Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

87results about "Electrographic patterning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

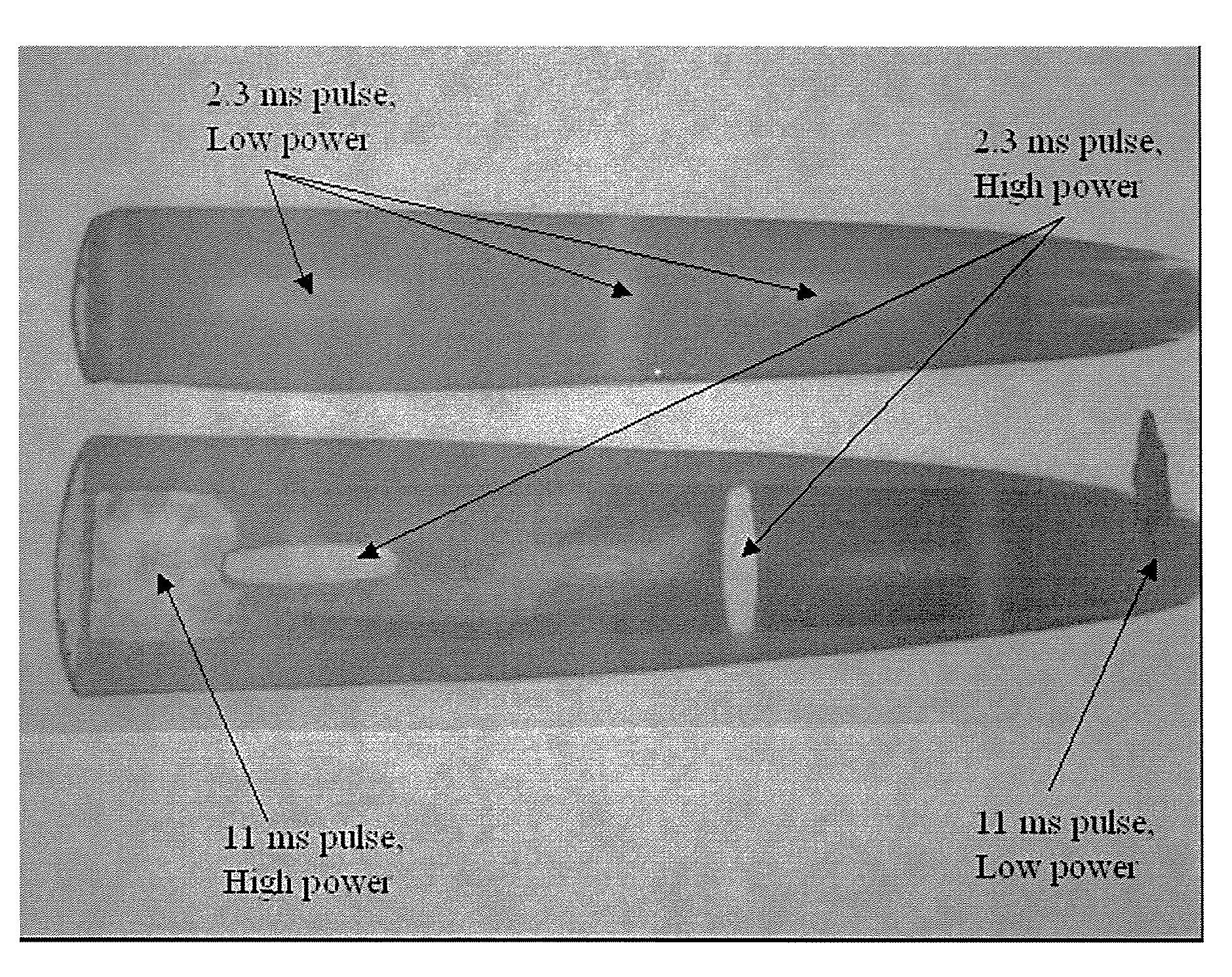

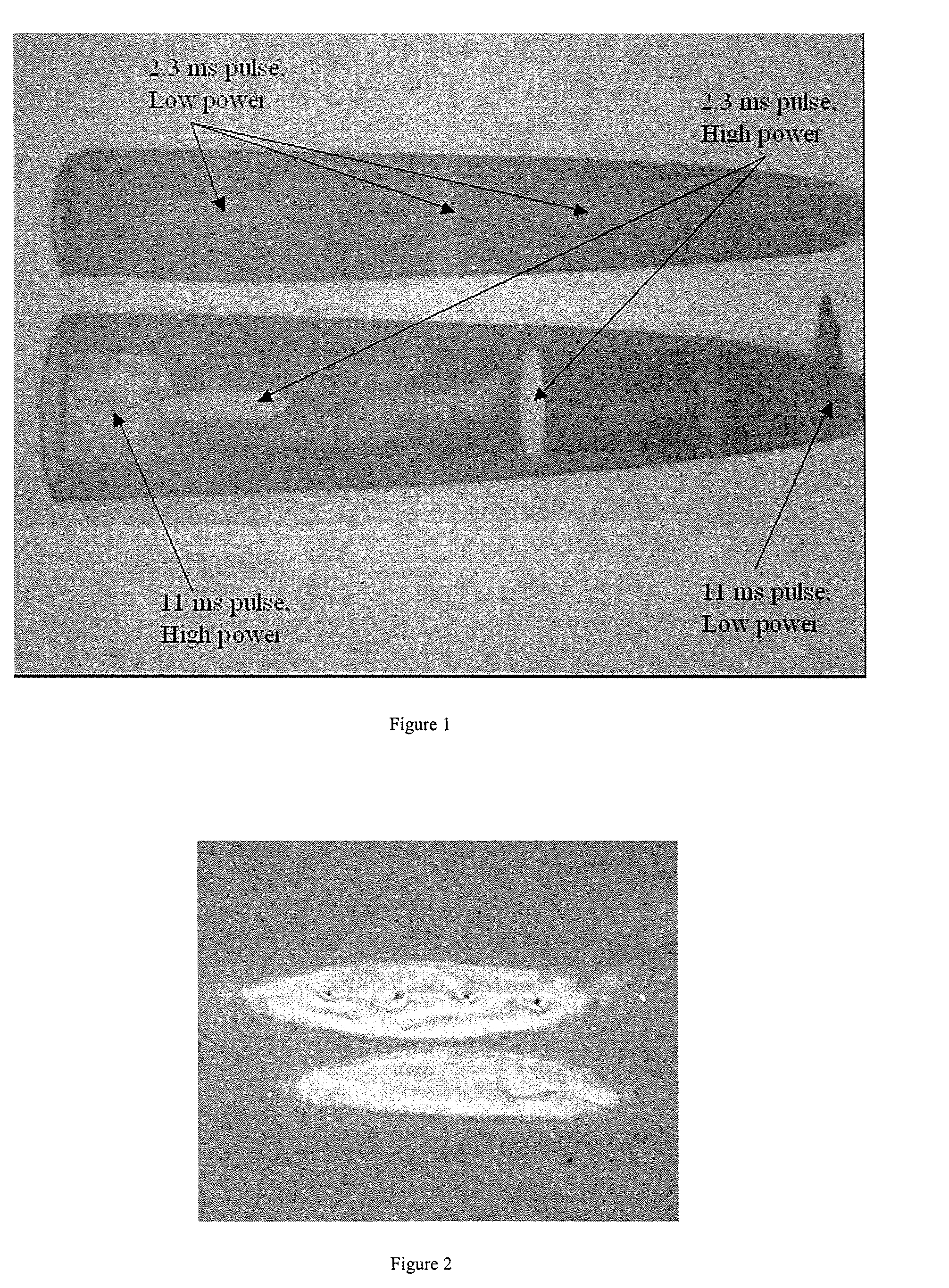

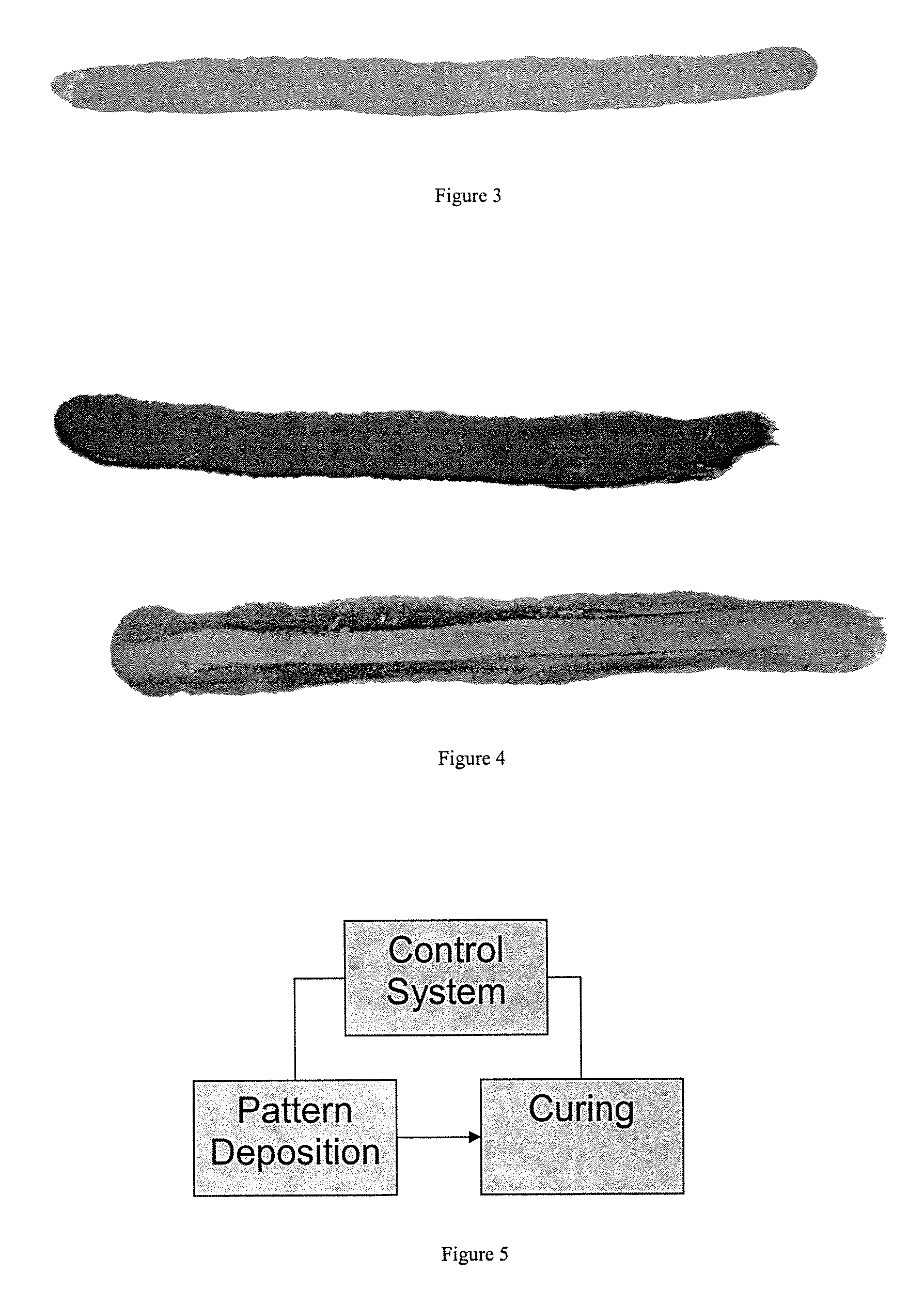

Electrical, plating and catalytic uses of metal nanomaterial compositions

ActiveUS7820097B2Improve absorption rateReduce reflectivityOptical radiation measurementMangetographic processBiological activationElectroplating

Owner:NCC NANO LLC

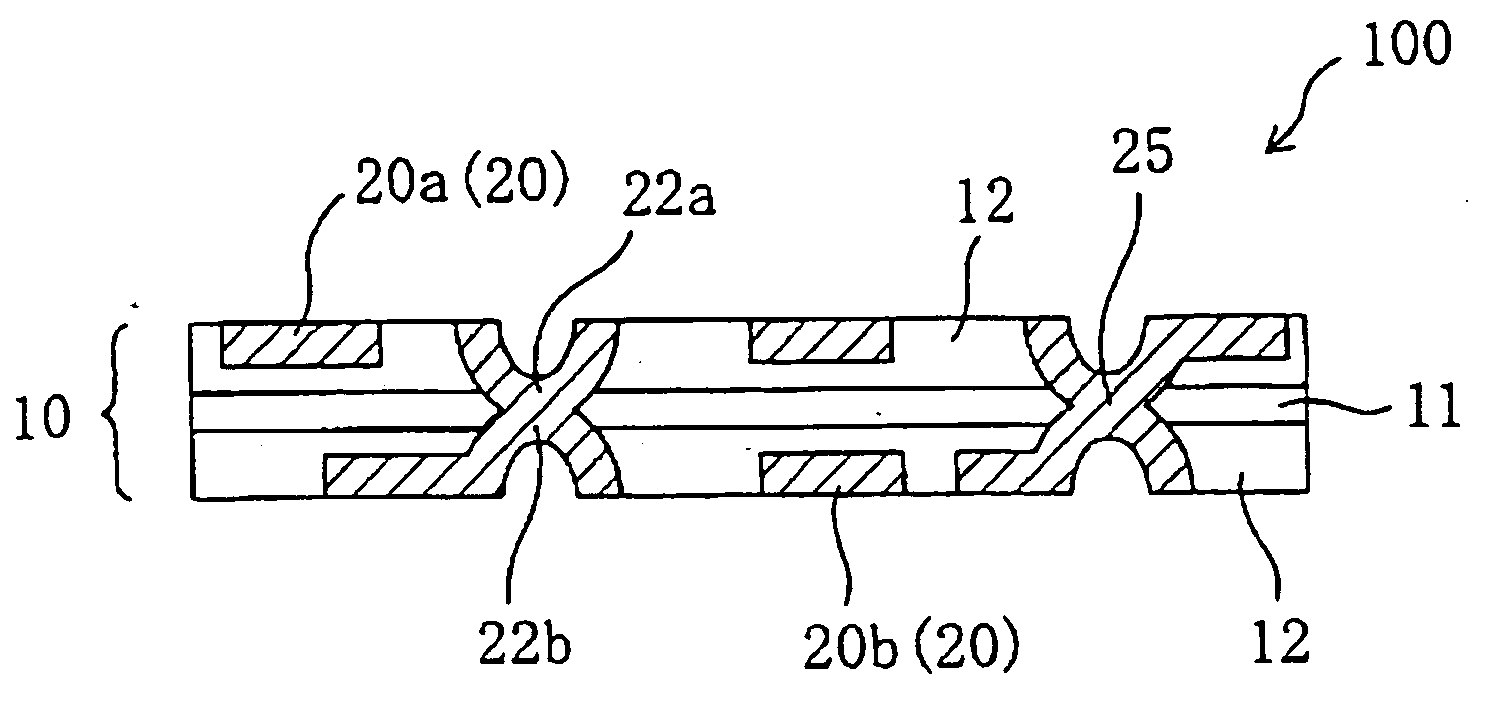

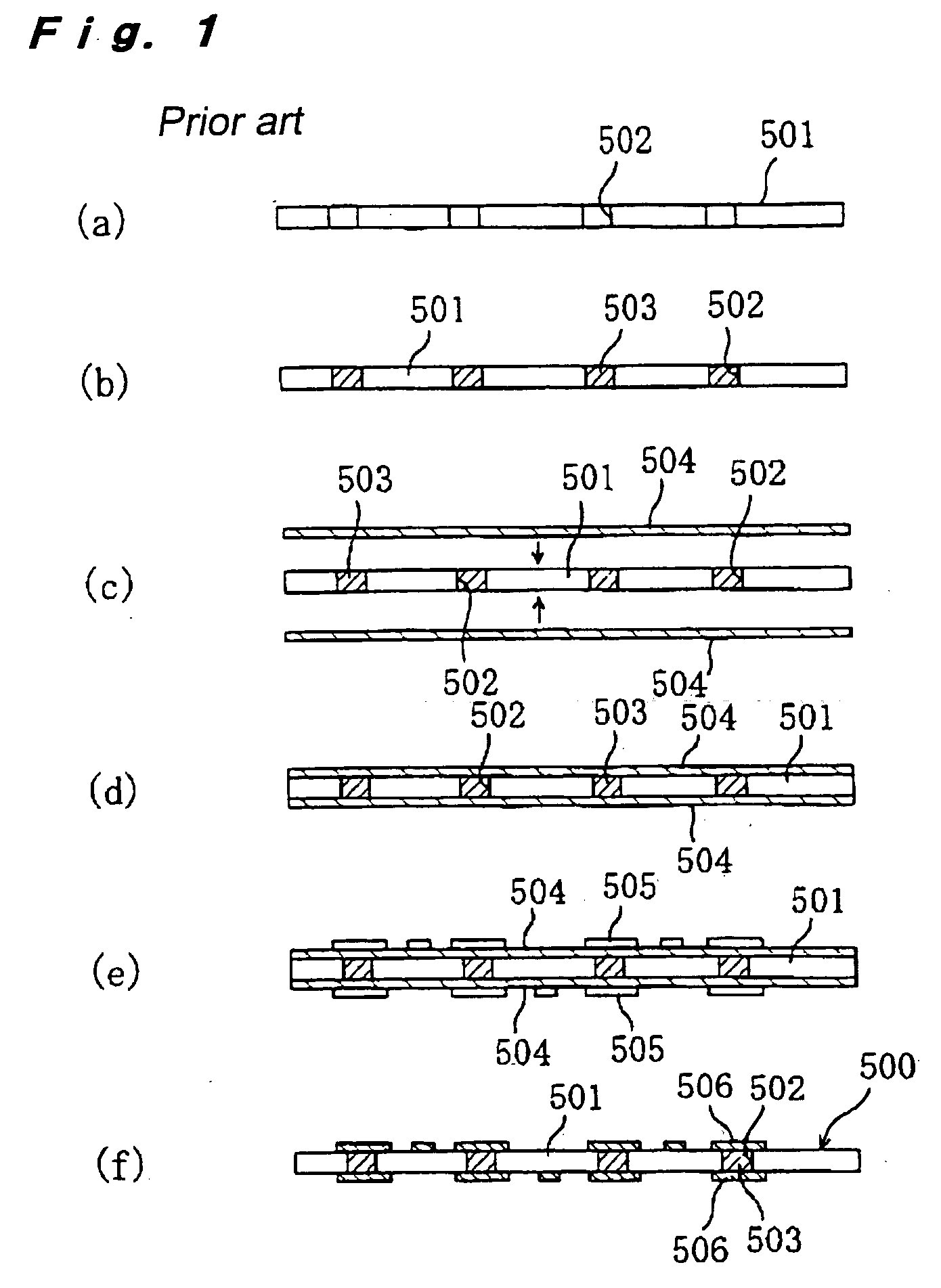

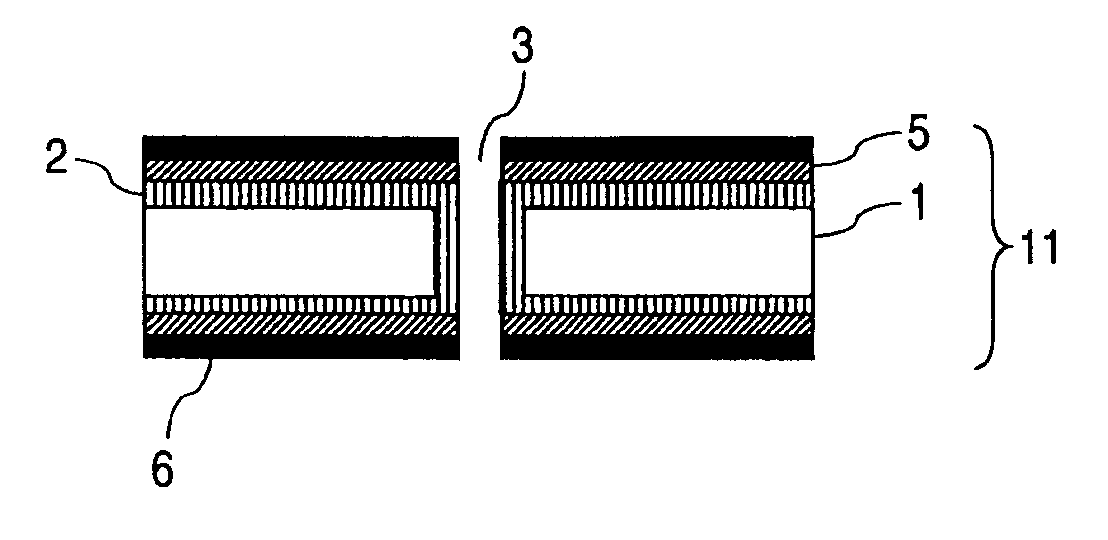

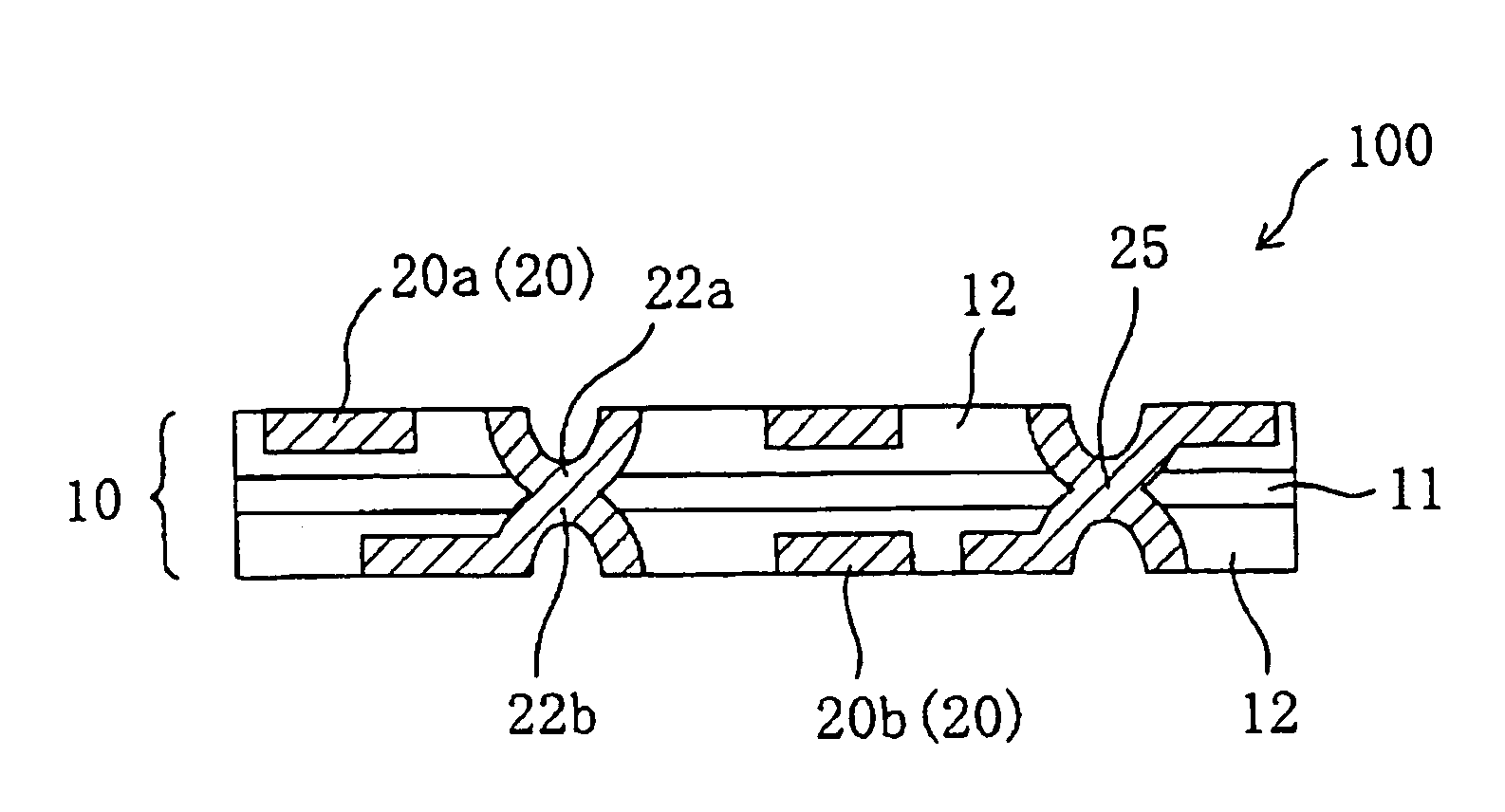

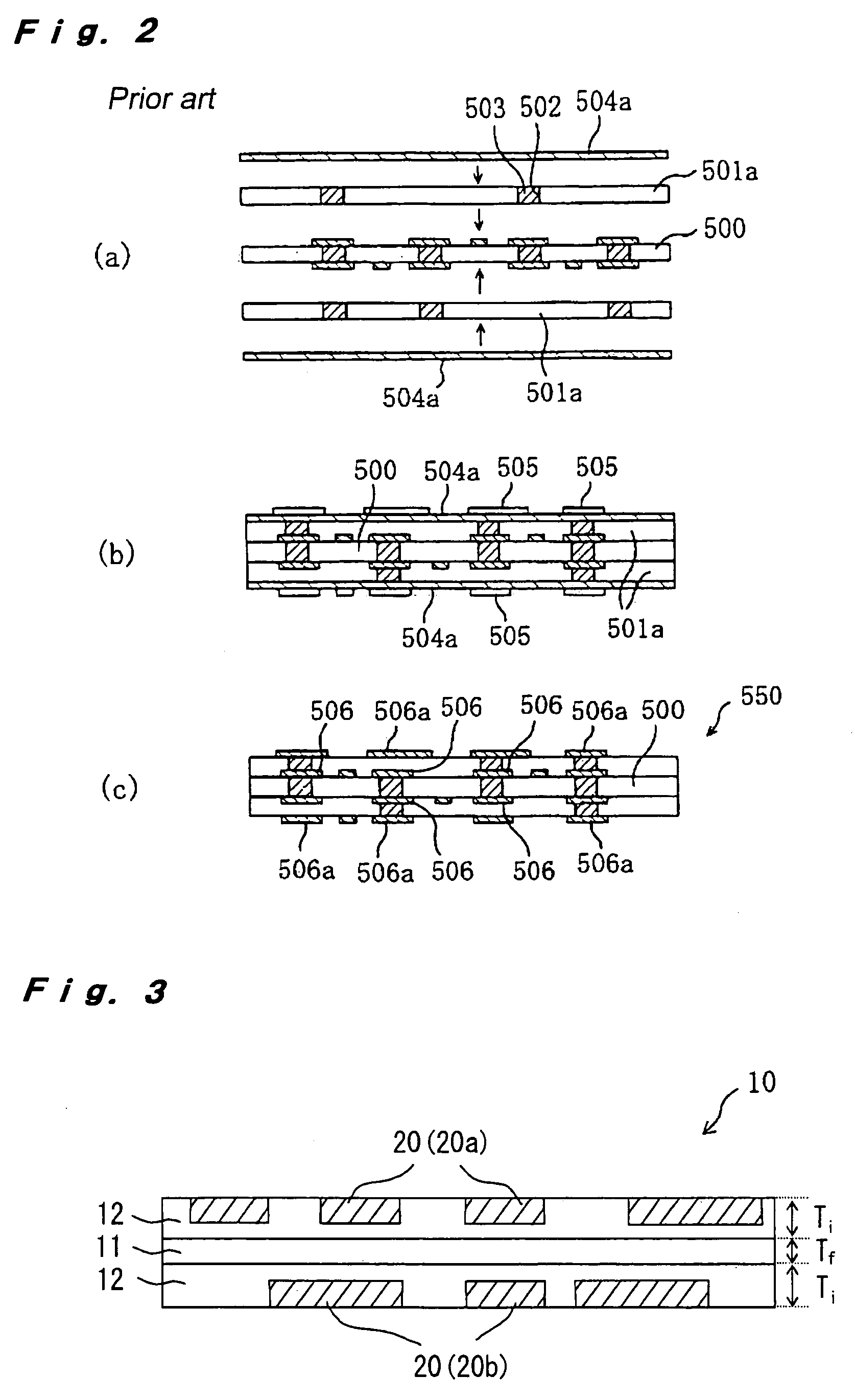

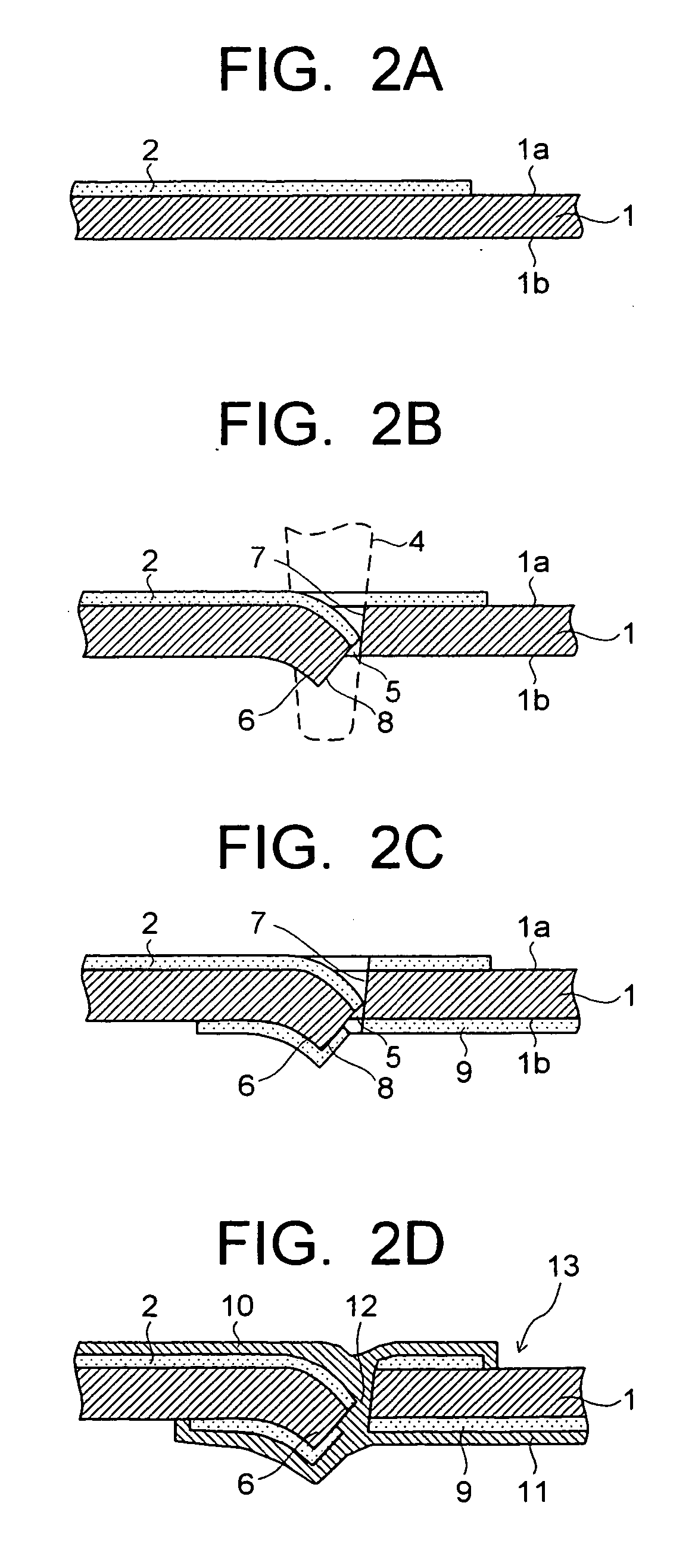

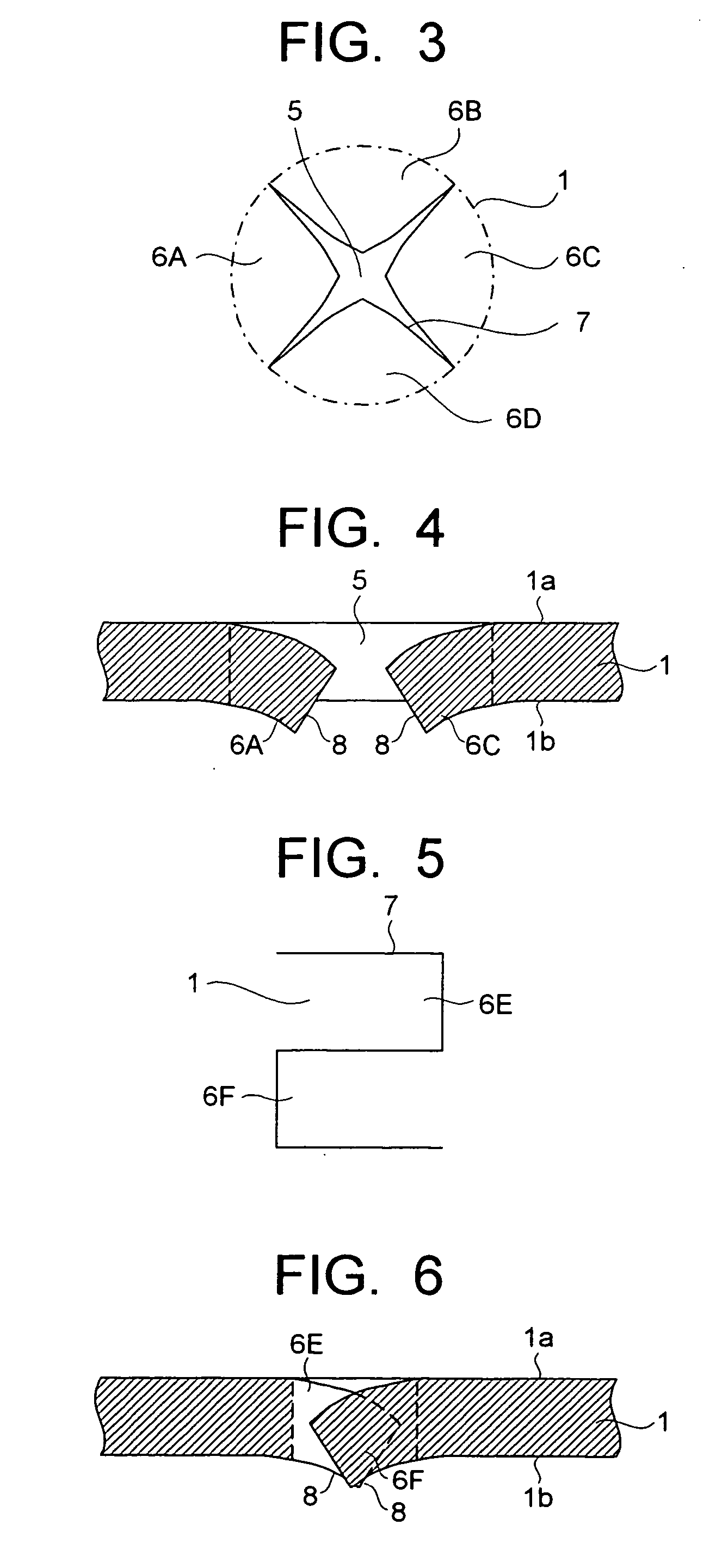

Flexible substrate having interlaminar junctions, and process for producing the same

ActiveUS20050205291A1Improve productivityEasy to holdInsulating substrate metal adhesion improvementPrinted circuit aspectsEngineeringElectrical and Electronics engineering

