Ophthalmic measurement system

A measurement system and ophthalmology technology, applied in medical science, eye testing equipment, diagnosis, etc., can solve problems such as high cost and complex structure, and achieve the effect of beautiful appearance, overcoming complex structure, and avoiding pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0081] This embodiment provides an ophthalmological measurement system (hereinafter referred to as "system") for detecting the eye E to be inspected, so as to determine the axial length of the eye E to be inspected. Preferably, the system can also determine multiple parameters of the inspected eye E, such as the corneal curvature of the inspected eye E, the depth of the anterior chamber of the eye, the white-to-white distance, and the pupil diameter.

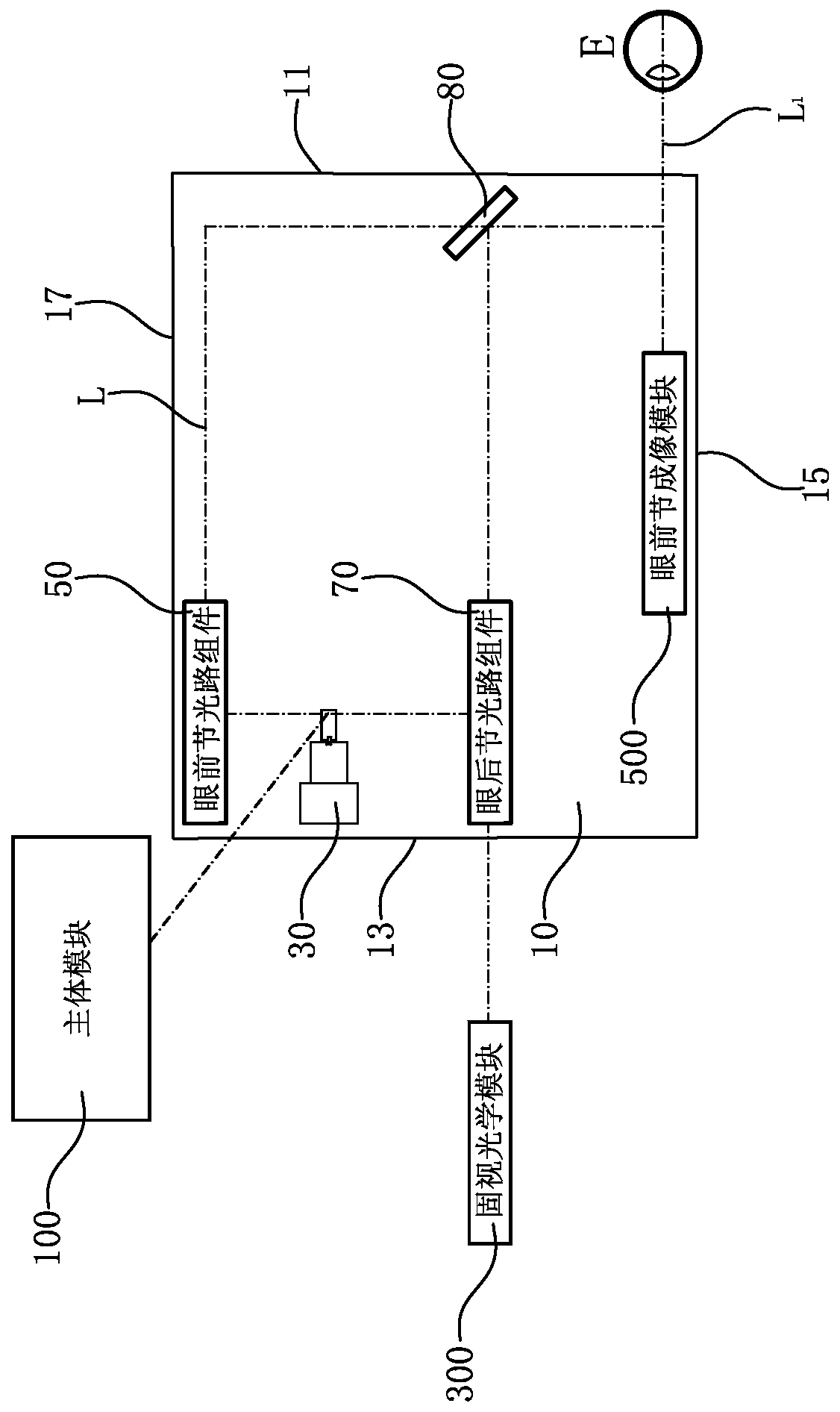

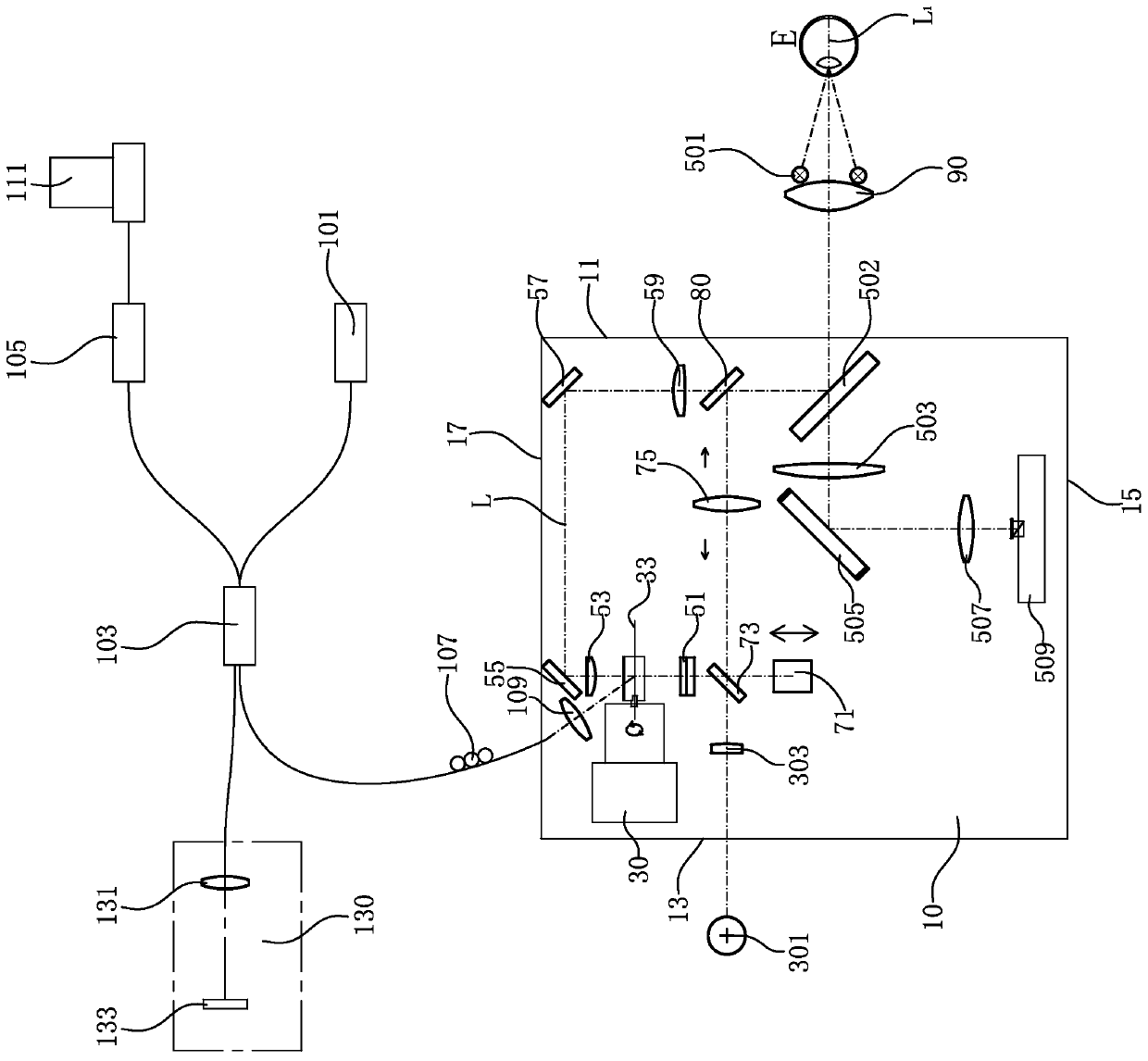

[0082] Please refer figure 1 with figure 2 The system includes a main body module 100, a reference plane 10, a scanning plane (not shown), a switching scanning element 30, an anterior segment optical path assembly 50, a posterior segment optical path assembly 70, a beam splitting element 80, and the main optical axis L of the system. Preferably, the system further includes an eye lens 90, a fixation optical module 300, and an anterior segment imaging module 500.

[0083] figure 1 , figure 2 The dotted line indicates the main optica...

