Chemical heater packaging and liquid flow pipe butting apparatus and assembling method

A chemical heater and docking device technology, applied in the direction of delayed action cells, etc., can solve the problems of large size, achieve the effects of reducing space, avoiding electro-hydraulic residues, and shortening the length of pipelines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

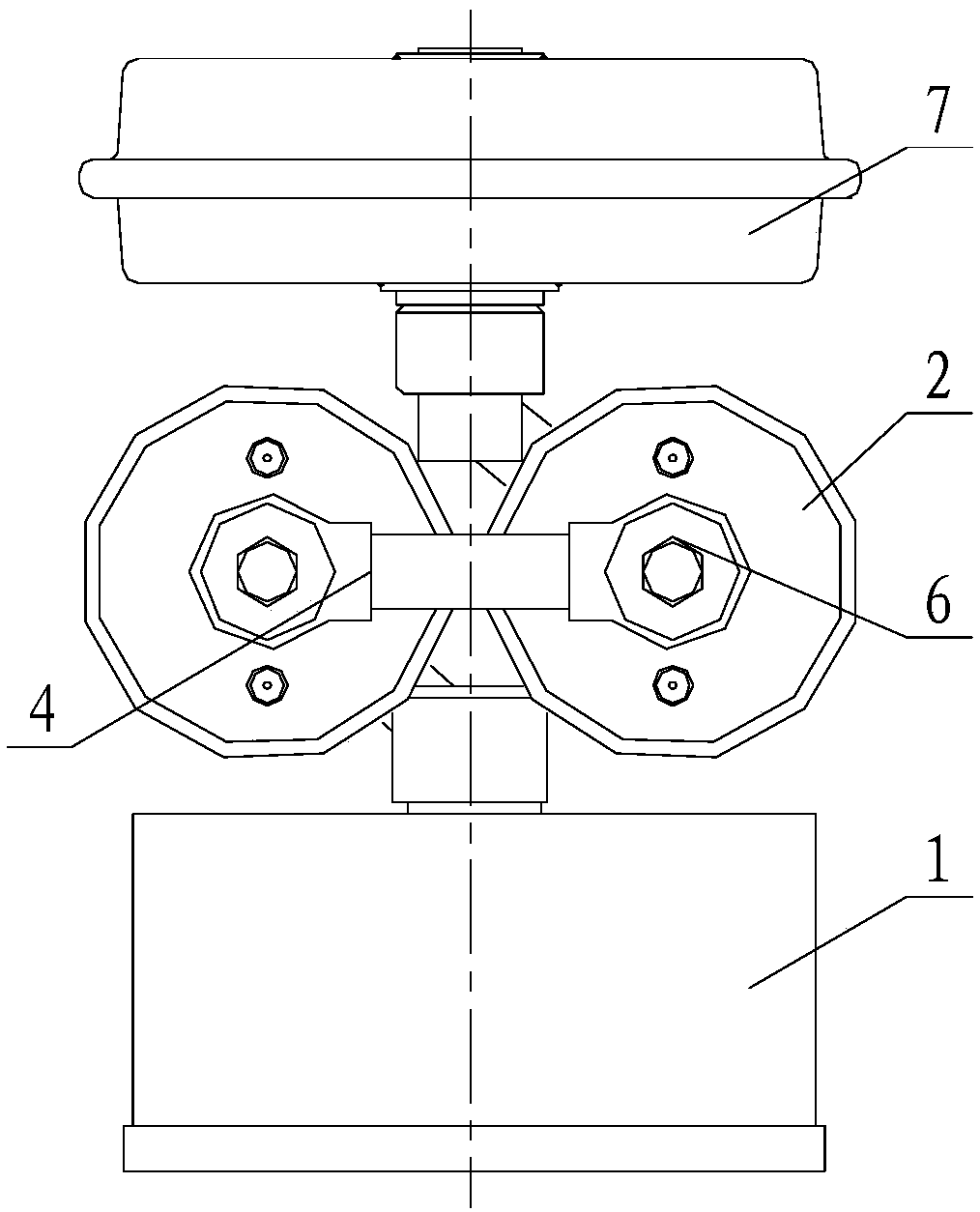

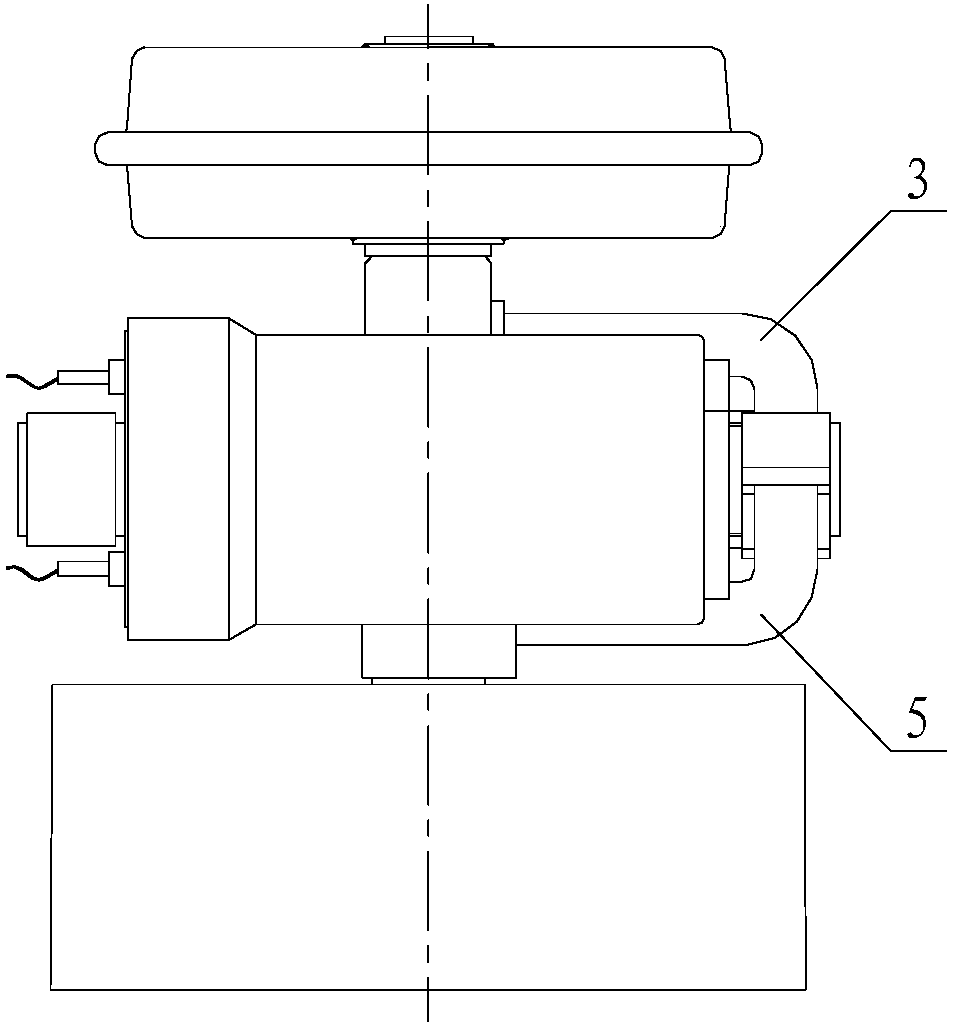

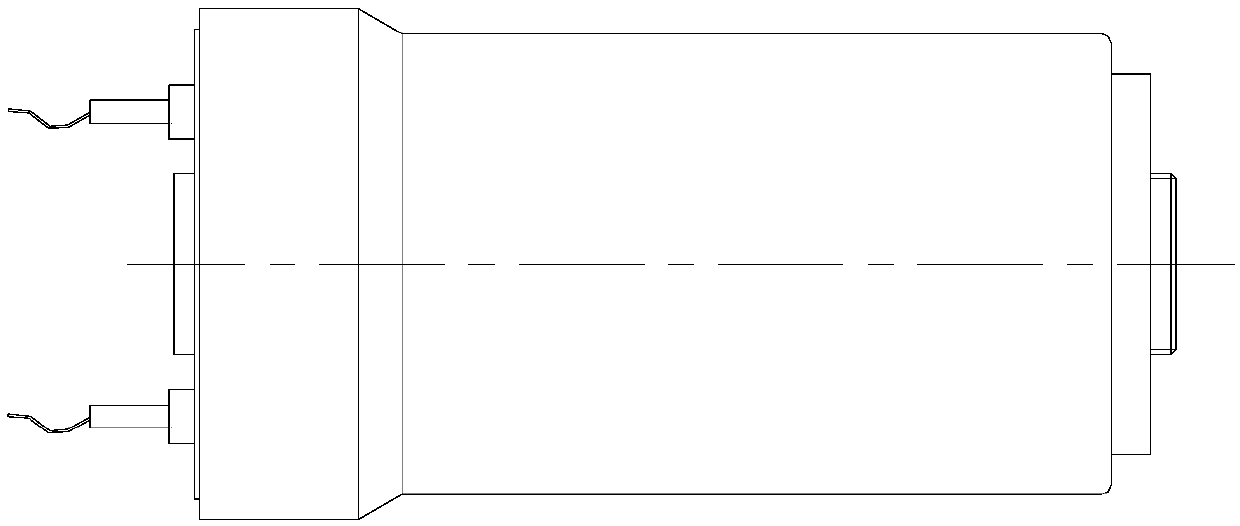

[0031] see Figure 1 to Figure 8 , a chemical heater package and liquid flow tube docking device, comprising:

[0032] Two chemical heaters 2 arranged in parallel; two chemical heaters 2 are located in the same horizontal plane; two chemical heaters 2 are respectively chemical heater A and chemical heater B; the liquid outlet of said chemical heater A and The liquid inlet of the chemical heater B is located on the same side; a second connecting pipe 4 is arranged between the liquid outlet of the chemical heater A and the liquid inlet of the chemical heater B; The end communicates with two chemical heaters through the compression screw 6;

[0033] The liquid reservoir 7 above the two chemical heaters, the bottom of the liquid reservoir 7 com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com