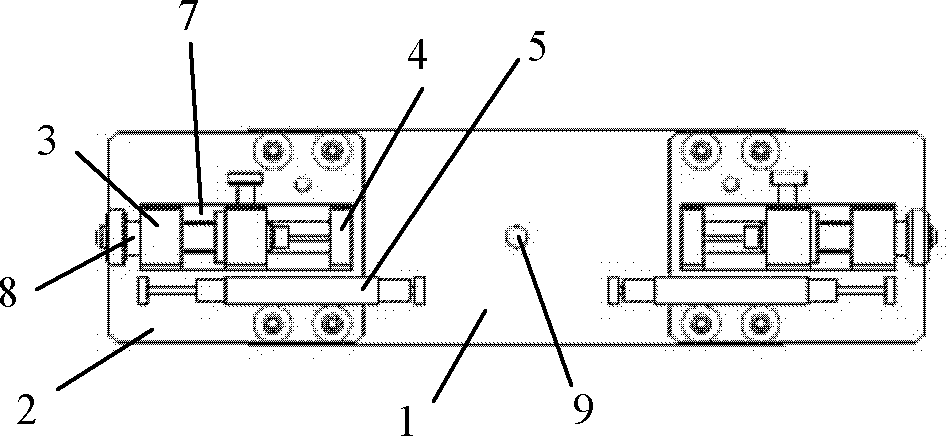

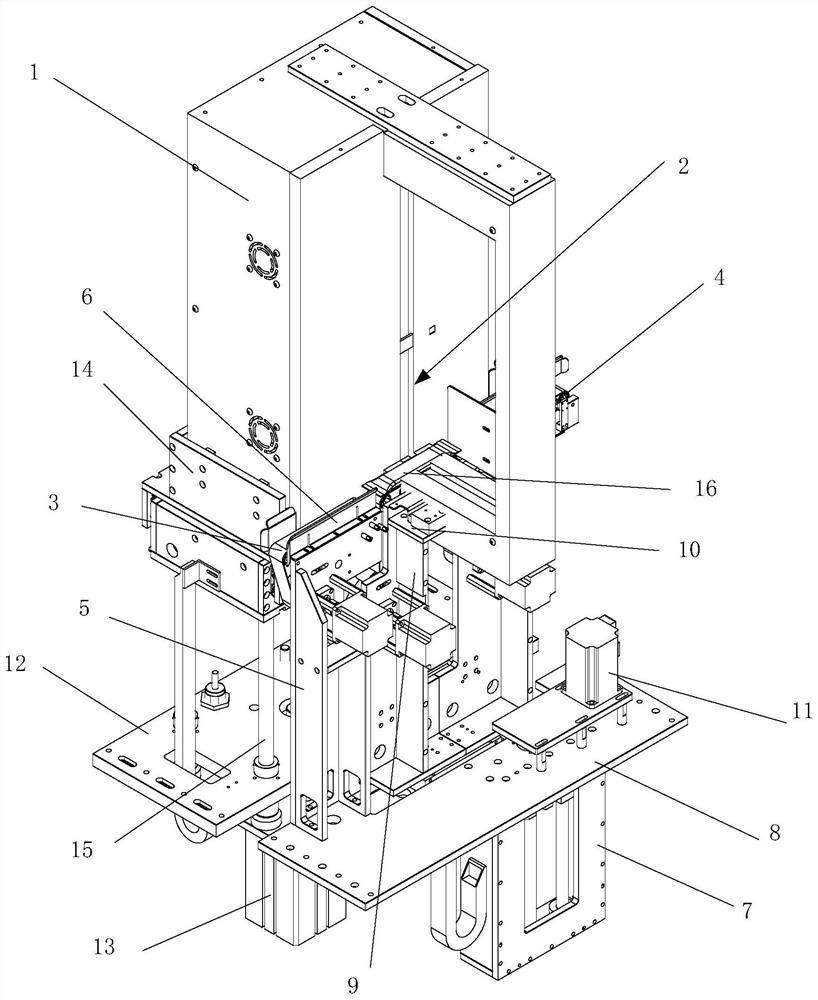

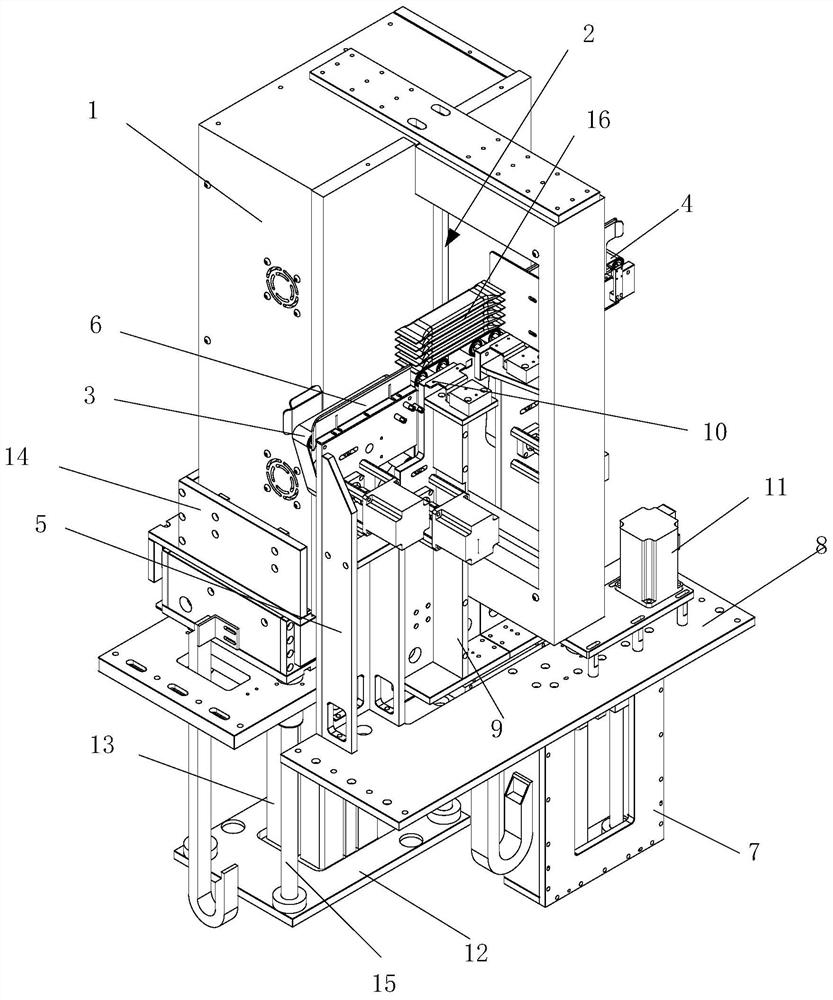

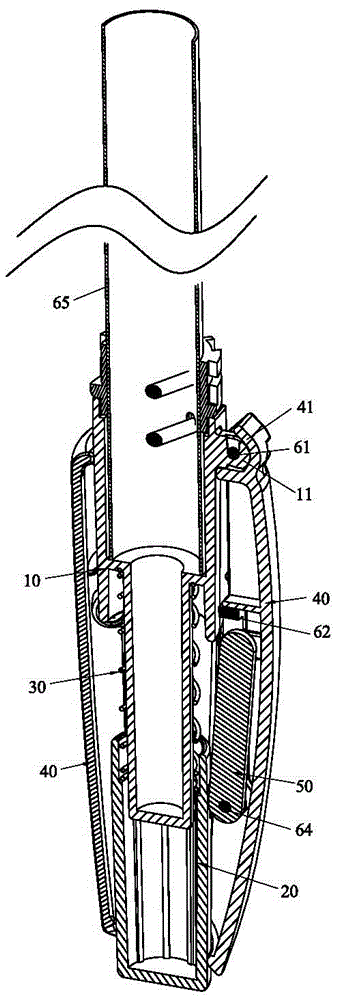

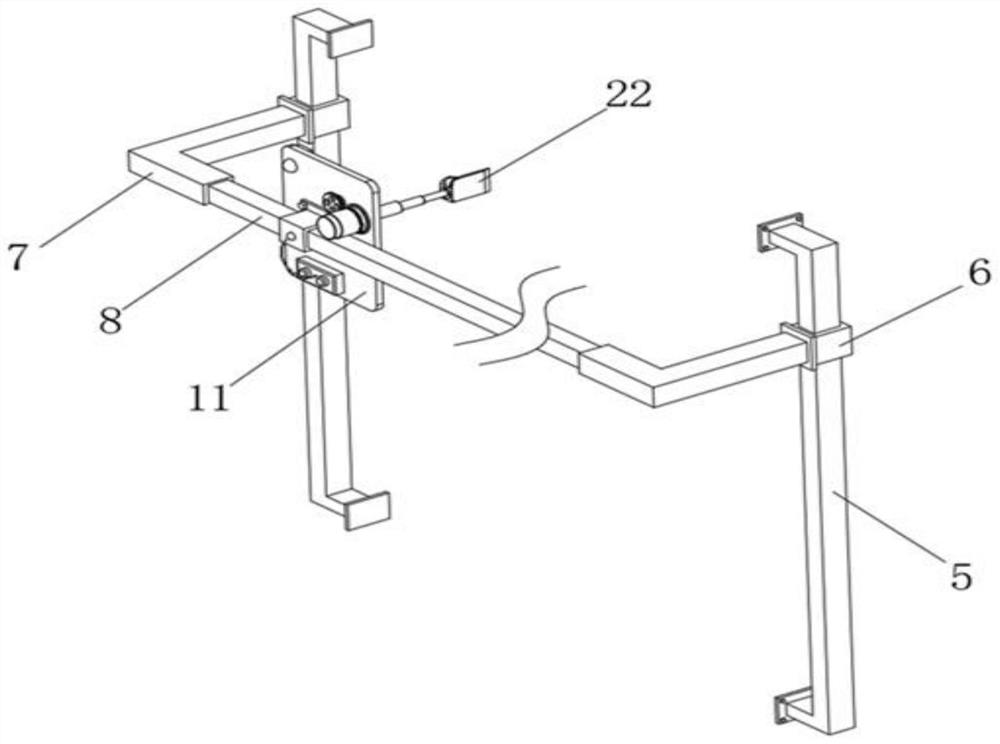

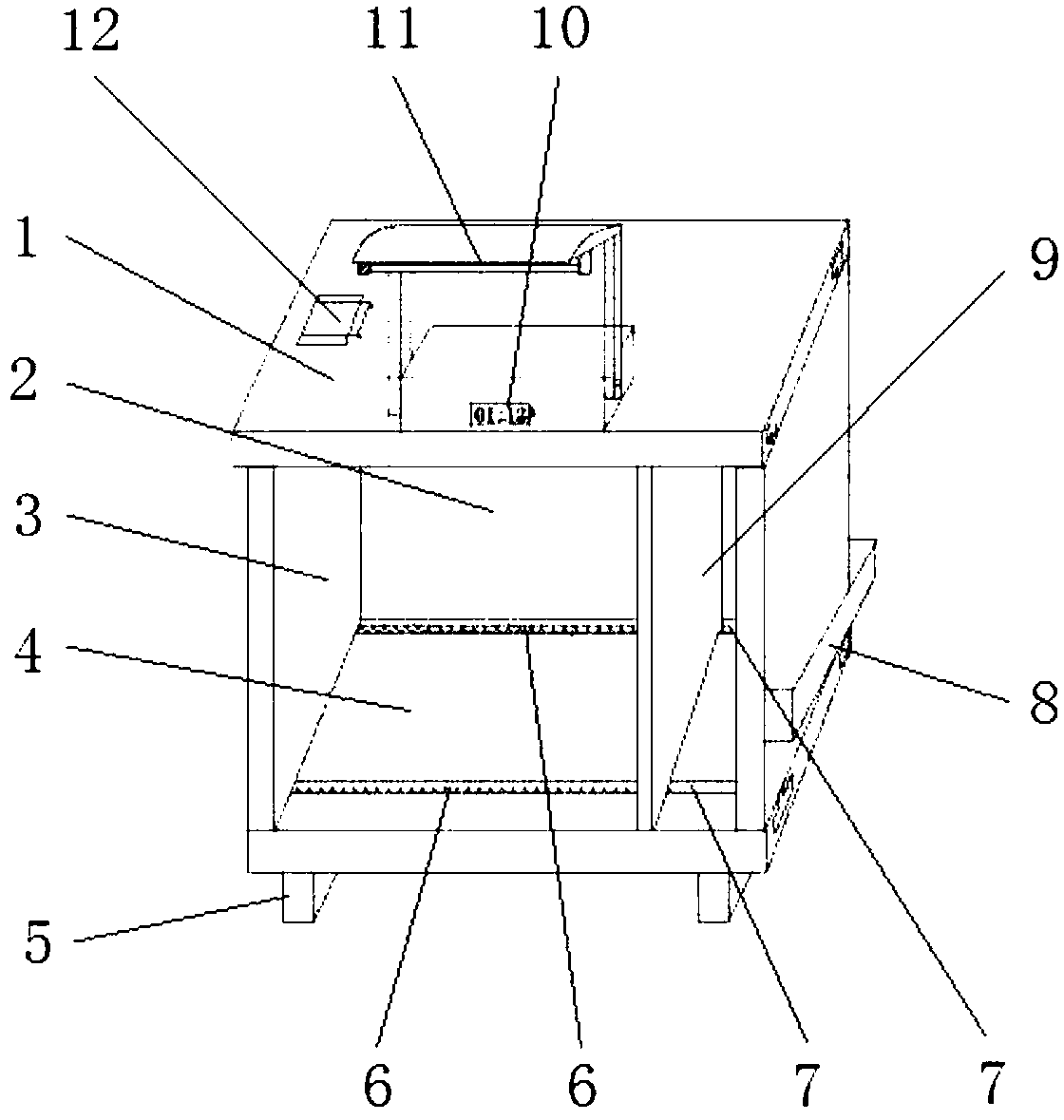

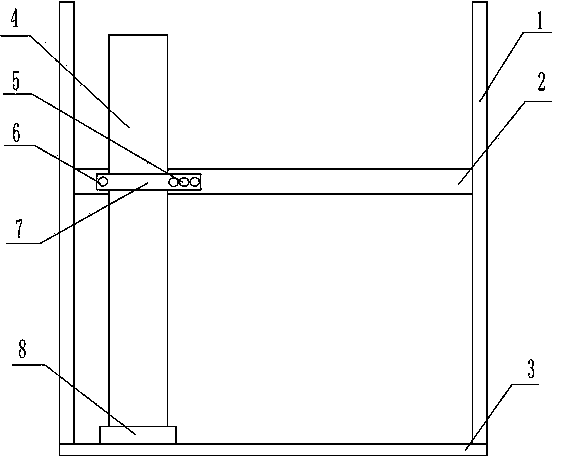

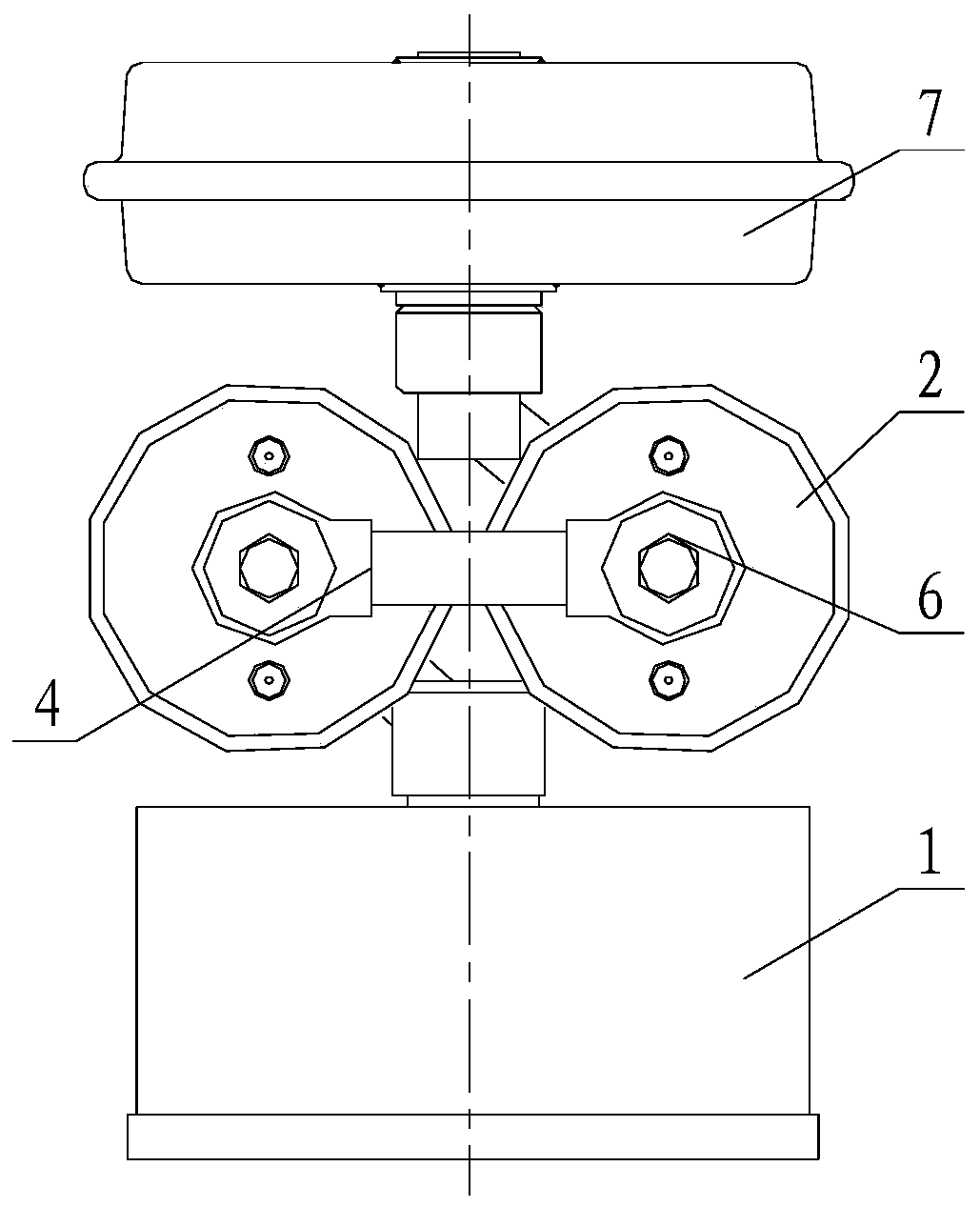

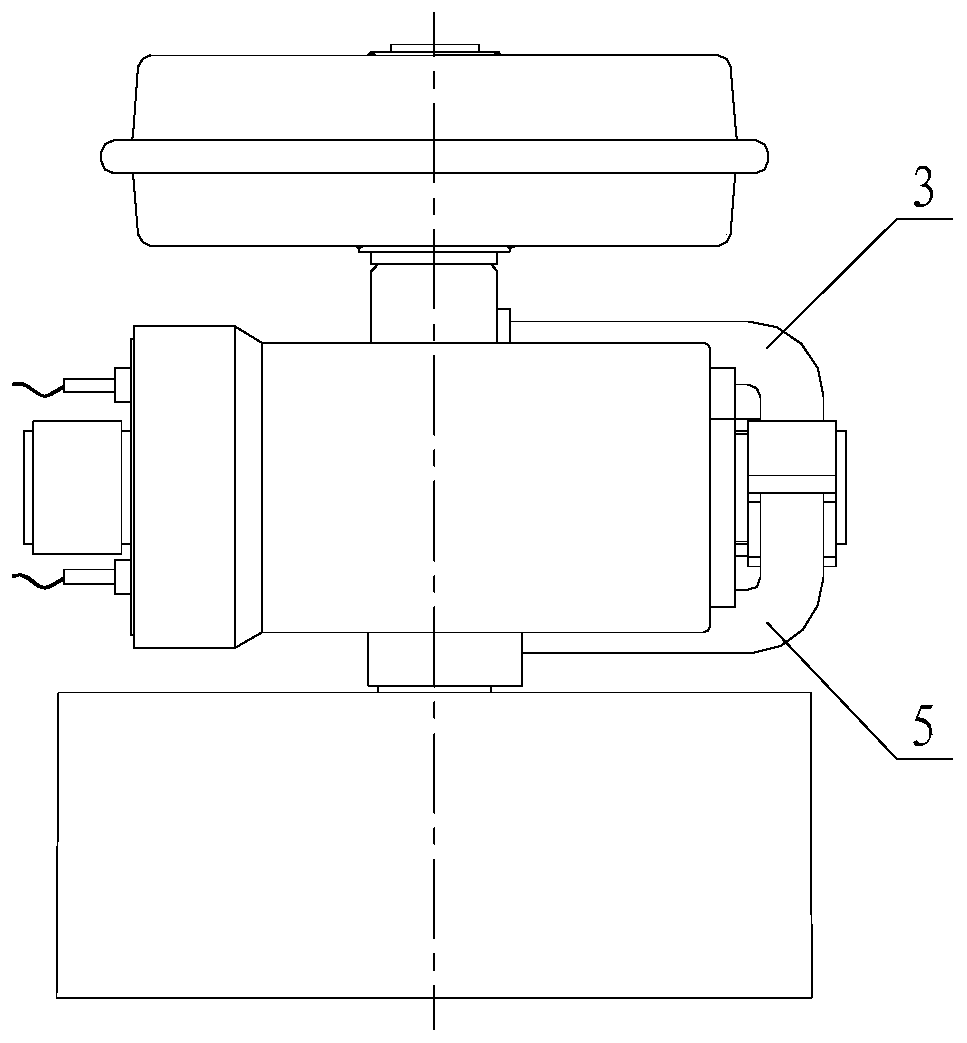

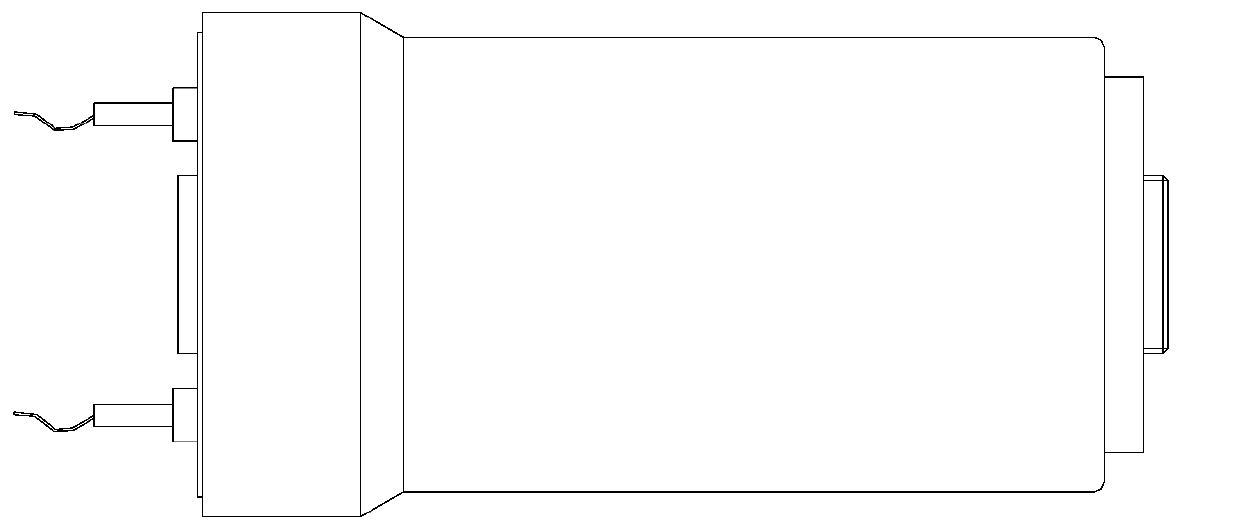

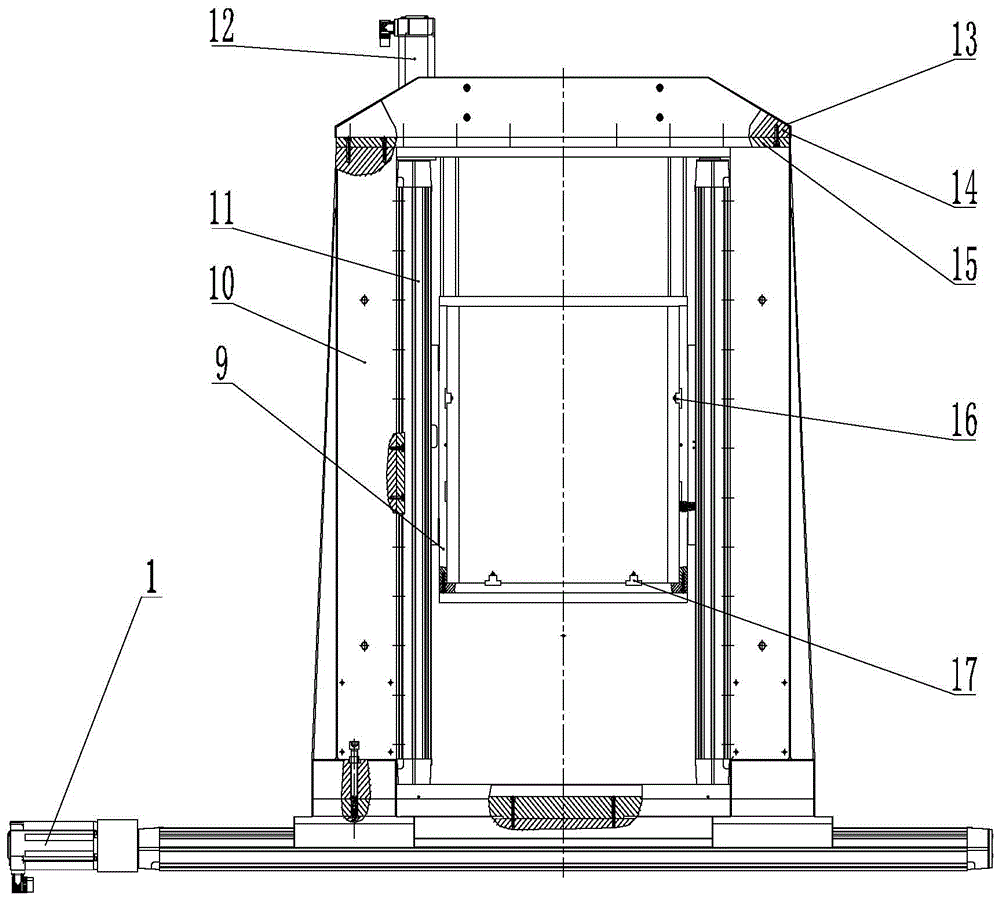

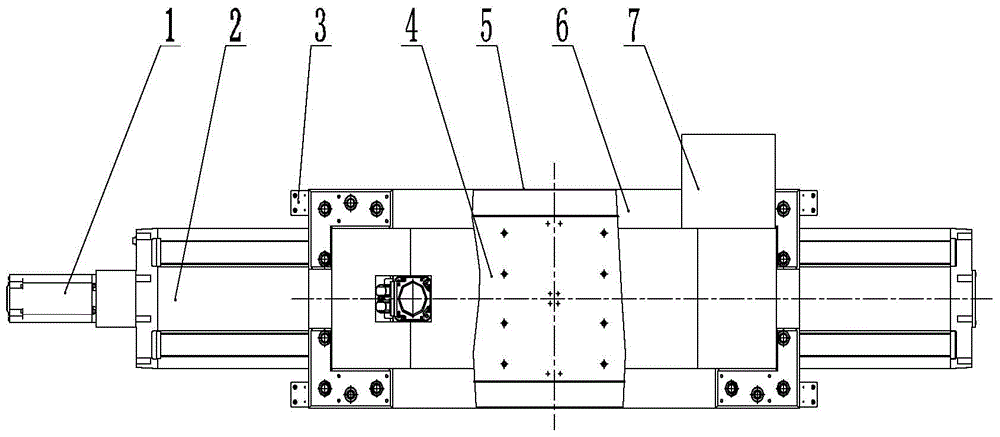

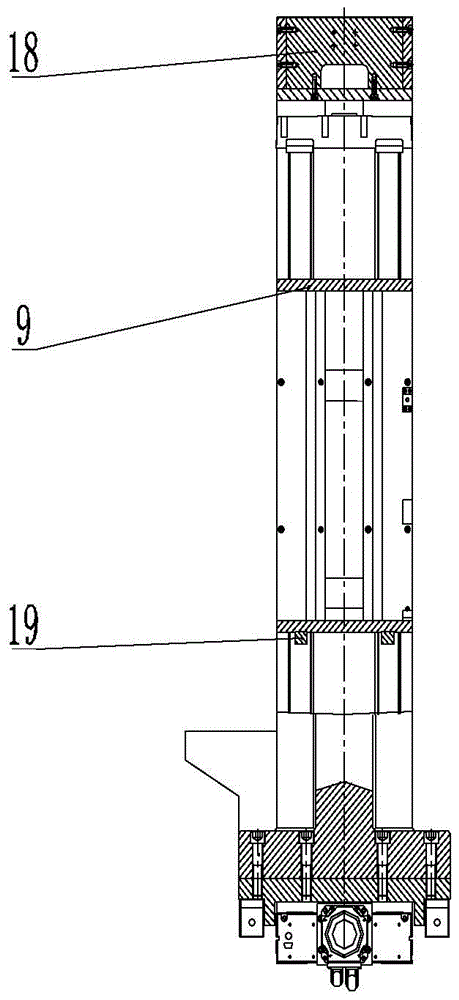

Vertically-arranged two-dimensional large-stroke rapid moving device for repairing microdefects of surface of large-caliber hook-face optical element