Embodiment 2

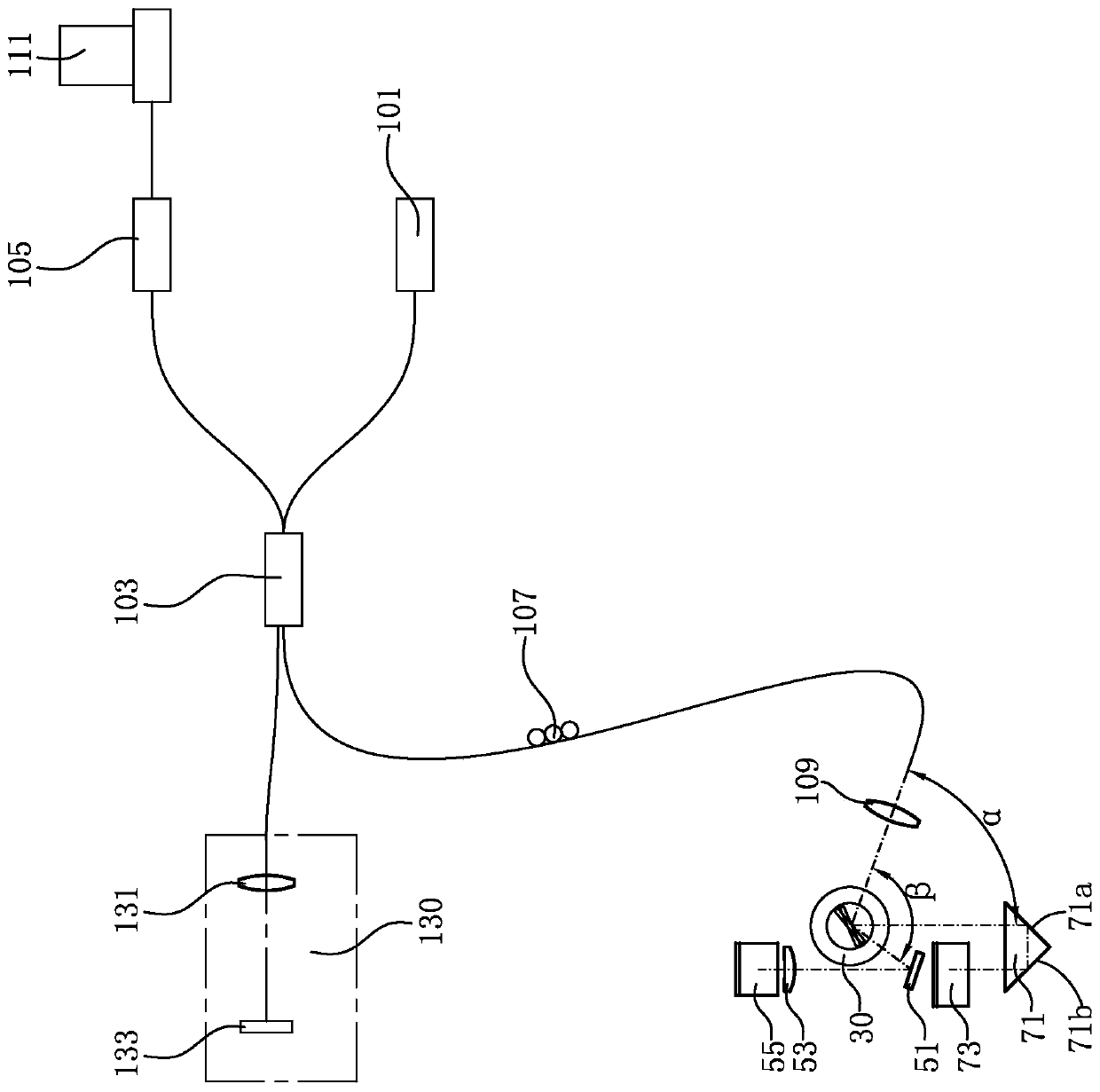

[0131] This embodiment provides an ophthalmological measurement system (hereinafter referred to as the "system"). Embodiment 1 is a basic embodiment of the present invention. For the sake of simplicity, the ophthalmological measurement system provided in this embodiment is similar to Embodiment 1, and will not be To repeat, the first embodiment is incorporated into this embodiment by reference.

[0132] The ophthalmic measurement system provided in this embodiment is used to detect the eye E to be inspected, so as to determine parameters such as the axial length of the eye E to be inspected. Please refer Figure 7 , The system includes a main body module 2100, a reference plane 210, a switching scanning element 230, an anterior segment optical path assembly 250, a posterior segment optical path assembly 270, and a beam splitting element 280. Please join Picture 8 Preferably, the system further includes an eye lens 290, a fixation optical module 2300, and an anterior segment imag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com