Owner:PANASONIC CORP

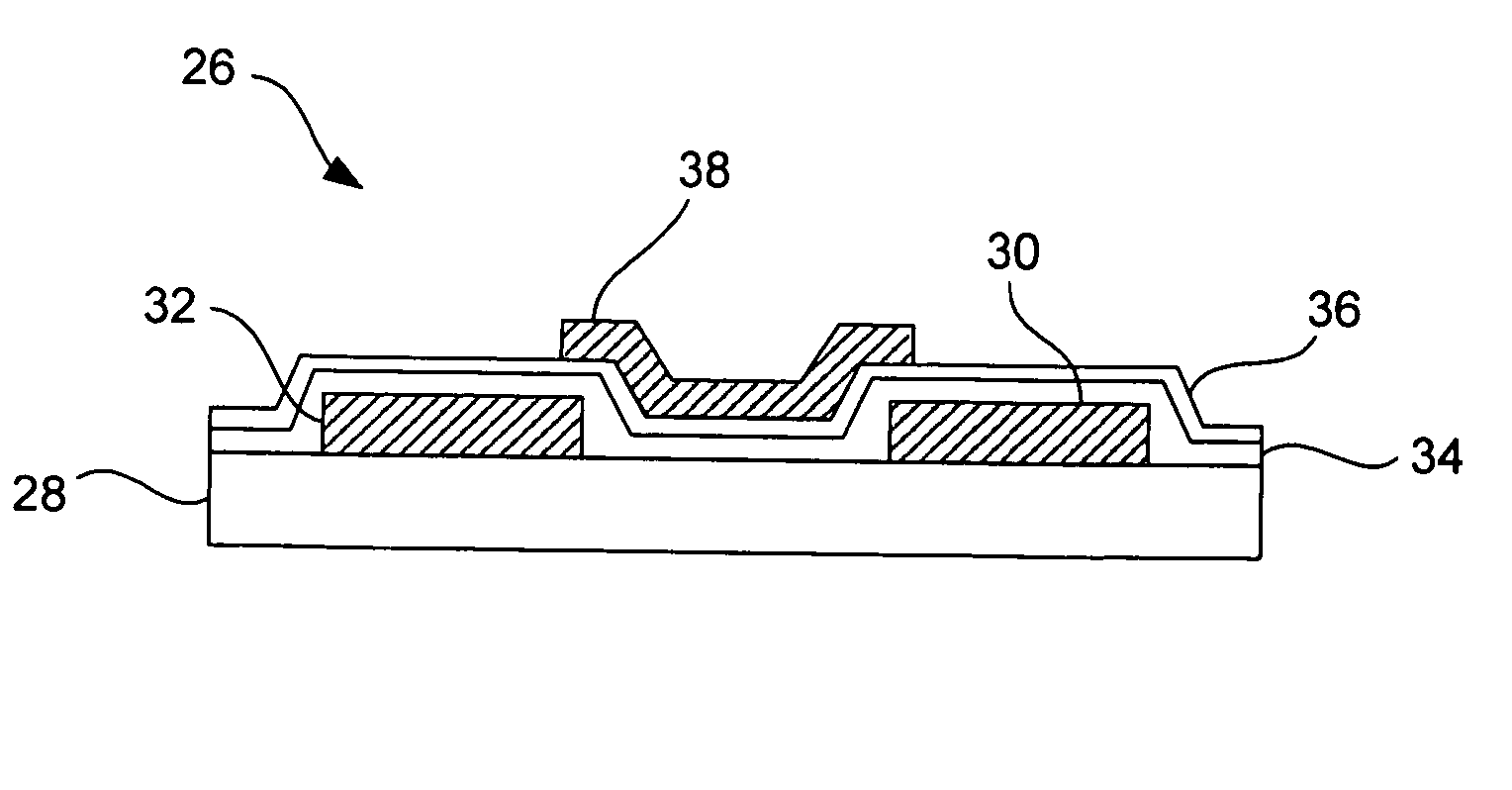

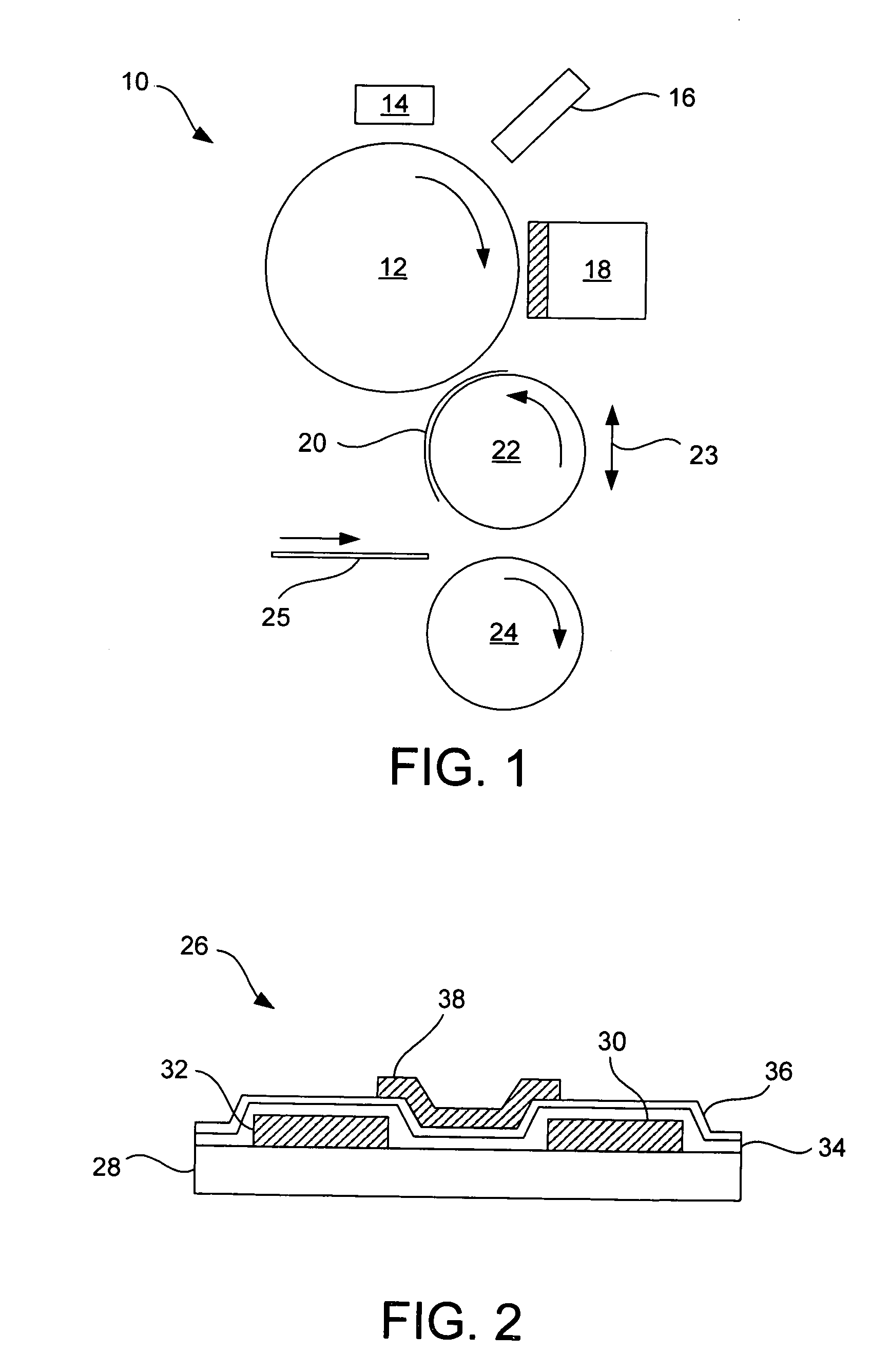

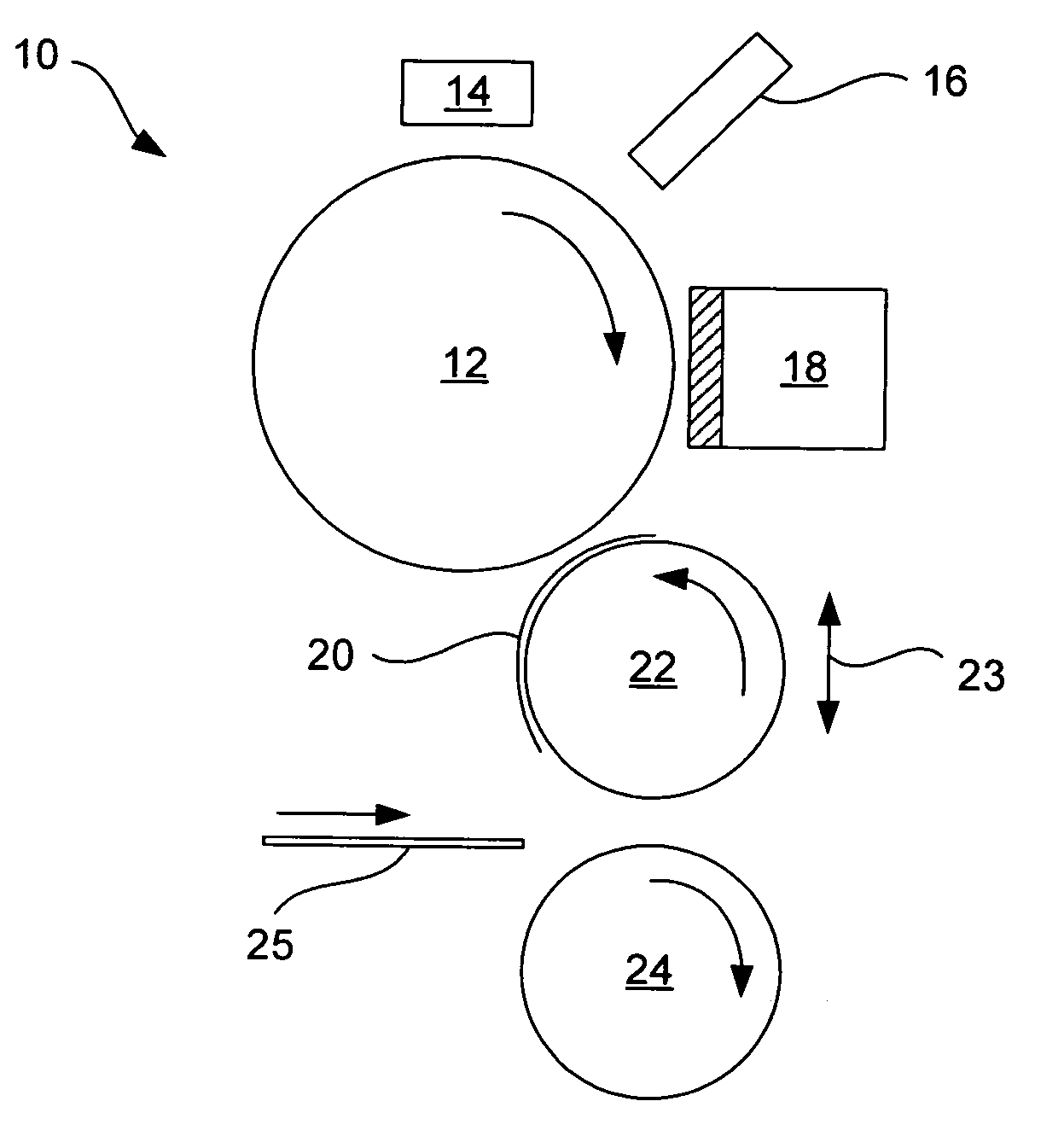

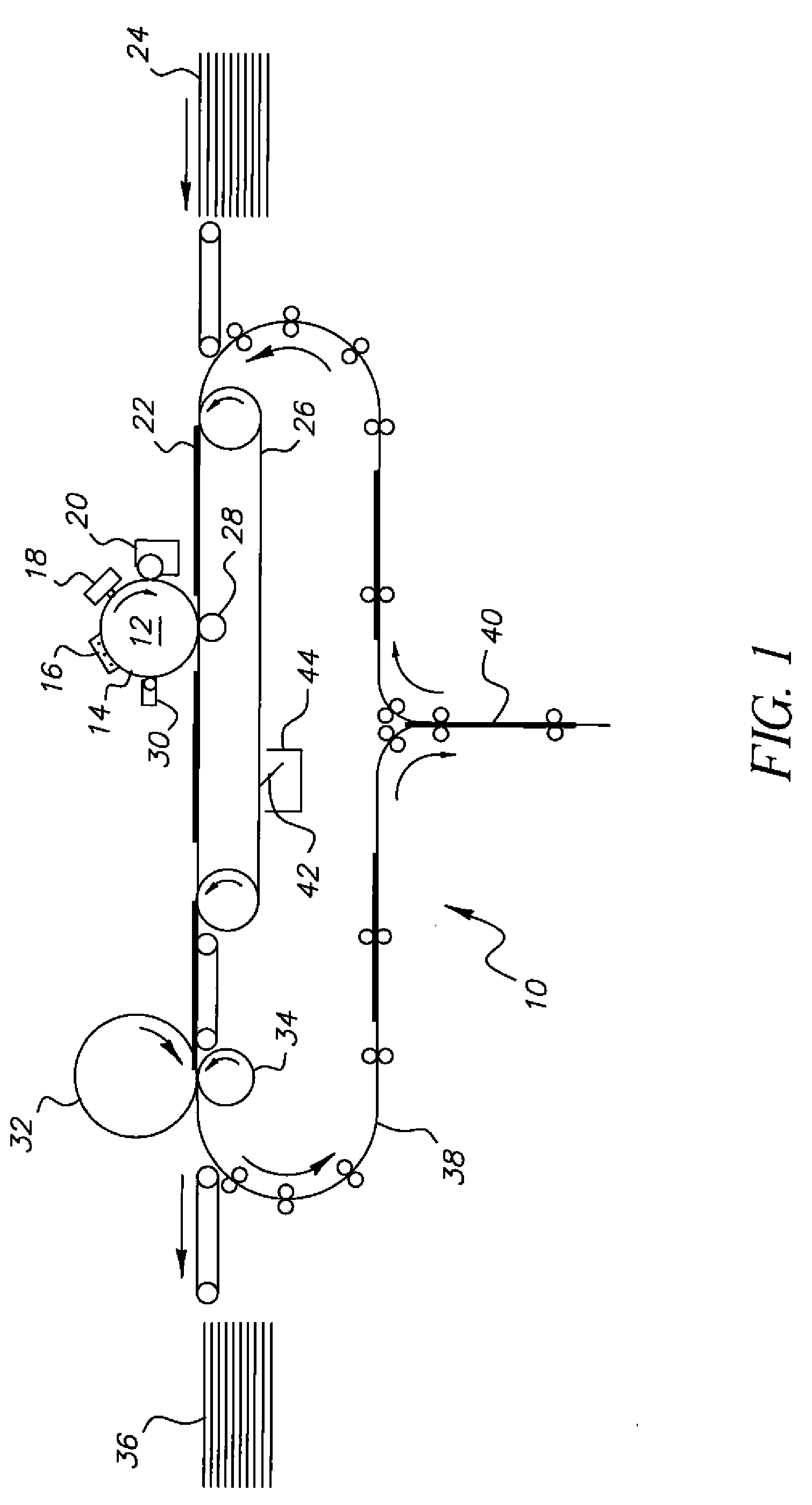

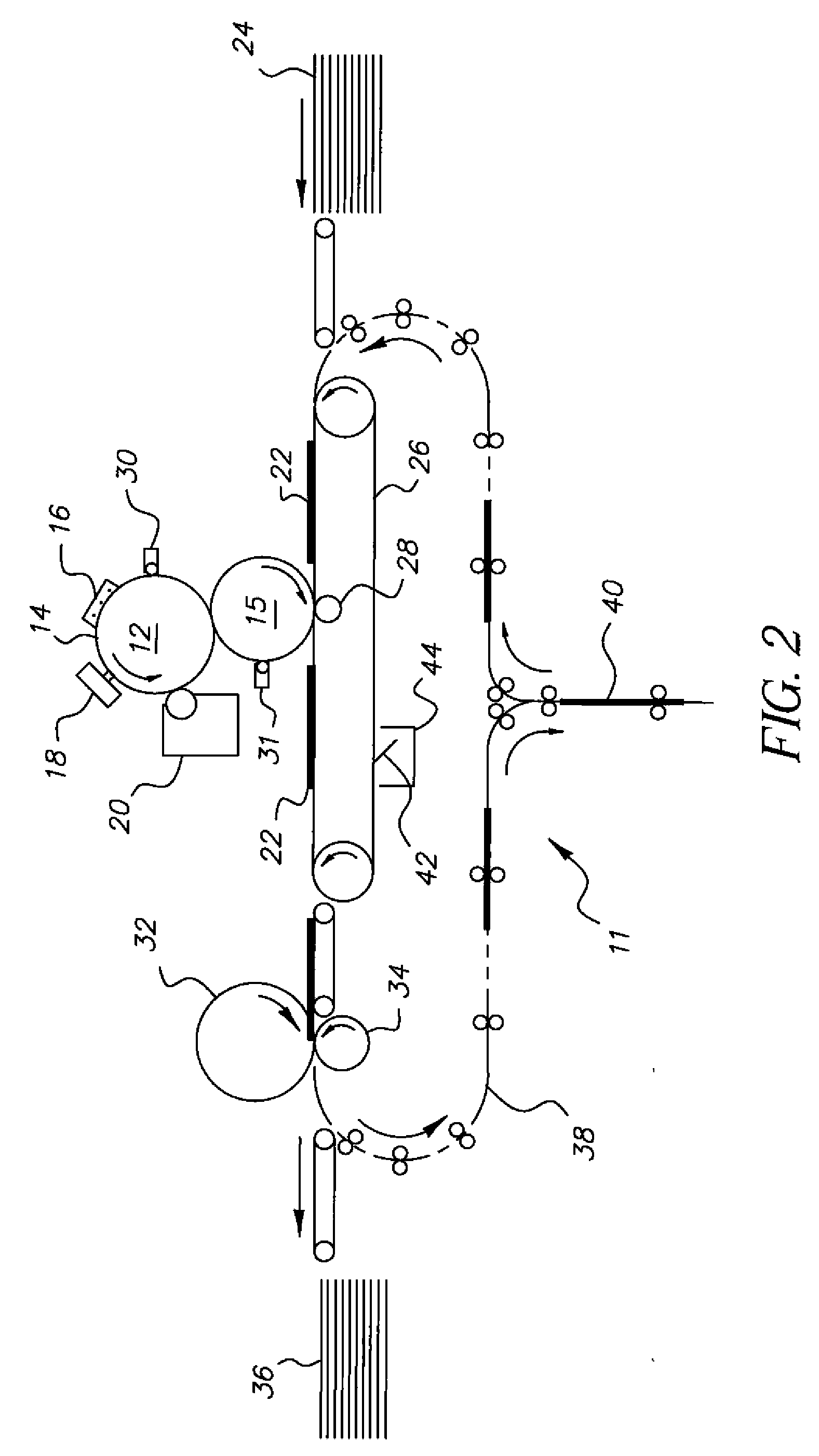

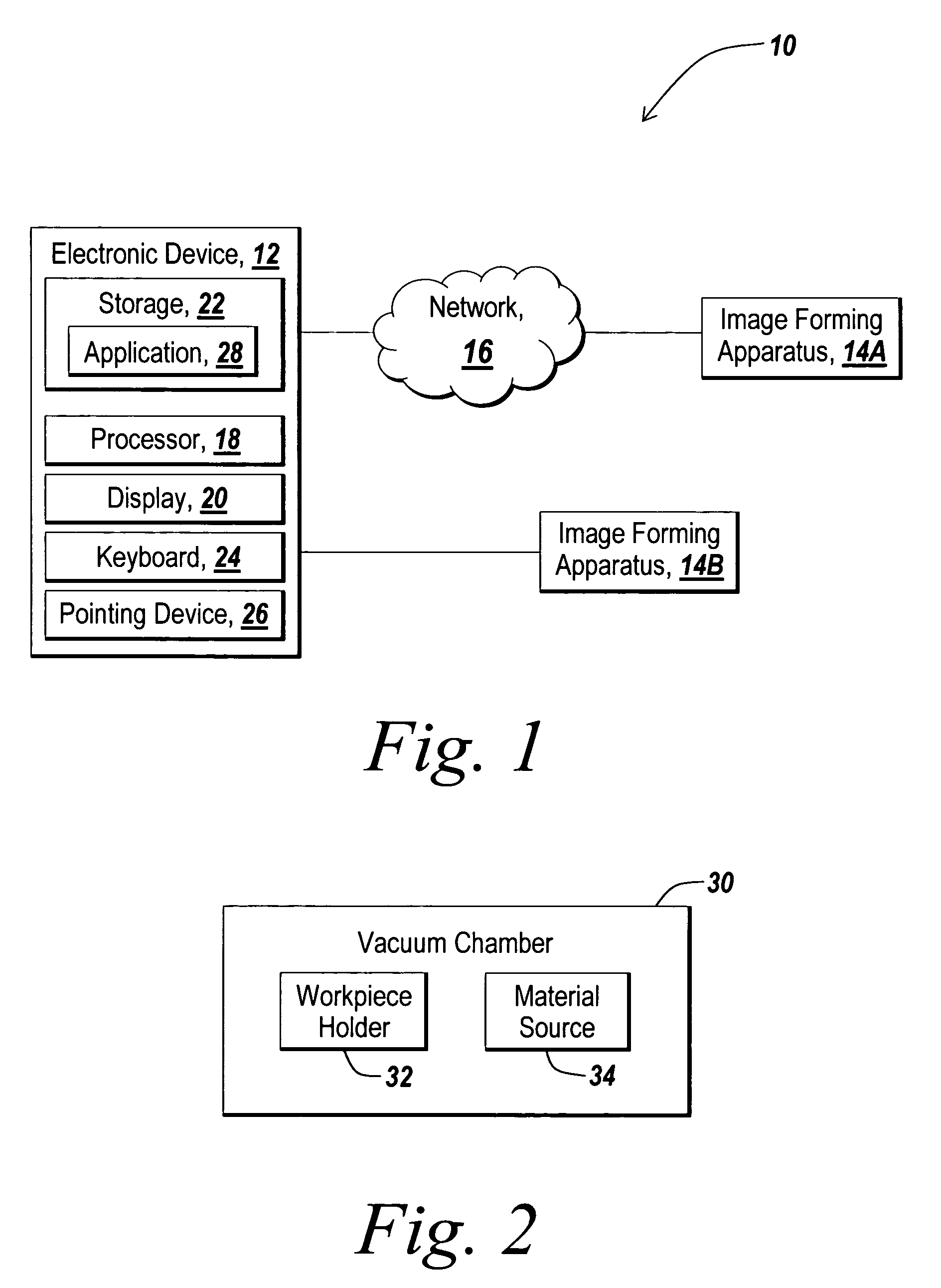

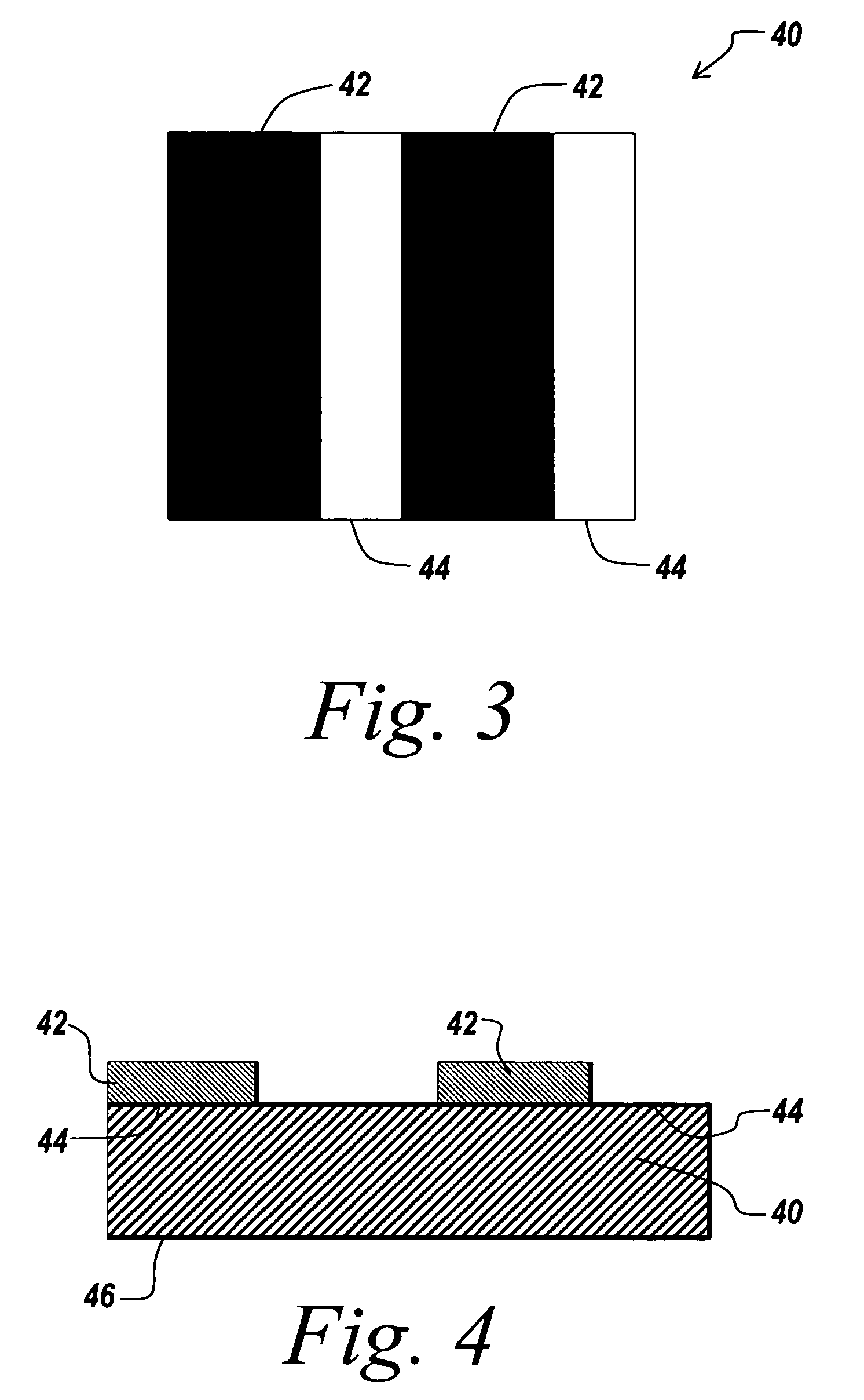

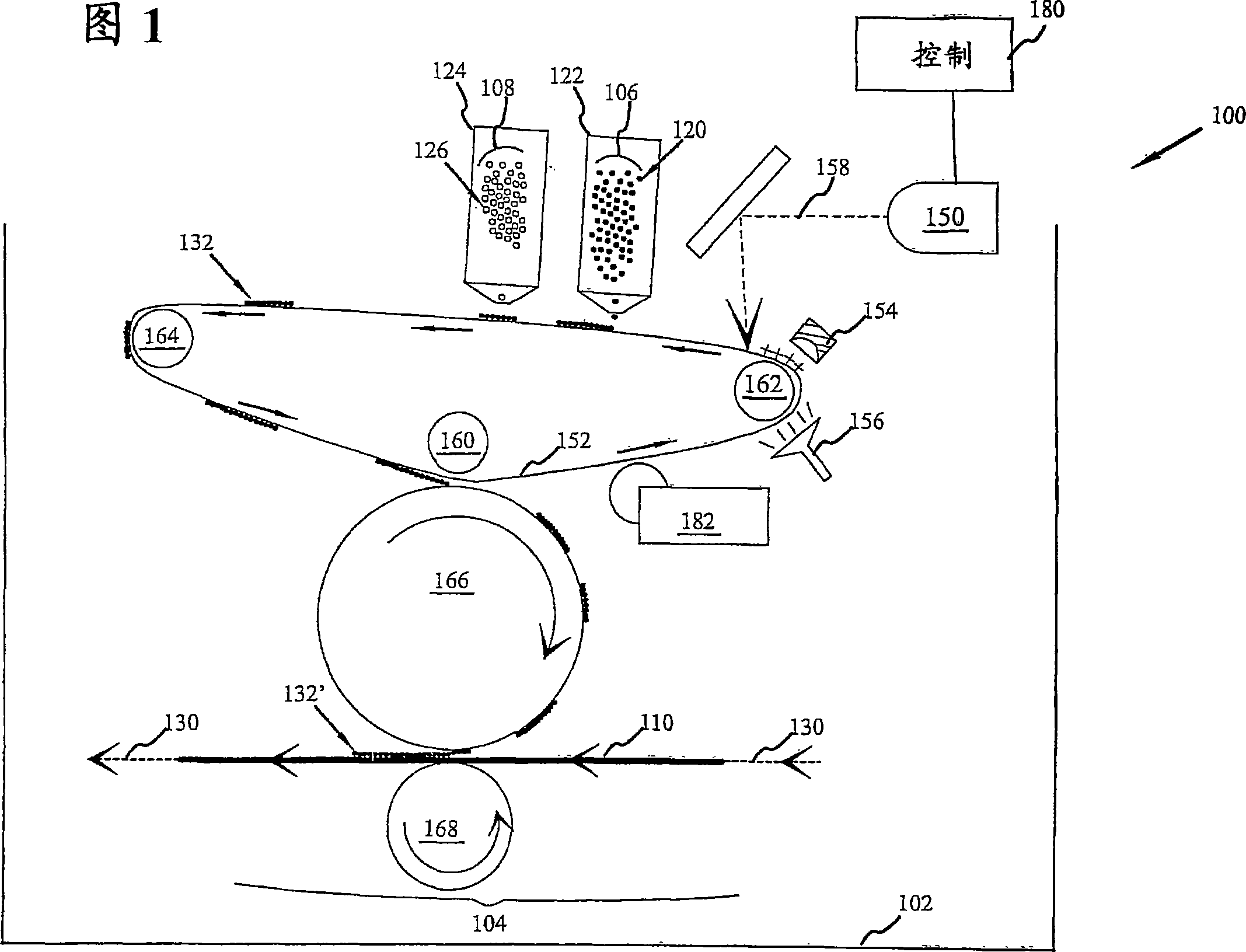

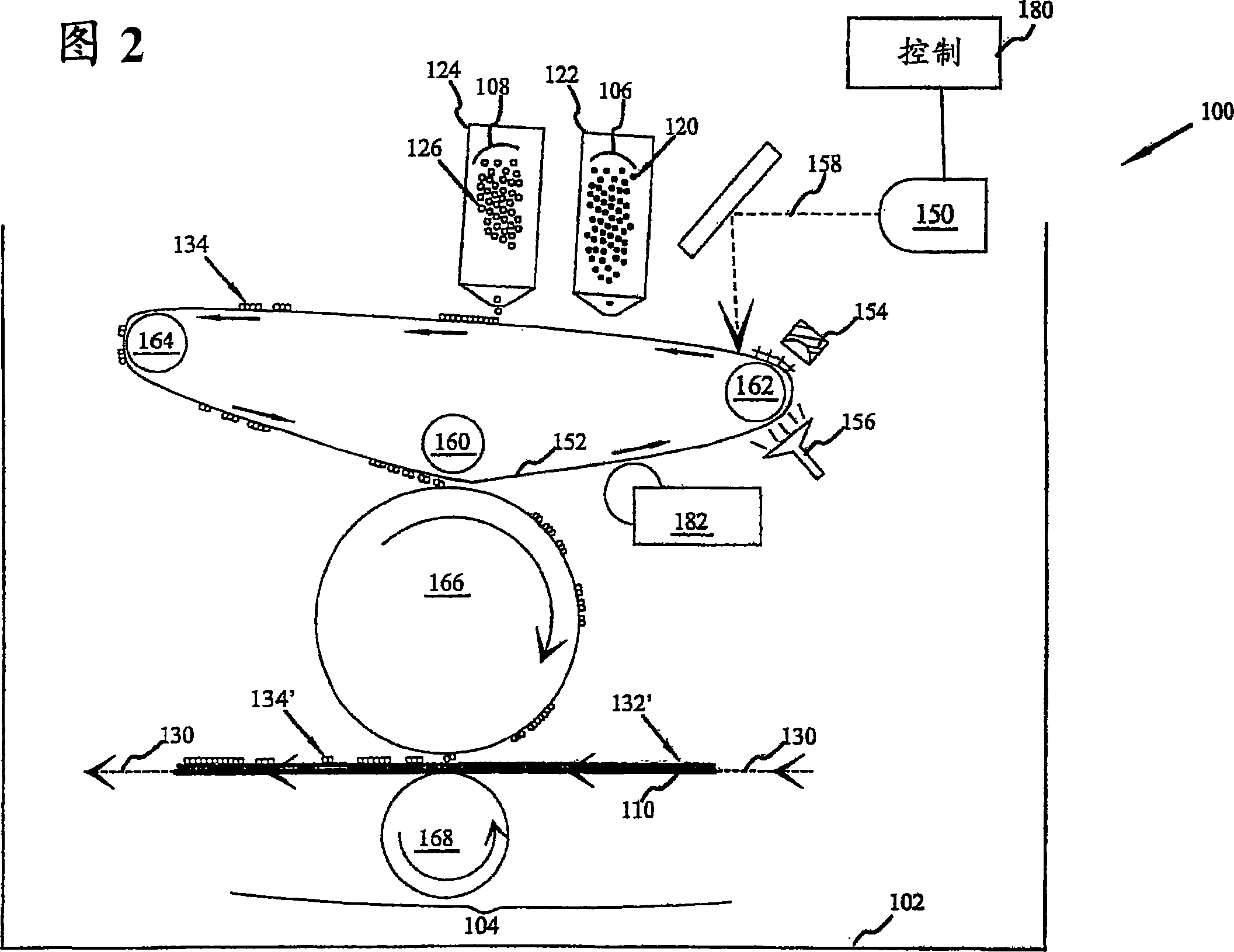

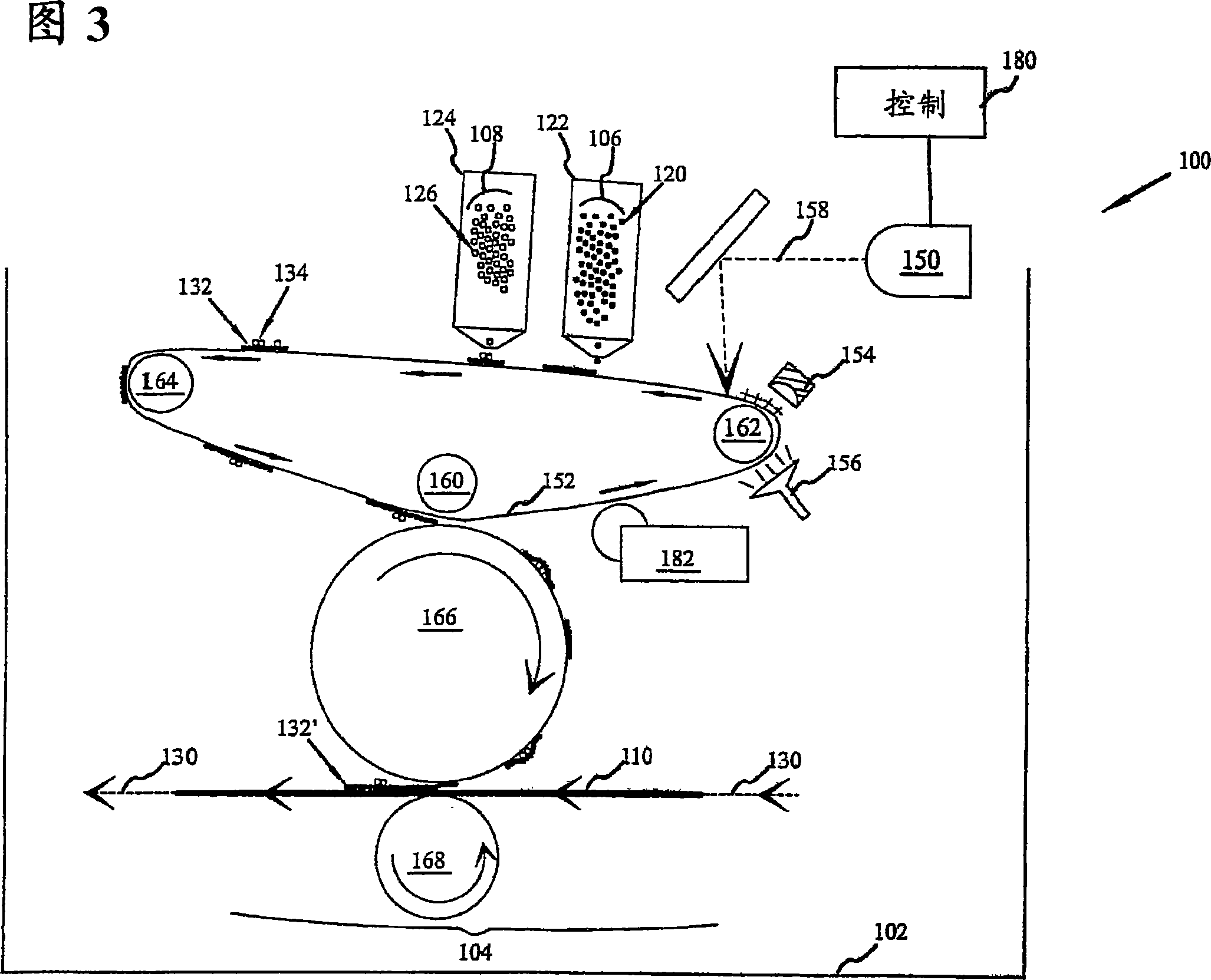

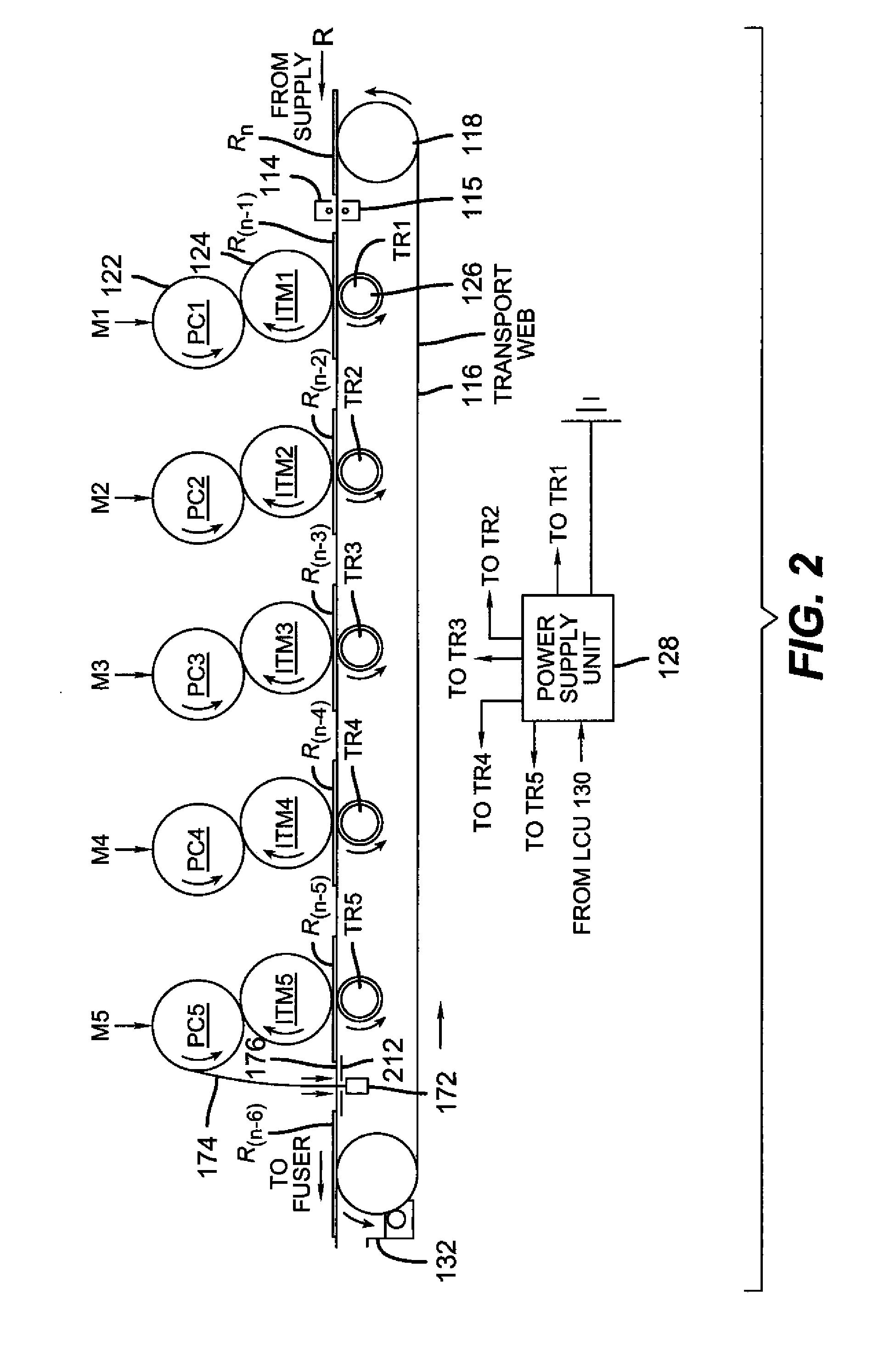

Electrophotographic printing of electronic devices

ActiveUS20060172219A1Reduce manufacturing costLiquid surface applicatorsPrinted electric component incorporationElectrical devicesEngineering

A method of forming electrical devices can include electrophotographically printing a particulate material on a device substrate, and the particulate material can form at least a portion of the electrical device. An optional intermediate transfer member can also be used to improve reliability and performance of the process. Dry or liquid electrophotographic methods can be effectively used to form electronic devices on a wide variety of substrates not conventionally available in device fabrication.

Owner:HEWLETT PACKARD DEV CO LP

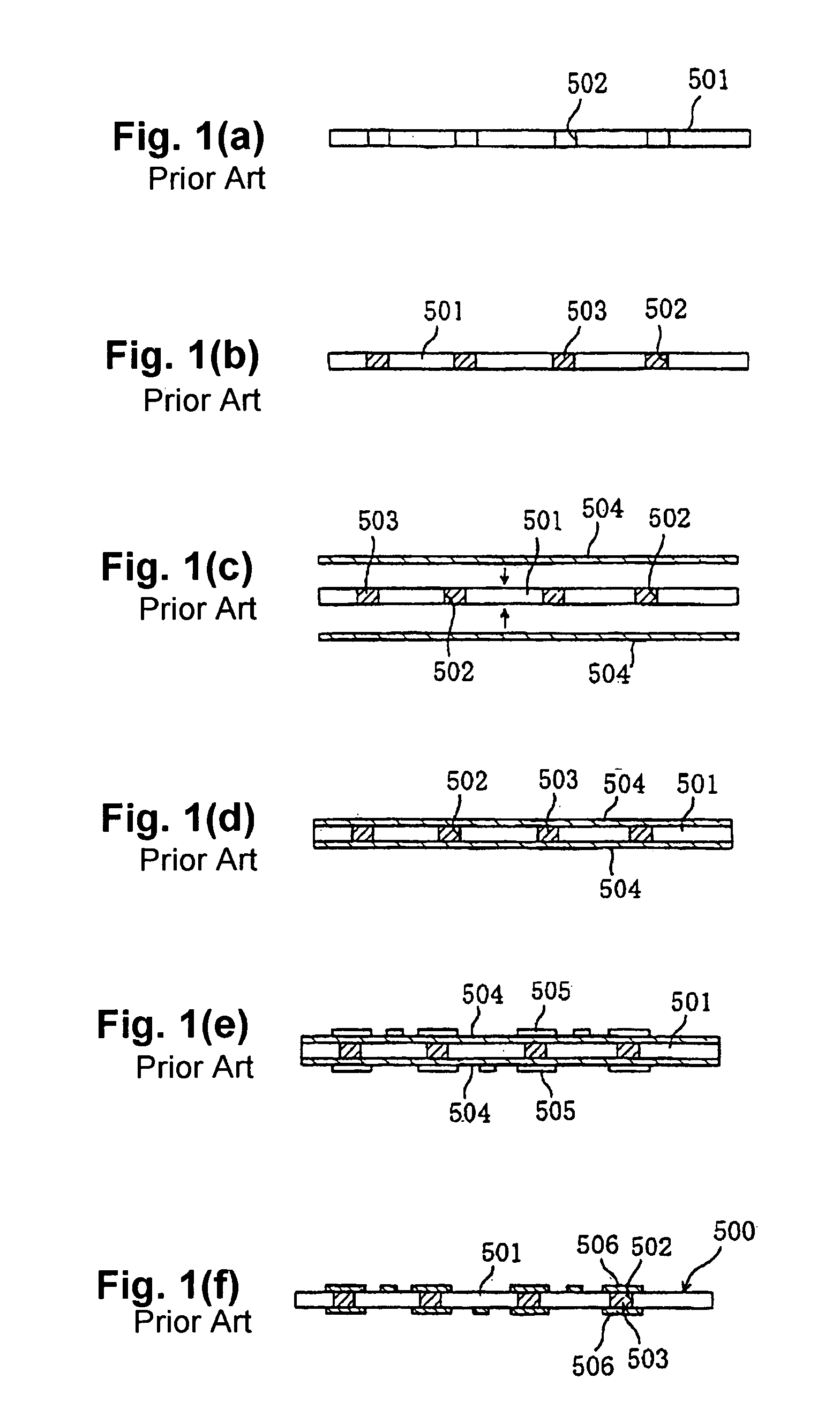

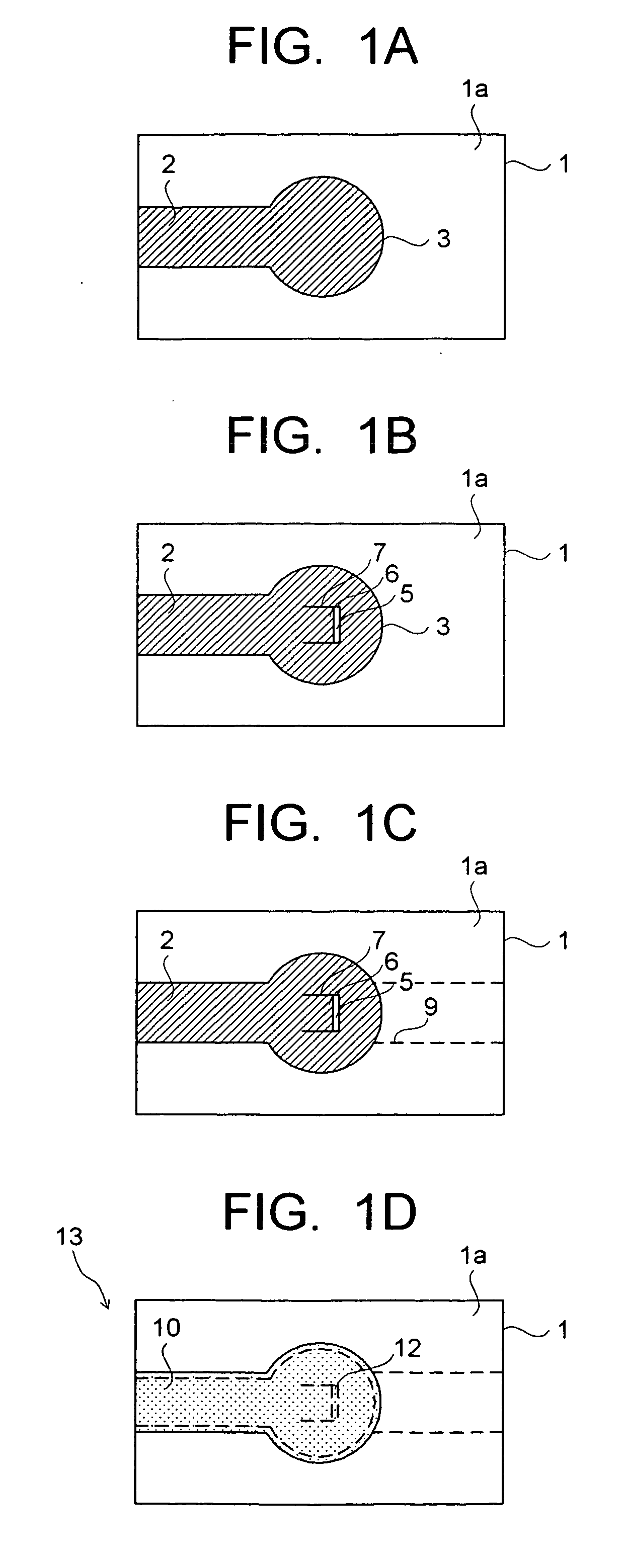

Circuit board manufacturing method and circuit board

InactiveUS20070181994A1Easy to manufactureSemiconductor/solid-state device detailsSolid-state devicesResistPotential difference

As means for solving a problem of a positional shift of a land and a hole which is caused by an alignment in the formation of an etching resist layer and a plated resist layer in a method of manufacturing a circuit board, there are provided a method of manufacturing a circuit board including the steps of forming a first resin layer on a surface of an insulating substrate having a conductive layer on the surface and an internal wall of a through hole or / and a non-through hole, forming a second resin layer which is insoluble or slightly soluble in a developing solution for the first resin layer on the first resin layer provided on the surface conductive layer, and removing the first resin layer provided over the hole with the developing solution for the first resin layer, and a method of manufacturing a circuit board including the step of uniformly charging a surface of the first resin layer to induce a potential difference to the first resin layer provided over the hole and the first resin layer provided on the surface conductive layer before forming the second resin layer. Moreover, there is provided a circuit board having a hole with a small positional shift and high precision.