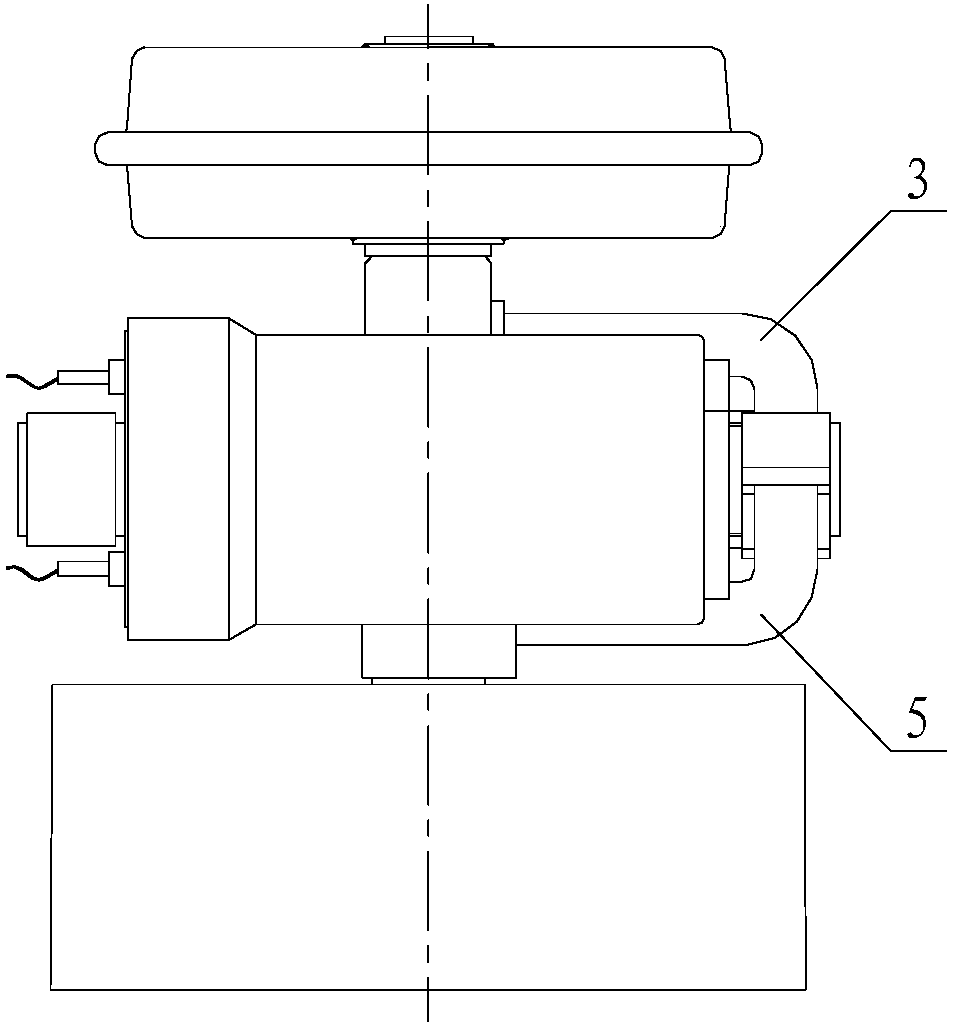

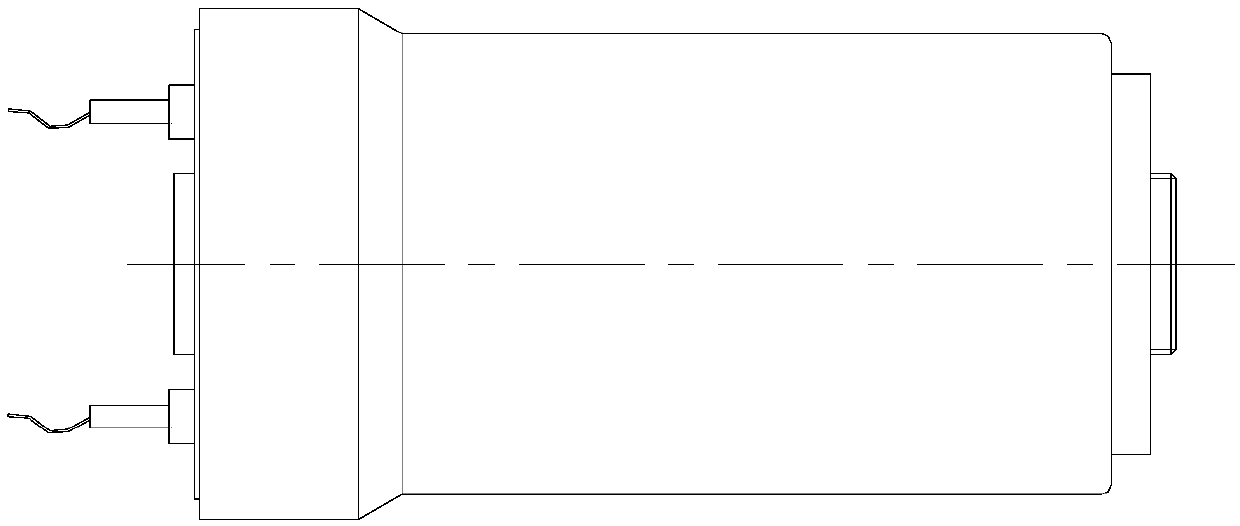

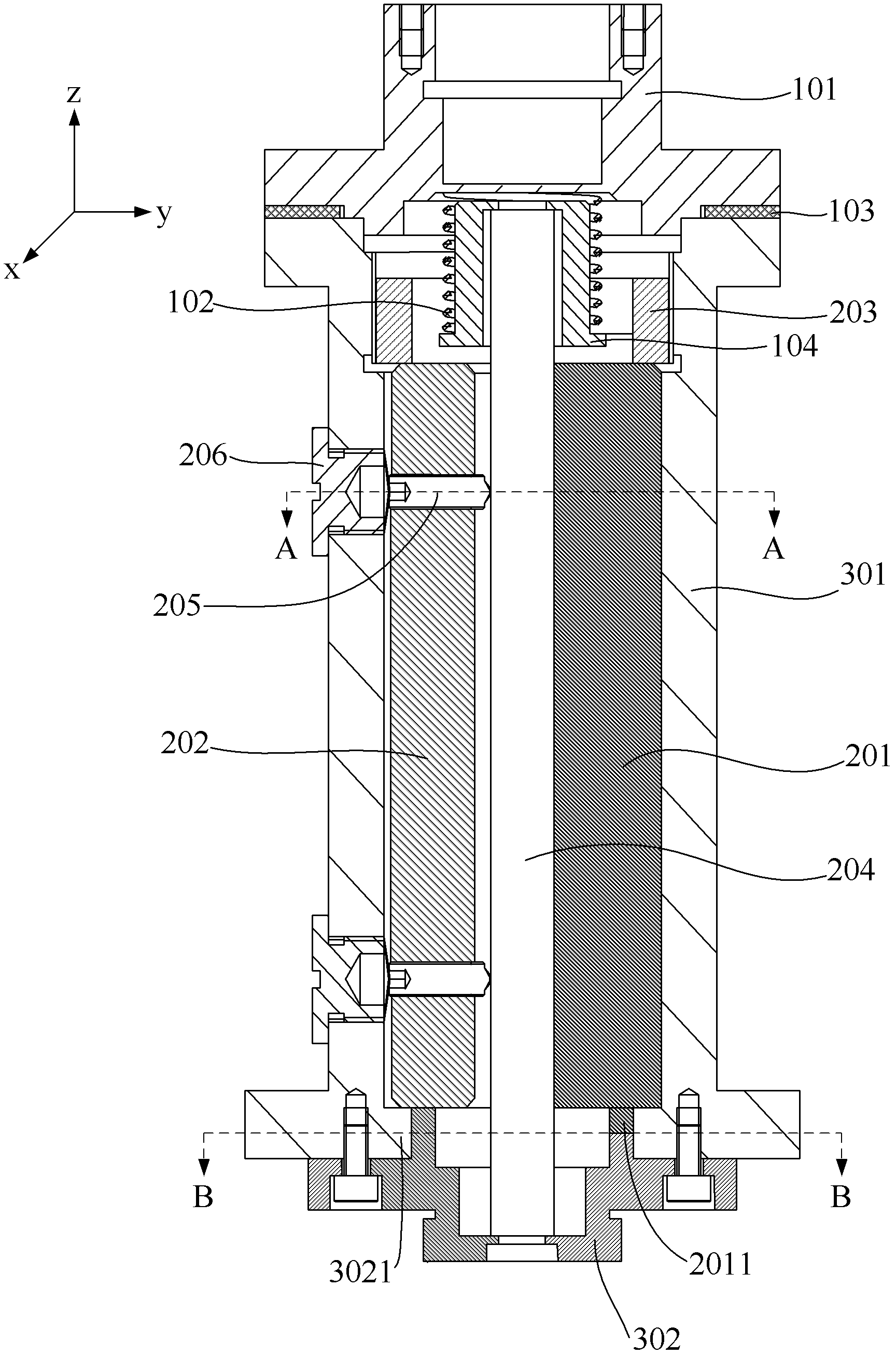

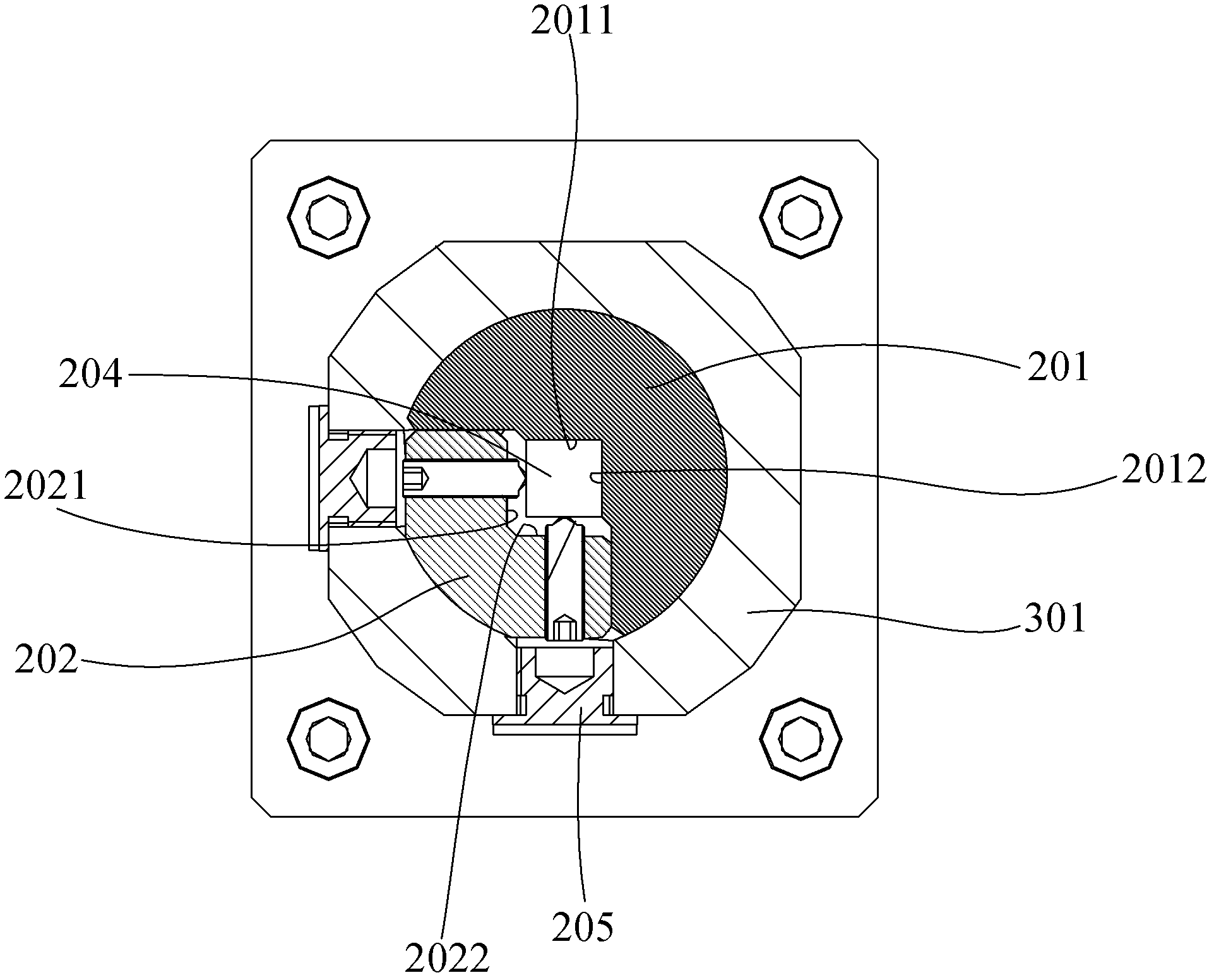

InactiveCN105127591AAchieve vertical placementConducive to horizontal light requirementsMaterial analysis by optical meansLaser beam welding apparatusMotor driveEngineering

The invention discloses a vertically-arranged two-dimensional large-stroke rapid moving device for repairing microdefects of the surface of a large-caliber hook-face optical element, and relates to a two-dimensional large-stroke rapid moving device. The problems that in the existing optical element laser repairing process, the movement speed of a two-dimensional large-stroke rapid moving device is low among three stations, and installation errors are caused by multiple times of clamping are solved. An X-axis servo motor drives an X-axis movement guide rail to linearly move in the X-axis direction. A load bearing plate is fixed to a guide rail sliding table. A portal frame structure is formed by two stand columns and a transverse portal plate. A closed structure is defined by two vertical portal plates, portal rib plates and the transverse portal plate. Two Y-axis movement guide rails are fixed to the inner sides of the two stand columns respectively. A Y-axis servo motor drives one Y-axis movement guide rail to vertically move. A left border and a right border of a load bearing frame are fixed to guide rail sliding tables of the two Y-axis movement guide rails respectively. The vertically-arranged two-dimensional large-stroke rapid moving device is suitable for repairing the microdefects of the surface of the large-caliber hook-face optical element.

Owner:HARBIN INST OF TECH +1

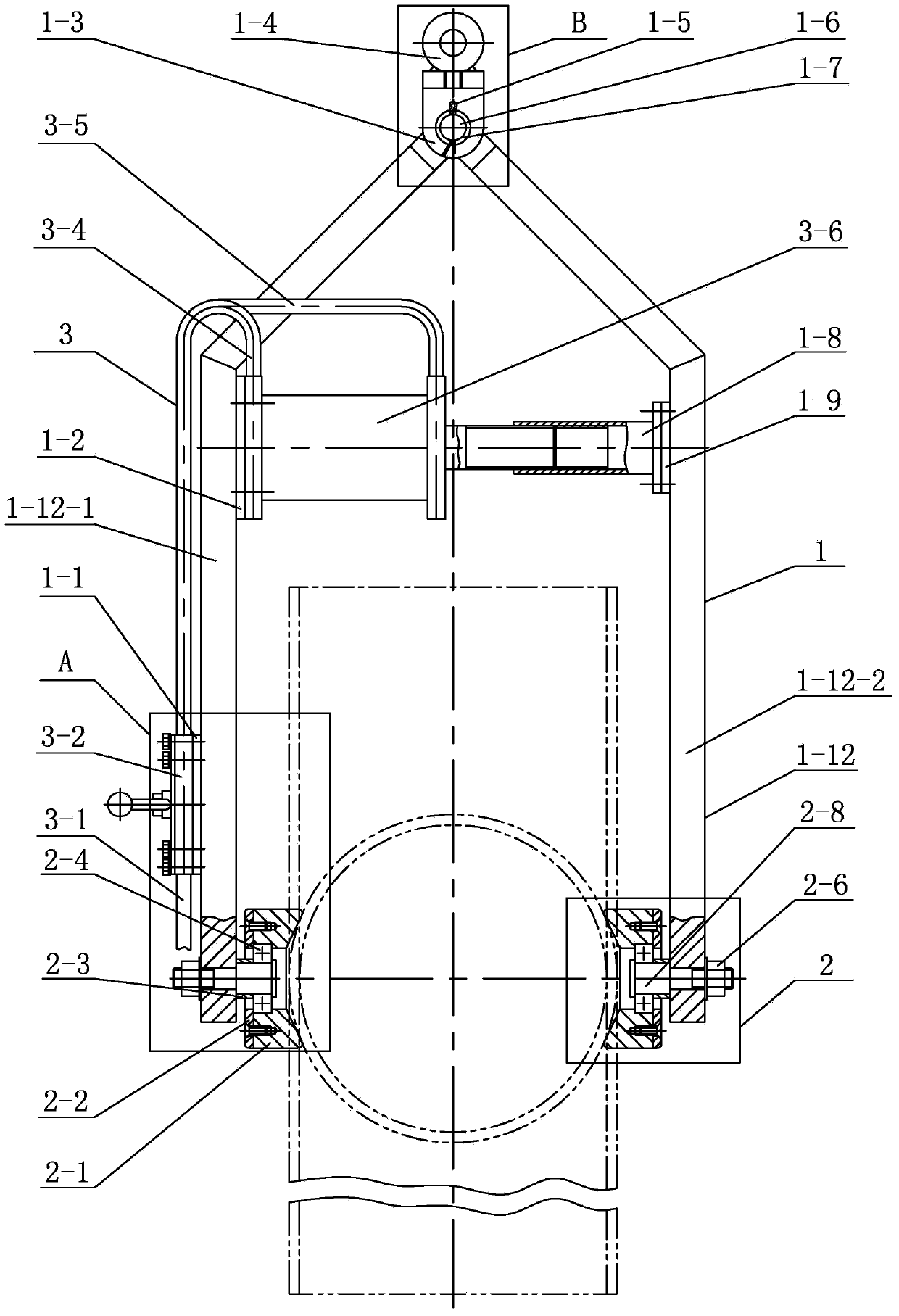

Pneumatic clamping machine for lifting and self-weight turning of steel pipe for heating

The invention discloses a pneumatic clamping machine for lifting and self-weight turning of a steel pipe for heating, and relates to a lifting and clamping device of the steel pipe for heating. The pneumatic clamping machine can be used for the lifting and the clamping of the steel pipe for heating and enables the steel pipe to turn from a horizontal state to a vertical state by dint of self-weight. Two clamping arms are oppositely arranged horizontally; an air distributing valve base is fixed on the outer side surface of the left clamping arm; a cylinder base is fixed on the inner side surface of the left clamping arm; a clamping arm shaft is mounted in first through holes in the upper ends of the two clamping arms and in a first through hole of a clamping arm connecting base; a lifting ring is connected with the clamping arm connecting base; a connecting sleeve base is fixed on the inner side surface of the right clamping arm; a connecting sleeve is fixed on the connecting sleeve base; a piston rod of a cylinder is arranged in the connecting sleeve; the cylinder is fixed on the cylinder base; two clamping head components are fixed at the lower ends of the two clamping arms; an air source guide pipe is communicated with an air reversing valve; the upper and lower ends of a left air guide pipe of the cylinder are communicated with a left cavity of the cylinder and the air reversing valve; and the upper and lower ends of a right air guide pipe of the cylinder are communicated with a right cavity of the cylinder and the air reversing valve. The pneumatic clamping machine is used for lifting, self-weight turning and clamping of the steel pipe for heating.

Owner:HARBIN JIANCHENG GRP

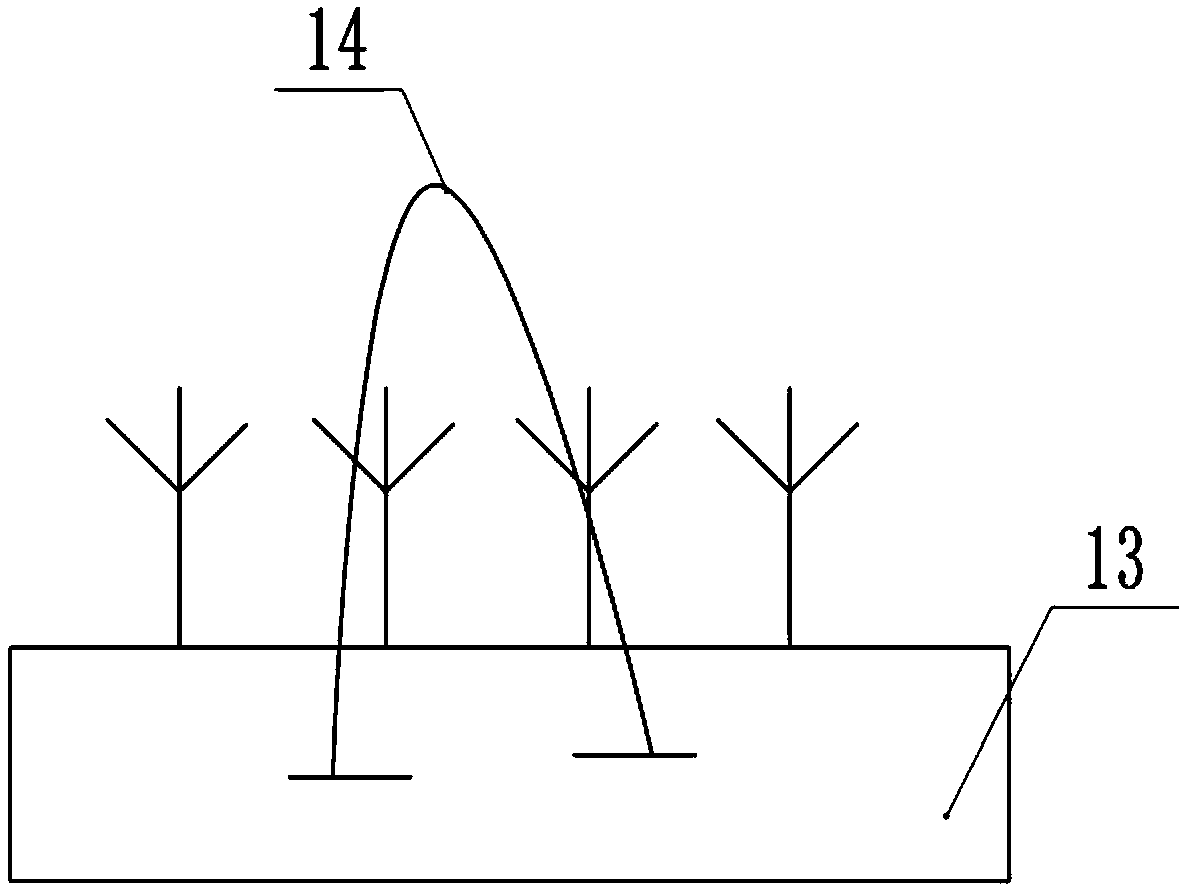

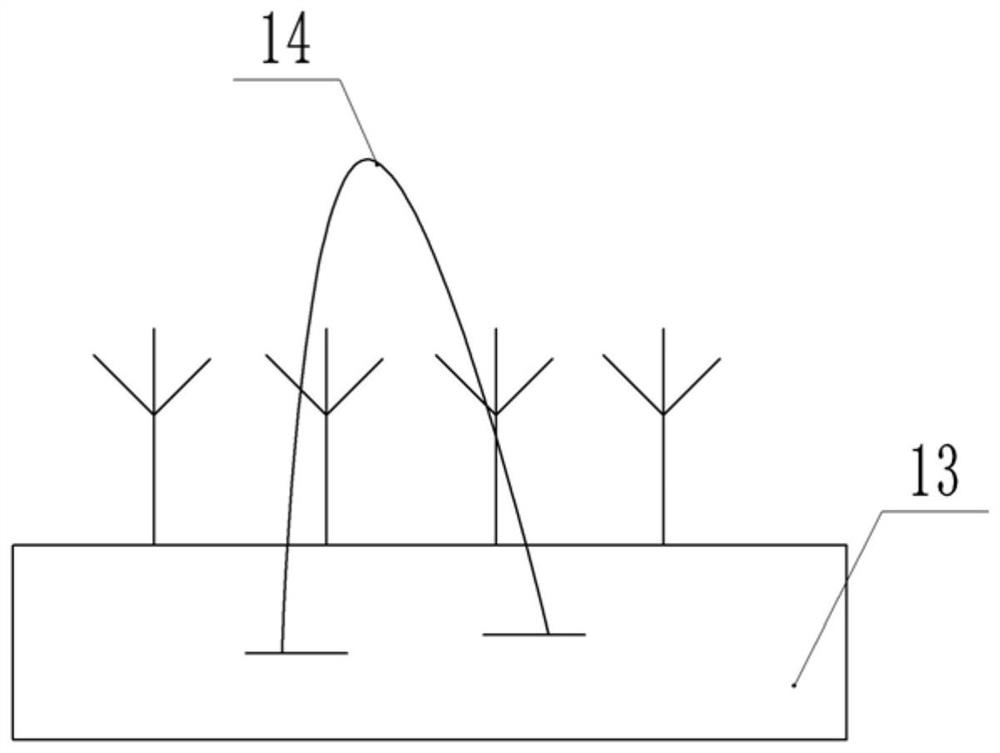

Cultivation planting method for scrophularia ningpoensis

ActiveCN108617451AImprove space utilizationEasy to placeFertilising methodsRoot crop cultivationEngineeringScrophularia ningpoensis

The invention relates to a cultivation planting method for scrophularia ningpoensis. The method comprises the steps of preparing seedbeds and preparing a seedbed frame; and the method specially comprises the following steps: a, performing preparation at the earlier stage: selecting a bottom plate and a pair of clamping plates, and forming through holes in each clamping plate; and preparing supporting plates, limit blocks, fixing blocks, sliding rods, sliding sleeves, springs, connecting rods and the seedbeds; b, installing the bottom plate and the clamping plates; c, installing the supportingplates: enabling each supporting plate to be rotatably connected in the corresponding through hole, and installing each spring in the corresponding through hole; d, connecting the supporting plates: installing the corresponding sliding rod on one end, far away from placing space, of each supporting plate, and installing the corresponding sliding sleeve on each sliding rod; installing the corresponding fixing block on one end, far away from the placing space, of each supporting plate; and enabling two ends of each connecting rod to be separately and rotatably connected with the corresponding fixing block and the corresponding sliding sleeve which are located on adjacent supporting plates; and e, installing the limiting blocks. The method provided by the invention realizes an effect that a plurality of layers of seedbeds can be placed on the seedbed frame, thereby improving a space utilization rate.

