Gasoline engine crankshaft box

A crankcase and gasoline engine technology, which is applied in crankcase ventilation, mechanical equipment, engine components, etc., can solve the problems of low production cost, and achieve the effects of low production cost, tightness control, and reduction in the amount of parts and components.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

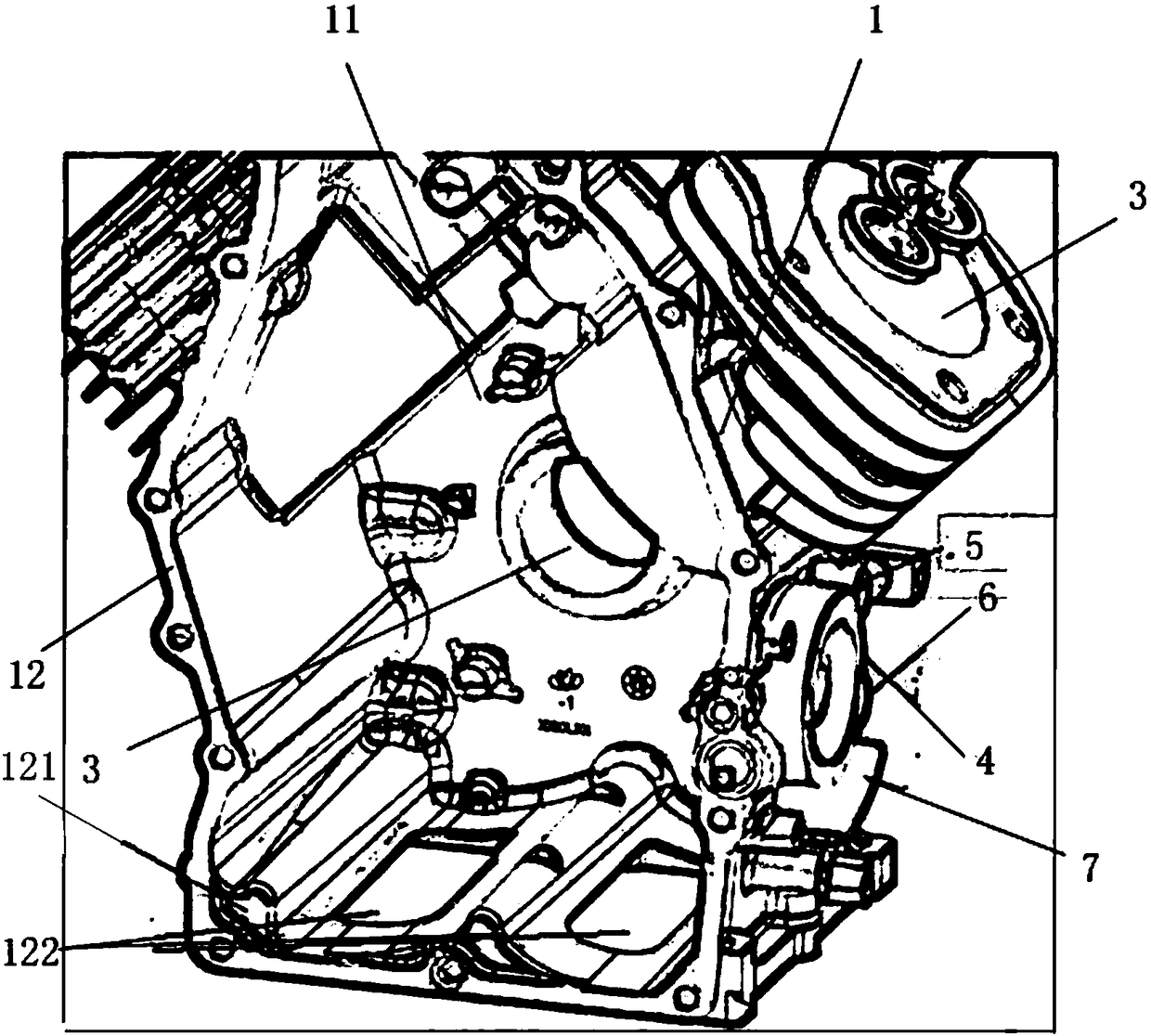

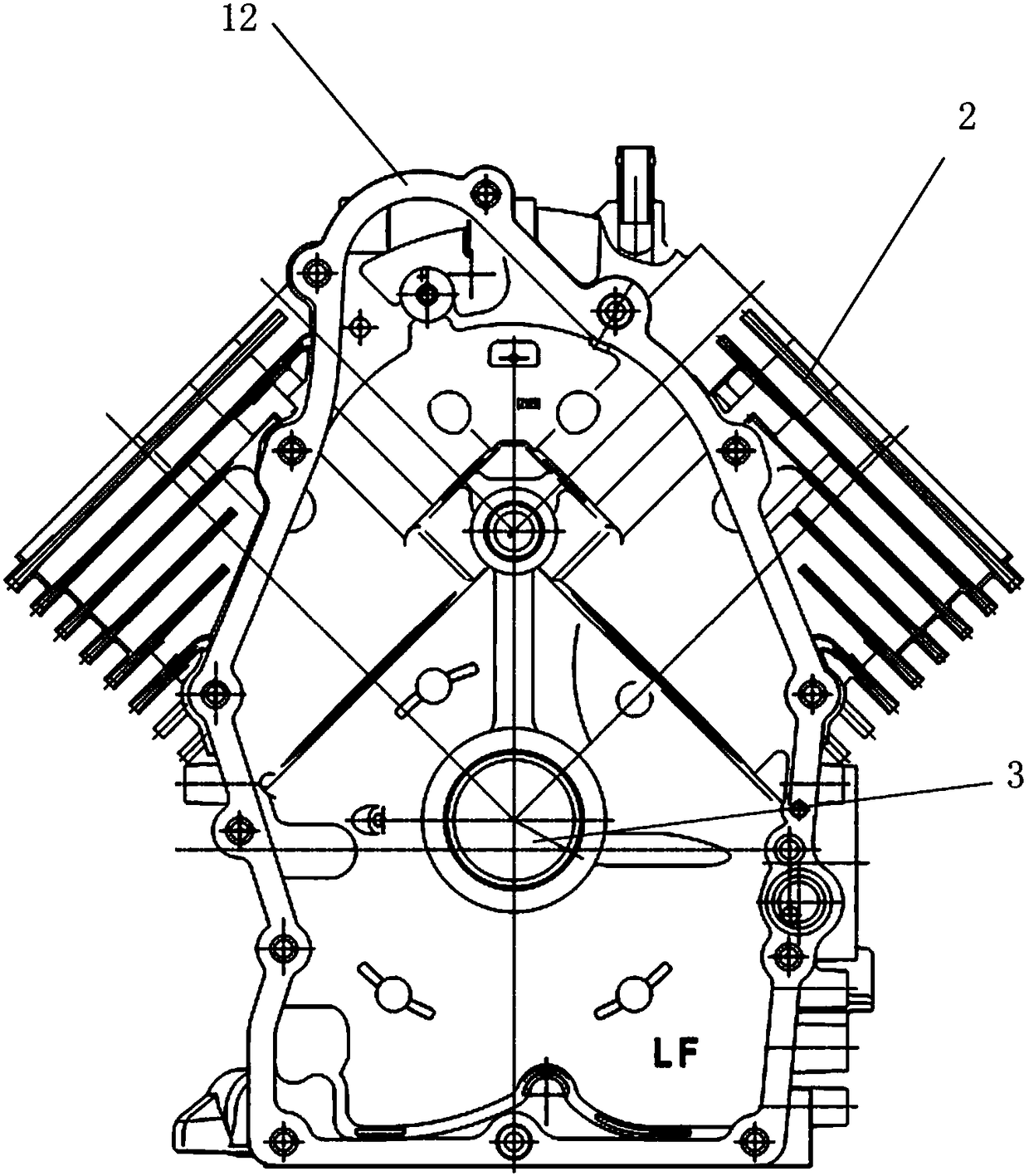

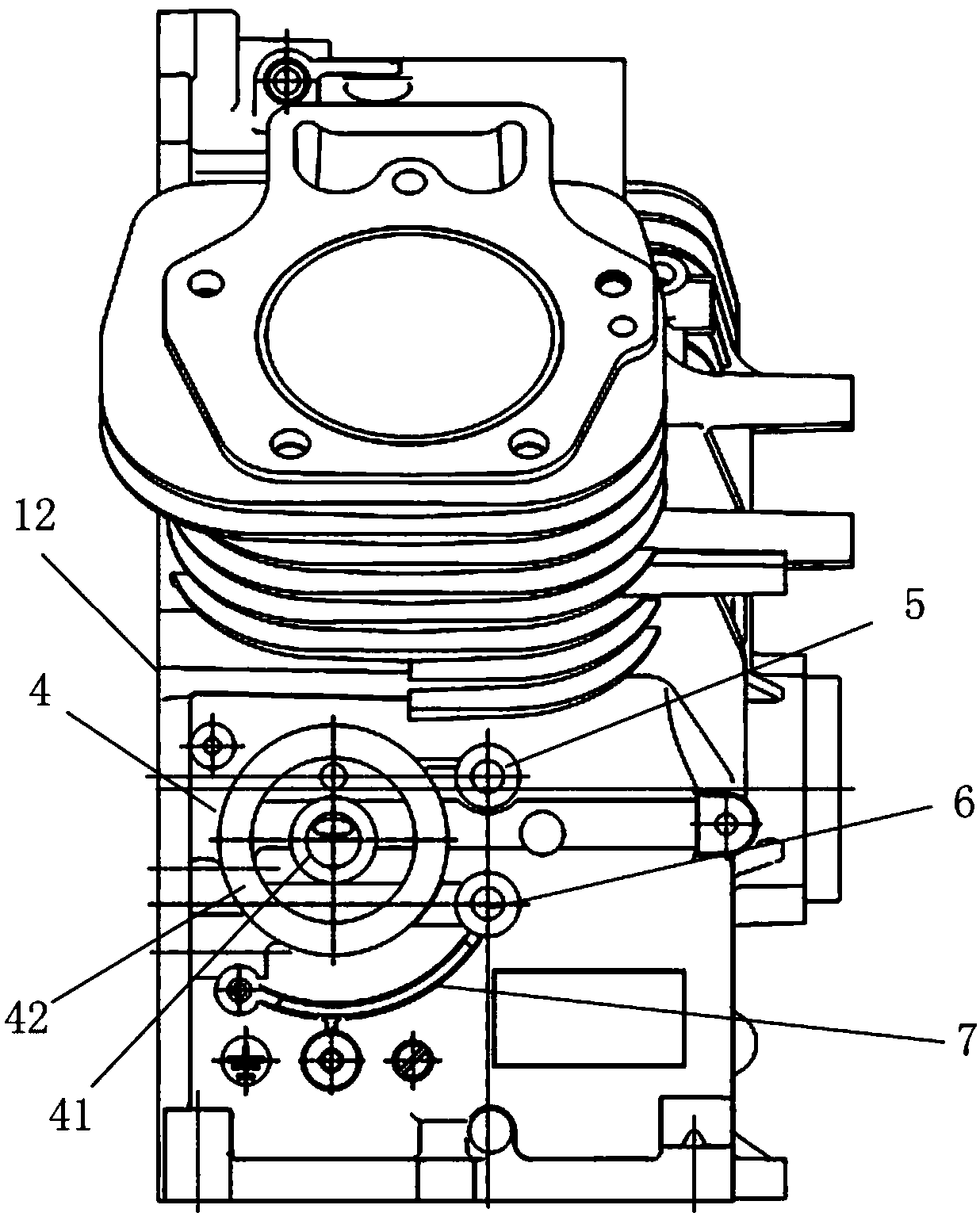

[0042] The specific embodiments provided by the present invention will be described in detail below in conjunction with the accompanying drawings.

[0043]The reference signs and components involved in the accompanying drawings are as follows:

[0044] 1. Box body 11. Panel body

[0045] 12. Side body 121. Reduce flesh

[0046] 122. Enlarging hole 2. Cylinder block

[0047] 3. Crankshaft hole 4. Pipe joint

[0048] 41. Inner pipe 42. Outer pipe

[0049] 5. Oil inlet 6. Oil outlet

[0050] 7. Oil pan 8. Oil and gas separator

[0051] 81. Reed valve 82. Support plate

[0052] 821. Notches 83. Vents

[0053] 84. Labyrinth oil return channel 841. Labyrinth cavity mechanism

[0054] 8411. First labyrinth chamber 8412. Second labyrinth chamber

[0055] 8413. Third labyrinth cavity 8414. Fourth labyrinth cavity

[0056] 842. Partition mechanism 8421. First partition

[0057] 8422. Second partition 8423. Upper wall partition

[0058] 8424. Lower wall partition 8425. Splitt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com