Owner:SHINKO ELECTRIC IND CO LTD +1

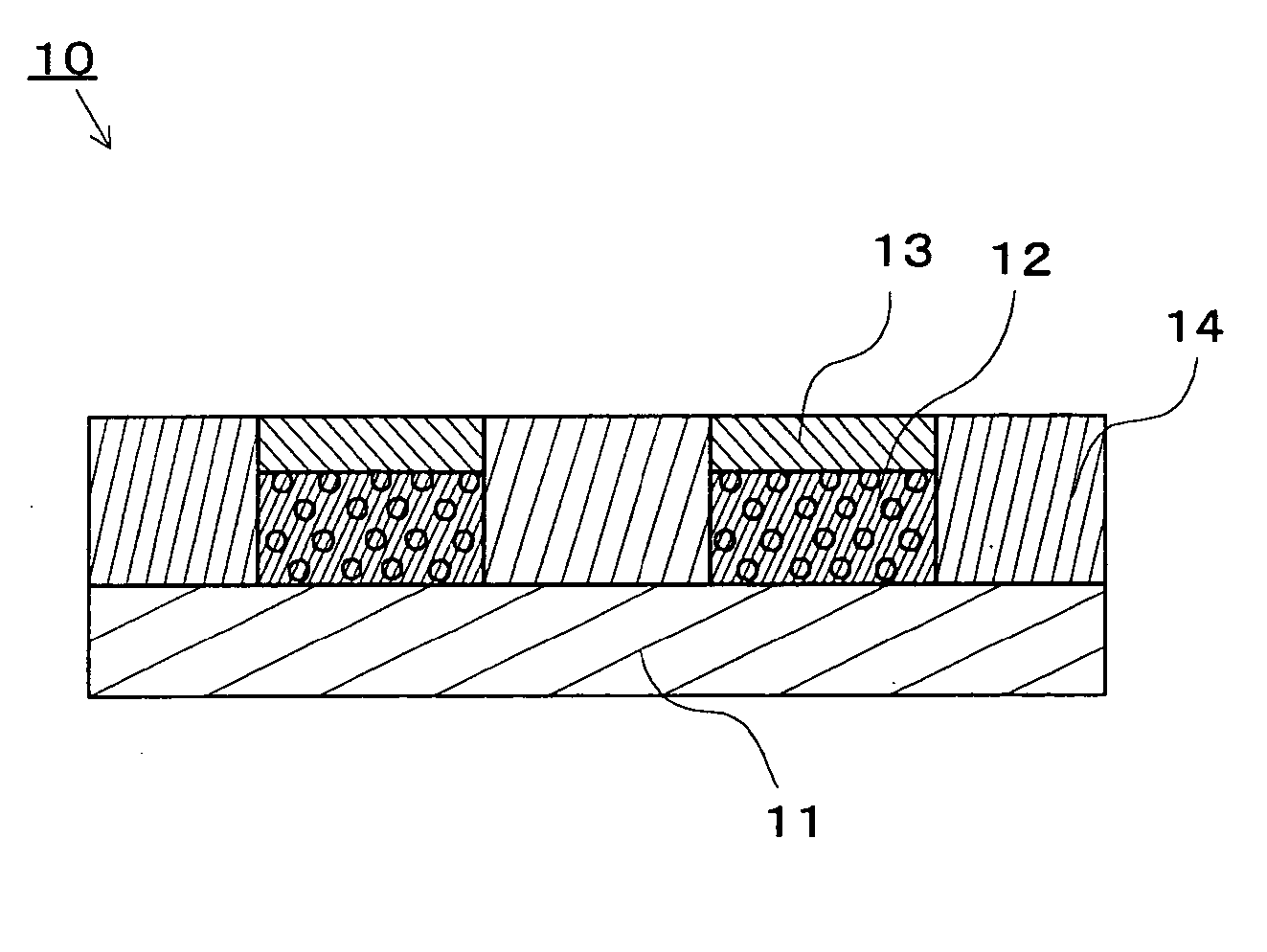

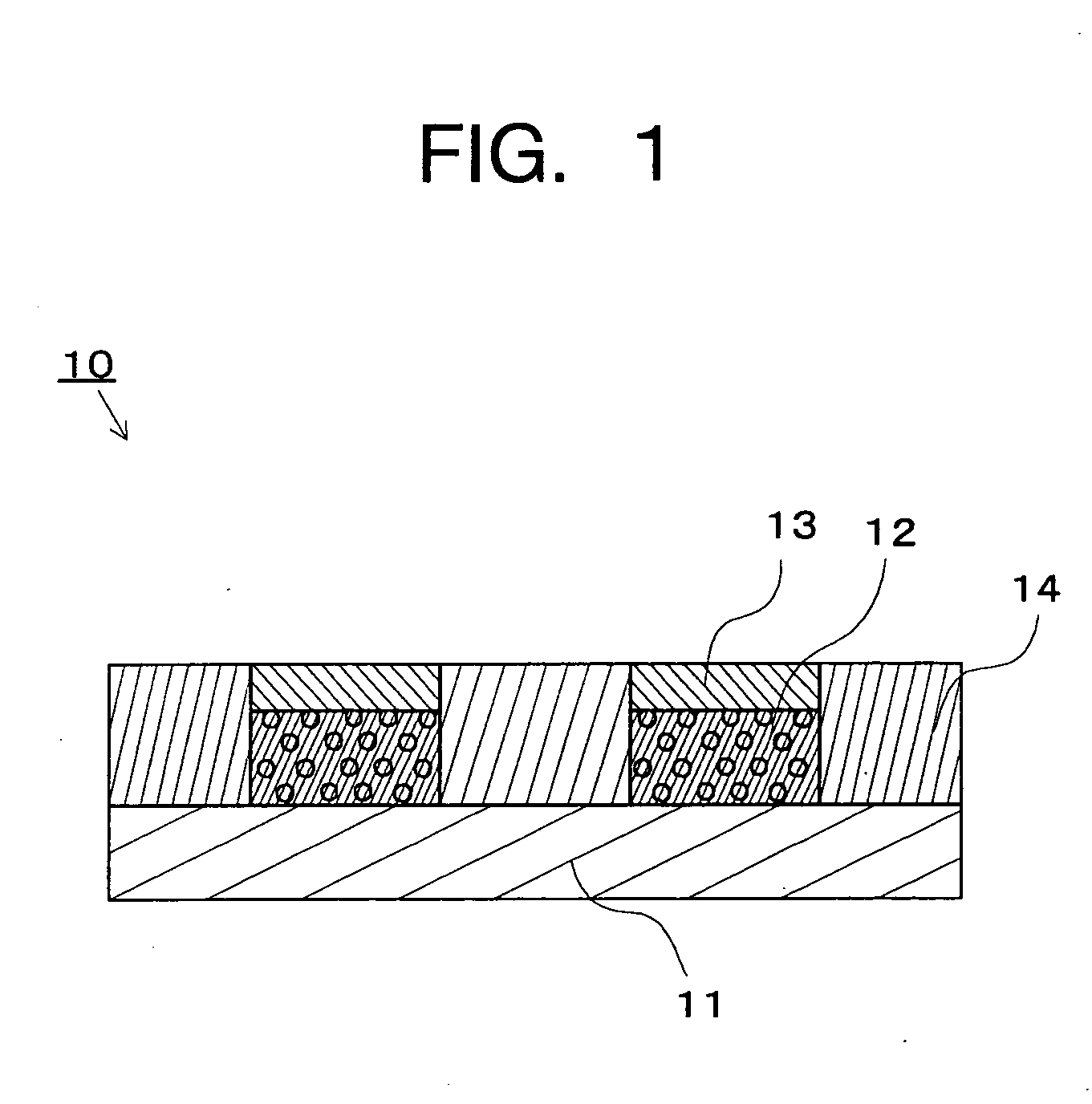

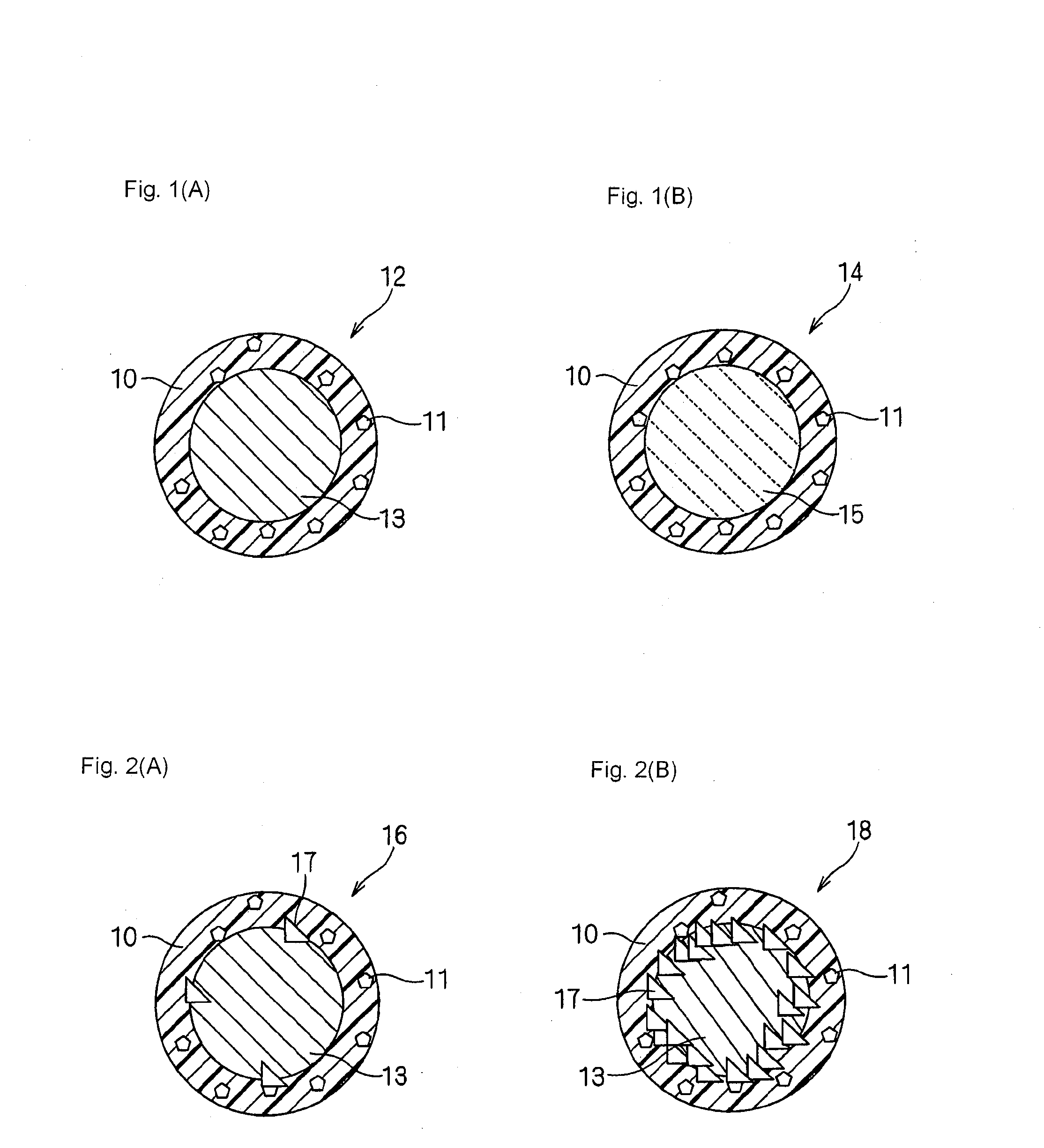

Circuit board and manufacturing method of the circuit board

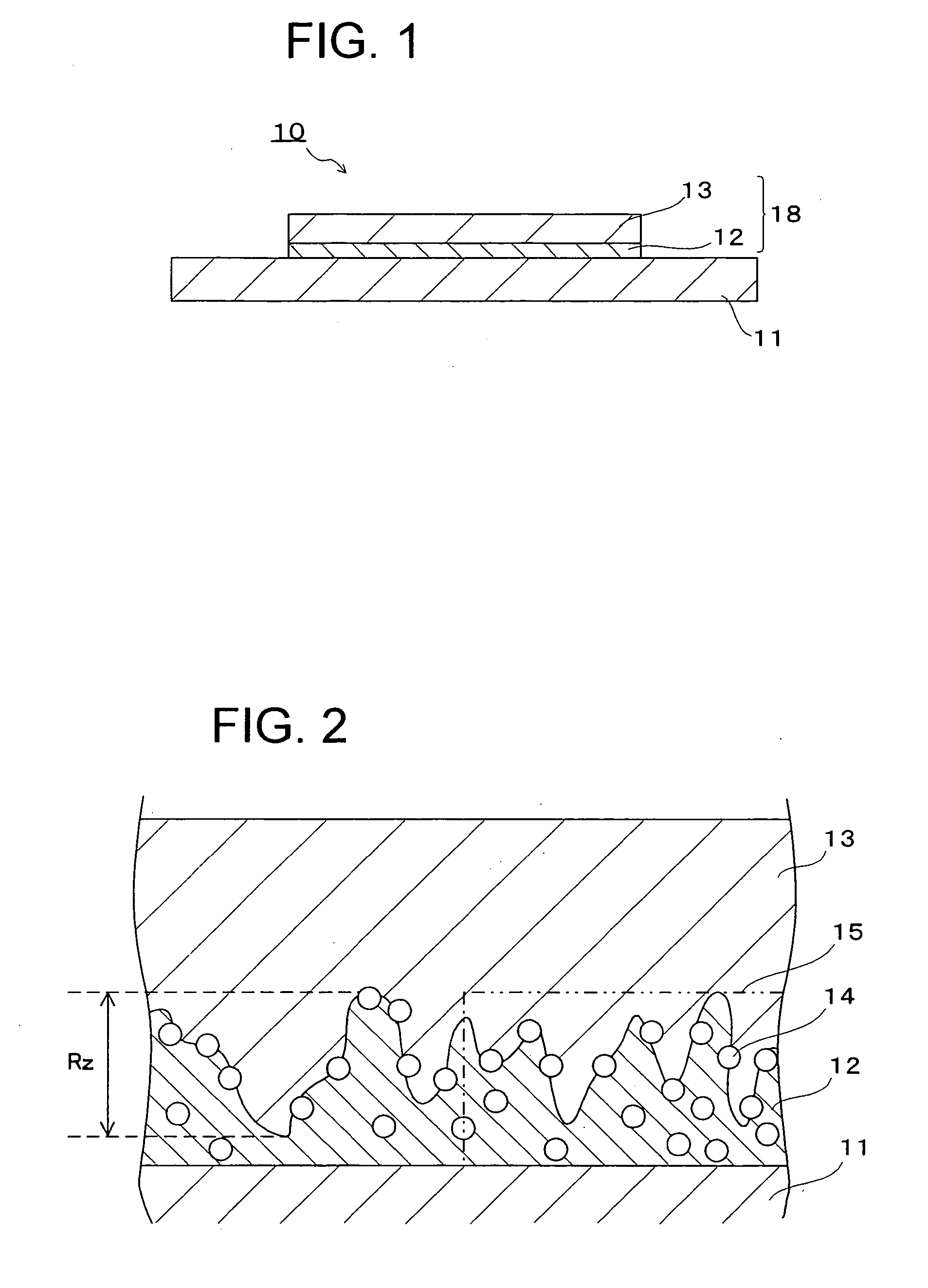

InactiveUS20070065639A1Improve adhesionImprove accuracyPrinted circuit aspectsRecord information storageMetal particleLength wave

A circuit board includes a substrate, a nonconductive resin layer selectively formed on the substrate and containing fine metal particles, and a conductive metal layer formed on the resin layer, in contact with the fine metal particles which are exposed from the resin layer. A surface of the resin layer has irregularities, in an interface between the resin layer and the conductive metal layer. In a roughness curve of a section of the resin layer, in a case of an wavelength (λc) at the boundary of a roughness component and a waviness component is 1 μm, a maximum height (Rz) per reference length (1r) of 1 μm is 20 nm to 500 nm.

Owner:KK TOSHIBA

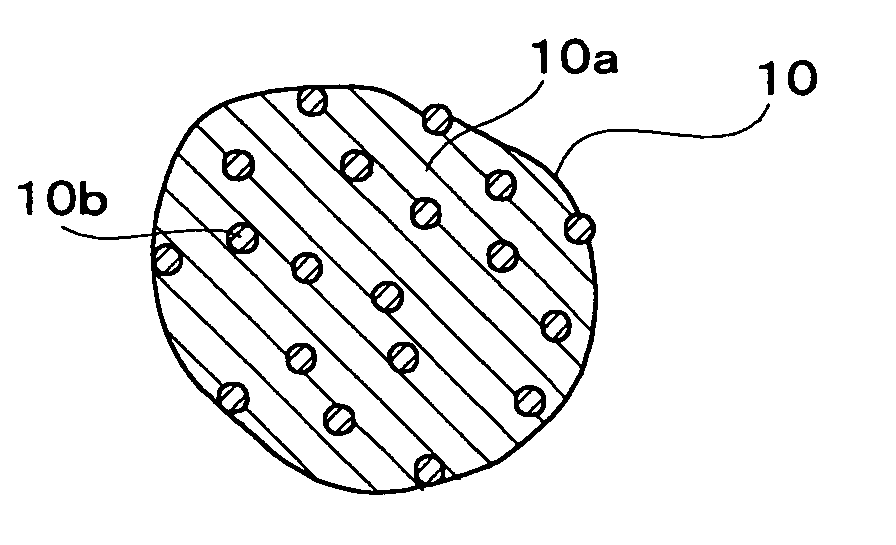

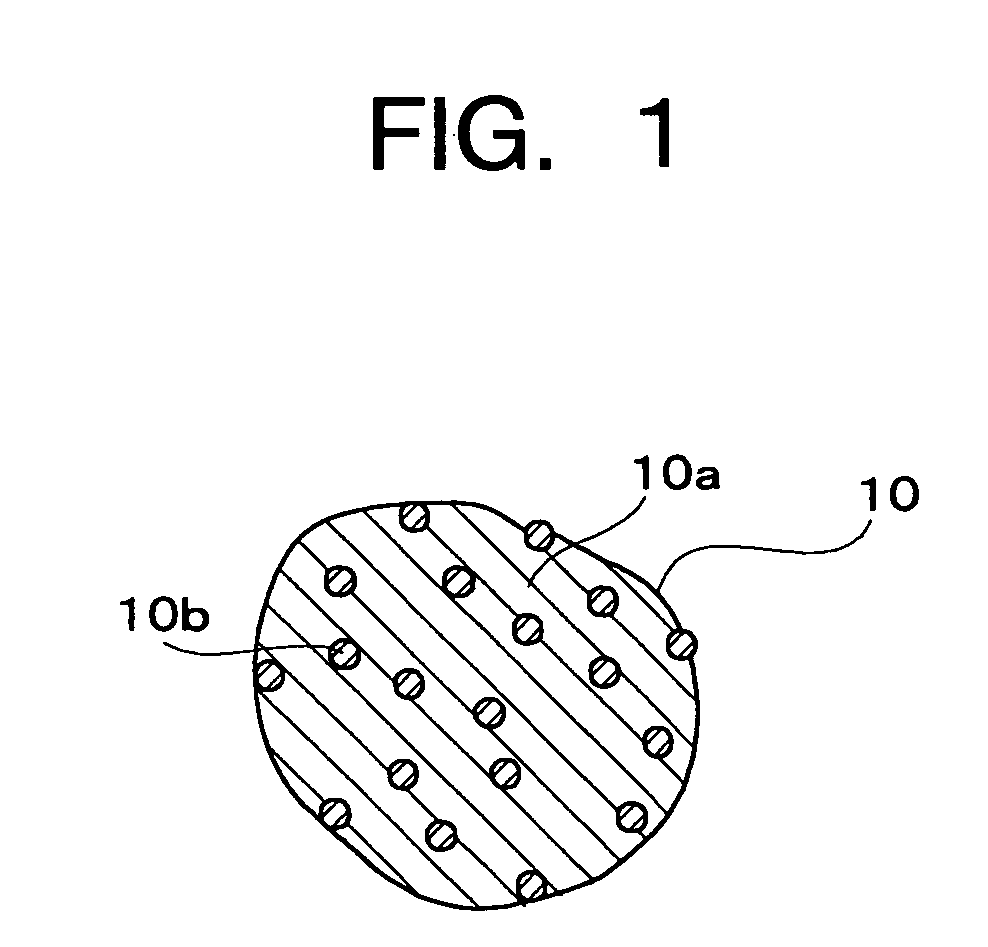

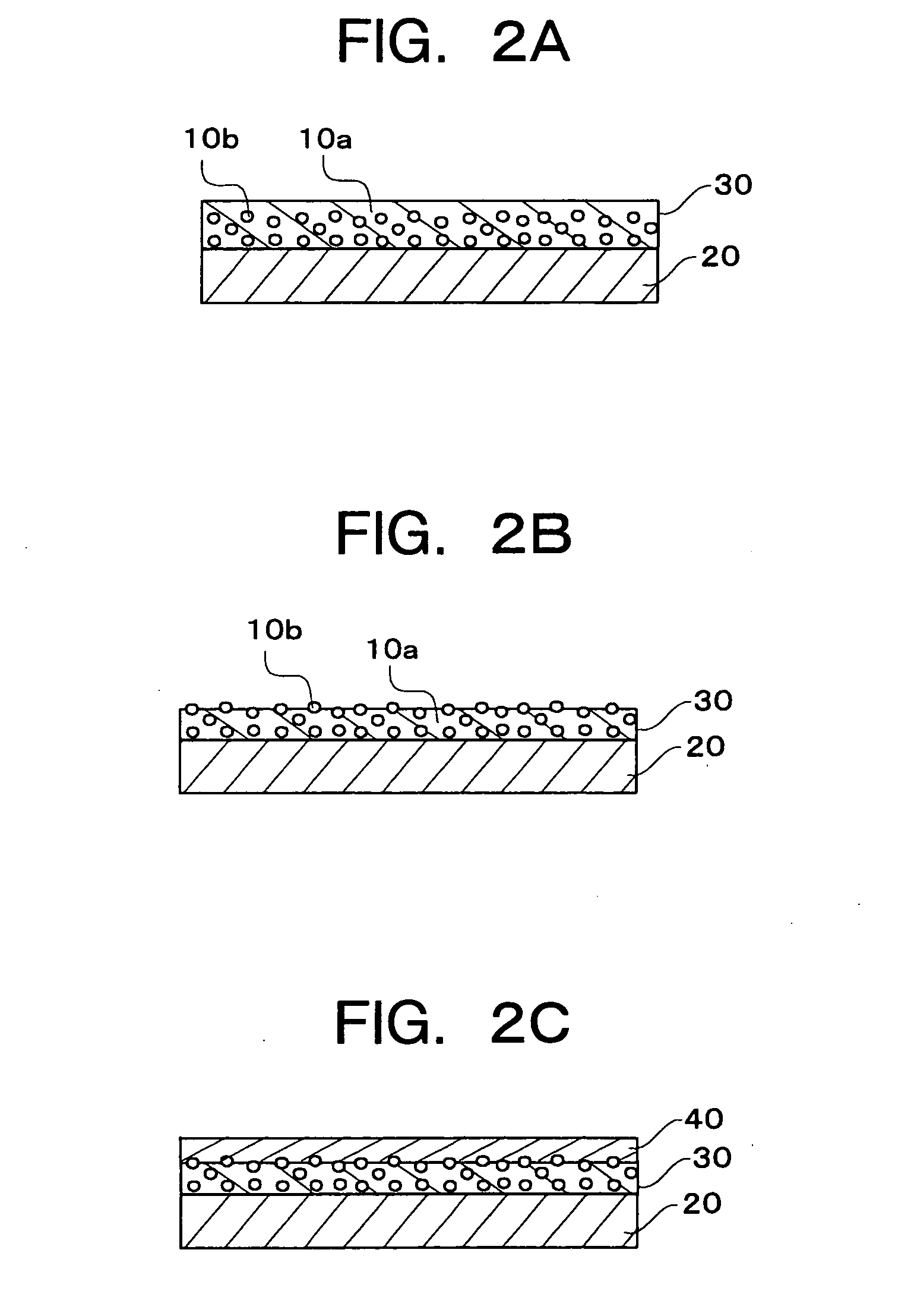

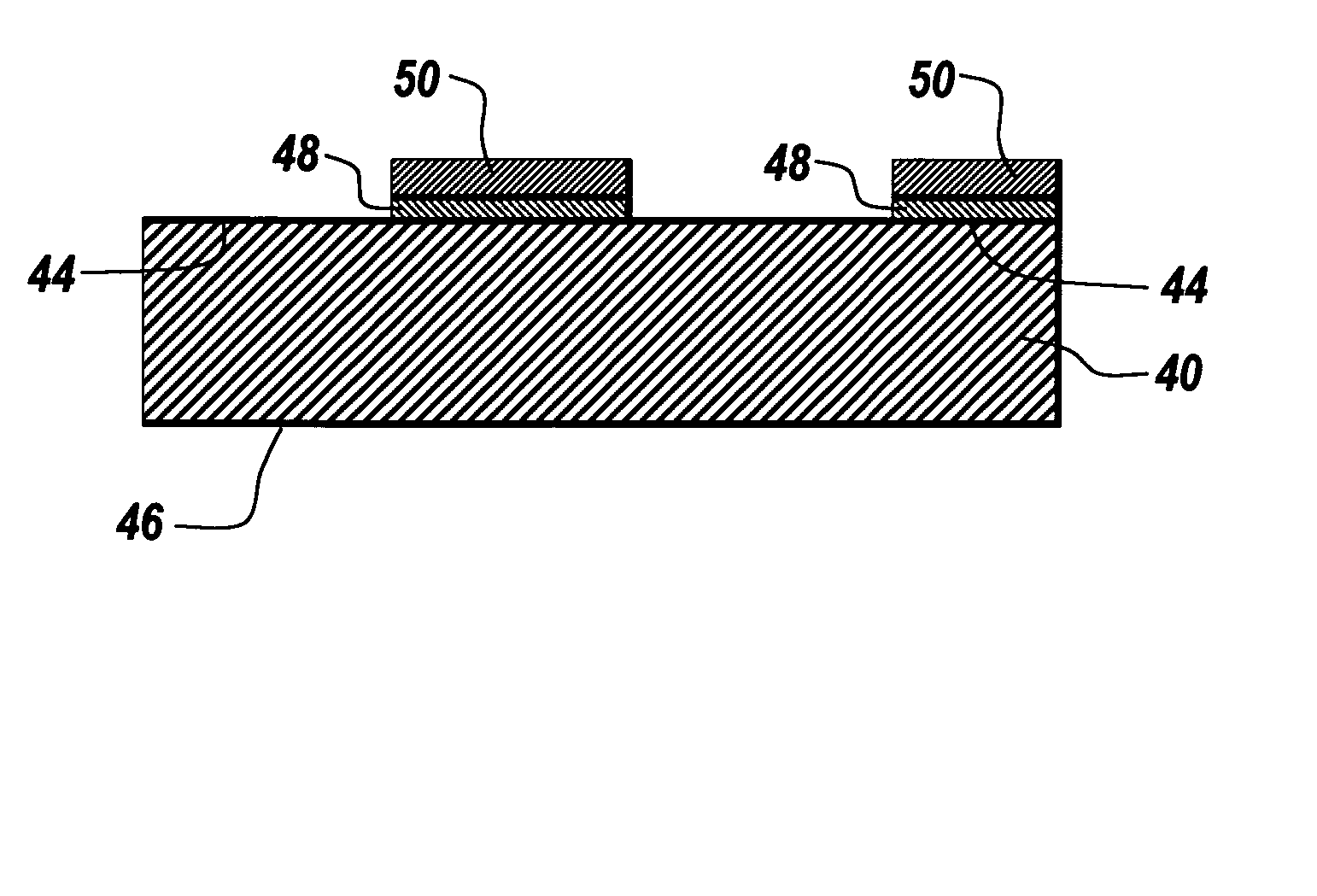

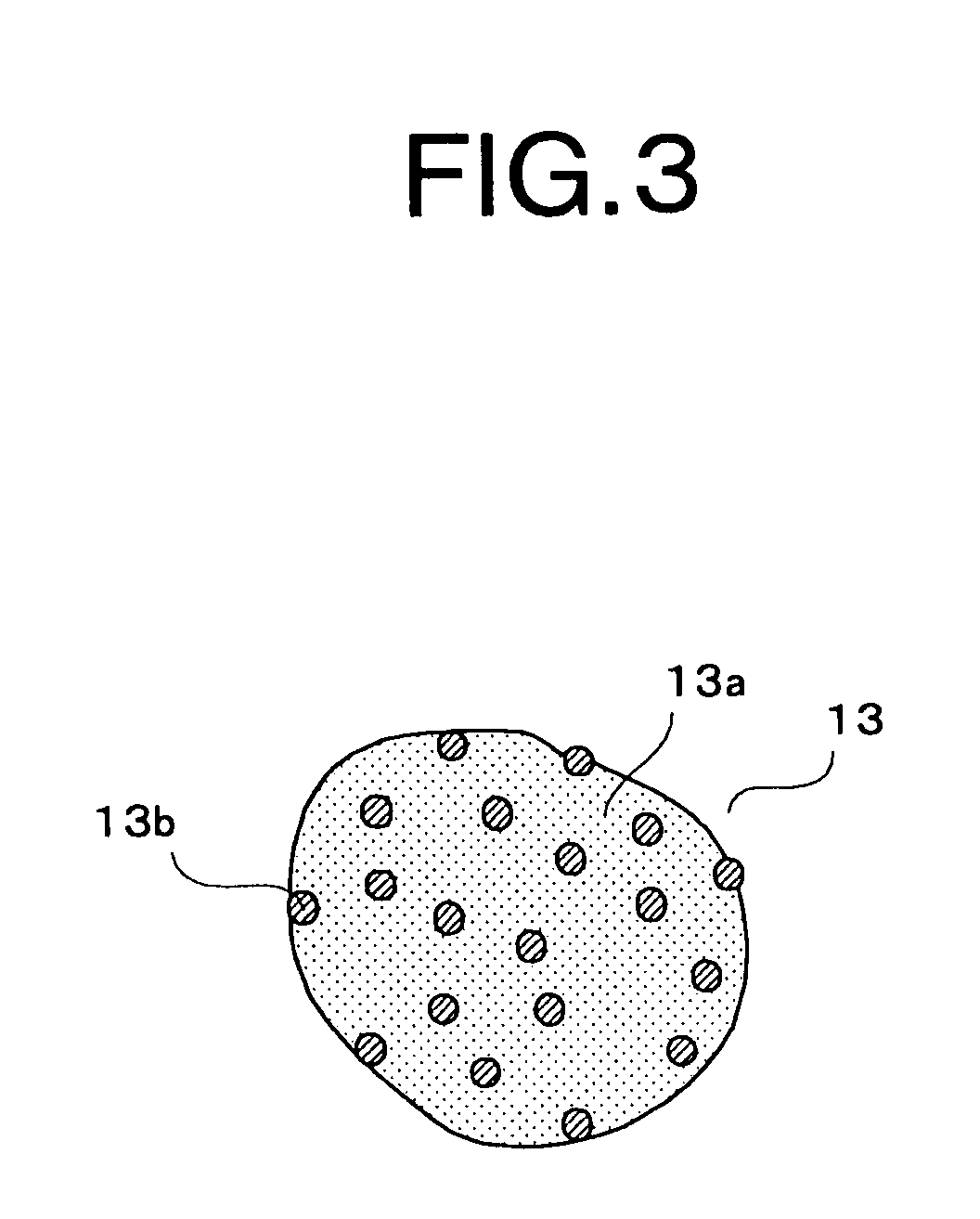

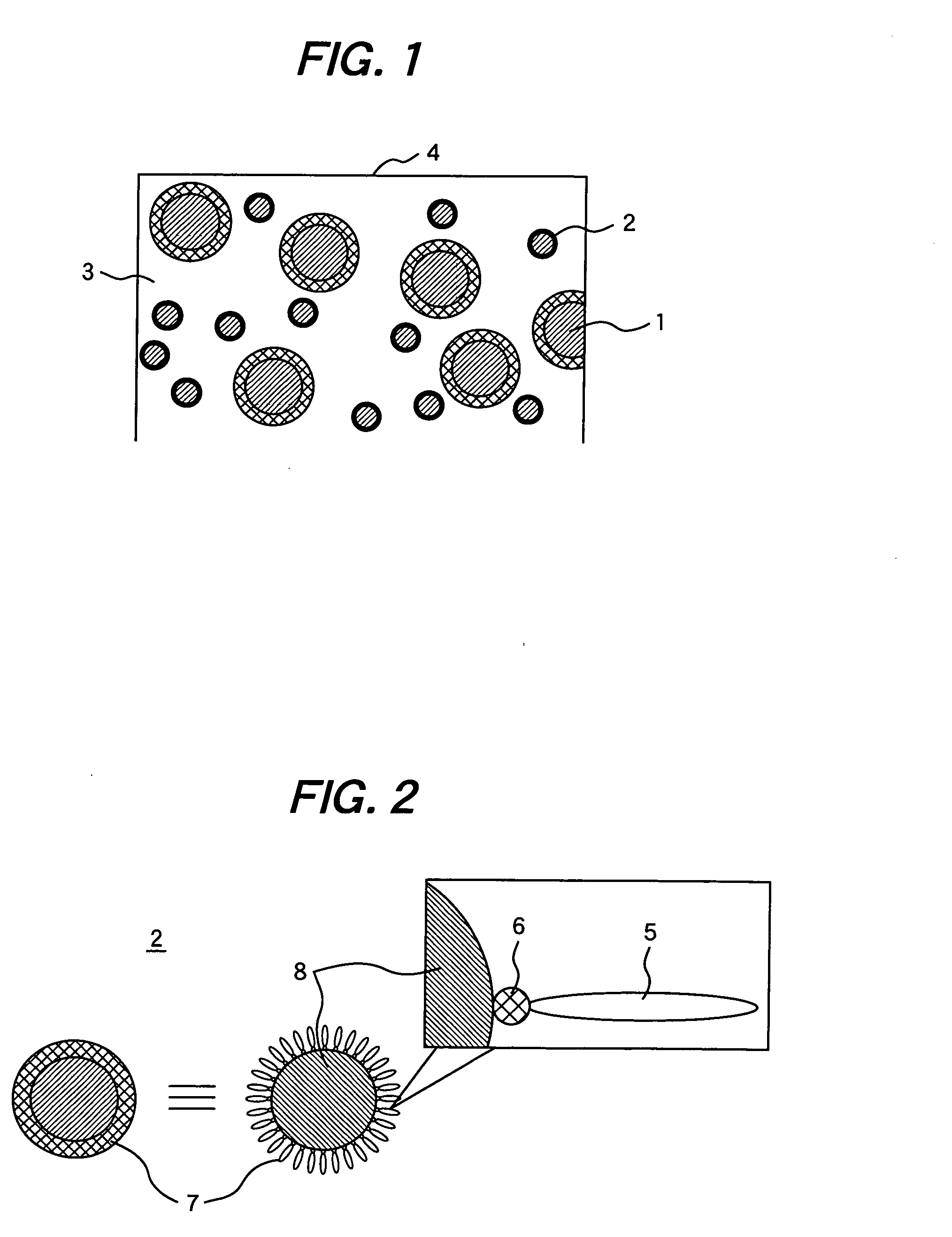

Metal-containing resin particle, metal-containing resin layer, method of forming metal-containing resin layer, and substrate for electronic circuit

InactiveUS20050191511A1Semiconductor/solid-state device manufacturingElectrographic patterningElectrical conductorResin matrix

Provided is metal-containing resin particle for forming a conductor pattern in which the metal particles are dispersed in a resin matrix, and the content of the metal particles is 70 wt % or less.