Owner:玉环市几偶孵化器有限公司

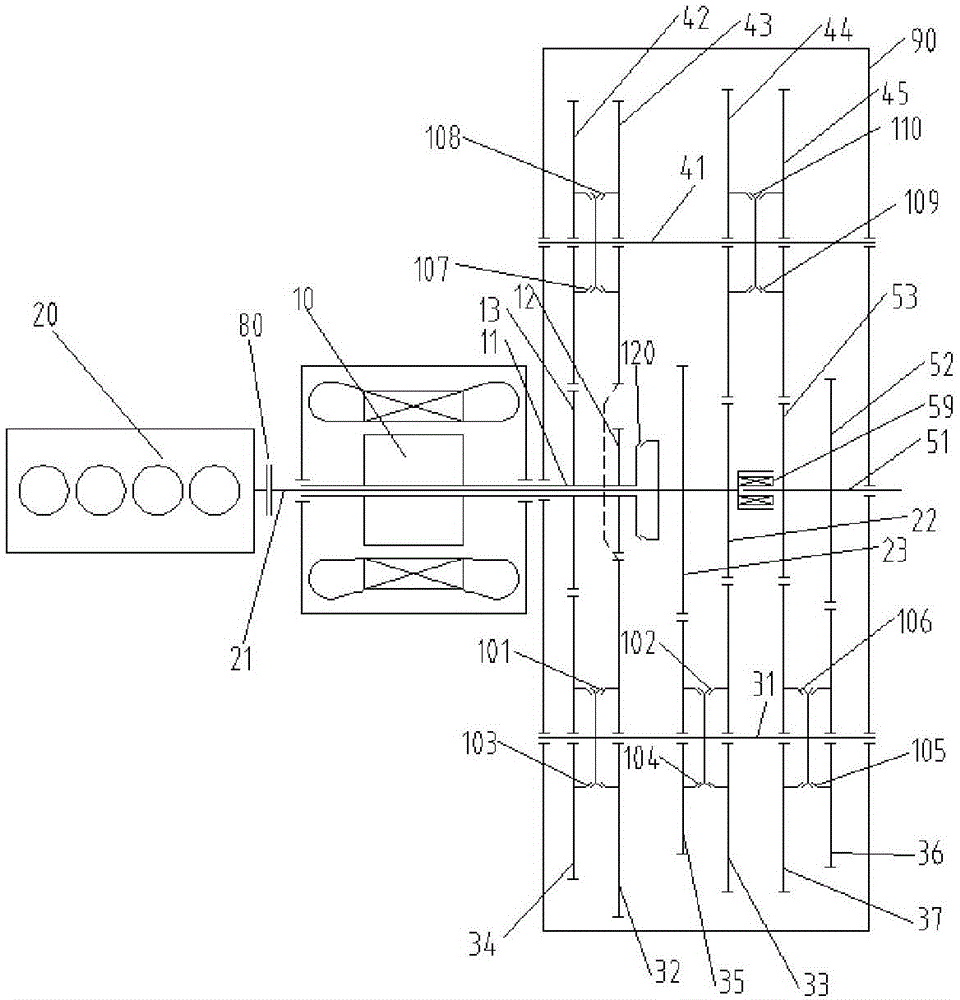

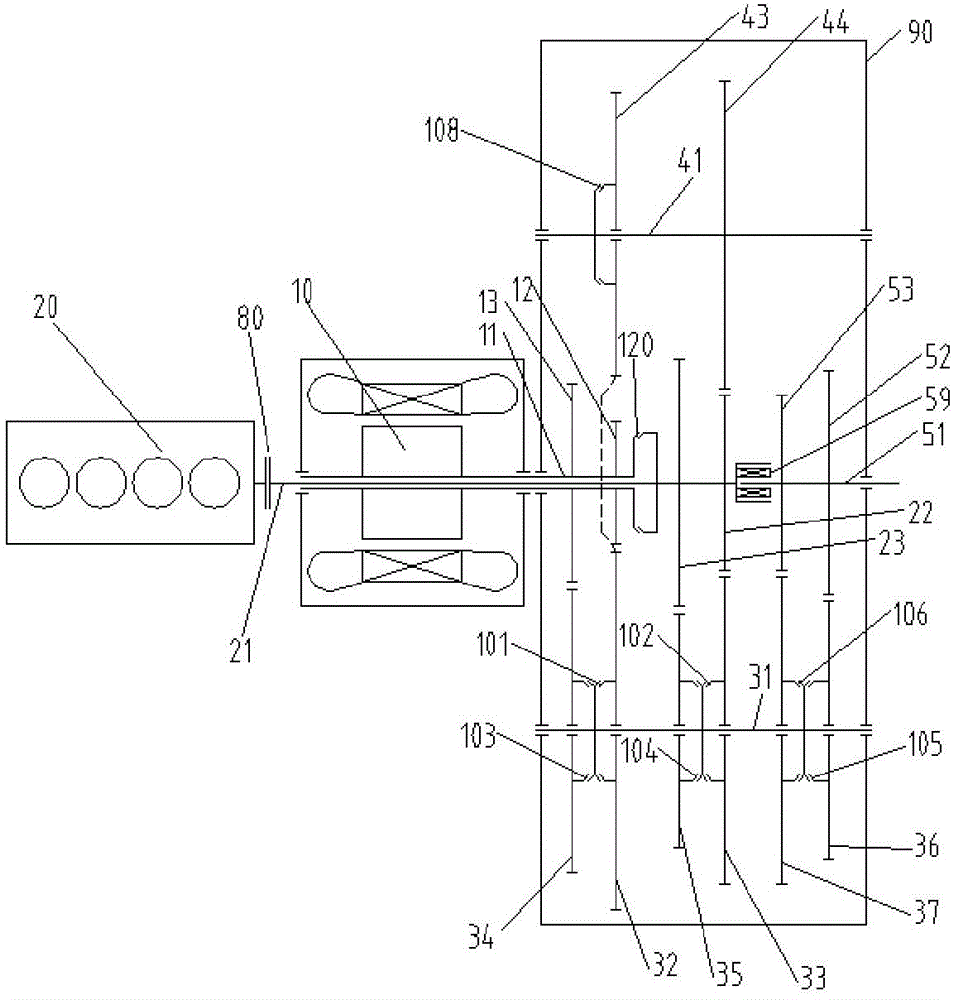

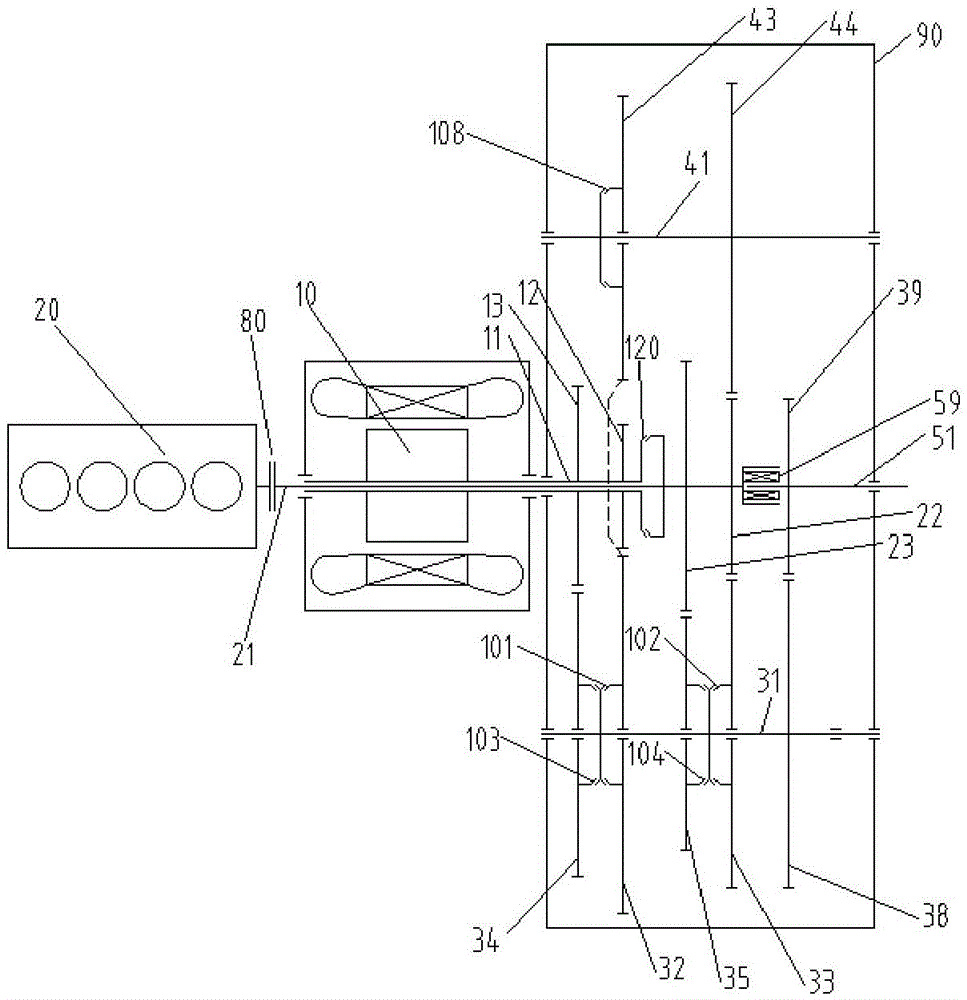

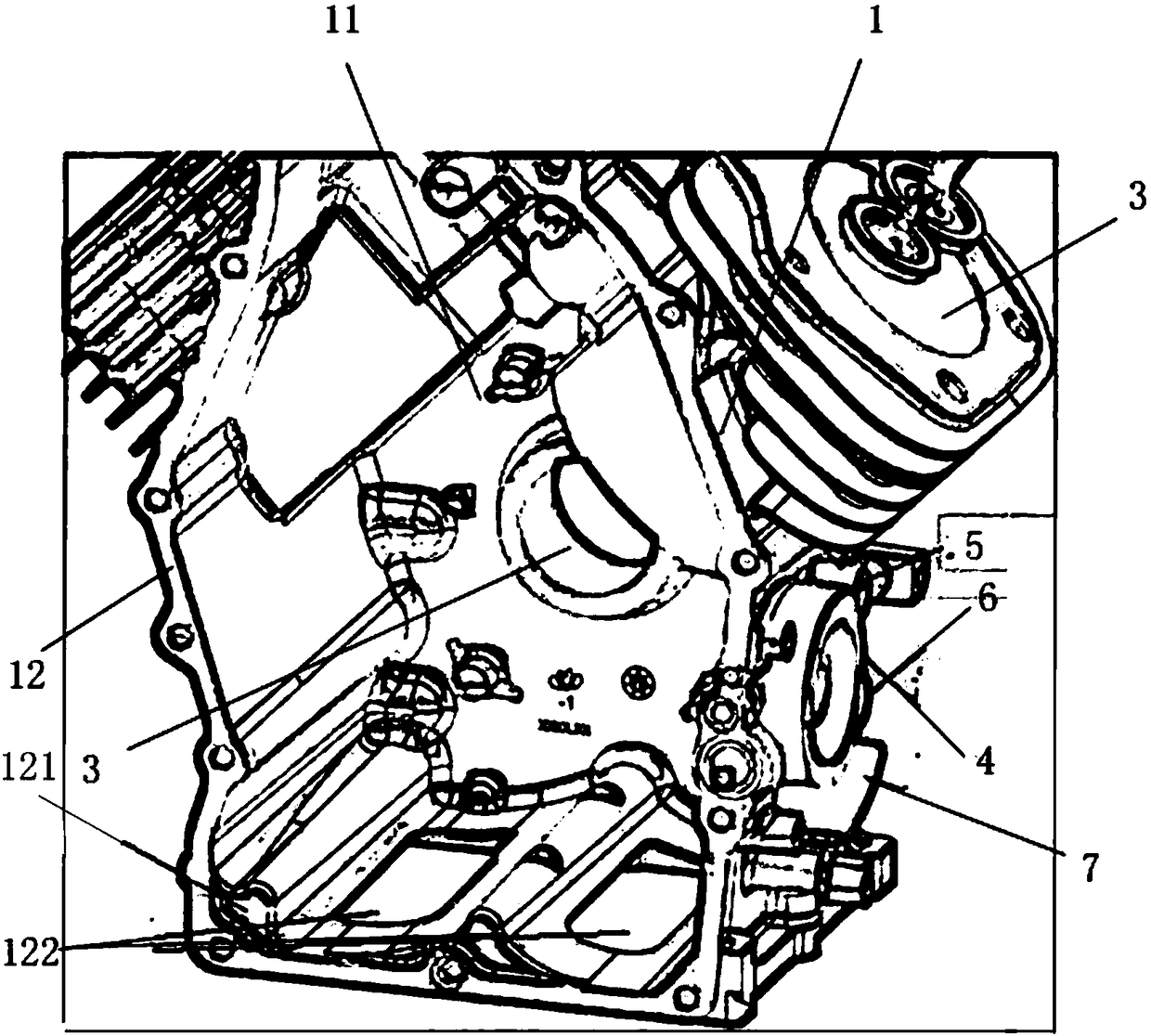

Hybrid power system

InactiveCN104816622AAchieve vertical placementIncrease gearHybrid vehiclesGas pressure propulsion mountingIn vehicleEngineering

The invention discloses a hybrid power system. The hybrid power system comprises a first driving motor, an engine, a clutch and a speed change device; the speed change device comprises a gear box body, a first input shaft, a first clutch transmission unit, a third clutch transmission unit, a second input shaft, a second clutch transmission unit, a fourth clutch transmission unit, an intermediate shaft, a fifth clutch transmission unit, a sixth clutch transmission unit, a gear reversing shaft, a seventh clutch transmission unit, an eighth clutch transmission unit, a ninth clutch transmission unit and an output shaft; the first input shaft is arranged in the gear box body; the first clutch transmission unit and the third clutch transmission unit are corresponding to the first input shaft; the second clutch transmission unit and the fourth clutch transmission unit are corresponding to the second input shaft; the fifth clutch transmission unit and the sixth clutch transmission unit are corresponding to the intermediate shaft; the seventh clutch transmission unit, the eighth clutch transmission unit and the ninth clutch transmission unit are corresponding to the gear reversing shaft. According to the hybrid power system, the longitudinal arrangement of the power system can be implemented, gears under the driving conditions are greatly increased, the engine can participate in vehicle reversing or can be used for independently driving the vehicle reversing, and accordingly the possibility of the operation of the engine in the high efficiency area is greatly improved and the application rage of a vehicle is greatly extended.

Owner:安徽易佳斯动力科技有限公司

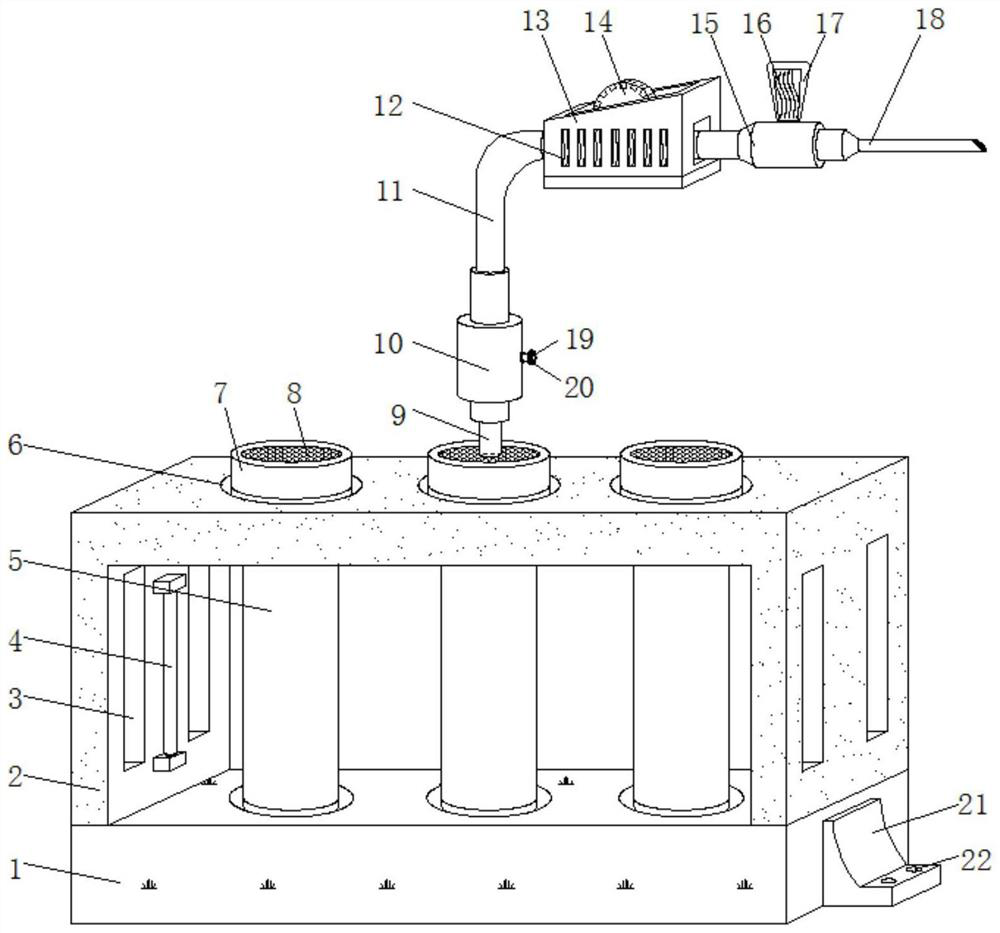

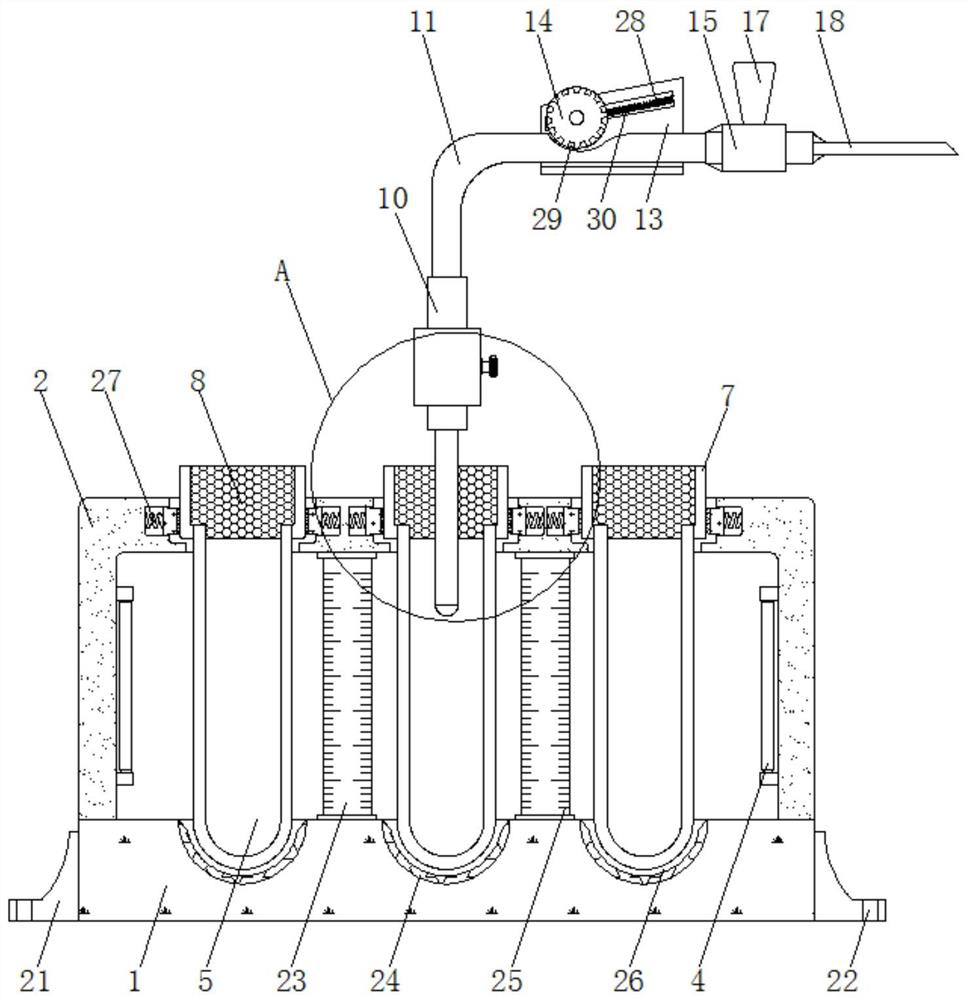

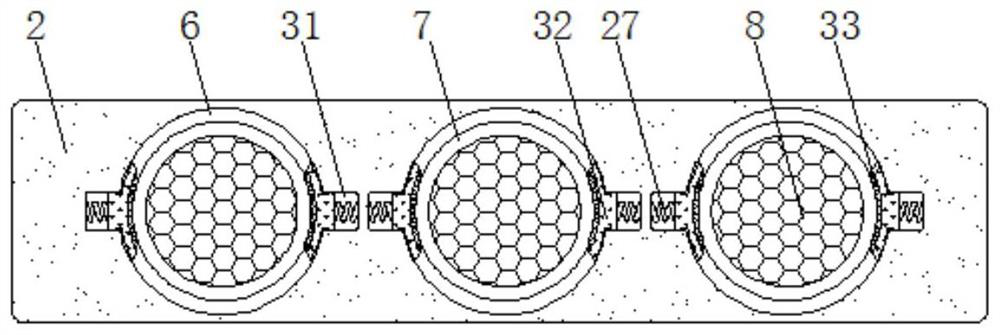

Chemical heater packaging and liquid flow pipe butting apparatus and assembling method

ActiveCN107706434ASave spaceAvoid electro-hydraulic residueDeferred-action cellsZincChemical engineering

The invention discloses a chemical heater packaging and liquid flow pipe butting apparatus and assembling method. The chemical heater packaging and liquid flow pipe butting apparatus is characterizedby at least comprising two chemical heaters, a liquid reservoir positioned above the two chemical heaters and a zinc silver battery positioned below the two chemical heaters, wherein the two chemicalheaters are arranged in parallel and positioned in the same horizontal plane; the two chemical heaters include a chemical heater A and a chemical heater B; the liquid outlet of the chemical heater A and the liquid inlet of the chemical heater B are positioned on the same side; a second connecting pipe is arranged between the liquid outlet of the chemical heater A and the liquid inlet of the chemical heater B; the two ends of the second connecting pipe are connected with the two chemical heaters through compressing screws; the bottom of the liquid reservoir is connected with the liquid inlet ofthe chemical heater A through a first connecting pipe; and the liquid outlet of the chemical heater B is connected with the liquid inlet of the zinc silver battery through a third connecting pipe.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 18 RES INST

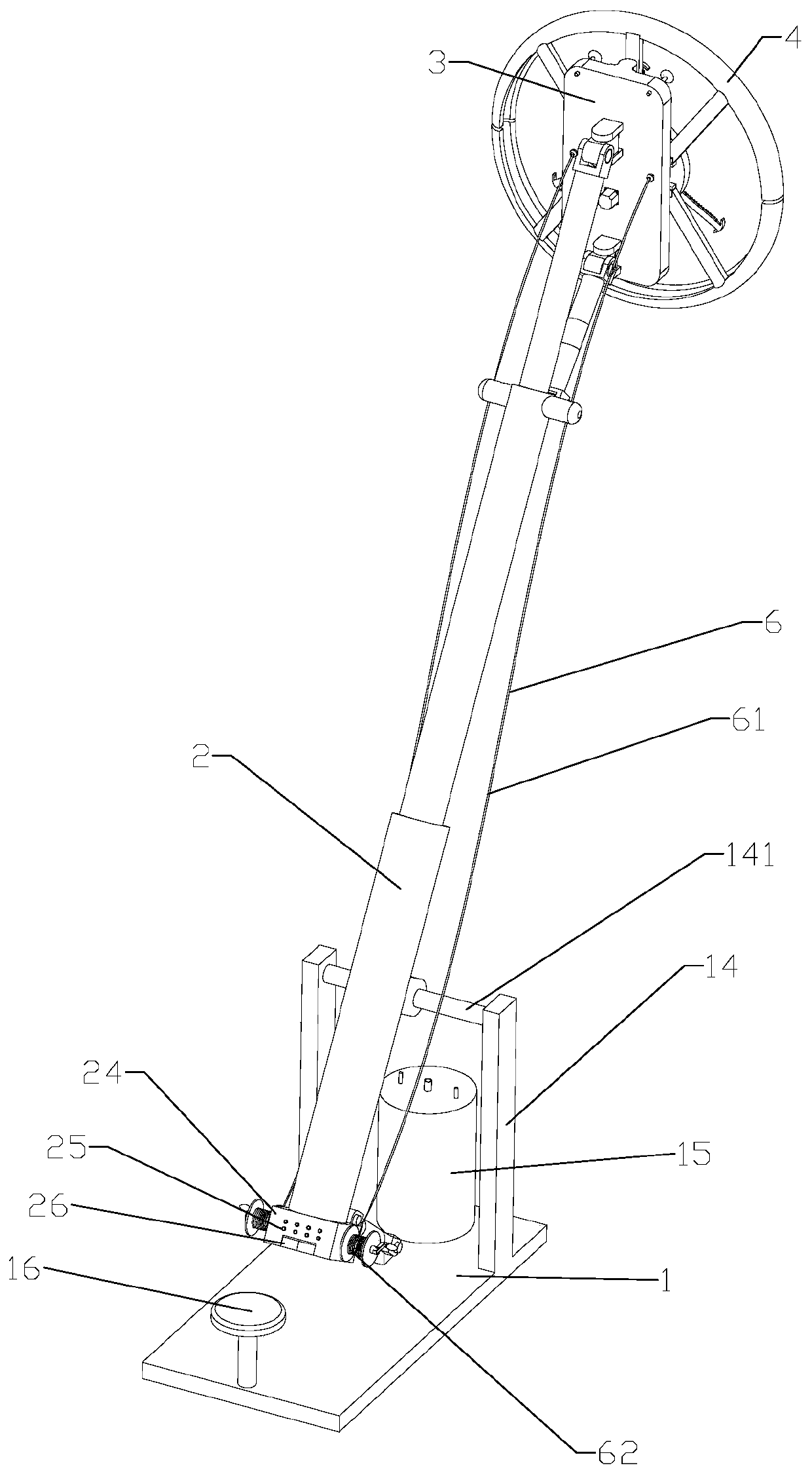

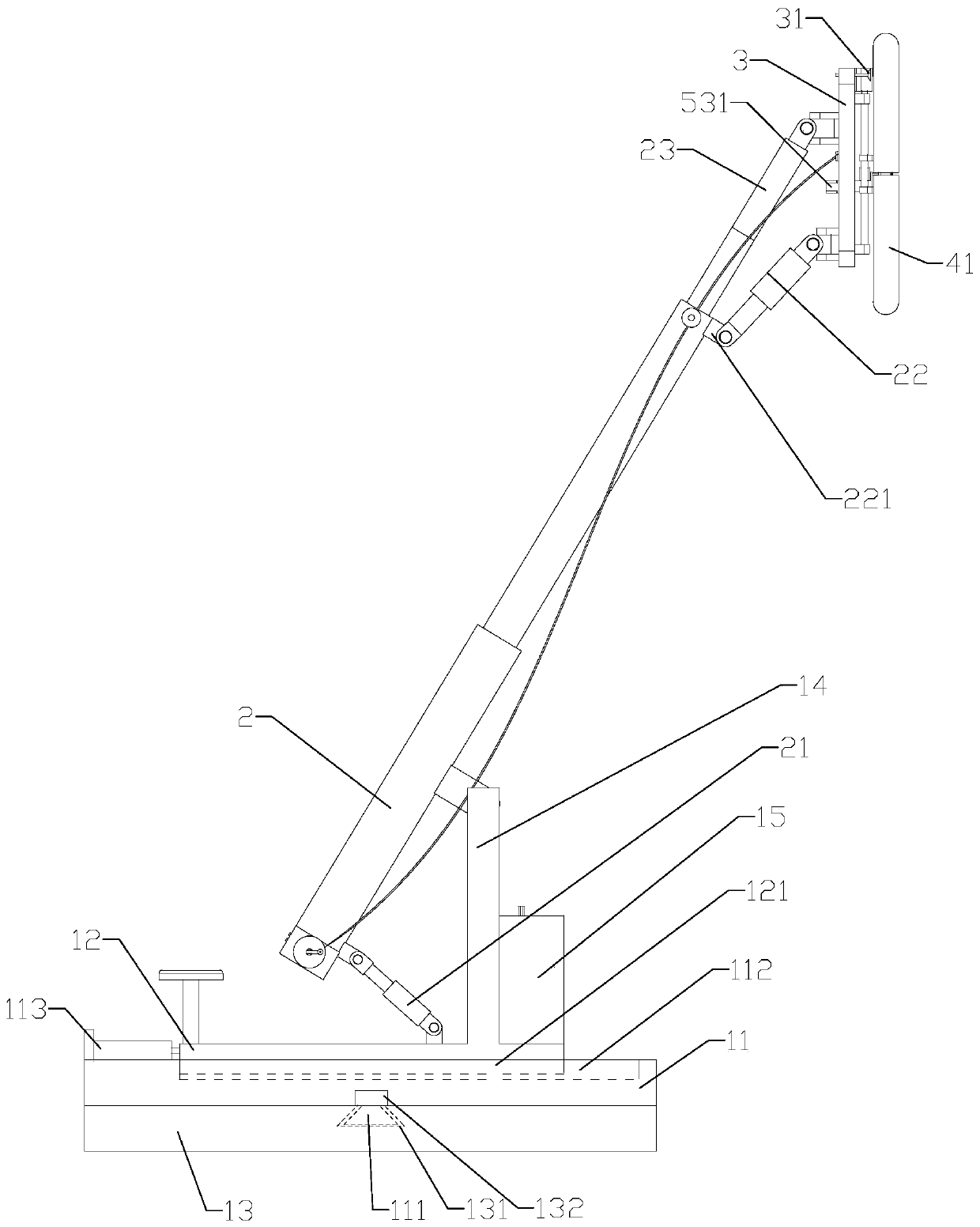

Highway signboard cleaning machine

InactiveCN110116107AQuick cleanReplace manual workCleaning using toolsCleaning using liquidsHydraulic cylinderSafe operation

The invention discloses a highway signboard cleaning machine. The highway signboard cleaning machine comprises a base, a lifting arm and a support plate; the base is fixed on a vehicle body; the lifting arm is a multistage hydraulic cylinder; two vertical rods are symmetrically arranged on the upper surface of the front end of the base; a horizontal support rod is fixedly connected between the twovertical rods; the lower part of the lifting arm is hinged to the support rod; and the bottom end of the lifting arm is hinged to the base through a lifting cylinder. The support plate is a square plate; the upper part of the back side of the support plate is in intersecting connection with the top end of the lifting arm; and the lower part of the back side of the support plate is hinged to the upper part of the lifting arm through an adjusting cylinder. The support plate is provided with a nozzle, a clamping device and a cleaning device; and the clamping device comprises a clamping plate, aslide base and a slide base driving mechanism. The cleaning device comprises a rotating disc, a scraper and a rotating disc driving mechanism. The highway signboard cleaning machine has the characteristics of quick cleaning, replacement of manual operations and safe operation.

Owner:刘凌晓

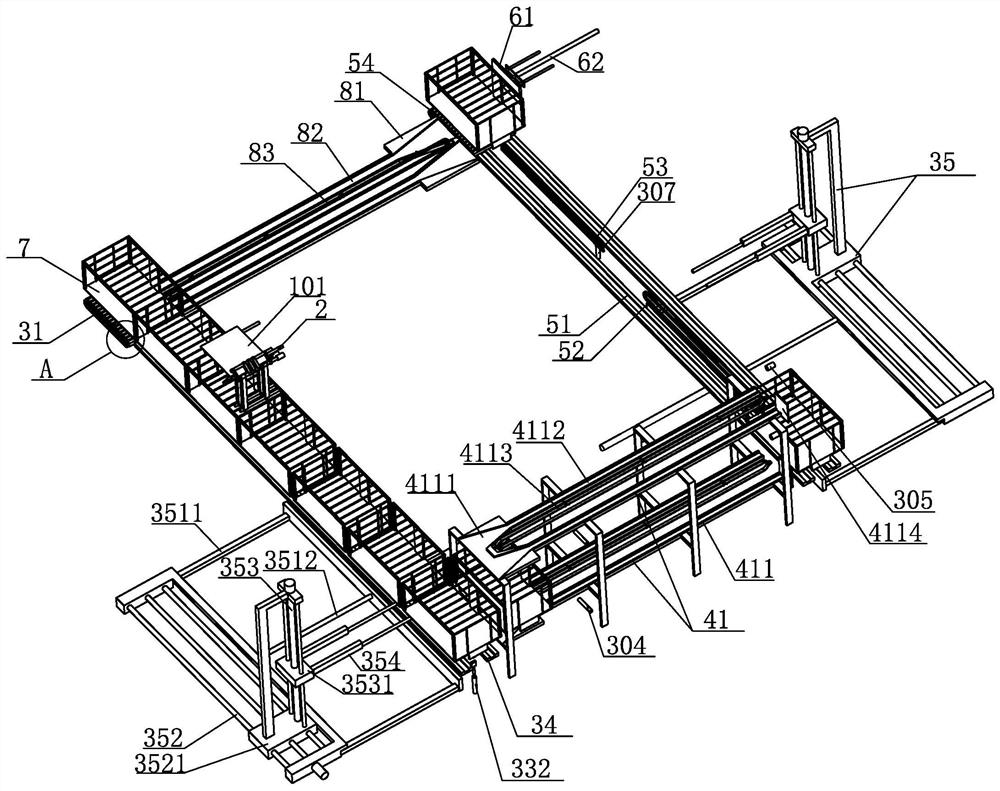

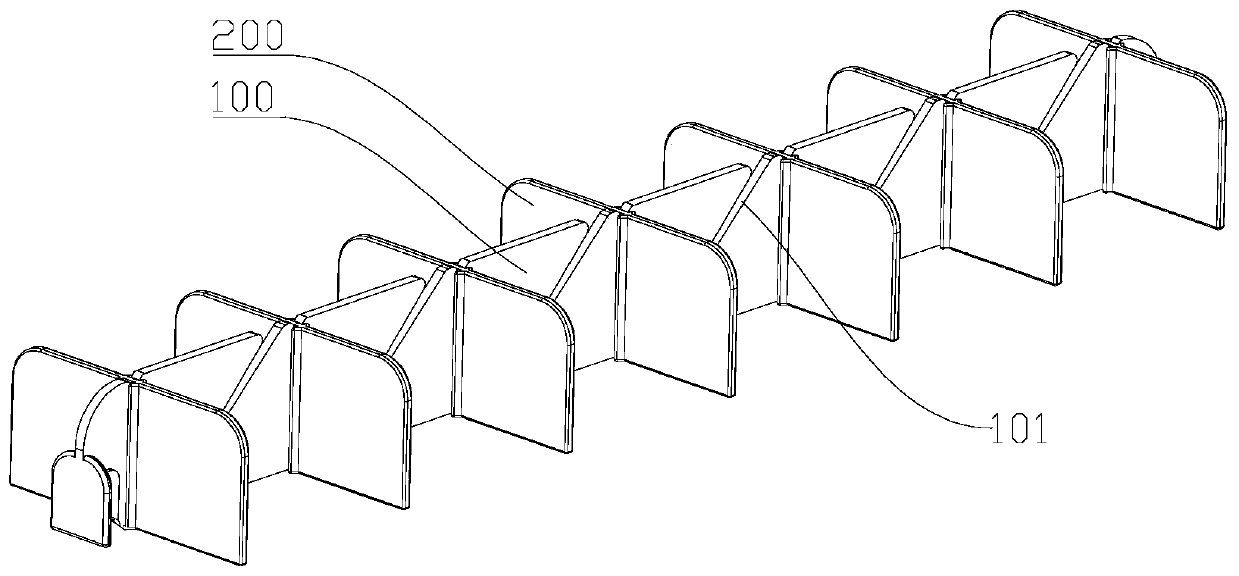

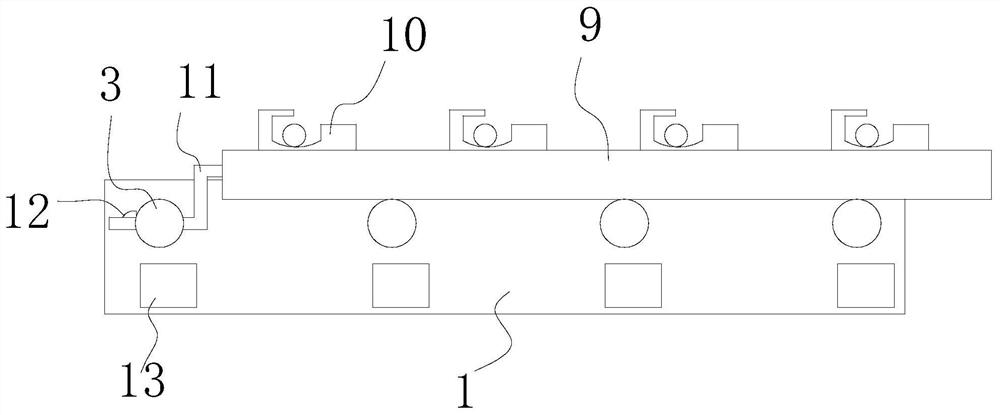

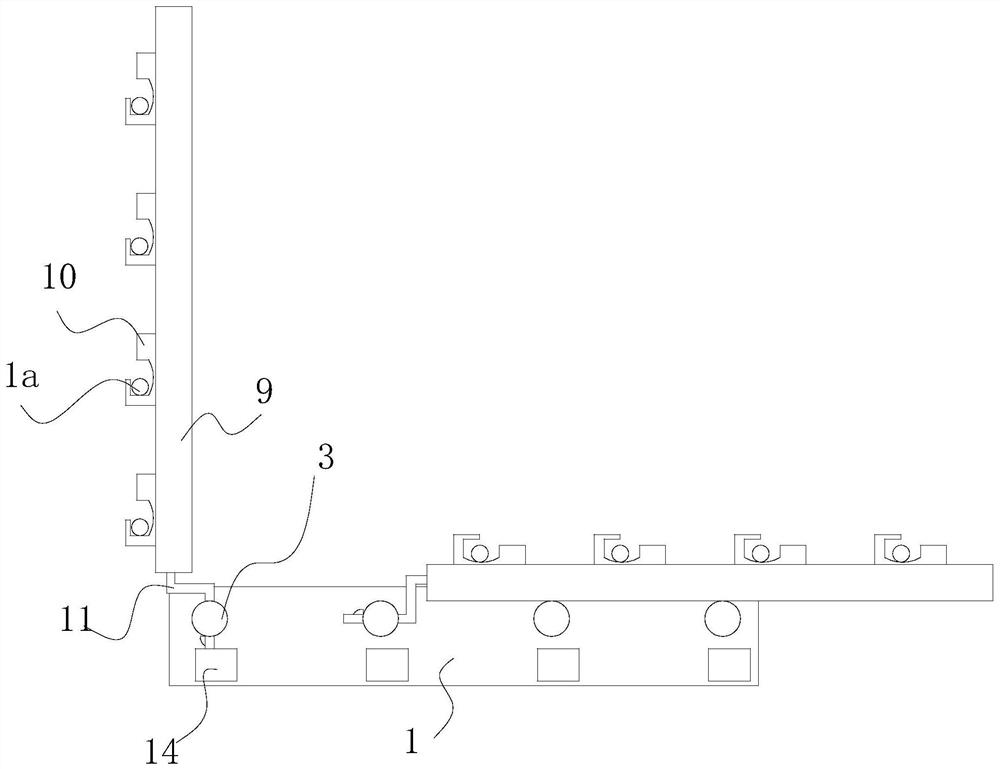

Veneer inserting, veneer airing and veneer stacking and collecting integrated assembly line

PendingCN112173554AAutomate operationAchieve vertical placementConveyorsDrying solid materialsStructural engineeringAssembly line

The invention provides a veneer inserting, veneer airing and veneer stacking and collecting integrated assembly line of a veneer inserting mechanism. The veneer inserting, veneer airing and veneer stacking and collecting integrated assembly line of the veneer inserting mechanism comprises a veneer inserting assembly line, a veneer airing assembly line, a veneer stacking and collecting assembly line, a buffer assembly line, a carrying mechanism and a plurality of veneer conveying racks; the veneer inserting assembly line, the veneer airing assembly line, the veneer stacking and collecting assembly line and the buffering assembly line are end to end in sequence to form a circulating assembly line; and a controller can control the veneer inserting assembly line, the veneer airing assembly line, the veneer stacking and collecting assembly line, the buffering assembly line and the carrying mechanism to operate in a matched mode. According to the veneer inserting, veneer airing and veneer stacking and collecting integrated assembly line of the veneer inserting mechanism, mechanical operation of collection before veneer inserting, veneer airing and veneer stacking is achieved, so that thelabor intensity of workers can be greatly reduced, and the veneer processing efficiency is improved.