Owner:KK TOSHIBA

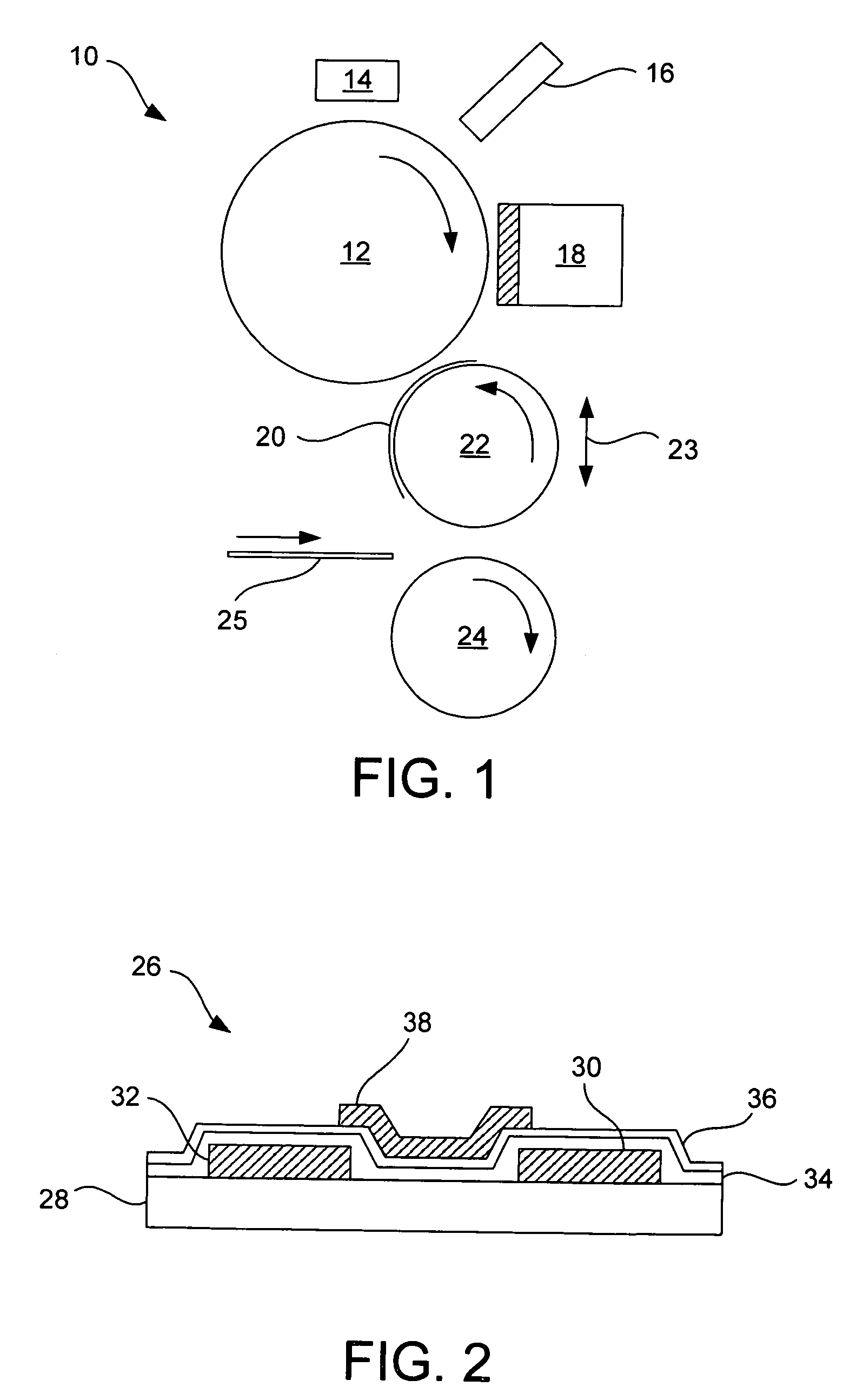

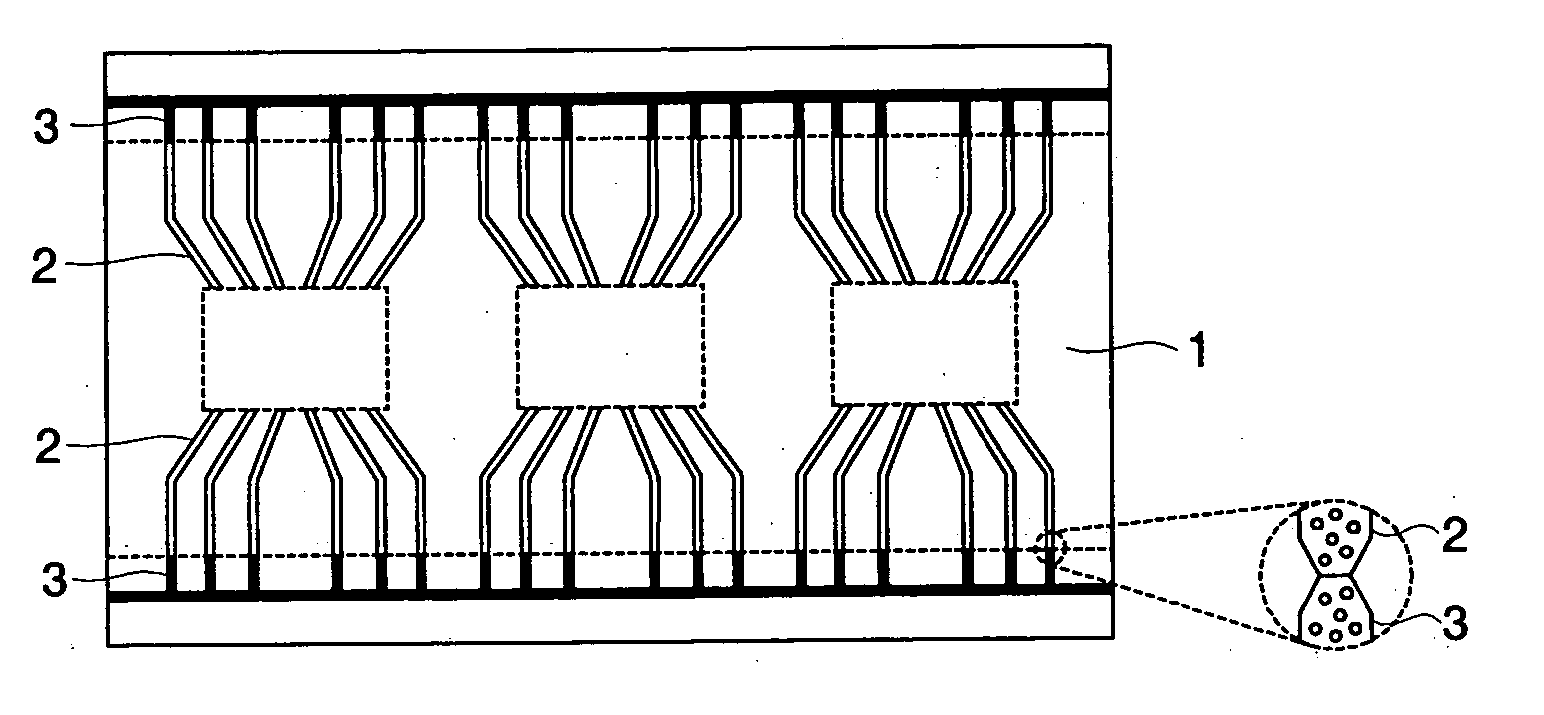

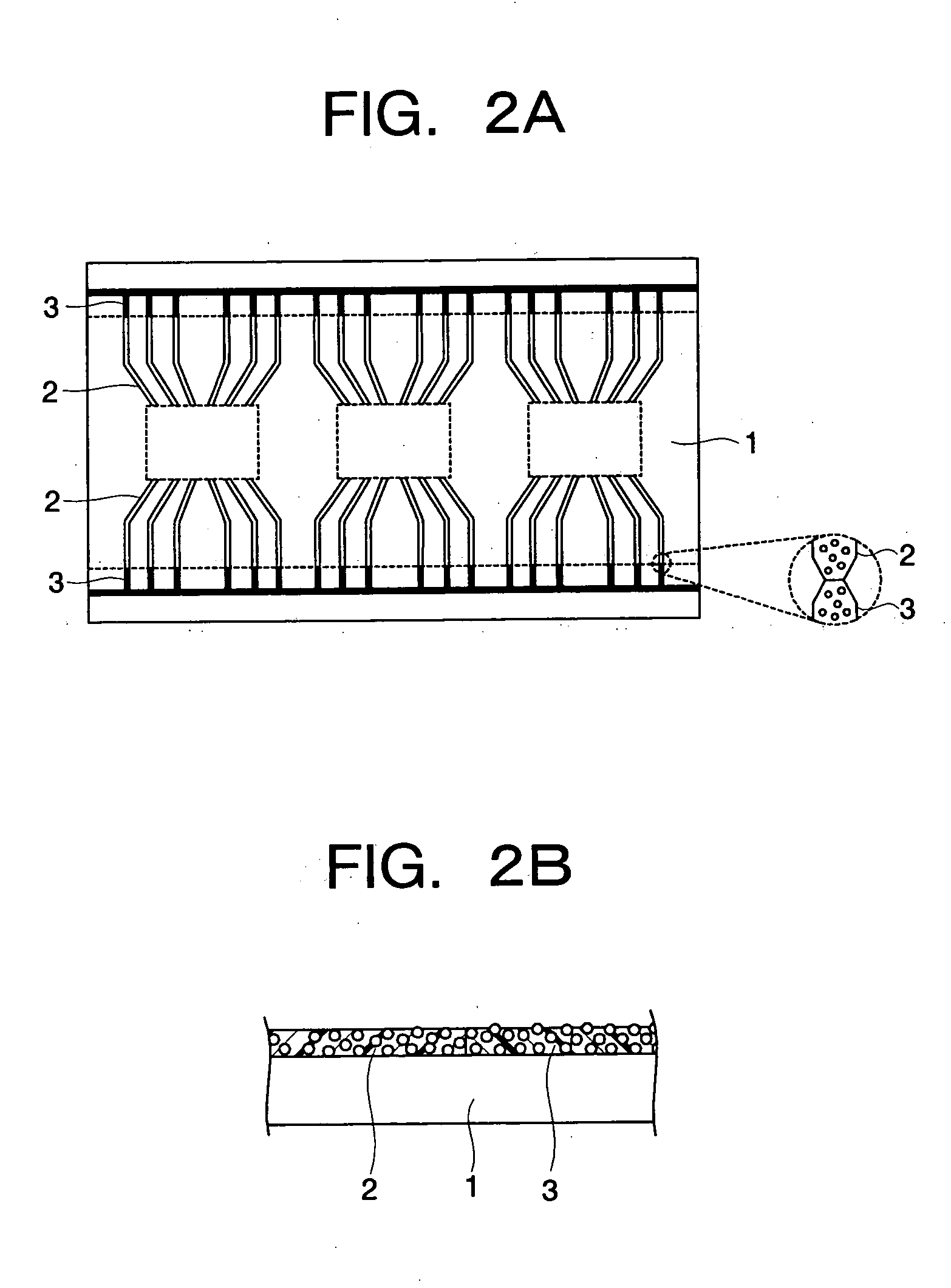

Wiring board and multilayer wiring board

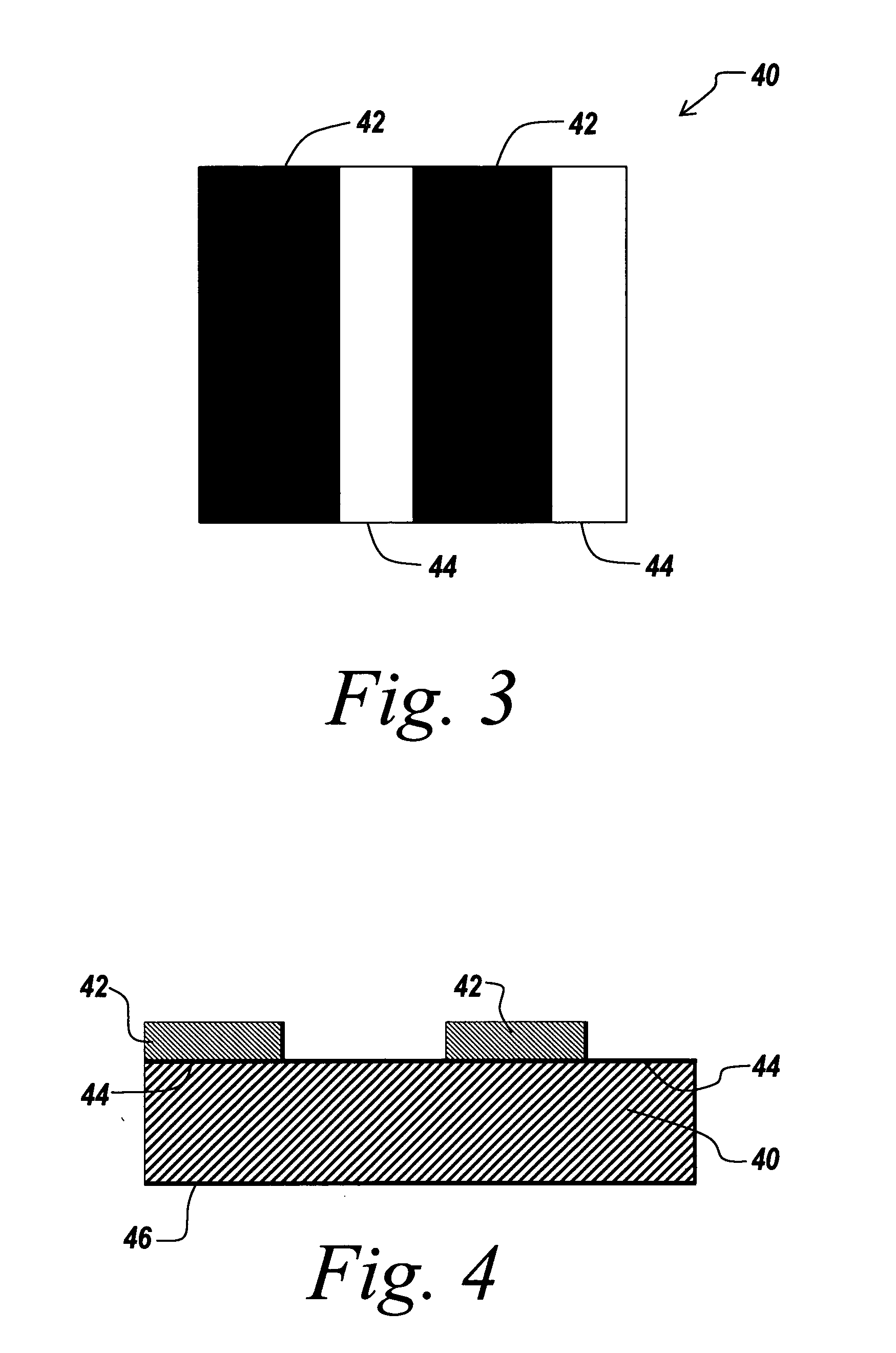

InactiveUS20050053772A1Low costDiversified small-quantity productionPrinted circuit aspectsSynthetic resin layered productsParticulatesElectrical conductor

A wiring board formed by an electrophotographic system of transferring a visible image to a substrate, the wiring board including: a substrate to which a visible image is transferred; a nonconductive metal-containing resin layer selectively formed on the substrate and containing metal particulates dispersed therein; a conductive conductor metal layer formed on the metal-containing resin layer; and a resin layer formed contiguously to the metal-containing resin layer on the substrate.

Owner:KK TOSHIBA

Electrophotographic printing of electronic devices

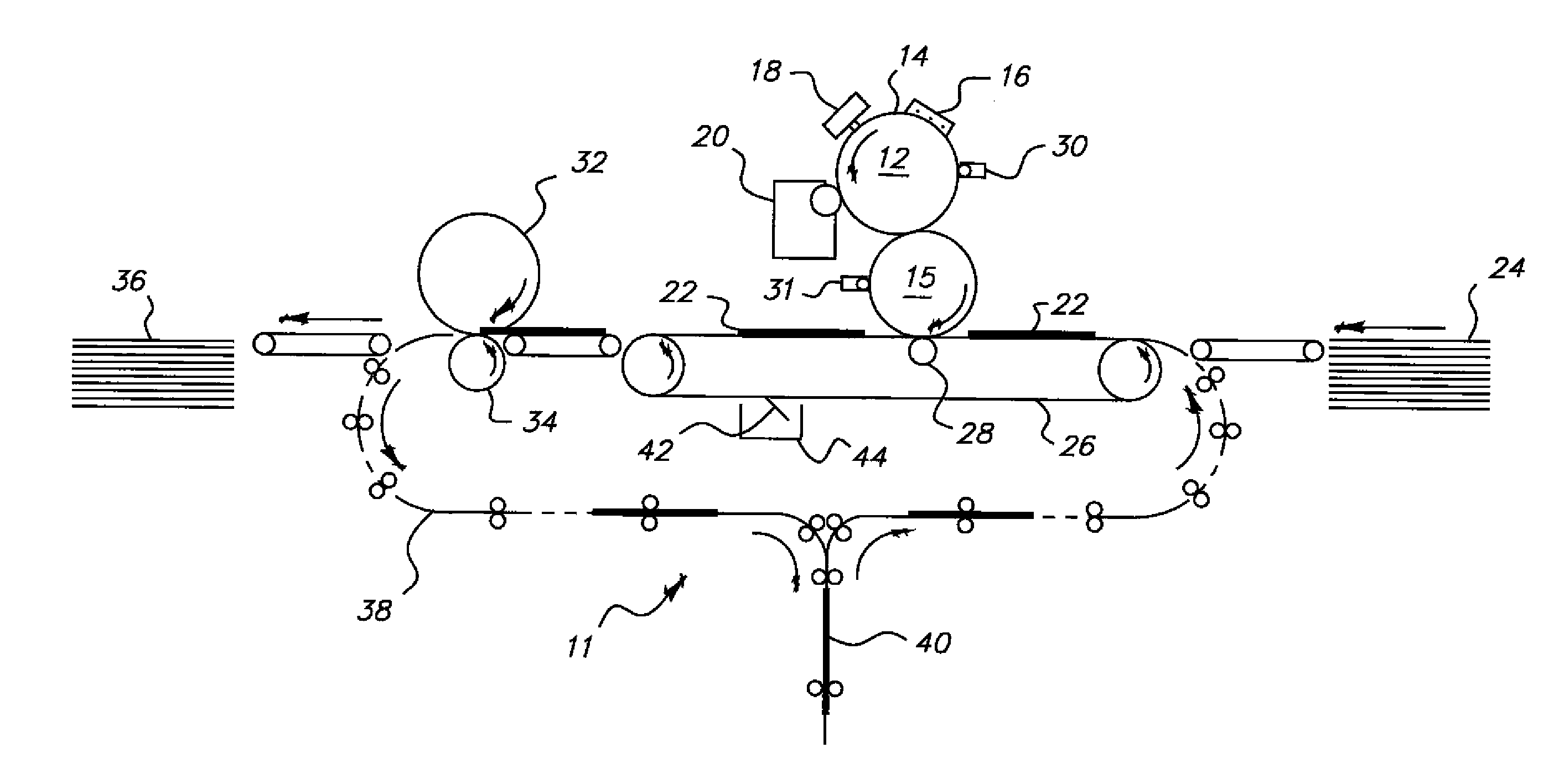

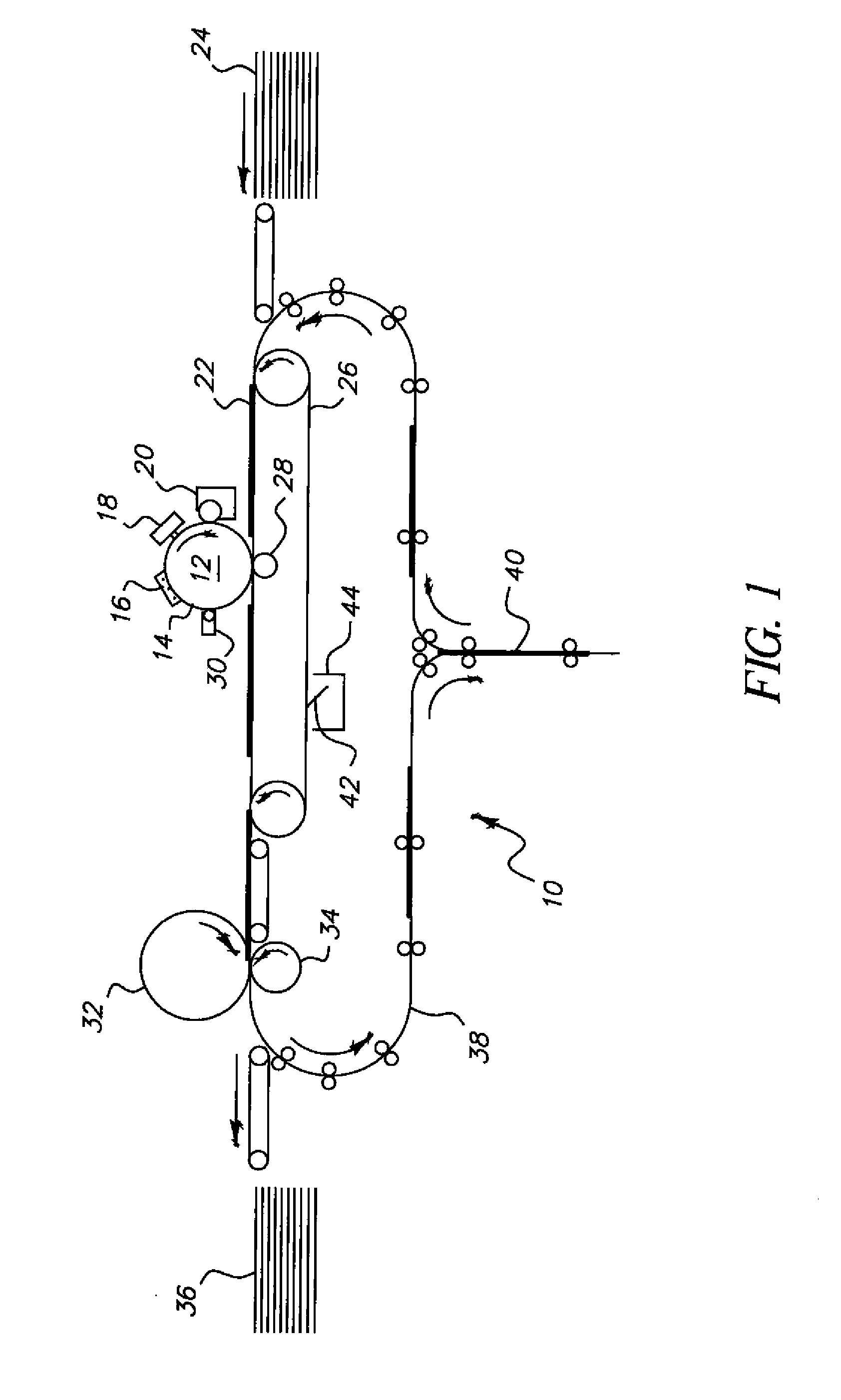

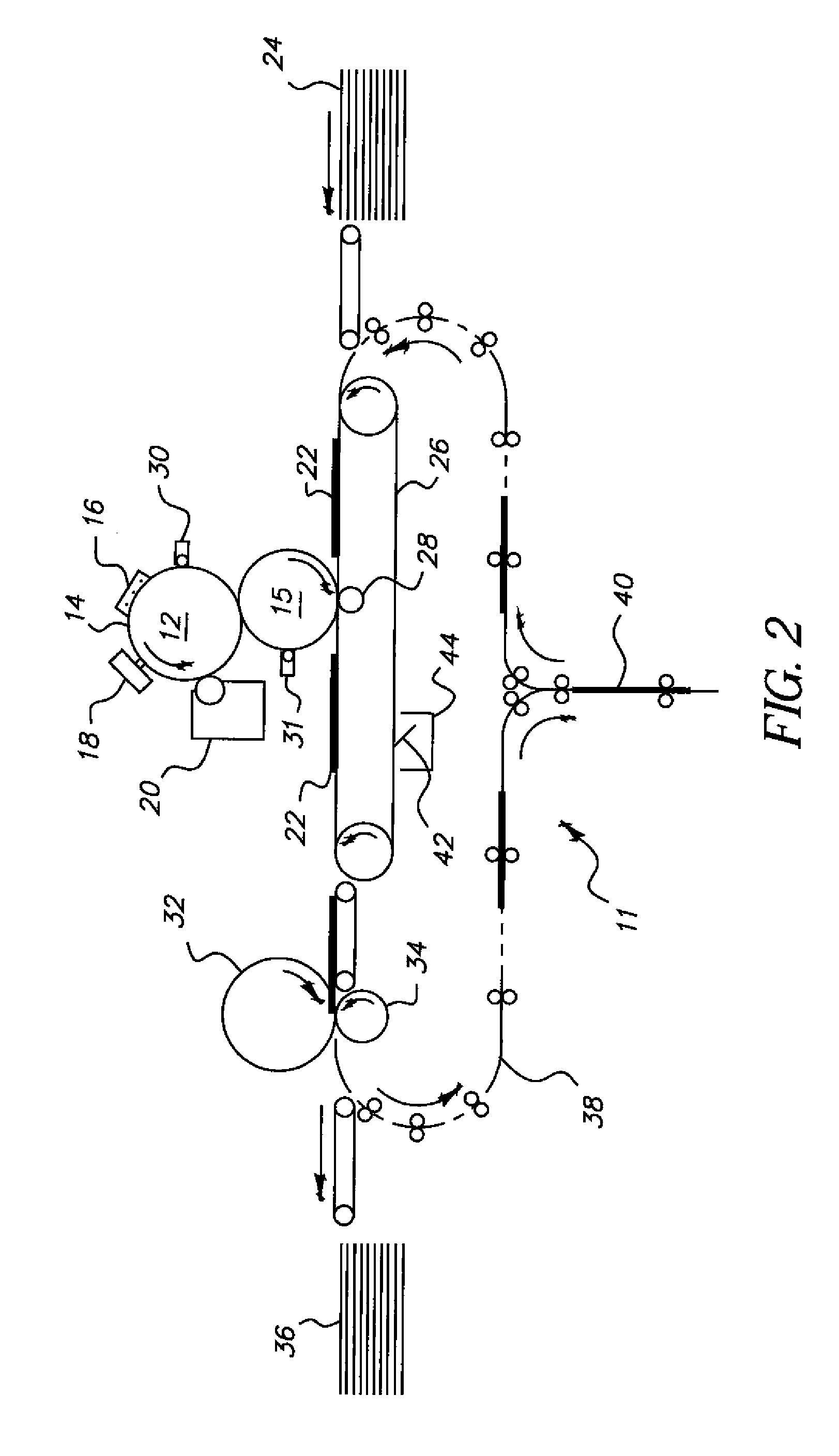

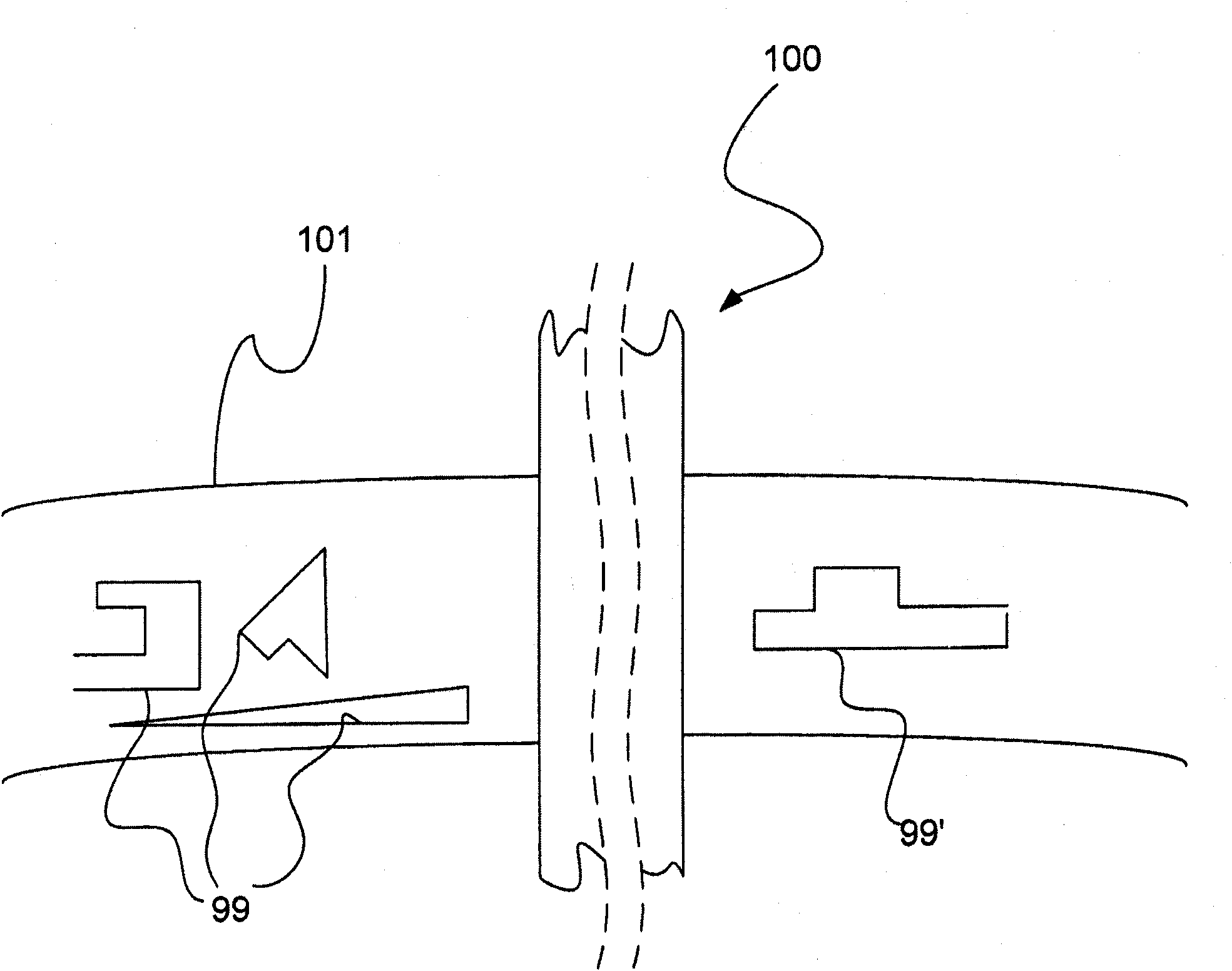

ActiveUS7638252B2Reduce manufacturing costLiquid surface applicatorsPrinted electric component incorporationElectrical devicesParticulate material

A method of forming electrical devices can include electrophotographically printing a particulate material on a device substrate, and the particulate material can form at least a portion of the electrical device. An optional intermediate transfer member can also be used to improve reliability and performance of the process. Dry or liquid electrophotographic methods can be effectively used to form electronic devices on a wide variety of substrates not conventionally available in device fabrication.

Owner:HEWLETT PACKARD DEV CO LP

Flexible substrate having interlaminar junctions, and process for producing the same

ActiveUS7205483B2Add additional massImproved producibilitySolid-state devicesSemiconductor/solid-state device manufacturingEngineeringElectrical and Electronics engineering

Owner:PANASONIC CORP

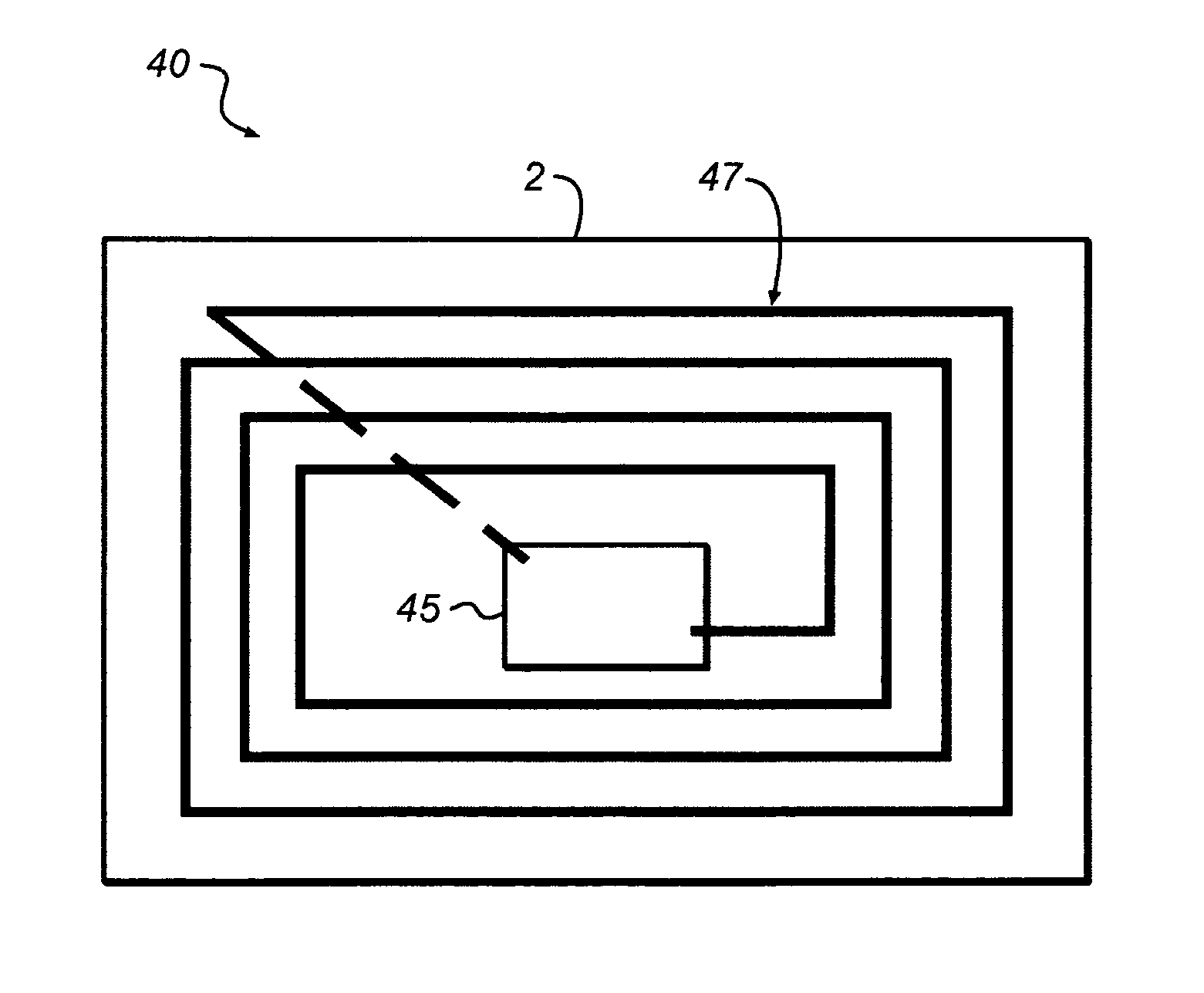

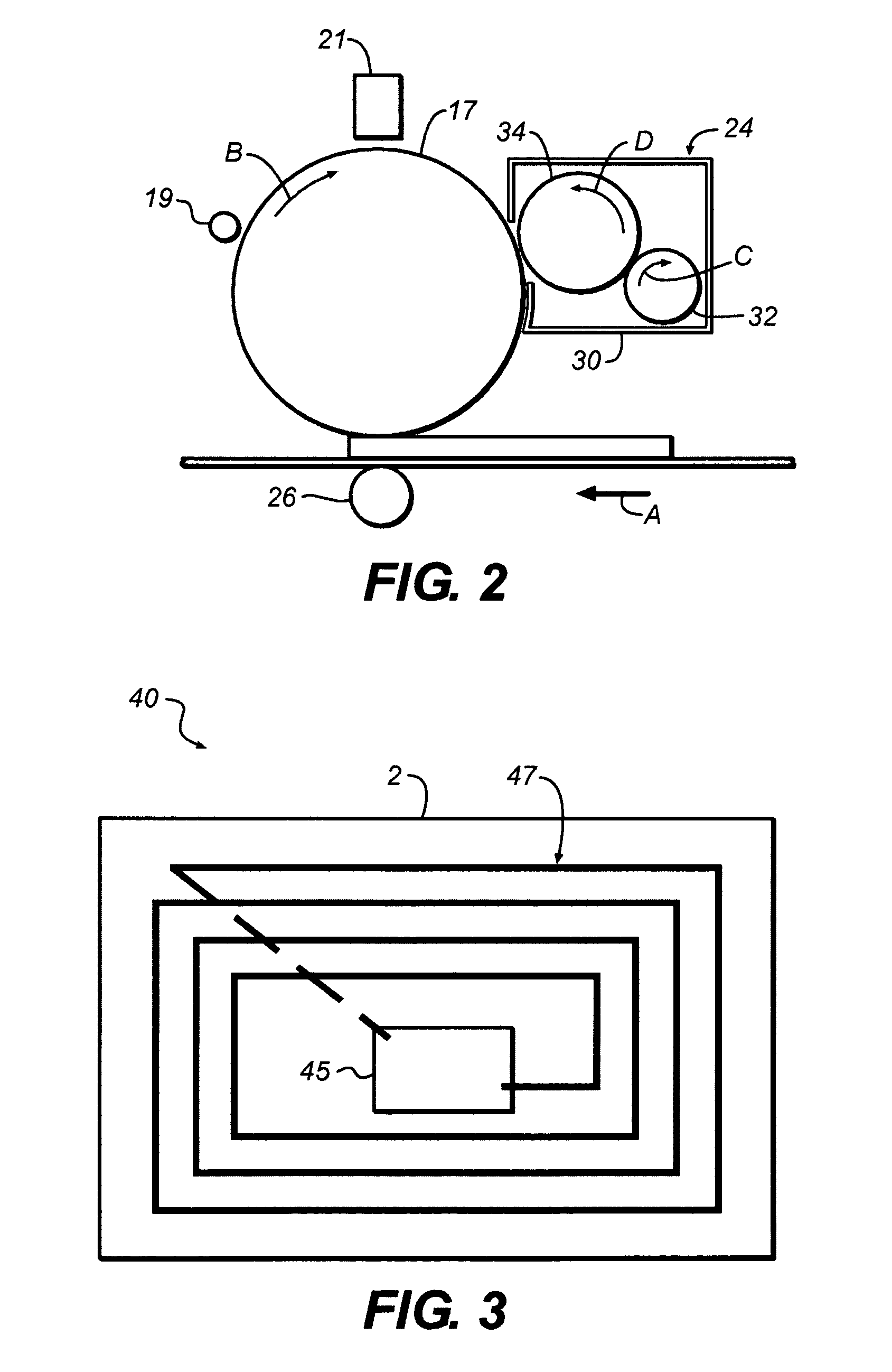

Method for producing an antenna structure for an RFID device, and dry toner for use in producing such antenna structure

InactiveUS20110017834A1Overcome problemsElectrographic patterningElectrographic process apparatusInductive chargingElectrical and Electronics engineering

A method for producing an antenna structure for an RFID device, a dry toner for use in producing an antenna for an RFID device and a RFID device comprising an antenna structure made of fused toner are disclosed. In a method for producing an antenna structure for an RFID device, a dry toner comprising a polymeric binder and metallic particles is provided. The toner comprises particles having a resistance allowing triboelectric charging or a resistance allowing inductive charging, wherein said metallic particles are nanoparticles having a mean particle size below approximately 500 nm in at least one direction. In the method, a continuous layer of the dry toner is applied to a substrate in a desired shape of an antenna via an electrophotographic printing process, and subsequently the toner is fused to the substrate by heating the toner above its glass transformation temperature. The dry toner for use in producing an antenna for an RFID device comprises toner particles having a resistance allowing triboelectric charging or a resistance allowing inductive charging. The toner particles comprise a polymeric binder and metallic particles, wherein said metallic particles are nanoparticles having a mean particle size below approximately 500 nm in at least one direction.

Owner:EASTMAN KODAK CO

Printed electronic circuit boards and other articles having patterned coonductive images

InactiveUS20100155128A1Electrographic patterningElectrographic process apparatusEngineeringElectronic circuit

The present invention provides an article of manufacture using an electrophotographic printer to produce printed electronic circuits by printing a second conductive powder layer and a first thermoplastic layer in registration. The second conductive powder layer is permanently fixed to the first layer before removing conductive powder from portions of the substrate other than that coated with the thermoplastic patterned image.

Owner:EASTMAN KODAK CO

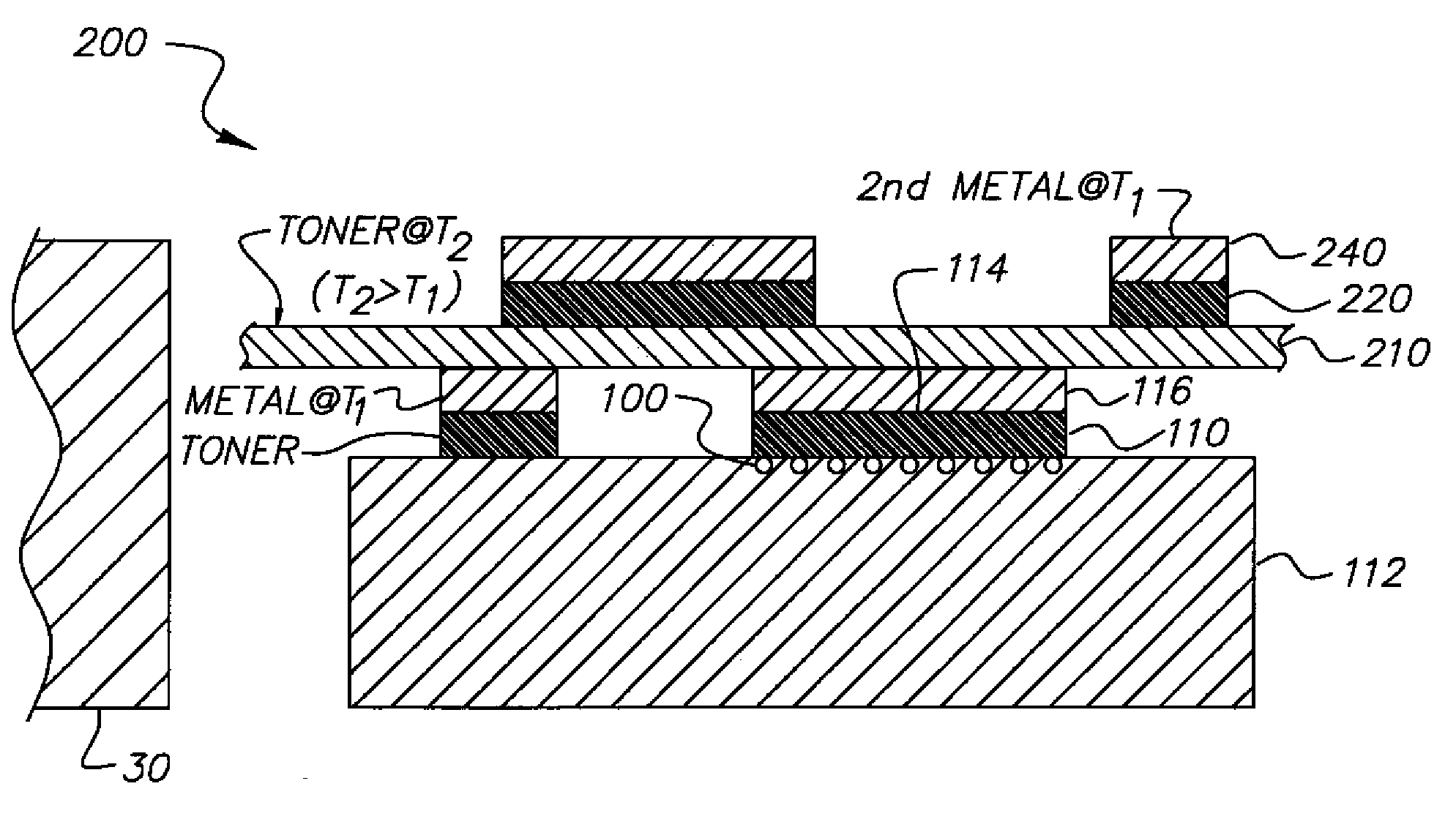

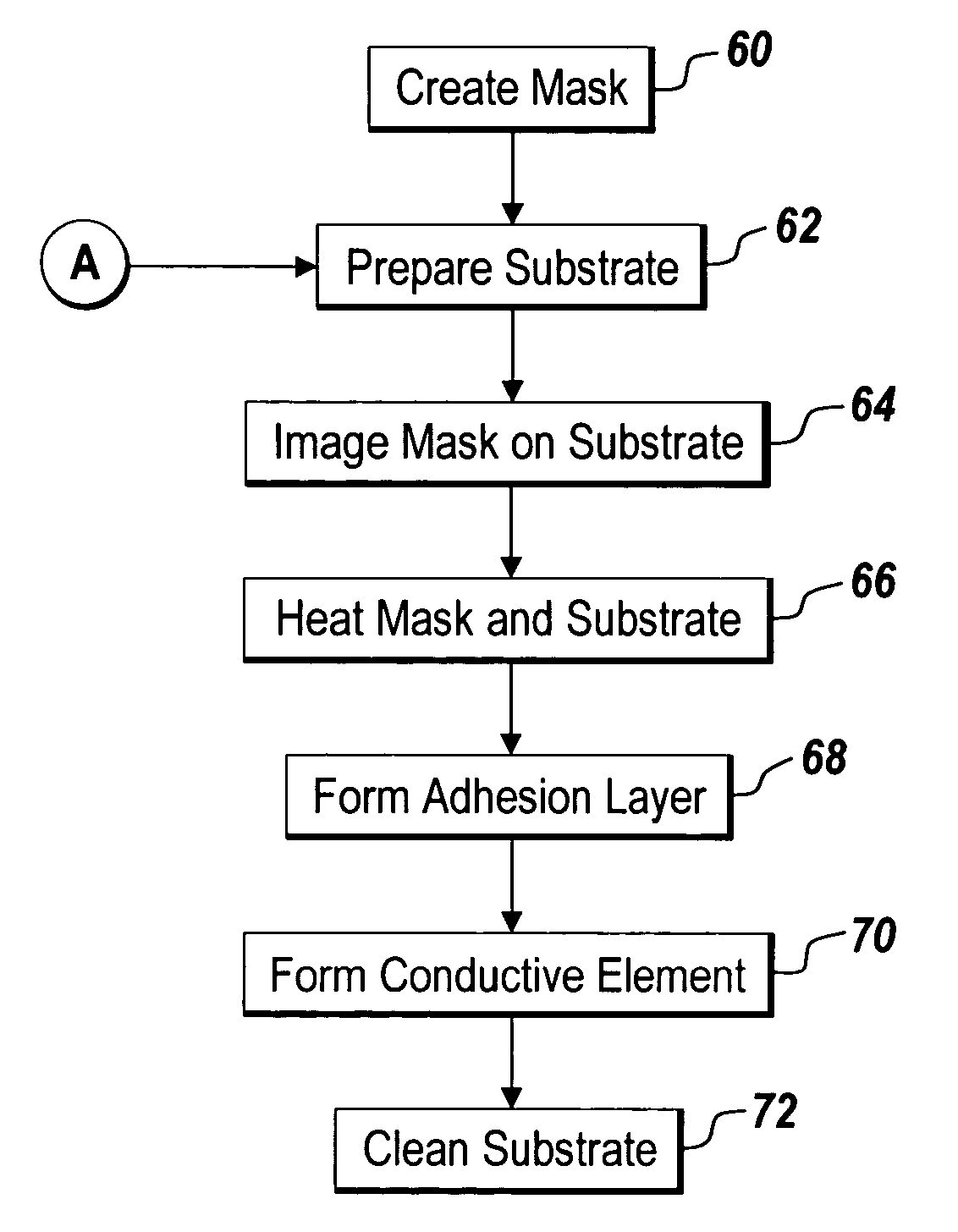

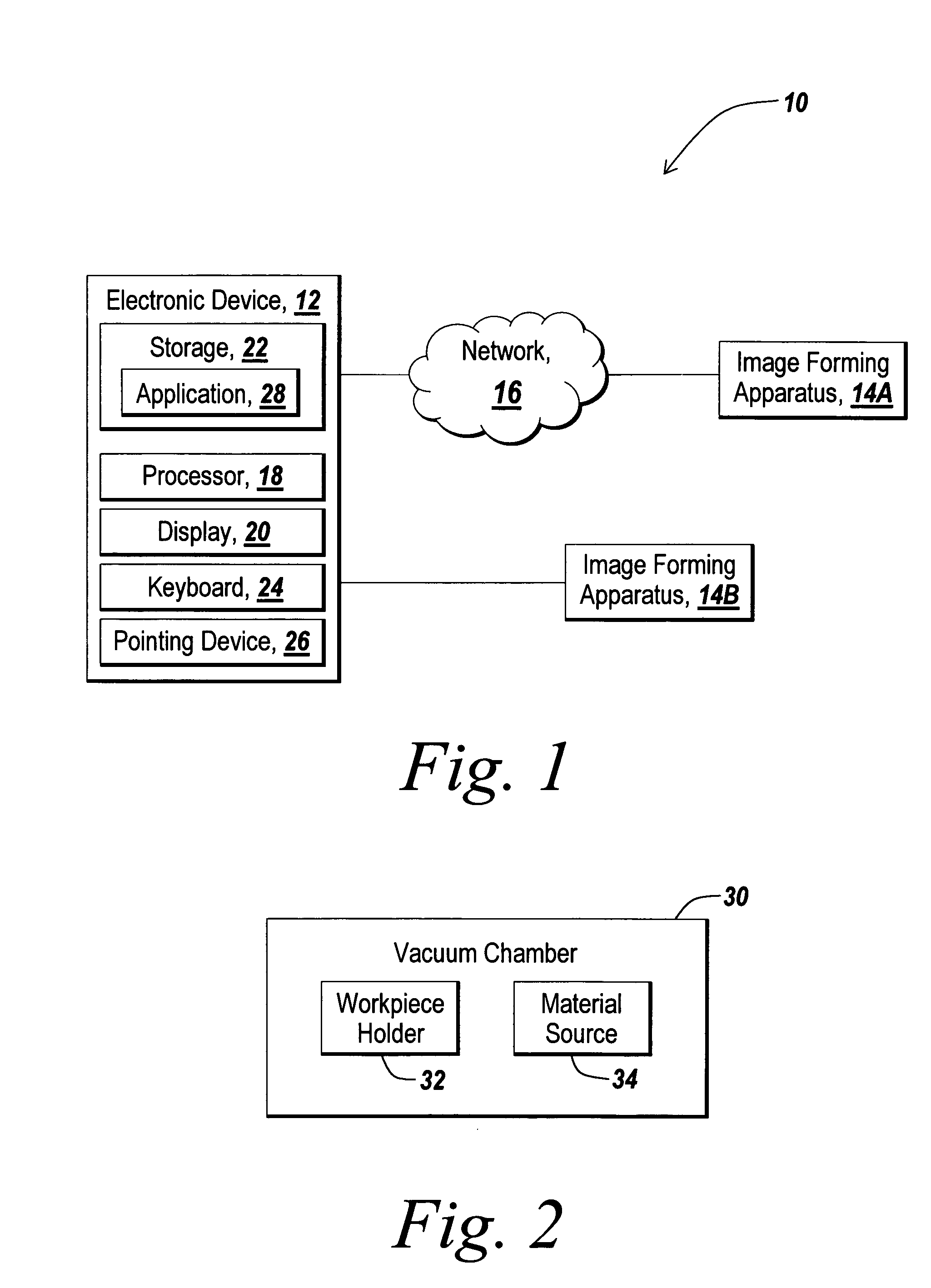

Method for pattern metalization of substrates

InactiveUS20050263903A1Improve adhesionTransistorInsulating substrate metal adhesion improvementEngineeringElectron

The present invention provides a method for forming an adhesion layer in contact with a first surface of a substrate and a surface of a layer having electrically conductive properties using electrophotographic imaging compound as a mask. The adhesion layer improves the lamination properties of the electrically conductive layer to the substrate. The improved lamination properties to facilitate and increase the reliability and quality of a resulting product having an electronic circuit formed in accordance with the present invention. The method disclosed herein is well suited for use with rigid polymeric substrates and flexible polymeric substrates.

Owner:VISIBLE TECH KNOWLEDGY +1

Method for pattern metalization of substrates

InactiveUS20050205999A1Improve adhesionTransistorInsulating substrate metal adhesion improvementEngineeringElectron

The present invention provides a method for forming an adhesion layer in contact with a first surface of a substrate and a surface of a layer having electrically conductive properties using electrophotographic imaging compound as a mask. The adhesion layer improves the lamination properties of the electrically conductive layer to the substrate. The improved lamination properties to facilitate and increase the reliability and quality of a resulting product having an electronic circuit formed in accordance with the present invention. The method disclosed herein is well suited for use with rigid polymeric substrates and flexible polymeric substrates.

Owner:METROLOGIC INSTR +1

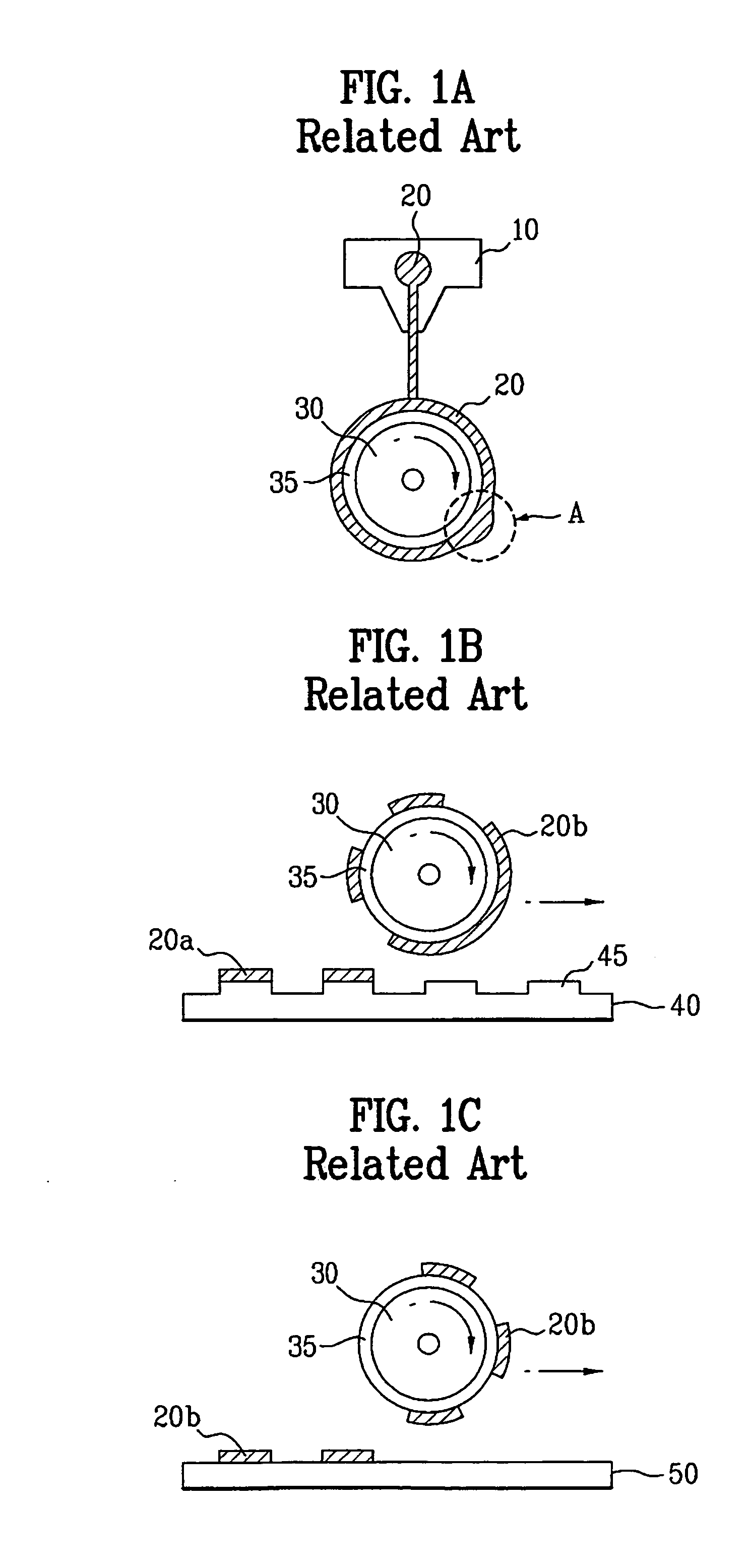

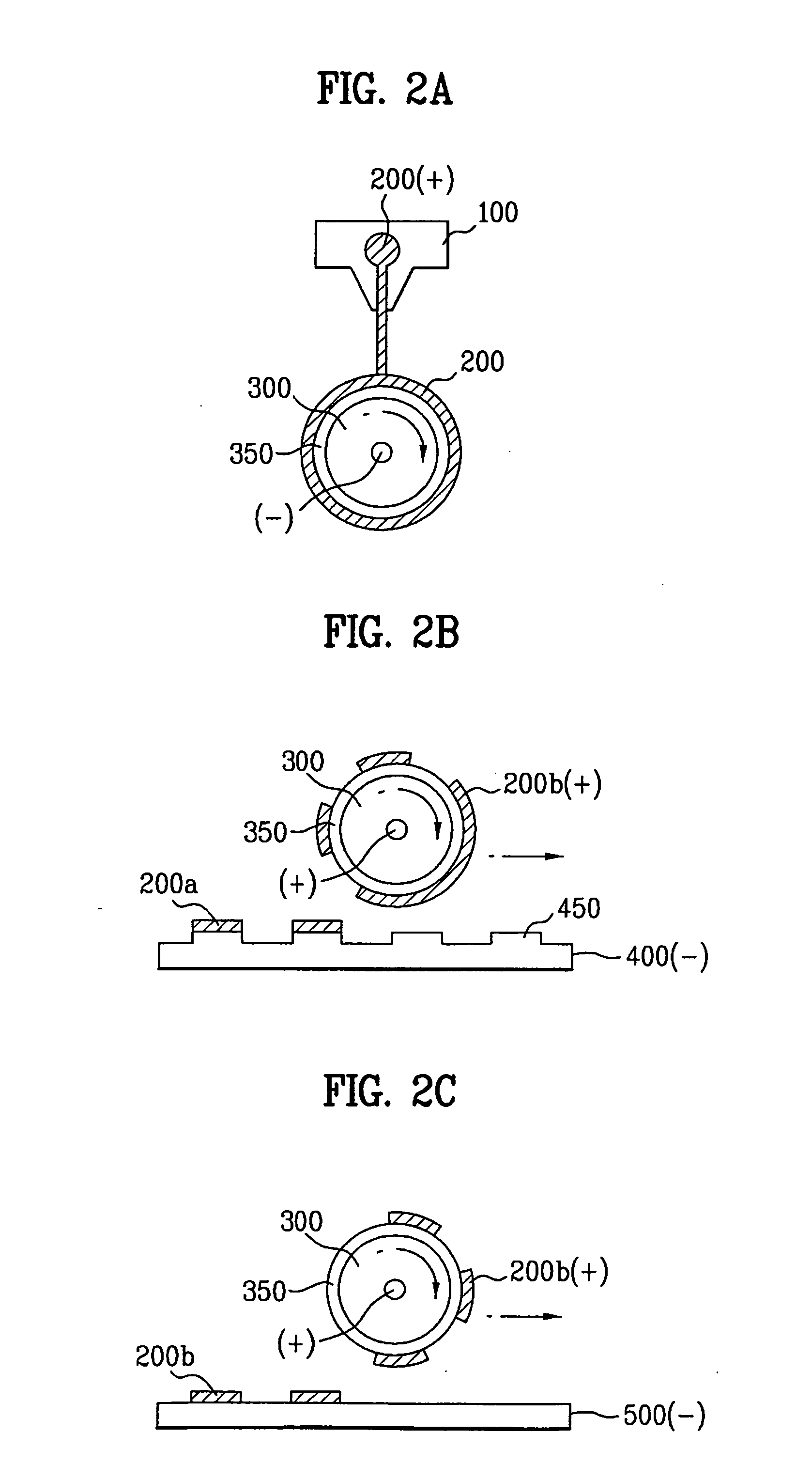

Patterning method of liquid crystal display device

InactiveUS20060210720A1Preciseness in patterningPrevent materialPretreated surfacesElectrographic patterningLiquid-crystal displayElectrical polarity

A patterning method of a liquid crystal display (LCD) device is disclosed, to prevent a pattern material from having a swelling portion when using a printing method, thereby obtaining preciseness in patterning, the patterning method including a first step for coating a pattern material containing charged particles on a printing roll having a blanket adhered thereto; a second step for rolling the printing roll on a printing plate having a plurality of projections for printing some pattern material on the projections of the printing plate and form a predetermined pattern on the blanket of the printing roll with the pattern material remaining on the blanket; and a third step for rolling the printing roll on a substrate to re-print the predetermined pattern of pattern material on the substrate, wherein the first step includes applying a voltage of the opposite polarity to the pattern material to the printing roll.

Owner:LG DISPLAY CO LTD

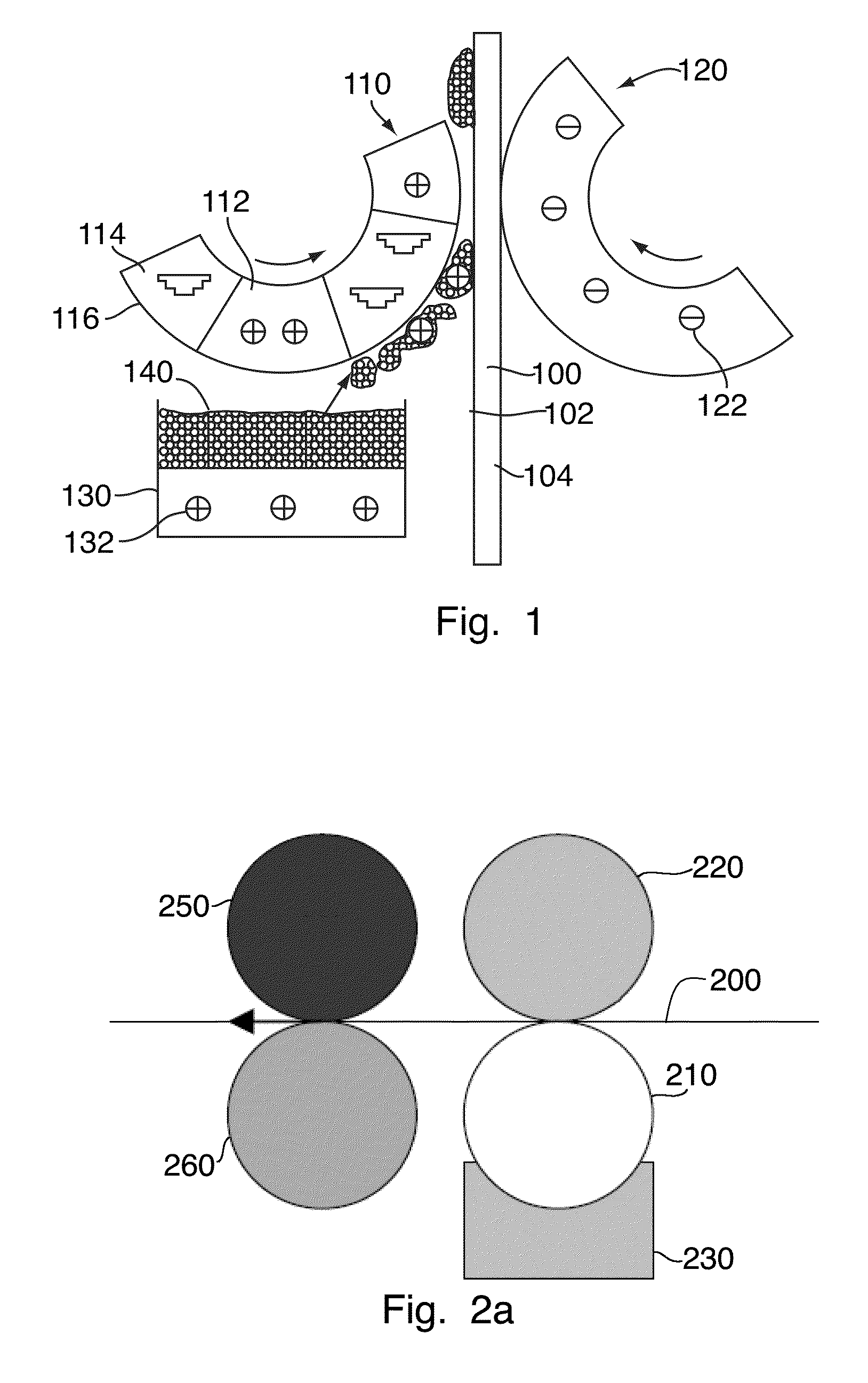

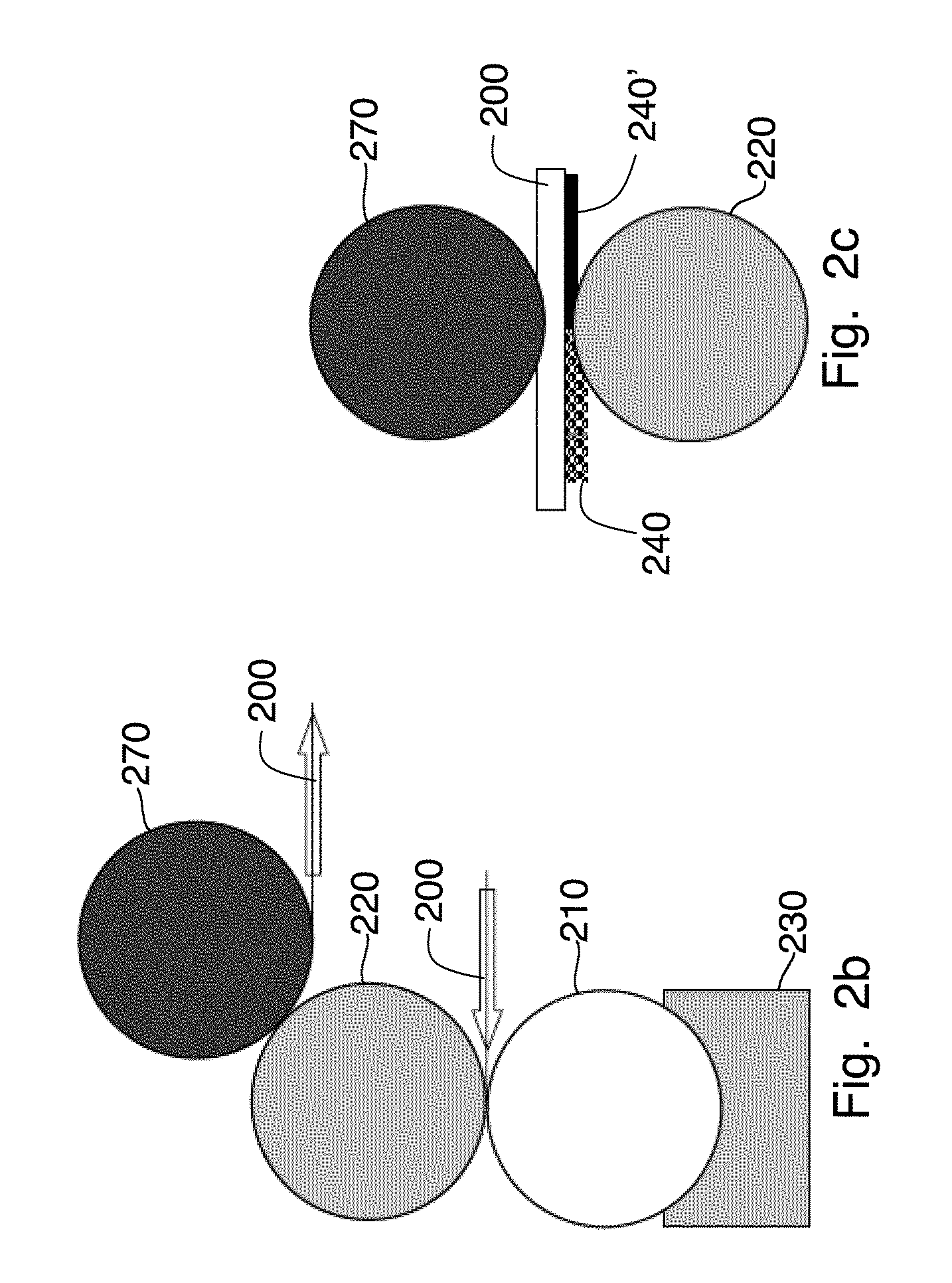

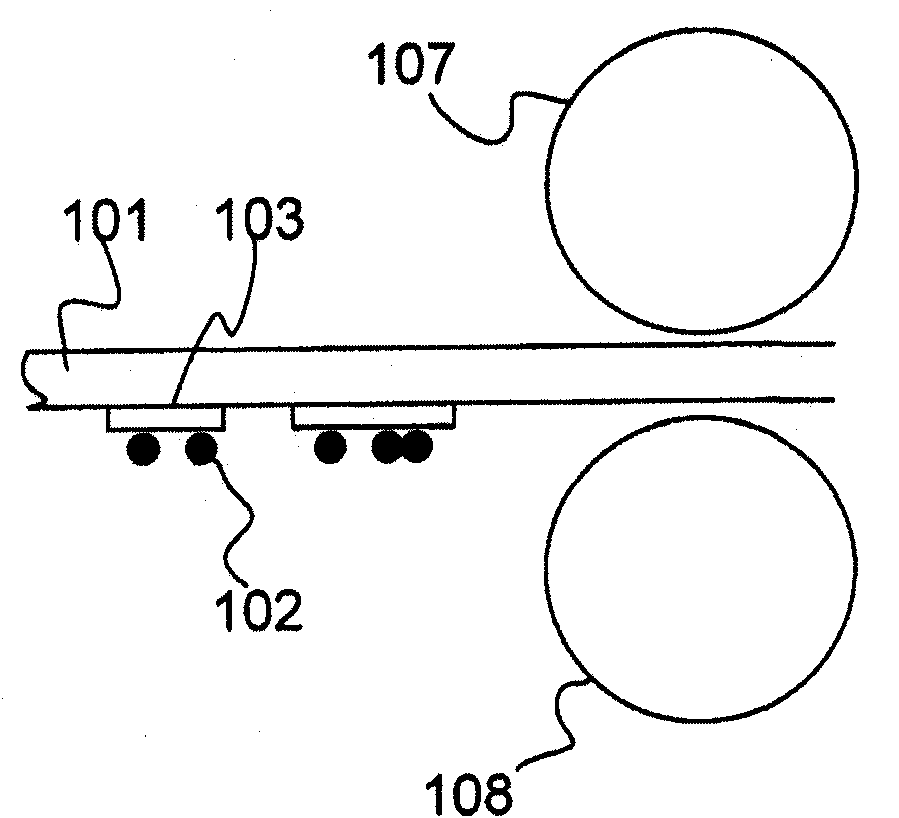

Method and apparatuses for printing and printed product

ActiveUS20090277007A1Simple and efficientHigh resolutionElectrographic patterningElectrographic process apparatusElectrical conductorOptoelectronics

The invention concerns a method for forming a conductive pattern on an insulating substrate and a related apparatus. In the method, particle-type conductive matter is transferred onto a surface of the substrate and the particle-type conductive matter is at least partially sintered at elevated temperature and pressure in order to convert the particle-formed pattern into a continuously conducting pattern affixed to the substrate. According to the invention, the conductive matter is transferred in the form of a predefined pattern, and the sintering is carried out by using a nip comprising two opposing nip members between which the substrate is fed. The method provides an efficient way of making high-resolution conductor structures at low temperatures.