Owner:刘全满

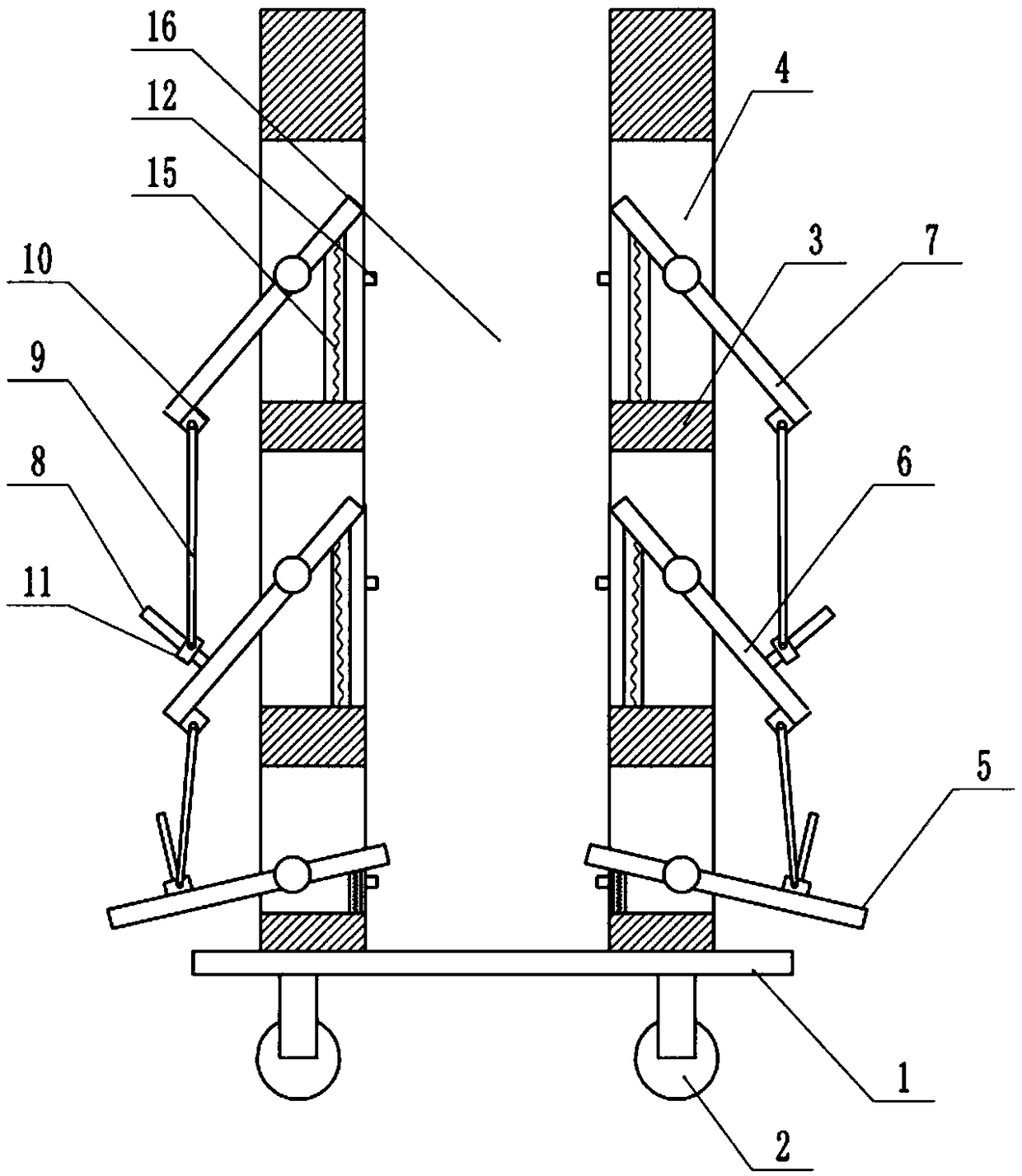

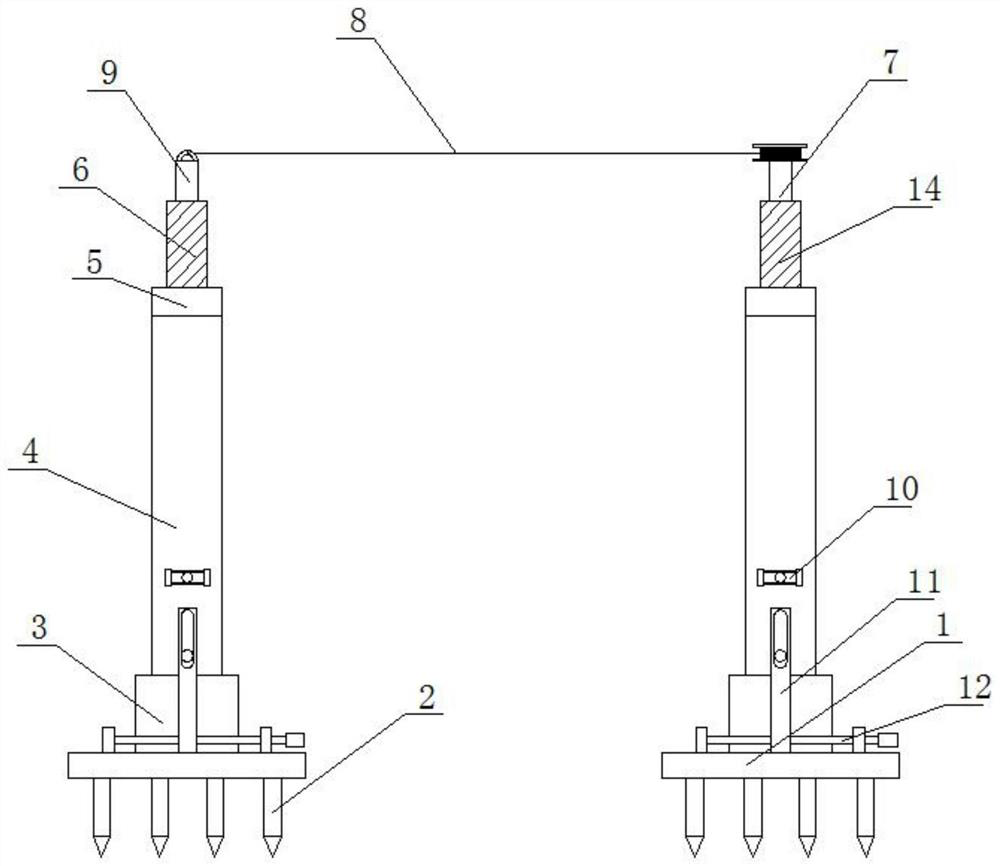

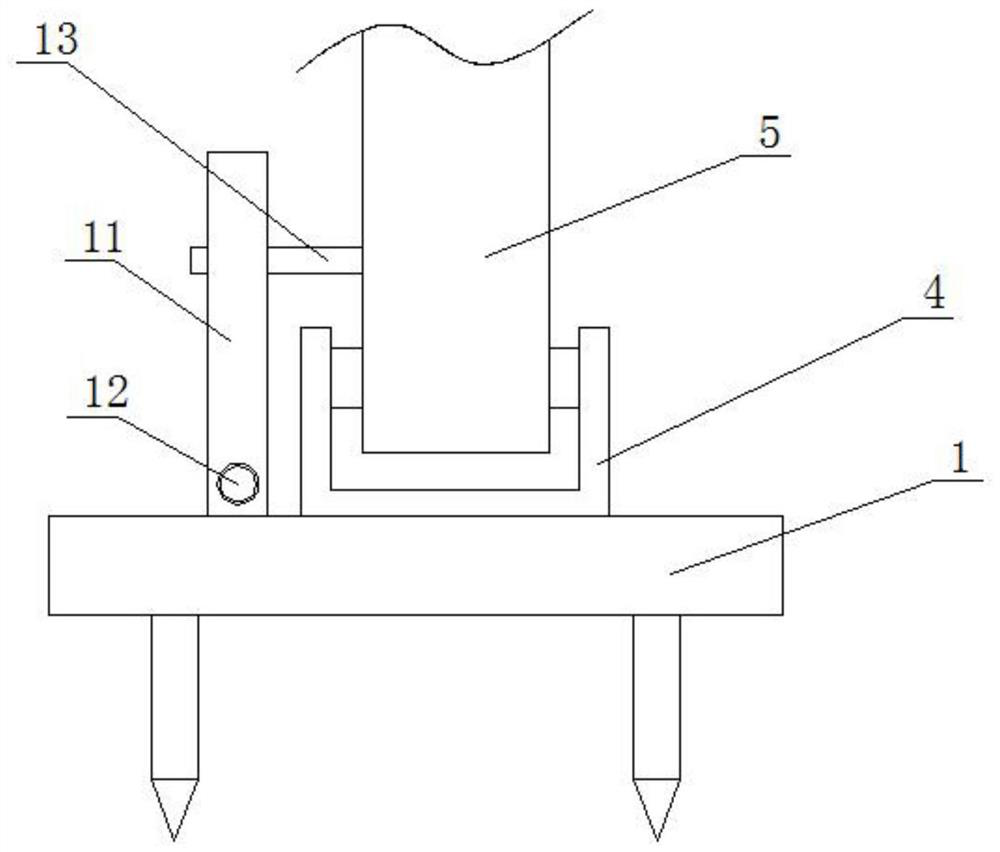

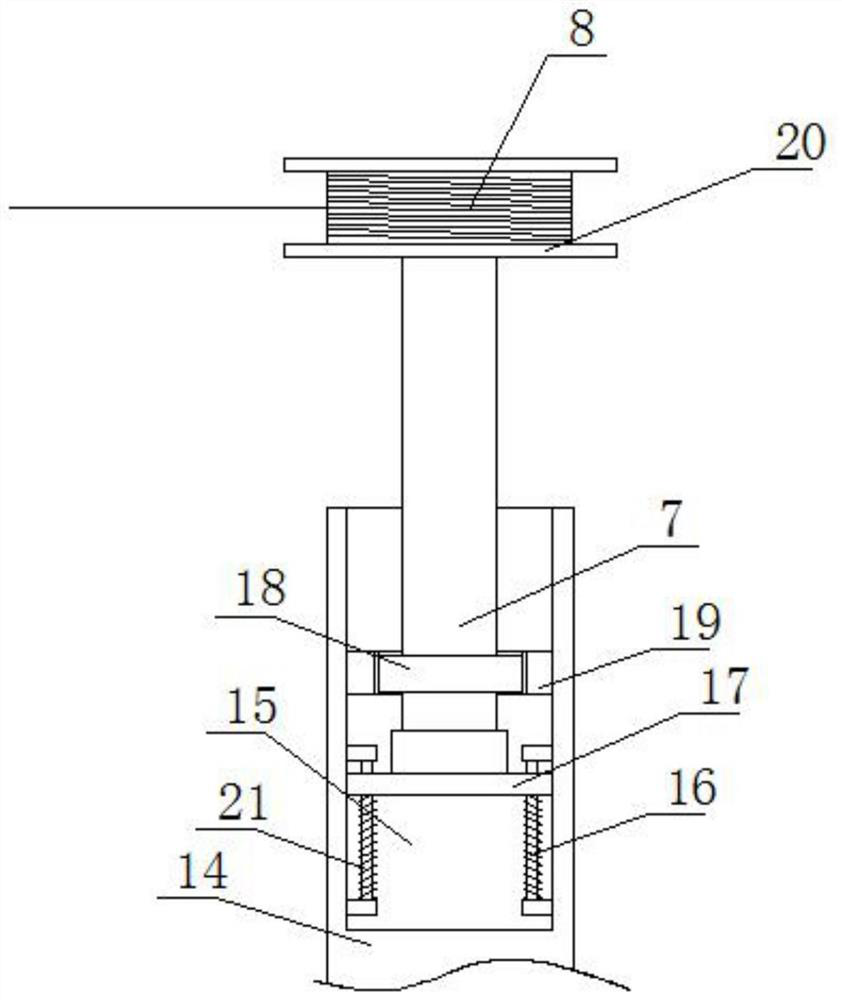

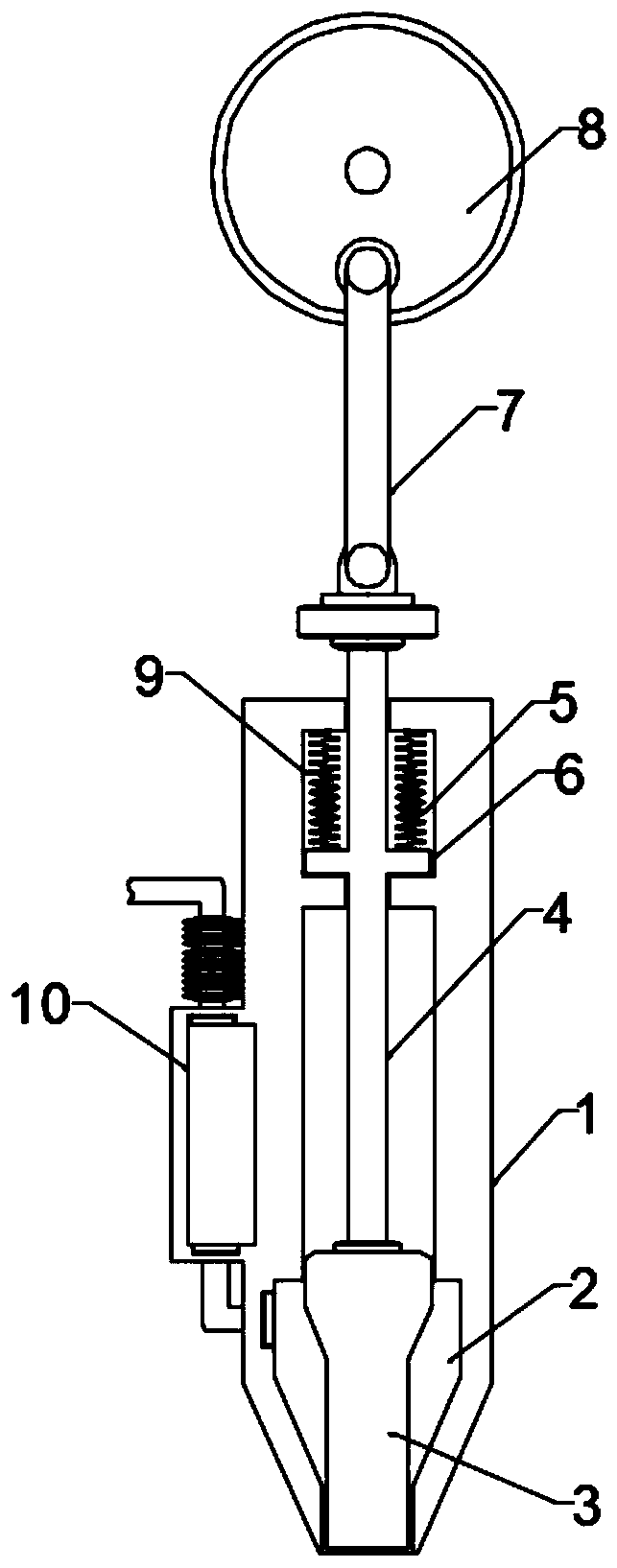

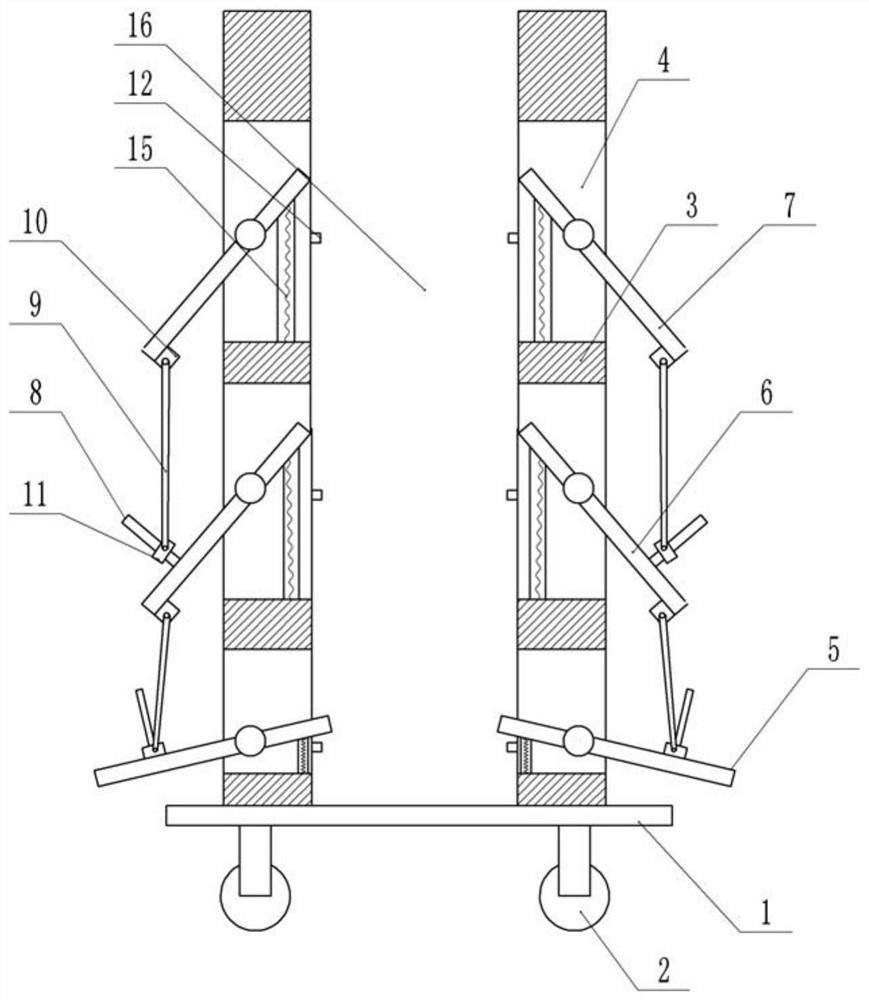

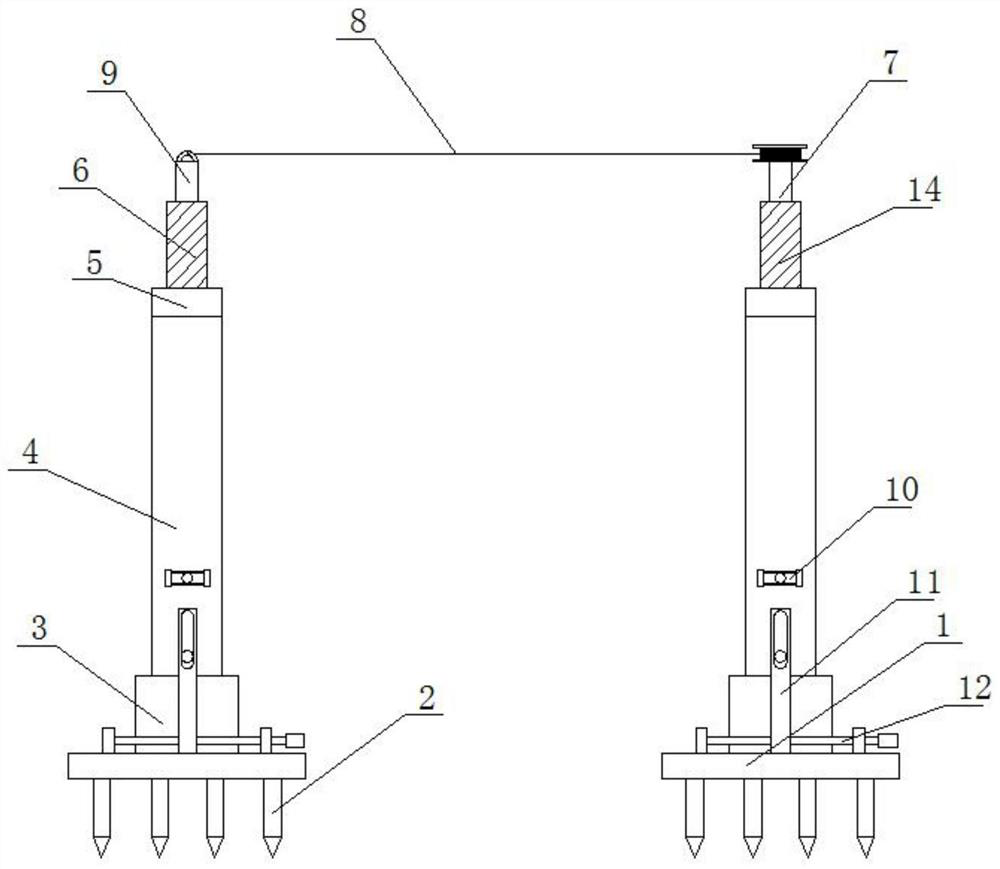

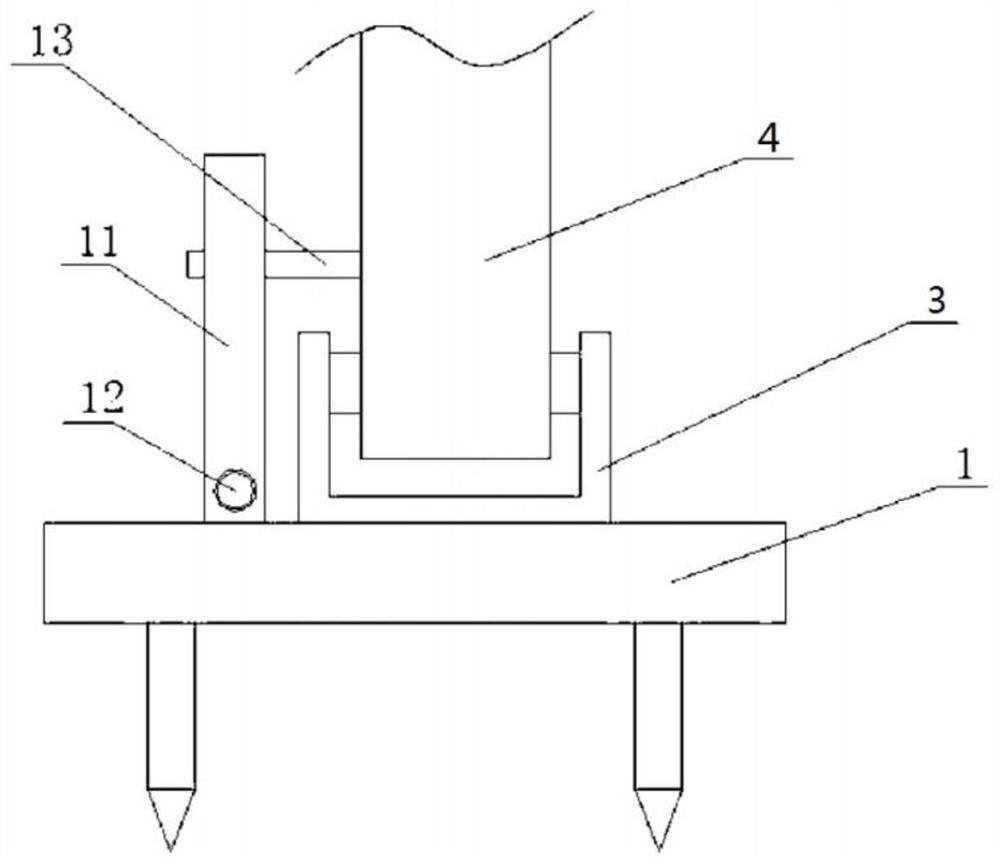

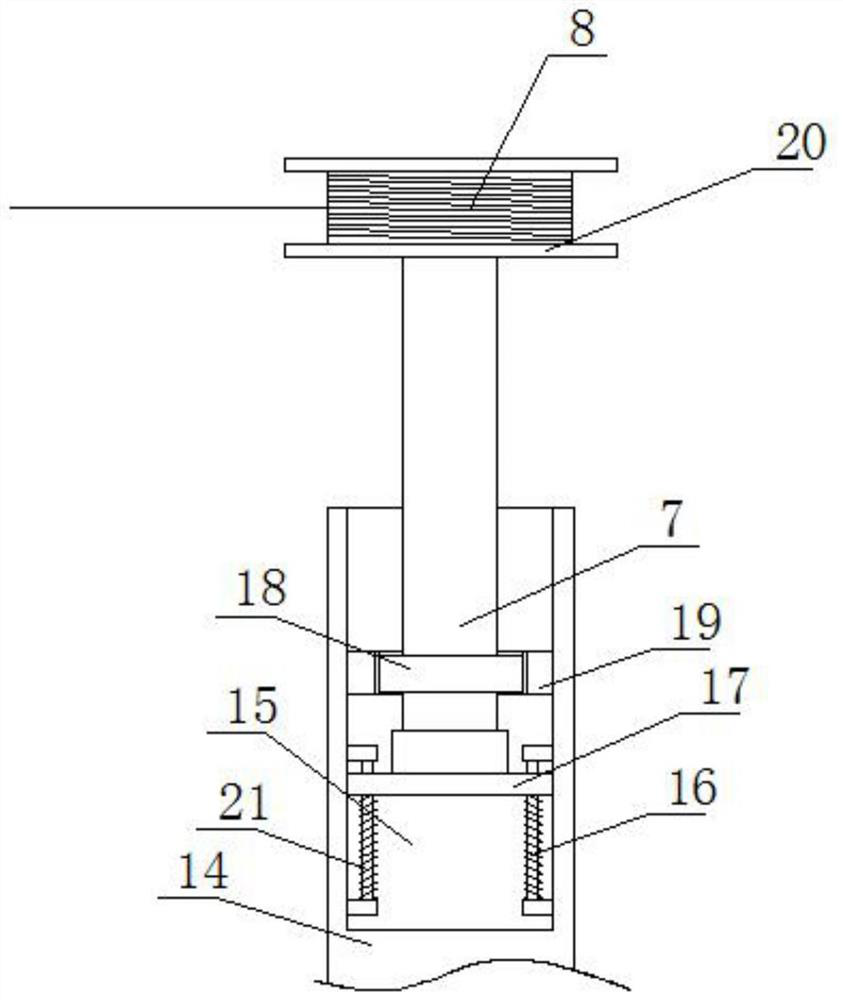

Wall building equipment for building construction engineering

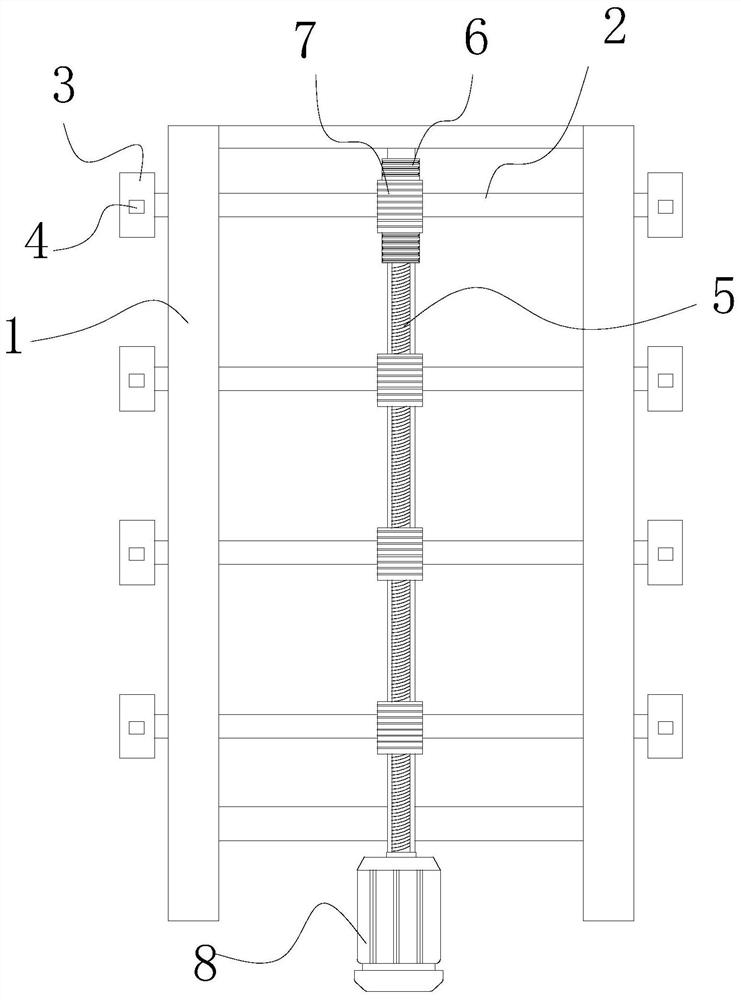

ActiveCN112049442AHeight adjustableAchieve vertical placementBuilding material handlingArchitectural engineeringScrew thread

The invention belongs to the field of buildings, and particularly relates to wall building equipment for building construction engineering. The wall building equipment aims to solve the problem that an existing auxiliary line cannot be conveniently adjusted and is often fixedly arranged at a certain position, so that the existing auxiliary line is not convenient to use. The following scheme is provided: the wall building equipment comprises two supporting plates. A plurality of pins are fixedly installed at the bottoms of the supporting plates at equal intervals. The tops of the supporting plates are rotationally connected with supporting covers. The tops of the supporting covers are rotationally connected with nuts, and the two nuts are in threaded connection with a first screw and a second screw correspondingly. According to the wall building equipment for building construction engineering, the supporting covers can be vertically placed after being fixedly installed on the ground, the height of an auxiliary line can be adjusted, and therefore when the wall building equipment is used, the wall surface can be in a standard state in the vertical direction and the horizontal direction, and compared with a traditional auxiliary device, the technical scheme has good practicability.

Owner:广东聚源建设集团有限公司

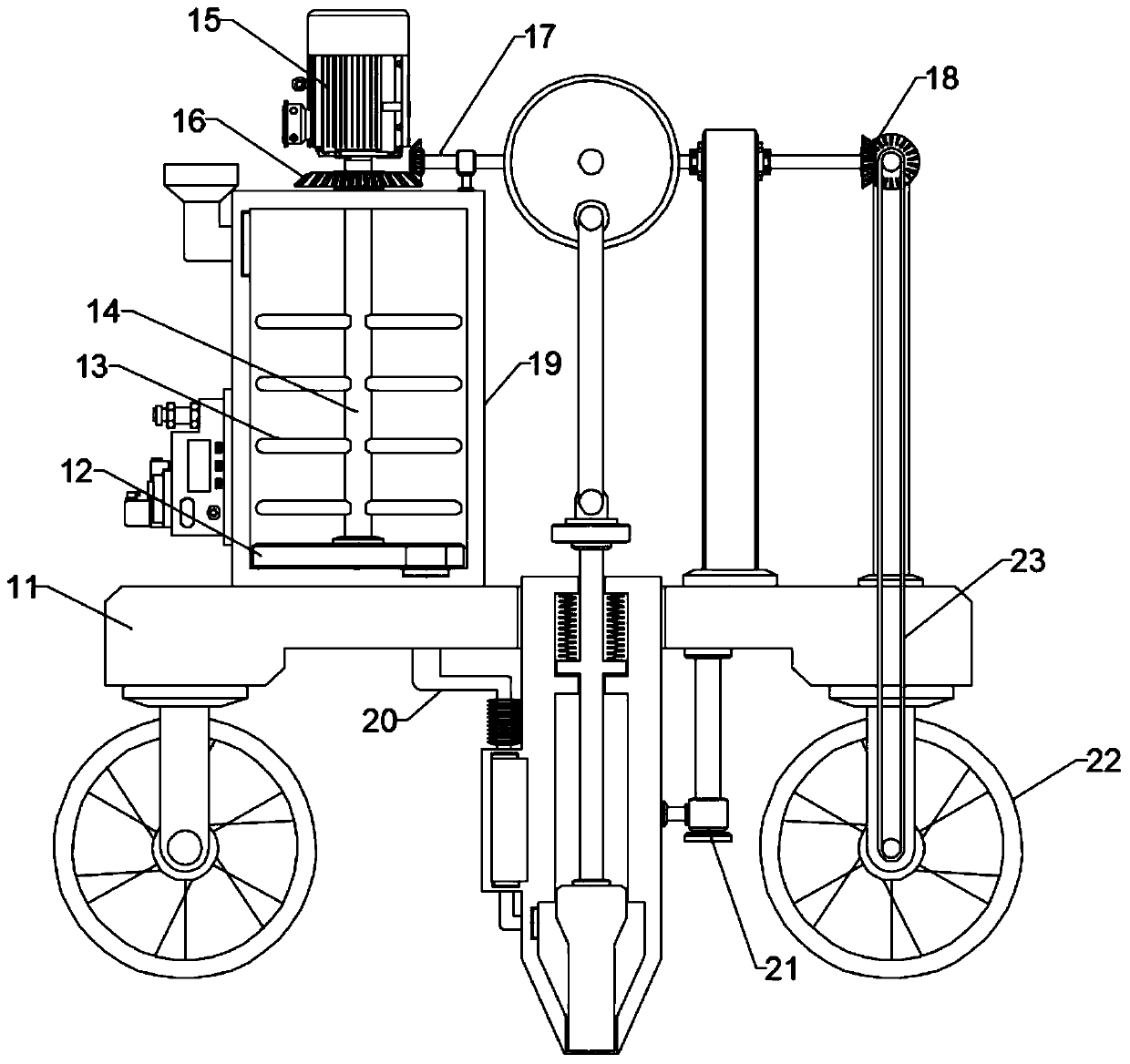

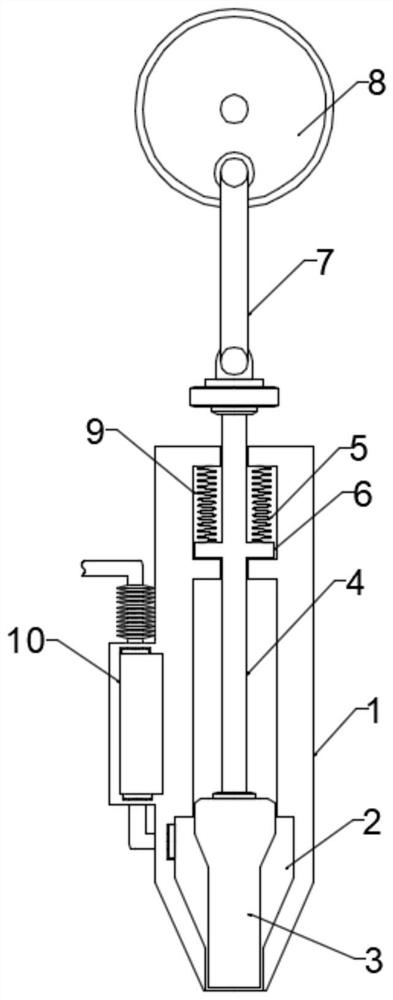

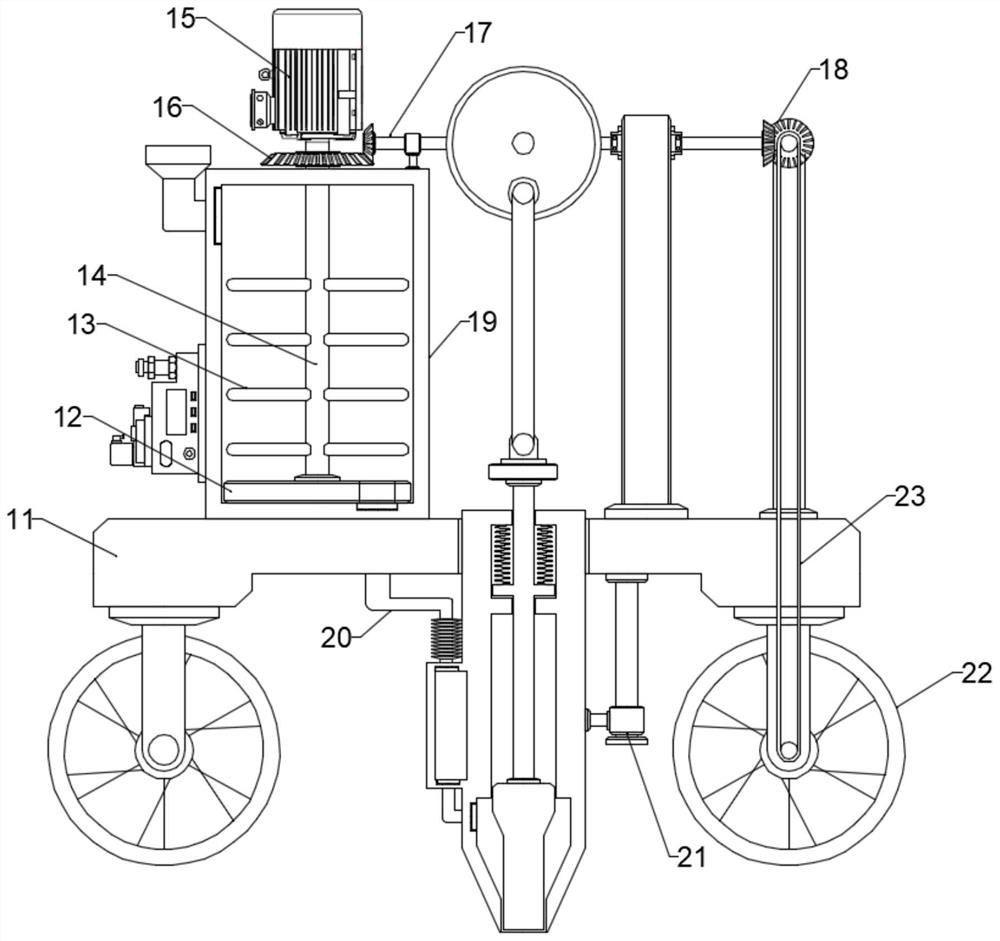

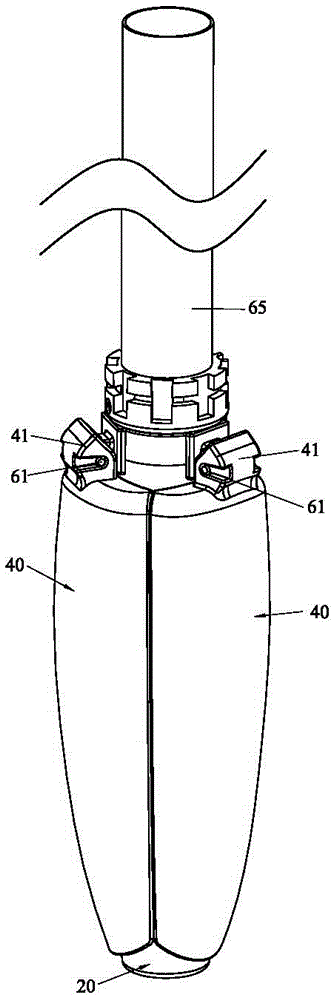

Hole planting mechanism and vegetable seed sowing device

The invention relates to the technical field of agriculture, in particular to a hole planting mechanism and a vegetable seed sowing device. The hole planting mechanism includes a sowing tube and a movable rod inserted in the sowing tube, a plug is installed at one end of the movable rod, the other end of the movable rod is connected with a driving part, and the driving part drives the movable rodto drive the plug to reciprocate in the sowing tube; an imbedding groove is formed in the inner wall of the sowing tube, and the imbedding groove communicates with a buffer cavity installed in the side end of the sowing tube; and an insertion tube is further connected with the movable rod through a limiting assembly. The hole planting mechanism and the vegetable seed sowing device are novel in design, the movable rod is driven to reciprocate by the driving part, so that the reciprocating movement of the sowing tube is driven through the limiting assembly, the vertical insertion and placement of the sowing tube is realized, when the plug moves to the end of a stroke, the imbedding groove communicates with an end port of the sowing pipe to realize sowing, and when the plug continues to move,the sowing pipe is driven to separate from the soil, so that the sowing process is realized.