Owner:DIGITAL TAGS FINLAND OY

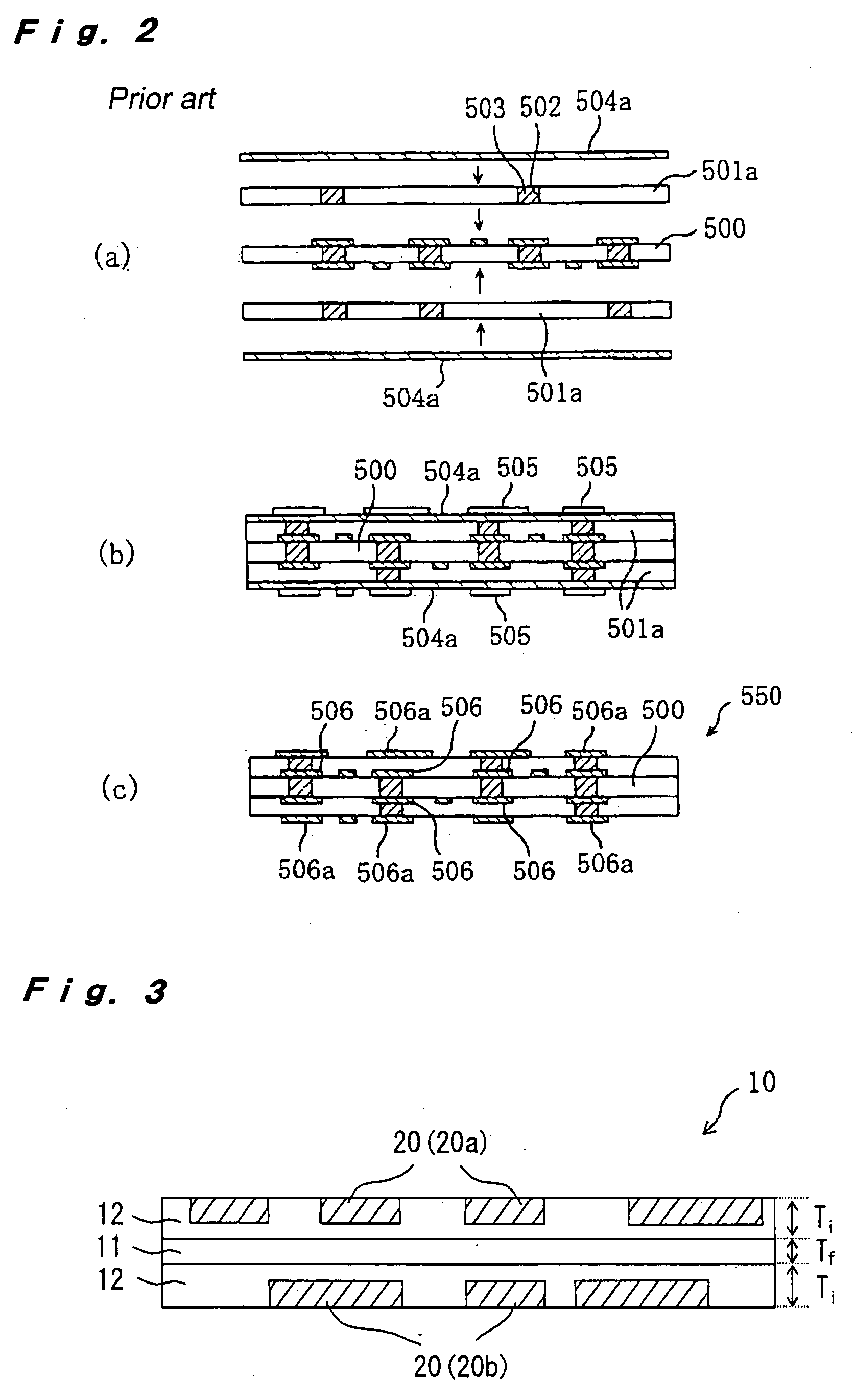

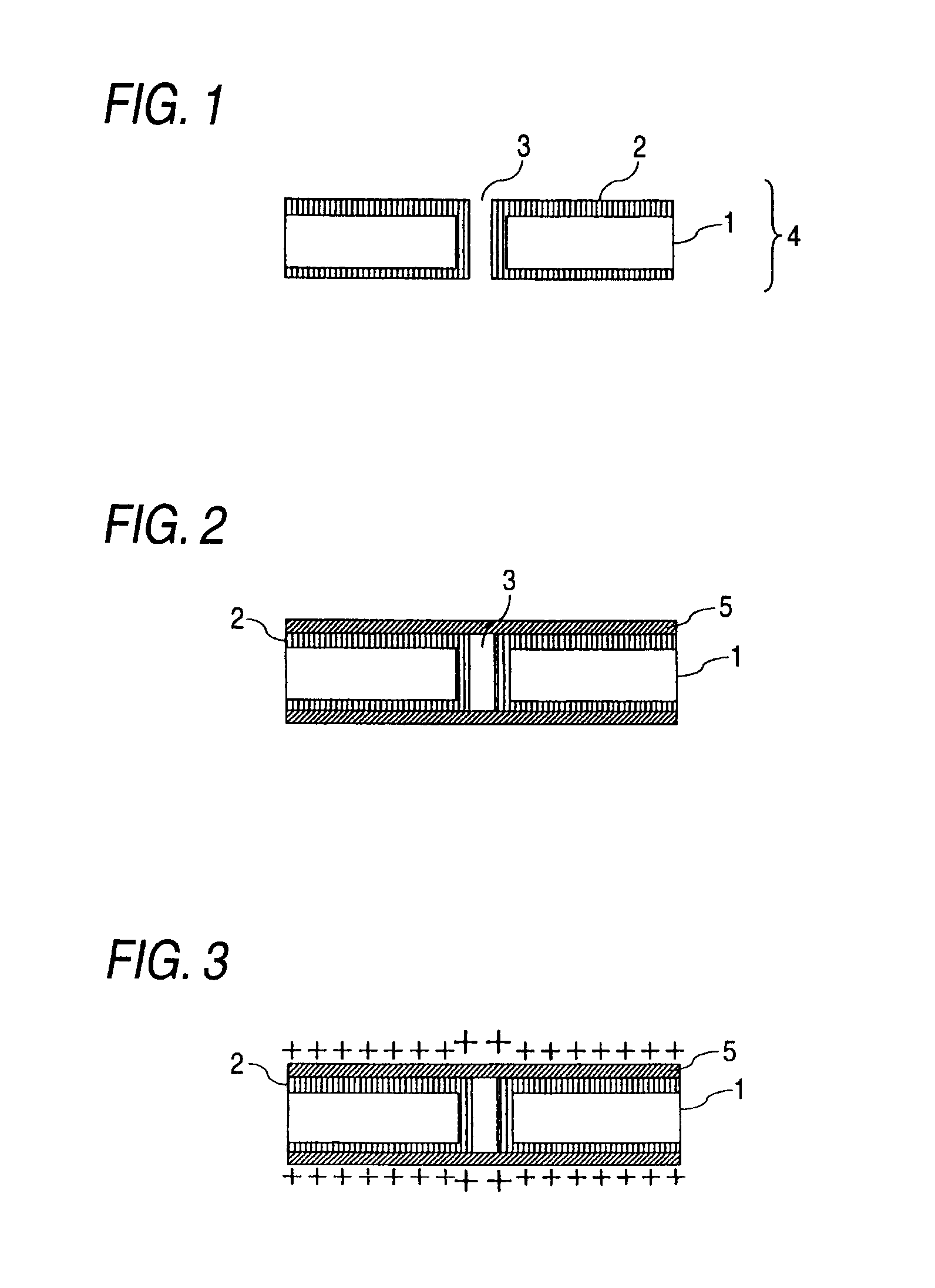

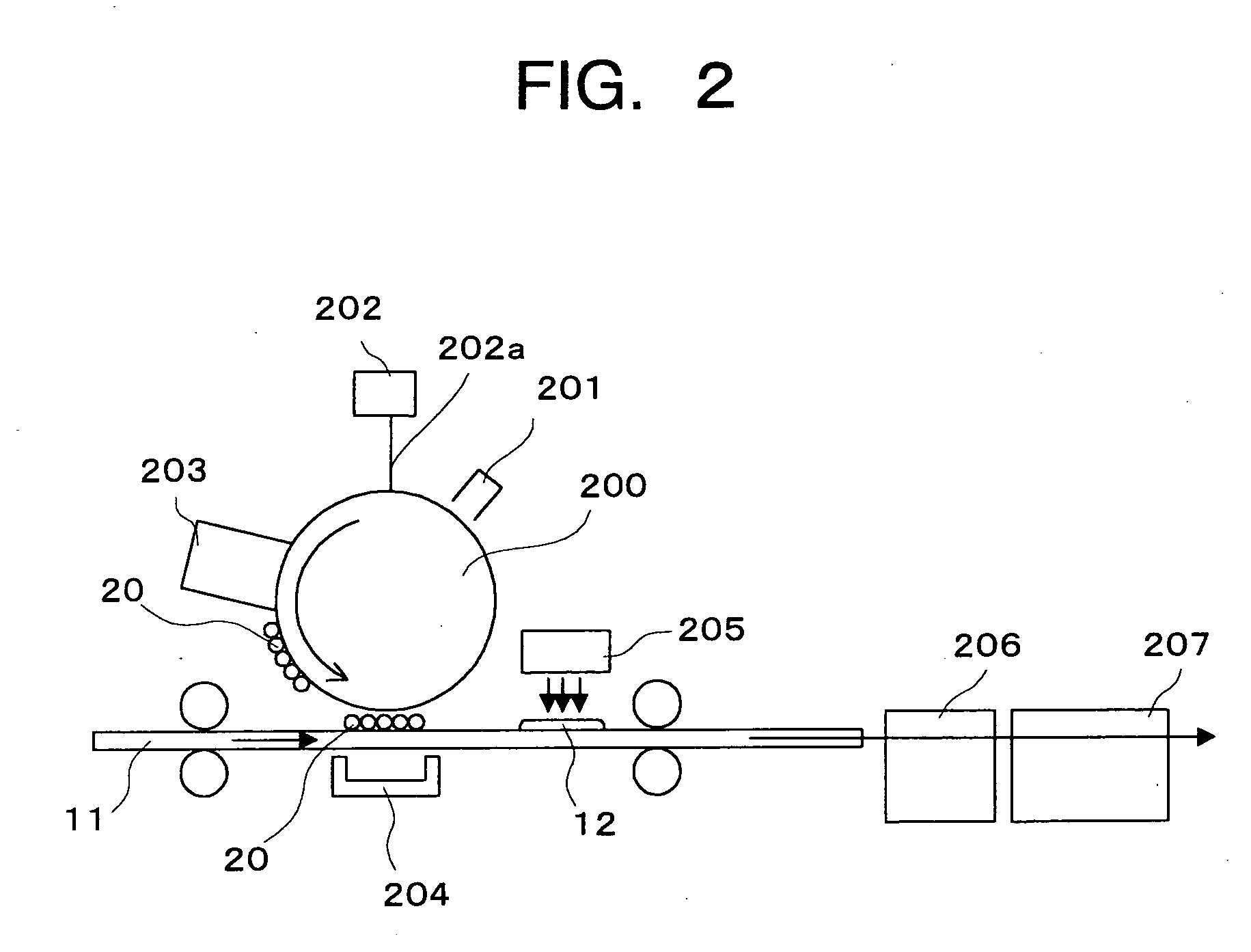

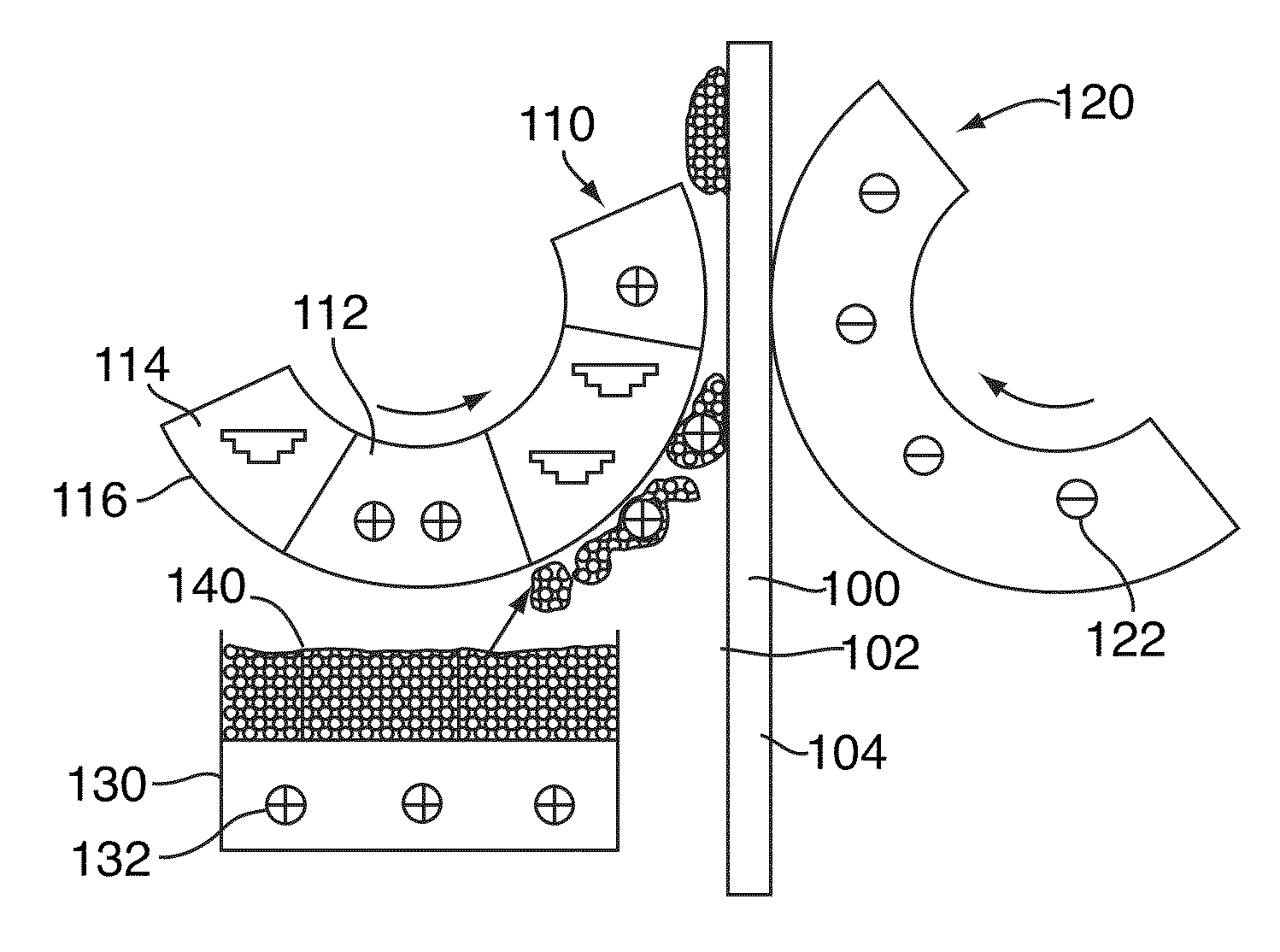

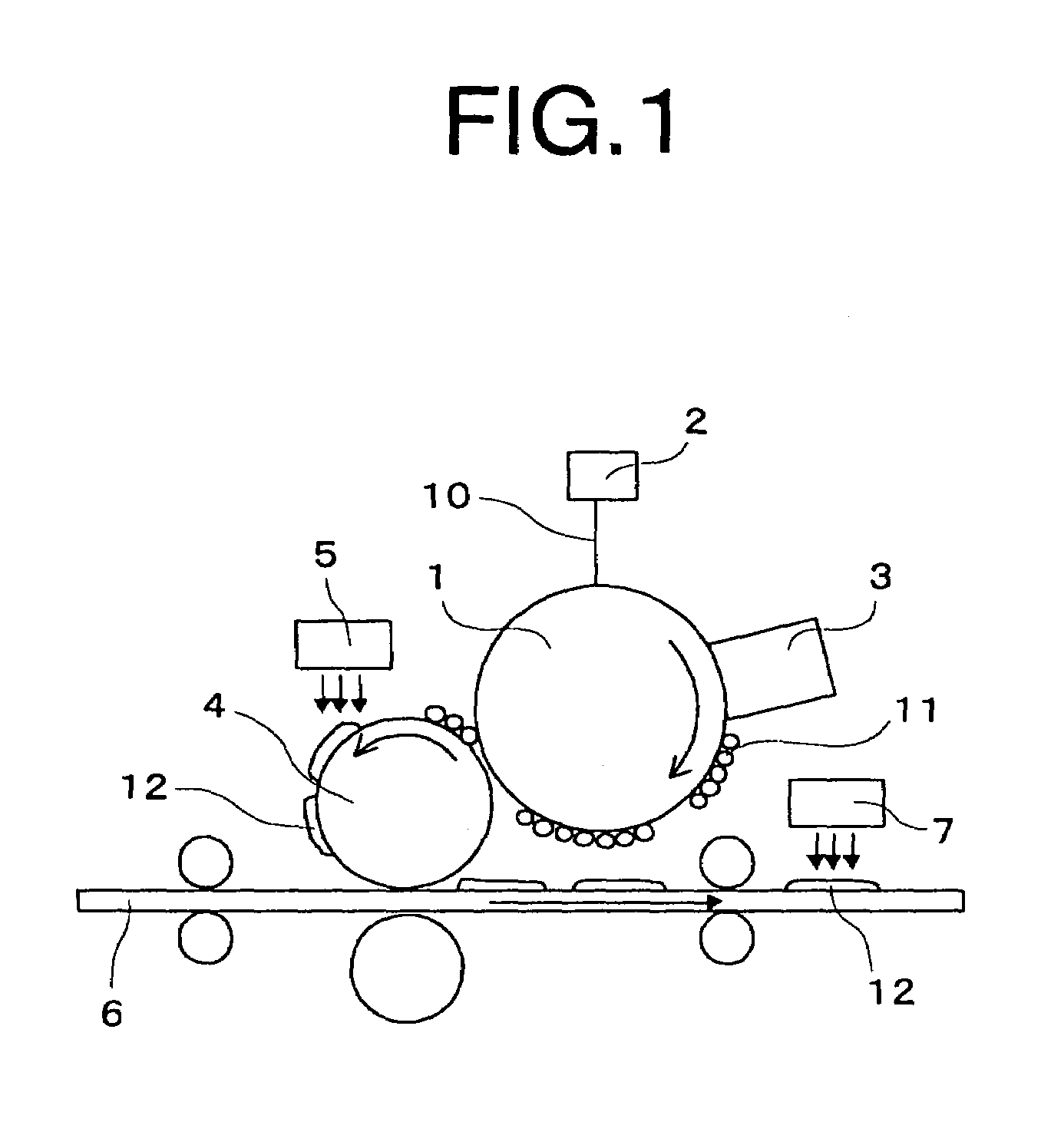

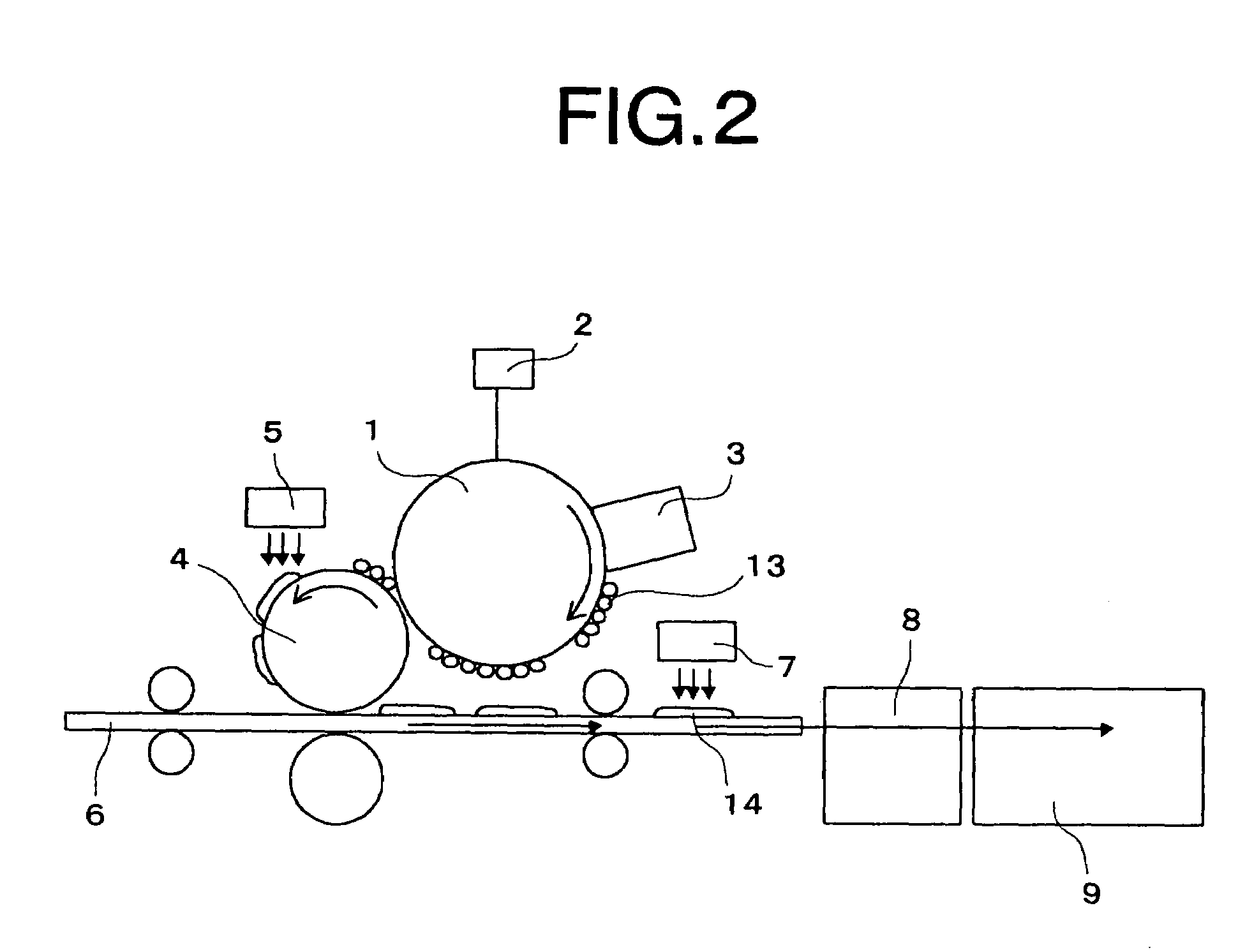

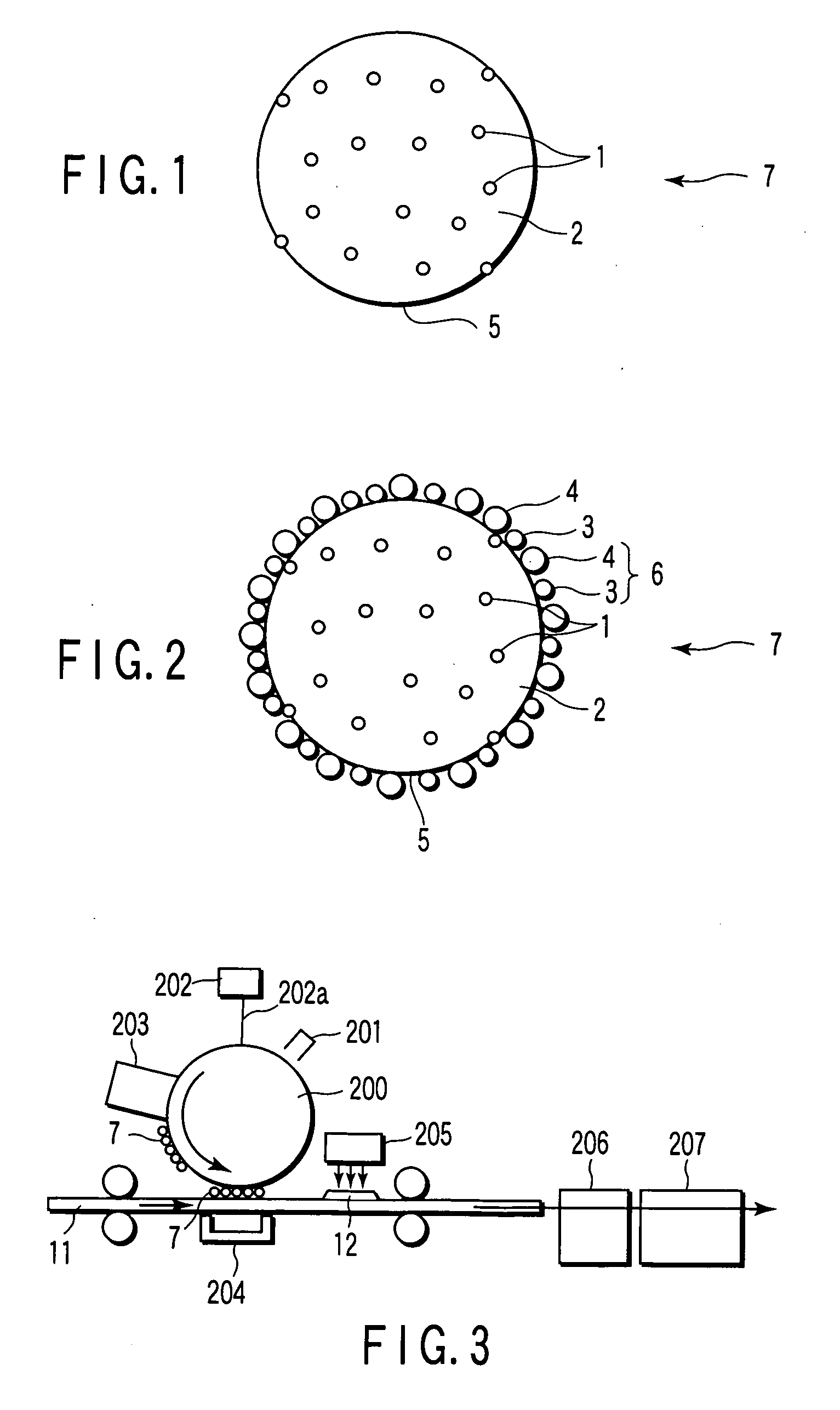

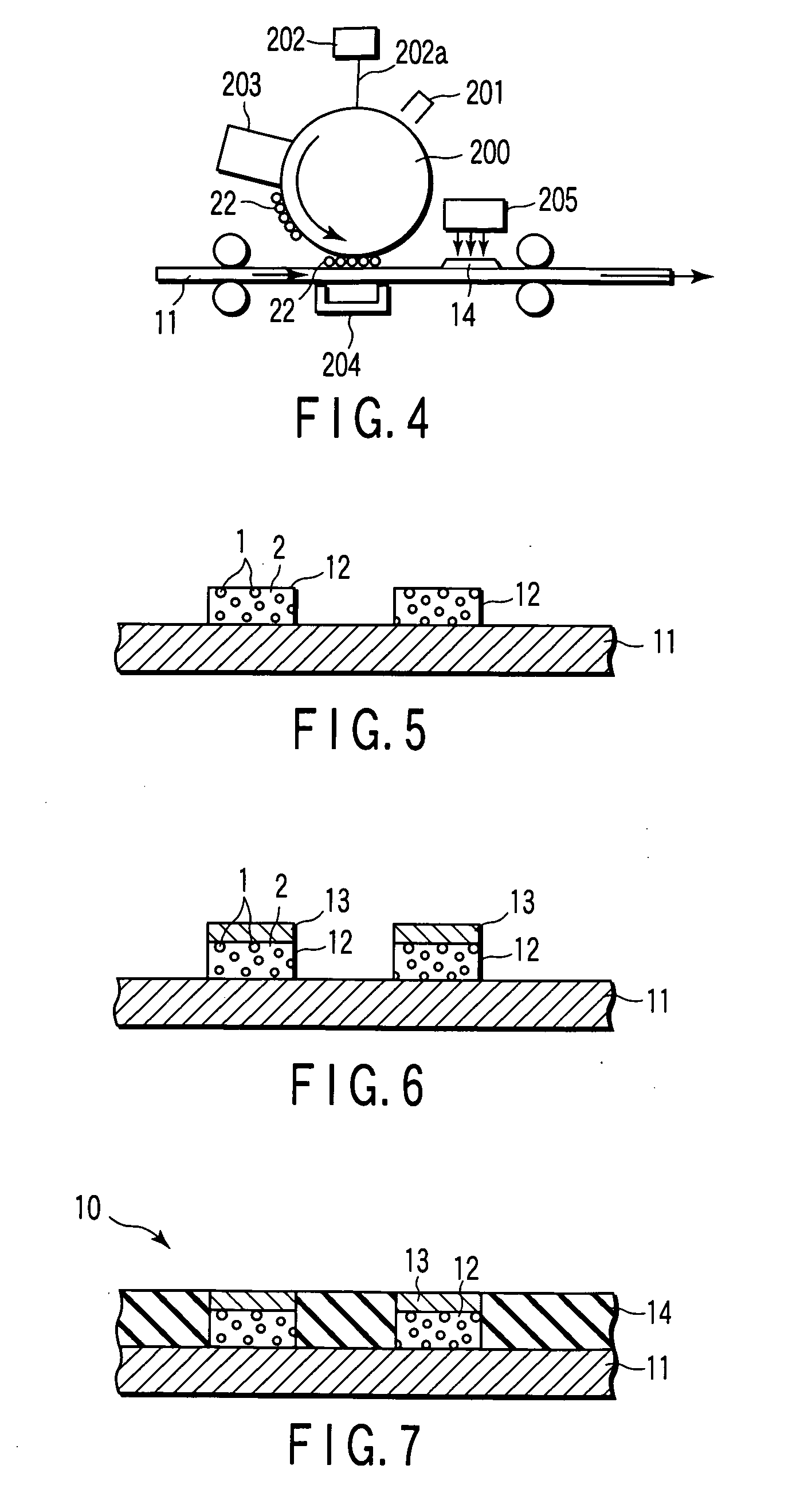

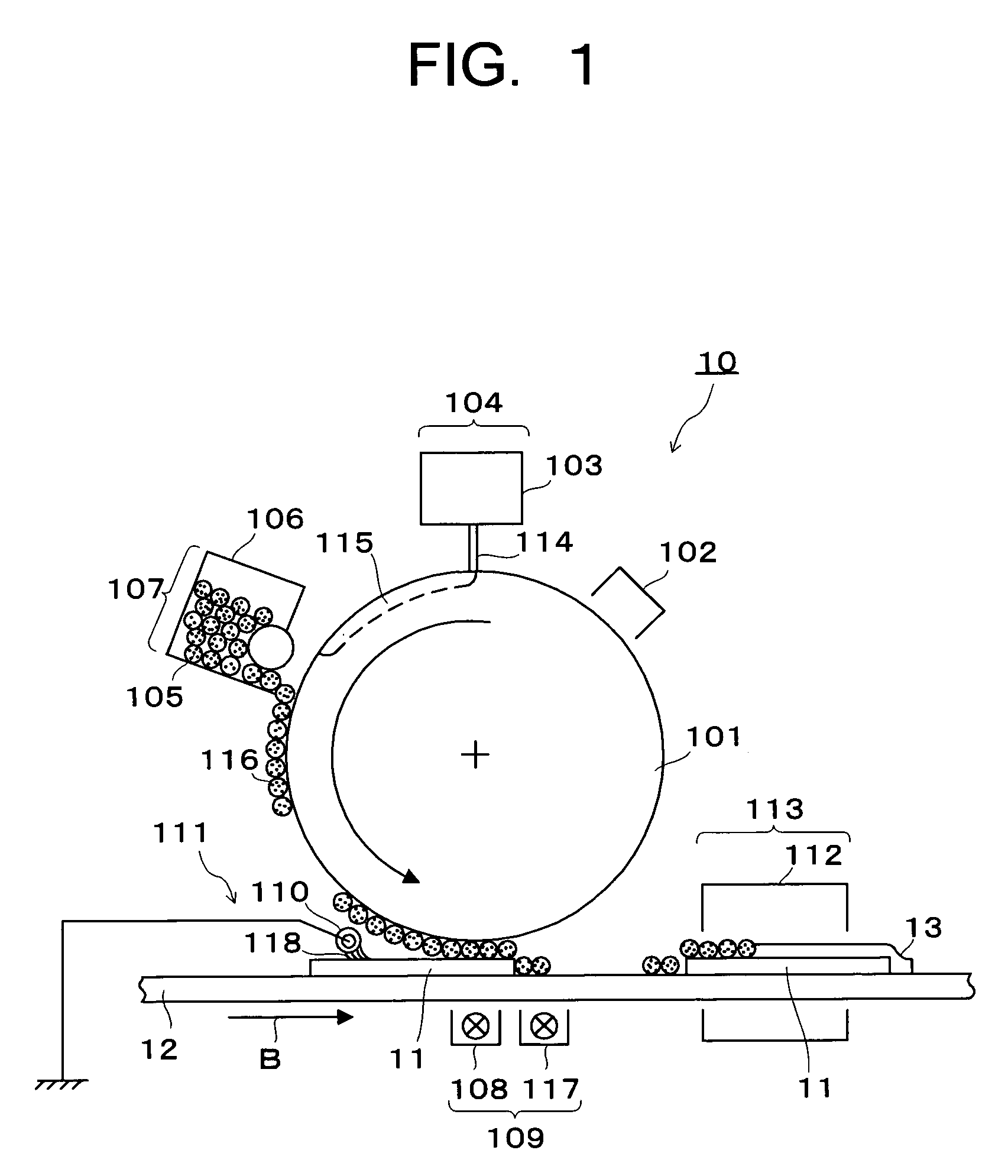

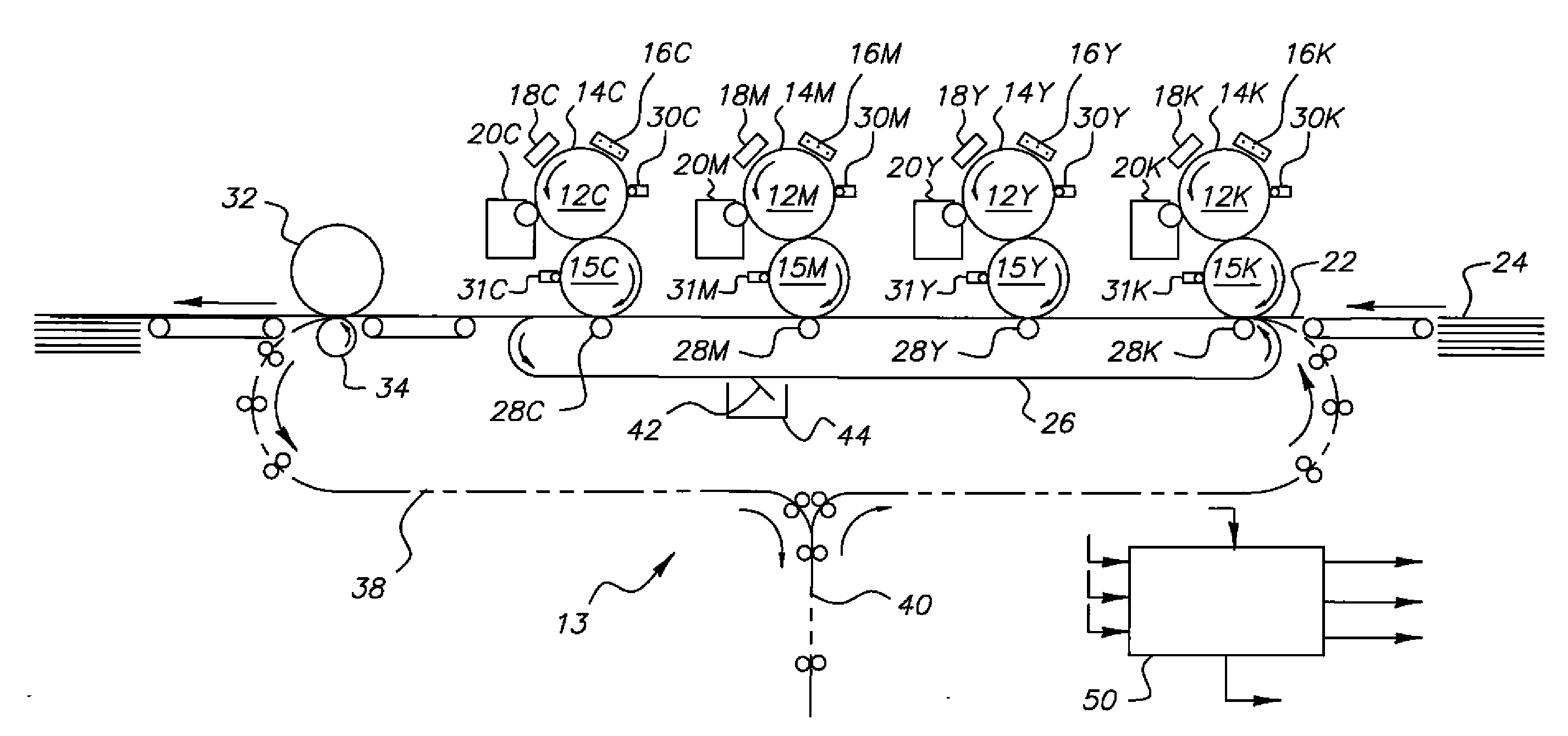

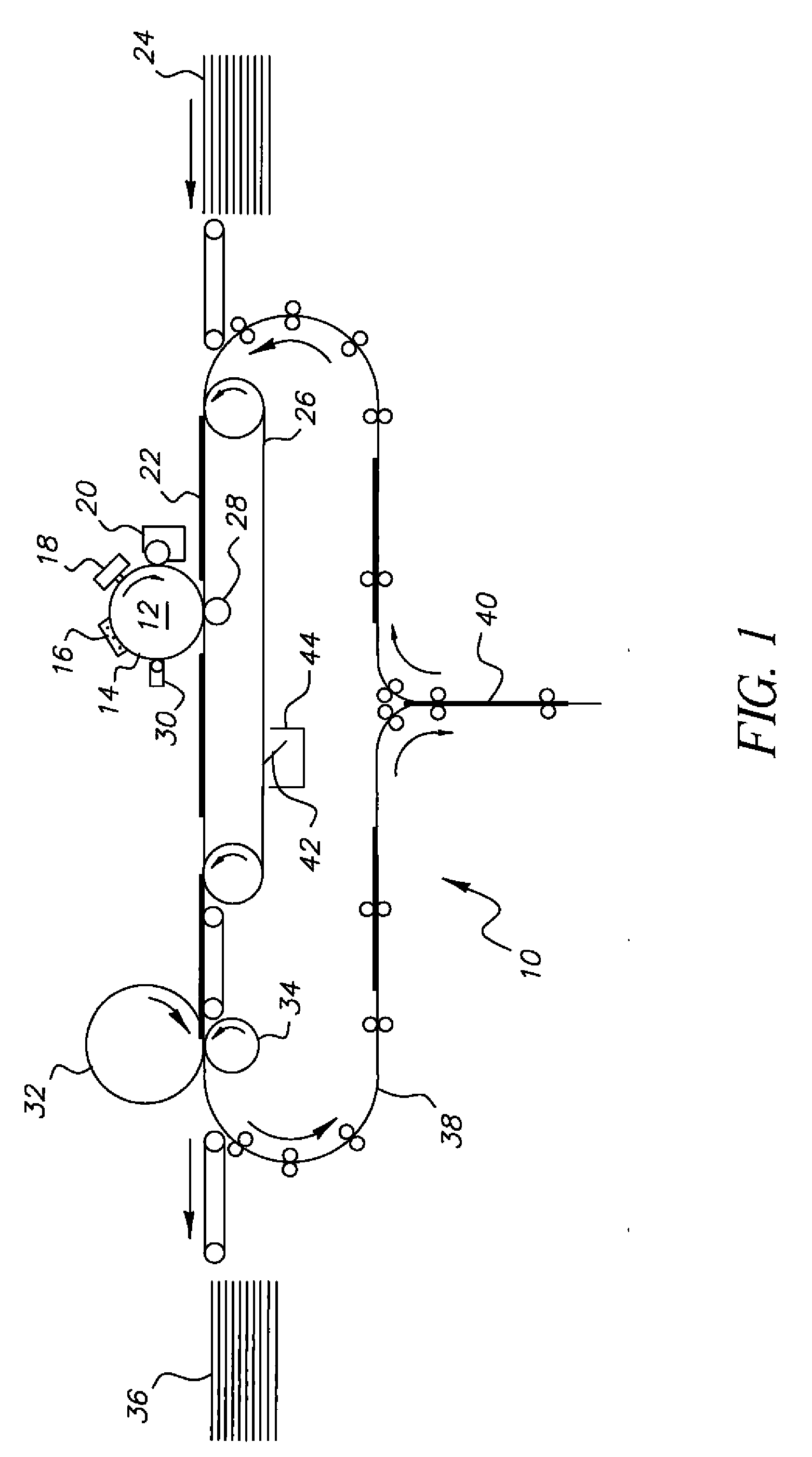

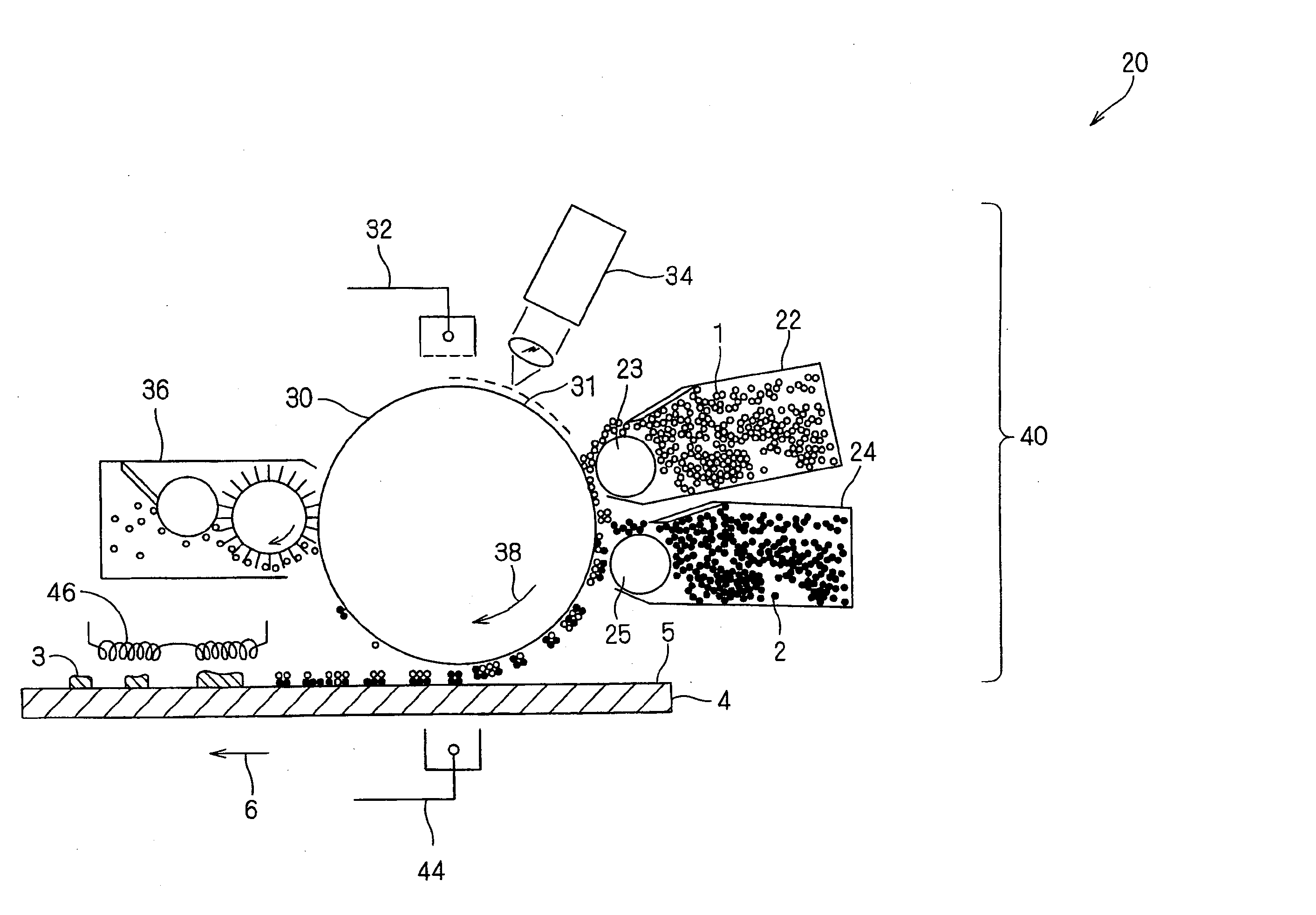

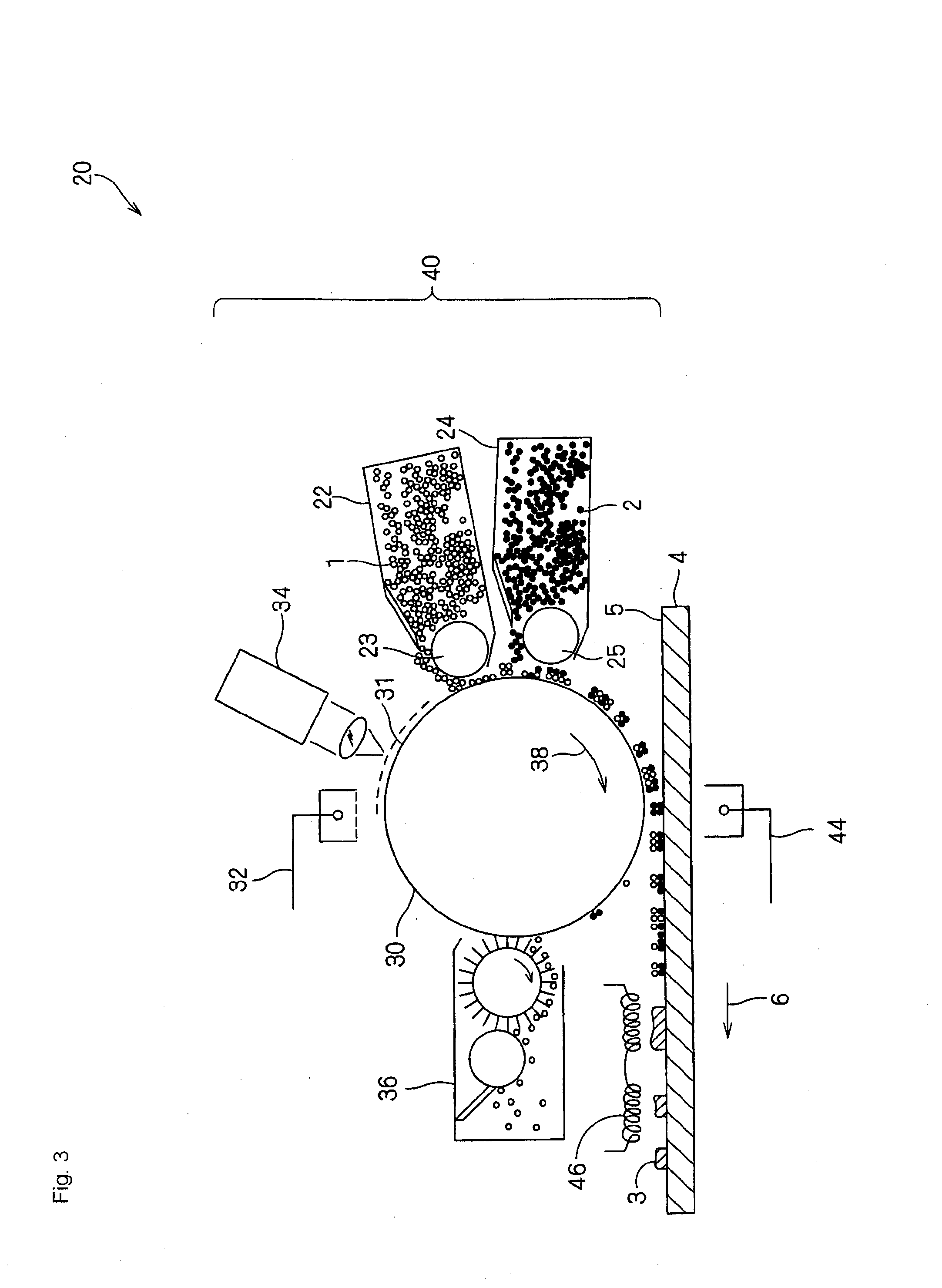

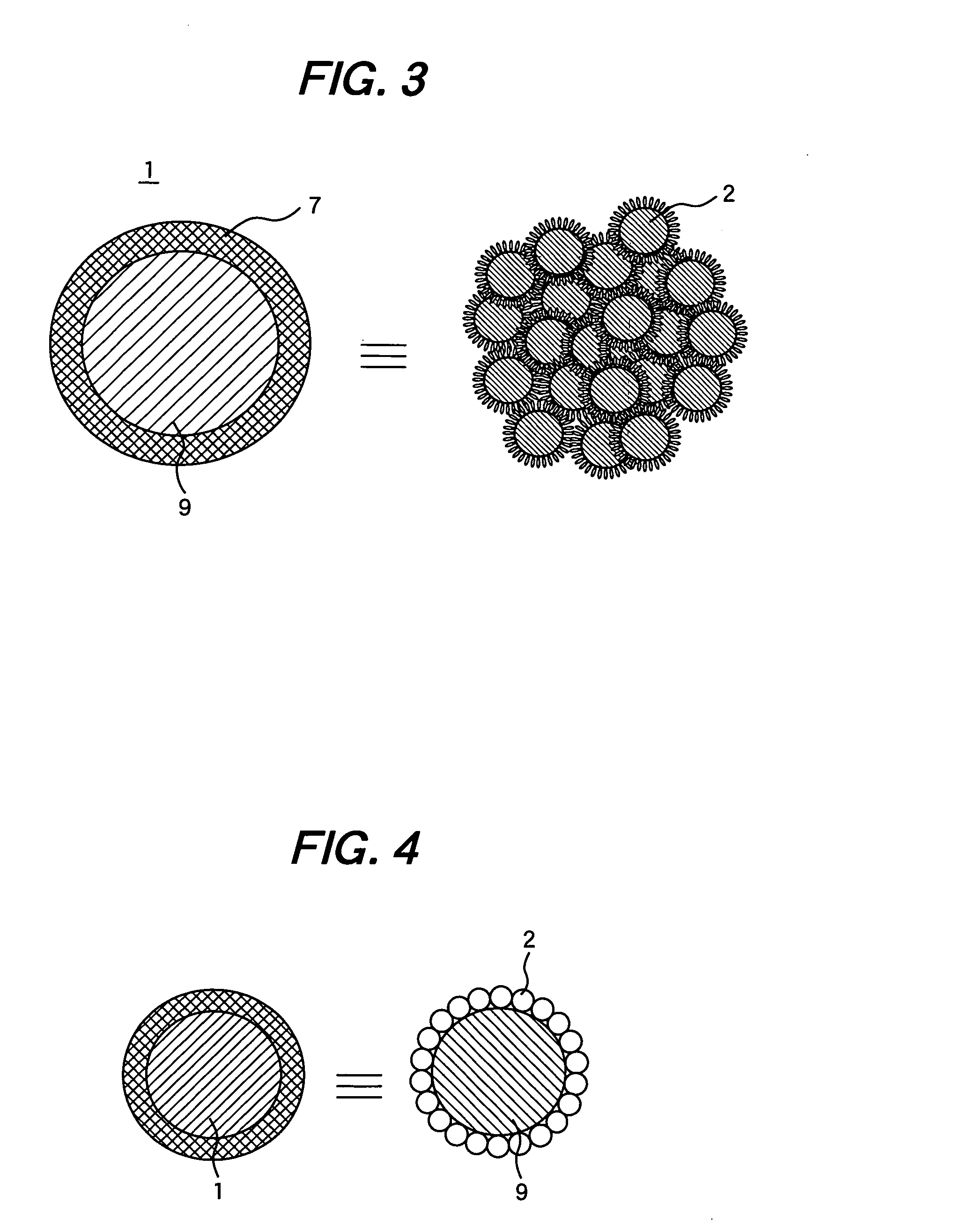

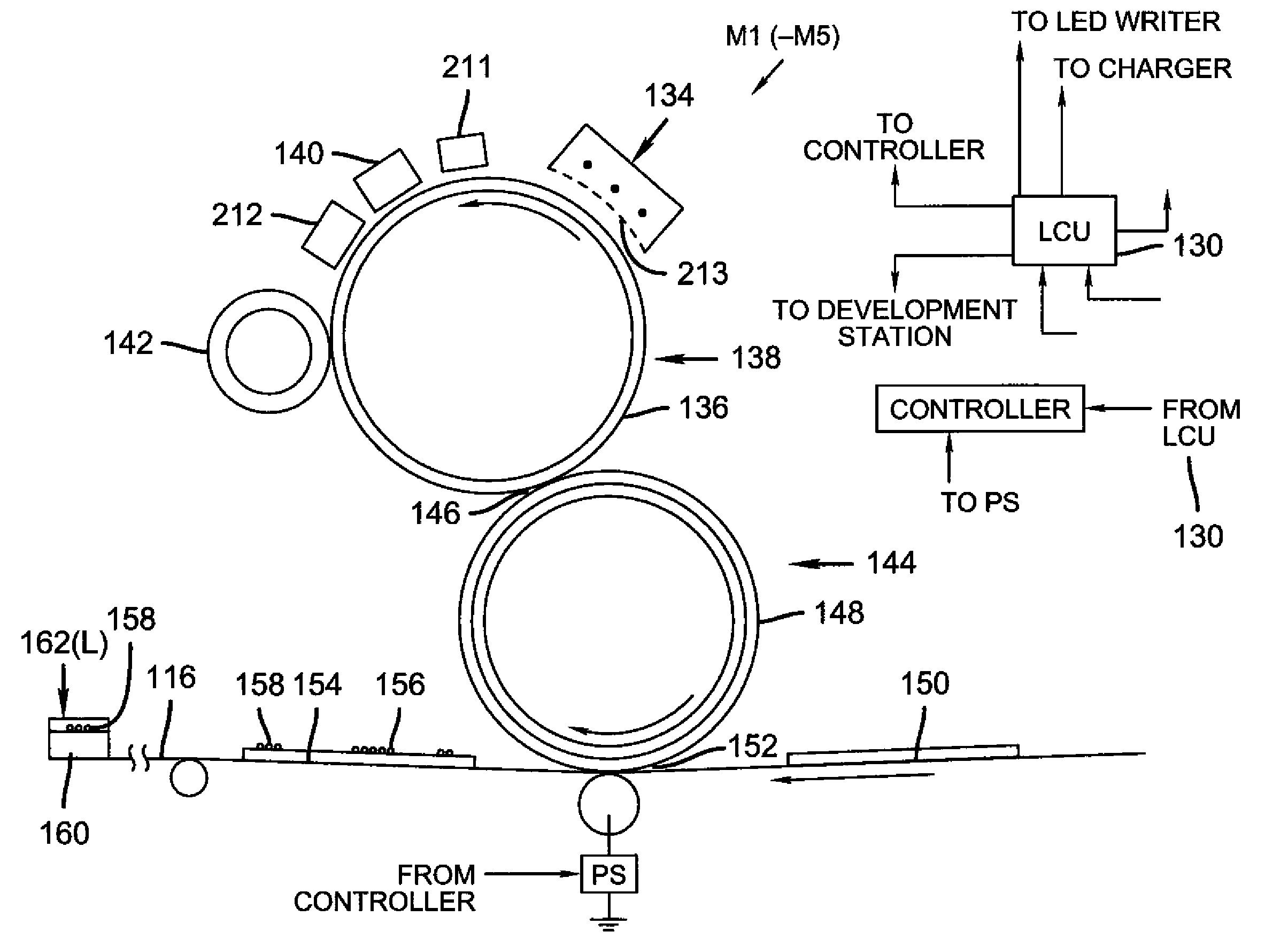

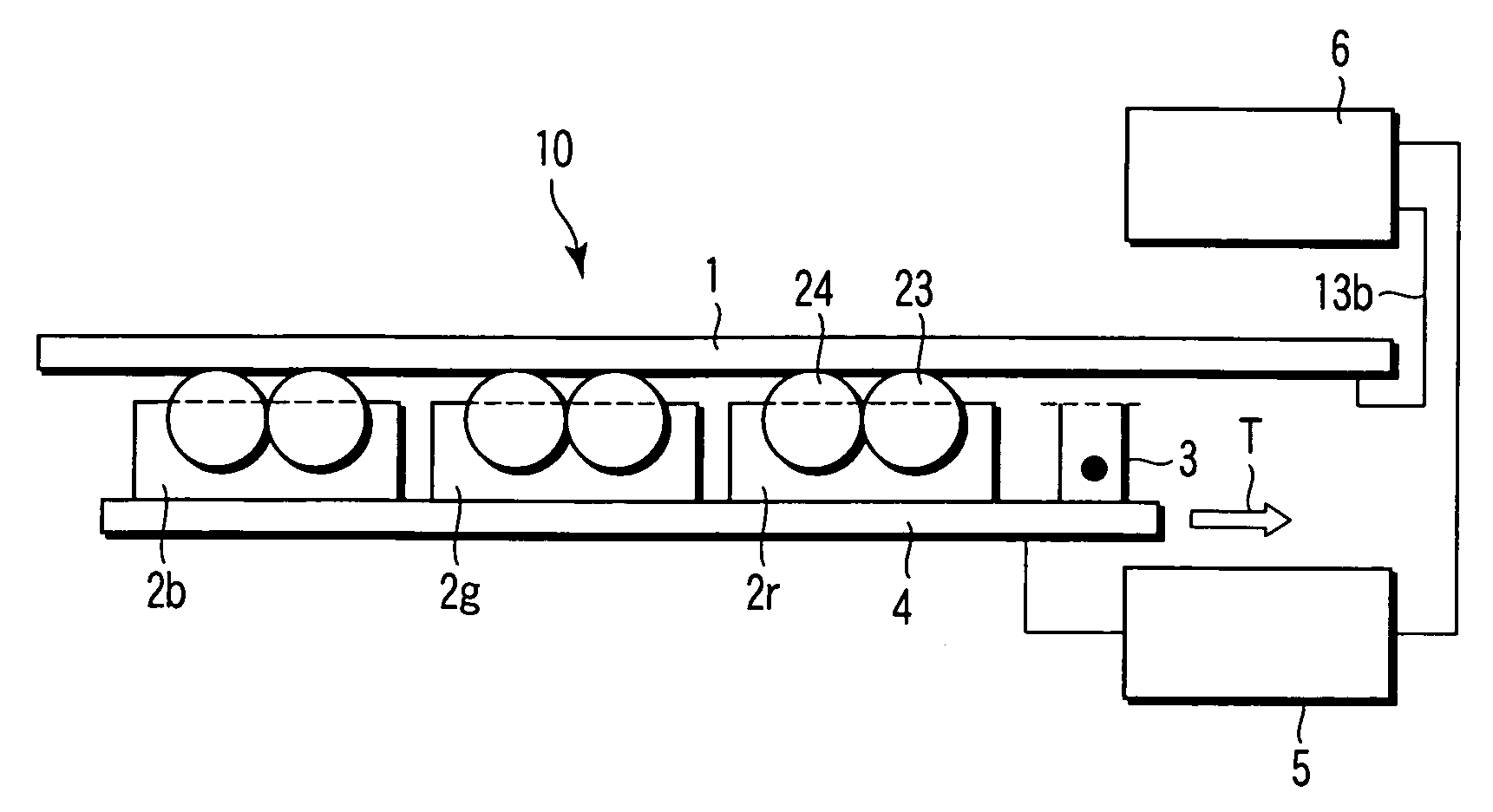

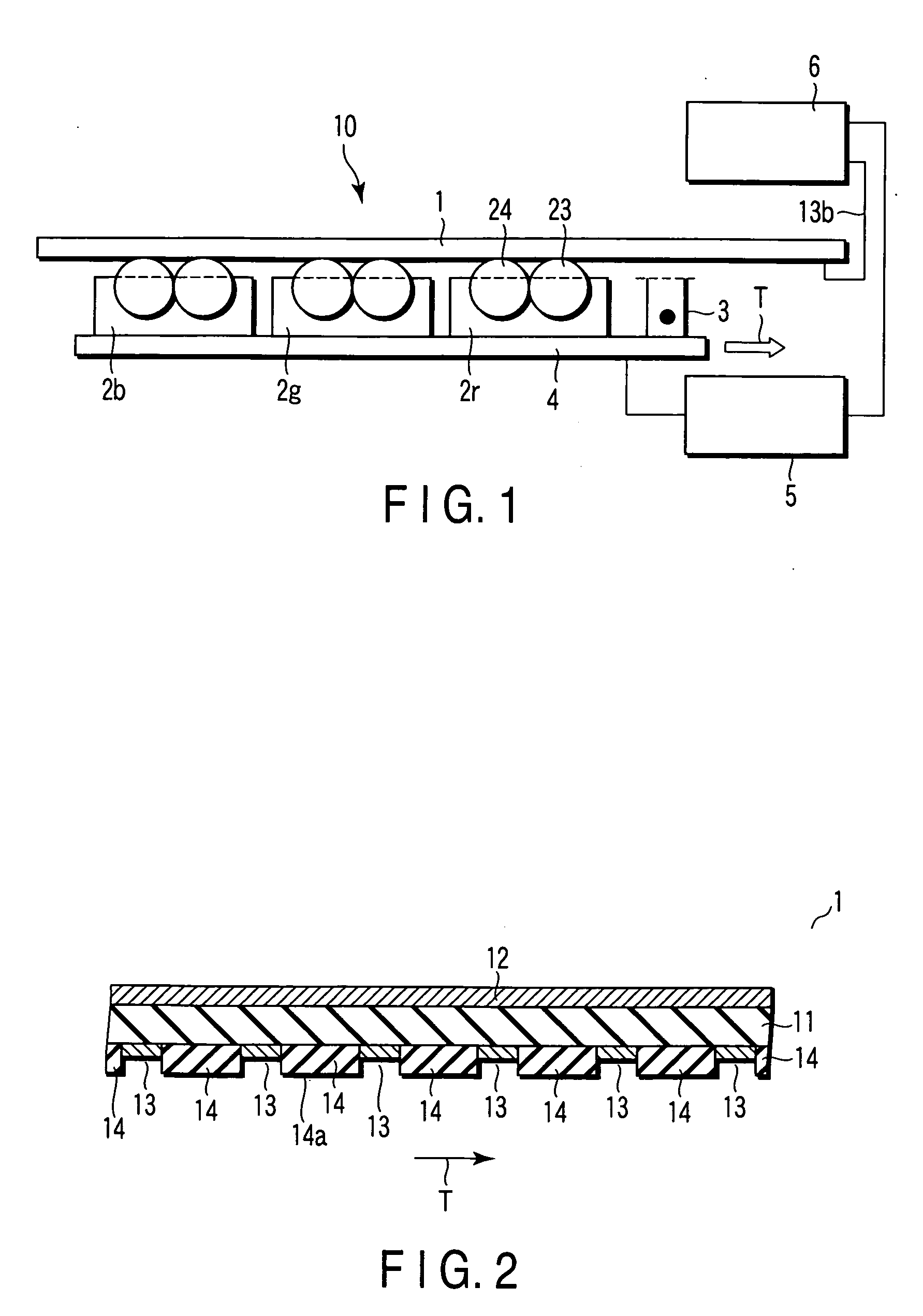

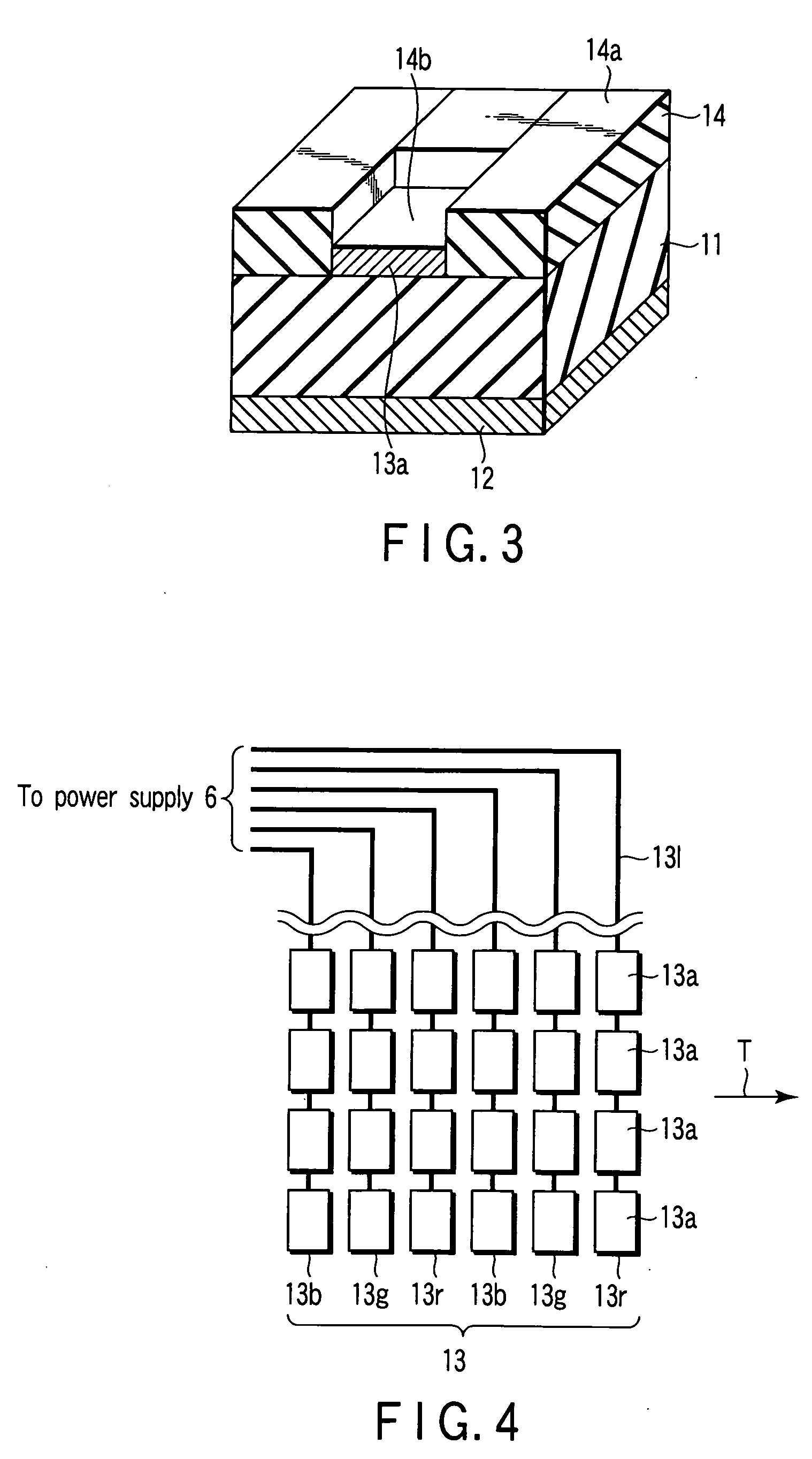

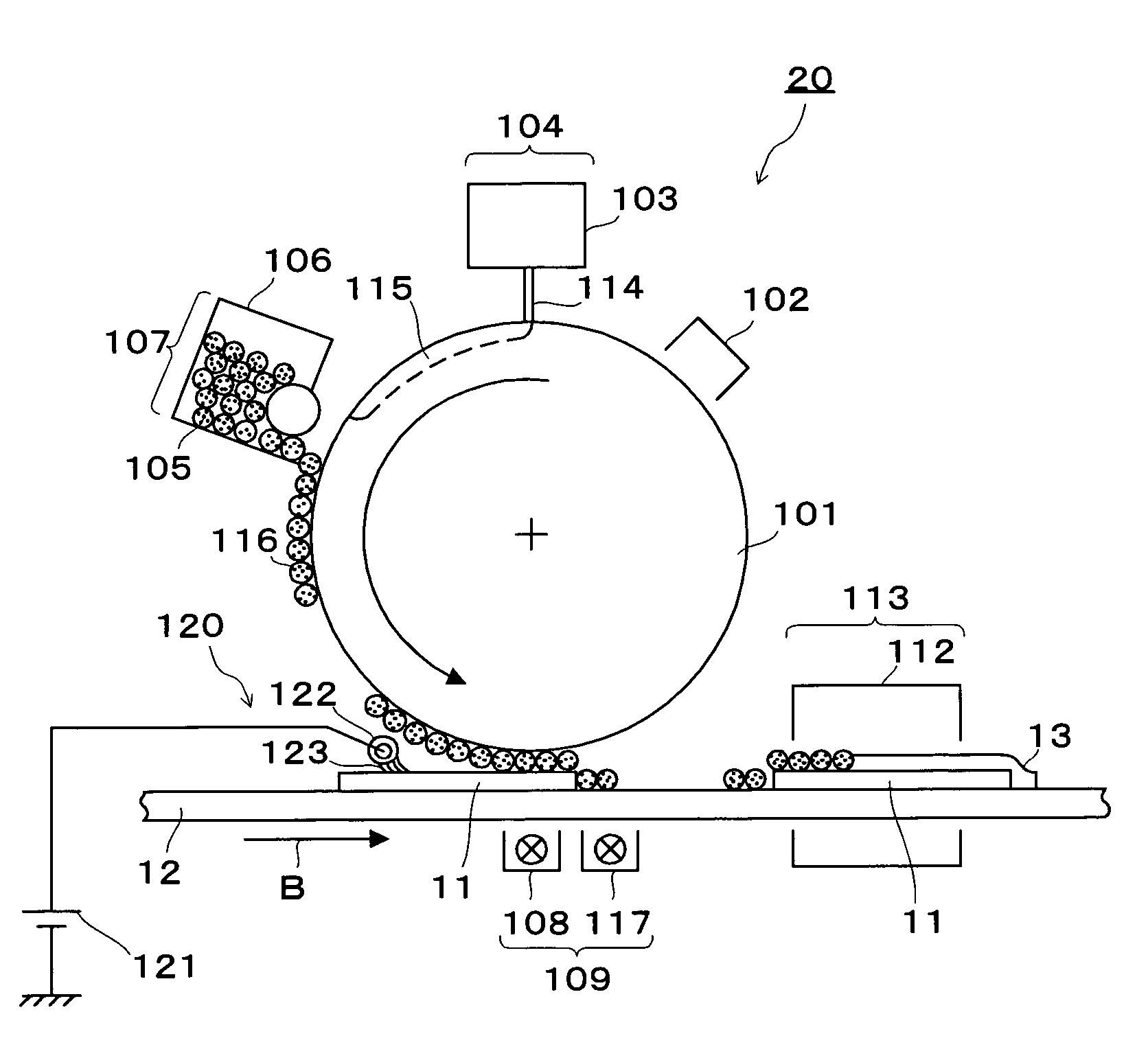

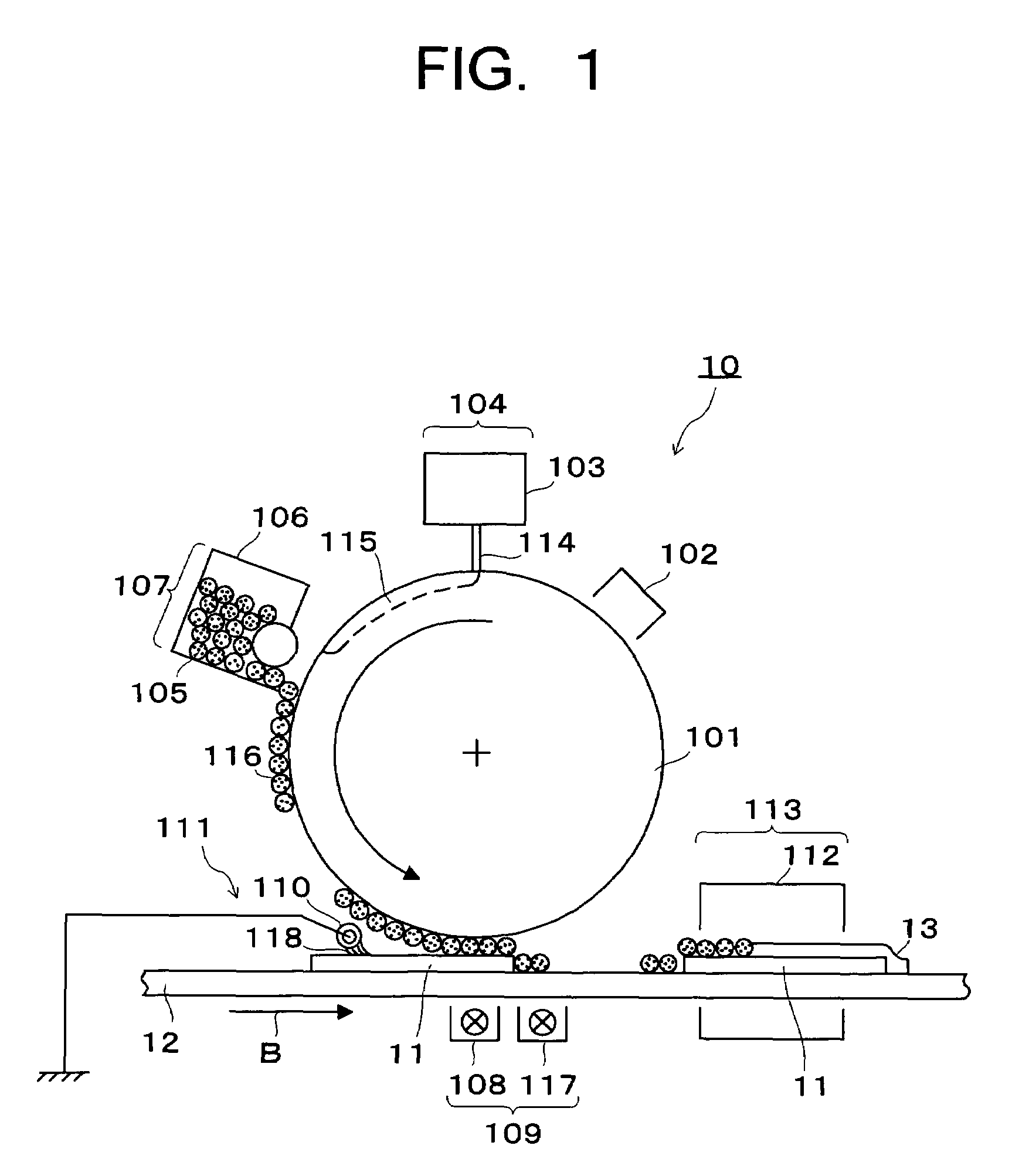

Method of manufacturing an electronic circuit and manufacturing apparatus of an electronic circuit

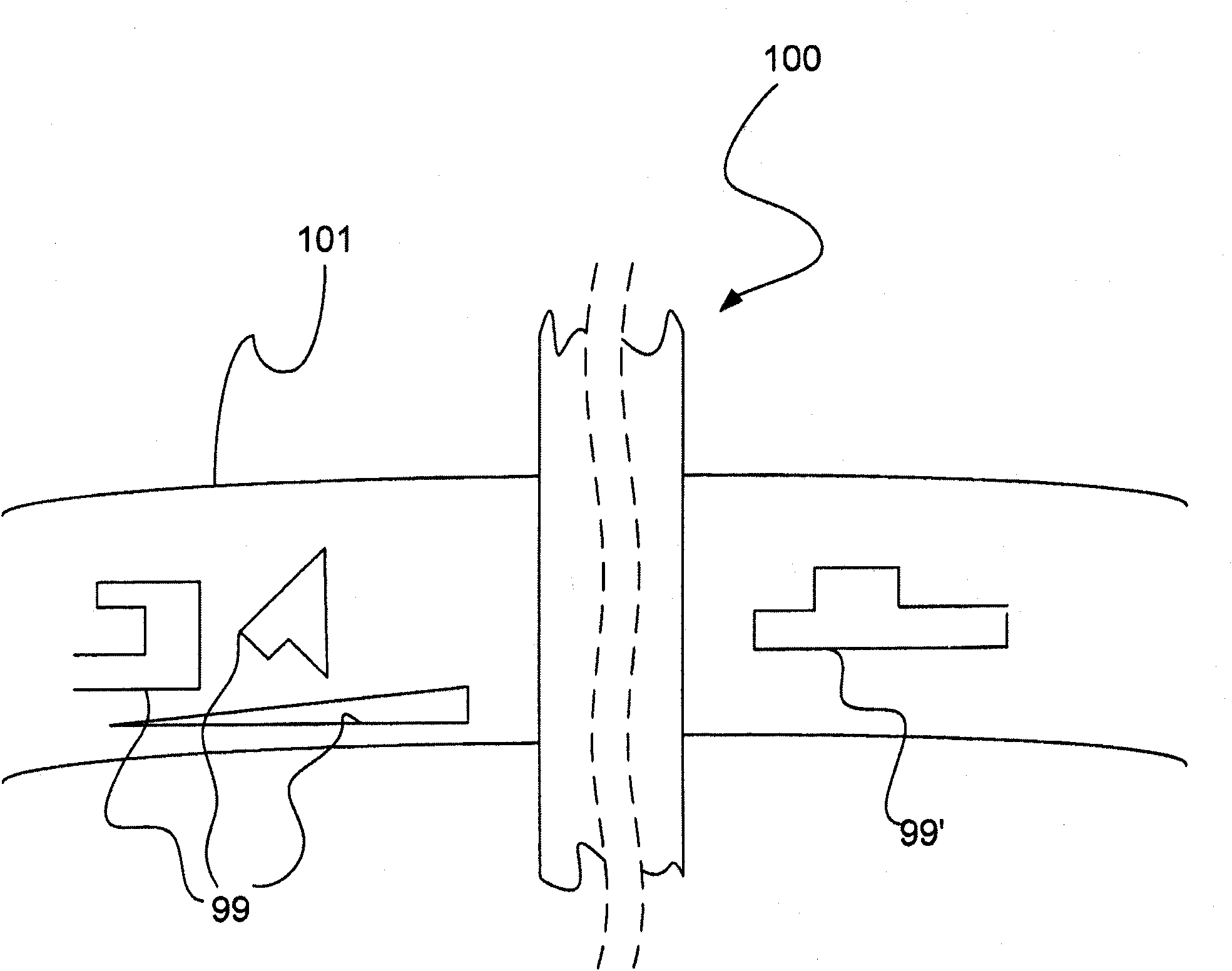

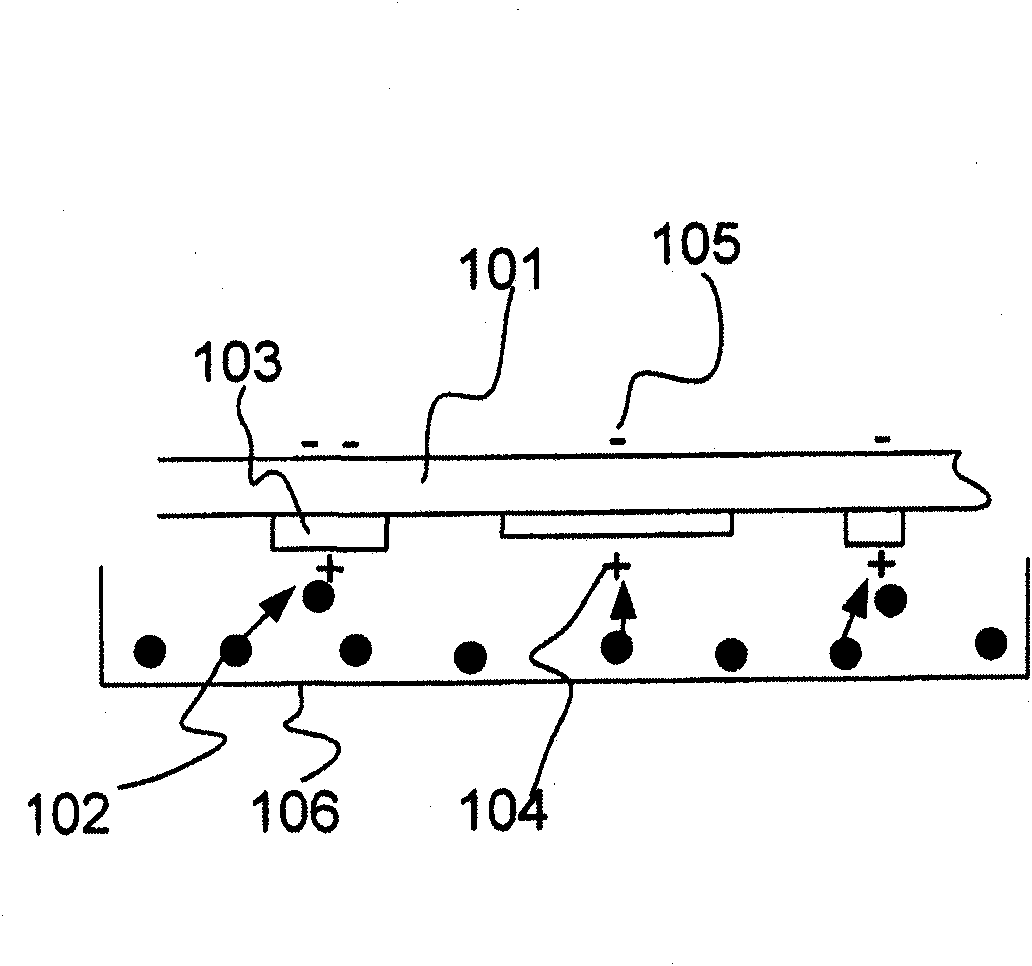

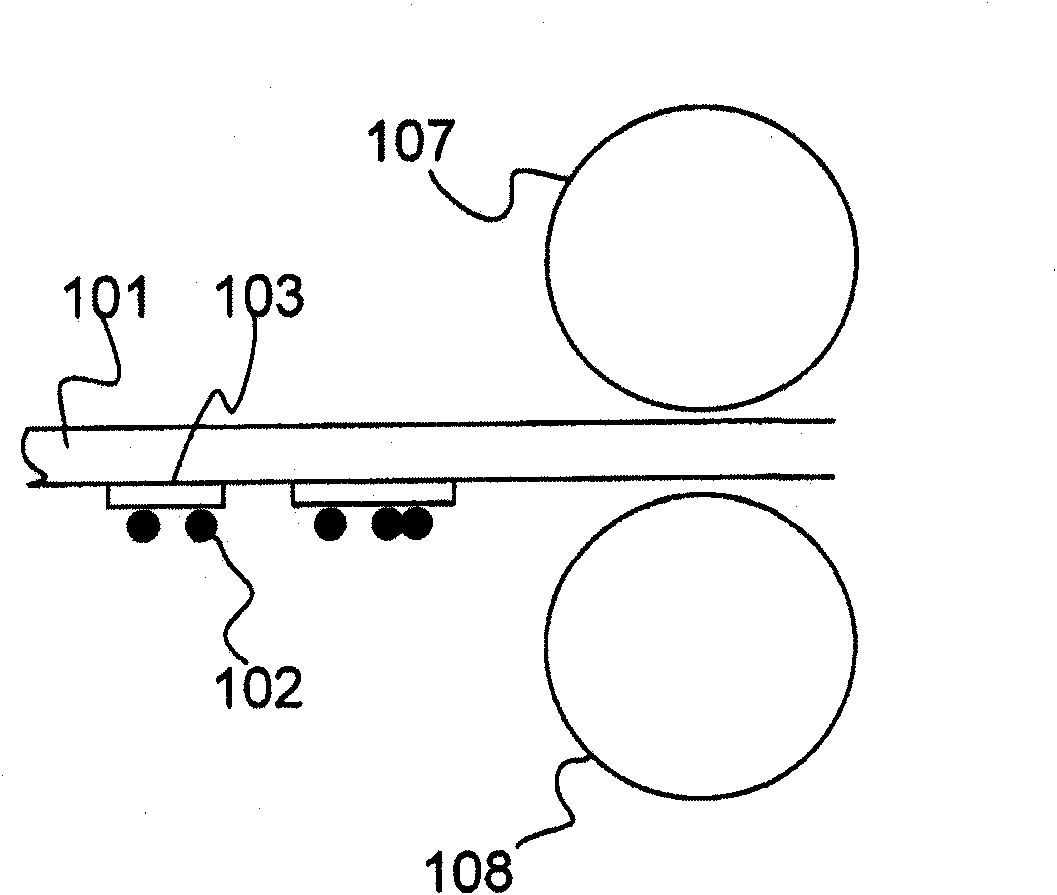

A method of manufacturing an electronic circuit satisfying demands for cost reduction, diversified small-quantity production, and a shorter cycle of design, manufacture, evaluation, correction, and so on is provided. The method includes at least forming a first pattern or forming a second pattern. Forming the first pattern comprises: forming a visible image on an electrostatic latent image formed on a photosensitive base, by the adhesion of charged particles essentially made