Owner:CHONGQING ACAD OF AGRI SCI

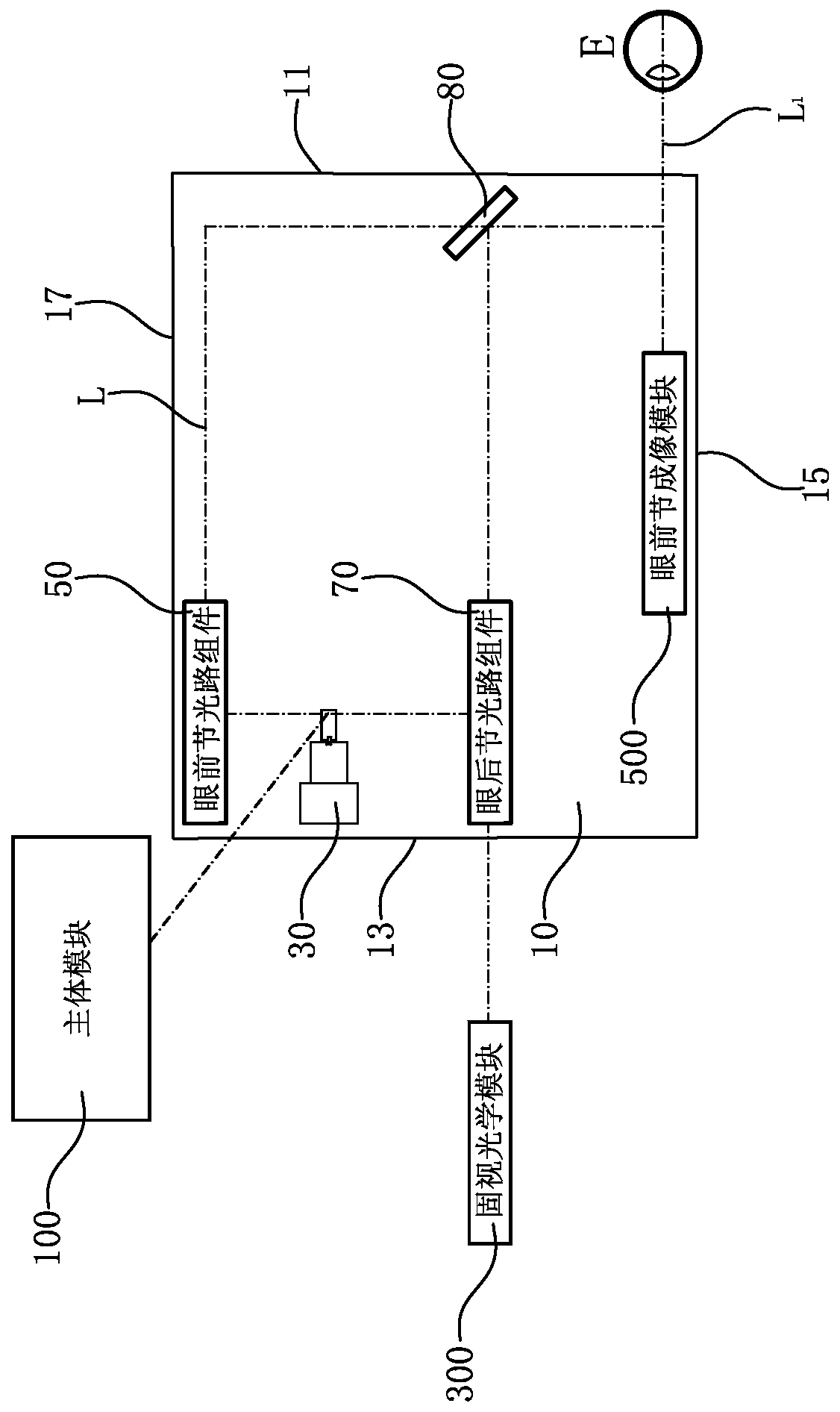

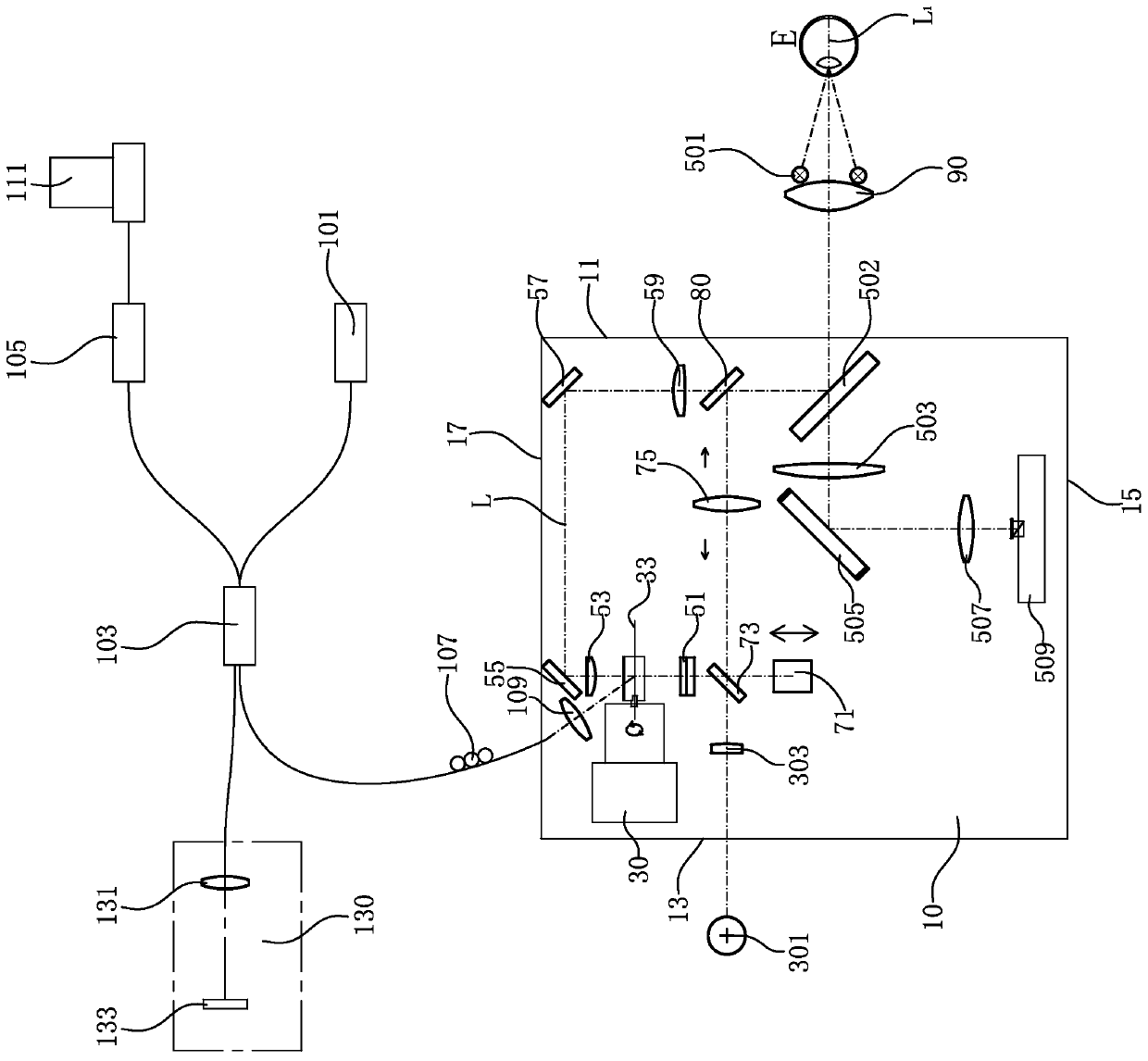

Ophthalmic measurement system

The invention discloses an ophthalmic measurement system for inspected eye detection. The system comprises a main body module, a reference plane, a switching scanning element, an anterior segment light path assembly, a posterior segment light path assembly and a light splitting element, the anterior segment light path assembly, the posterior segment light path assembly and the light splitting element are all arranged on the reference plane, and the switching scanning element can rotate around a fixed shaft, so that switching between the anterior segment light path assembly and the posterior segment light path assembly is realized, and the anterior segment and the posterior segment of a detected eye can be horizontally scanned. According to the invention, switching between anterior segmentscanning and posterior segment scanning of the detected eye can be realized based on the spectral domain OCT technology so as to determine the axial length of the detected eye, the defects of complexstructure and high cost in the prior art can be overcome, and horizontal scanning can be realized.

Owner:SHENZHEN CERTAINN TECH CO LTD

A hole sowing mechanism and vegetable seed sowing device

ActiveCN111543145BAchieve vertical placementEnsure continuityDibble seedersReciprocating motionAgricultural engineering

The present invention relates to the technical field related to agriculture, in particular to a hole sowing mechanism and a vegetable seed sowing device. The hole sowing mechanism includes a sowing tube and a movable rod inserted into the sowing pipe, and a plug is installed at one end of the movable rod , the other end is connected with the driving part, and the driving part drives the movable rod to drive the plug to reciprocate in the seeding pipe; the inner wall of the seeding pipe is provided with an embedded groove, and the embedded groove and The buffer cavity installed at the side end of the seeding pipe communicates; the seeding pipe is also connected with the movable rod through a limiting assembly. The present invention is novel in design, and drives the movable rod to reciprocate through the provided driving member, thereby driving the sowing tube to reciprocate through the limit assembly, so as to realize the vertical insertion of the sowing tube. When the plug moves to the end of the stroke, the embedded The slot communicates with the port of the sowing pipe to realize sowing, and when the plug continues to move, it drives the sowing pipe to break away from the soil, thereby realizing the sowing process.

Owner:CHONGQING ACAD OF AGRI SCI

Blood collection needle capable of controlling flow through switch structure and blood collection tube

InactiveCN114652309ARealize current limit controlConvenient blood collection workDiagnostic recording/measuringSensorsBlood Collection TubeBlood lancet

The blood taking needle and the blood taking tube capable of controlling the flow through the switch structure comprise a placing plate, a supporting frame is fixedly connected to the upper surface of the placing plate, a set of clamping holes are formed in the upper surface of the supporting frame, and a vacuum blood taking tube is clamped to the inner wall of each clamping hole. The top end of each vacuum blood collection tube is fixedly connected with a protective sleeve head. The blood taking needle and the blood taking tube capable of controlling the flow through the switch structure comprise a placement plate, a first connector, a spherical cavity, a sealing ball plug, a through hole rotating shaft and a rotating wheel are arranged, the rotating wheel can be rotated to drive the rotating shaft to rotate, then the sealing ball plug is driven to rotate in the spherical cavity, a through hole is made to rotate, and adjustment of the opening of the through hole is completed; according to the vacuum blood collection tube, the secondary flow limiting work effect of blood collection is achieved, the blood flow speed during blood collection is effectively controlled, through cooperation with the scale paste, stable and accurate blood collection of workers is achieved, the situation that the collection amount of the vacuum blood collection tube is too large is avoided, and blood detection work is facilitated.

Owner:QINGDAO BLOOD CENT

Flexible fixing device for optical element

ActiveCN102928939AAccurate and stable positioningAchieve mechanical propertiesMountingsEngineeringPallet

The invention discloses a flexible fixing device for an optical element. The flexible fixing device comprises a pressure plate, a spring, a gland, a 3 / 4 cylinder, a 1 / 4 cylinder, elastic plungers, a support seat and a pallet. The optical element is clamped in an integral cylinder formed by the 3 / 4 cylinder and the 1 / 4 cylinder. The 3 / 4 cylinder and the 1 / 4 cylinder are arranged in the support seat. The two ends of the 3 / 4 cylinder and the 1 / 4 cylinder are positioned in the support seat. One end of each elastic plunger penetrates through the support seat and the 1 / 4 cylinder, and is pressed against the outer sidewall of the optical element. The pallet is arranged at one end of the support seat. One end of the optical element is positioned on the pallet. The gland is arranged at the other end of the optical element. The spring is sleeved on the gland. The spring is tightly pressed by the pressure plate which is connected with the other end of the support seat.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

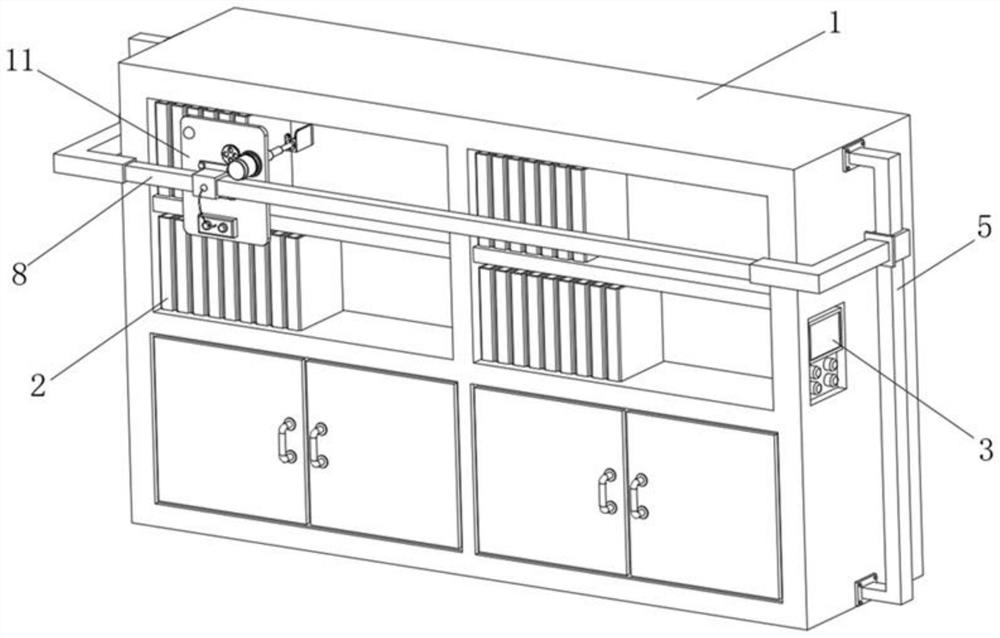

LED display screen assembling equipment

InactiveCN113319545AAchieve vertical placementAvoid unnecessary troubles caused by assemblyMetal working apparatusLED displayMetal framework

The invention relates to the technical field of LED display screens, and discloses LED display screen assembling equipment which comprises a workbench. A supporting plate is fixedly installed on the top of the left side of the workbench, an illuminating lamp is fixedly installed on the right side of the lower surface of the top wall of the supporting plate, four sets of limiting plates are placed on the left side of the top of the workbench, and a magnet block is fixedly mounted in the middle of the outer wall of each limiting plate. Through the arrangement of tension springs and the magnet blocks, after a metal frame of a display screen is assembled, two groups of inner rods are staggered in the frame in a cross shape, and sleeves are pulled towards two sides, so that the four groups of magnet blocks of the two groups of limiting plates are adsorbed on the inner sides of four groups of frames, the tension springs apply acting force to the sleeves, the borders of the frames and the corners of the frames can be stably clamped, vertical placement of the metal frame can be achieved, follow-up self-tapping screw driving operation is further facilitated, unnecessary troubles caused by the fact that the frame is horizontally arranged on the plane during assembly of the self-tapping screws are avoided, and the assembly efficiency is indirectly improved.

Owner:江苏彩晶光电科技有限公司

Bidirectional horizontal connection block

InactiveCN103541954AAchieve vertical placementEasy to installSecuring devicesMetal stripsStructural engineering

The invention provides a bidirectional horizontal connection block which comprises a fixing block made of stainless steel, wherein the fixing block is provided with a first fixing base, a third fixing base is arranged on the bottom of the fixing block, the first fixing base is arranged at one end of the fixing block, the third fixing base is arranged at the other end of the fixing block, the first fixing base and the third fixing base are vertically arranged, the first fixing base is formed by two fixing pieces arranged in parallel and having the same shape and size, and the third fixing base is formed by two fixing pieces arranged in parallel and having the same shape and size. The bidirectional horizontal connection block facilitates fixing and installing of a metal pipe or a metal strip, and the metal pipe or the metal strip can be vertically arranged.

Owner:李明科

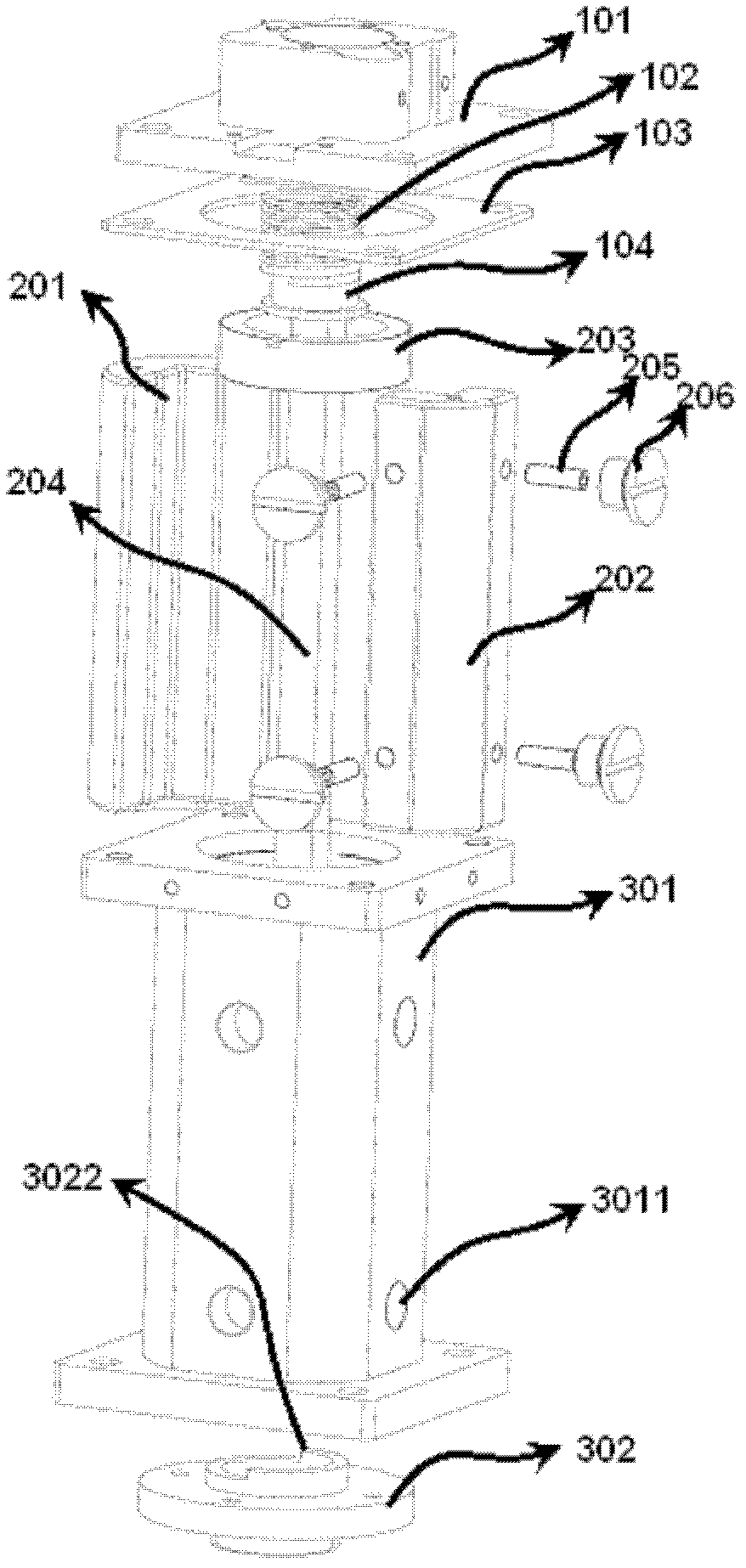

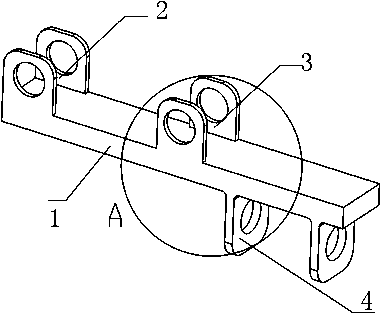

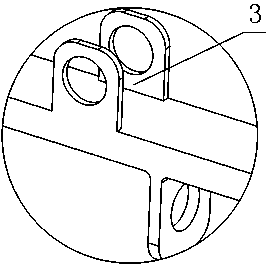

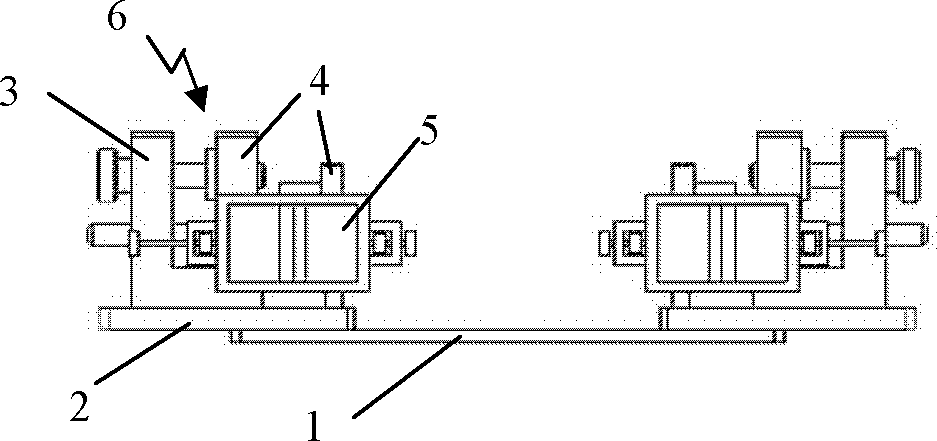

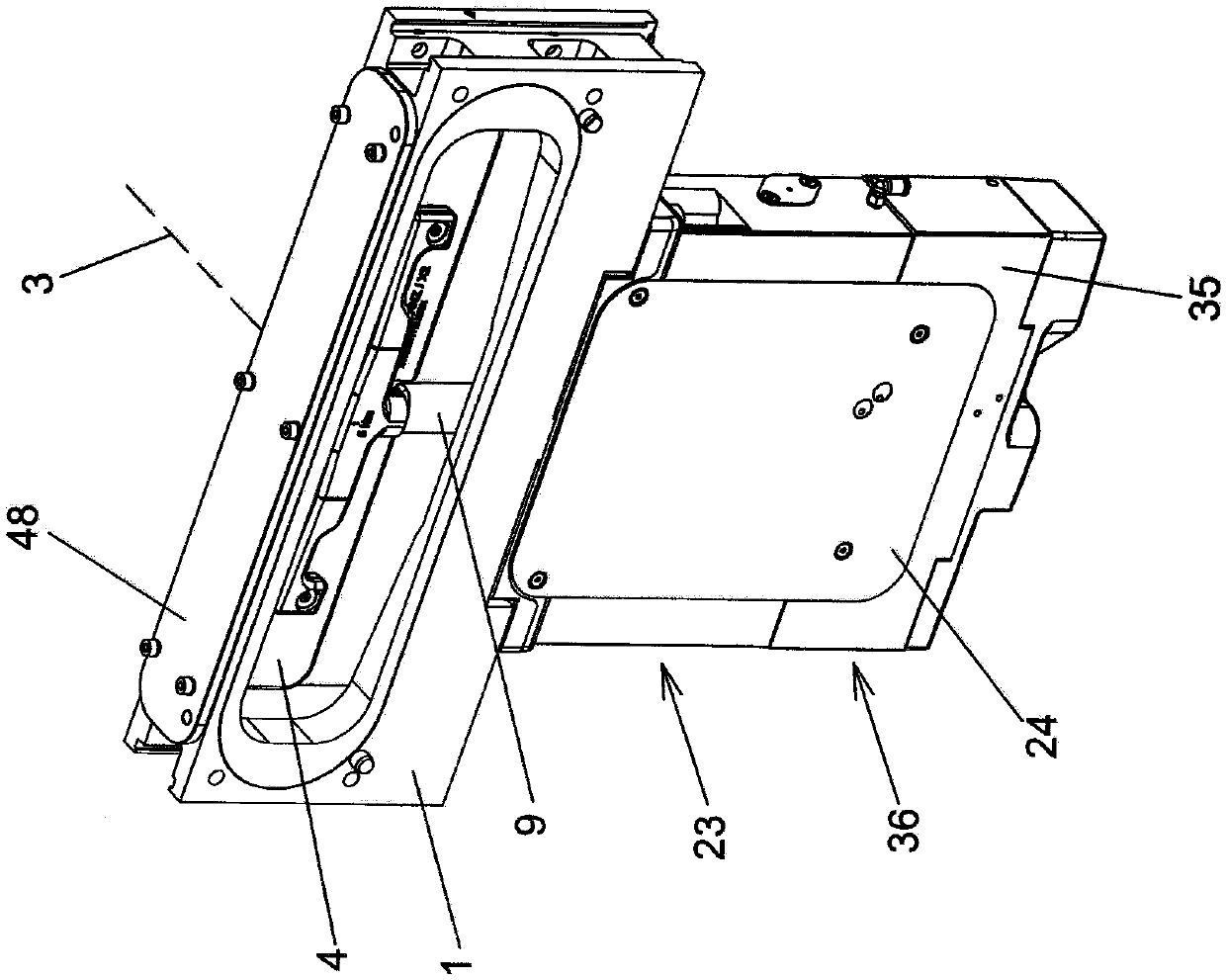

Solid sample carrying stage, spectrophotometer and LSPR (localized surface plasma resonance) detection method

InactiveCN103185696BPrecise and stable translationFacilitates high-throughput detectionRadiation pyrometryColor/spectral properties measurementsHigh fluxPlasma resonance