of a resin; transferring the visible image onto the intermediate transfer base by the contact and pressurization of the visible image; heating / softening on the intermediate transfer base; and transferring a heated / softened resin layer onto a base material by the contact and pressurization of the resin layer. In forming the second pattern, using charged particles containing conductive metal particulates, a conductor metal layer is formed by electroless plating after a metal-containing resin pattern is transferred similarly to the first pattern formation.

Owner:KK TOSHIBA

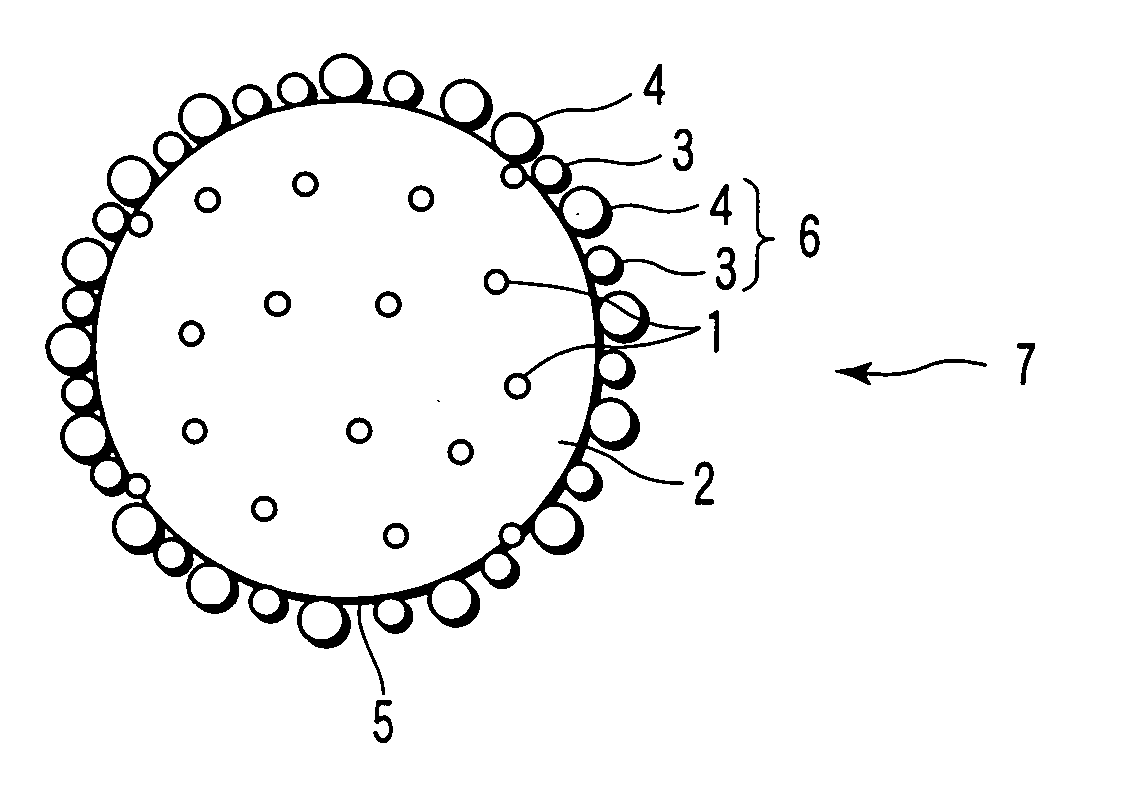

Toner for producing wiring board and method of producing wiring board using thereof

InactiveUS20050227158A1Low costImprove charging effectPrinted circuit aspectsElectrographic patterningEngineeringLarge size

A conductive underlayer is formed in an electrophotographic manner using a toner comprising toner particles containing a binder resin containing a green thermosetting resin and conductive particles having an average particle diameter of 0.05 μm to 1 μm, wherein 50% by volume particle diameter of the toner is in a range 4 μm to 12 μm and the ratio of the toner with a size of 4 μm or smaller is 20% by number or less, or a toner including external additives containing hydrophobic-treated small size metal oxide particles having a BET specific surface area of 150 m2 / g to 400 m2 / g and large size metal oxide particles having a BET specific surface area of 10 m2 / g to 70 m2 / g and then a conductive layer is formed thereon by plating.