The invention provides a solid sample carrying stage for a spectrophotometer. The solid sample carrying stage comprises an adjusting seat and a moving frame, wherein the adjusting seat is L-shaped, and comprises a base part and an arm part, the base part is provided with a groove, a first guide rail groove is formed in the base part, and a screw hole and an ejector pin through hole are formed in the arm part; the moving frame is U-shaped, comprises a base connecting part, a first arm part and a second arm part; the base connecting part is embedded in the groove of the base part of the adjusting seat, a second guide rail groove is formed in the base connecting part, the first guide rail groove is matched with the second guide rail groove to form a complete guide rail groove and a guide rail is embedded in the complete guide rail groove, clamping grooves are formed in the upper sides of the first arm part and the base connecting part, and a through hole and an ejector pin through hole are formed in the second arm part; and a moving knob is in threaded connection with the screw hole of the arm part and penetrates through the screw hole and the through hole of the second arm part, and the ejector pin penetrates through the ejector pin through hole of the arm part and the ejector pin through hole of the second arm part. The invention further provides a corresponding LSPR detection method. The solid sample carrying stage and the LSPR detection method provided by the invention are very convenient for high-flux detection and suitable for measuring a sample with a small width.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

A kind of cultivation and planting method of Scrophularia scrophulariae

ActiveCN108617451BImprove space utilizationEasy to placeFertilising methodsRoot crop cultivationAgricultural engineeringScrophularia

Owner:玉环市几偶孵化器有限公司

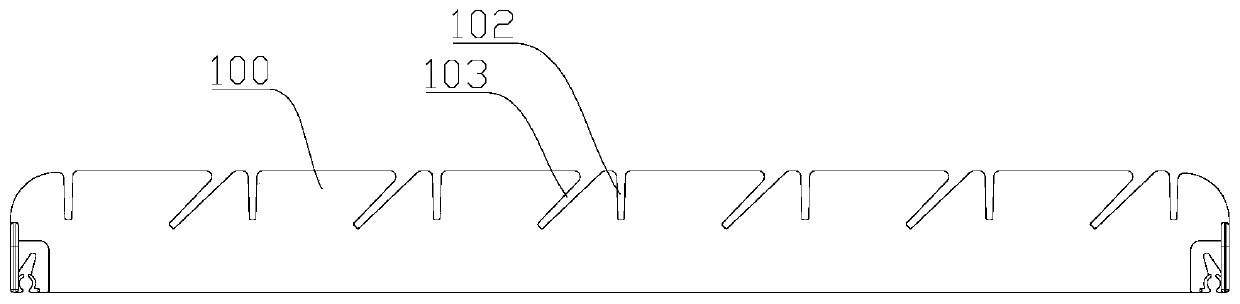

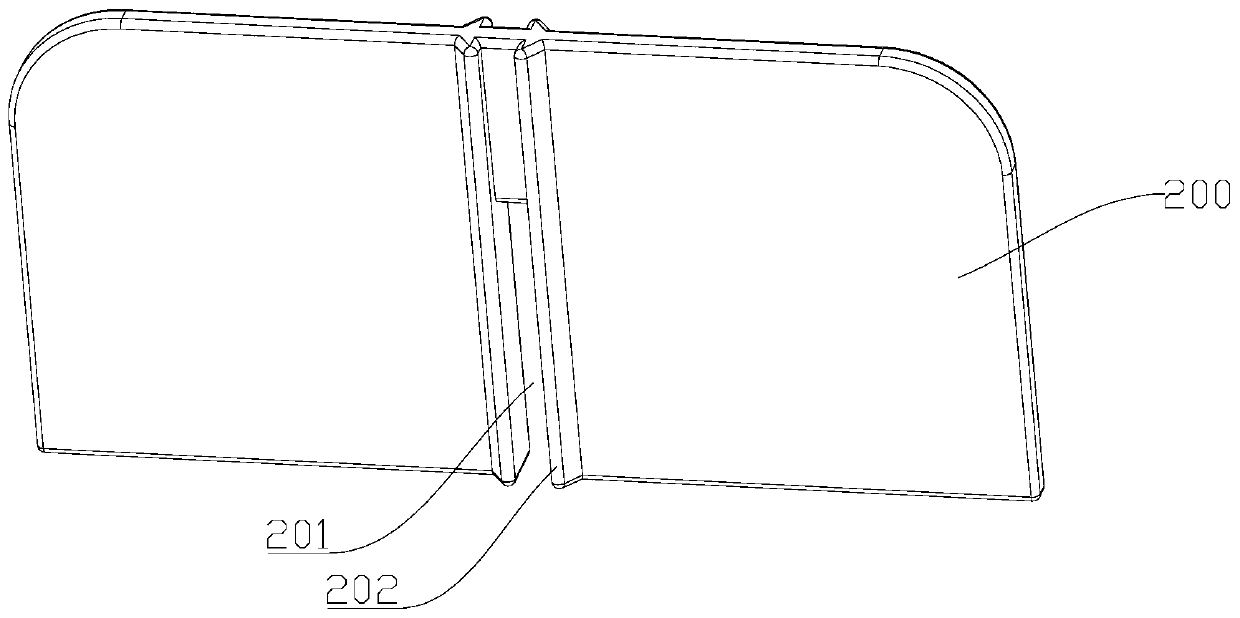

Goods bearing partition plate assembly and goods shelf

PendingCN111345642AAdjustable angleAchieve vertical placementFurniture partsDismountable cabinetsStructural engineeringMechanical engineering

The invention discloses a goods bearing partition plate assembly and a goods shelf, the goods shelf is provided with the goods bearing partition plate assembly, and the goods bearing partition plate assembly comprises at least one partition plate main body and a plurality of fins installed on the partition plate main body in an angle-adjustable mode. Through the arrangement of the fins, a plurality of areas can be formed in the length direction of the partition plate main body, different types of commodities can be effectively separated, meanwhile, commodities of the same type can be separated, and the angles of the fins are adjustable, for example, the fins are arranged perpendicular to the partition plate main body in the vertical direction, for example, the fins are obliquely arranged perpendicular to the partition plate main body in the vertical direction, vertical placement and oblique placement of commodities can be achieved, a user can flexibly set the placement area and the placement mode of the commodities according to needs, buyers can select and purchase the commodities conveniently, and practicability is high.

Owner:长沙中谷智能设备制造有限公司

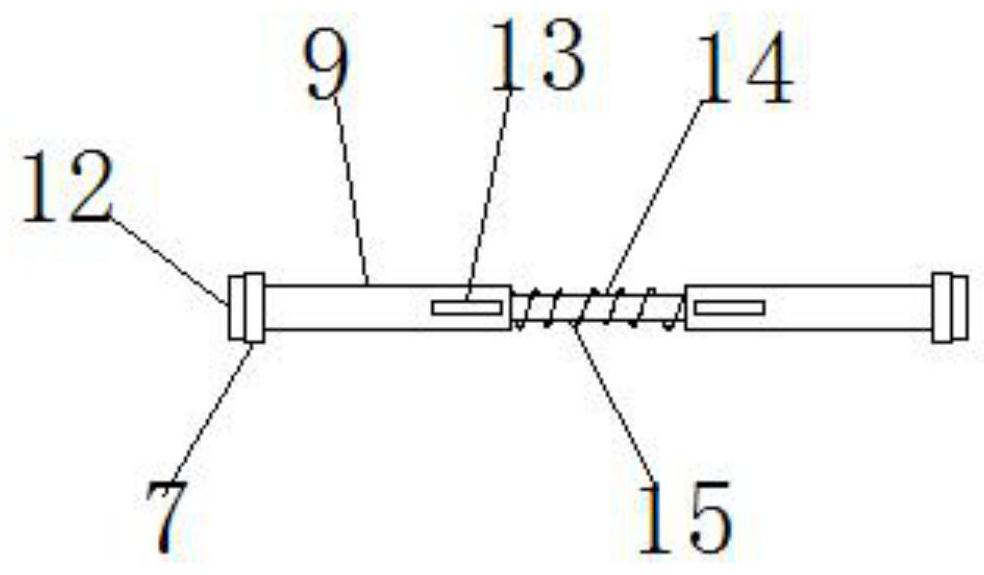

vacuum valve

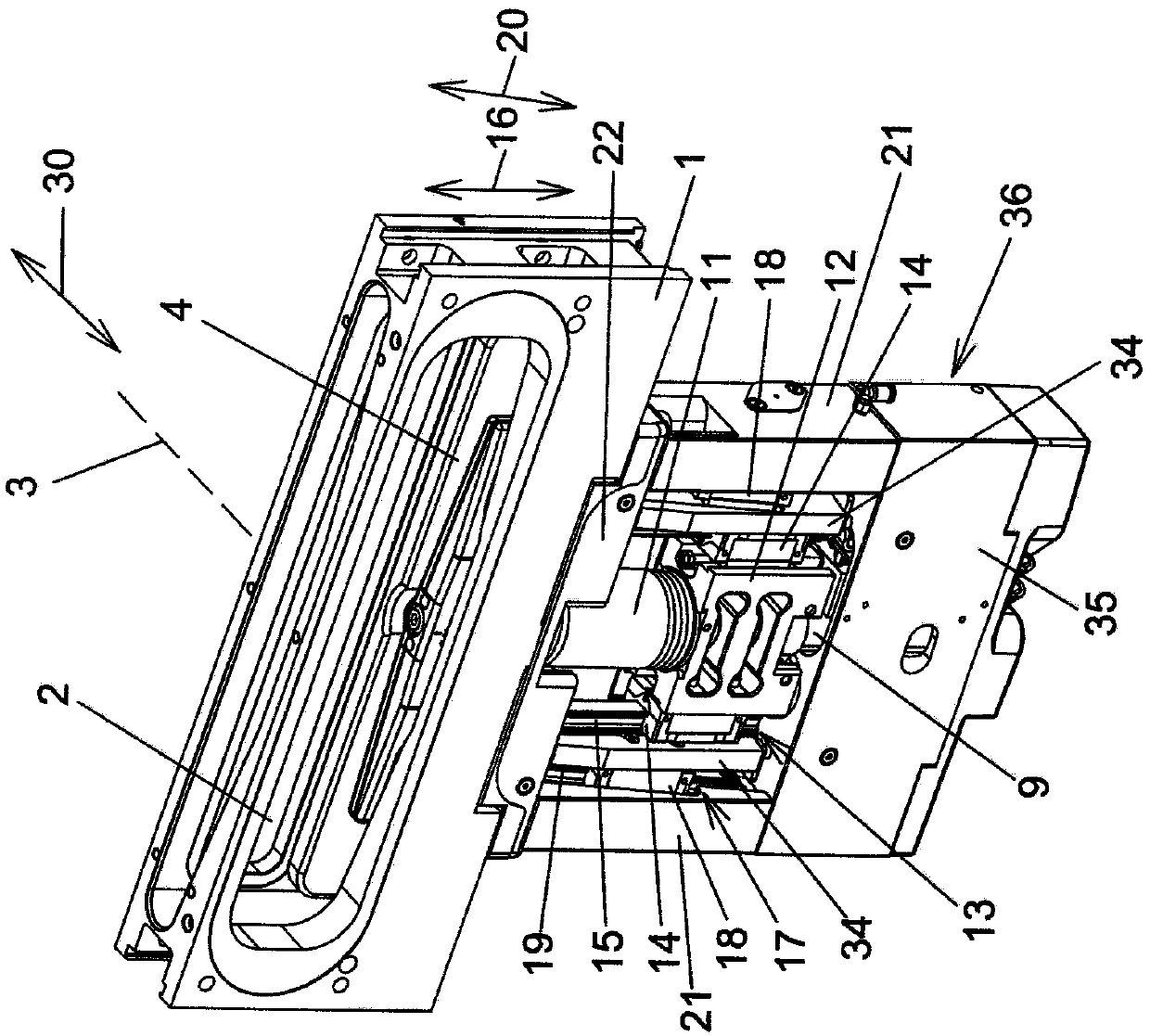

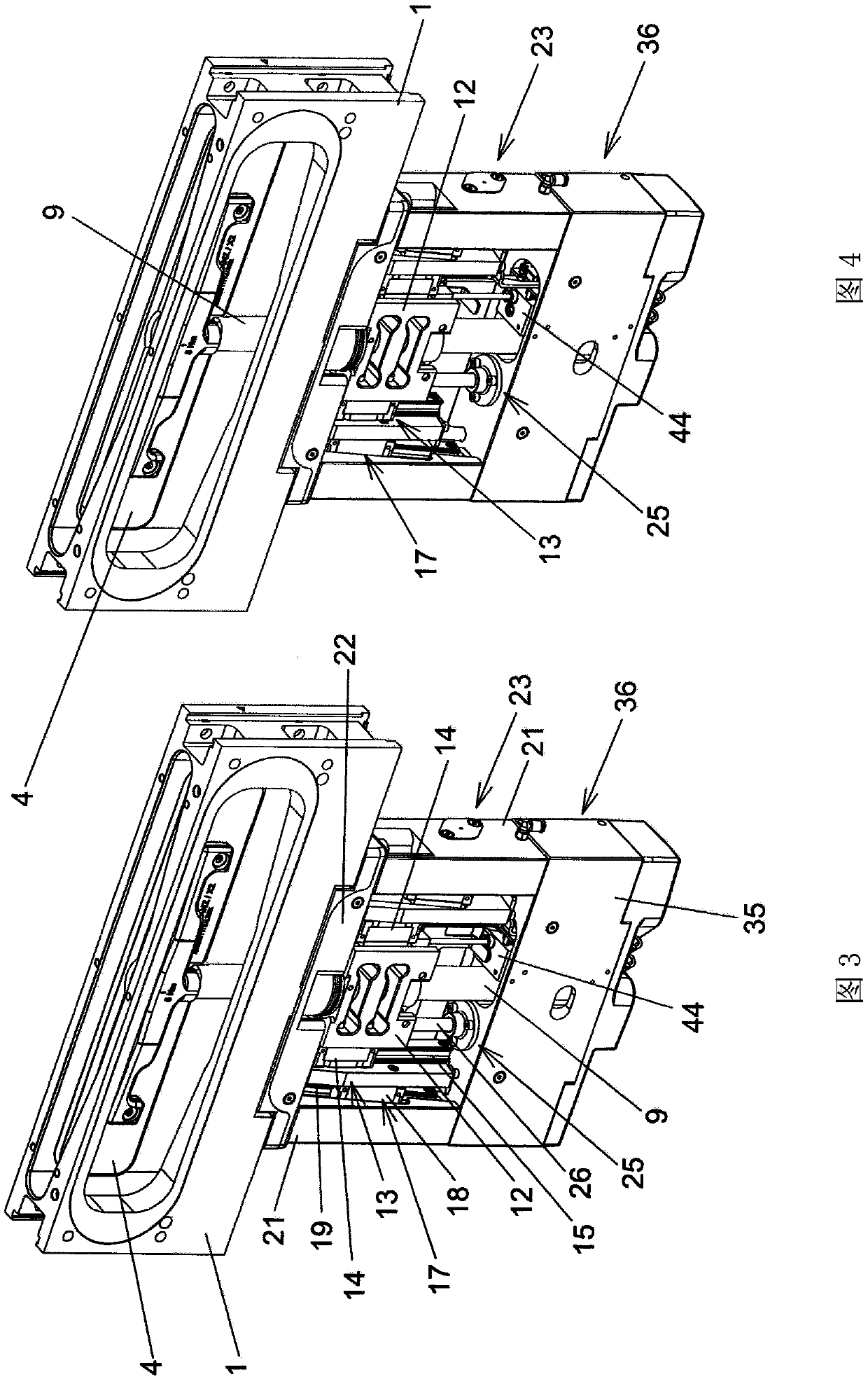

ActiveCN107407443BLow costLarge construction widthOperating means/releasing devices for valvesSlide valveEngineeringValve stem

A vacuum valve comprising a valve body (1) having a valve opening (2) surrounded by a valve seat (5), the valve opening having an axis (3), the vacuum valve also comprising a closing mechanism (4), the closing mechanism is movable parallel to the direction of longitudinal movement (16) between an open position in which it exposes the valve opening (2) and an intermediate position in which it covers the valve opening (2) but removed from the valve seat (5) and the closing mechanism can move parallel to the direction of lateral movement (30) between an intermediate position and a closed position in which it rests on the valve seat (5) Above, the vacuum valve also includes a valve stem (9) carrying the closing mechanism (4), a longitudinal travel linear guide (13), and the longitudinal travel linear guide has a longitudinal travel slide connected to the valve stem (9). block (14) and longitudinal travel guide member (15), wherein the longitudinal travel slide block (14) is guided linearly and deflectably in the longitudinal movement direction (16) by the longitudinal travel guide member, and the vacuum valve also includes a transverse travel linear guide Device (17), the transverse stroke linear guide device comprises the transverse stroke slider (18) and the transverse stroke guide component (19) that are connected with the longitudinal stroke guide part (15), wherein the transverse stroke slider (18) is formed by the transverse stroke The guide element is guided linearly deflectably in an oblique movement direction (20) oblique to the longitudinal movement direction (16).

Owner:VAT HLDG AG

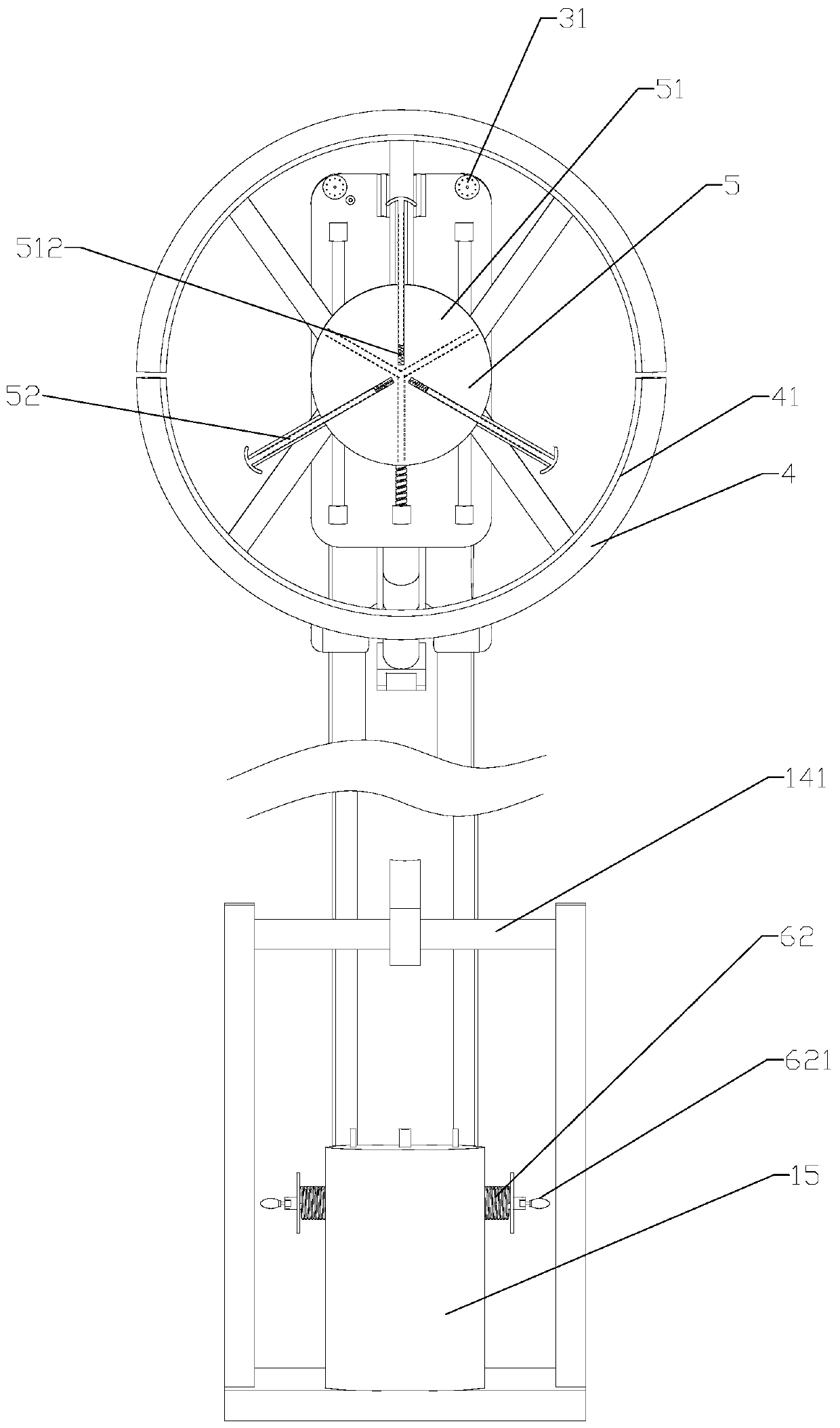

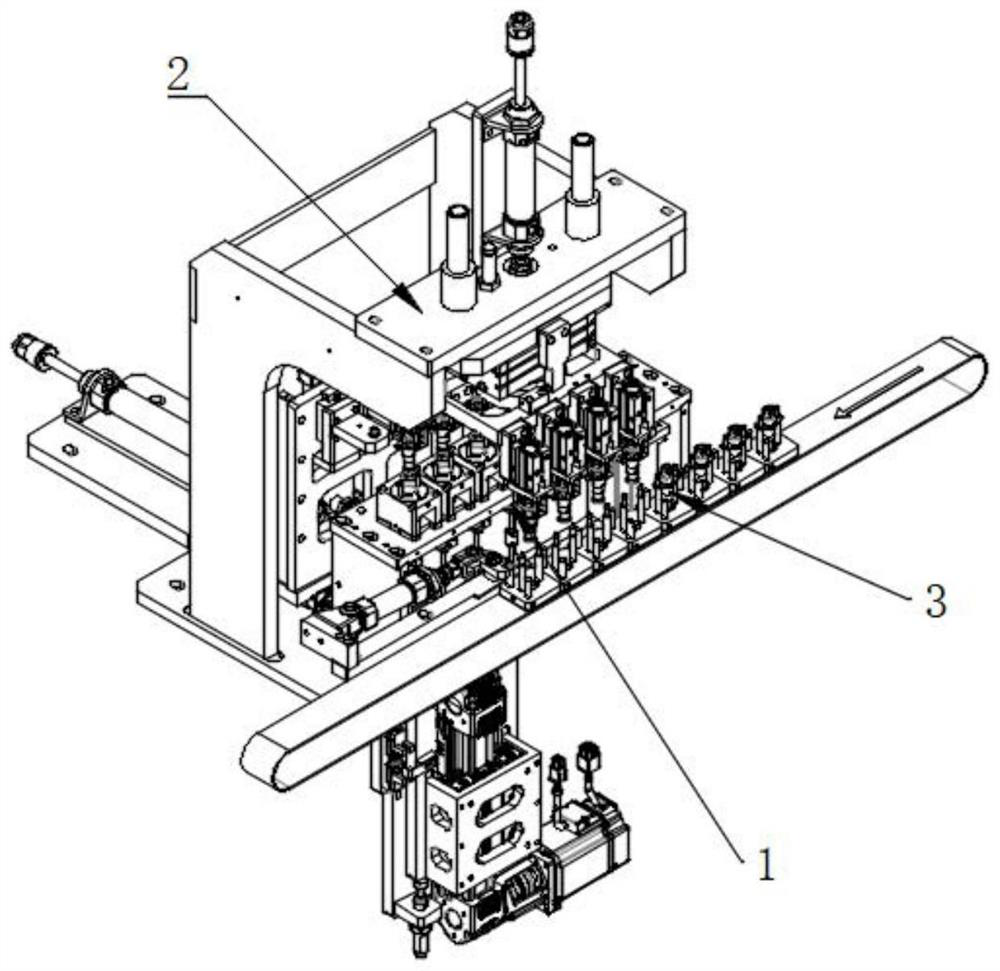

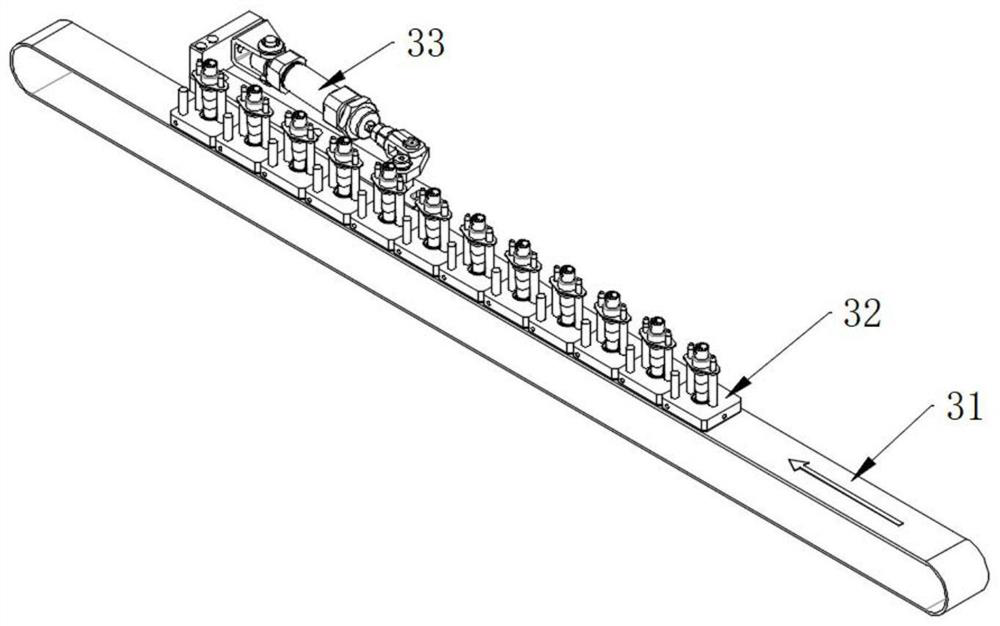

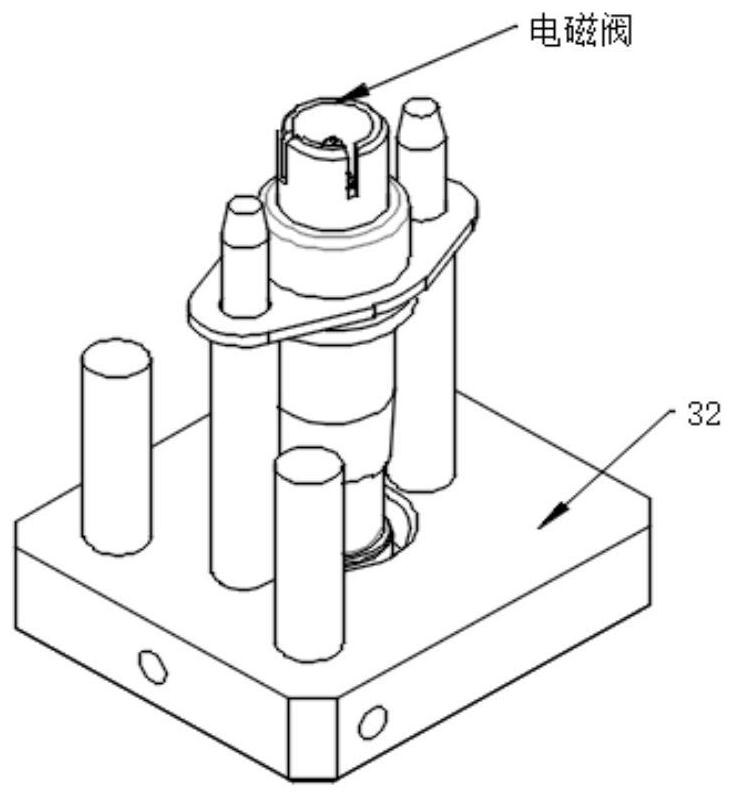

Automatic detection device for actuation performance of gas protection solenoid valve

PendingCN114636926AImprove detection efficiencyShorten the timeMeasurement instrument housingCircuit interrupters testingGas protectionFully automated

The invention discloses an automatic detection device for actuation performance of a gas protection solenoid valve, which comprises a multi-position rotary material taking unit, a multi-position current measuring unit and a conveying unit, and is characterized in that the conveying unit is used for conveying the solenoid valve; the electromagnetic valve is transferred to a station where the multi-position current measuring unit is located through the multi-position rotary material taking unit, and then the electromagnetic valve is detected through the multi-position current measuring unit; the multi-position rotary material taking unit comprises a positioning frame, a material taking up-down air cylinder and a material taking clamping jaw. The multi-position current measuring unit comprises an electrode module, a testing module and an upward pushing module. And full-automatic grabbing, placing, detecting and judging of the electromagnetic valve and putting back of the electromagnetic valve can be achieved. Manual intervention is not needed, and the detection precision of the electromagnetic valve is ensured.