Owner:KK TOSHIBA +1

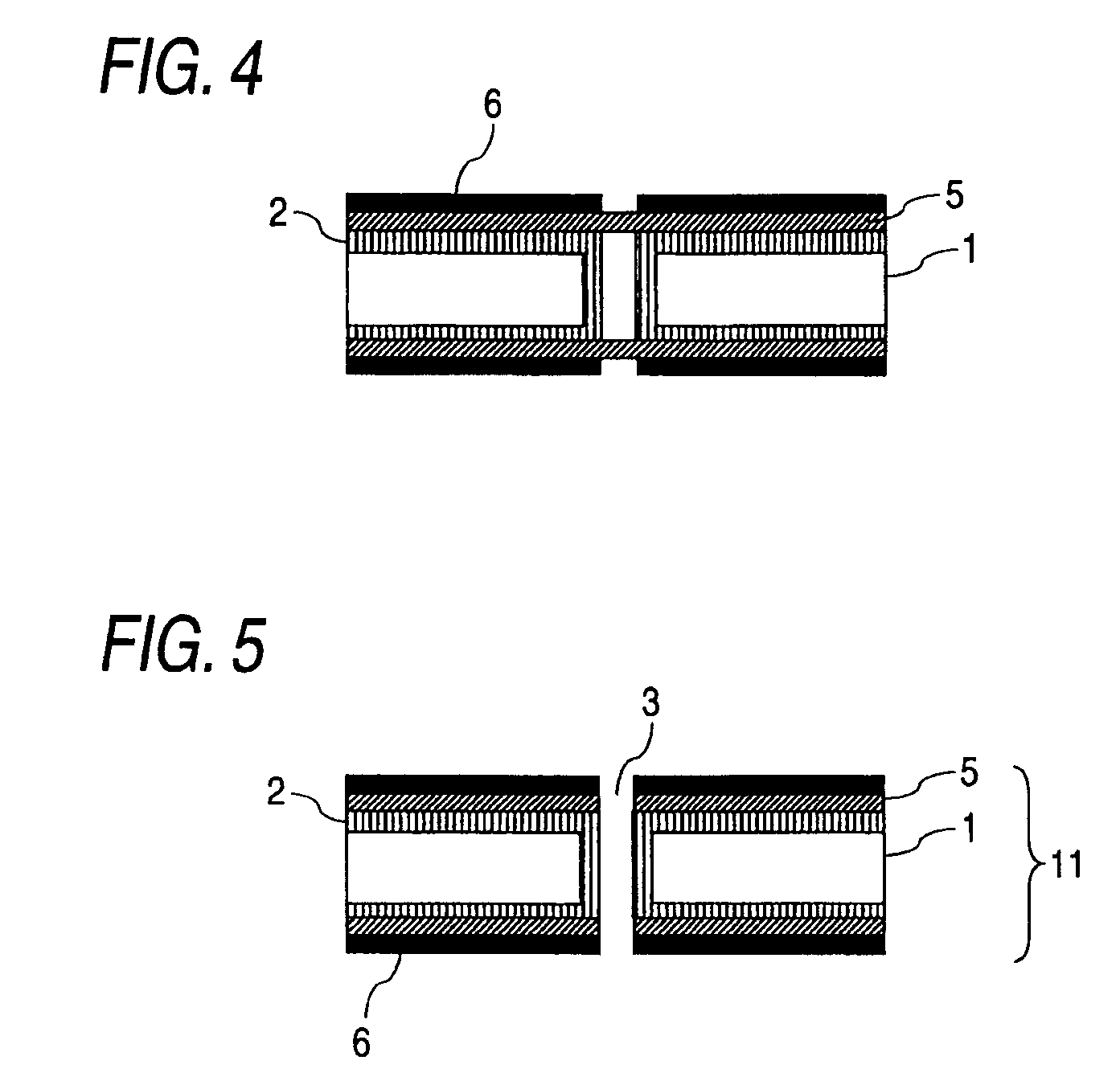

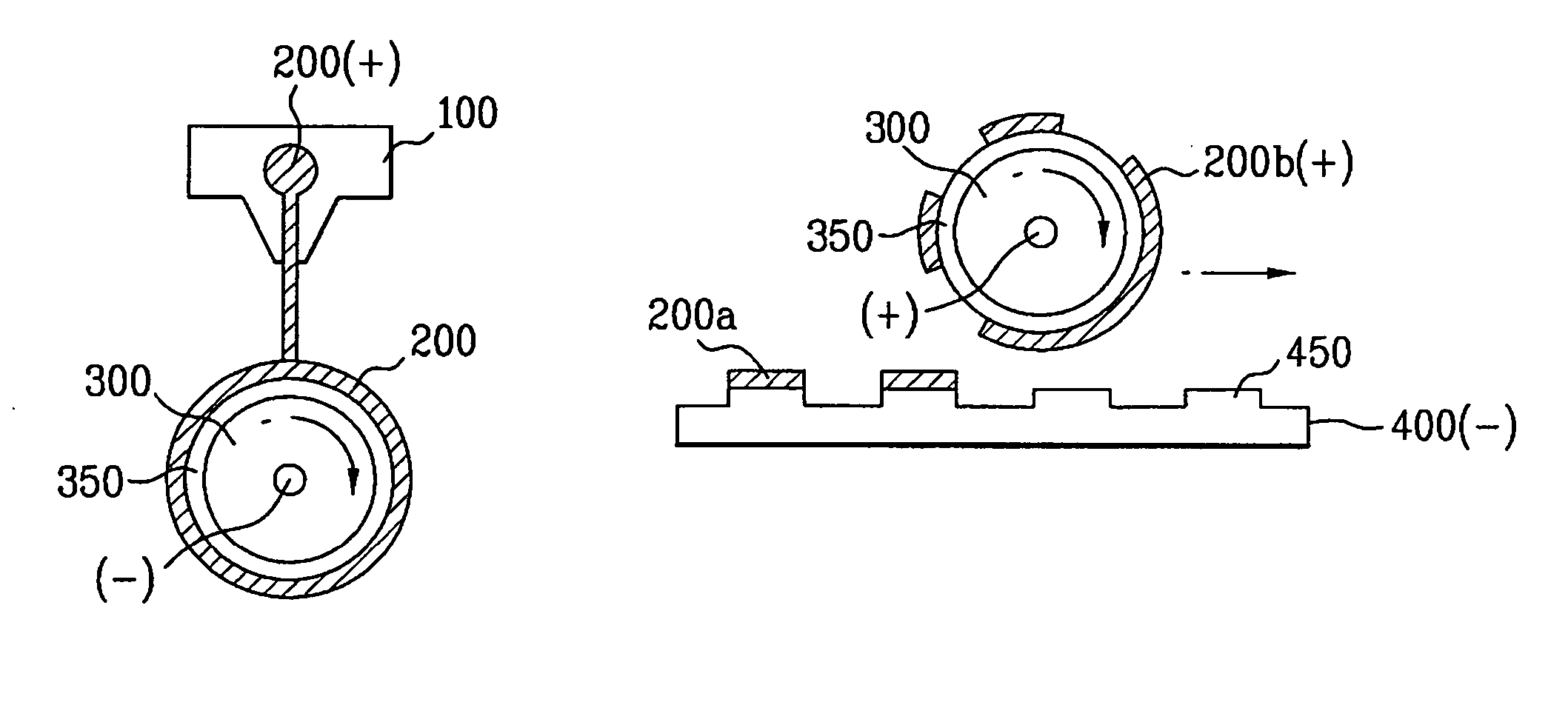

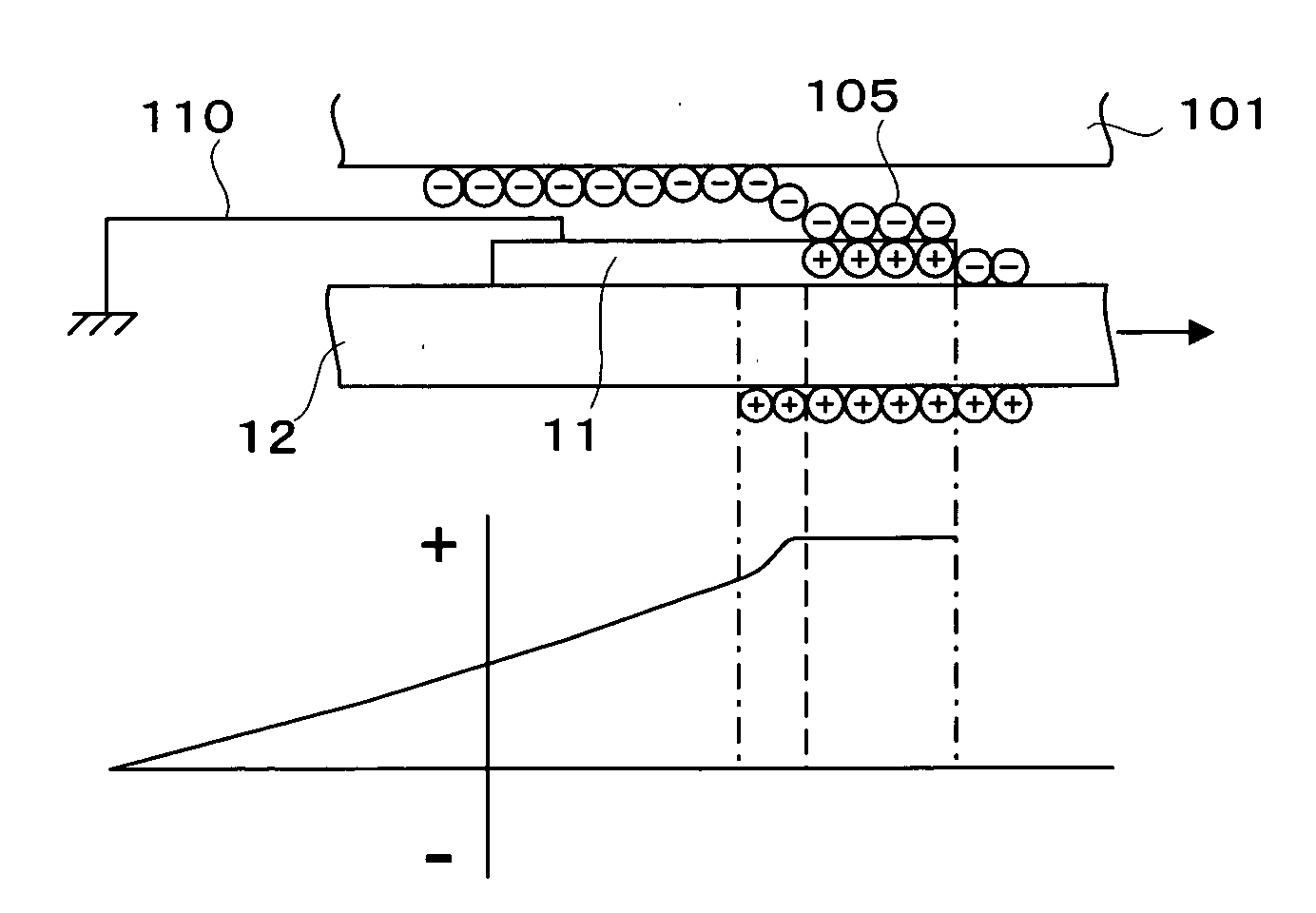

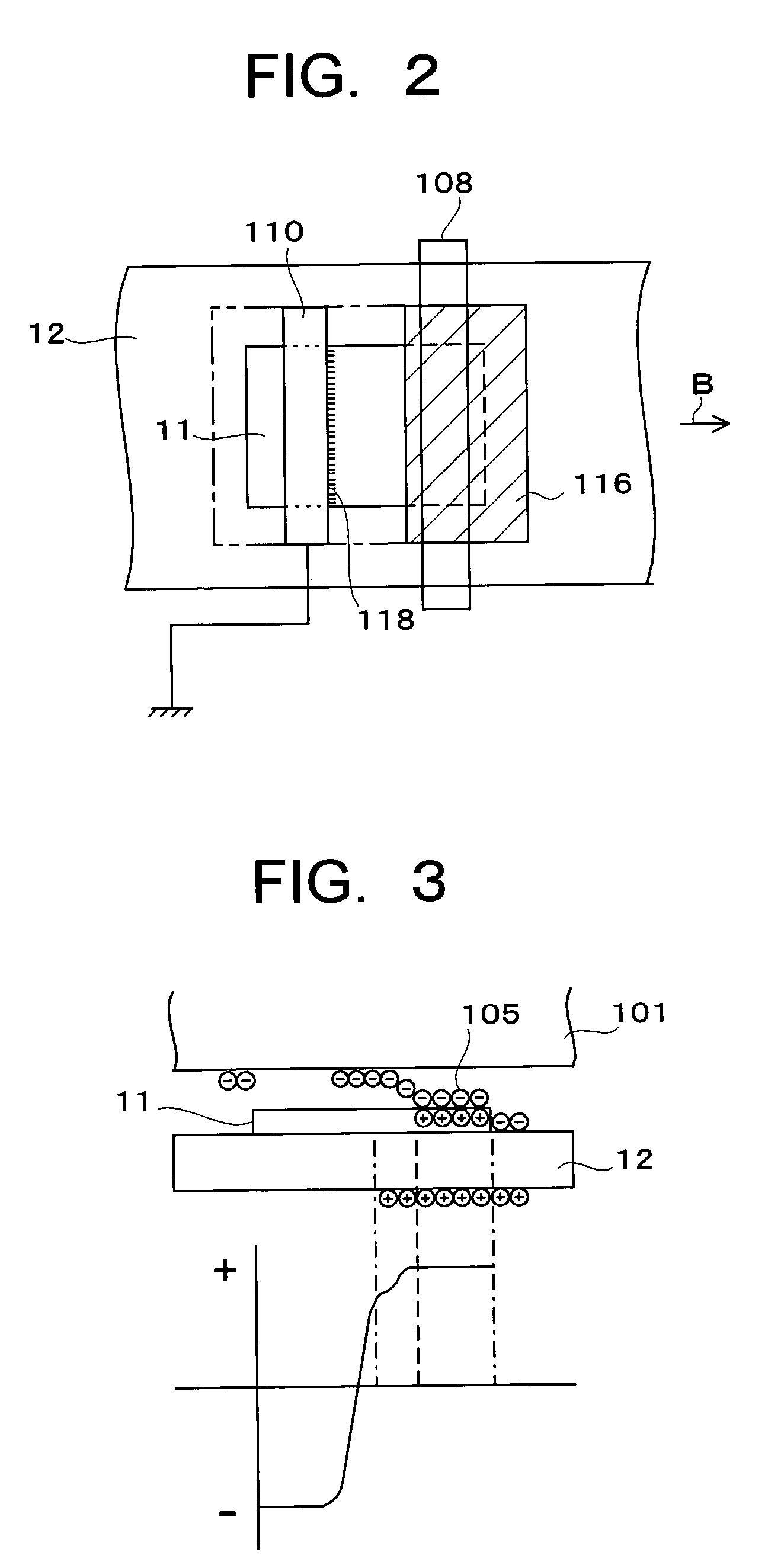

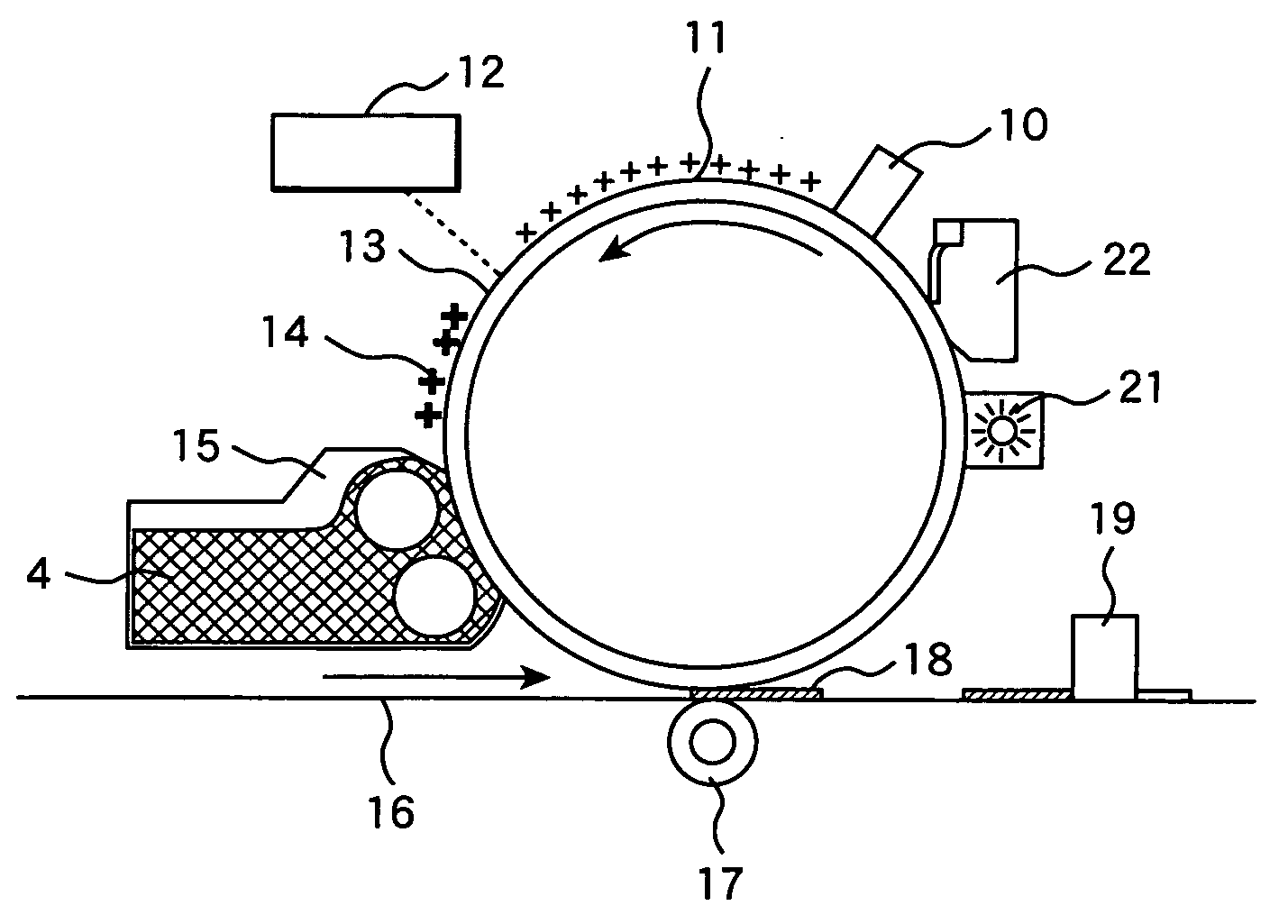

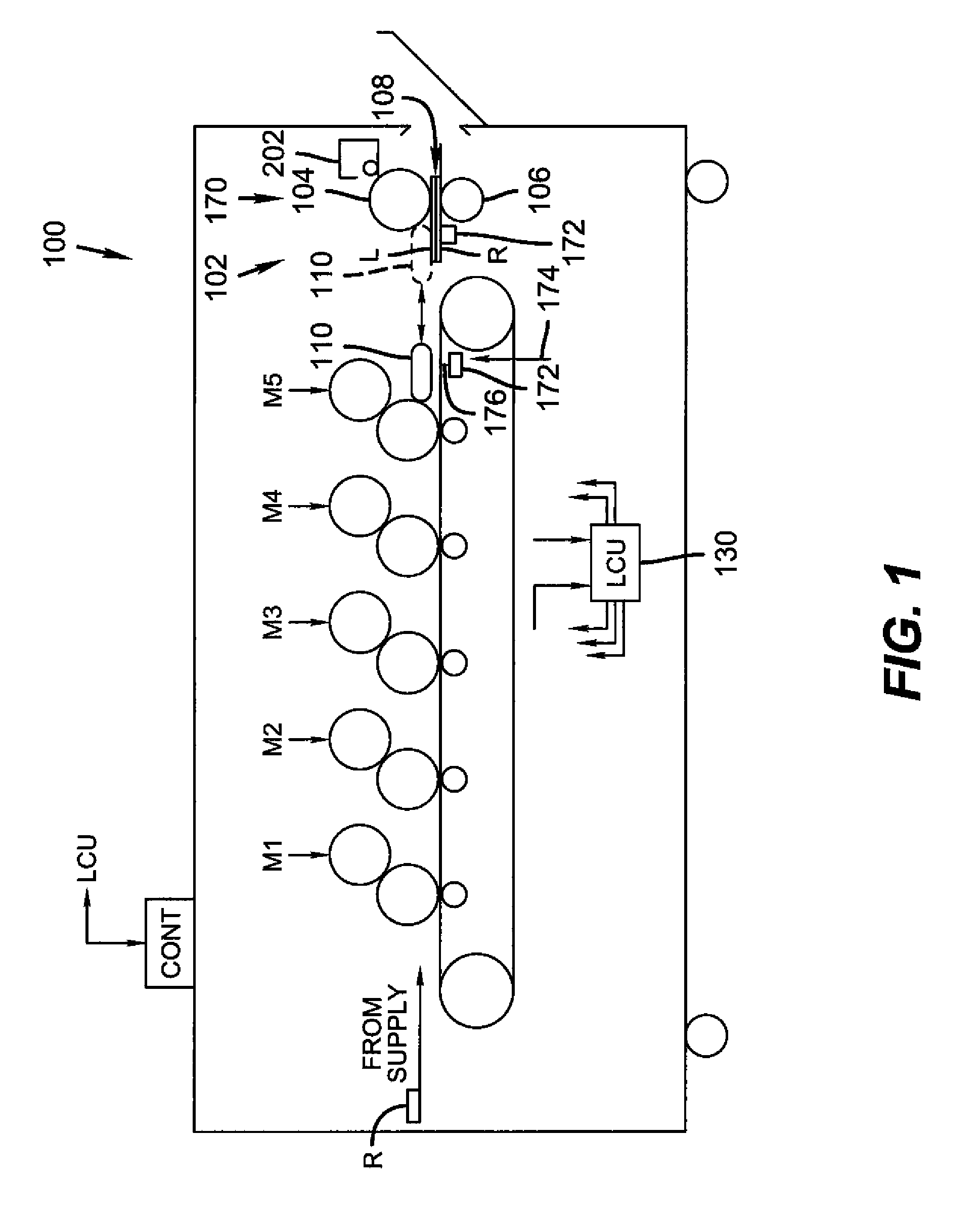

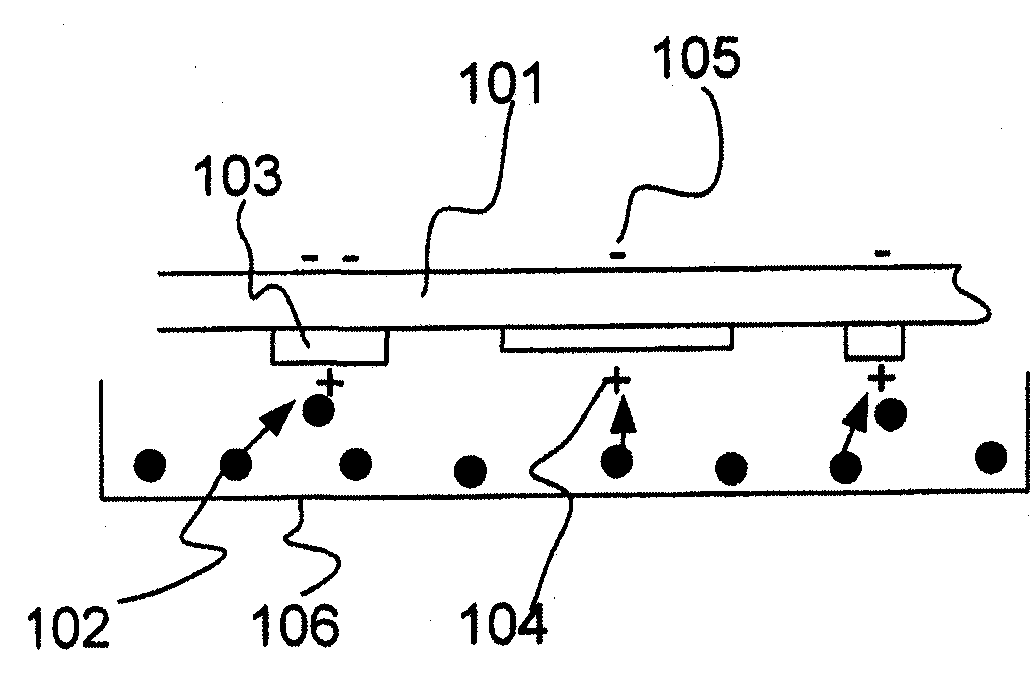

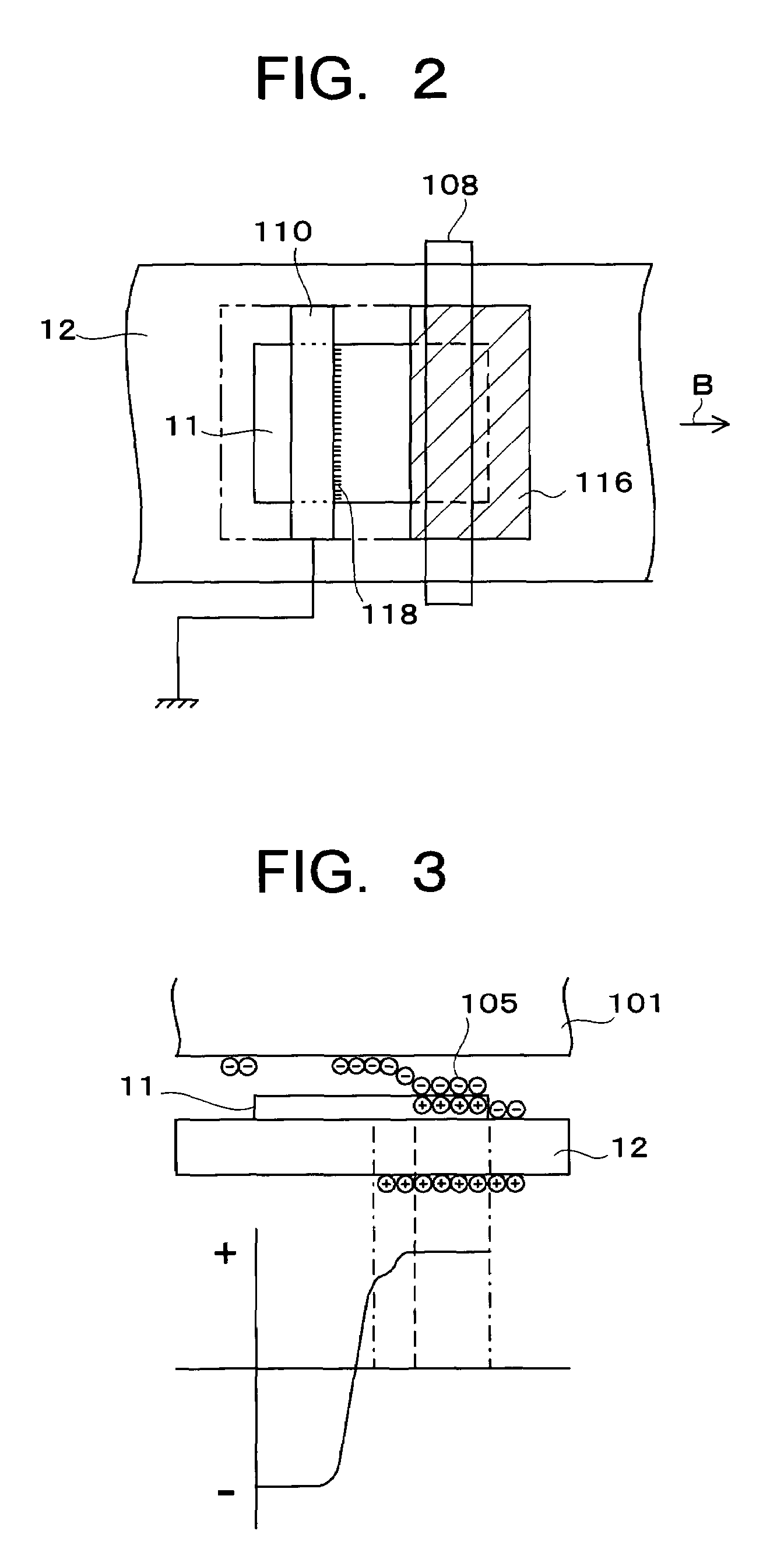

Image forming apparatus and method of manufacturing electronic circuit using the same

InactiveUS20050227161A1Prevent defective shapeGood reproducibilityPrinted circuit aspectsDevices with sensorElectrical conductorLatent image

An image forming apparatus comprises an exposure unit forming an electrostatic latent image on a photoconductor based on image information, a developing unit developing the electrostatic latent image by toner made of formation material of a circuitry layer, and an electrostatic transferring unit transferring a toner image on the photoconductor onto a substrate. The toner image is transferred so as to cover at least a part of a conductor layer formed on the substrate. At this time, excessive charges caused in the conductor layer accompanying the start of the transfer of the toner image are removed. Alternatively, charges of which polarity is reverse to that of the toner are added to the conductor layer. These allow the circuitry layer to be formed to have a desired pattern favorably and securely on the conductor layer.

Owner:KK TOSHIBA +1

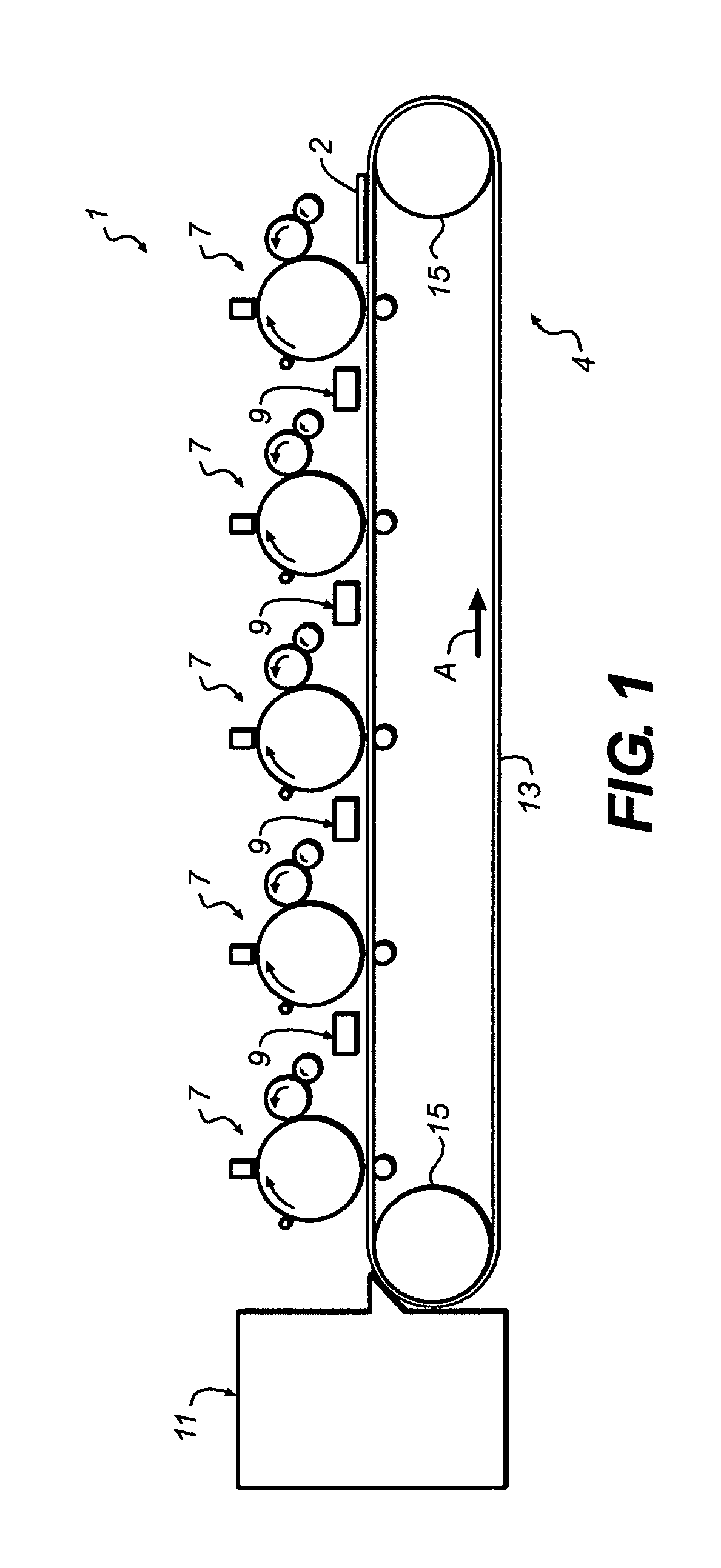

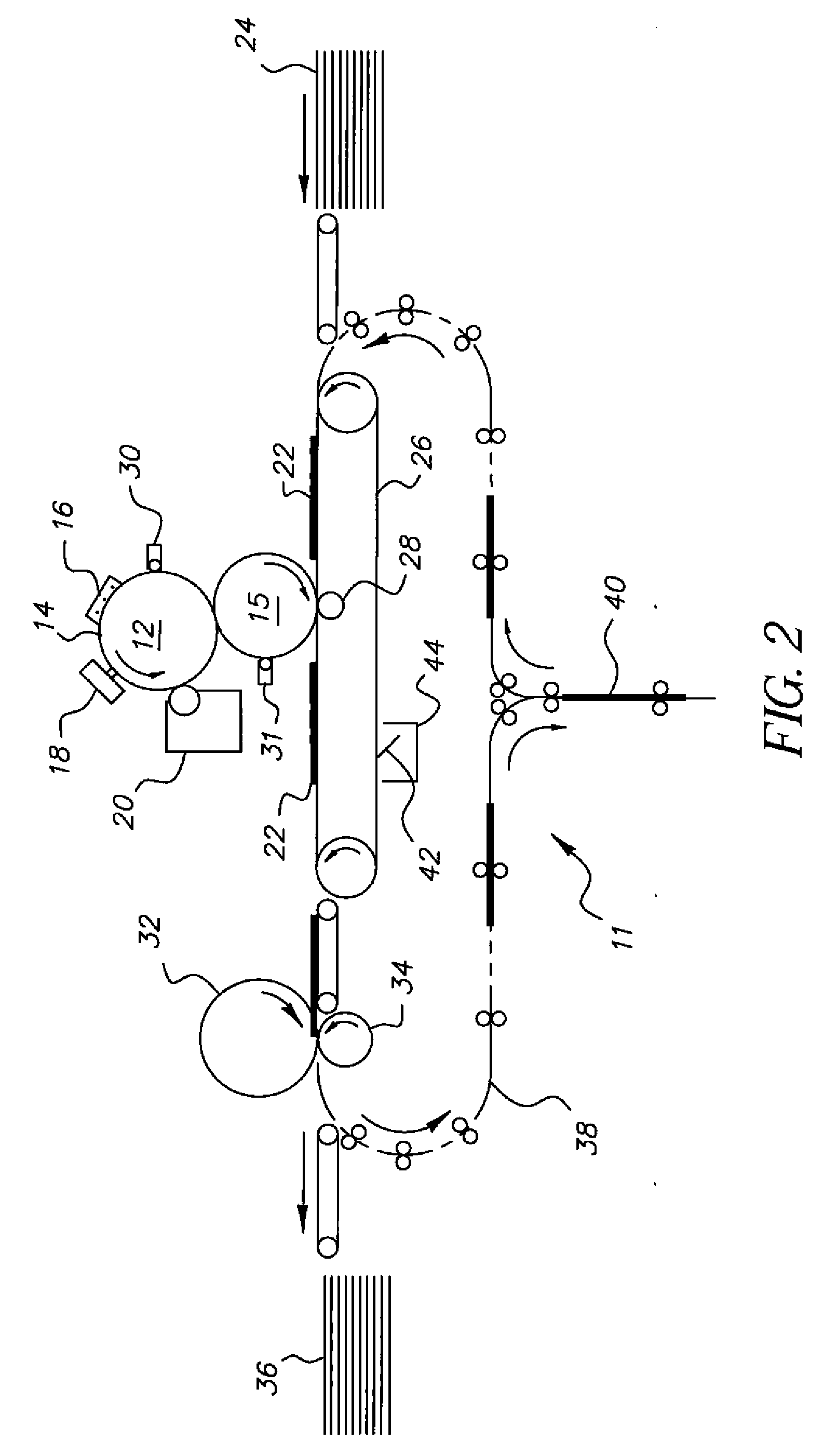

Printed circuit board printing system and method

The invention provides a printed circuit board (PCB) printing system. In a particular embodiment, the system includes a liquid electrophotographic printing device. At least one supplier of electrically conductive ink supplying electrically conductive ink to the electrophotographic printing device is also provided. In addition, at least one supplier of dielectric ink supplying dielectric ink to the electrophotographic printing device is also provided. The liquid electrophotographic printing device is operable to apply the electrically conductive ink and the dielectric ink to a provided substrate such that substantially immiscible boundary delineation occurs at any points of contact between the applied electrically conducive ink and the applied dielectric ink. An appropriate method of use for the rendering of a printed circuit board is also provided.

Owner:HEWLETT PACKARD DEV CO LP

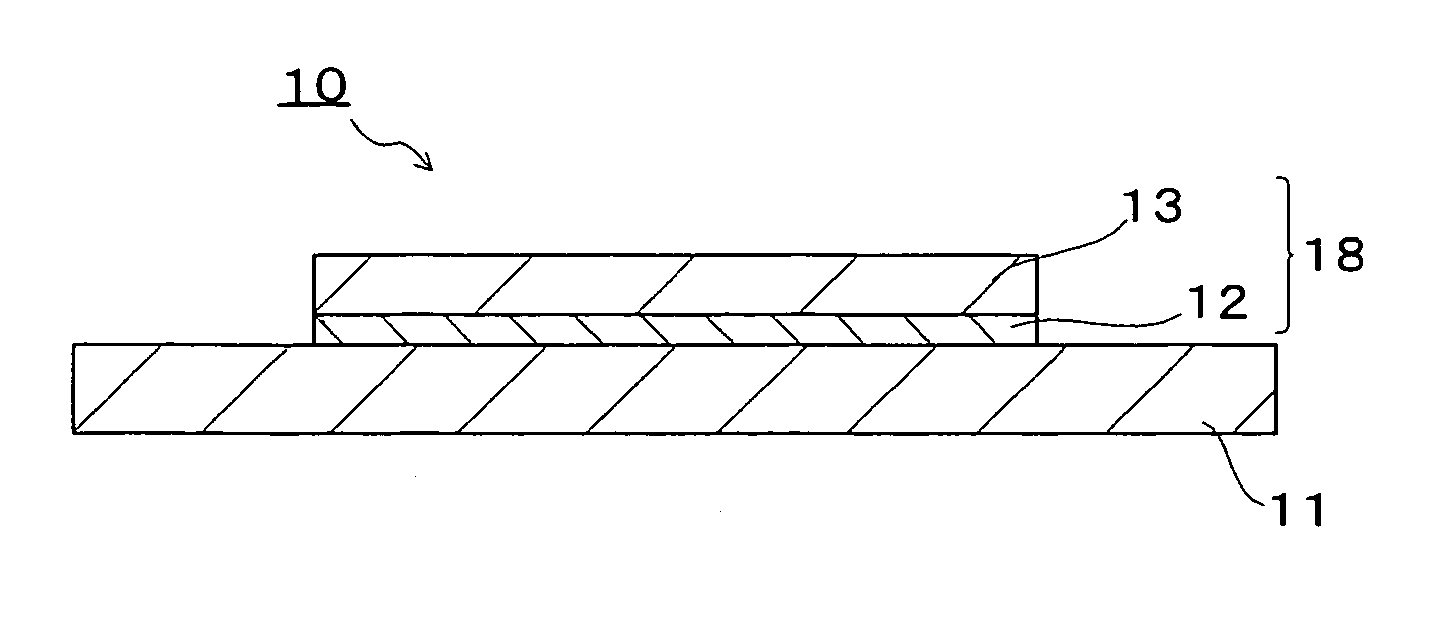

Wiring substrate and manufacturing method thereof

ActiveUS20060194031A1Improve reliabilityExcellent characteristicsDecorative surface effectsPretreated surfacesEngineeringElectroplating

A first plating foundation layer is formed by printing on a front face of a sheet-shaped insulating substrate. By inserting a punch into the sheet-shaped insulating substrate having the first plating foundation layer, a through hole is formed while leaving a piece having the plating foundation layer in the portion where the punch is inserted. A second plating foundation layer is formed by printing on a rear face of the sheet-shaped insulating substrate. A first and second wiring layers composed of a metal plating layer are formed by performing electroless plating, and at the same time, a metal plating layer connecting between the first and second wiring layers is formed in the through hole using the plating foundation layer on the piece.

Owner:KIOXIA CORP

Method of producing electronic circuit boards using electrophotography

Owner:EASTMAN KODAK CO

Method for forming circuit pattern

InactiveUS20080305425A1Efficiently formedEasy resistanceElectrographic patterningPrinted resistor incorporationElectrical resistance and conductance

A method for forming circuit patterns having different resistances. The method includes (1) a first step of forming a first toner image using a first toner and a second toner image using a second toner, each by electrophotography, the first toner containing a resistive material, the second toner having a resistance different from that of the first toner; and (2) a second step of transferring and fixing the first toner image and the second toner image to an object to be printed such as a ceramic green sheet, to form a circuit pattern.

Owner:MURATA MFG CO LTD

An apparatus, a method for establishing a conductive pattern on a planar insulating substrate, the planar insulating substrate and a chipset thereof

ActiveCN102017818AForming accuratelyPromote formationElectrographic patterningConductive pattern formationChipsetOptoelectronics

An apparatus, a method, a planar insulating substrate and a chipset have been presented, comprising at least one module configured to establish a predefined pattern on a planar insulating substrate so that conductive particles can gather according to the predefined pattern. At least one another module is configured to transfer the conductive particles to the planar insulating substrate, wherein the conductive particles are arranged to gather according to the predefined pattern. A sintering module is configured to fuse the conductive particles on the planar insulating substrate, wherein the conductive particles are arranged to fuse according to the predefined pattern to establish a conductive plane on the planar insulating substrate. Embodiment of the invention relate to printable or printing electronics on a fibrous web.

Owner:DIGITAL TAGS FINLAND OY

Decentralized solution of microscopic particles and circuit formation device

InactiveUS20070159157A1Increasing the thicknessIncrease speedDecorative surface effectsConductive materialGranularityLarge particle

Microscopic particle decentralized solution having microscopic particles with different diameters are decentralized, wherein: the microscopic particle decentralized solution has two peaks in a granularity distribution, at a large diameter and a small diameter; and microscopic particle mixtures satisfying the following relationships are decentralized in the solution;R>r and n>3.84×(R / r)3×N, where R is a large particle diameter, r is a small particle diameter, N is the number of large particles, and n is the number of small particle.

Owner:HITACHI LTD

Digital manufacture of an electrical circuit

The electrographic printing of one or more multi-channeled layers having a particular pattern by electrographic techniques that produces a specialty item electrographically. Such electrographic printing comprises the steps of forming a desired print image, electrographically, on a receiver member utilizing predetermined sized marking particles; and, where desired, forming one or more final multi-channeled layers utilizing marking particles of a predetermined size or size distribution.

Owner:EASTMAN KODAK CO

Pattern forming apparatus and pattern forming method

InactiveUS20090053632A1Increasing the thicknessHigh resolutionElectrographic patterningElectrographic process apparatusElectrical and Electronics engineering

Owner:KK TOSHIBA

Printed electronic circuit boards and other articles having patterned conductive images

InactiveUS20120110843A1Electrographic patterningElectrographic process apparatusThermoplastic elastomerEngineering

The present invention provides an article of manufacture using an electrophotographic printer to produce printed electronic circuits by printing a second conductive powder layer and a first thermoplastic layer in registration. The second conductive powder layer is permanently fixed to the first layer before removing conductive powder from portions of the substrate other than that coated with the thermoplastic patterned image.

Owner:TOMBS THOMAS N +1

An apparatus, a method for establishing a conductive pattern on a planar insulating substrate, the planar insulating substrate and a chipset thereof

ActiveCN102017818BForming accuratelyPromote formationElectrographic patterningConductive pattern formationFiberOptoelectronics

The present invention discloses an apparatus, a method, a flat insulating substrate and a chip set, comprising at least one module configured to form a predetermined pattern on the flat insulating substrate, so that conductive particles can be aggregated according to the predetermined pattern . At least one other module is configured to transfer conductive particles to a flat insulating substrate, wherein the conductive particles are arranged to aggregate according to a predetermined pattern. The sintering module is configured to melt the conductive particles on the flat insulating substrate, wherein the conductive particles are arranged to melt according to a predetermined pattern to form a conductive plane on the flat insulating substrate. Embodiments of the present invention relate to printable or printable electronic devices on fiberboards.

Owner:DIGITAL TAGS FINLAND OY

Image forming apparatus and method of manufacturing electronic circuit using the same

InactiveUS7433637B2Prevent defective shapeGood reproducibilityPrinted circuit aspectsDevices with sensorElectrical conductorLatent image

An image forming apparatus comprises an exposure unit forming an electrostatic latent image on a photoconductor based on image information, a developing unit developing the electrostatic latent image by toner made of formation material of a circuitry layer, and an electrostatic transferring unit transferring a toner image on the photoconductor onto a substrate. The toner image is transferred so as to cover at least a part of a conductor layer formed on the substrate. At this time, excessive charges caused in the conductor layer accompanying the start of the transfer of the toner image are removed. Alternatively, charges of which polarity is reverse to that of the toner are added to the conductor layer. These allow the circuitry layer to be formed to have a desired pattern favorably and securely on the conductor layer.

Owner:KK TOSHIBA +1

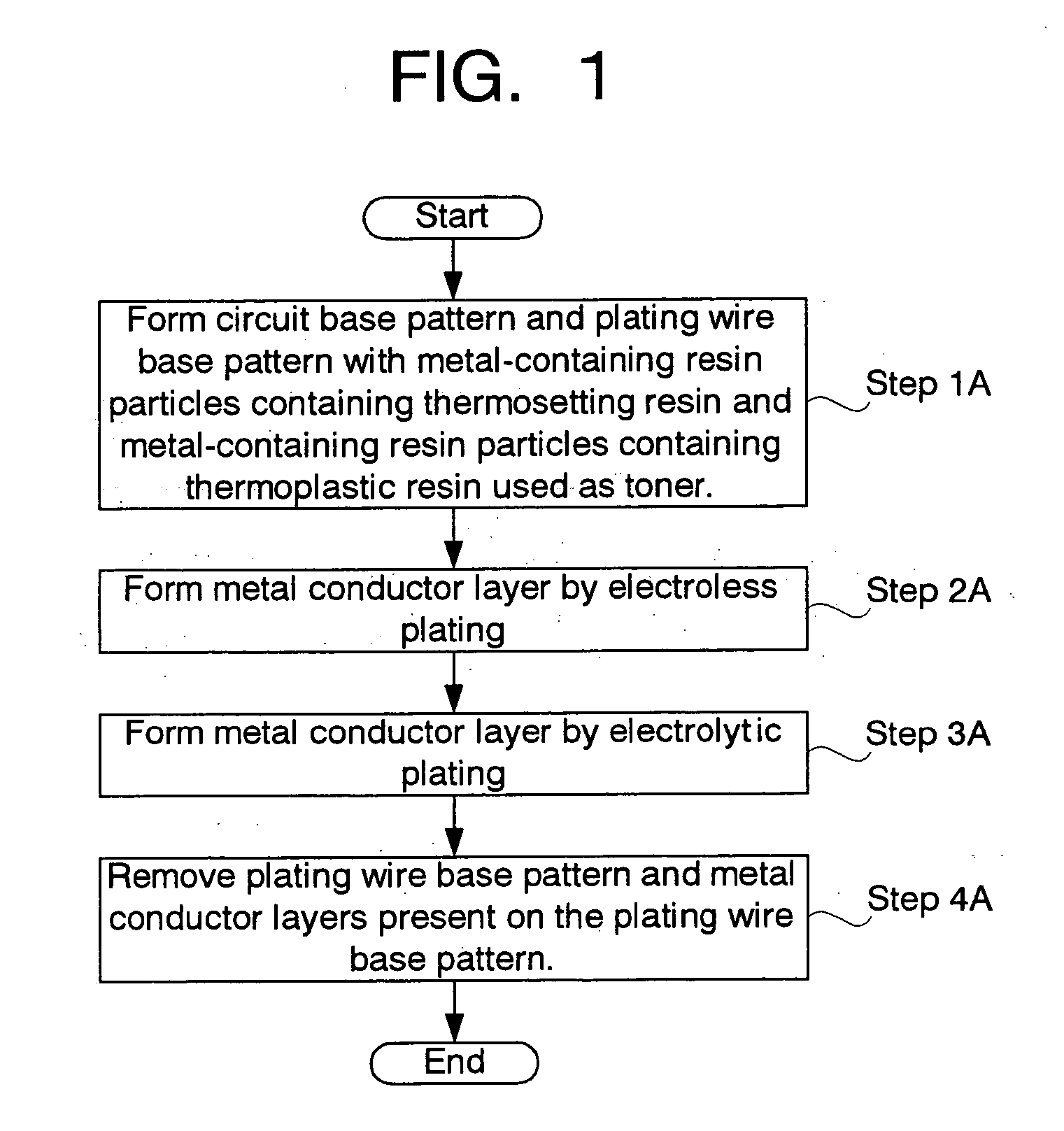

Method of producing electronic circuit and electronic circuit

ActiveUS20050224931A1Low wettabilitySemiconductor/solid-state device detailsSolid-state devicesThermoplasticElectrical conductor

According to an embodiment of the present invention, a method of producing an electronic circuit comprises printing first metal-containing resin particles which consist of at least a thermosetting resin and fine metal particles and second metal-containing resin particles which consist of at least a thermoplastic resin and fine metal particles by electrophotography to form a first base pattern which consists of the first metal-containing resin particles and a second base pattern which consists of the second metal-containing resin particles on a substrate; forming a first metal conductor layer on the first and second base patterns; forming a second metal conductor layer on the first metal conductor layer by electrolytic plating by supplying electric current to the first metal conductor layer; and removing the second base pattern and the first and second metal conductor layers which are formed on the second base pattern.

Owner:KK TOSHIBA

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com