Owner:昆山熠林森自动化设备有限公司

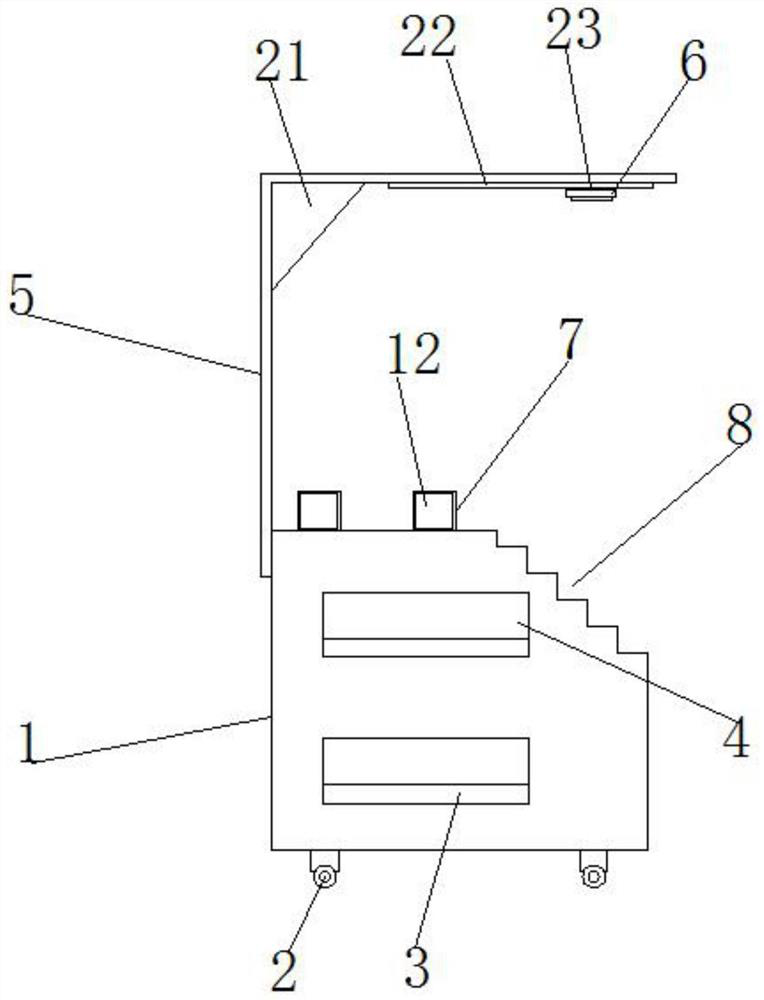

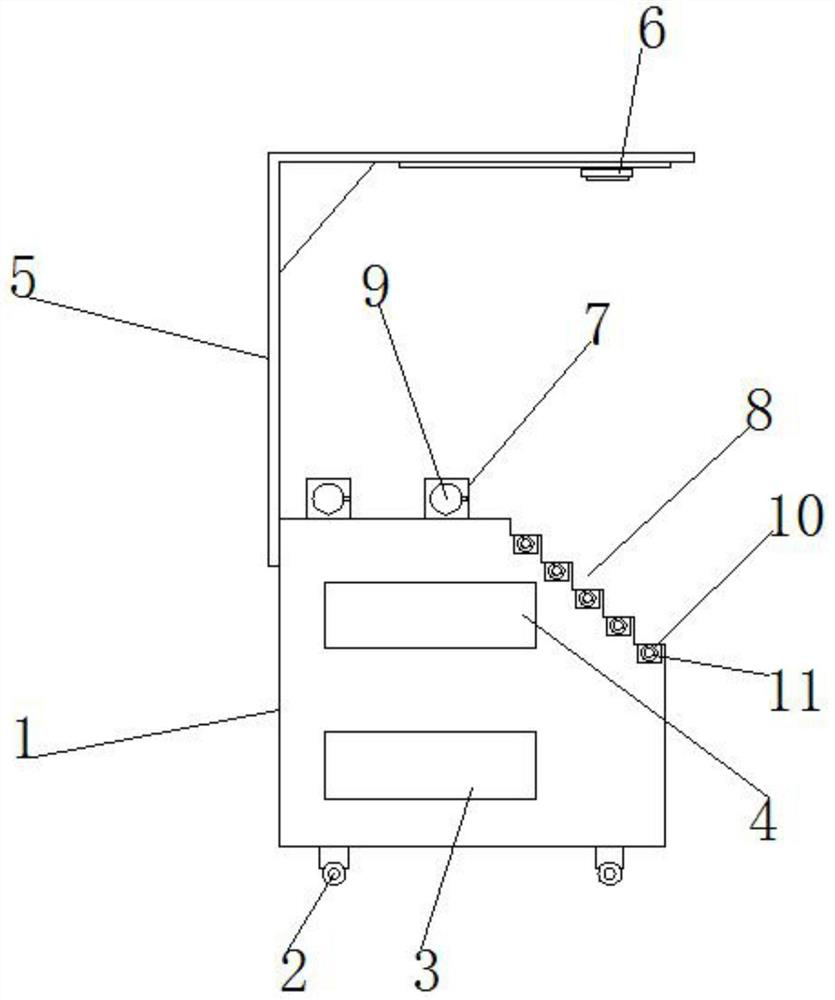

Automatic bundling equipment

PendingCN112389706AAchieve vertical placementStable positioning and bindingBundling machine detailsMechanical engineeringIndustrial engineering

The invention relates to automatic bundling equipment. The automatic bundling equipment comprises an equipment body, a vertical bundling device is arranged on the equipment body, a bundling opening isformed in the vertical bundling device, a feeding guide device is arranged at the feeding end of the bundling opening, a discharging guide device is arranged at the discharging end of the bundling opening, a height-adjustable type containing device is arranged on a position, located at the bundling opening, of the vertical bundling device, a maintenance adjusting device is further arranged on theequipment body, the vertical bundling device is connected with the maintenance adjusting device, a control device is arranged on the equipment body, and the control device is connected with the controlled ends of the vertical bundling device, the feeding guide device, the discharging guide device and the height-adjustable containing device. Therefore, the vertical placement of the bundling deviceis realized, and the effect that materials are positioned and bundled more stably can be realized; and through mutual cooperation of the feeding guide device and the discharging guide device, automatic feeding and discharging are achieved, manual participation is not needed, and the machining efficiency is high.

Owner:苏州矽微电子科技有限公司

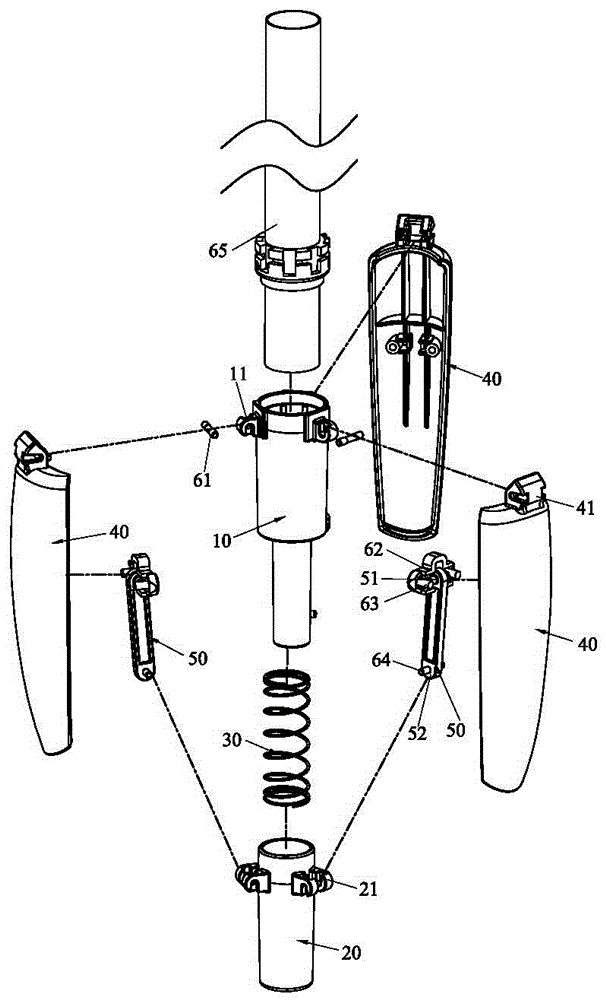

Umbrella tip structure capable of enabling umbrella to be vertically put

Owner:DONGGUAN WEIKUAN PLASTIC PROD CO LTD

An intelligent bookshelf with a book organizing mechanism

ActiveCN113142822BEasy accessEasy to take outBook cabinetsCash registersSoftware engineeringDrive motor

The invention relates to the technical field of a library bookshelf device, and discloses an intelligent bookshelf with a book organization mechanism. Through the setting of a touch screen and a scanner, etc., the name information of a plurality of books on the bookshelf is scanned and transmitted to a first controller to communicate with The name information of the books entered by the reader is compared, and when the name information is consistent, the first controller controls the moving mechanism to stop running, and controls the prompt light to light up, so as to quickly guide the reader to read the book at the corresponding position, and the reader passes the second control. The controller controls the horizontal electric slider to move a certain distance to one side, so that it is convenient to take out the required books. When returning the books, the reader only needs to place the books anywhere on the bookshelf, saving time and effort and quickly accessing the books. The setting of the level cylinder and the reset block can complete the wrinkle removal operation on the cover of the book. Through the settings of the splint clamp and the driving motor, the position of the multiple books on the bookshelf can be corrected, and another function of the sorting mode can be realized.

Owner:SHANDONG JIAOTONG UNIV

Multifunctional book end

The invention discloses a multifunctional book end. The multifunctional book end comprises a top plate, a bottom plate, and two side plates arranged between the top plate and the bottom plate; the topplate and the bottom plate are arranged in parallel; the two side plates are arranged in parallel, and are arranged at the left side and the right side of the space between the top plate and the bottom plate; the space formed by encircling of the top plate, the bottom plate, and the side plates is a book placing zone; a clamping mechanism is arranged between the top plate and the bottom plate; atable lamp is arranged on the upper surface of the top plate close to the front edge of the top plate. The book end is novel in design, simple and reliable in structure, and excellent in practicality.

Owner:陈志宇

Wall-laying equipment for building construction engineering

ActiveCN112049442BHeight adjustableAchieve vertical placementBuilding material handlingArchitectural engineeringHorizontal orientation

The invention belongs to the field of construction, especially a kind of wall-laying equipment for building construction engineering. The existing auxiliary lines cannot be adjusted conveniently, and are often fixed at a certain position, making it inconvenient to use. Problem, the following solution is now proposed, which includes two support plates, the bottom of the support plate is fixedly installed with a plurality of pins at equal intervals, the top of the support plate is rotatably connected to a support cover, and the top of the support cover is rotatably connected to a nut, and the first screw rod and the second screw rod are screwed on the two nuts respectively, the present invention can realize the vertical placement after the support cover is fixedly installed on the ground, and can realize the adjustment of the height of the auxiliary line, therefore When in use, both the vertical direction and the horizontal direction of the wall can be in a standard state, so compared with traditional auxiliary devices, the technical solution has good practicability.

Owner:广东聚源建设集团有限公司

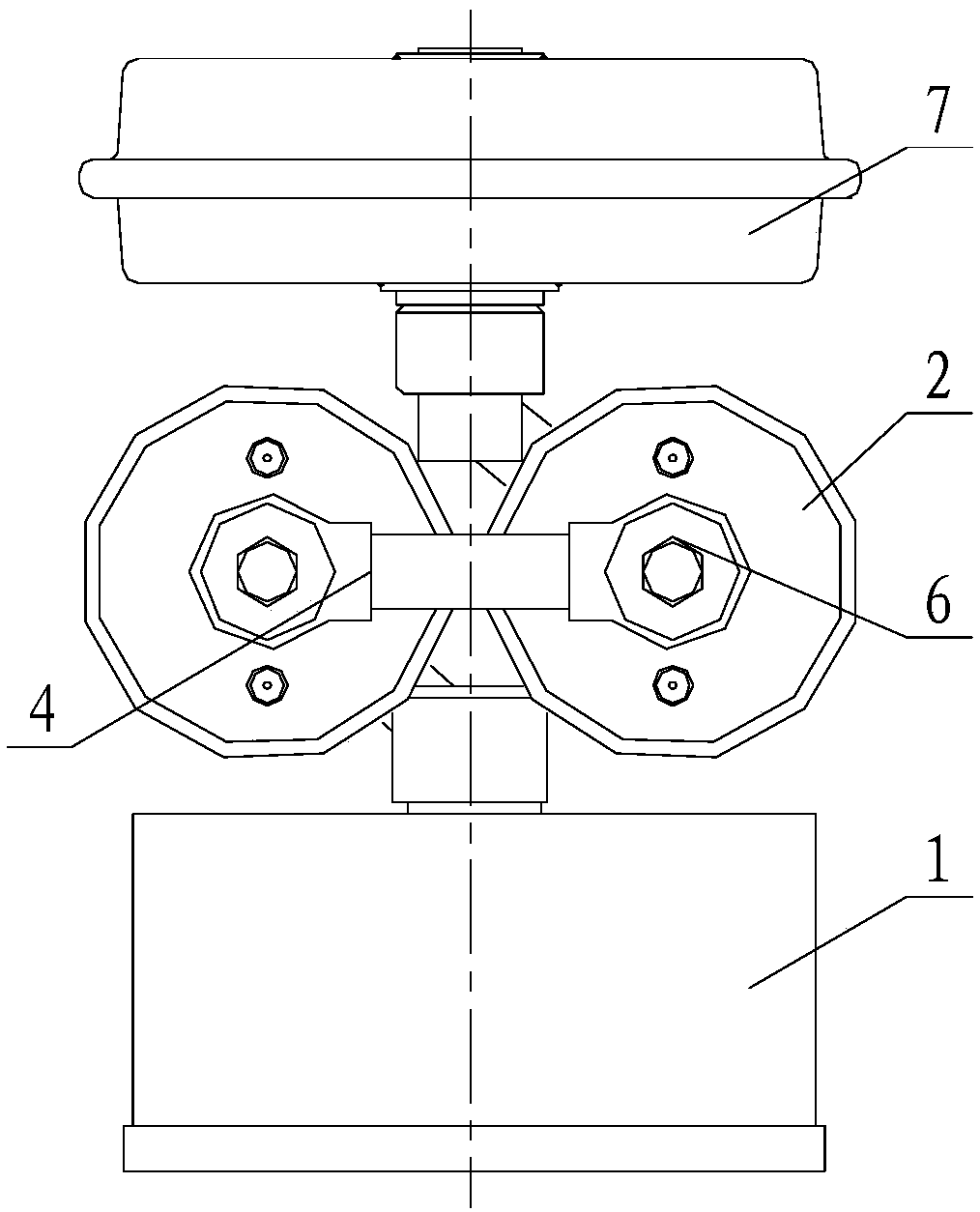

Method for large-size workpiece processing vertical placement

InactiveCN104209777AAchieve vertical placementWork clamping meansPositioning apparatusMechanical engineeringIndustrial engineering

The invention relates to a method for large-size workpiece processing vertical placement. In the vertical placement process, a fixing sheet perfectly fixes a processing workpiece, in addition, the fixing sheet can fix the processing workpiece in different dimensions and specifications, a clamp can effectively avoid the defect of non-perpendicular fixation of the processing workpiece due to unsmoothness of the lower end of the processing workpiece, the method provided by the invention has the advantages that the perpendicular fixation of the large-size processing workpiece is realized, and in addition, the method can be used for simultaneously processing a plurality of processing workpieces.

Owner:四川富临集团成都机床有限责任公司

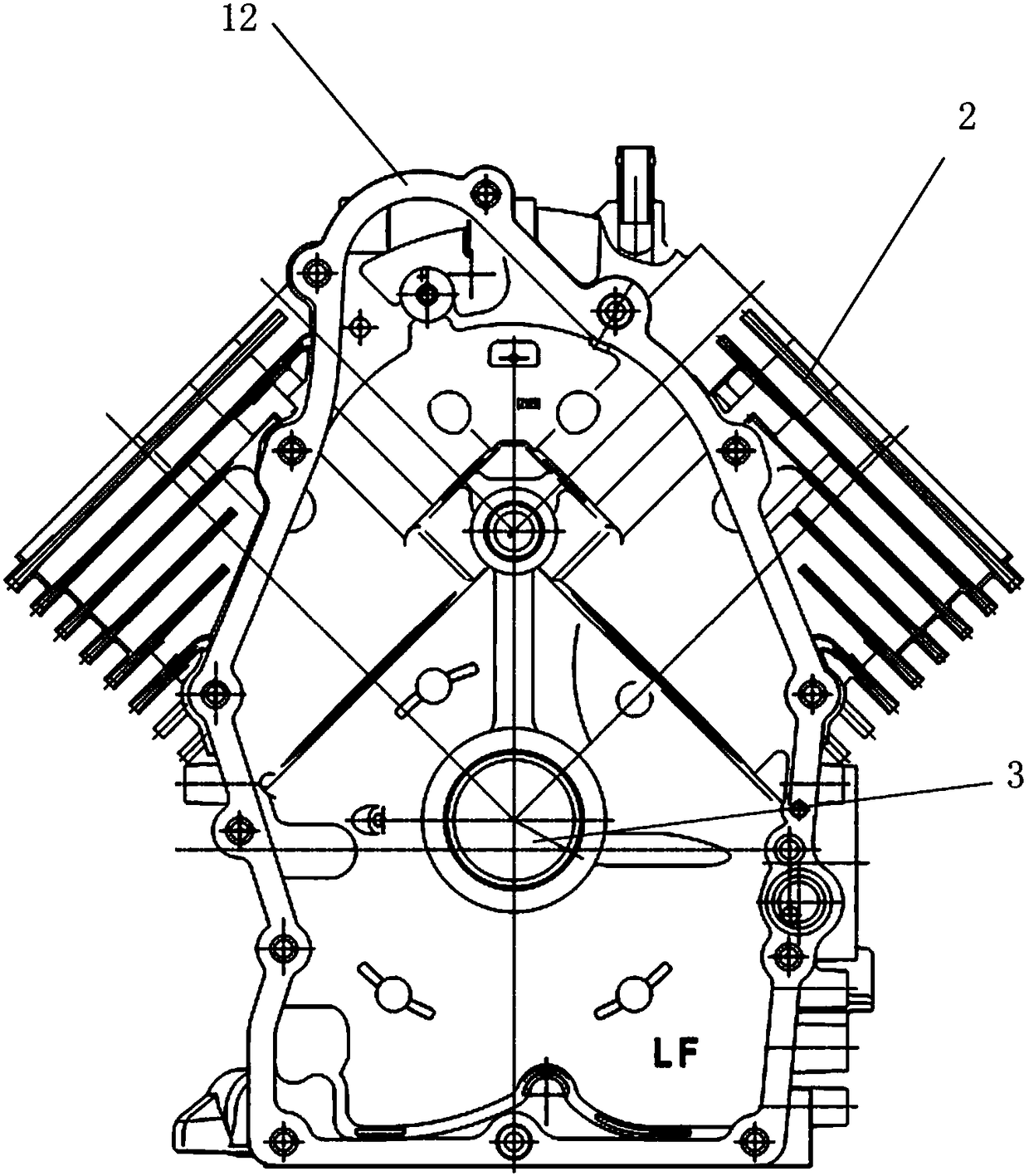

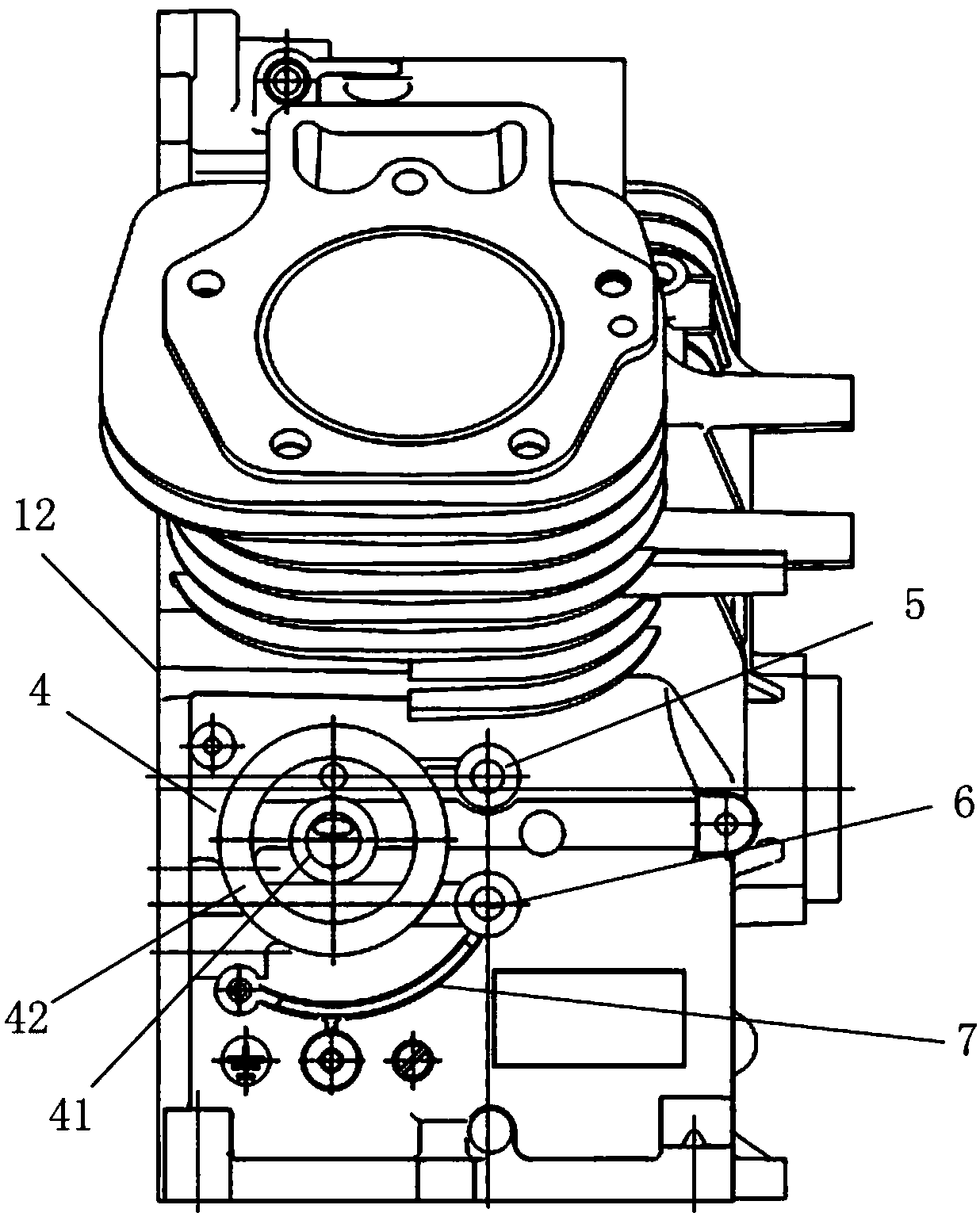

Gasoline engine crankshaft box

PendingCN108547708ASimple structureReduce manufacturing costCasingsMachines/enginesGasolineEngineering

The invention relates to a gasoline engine crankshaft box which comprises a box body, an air cylinder body, a hydraulic tappet, an oil gas separator and an engine oil filter. The air cylinder body isarranged on the box body. The box body is composed of a panel body and a side face body. The side face body surrounds the edge of the panel body. An expansion hole is formed in the bottom of the sideface body. One side of the side face body is provided with an oil inlet, an oil outlet, a pipe connector and an oil receiving disc. The engine oil filter is directly connected with the box body through the pipe connector. The gasoline engine crankshaft box has the beneficial effects that the structure is simple, the manufacturing cost is low, oil gas separation is improved, the sealing performanceis easy to control, the valve clearance does not need to be adjusted, repeated die opening is not needed, few parts are used, the product weight is reduced, and while the use requirement of the function of the product is enhanced, the competitiveness is improved.

Owner:力帆科技(集团)股份有限公司

A chemical heater packaging and liquid flow tube docking device and assembly method

ActiveCN107706434BReduce the size of the accountReserve battery is not limitedDeferred-action cellsZincChemical engineering

The invention discloses a chemical heater packaging and liquid flow pipe butting apparatus and assembling method. The chemical heater packaging and liquid flow pipe butting apparatus is characterizedby at least comprising two chemical heaters, a liquid reservoir positioned above the two chemical heaters and a zinc silver battery positioned below the two chemical heaters, wherein the two chemicalheaters are arranged in parallel and positioned in the same horizontal plane; the two chemical heaters include a chemical heater A and a chemical heater B; the liquid outlet of the chemical heater A and the liquid inlet of the chemical heater B are positioned on the same side; a second connecting pipe is arranged between the liquid outlet of the chemical heater A and the liquid inlet of the chemical heater B; the two ends of the second connecting pipe are connected with the two chemical heaters through compressing screws; the bottom of the liquid reservoir is connected with the liquid inlet ofthe chemical heater A through a first connecting pipe; and the liquid outlet of the chemical heater B is connected with the liquid inlet of the zinc silver battery through a third connecting pipe.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 18 RES INST

Vertically placed two-dimensional large-stroke fast moving device for repairing micro-defects on the surface of large-aperture curved optical elements

InactiveCN105127591BAchieve vertical placementConducive to horizontal light requirementsMaterial analysis by optical meansLaser beam welding apparatusMotor driveEngineering

Owner:HARBIN INST OF TECH +1

An axle finished product transfer device

Owner:涡阳县康仕达机电有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com